Silver paste for back face of lead-free crystal silicon solar cell and preparation method thereof

A technology of solar cells and crystalline silicon, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of poor adhesion between silver electrodes and silicon substrates, environmental and human toxicity, The problem of high battery scrap rate, to achieve the effect of good weldability, less harm to human body and environment, and beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

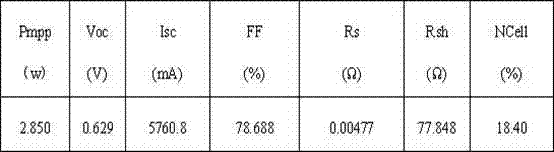

Embodiment 1

[0027] 1. Silver powder

[0028] Spherical silver powder with a purity of 99.95% and an average particle size of 0.86 μm was made by physical vapor phase method.

[0029] 2. Preparation of modified organic binder

[0030] Weigh 50% terpineol, 17% benzyl alcohol, 20% butyl carbitol acetate, 5% ethyl cellulose, 3.5% organosilicon compound, 2% hydrogenated castor oil, 2.5% The above-mentioned sorbitan stearate is mixed and heated to 80-100°C to dissolve for 100 minutes to obtain a transparent colloid with good lubricity and printability.

[0031] 3. Preparation of lead-free glass powder

[0032] By mass percentage 25% of B 2 o 3 , 40% Bi 2 o 3, 15% SiO2 2 , 10% Al 2 o 3 , 6% ZnO, 2% V 2 o 5 , prepared from 2% ZrO. After mixing evenly with a mixer, put it into a ceramic crucible, dry it in an oven at 150°C for 2h, put it in a muffle furnace, melt it at 1000-1200°C for 1h, and water quench (the industry’s conventional water quenching process, Example 2- 3 is the sam...

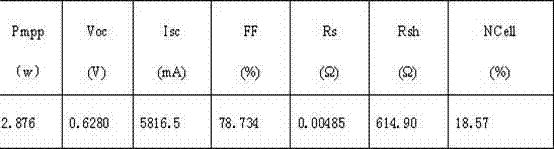

Embodiment 2

[0040] 1. Silver powder

[0041] Spherical silver powder with a purity of 99.95% and an average particle size of 0.86 μm was made by physical vapor phase method.

[0042] 2. Preparation of modified organic binder

[0043] 48% terpineol, 17% benzyl alcohol, 18.5% butyl carbitol acetate, 8% ethyl cellulose, 1.5% organosilicon compound, 3.5% sorbitan stearate, 1.5% hydrogenated castor oil and 2% additives are mixed and heated to 80-100°C to dissolve for 100 minutes to obtain a transparent colloid with good lubricity and printability.

[0044] 3. Preparation of lead-free glass powder

[0045] 15% B 2 o 3 , 45% Bi 2 o 3, 12% SiO2 2 , 15% Al 2 o 3 , 6% ZnO, 5% V 2 o 5 , prepared from 2% ZrO. After mixing evenly with a mixer, put it into a ceramic crucible, dry it in an oven at 150°C for 2 hours, put it in a muffle furnace, melt it at 1000-1200°C for 1 hour, and dry it after water quenching, then use a planetary ball mill for 3 hours, and dry it A lead-free metallic glas...

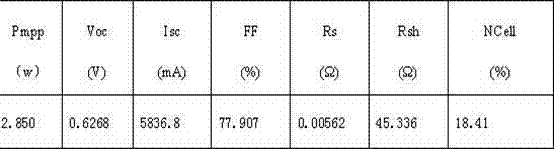

Embodiment 3

[0053] 1. Silver powder

[0054]Spherical silver powder with a purity of 99.95% and an average particle size of 0.10 μm was made by physical vapor phase method.

[0055] 2. Preparation of modified organic binder

[0056] 49% terpineol, 18% benzyl alcohol, 16.5% butyl carbitol acetate, 7.5% ethyl cellulose, 1.5% organosilicon compound, 3.5% sorbitan stearate, 1.0% hydrogenated castor oil, 3% additives, the above materials are mixed and heated to 80-100 ℃ to dissolve for 100 minutes to obtain a transparent colloid with good lubricity and printability.

[0057] 3. Preparation of lead-free glass powder

[0058] 12% B 2 o 3 , 50% Bi 2 o 3, 8% SiO 2 , 12% Al 2 o 3 , 6% ZnO, 8% V 2 o 5 , prepared from 4% ZrO. After mixing evenly with a mixer, put it into a ceramic crucible, dry it in an oven at 150°C for 2 hours, put it in a muffle furnace, melt it at 1000-1200°C for 1 hour, and dry it after water quenching, then use a planetary ball mill for 3 hours, and dry it A lead-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com