One-step method production process of high-strength high-shrinkage combined filament yarns

A production process, high shrinkage technology, applied in the directions of melt spinning, fiber processing, filament forming processing, etc., can solve problems such as low elasticity, and achieve the effect of plump, layered, and controllable fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

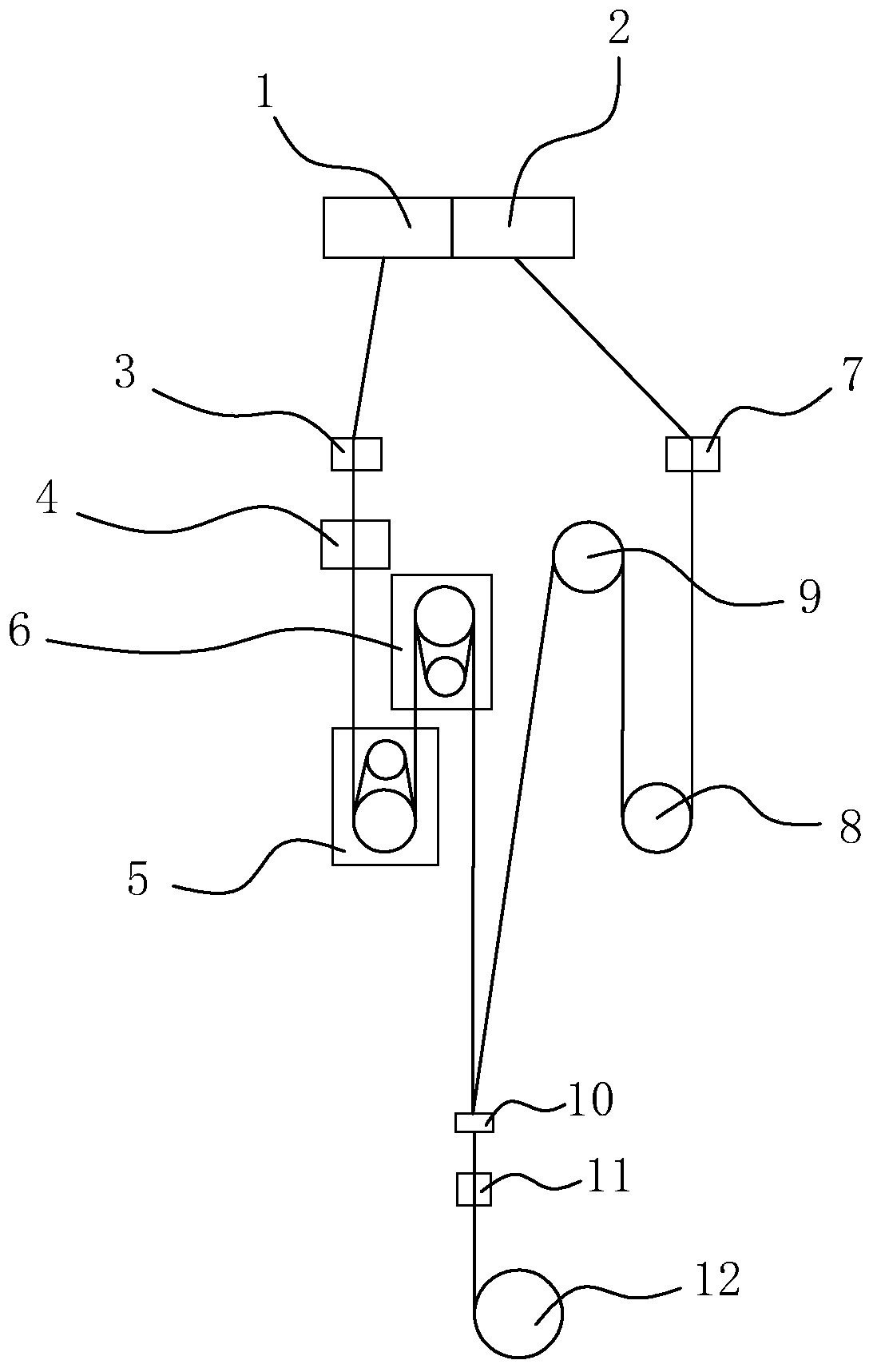

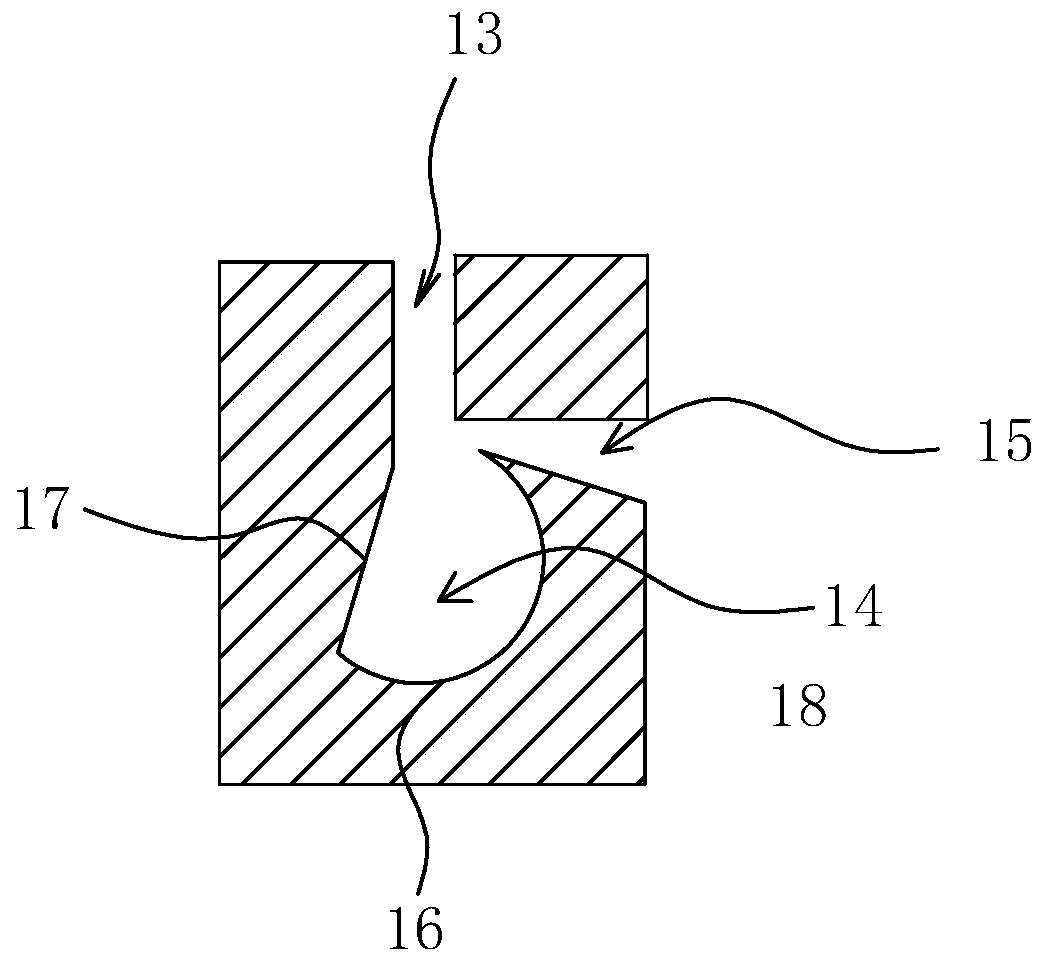

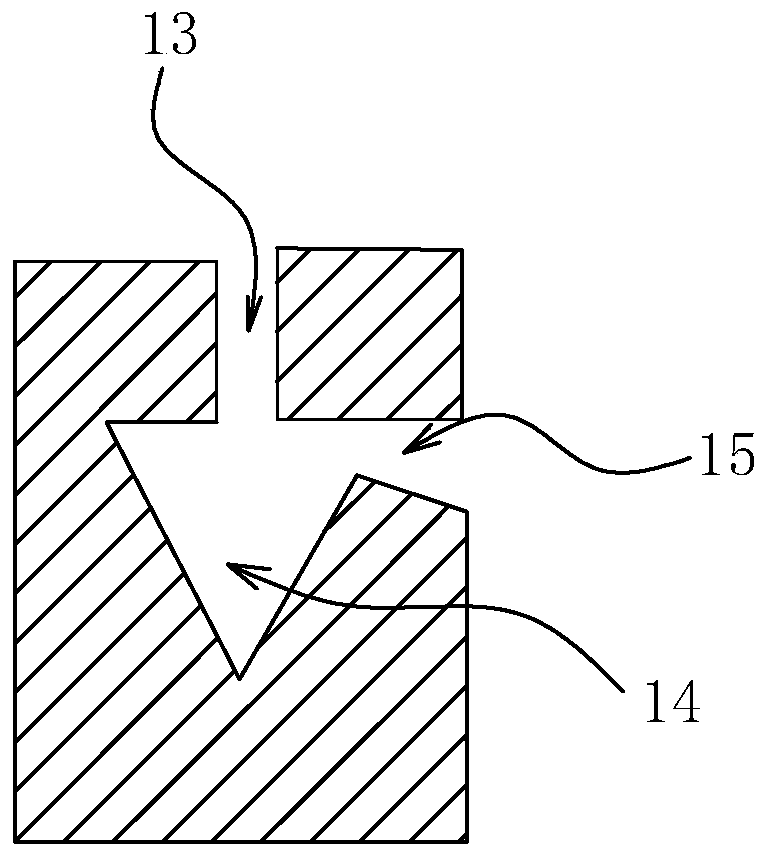

[0029] combine Figure 1 to Figure 2 , to describe this embodiment in detail. The one-step production process of high-strength and high-shrinkage mixed fiber yarn involved in this embodiment includes the following steps: S1 slice drying, S2 spinning of high-strength polyester filament part, S3 spinning of high-elastic polyester filament part, S4 high-strength polyester filament and high-elastic polyester filament are connected to the grid, and S5 is wound.

[0030] In step S1 slice drying, the high-shrinkage copolyester slices are dried with hot air in a hot-air drying device, so that the moisture content of the high-shrinkage copolyester slices is ≦25×10 -6 , fluctuation value≦5×10 -6 Dew point of drying air≦-35℃, air inlet pressure of drying tower≧7MPa, air outlet air pressure≧8MPa, inlet and outlet pressure difference of about 1MPa; the high-shrinkage copolyester chip component is purified p-phenylene Copolymer formed by chemical reaction of dicarboxylic acid, ethylene g...

Embodiment 2

[0050] combine Figure 1 to Figure 2 , to describe this embodiment in detail. The one-step production process of high-strength and high-shrinkage mixed fiber yarn involved in this embodiment includes the following steps: S1 slice drying, S2 spinning of high-strength polyester filament part, S3 spinning of high-elastic polyester filament part, S4 high-strength polyester filament and high-elastic polyester filament are connected to the grid, and S5 is wound.

[0051] In step S1 slice drying, the high-shrinkage copolyester slices are dried with hot air in a hot-air drying device, so that the moisture content of the high-shrinkage copolyester slices is ≦25×10 -6 , fluctuation value≦5×10 -6 Dew point of drying air≦-35℃, air inlet pressure of drying tower≧7MPa, air outlet air pressure≧8MPa, inlet and outlet pressure difference of about 1MPa; the high-shrinkage copolyester chip component is purified p-phenylene Copolymer formed by chemical reaction of dicarboxylic acid, ethylene g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com