Machine and turntable clamp for four-axis processing center

A four-axis machining center and fixture technology, used in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problem of inability to use high-speed and high-feed processing, unstable parts processing quality, and unstable fixture input air pressure and other problems, to achieve the effect of improving the utilization rate of the machine tool, selecting the clamping point reasonably, and shortening the clamping time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

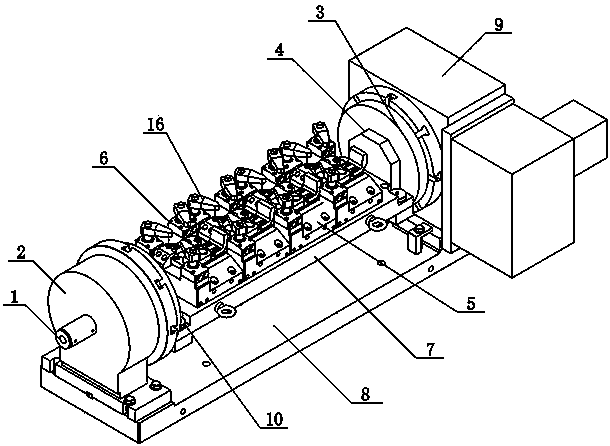

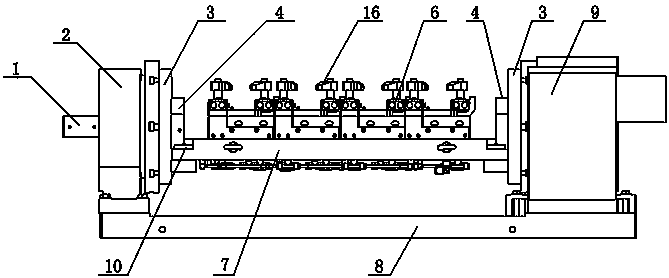

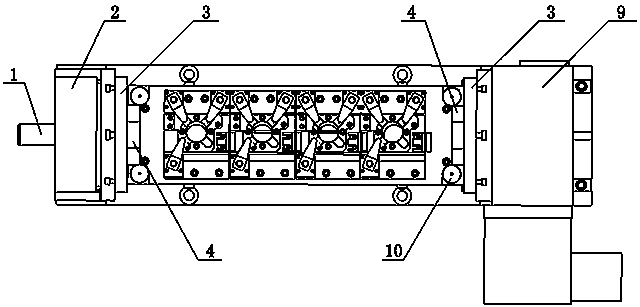

[0020] like figure 1 , figure 2 and image 3 As shown, a machine-added turntable fixture for a four-axis machining center includes a fixture base plate 8, a tailstock 2, an indexing head 9, an oil and air distributor assembly 1, an L plate 4, a bridge plate 7 and a fixture positioning clamp Tight unit, the tailstock 2 and the indexing head 9 are fixedly installed on the fixture bottom plate 8, the oil circuit and air circuit distributor assembly 1 is installed on the outer surface of the tailstock 2, and the two L plates 4 are arranged opposite to each other, and pass through the transition plate respectively 3. It is fixedly connected with the rotating flange of the tailstock 2 and the indexing head 9. The two ends of the bridge plate 7 are respectively connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com