Patents

Literature

2872results about How to "Avoid scrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

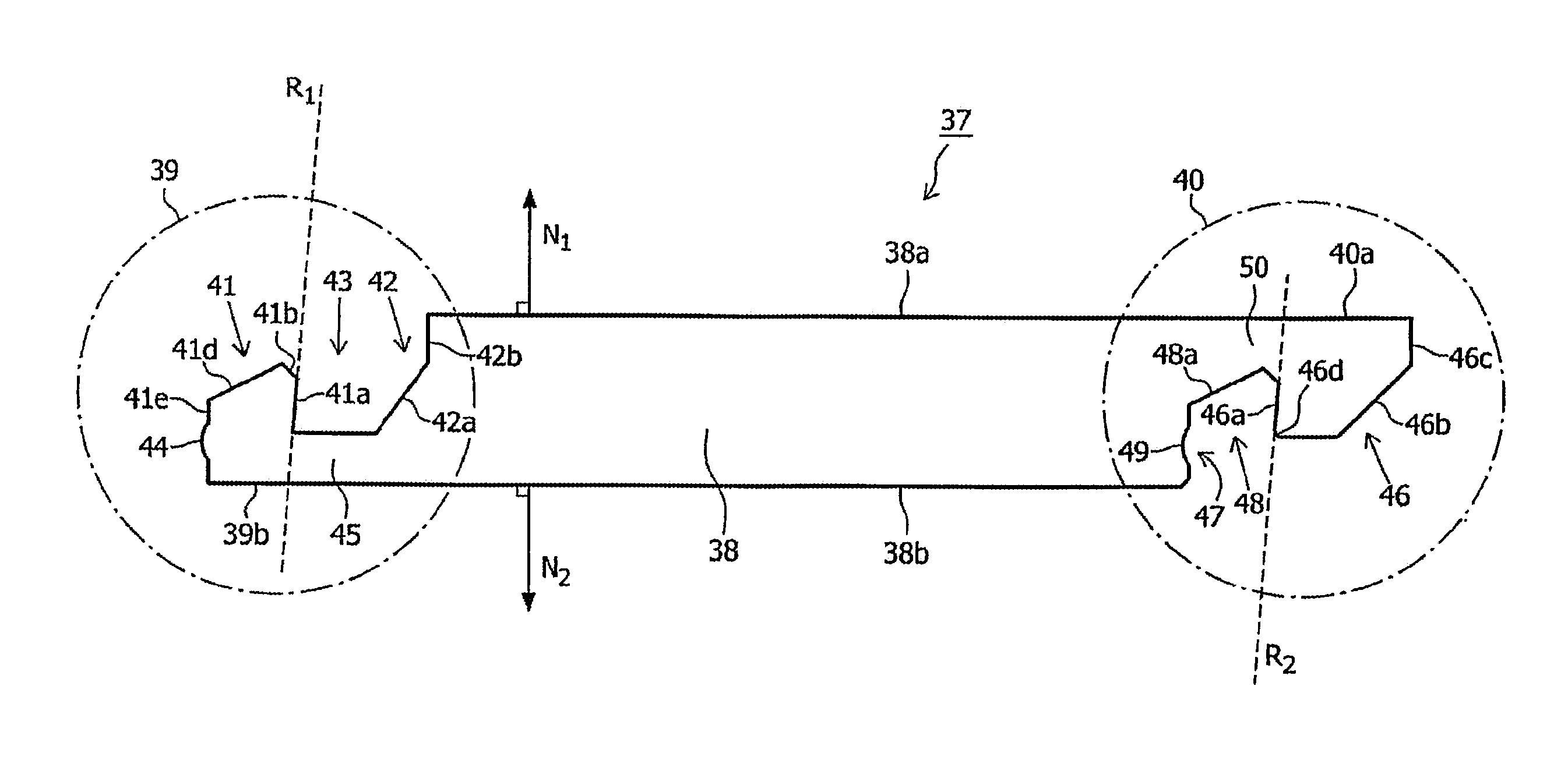

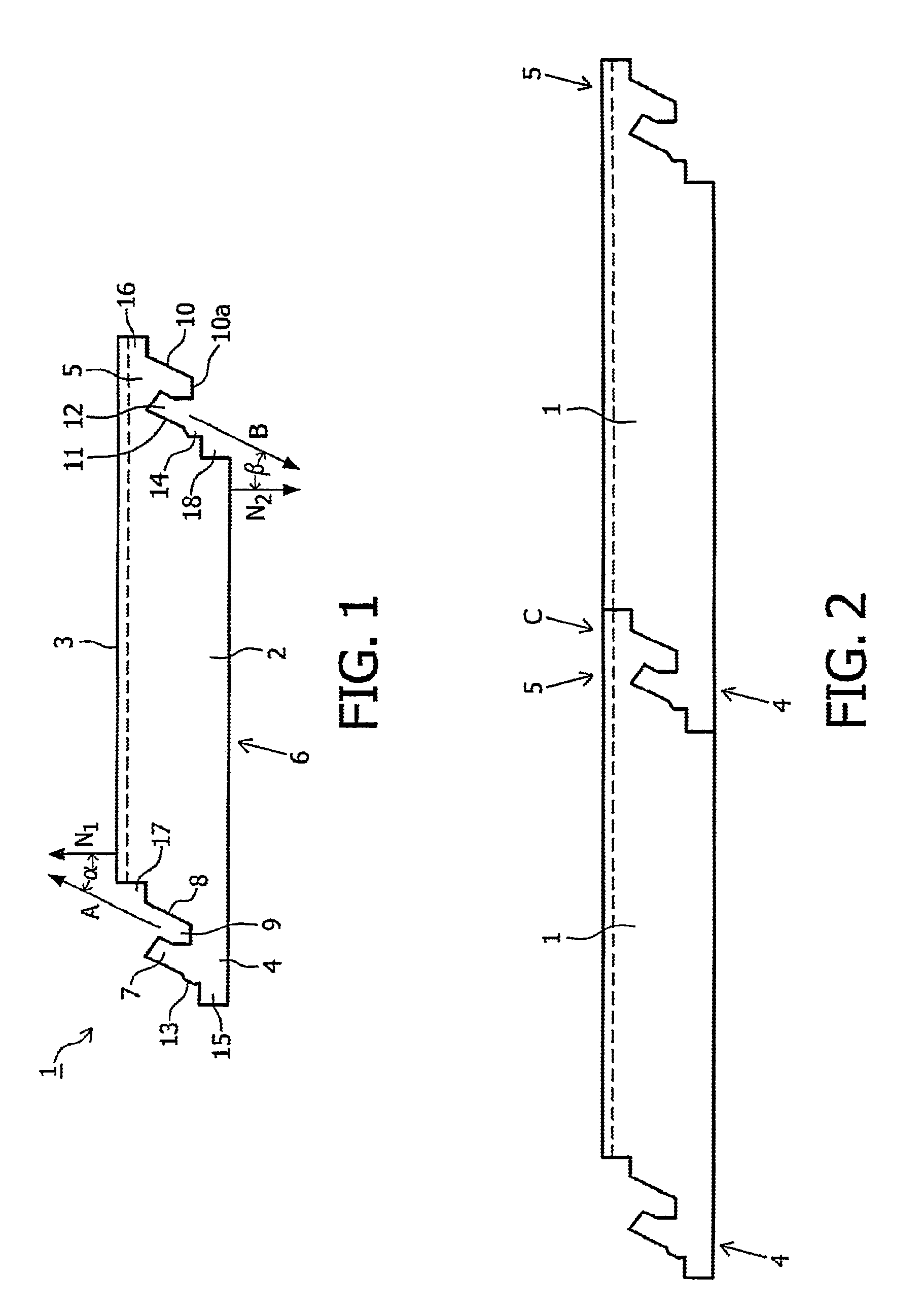

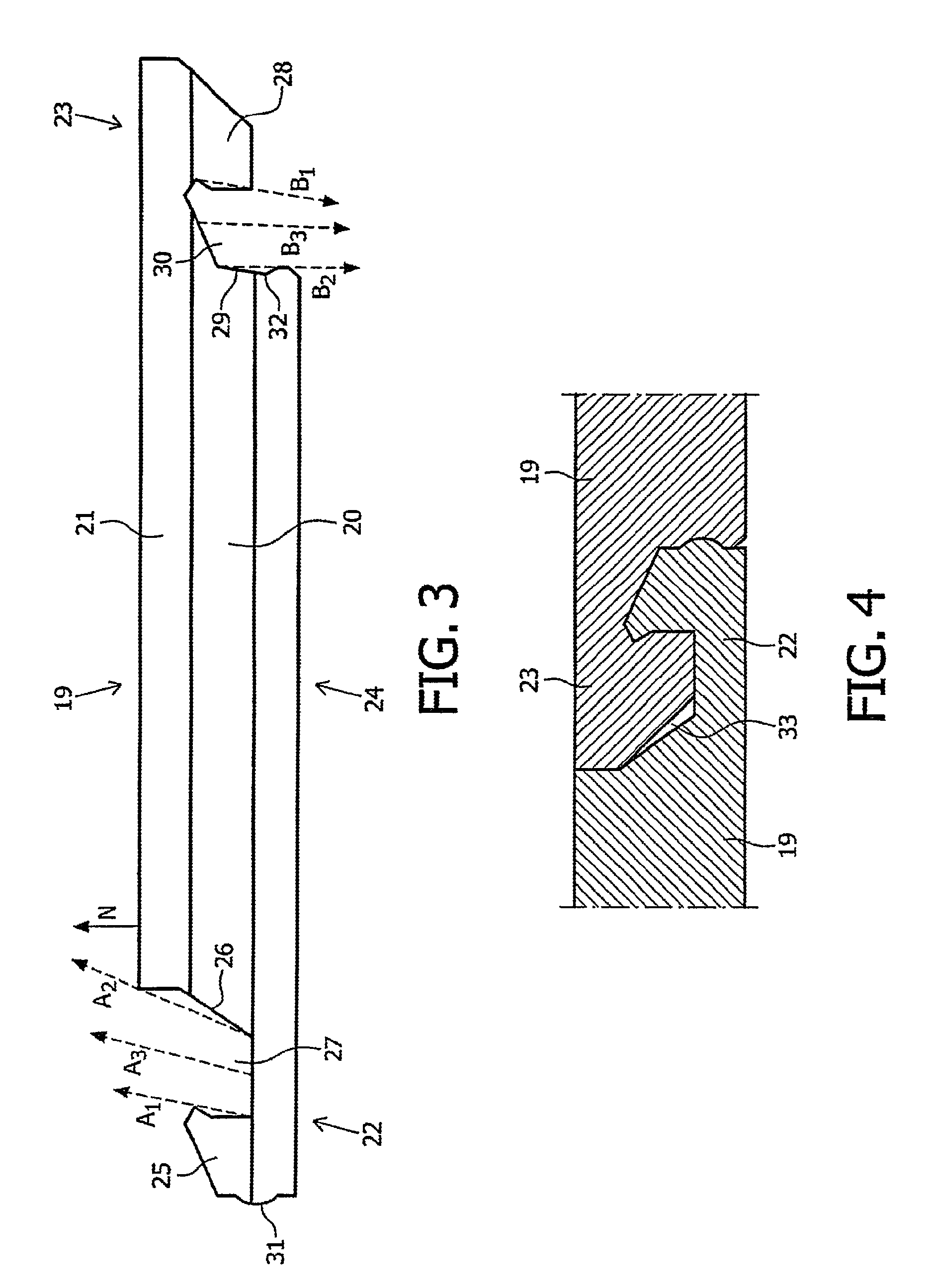

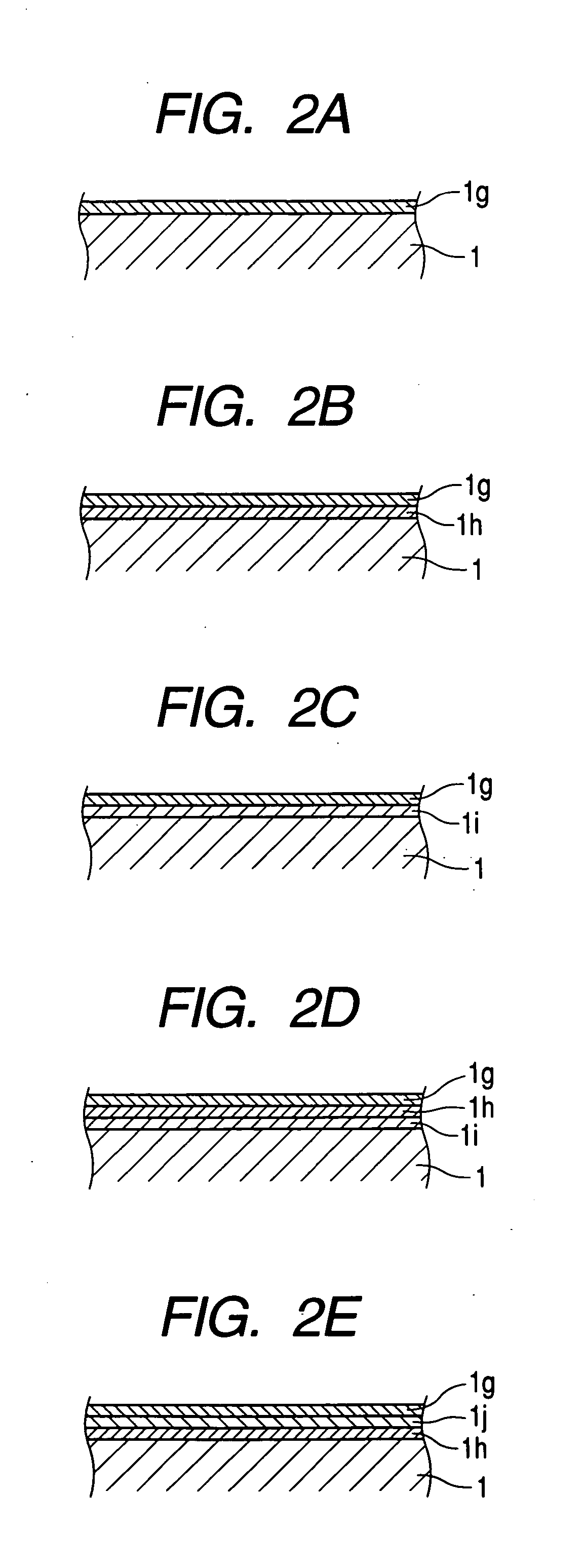

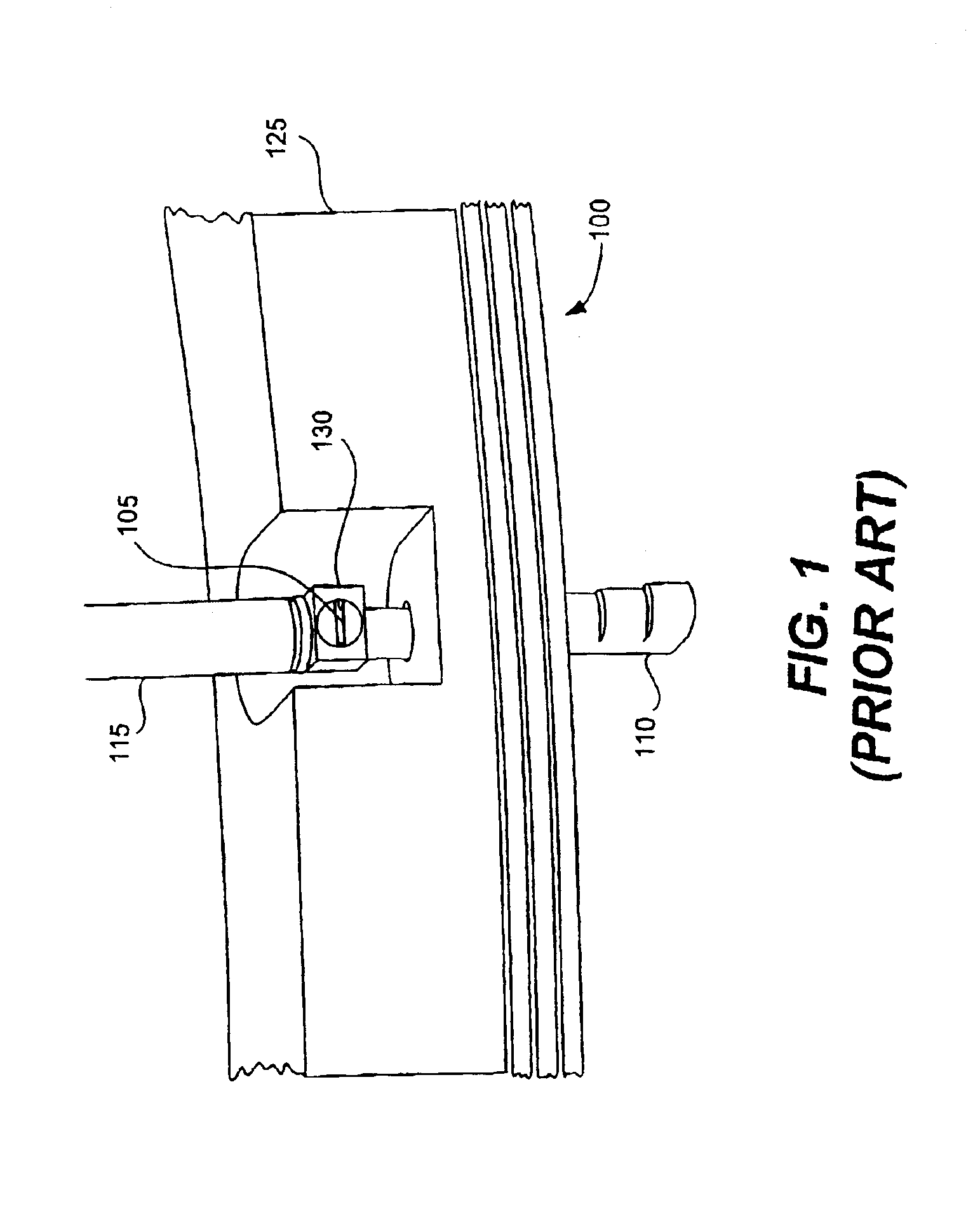

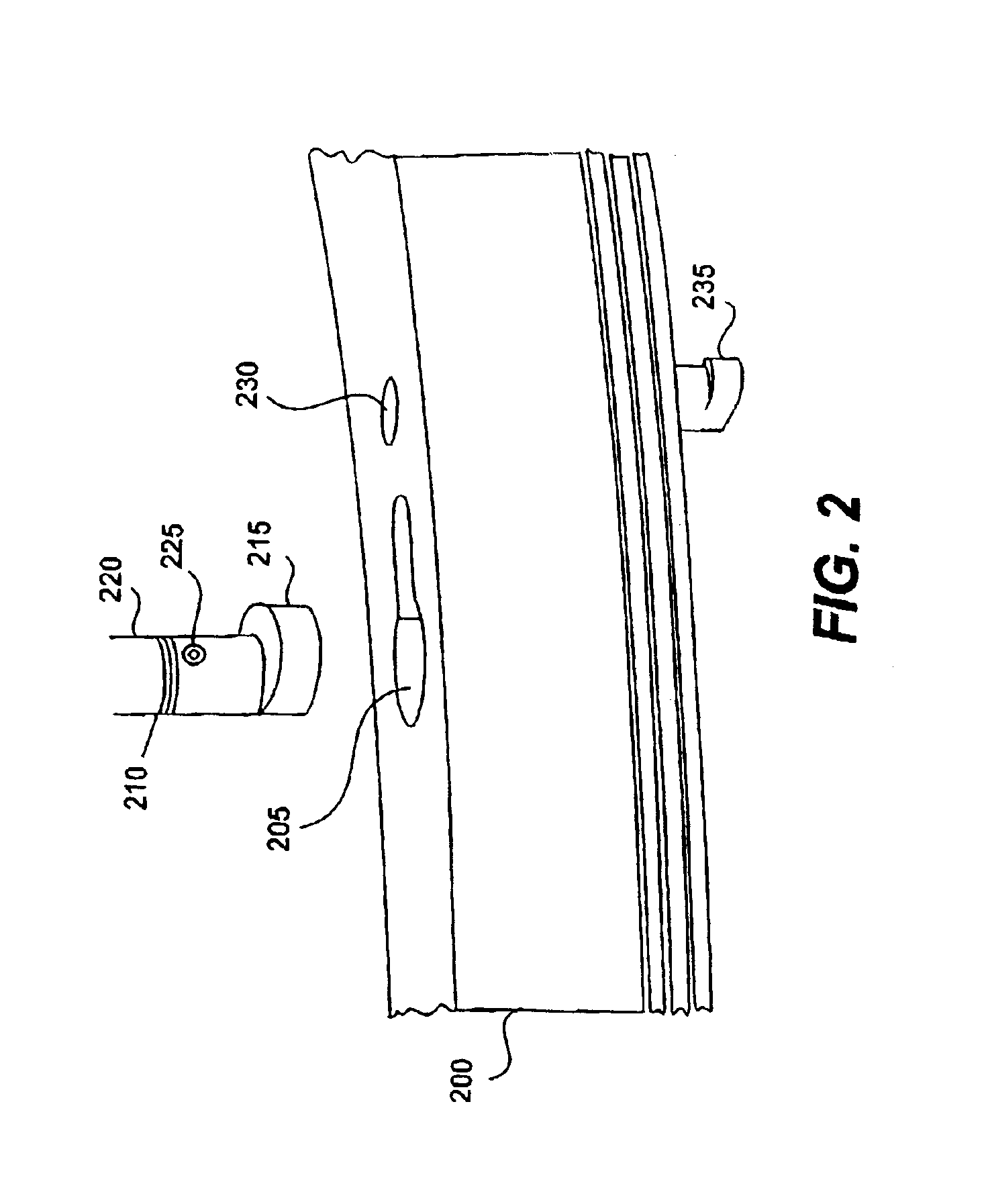

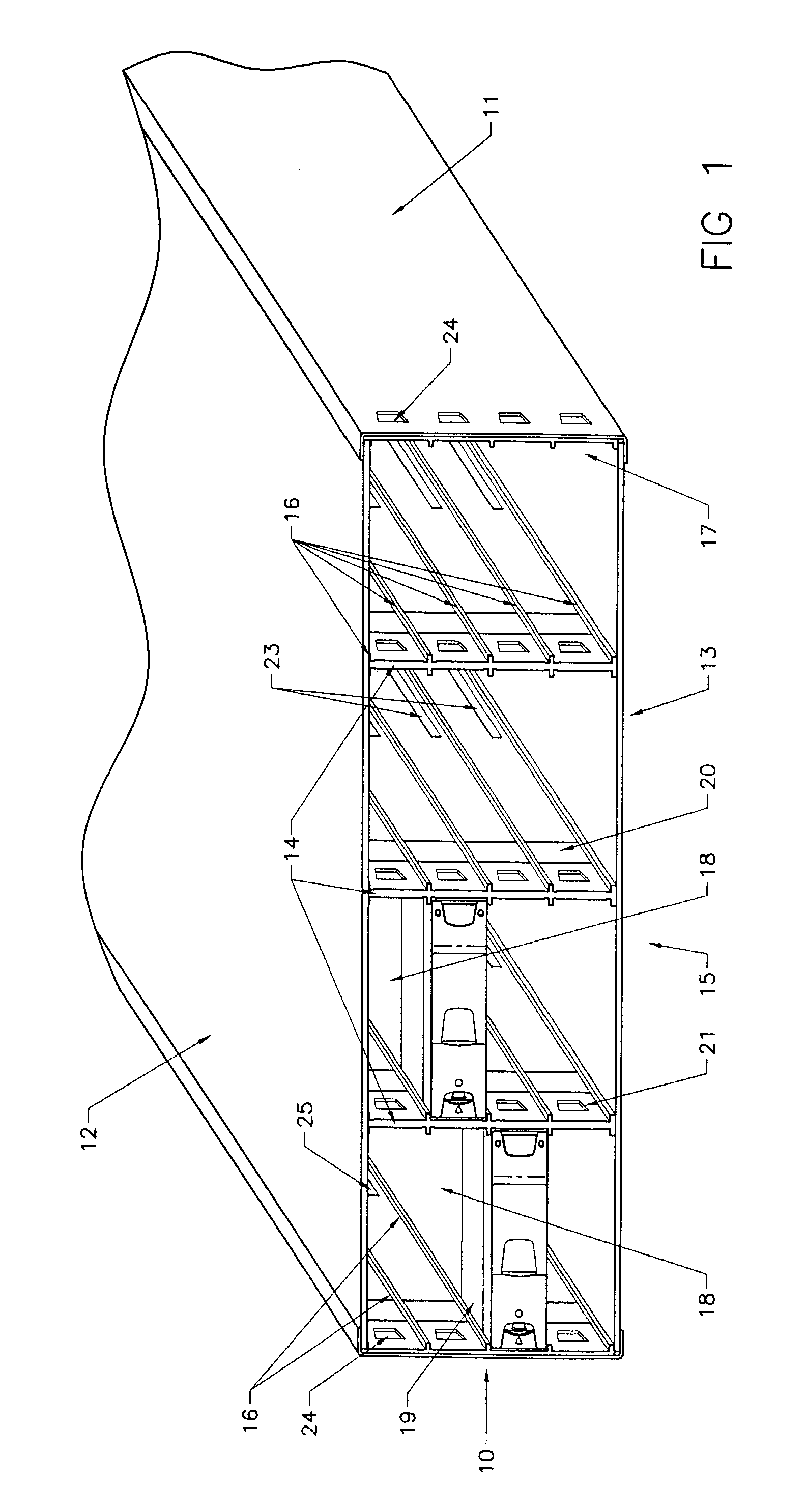

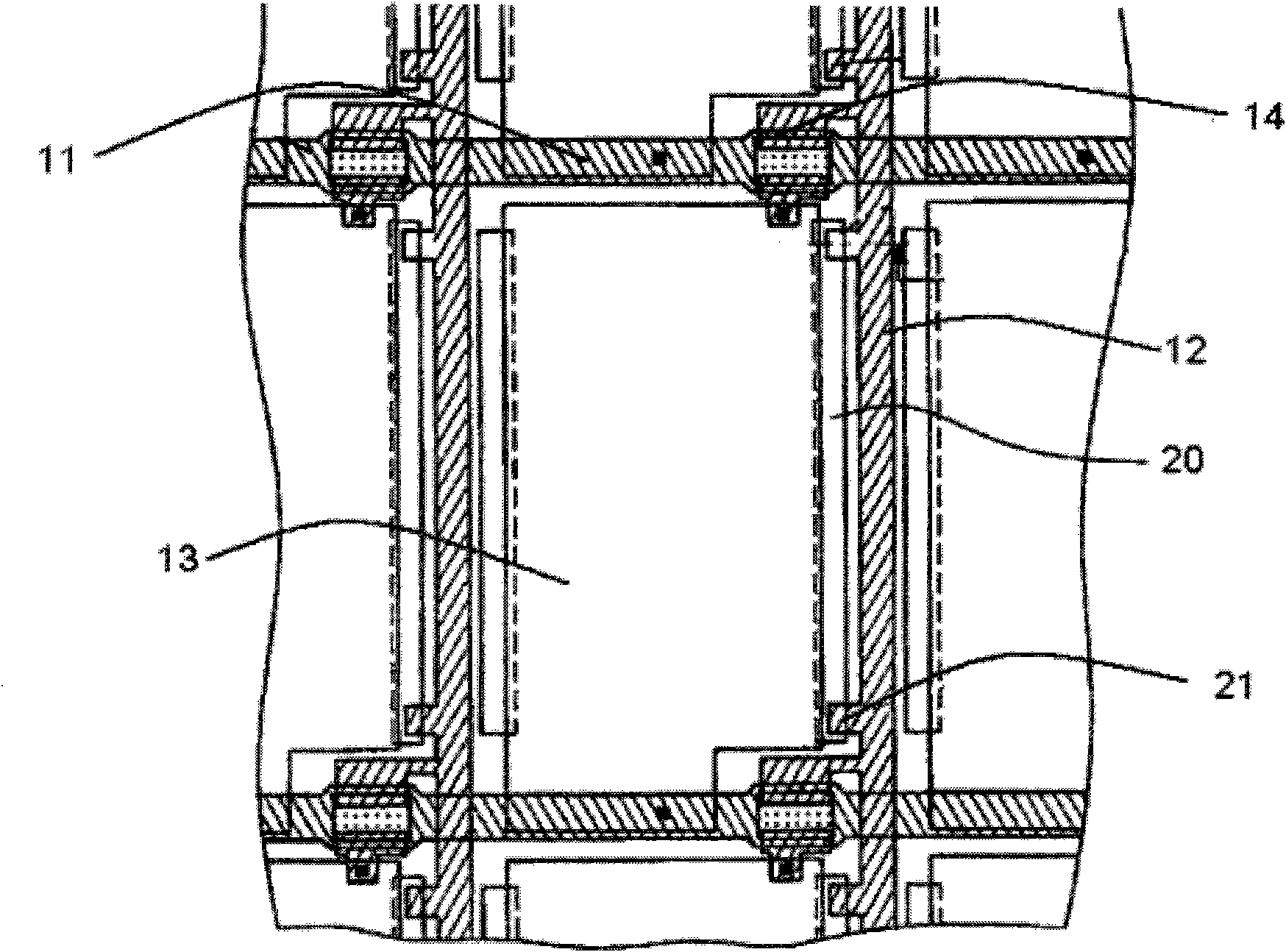

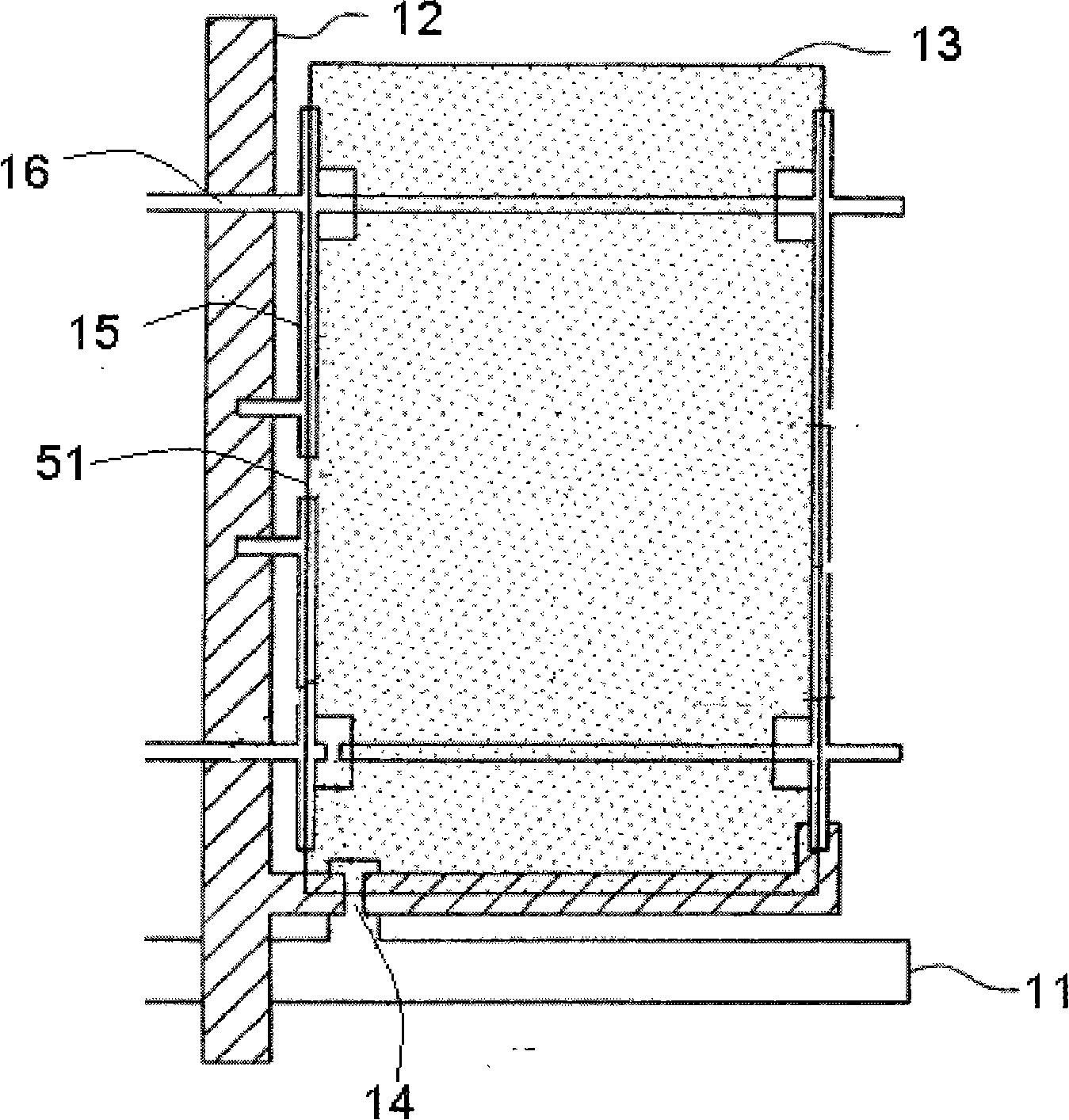

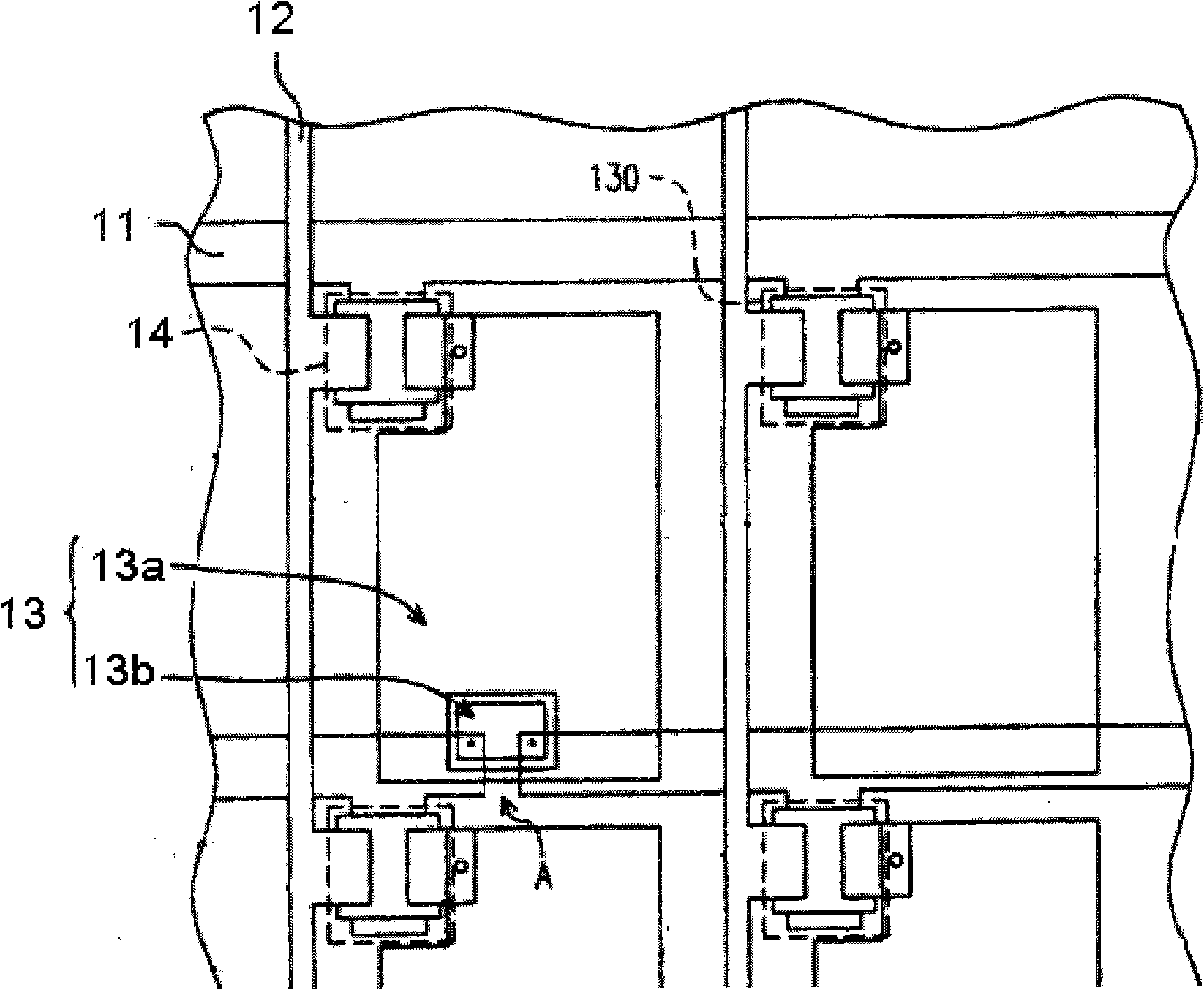

Floor panel and floor covering consisting of a plurality of such floor panels

ActiveUS8745952B2CouplingEnhanced couplingRoof covering using tiles/slatesBuilding repairsEngineeringFloor covering

The invention relates to a floor panel; in particular a laminated floor panel. The invention also relates to a floor covering consisting of a plurality of mutually coupled floor panels according to the invention. The invention further relates to a method for mutually coupling two floor panels, in particular laminated floor panels, according to the invention.

Owner:I4F LICENSING NV

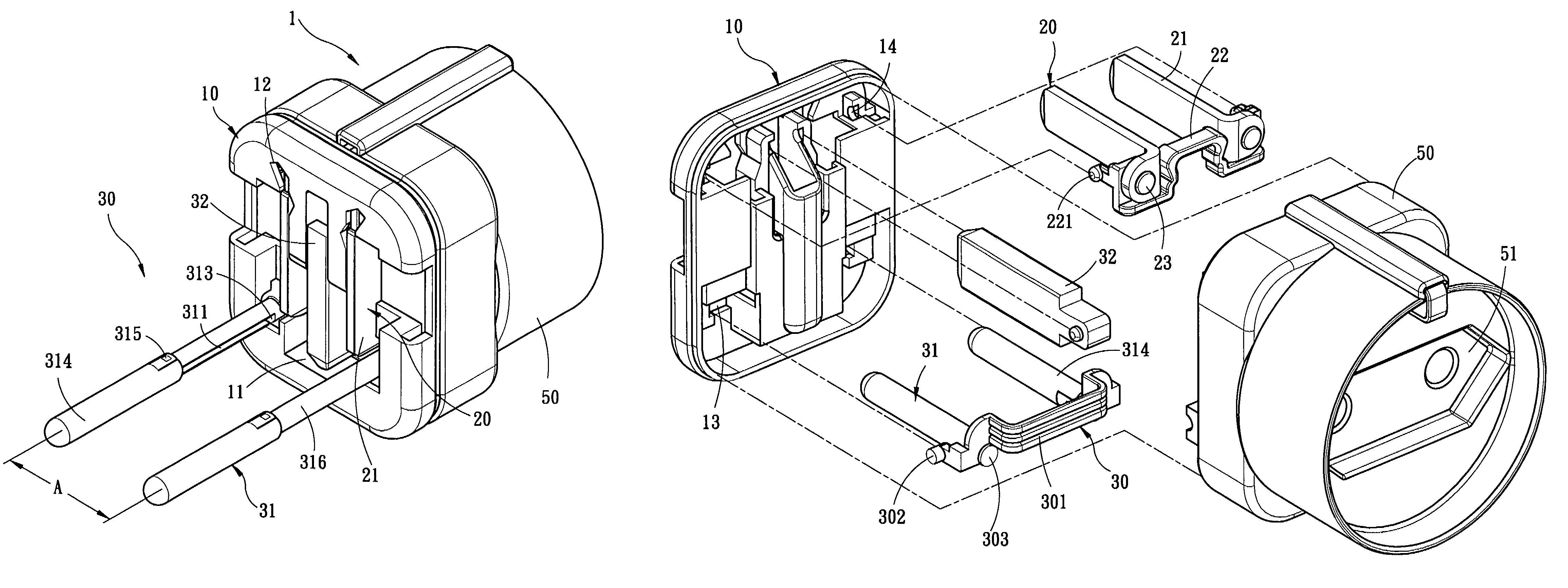

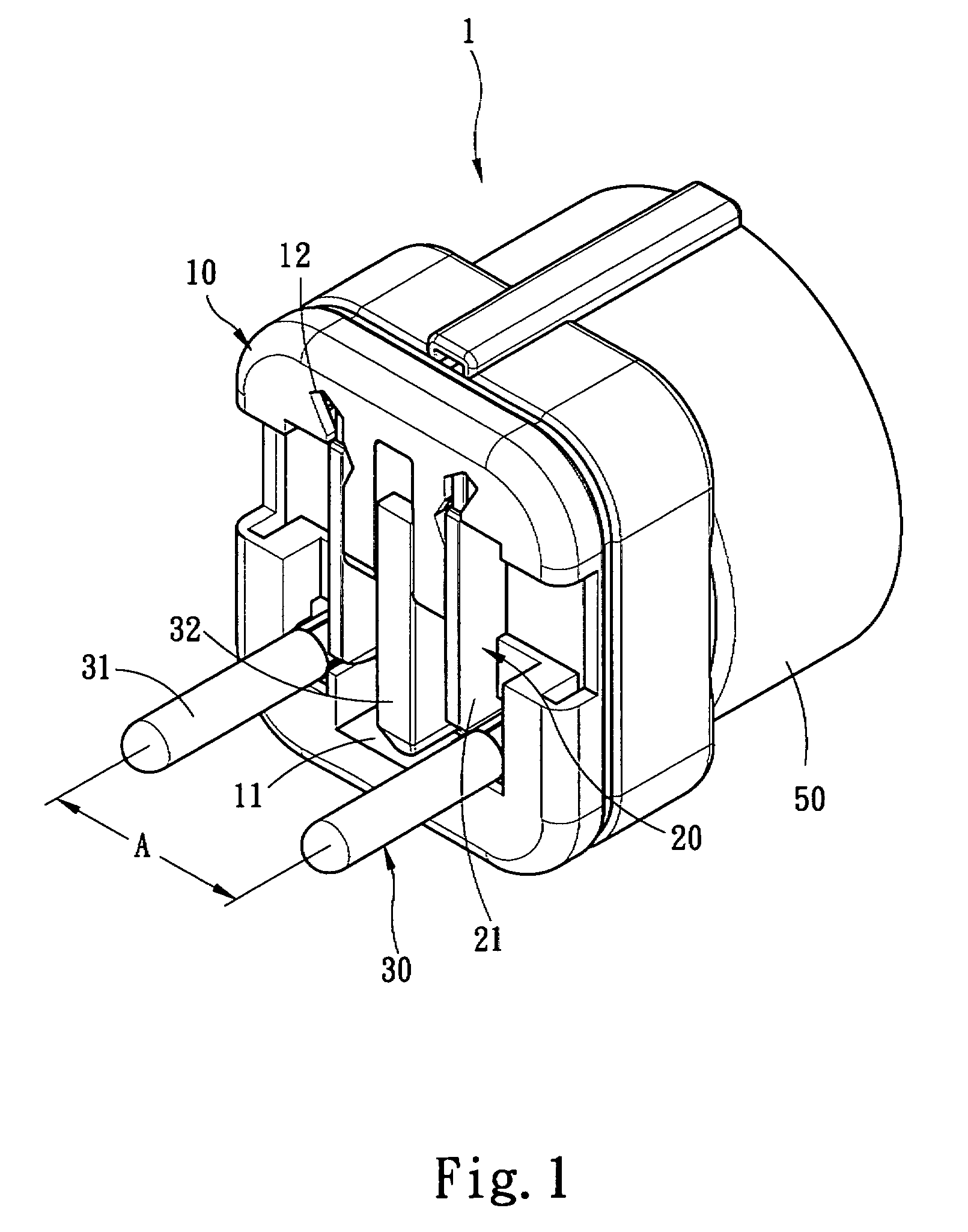

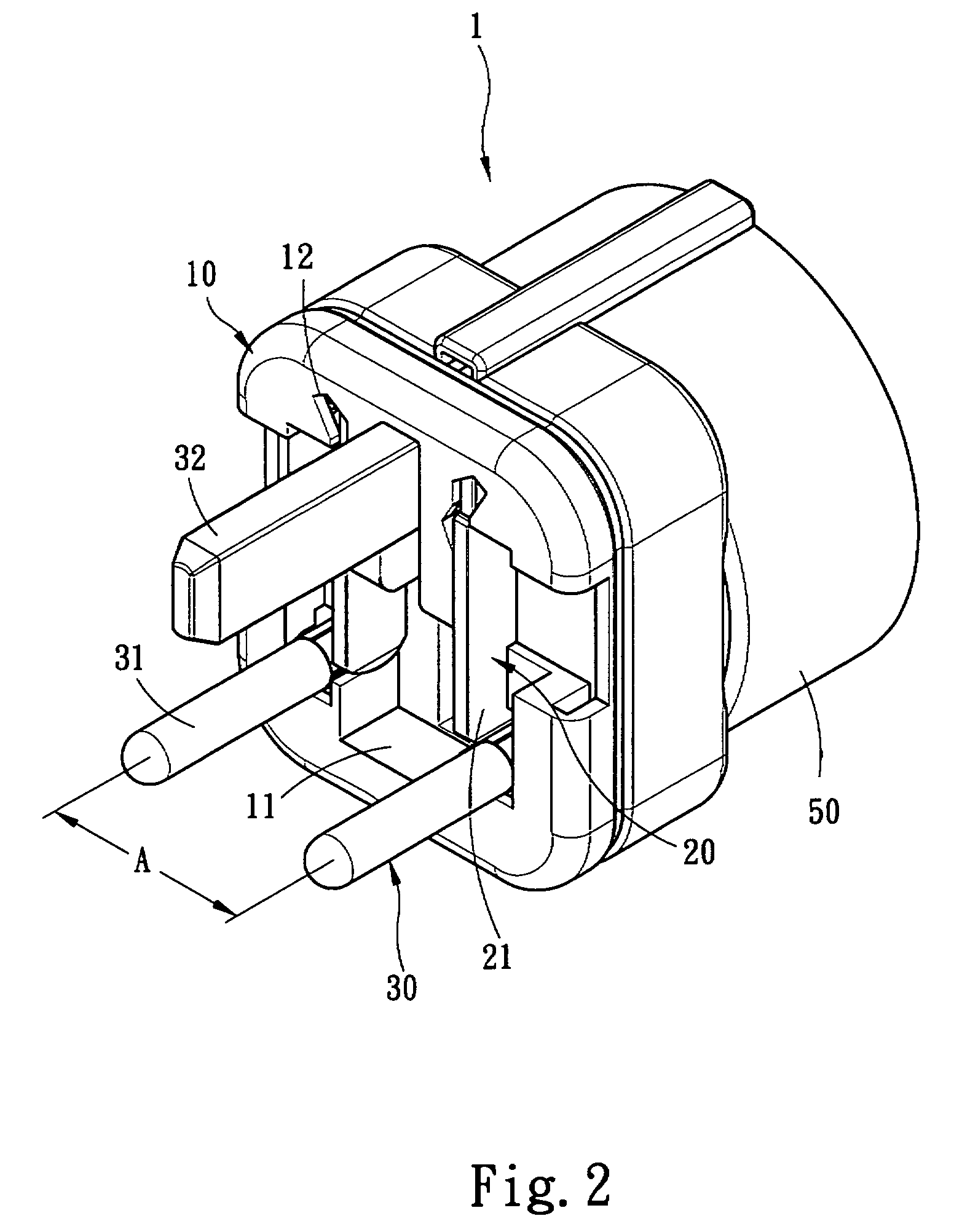

Adapter for connectors

ActiveUS7354286B1Reduce spacingEasy to carryElectric discharge tubesLive contact access preventionEngineeringNormal conditions

An adapter for connectors to couple connectors and power supply sockets of different specifications to establish electric connection between them includes two terminal sets that are insertable into the power supply sockets. The two terminal sets are pivotally coupled on one end of the adapter in an opposite open manner, and are held in a housing trough formed on the adapter in normal conditions. When in use desired terminals can be inserted into a corresponding power supply socket of a selected specification and raised upright. The terminal sets can be retracted and extended so that the size of the adapter is smaller. Such a design also can keep the terminals from extending to prevent hurting people or articles.

Owner:XYZ SCI CO LTD

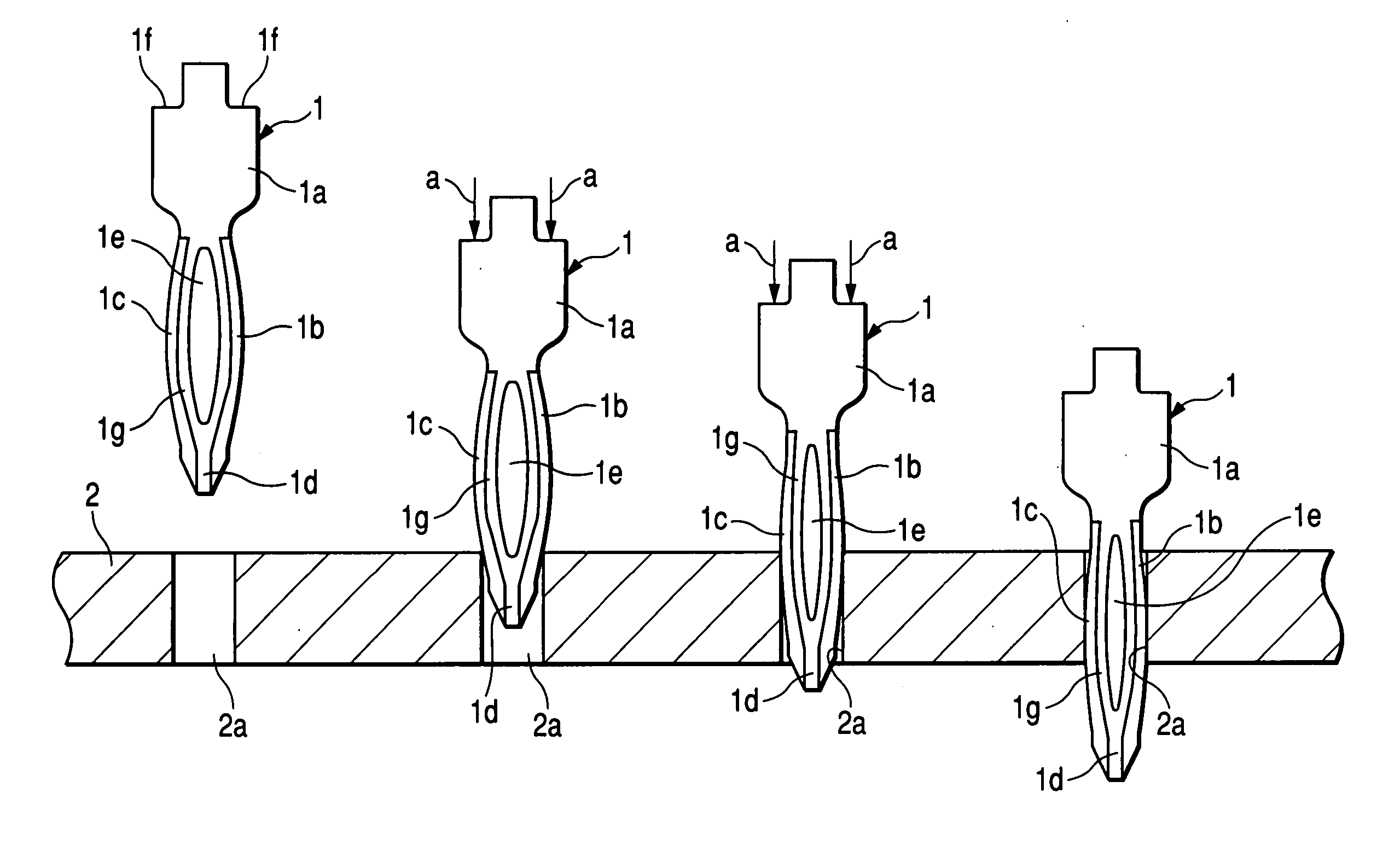

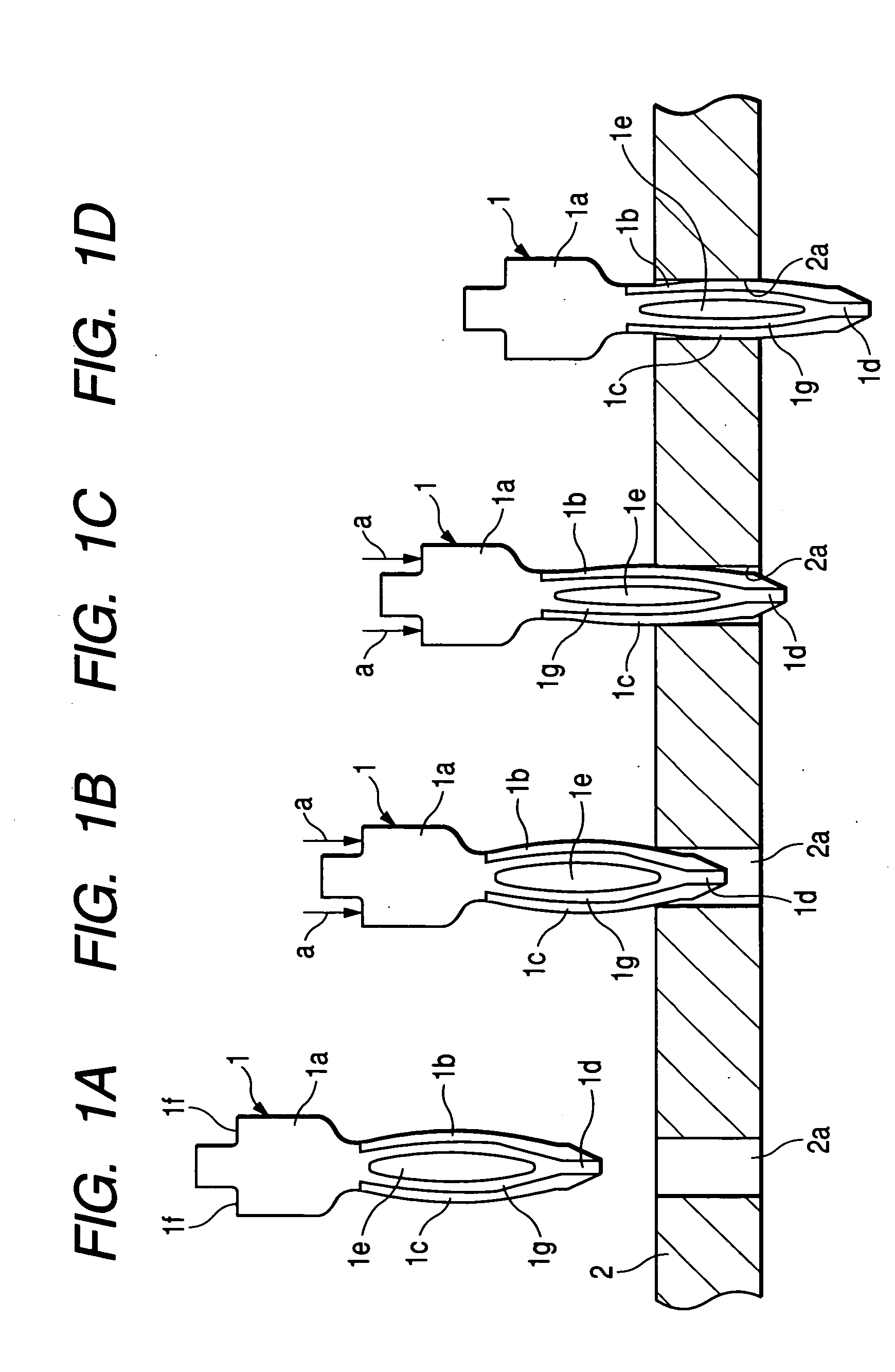

Press-fit terminal

ActiveUS20050176267A1Avoid scrappingPrinted circuit assemblingSubstation/switching arrangement detailsEngineeringElectrical and Electronics engineering

A press-fit terminal is adapted to be press-fitted in an through-hole of board for electrically conducting with the press-fit terminal. The press-fit terminal includes a terminal-base portion and a board inserting portion at least partially plated with tin. A thickness of the plated tin is from 0.1 to 0.8 μm.

Owner:AUTONETWORKS TECH LTD +2

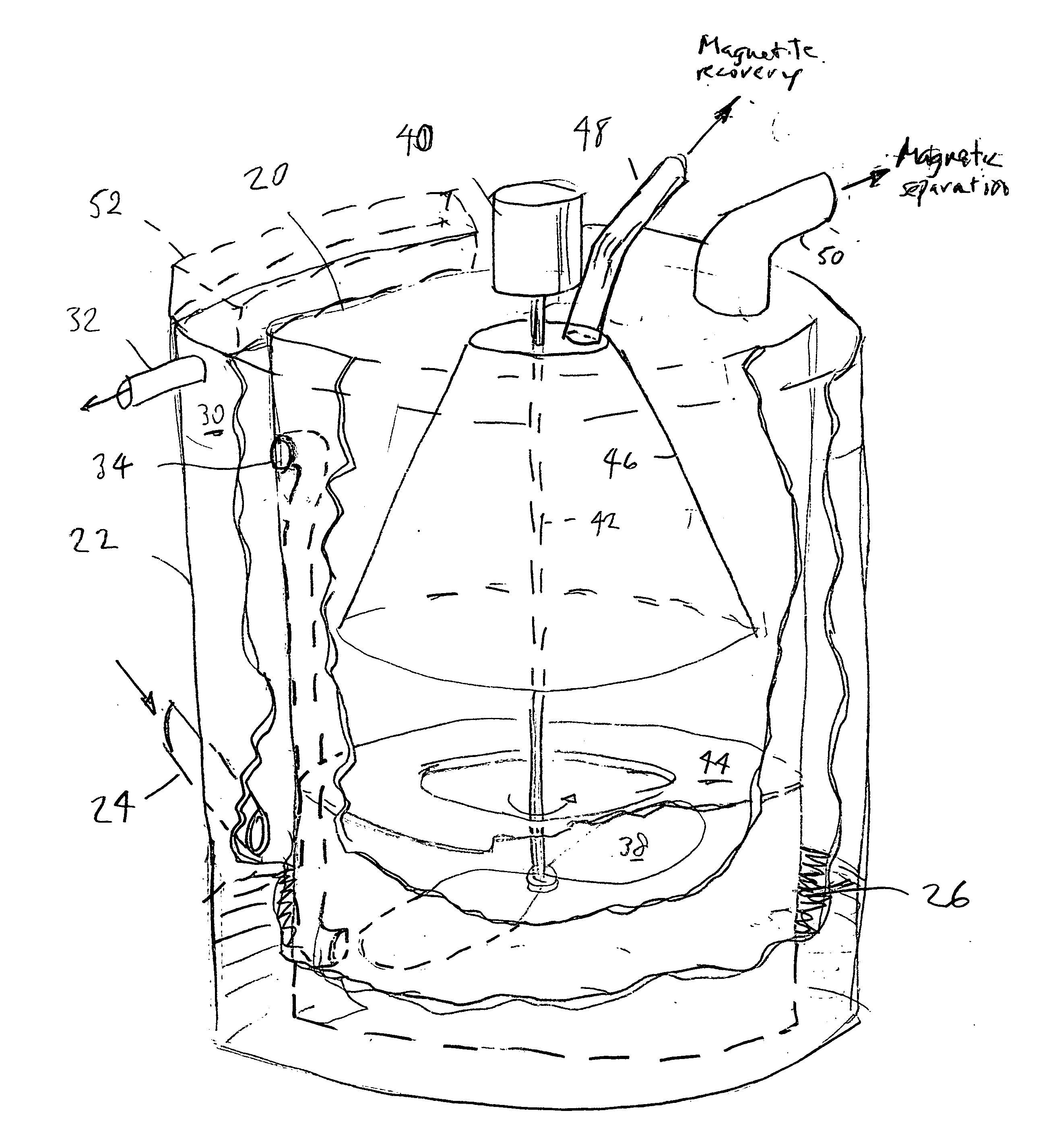

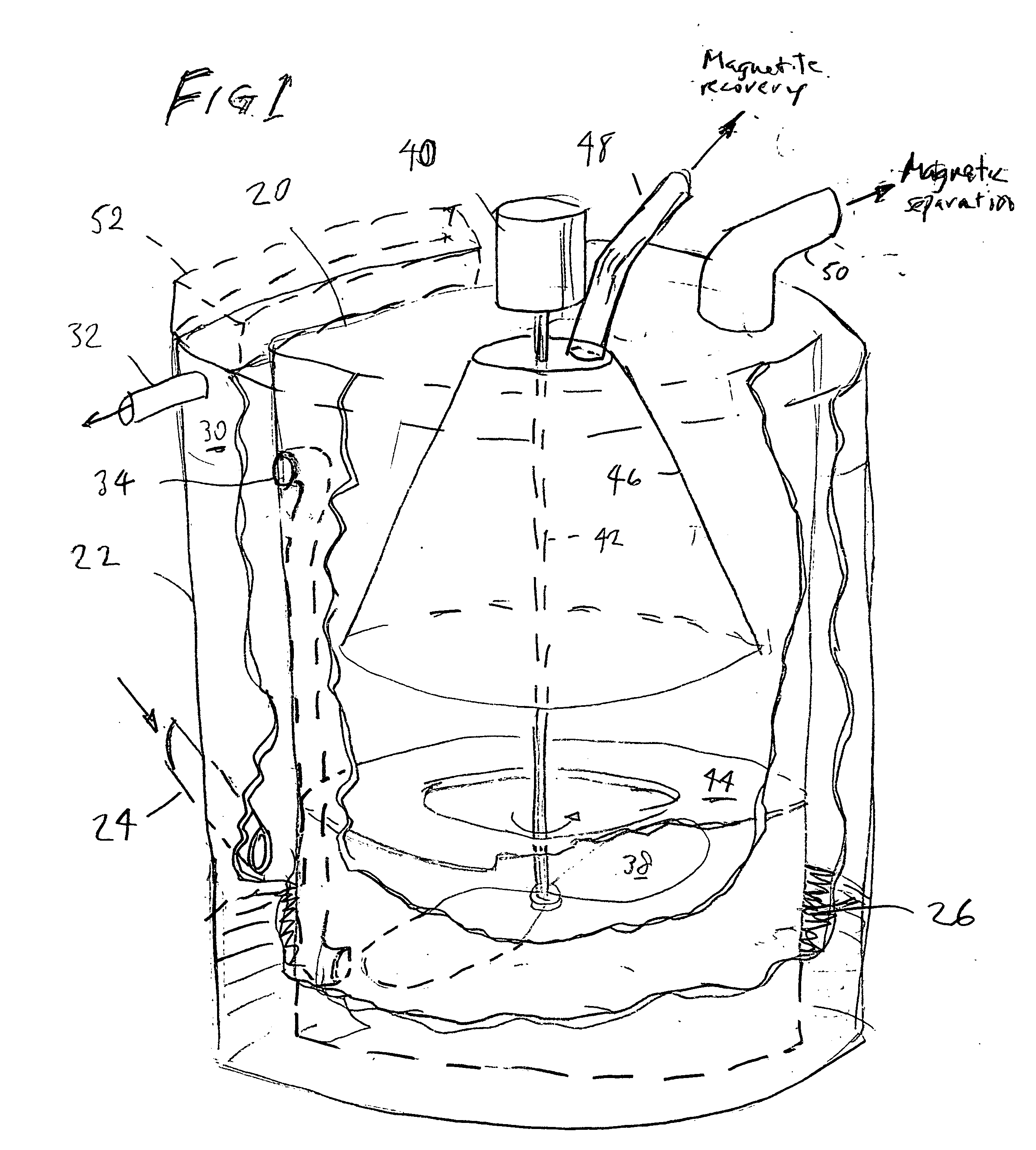

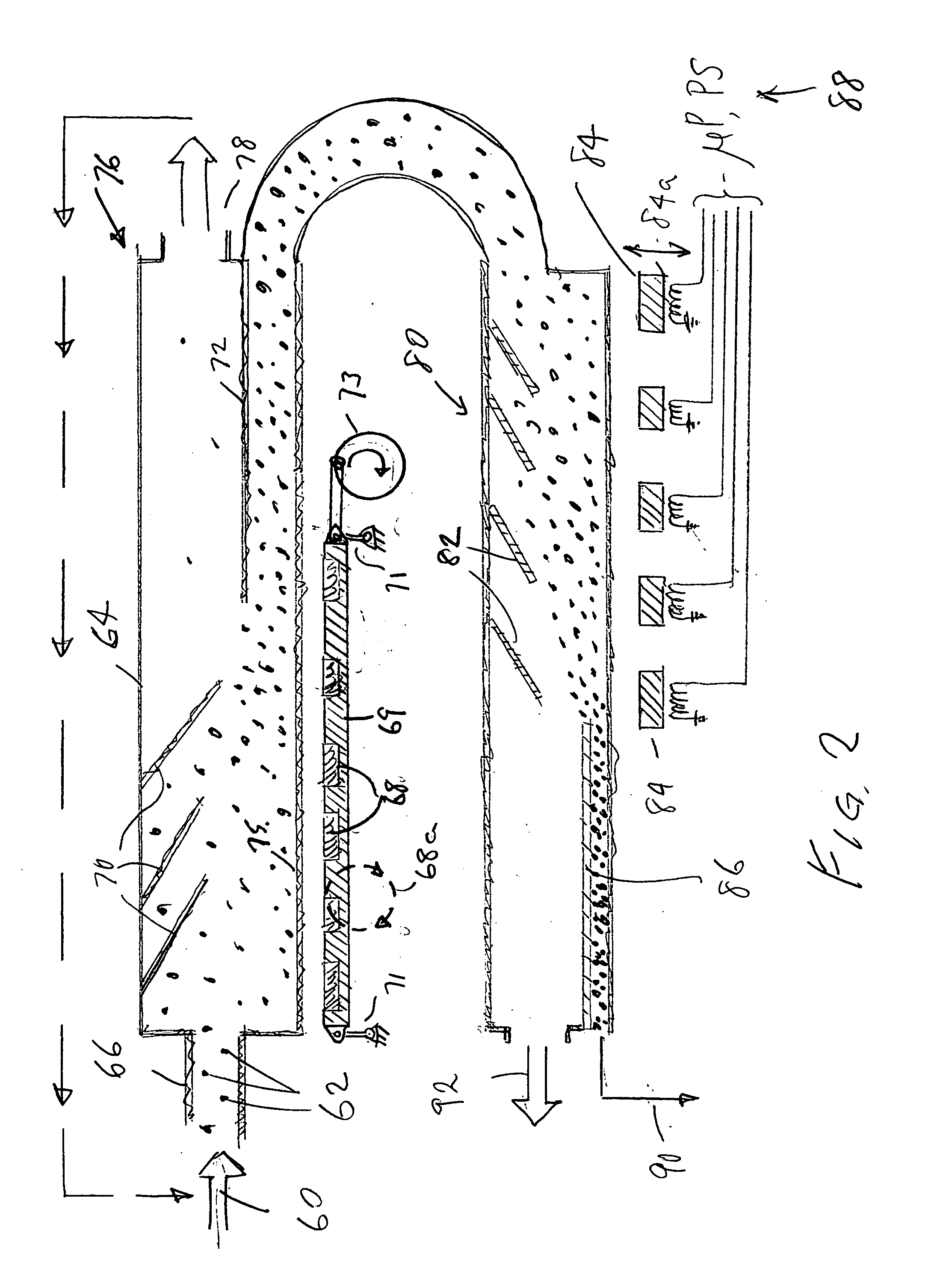

Water treatment using magnetic and other field separation technologies

InactiveUS20070039894A1Avoid scrappingInexpensive and mechanically simpleWater/sewage treatment by magnetic/electric fieldsSedimentation separationWater flowField separation

Apparatus and methods for removal of pollutants from a stream of water, by binding the pollutant particles to magnetic seeding particles using a flocculating polymer, and then removing the composite magnetic particles from the water stream in a simple and efficient apparatus. The invention is applicable to many common water treatment applications but is especially important for high flow applications requiring efficiency and simplicity. Magnetic fields concentrate the composite magnetic particles in a stratified layer that is then continually separated from the moving stream of water. In another preferred embodiment, vortex separation is combined with magnetic separation to enhance magnetic seed material cleaning and to reduce the solids load on the final magnetic collector.

Owner:CORT STEVEN L

Production process of honey peach CZ diamond

InactiveCN102838277ANo pollution damagePlay a role in fluxingGlass furnace apparatusGlass productionMachine toolKiln

The invention relates to a production process of a honey peach CZ diamond. The honey peach CZ diamond comprises the following raw materials in parts by weight: 60-70 parts of SiO2, 0.5-1.5 parts of Al2O3, 0.5-2.5 parts of BaO, 1.5-5 parts of ZnO, 1.0-2.5 parts of B2O3, 3-8 parts of K2O3, 8-15 parts of Na2O, 0.5-1.5 parts of CaO, 0.3-1.5 parts of Se and 0.03-0.3 parts of S. The production process comprises the following steps of: smelting by a hot smelting kiln and classifying; discharging to obtain a CZ diamond bead blank; sequentially carrying out fire polishing by a fire polishing furnace, and grinding by a grinding machine; and grinding a plurality of cutting surfaces of the CZ diamond by a multi-faced grinding machine tool and chemically plating to obtain a CZ diamond finished product.

Owner:JIANGSU JINCHENG GRP TECH

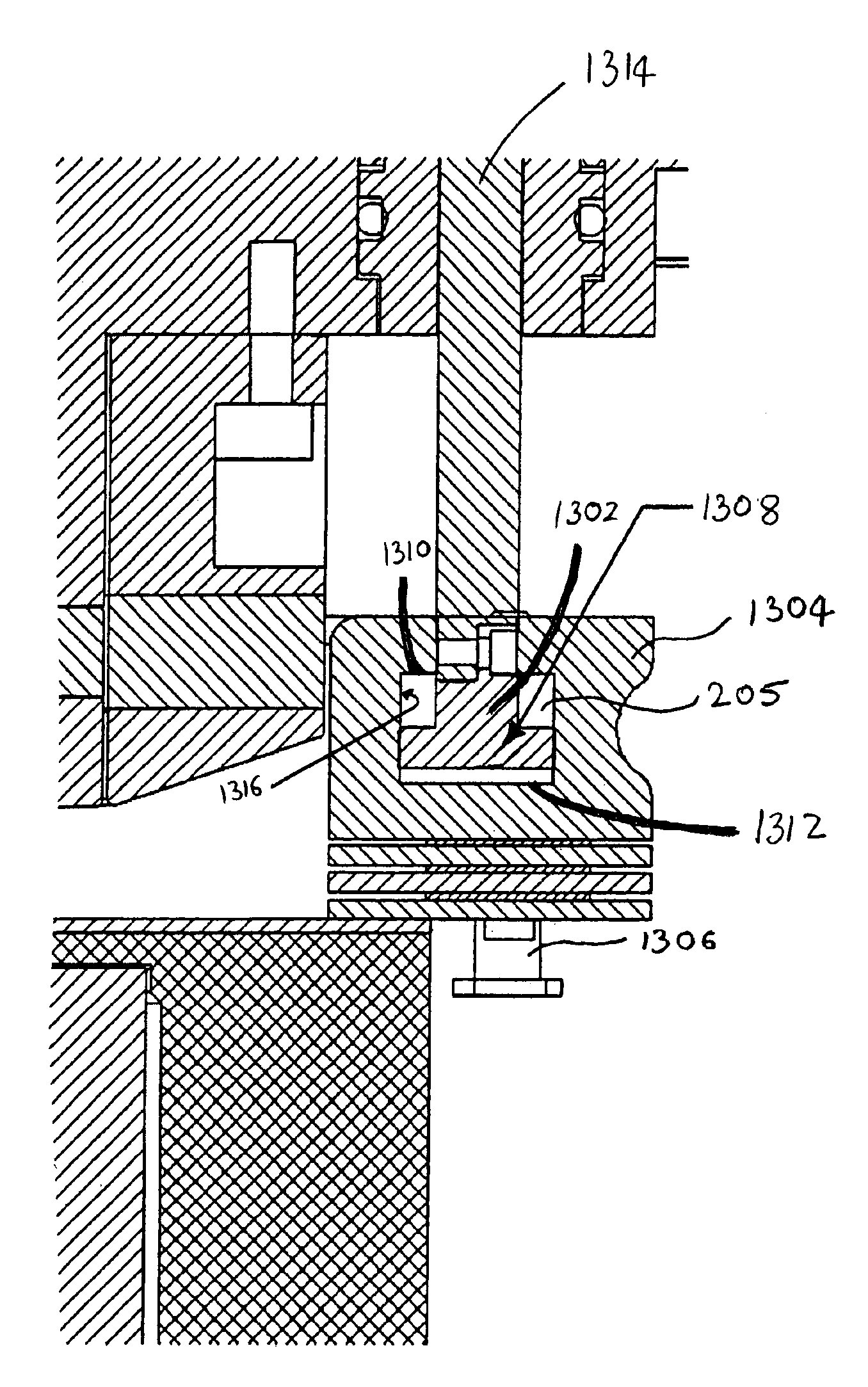

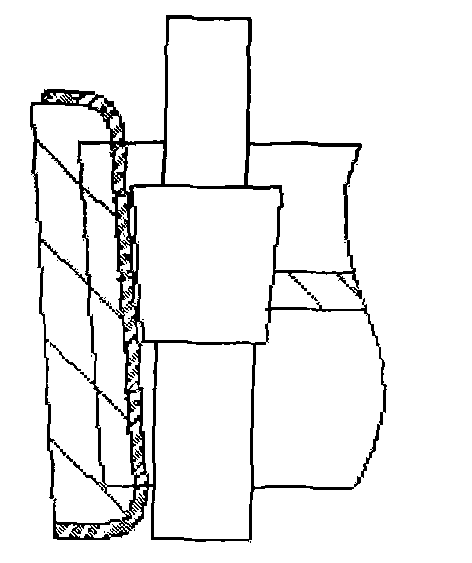

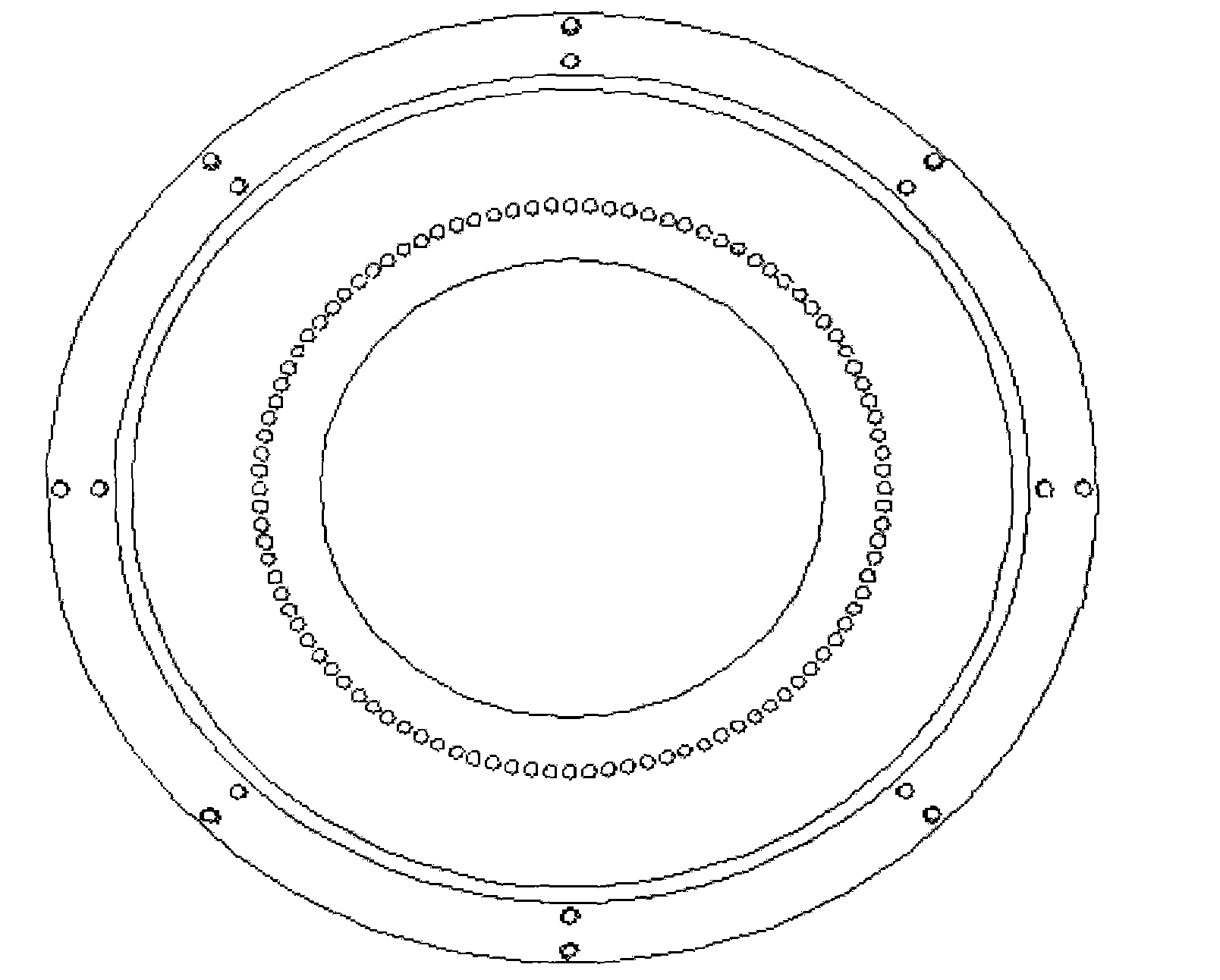

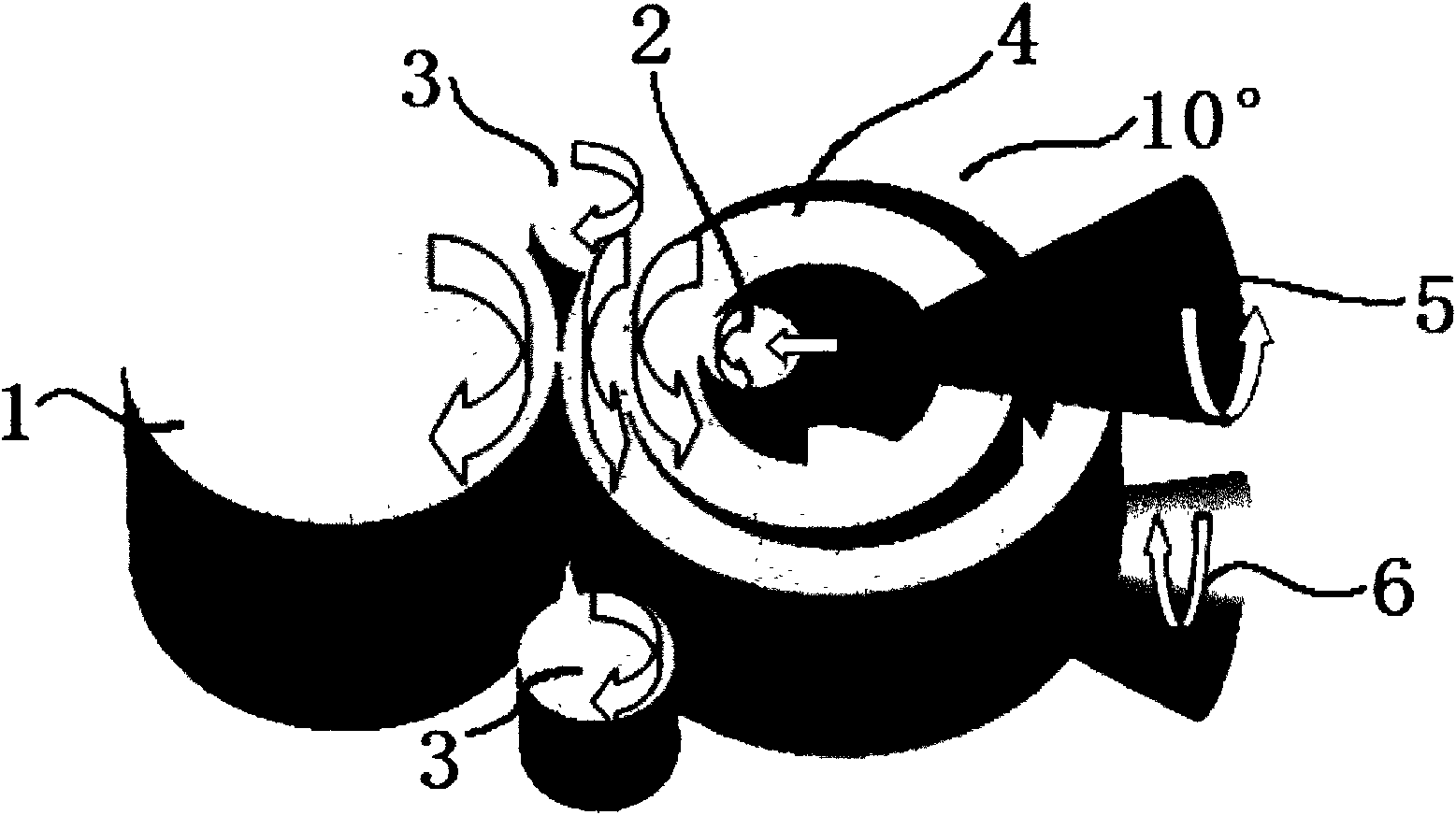

Twist-N-Lock wafer area pressure ring and assembly for reducing particulate contaminant in a plasma processing chamber

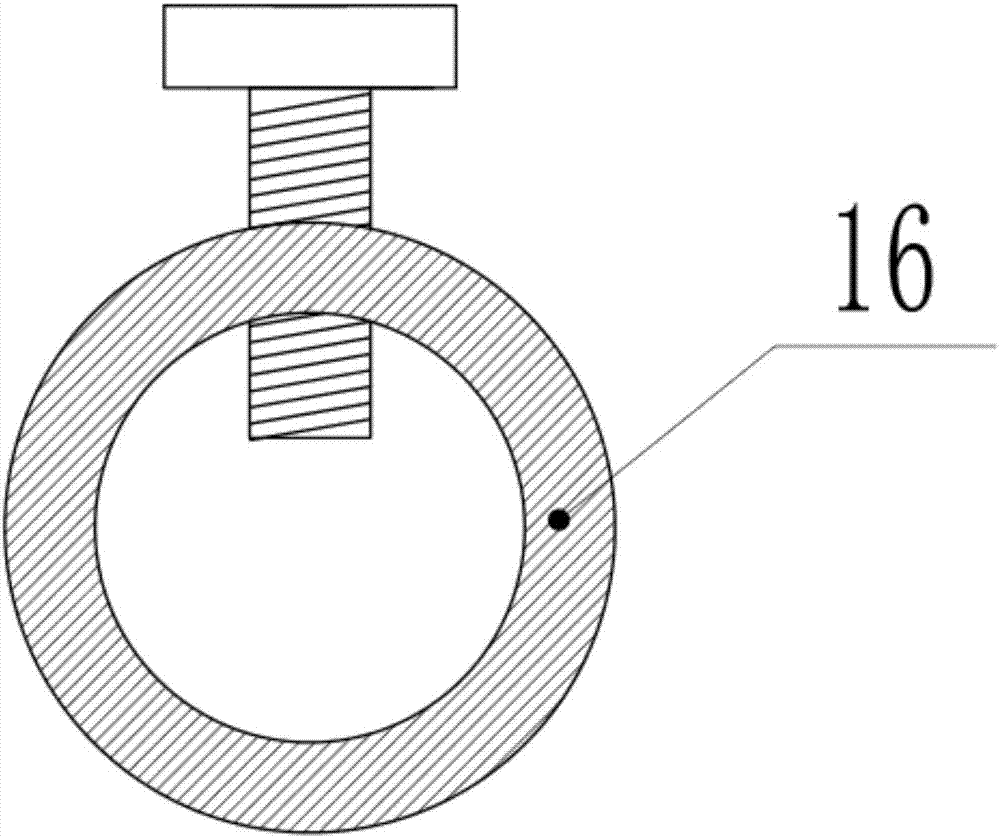

ActiveUS6936135B2Easy to processAvoid scrappingLiquid surface applicatorsElectric discharge tubesParticulatesCoupling

A confinement ring coupling arrangement for coupling, in a plasma processing chamber, a confinement ring to a plunger. The plunger is configured to move the confinement ring to deploy and stow the confinement ring to facilitate processing of a substrate within the plasma processing chamber. The confinement ring coupling arrangement includes a hanger adapter having a locking head, the hanger adapter being configured to be coupled with the plunger. The confinement ring coupling arrangement further includes a hanging bore disposed in the confinement ring and configured to receive the locking head and to secure the locking head within the hanging bore during stowing and deployment of the confinement ring, wherein a diameter of the locking head is sufficiently smaller than a cross-section dimension of the hanging bore to prevent a sidewall of the locking head from scraping against a sidewall of the hanging bore during the stowing and deployment of the confinement ring.

Owner:LAM RES CORP

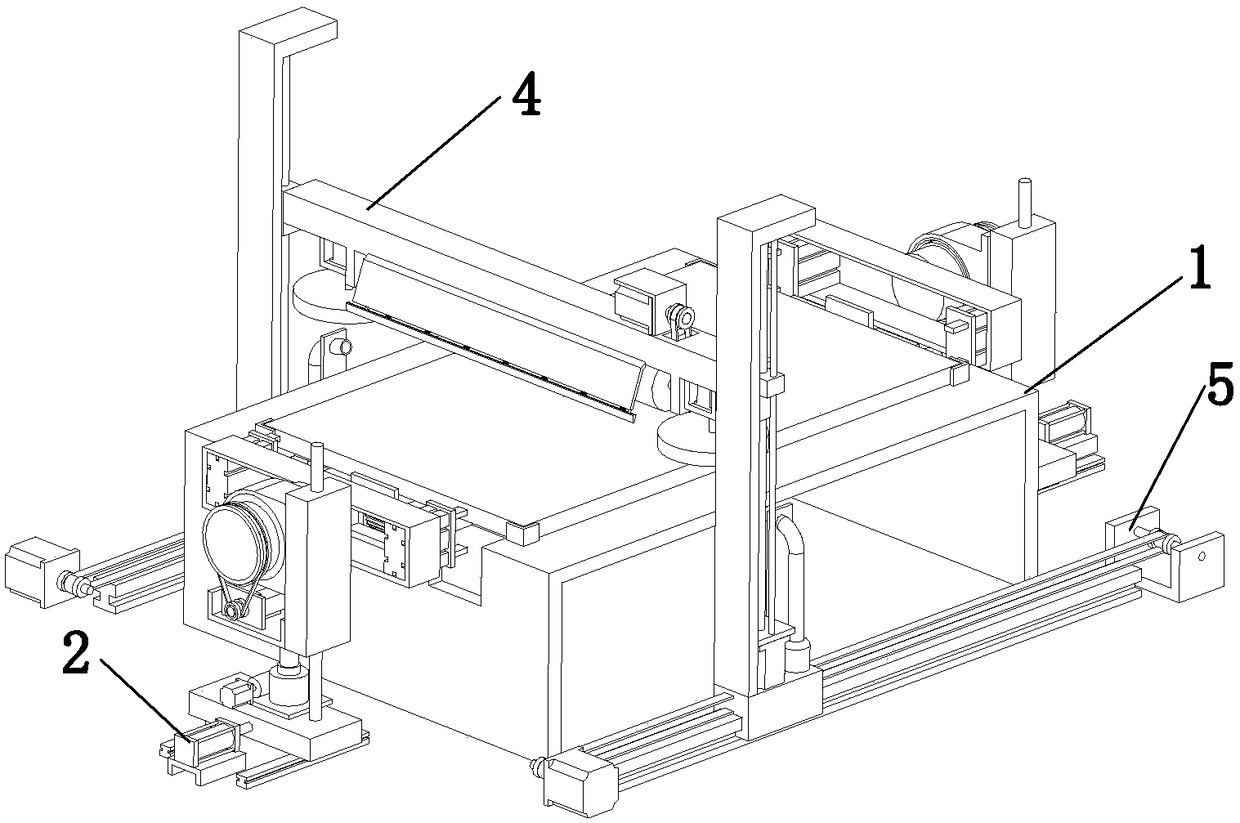

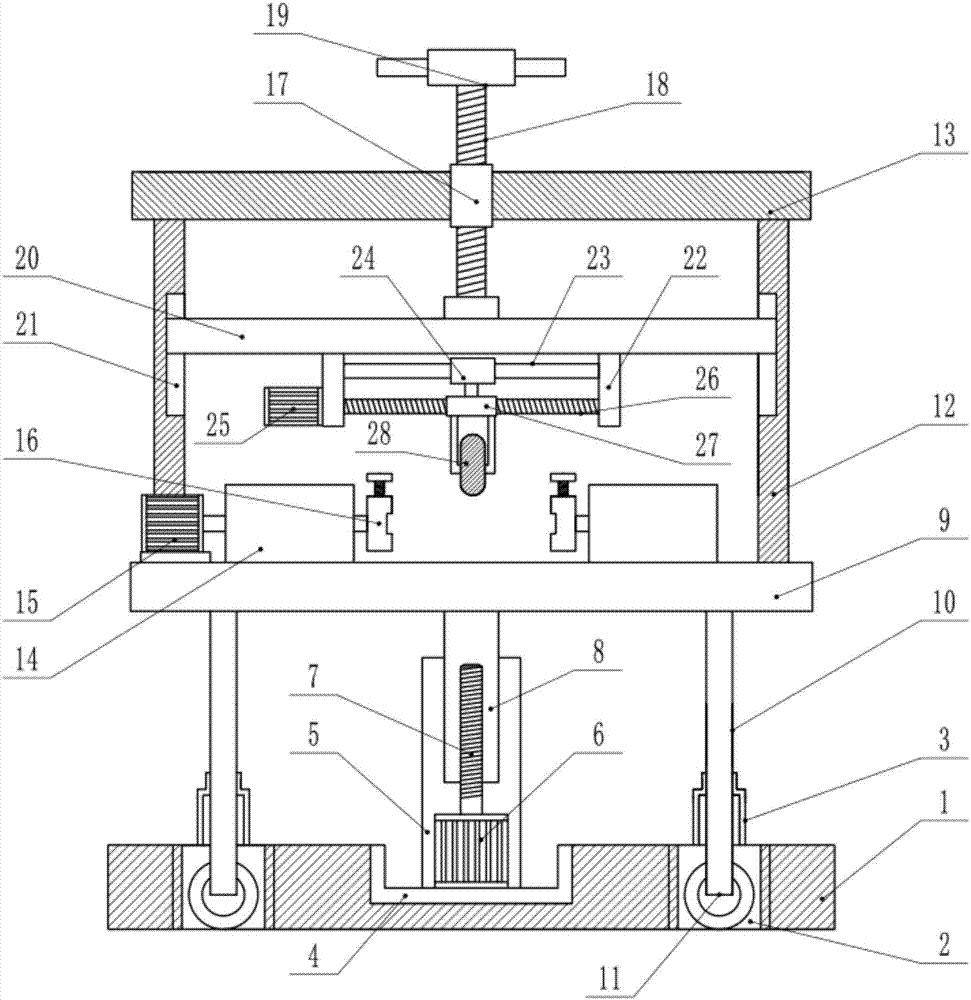

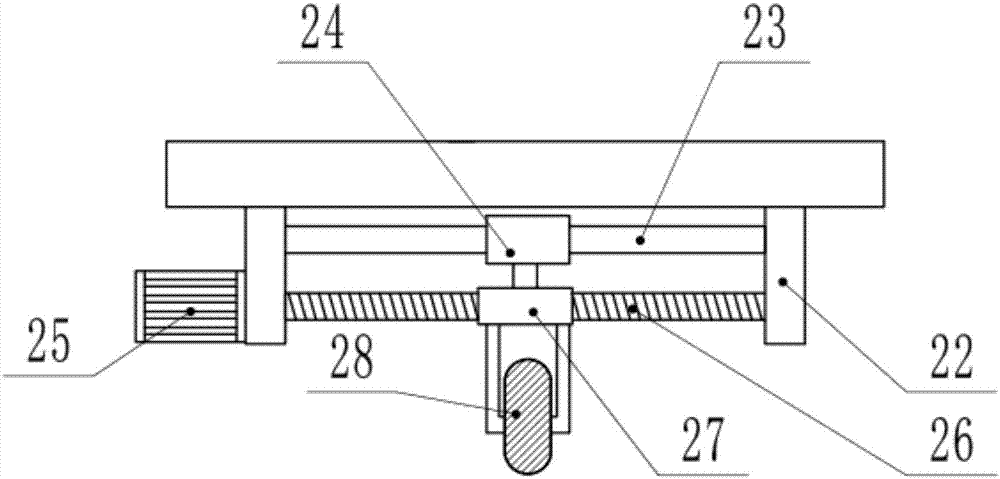

Grinding device for wooden door manufacturing

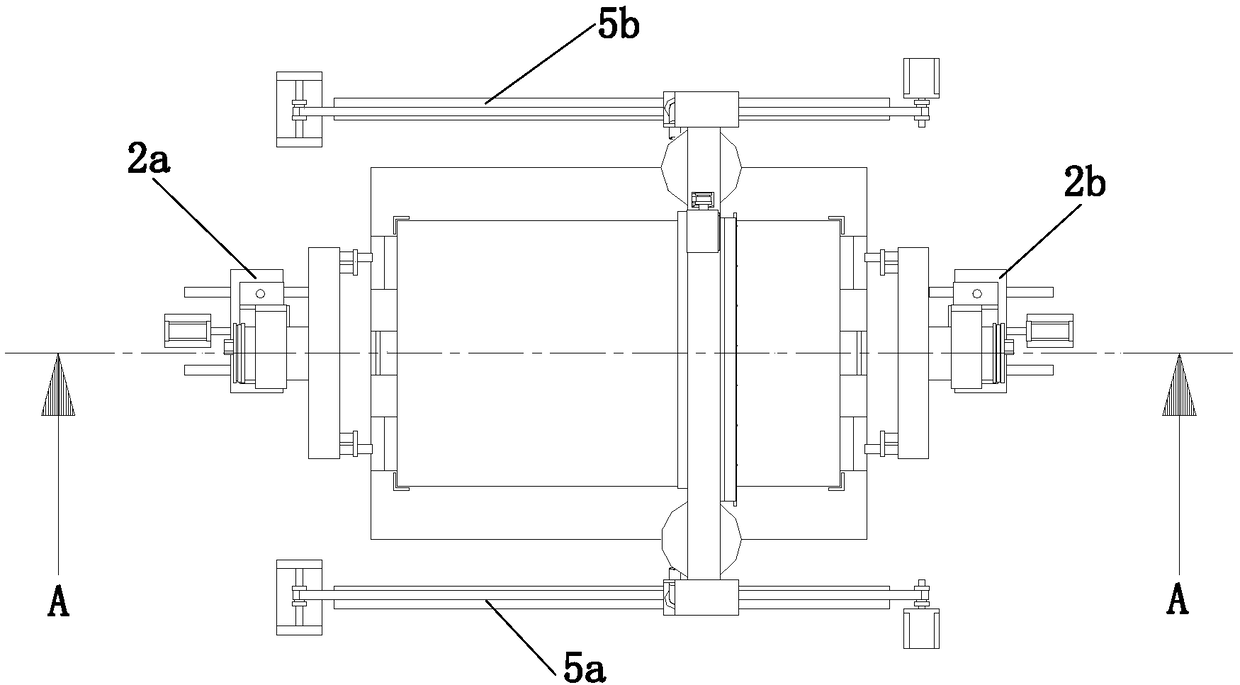

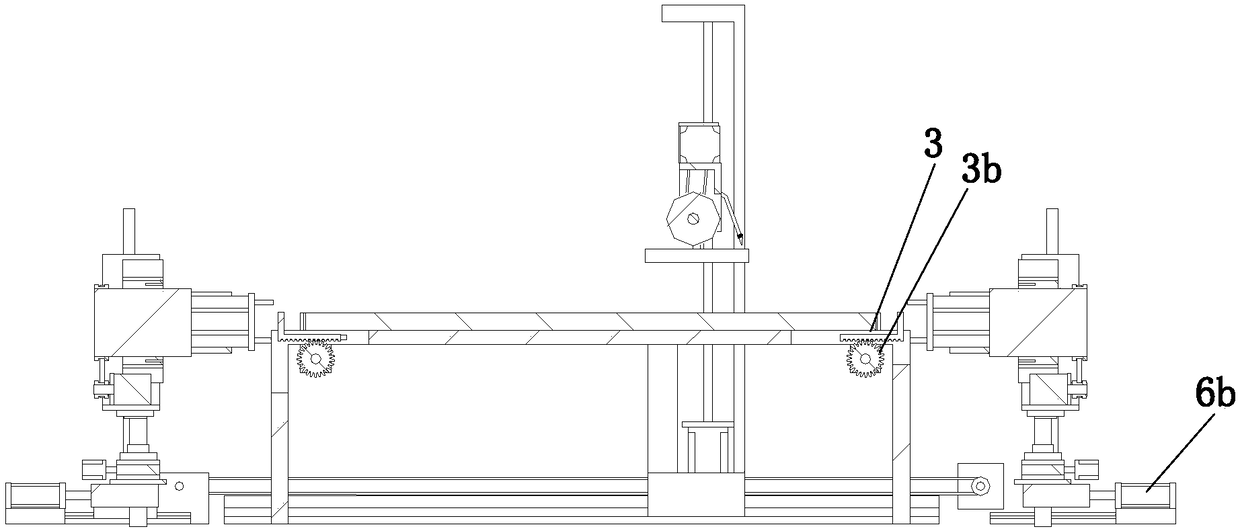

InactiveCN108581773AReduce labor intensityAvoid scrappingEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention provides a grinding device for wooden door manufacturing. The grinding device for wooden door manufacturing comprises a bracket, an overturning assembly, a limiting assembly, a grindingassembly and a material moving assembly used for driving the grinding assembly to move horizontally. The bracket comprises a left side plate, a right side plate and a top plate of a cuboid structure.The material moving assembly comprises a first feed assembly and a second feed assembly. The overturning assembly comprises a first material overturning assembly and a second material overturning assembly. The first material overturning assembly and the second material overturning assembly are of the same structure and each comprise a rotary tube, a clamping assembly located the end, close to thetop plate, of the rotary tube and a rotating assembly used for driving the rotary tube to rotate in the axial direction of the rotary tube. The grinding device has the beneficial effects that workpieces can be turned over through the overturning assembly and can be limited through the limiting assembly, and the situation that the workpieces are scrapped due to not being limited; the surface and the two sides of each workpiece can be ground through the grinding assembly, and the grinding device can also conduct processing on wood bits produced during grinding.

Owner:SHENZHEN DAVINCI INNOVATION TECH CO LTD

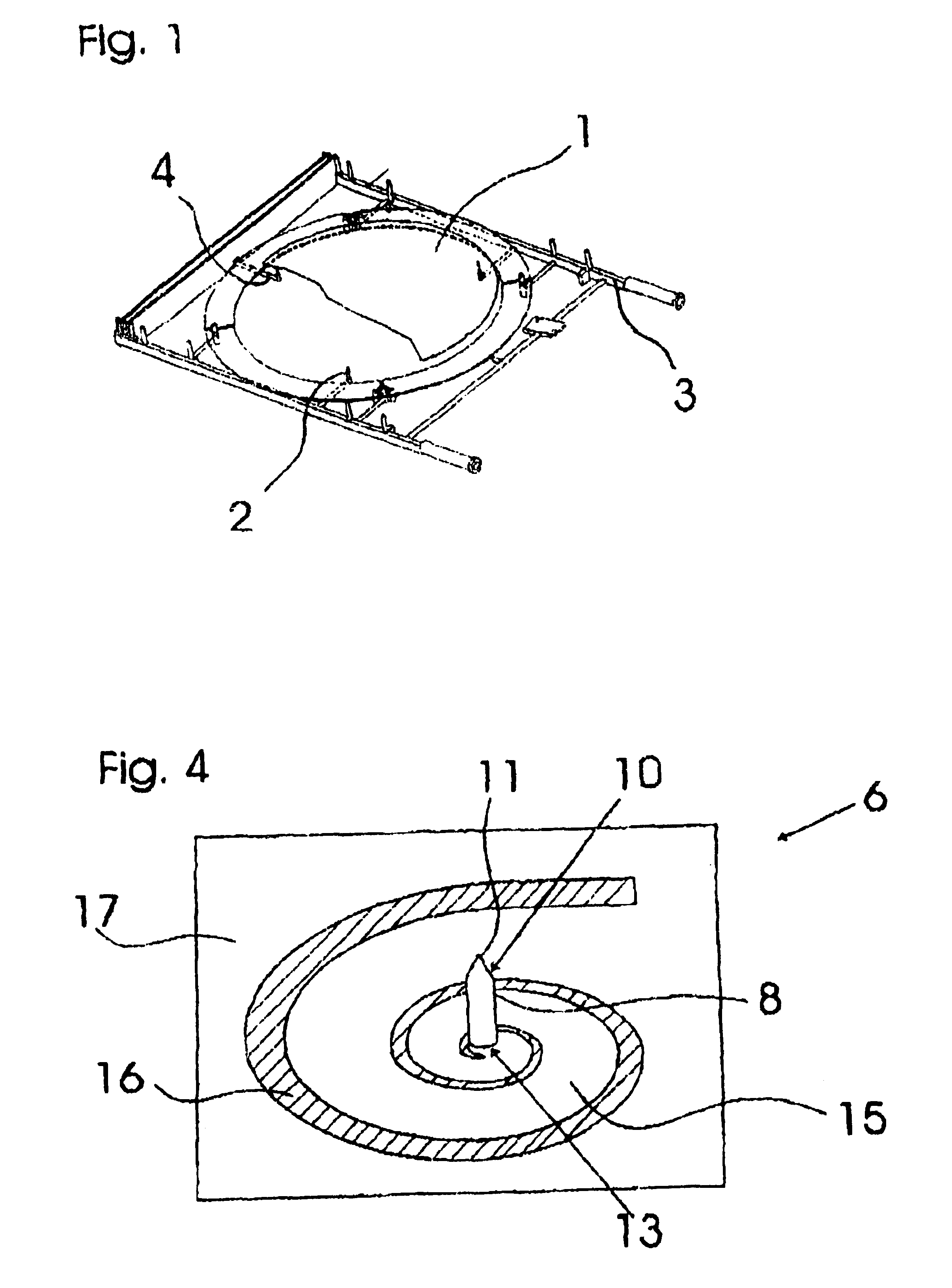

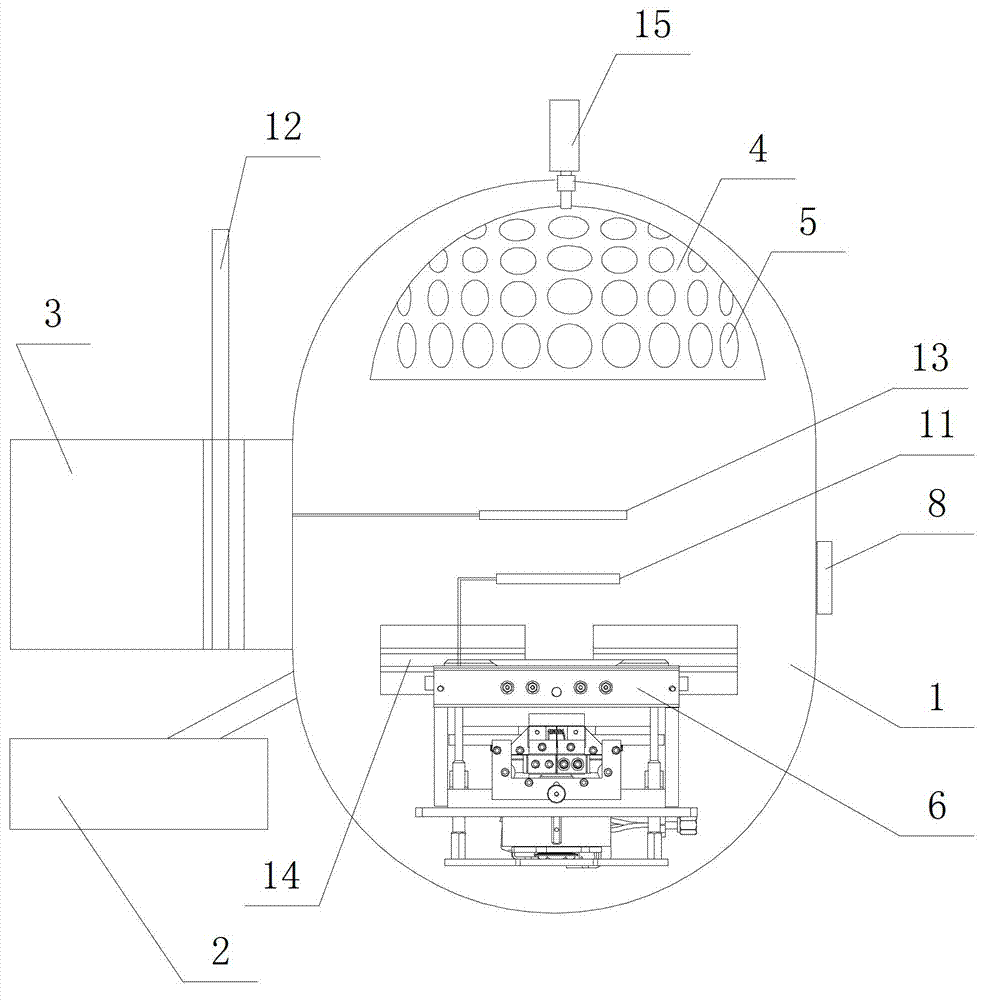

Infrared information-based metal additive manufacturing process control apparatus and method

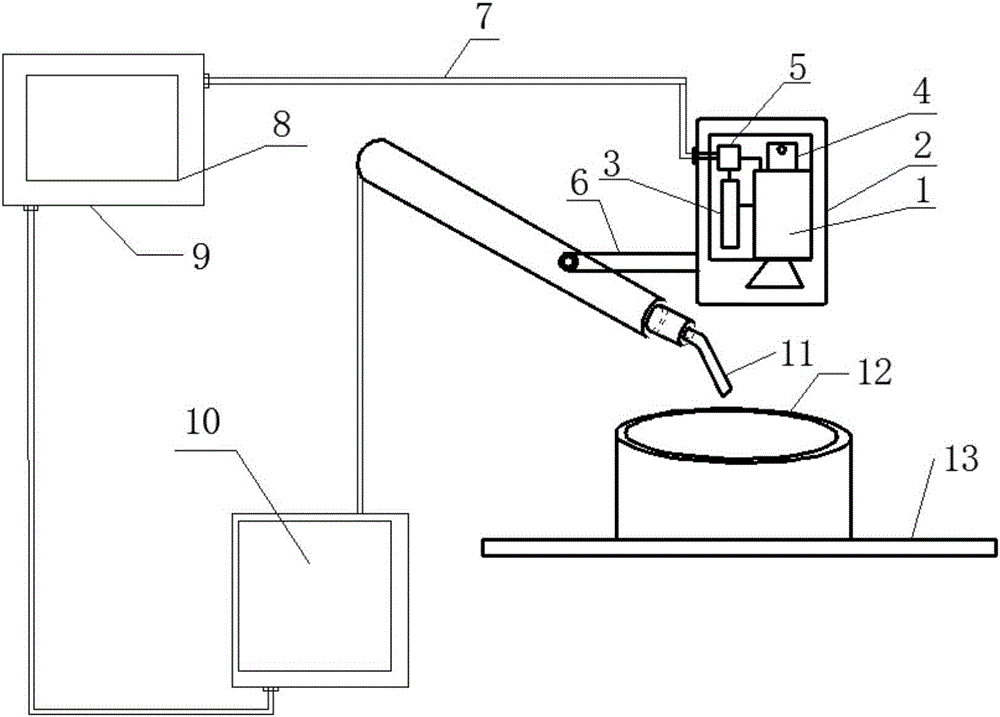

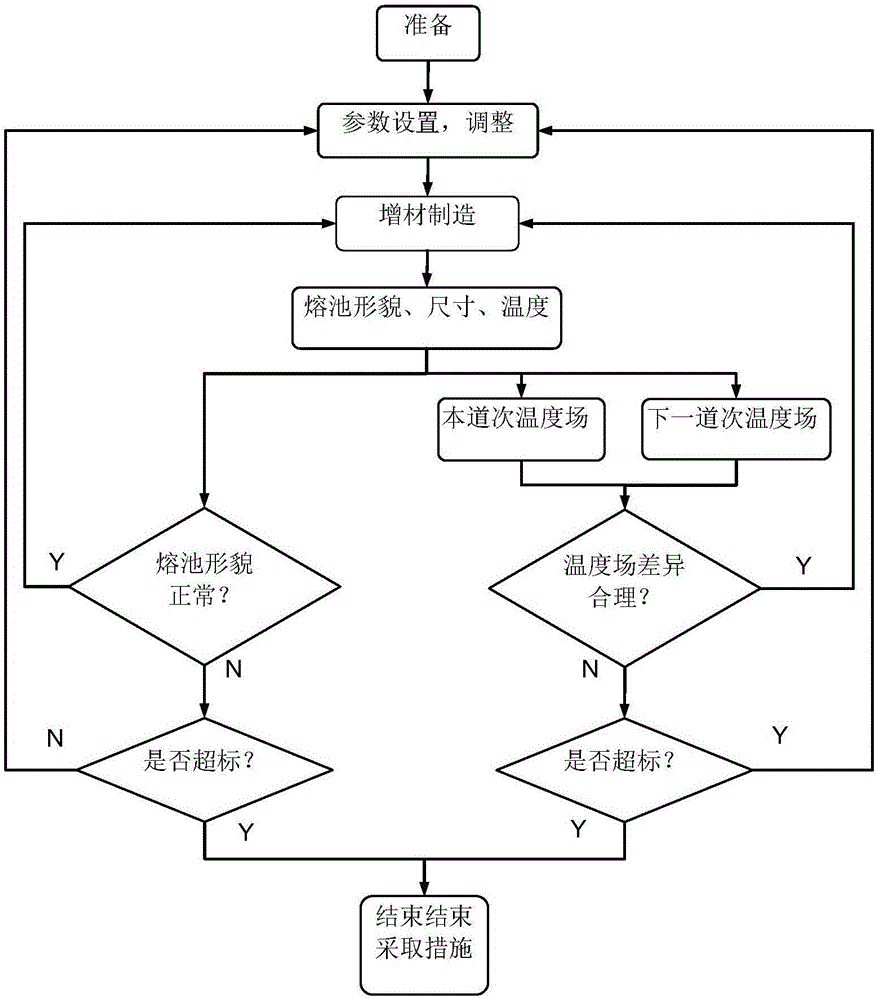

PendingCN106404795ARealize real-time quality monitoringInhibition of Defect ExpansionRadiation pyrometryOptically investigating flaws/contaminationImaging processingFeedback control

The invention discloses an infrared information-based metal additive manufacturing process control apparatus. The apparatus comprises: an additive manufacturing operating unit used for manufacturing a metal workpiece; an infrared image information acquisition unit comprising an infrared acquisition device (1) and used for acquiring infrared temperature field images of a melting bath of the workpiece and the circumference of the melting bath in real time; an image processing unit (9) connected with the infrared image information acquisition unit through a data bus (7) and used for processing the infrared temperature field images and generating a feedback instrument; and a feedback control unit (10) used for controlling the additive manufacturing operating unit to adjust parameters in order to eliminate defect or alarm shutdown. The invention also discloses a control method applying the apparatus. The apparatus can realize real-time quality detection of the whole metal additive manufacturing process, and can timely adopt measures to inhibit defect expansion or timely stop operation in order to prevent product discard or repairing after completion.

Owner:HUAZHONG UNIV OF SCI & TECH

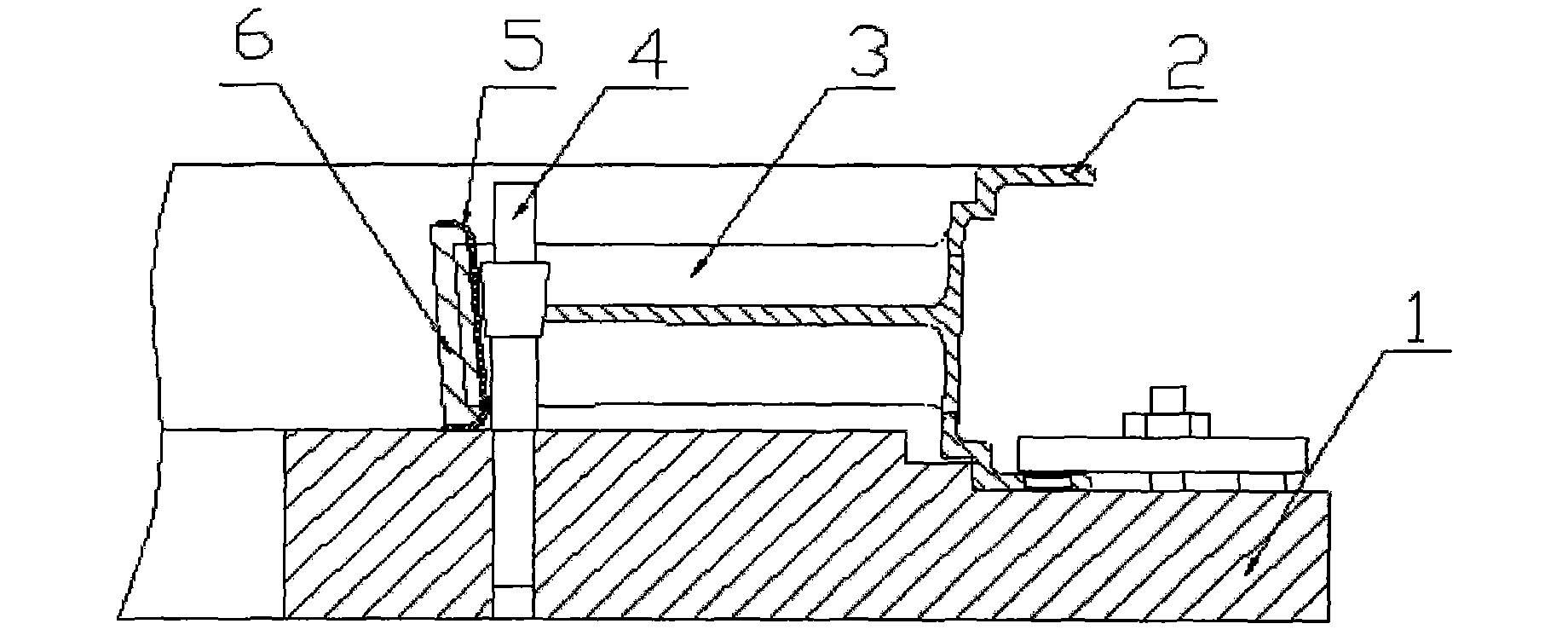

Correction device and correction method for inner ring of engine crankcase

The invention provides a correction device and a correction method for an inner ring of an engine crankcase. The correction device comprises a correction clamp base, positioning pins and a pressure plate; the tooling surface of the correction clamp base is provided with a circular seam allowance, and the inner side of the seam allowance is provided with a circle of uniform positioning pin holes; and the middle section of the positioning pin has a round table step-shaped columnar structure, the taper of the round table of the middle section is as same as that of the inner ring of the crankcase, and the maximum diameter of the positioning pin enables the positioning pin inserted into the positioning hole not to interfere with a blade of the crankcase. The correction method comprises the following steps of: jointing the seam allowance of the crankcase and the seam allowance on the correction clamp base; inserting the positioning pins into the positioning pin holes, positioning the positioning pins and the inner ring of the crankcase in a two-section contact mode, and then fixing the crankcase on the correction clamp base through the pressure plate; welding the inner ring and the blade of the crankcase; and finally, pouring a glue layer into the inner side of the inner ring of the crankcase, and gluing the inner ring and the blade of the crankcase. The device and the method ensurethe concentricity of the easily-deformed inner ring and the outer crankcase and the ellipticity of the inner ring.

Owner:AECC AVIATION POWER CO LTD

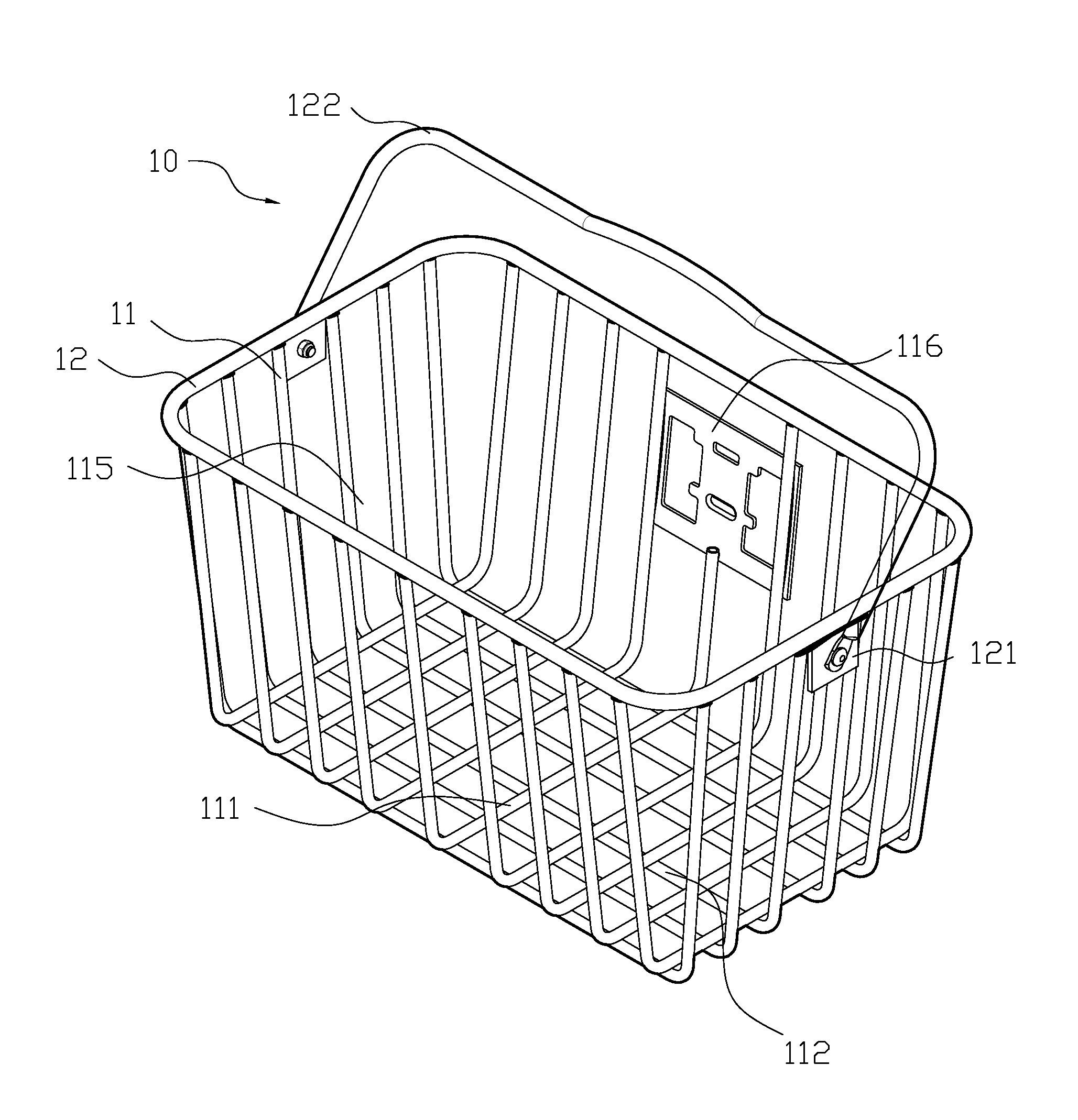

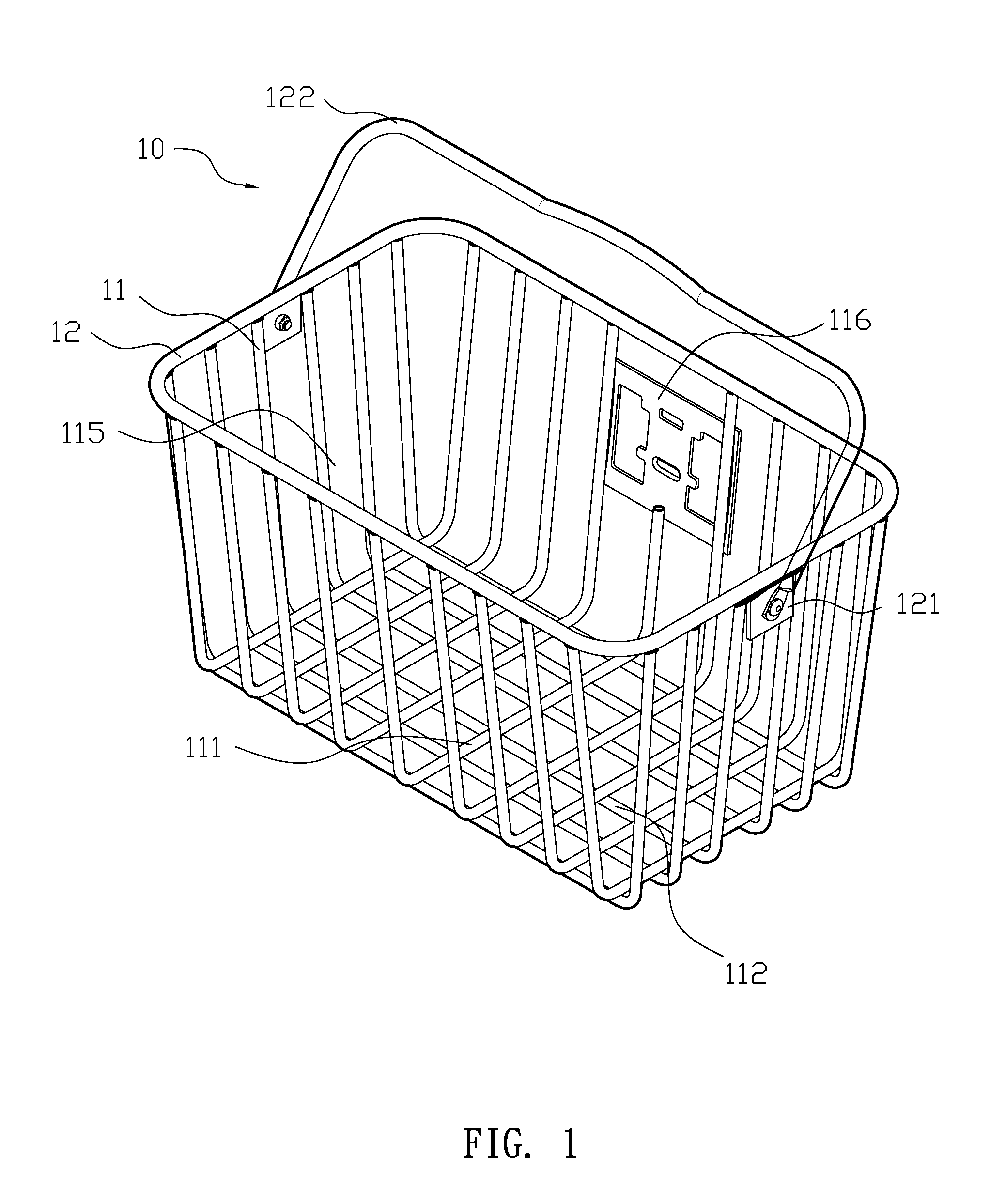

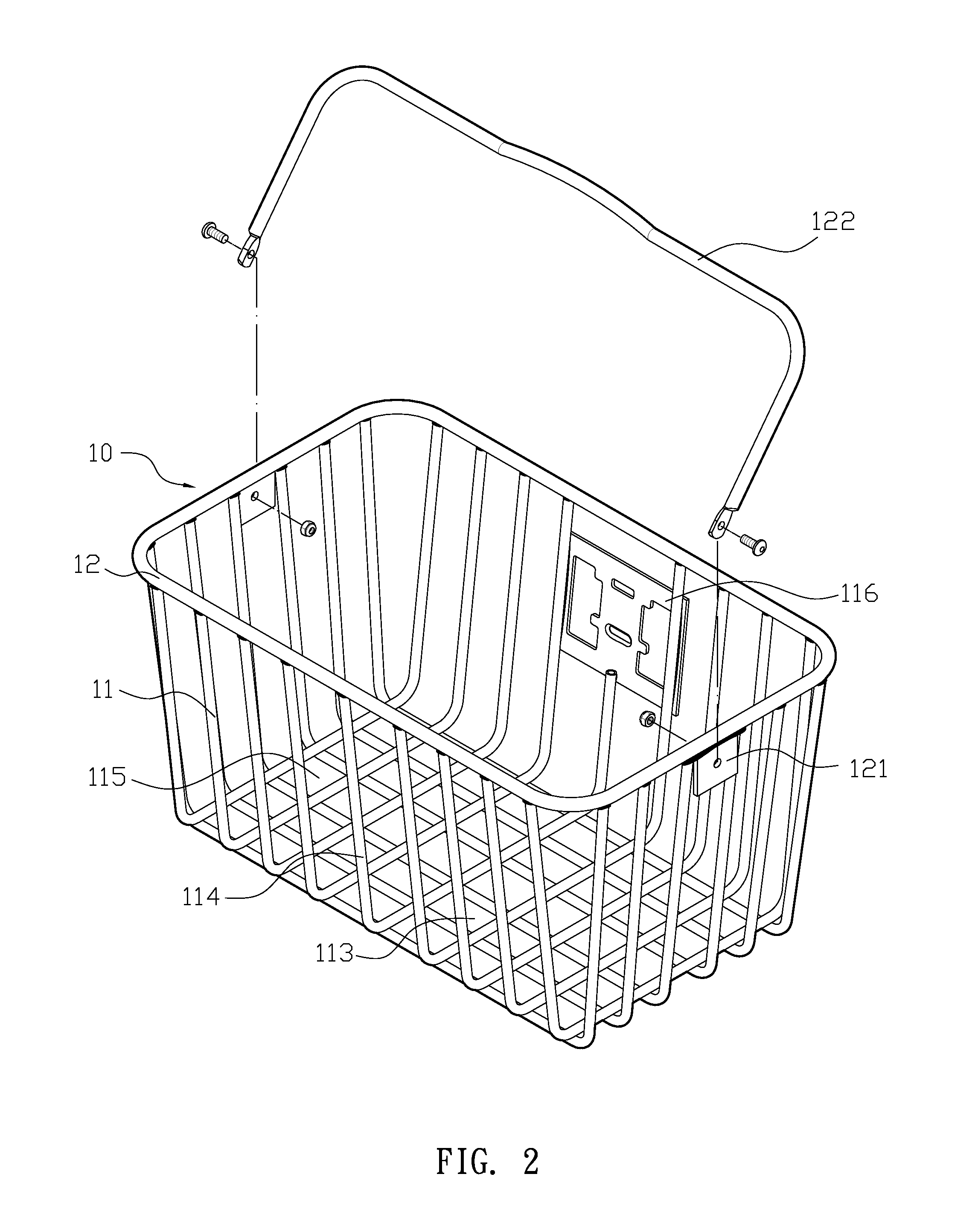

Lightweight bicycle basket

InactiveUS20120152993A1Light weightHigh strengthLuggage carriersArticle supporting devicesTransverse planeEngineering

A lightweight bicycle basket is made from supporting pipes and a frame. Each of the supporting pipes is made of a material that is lightweight and sufficiently strong for its intended purpose and is formed into a Ushaped hollow pipe. The supporting pipes are arranged at intervals to form a longitudinal layer and a transverse layer. The longitudinal layer is superposed on the transverse layer to form a mesh structure. In this way, the basket has a supporting surface on its bottom, retaining surfaces on its sides, and an accommodating space in its interior. The tips of the supporting pipes are connected by the frame to form a firm structure. The frame is also made of a material with a light weight and sufficient strength and is formed into a loop of hollow pipe.

Owner:BRANC

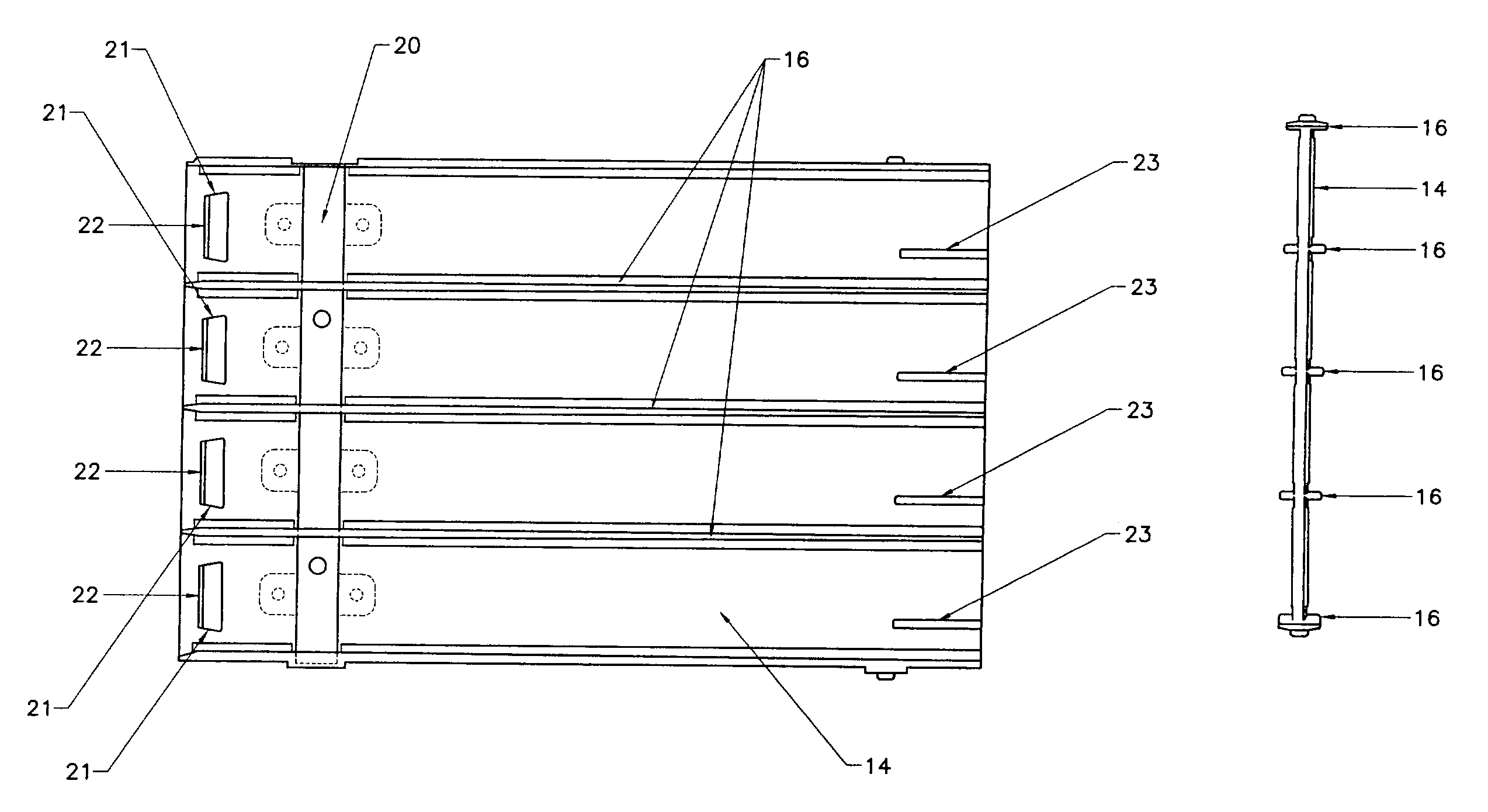

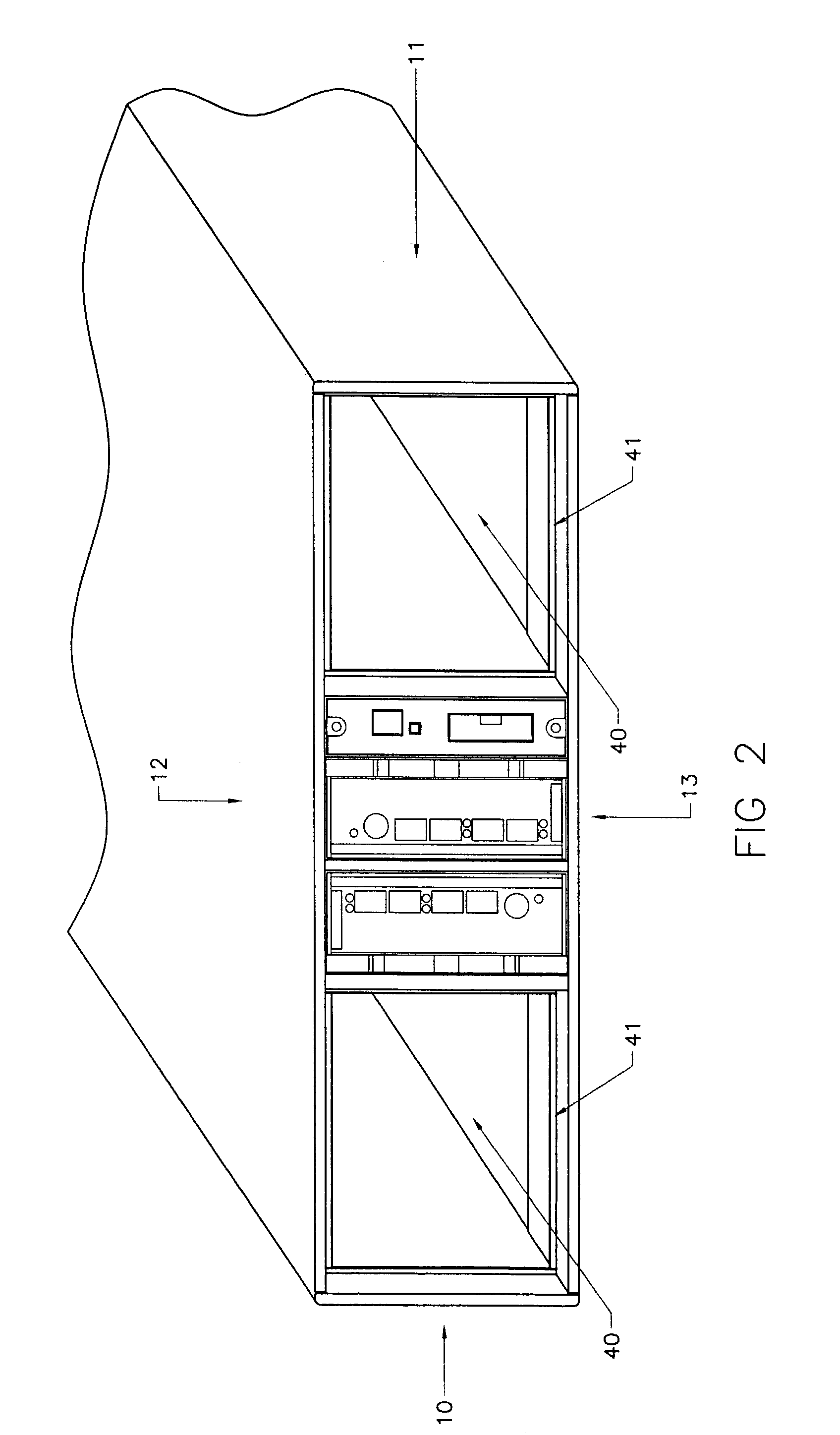

Data storage device chassis, case and clamp mechanism

InactiveUS7298624B2Vibration minimizationAvoid scrappingCarrier constructional parts dispositionMagnetic/electric field screeningMetallic materialsEngineering

A data storage device chassis for housing a plurality of data storage devices has a plurality of walls at least some of which have at least one guide strip along at least part of the length of the wall to define a plurality of bays in which data storage devices (18) can be housed. The guide strips support respective data storage devices in the bays such that the data storage devices can be slid into and out of the bays by sliding along the guide strips. The at least some of the walls are composed of a non-metallic material such that the surface of said guide strips along which a data storage device slides is non-metallic. Each of said at least some of the walls have an electrically conductive portion passing through the wall to provide for electrical conduction between the bays thereby providing electrical shielding for data storage devices housed in the bays.

Owner:XYRATEX TECH LTD

Roll forming method of TC25 titanium alloy thin-walled ring forging

The invention discloses a roll forming method of a TC25 titanium alloy thin-walled ring forging. In order to roll-form a thin-walled ring forging with high dimensional precision and excellent tissue and performance, the technical scheme comprises the steps of: firstly, sleeving a preheated follower die sleeve and a titanium alloy pre-rolled blank heated to a deformation temperature in a ring rolling mill, sleeving the follower die sleeve in the pre-rolled blank, and positioning the two workpieces by using a main roll, a core roll, clutching rolls, an upper cone roll and a lower cone roll of the ring rolling mill; and starting the ring rolling mill, making a feeding motion by the core roll towards the direction of the main roll along the radial direction and rolling the pre-rolled blank at a rolling force of 200-4000KN under the support of the follower die sleeve by the core roll together with the main roll to ensure that the pre-rolled blank expands radially at a speed of 5-10mm / s, wherein the wall thickness is gradually reduced, and the pre-rolled blank is rolled into the thin-walled ring forging when the deformation reaches 25-45 percent. The minimum value of the wall thickness of the titanium alloy thin-walled ring forging roll-formed by adopting the method is 25mm, the maximum value of the height-thickness ratio is 25mm, and the ring forging is mainly used for gyrorotor parts, such as a cylindrical shell and the like used in the fields, such as aerospace and the like.

Owner:GUIZHOU AVIATION TECHN DEV

Liquid crystal display array base plate and patching method thereof

ActiveCN101776808AAvoid scrappingRepair Line DefectsSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayDisplay device

The invention provides a a patching method of a liquid crystal display array base plate. The patching method comprises the following patching flow processes: firstly, providing the liquid crystal display array base plate; then, detecting a linear defect part and simultaneously determining the position of the linear defect; next, using laser light beams for removing baffle layers formed by extending the two adjacent ends of the linear defect to a common electrode line; then, using a laser chemical deposition method for depositing a connection metal layer on the baffle layer removing position; finally, cutting off the adjacent external end electric connection part of the baffle layer on the common electrode line through laser light beams; and then, making a signal transmission line of the linear defect be able to complete the signal transmission through the common electrode line section. Thereby, the restoration method can effectively restore the defect of the signal transmission line on the original design, and the generation of other adverse defects caused by design modification can be avoided.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

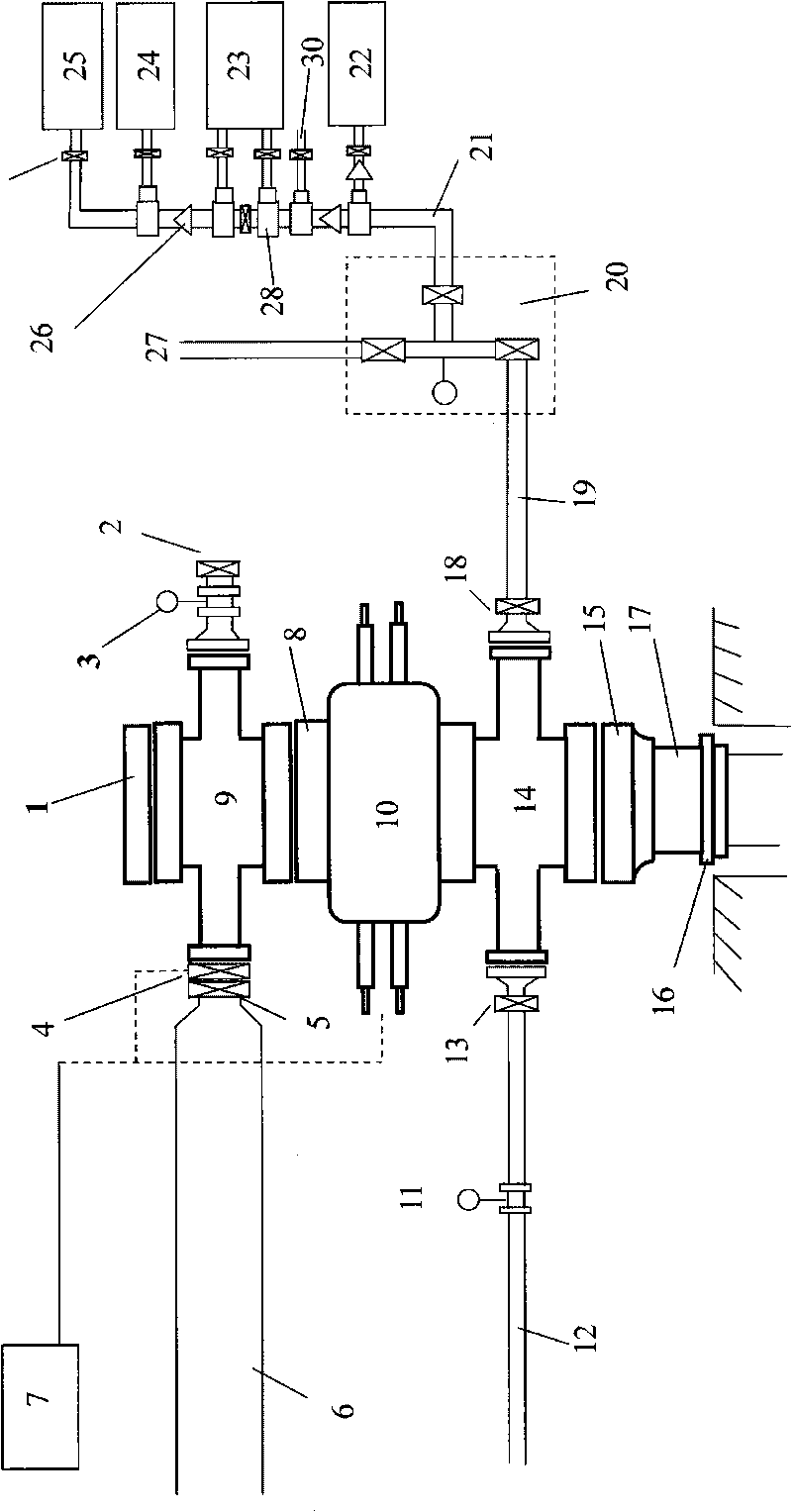

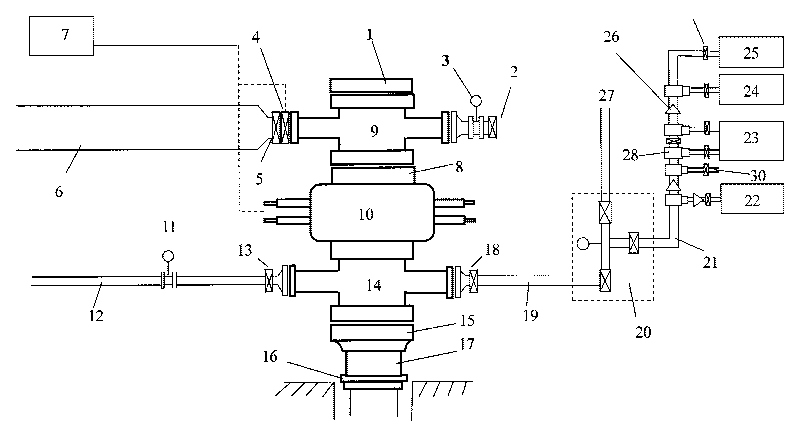

Reverse circulation aerodynamic cavitation method for coalbed methane well and equipment

The invention discloses a reverse circulation aerodynamic cavitation method for a coalbed methane well and equipment. The reverse circulation aerodynamic cavitation method comprises the following steps of: arranging wellhead equipment on a wellhead and sinking a working pipe to a bottom hole; clearly eliminating rock coal dust and water inside the well by using an air compressor in a circulating way; then lifting the working pipe upwards and injecting air / foam by using the air compressor and a supercharger, wherein the air injecting pressure is 3-15 MPa; meanwhile continuously injecting atomized water into the well with the water injecting amount of 3.0-5.0 m<3> each time; opening a hydraulic flat plate gate valve for discharging; after discharging, sinking the working pipe to a coalbed part; injecting the air simultaneously by the air compressor and the supercharger; meanwhile injecting water / foam with the amount of 3.0-10.0 m<3> by using an injection pump for washing the well to thebottom hole; after completing one cycle of discharging and well washing, detecting initial data; closing the air compressor, the supercharger, the injection pump and the hydraulic flat plate gate valve to enable gas inside the well to return freely; measuring the change of gas output of coalbed gas in one hour by using a flow meter; and placing a torch at a discharge port to ignite the gas. The invention improves the construction safety, improves the yield of single well coalbed gas, and saves the construction cost.

Owner:河南省资源环境调查二院

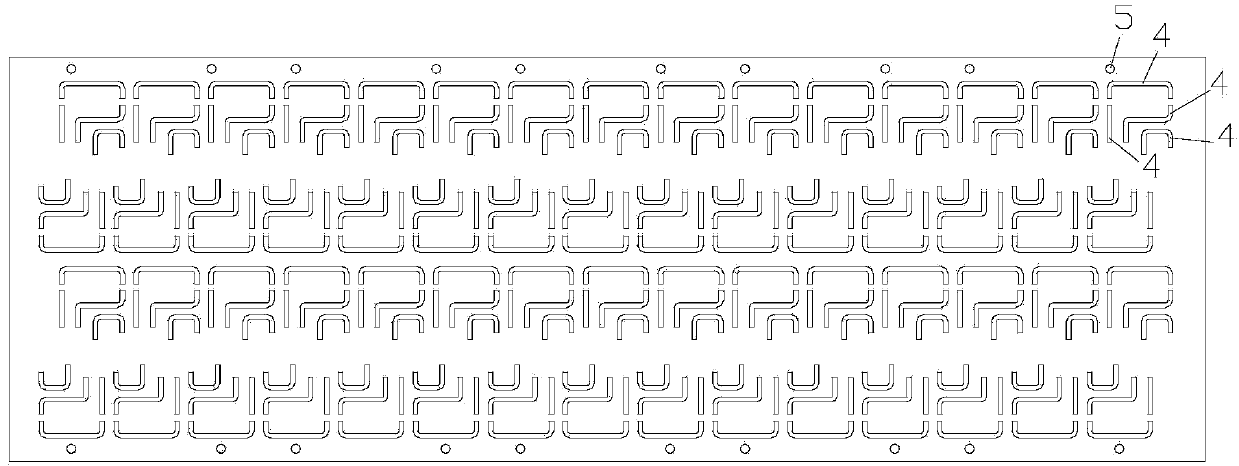

Base station antenna and antenna array module thereof

The invention discloses an antenna array module. More than two antenna units are arranged on a surface, which two power division circuits are arranged, of a feeding network circuit board, a filter isarranged on a surface, which two coupling circuits are arranged, of the feeding network circuit board, each power division circuit is provided with an input end and a plurality of output ends, the plurality of output ends of one of the power division circuits is used for performing polarization feeding on one of the antenna units at -45 degrees, the plurality of output ends of the other power division circuit are used for performing polarization feeding on one of the antenna units at +45 degrees, each coupling circuit is provided with a radio frequency input end and an output end, the output end of each coupling circuit is electrically connected with the input end of one of power division circuits, the filter is at least provided with two output ends, and the two output ends of the filterare electrically connected with the radio frequency input end of one of the coupling circuits. The invention also discloses a base station antenna. Integration and modularization are achieved, the expansibility is improved, an installation structure and a connection structure are simple, the antenna array module is easy to debug and maintain subsequently, and the manufacturing cost and the application cost are reduced.

Owner:TONGYU COMM INC

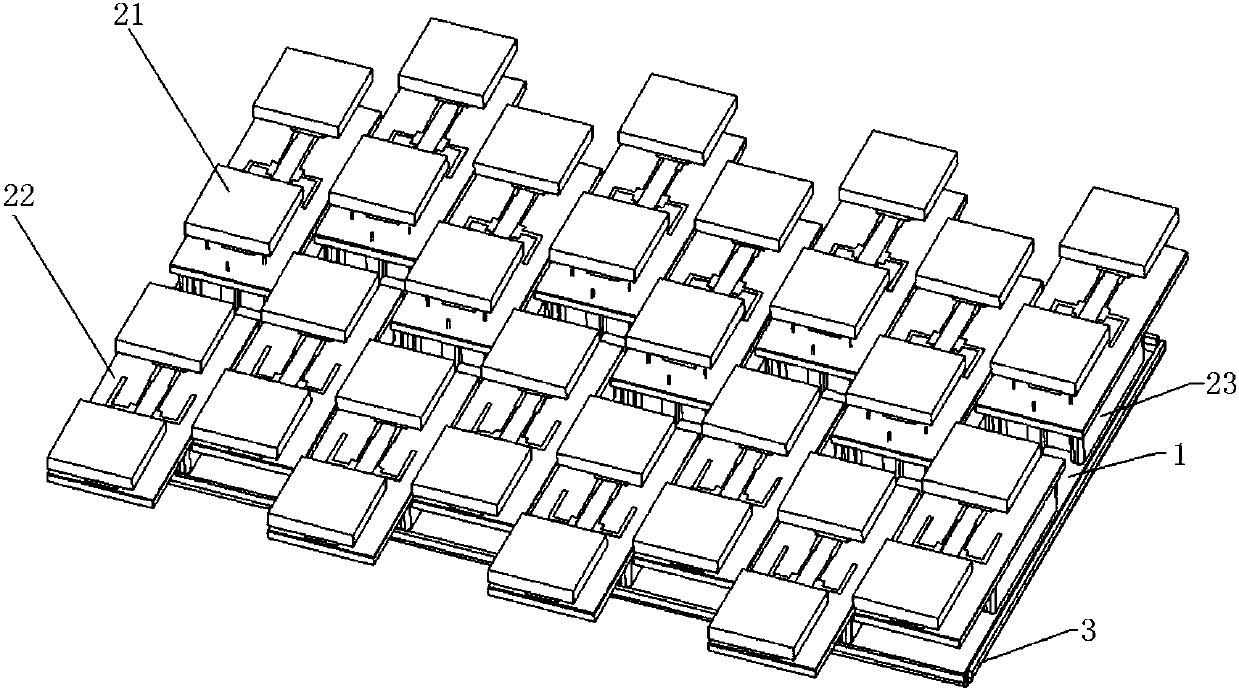

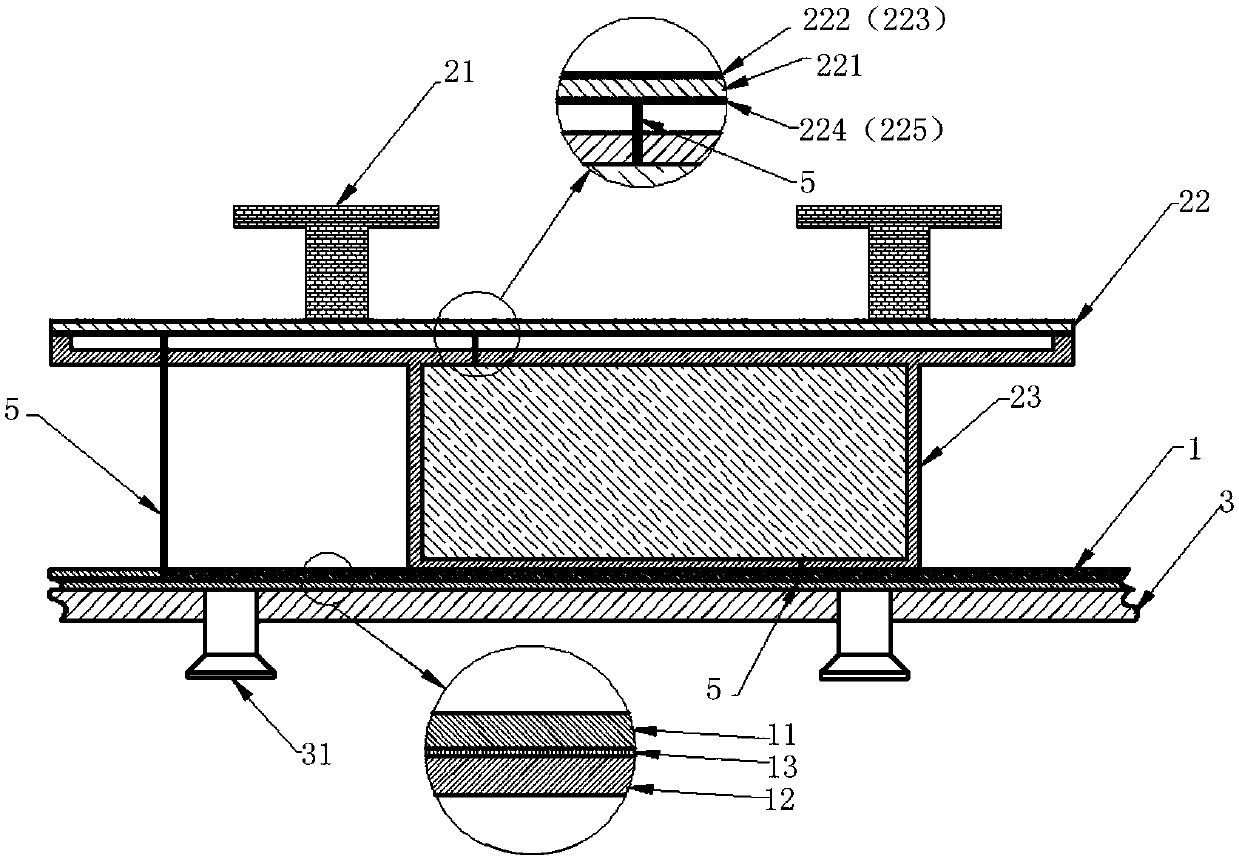

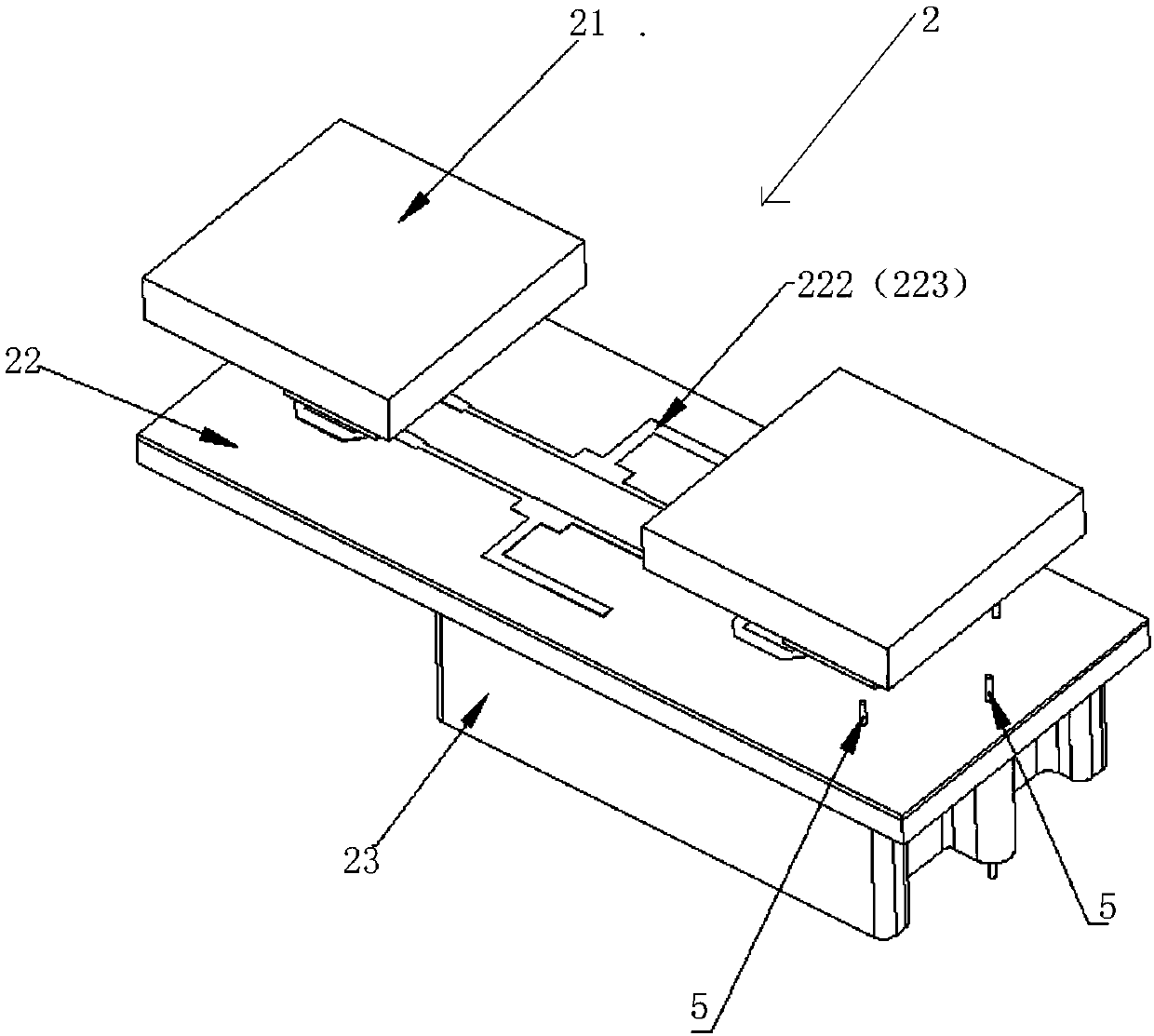

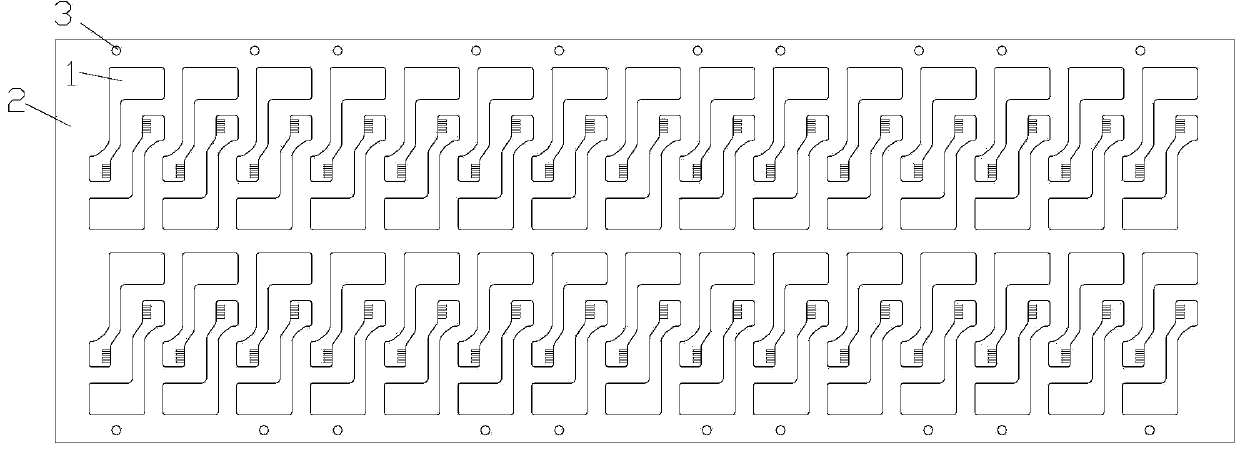

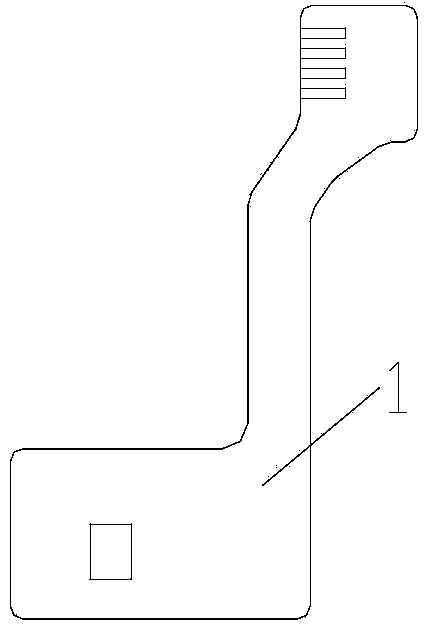

Flexible circuit board capable of being continuously discharged one by one, and preparation method thereof

InactiveCN103997859AAvoid lossAvoid scrappingPrinted circuit detailsPrinted circuit manufactureFlexible circuitsEngineering

The invention provides a preparation method of a flexible circuit board capable of being continuously discharged one by one. The method includes the following steps of firstly, stamping the flexible circuit board multiple times, and preparing a slightly-adhering film with drilled holes; secondly, pasting the slightly-adhering film; thirdly, stamping the stamped flexible circuit board to which the slightly-adhering film adheres again; fourthly, tearing off waste. According to the preparation method, the flexible circuit board does not need to be taken out each time after being stamped, the whole FPC is machined, and time and labor are saved; statistics can be conveniently and rapidly conducted on the single pcs number after stamping is conducted; FQC can be conducted on the whole flexible circuit board after a bubble cushion is slightly torn off, and detection efficiency is improved; the risks that folds are formed on the FPC and 3M glue release paper falls off due to the fact that the FPC is touched by hand during detection are avoided, and quality is ensured; the process that multiple pieces of single pcs are sequentially arrayed and placed on the slightly-adhering film through manual operation is replaced by the process that the waste is overall torn from the slightly-adhering film, efficiency is improved, and time and labor are saved.

Owner:深圳市华大电路科技有限公司

Device for grinding burrs on surface of rotating shaft of commercial coil motor

The invention discloses a device for grinding burrs on the surface of a rotating shaft of a commercial coil motor. The device comprises a base, groove holes, a first driving motor, a threaded bushing, bearing seats, clamping threaded couplers, a threaded sleeve, a third driving motor and a grinding wheel, wherein the groove holes are formed in the base, an output shaft of the first driving motor is vertically upward and connected with a screw rod A, the threaded bushing is arranged on the screw rod A in a threaded mode, the two sets of bearing seats are fixedly arranged on the upper surface of a machine table, and the bearing seats are further rotationally provided with the clamping threaded couplers. According to the device, movement and fixation can be freely switched, on the one hand, the stability of the device during production and processing can be improved, and on the other hand, the situation that universal wheels are scrapped due to the fact that the universal wheels are under stress for a long time can be prevented, and the service life of the universal wheels is prolonged; and meanwhile, omni-directional grinding can be carried out on the rotating shaft in the rotating process of the rotating shaft, and therefore the burring effect on the rotating shaft can be improved, and the situation that parts of the rotating shaft are too thick or too thin in the grinding process of the rotating shaft can be effectively avoided.

Owner:李晔

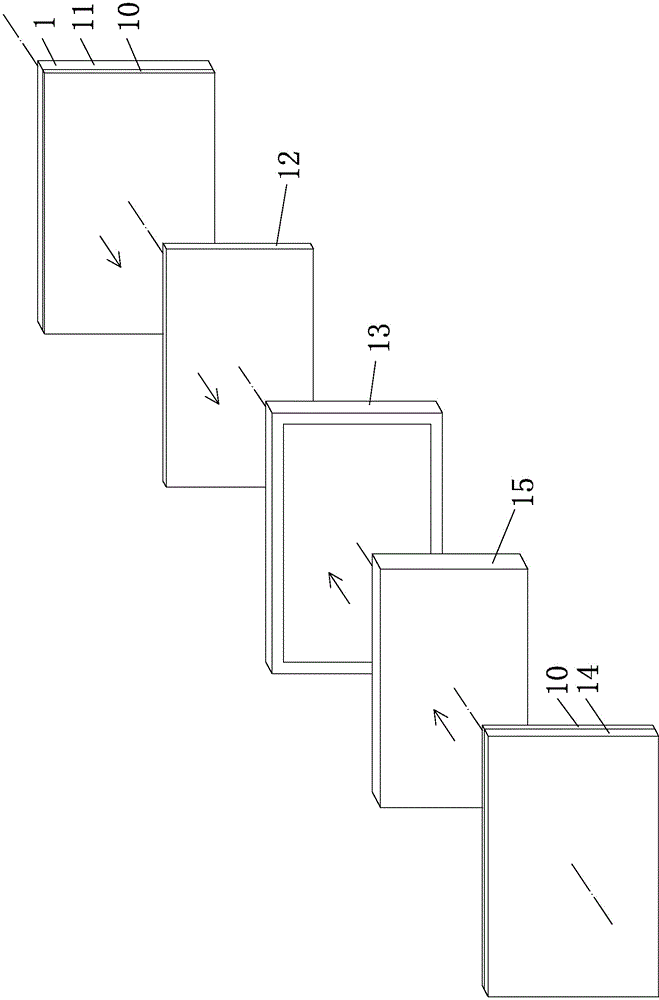

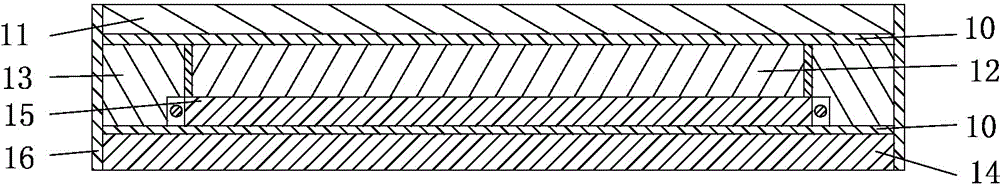

Integrated fully-sealed liquid crystal screen and manufacturing process for same

ActiveCN104679339AScreen thickness is light and thinGood solid fluidityNon-linear opticsInput/output processes for data processingLiquid-crystal displayGlass cover

The invention discloses manufacturing process for an integrated fully-sealed liquid crystal screen. Components which are sequentially arranged are laminated into a whole through a solid ultraviolet flexible adhesive, wherein the components comprise screen protecting glass, a liquid crystal screen set, a support frame and a rear glass cover plate, wherein edge lighting type backlight module is nested in the support frame. The integrated fully-sealed touch and display screen manufactured by the process is waterproof, damp-proof and ultrathin, all gaps of the screen protecting glass or the touch screen set, a liquid crystal display screen set and the side lighting type backlight module are eliminated, image definition is improved, and brightness can be reduced to achieve a remarkable energy-saving effect.

Owner:OPTON (SHUNCHANG) OPTICS CO LTD

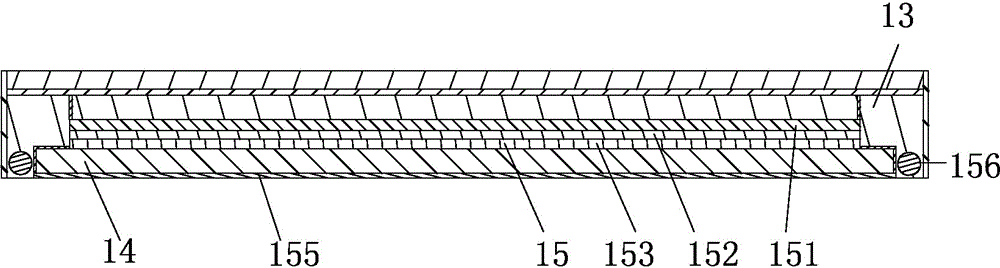

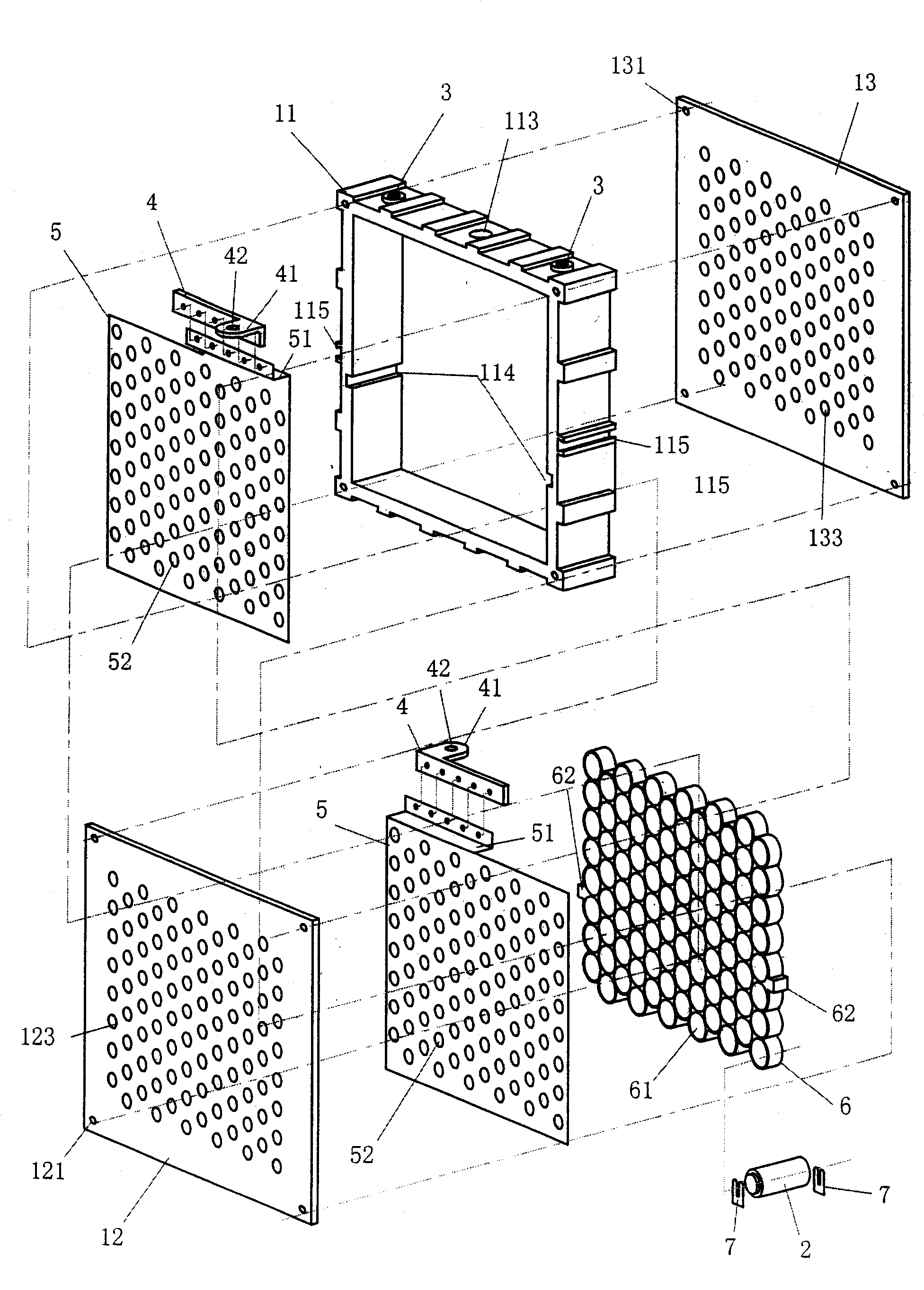

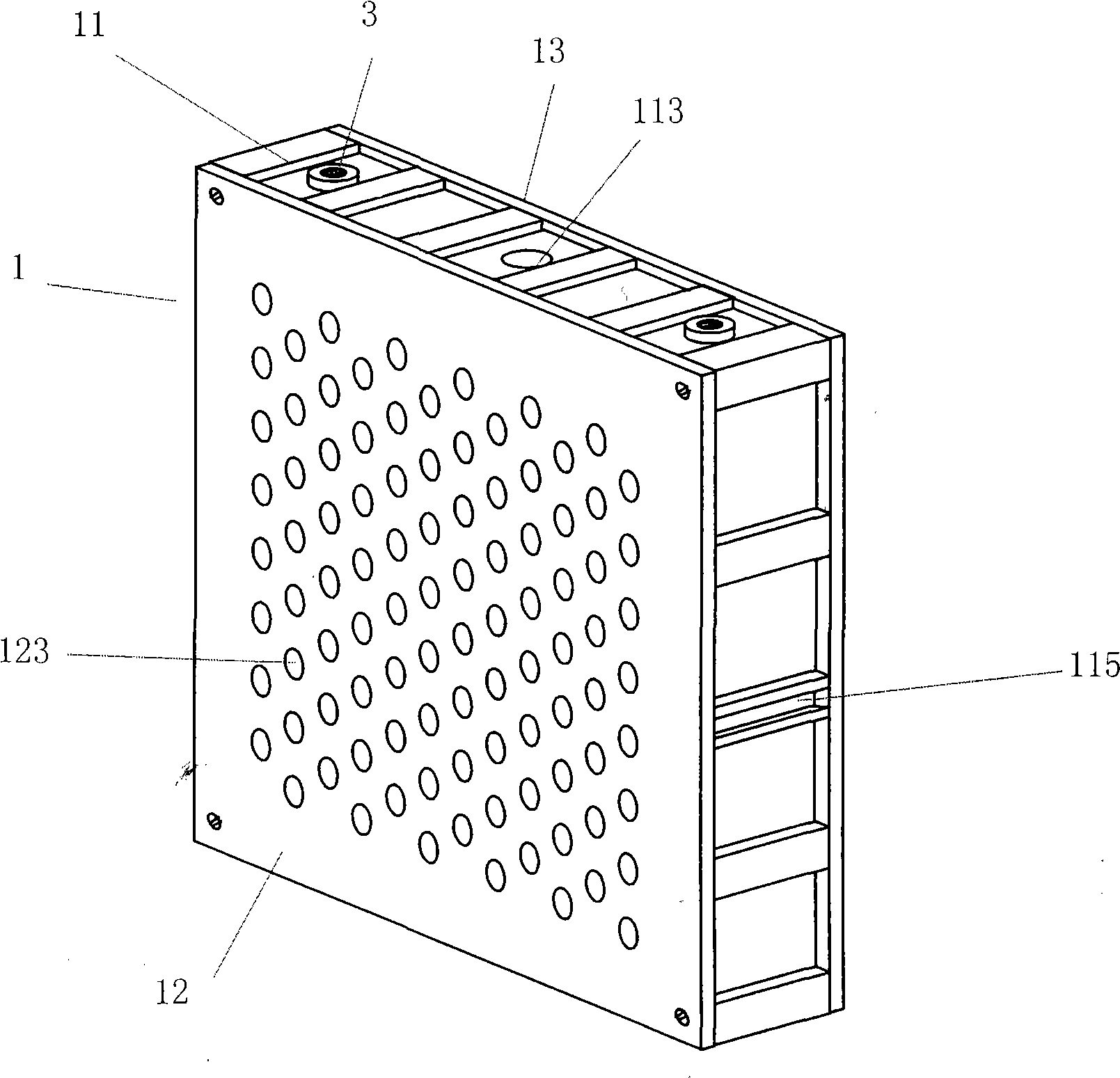

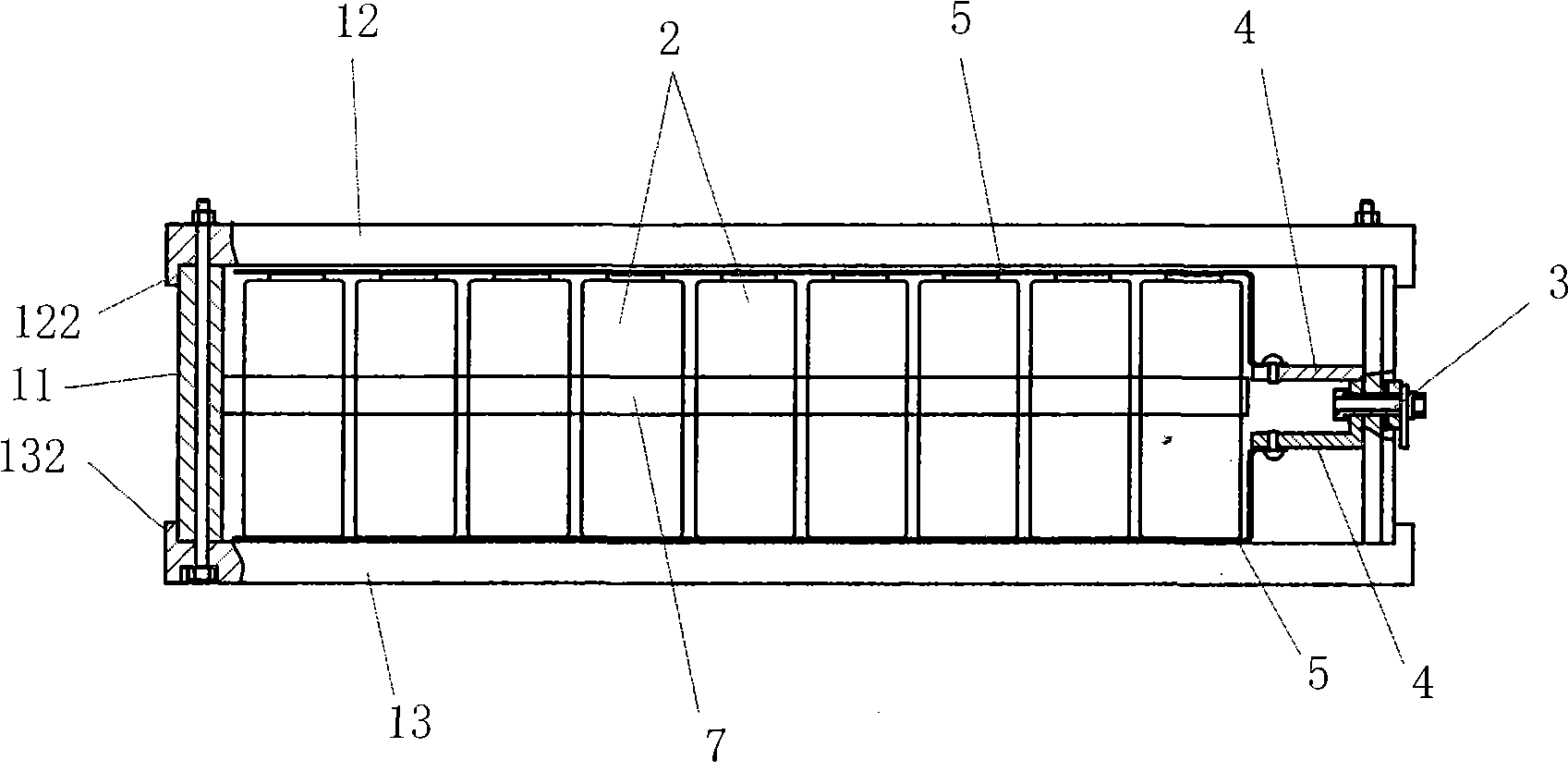

Automobile-used power cell module and manufacturing method thereof

ActiveCN101521269AAvoid scrappingImprove productivityPrimary cell to battery groupingPrimary cell maintainance/servicingProduction rateElectrical battery

The invention relates to a cell device, in particular to an automobile-used power cell module with low maintaining cost. The automobile-used power cell module comprises a cell box, a plurality of cells installed in the cell box, anode and cathode output brass bolts arranged on the cell box, current collectors respectively fixed on the anode and cathode output brass bolts, as well as bus boards which make the anodes and the cathodes of a plurality of cells connected with the current collectors on the anode and cathode output brass bolts. The automobile-used power cell module is characterized in that a plurality of cells are small-capacity cells, and the cell box consists of a box frame and upper and lower box covers which are detachably and respectively arranged at the two ends of the box frame. The small-capacity cells are mechanized winding cells with high production rate, good consistency and lower price. The invention uses the cell box the box cover of which can be opened, if certain cell is out of work, the cell box can be opened for replacing, thereby avoiding the disability of the whole module and reducing the maintaining cost during the running process.

Owner:上海瑞旋新能源科技有限公司

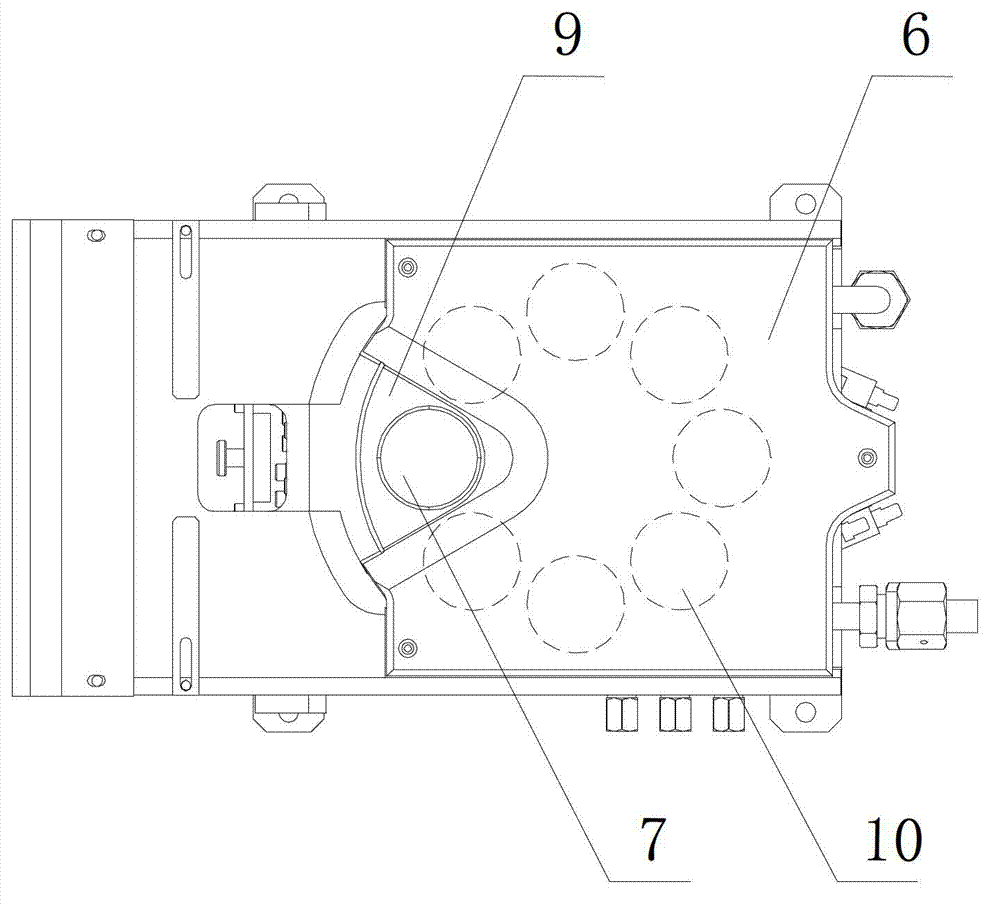

Machine and turntable clamp for four-axis processing center

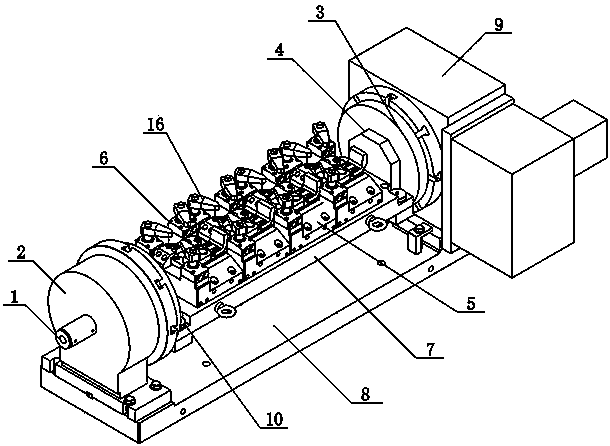

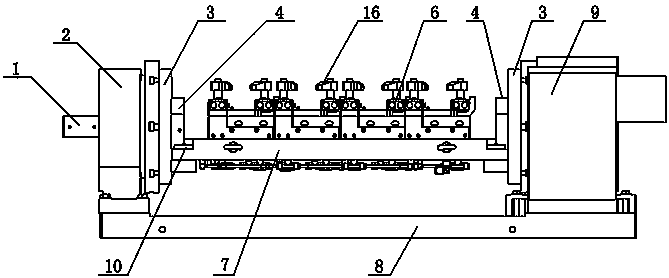

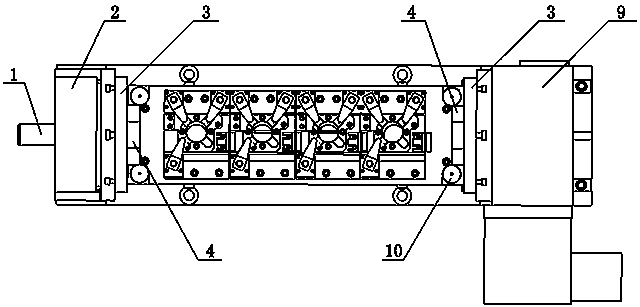

InactiveCN104325324ASimple changeover operationQuick changeoverMeasurement/indication equipmentsPositioning apparatusProduction lineModular design

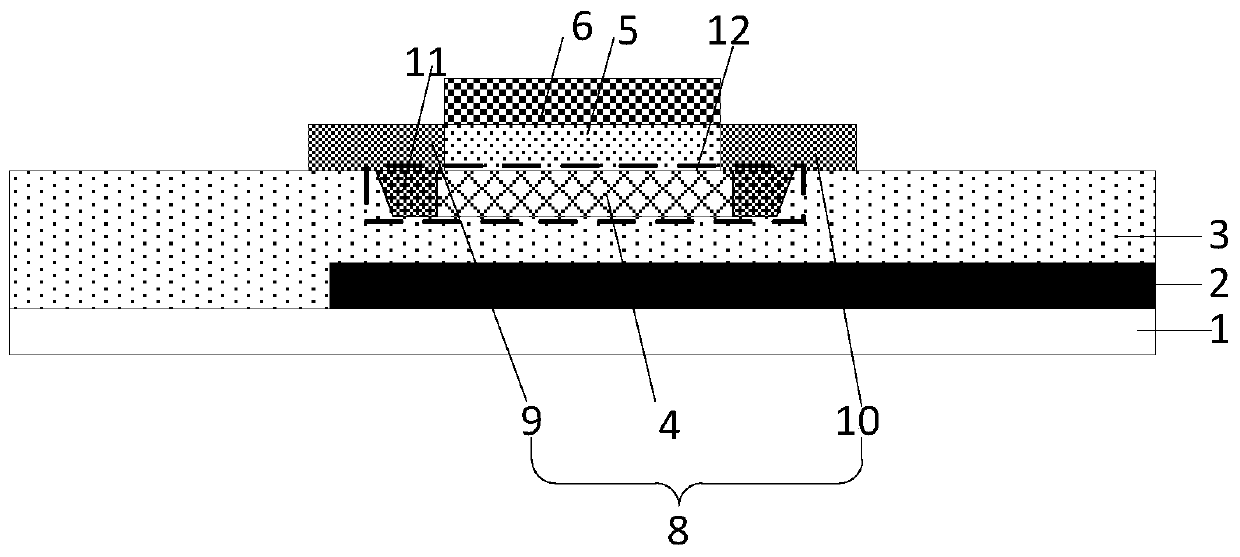

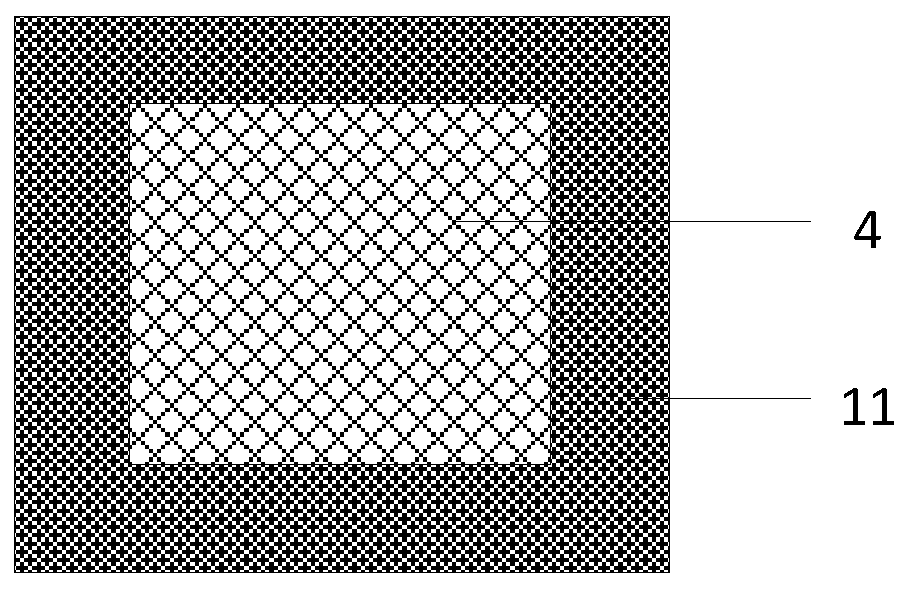

The invention relates to a machine and turntable clamp for a four-axis processing center. The clamp comprises a clamp bottom plate (8), a tail seat (2), a dividing head (9), an oil / gas path distributor component (1), L-shaped plates (4), a bridge plate (7) and clamp location clamping units, wherein the tail seat (2) and the dividing head (9) are fixedly arranged on the clamp bottom plate (8); the oil / gas path distributor component (1) is arranged on the outer side face of the tail seat (2); two L-shaped plates (4) are oppositely arranged and are respectively connected with the tail seat (2) and the dividing head (9) by a transition plate (3); two ends of the bridge plate (7) are respectively connected with the L-shaped plates (4); a plurality of clamp location units are provided and are uniformly spaced and fixed on the bridge plate (7) in sequence. The machine and turntable clamp has the advantages that a modular design and a ball lock location system are used for realizing fast changing the clamp when the type of a production line is changed; hydraulic clamping is used, so that a reliable clamping force is provided; an airtight detection technology and a fast assembling / disassembling limit block are used, so that an error proofing function is available.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

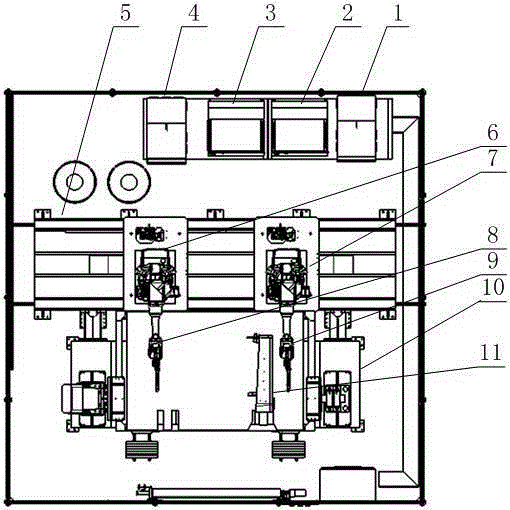

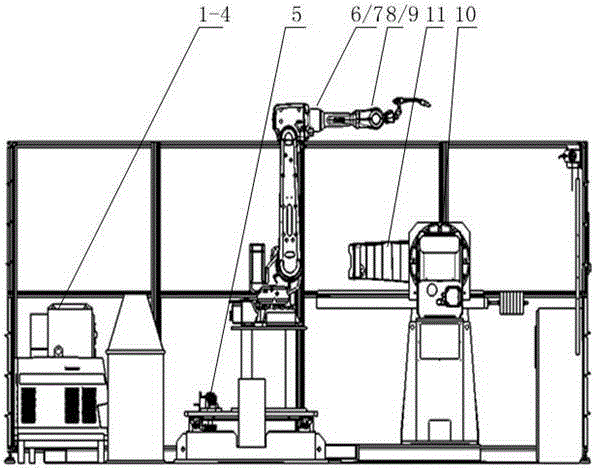

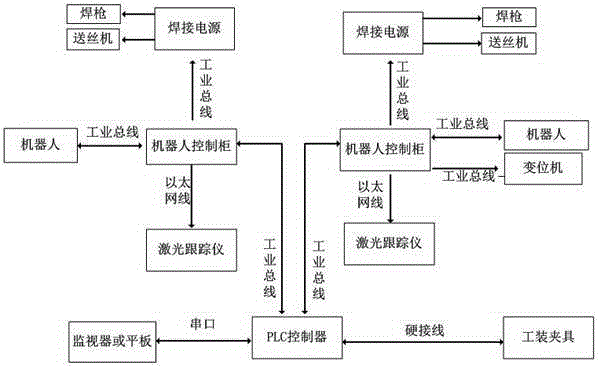

Double-robot working station for double-weld-joint arc welding

ActiveCN105195864AAvoid scrappingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesSynchronous controlEngineering

The invention discloses a double-robot working station for double-weld-joint arc welding, and belongs to the field of intelligent welding robots. The double-robot working station is provided with a double-joint double-arc welding system, the system is provided with two robots and performs synchronous control, and therefore the problems that when irregular weld joints in a symmetrical weld joint box segment component are welded manually, the welding quality stability is poor, welding deformation is large, the welding connector quality is instable, and the part machining cycle is long are solved.

Owner:JIANGXI HONGDU AVIATION IND GRP

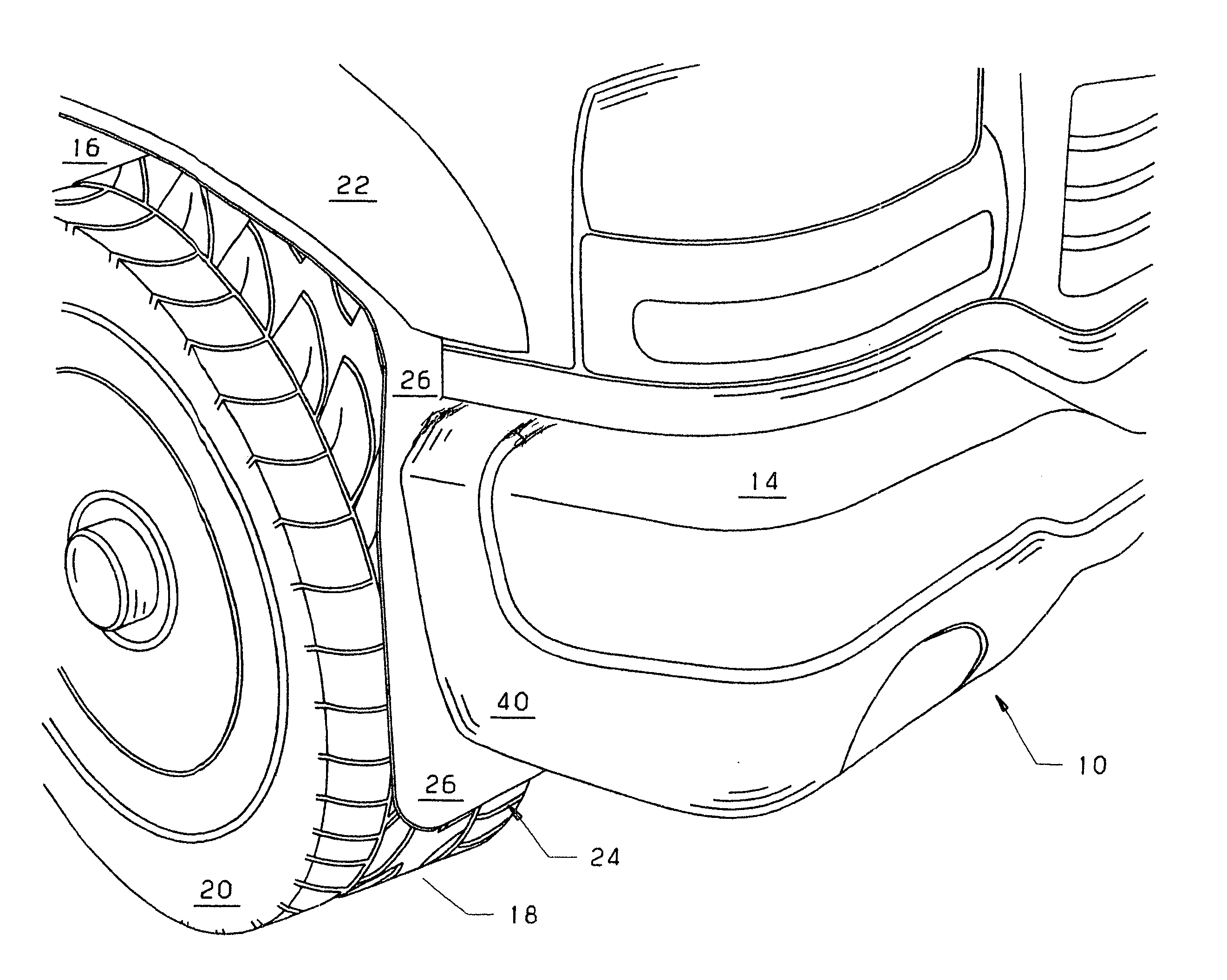

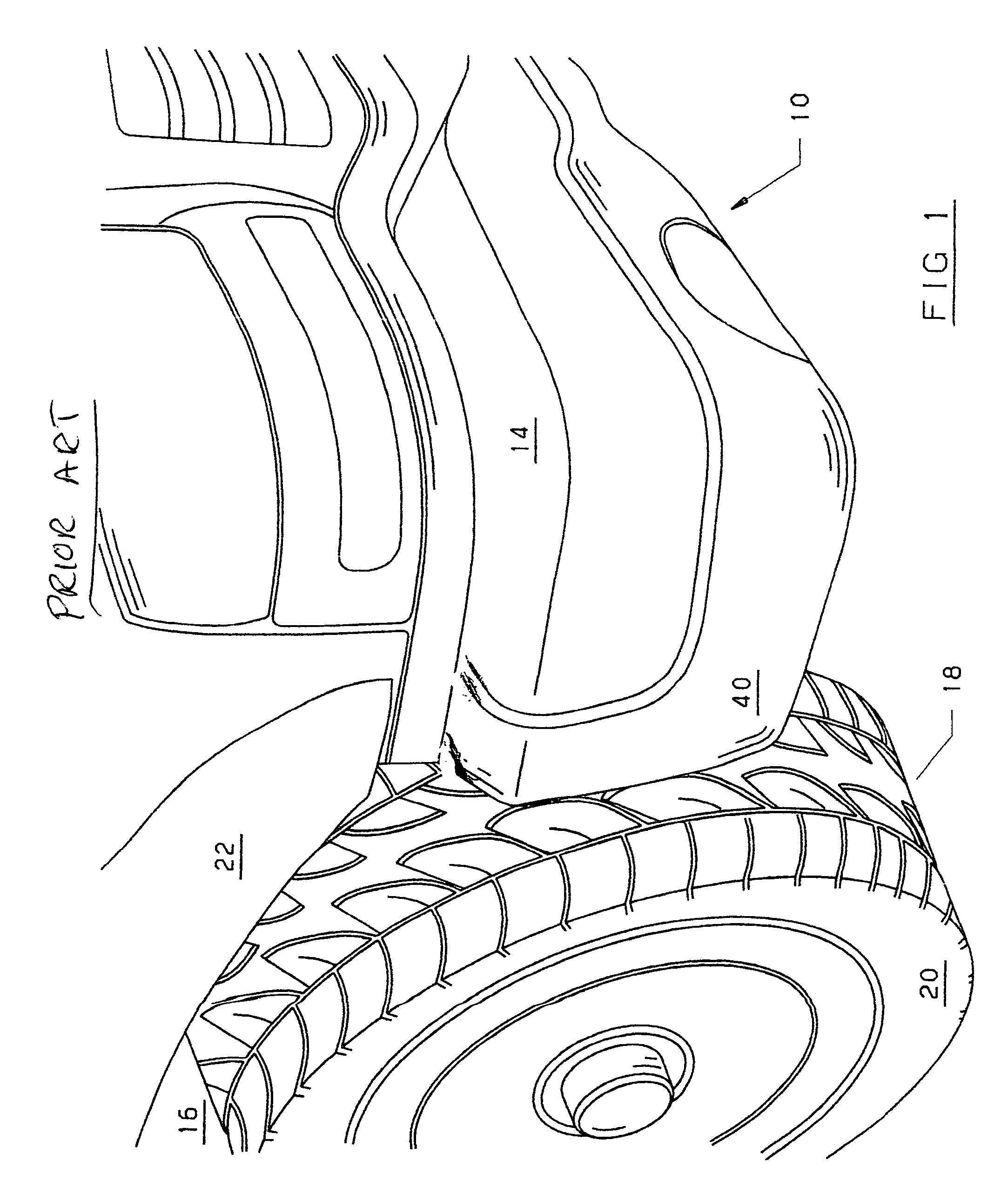

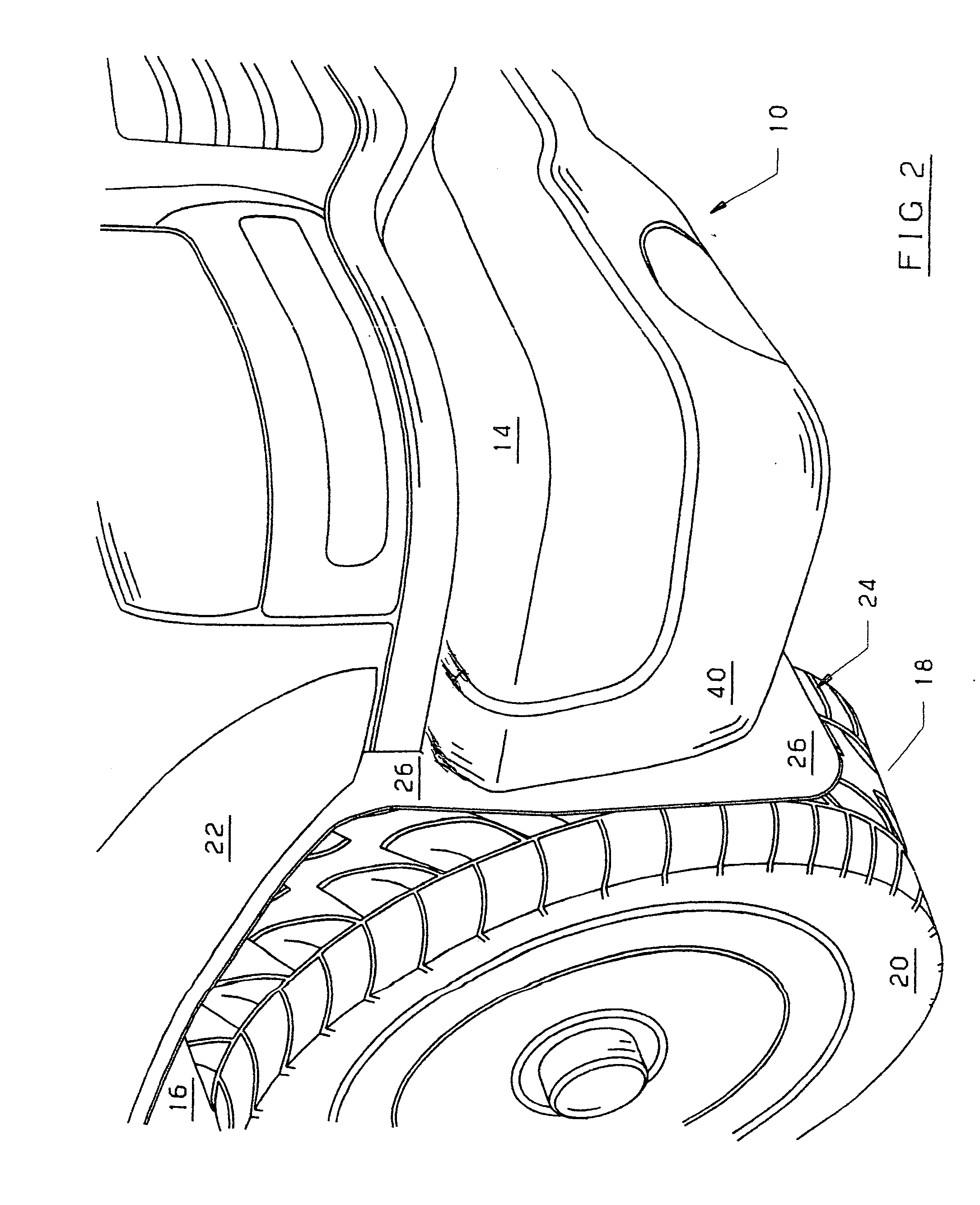

Flexible truck fender flare with integral front and rear mud flaps

InactiveUS20050275212A1Interference be notAvoid scrappingSuperstructure subunitsRoad debrisEngineering

The present invention is drawn to an integrally formed flat flexible fender flare and mud flap assembly made to be easily fitted on existing wheel wells, even ones having existing factory flare sections, which will prevent mud and road debris from being thrown unto the truck body sections such as the front end bumper and the running board.

Owner:ANGELAITIS ROBERT J

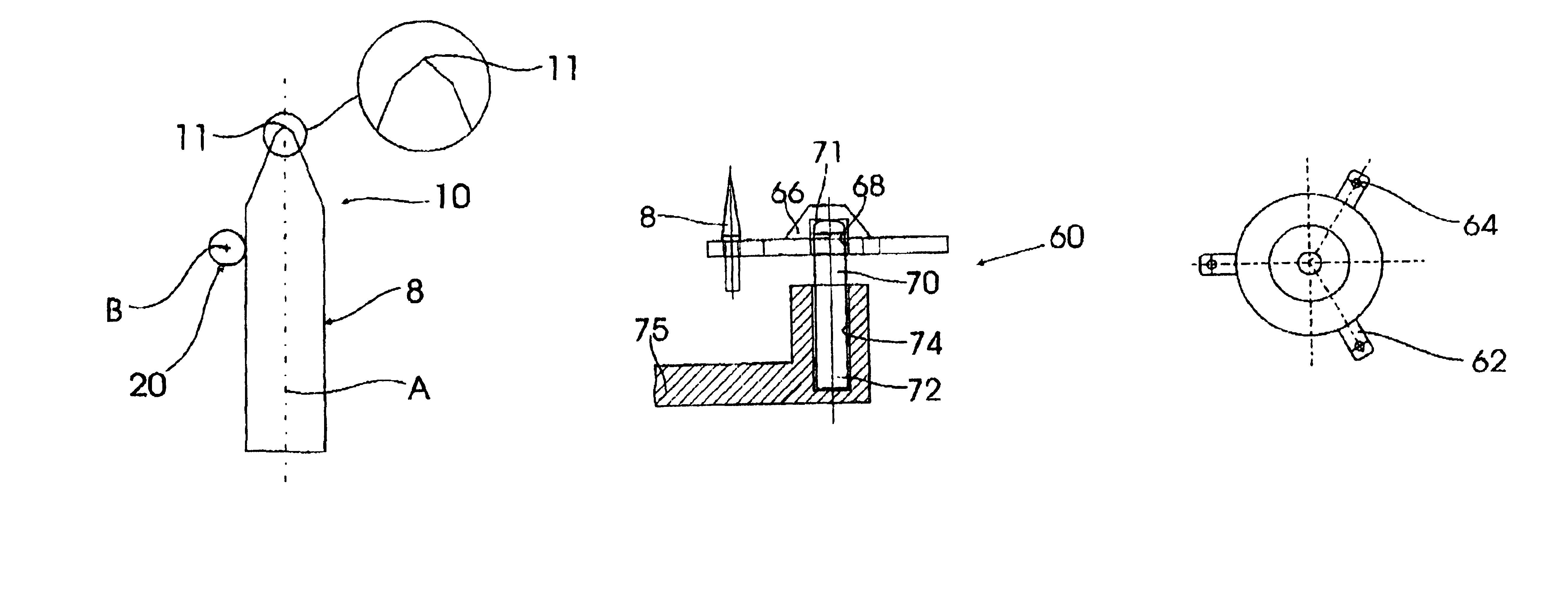

Device for thermal treatment of substrates

InactiveUS6953338B2Avoid supportAvoid scrappingCharge supportsSemiconductor/solid-state device manufacturingThermal treatmentSemiconductor

The aim of the invention is to reduce the formation of scratches in a device for the thermal treatment of substrates, in particular, semiconductor substrates, in a chamber in which the substrate is placed upon support elements. According to the invention, said aim is achieved by means of displaceable support elements.

Owner:MATTSON TECHNOLOGY +1

Electroless copper plating method for PCBs (printed circuit boards) with high aspect ratios

InactiveCN103228112AAvoid scrappingAvoid the problem of copper erosionPrinted element electric connection formationCopper platingElectroplating

The invention discloses an electroless copper plating method for PCBs with high aspect ratios. According to the method, the intervals between adjacent PCBs with high aspect ratios are adjusted, and a plug board rack is enabled to swing in a an electroless copper plating potion in a direction perpendicular to the board surface, so that bubbles are discharged from holes in the PCBs with high aspect ratios; then electroless copper plating processes are performed twice on the PCBs with high aspect ratios, and total board electroplating flashing is performed on the PCBs after the primary electroless copper plating; accordingly, the thickness of copper on the hole wall is increased; and then the secondary total board plating is performed to thicken the copper. Compared with the prior art, the method effectively solves the problem that the circuit boards are scrapped due to copper absence in the holes caused by the fact that the bubbles in the holes cannot be cleared out or potion exchange in the holes is poor in the electroless copper plating process; and further, the total board electroplating flashing is adopted after the primary electroless copper plating process, therefore, the problem that original copper is corroded away in the secondary electroless copper plating pretreatment is solved, and accordingly, production scrapping is reduced effectively, and the manufacturing rework cost is reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

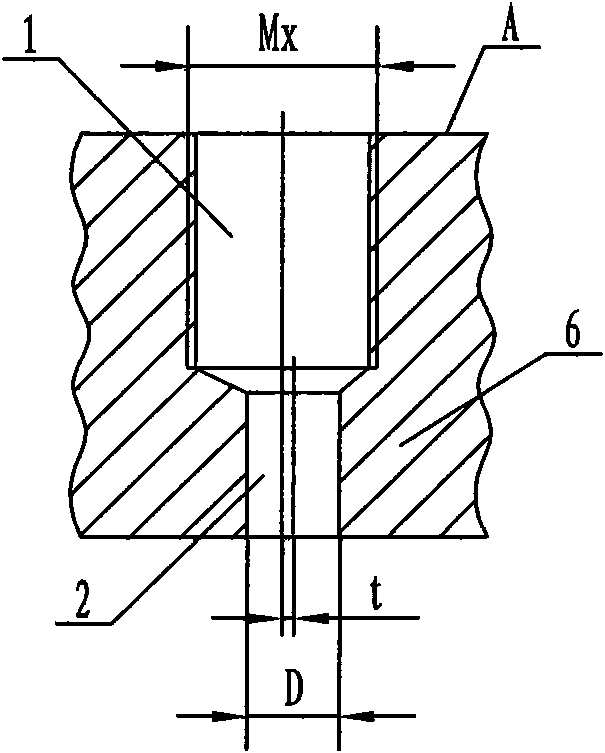

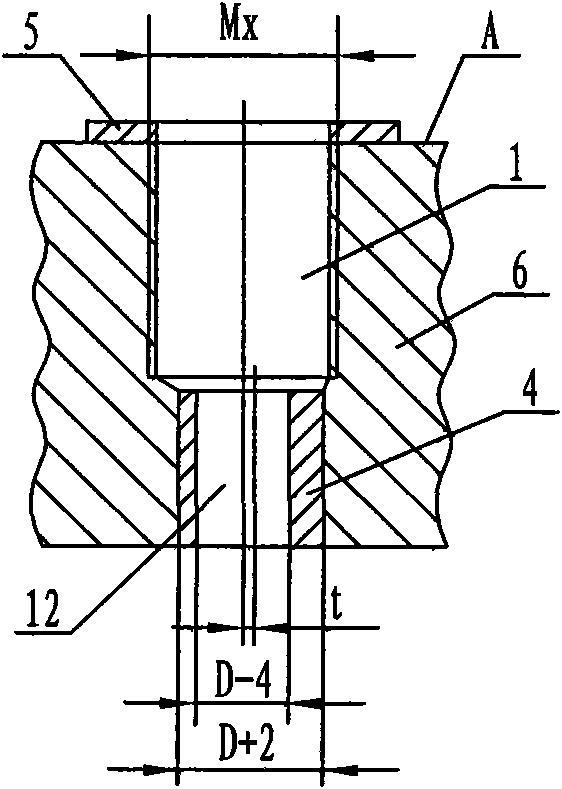

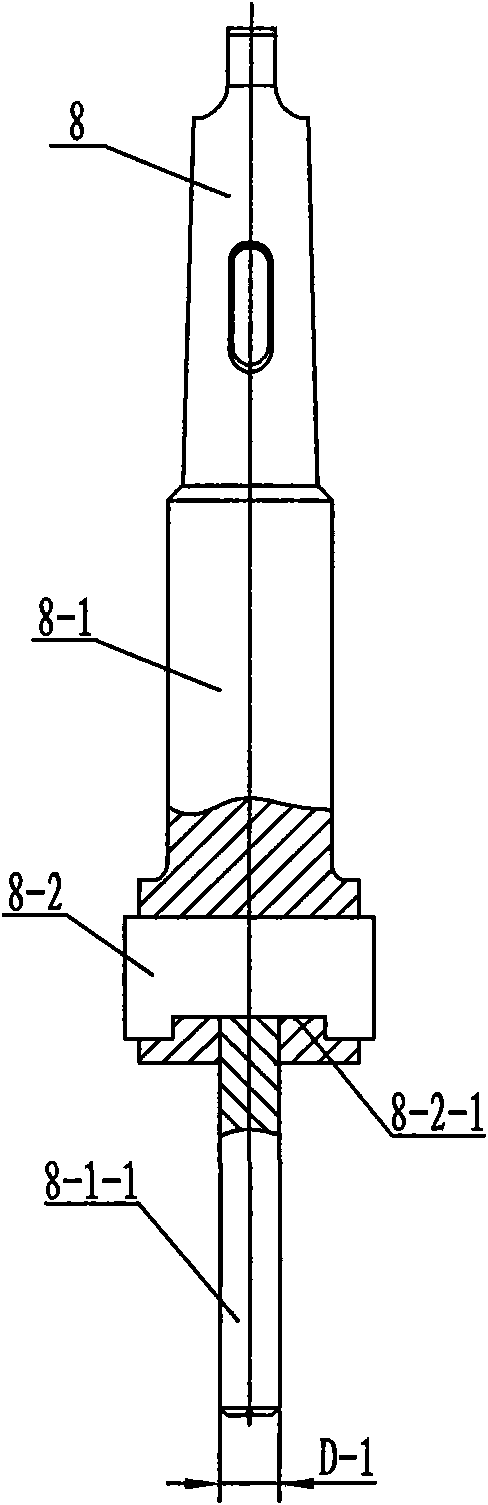

Method for repairing cylinder screw holes and special scraper and screw tap for implementing method

InactiveCN101941131AAvoid scrappingAccuracy requirements metThread cutting toolsTransportation and packagingEngineeringDrilling machines

The invention provides a method for repairing cylinder screw holes and a special scraper and a screw tap for implementing the method and relates to the method for repairing the cylinder screw holes, which solves the problem that a cylinder is scrapped owing to great repair processing difficulty of the cylinder screw holes and difficulty in achieving repair precision. The method comprises the following steps: 1. installing a radial drilling machine; 2. broaching; 3. boring holes; 4. scraping threaded holes; and 5. tapping. In the scraper, an upper end of a scraper blade is equipped with a groove matched with a shoulder, and the external diameter of the cutting edge of the scraper blade is Mx+1. In the screw tap, a tip is abutted with the center of a wrench, a connecting rod is symmetrically equipped with two first locating key slots, an upper end surface of a screw tap sleeve is symmetrically equipped with two second locating key slots width of which is equal to that of the first locating key slots, and two locating keys are respectively arranged in the first locating key slots at two sides of the connecting rod and the second locating key slots at two sides of the upper end surface of the screw tap sleeve. In the invention, the special scraper and the screw tap are used for processing the cylinder screw holes through the radial drilling machine so that the repaired cylinder screw holes conform to the precision requirement of the cylinder screw holes, thus avoiding the cylinder being scrapped.

Owner:HARBIN TURBINE

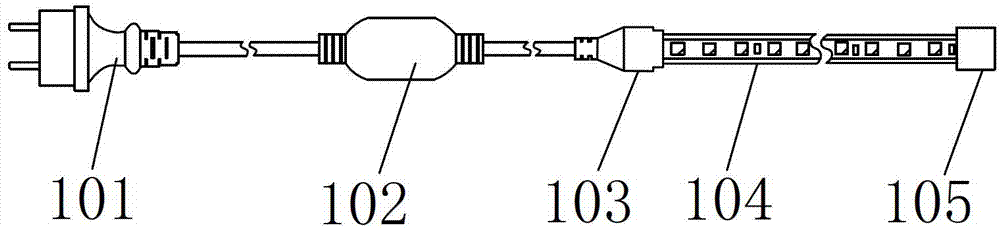

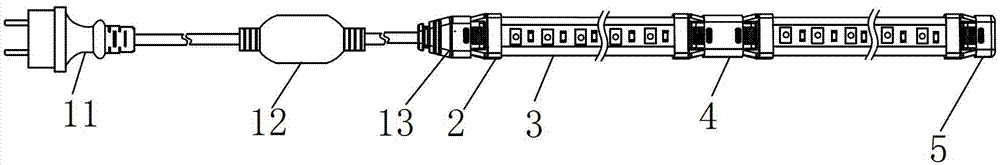

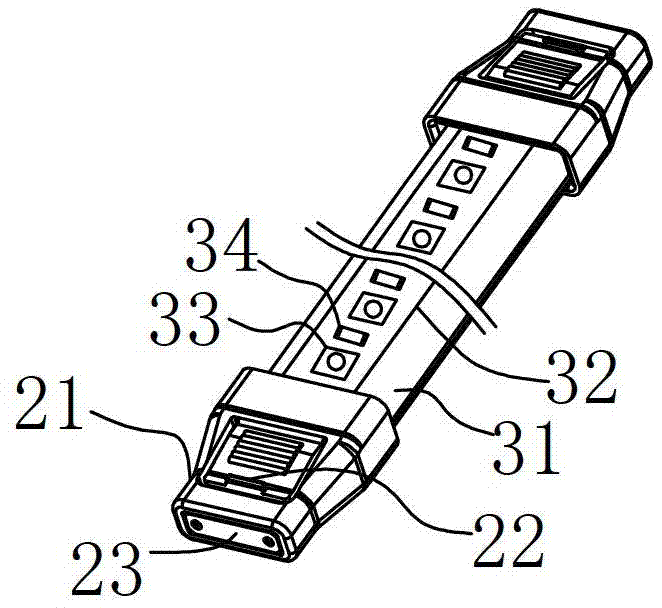

High-voltage flexible LED patch lamp tape and manufacturing technology and mounting method thereof

ActiveCN103398317ASimple circuit structureImprove reliabilityPoint-like light sourceElongate light sourcesEngineeringHigh pressure

The invention discloses a high-voltage flexible LED patch lamp tape and a manufacturing technology and a mounting method thereof. The high-voltage flexible LED patch lamp tape is mainly composed of one lamp tape unit or more than one lamp tape units connected back and forth. Each lamp tape unit comprises a transparent flexible casing and a double-sided flexible strip circuit board encapsulated in the transparent flexible casing. The front and rear ends of each lamp tape unit are respectively sleeved with an end cap, and more than one lamp tape unit can be connected back and forth through connecting parts matched with the end caps. Compared with the prior art, the high-voltage flexible LED patch lamp tape has the advantages that the high-voltage flexible LED patch lamp tape is light in weight, small in size, process saving, safe and reliable, convenient to mount, and the like.

Owner:GUANGDONG COOPER OPTOELECTRONICS INC

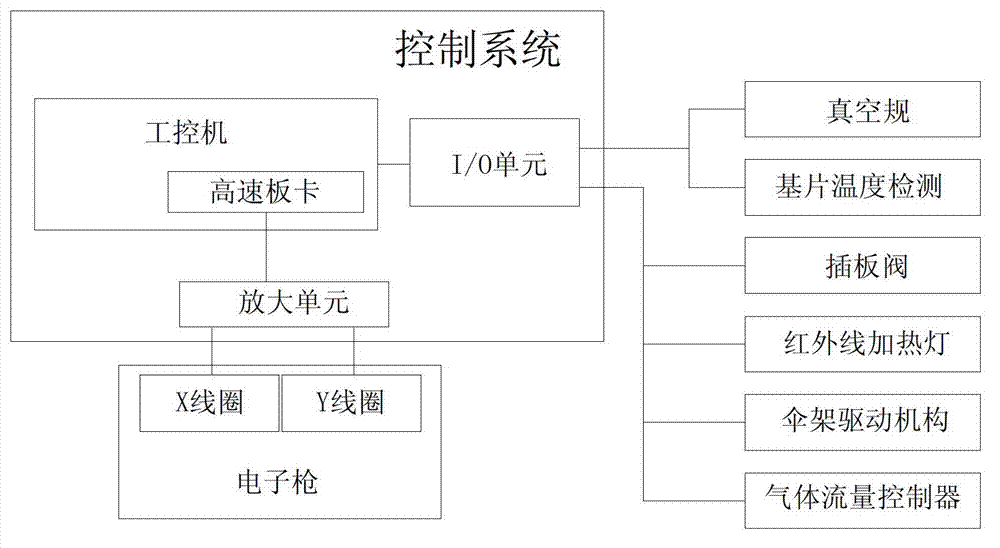

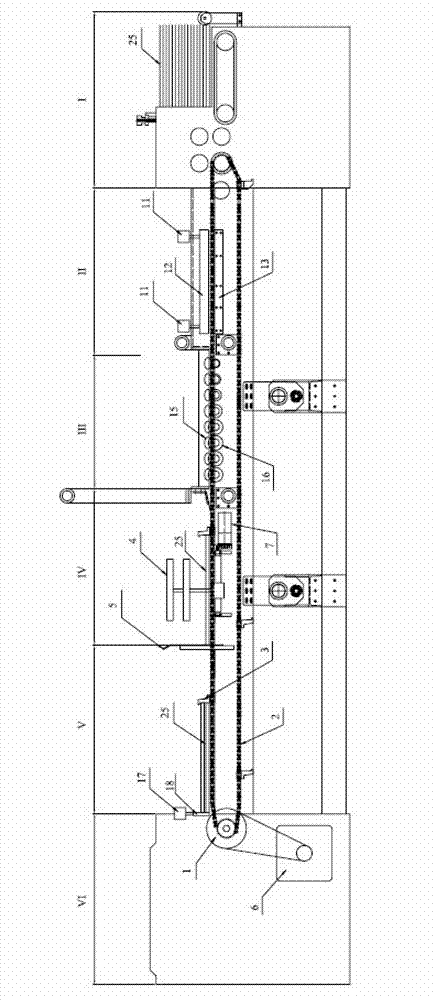

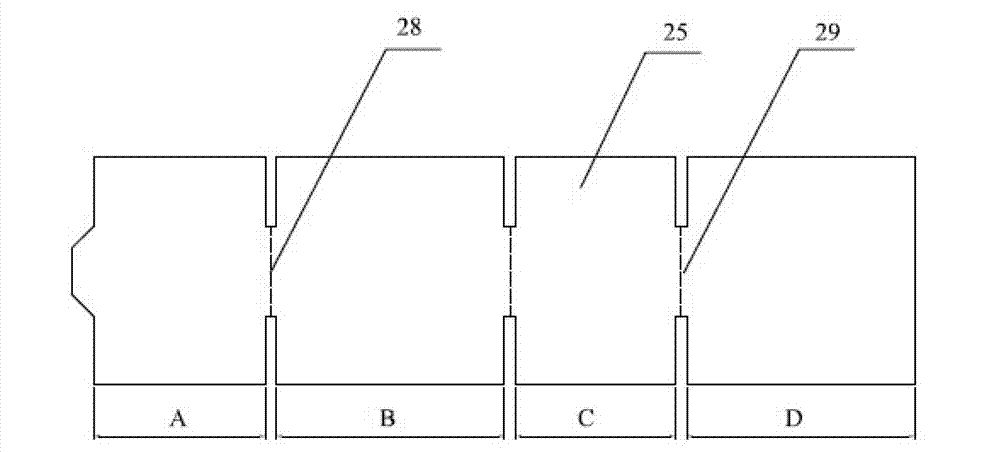

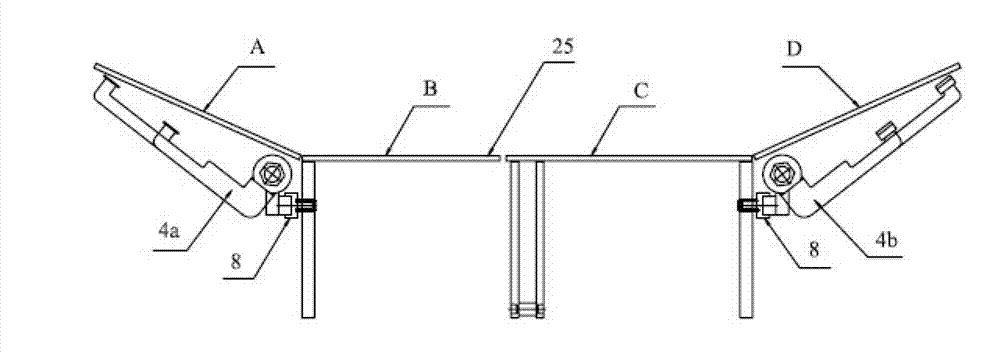

Vacuum coating device, vacuum coating control system and control method

ActiveCN102787299AAvoid damageAvoid scrappingVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses a vacuum coating device, a vacuum coating control system and a control method. The vacuum coating device comprises a vacuum chamber, a vacuum pump and a cryogenic pump. The top of the vacuum cavity is provided with an umbrella frame, and a substrate to be coated is placed on the umbrella frame; the vacuum cavity is provided with an e-type electron gun, which is provided with crucibles in a circle and capable of rotating around the center of the circle; a crucible is provided with a coating material; a baffle is arranged above a crucible heating position; and a pipe connecting the cryogenic pump and the vacuum chamber is provided with a flapper valve. According to the invention, a zoning control principle is applied to trajectory control of electron beam from the electron gun; current frequencies of an X axis scanning coil and a Y axial scanning coil in each zone are respectively controlled, thereby further controlling scan time of the electron beam in each block on the surface of the coating material. The invention avoids pit phenomenon caused by uneven evaporation of an oxide material, and effectively prevents crucible damage or substrate scrapping.

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

Carton manufacturing device

ActiveCN103029323APrevent crashPrevent overrunningBox making operationsPaper-makingProduction lineCardboard

The invention relates to a carton manufacturing device. A chain driving shaft and a manipulator are respectively controlled by different servo motors, and a line pressing part and an extrusion part are added to carry out secondary line pressing and extrusion processing on cardboards; and meanwhile, a gap adjusting part is added and comprises a carton aligning device for carrying out alignment processing on the cardboards, and a nail wire conveying mechanism is added in a box nailing and sticking part. According to the device, the cost of the whole production line is greatly reduced, so that the device is suitable for being installed and used by small-and-medium-sized enterprises; and the control accuracy is high, so that the pass rate of the manufactured carton is greatly increased, and the quality of the carton is strictly ensured.

Owner:无锡唐诚机械有限公司

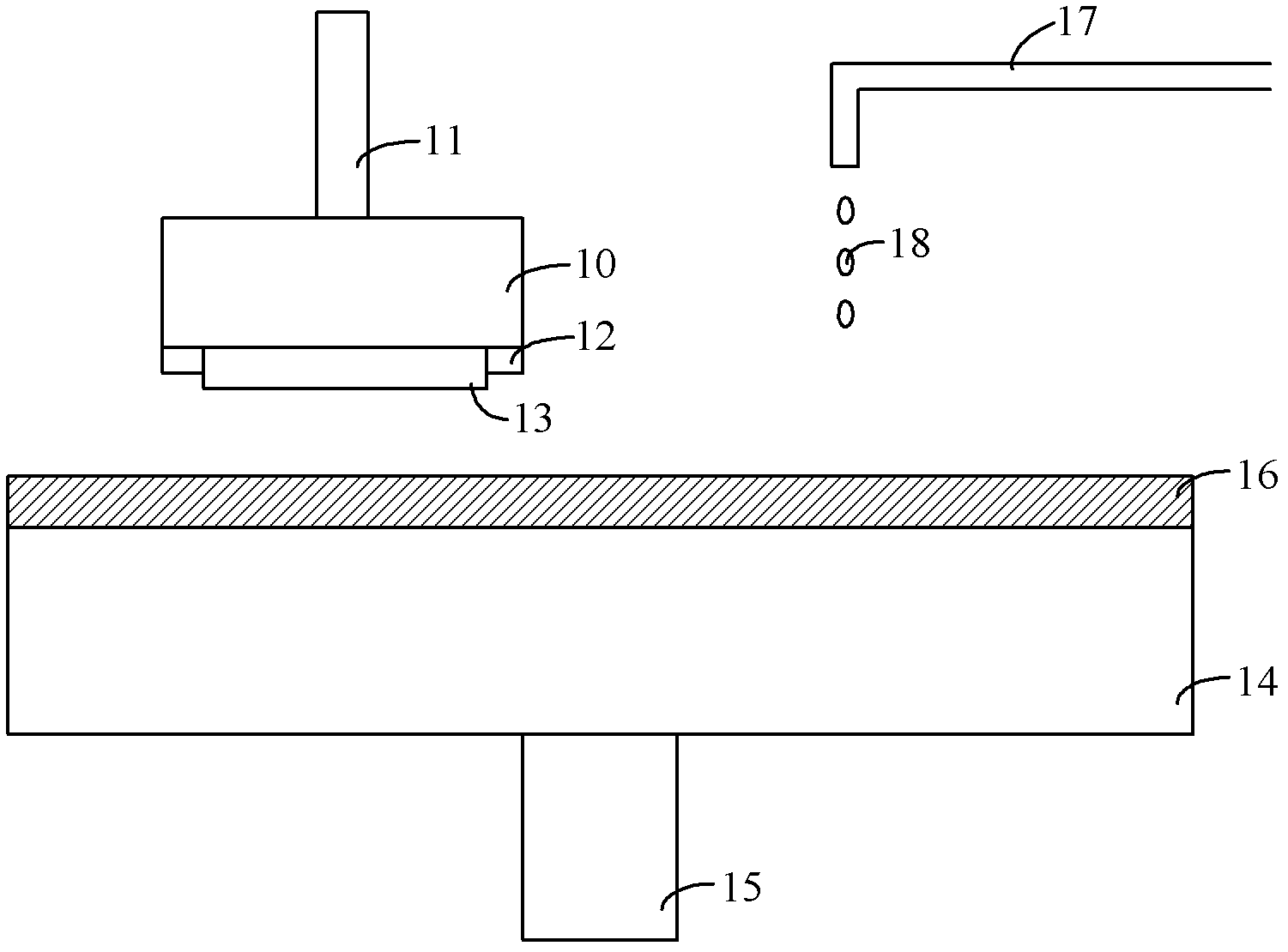

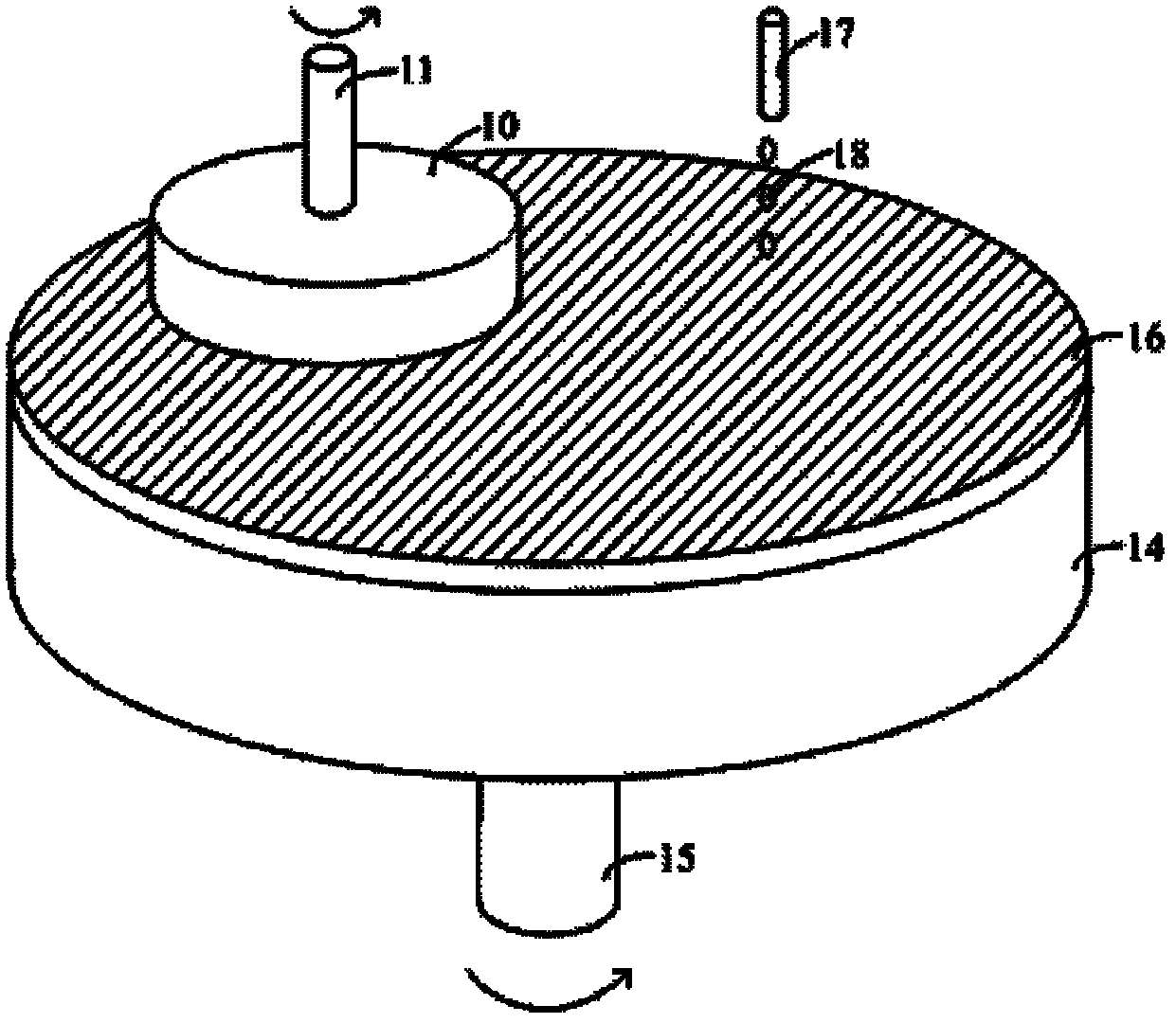

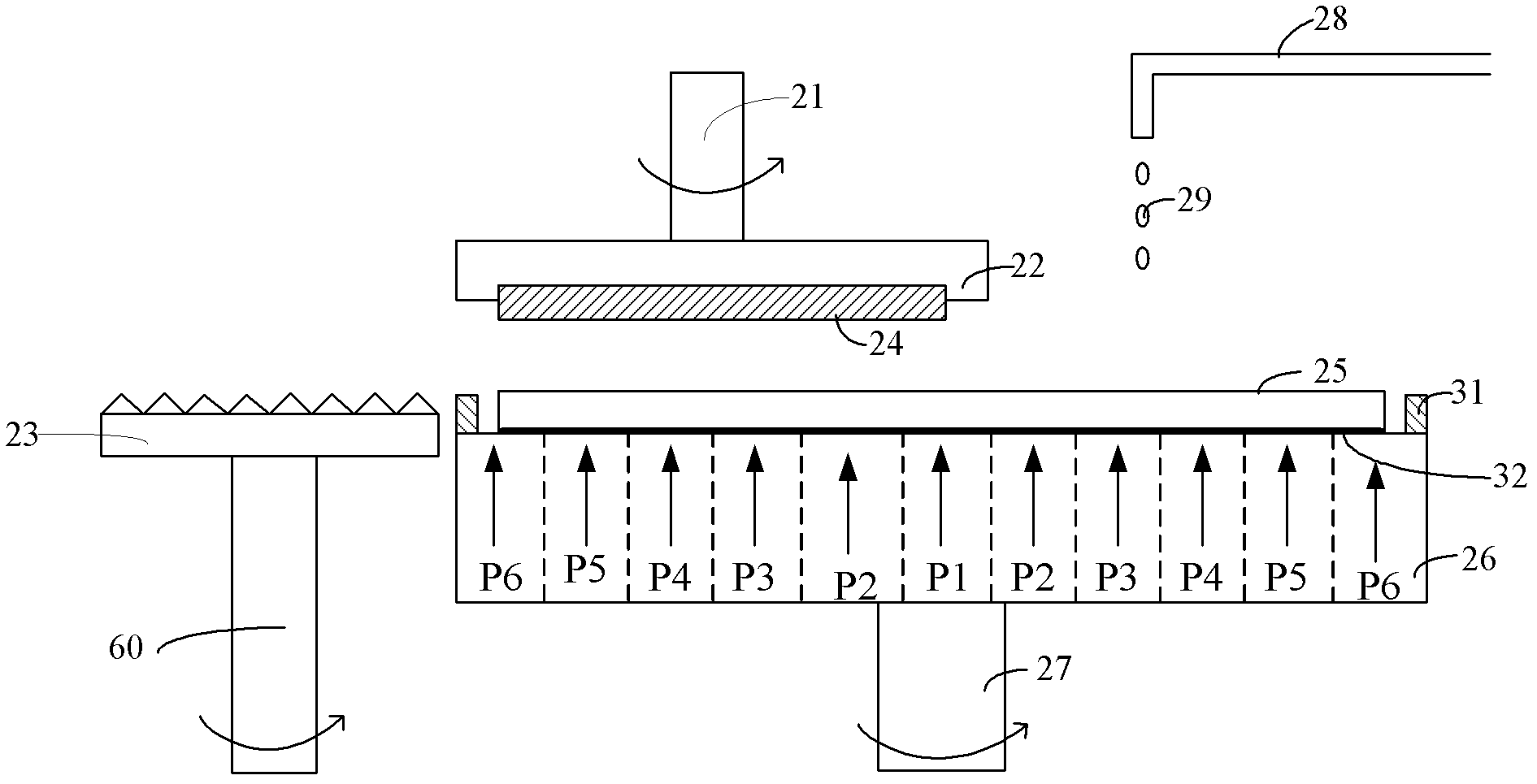

Chemical mechanical lapping device and system

ActiveCN103100966AReduce layoutGuaranteed stabilitySemiconductor/solid-state device manufacturingLapping machinesElectrical and Electronics engineeringRaw material

The invention provides a chemical mechanical lapping device and a system. The chemical mechanical lapping device comprises a wafer supporting seat, a lapping pad, a lapping pad fixed piece, a shaft lever and a raw material providing device, wherein the wafer supporting seat is used for supporting a wafer to be lapped, and a surface to be lapped of the wafer is upward, the lapping pad is arranged on the upper part of the wafer supporting seat, a lapping surface of the lapping pad is downward and is opposite to the surface to be lapped of the wafer, the area of the lapping area of the lapping pad is less than the area of the surface to be lapped of the wafer, the lapping pad fixed piece is fixed on the upper portion of the lapping pad and for fixing the lapping pad, the shaft lever is arranged on the upper part of the lapping pad fixed piece and for driving the lapping pad fixed piece and the the lapping pad to rotate, and the raw material providing device is arranged on the upper part of the wafer supporting seat for providing lapping liquids for the surface to be lapped of the wafer. According to the chemical mechanical lapping device and the system, wafers with diameters of 450mm or more can be lapped simply and accurately.

Owner:SEMICON MFG INT (SHANGHAI) CORP

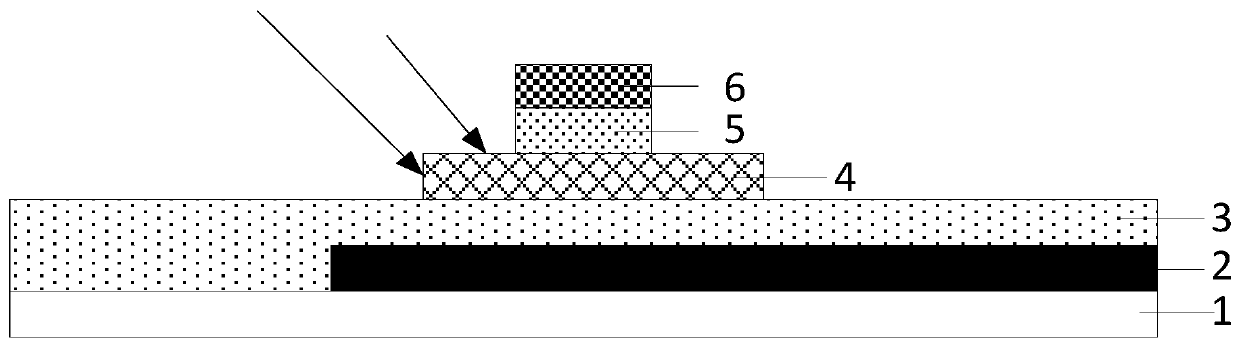

Array substrate, preparation method thereof and display panel

ActiveCN110911424AImprove job stabilityAvoid display unevennessTransistorSolid-state devicesPhysicsThin membrane

The invention discloses an array substrate, a preparation method thereof and a display panel, which are used for preventing a semiconductor region of an active layer of a thin film transistor from being illuminated, improving the working stability of the thin film transistor, avoiding uneven display pictures and improving the display effect. The array substrate comprises a substrate body, a shading layer located on the substrate body, a buffer layer located on the shading layer, an active layer located on the buffer layer and a shading part. The buffer layer is provided with a groove. The active layer includes a semiconductor region, and a first conductive region and a second conductive region connected to the semiconductor region. The semiconductor region and the shading part fill the groove. The orthographic projection of the shading part on the substrate is annular, the side surface of the semiconductor region is completely surrounded by the shading part, and the first conductor region and the second conductor region are located above the shading part and the semiconductor region. The orthographic projection of the shading layer on the substrate covers the orthographic projection of the semiconductor region on the substrate.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com