Lighting equipment

A technology of lighting fixtures and semiconductors, applied in lighting devices, lighting auxiliary devices, fixed lighting devices, etc., can solve the problems of reduced light extraction efficiency and achieve the effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

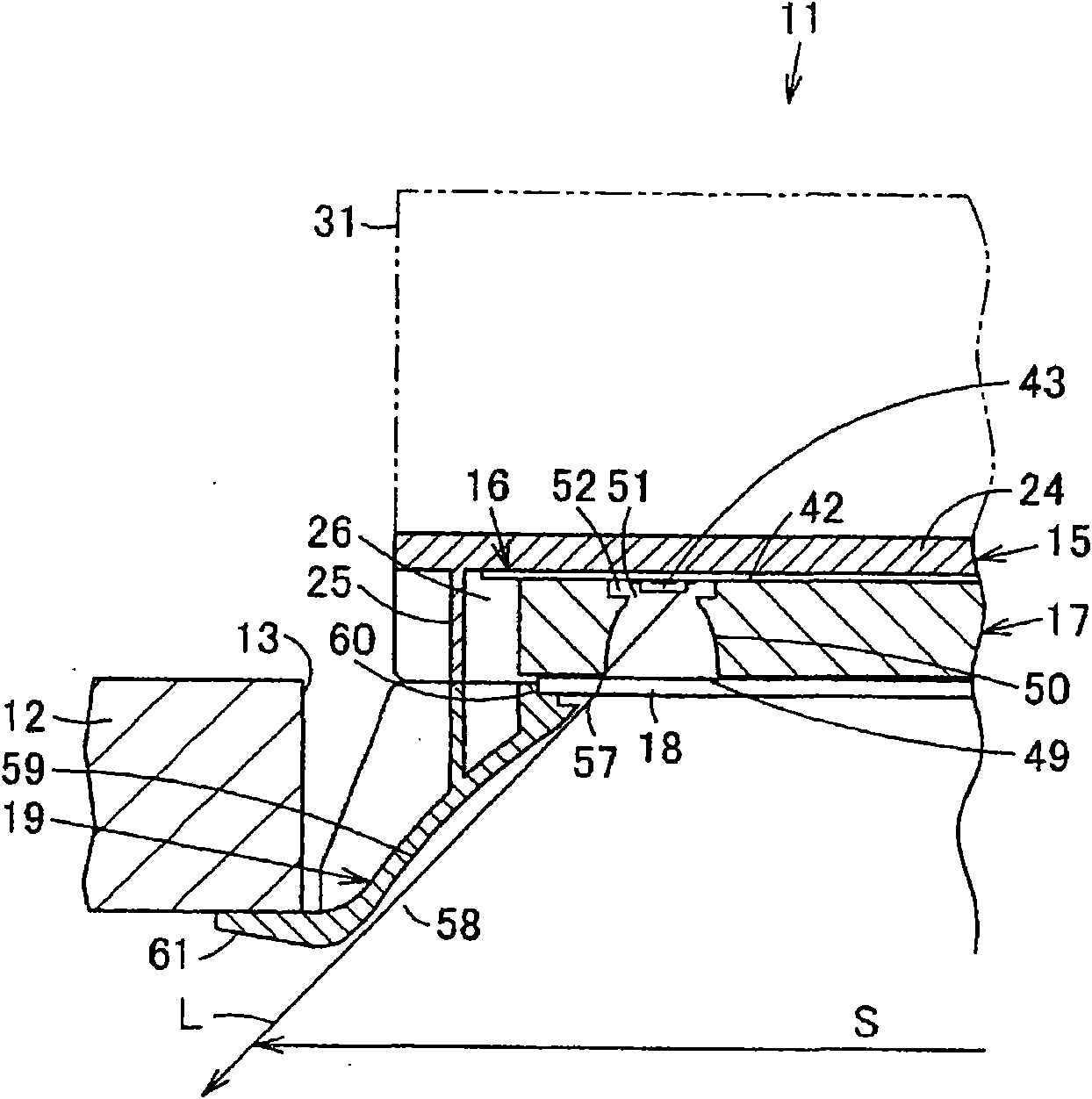

[0050] Such as figure 1 As shown, the lighting fixture 11 is, for example, a downlight, and is embedded in a circular embedding hole 13 provided in a ceiling member 12 such as a ceiling.

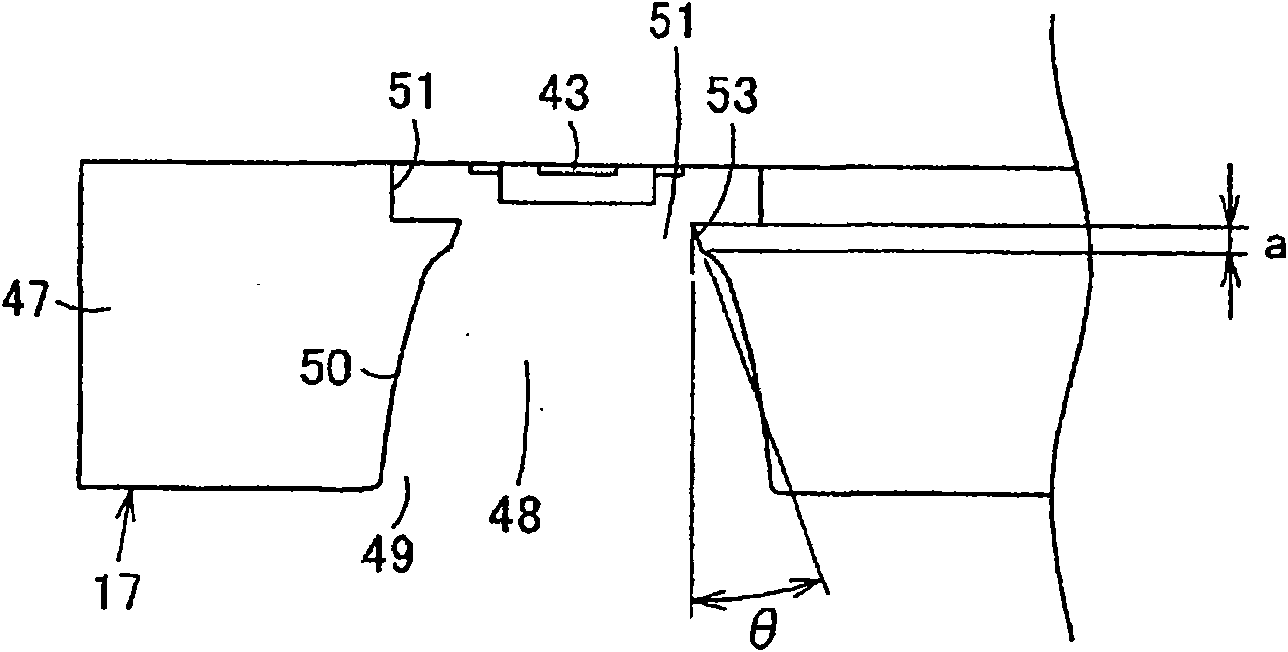

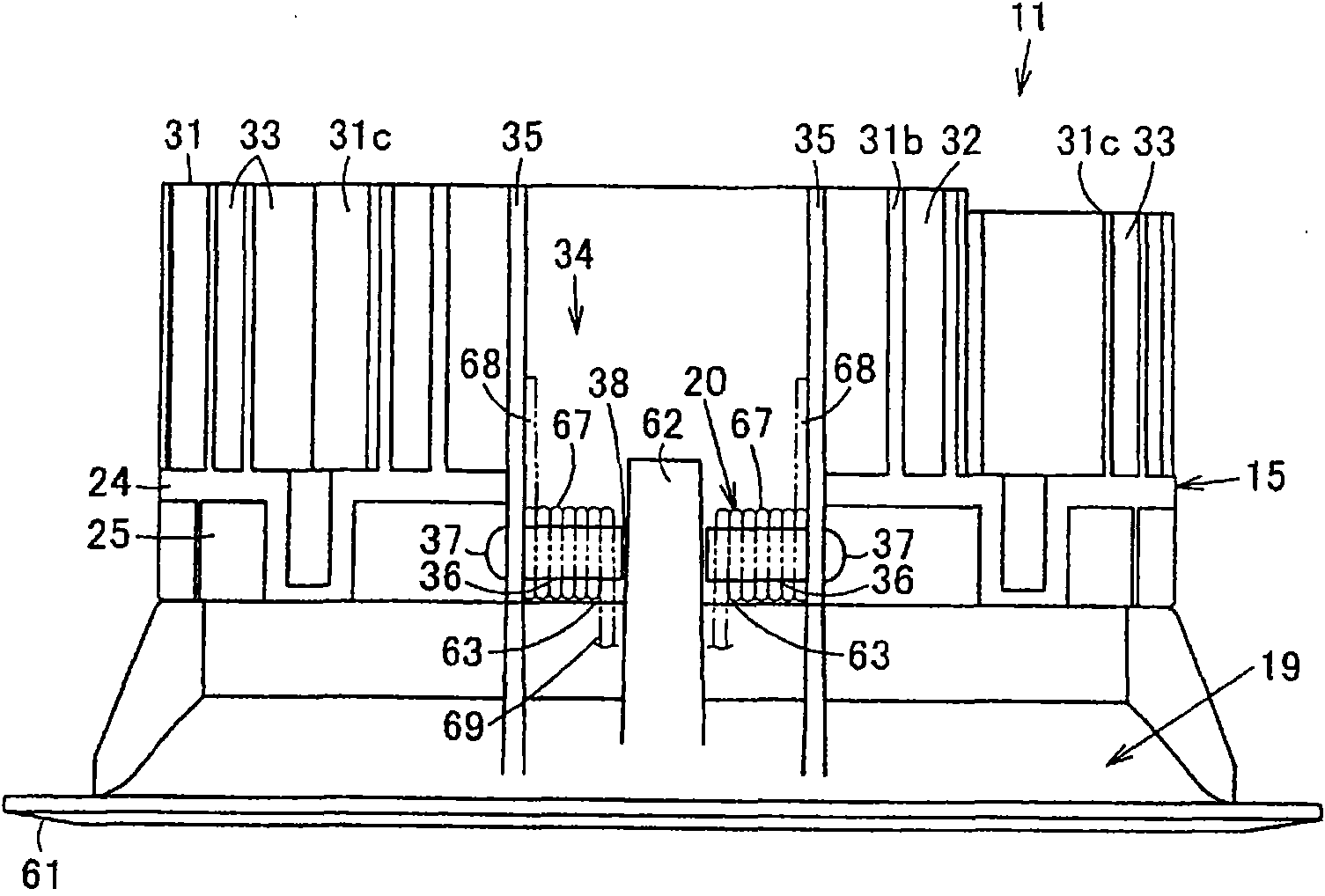

[0051] Such as Figure 1 to Figure 6As shown, the lighting fixture 11 includes a fixture body 15, a light source module (module) 16 installed on the lower surface of the fixture body 15, a reflector 17 as a first reflector installed on the lower side of the light source module 16, and configured on The translucent cover 18 on the lower surface of the reflector 17, the baffle plate 19 as the second reflector attached to the underside of the appliance body 15, and a pair of mounting springs for attaching to the top plate member 12 20 and a power supply device and a terminal block not shown in the figure, wherein the installation spring 20 is installed on the outer surface of the ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com