A bilateral slitting machine for sheet metal which is easy to process

A technology that facilitates processing of sheet metal, applied in metal processing equipment, attachments of shearing machines, shearing devices, etc., can solve problems that affect the normal production of the production line, cannot handle coil materials, and the rigidity of waste materials, etc., to reduce labor intensity and operation difficulty, improve automation level, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

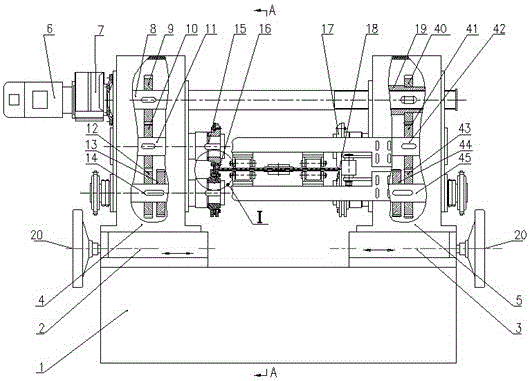

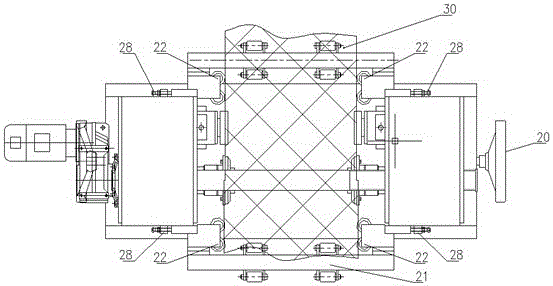

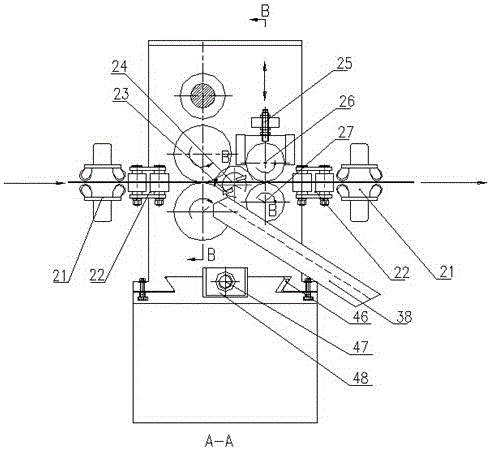

[0019] The present invention is made up of bed 1, left box body 4, right box body 5, transmission mechanism, width adjustment mechanism, shearing mechanism, crushing mechanism, rolling mechanism, front and rear pressure roller device, front and rear side leaning adjustment device, left box The body 4 and the right box body 5 are installed on both sides of the bed 1 respectively.

[0020] Show among the figure, transmission mechanism is made up of motor 6, speed reducer 7, main transmission shaft 8, upper left transmission shaft 11, lower left transmission shaft 14, upper right transmission shaft 42, lower right transmission shaft 45. The motor 6 is connected with the reducer 7 and the main transmission shaft 8 in sequence, and one end of the motor 6, the reducer 7 and the main transmission shaft 8 is installed on the upper end of the left box body 4, and the other end of the main transmission shaft 8 passes through the main transmission spline sleeve 19 It is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com