LED (light emitting diode) driving power supply large chip

An LED driver and LED chip technology, applied in the field of LED lighting, can solve the problems of inability to place opto-mechanical modules, difficult LED driver power miniaturization, light weight and transparency, etc., to reduce complexity, small size, and easy to standardize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

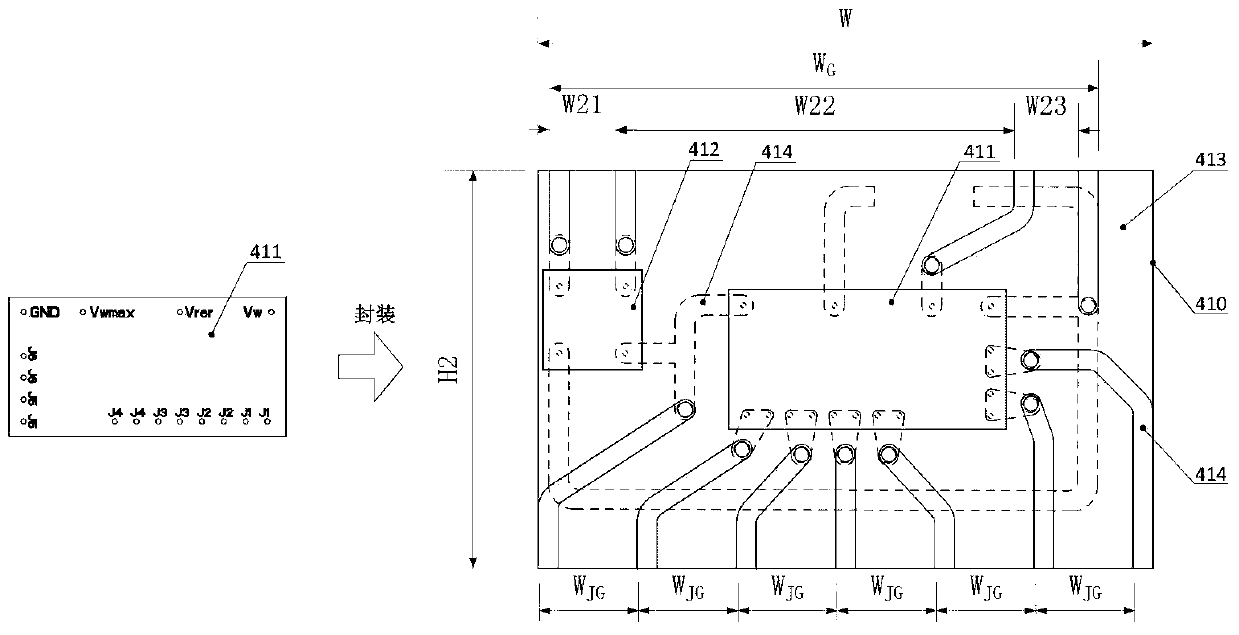

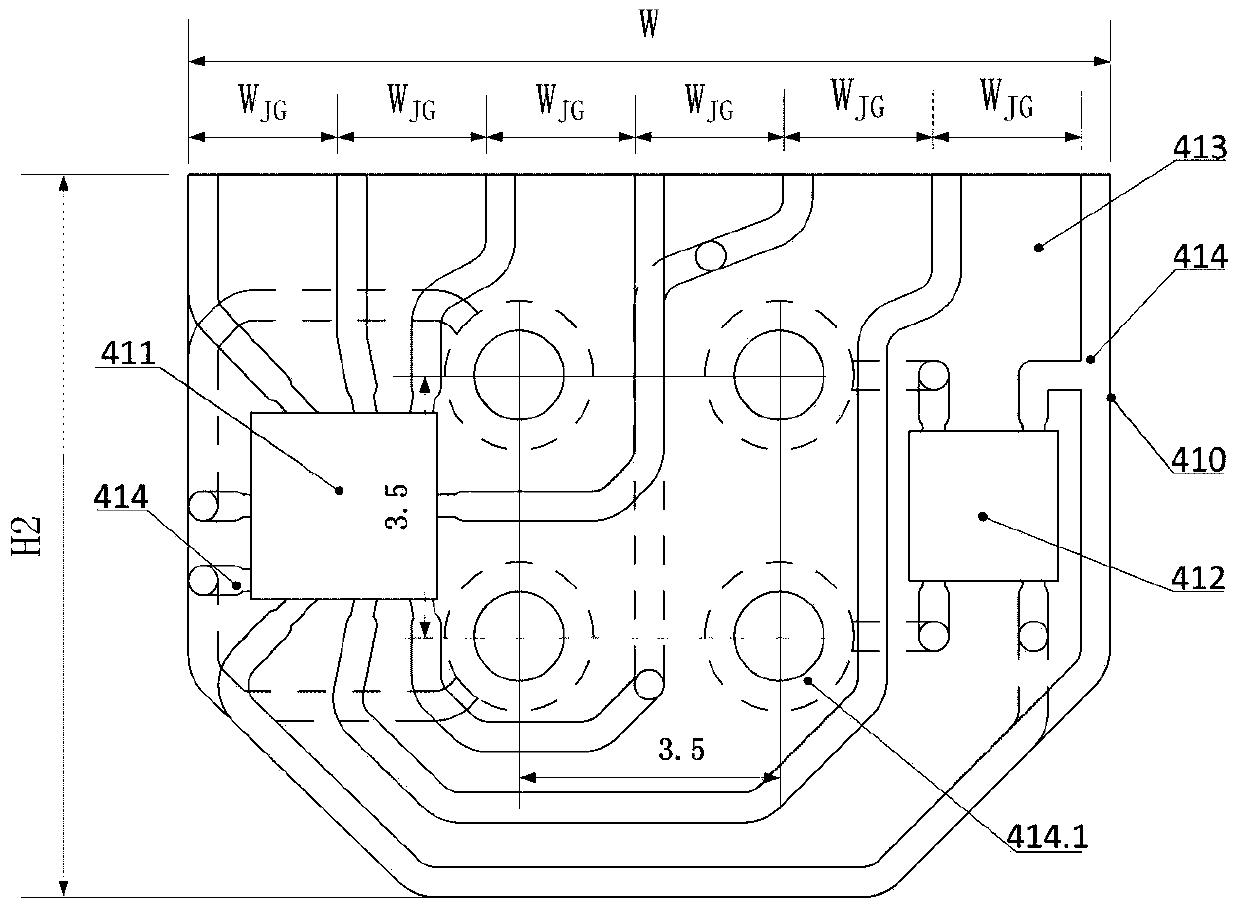

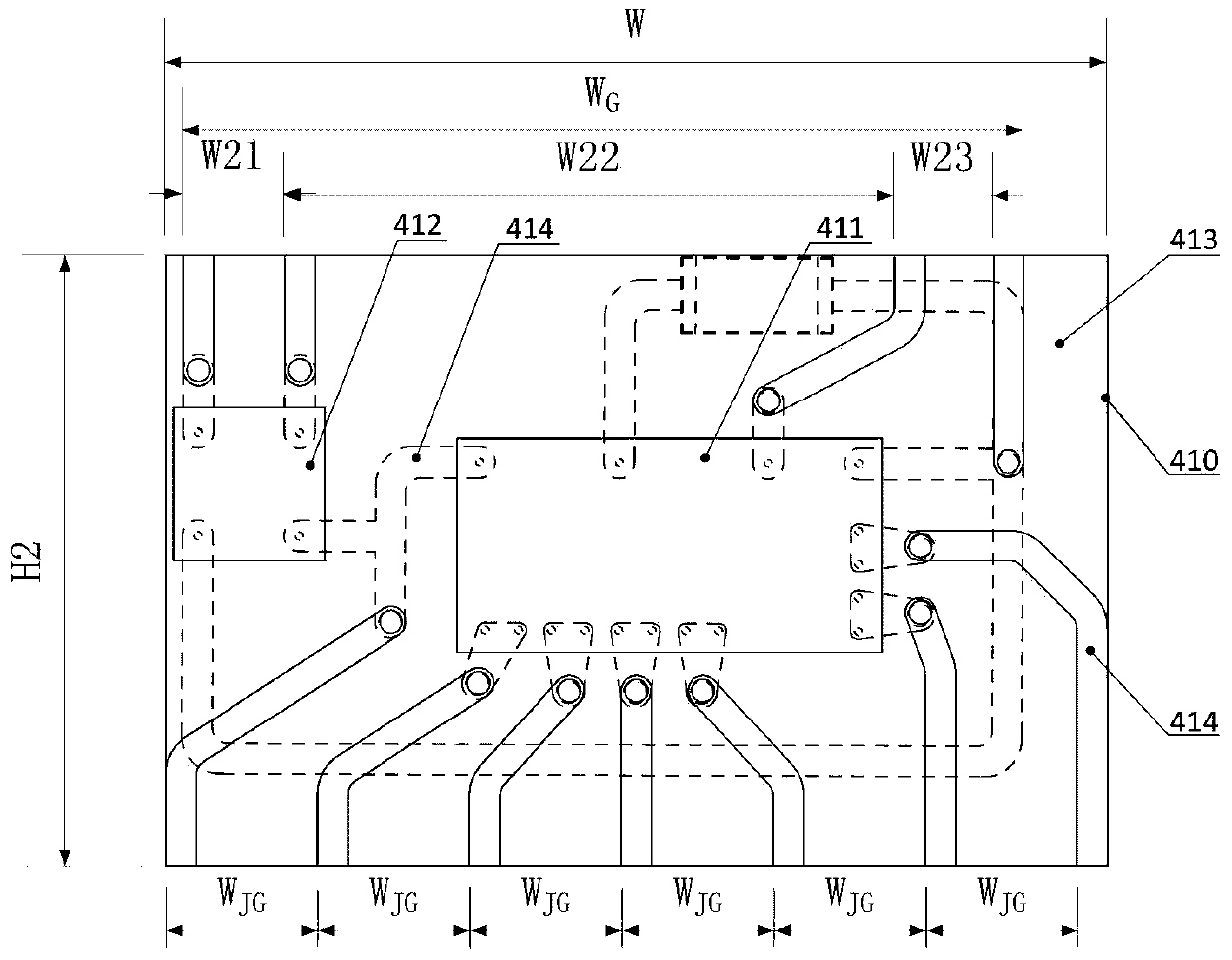

[0040] Example. Large chip of LED driving power supply: including a second transparent substrate 413 with a fixed width of W, the second transparent substrate 413 is printed with a silver paste circuit, an interface wire is formed on the silver paste circuit, and the interface wire has an input end and an output end; The width of the input end and the width W of the lead access end of the optomechanical template 43 G The same or have a pad connected to the electrical connector; there are N+1 parallel interface wires on the silver paste circuit at the output end, and the distance between two adjacent interface wires is W JG It is equal to W minus the interface wire width and then divided by N(W JG =(W-interface wire width) / N); On the second transparent substrate 413, first stick unpackaged power dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com