Cam follower device

A technology of cams and supporting walls, applied to valve devices, engine components, machines/engines, etc., can solve the problems of reduced durability and achieve the effects of manufacturing costs, weight reduction, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

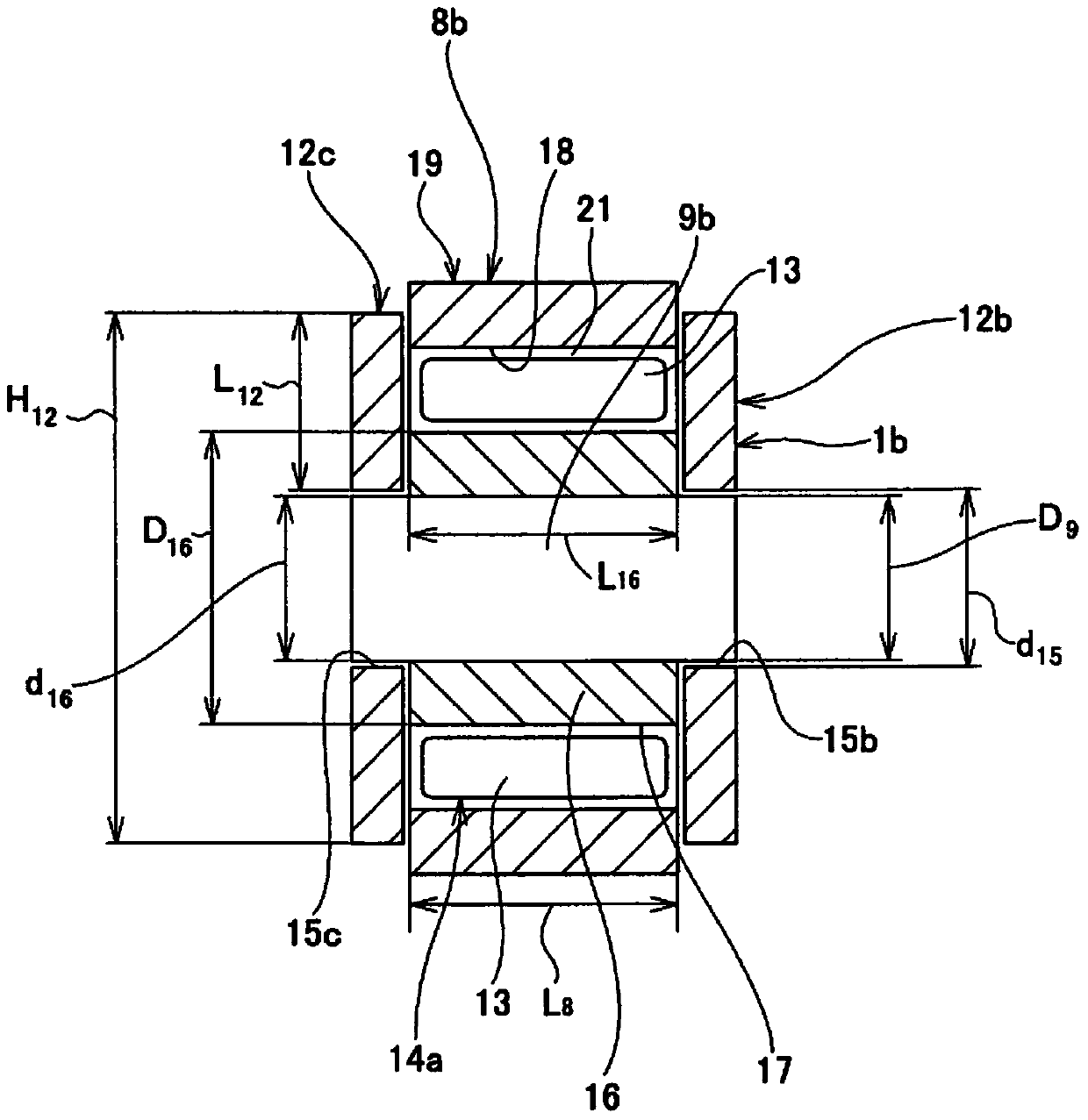

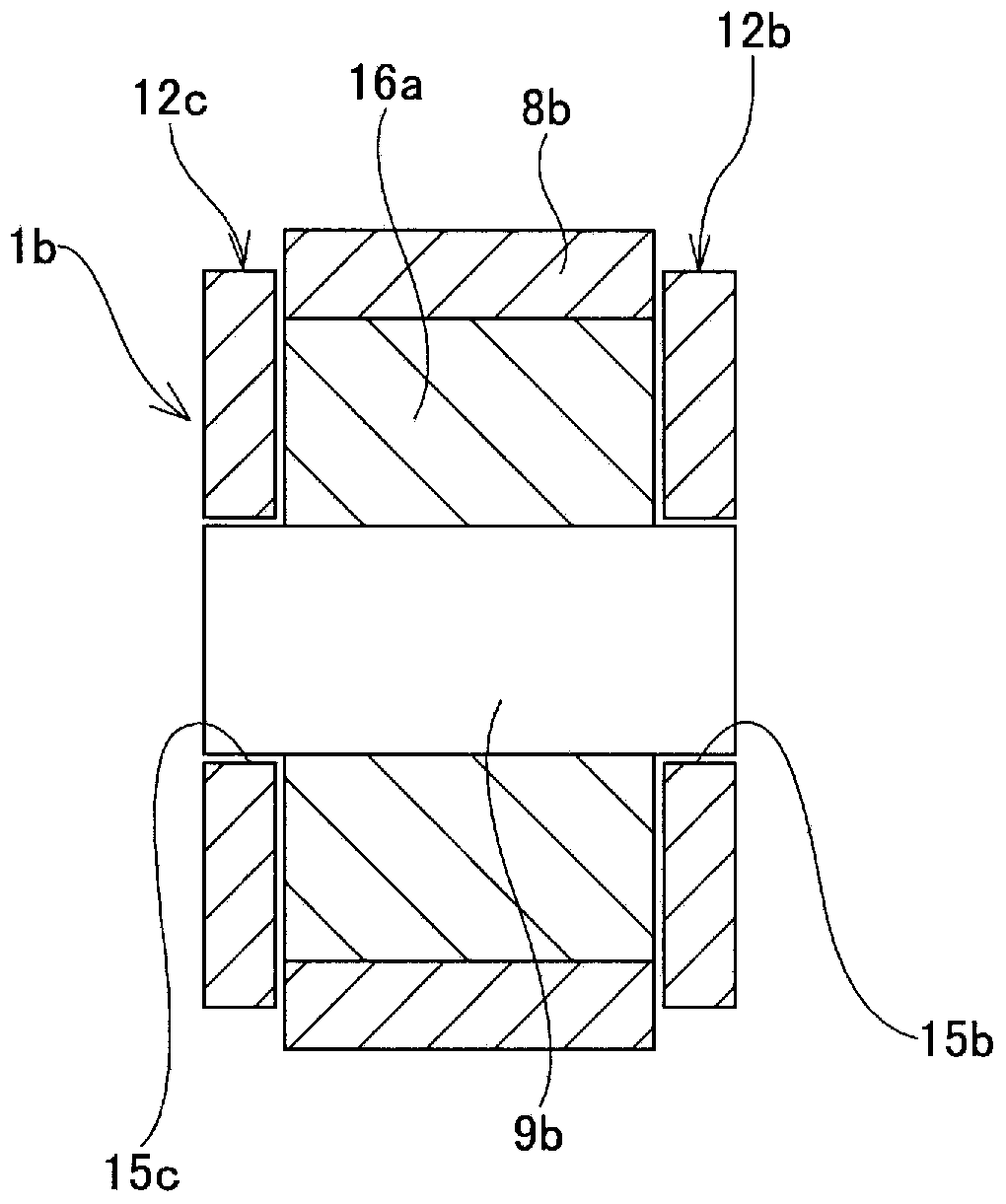

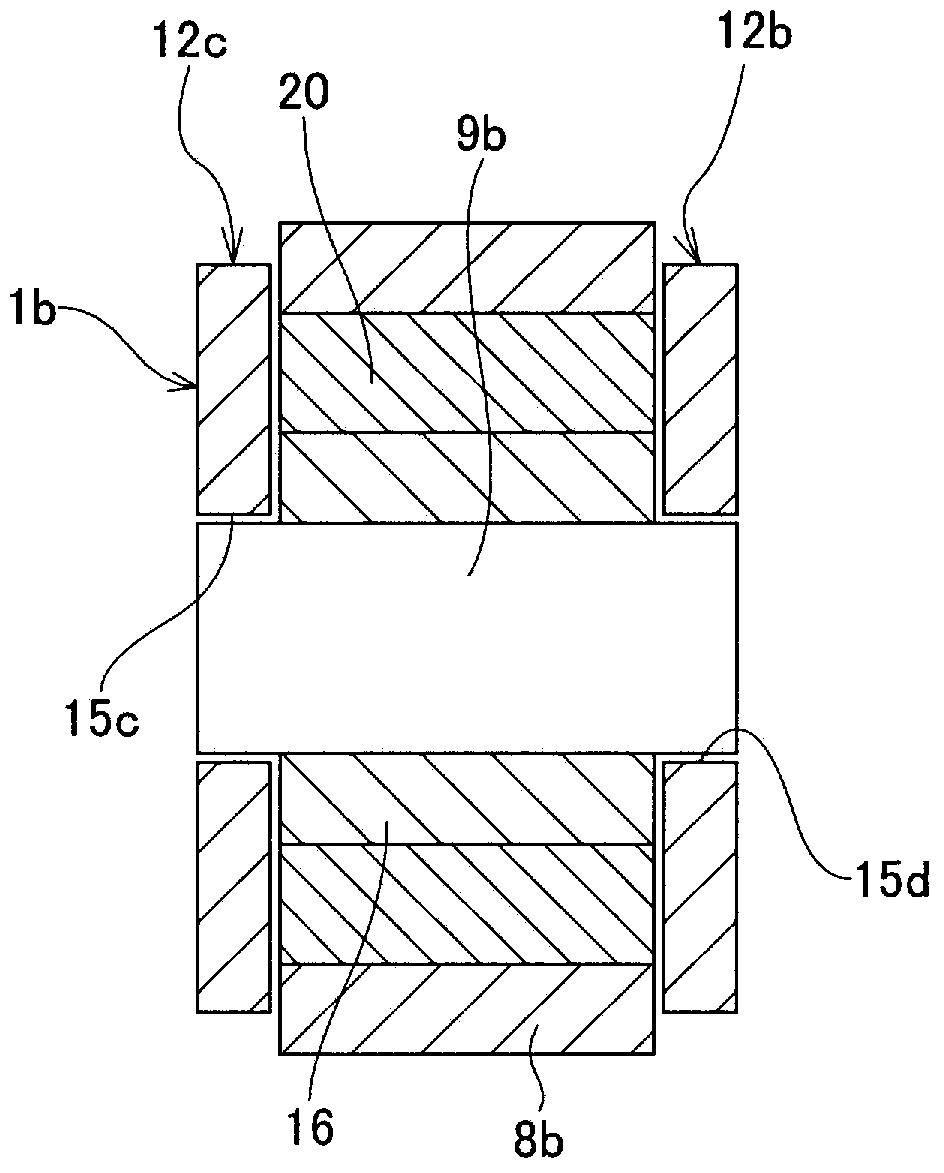

[0048] [First example of embodiment]

[0049] figure 1 The first example of the embodiment of the present invention is shown. Including this example, the cam follower of the present invention is characterized in that the support structure of the support shaft 9b to the support wall portions 12b, 12c, and that an inner ring equivalent member is provided between the support shaft 9b and the tappet roller 8b Namely the inner ring 16 . The structure of the cam follower other than the characteristic parts of the present invention and the state of assembly to the engine include Figure 12 to Figure 15 The shown structure is basically the same as the conventional structure, and the description thereof will be omitted or simplified, and the following description will focus on the characteristic parts of this example.

[0050] The cam follower of this example has a rocker arm 1b, a support shaft 9b, an inner ring 16 that is a member corresponding to the inner ring, a tappet roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com