Patents

Literature

397results about "Spinning solution de-aerating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SMS-type non-woven fabric manufacture method, SMS-type non-woven fabric and application thereof

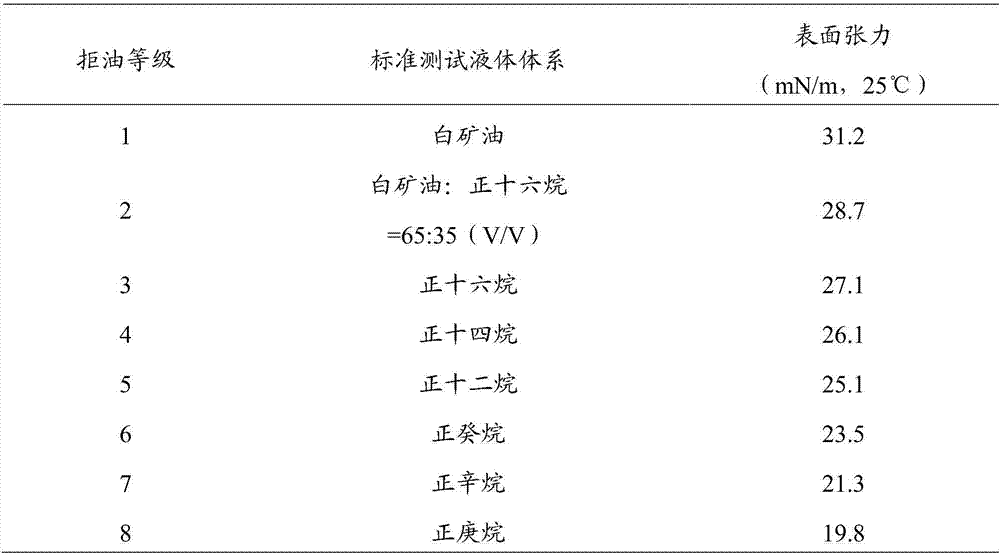

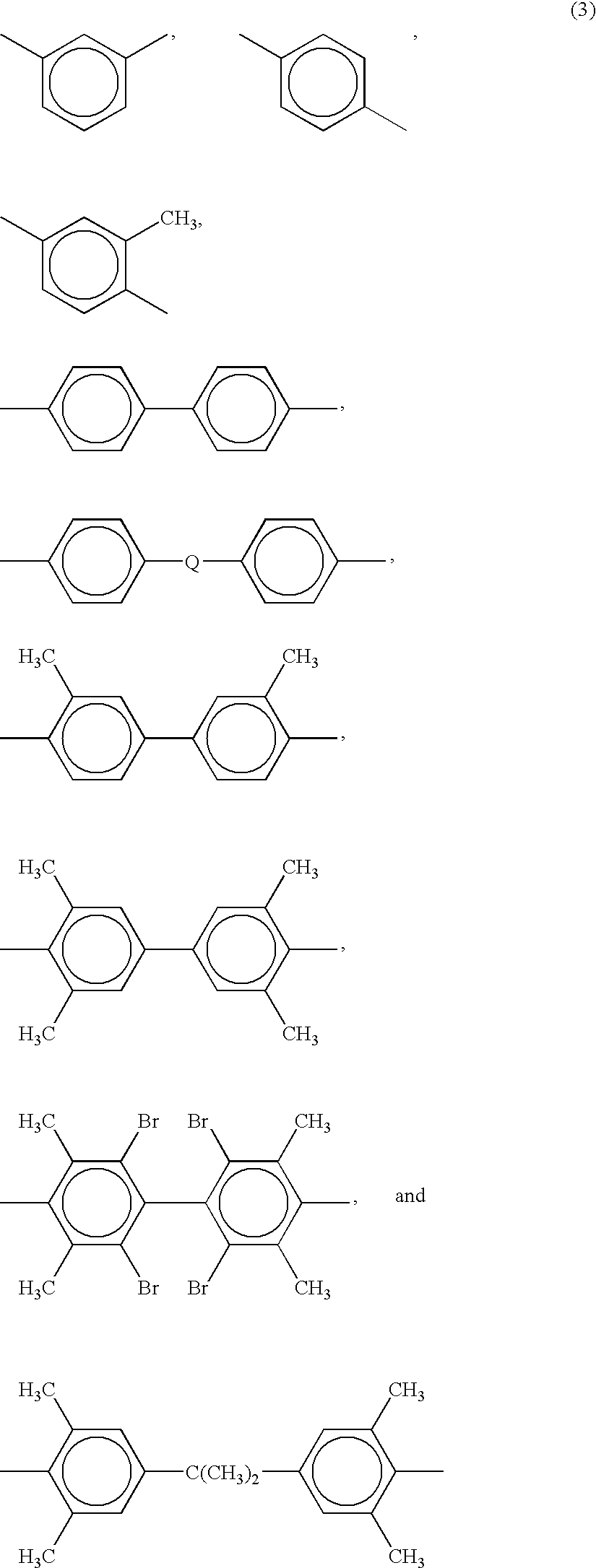

InactiveCN107447372AWith hydrostatic pressureBreathableSpinning solution de-aeratingSpinning head liquid feederFiberInter layer

The invention provides an SMS-type non-woven fabric manufacture method. The SMS-type non-woven fabric manufacture method comprises mixing, extruding and fusing, spinning, and splitting and lapping spunbond raw material polypropylene and spunbond master batch to obtain a spunbond layer fiber web; mixing, extruding and fusing, spinning and lapping meltblown raw material modified polypropylene and meltblown master batch to obtain a meltblown layer fiber web; taking the meltblown layer fiber web as the intermediate layer, and the spunbond layer fiber webs as the upper layer and the lower layer, and bonding the three layers of fiber webs in a hot pressing manner to obtain the SMS-type non-woven fabric. The invention also provides an SMS-type non-woven fabric prepared through the above method, and an application of the SMS-type non-woven fabric for preparing a disposable hygienic material. The SMS-type non-woven fabric is characterized by being excellent in blood repellent property, oil repellent property and alcohol repellent property.

Owner:山东荣泰新材料科技有限公司

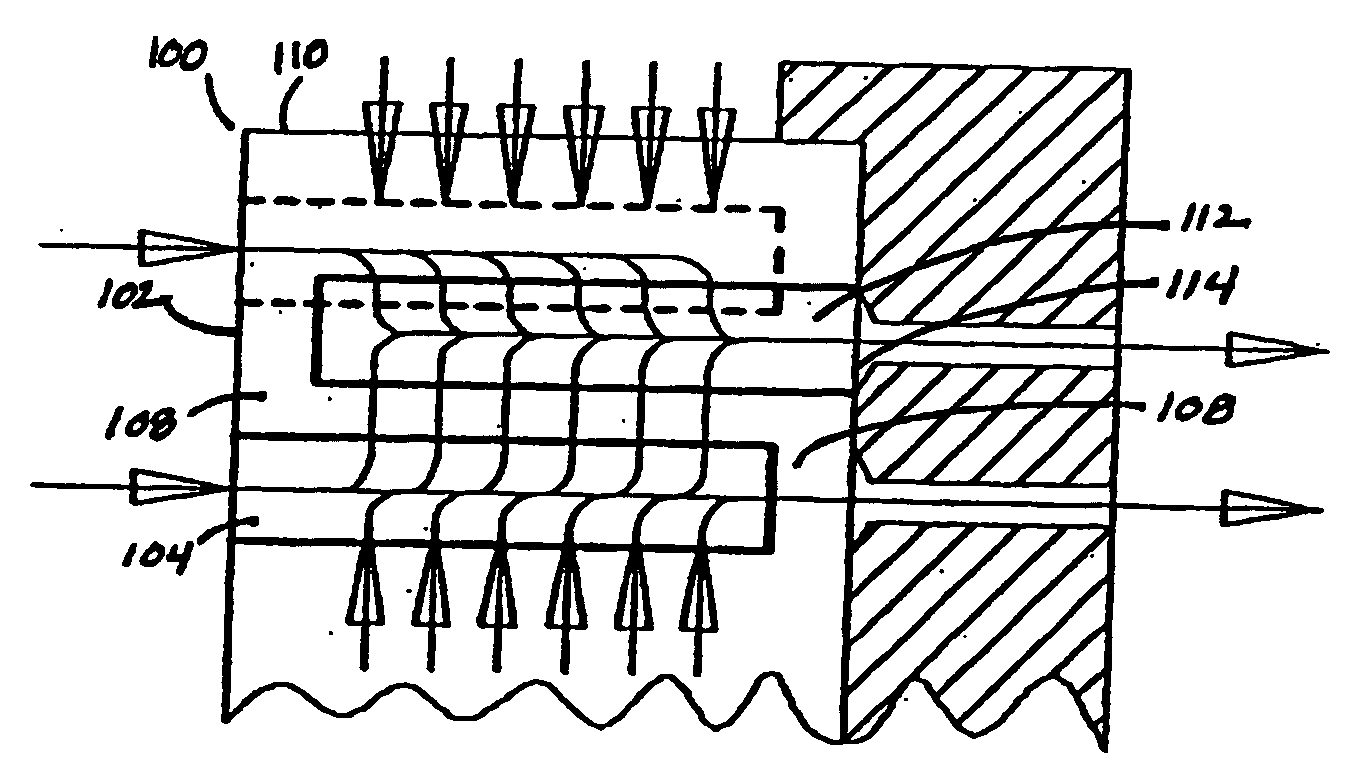

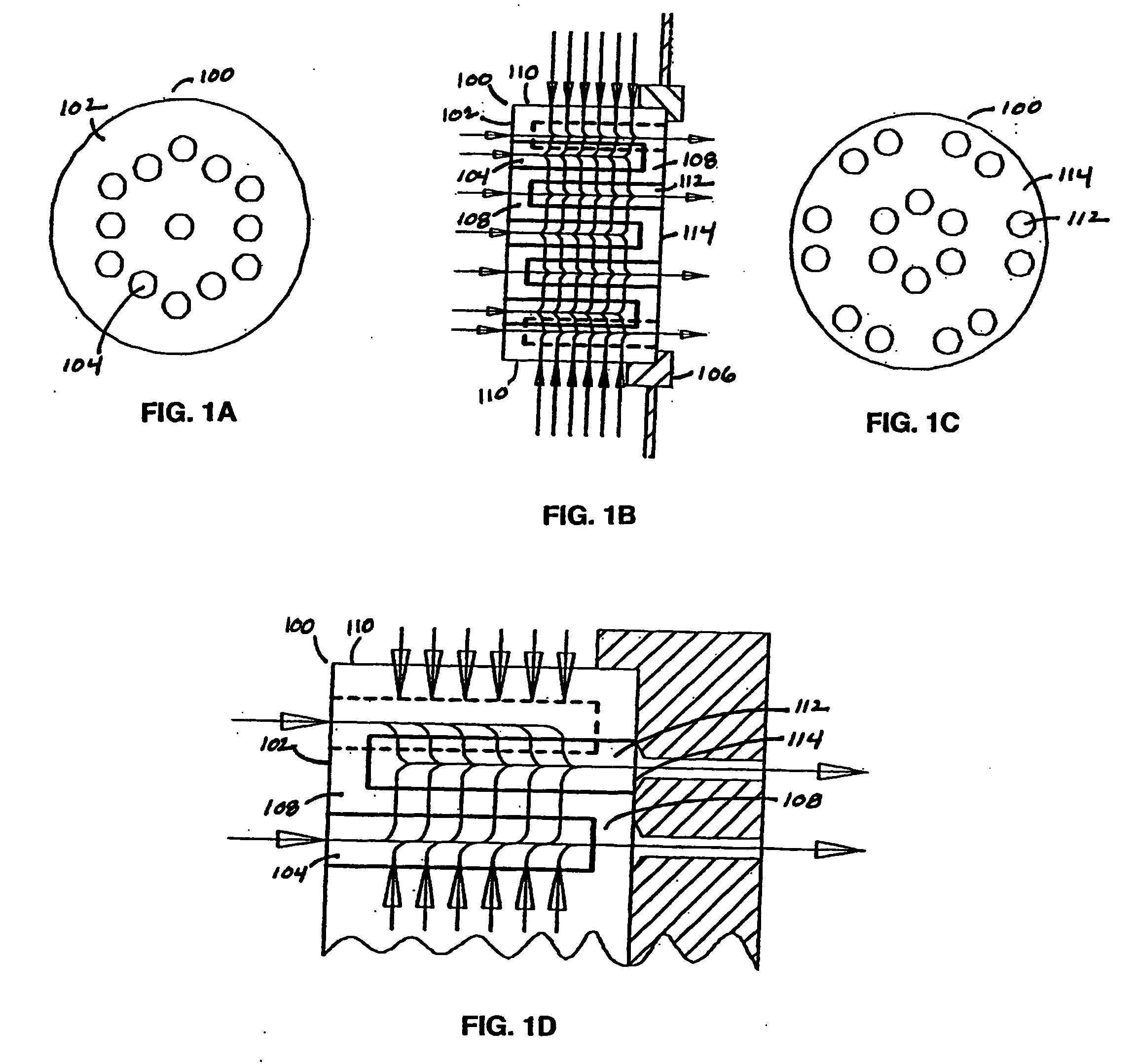

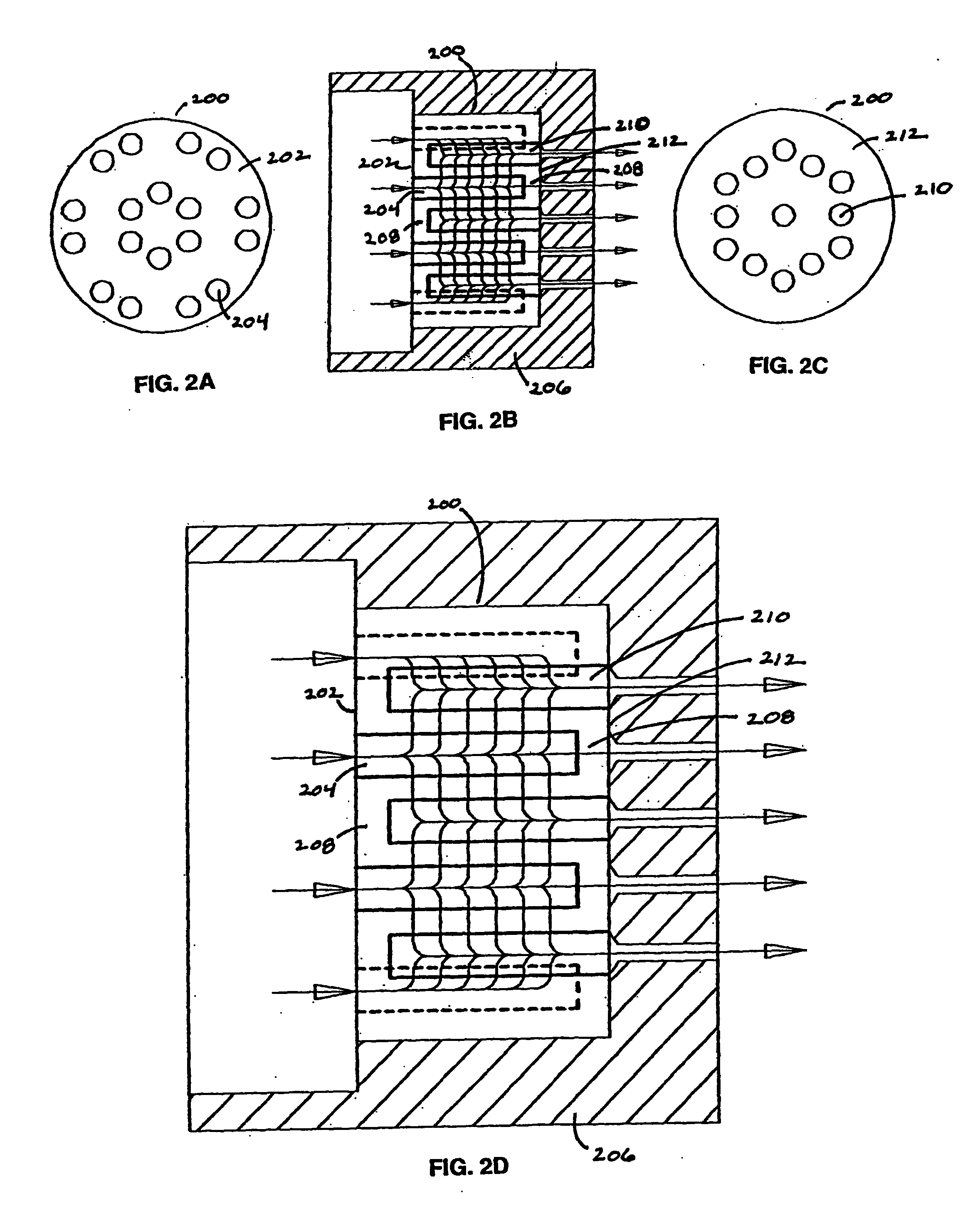

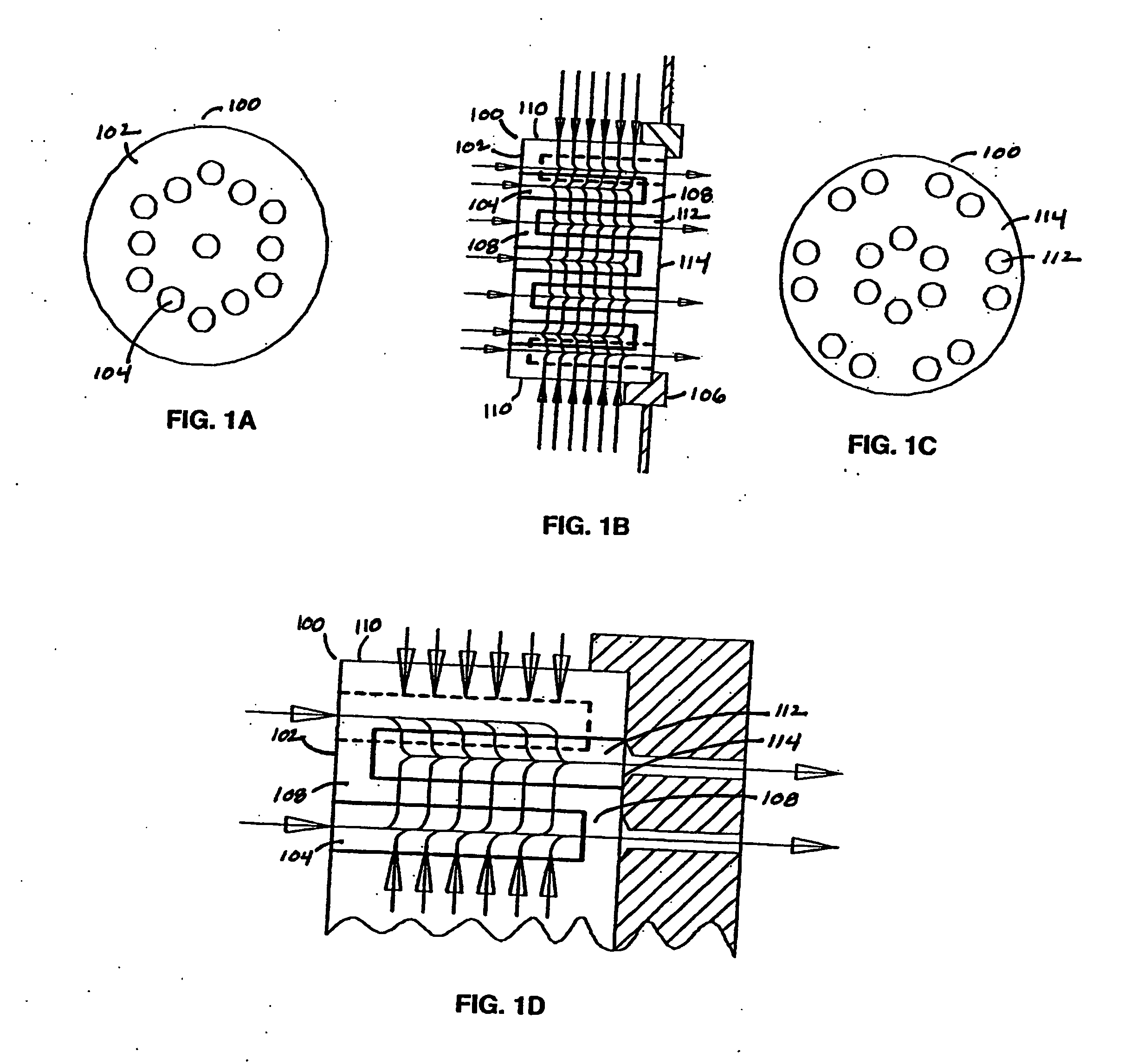

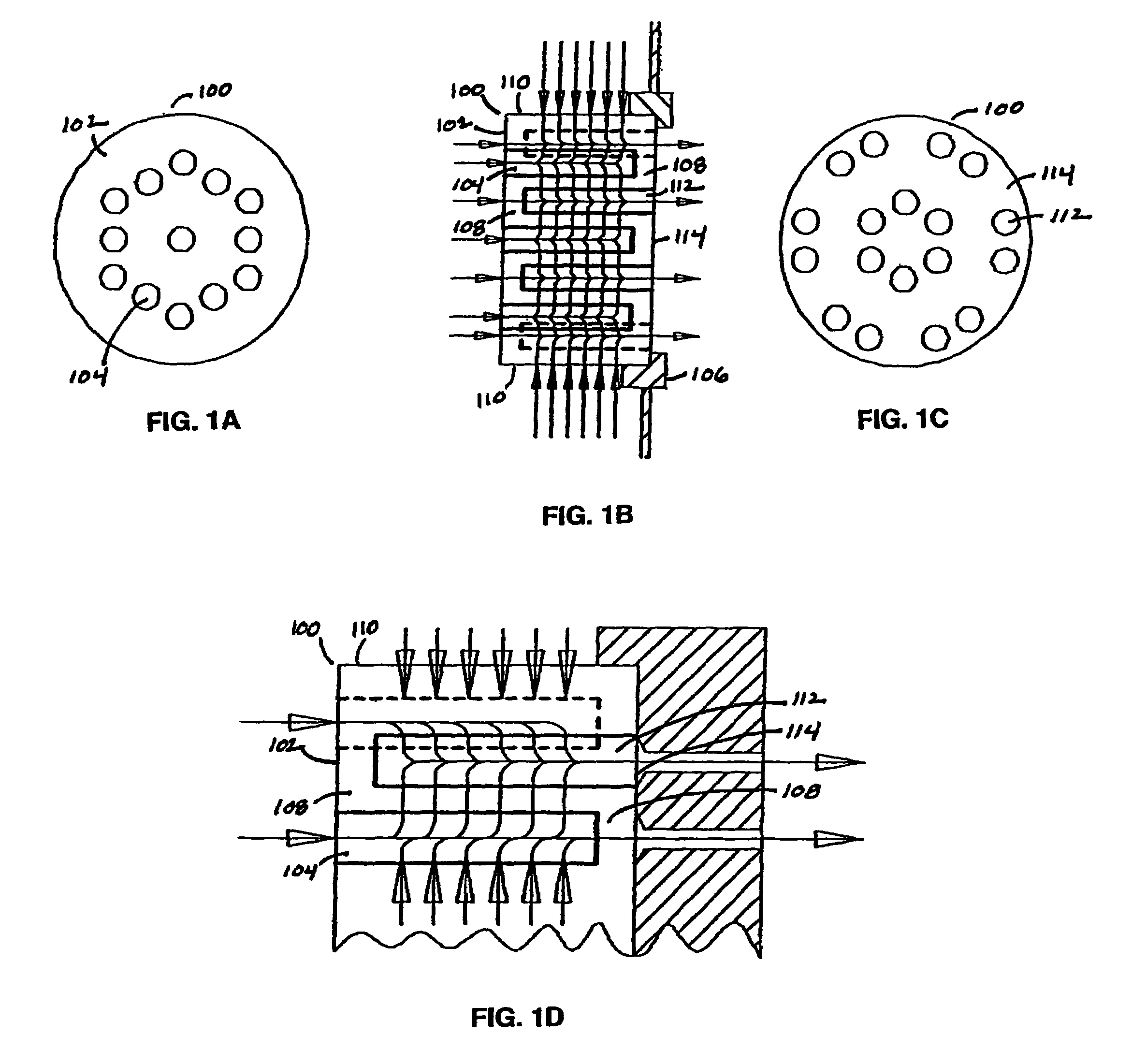

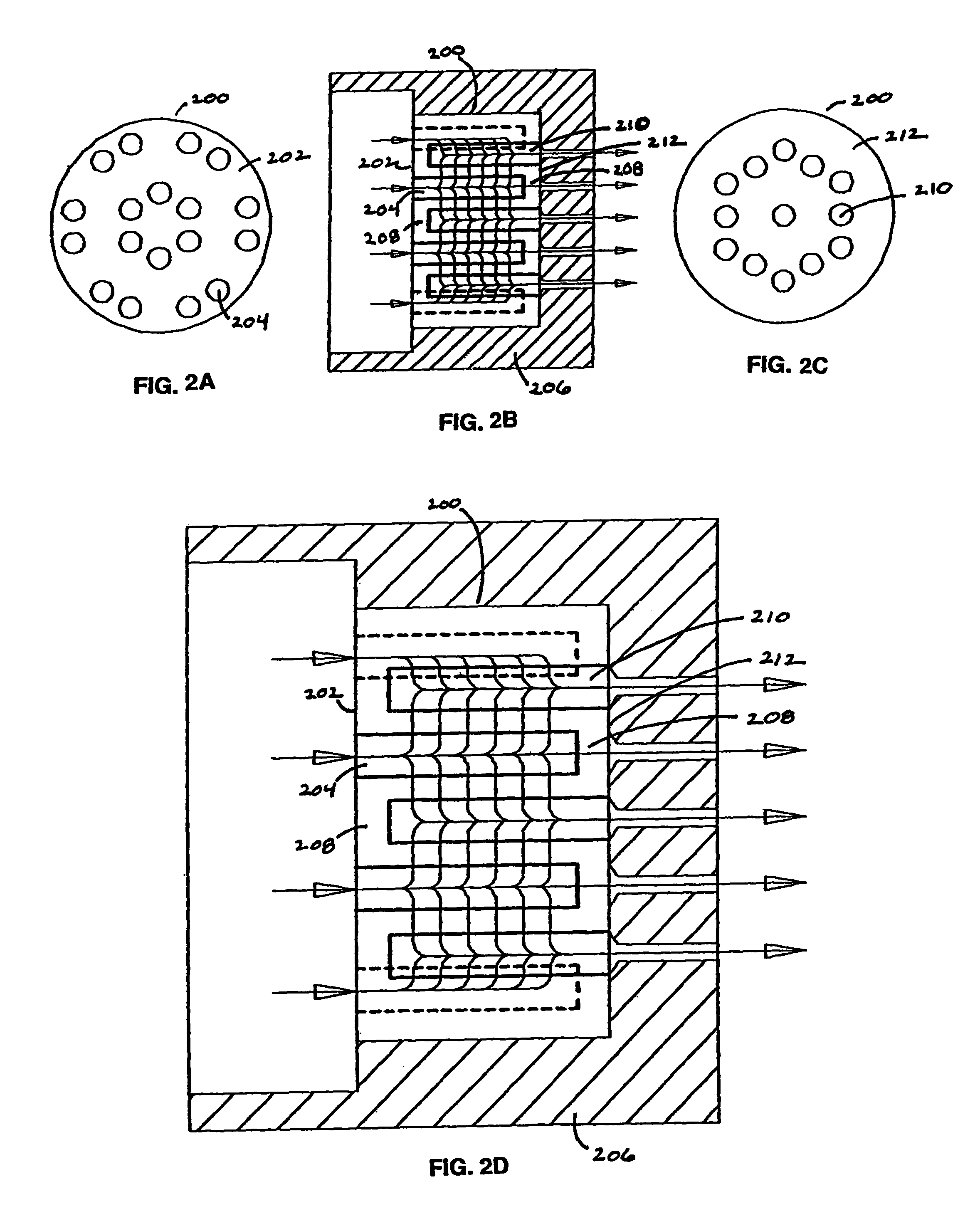

Method of making extended area filter

InactiveUS20050035052A1Improve flow uniformityImprove throughputSpinning solution de-aeratingSpinnerette packsEngineeringMetal powder

Methods are provided for making a porous filter that is useful in polymer melt spinning. The methods include pressing particles, such as a metal powder, to form a filter having a filter body integrally formed with a top cap and a bottom cap. The filter body and caps are formed as a single component or, alternatively, are formed as two or three separate parts that are fitted and pressed together to form a single component having blind inlet and outlet cavities. After pressing, the component is sintered to form the porous filter. The particles are pressed and cohere to form the caps and filter body without the use of a polymeric binder, and the inlet and outlet cavities are formed substantially without machining.

Owner:MOTT CORP

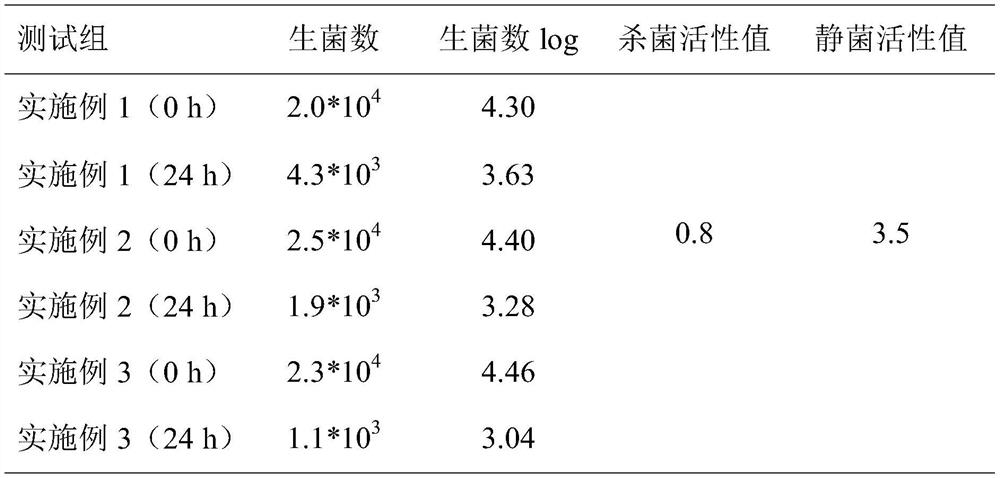

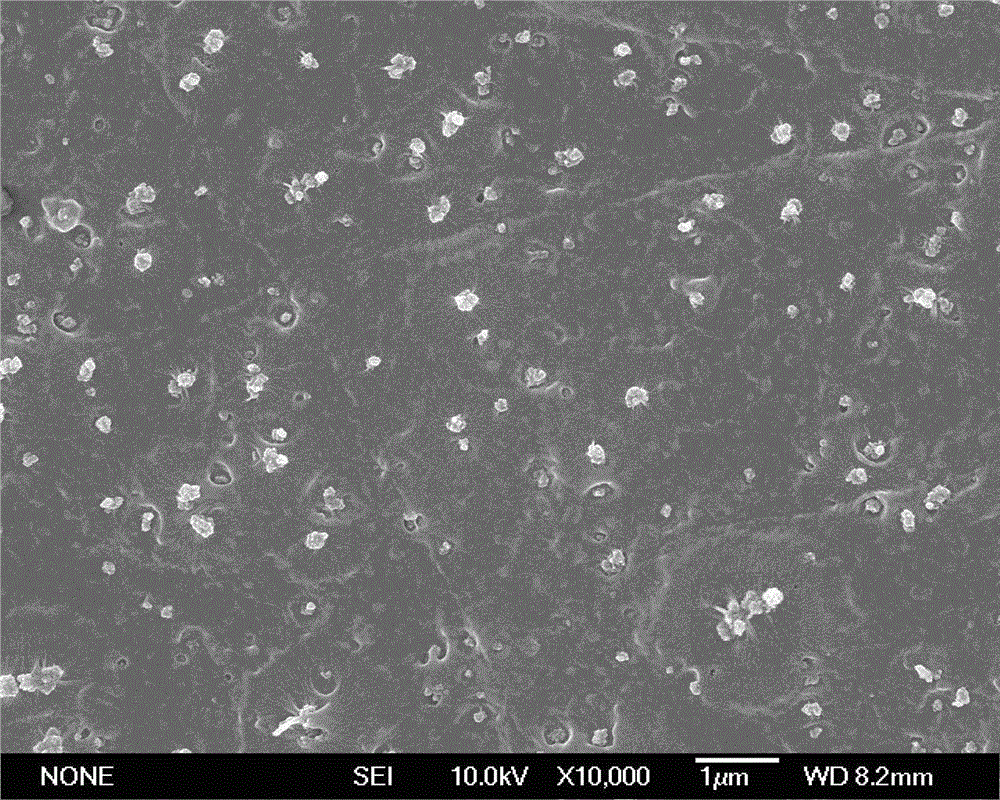

Method of producing a swellable polymer fibre

ActiveUS20160222548A1Reduce solubilityEnhanced hydrogen bondingBiocideSpinning solution de-aeratingFiberWound dressing

A swellable polymer based fibre and a method of preparing the same optionally comprising glycol, lecithin and optionally an antimicrobial metal species suitable, for example, for medical applications including wound dressings. A method of manufacture may comprise fibre extrusion or spinning involving one or a plurality of in-series coagulation baths to add single or multiple antimicrobial metal species to the as-formed fibre.

Owner:XIROS

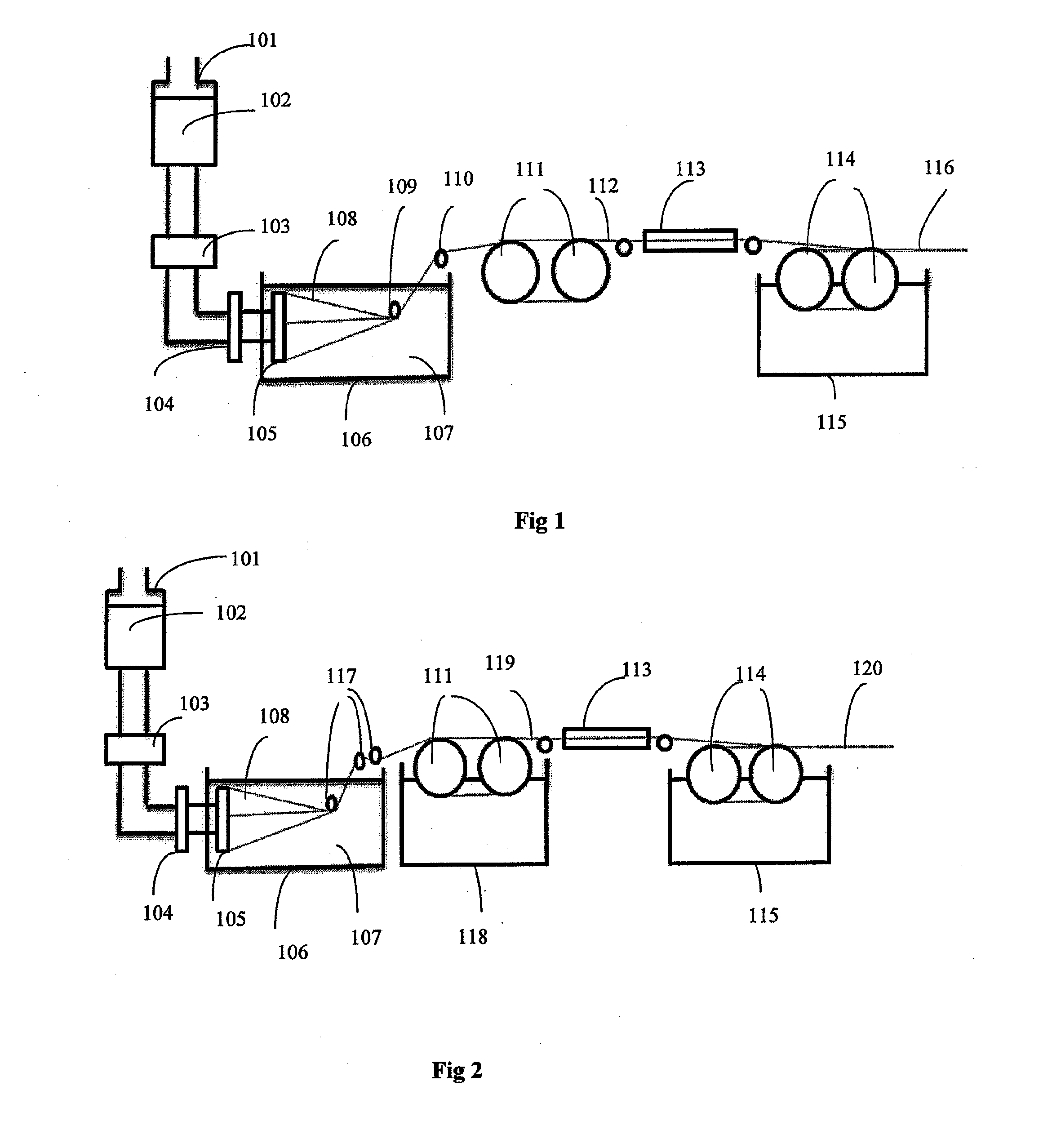

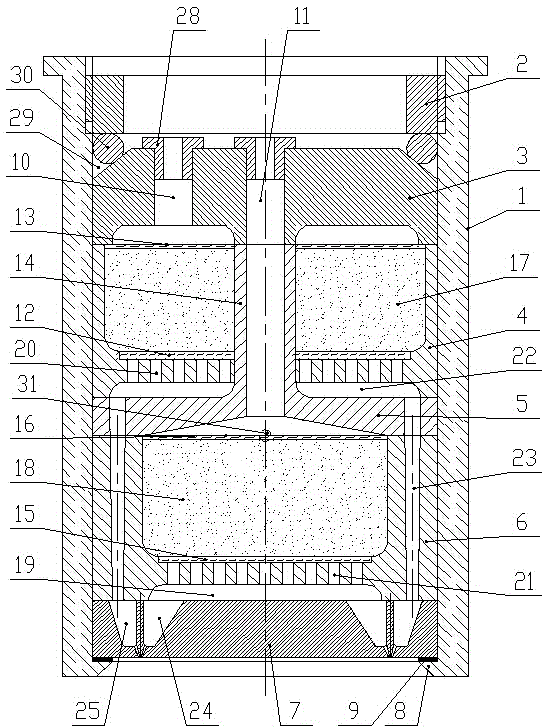

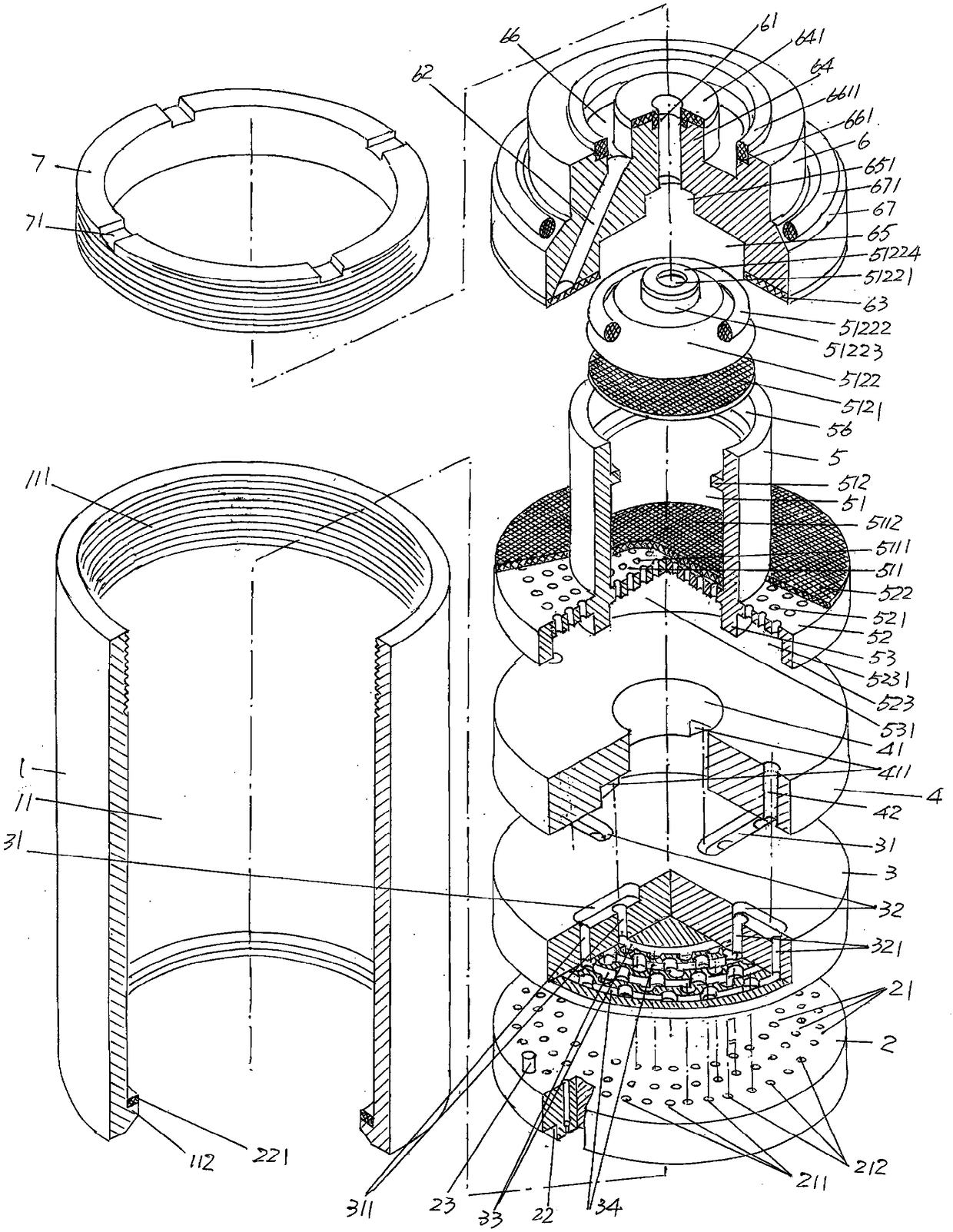

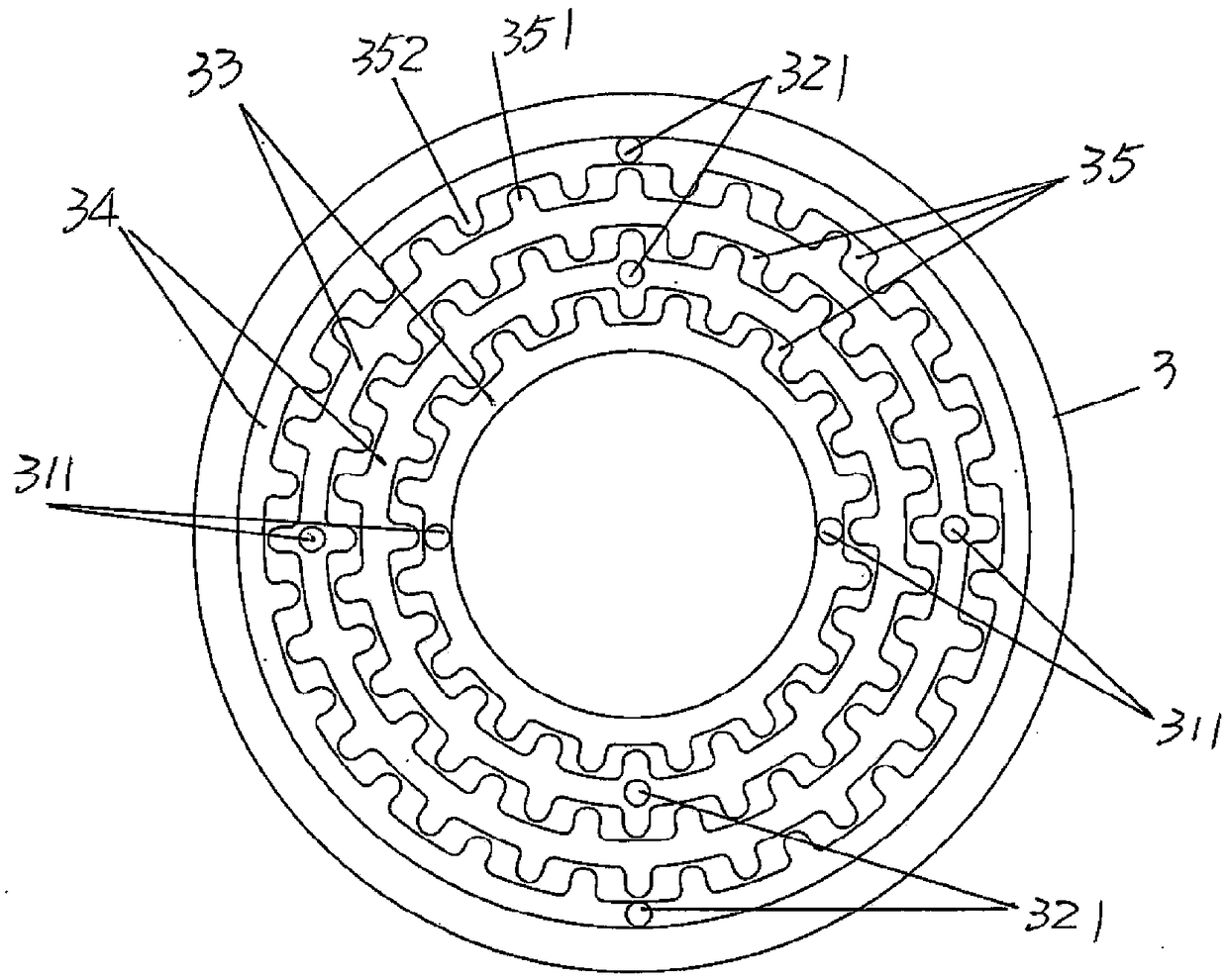

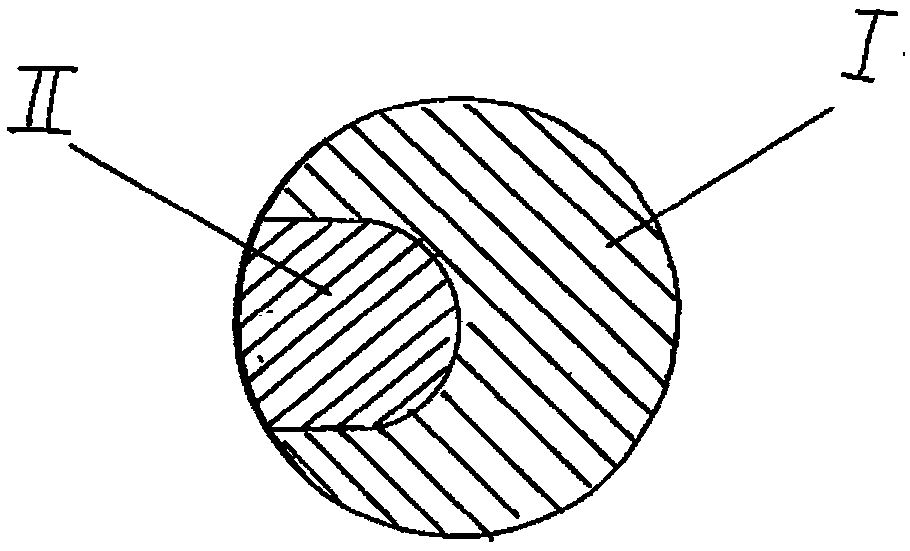

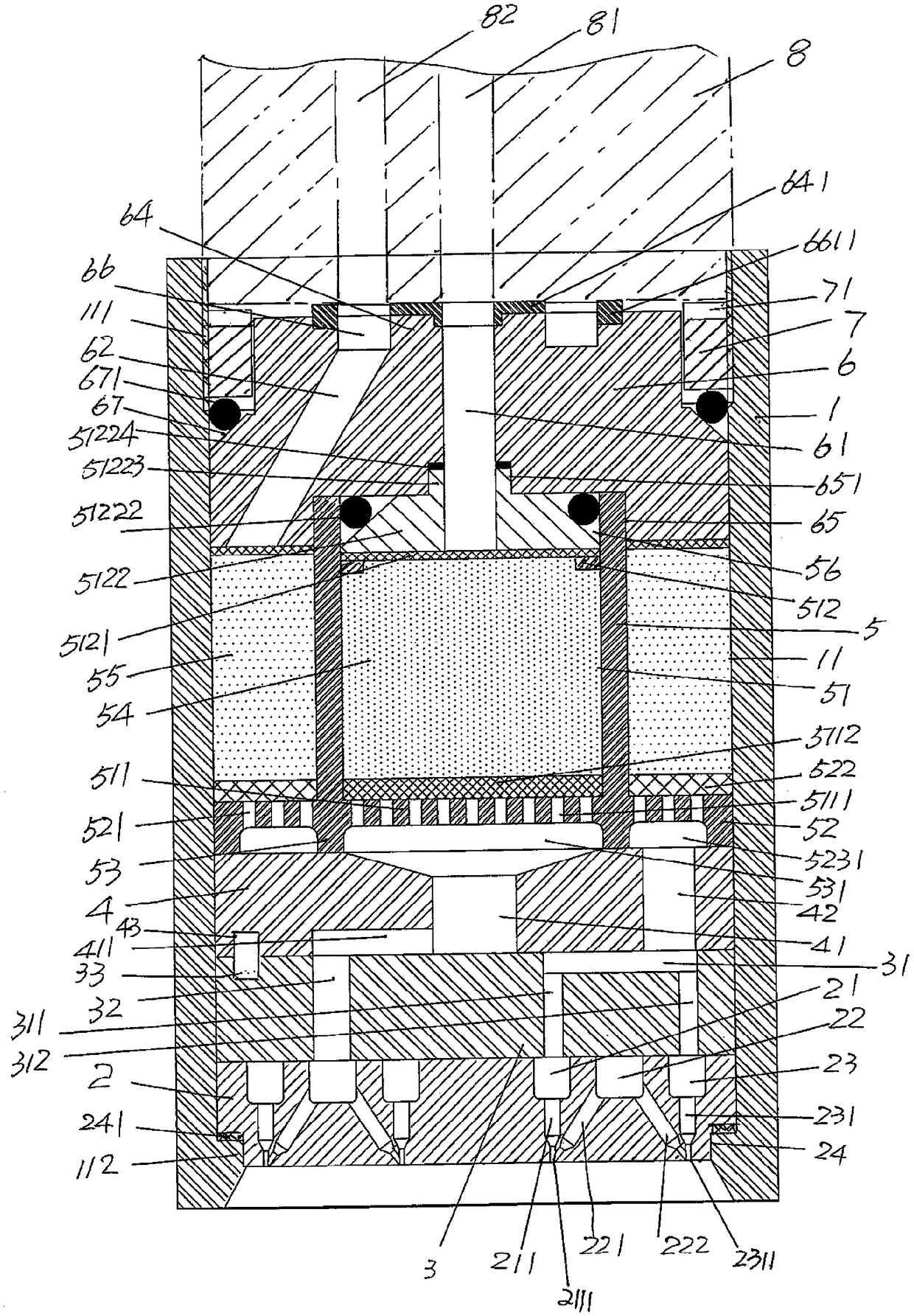

Polylactic acid double-component composite fiber double-spray-orifice parallel type spinning component

ActiveCN104562245ALarge filter areaImprove filtering effectSpinning solution de-aeratingSpinnerette packsFiberEngineering

A polylactic acid double-component composite fiber double-spray-orifice parallel type spinning component comprises cylinder with a top opening and a bottom opening. A compression nut, a melt distribution plate, an upper sand cup, a feed distribution plate, a lower sand cup and a spinneret plate are sequentially disposed inside the cylinder from top to bottom. A limit ring is disposed on the inner wall at the lower end of the cylinder. A seal gasket is disposed between the limit ring and the lower end of the spinneret plate. The compression nut is connected with the upper portion of the inner wall of the cylinder in a threaded manner. The polylactic acid double-component composite fiber double-spray-orifice parallel type spinning component has the advantages that the spinning component is reasonable in design, unique in structure, high in spinning efficiency, large in filter area, less prone to vortex generation, less prone to melt breaking during spinning jet, high in part matching precision, stable in work pressure and convenient to demount and mount, melt quality is increased, and spinning production is facilitated.

Owner:HENAN LONGDU BIOLOGY TECH

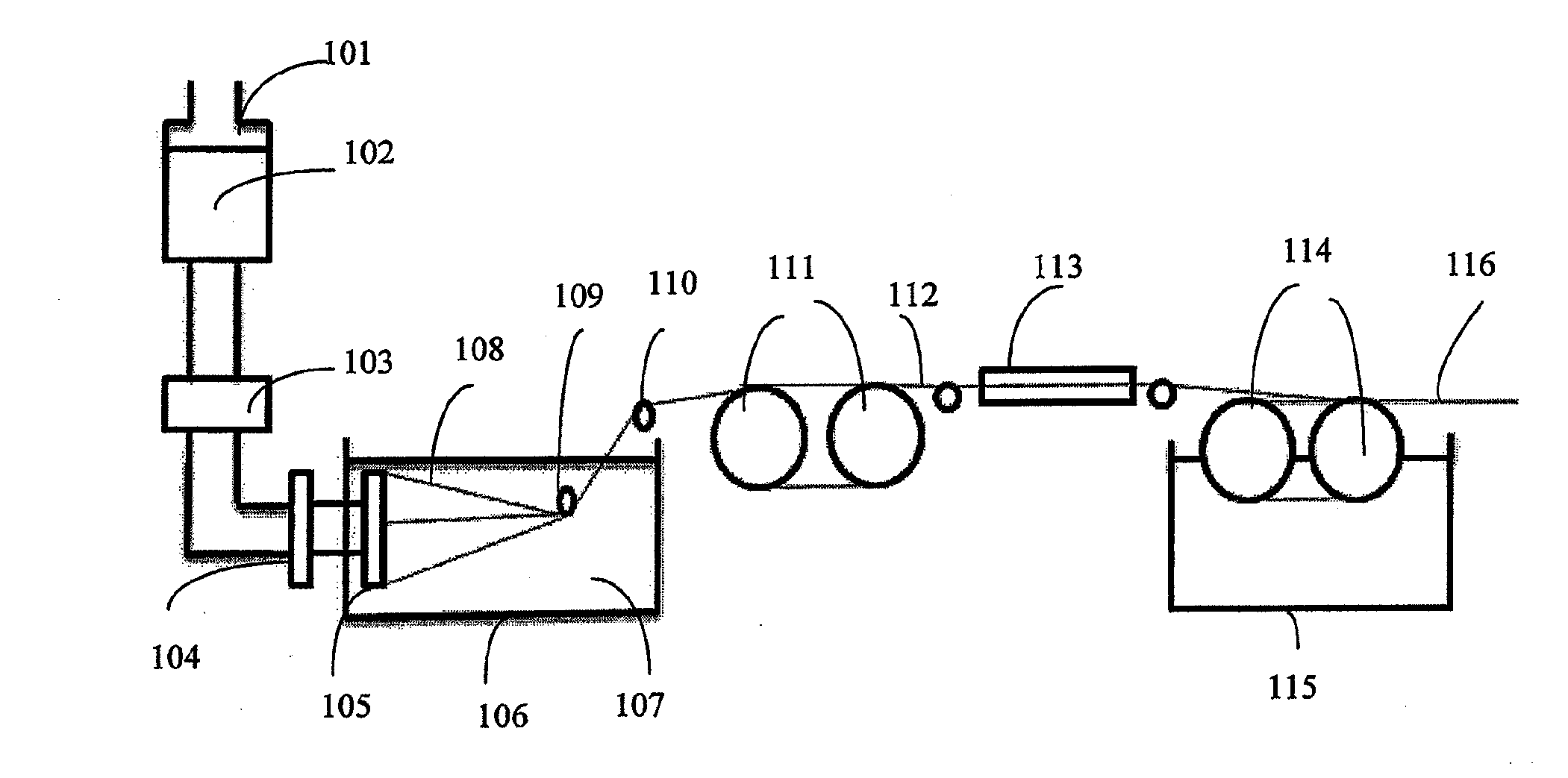

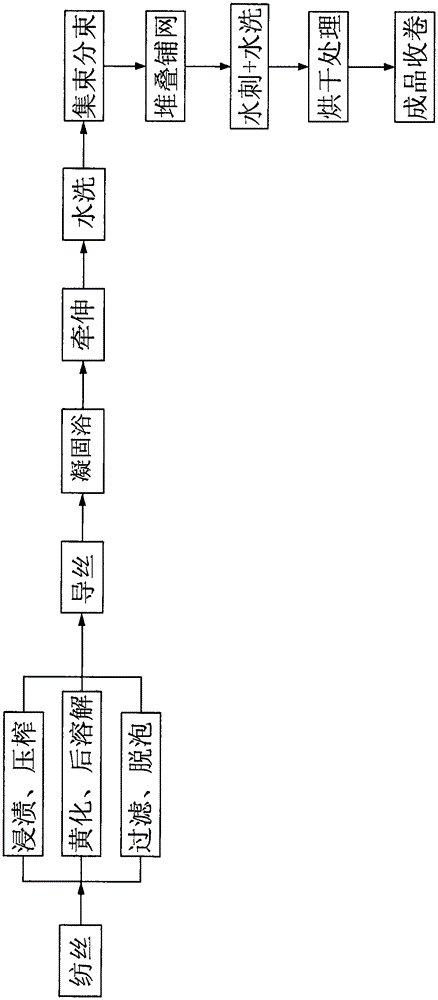

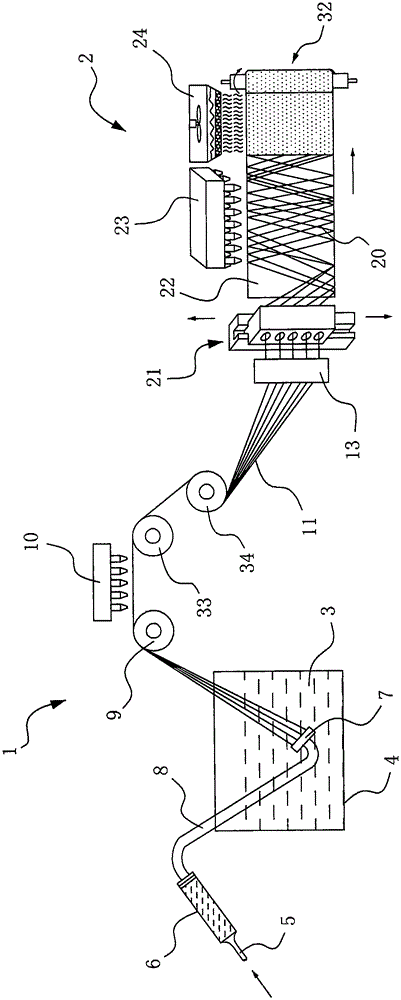

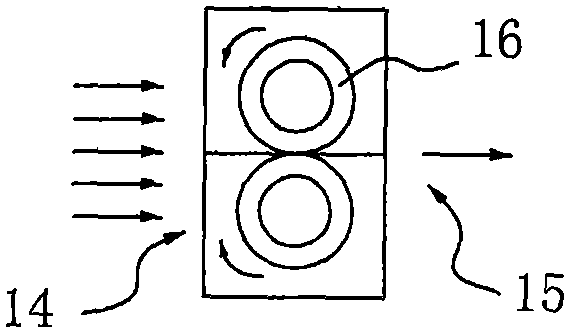

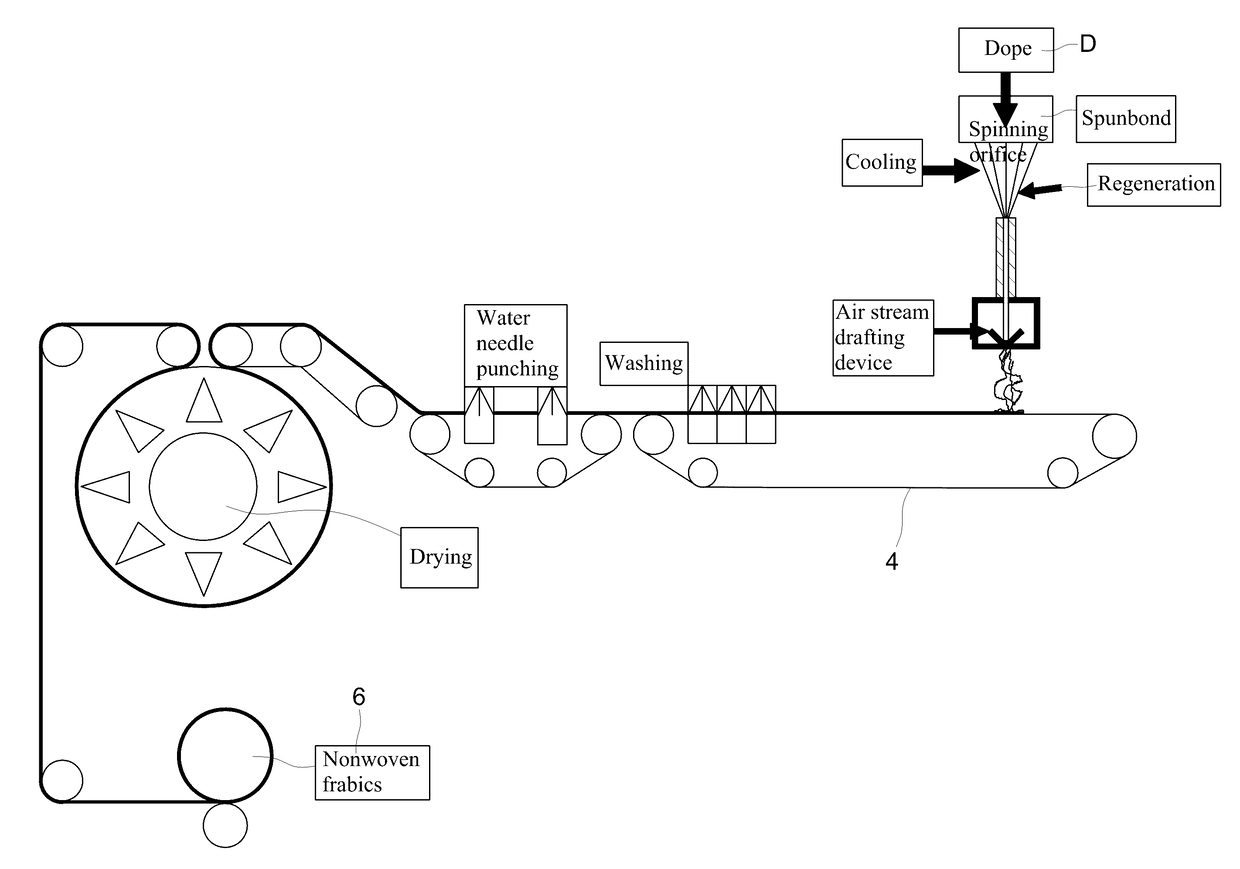

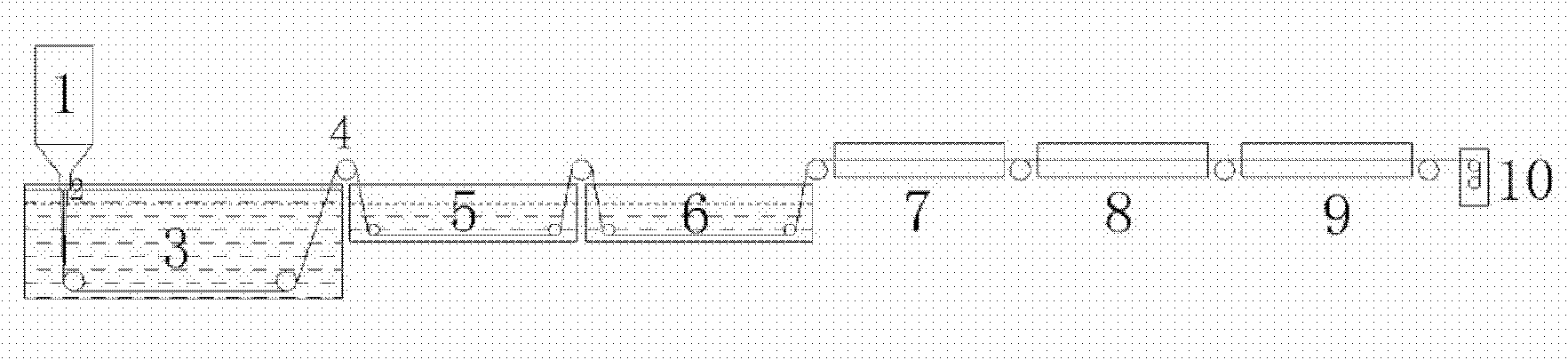

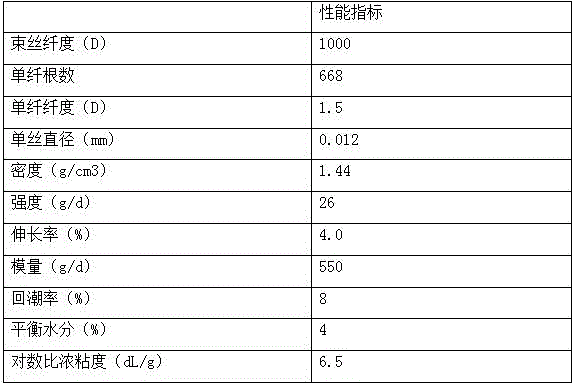

Method and equipment preparing viscose filament non-woven fabric through wet spinning technology

ActiveCN105401332AIncreased tangleOvercoming complexitySpinning solution filteringSpinning solution de-aeratingEngineeringWork in process

The invention discloses a method and equipment preparing viscose filament non-woven fabric through wet spinning technology; the method comprises the following steps: 1, spinning technology, spinning dope preparation; 2, spinning soup solidification reaction; 3, viscose formation; 4, washing; 5, drying: non-woven fabric formation technology; 6, lapping: uniformly scattering and lapping dried primary viscose fiber beams on a lapper web curtain, thus forming intersecting stacked filament fiber web; 7, spunlace reinforcement; 8, baking; 9, winding. The equipment comprises a wet spinning device and a non-woven fabric forming device; related steps in a conventional wet spinning technology can be omitted; semi-finish viscose filament can be directly used for non-woven fabric production; in the prior art, finished fiber filaments are secondarily used for non-woven fabric production; the novel method can break the conventional concept, can effectively save production cost, can reduce environment pollution in the production process, and can improve production efficiency.

Owner:QINGDAO UNIV

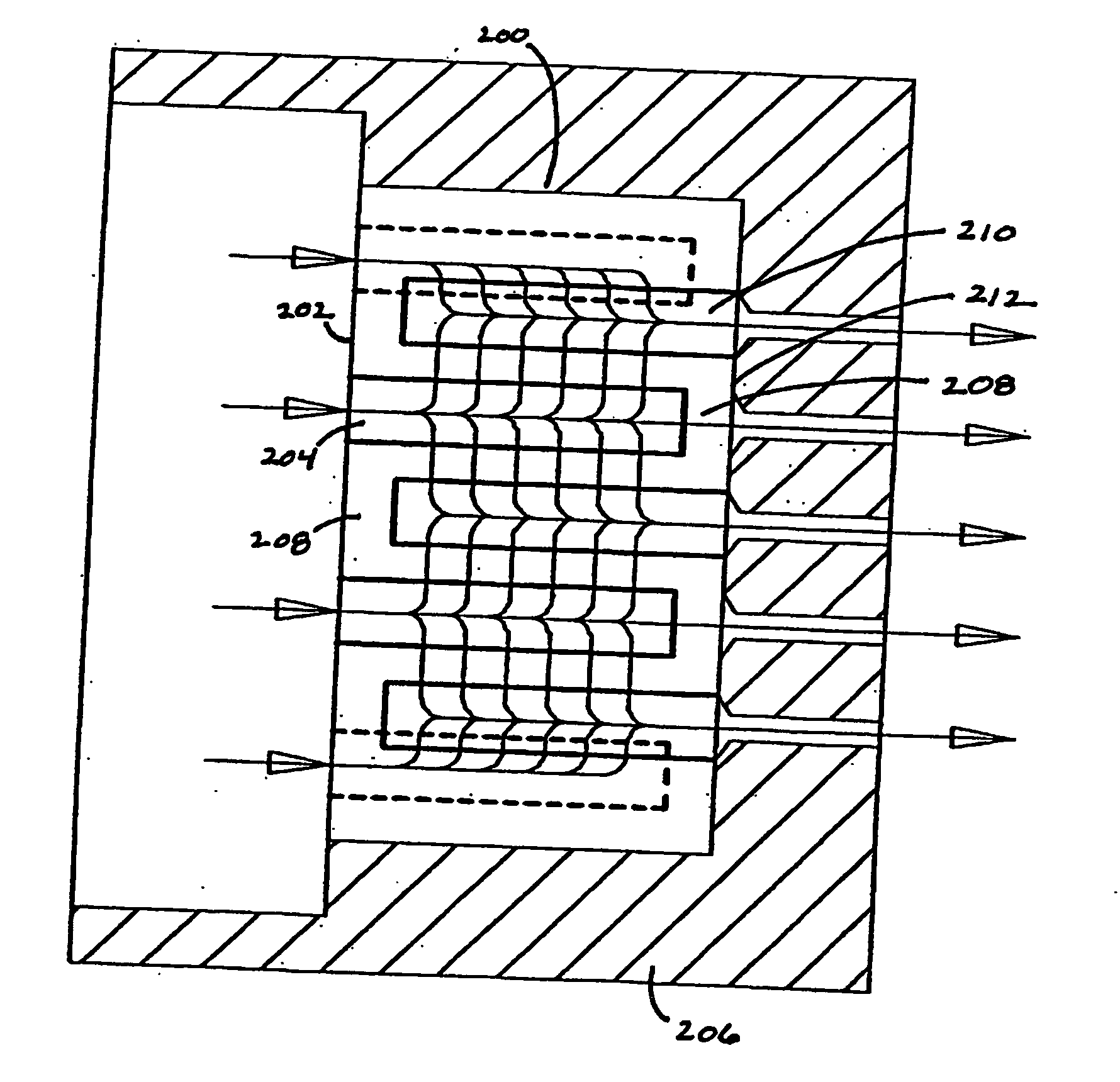

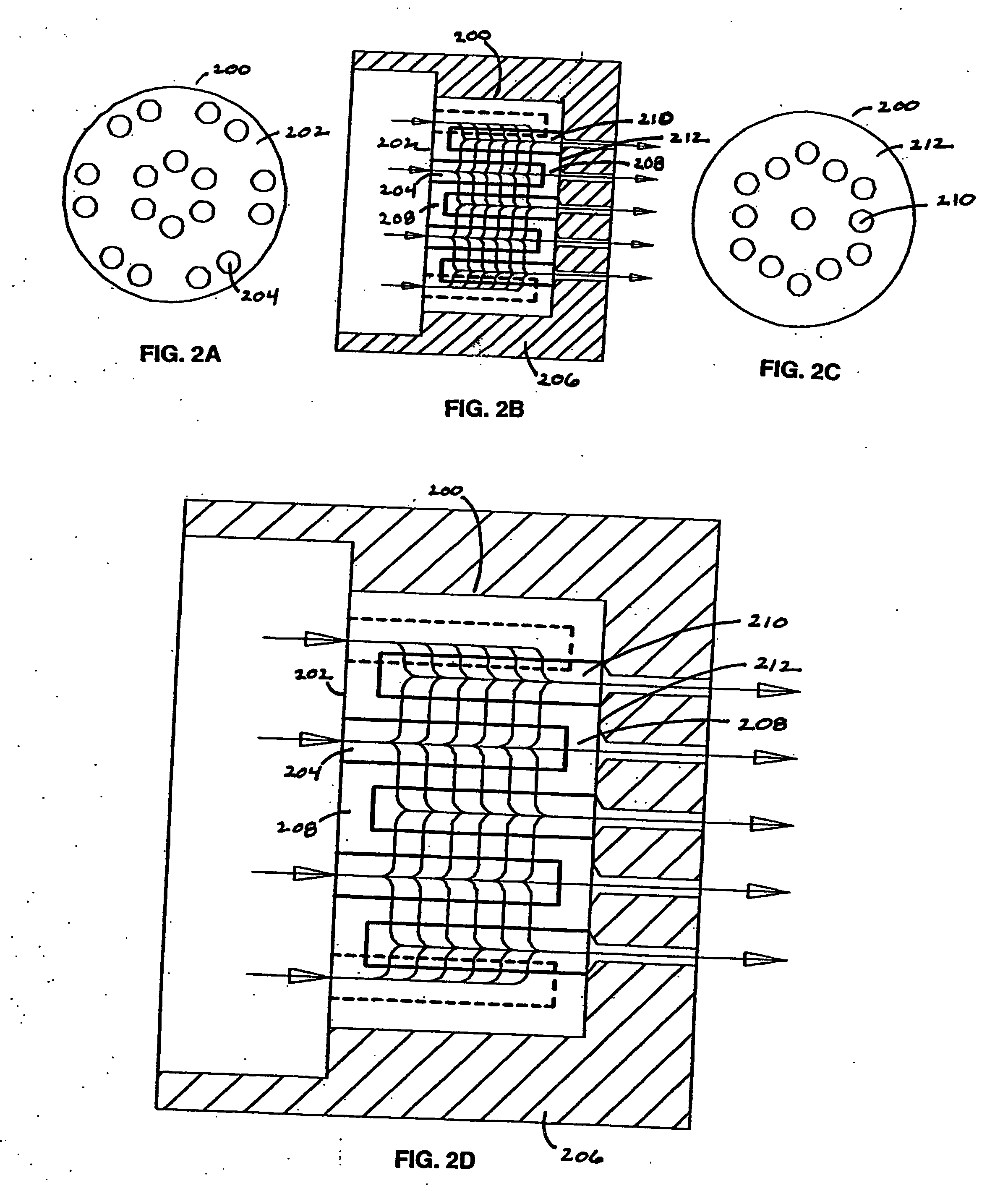

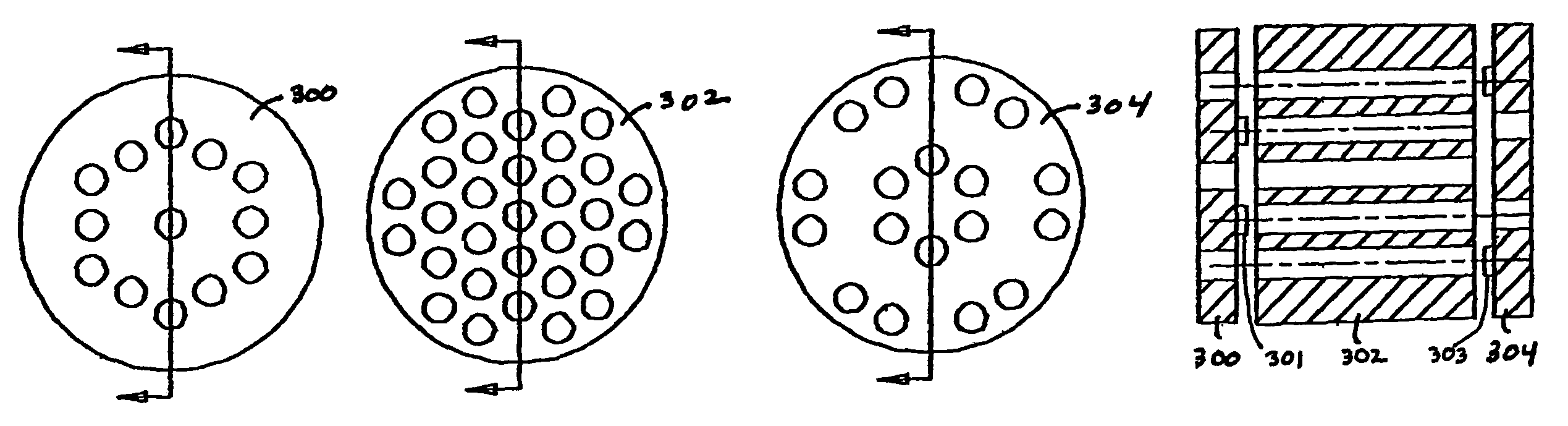

Extended area filter

InactiveUS20050035051A1Improve flow uniformityImprove throughputSpinning solution de-aeratingSpinnerette packsPolymer scienceFiltration

An extended area filter is provided that is useful in polymer melt spin pack assemblies. The filter is a uniform porous body that is made, for example, of sintered powder metal, and contains multiple opposing spaced apart inlet and outlet cavities. The filter has substantially uniform pore structure and density, and is substantially free from polymer binder decomposition products, allowing for more uniform flow with improved throughput and filtration life.

Owner:MOTT CORP

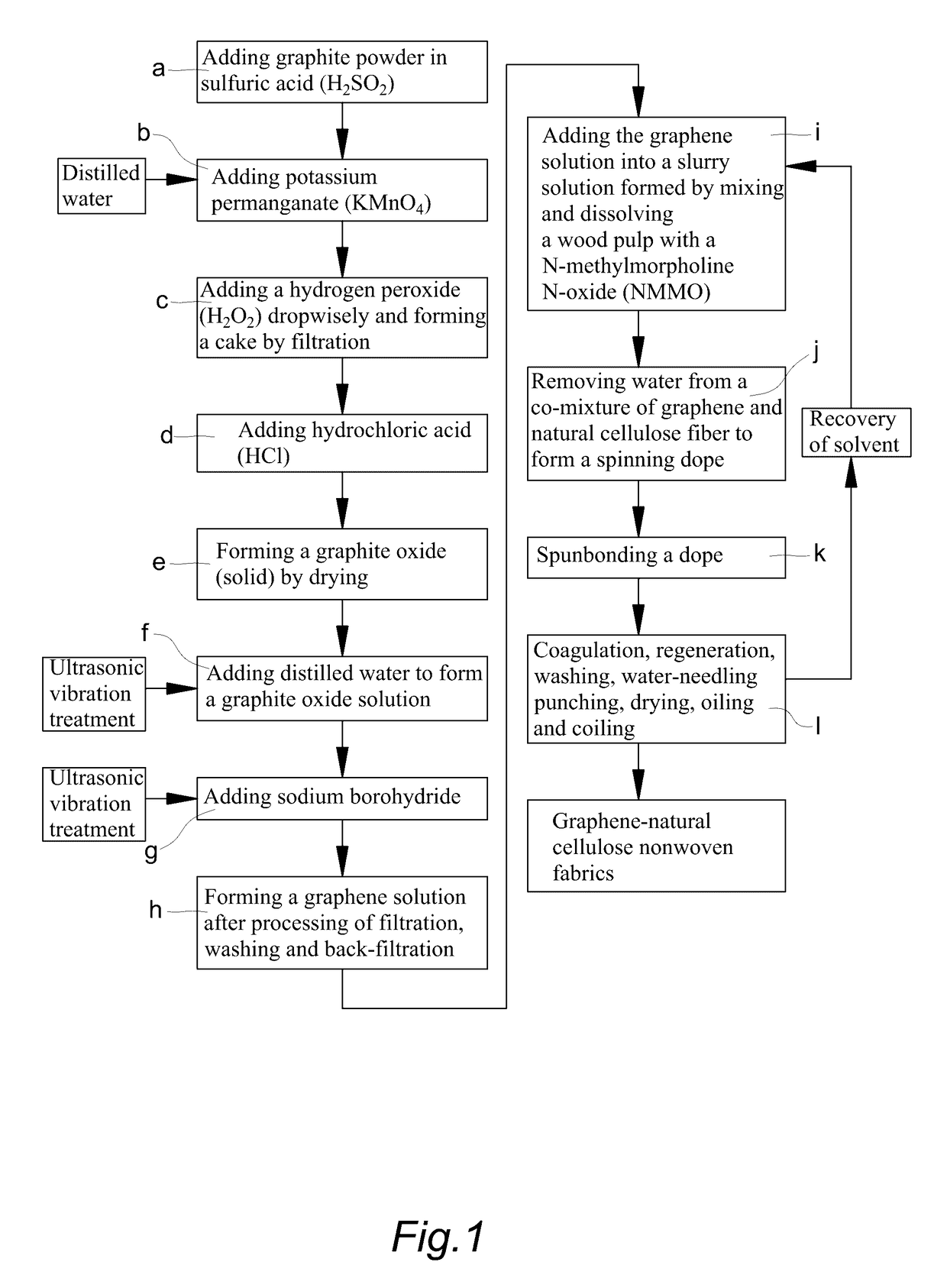

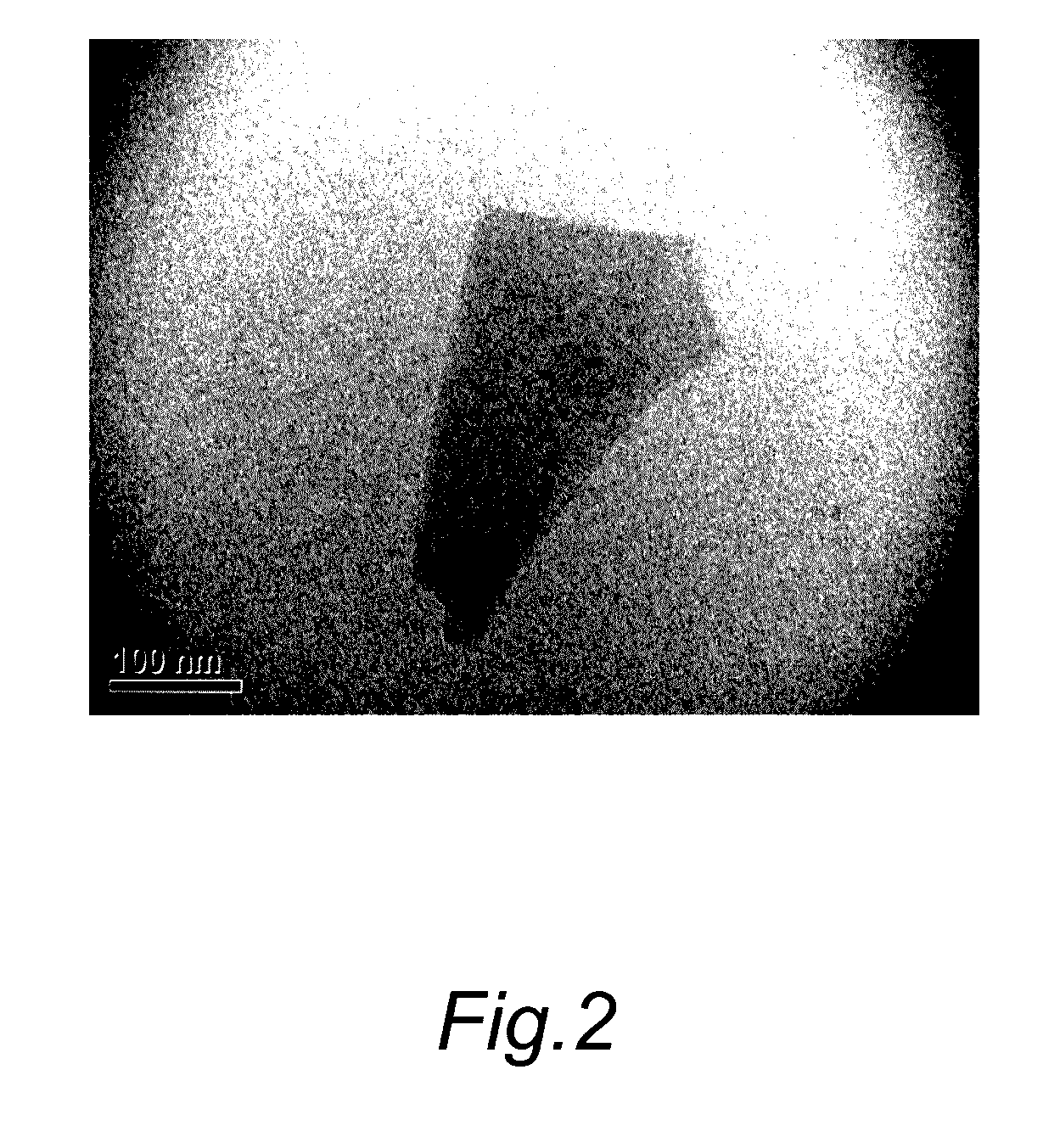

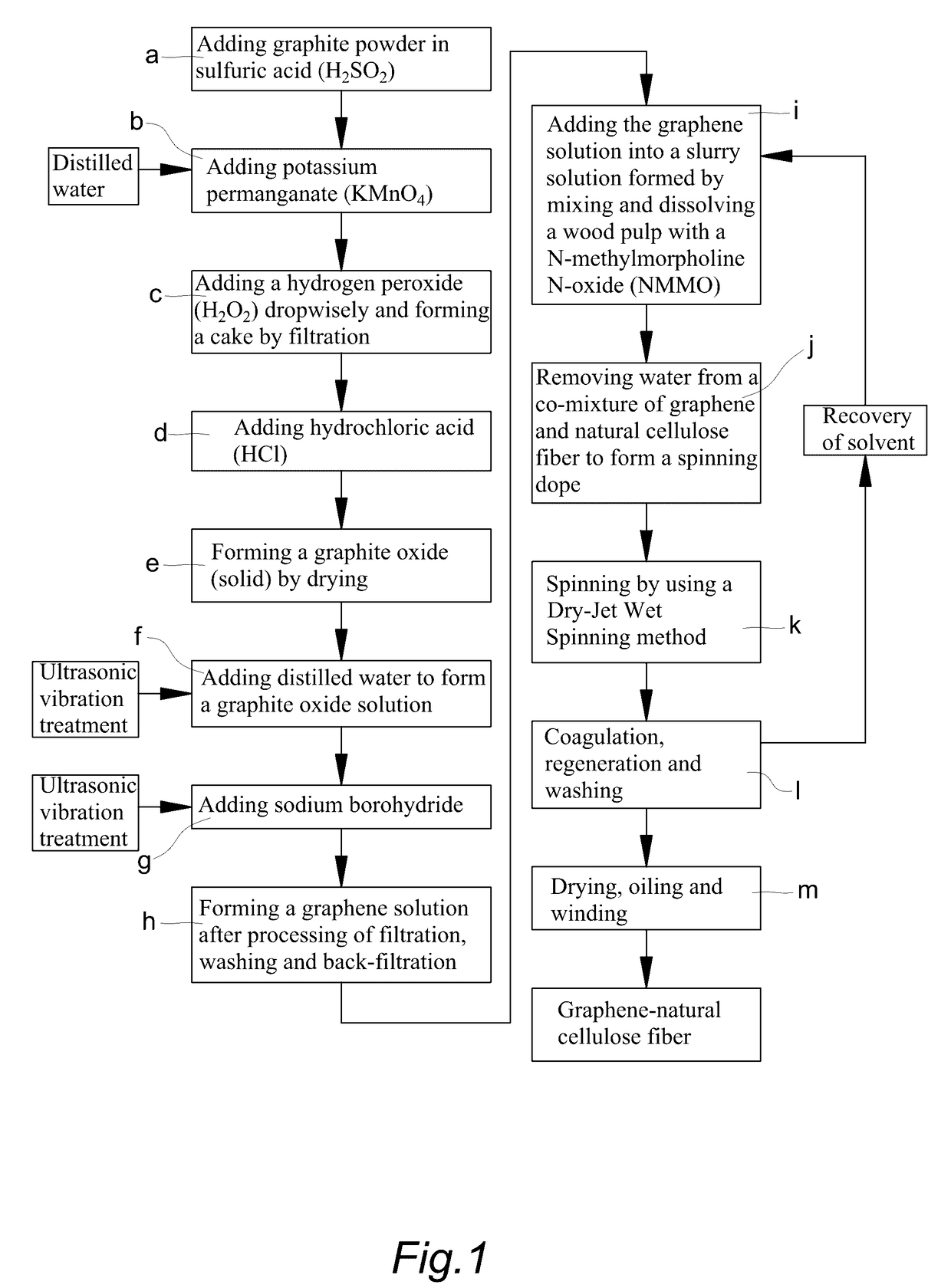

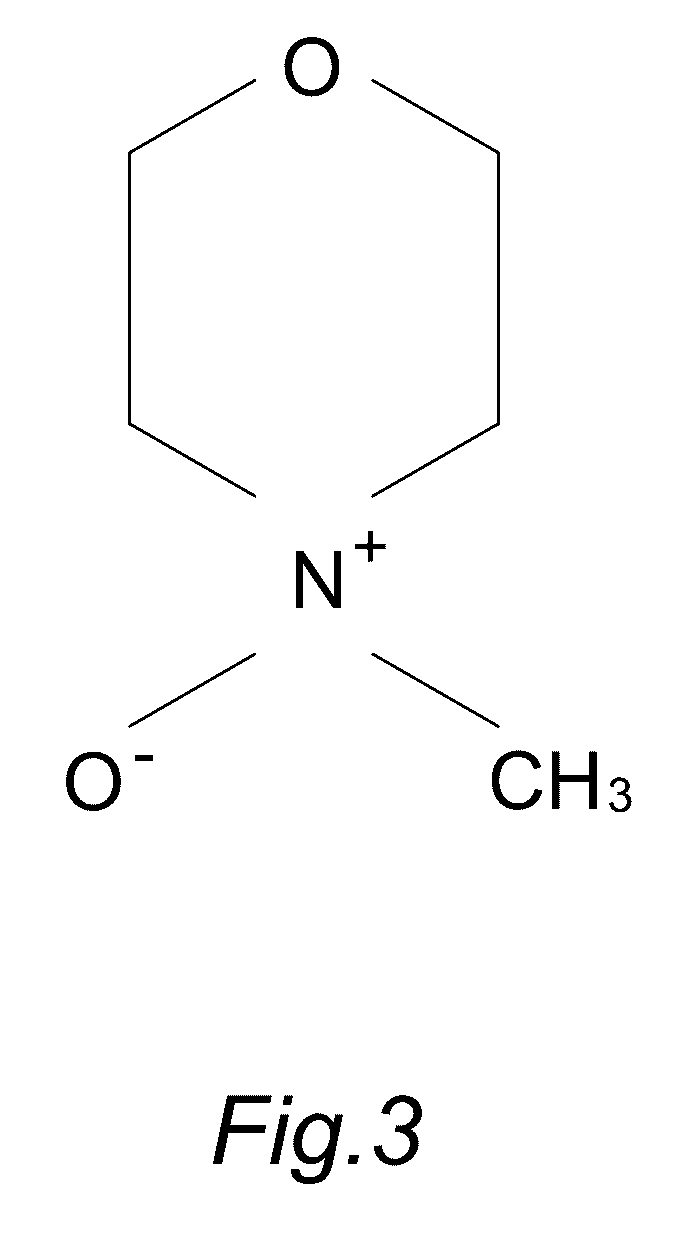

Method of Preparing of Natural Graphene Cellulose Blended Spunbond Nonwoven Fabric

ActiveUS20170107644A1Avoiding health hazard associated with solutionAltered propertySpinning solution de-aeratingCarbon compoundsPresent methodSlurry

This application describes a method of preparation of a natural graphene cellulose blended spunbond nonwoven fabric, which comprises using a graphite powder as a raw material for preparing a graphene solution, adding the graphene solution to a slurry formed by mixing and dissolving a wood pulp with N-methylmorpholine N-oxide (NMMO), removing the water content thereof to form a spinning dope, and then directly preparing the natural graphene cellulose blended spunbond nonwoven fabric by a spunbond process. The present method does not require a highly toxic hydrazine hydrate solution. Further, by increasing the adding ratio of the graphene solution in the manufacturing process, control of the antistatic properties and thermal transferring function can be achieved, and thereby various requirements of different consumers can be satisfied. Besides, the fabric can decompose naturally after being used, and thus the product is harmless, natural, and environmentally friendly.

Owner:LIN CHIH HSIN

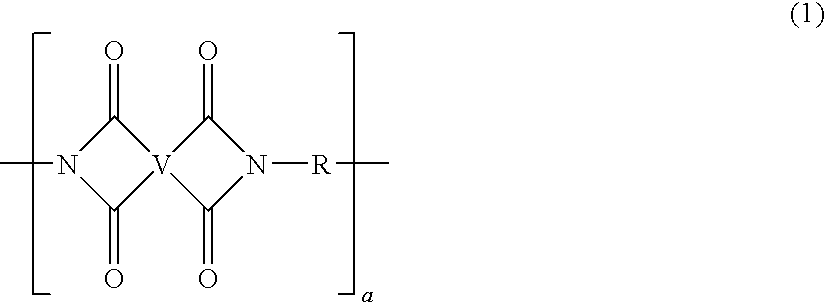

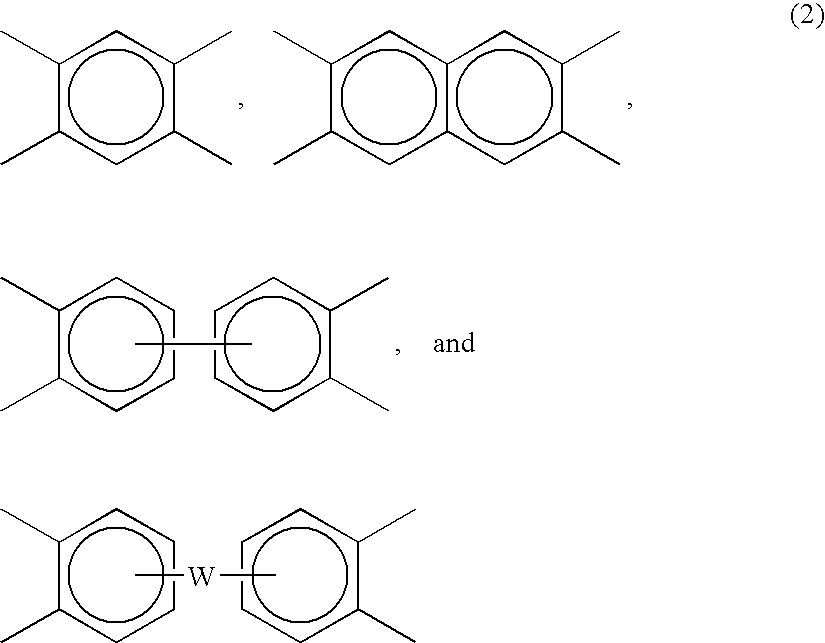

Polyetherimide polymer for use as a high heat fiber material

Various embodiments of polymer fibers comprising a high heat polymer and process for making the polymer fibers are provided. In one embodiment, synthetic polymer fibers comprise polyetherimide polymer that is substantially free of foreign particulate matter greater than about 100 microns in size. A process for producing polymer fiber includes melting polymer comprising polyetherimide to a melt temperature that ranges from about 180-500° C. to form a molten polymer; passing the polyetherimide that is substantially free of foreign particulate matter above about 100 microns in size, through a spinneret comprising a plurality of hole openings to produce a fiber bundle; and cooling the fiber bundle with a cooling medium having a temperature that ranges from about 0° C. to about 80° C.

Owner:SHPP GLOBAL TECH BV

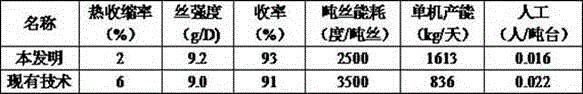

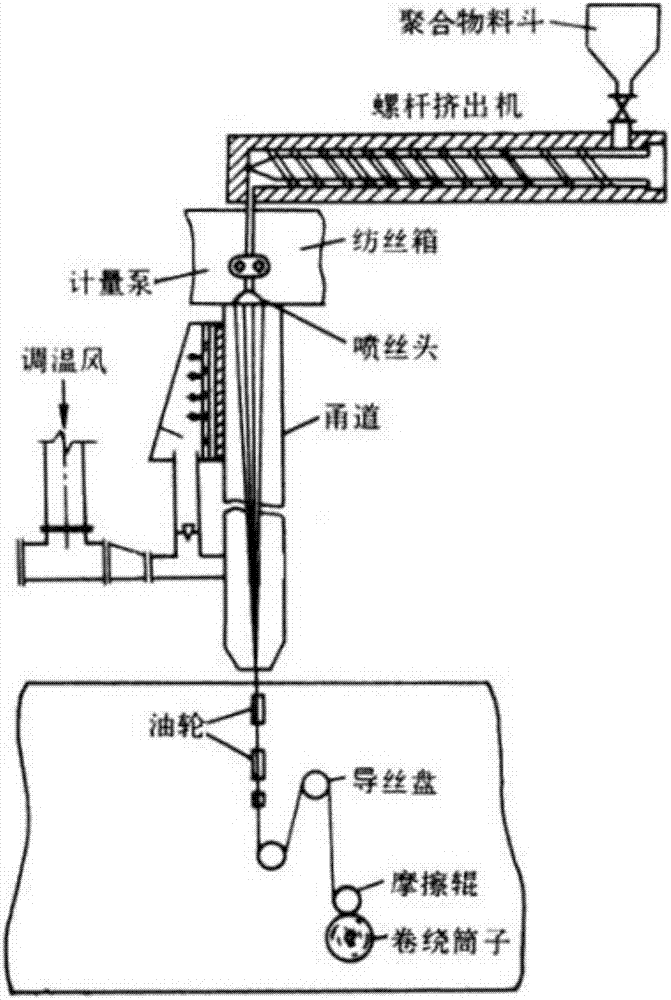

Preparation method of low-shrinkage polyamide 66 industrial yarn

ActiveCN106367817ALow shrinkageHigh strengthSpinning solution de-aeratingSpinnerette packsYarnPolyamide

Provided is a preparation method of low-shrinkage polyamide 66 industrial yarn. The preparation method comprises the following steps that 1, slices enter a drying tower to be dried so as to be tackified; 2, the treated slices are subjected to humidifying treatment till the optimal moisture content and viscosity are achieved; 3, the treated slices enter a screw extruder to be heated, and melt is obtained; 4, the melt enters a spinning component, and after metering is conducted through metering pumps and filtering is conducted through filter devices, spinning is conducted through a spinneret plate under high pressure; 5, melt trickles sprayed by the spinneret plate enter a spinning channel to be cooled to form tows; 6, after cooling is conducted, the tows are oiled through an oiling roller; 7, six pairs of hot rollers conduct drafting and shaping on the tows; 8, the tows obtained after being drafted and shaped are subjected to winding on an eight-head winding device. The preparation method is high in winding efficiency and low in breakage rate, the hot-shrinkage rate of the prepared polyamide 66 industrial yarn is lower than or equal to 2%, the denier ranges from 100 D to 1,890 D, the breaking strength is higher than or equal to 9.2 g / D, and the elongation at break becomes 18%-22%.

Owner:中维化纤股份有限公司

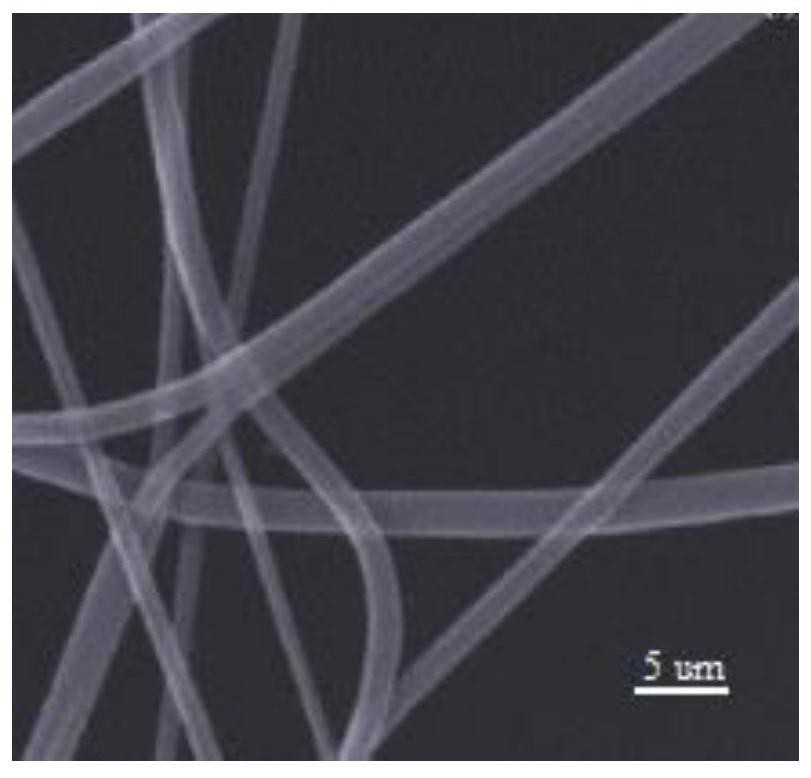

Preparation method of graphene antibacterial melt-blown cloth and application thereof

InactiveCN111636147AExtended use timeReduce hydrophilicitySpinning solution de-aeratingMelt spinning methodsFiberPolymer science

The invention discloses a preparation method of graphene antibacterial melt-blown cloth and application thereof. The preparation method comprises the following preparation steps of preparing modifiedpolypropylene resin, taking materials and carrying out weighing, mixing the materials, and carrying out melt extrusion, filtering, spinning, melt-blown fiber cloth forming, cutting, packaging and sealing for storage. The graphene antibacterial melt-blown cloth is applied to the field of processing and preparation of medical surgical masks. The preparation method disclosed by the invention is scientific and simple in process flow and can be widely popularized and produced in the industry; in addition to a two-dimensional carbon nano material with relatively strong antibacterial property, the melt-blown cloth is also added with bactericidal substances such as titanium dioxide and zinc oxide, so that the bactericidal effect of the material is further enhanced; the service time of a mask prepared by utilizing the graphene antibacterial melt-blown cloth is greatly prolonged, the effective service time of a novel graphene mask exceeds 48 hours and is more than 10 times that of a traditionalmask, and the filtering efficiency of the novel graphene antibacterial mask is only reduced by 4% after the novel graphene antibacterial mask is continuously worn for 48 hours.

Owner:青岛领军新材料科技创新园发展有限公司

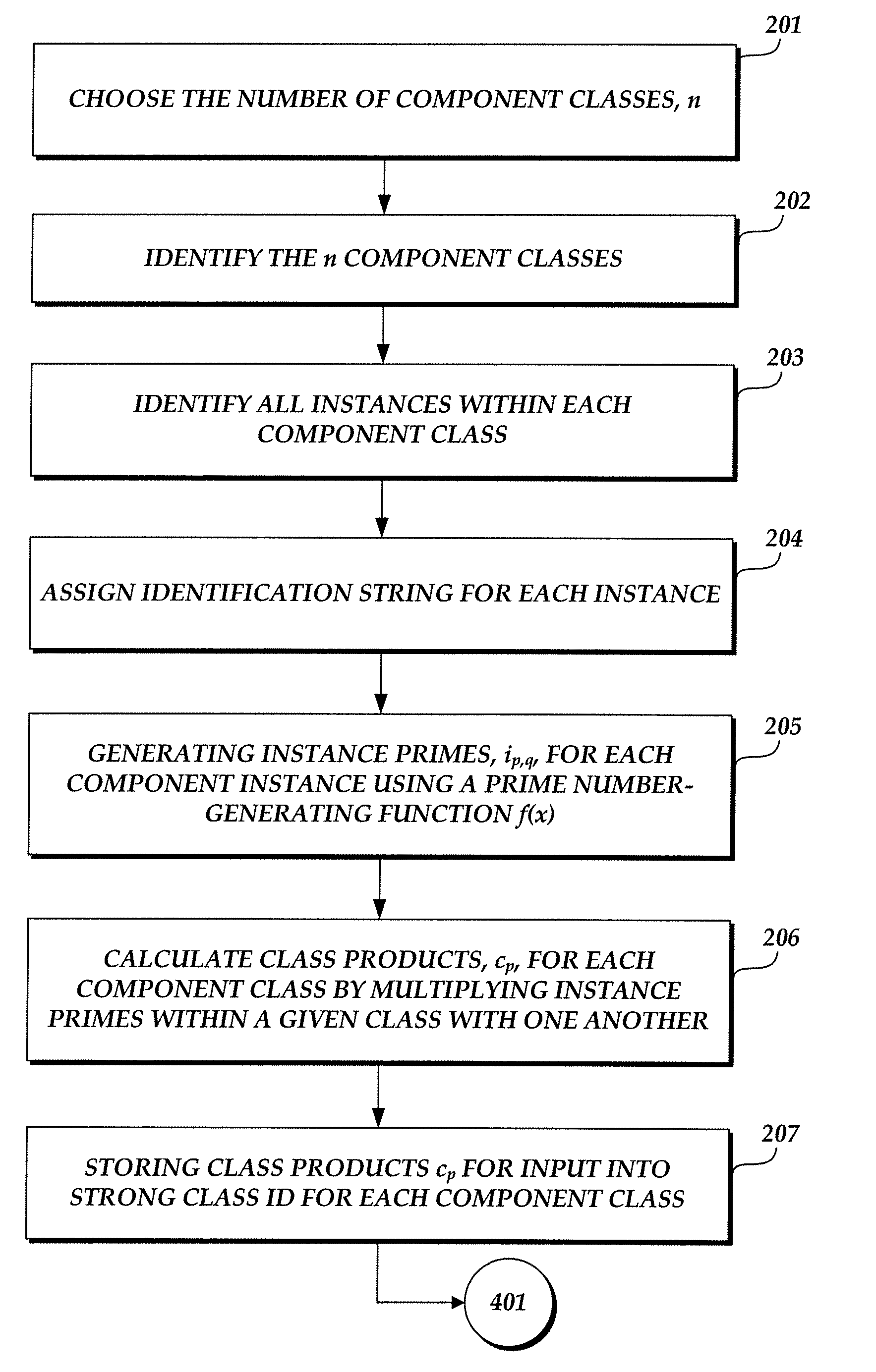

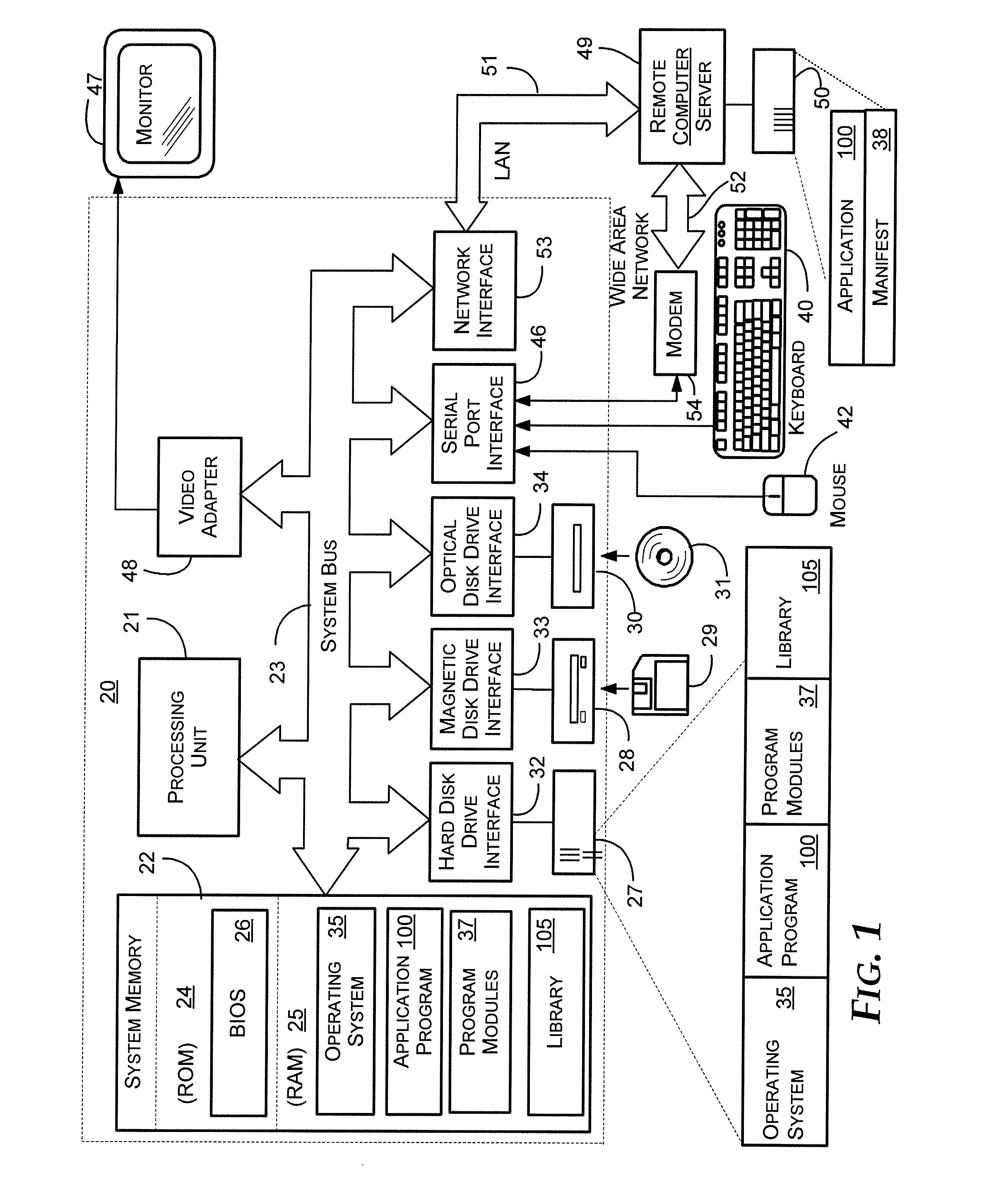

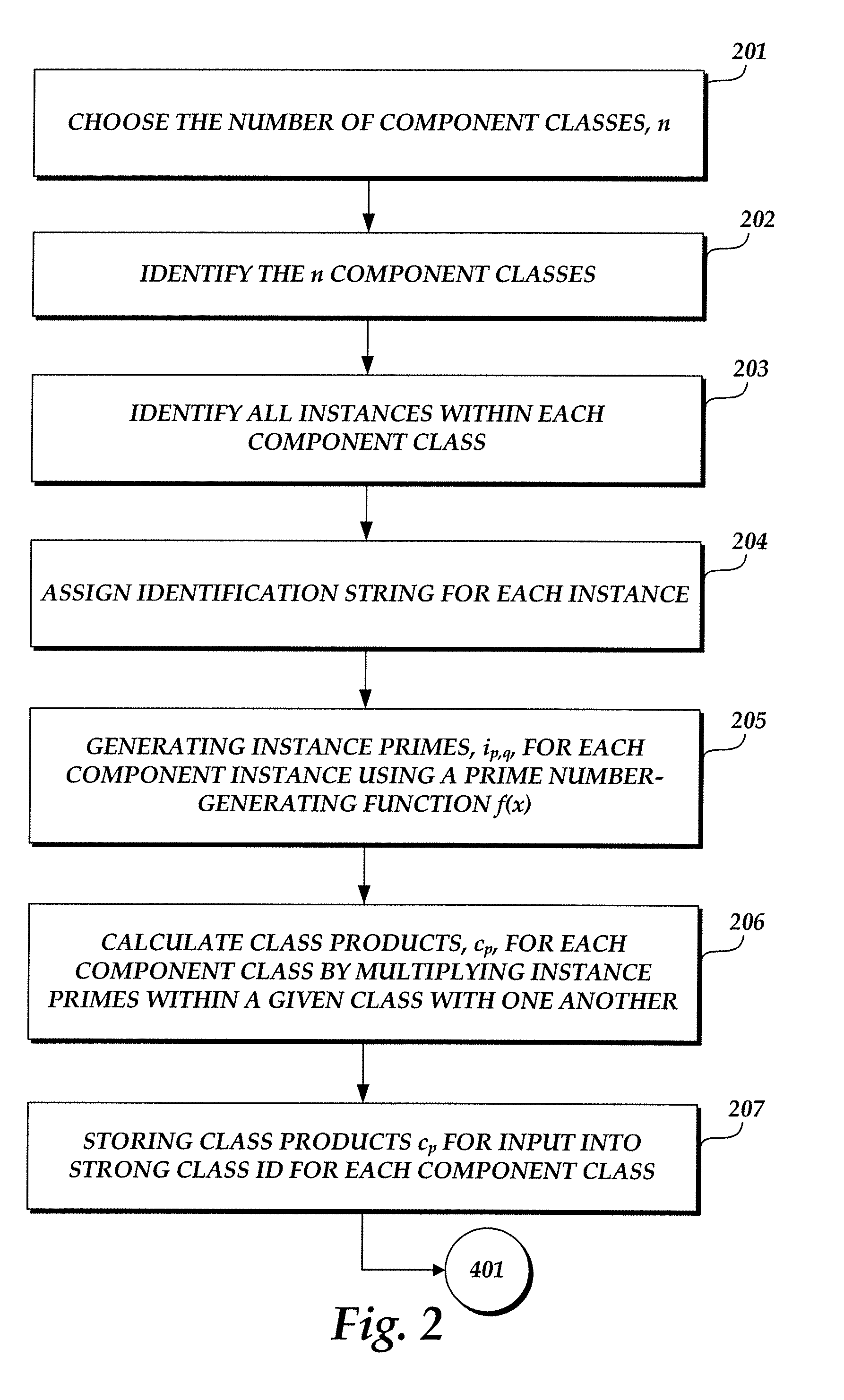

System for binding secrets to a computer system having tolerance for hardware changes

InactiveUS20080098482A1Preventing and minimizingAntibacterial agentsSpinning solution de-aeratingComputer hardwareComputerized system

Systems and methods for binding a secret to a computer system are disclosed. Systems and methods for generating a strong hardware identification (SHWID) for a given computer system are also disclosed. The strong hardware identification (SHWID) is coupled to a bound secret. The strong hardware identification (SHWID) may be used to control the use of software on the given computer system depending on the degree of hardware changes to the computer system.

Owner:MICROSOFT TECH LICENSING LLC

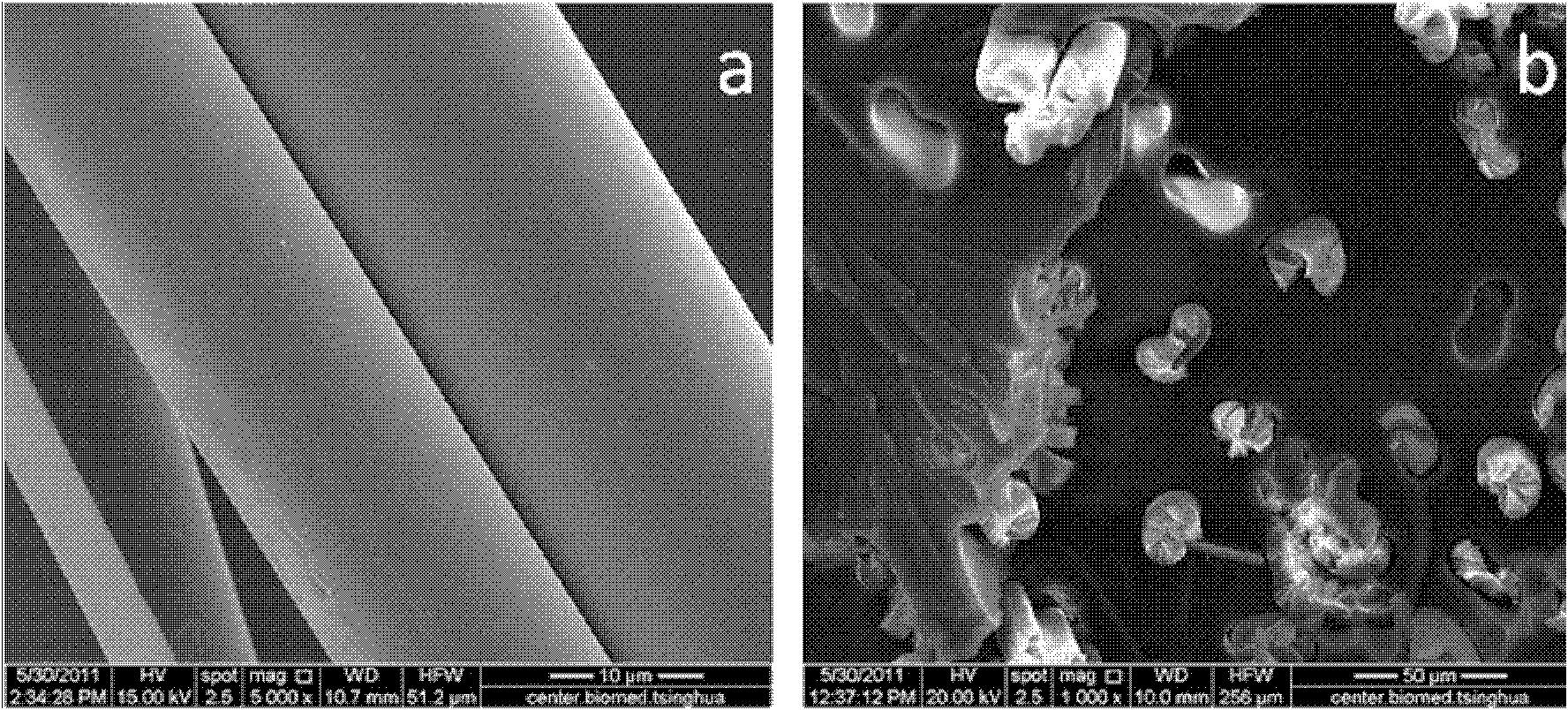

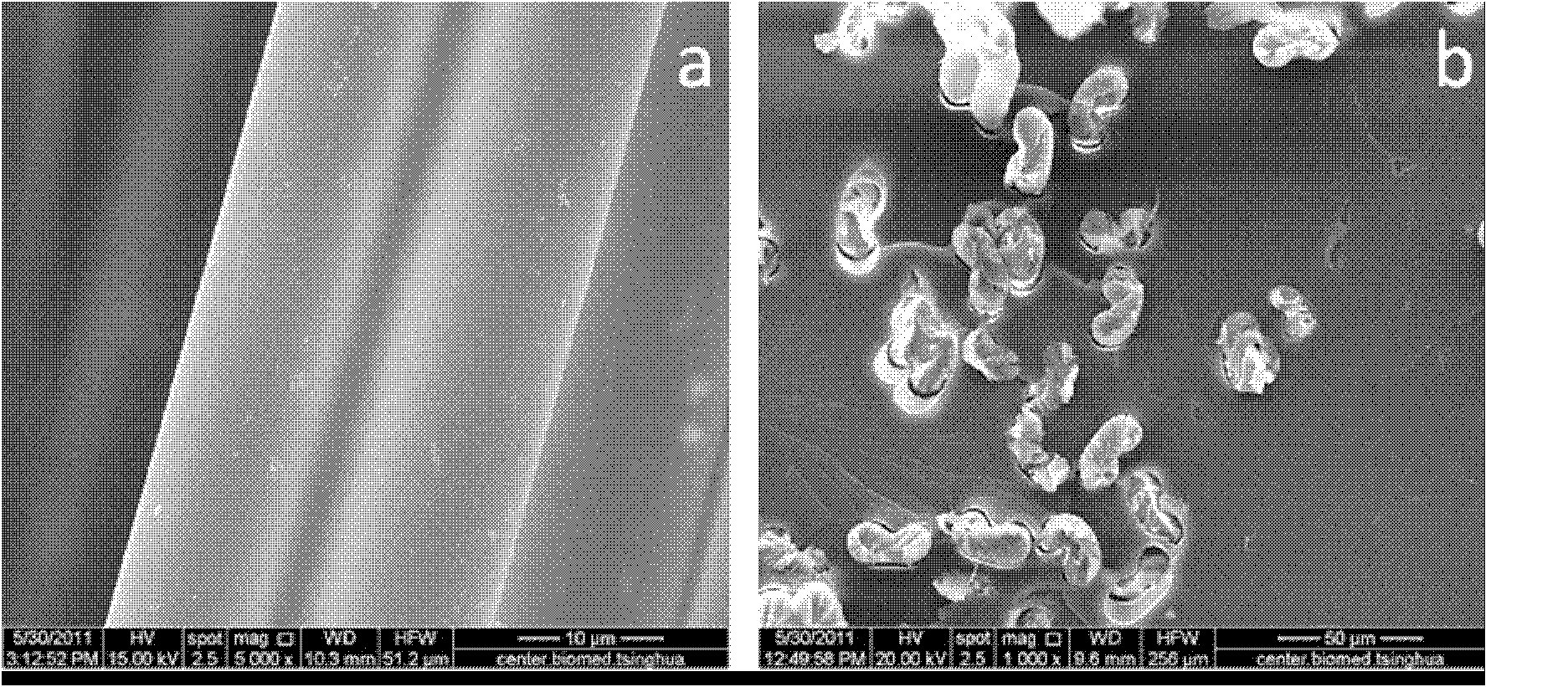

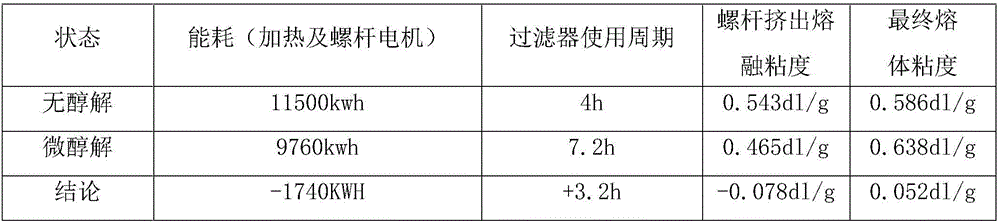

Polyimide fiber with kidney-shaped section and preparation method thereof

ActiveCN102560707AImprove production efficiencySimple preparation processSpinning solution filteringSpinning solution de-aeratingFiberConductor Coil

A polyimide fiber with kidney-shaped section and a preparation method thereof belong to the technical field of polyimide fibers. The preparation method includes: utilizing polyamide acid (PAA) solution synthesized by aromatic dianhydride and aromatic diamine to perform the wet spinning process by the aid of circular spinneret holes, adjusting spinning conditions including spinneret speed, composition, proportion and temperature of coagulating bath, the length of hydrazine and the like to obtain a PAA as-formed fiber with kidney-shaped section, then washing and drying the PAA as-formed fiber, cyclizing and drafting the same at high temperature stage by stage, and winding and the like, finally obtaining the polyimide (PI) fiber with the kidney-shaped section. The preparation method of the polyimide fiber with the kidney-shaped section has the advantages of simplicity in spinneret hole design and processing, easiness in control of spinning process, high preparation efficiency, low cost for raw materials, low energy consumption and the like and can be used for large-scale industrialized production.

Owner:BEIJING UNIV OF CHEM TECH

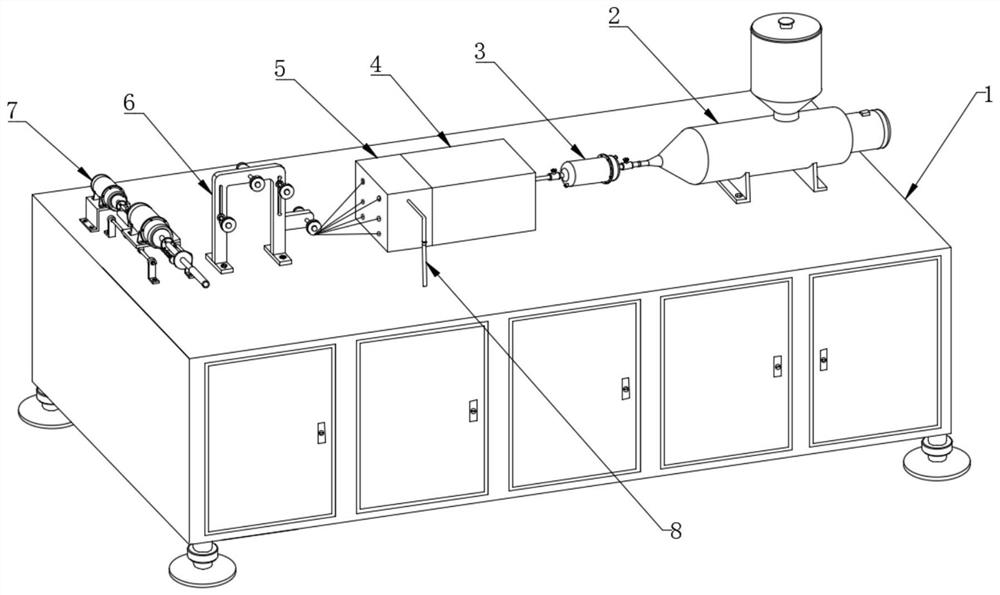

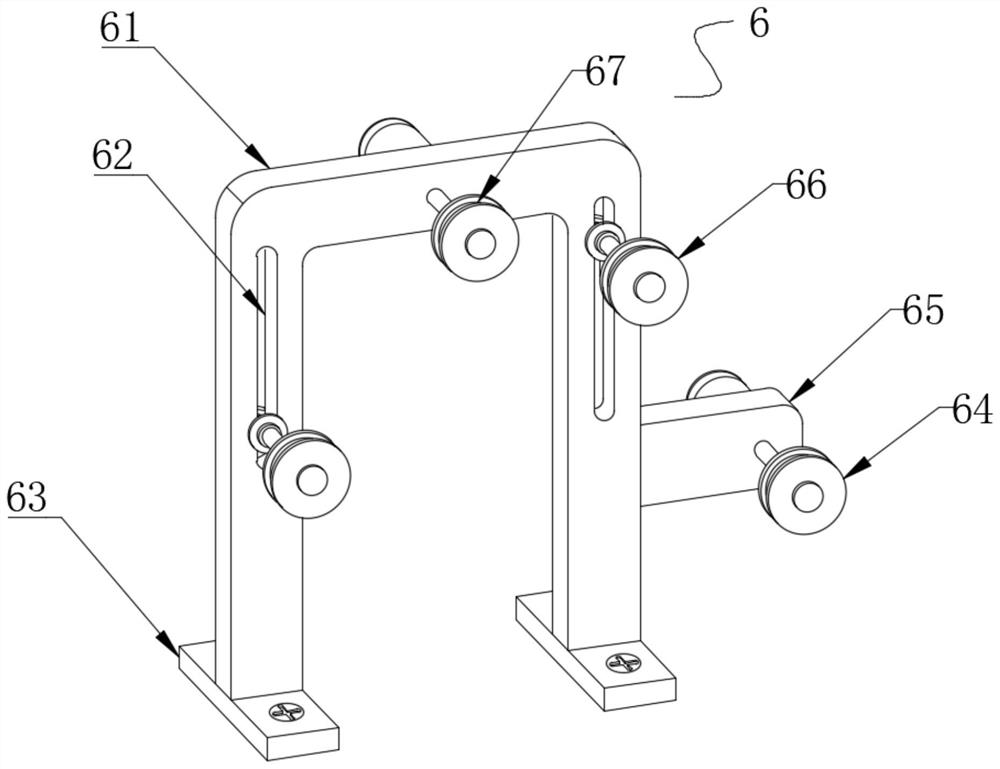

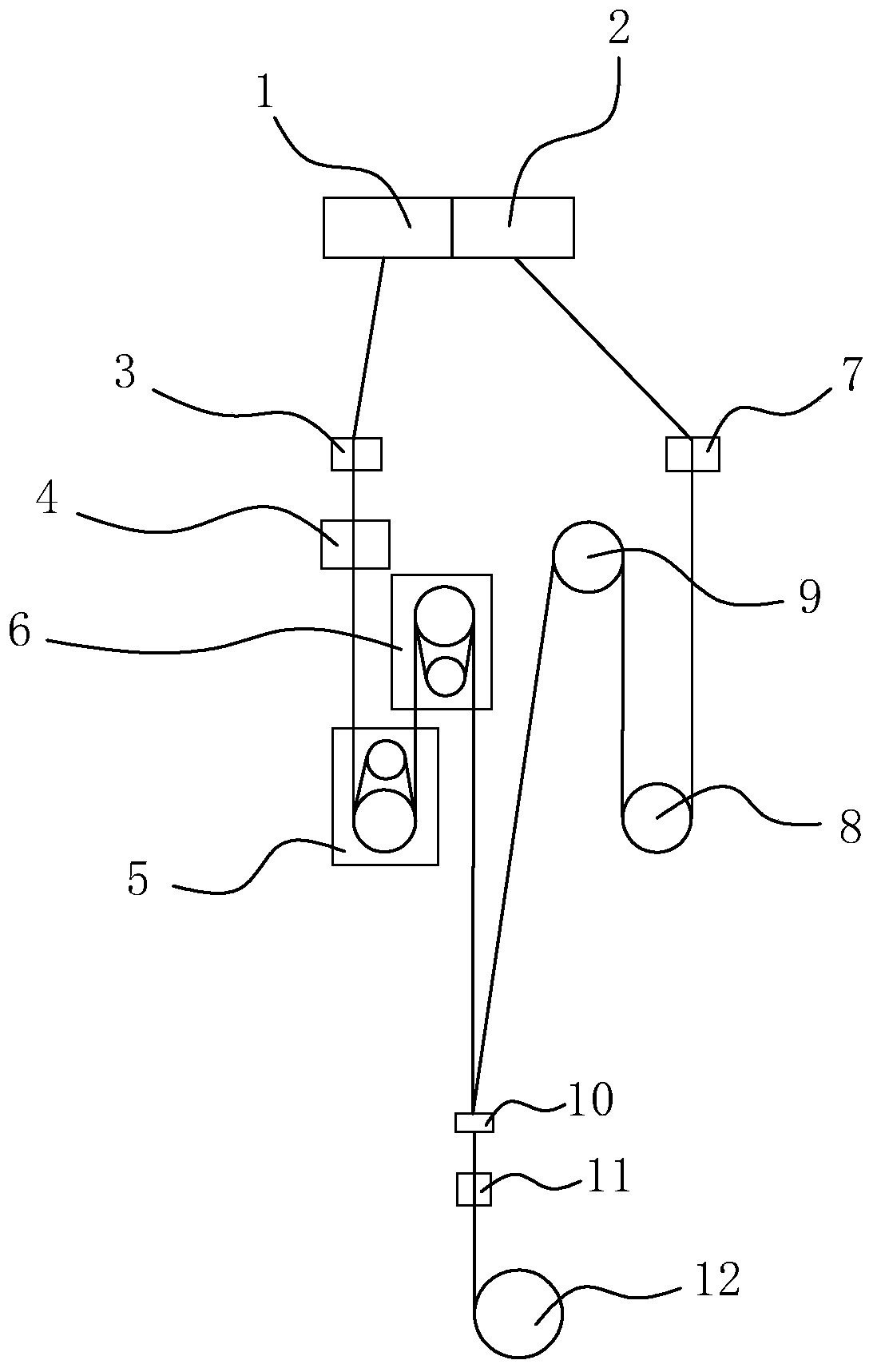

Spinning device for producing chinlon high-strength yarn

InactiveCN111826731AImprove work efficiencyHigh degree of automationSpinning solution de-aeratingSpinnerette packsYarnSpinning

The invention relates to the technical field of chinlon spinning and discloses a spinning device for producing chinlon high-strength yarn. The spinning device comprises a workbench, a screw extrusionmechanism is installed on one side of the top end of the workbench, one end of a filter is fixedly connected with a spinning mechanism, a stretching mechanism is installed on the side, close to a cooling box, of the top end of the workbench, and a winding mechanism is installed on the side, close to the stretching mechanism, of the top end of the workbench. According to the spinning device for producing the chinlon high-strength yarn, chinlon slices can be fused and fed through the screw extrusion mechanism; the molten chinlon is spun into a plurality of pieces of chinlon high-strength yarn through the spinning mechanism; the chinlon high-strength yarn entering the cooling box is subjected to air cooling through the cooling mechanism; the plurality of pieces of chinlon high-strength yarn is subjected to tow combining and stretching treatment through the stretching mechanism; and the finished chinlon high-strength yarn is wound through the winding mechanism, so that the automation degree is improved, the working efficiency is high, and the production cost is relatively low.

Owner:南通九州化纤有限公司

Method of preparing natural graphene cellulose blended fiber

This application describes a method of preparation of a natural graphene cellulose blended fiber, which comprises using a graphite powder as a raw material for preparing a graphene solution, adding the graphene solution to a slurry formed by mixing and dissolving a wood pulp with N-methylmorpholine N-oxide (NMMO), removing the water content thereof to form a spinning dope, and then spinning the spinning dope by a Dry-Jet Wet method to manufacture a natural graphene cellulose blended fiber. The present method does not require a highly toxic hydrazine hydrate solution. Further, by increasing the adding ratio of the graphene solution in the manufacturing process, control of the antistatic properties and thermal transferring functions can be achieved, and thereby various requirements of different consumers can be satisfied. Besides, the fibers can decompose naturally after being used, and thus the product is harmless, natural, and environmentally friendly.

Owner:LIN CHIH HSIN

Method of making extended area filter

InactiveUS7361300B2Improve flow uniformityEfficiently and economically produced and and maintained and replacedSpinning solution de-aeratingSpinnerette packsMetal powderPolymer melt

Methods are provided for making a porous filter that is useful in polymer melt spinning. The methods include pressing particles, such as a metal powder, to form a filter having a filter body integrally formed with a top cap and a bottom cap. The filter body and caps are formed as a single component or, alternatively, are formed as two or three separate parts that are fitted and pressed together to form a single component having blind inlet and outlet cavities. After pressing, the component is sintered to form the porous filter. The particles are pressed and cohere to form the caps and filter body without the use of a polymeric binder, and the inlet and outlet cavities are formed substantially without machining.

Owner:MOTT CORP

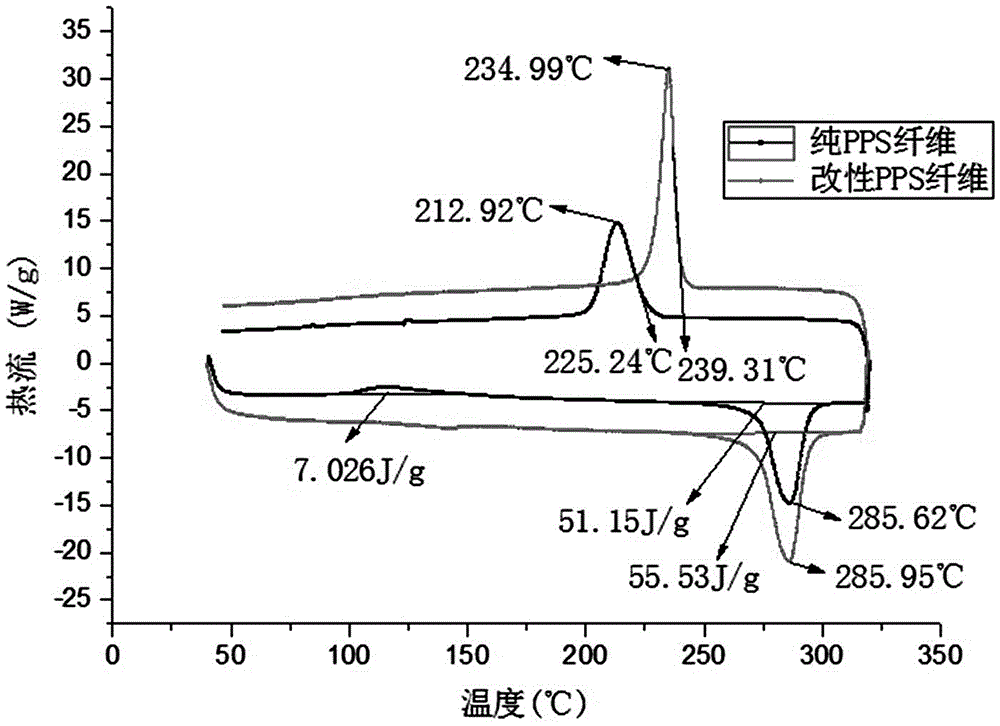

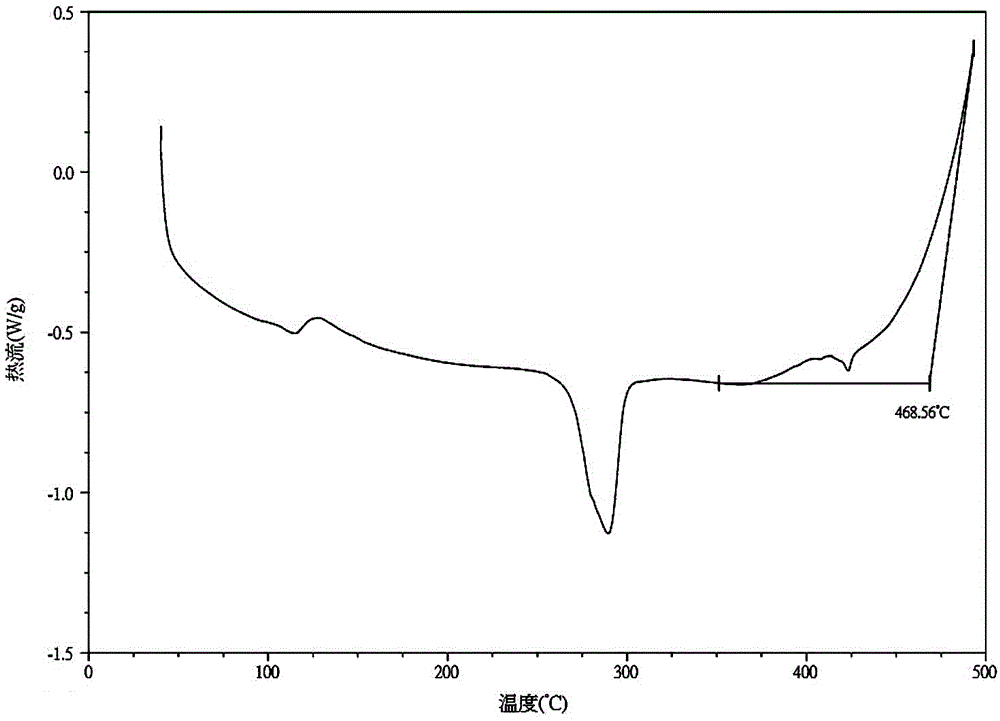

High-temperature-oxidation-resistant composite nano PPS / Ti-SiOx short fiber and preparation method thereof

ActiveCN105544000AHigh strength retentionOxidation-induced temperature increaseSpinning solution de-aeratingSpinnerette packsFiberAfter treatment

The present invention discloses a high-temperature-oxidation-resistant composite nano PPS / Ti-SiOx short fiber which is prepared as follows: adding nano Ti-SiOx into linear PPS resin to prepare composite nano PPS / Ti-SiOx masterbatch, melting the composite nano PPS / Ti-SiOx masterbatch at the low temperature of 295-320 DEG C and under pressure of 7-10Mpa to form a melt, spinning through a spinneret plate, and cooling and solidifying by a 20-30 DEG C circular air blow in the wind speed of 0.2-0.5m / s. The oxidative induction temperature of the prepared composite nano PPS / Ti-SiOx short fiber is 470-480 DEG C, after treatment at 230 DEG C for 72h, strength retention is 88% to 95%, and high temperature oxidation resistance can be improved significantly.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS +1

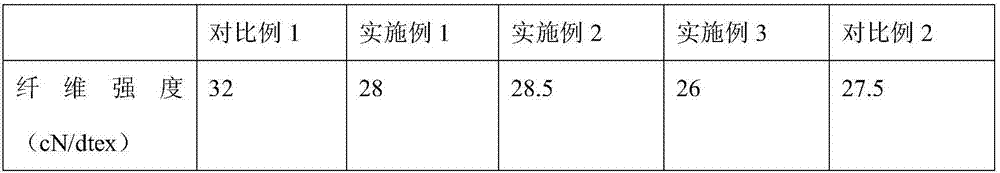

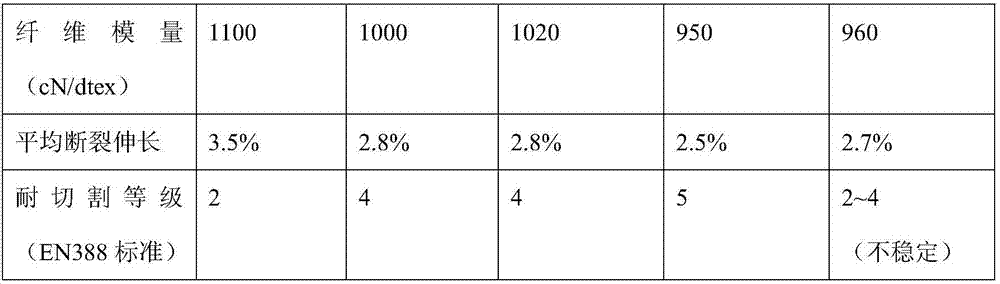

High cutting-resistant high-strength and high modulus polyethylene filament and preparation method thereof

InactiveCN107419354AImprove bindingEvenly dispersedSpinning solution de-aeratingArtificial filament heat treatmentFiberPolymer science

The invention discloses a high cutting-resistant high-strength and high modulus polyethylene filament and a preparation method thereof. A product is composed of an ultrahigh molecular weight polyethylene filament and a soft wear-resisting short fiber, wherein the mass content of the soft wear-resisting short fiber is 20 to 40% of that of an ultrahigh molecular weight polyethylene matrix. The preparation method comprises the steps of preparing the soft wear-resisting short fiber, preparing an ultrahigh molecular weight polyethylene spinning solution, preparing short fiber pre-dispersion liquid, adding the short fiber pre-dispersion liquid into the ultrahigh molecular weight polyethylene spinning solution, and further preparing to obtain an ultrahigh molecular weight polyethylene fiber. The cutting-resistant ultrahigh molecular weight polyethylene filament with optimized performance, which is prepared by the method provided by the invention, has the advantages that the strength is high, the modulus is high, the residual oil content is low, the cutting-resistant performance is stable and the hand feel is soft.

Owner:JIANGSU JIUJIUJIU TECH

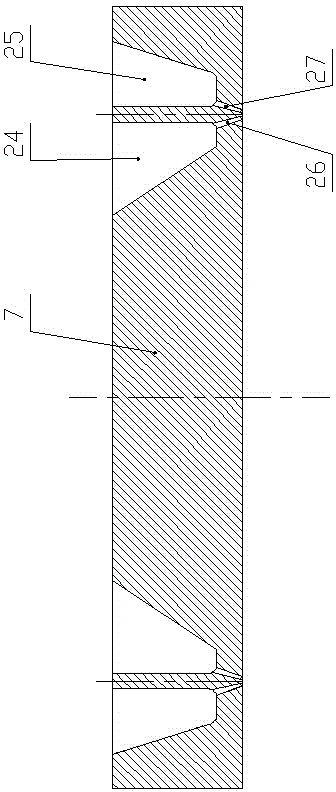

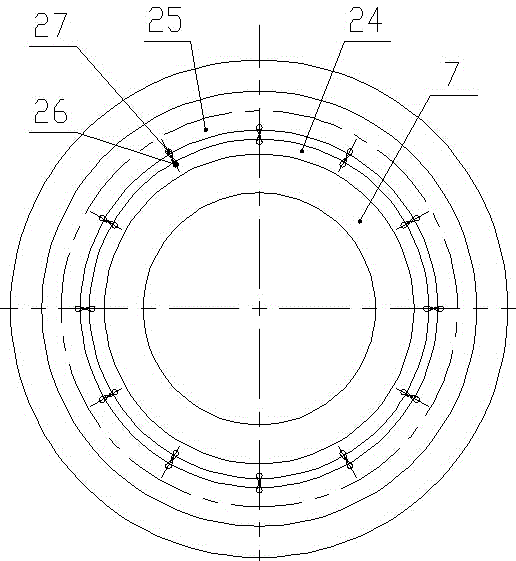

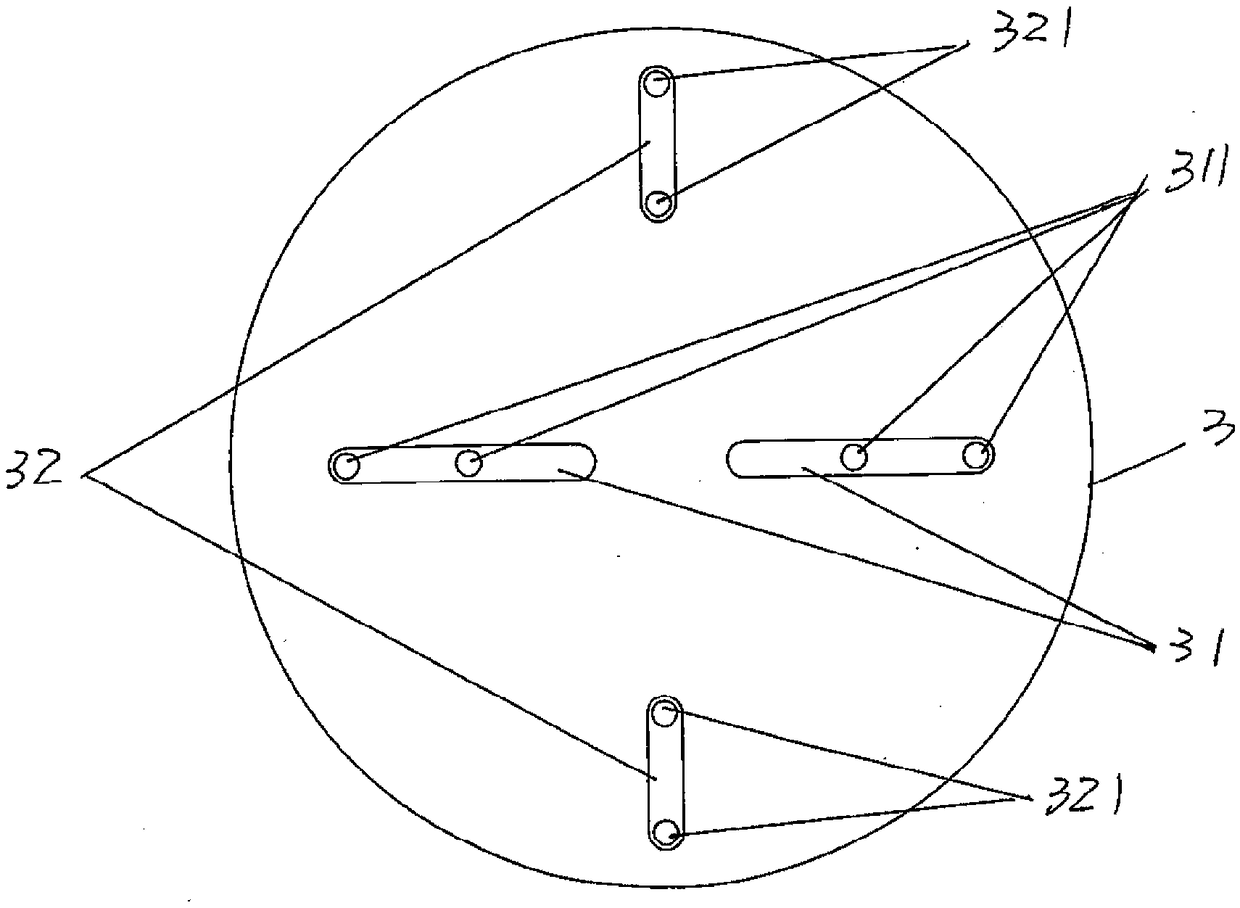

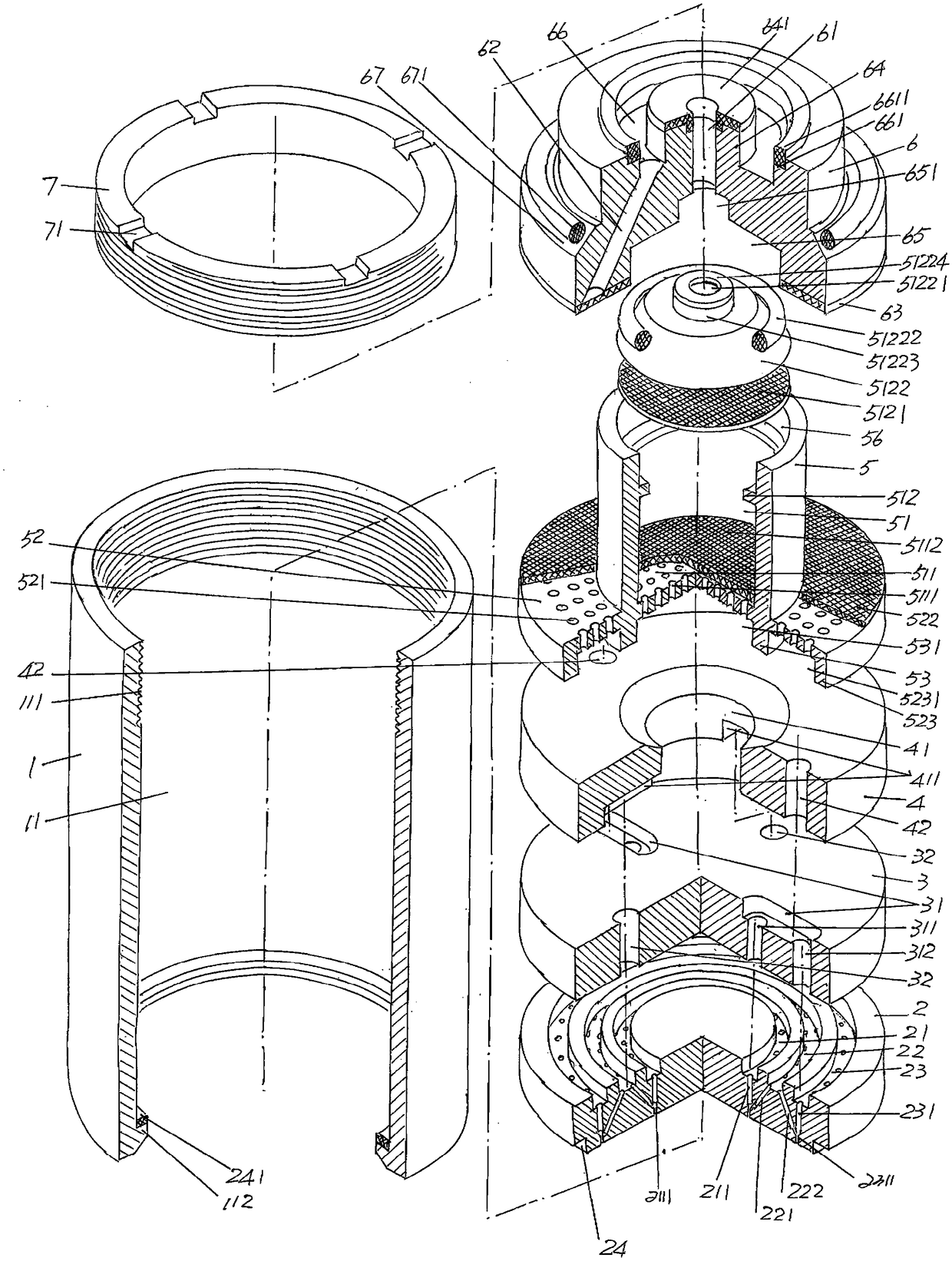

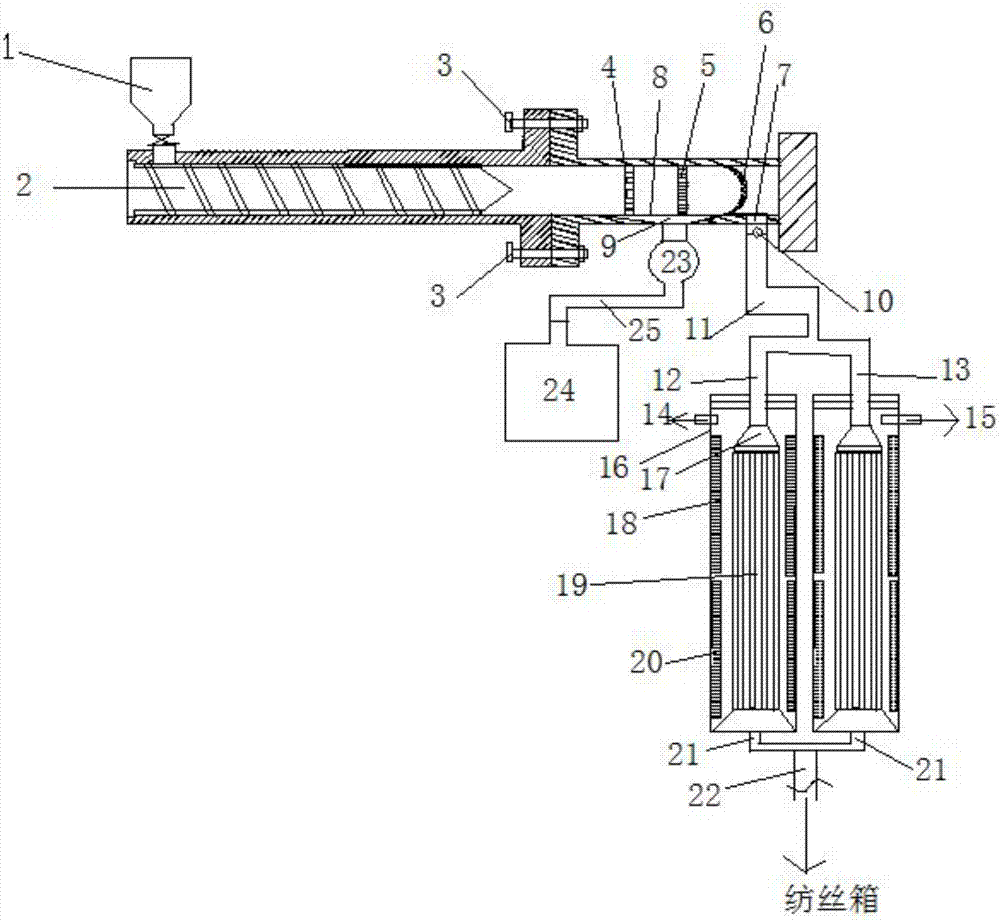

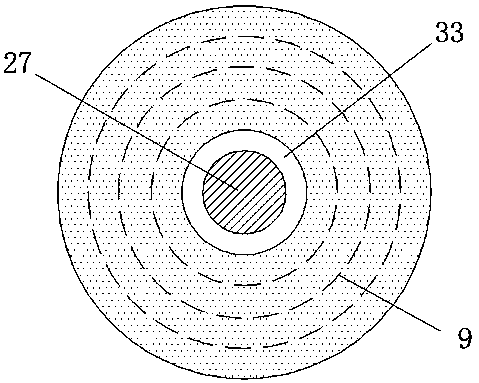

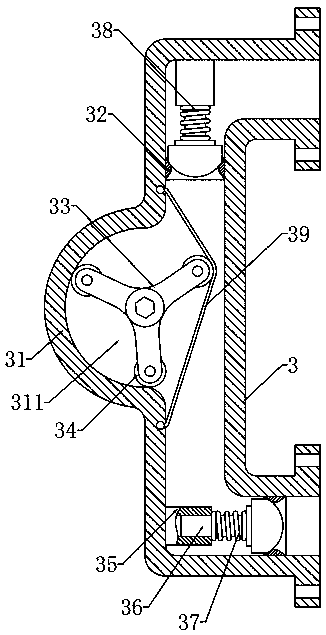

Spinning component for double-component fibers

ActiveCN108707987AEvenly distributedUniform blend production requirementsSpinning solution de-aeratingSpinnerette packsFiberEngineering

The invention relates to a spinning component for double-component fibers. The spinning component comprises a cylinder and a spinneret plate, a melt distribution plate, a guide plate, a filter cylinder, a melt guide-in plate and a locking nut which are arranged in the cavity of the cylinder from bottom to top and is characterized in that the upper inner wall of the cavity of the cylinder is provided with a thread coordinated with the locking nut, and the lower inner wall of the cavity of the cylinder is provided with a limit ring; the spinneret plate is supported on the limit ring and providedwith an annular spinneret orifice distribution area, the annular spinneret orifice distribution area is provided with spinneret orifices I and spinneret orifices II, the melt distribution plate is supported on the spinneret plate and provided with a distribution plate melt guide groove I and a distribution plate melt guide groove II, the bottom of the melt distribution plate is provided with a distribution plate melt distribution groove I and a distribution plate melt distribution groove II, the center of the guide plate is provided with a central guide hole, the bottom of the filter cylinderis supported on the guide plate, the bottom wall of the cavity of the cylinder is provided with a filter cylinder central guide hole, the middle of the melt guide-in plate is supported on the upper portion of the filter cylinder, the center of the melt guide-in plate is provided with a melt guide-in -late central guide hole, the lateral wall of the melt guide-in plate is provided with melt guide-in plate lateral guide holes, and the locking nut sleeves the melt guide-in plate. By the spinning component, two different-component melt trickles can be evenly distributed.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

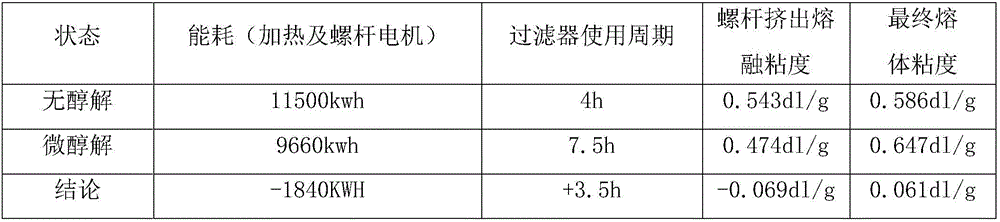

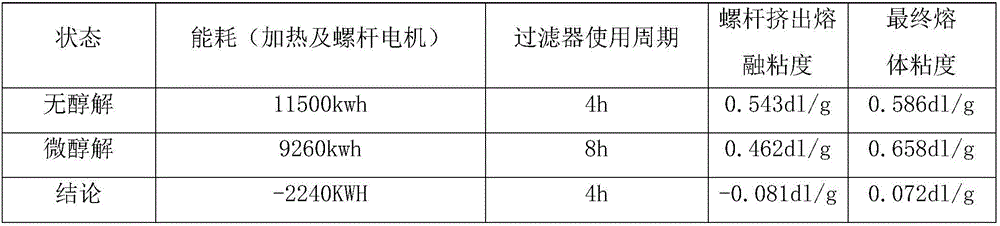

Method for preparing high-quality fusant from waste polyester textiles

InactiveCN106283226ARapid alcoholysisHigh intrinsic viscositySpinning solution de-aeratingFilament forming substance formingPolyesterPolymer science

The invention relates to high-value cycling and reusing techniques of waste polyester and particularly relates to a method for preparing a high-quality fusant from waste polyester textiles. The method comprises the following steps: adding 1-8% of alcohol into the raw material according to the mass of the raw material, and carrying out blending and melt extrusion by virtue of a screw extruder, wherein the melt viscosity of the fusant from the screw extruder is 0.40dl / g-0.50dl / g; and then adding the material into a tempering and viscosity-regulating device, wherein the melt viscosity of the fusant from the tempering and viscosity-regulating device is 0.620dl / g-0.685dl / g. According to the method, by adding a proper amount of glycol, the melt viscosity is increased, meanwhile, the problems that the cycle of a filter is short, and the maintenance quantity of a vacuum system is great are further effectively solved, the production cost is lowered, and the additional value of products is further increased.

Owner:NINGBO DAFA CHEM FIBER

PLA and PTT double-component semi-embedded composite fiber and preparation method thereof

ActiveCN108893790AImprove evennessGood orientationSpinning solution de-aeratingMelt spinning methodsFiberIntrinsic viscosity

The invention discloses PLA and PTT double-component semi-embedded composite fiber and a preparation method thereof. The preparation method includes: respectively drying a first component and a secondcomponent, wherein the first component is formed by PLA slice of 0.8-1.8dL / g in intrinsic viscosity and 60-70% in mass percentage, and the second component is PTT slice of 0.6-1.3dL / g and of 30-40% in mass percentage; subjecting a dried material of each of the first component and the second component to melt extrusion through a screw, conveying through a melt pipeline and metering through a metering pump; guiding spinning melt of the first and second components into a spinning component of a spinning box, allowing the spinning melt to respectively flow towards a spinneret plate, converge on the same and be ejected by the same to form melt streamlet with the second component semi-embedded in the first component, and subjecting the melt streamlet sequentially to lateral-air-blowing cooling,oiling, stretching, networking and winding to obtain the composite fiber. The composite fiber is high in wear resistance, elasticity and production efficiency and has good cohesive force.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

One-step method production process of high-strength high-shrinkage combined filament yarns

ActiveCN110552096AFull of layersFluffy appearanceSpinning solution de-aeratingMonocomponent copolyesters artificial filamentShrinkage rateHeat stability

The invention discloses a one-step method production process of high-strength high-shrinkage combined filament yarns. The process comprises the following steps of S1 chip drying, S2 spinning of high-strength polyester filaments, S3 spinning of high-elasticity polyester filaments, S4 web connection of the high-strength polyester filaments and the high-elasticity polyester filaments and S5 winding.The invention relates to the one-step method production process of the high-strength high-shrinkage combined filament yarns, and the produced combined filament yarns have both high-strength performance and high-shrinkage performance. Sulfonic-acid-group negative dyeing bases capable of being dyed by cationic dyes, polydihydric alcohol for improving heat stability and dihydric alcohol for reducingthe crystallization performance are added, so that the performance such as hydrophilia, dyeability, lustre and flexibility is comprehensively improved. Under the effect of high-shrinkage polyester fibers, compared with conventional pre-oriented yarns / fully-drawn-yarn combined filament yarns, pile loops formed after thermal treatment are richer in layering sense, the appearance is fluffier, and a formed fabric is fuller, stereoscopic and larger in controllable range of the different shrinkage rate.

Owner:浙江大地蓝化纤有限公司

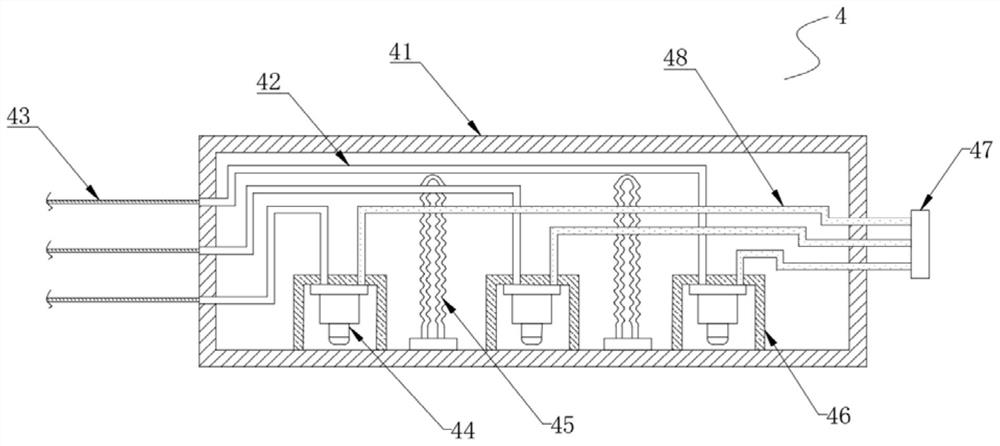

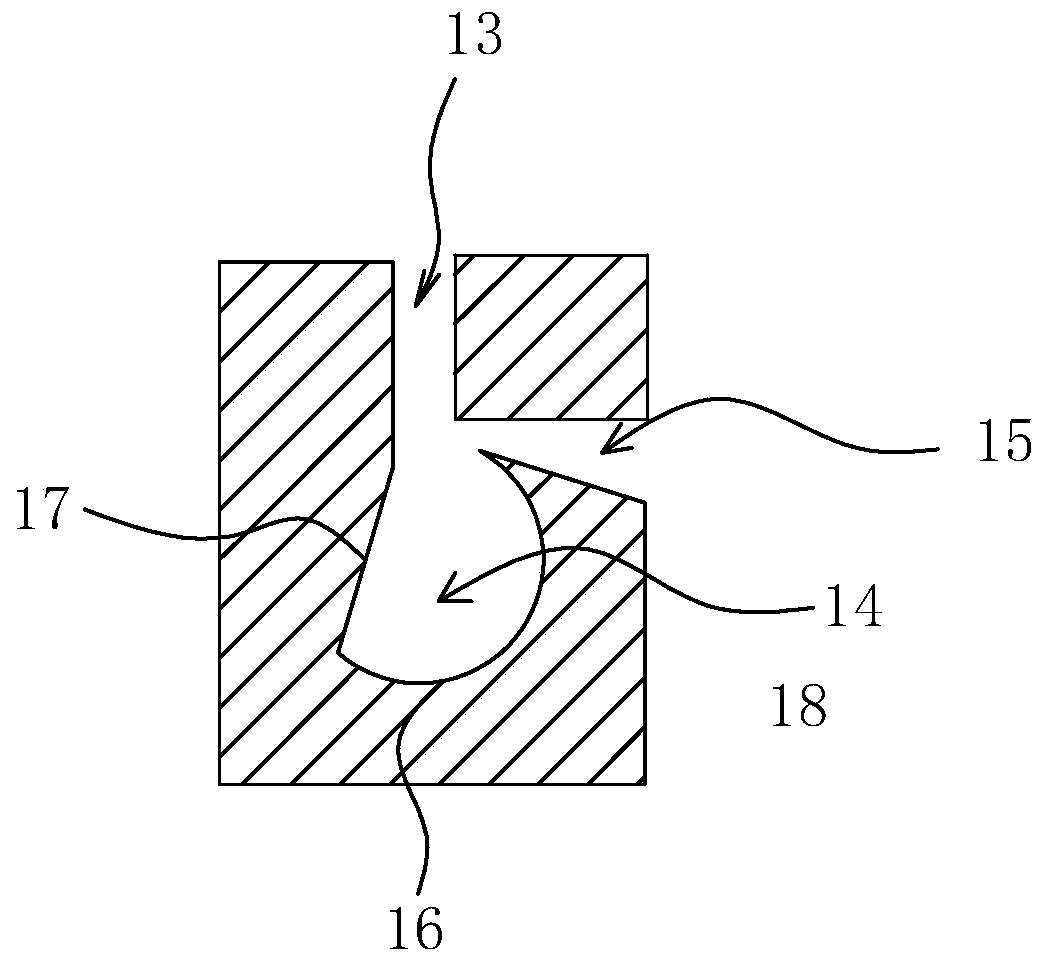

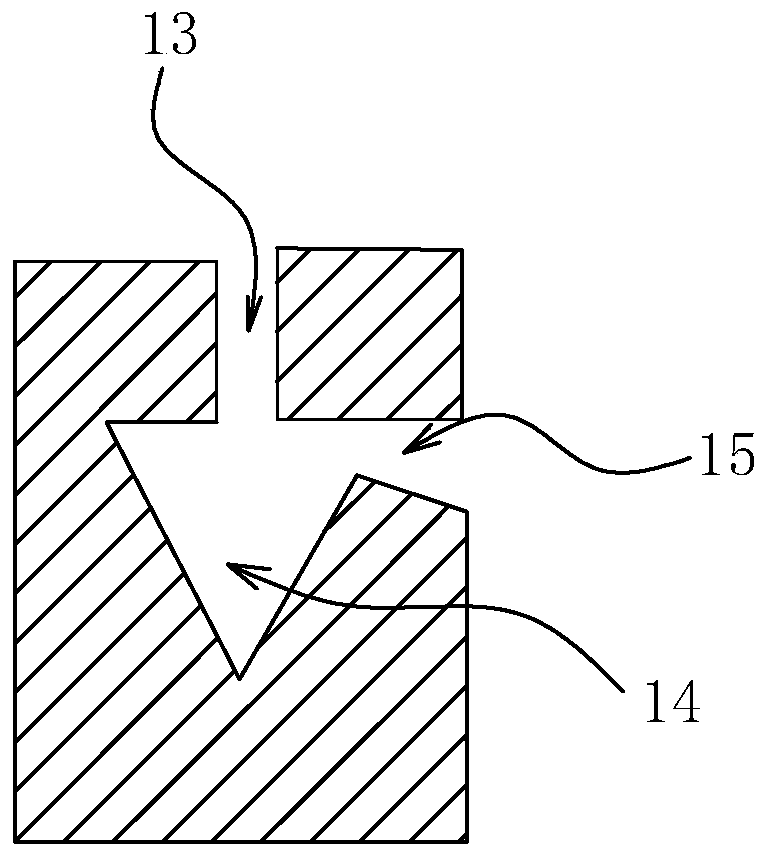

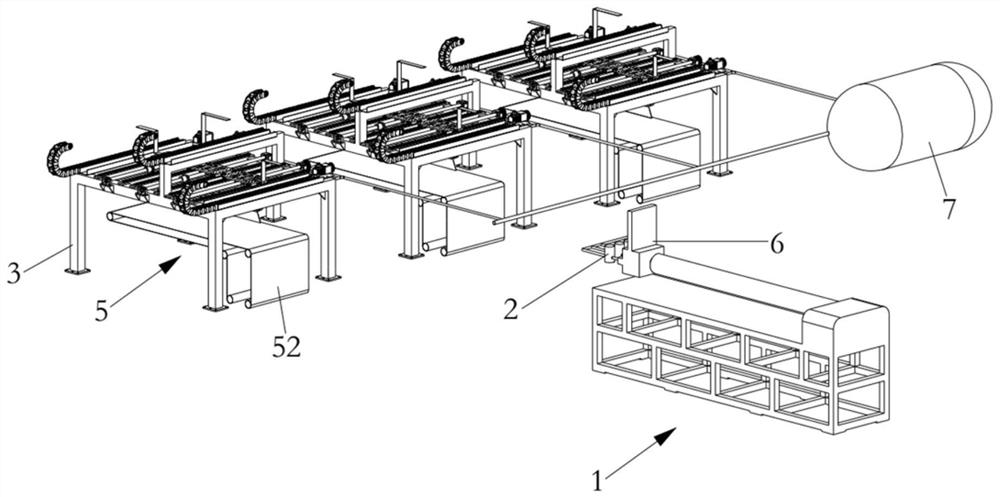

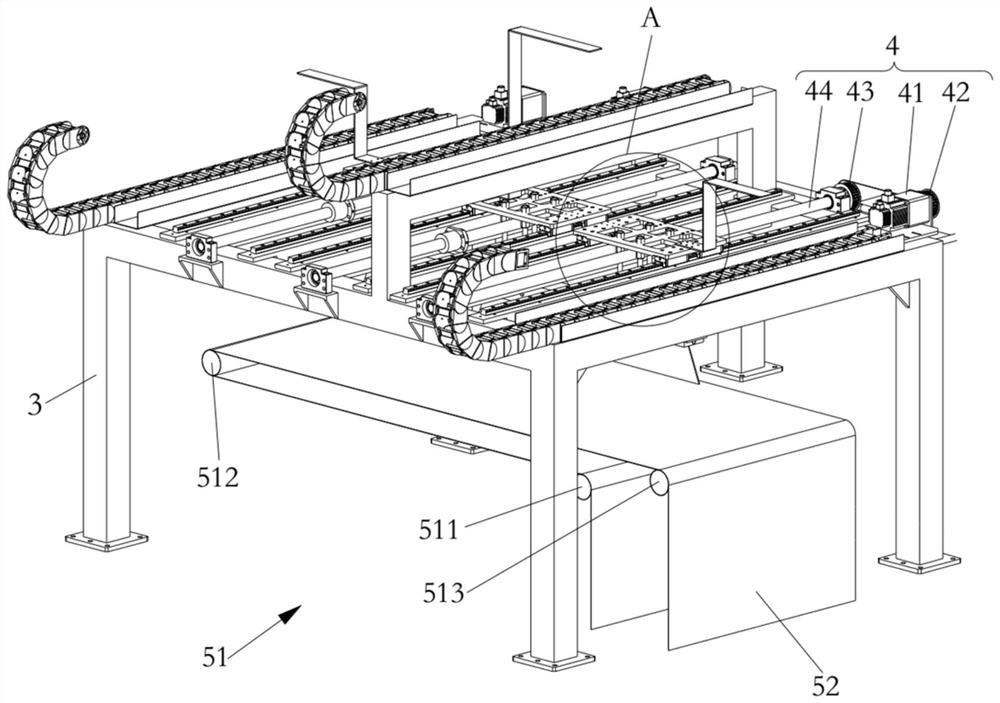

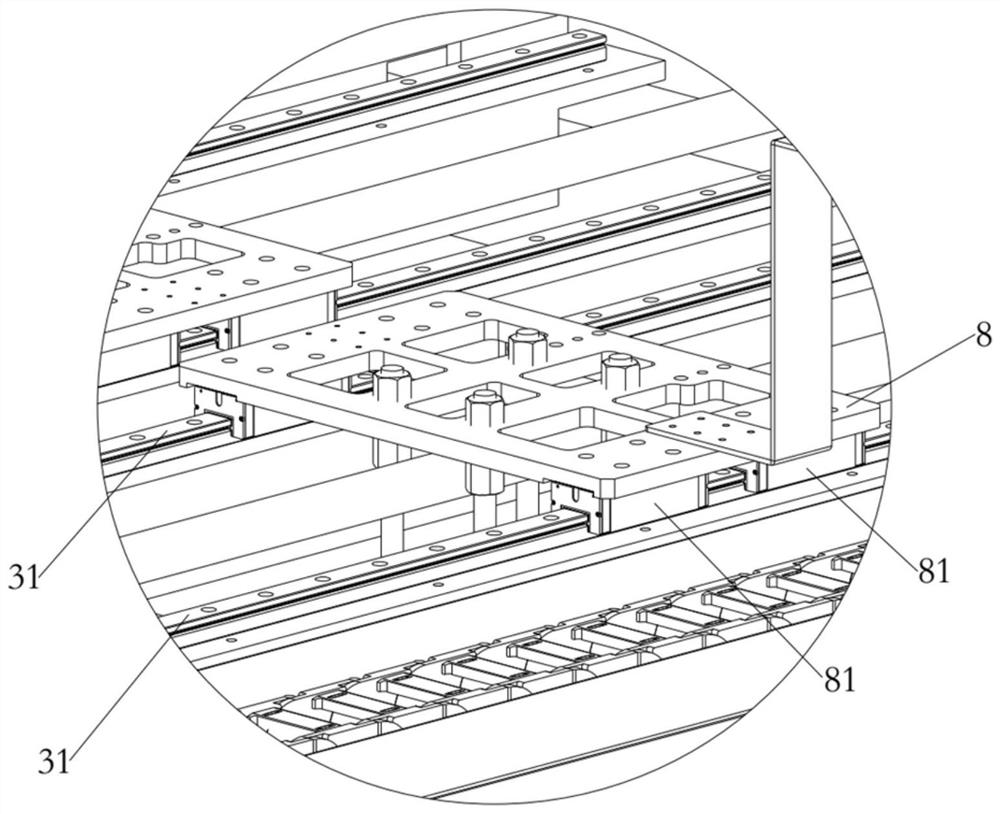

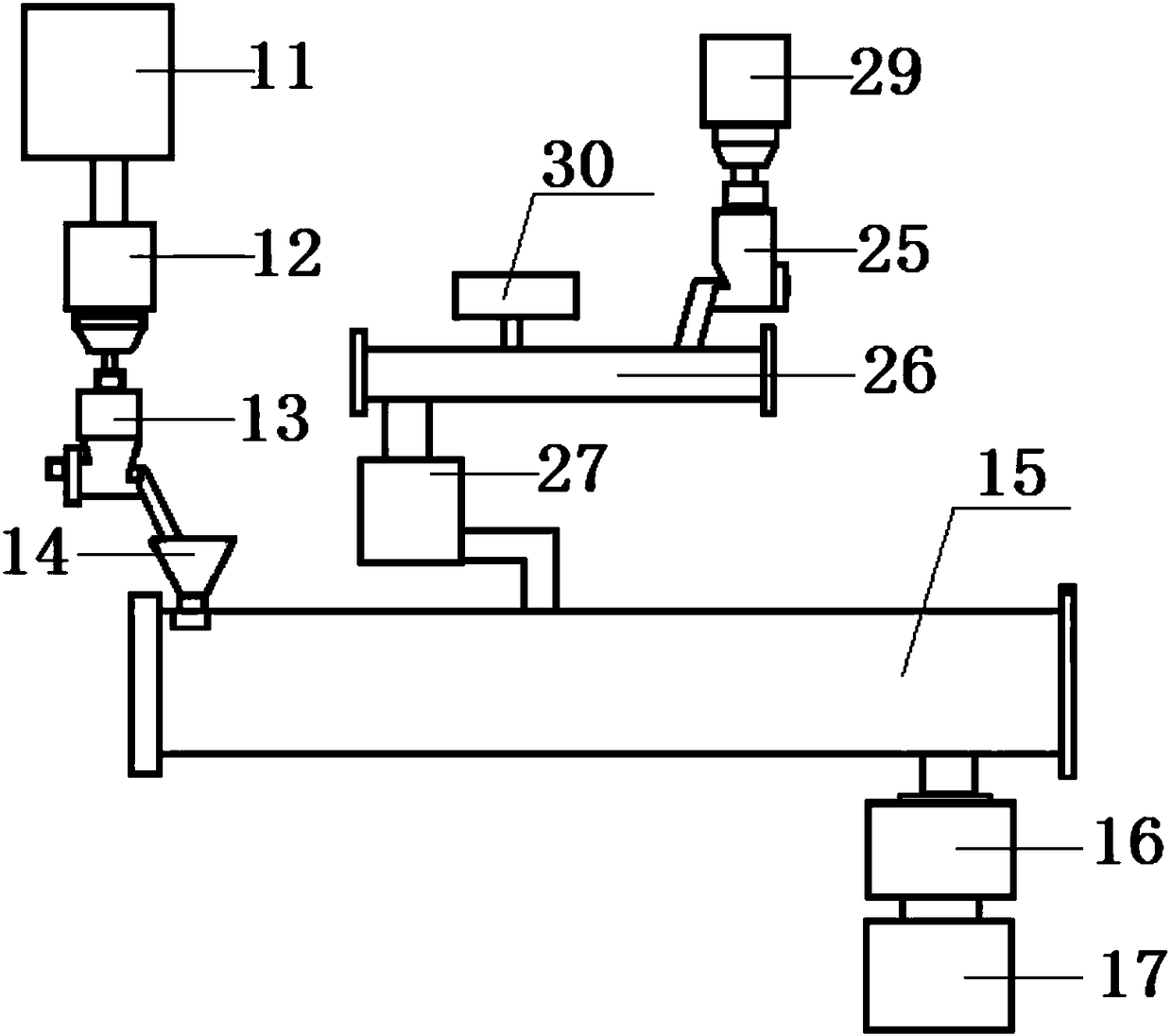

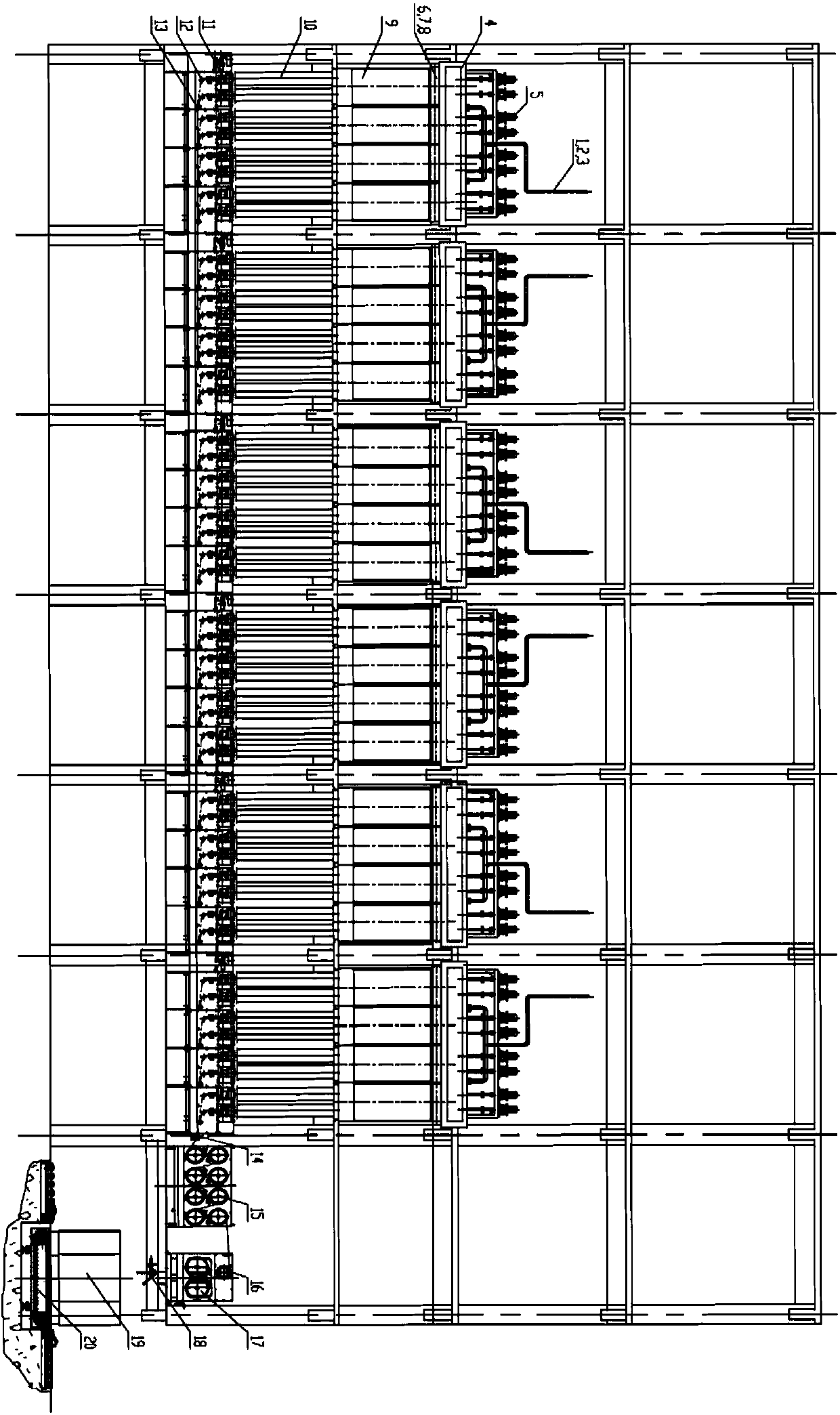

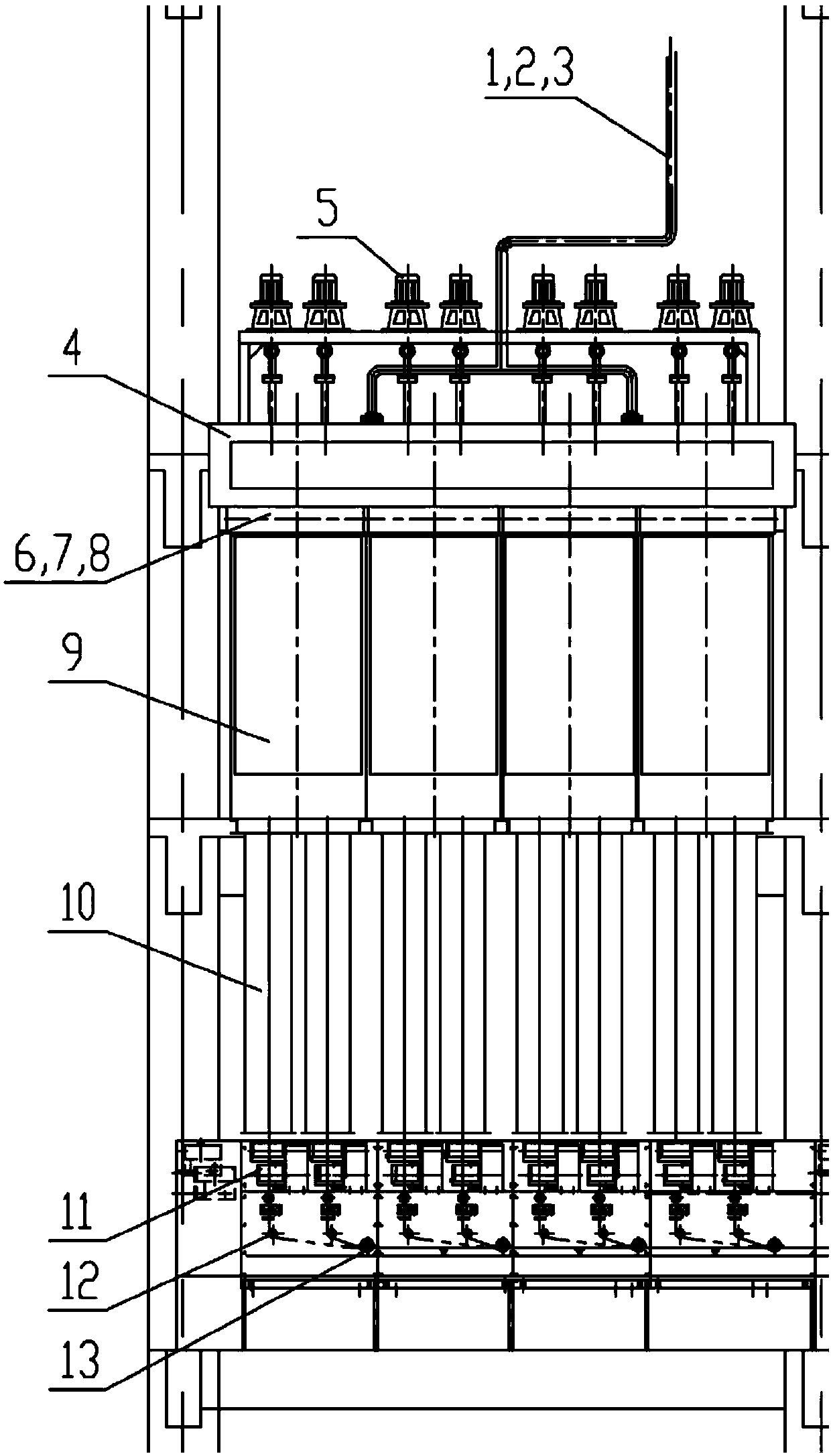

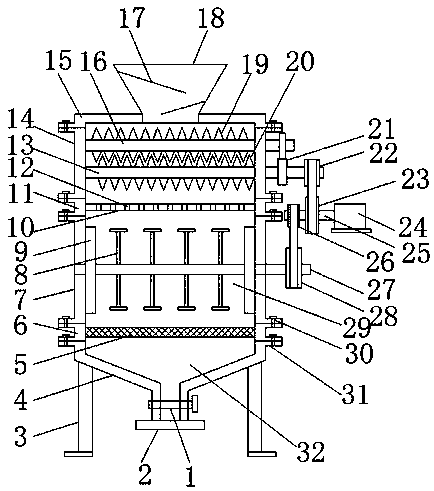

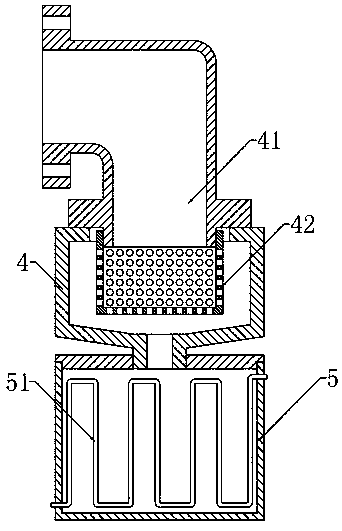

Melt-blown fabric production equipment

PendingCN111607903AAdjustable widthImprove product qualitySpinning solution de-aeratingSpinning head liquid feederWoven fabricManufacturing engineering

The invention discloses melt-blown fabric production equipment, and belongs to the technical field of non-woven fabric production equipment. The melt-blown fabric production equipment comprises a screw extruder, a web curtain fabric forming mechanism and a supporting frame, wherein a discharging outlet of the screw extruder is connected with a plurality of metering pumps; the web curtain fabric forming mechanism comprises a receiving web curtain and a driving structure capable of driving the receiving web curtain to move; a plurality of sprayer driving structures and a plurality of sprayer sets arranged in the moving direction of the receiving web curtain at intervals are arranged on the supporting frame; each sprayer set comprises at least one sprayer, and each sprayer communicates with one corresponding metering pump; the sprayer sets are located above the receiving web curtain, and in the vertical direction, the interval between the sprayer sets and the receiving web curtain is adjustable; each sprayer driving structure is configured to drive one or more sprayer sets to reciprocate in the width direction of the receiving web curtain; and the controller, the screw extruder, the metering pumps, the sprayer driving structures and the web curtain driving structure are all electrically connected with the controller. The melt-blown fabric production equipment can improve the spraying uniformity of the sprayers, improves the uniformity of fabric forming density of melt-blown fabric and can adjust the fabric forming speed of the melt-blown fabric.

Owner:东莞市宜康智能科技有限公司

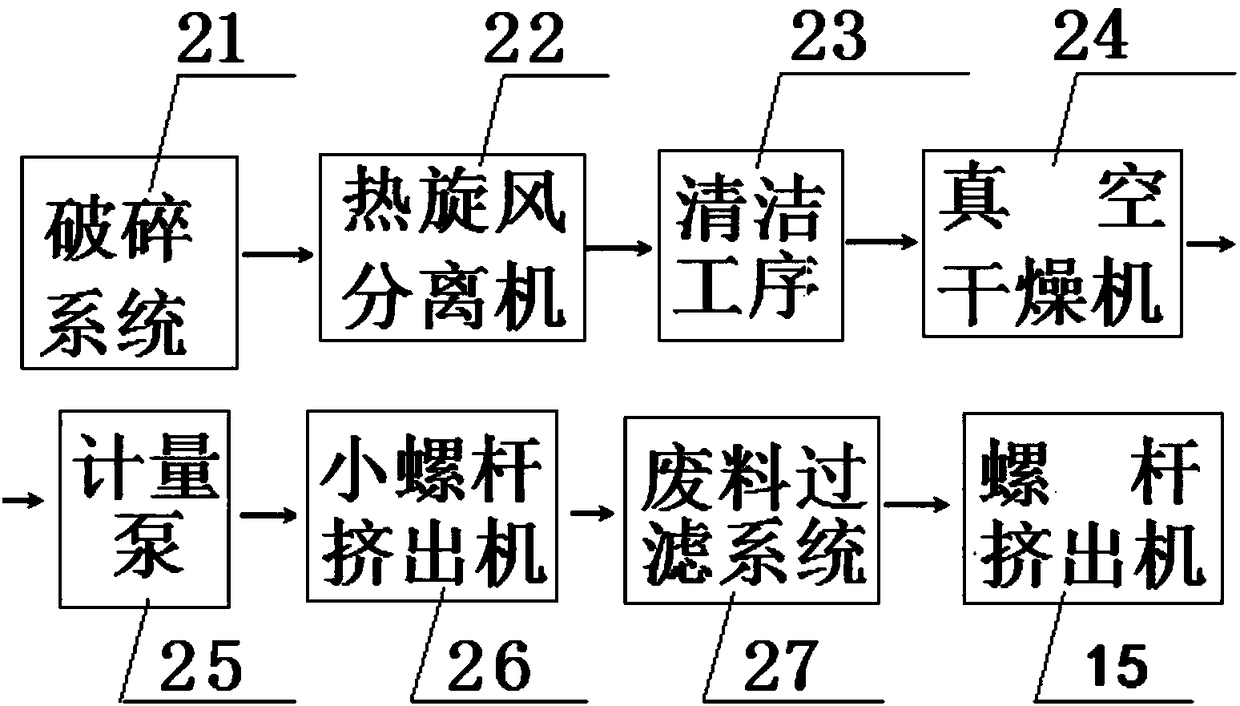

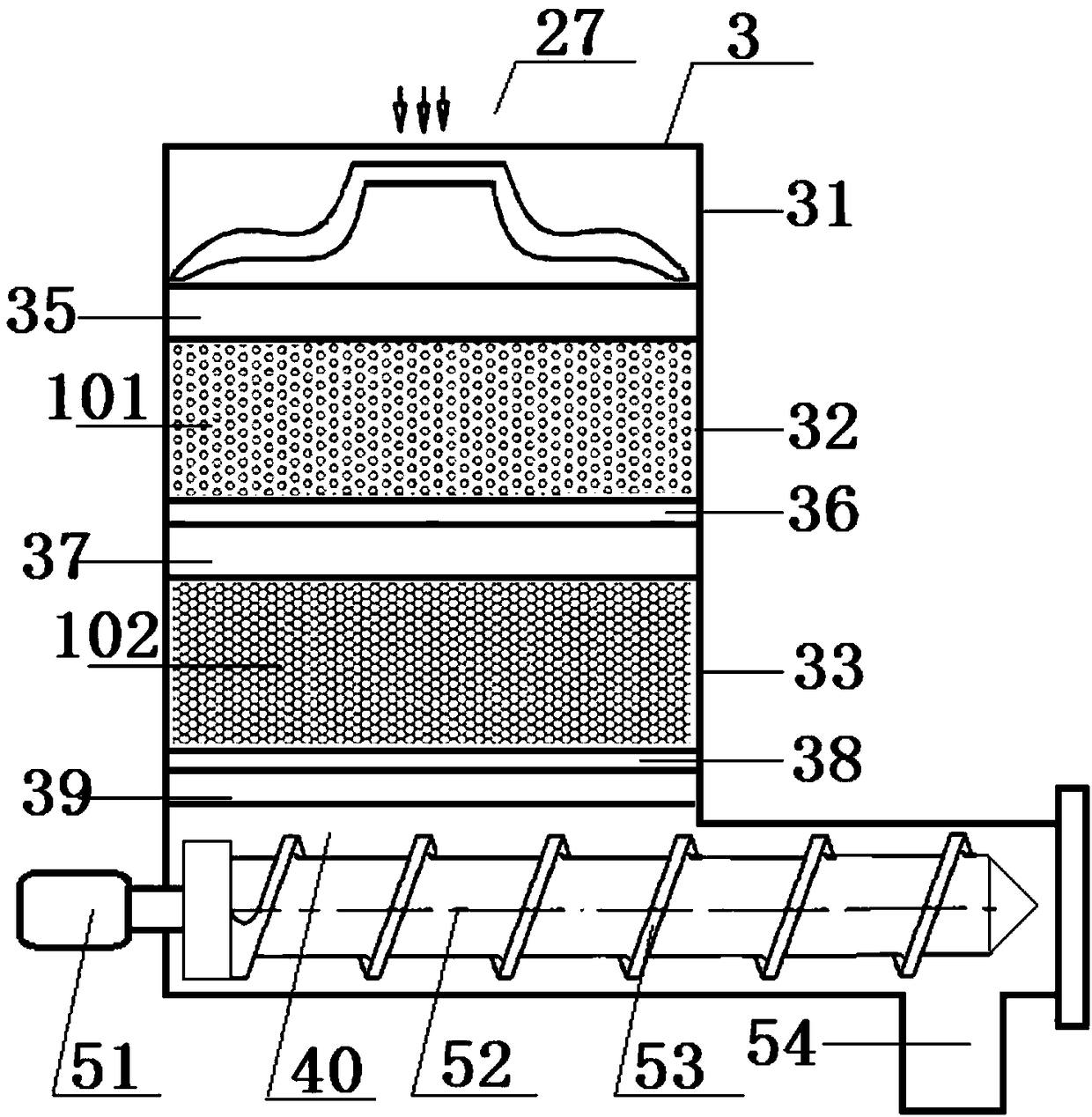

Method for preparing fibers by adding reclaimed materials of waste nonwoven fabric

ActiveCN108251901ARealize recyclingAvoid pollutionSpinning solution de-aeratingArtificial thread manufacturing machinesFiltrationWater vapor

The invention relates to a method for preparing fibers by adding reclaimed materials of a waste non-woven fabric. The method comprises the steps that the waste non-woven fabric is subjected to regeneration treatment, wherein the waste non-woven fabric is crushed and pre-treated to form a sheet-like cloth pre-treatment material, the sheet-like cloth pre-treatment material is transported to a feeding hopper of a waste feeding system through a material sucking machine and metered and pressurized by a metering pump and then enters a small screw extruder for heating and melting treatment to obtaina waste melt, and a vacuuming device conducts vacuuming to suck out oil, water vapor and other volatile substances generated in the heating and melting process of the sheet-like cloth pre-treatment material; then, the waste melt is sent to a waste filtration system to obtain a waste reclaimed melt; the waste reclaimed melt enters an inner bin of a feeding bin, a driving motor drives a material conveying screw rod to rotate, under the action of an extrusion and shearing force of the material conveying screw rod, the waste reclaimed melt is conveyed to a discharge port and enters a screw extruding machine of a spinning device to be mixed and homogenized with main materials, and the fibers are made through a spinning pack.

Owner:泉州市易斯特永隆新材料科技有限公司

Production technology of high-tenacity polyester yarns based on melt spinning method

ActiveCN107488883AHigh strengthIncrease elasticitySpinning solution de-aeratingSpinning head liquid feederYarnPolyester

The invention discloses a production technology of high-tenacity polyester yarns based on a melt spinning method. The technology comprises the steps of polymer melting extrusion, melt filtration, liquid phase adhesion promotion, extrusion through spinneret holes and trickle formation, cross air blow cooling, spinning silk silver oiling and winding and forming. On the basis of a traditional melt spinning technology, an automatic residue discharging filtering device and a liquid phase adhesion promotion device are additionally arranged, the automatic residue discharging filtering device is horizontally connected with a threaded rod extruder in a screwed mode through a bolt, the melt is subjected to rough filtration through a first buffer screen net and a second buffer screen net in sequence, and then a pure melt is obtained by filtration with a filter net; filter residue is taken out with continuous discharging of an extrusion machine. Two identical liquid phase adhesion promotion kettles are arranged below the filtering device, and the melt viscosity is increased from 0.53 dl / g-0.66 dl / g to 0.98 dl / g-1.21 dl / g. According to the obtained high-tenacity polyester yarn finished threads, the density is 866 dtex, the strength is 6.6 cN / dtex-8.5 cN / dtex, the elastic modulus is 97-146 cN / dtex, the variation coefficient is smaller than 3.2%, the strength is high, the elasticity is good, and the production cost is reduced.

Owner:安徽嘉明新材料科技有限公司

Spinning machine and method for producing biomass polyamide 56 fibers

PendingCN107904685AEnsure stabilityQuality assuranceSpinning solution de-aeratingNew-spun product collectionFiberPolymer science

The embodiment of the invention discloses a spinning machine for producing biomass polyamide 56 fibers. The spinning machine includes: N spinning subsystems which are sequentially disposed on a frameof the spinning machine, each spinning subsystem is sequentially provided with a screw extruder, a melt pipeline system, M spinning boxes, a cooler component, a side blowing and cooling component, a channel component, an opposite oil tanker, and a godet wheel in the traveling direction of tows, each spinning box is internally provided with P spinning bits, each spinning bit is provided with a spinning component, the lower portion of a spinning plate of each textile component is provided with a slow cooler component and the side blowing and cooling component, the lower part of each side blowingand cooling component is connected with a channel component, the lower portion of each opposite oil tanker is provided with a godet wheel, and a godet disc is arranged between every M godet wheels; afeeder is arranged on one side of the godet disc at the furthest end of the plurality of godet discs arranged in sequence, and a filament cylinder reciprocating device is arranged at a position corresponding to the feeder.

Owner:BEIJING CHONGLEE MACHINERY ENG

Dyeing-free chinlon 66 industrial color silk and preparation method thereof

InactiveCN107829160AHigh strengthRealize dope dyed spinningSpinning solution de-aeratingArtificial thread manufacturing machinesPolymer scienceSpinning

The invention provides dyeing-free chinlon 66 industrial color silk and a preparation method thereof. The preparation method particularly comprises the following steps: 1, conveying a chinlon 66 sliceto a drying tower to dry; 2, performing humidifying treatment on the dried chinlon 66 slice and feeding into a pre-spinning cabin; 3, mixing master batches and high-viscosity chinlon 66 slice in thepre-spinning cabin into a mixed material, and performing melt extrusion on the mixed material by a screw extrusion machine; 4, enabling the equivalently distributed melt to enter a spinning box body and jetting silk; 5, cooling the melt fine flow jetted by a spinneret plate to form tows; and 6, after cooling, performing oiling, drafting and hot setting as well as networking and winding on the towsto obtain the dyeing-free chinlon 66 industrial color silk. By the method, original liquid dyeing spinning of the chinlon 66 is realized, the process route does not need dyeing and environmental pollution caused by chinlon 66 dyeing is avoided; and in the dyeing-free chinlon 66 industrial color silk, the thermal shrinkage rate is 4 to 7 percent, the denier number is 150 to 1260 D, the breaking strength is more than or equal to 8.0 g / D and the elongation at break is 17 to 21 percent.

Owner:中维化纤股份有限公司

Breaking and smelting device for chemical fiber raw materials

InactiveCN107837872ACompact structureEasy to assemble and disassembleSpinning solution de-aeratingFilament forming substance formingPolymer chemistryFiber

The invention discloses a breaking and smelting device for chemical fiber raw materials. The breaking and smelting device comprises a material liquid collection box, a stirring box, a breaking box anda feeding hopper. A discharging pipe is welded to the bottom of the material liquid collection box. A melt filter box is connected to the upper end of the material liquid collection box. A filter netis mounted in the melt filter box. The stirring box is connected to the upper end of the melt filter box. A melting stirring chamber is arranged in the stirring box. A heating disc is mounted on theinner wall of the stirring box. The heating disc is an annular disc body. A shaft hole is formed in the middle of the heating disc. A stirring shaft is mounted in the shaft hole. Multiple stirring rods are vertically welded to the stirring shaft. The breaking and smelting device for the chemical fiber raw materials is simple in structure and convenient to assemble and disassemble, raw material feeding and adding are facilitated, breaking is convenient and fast, the screening effect is good, heating is conducted while stirring is conducted, the raw material melting efficiency is improved, meltis filtered, the production quality of chemical fiber products is improved, and the sufficient melting of the raw materials is guaranteed.

Owner:王赟

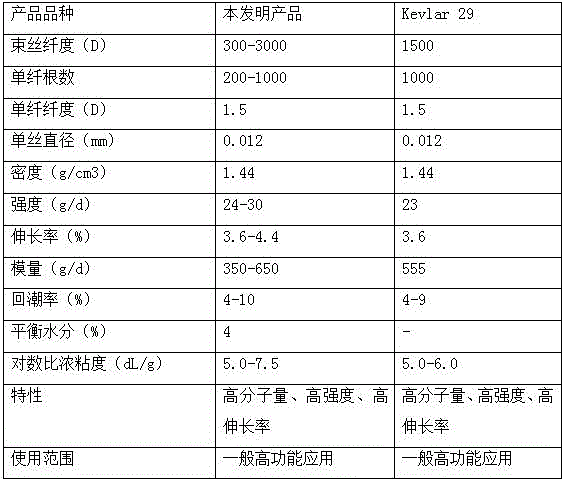

Preparation method of poly (p-phenylene terephthalamide) (PPTA) fiber with high elongation at break

InactiveCN106591996AImprove impact resistanceImprove fatigue resistanceSpinning solution de-aeratingSpinnerette packsFiberPolymer science

The invention relates to a preparation method of poly (p-phenylene terephthalamide) (PPTA) fiber with high elongation at break, and belongs to the technical field of artificial fiber. The preparation method is characterized by after preparing a spinning solution by taking a PPTA polymer of which the logarithmic viscosity is 4.5 to 7.5 dl / g as a raw material and concentrated sulfuric acid of which the concentration is 96 to 100 percent as a solution, forming as-spun filaments through a spinneret plate by adopting a dry-jet wet-spinning technology, then entering a coagulating bath to realize coagulation forming, and winding fiber after coagulation forming into a product after washing, neutralizing, drying and oiling the fiber, wherein the filament tension is controlled to be 0.5g / d or lower during the processes of washing, neutralizing, drying, oiling and winding. The PPTA fiber with the high elongation at break has good impact resistance and good fatigue resistance, and is relatively suitable for the field of rubber composite materials and bulletproof composite materials.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Equipment and process for preparing low-melting-point chinlon hot melt yarn

ActiveCN111020729AHigh strengthReduced strengthSpinning solution de-aeratingFilament forming substance formingYarnSpinning

The invention discloses equipment and a process for preparing a low-melting-point chinlon hot melt yarn. The process comprises the steps: putting polyamide slices into a heating extruder; pressing, melting, homogenizing and the like by a screw extrusion process to obtain a melt; and after being pressurized by the pressurizing device, the melt is filtered by a filter box. The problems of high meltviscosity and low filtering speed are solved; the filtered melt enters a heat preservation box to be subjected to heat preservation and is pressed out through a spinning assembly and a spinneret plateto form trickles and is cooled into filaments under cross air blowing and is subjected to drafting and heat setting through a first hot roller and a second hot roller and then is wound through a winding device to obtain the low-melting-point chinlon hot melt yarn, and the strength of the low-melting-point chinlon hot melt yarn is improved. The equipment and the process for preparing the low-melting-point chinlon hot melt yarn are reasonable in structure and convenient to use and can effectively solve the problem of low strength of the low-melting-point chinlon hot melt yarn.

Owner:浙江及时宇新材料有限公司

Production method of pre-spinning colored high-shrinkage polyester FDYs (Fully Drawn Yarns)

InactiveCN106400175AStrong three-dimensional senseSoft touchSpinning solution de-aeratingArtificial filament heat treatmentPhthalic acidIsophthalic acid

The invention relates to the technical field of the manufacture of fibers, in particular to a production method of pre-spinning colored high-shrinkage polyester FDY (Fully Drawn Yarns). Chemically modified high-shrinkage PET sections and coloring master batches are taken as raw materials to prepare the pre-spinning colored high-shrinkage polyester FDY, wherein the chemically modified high-shrinkage PET sections are obtained by adding m-phthalic acid in a PET copolymerization process. The high-shrinkage polyester FDYs disclosed by the invention are differentiated polyester filament yarn products which are developed based on taking the chemically modified high-shrinkage PET sections as raw materials, and the boiling water shrinkage is higher than 30%.

Owner:CHANGZHOU XINZHANJIANG SPECIAL FIBER

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com