Production technology of high-tenacity polyester yarns based on melt spinning method

A high-strength polyester yarn and melt spinning technology, which is applied in the spinning field, can solve problems such as poor elasticity, low density, and low viscosity, and achieve the effects of good elasticity, reduced production costs, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

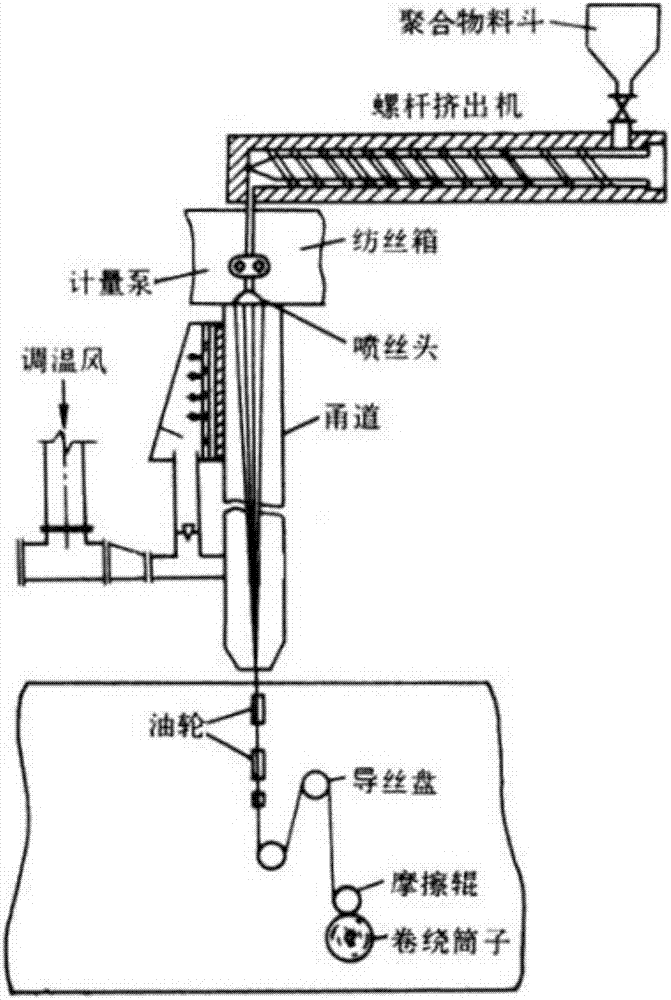

[0030] Such as figure 1 As shown, a traditional process of melt spinning includes the steps of polymer melt extrusion-spinneret hole extrusion to form a fine stream-side blowing cooling-filament oiling and winding molding;

[0031] (1) Polymer melt extrusion: The polymer enters the screw extruder 2 from the hopper 1 for melting, and the melting temperature of the spinning screw is 310° C., and extrudes after melting;

[0032] (2) The spinneret hole is extruded to form a thin stream: the extruded melt has a viscosity of 0.59dl / g, and the melt is transported to the spinning box, and then enters the spinning assembly through a metering pump and extrudes from the spinneret. Heated by the slow cooling heater, the slow cooling heating temperature is 320°C, and the height is 330mm;

[0033] (3) The extruded stream is cooled and formed by a side blowing device. The blowing temperature is 21°C, the humidity is 75%, and the wind speed is 0.55m / s. Then enter the spinning tunnel, the sp...

Embodiment 2

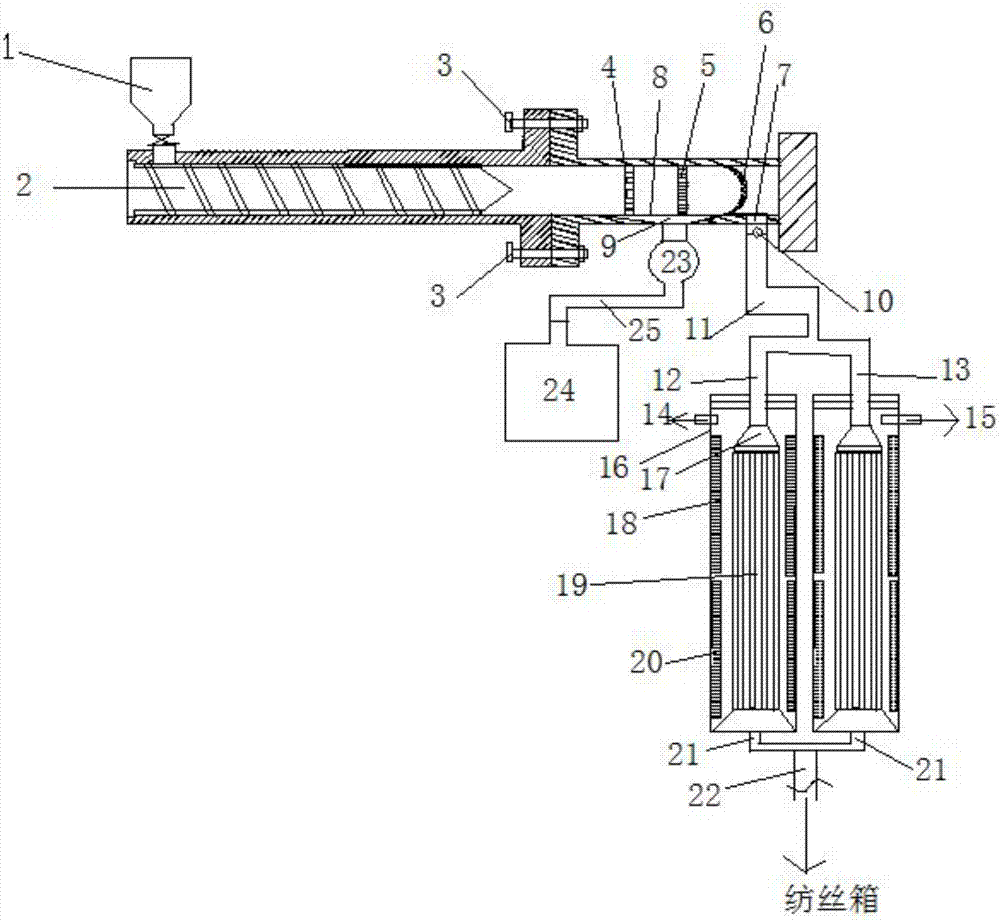

[0036] Such as figure 2 As shown, a process for producing polyester high-strength yarn based on melt spinning method, including polymer melt extrusion - melt filtration - liquid phase viscosity increase - spinneret hole extrusion to form fine stream - side blowing cooling - filament Oiling - winding forming process step.

[0037] (1) Polymer melt extrusion: The polymer enters the screw extruder 2 from the hopper 1 for melting, and the melting temperature of the spinning screw is 310°C;

[0038] (2) Melt filtration: The melted polymer melt enters the automatic slagging filter device connected horizontally with the screw extruder 2 through the bolt 3, and the melt passes through the first buffer screen 4 and the second buffer screen successively. The sieve 5 is used for coarse filtration, and finally the pure melt is obtained by filtering through the sieve 6 . The filter residue enters into the conical storage chamber 9 through the large hole backing plate 8 . An electromagn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com