Patents

Literature

159results about How to "Full of layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

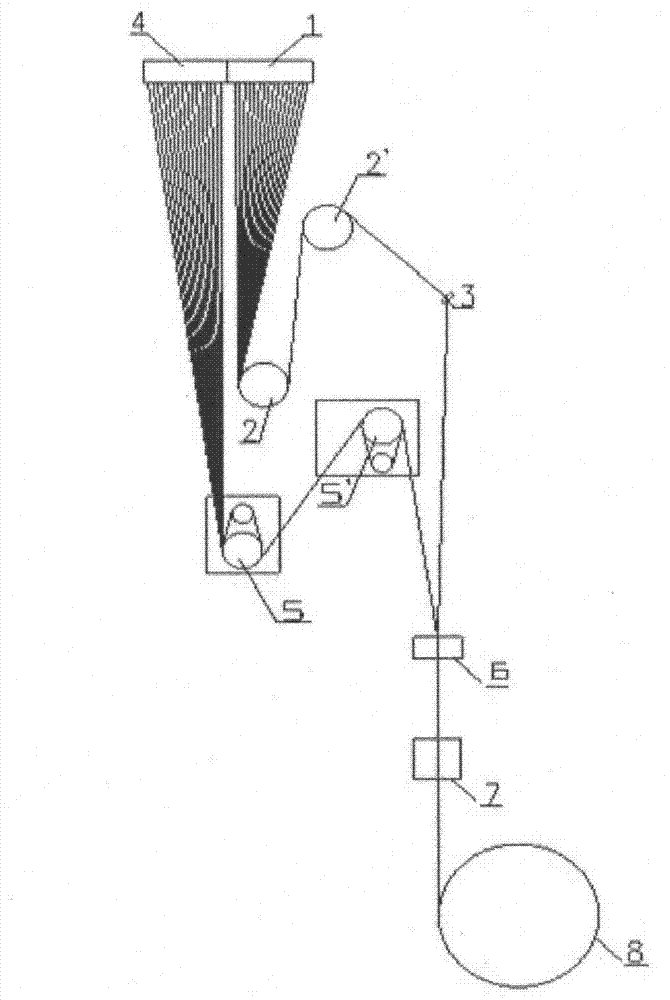

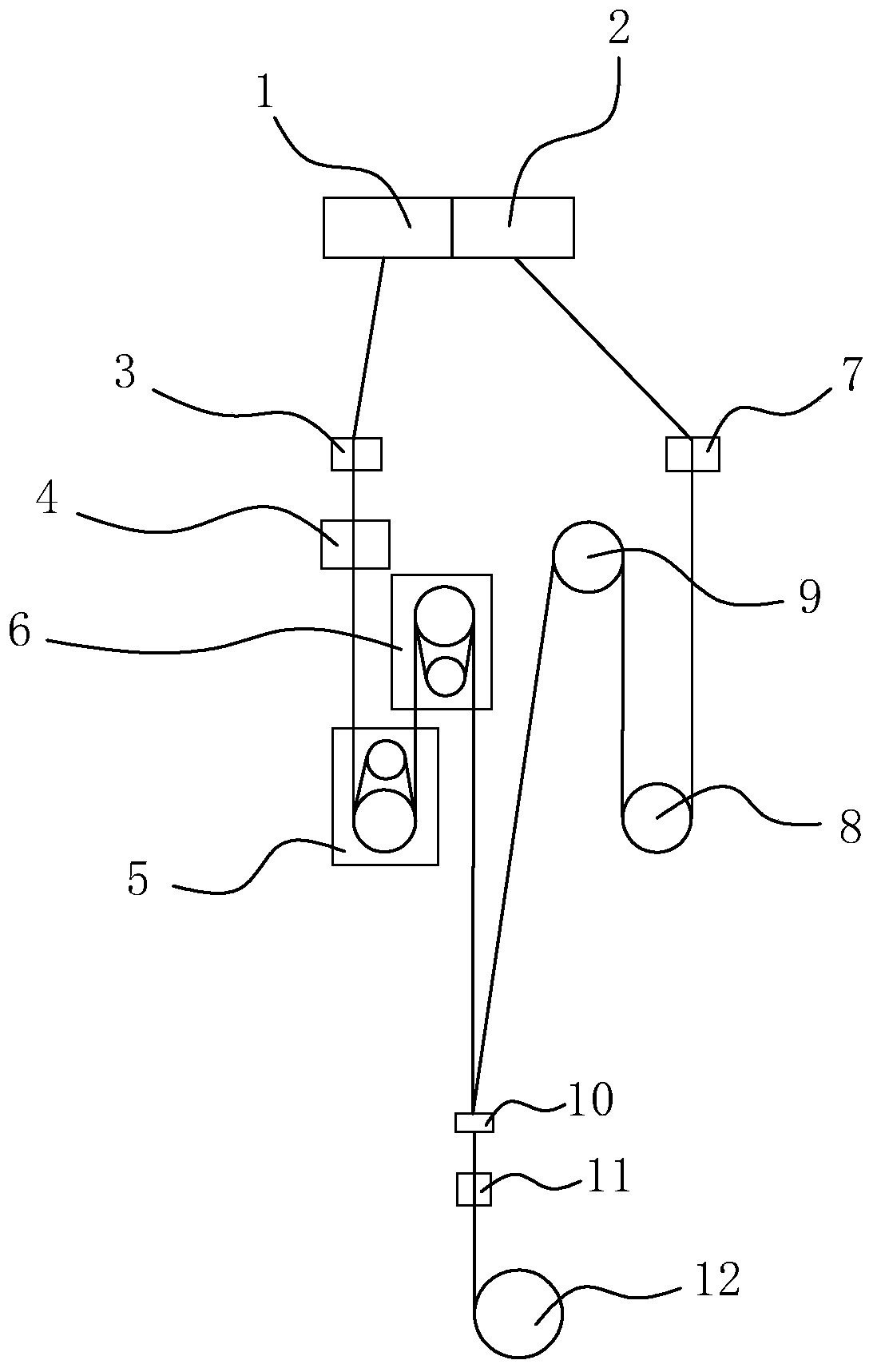

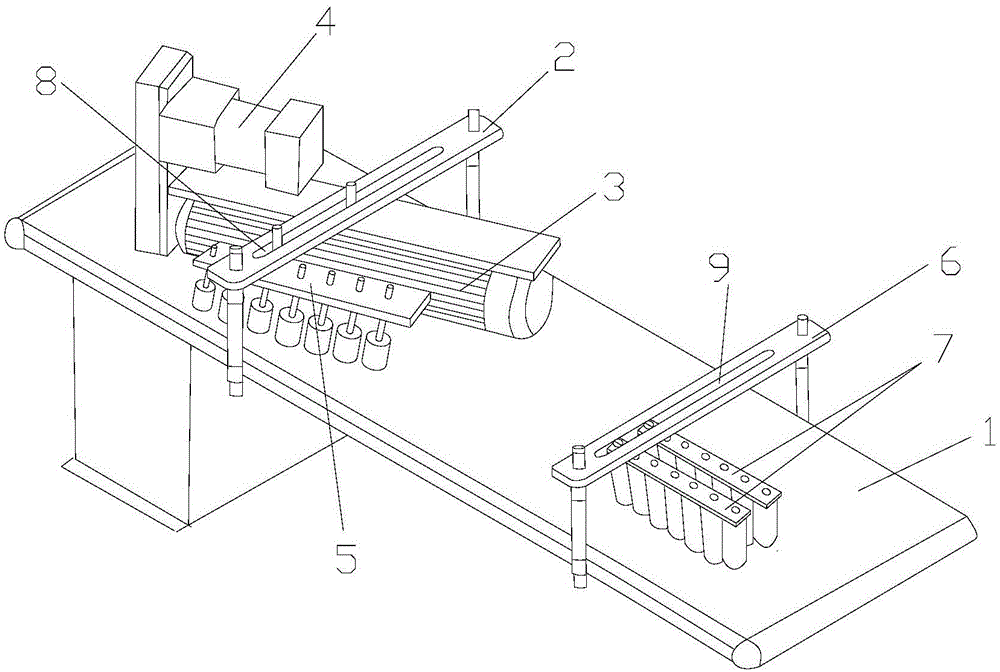

Preparation method and device of dual different-shrinkage combined filament yarn

InactiveCN102140700AFluffy appearanceFull of layersArtificial thread manufacturing machinesArtificial filament heat treatmentSpinningEngineering

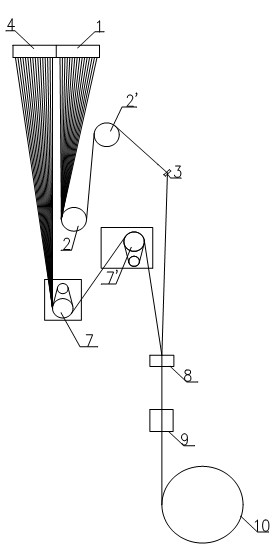

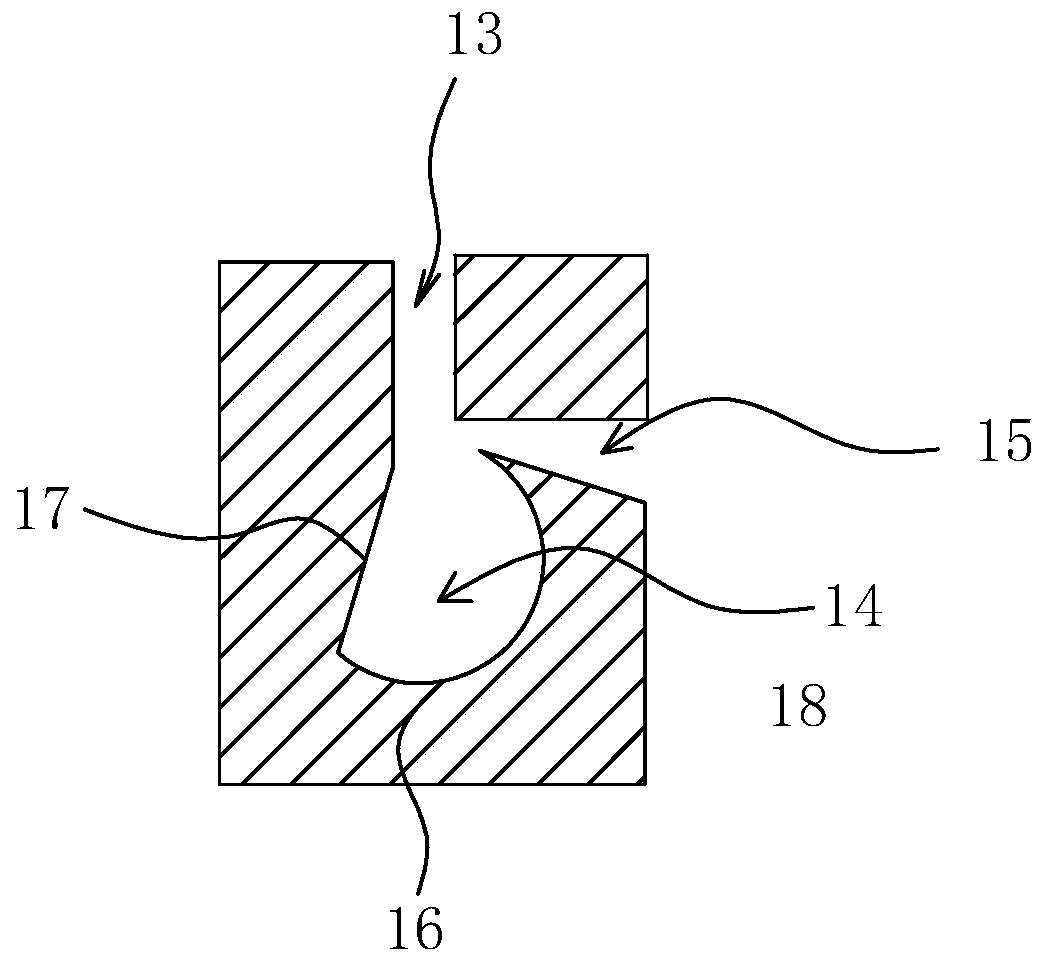

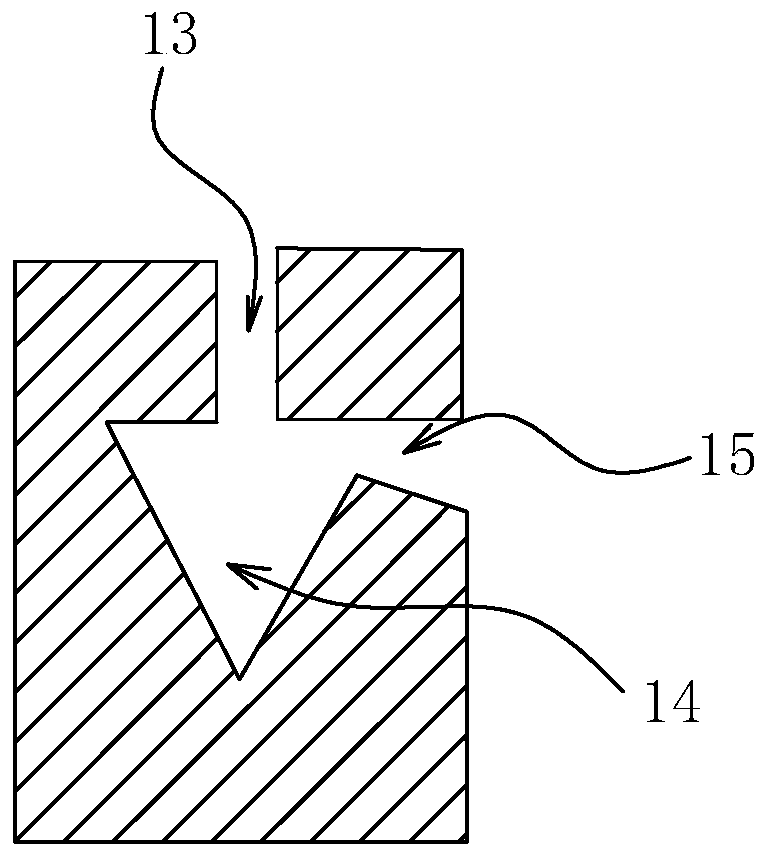

The invention relates to a preparation method and device of dual different-shrinkage combined filament yarn. The device comprises a first spinning component, a second spinning component, a lower spinning reel, an upper spinning reel, a first hot roll, a second hot roll, a first redirector, a doubling machine, a netting device and a winding roll, and is characterized by also comprising a third hot roll, a fourth hot roll and a second redirector. The preparation method is characterized in that one part of yarn output by the second spinning component is input to the doubling machine through the first hot roll and the second hot roll; the other part of yarn output by the second spinning component is input to the doubling machine through the third hot roll, fourth hot roll and second redirector; and after the doubling machine merges all the input yarn, the yarn is processed by the netting device and the winding roll, thereby finally obtaining the dual different-shrinkage combined filament yarn. The looped piles formed on the surface of the dual different-shrinkage combined filament yarn are more stratified; and the loops with different sizes are tangled, so that the combined filament yarn looks fluffier, and the formed fabric is plumper and has stereo perception.

Owner:DONGHUA UNIV

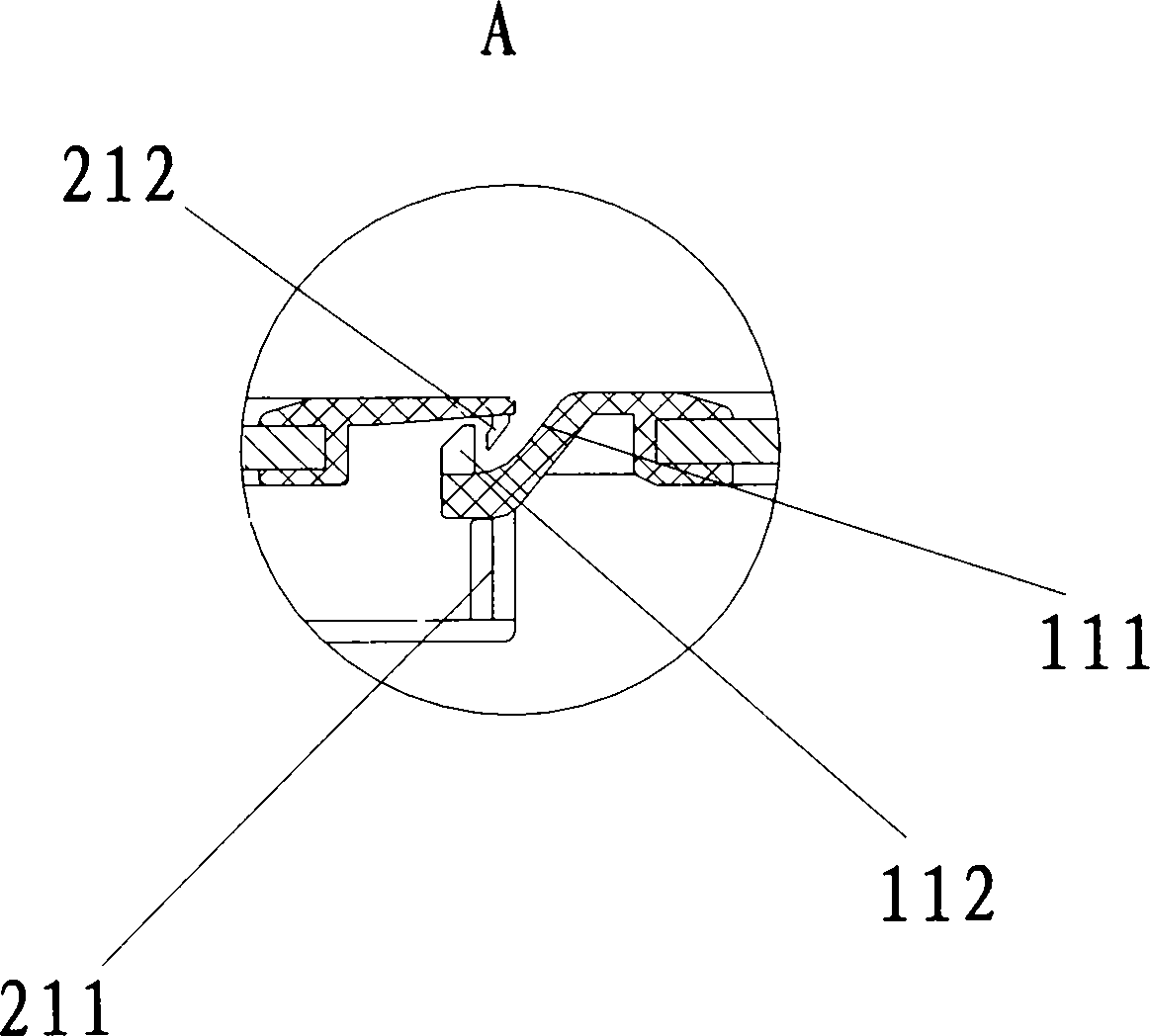

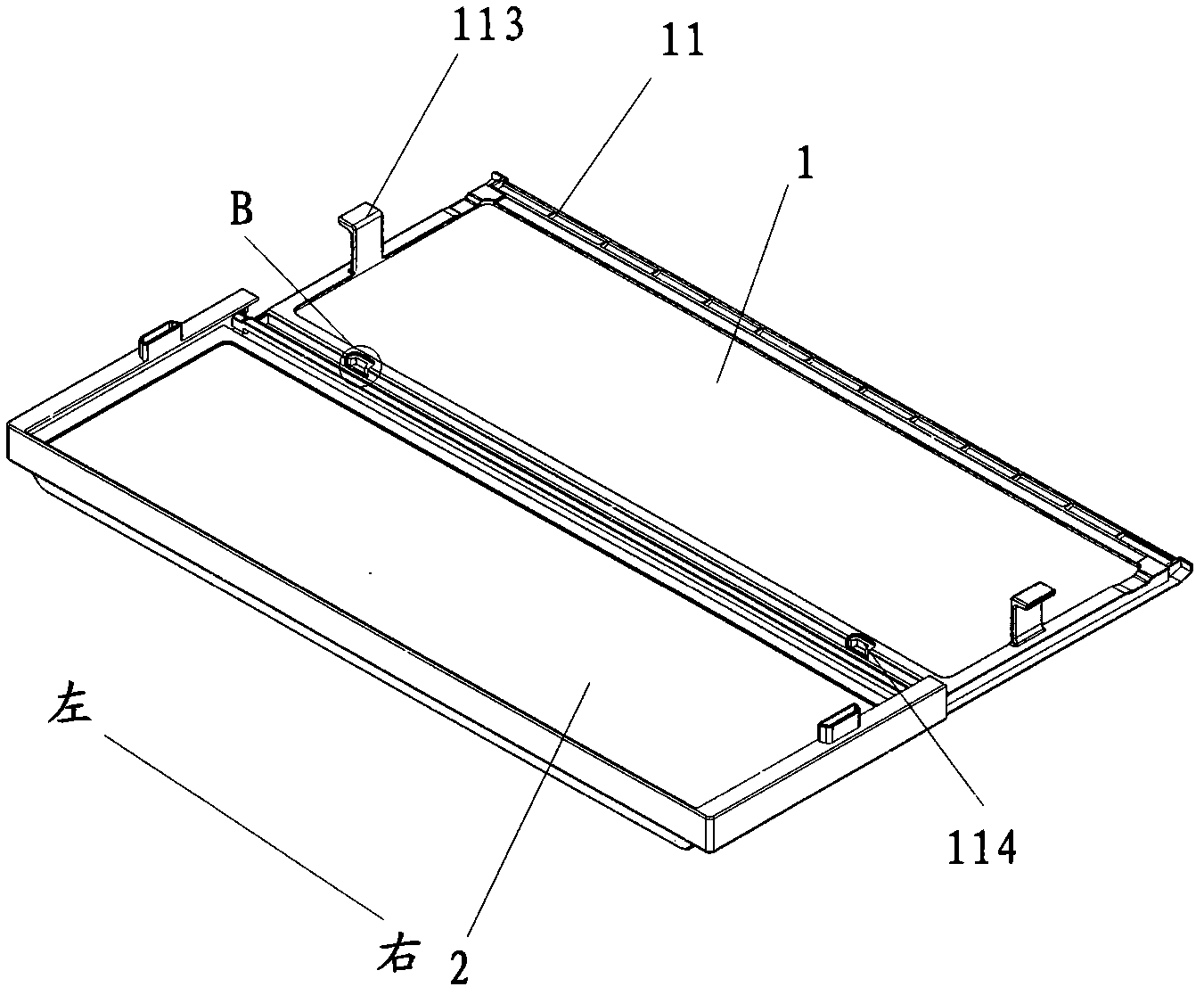

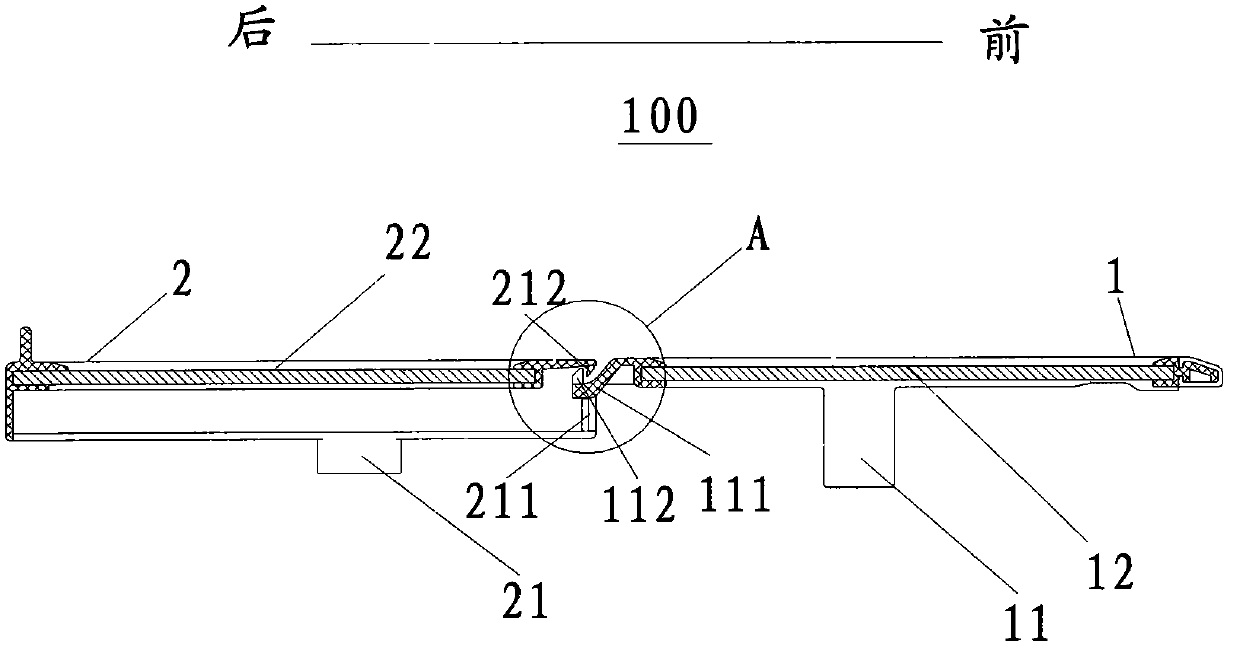

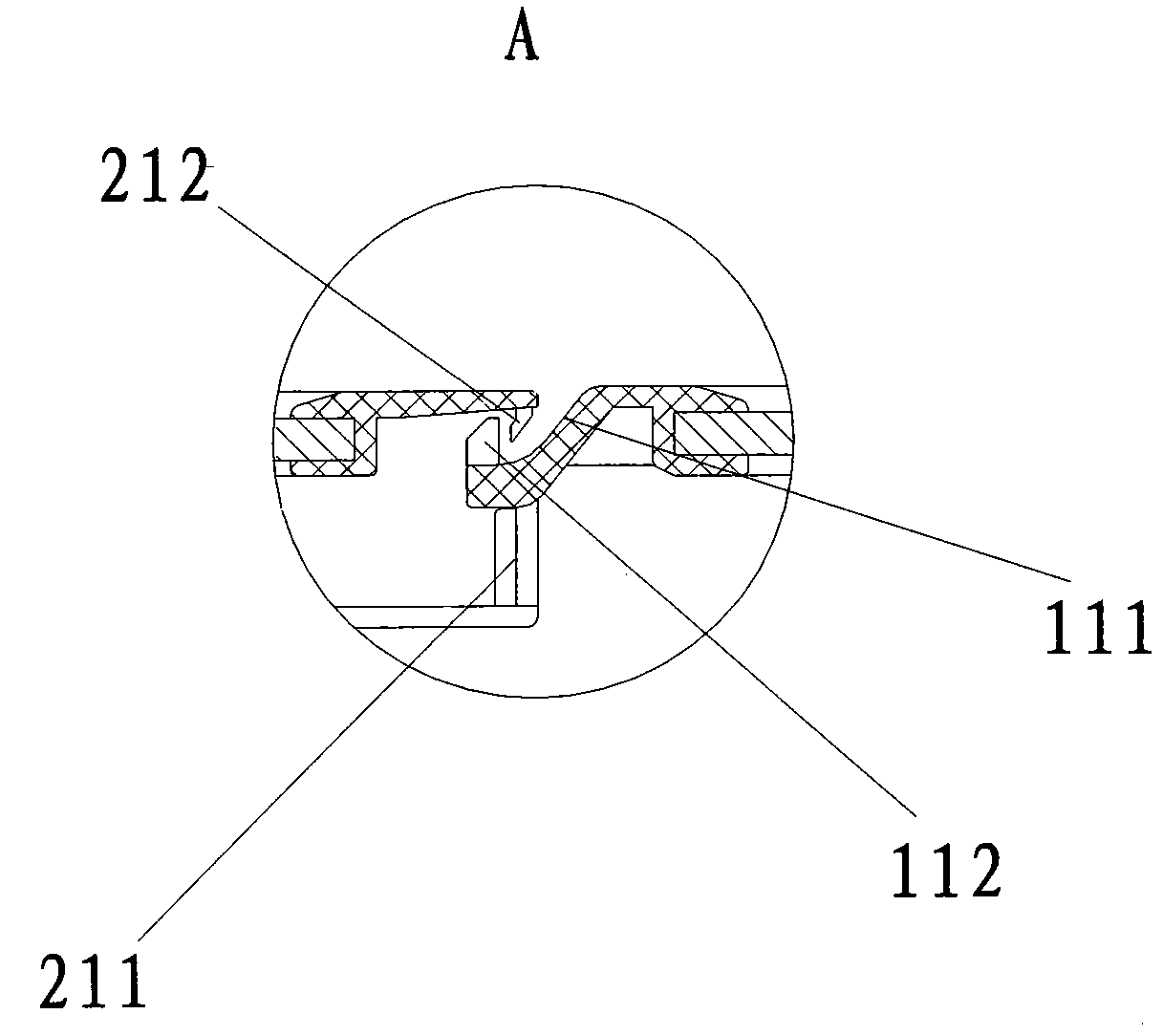

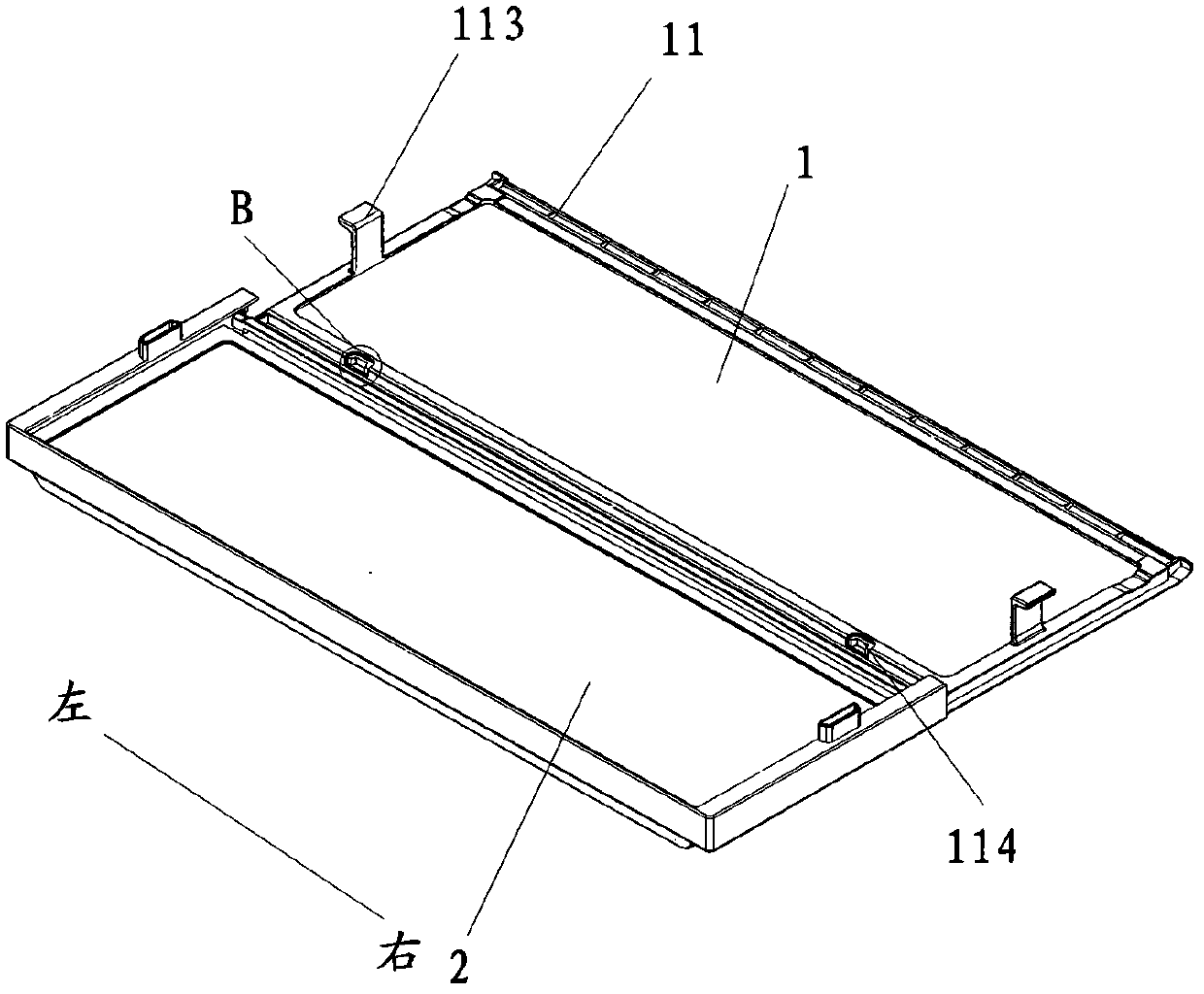

Foldable shelf structure used for refrigeration equipment and refrigerator

ActiveCN102353223AFull of layersEasy to useLighting and heating apparatusSupportSpatial structureEngineering

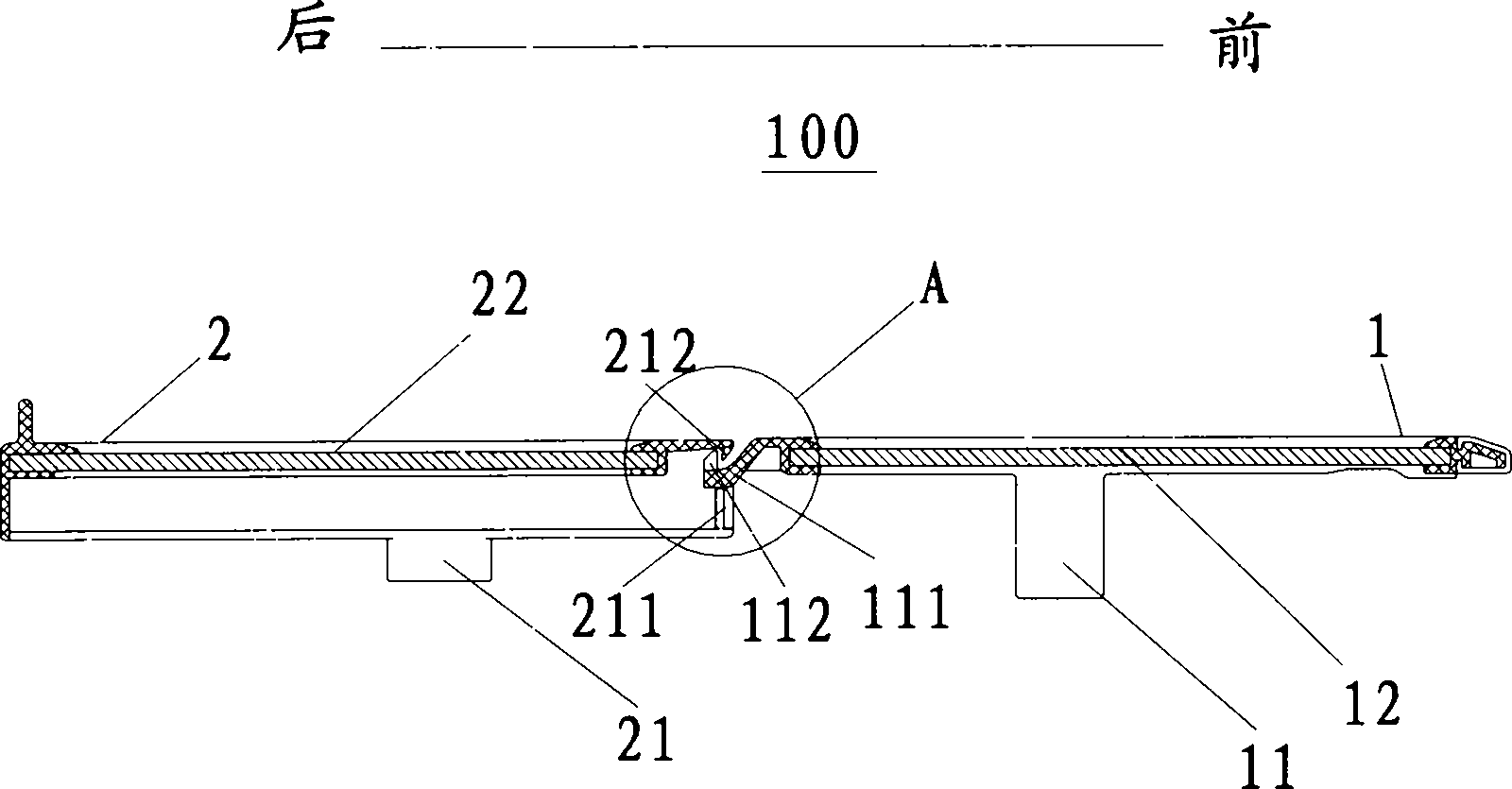

The invention discloses a foldable shelf structure used for refrigeration equipment and a refrigerator. The foldable shelf structure comprises a first shelf and a second shelf, wherein the first shelf comprises a first decorating strip frame and a first shelf glass embedded in the first decorating strip frame; the second shelf comprises a second decorating strip frame and a second shelf glass embedded in the second decorating strip frame; and the first shelf and the second shelf are parallelly arranged, and slipped into the lower part of the second decorating strip frame in a foldable manner. According to the foldable shelf structure of the embodiment of the invention, the shelf glasses are embedded in the decorating strip frames, and the first shelf can slip into the lower part of the second decoration strip frame in a foldable manner, so the foldable shelf structure provided by the invention has the advantages of convenience in cleaning, beauty in structure, and effectively adjusts the space structure in the refrigerator according to the requirements of clients.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Cotton and spun silk segment-color yarn and production method thereof

The invention relates to a type of cotton and spun silk segment-color yarn and a production method thereof. The cotton and spun silk segment-color yarn comprises colored decorative yarn and white base yarn, wherein the colored decorative yarn is spun silk yarn, and the white base yarn is pure cotton yarn. The process comprises the following steps that scouring, opening and carding are carried out on spun silk raw materials, then, combing is carried out, four drawing is carried out so that spun silk drawn slivers can be made, the spun silk drawn slivers are cut into spun silk fibers with a fiber cutting-off machine, the average length of the spun silk fibers ranges from 28 mm to 35 mm, dyeing is carried out, and colored spun silk roving is made through roving; cotton fibers is processed through opening picking, carding, combing, drawing and roving to form white cotton roving; in the working procedure of spun yarn, the spun silk serves as the colored decorative yarn, cotton serves as base yarn, and spinning is carried out to form the cotton and spun silk segment-color yarn. By the adoption of the process, resource allocation is fully utilized, the cotton fibers serve as the main body of the yarn, the expensive spun silk is used for forming colored segments, the production of the high value-added cotton and spun silk segment-color yarn is achieved, and the product profit is increased.

Owner:安徽寿县银丰棉业有限责任公司

Manufacturing process for printing roller multi-depth forme

InactiveCN102423955AEmbossed effect arrivesFull of three-dimensional sensePrinting pre-treatmentForme preparationManufacturing technologyLaser engraving

The invention relates to a printing roller manufacturing technology, and concretely relates to a manufacturing process for a printing roller multi-depth foaming forme. The process comprises steps of mechanical processing, nickel plating, grinding, manuscript manufacturing, glue spraying, laser engraving, and corroding. The process is characterized in that: secondary glue spraying processing, secondary laser engraving processing, secondary corrosion processing and chrome plating processing are carried out after the corrosion step. Compared with the prior art, different patterns can have different depths on the printing roller as needed in the invention, so embossing effects on pure raw paper and nonwoven paper which can reach embossing effects on rubber surface wallpaper have rich stereoscopic and layered sense.

Owner:上海希尔彩印制版有限公司

One-step-process hydrophilic dacron/high-shrinkage dacron combined yarn and preparation method thereof

InactiveCN102965761AImprove thermal stabilityReduce crystallinityArtificial filament heat treatmentMelt spinning methodsYarnSulfonate

The invention discloses a one-step-process hydrophilic dacron / high-shrinkage dacron combined yarn and a preparation method thereof. The combined yarn is prepared from hydrophilic copolyester chips and high-shrinkage copolyester chips by using one-step-process spinning, wherein the hydrophilic copolyester chips comprise purified terephthalic acid, ethylene glycol, m-phenylene dihydric alcohol binary acid ester-5-sodium sulfonate, polydihydric alcohol and other dihydric alcohols, and the high-shrinkage copolyester chips comprise purified terephthalic acid, ethylene glycol and isophthalic acid. The combined yarn obtained according to the preparation method has the fiber moisture regain being 1.0-3.0% and the differential shrinkage rate being 10-60%, is improved in softness, hydrophily and dyeing property, and can be used in cotton-like and wool-like fabric.

Owner:DONGHUA UNIV

Method for preparing anti-bacteria cool graphene slubby yarn and application thereof to home textile products

The invention discloses a method for preparing anti-bacteria cool graphene slubby yarn. The yarn is composed of, by weight parts, 30-60 parts of graphene chinlon composite fiber, 20-30 parts of bamboo fiber and 10-20 parts of viscose fiber. The fibers are spun into the slubby yarn through a ring spinning frame spinning process. The process comprises the steps of cotton blending, cotton carding, drawing, spinning and spooling. The obtained anti-bacteria cool graphene slubby yarn is formed by blending of various function fibers and integrates the advantages of the used fibers. Compared with conventional cotton yarn, the anti-bacteria cool graphene slubby yarn has viscose glue, is more excellent than natural cotton fiber in softness, moisture absorption and light self-weight and has anti-bacteria and cool performances of the bamboo fiber; the novel graphene chinlon composite fiber is adopted to intensify anti-static anti-bacteria, cool, comfortable and conformable performance and the like. The prepared yarn is applied to home textiles, and the finished home textiles are rich in layering sense and third dimension and have multiple functions.

Owner:IANGSU COLLEGE OF ENG & TECH

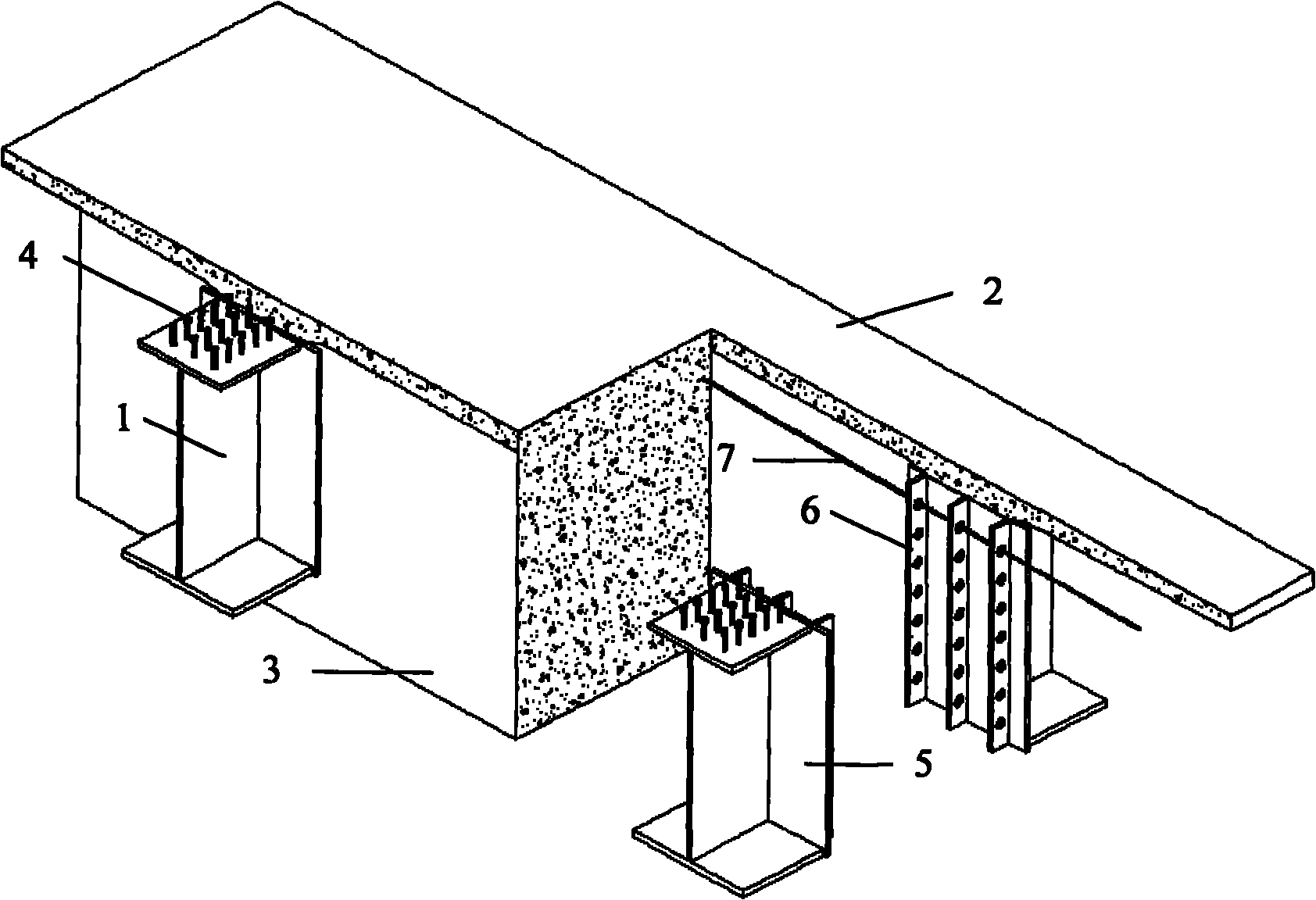

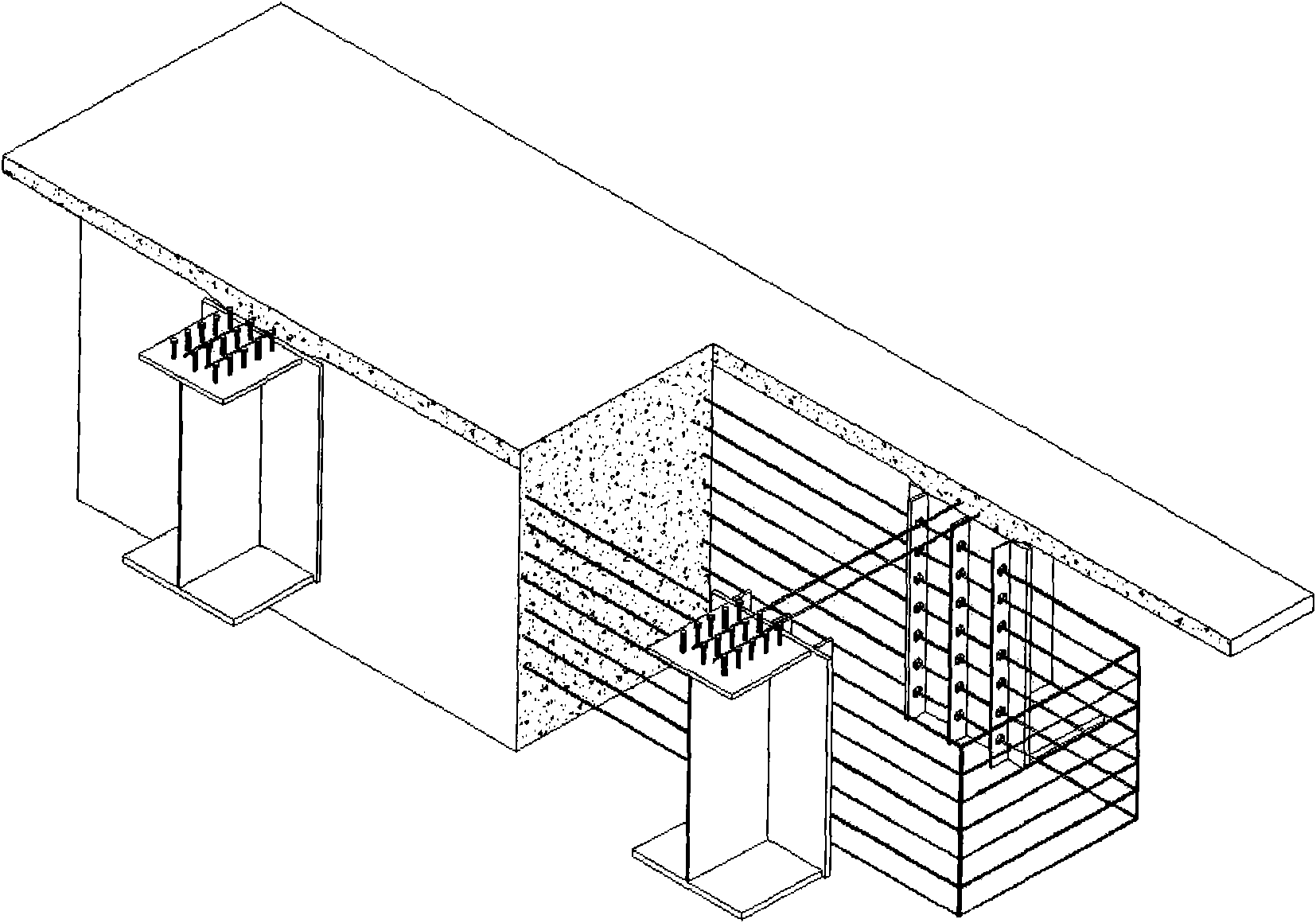

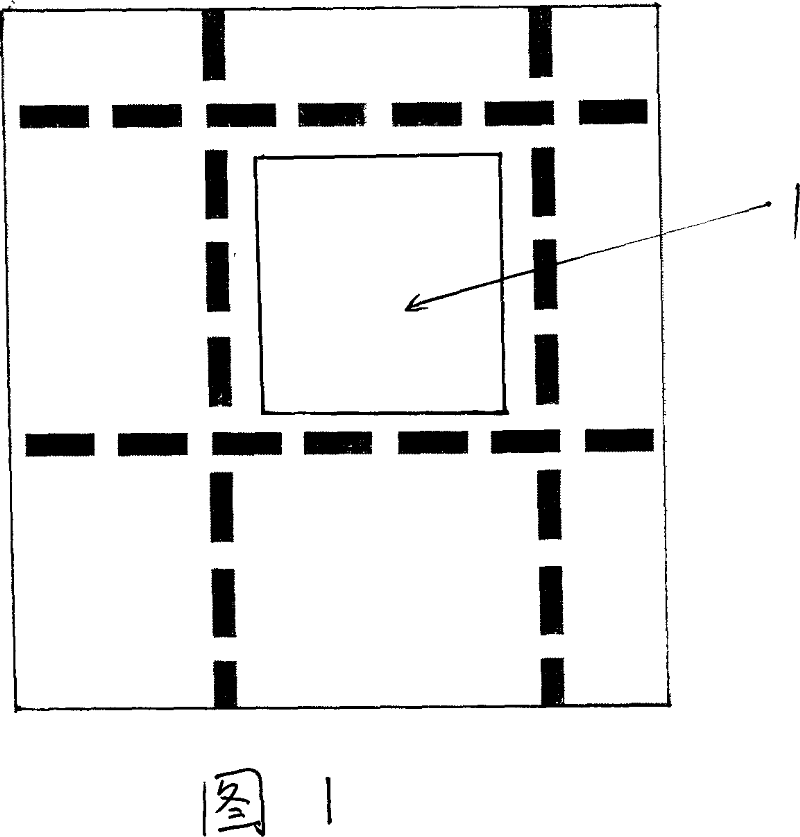

Connecting structure of combined beam and concrete bearing cross beam

The invention discloses a connecting structure of a combined beam and a concrete supporting cross beam, comprising a steel girder and a concrete supporting cross beam, wherein the steel girder is disconnected at an intermediate pivot and is connected with the concrete supporting beam; an end plate is arranged at the end part of the steel girder and is provided with an open pore plate or is connected with the steel girder and the concrete supporting cross beam through weld screws so as to transfer the shearing force and the bending moment of a beam body; constructional steel bars are arranged in the concrete supporting cross beam; the constructional steel bars and a main forced steel bar form a steel reinforcement cage together; and a concrete pier is provided with a support seat which is supported on the bottom of the concrete supporting cross beam. The connecting structure reduces the tensile stress of a bridge panel in a negative bending moment area, caused by the shrinkage, the creep and the temperature of the concrete, and has concise and definite force transfer; and in addition, the prestress is not required to apply on the negative bending moment area and a bent cap is omitted. A steel structure is not required for welding on site and the adjustability of the distribution position of the pier is favorable.

Owner:TONGJI UNIV

Ornamental glass having etching pattern and multicolor pattern and and method for manufacturing same

InactiveCN101041555AHigh precisionFull of three-dimensional senseSurface treatment compositionsFlat glassScreen printing

The invention discloses a decorative glass with acid-frosted pattern and colored pattern and preparing method, which comprises the following steps: one, acid-frosting to acid-frosting pattern on the plate glass through acid-frosting treatment; two, cleaning; airing or drying; three, combining with self pattern of acid-frosting glass; adopting silk-printing or spraying method; printing or spraying coloured material on the acid-frosting glass; forming colored pattern; four, natural drying or drying the coloured glass; getting end product.

Owner:ZHENGZHOU HENGHAO GLASS TECH

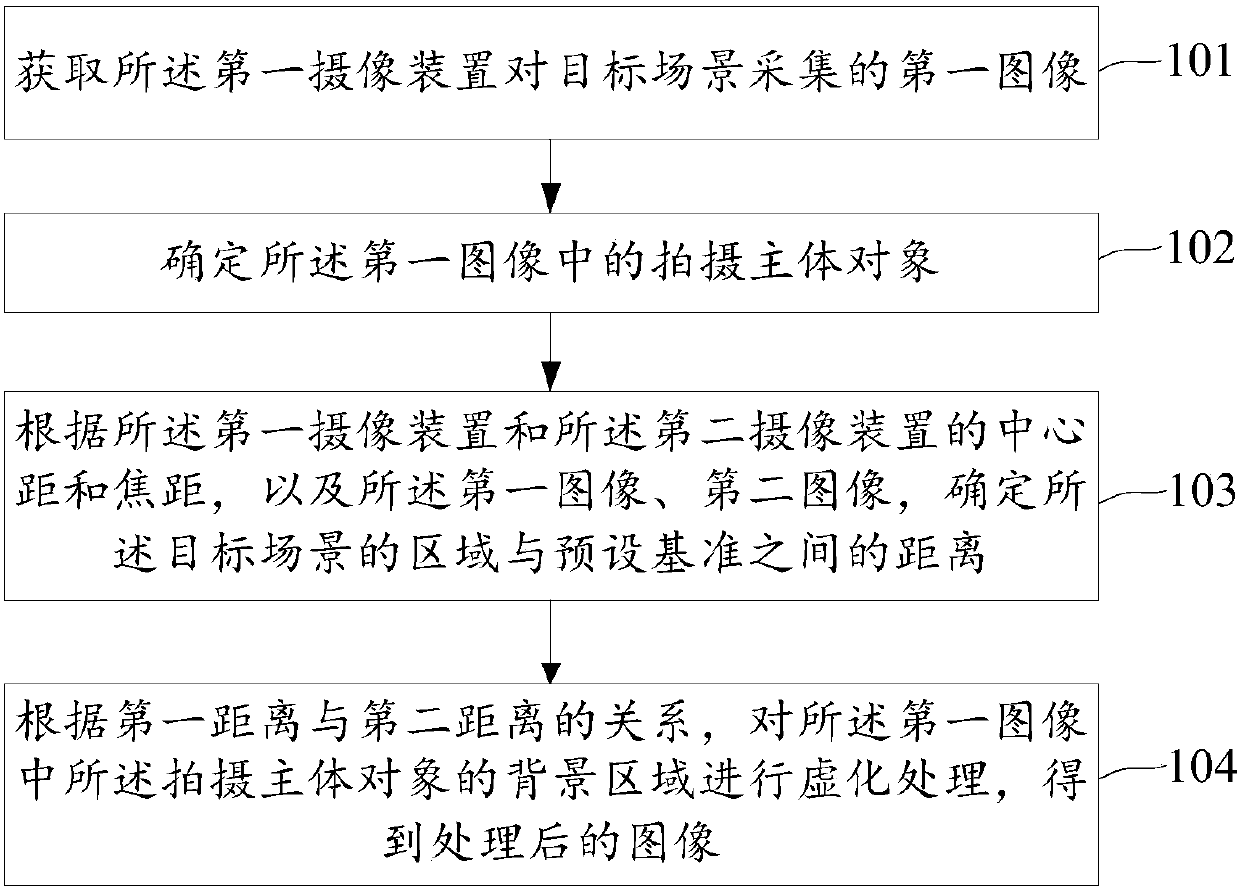

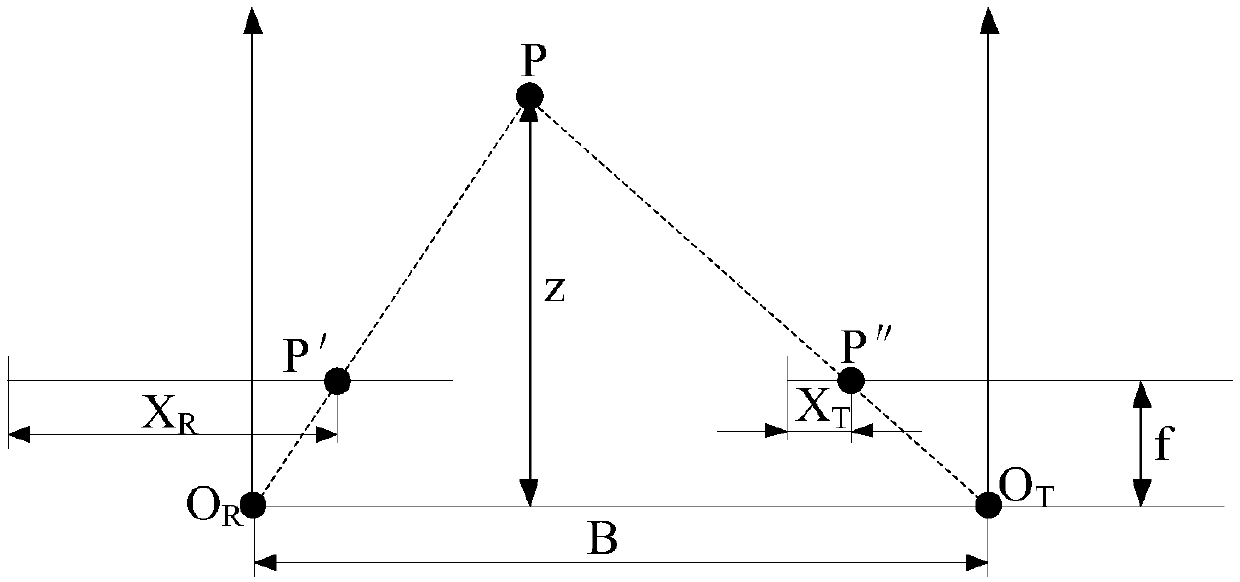

Image processing method, image processing apparatus and mobile terminal

InactiveCN107948516AImprove shooting experienceFull of layersTelevision system detailsGeometric image transformationImaging processingComputer terminal

The invention discloses an image processing method, an image processing apparatus and a mobile terminal, the method and the apparatus are applied to the mobile terminal comprising a first photographicapparatus and a second photographic apparatus, and the method comprises the following steps: obtaining a first image acquired from a target scene by the first photographic apparatus; determining a photographing principal object in the first image; according to a center distance and a focal length of the first photographic apparatus and the second photographic apparatus, the first image and a second image, determining a distance between a region of the target scene and a default benchmark, wherein the second image is the one acquired from the target scene by the second photographic apparatus;and according to a relation between a first distance and a second distance, blurring a background region of the photographing principal object in the first image to obtain a processed image. Thus, anaim that a user can shoot images, dynamic images and videos with clear photographing principal object and visional background through the mobile terminal can be realized.

Owner:VIVO MOBILE COMM CO LTD

One-step method production process of high-strength high-shrinkage combined filament yarns

ActiveCN110552096AFull of layersFluffy appearanceSpinning solution de-aeratingMonocomponent copolyesters artificial filamentShrinkage rateHeat stability

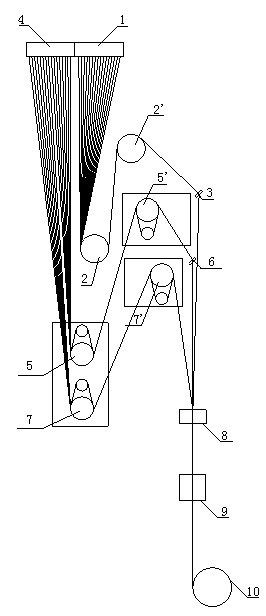

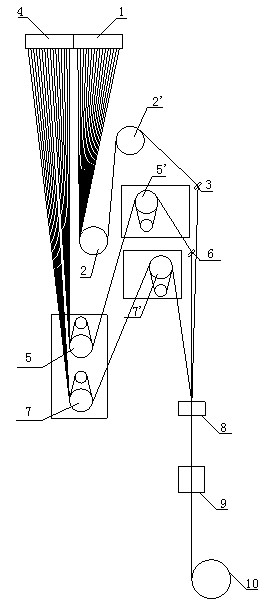

The invention discloses a one-step method production process of high-strength high-shrinkage combined filament yarns. The process comprises the following steps of S1 chip drying, S2 spinning of high-strength polyester filaments, S3 spinning of high-elasticity polyester filaments, S4 web connection of the high-strength polyester filaments and the high-elasticity polyester filaments and S5 winding.The invention relates to the one-step method production process of the high-strength high-shrinkage combined filament yarns, and the produced combined filament yarns have both high-strength performance and high-shrinkage performance. Sulfonic-acid-group negative dyeing bases capable of being dyed by cationic dyes, polydihydric alcohol for improving heat stability and dihydric alcohol for reducingthe crystallization performance are added, so that the performance such as hydrophilia, dyeability, lustre and flexibility is comprehensively improved. Under the effect of high-shrinkage polyester fibers, compared with conventional pre-oriented yarns / fully-drawn-yarn combined filament yarns, pile loops formed after thermal treatment are richer in layering sense, the appearance is fluffier, and a formed fabric is fuller, stereoscopic and larger in controllable range of the different shrinkage rate.

Owner:浙江大地蓝化纤有限公司

Device for detecting image sensor performance and use method thereof

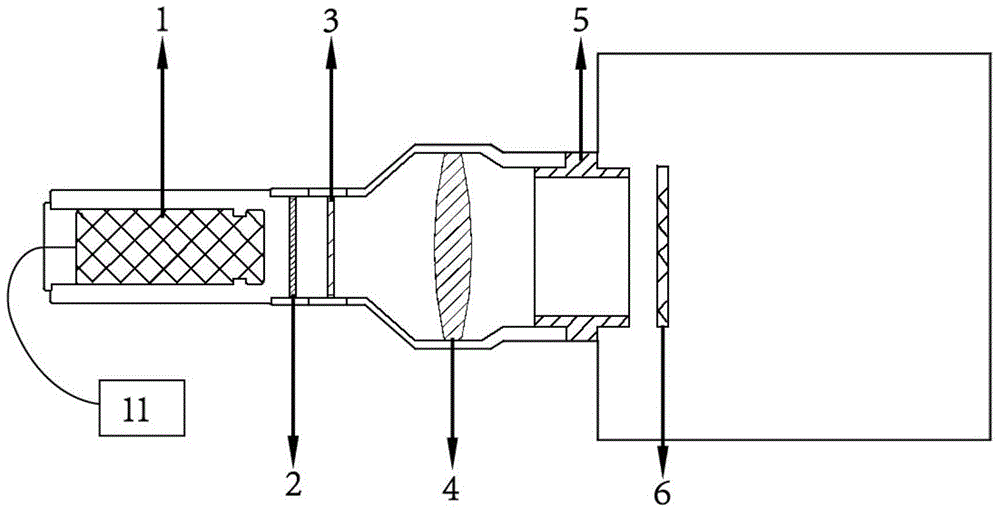

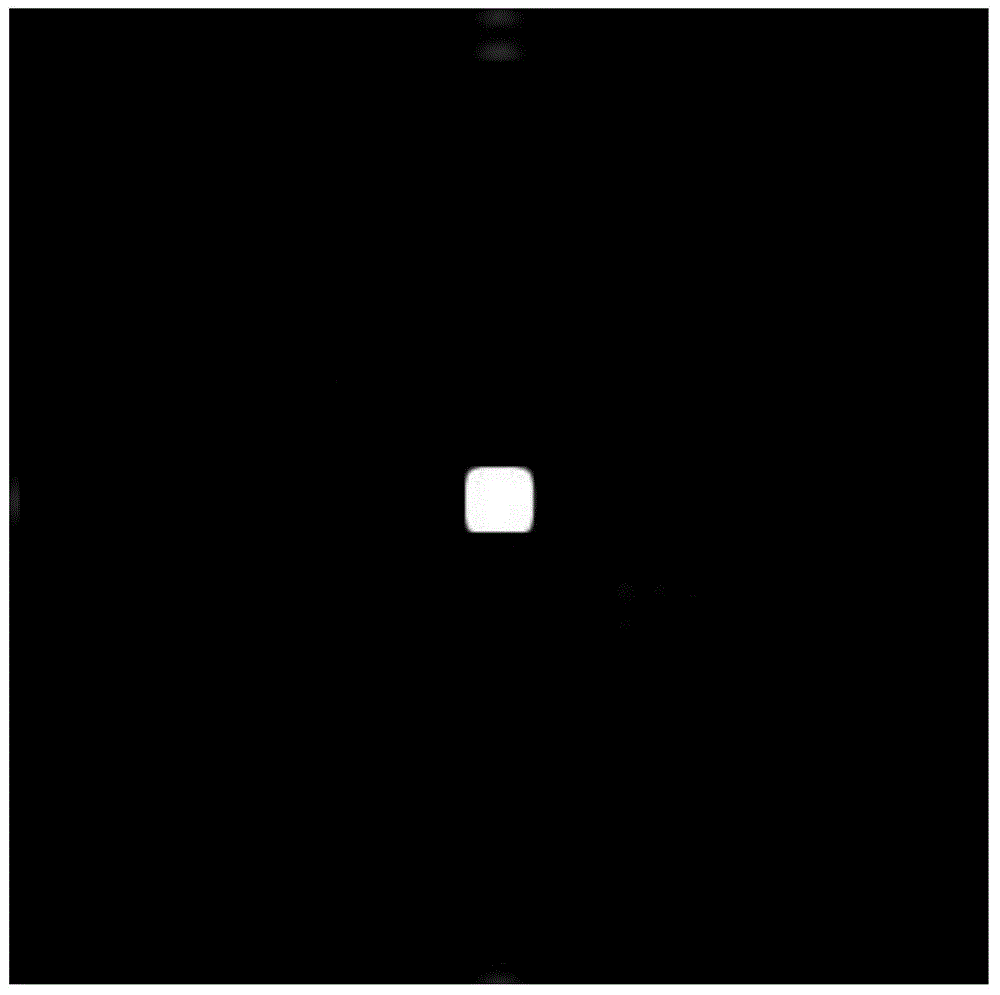

The present invention discloses a device for detecting image sensor performance and a use method thereof, belonging to the field of optical imaging. The method comprises the following steps that a device right side interface is connected to a left side interface of an image sensor external frame, a closed space which is not interfered by the outside is formed, a laser emits parallel light to go through an adjustable light attenuation sheet, the adjusted parallel light is irradiated to a diffraction screen with a hole to generate diffraction, the diffracted light goes through a converging lens to be focused to the image element surface of the image sensor to form a diffraction pattern, and finally an adjustable ring is adjusted to focus the diffraction pattern. Through the light intensity information of a calibrated diffraction spot, the various performance parameters of the image sensor can be quantitatively obtained. The disadvantages of long time consumption, complicated operation, complex scene, difficult analysis and the like of a traditional test and comparison method are overcome, and the invention provides the intuitive, simple, fast, small and portable image sensor performance testing and comparison device with qualitative and quantitative functions and without outside interference and the method thereof.

Owner:福州鑫图光电有限公司

Method for manufacturing gold spraying plate of dyeing and printing roller

InactiveCN102407709AEmbossed effect arrivesFull of three-dimensional sensePrinting pre-treatmentForme preparationLaser engravingPulp and paper industry

The invention relates to a technology for manufacturing a roller by dyeing and printing, in particular to a method for manufacturing a gold spraying plate of the dyeing and printing roller. The method comprises the following steps of machining, nickel plating, grinding, manuscript production, glue spraying, laser engraving and etching. Compared with the prior art, the method has the advantages that different patterns can be made into patterns with different depth on a printing roller according to requirements, so that an embossing effect of pure paper or non-woven paper achieves the embossing effect of vinyl wall coverings, and the pure paper or the non-woven paper has a three-dimensional effect and hierarchy sense.

Owner:上海希尔彩印制版有限公司

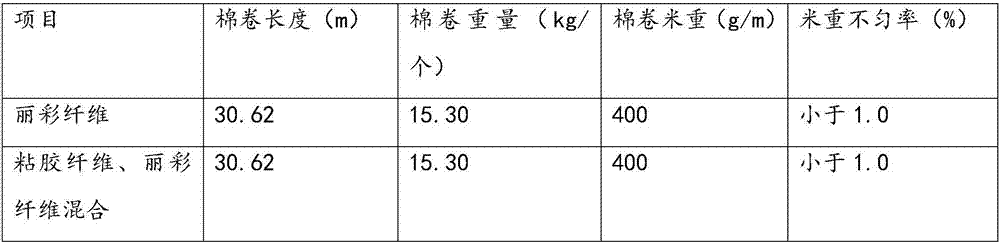

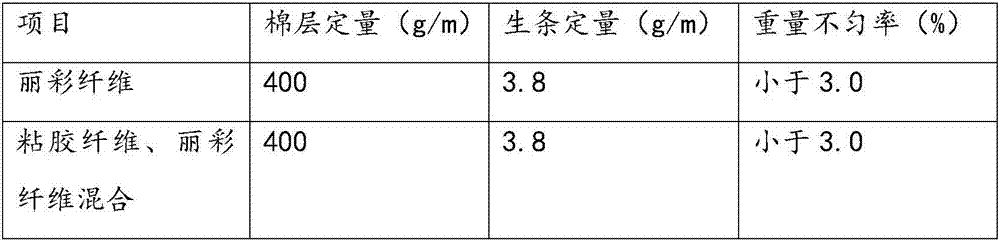

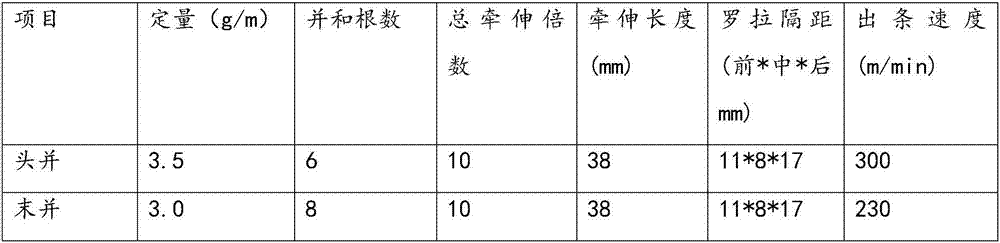

Viscose fiber and leecy fiber blended yarn and spinning technology thereof

The invention discloses a viscose fiber and leecy fiber blended yarn and a spinning technology thereof. The blended yarn comprises viscose fibers with the fiber content blending ratio of 60-70%, and leecy fibers with the fiber content blending ratio of 30-40%. The fibers are woven into the yarn through the spinning technology. Firstly, after the leecy fibers are subjected to opening and picking and cotton carding, the leecy fibers and the viscose fibers are mixed, then opening and picking and cotton carding are carried out, and the leecy fibers and the viscose fibers can be mixed to be uniform; due to the fact that the leecy fibers with the durable physical bacteriostasis function are added, the viscose fiber finished products can be prepared into the yarn with the antibacterial function directly through the following spinning technology, it is not needed to independently carry out antibacterial treatment on the viscose fiber finished products, the technology is simplified while the antibacterial effect is guaranteed, the production cost is reduced, fabric woven from the viscose fiber and leecy fiber blended yarn can be rapidly dyed, the colors are gorgeous, gradually varied and rich in layering sense after the fabric is colored, and multiple colors can be obtained through one time of dyeing.

Owner:宜宾恒丰丽雅纺织科技有限公司

Clear wood paint and preparation method thereof

The invention discloses a clear wood paint and a preparation method thereof, belonging to the technical field of application of paints. The invention solves the problem of poor transparency of the wood paint in the construction process, and the problem of white paint film after recoating. The clear wood paint is composed of a component A and a component B, wherein the component A is composed of an addition product of toluene diisocyanate (TDI) and trimethylolpropane or TDI tripolymer or mixture thereof, butyl acetate and ethyl acetate; the component B is composed of alkyd resin or modified alkyd resin or mixture thereof, butyl acetate, ethyl acetate, dimethylbenzene, defoaming agent, leveling agent, flatting agent, antimicrobial agent, dispersing agent, anti-settling agent and modified resin; and the weight ratio of the component A to the component B is 1:0.5 or 1:0.25. The invention also provides a preparation method of the wood paint. The wood paint disclosed by the invention has the advantage of clear and layered paint film, and can better display the beautiful texture of the wood.

Owner:NIPPON PAINT CHENGDU

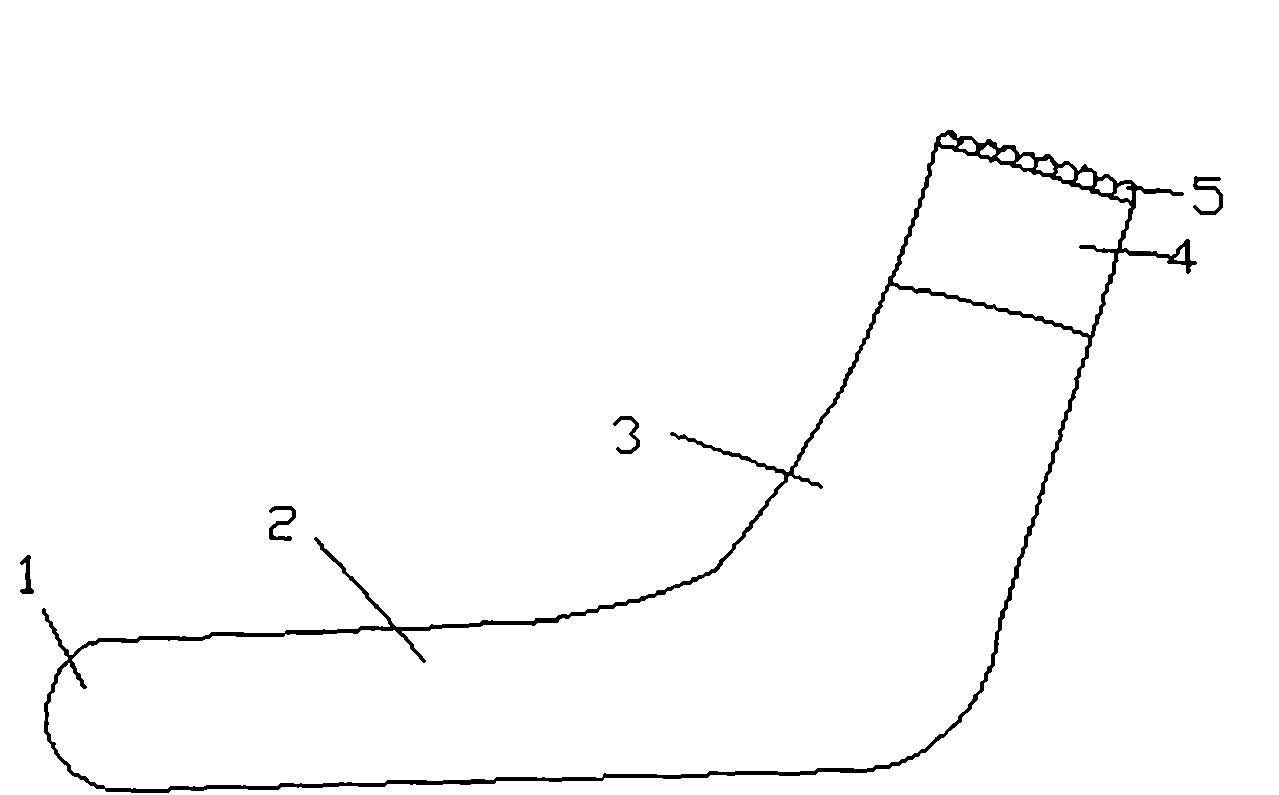

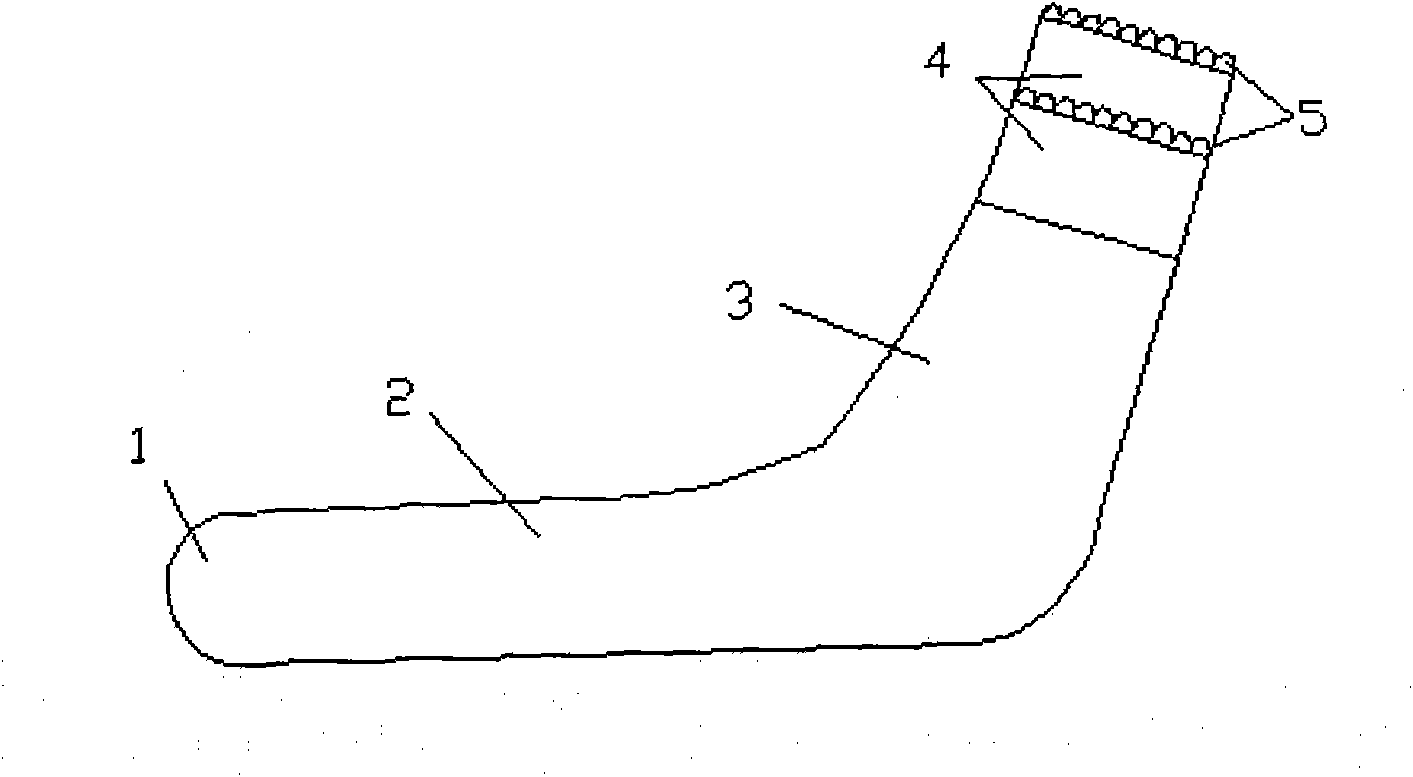

Waterproof lace socks

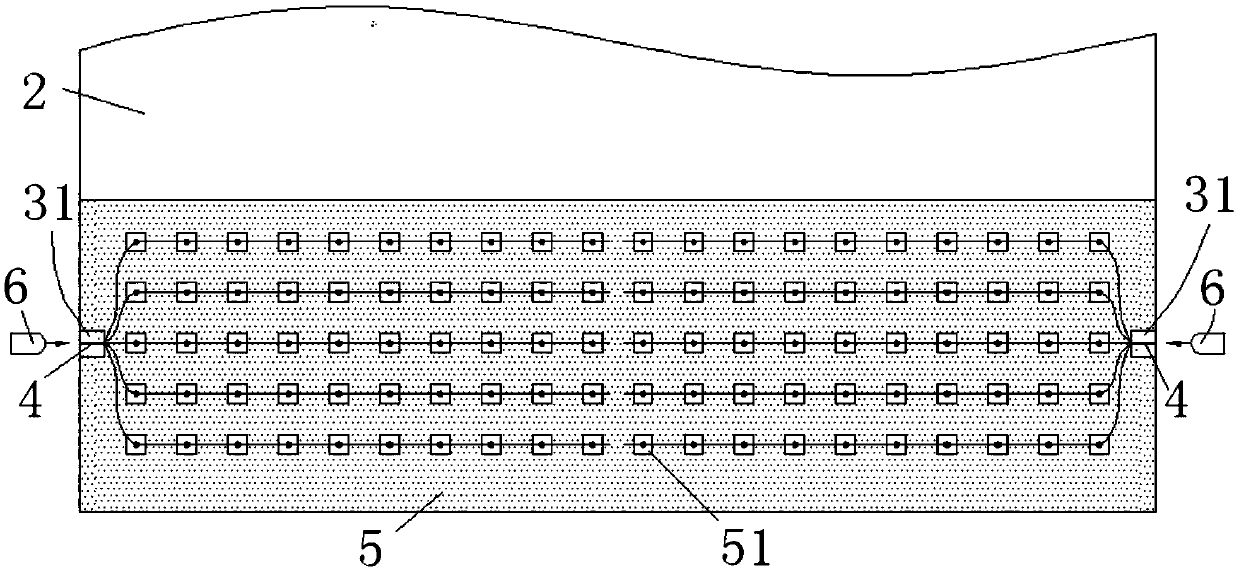

InactiveCN103141946AFull of layersPermanently waterproofPanty-hoseHosieryEngineeringMechanical engineering

The invention relates to a pair of waterproof lace socks, belonging to the field of articles for daily use. The pair of waterproof lace socks comprises sock toes (1), sock bodies (2), sock legs (3) and elastic cords (4) which are connected end to end. The pair of waterproof lace socks is characterized in that laces (5) are arranged on upper edges or / and middle parts of the elastic cords (4) and protrude out of a plane where the elastic cords (4) are positioned; and the outside surfaces of the sock toes (1), the sock bodies (2), the sock legs (3) are coated with silicon layers. The lace socks are worn on feet and the raised laces enable the socks to be rich in layering feeling without dull feeling. In addition, the waterproof lace socks can achieve the effect of permanently resisting water.

Owner:许永新

Method for brewing rice-fragrant type Xiaoqu rice wine

InactiveCN101260352AHigh sugar contentStrong rice fragranceAlcoholic beverage preparationRice dishesFood flavor

The invention relates to a brewing method for rice flavor type xiaoqu rice wine and is characterized in that: (1) fresh and mature cherokee roses are broken, fine hairs and fruit kernels in the shells are removed, and the cherokee roses are crushed into powder after sun-drying; (2) rice 100 (mass portion) is soaked in the water for 50 to 70 minutes, taken out to be mixed with cherokee rose powder 4-6 (mass portion), and put into a container to steam and boil, and the cooked rice is taken out; (3) when the temperature of the cooked rice is decreased to 30 to 35 DEG C, fermented grains can be performed by adding wine ball with the mass portion of 0.8 to 1, and are placed into the container; (4) when the temperature of the fermented grains rises to 36 to 38 DEG C, the water 130-150 (mass portion) is added, the fermentation temperature of the fermented grains is controlled between 30 and 38 DEG C, the fermentation time is between 11 and 13 days, and the fermented grains are distilled to obtain the xiaoqu rice wine. The rice flavor type xiaoqu rice wine of the invention has strong rice fragrance, faint fruit fragrance, mellow taste and slightly sweet after-taste; the wine aroma has more sense of hierarchy; and the wine yield is high up to 83 percent.

Owner:GUANGDONG JIAOLING YIXIANTIAN WINE

Making method of white-ground colored crystal flower crystal glaze

A making method of a white-ground colored crystal flower crystal glaze comprises the following steps: 1, crystal glaze material preparation: mixing albite, potash feldspar, quartz, mud, calcite, barium carbonate, zinc oxide and titanium dioxide, carrying out fine grinding, sieving by a 200 mesh sieve, and removing iron to obtain a crystal glaze material for later use; 2, engobe preparation: respectively selecting one of golden brown engobe prepared by fully and uniformly mixing praseodymium yellow with vanadium-zirconium yellow and finished mud, yellowish green engobe prepared by fully and uniformly mixing vanadium-zirconium blue with the praseodymium yellow and the finished mud and pinky engobe prepared by fully and uniformly mixing manganese red with the finished mud according to the color difference; 3, applying the engobe to white adobe, drying, applying the crystal glaze to the thickness of the obtained glaze layer of about 1mm; and 4, firing to a highest temperature, and cooling to room temperature. The controllable color change of crystal flowers is realized through different engobes, so the obtained white-ground colored crystal flower crystal glaze has the advantages of brilliant, multiple and hierarchic color, simple technology, wide firing temperature range, high yield and low cost.

Owner:CHAOZHOU YUBINGHUA CERAMIC

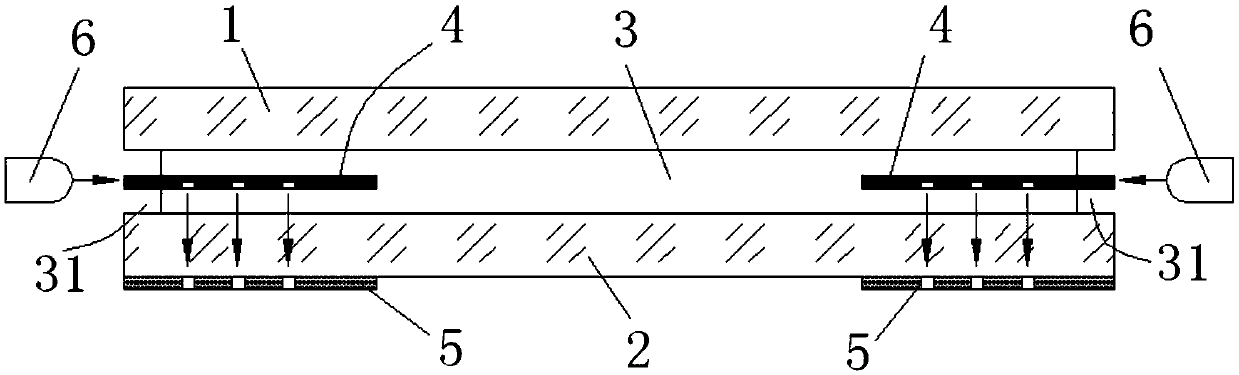

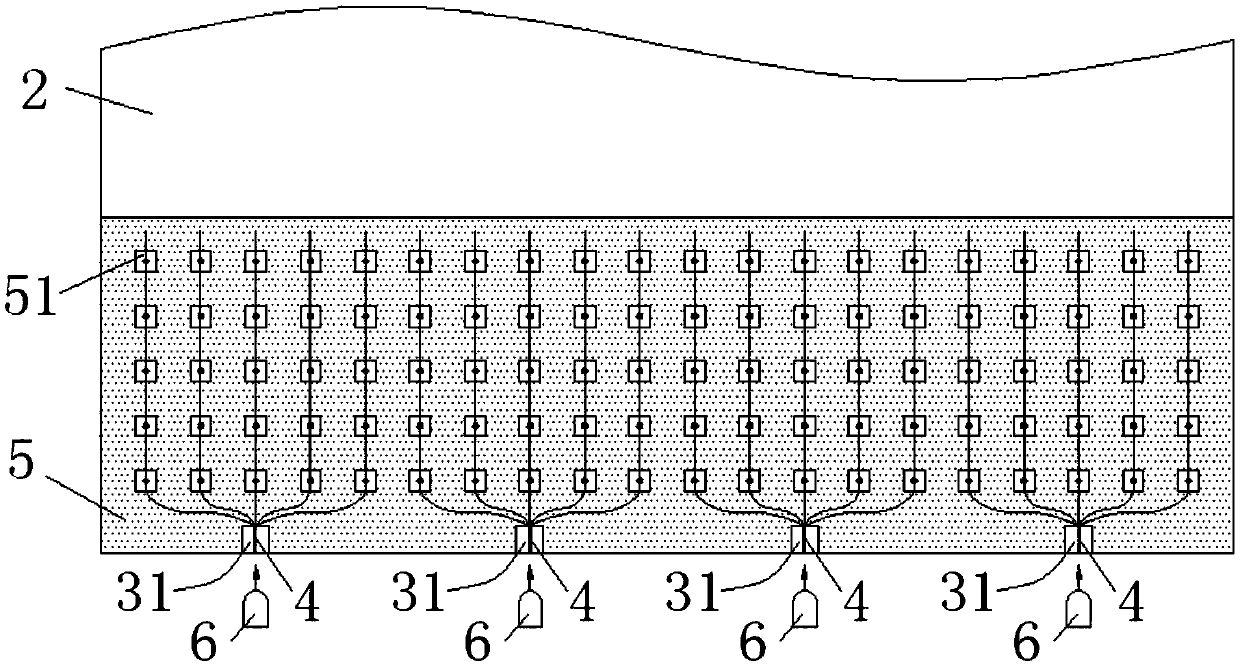

Laminated glass capable of emitting light

The invention belongs to the technical field of light emitting glass, in particular to a vehicle skylight laminated glass capable of emitting light. The laminated glass comprises outer-layer glass, inner-layer glass and a polymer middle layer. The laminated glass is characterized in that a fiber-optic bundle is arranged inside the polymer middle layer, the head end of a fiber-optic core is provided with an incidence hole, and the tail end or body of the fiber-optic core is provided with an emergence hole. When the tail end of the fiber-optic core is provided with the emergence hole, the tail end of the fiber-optic core is located in the projection area of a hollow ink area in the polymer middle layer. When the body of the fiber-optic core is provided with the emergence hole, the tail end of the fiber-optic core is located in a shielding area of an ink pattern. The fiber-optic core extends from the side face of the polymer middle layer to the interior of the ink pattern and penetrates through the projection area of at least one hollow ink area. The laminated glass has the advantages that the structure is simple and compact, and the light emitting effect is rich in layering sensation and stereoscopic sensation.

Owner:FUYAO GLASS IND GROUP CO LTD

Gold glaze material and glazing method thereof

ActiveCN111792844AUnique colorWith health functionCeramic shaping apparatusPhysical chemistryBasaltic rock

The invention provides a gold glaze material, which comprises the following components: 80-120 parts of the potassium feldspar, 40-60 g of the calcite, 5-20 g of the aluminum ore, 5-20 parts of iron ore, 40-60 parts of limestone, 5-15 parts of fluorite, 40-60 parts of dark jade, 90-120 g of the Lushan jade, 25-35 g of plant ash and 15-25 g of basalt. According to the invention, the gold glaze material with golden color is prepared, is unique in color, stable and durable, has a certain health-care function, and has the effects of clearing and activating the channels and collaterals, prolonginglife, purifying water, activating blood, expelling toxin, improving eyesight, moistening lung and reducing blood pressure; and the glazing method suitable for the gold glaze material is designed, wherein glazing is completed through mechanical operation, and the obtained finished product is uniform in color and luster and rich in layering sense.

Owner:鲁山花瓷股份有限公司

Craft porcelain with raised particle effect on glaze surface and preparation method thereof

The invention discloses a craft porcelain with a raised particle effect on a glaze surface and a preparation method thereof. The craft porcelain with a raised particle effect on a glaze surface comprises a green body and overglaze arranged on the green body, the overglaze comprises a glaze slurry and frit dry particles, the glaze slurry comprises the following raw materials: Dehua quartz, halloysite, Dehua feldspar, montmorillonite, sepiolite, dickite, pyroxene, aluminum oxide and lanthanum oxide, during preparation of the craft porcelain, the overglaze is uniformly applied to the surface of the green body, then the green body is sent into a kiln for firing, the surface of the fired craft porcelain has the decoration effect of naturally fused convex bumped artistic patterns, and bump points are clear, vivid, full and rich in layering sense, thus further improving the aesthetic sense of the craft porcelain.

Owner:FUJIAN DEHUA JIASHUN CRAFTS

Collar fabric

The invention discloses a collar fabric comprising a fabric body. The collar fabric innovates in a way that a plurality of concave-convex structures are arranged on the fabric body; the concave-convex structures are embedded in a plane where the fabric main body lies, and are integrated; the concave-convex structures are covered with animal wool fibers; the animal wool fibers are evenly distributed on the concave-convex structures; preferably, the number of the concave-convex structures is seven; and the animal wool fibers are sheep wool or rabbit hair. The collar fabric is laminated and possesses warming and wind resisting performance; collar fabric stereoscopic impression can be enhanced via the concave-convex structures; and warming property of the collar fabric can be strengthened via the animal wool fibers on the fabric body and the back surfaces of the concave-convex structures.

Owner:JIANGSU JUWEI NEW MATERIALS

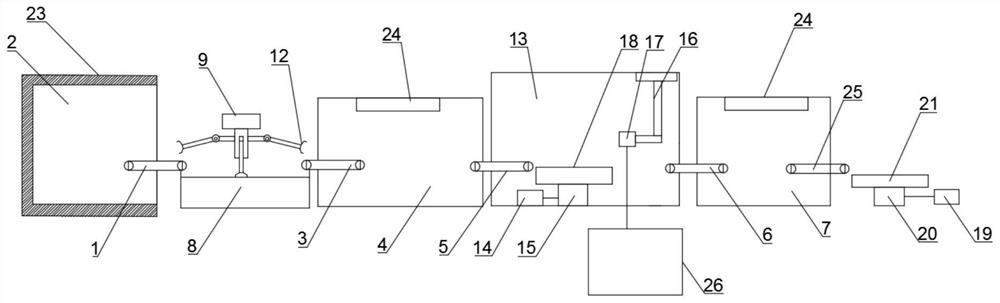

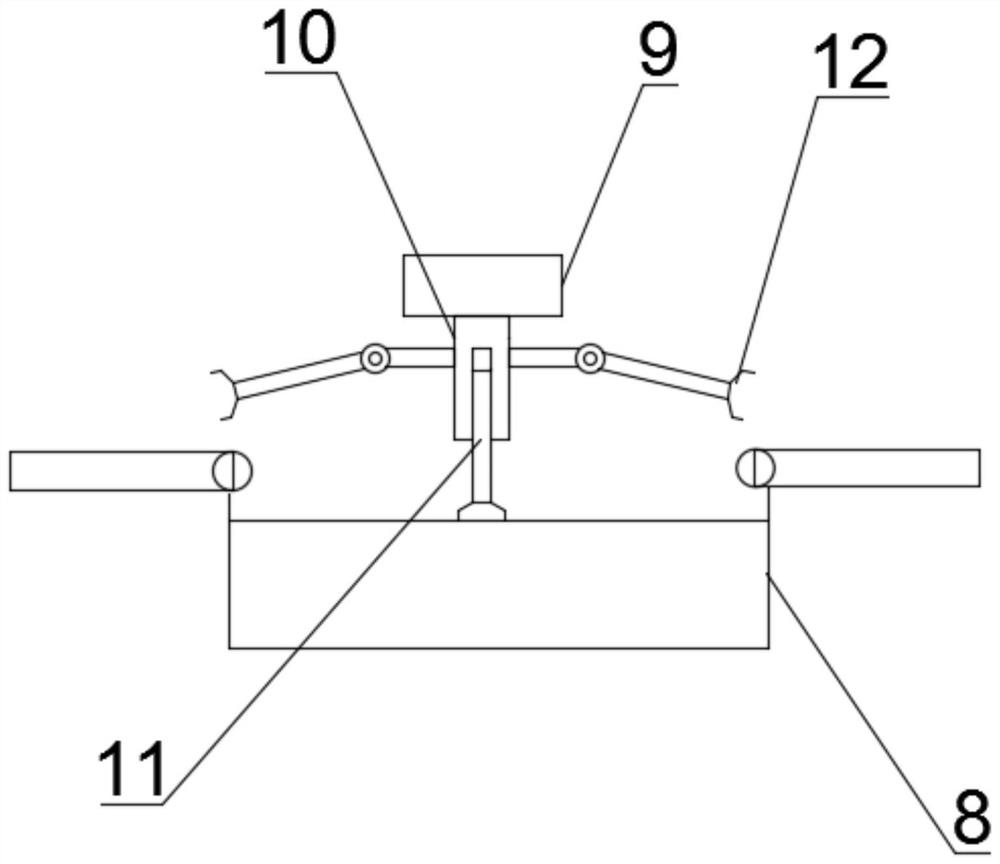

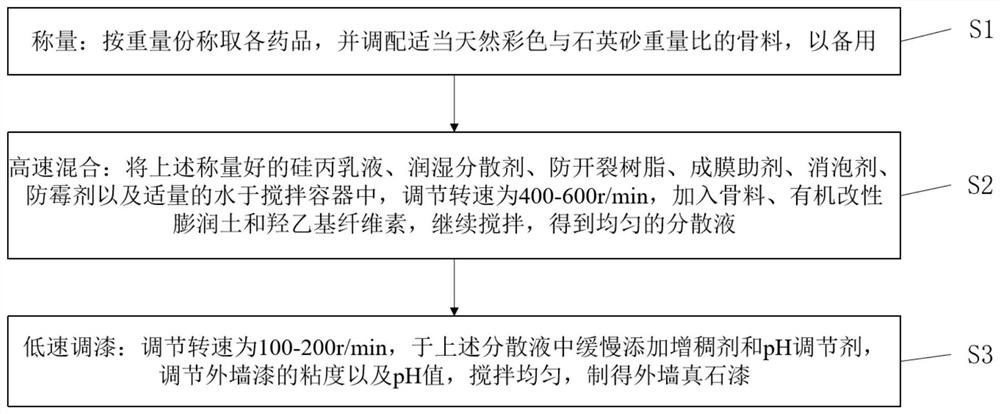

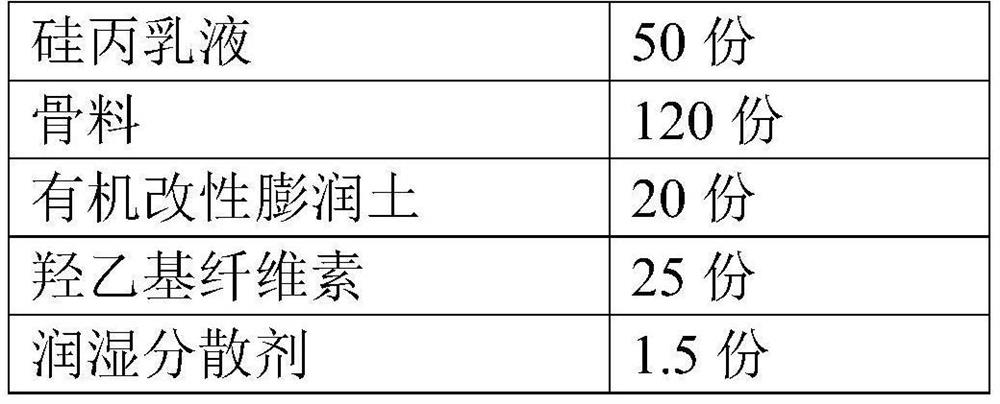

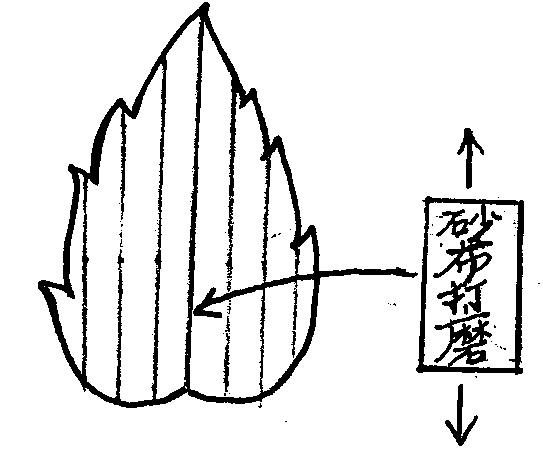

Stone-like coating for exterior wall and preparation method of stone-like coating

The invention relates to the technical field of decoration materials for building exterior walls, in particular to a stone-like coating for an exterior wall. The stone-like coating comprises the following components in parts by weight: 25-50 parts of a silicone acrylic emulsion, 80-120 parts of aggregate, 15-20 parts of organic modified bentonite, 10-25 parts of hydroxyethyl cellulose, 0.5-1.5 parts of a wetting dispersant, 1-2 parts of anti-cracking resin, 1-4 parts of a coalescing agent, 0.5-0.8 part of a defoaming agent, 0.5-1.2 parts of a thickening agent, 0.5-1.5 parts of a mildew preventive, 0.5-3 parts of a pH regulator and a proper amount of water, wherein the aggregate is composed of natural colored sand and quartz sand according to a weight ratio of (1-3): (1-2), the particle size of the natural colored sand is 40-80 meshes, and the particle size of the quartz sand is 80-120 meshes. The invention also provides a preparation method of the stone-like coating. The stone-like coating prepared by the invention is smooth in spraying, clear in sand grains, high in hard drying speed, more layered in paint surface tone and better in stone-like effect, the weather resistance, acid and alkali resistance, color retention, water resistance and stain resistance of the exterior wall coating are enhanced, the comprehensive functionality of the exterior wall coating is improved, and the development and application of the exterior wall coating are facilitated.

Owner:安徽朗凯奇科技股份有限公司

Double-color injection molding process

ActiveCN102211380ABeautiful appearanceFull of three-dimensional senseMolding machineTransfer molding

The invention relates to a double-color injection molding process. A double-color molding product is molded by using a double-color molding machine provided with a molding die; the double-color molding machine is provided with a first color injecting area, a second color injecting area and a turntable; the molding die comprises a male die and a female die, wherein the male die is arranged on the turntable; and the double-color molding product comprises a first color part and a second color part. The double-color injection molding process comprises the following steps of: (1) molding the firstcolor part in the first color injecting area; (2) turning the turntable after the die is opened, wherein the turntable drives the male die to turn to the second color injecting area, and molding the second color part in the second color injecting area by adopting an in-mold transfer molding process, wherein the second color part is made of a transparent raw material; and (3) obtaining the double-color molding product after the die is opened. As the double-color injection molding process is adopted, both the appearance of a transfer film and the appearance of the first color part can be presented while efficiency is increased and the production process is shortened, so that the molding product has the advantages of more attractive appearance, three-dimensional effect and gradation.

Owner:SHENGMEI PRECISION INDAL KUSN

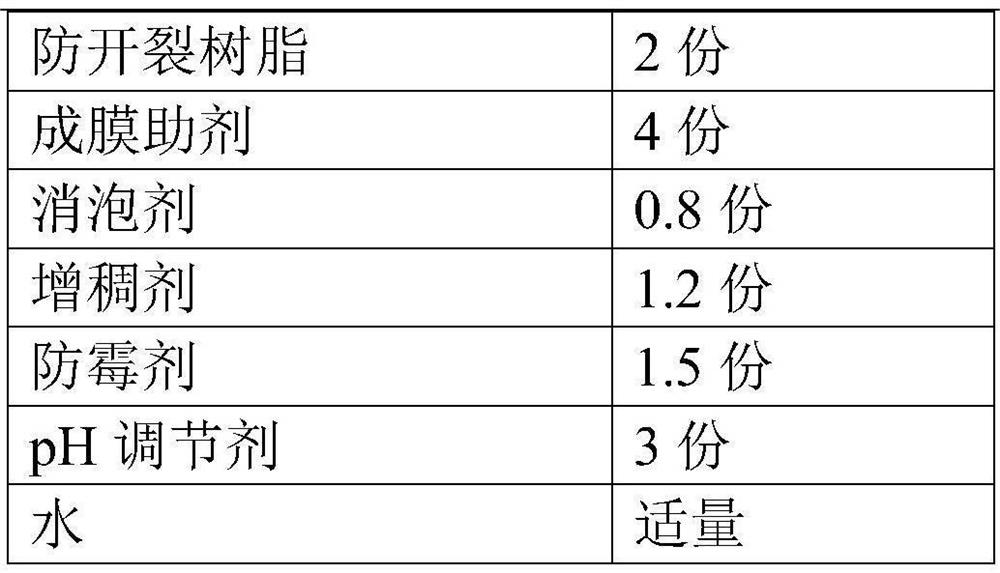

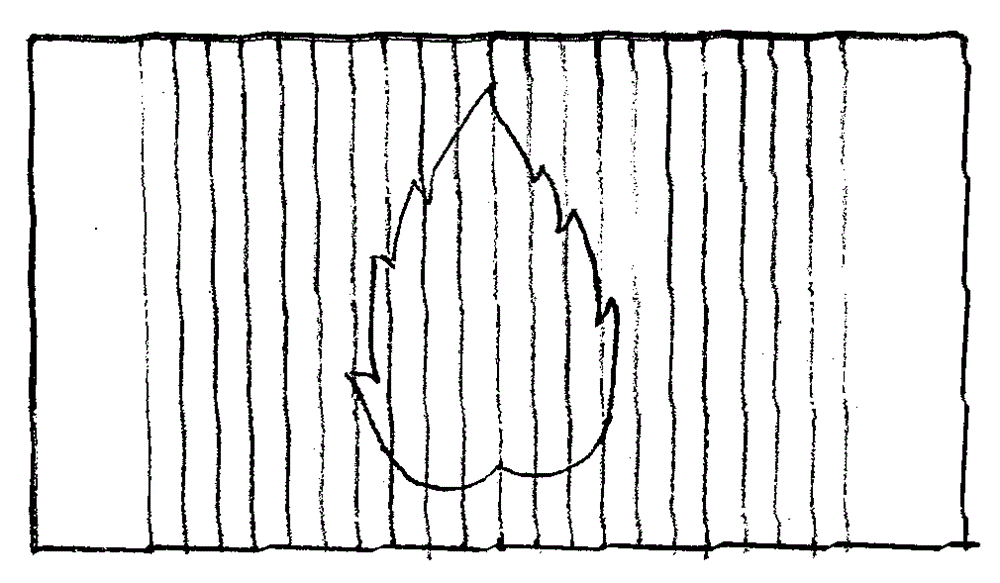

Colorful craft picture coloring method taking wheat stalks or reed stems as raw materials

InactiveCN104648030ANatural color transitionFull of layersSpecial ornamental structuresEngineeringColor changes

The invention discloses a colorful craft picture coloring method taking wheat stalks or reed stems as raw materials. The colorful craft picture coloring method is characterized in comprising following steps: 1, processed and flat wheat stalks or reed stems are joined together and pasted on paper with glossy surfaces upward so as to form a pattern, and a designed pattern is formed via engraving and cutting; 2, the parts of the designed pattern, i.e. the glossy surfaces of wheat stalks or reed stems, which are required to be colored are subjected to polishing using polishing tools; 3, the designed pattern obtained via polishing directly is subjected to handcraft coloring using liquid pigments on polished surfaces. According to the colorful craft picture coloring method, polishing and handcraft direct coloring are combined, so that color change and transition are natural, and pictures are vivid and are rich in layering sense.

Owner:邹晋洪

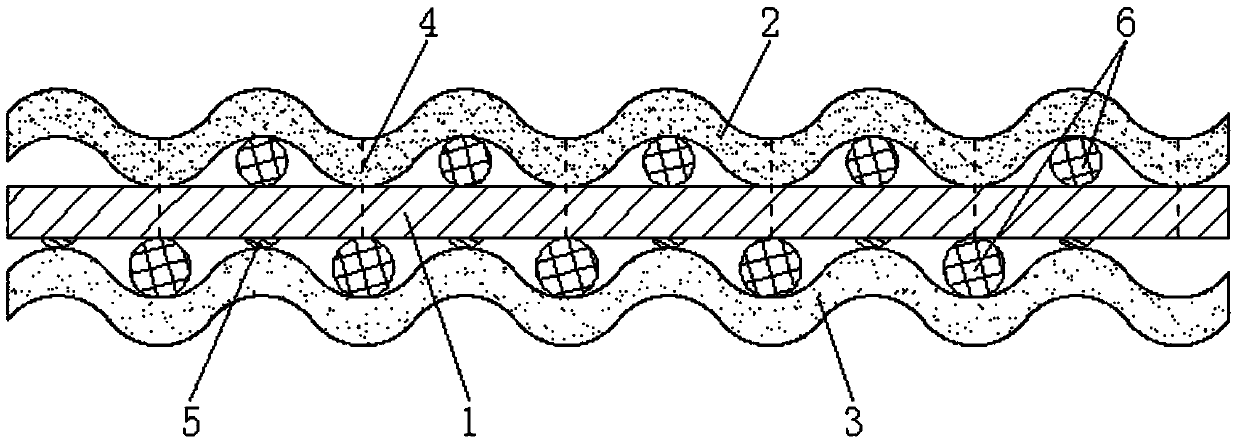

Novel shell fabric

InactiveCN109720067AEasy to processGood elasticity and flexibilitySynthetic resin layered productsWoven fabricsYarnFiber

The invention discloses a novel shell fabric. The novel shell fabric comprises a basal layer, wherein an upper outer layer and a lower outer layer are separately arranged at the two sides of the basallayer, both the upper outer layer and the lower outer layer are wavy, the upper outer layer and the basal layer are sewn together through connecting yarns at wave troughs, cotton fibers are filled between wave peaks of the upper outer layer and the basal layer, the lower outer layer is fixedly connected with the basal layer through an adhesive layer, the adhesive layer is made of a plurality of long-strip adhesive blocks which are arranged at equal intervals, one adhesive block is arranged on each wave peak of the lower outer layer, and cotton fibers are filled between wave troughs of the lower outer layer and the basal layer. The shell fabric disclosed by the invention is simple to process, good in moisture absorption and air-permeable properties and rich in layered feeling and is soft and warm-keeping, and individuality is embodied.

Owner:绍兴永泽纺织股份有限公司

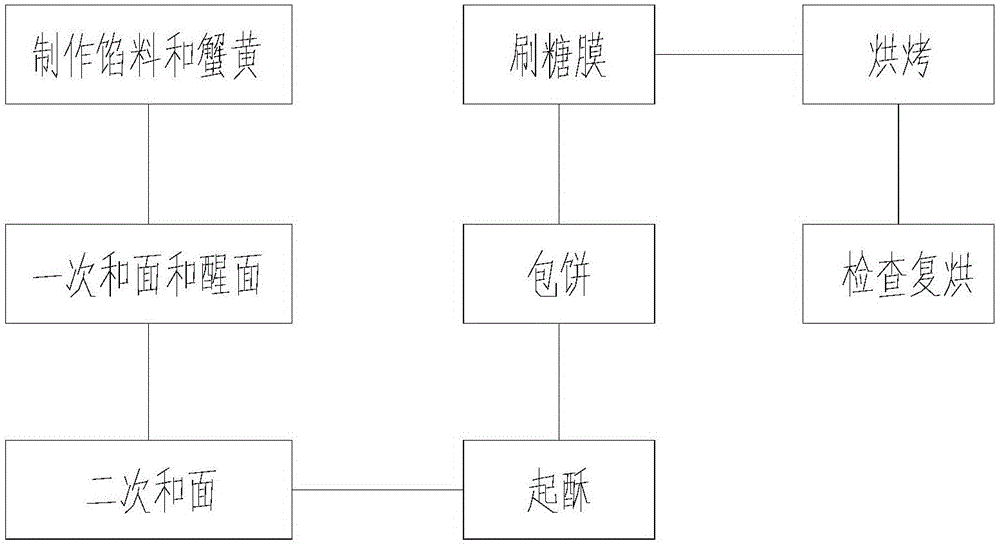

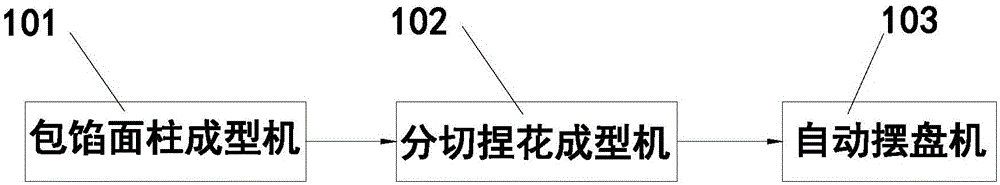

Method for making crabshell yellow sesame seed cake

InactiveCN105145743AReduce distanceAvoid scrappingDough treatmentBakery productsPreservativeEngineering

The invention discloses a method for making a crabshell yellow sesame seed cake. The method includes the seven steps of stuffing and crab cream making, primary dough kneading and leavening, secondary dough kneading and leavening, puffing, cake covering, sugar film brushing and baking. The temperature in a material barrel is controlled in the primary dough kneading and leavening process, the amount of required water is adjusted according to specific seasons, and dough leavening efficiency is greatly improved. Besides, the crisp degree and chewiness of the cake are remarkably improved. The making method is unique and low in cost. No pigment or preservative is added in the making process. The requirements for nutrients, health care and fresh taste of people are met. The bottleneck that standard, industrial and large-scale production of a crabshell yellow sesame seed cake is difficult to achieve is broken through. The cake made through the method is in the color of crab cream, crisp, layering, scorched outside but tender inside, oily but not greasy and popular with mass customers.

Owner:HUANGSHAN HANBAIQI FOOD CO LTD

Foldable shelf structure used for refrigeration equipment and refrigerator

ActiveCN102353223BFull of layersEasy to useLighting and heating apparatusSupportSpatial structureEngineering

The invention discloses a foldable shelf structure used for refrigeration equipment and a refrigerator. The foldable shelf structure comprises a first shelf and a second shelf, wherein the first shelf comprises a first decorating strip frame and a first shelf glass embedded in the first decorating strip frame; the second shelf comprises a second decorating strip frame and a second shelf glass embedded in the second decorating strip frame; and the first shelf and the second shelf are parallelly arranged, and slipped into the lower part of the second decorating strip frame in a foldable manner. According to the foldable shelf structure of the embodiment of the invention, the shelf glasses are embedded in the decorating strip frames, and the first shelf can slip into the lower part of the second decoration strip frame in a foldable manner, so the foldable shelf structure provided by the invention has the advantages of convenience in cleaning, beauty in structure, and effectively adjusts the space structure in the refrigerator according to the requirements of clients.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

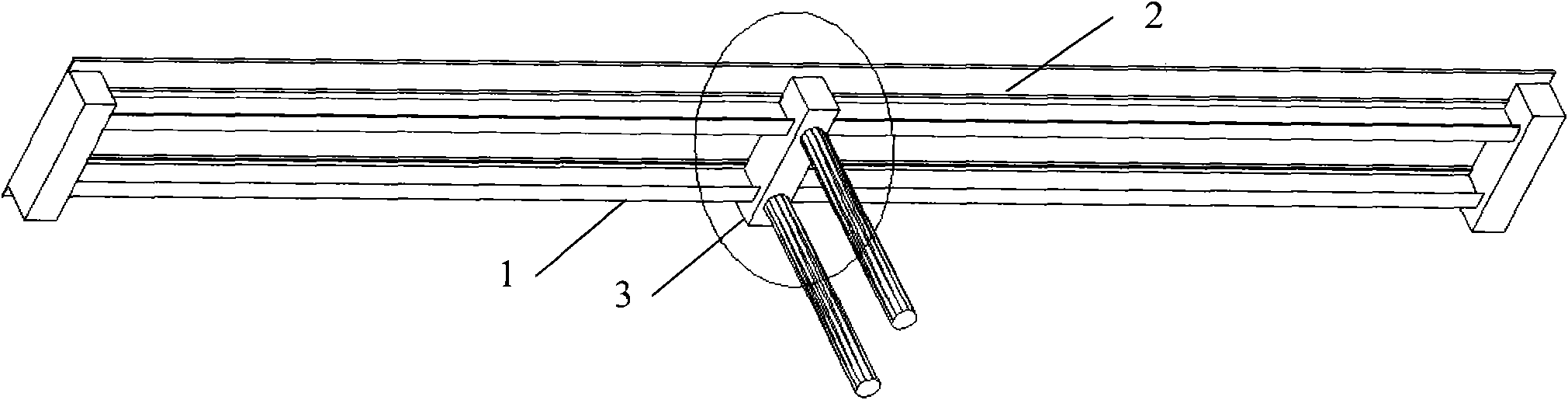

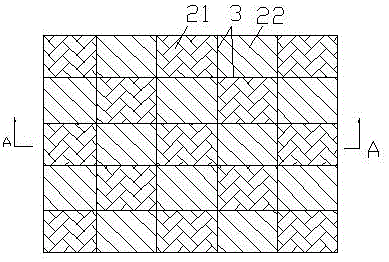

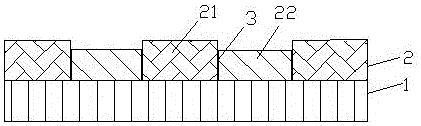

Comfortable, bactericidal and good-air-permeability thick grid fabric

The invention relates to a coarse lattice fabric which is comfortable, sterilized and has good air permeability. It includes a fabric body (1), a composite layer (2) of linen strips and leather strips and a braided thread (3) arranged on the front of the fabric body, and the braided thread (3) is arranged between the linen strips (21) and the leather strips (22). The back of the fabric body is provided with a lining layer. The lining layer includes a lining layer body woven by warp yarns and weft yarns. The warp yarns and weft yarns are interwoven into a three-up and three-down plain weave structure. The surface is provided with an elastic cotton layer, the upper surface of the elastic cotton layer is provided with a flocking layer, and the upper surface of the flocking layer is provided with an antibacterial layer; the lower surface of the lining layer body is provided with a breathable layer, and the lower surface of the breathable layer is provided with an activated carbon cloth layer. The invention is comfortable, sterilized, and has good air permeability. The thick grid fabric combines the fineness of leather strips and the roughness of linen strips, and is full of layering. The invention is comfortable, sterilized and has good air permeability.

Owner:JIANGYIN YUEDA DYEING & PRINTING

Method for making glutinous rice cake with thick flower fragrance

The invention discloses a preparation method of glutinous rice cake with strong floral fragrance, which comprises uniformly mixing scented tea extract, fruit juice, milk, honey, salt, high fructose syrup, neotame and water to obtain a mixture liquid; glutinous rice flour and barley powder , lotus root powder, oat noodles, yam powder, corn flour, purple sweet potato powder, black sesame powder, papaya powder, gorgon powder and traditional Chinese medicine powder are evenly mixed, then add the mixture liquid to knead the dough, knead the dough, and steam it in a mold to get Glutinous rice cake with strong floral aroma. The preparation method of scented tea extract is as follows: wash roselle, rosemary, chamomile, jasmine, lavender, peppermint, Luo Han Guo and put them in a decoction container, add water for the first time and decoct to obtain the first decoction liquid, the second Water is added for the second time and then decocted to obtain the second decoction liquid, and the first decoction liquid and the second decoction liquid are combined and then filtered to obtain the scented tea extract. The glutinous rice cake obtained by the invention has a balanced and reasonable nutritional mix, strong floral fragrance, and the effects of invigorating the spleen, nourishing the stomach, warming the middle and replenishing qi.

Owner:WUHU SHOUJI FOOD FACTORY

Lipid coating of ice cream carrier and preparation process and implementation method thereof

The invention relates to a lipid coating of ice cream carrier and a preparation process and an implementation method thereof. The granularity of the lipid coating is between 15-35 mu m, and the moisture content is lower than 1.5%. The lipid coating is prepared from 25-65% of lipid substances and 35-75% of non-lipid substances, the lipid substances comprise grease and an emulsifier, and the non-lipid substances are at least one of solid, liquid, paste, powder and granular. The invention has the advantages of making the flavor changes of the ice cream product to be more layered, increasing extraflavor feeling and eating pleasure for consumers, providing a healthy and nutrient substance intake opportunity and way for the consumers while the ice cream product is endowed with extra flavor, andisolating the moisture in the ice cream from migrating to the carrier, so that, the original taste characteristics of the carrier can not be changed.

Owner:嘉世明(珠海)食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com