Patents

Literature

404results about How to "Achieve long life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

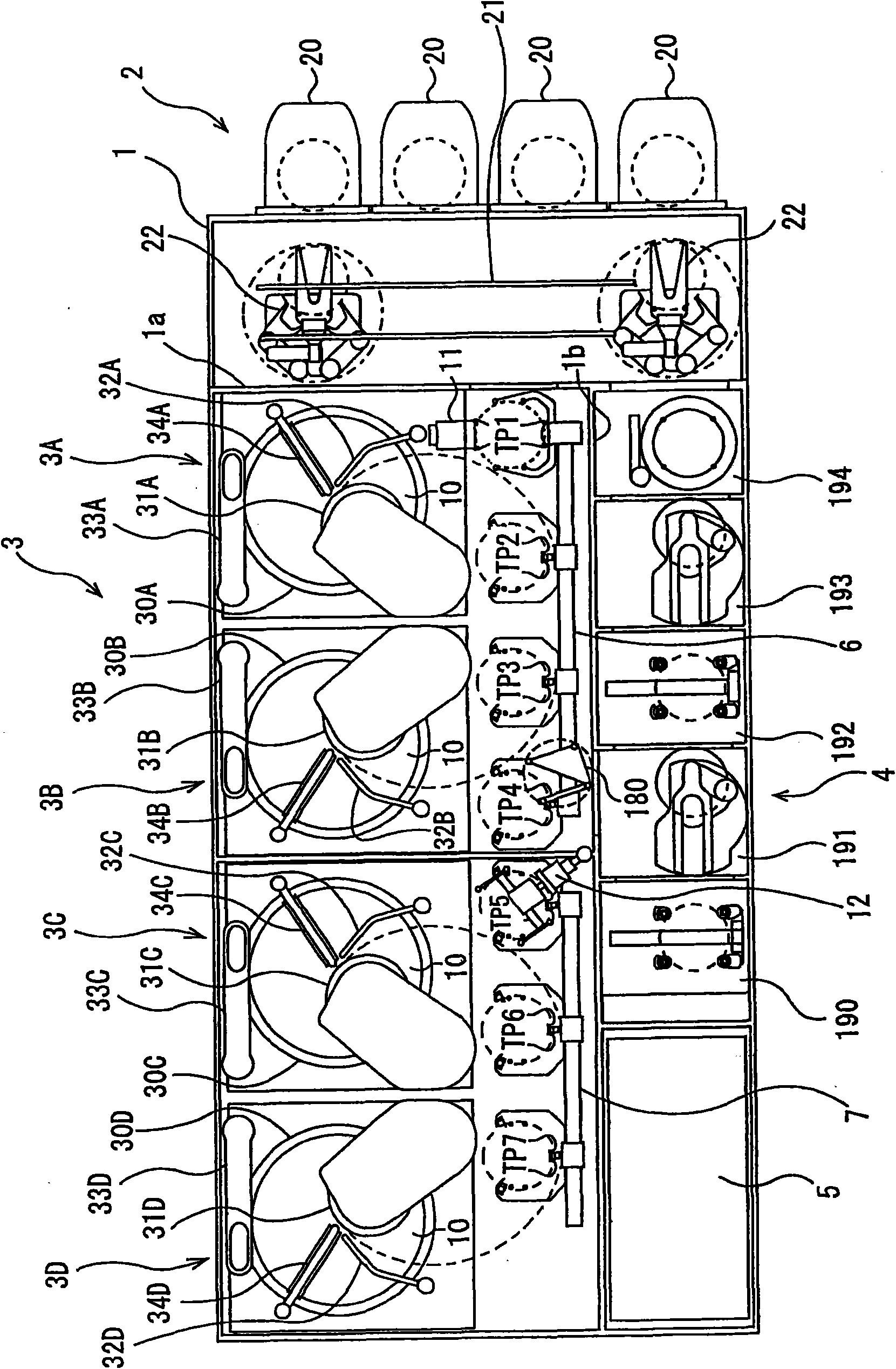

Substrate processing apparatus, substrate processing method, substrate holding mechanism, and substrate holding method

ActiveCN101599423AProcessing time equalizationImprove processing efficiencyPolishing machinesSemiconductor/solid-state device testing/measurementTransfer mechanismElectrical and Electronics engineering

A substrate processing apparatus, a substrate processing method, a substrate holding mechanism, and a substrate holding method are disclosed. The apparatus includes a polishing section configured to polish a substrate, a transfer mechanism configured to transfer the substrate, and a cleaning section configured to clean and dry the polished substrate. The cleaning section has plural cleaning lines for cleaning plural substrates. The plural cleaning lines have plural cleaning modules and plural transfer robots for transferring the substrates.

Owner:EBARA CORP

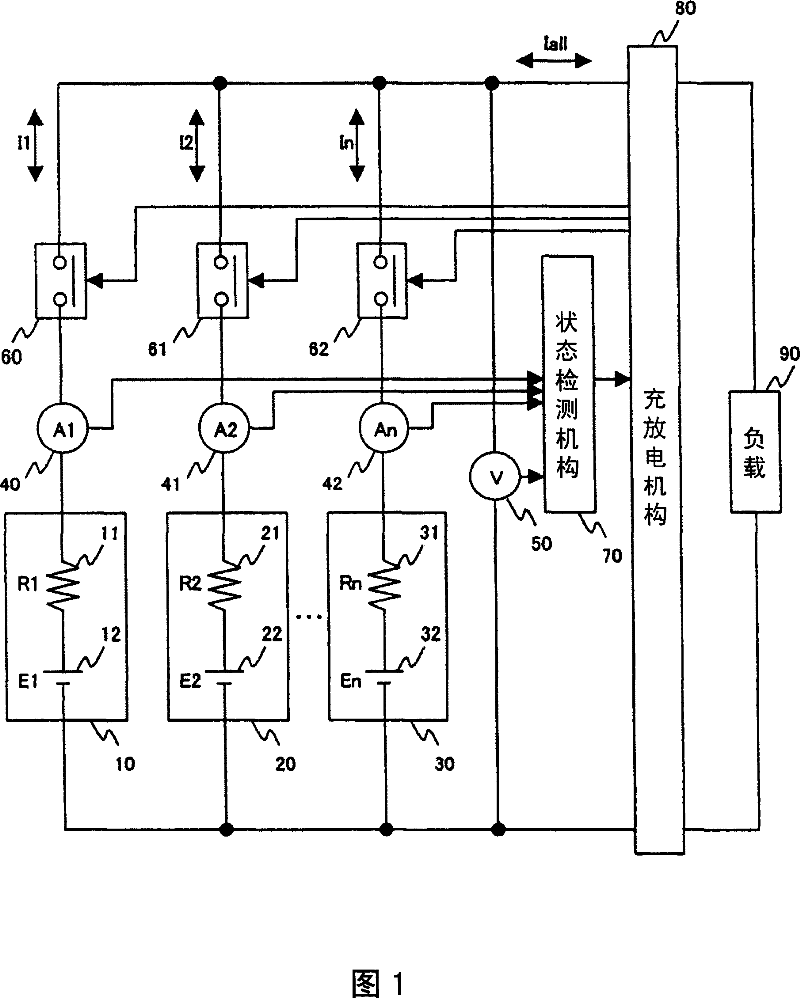

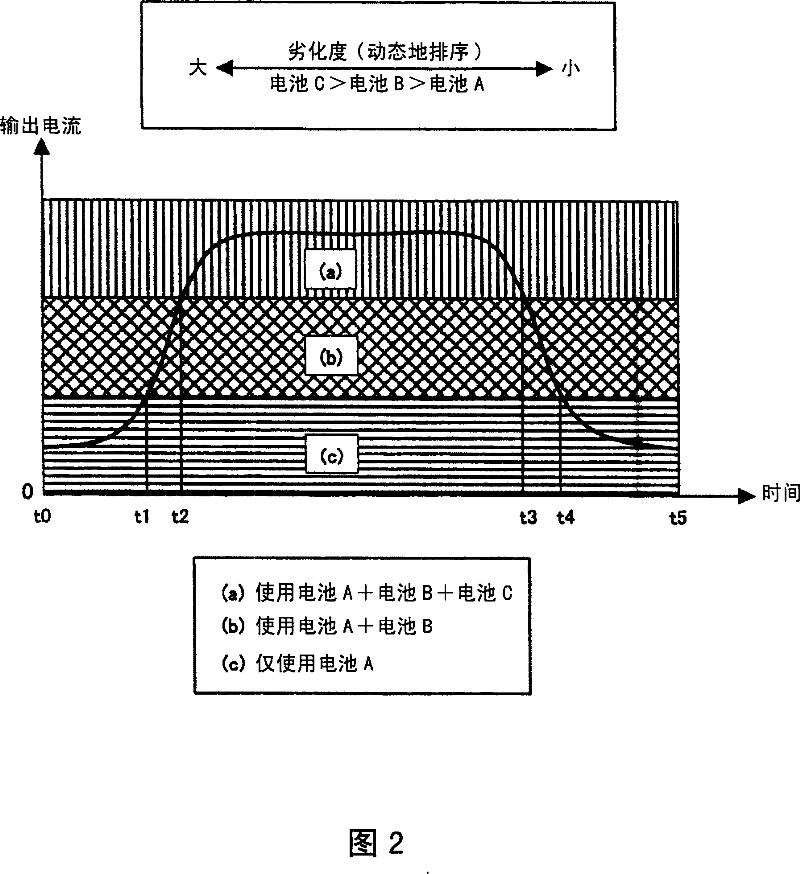

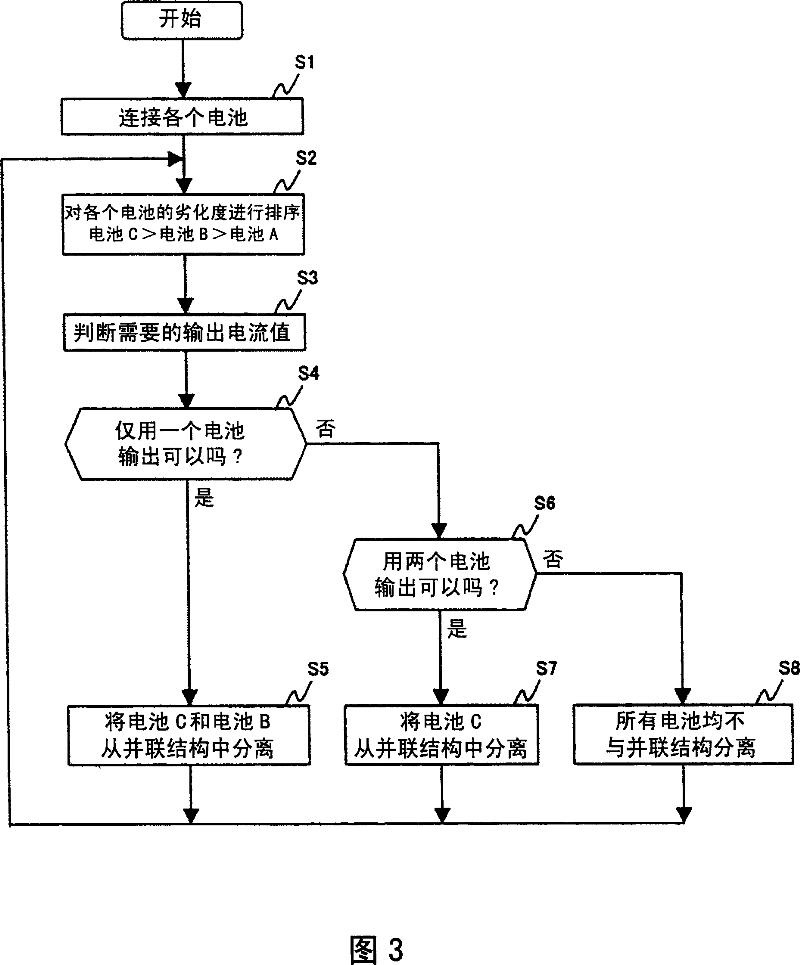

Electric power supply control apparatus

InactiveCN101043143AAchieve long lifeImprove maintainabilityCharge equalisation circuitIndicating/monitoring circuitsEngineeringElectric power

An electric power supply control apparatus according to the present invention is connected in parallel to plural electric storage means and comprises: plural current measurement means which respectively measure the currents of the plural storage means connected in parallel; plural voltage measurement means which respectively measure the voltages of the plural storage means connected in parallel; plural switching means which respectively disconnect and connect the plural electric storage means from and to the parallel connection; state detection means which receives the outputs of the current measurement means and the outputs of the voltage measurement means and outputs the respective states of the plural electric storage means; and charging and discharging means which receives the outputs of the state detection means and charges and discharges the plural electric storage means. The charging and discharging means judges the deterioration states of the plural electric power storage means from the outputs of the state detection means and, based on the judged respective deterioration states of the plural electric storage means, controls switching of the plural switching means.

Owner:HITACHI LTD

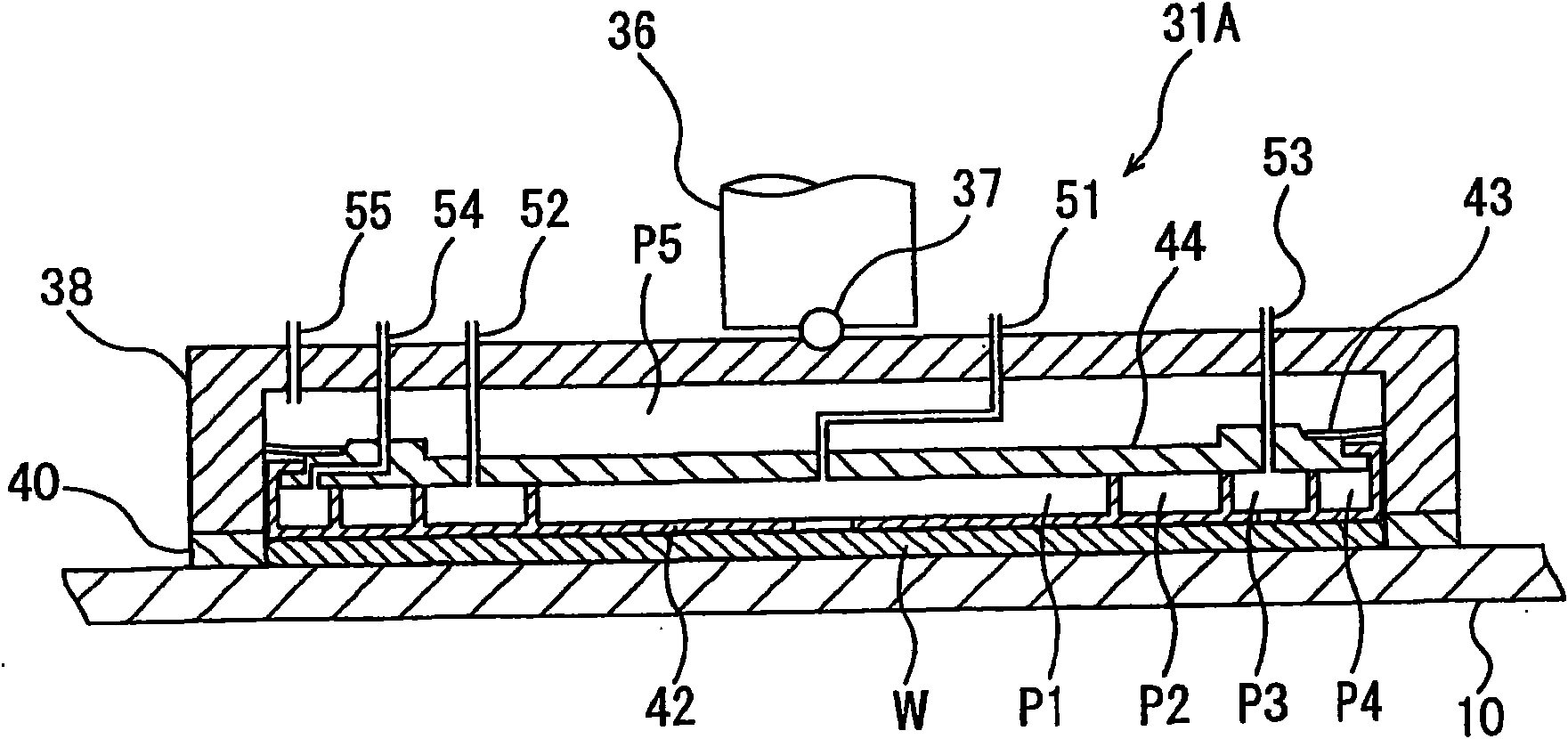

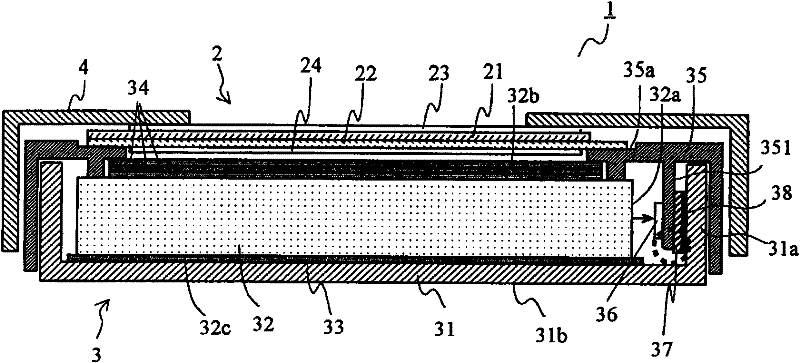

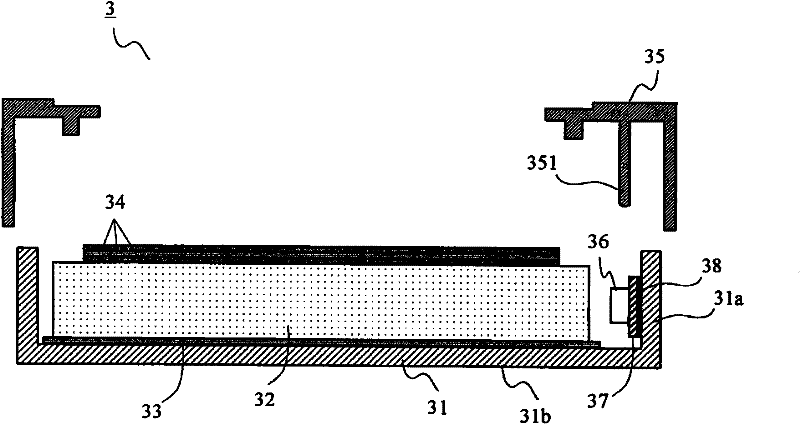

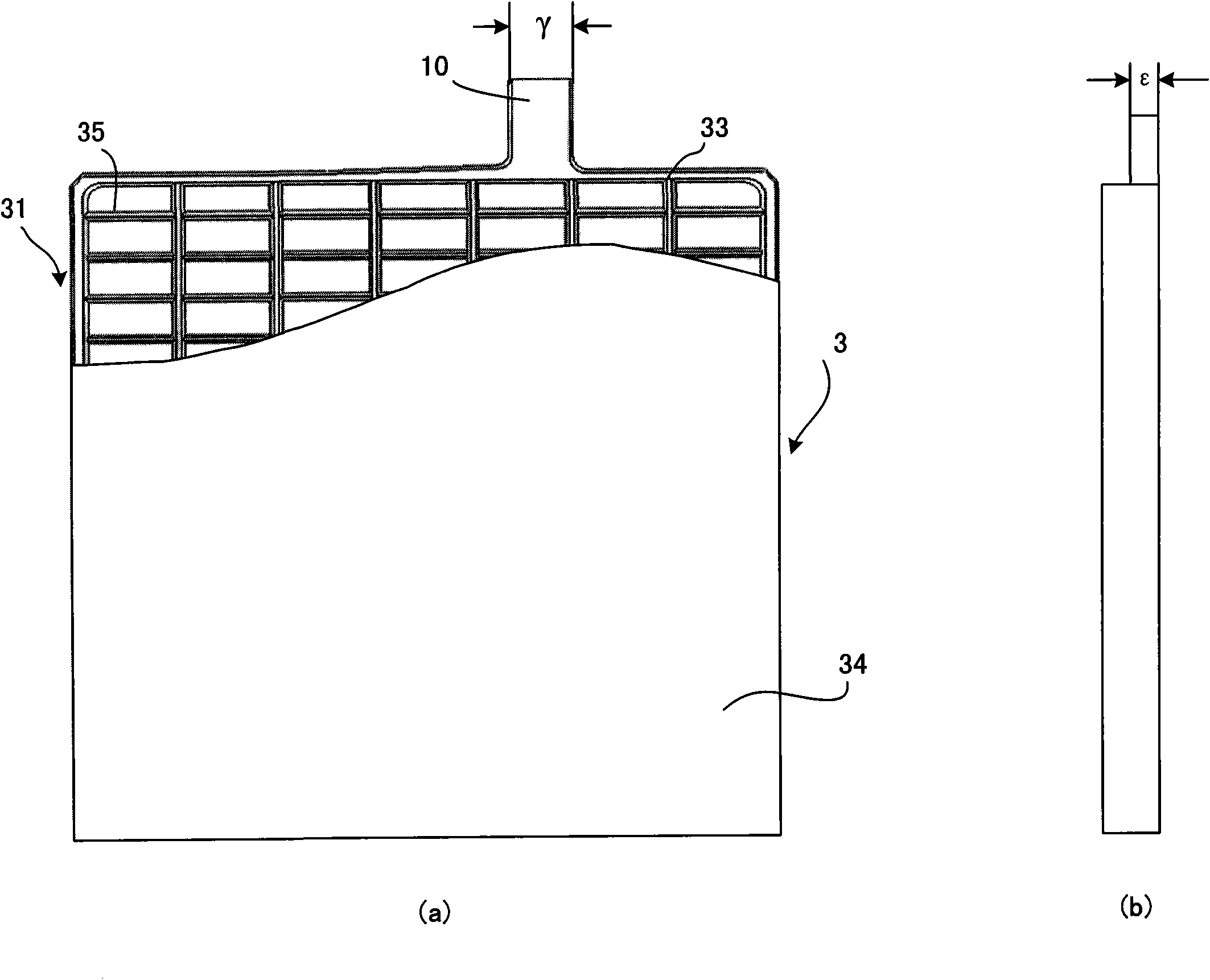

Backlight device and flat display device using same

InactiveCN102057209AEasy to assembleImprove image display qualityPoint-like light sourceLighting heating/cooling arrangementsLight guideAdhesive

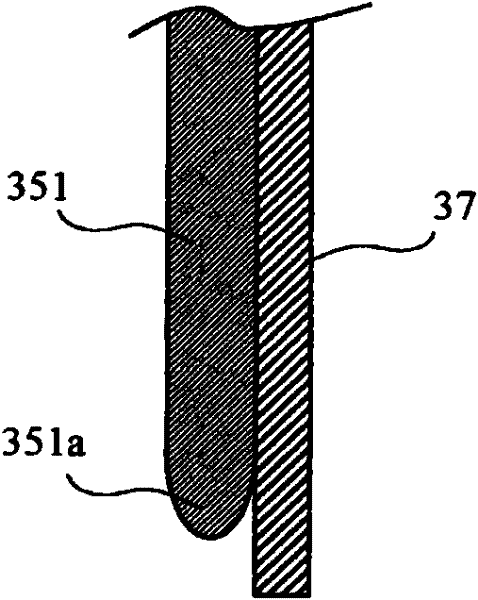

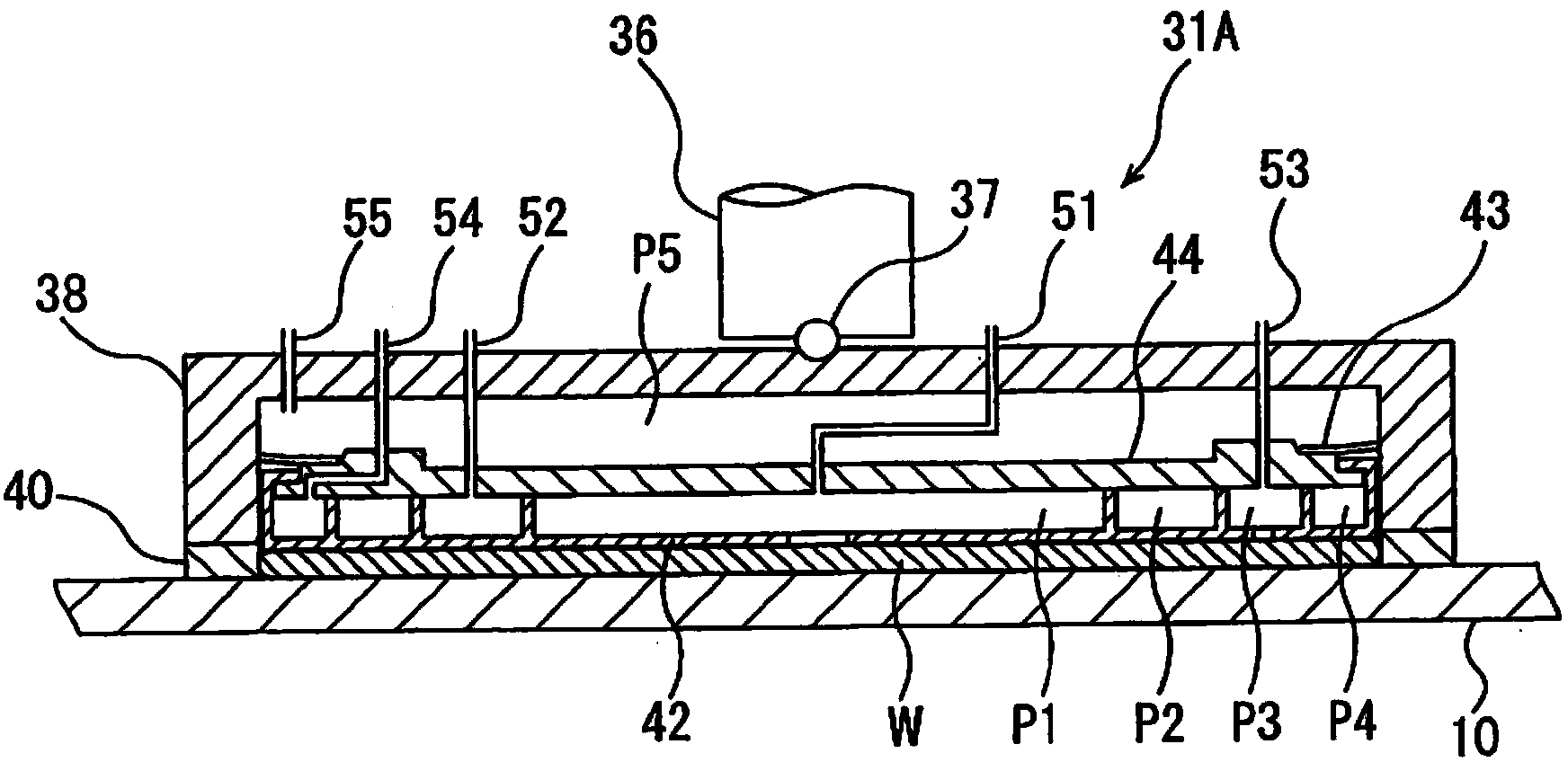

A backlight device (3) is equipped with a light guide plate (32), a chassis (31) whereon the light guide plate (32) is mounted, a frame (35) that grips the light guide plate (32) in conjunction with the chassis (31), a spot light source (36) provided near the side face of the light guide plate (32), a flexible printed circuit board (37) whereon the spot light source (36) is mounted, and a heat-dissipation plate (31a) (a part of the chassis (31)) adhered to the flexible printed circuit board (37) by means of a two-sided adhesive (38). A projecting part (351) is provided in contact with the flexible printed circuit board (37) on the frame (35) to press the flexible printed circuit board (37) toward the heat-dissipation plate (31a), and the tip of the projecting part (351) is tapered toward the end and is away from the flexible printed board (37).

Owner:SHARP KK

Enclosed compressor and refrigeration cycle device

InactiveCN102046981AInhibit local contactImprove reliabilityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRefrigeration

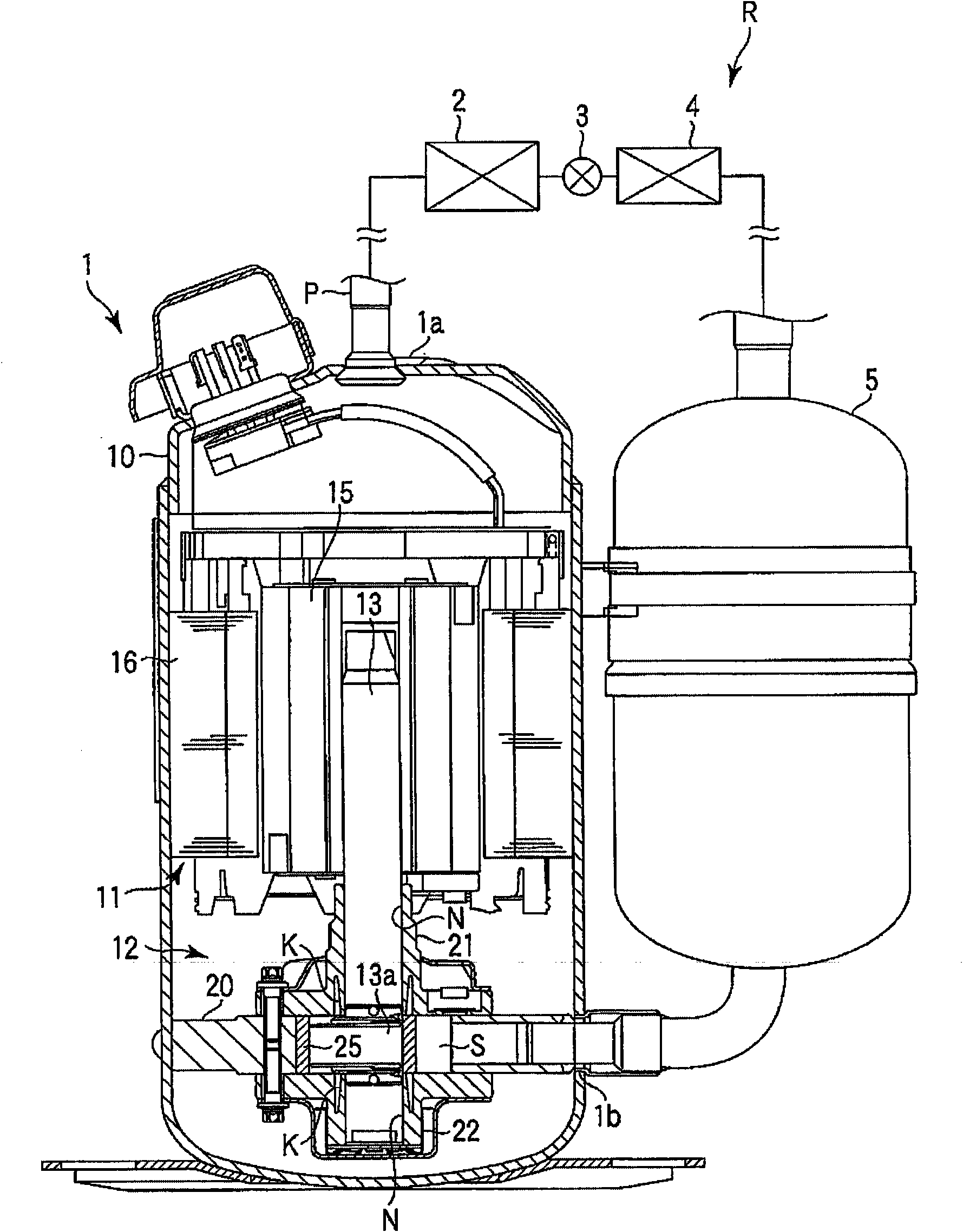

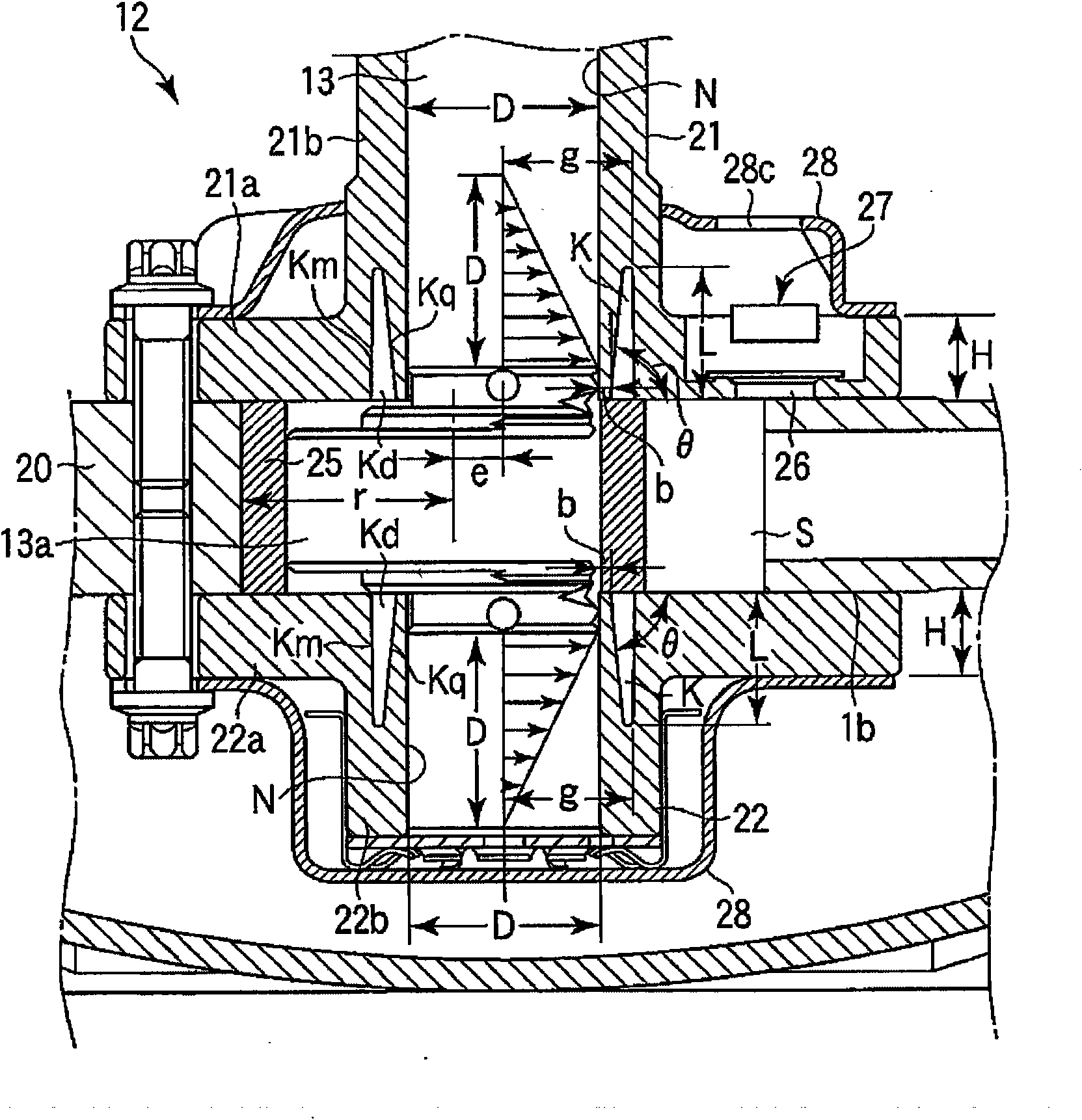

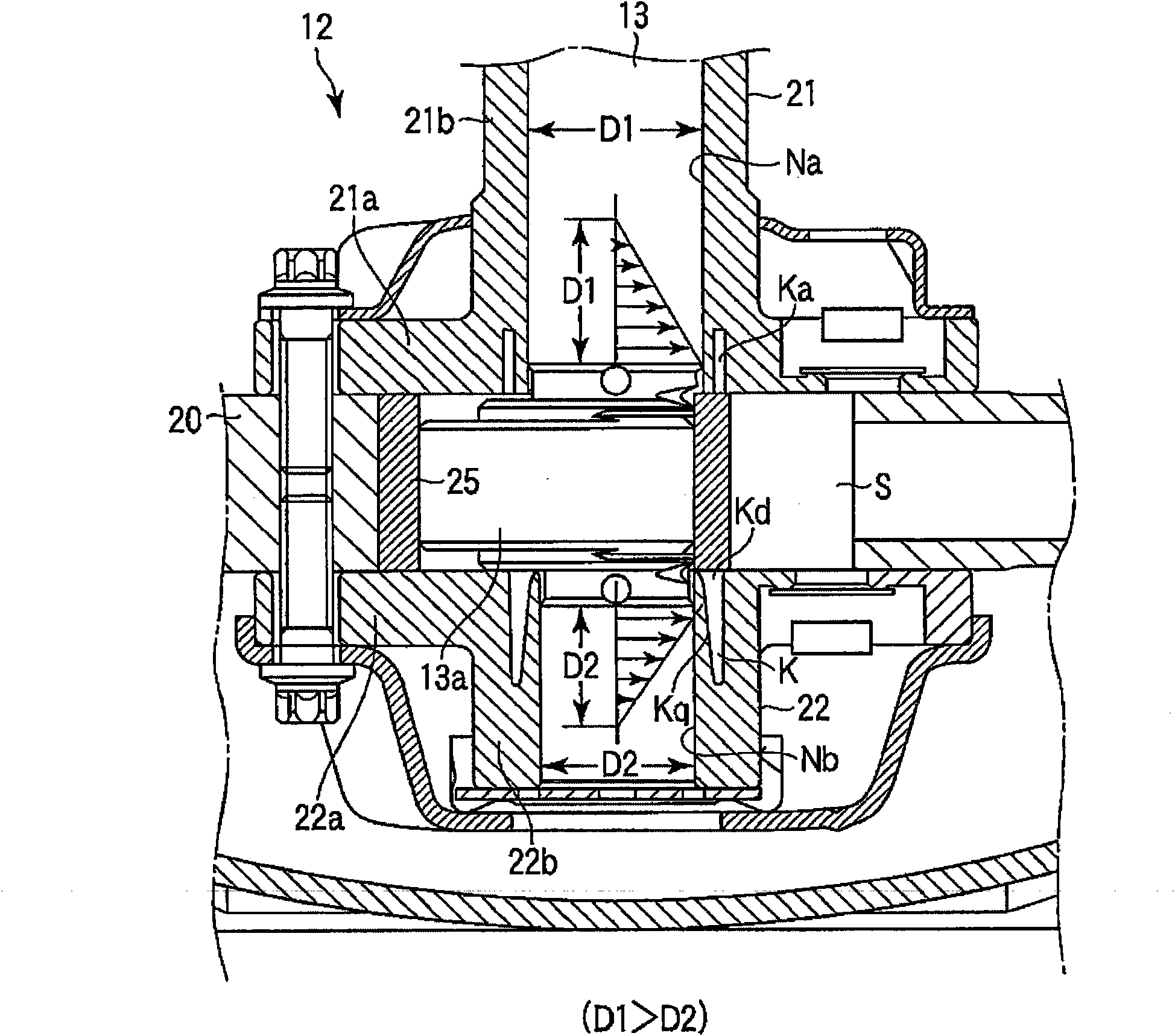

In the enclosed compressor (1), a motor section (11) and a compression mechanism section (12) connected to the motor section through a rotating shaft (13) are contained in an enclosed container (10). The compression mechanism section is provided with a cylinder (20) having an inner diameter hole (S), and also with a main bearing (21) and a sub-bearing (22) which have a bearing hole (N) rotatably supporting the rotating shaft and which close the inner diameter hole in the cylinder to form therein a cylinder chamber. At least either the main bearing or the sub-bearing has an annular groove (K) open to the cylinder chamber side. The inner peripheral surface of the annular groove has a tapered shape having a diameter gradually increased from the cylinder chamber side toward the side opposite to the cylinder chamber. The depth (L) of the annular groove is set greater than or equal to 40% of the diameter (D) of the bearing hole. Even if flexural deformation occurs in the rotating shaft due to a compression load in the cylinder, at least either the main bearing or sub-bearing is prevented from making partial contact with the rotating shaft, and this enhances the reliability of the compressor and extends the life of the compressor. The invention also provides a refrigeration cycle device which is equipped with the enclosed compressor to constitute the refrigeration cycle, thus enhancing the refrigeration efficiency.

Owner:TOSHIBA CARRIER CORP

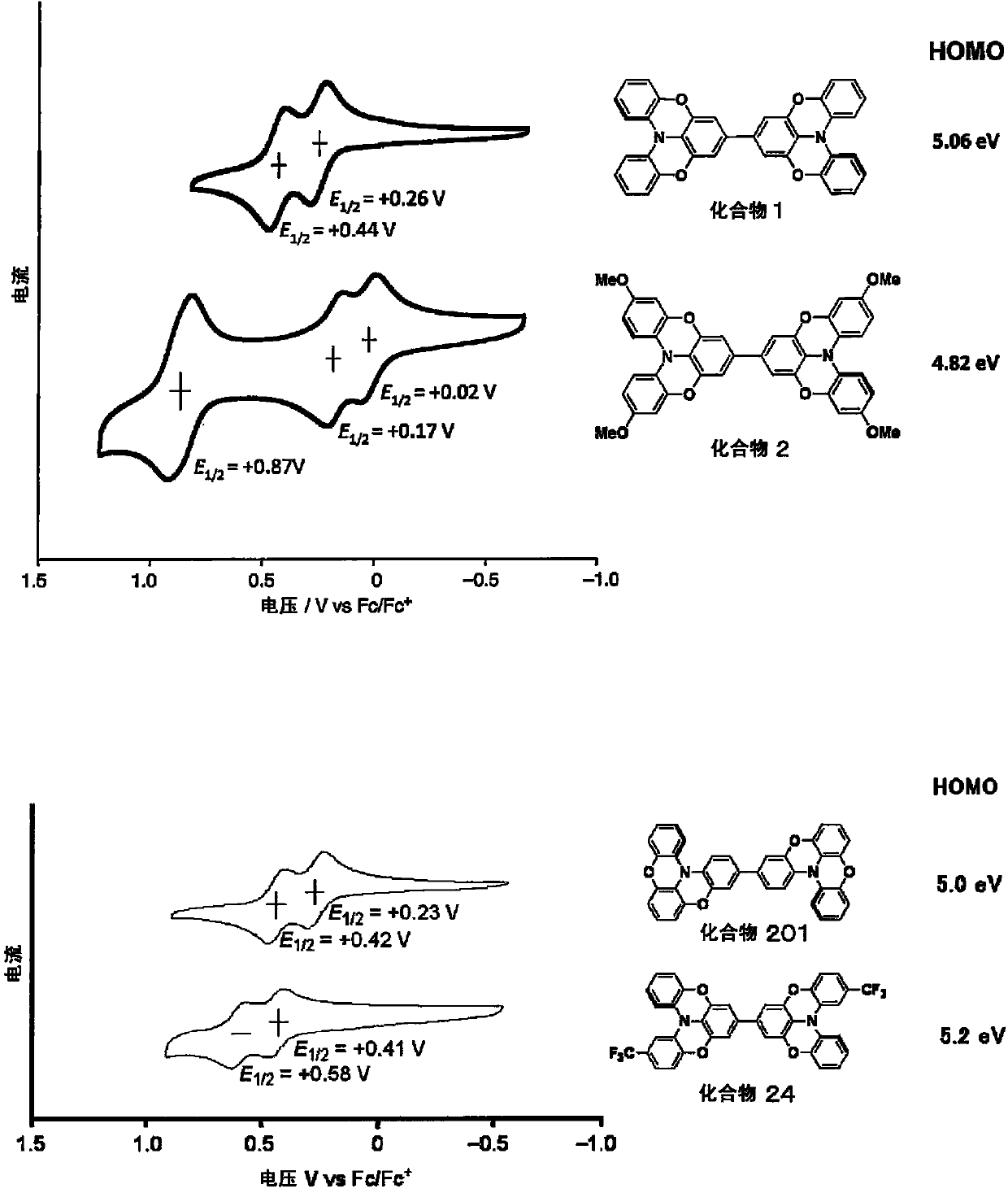

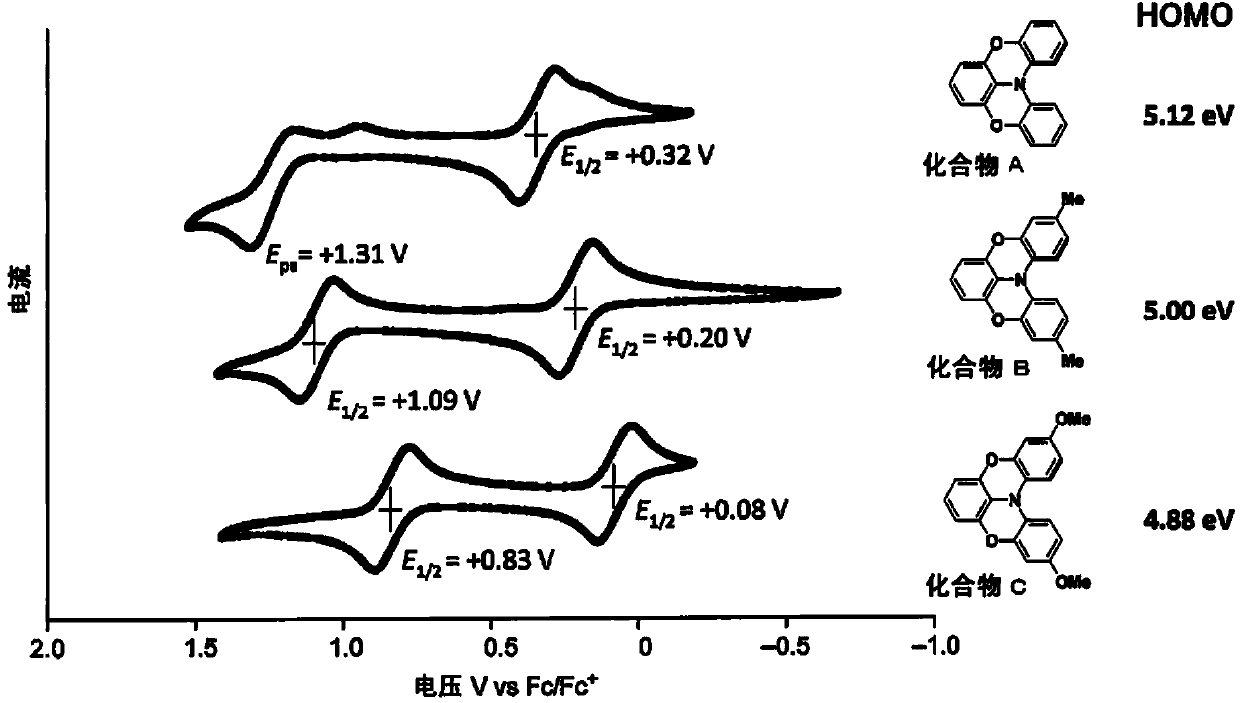

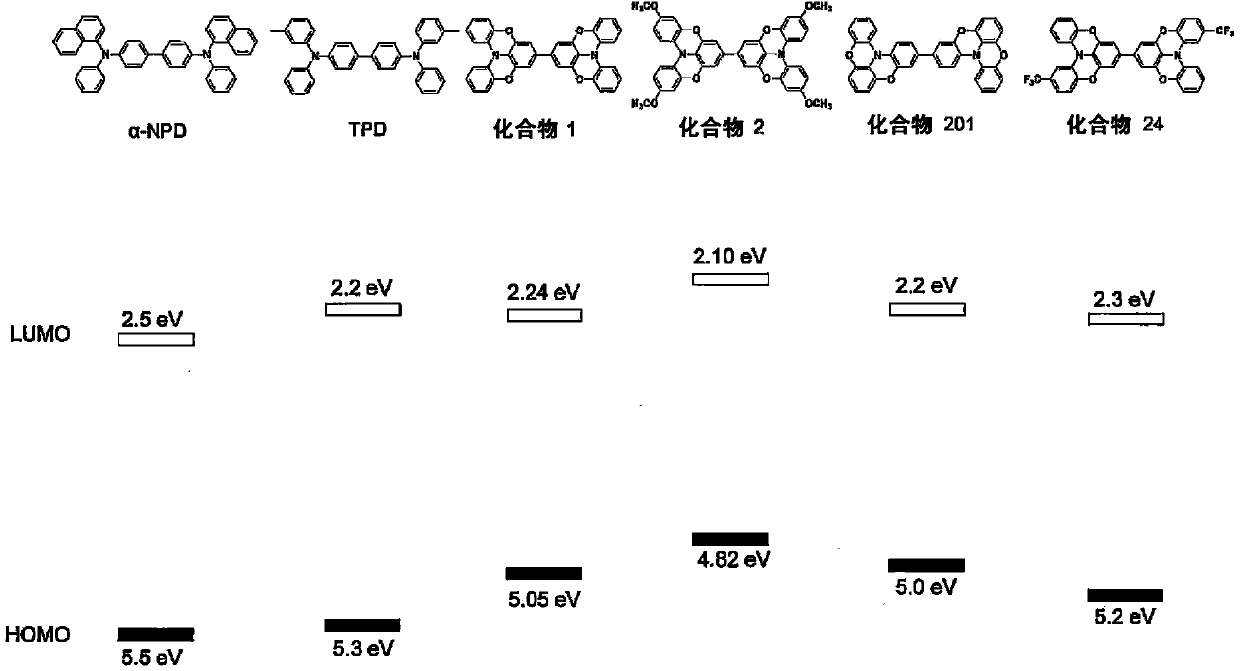

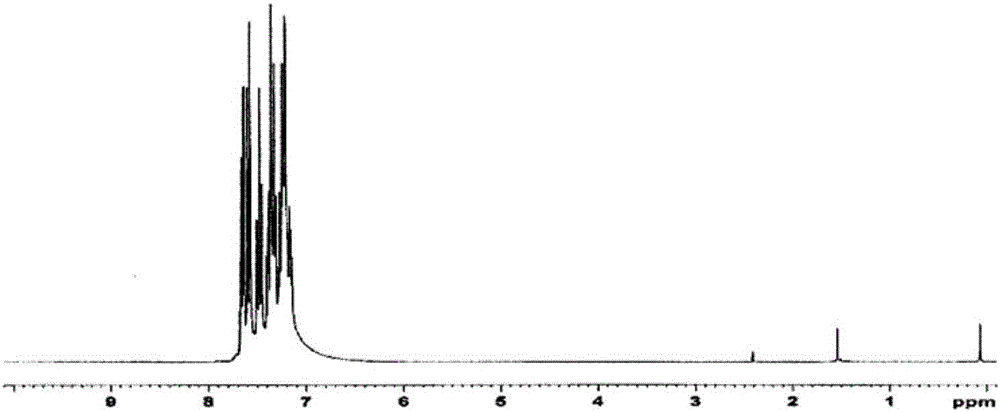

Novel compound, charge transport material, and organic device

InactiveCN103502252AAmorphous state is stableNot easy to crystallizeOrganic chemistrySolid-state devicesHydrogenHydrogen atom

A compound represented by the general formula below has high thermal stability and has excellent characteristics as a charge transport material. (Ar1 denotes a single bond, a benzene ring or the like; X1 denotes a linking group linked via an oxygen atom, a sulfur atom, a carbon atom, a nitrogen atom, a phosphorus atom or a silicon atom; one of L1 and L2 or L3 and L4 bond together to form a linking group linked via an oxygen atom, a sulfur atom, a carbon atom, a nitrogen atom, a phosphorus atom or a silicon atom and the other of L1 and L2 or L3 and L4 are hydrogen atoms or substituent groups; Y1 denotes a linking group linked via a nitrogen atom, a boron atom or a phosphorus atom; R1, R2, R5 to R7 and R10 to R12 are hydrogen atoms or substituent groups, and n1 is an integer of 2 or higher.)

Owner:KYUSHU UNIV

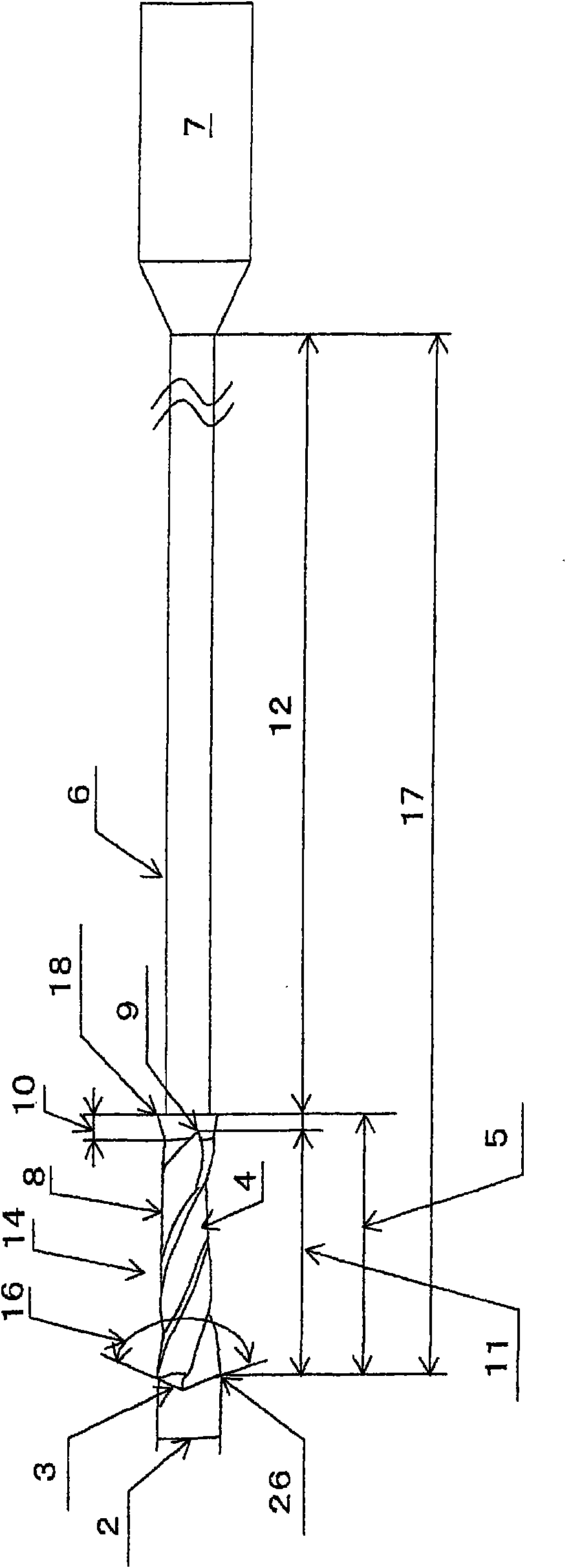

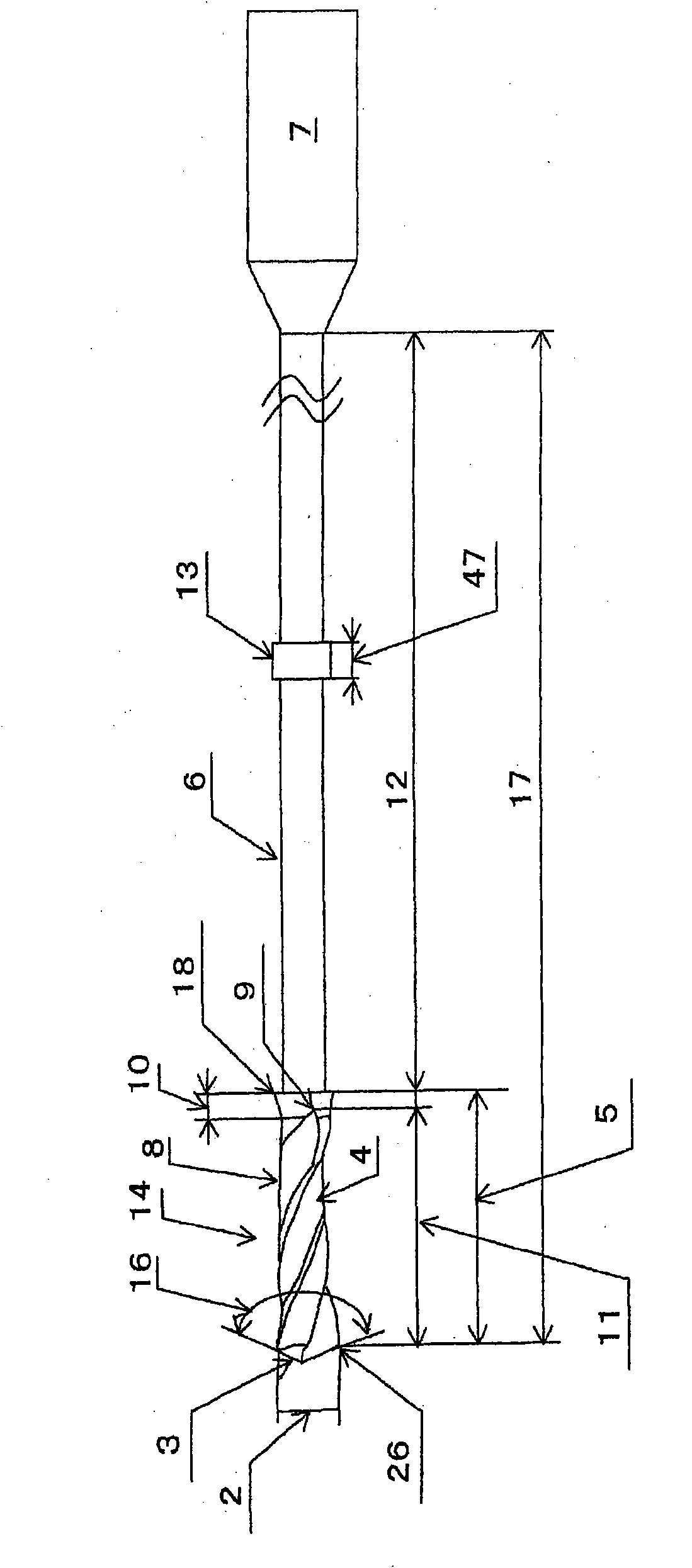

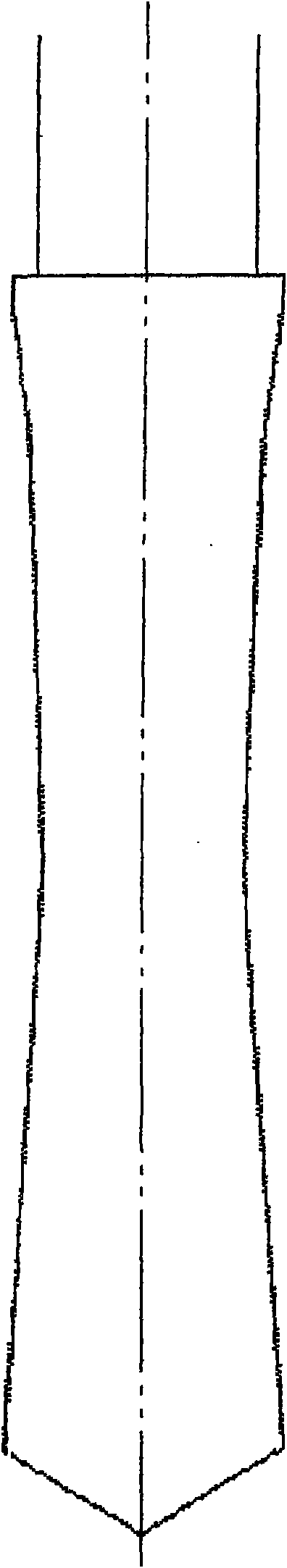

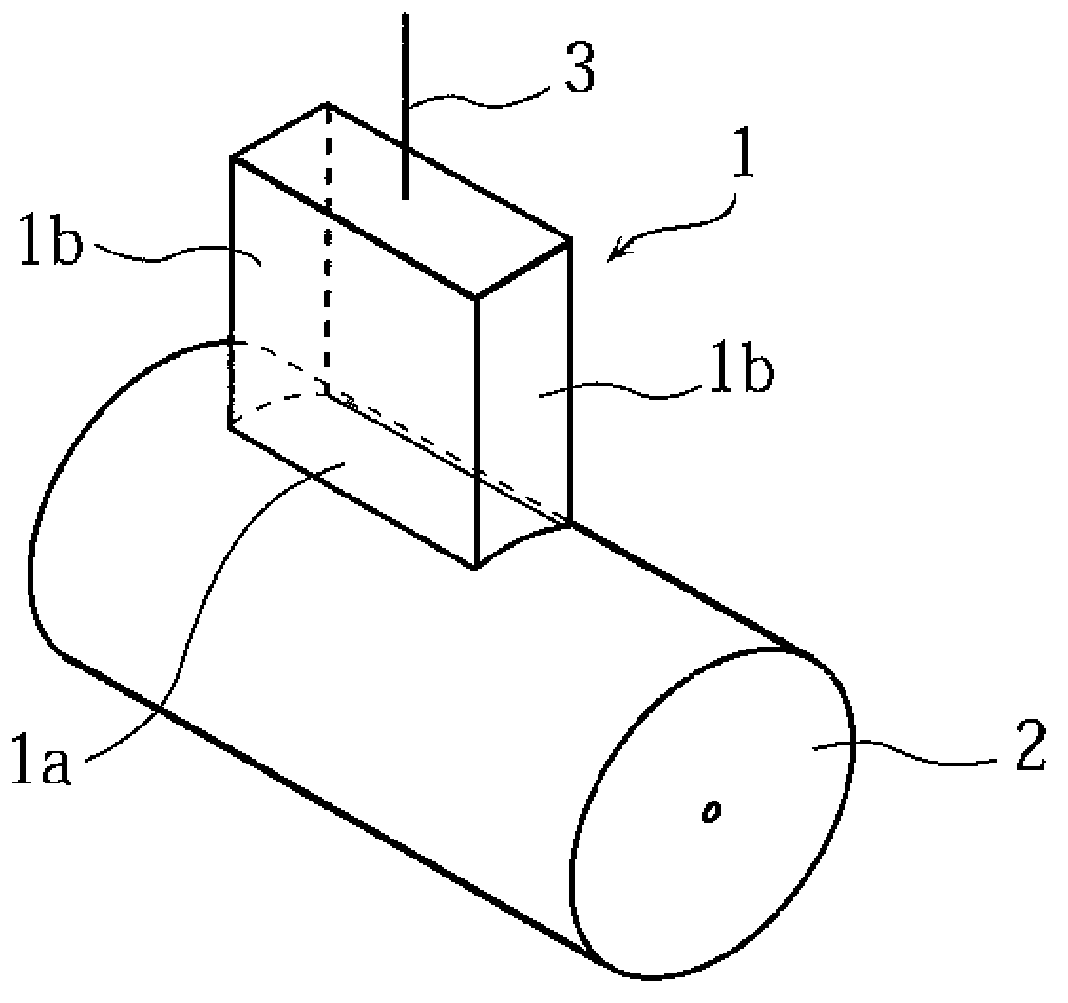

Small-diameter deep hole drill and fine deep hole processing method

InactiveCN101678475AImprove inner surface roughnessImprove straightnessTransportation and packagingMetal working apparatusFluteDeep hole

A small-diameter drill for deep hole drilling is provided which is capable of inhibiting the cutting chips from getting bitten and producing a straightness for a drilled hole, thus suitable for drilling a hole having a depth (L) which is 15 or more times the diameter (D) of a drilled hole. The small-diameter drill 1 has a diameter 2 which is 1 mm or less and a drill section 5 including cutting edge(s) 3 and flute(s) 4. The length 11 of the flute 4 is at least 5 times and at most 10 times the drill diameter 2. The diameter of the drill section 5, after being reduced in diameter from the cutting edge 3 toward the rear of the drill section 5, is expanded in diameter so that the outer diameter at the end of the flute 4 becomes at least 0.9 times and at most 0.98 times the drill diameter 2. Anexpanded-diameter portion 10 is provided between the drill section 5 and a neck section 6 connected to a shank 7 and is expended in diameter from the outer diameter at the end 9 of the flute 4 up to 1 or less times the drill diameter 2. The diameter of the neck section 6 is smaller than the drill diameter 2, and the length 12 of the neck section 6 is 10 or more times the drill diameter 2.

Owner:MOLDINO TOOL ENG LTD

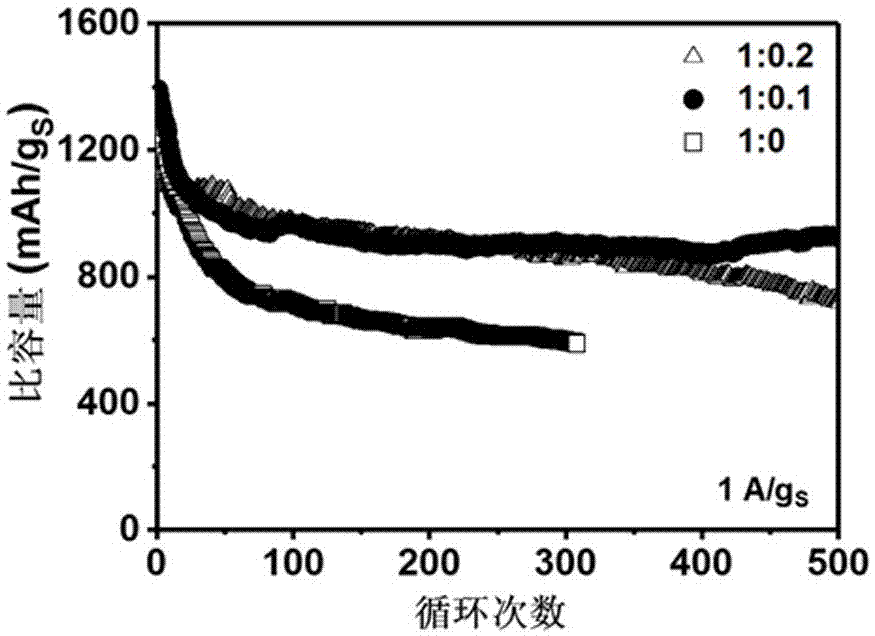

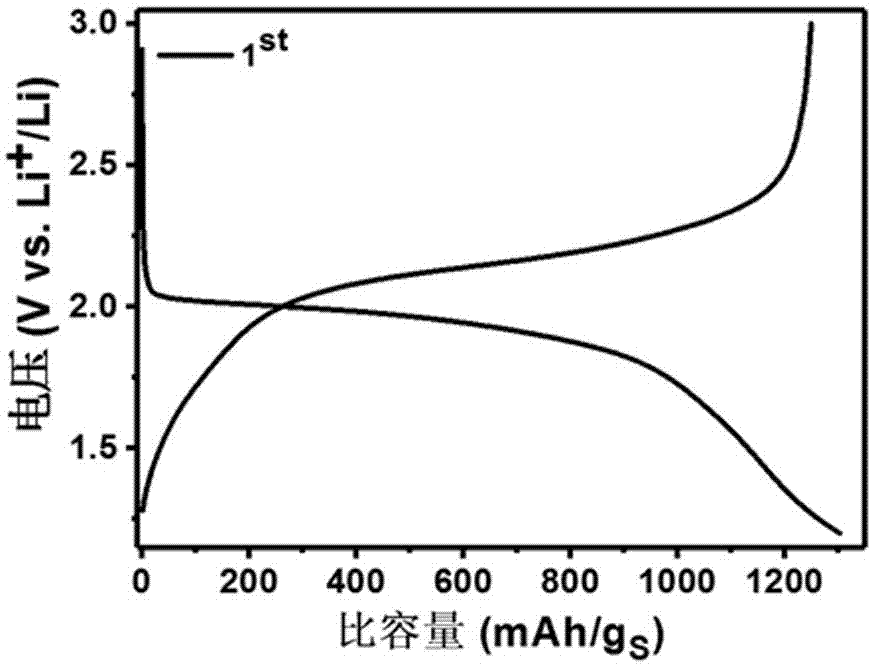

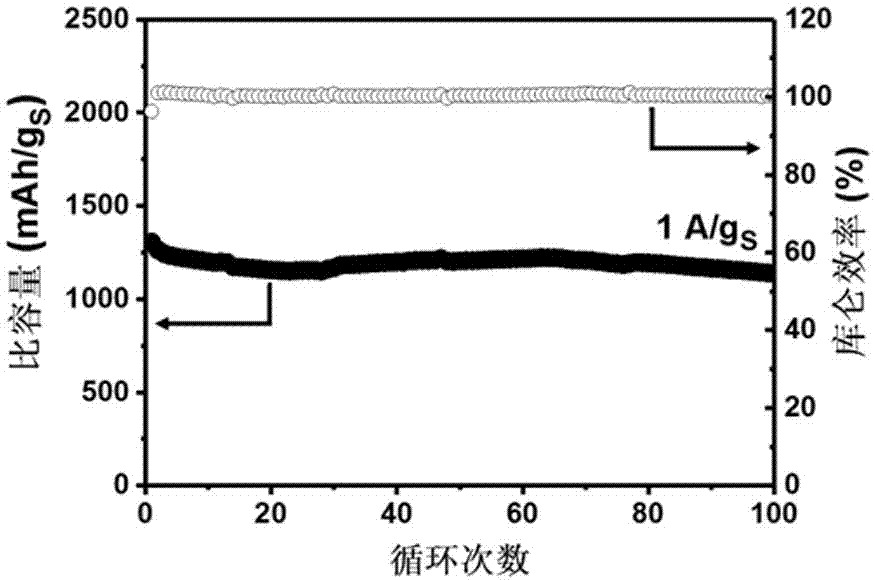

Metal-sulfur battery based on sulfur-rich transition metal sulfide and preparation method thereof

ActiveCN106898750AIncrease energy densityAchieve long lifeFinal product manufactureCell electrodesNiobiumLithium sulfur

The invention discloses a metal-sulfur battery based on sulfur-rich transition metal sulfide and a preparation method thereof. The metal-sulfur battery comprises a cathode, an anode and an electrolyte; the anode is metal; the cathode comprises transition metal sulfide; a chemical formula of the transition metal sulfide is MSx, wherein x is more than or equal to 3; M is one or more of vanadium, niobium, titanium, molybdenum, tungsten, iron, cobalt and nickel; the metal is lithium, sodium, potassium, magnesium, aluminum, zinc or iron; the electrolyte is an ester-based electrolyte or an ether-based electrolyte. The metal-sulfur battery based on the sulfur-rich transition metal sulfide and the preparation method thereof, disclosed by the invention, have the benefits that transition metal polysulfide is adopted as a cathode material equivalent to sulfur so as to realize the novel metal-sulfur battery such as a lithium sulfur and sodium sulfur battery system, and further the application potential of the metal-sulfur battery is further improved.

Owner:SUZHOU UNIV

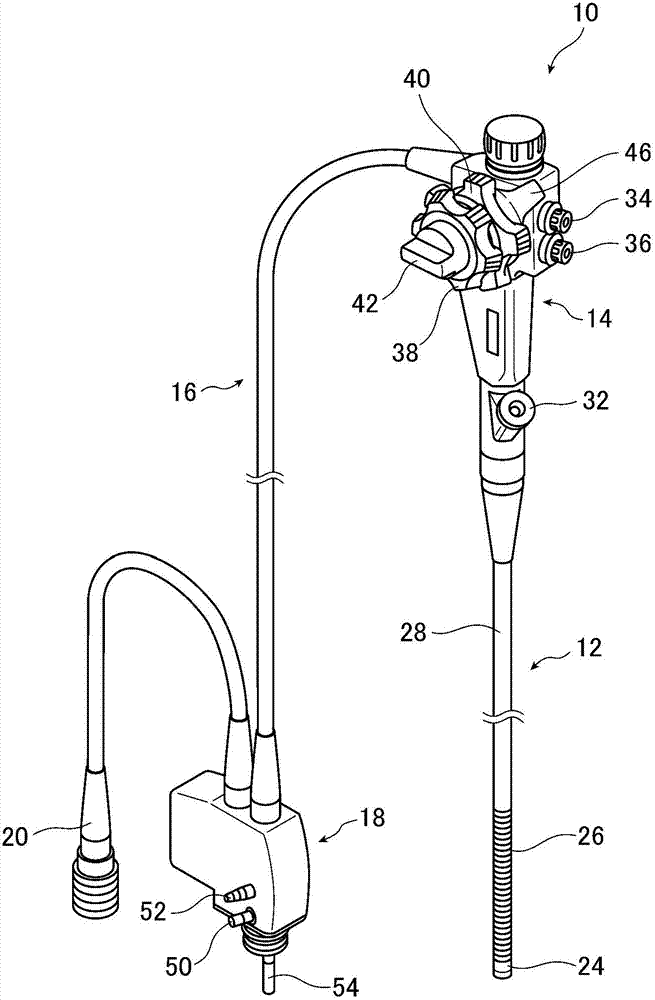

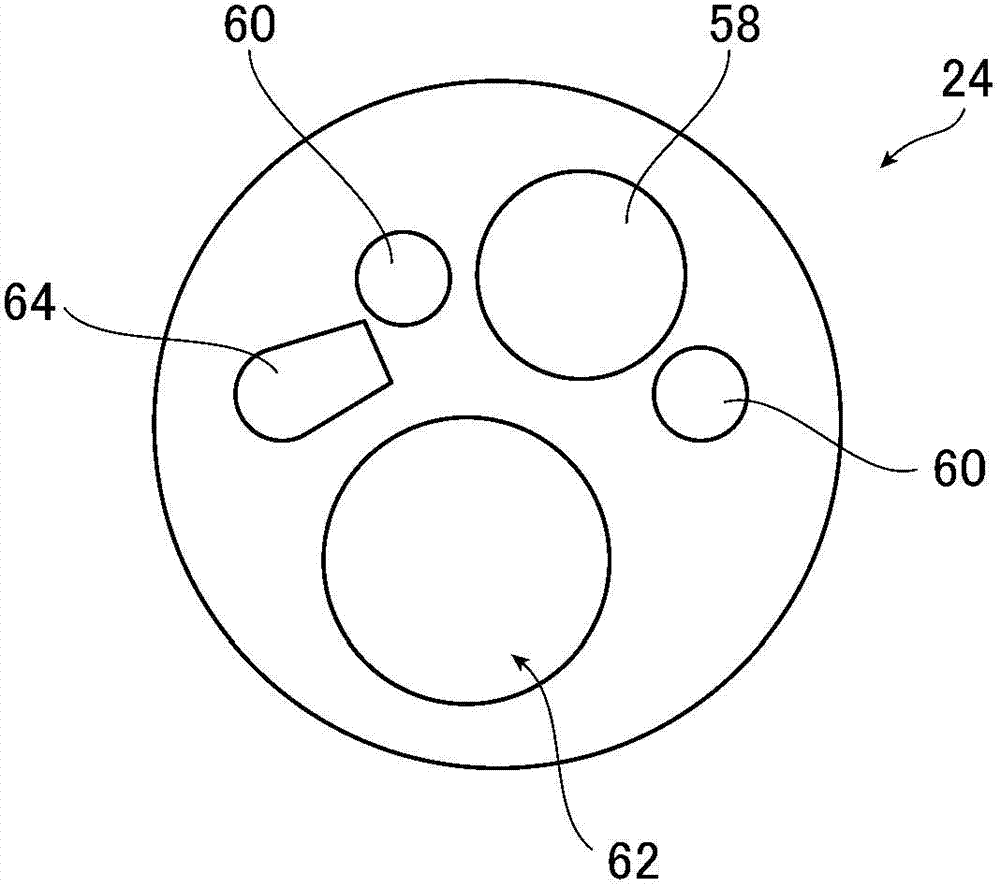

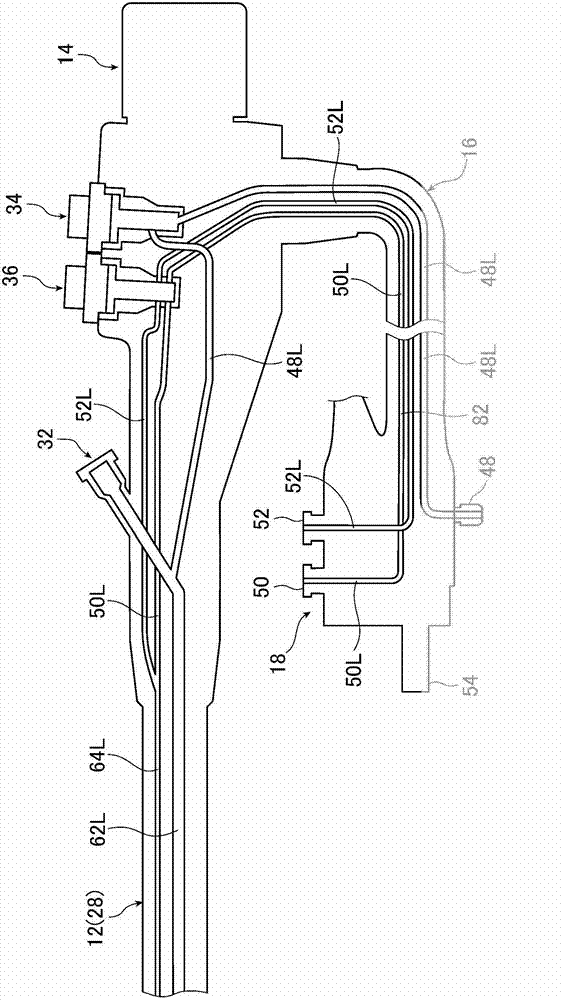

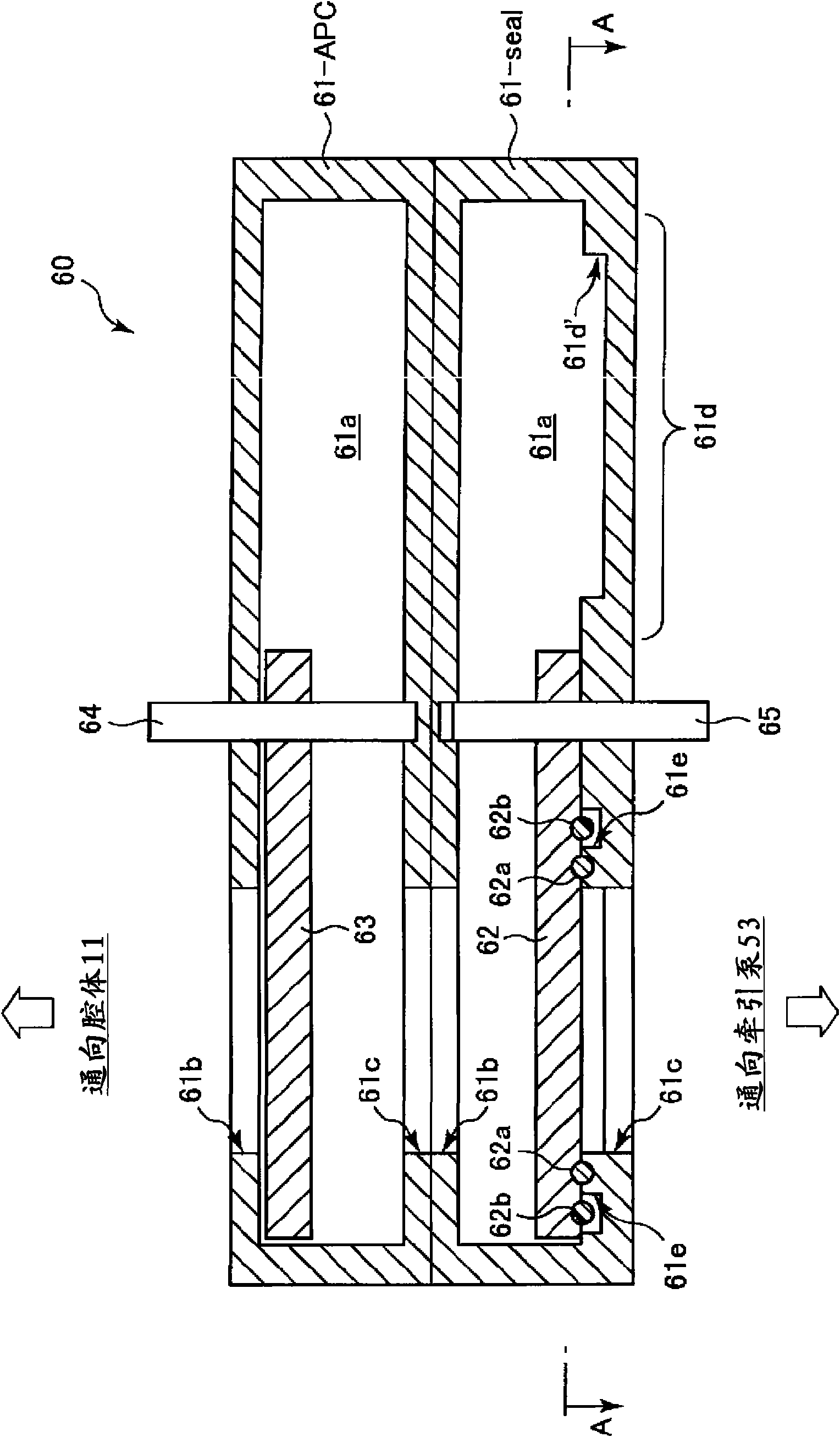

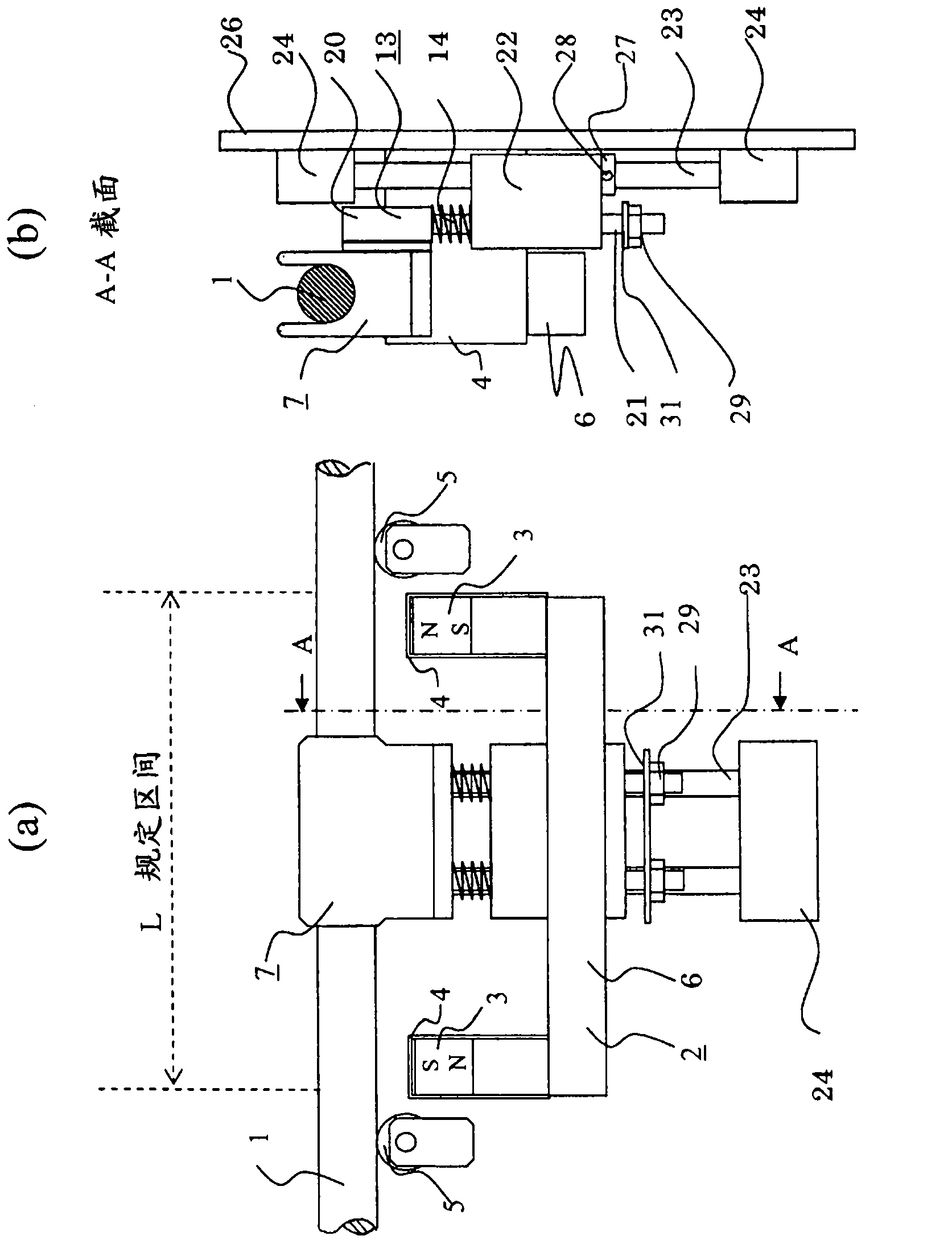

Fluid pipeline switching device and endoscope

The present invention provides a fluid pipeline switching device. In the fluid pipeline switching device for an endoscope, when a piston is detached, contact between the filter and connecting holes formed on an operating cylinder can be prevented, thereby preventing filler damage. The fluid pipeline switching device is provided with the following components: a press button which is provided with a piston and a plurality of sealing components; the operating cylinder which gradually necks in an insertion direction of the piston and is provided with the connecting holes connected with the fluid pipeline; and a limiting member which is used for limiting the lower position of the piston. The plurality of sealing components gradually thins to the front end and separates the space in the operating cylinder along the axis direction. The diameter of the sealing component is smaller than the inner diameter of the upper segment of the segment of the piston, which is in slidable contact with the sealing component. Furthermore the positions of the connecting holes for connecting each fluid pipeline with the operating cylinder are closer to the front end than the lower-end position of the sealing components which slidably contact with corresponding components, thereby settling the task of the invention.

Owner:FUJIFILM CORP

Aluminum alloy brazing fin material for heat exchanger

InactiveCN101124451AAchieve long lifeNo problems with disengagementSoldering apparatusWelding/soldering/cutting articlesPlate heat exchangerChemical composition

An aluminum alloy brazing fin material for an automobile heat exchanger, which comprises a core material and, being clad on the both surfaces thereof, an Al-Si based alloy brazing material, characterized in that the above core material is composed of an aluminum alloy having a chemical composition that Mn: 0.8 to 2.5 %, Si: 0.1 to 1.0 %, Fe: 0.06 to 0.3 %, Zn: 0.8 to 4.0 % and the balance: Al and impurities, and the above brazing material is composed of an aluminum alloy having a chemical composition that Si: 6 to 13 %, Cu: 0.06 to 0.4 % and the balance: Al and impurities, and that the brazing material is clad on both surfaces of the core material with a thickness of 3 to 20 % of the total thickness, respectively. The above aluminum alloy brazing fin material for an automobile heat exchanger exhibits excellent formability and excellent corrosion resistance even under a severe corrosion circumstance.

Owner:SUMITOMO LIGHT METAL INDS LTD

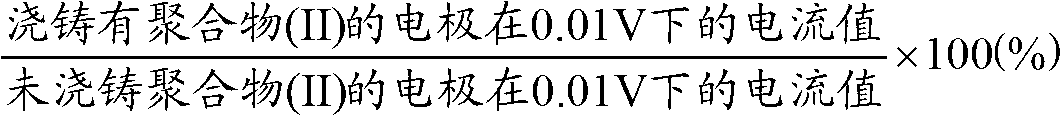

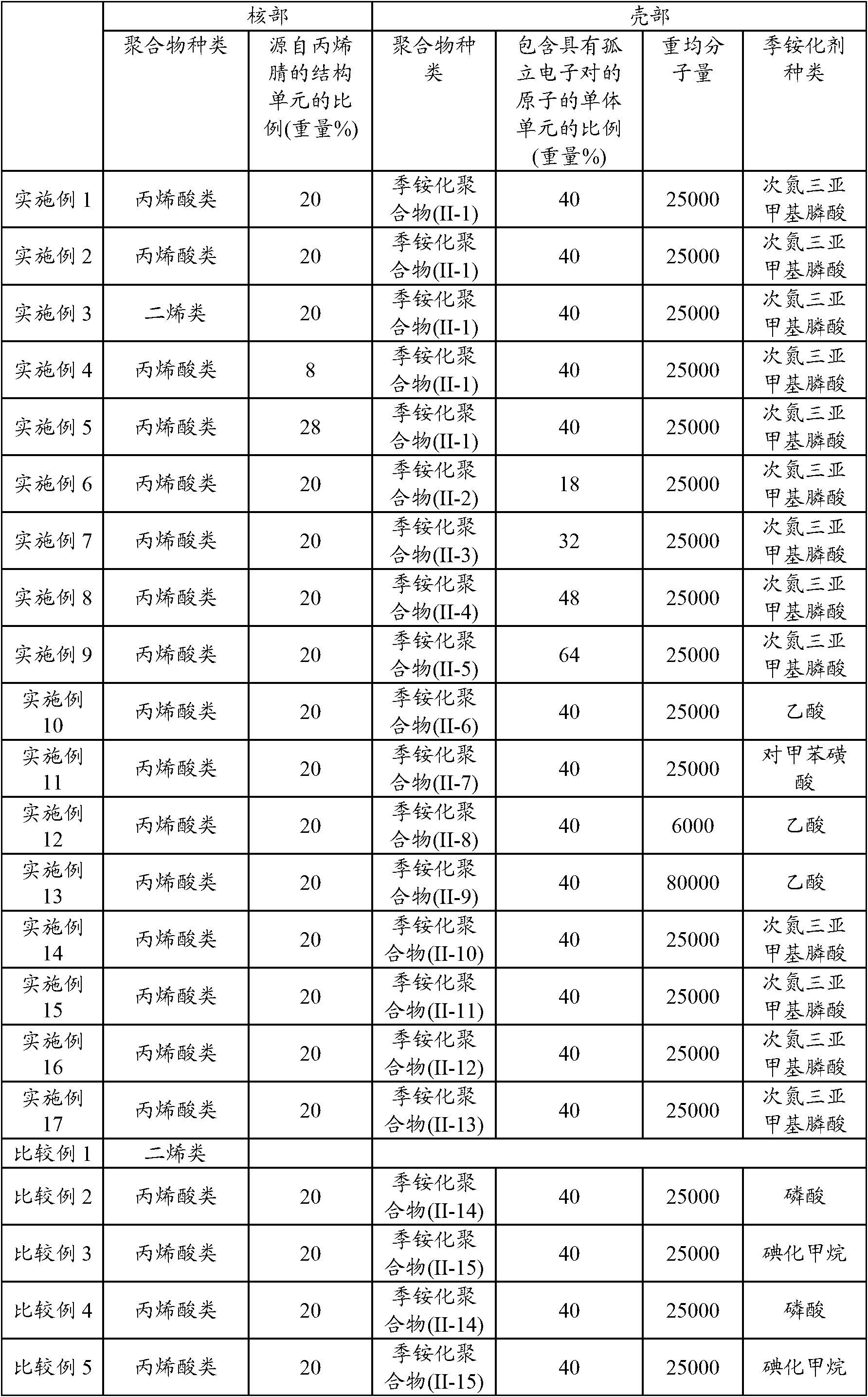

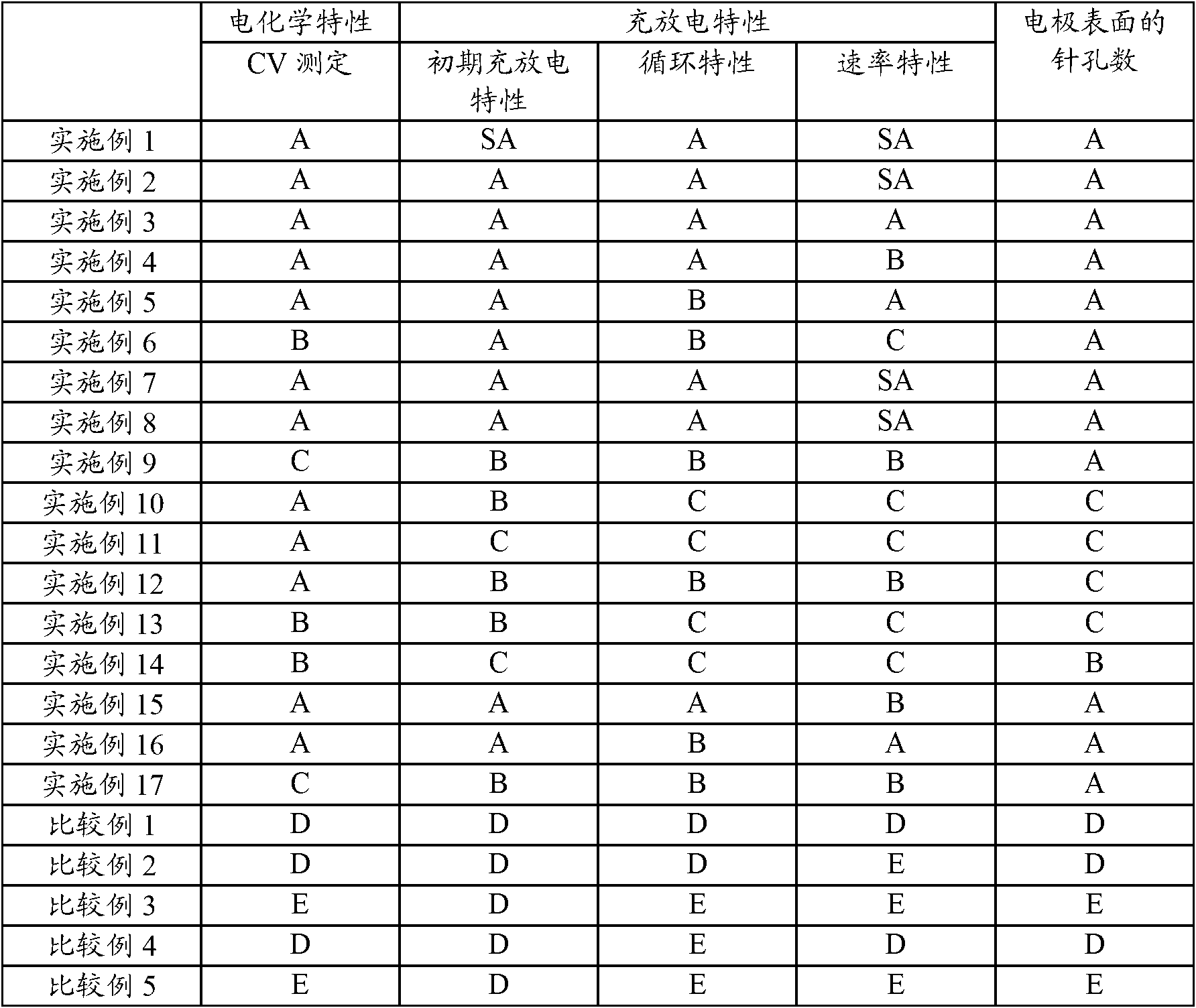

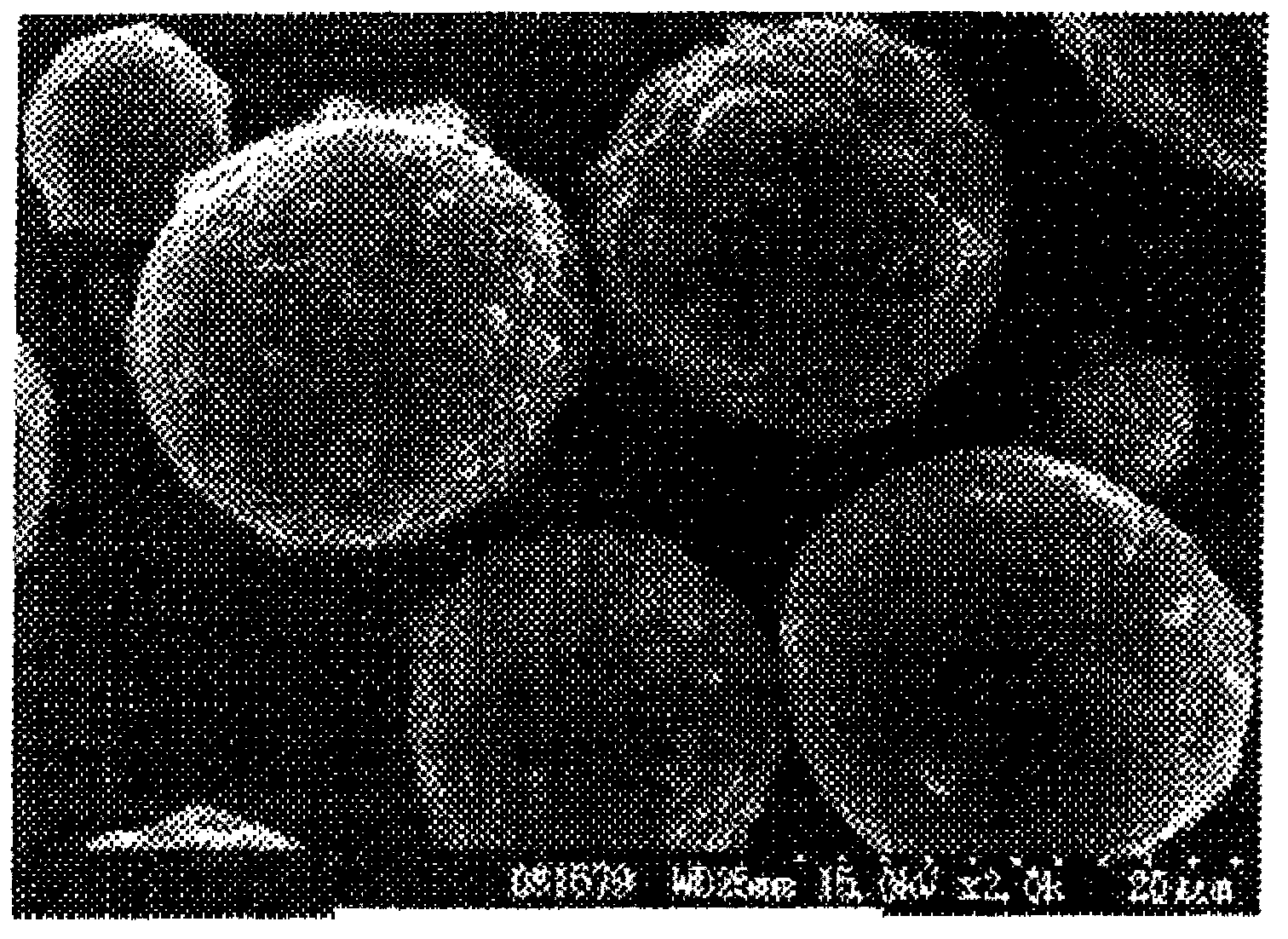

Binder particles for electrochemical element

InactiveCN102742051AAchieve long lifeImprove dispersion stabilityElectrolytic capacitorsHybrid capacitor electrodesLithiumOrganic acid

Disclosed is a binder for an electrochemical element, which does not contain any component that is decomposed at a voltage at which lithium is inserted into a negative electrode active material, and has excellent output properties ad life properties without being increased in internal resistance. Specifically disclosed are binder particles for an electrochemical element, each of which is composed of a core part and a shell part, and is characterized in that the shell part comprises a polymer that contains a monomer unit containing an atom having a lone pair wherein the atom is converted into the form of a quaternary cation with an organic acid.

Owner:ZEON CORP

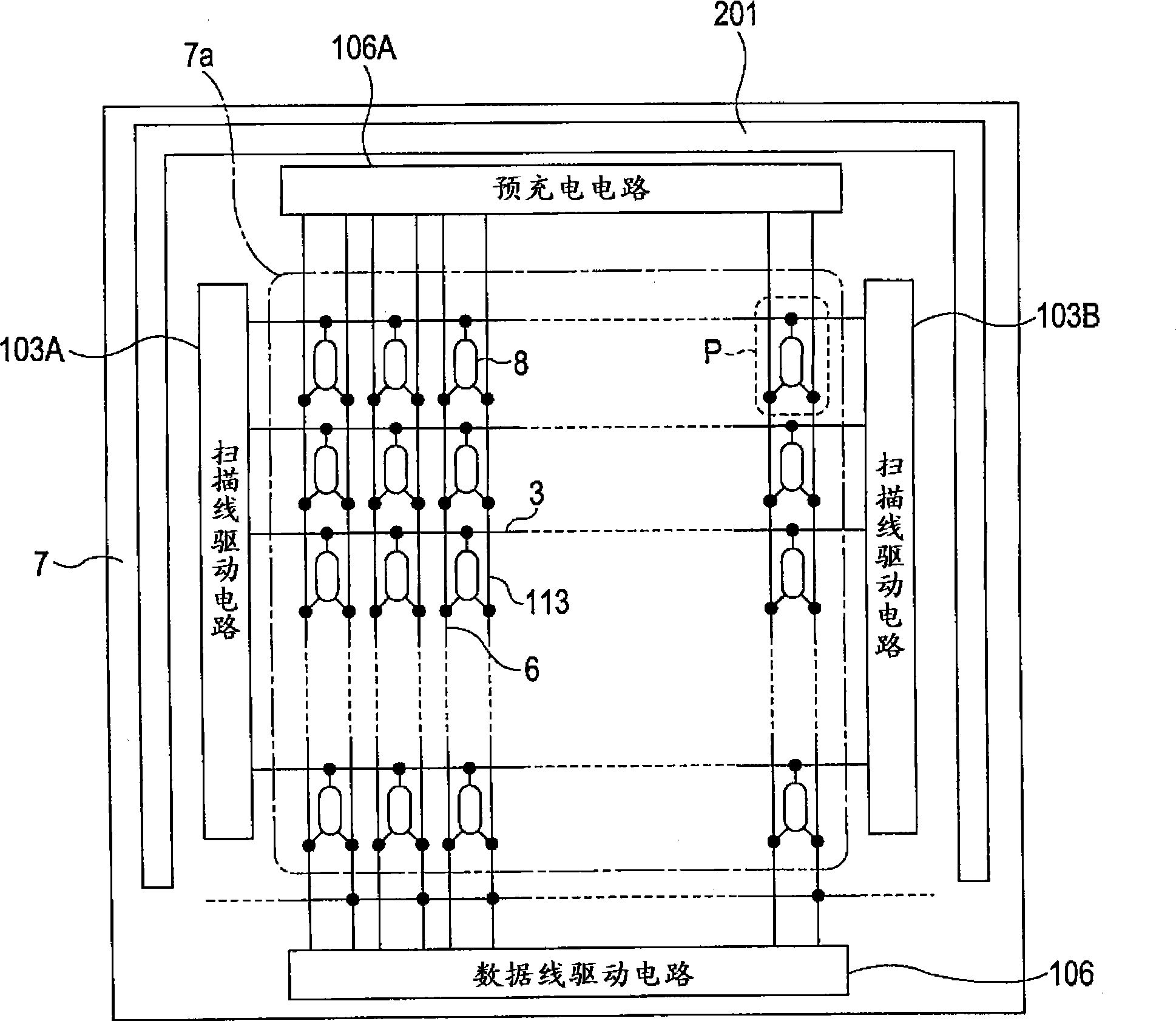

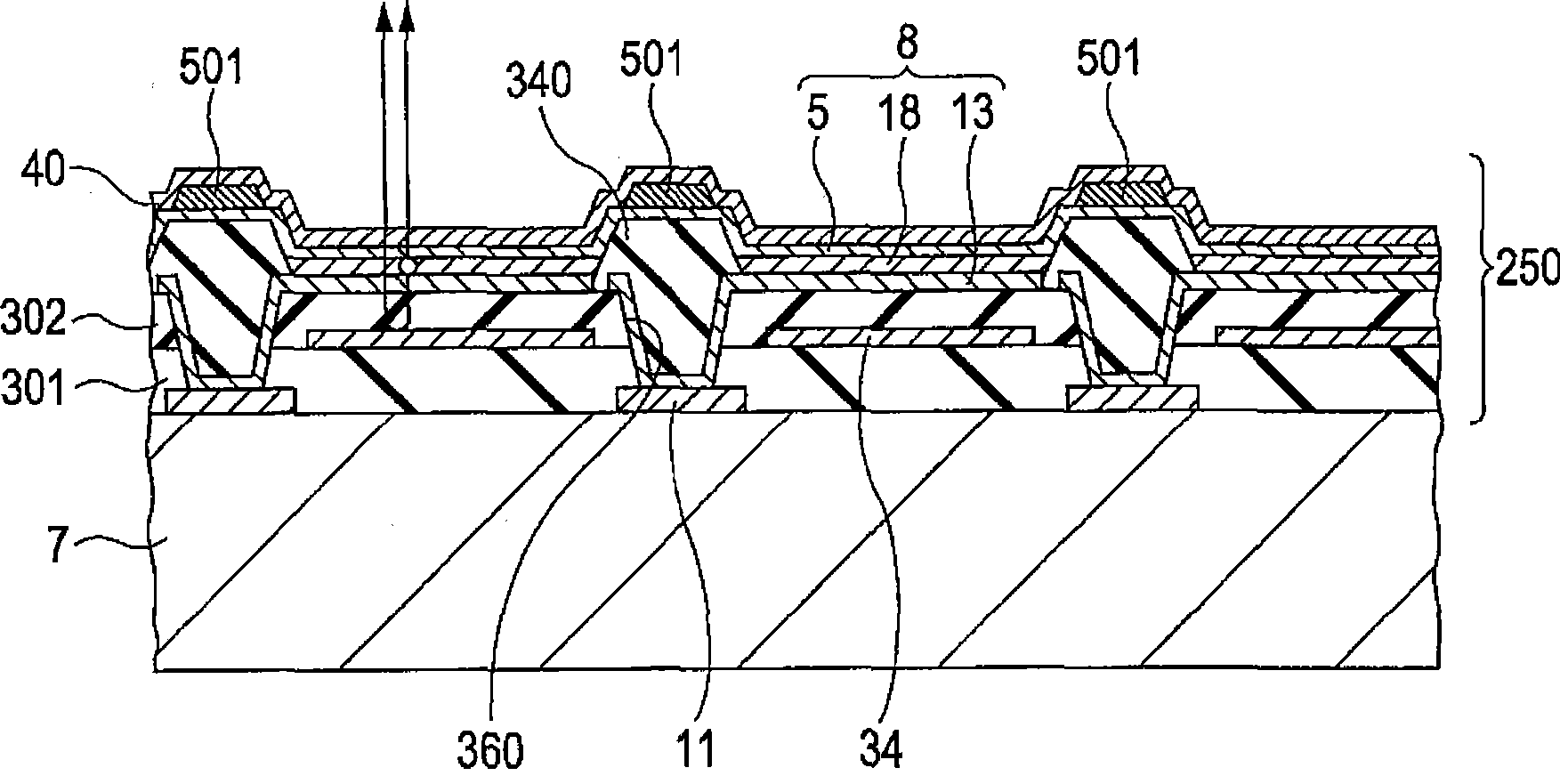

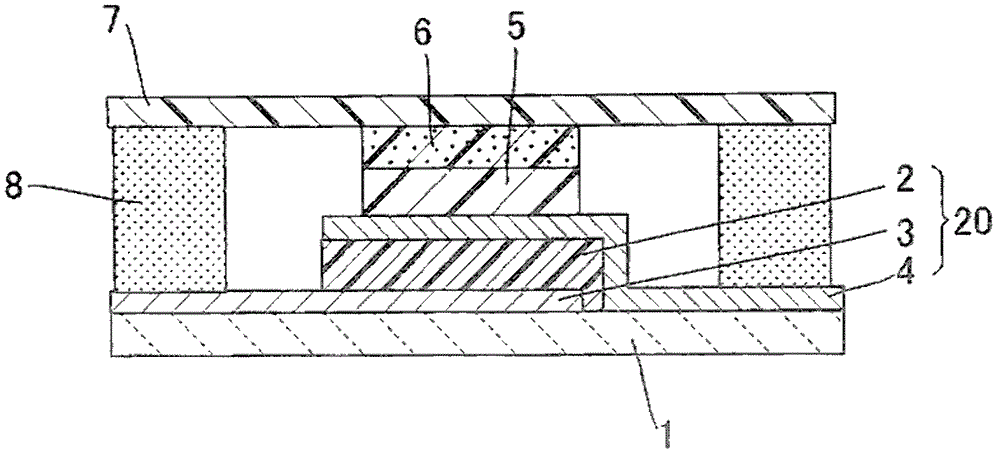

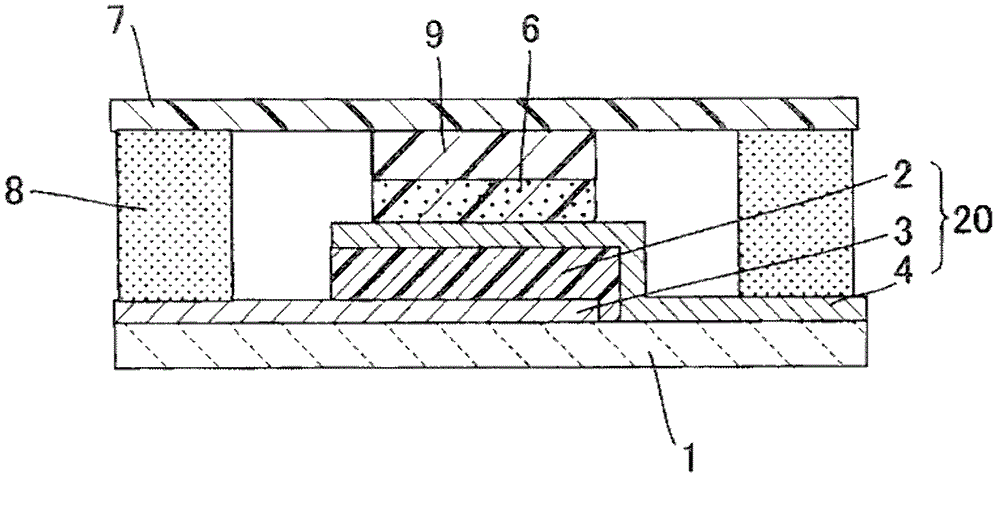

Light-emitting device, electronic apparatus, and film-forming method

InactiveCN101452947ANot prone to defects such as cracksAvoid crackingVacuum evaporation coatingSolid-state devicesEngineeringAuxiliary electrode

The present invention relates to a light-emitting device, electronic apparatus and film forming method. The light-emitting element includes: a pixel electric (13), a light-emitting function layer (18) and an organic EL element (8) of opposing electrode (5); an auxiliary electrode (501) formed on the opposing electrode with direction connection point with the opposing electrode; and a barrier layer (40) is formed so as to cover the auxiliary electrode and the opposing electrode, capable of preventing water and oxygen from penetrating into the organic EL element. In addition, the auxiliary electrode is in a strip shape extending in the first direction and has a cross section taken along the direction intersecting the first direction, having a shape including a tapered portion. Thus the organic EL element has long life.

Owner:SEIKO EPSON CORP

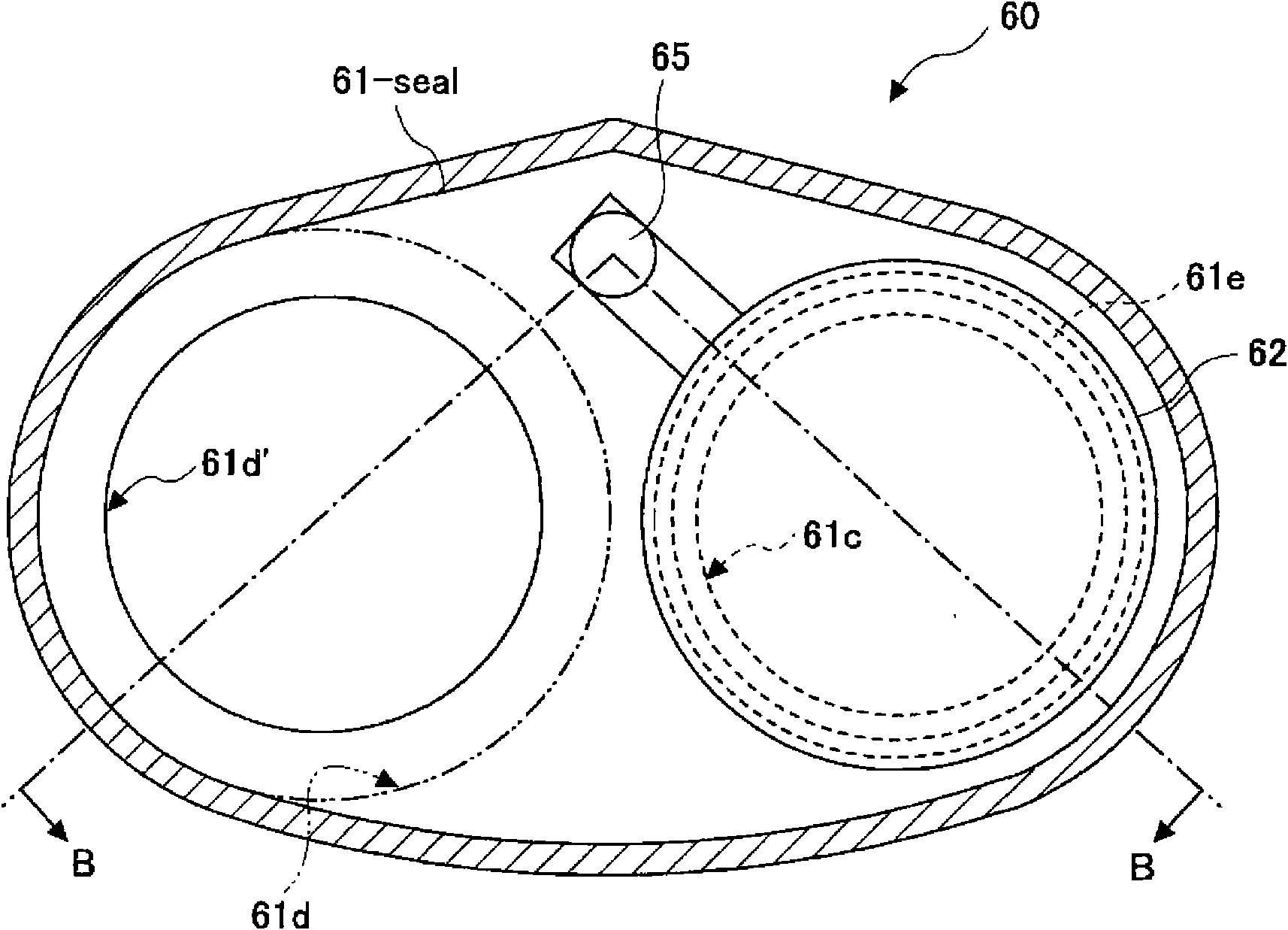

Valve and processing device with the valve

Owner:TOKYO ELECTRON LTD

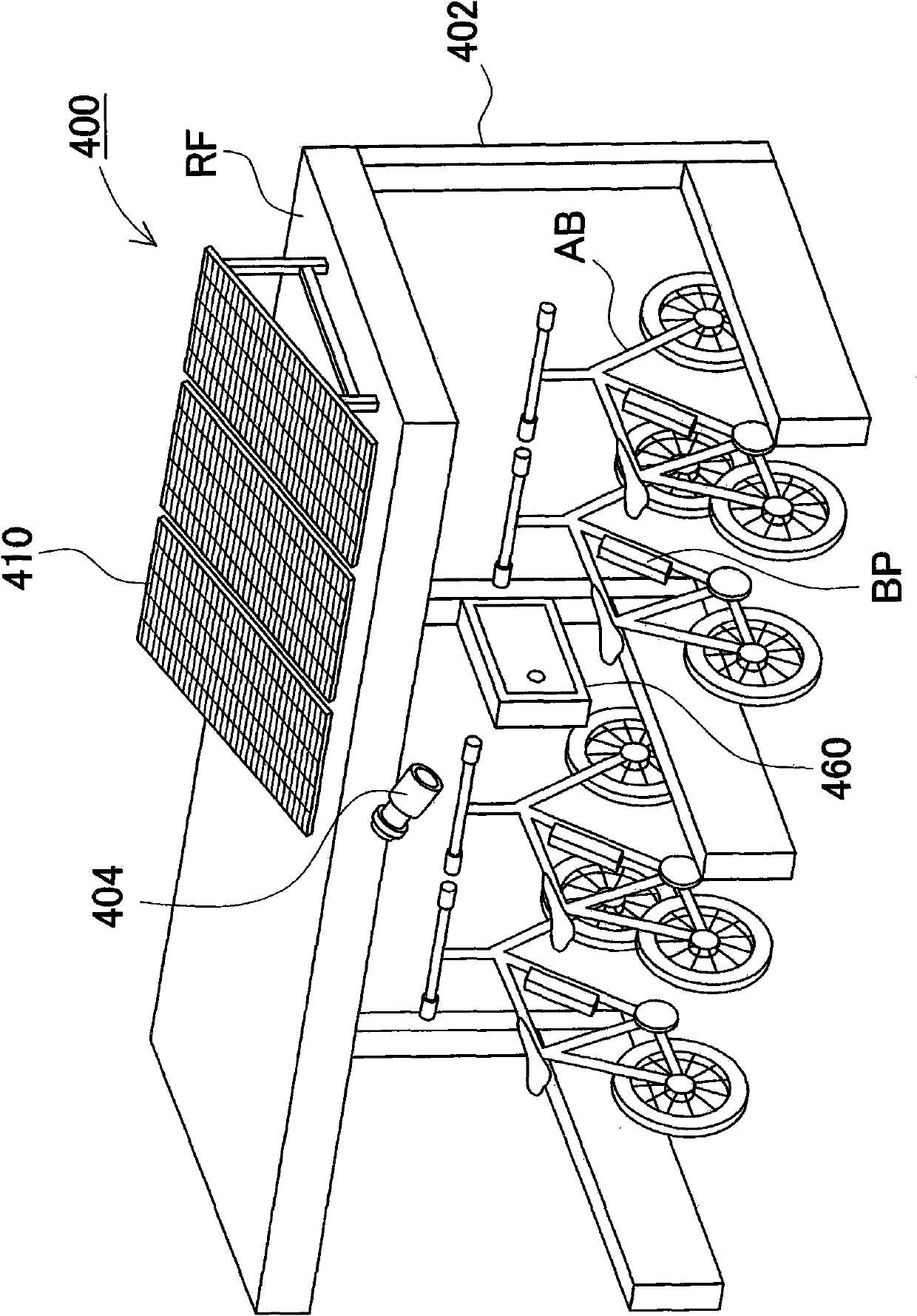

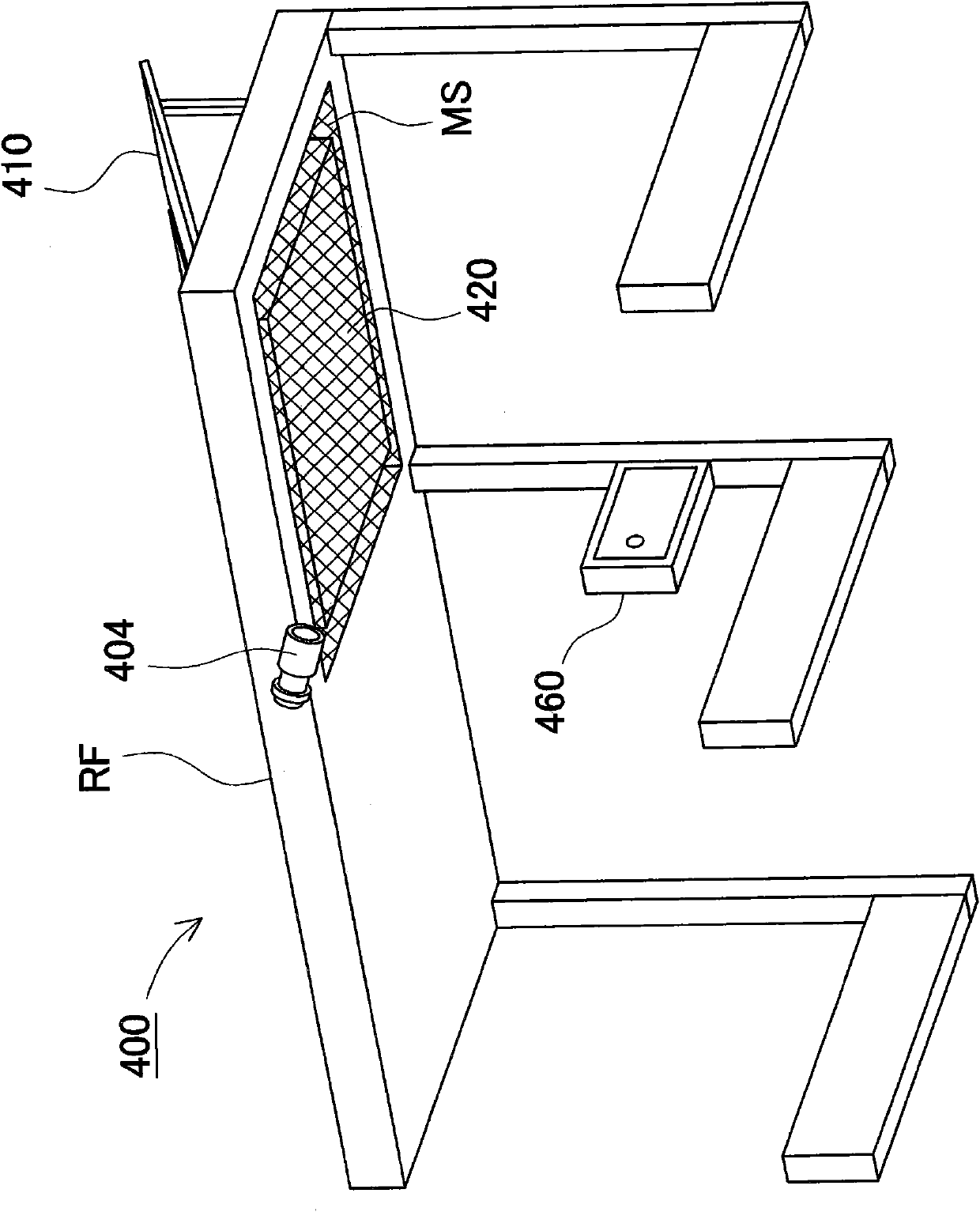

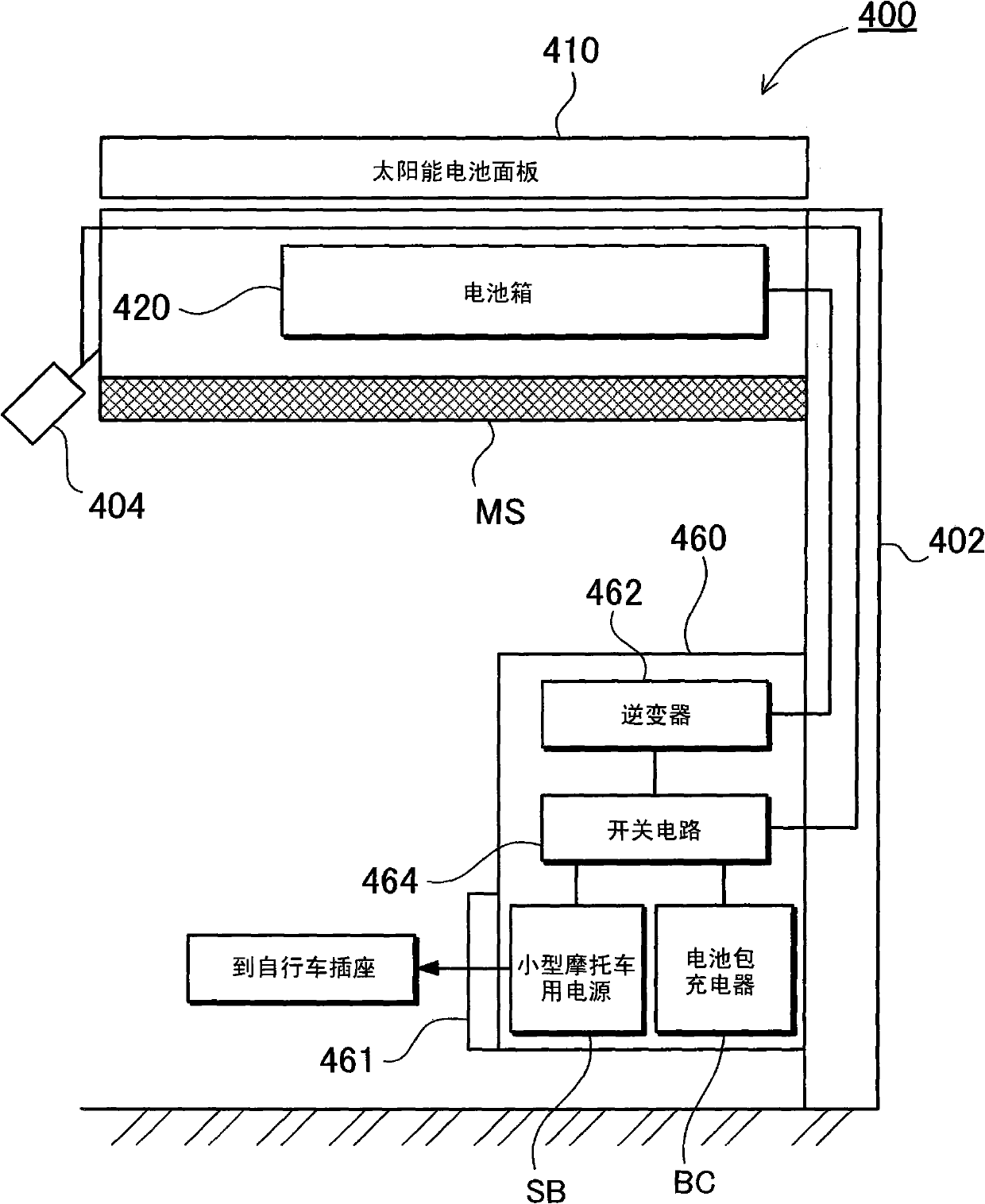

Solar cell power supply device and rechargeable battery solar charging method

InactiveCN102142702ARealize power generation and storageAchieve maintenanceCharge equalisation circuitCharging stationsElectrical batteryEngineering

Owner:SANYO ELECTRIC CO LTD

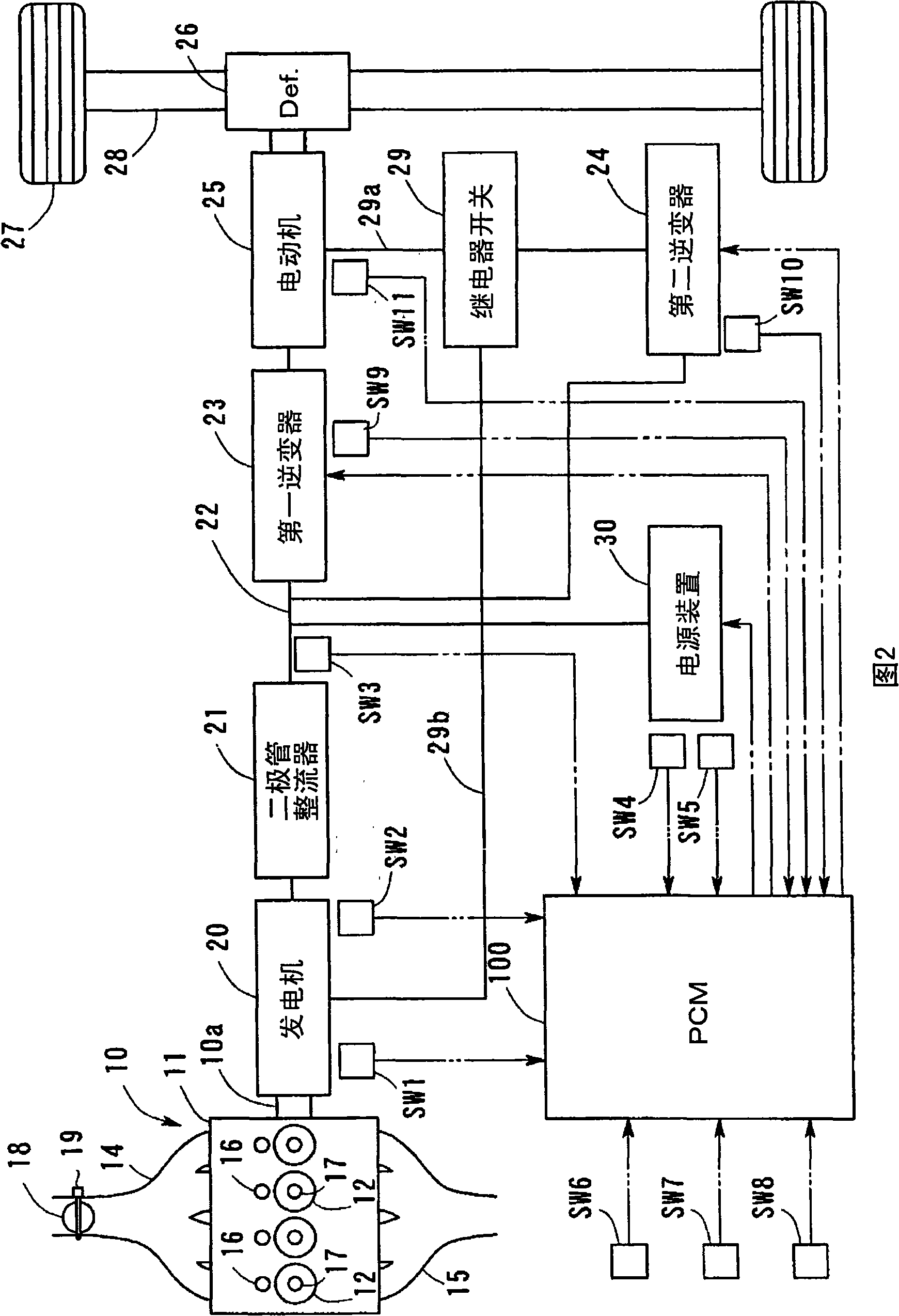

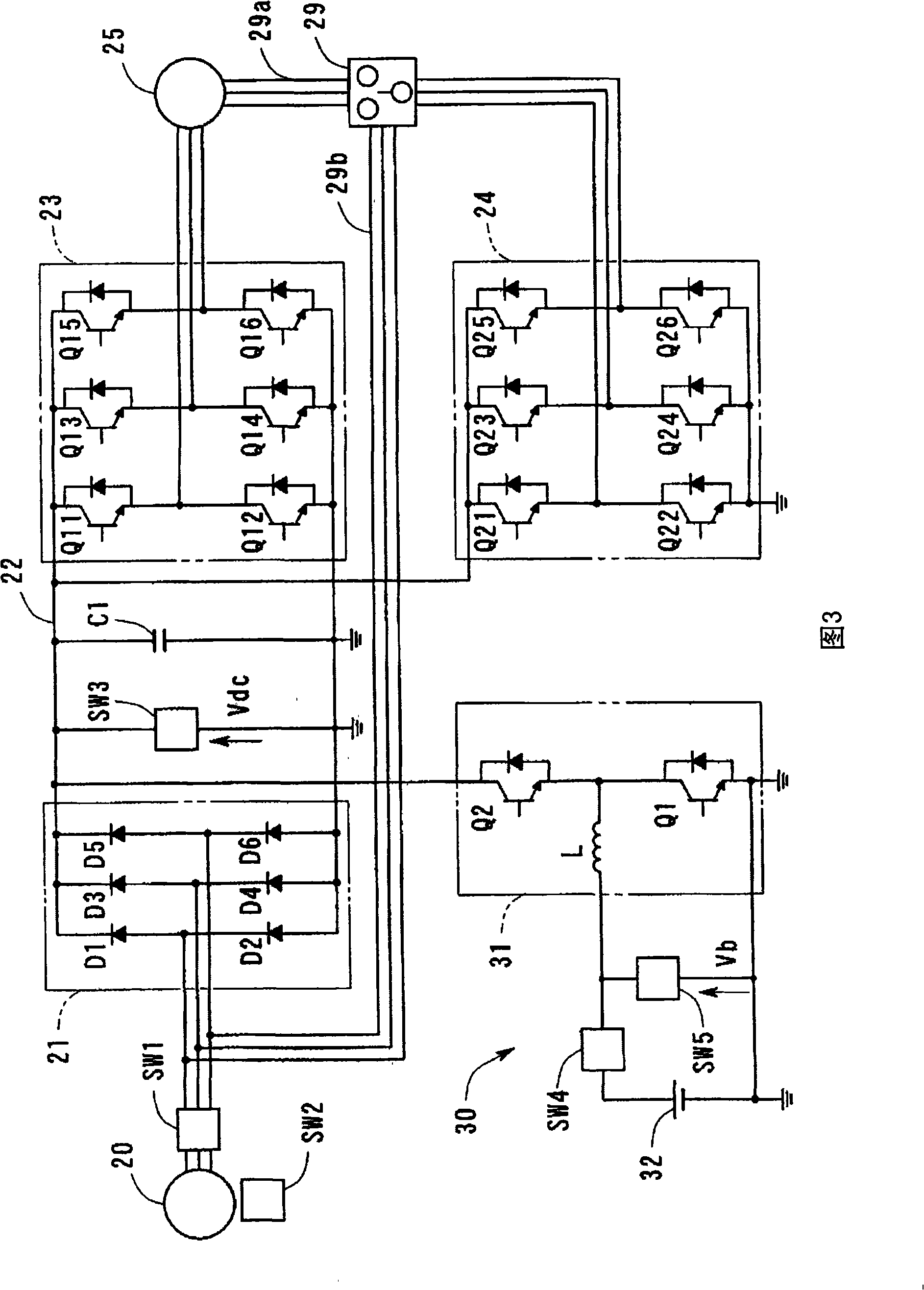

Control for hybrid electric vehicle and control method

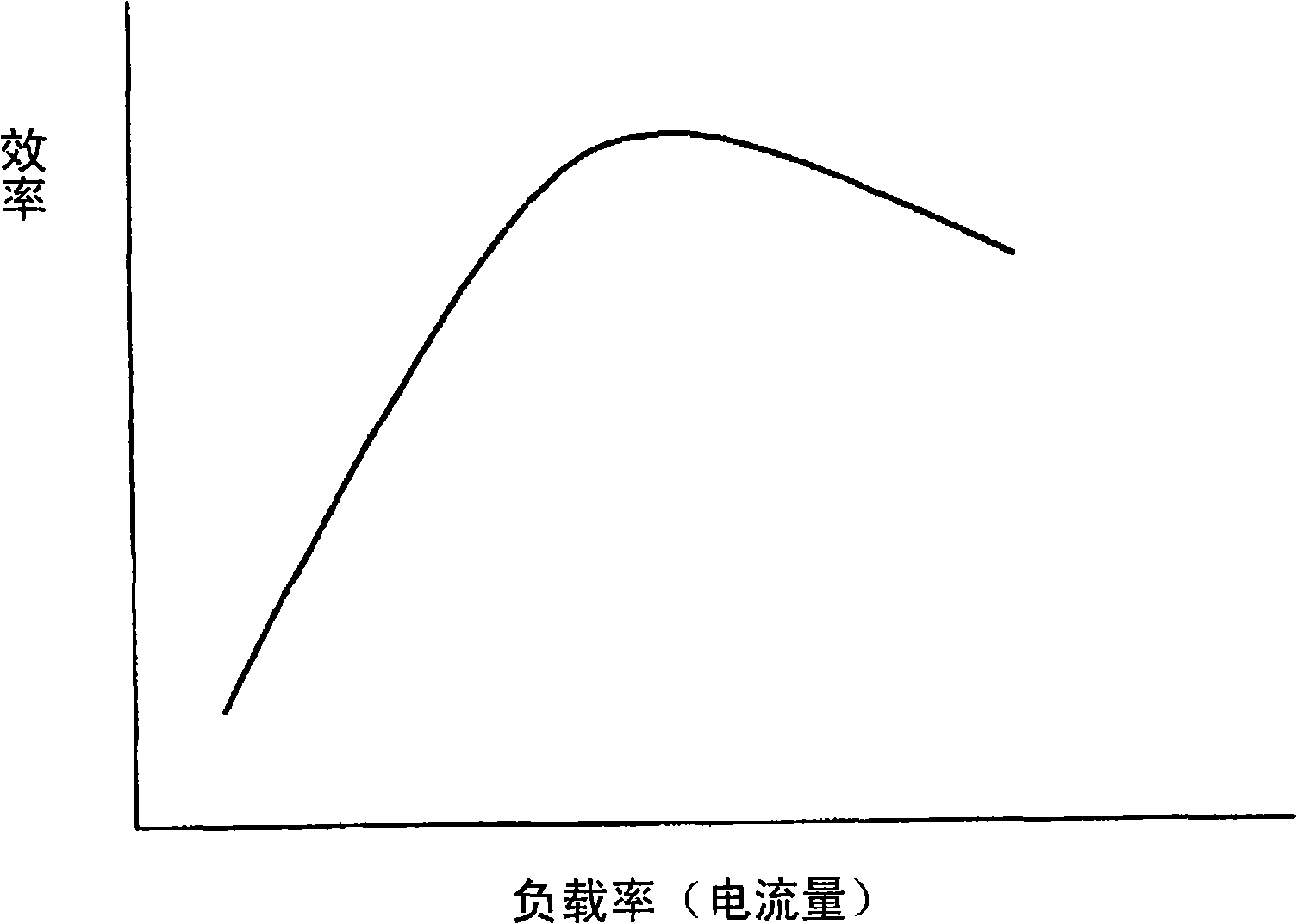

InactiveCN101332777AImprove operating rateImprove efficiencyHybrid vehiclesPropulsion using engine-driven generatorsAutomotive engineeringElectric vehicle

The present invention relates to a hybrid electric vehicle, a control system and method thereof. The hybrid electric vehicle comprises a first inverter (23) for converting the DC of a generator (20) into AC and a second inverter (24) connected with the first inverter (23) in parallel. A generator (25) connects with the first inverter (23) and the second inverter (24). The hybrid electric vehicle calculates needed current when generator (25) is driving, and controls selective operation of the first inverter (23) and the second inverter (24) based on the current so as to drive the first inverter and the second inverter to operate with optimal efficiency. In addition, the hybrid electric vehicle calculates the current generated by the generator (25) when using a current generating accumulator generated by the generator (25), and controls selective operation of the first inverter (23) and the second inverter (24) based on the current so as to drive the first inverter and the second inverter to operate with optimal efficiency. The hybrid electric vehicle can also avoid inverters overloading.

Owner:MAZDA MOTOR

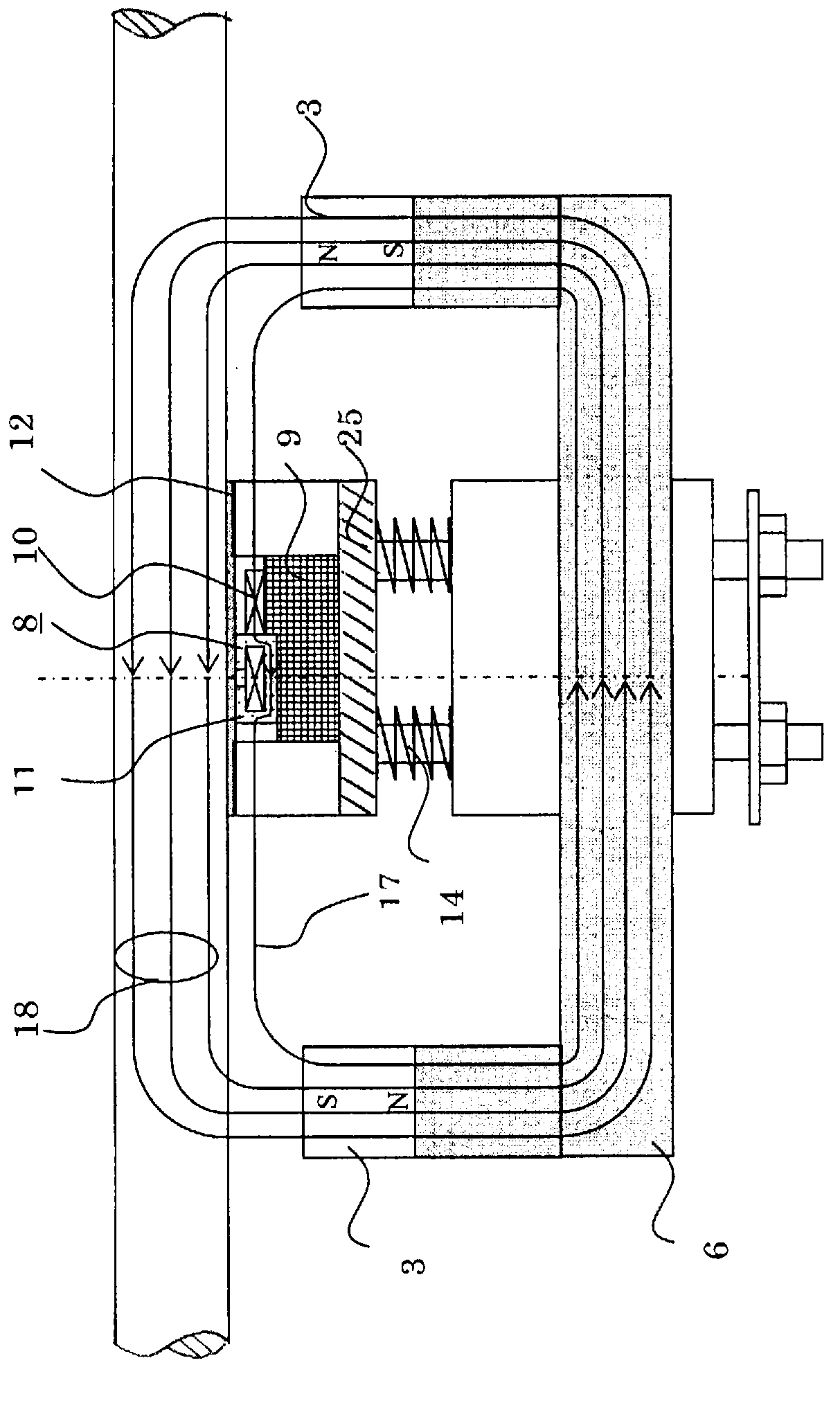

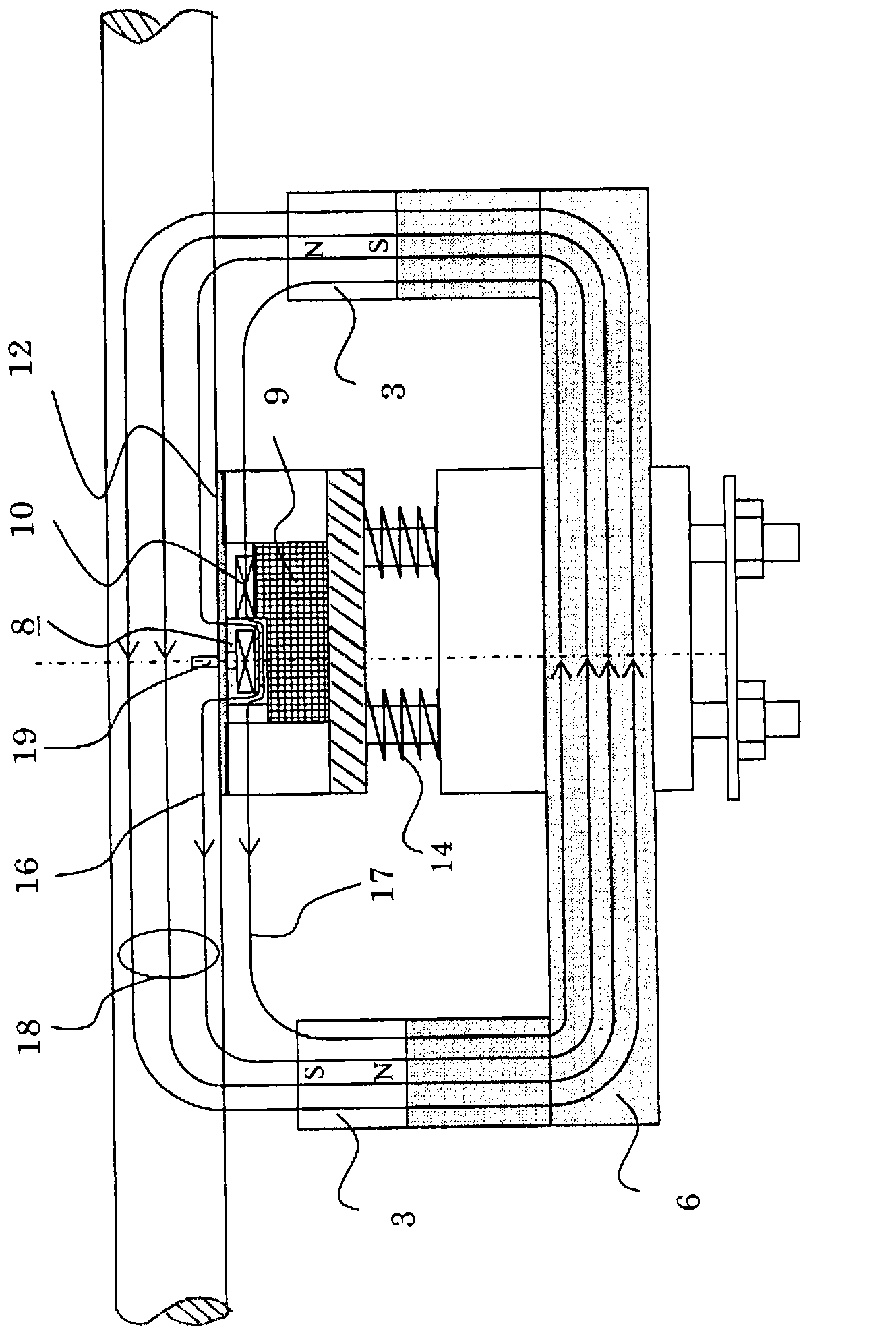

Wire rope flaw detection device

ActiveCN102713597AReduce wearDoes not compromise detection sensitivityMaterial magnetic variablesEngineeringMagnetic flux

Provided is a wire rope flaw detection device, wherein the life of the device is extended without impairing the detection sensitivity and S / N of a wire rope damaged portion. Specifically provided is a wire rope flaw detection device for magnetizing a predetermined section in the axial direction of a wire rope (1) by a magnetizer (2) configured from a back yoke (6) and a magnet (3) and detecting a leakage magnetic flux generated from a wire rope damaged portion (19) in the predetermined section by a magnetic sensor (8) to thereby detect the wire rope damaged portion (19). The magnetizer (2) for magnetizing the wire rope (1) is disposed without being in contact with the wire rope (1), and the magnetic sensor (8) is disposed in contact with the wire rope (1) with a protection plate (12) interposed therebetween.

Owner:MITSUBISHI ELECTRIC CORP

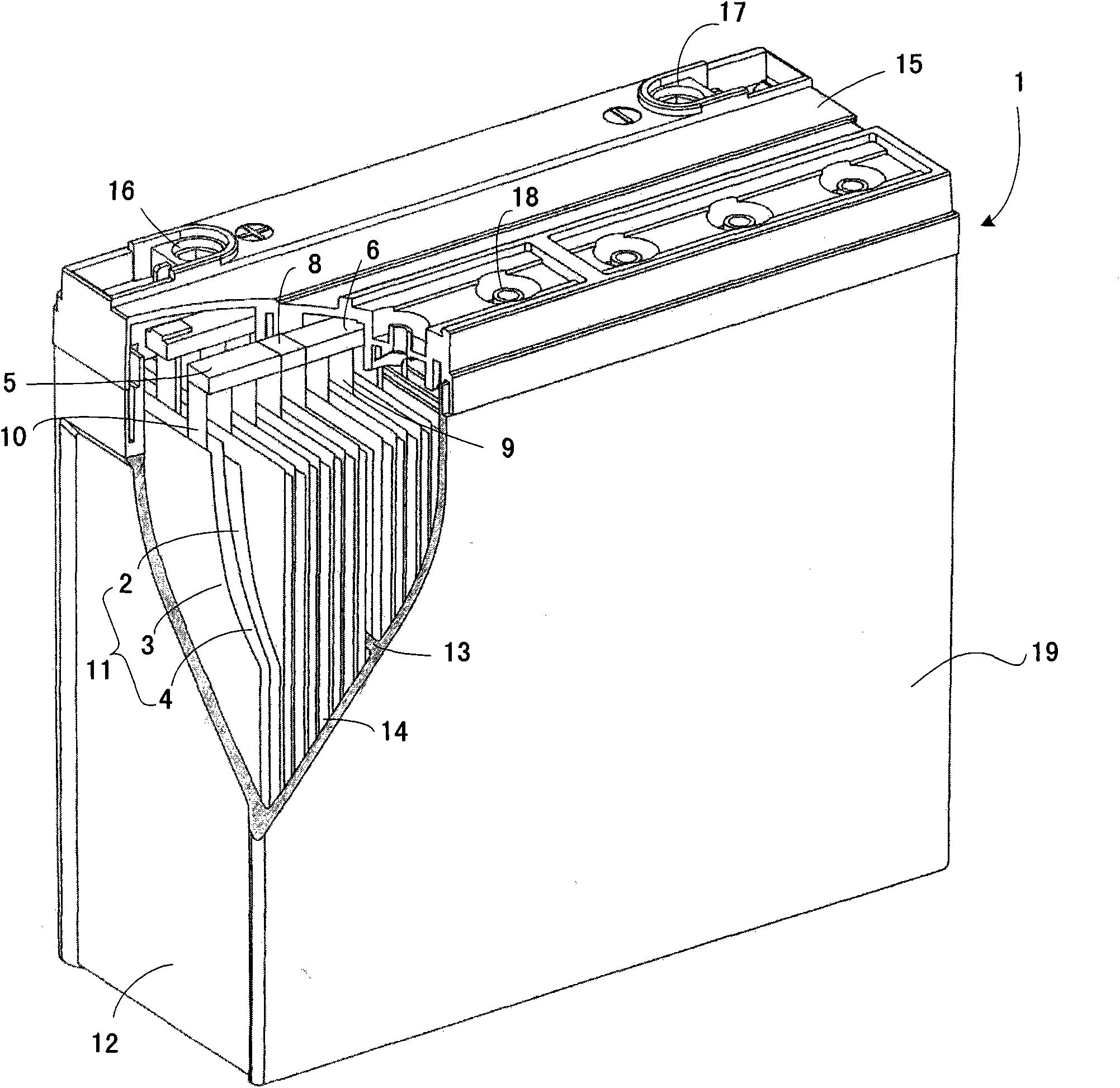

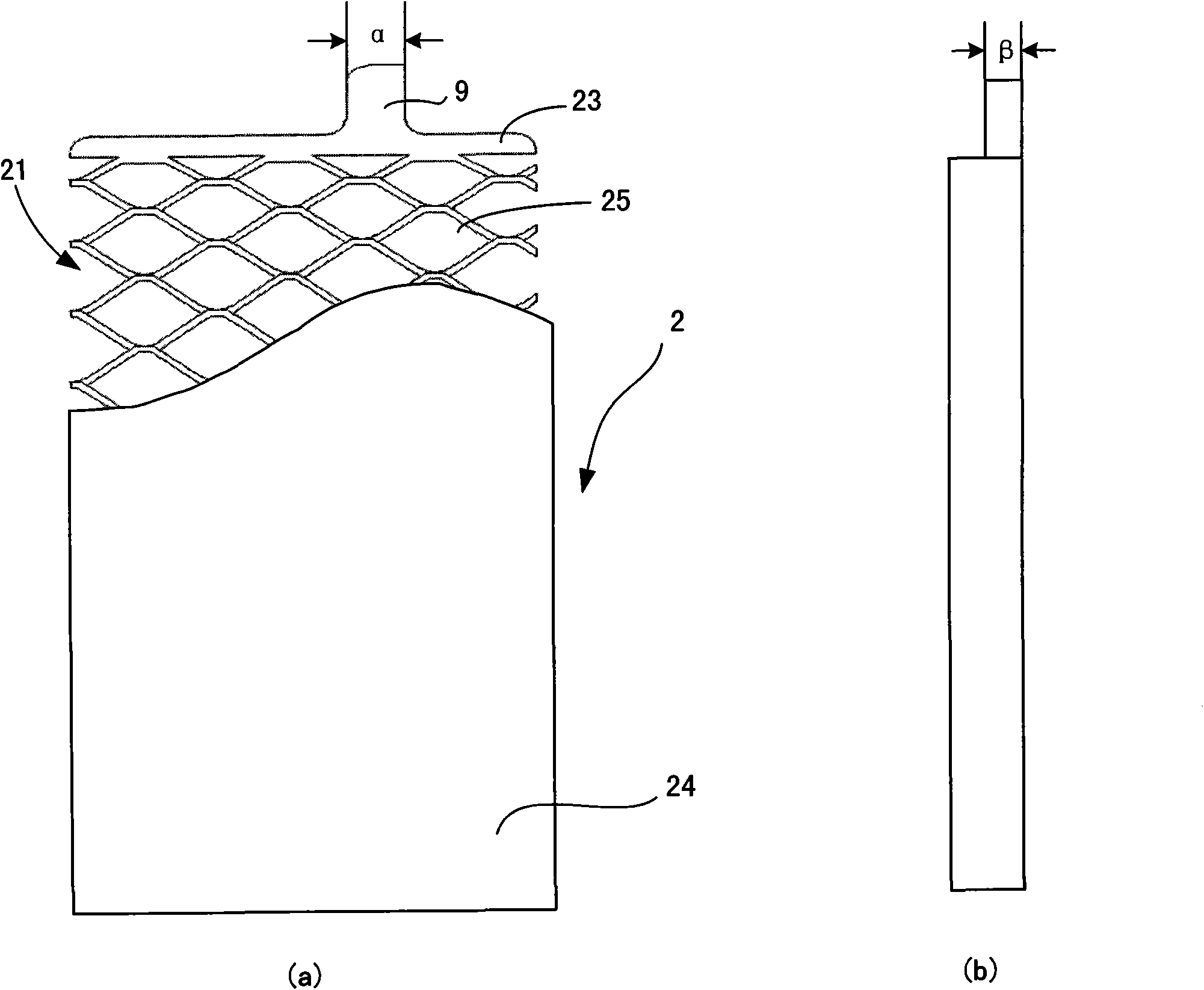

Lead storage battery

ActiveCN102738434AReduce volumeControl tortuosityFinal product manufactureElectrode carriers/collectorsBusbarEngineering

The invention provides a lead storage battery, which have a plurality of single cells (12). Each of the single cells includes an electrode plate group (11), an electrolyte and a single cell chamber (14). The electrode plate group (11) is accommodated in the single cell chamber (14) in the state of being impregnated in the electrolyte. The electrode plate group is composed of multiple positive electrode plates (2) and multiple negative electrode plates (3) that are alternately arranged via separators (4). Each positive electrode plate (2) comprises a positive electrode current collector with an electrode lug (9), and a positive active material layer held by the positive electrode current collector. Each negative electrode plate (3) comprises a negative electrode current collector with an electrode lug (10), and a negative active material layer held by the negative electrode current collector. The invention is characterized in that a positive electrode busbar (6) of the positive electrode plates of one single cell battery mentioned above and a negative electrode busbar (5) of the negative electrode plates are respectively connected with the respective negative electrode busbar (5) of the negative electrode plates and the positive electrode busbar (6) of the positive electrode plates of single cells adjacent to the single cell through non-electrode post direct welding, so that the plurality of single cells are connected in series. Moreover, the ratio of the sectional area of the electrode lug of each positive electrode plate to the sectional area of the electrode lug of each negative electrode plate is greater than or equal to 0.6 and less than 1.0.

Owner:松下蓄电池(沈阳)有限公司 +1

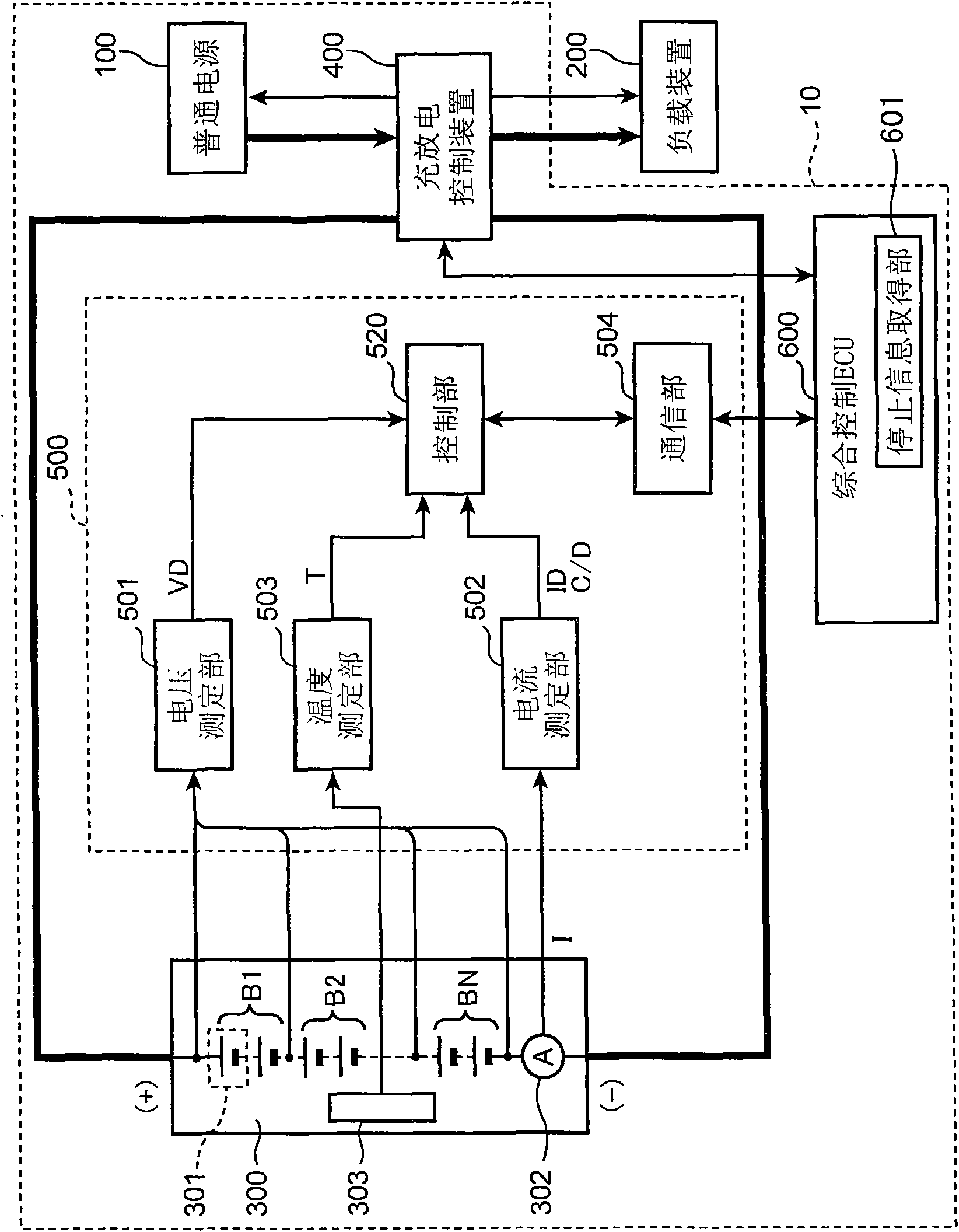

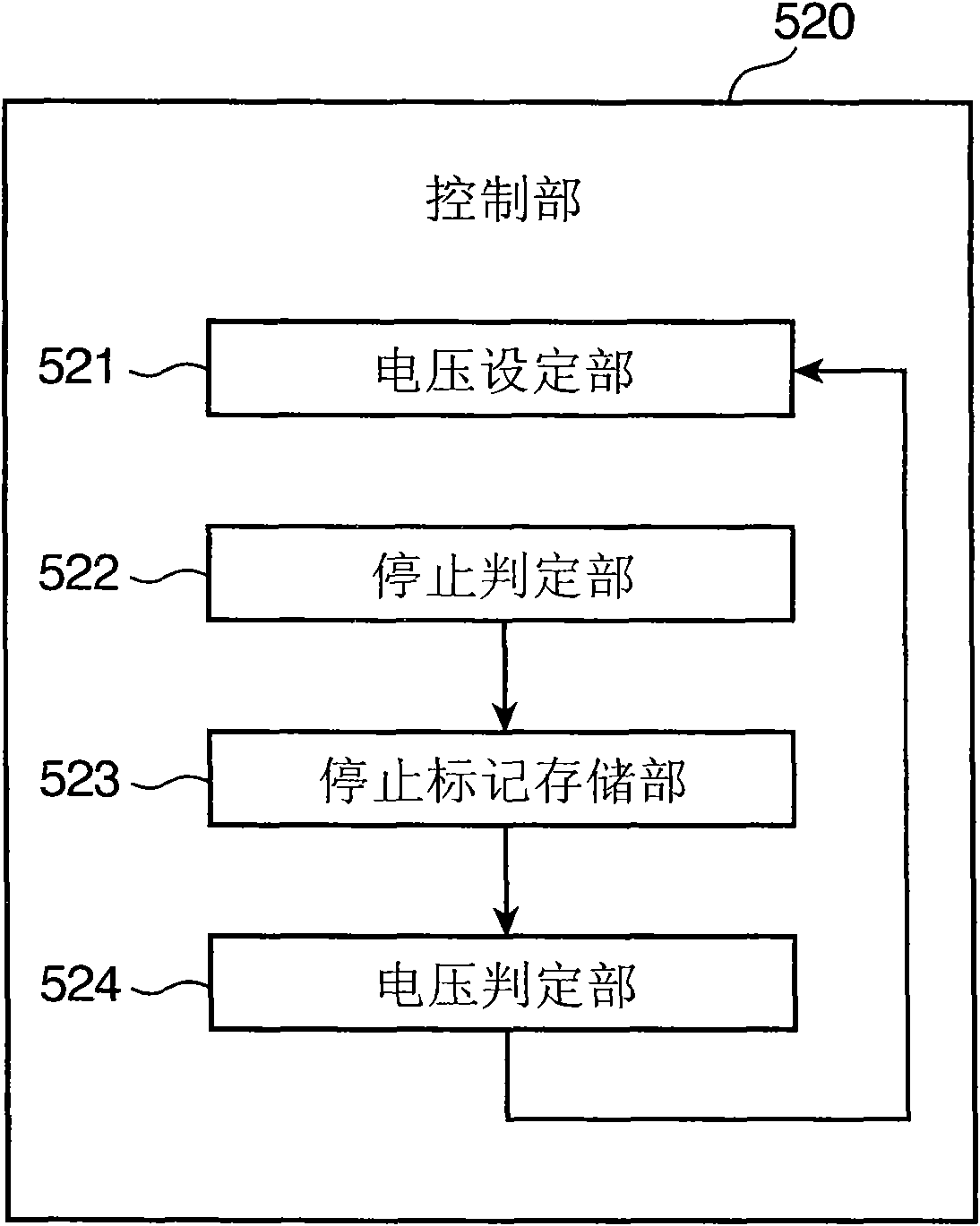

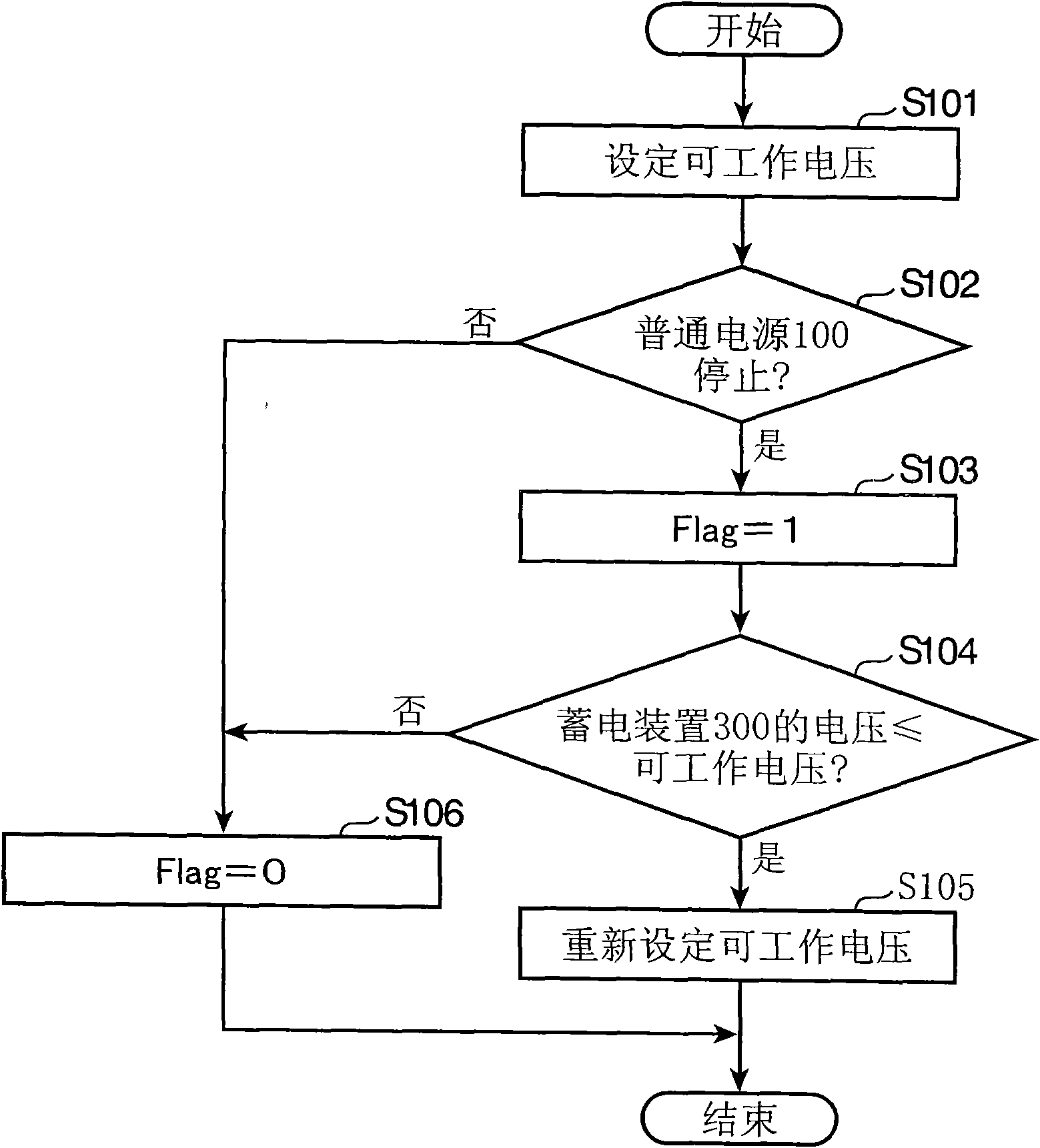

Power supply system, power supply control method of power supply system, power supply control program of power supply system, and computer readable recording medium having power supply control program

InactiveCN101563828AReduced working voltageDoes not increase the number of over-dischargesSecondary cells charging/dischargingElectric powerEngineeringElectric power

The invention provides a power supply system in which power supply capacity of an electric power accumulator can be increased temporarily when normal power supply is stopped, a power supply control method of the power supply system, a power supply control program of the system, and a computer readable recording medium having power supply control program of the system recorded thereon. Upon receiving normal power supply stop information from an integral control ECU, a control section lowers an operatable voltage determined as an output voltage for ending discharge of the electric power accumulator and delivers the lowered operatable voltage from a communicating section to the integral control ECU. Based on the lowered operatable voltage, the integral control ECU controls a charge / discharge controller to increase power supply capacity of the electric power accumulator.

Owner:PANASONIC CORP

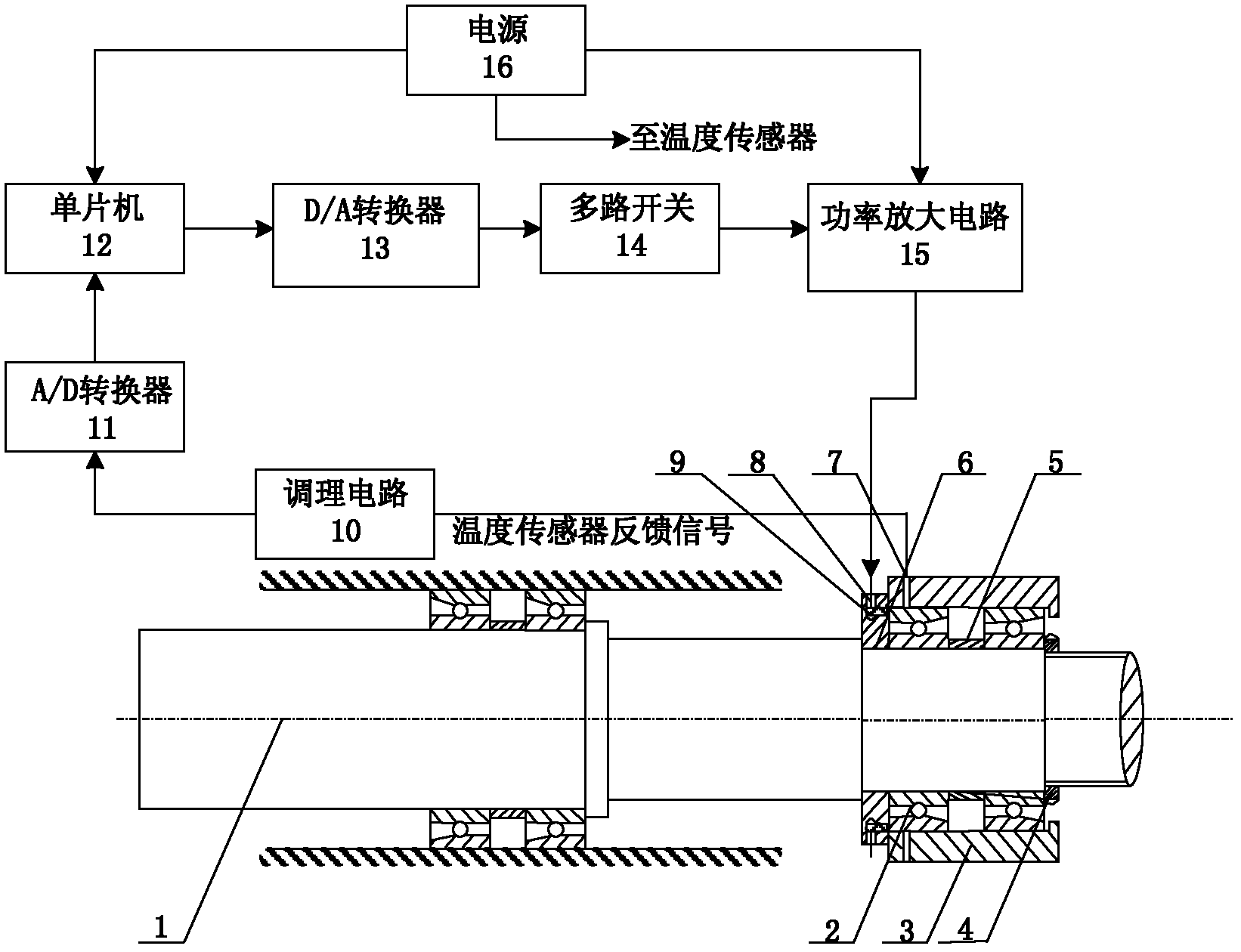

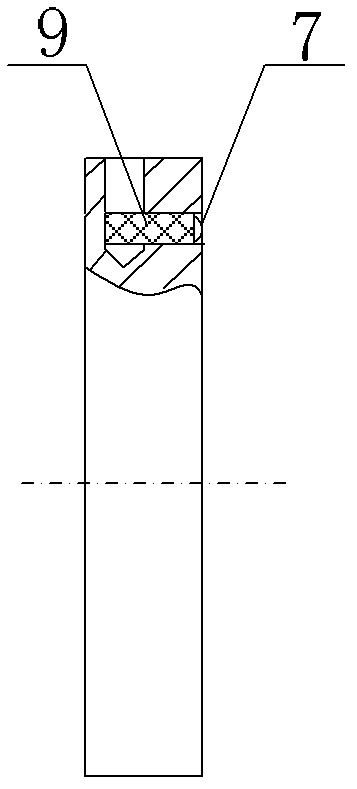

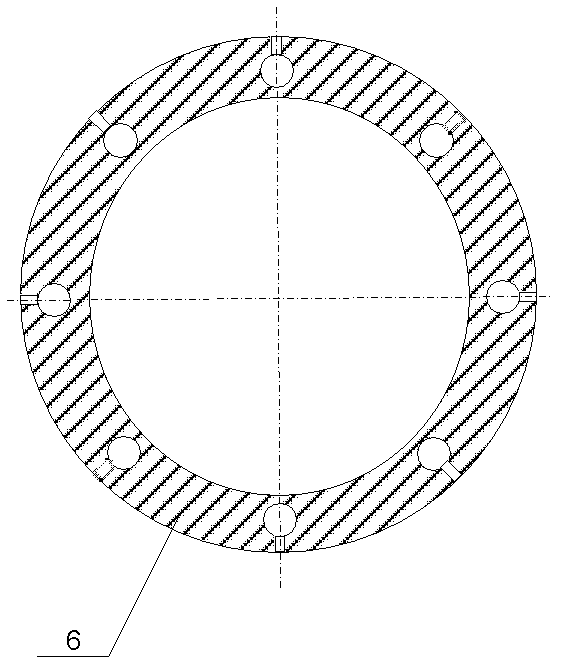

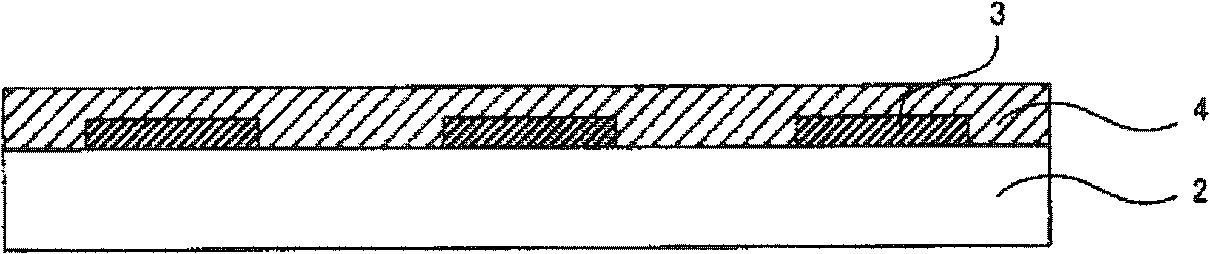

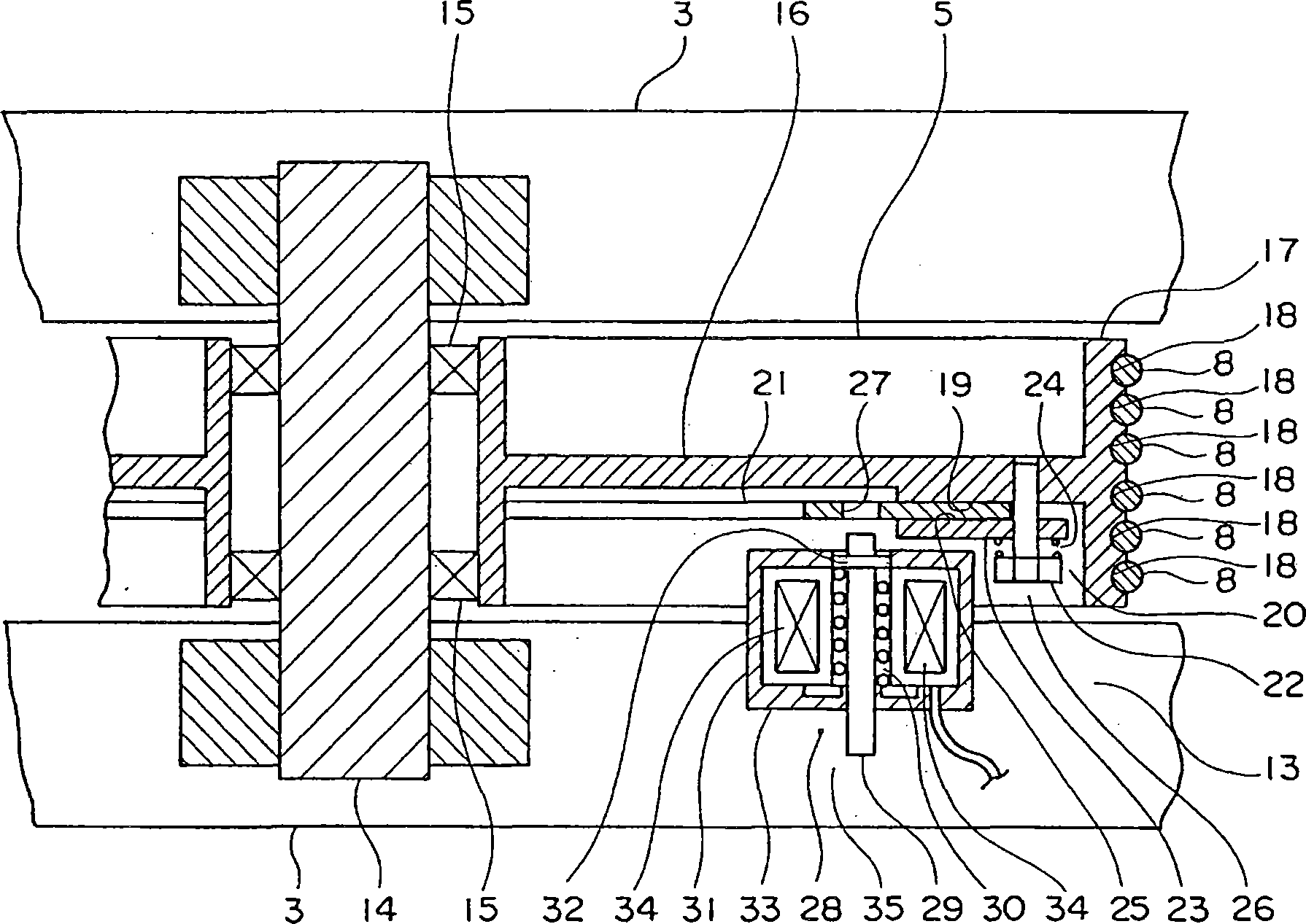

Non-uniform distribution preload controllable high-speed spindle based on piezoelectric actuator and its control method

InactiveCN102278379AAchieve high speedAchieve long lifeRolling contact bearingsShaftsElectricityPiezoelectric actuators

A non-uniform-distribution pretightening-force-controllable high-speed main shaft based on a piezoelectric actuator and a control method thereof. A bearing (2) is mounted on the periphery of a main shaft (1), the bearing (2) is fixed through a bearing support (3), and a temperature sensor (7) is mounted on the bearing support (3). A pretightening ferrule (6) is mounted on the outer ring of the main shaft (1), and a piezoelectric actuator (9) is mounted on the pretightening ferrule (6) through a mounting hole provided in the pretightening ferrule (6). A signal processing unit is connected between the piezoelectric actuator (9) and the temperature sensor (7), and the mounting position of the temperature sensor (7) is closed to the pretightening regulation and control point of the main shaft. After the temperature sensor (7) detects a temperature signal of the pretightening regulation and control point of the main shaft, the temperature signal is processed by the signal processing unit, and the pretightening force of the main shaft is adjusted by adjusting the pressure of the piezoelectric actuator (9). The high-performance high-speed main shaft under different working conditions is obtained by performing on-line regulation and control on the non-uniformly distributed pretightening force of the supporting bearing (2) of the main shaft.

Owner:XI AN JIAOTONG UNIV +1

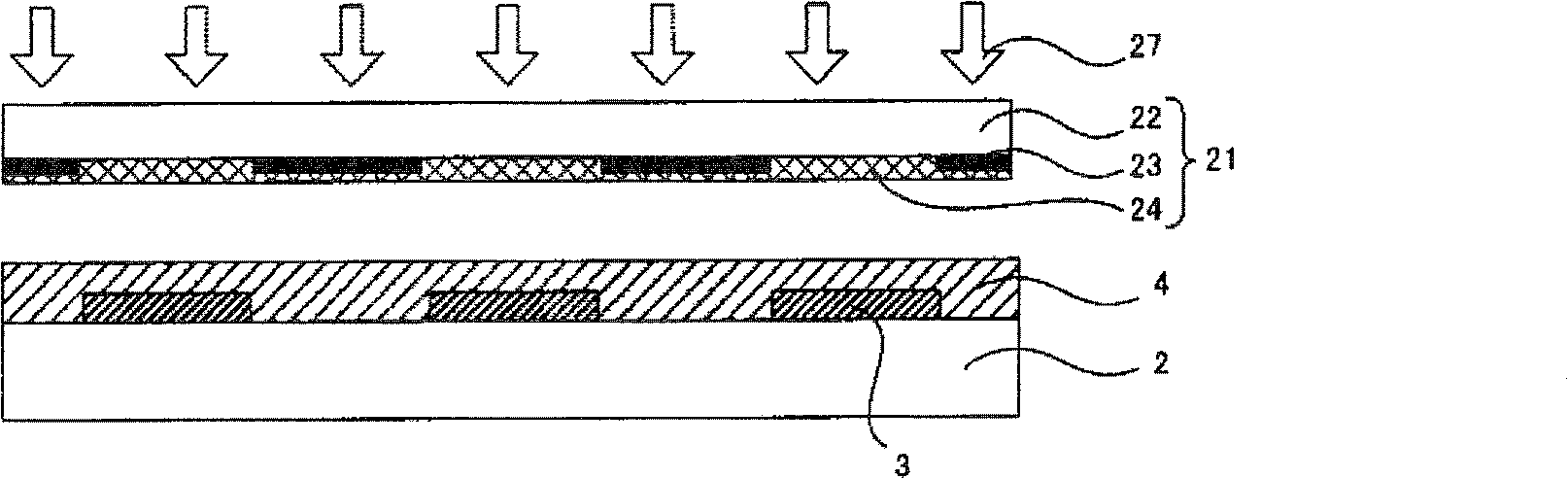

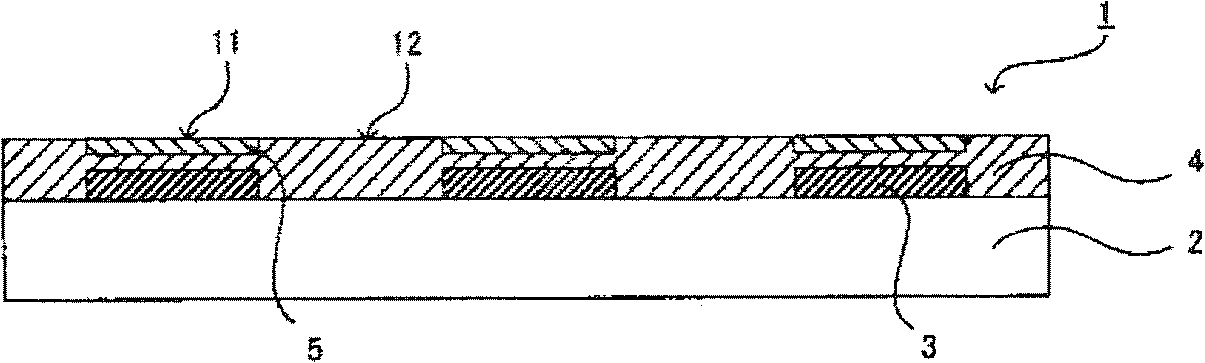

Device material for hole injection/transport layer, ink for forming hole injection/transport layer, device having hole injection/transport layer, and method for manufacturing same

InactiveCN102473849AImprove process toleranceExcellent hole injection and transport propertiesElectroluminescent light sourcesSolid-state devicesSimple Organic CompoundsTransport layer

Disclosed is a device material for a hole injection / transport layer, which has wettability that is changed by energy irradiation, high processing resistance and excellent hole injection / transport properties. The device material for a hole injection / transport layer is capable of forming a hole injection / transport layer by a solution coating method. Also disclosed are: an ink for a hole injection / transport layer, which uses the device material; a device having a long life, wherein a layer arranged on a hole injection / transport layer can be patterned; and a method for manufacturing the device. Specifically disclosed is a device material for a hole injection / transport layer, which is characterized in that a fluorine-containing organic compound adheres to an organic-transition metal oxide composite that is a reaction product of an organic transition metal complex. Also specifically disclosed are an ink for a hole injection / transport layer, a device and a method for manufacturing the device, each using the device material.

Owner:DAI NIPPON PRINTING CO LTD

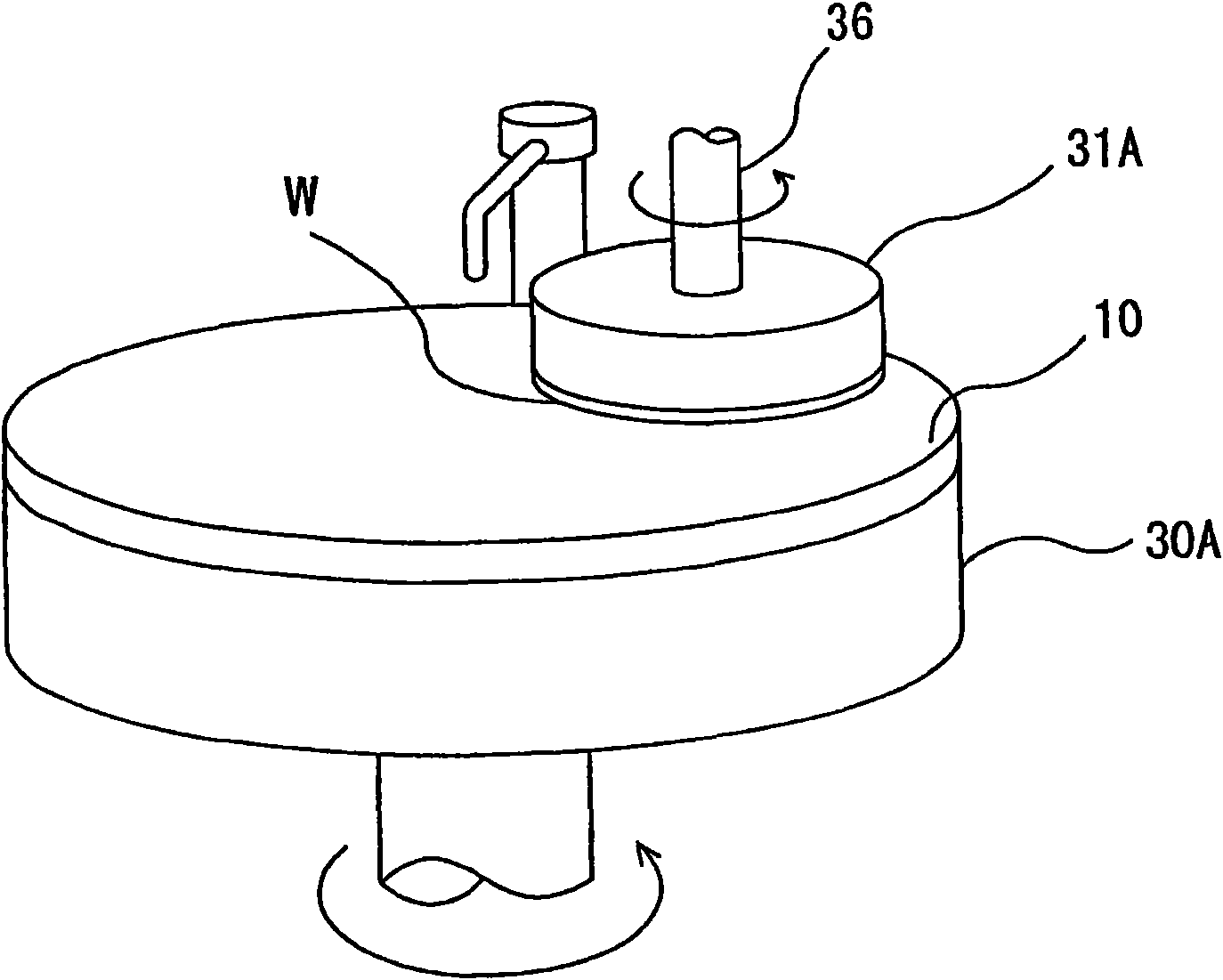

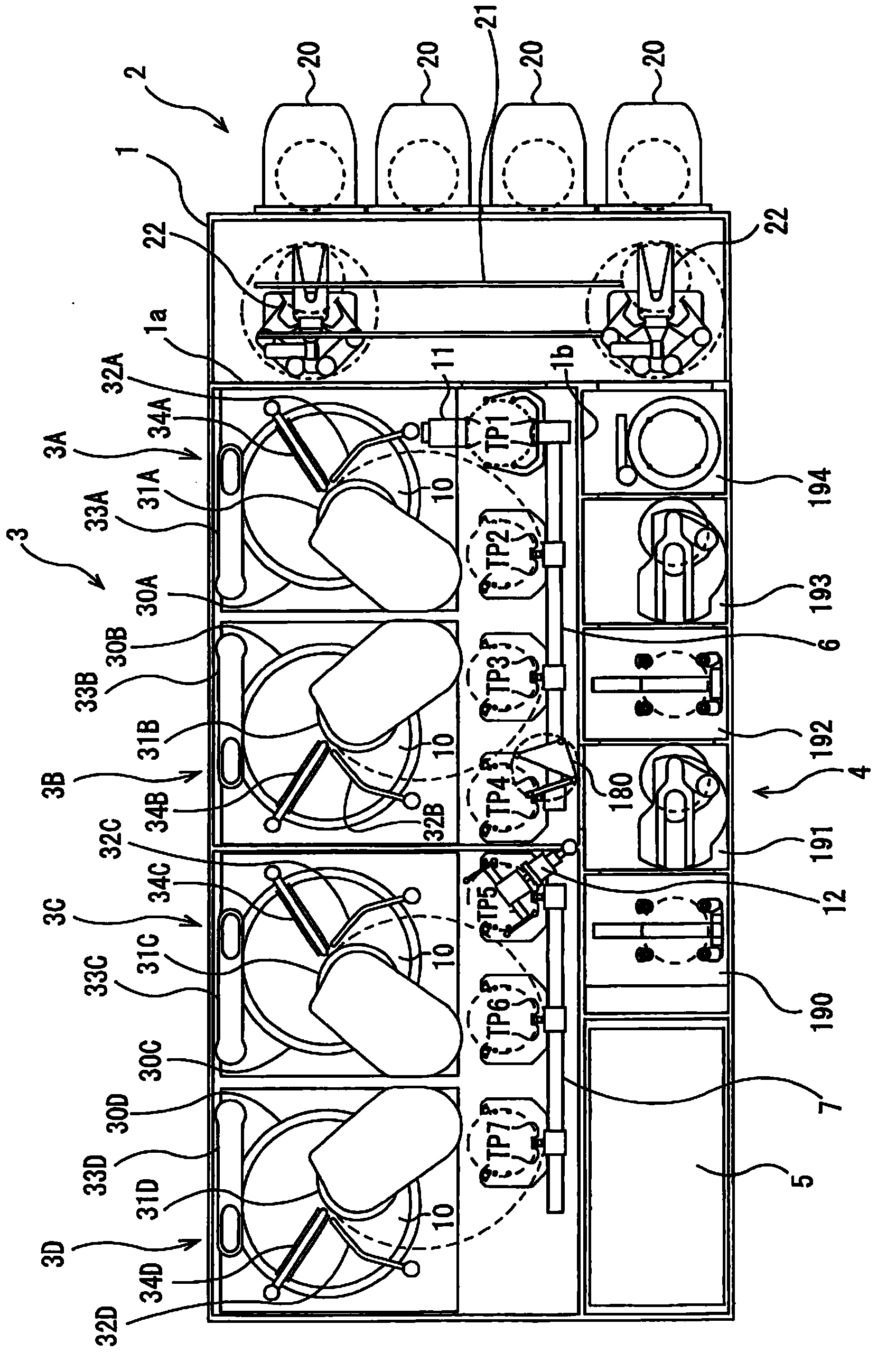

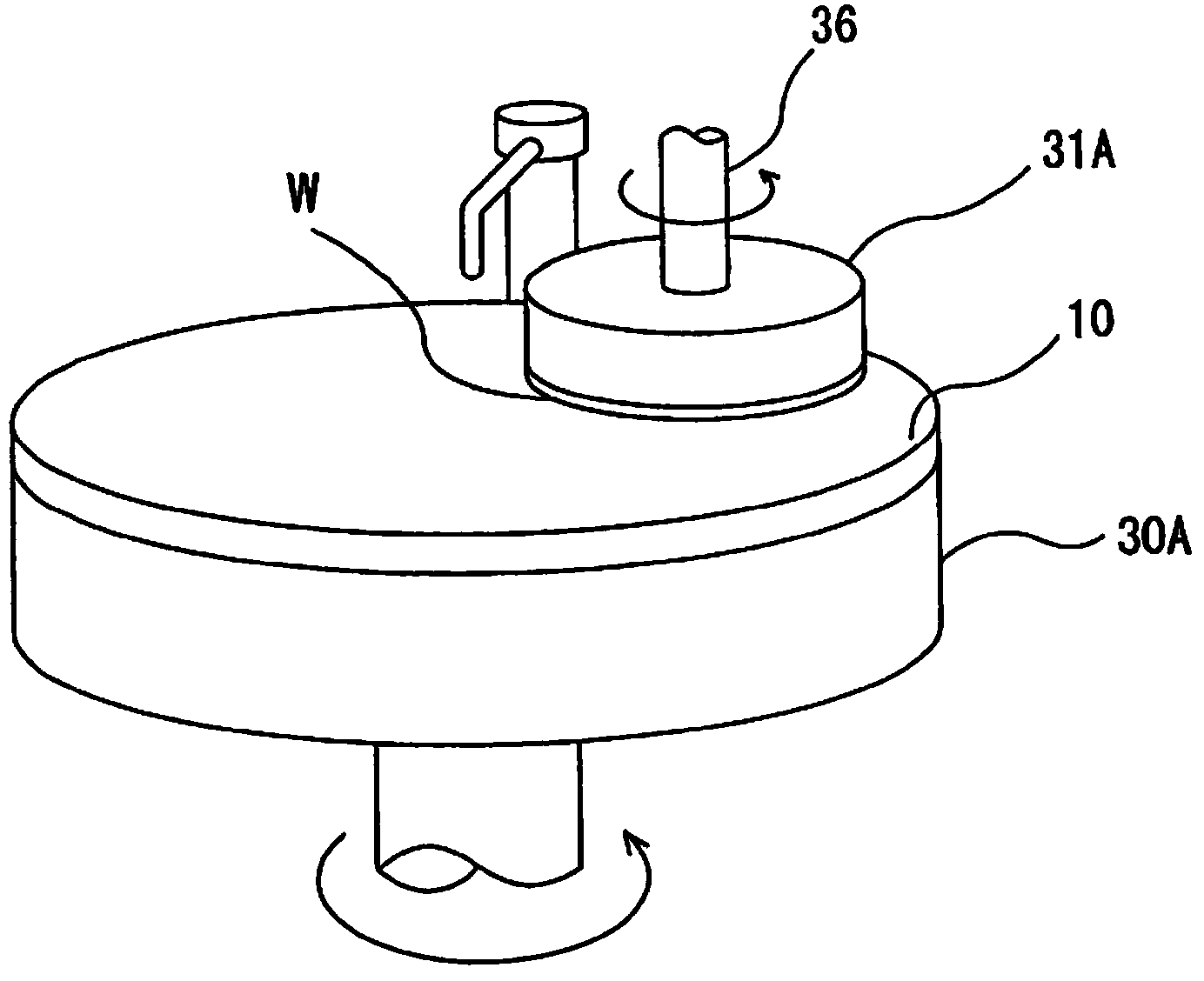

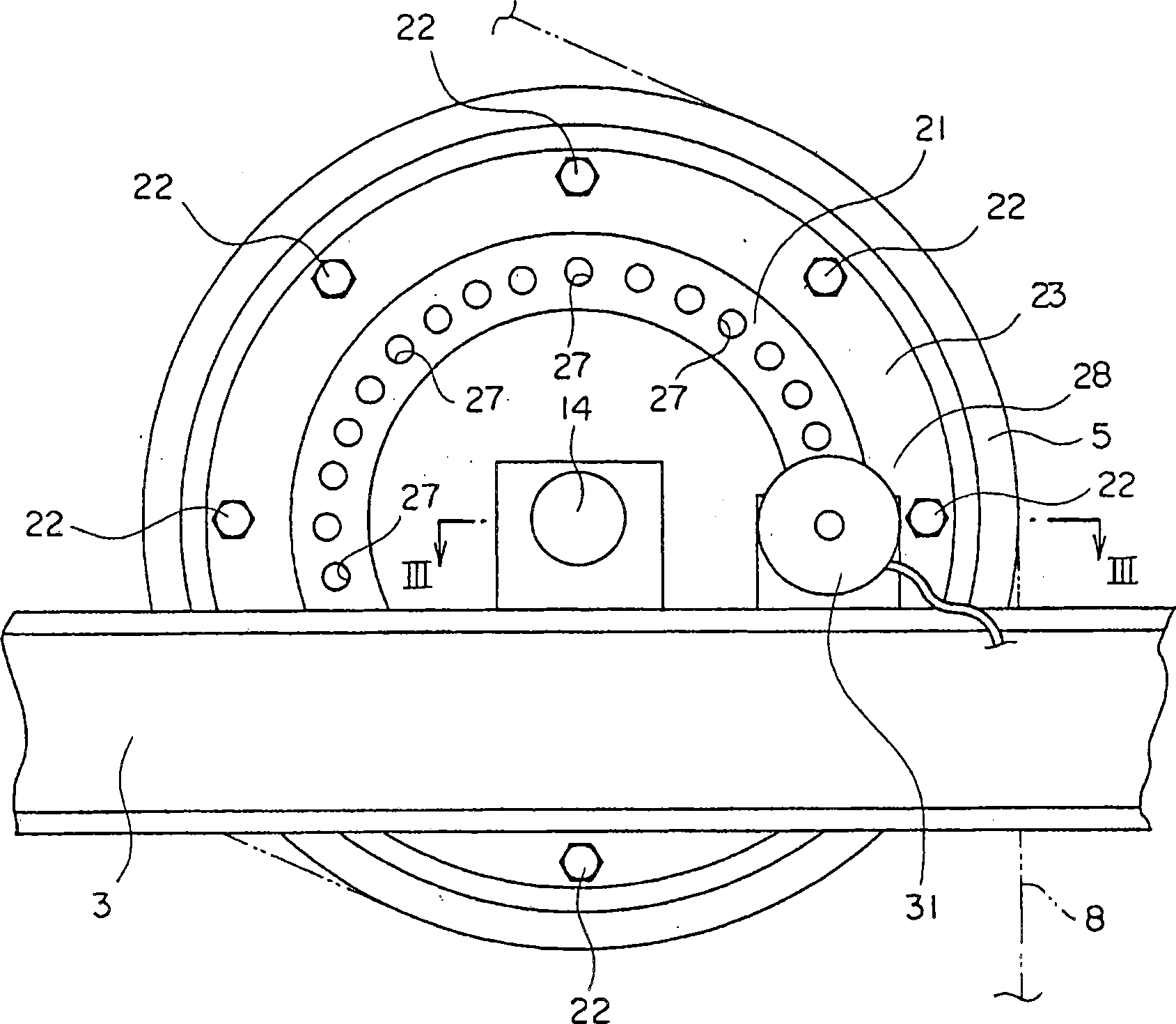

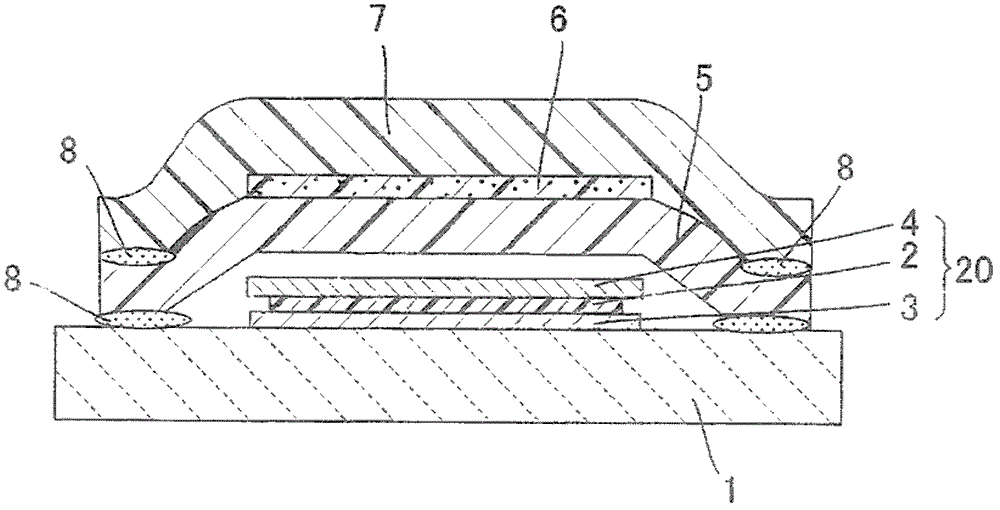

Substrate processing apparatus, substrate processing method, substrate holding mechanism, and substrate holding method

ActiveCN103839857AProcessing time equalizationImprove processing efficiencySemiconductor/solid-state device manufacturingLapping machinesTransfer mechanismElectrical and Electronics engineering

A substrate processing apparatus, a substrate processing method, a substrate holding mechanism, and a substrate holding method are disclosed. The apparatus includes a polishing section 3 configured to polish a substrate W, a transfer mechanism 5, 6 configured to transfer the substrate, and a cleaning section 4 configured to clean and dry the polished substrate W. The cleaning section 4 has plural cleaning lines for cleaning plural substrates. The plural cleaning lines have plural cleaning modules 201A, 201B, 202A, 202B and plural transfer robots 209, 210 for transferring the substrates.

Owner:EBARA CORP

Multi-port coupler, optical amplifier, and fiber laser

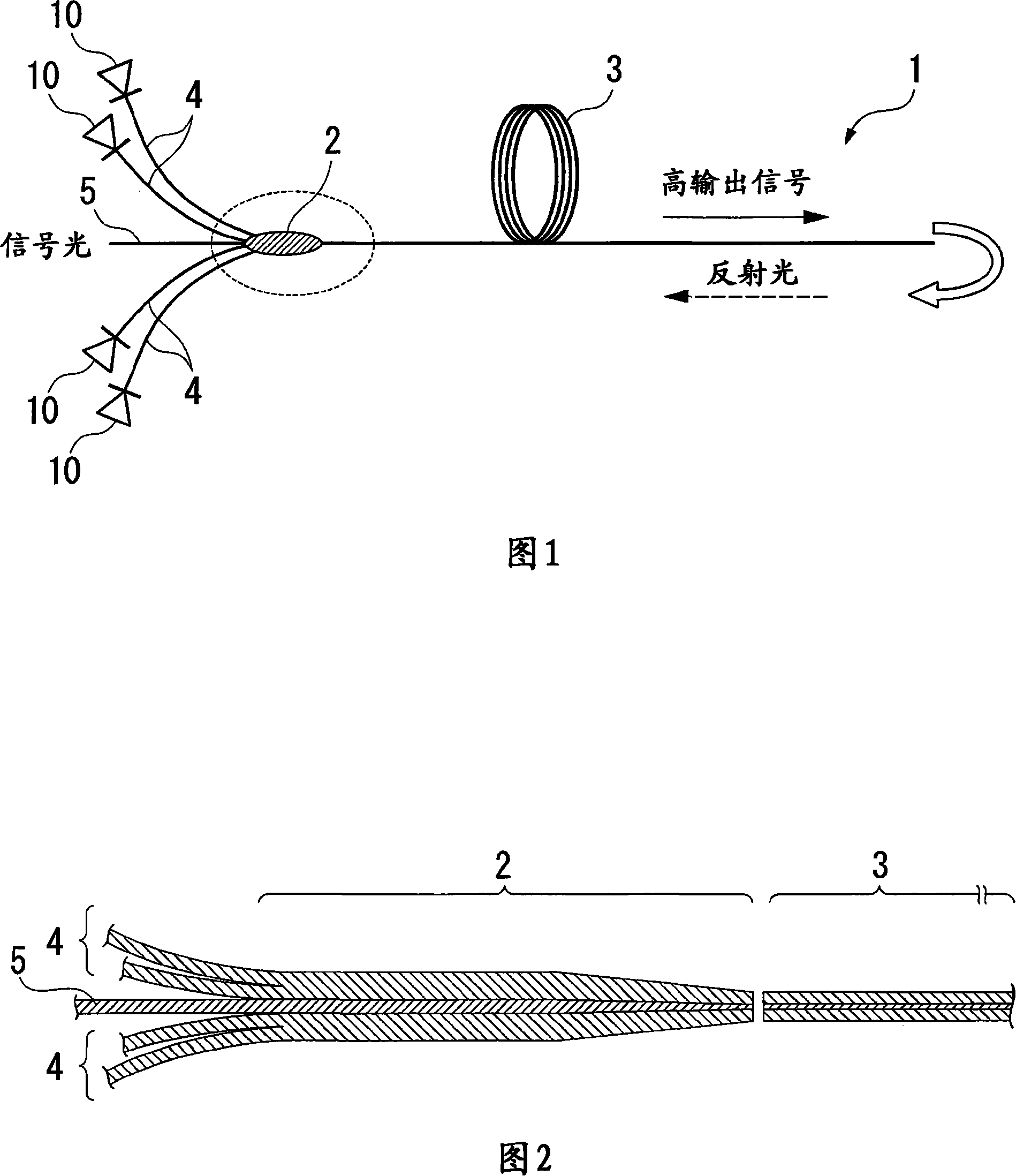

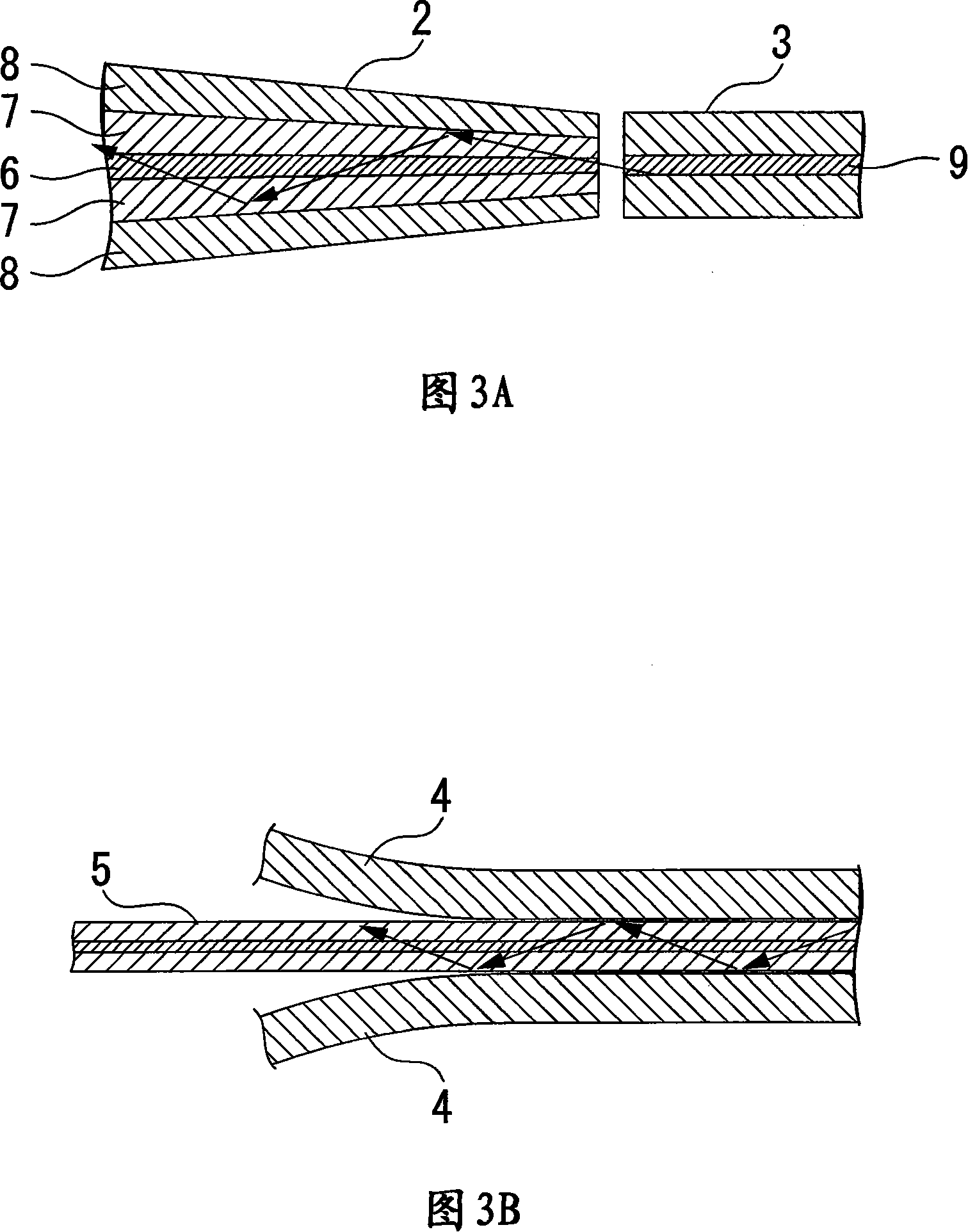

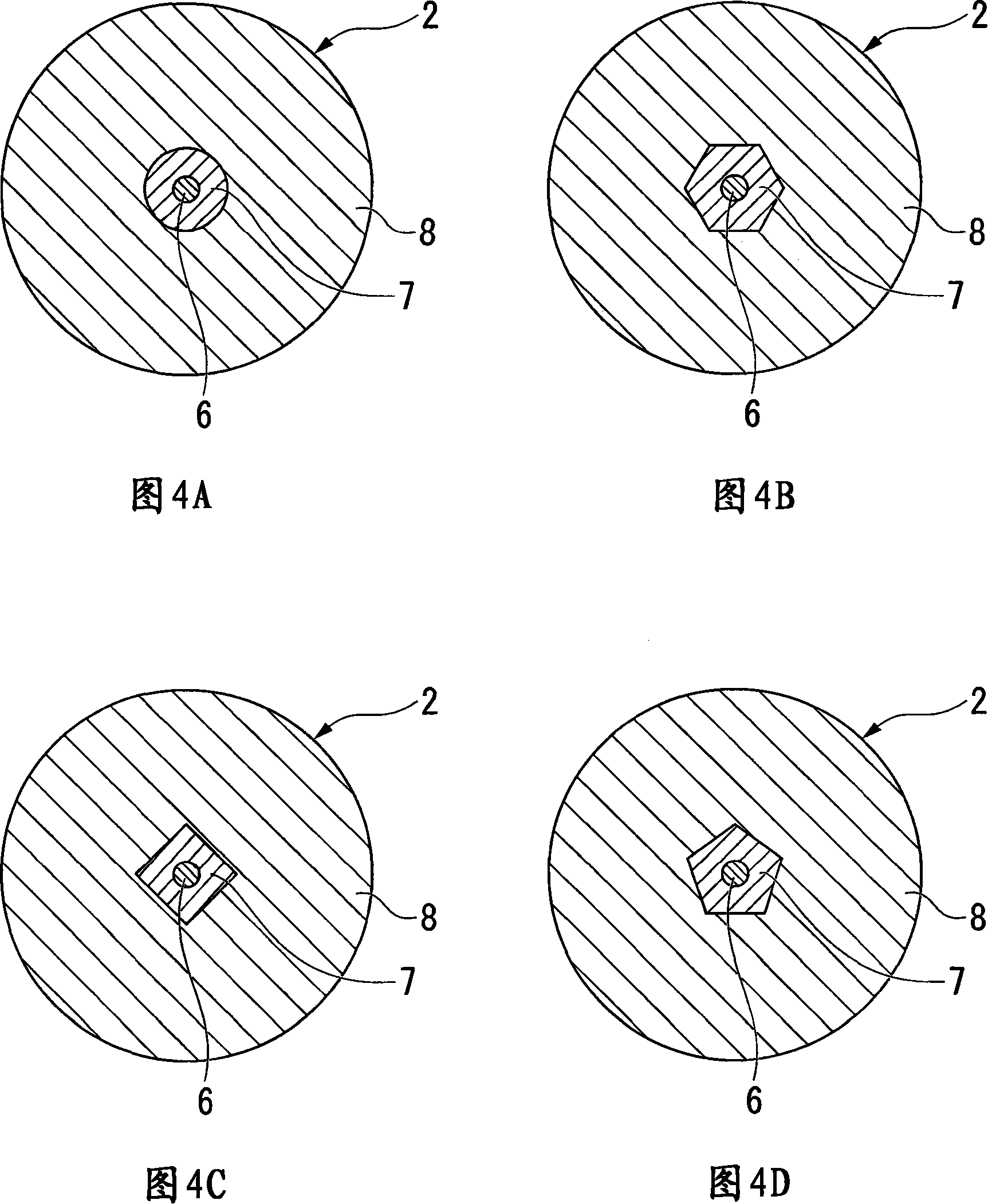

InactiveCN101082690AEliminate failureAchieve long lifeLaser detailsCoupling light guidesAudio power amplifierRefractive index

A multi-port coupler for coupling an pumping light source to a cladding pump fiber for optical amplification, includes a central signal fiber and a plurality of pumping fibers arranged around the central signal fiber, the central signal fiber and the plurality of pumping fibers being unified and a front side is reduced in diameter, wherein an emitted light confining waveguide part is provided around a core of the signal fiber located at the center, and the emitted light confining waveguide part whose outer diameter is larger than that of the core has a higher refractive index than a cladding and a lower refractive index than the core and the emitted light confining waveguide part is formed continuously from a splicing point of the cladding pump fiber to a coupler front end branched into multiple fibers.

Owner:THE FUJIKURA CABLE WORKS LTD

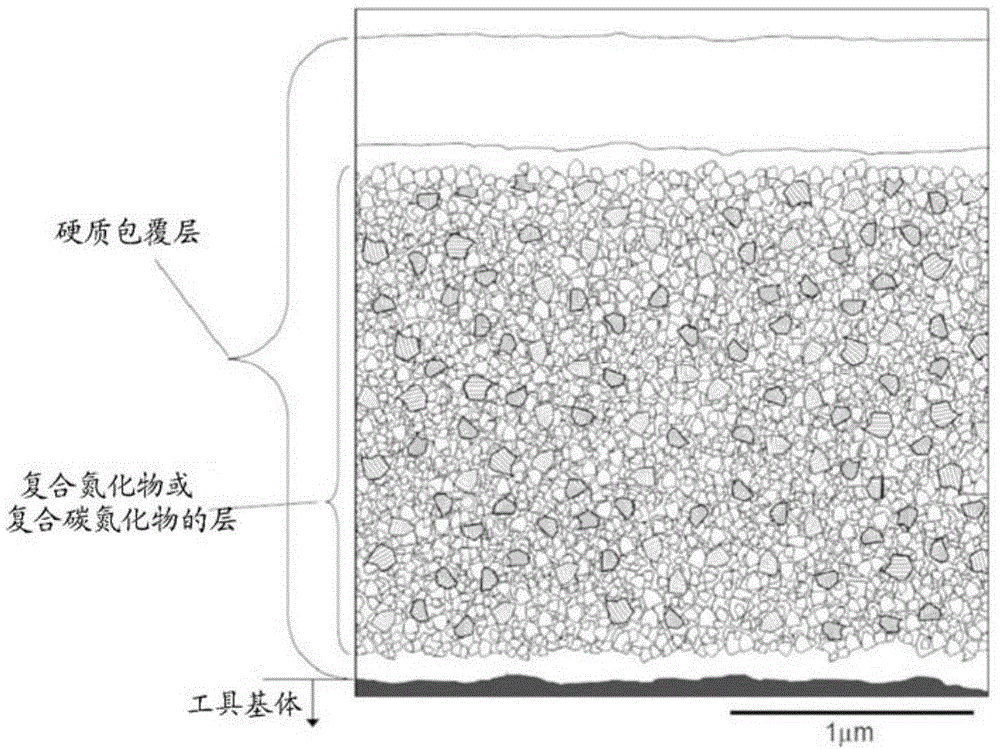

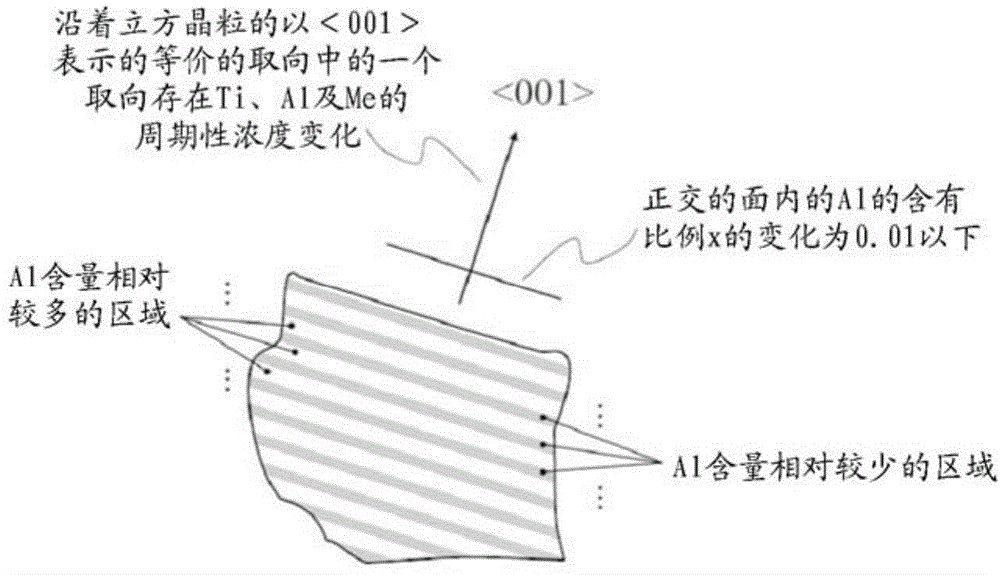

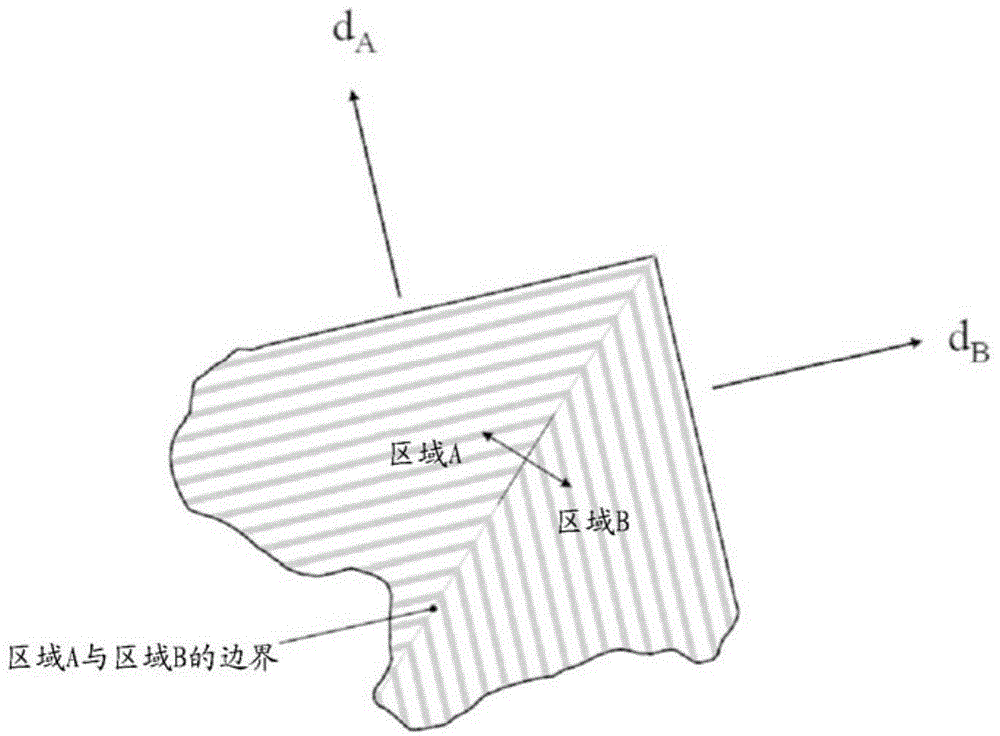

Surface coating cutting tool hard coating layer of which gives play to excellent anti-tipping performance

InactiveCN104789938AHigh hardnessImprove wear resistanceTurning toolsChemical vapor deposition coatingHardnessNitride

The subject of the invention is to provide a surface coating cutting tool a hard coating layer of which has excellent hardness and toughness and gives play to anti-tipping performance and defect-resistant performance. The hard coating layer contains a composite nitride represented by a compositional formula of (Ti<1-x-y>Al<x>Me<y>)(C<z>N<1-z>) or a layer of the composite nitride, wherein Me is an element selected from Si, Zr, B, V and Cr, the average contained proportion Xav of Al, the average contained proportion Yav of Me, the average contained proportion Zav of C meet 0.60<=Xav<=0.95, 0.005<=Yav<=0.10, 0<=Zav<=0.005 and Xav+Yav<=0955, the Xav, the Yav and the Zav are atomic ratios; and the layer at least contains cubic grains and has a granular structure the average particle width W of the cubic grains of which is 005-1.0[mu]m and the average aspect ratio A of which is lower than 5, and specified-period concentration changes of Ti, Al and Me exist in the cubic particles, so the subject is solved.

Owner:MITSUBISHI MATERIALS CORP

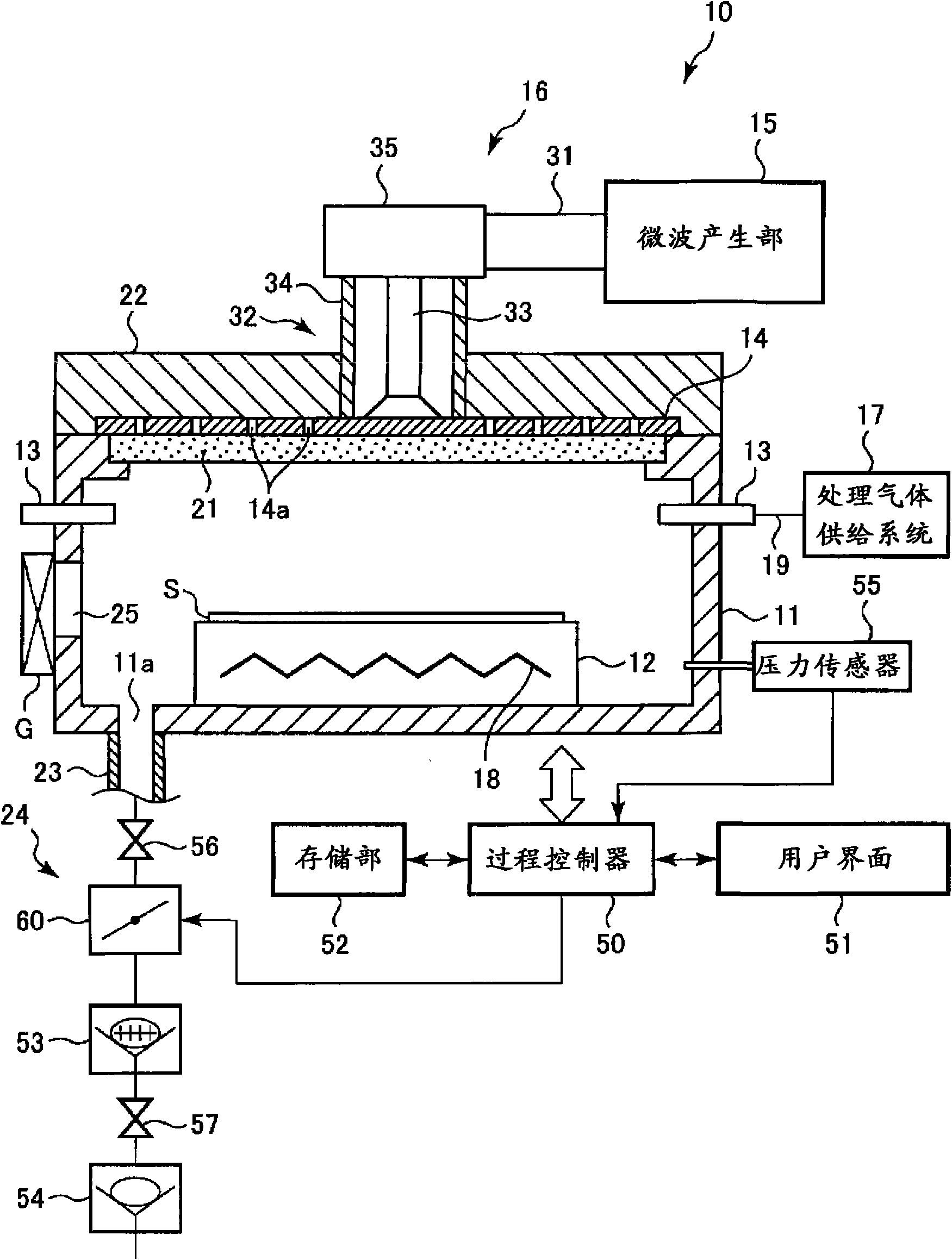

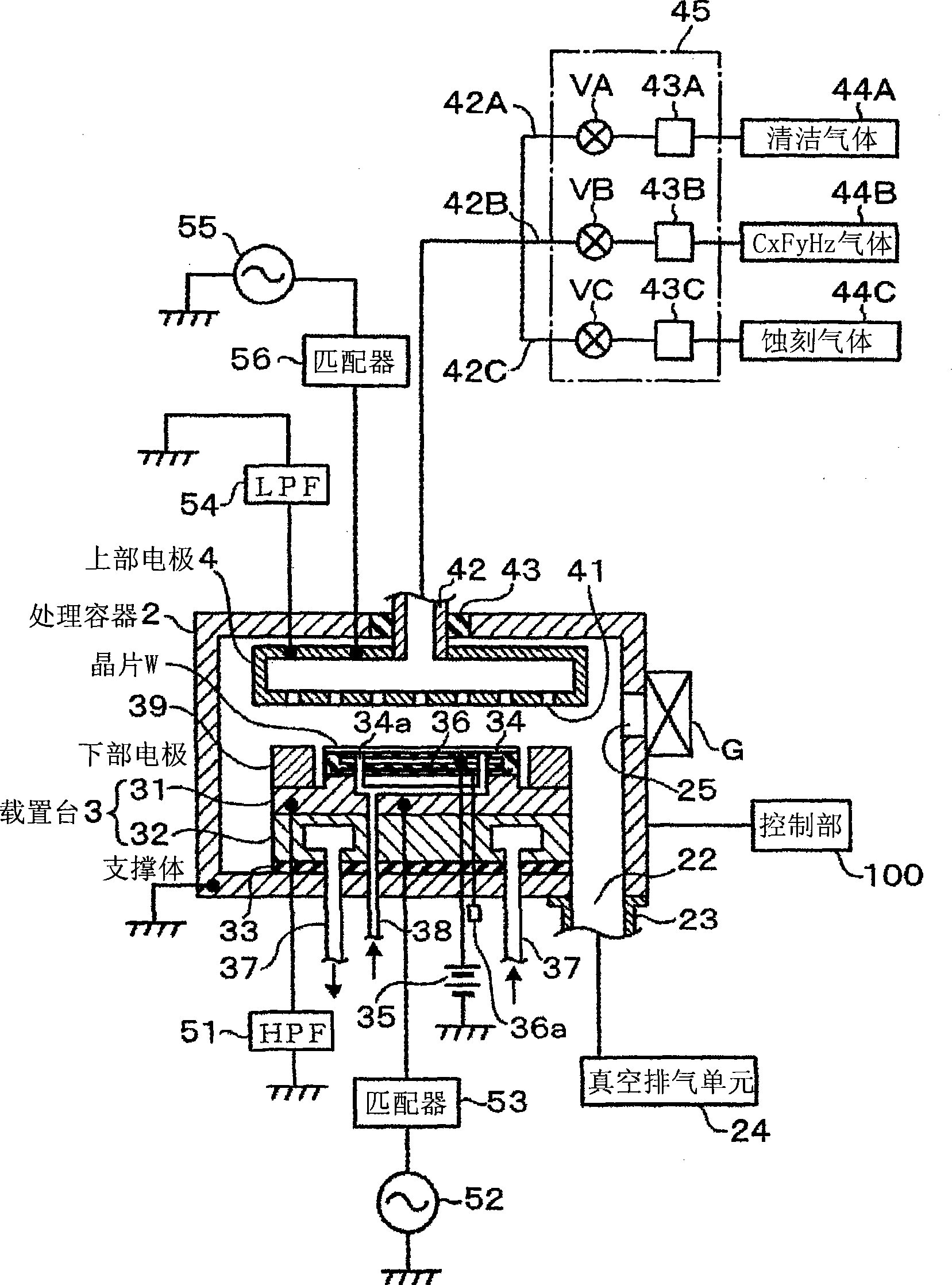

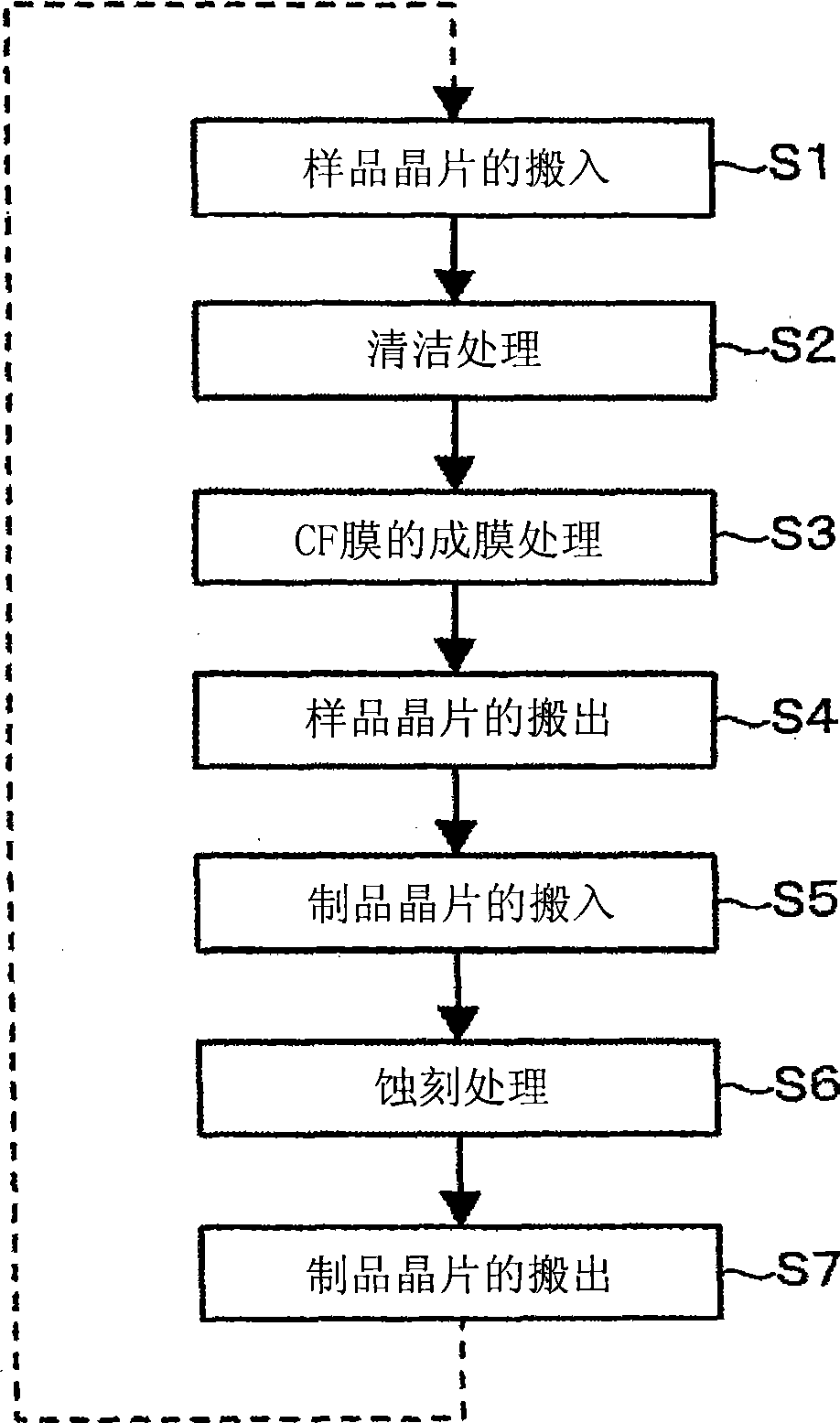

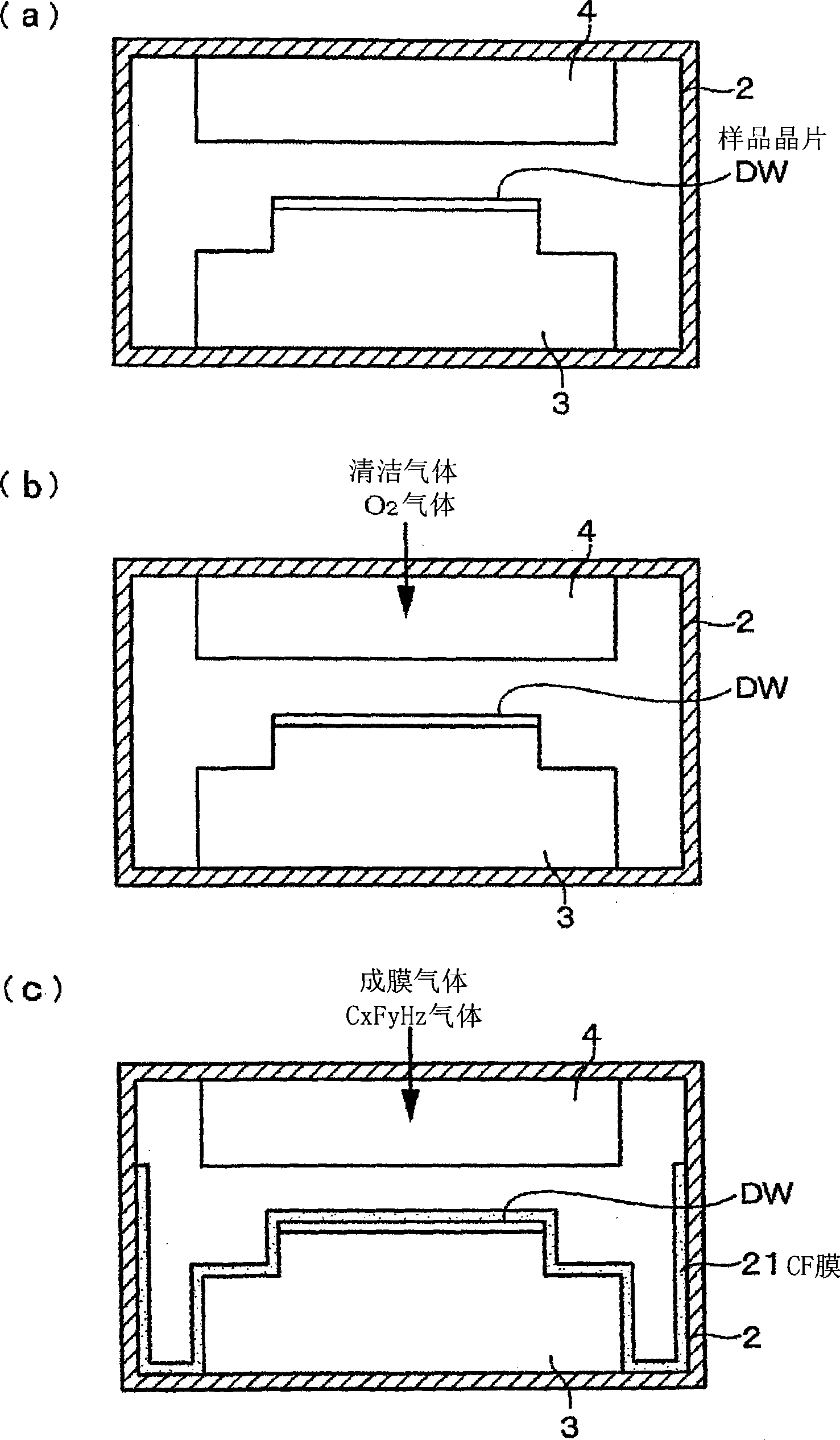

Plasma etching method and plasma etching apparatus

ActiveCN101504915ALess quantityImprove in-plane uniformityGas treatmentSemiconductor/solid-state device manufacturingGas plasmaMaterials science

The invention provides a plasma etching method and a plasma etching device, which are capable of controlling profile of the etching and prohibiting the generation of particles resulted from etching a treatment vessel and the like. Once a cleaning procedure (a) is implemented, the plasma, which is obtained by subjecting the cleaning gas to plasma treatment, is utilized to remove adhesions adhered to the treatment vessel (2); once a filming procedure (b) is implemented, the plasma, which subjects a filming gas containing carbon and fluorine to plasma treatment, is utilized to form a CF film at a part exposed to the plasma inside the treatment vessel; once an etching procedure (c) is implemented, a wafer W is carried on a carrying table inside the treatment vessel and the plasma subjecting an etching gas to plasma treatment is utilized to etch the wafer W; and once a procedure (d) of moving the wafer W out of the treatment vessel after the etching procedure (c) is implemented, the procedures (a)-(d) are implemented upon the end of the procedure (d).

Owner:TOKYO ELECTRON LTD

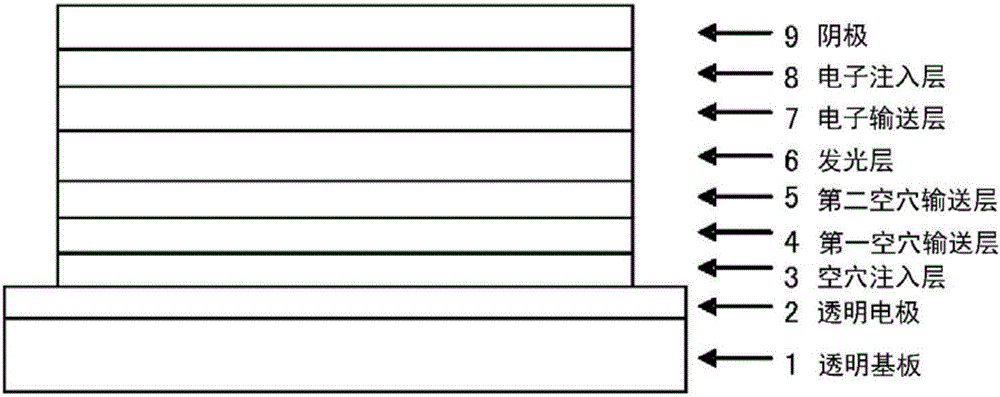

Organic electroluminescent element

ActiveCN106688119AExcellent hole injectionHigh hole mobilityOrganic chemistrySolid-state devicesOrganic electroluminescenceHole transport layer

This organic EL element comprises a positive electrode, a hole transport layer, a light emitting layer, an electron transport layer and a negative electrode in this order, and is characterized in that the hole transport layer contains an arylamine compound represented by general formula (1). In the formula, each of Ar1-Ar4 represents a monovalent aromatic hydrocarbon group or a monovalent aromatic heterocyclic group.

Owner:HODOGOYA CHEMICAL CO LTD

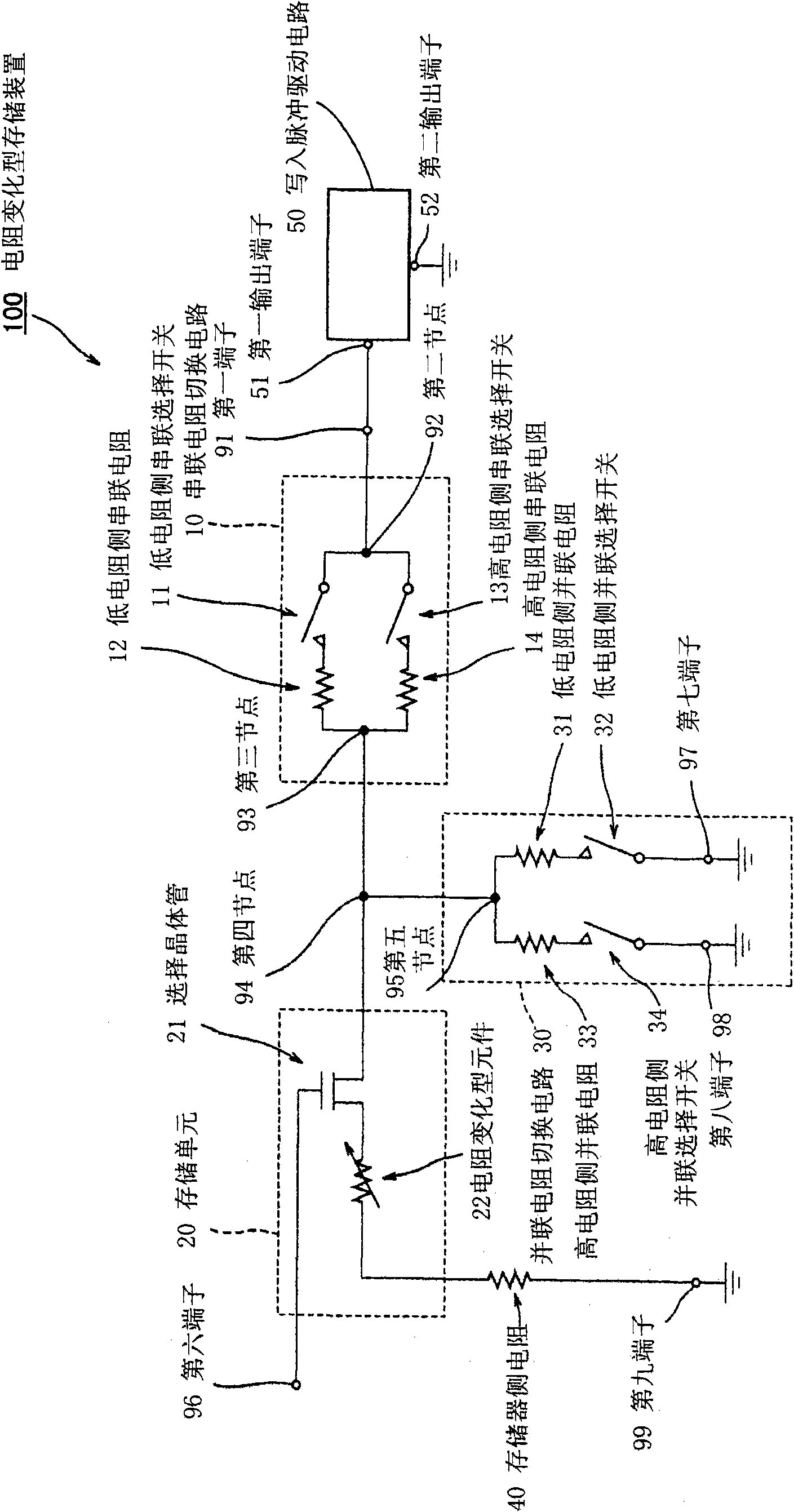

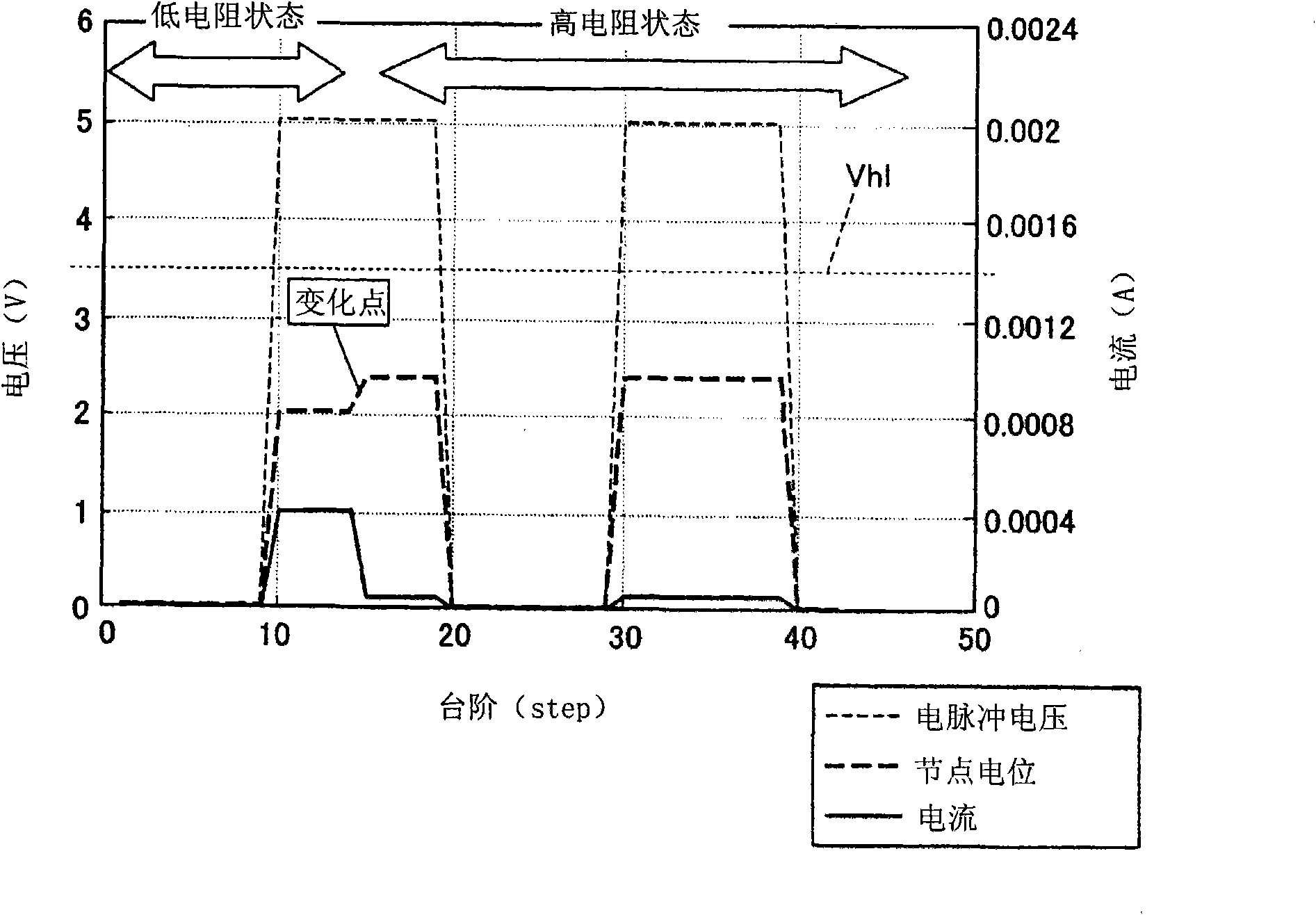

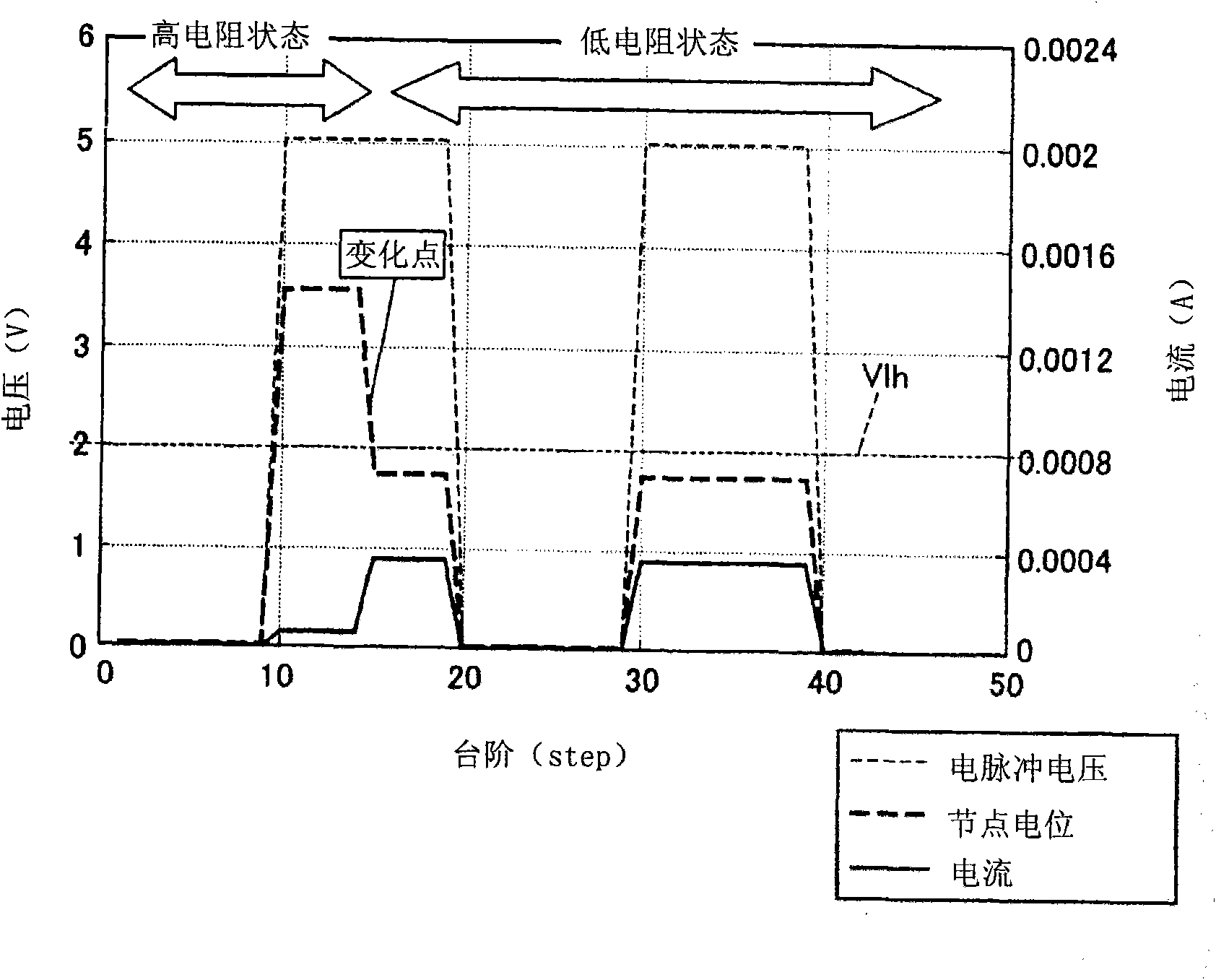

Nonvolatile storage apparatus and method for writing data into nonvolatile storage apparatus

InactiveCN101802921AAchieve long lifeImprove actionDigital storageHigh resistanceElectrical resistance and conductance

A nonvolatile storage apparatus (300) having a memory cell array that comprises a plurality of resistance-changeable elements each of which transitions from one of a plurality of resistance states to another in response to an electric pulse of the same polarity. A series-resistor setting unit (310) is disposed between a memory cell array (70) and an electric pulse applying device (50). The series-resistor setting unit is controlled, thereby varying, with time, the resistance value of a series current path within a predetermined range at least either when a selected resistance-changeable element is caused to change from a low resistance state to a high resistance state or when the selected resistance-changeable element is caused to change from the high resistance state to the low resistance state.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

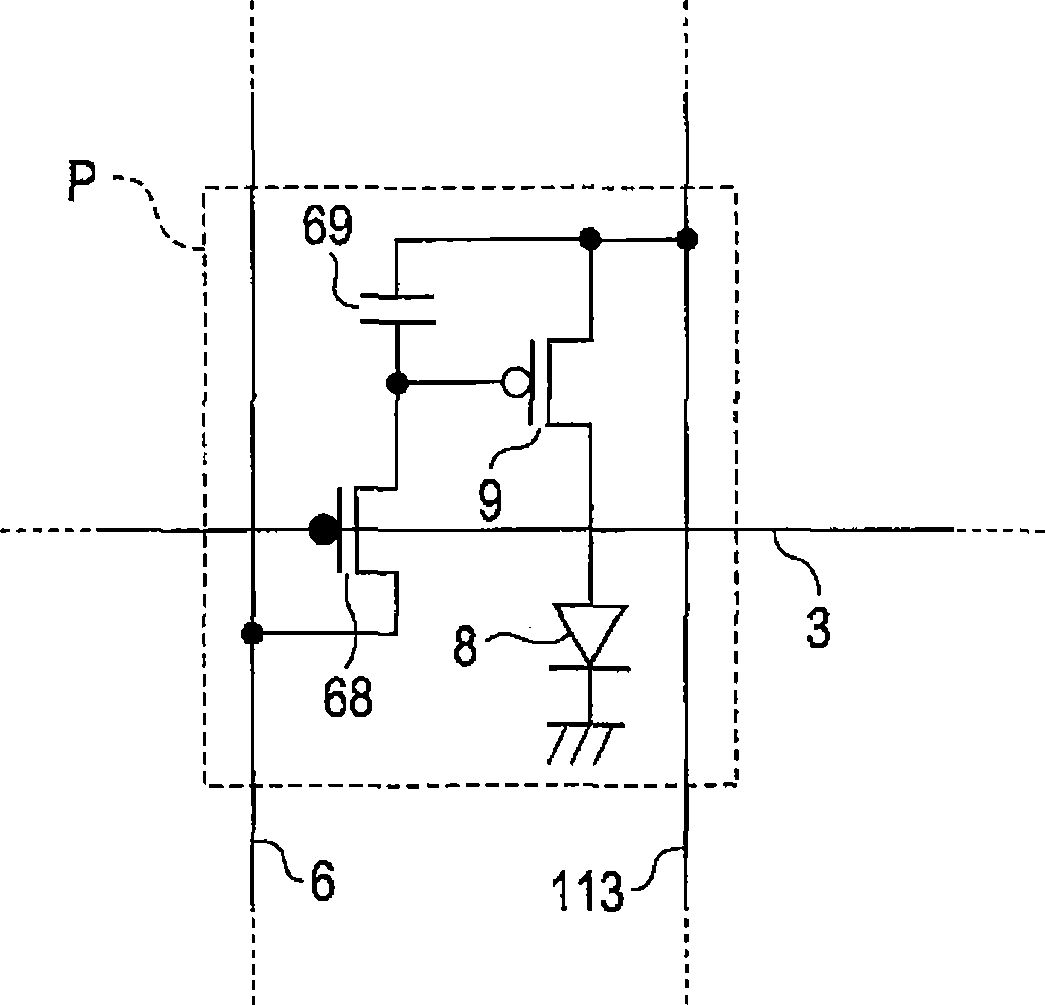

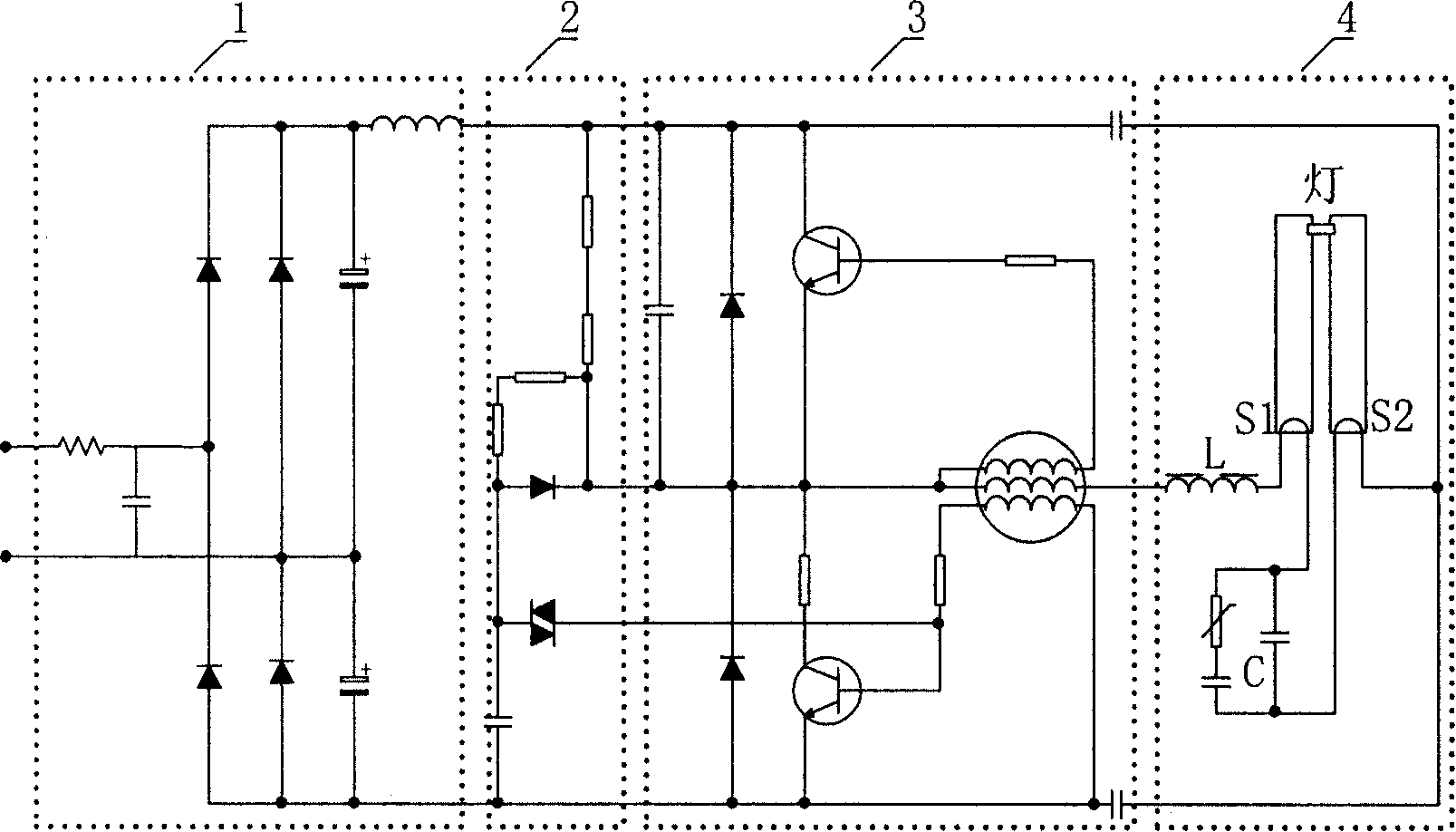

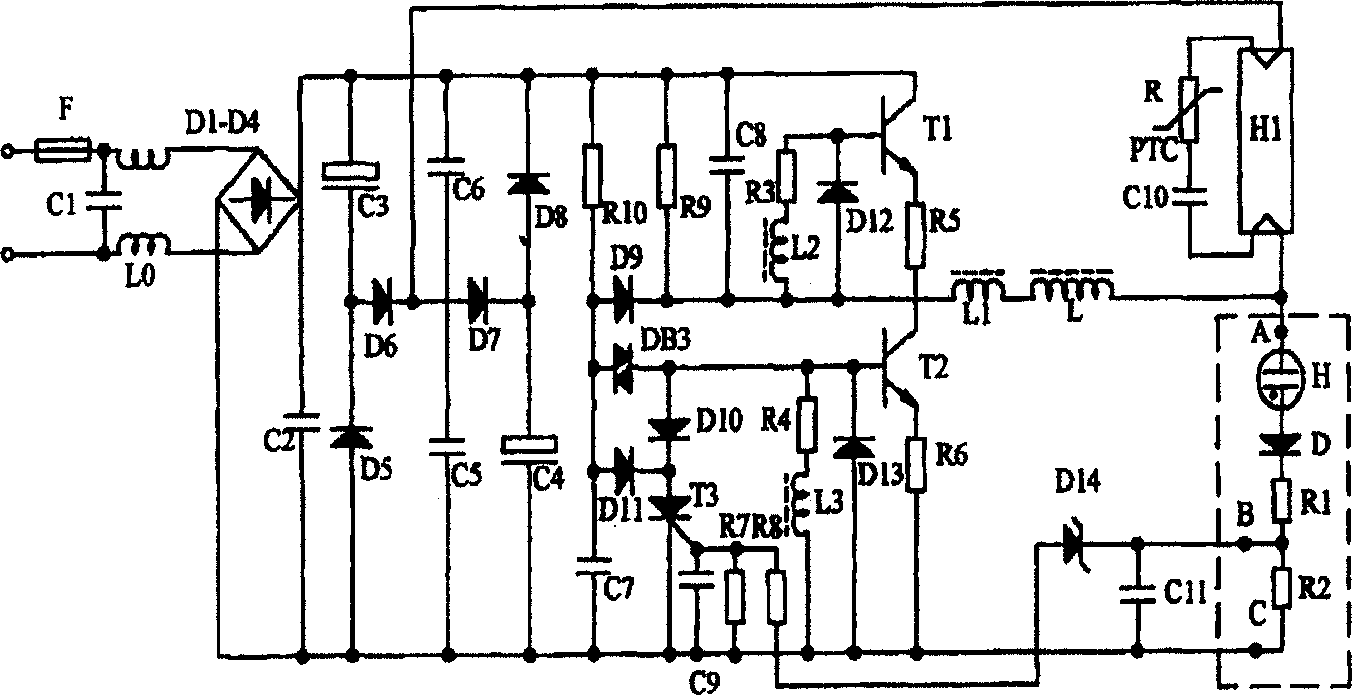

Electronic rectifier for exception protection of discharging lamp and discharging lamp

InactiveCN101166389AExtend your lifeAchieve regulationElectrical apparatusElectric lighting sourcesResonanceClosed loop

The resonance unit of ballast includes: resonant capacitor (RC), in which first end is connected to an end of first filament of discharge lamp, and second end is connected to an end of second filament of discharge lamp; resonant inductor (RI), in which an end is connected to the first end of RC, and second end of RC and the other end of RI are connected to inversion unit to constitute closed loop. The ballast also includes filament warming up unit and abnormal protection unit (APU). APU includes warming and protecting branches connected to first and second filaments respectively to form closed loop. Each branch includes: drive part in use for generating drive signal in branches based on voltage at two ends of (RI); control part in use for controlling on / off of switching element in the inversion unit based on the drive signal; overflow protection element in use for shutting off the branch, in which current is larger than the specific value.

Owner:PANASONIC CORP

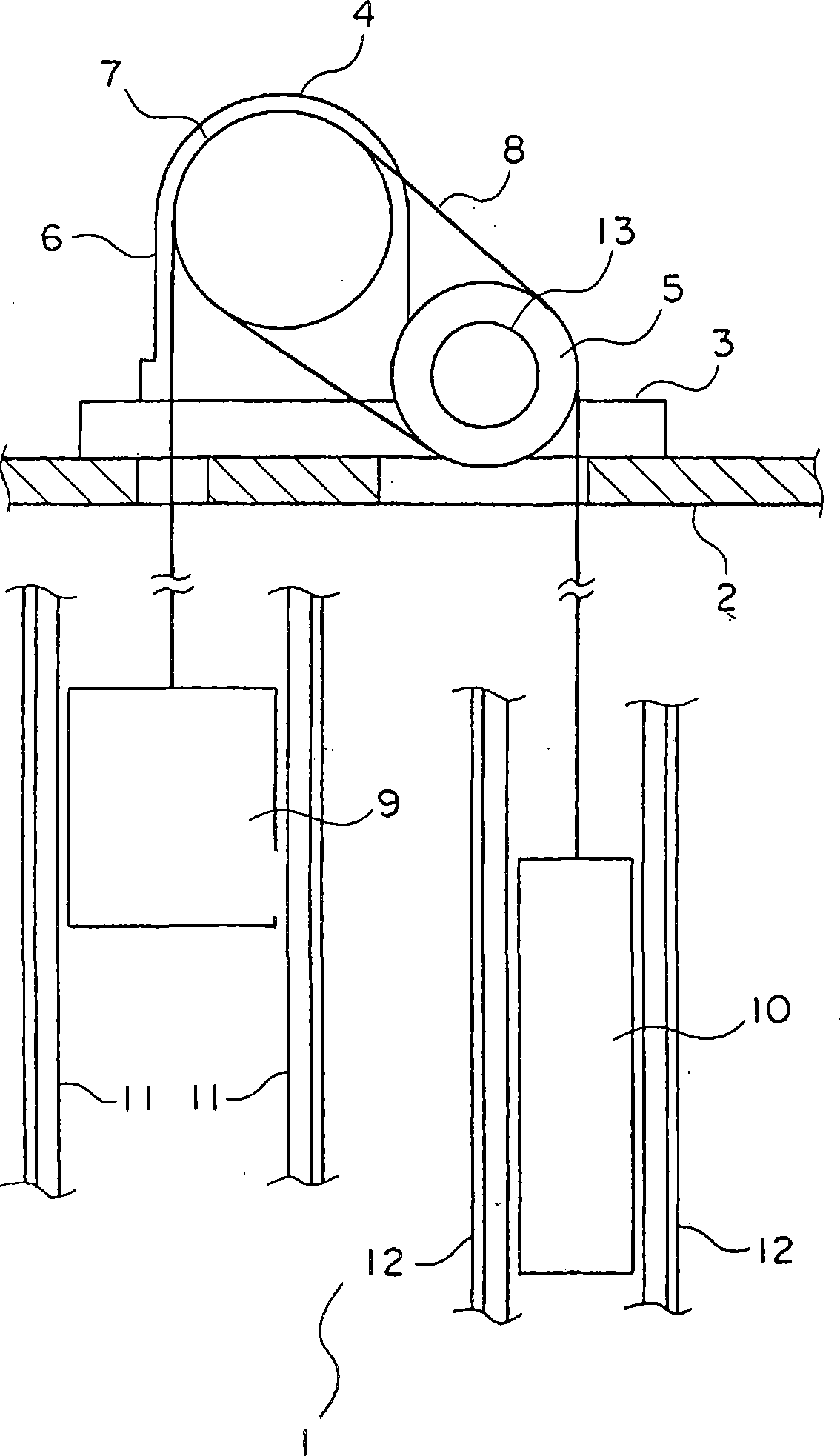

Brake device for elevator

InactiveCN1902122AAchieve long lifeSave setup spaceBrake typesElevatorsEngineeringMechanical engineering

In a brake device for an elevator, a hold-down device is provided on a sheave on which a main rope for suspending a cage and a balance weight runs. A brake disk on which engagement sections are arranged is pressed to the sheave by the hold-down device. An engagement device has a movable section displaceable between an engagement position at which the movable section is engaged with an engagement section is engaged and a release position at which the engagement of the movable section with the engagement section is released. The brake disk is rotatable together with the sheave when the movable section is in the release position, and the brake disk is stopped when the movable section is in the engagement position, braking the rotation of the sheave.

Owner:MITSUBISHI ELECTRIC CORP

Organic electronic device and method for manufacturing the same

ActiveCN102804440AInhibit deteriorationPrevent thinningFinal product manufactureSolid-state devicesOrganic solar cellScavenger

The invention provides an organic electronic device which does not deteriorate the device performance over a long period of time, for example, a thin film organic solar cell element in which a lowering of the power generation efficiency is suppressed, and a method for manufacturing the organic electronic device. Disclosed is an organic electronic device formed by laminating an organic semiconductor element (B) provided with at least a pair of electrodes, a layer (C) containing a scavenger which absorbs at least one of water and oxygen, and a gas barrier film (d) in this order, wherein one or plural anticorrosion layers (E) is provided between at least one of the pair of electrodes and the layer (C) containing a scavenger which absorbs at least one of water and oxygen; the thickness of the anticorrosion layer (E) is 20 [mu]m or more; the moisture vapor transmission rate (Pe) (g / m2 / day) of the anticorrosion layer (E) in 40 DEG C and 90% RH environment with respect to the moisture vapor transmission rate (Pd) of the gas barrier film (D) in 40 DEG C and 90%RH environment satisfies a condition of 15 g / m2 / day>=Pe>Pd; and the moisture vapor transmission rate (Pd) of the gas barrier film (D) satisfies a condition of 10<->4<=Pd<=10<-1> g / m2 / day.

Owner:MITSUBISHI RAYON CO LTD

Carbon brush

InactiveCN102870319ALow efficiencyAchieve long lifeRotary current collectorDynamo-electric machinesSpherical shapedConstruction aggregate

Provided is a carbon brush such that it is possible to improve motor efficiency and to achieve a prolonged service life. Disclosed is a carbon brush (1) which is pressed against a conductive rotating body (2) and which is characterized by containing mesocarbon powder and an aggregate containing at least carbon as one component. Preferably, the mesocarbon powder has a roughly spherical shape, and is subjected to pre-heating treatment. Moreover, the temperature for the pre-heating treatment is preferably 500 DEG C to 700 DEG C inclusive.

Owner:TOTANKAKO

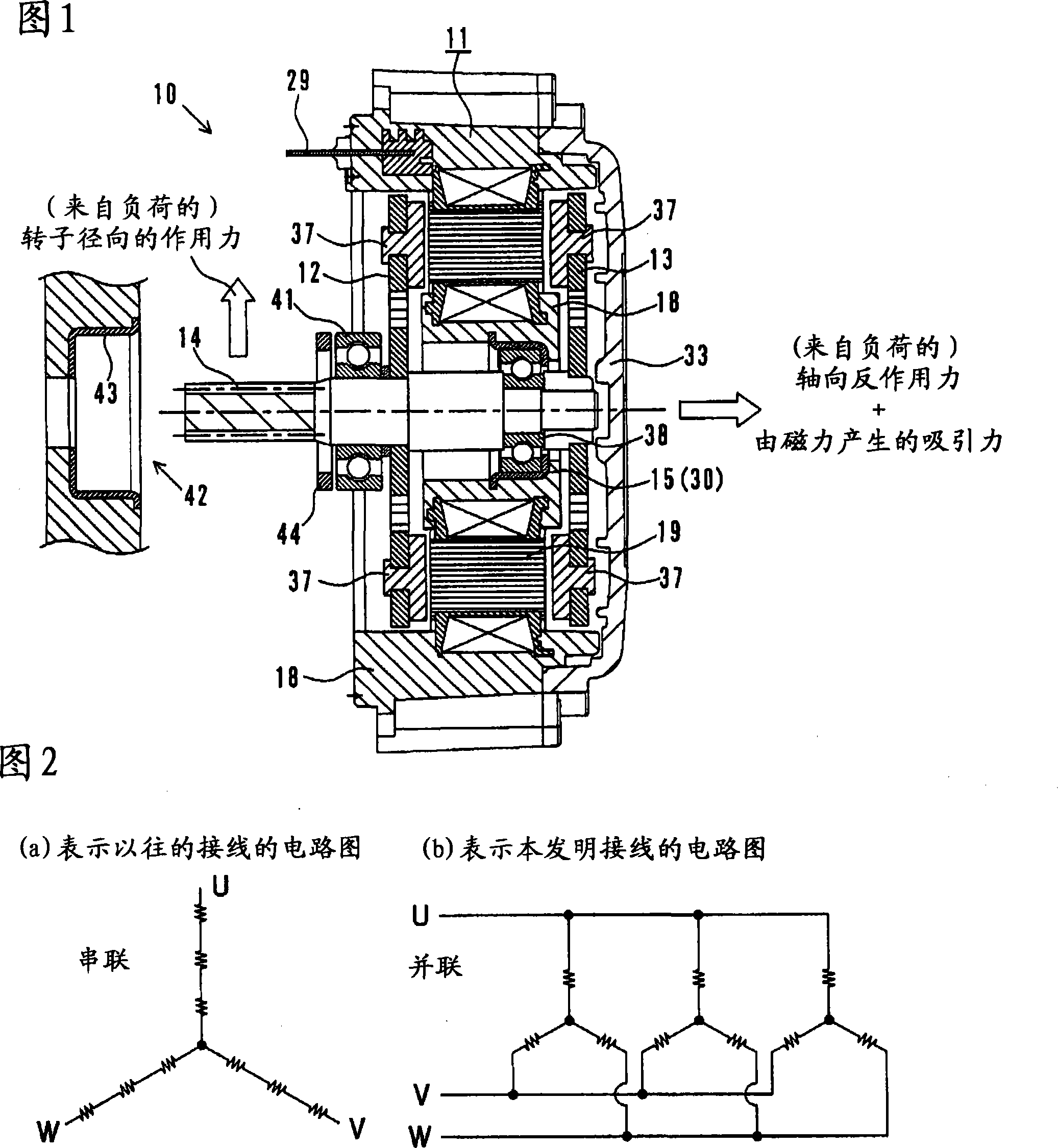

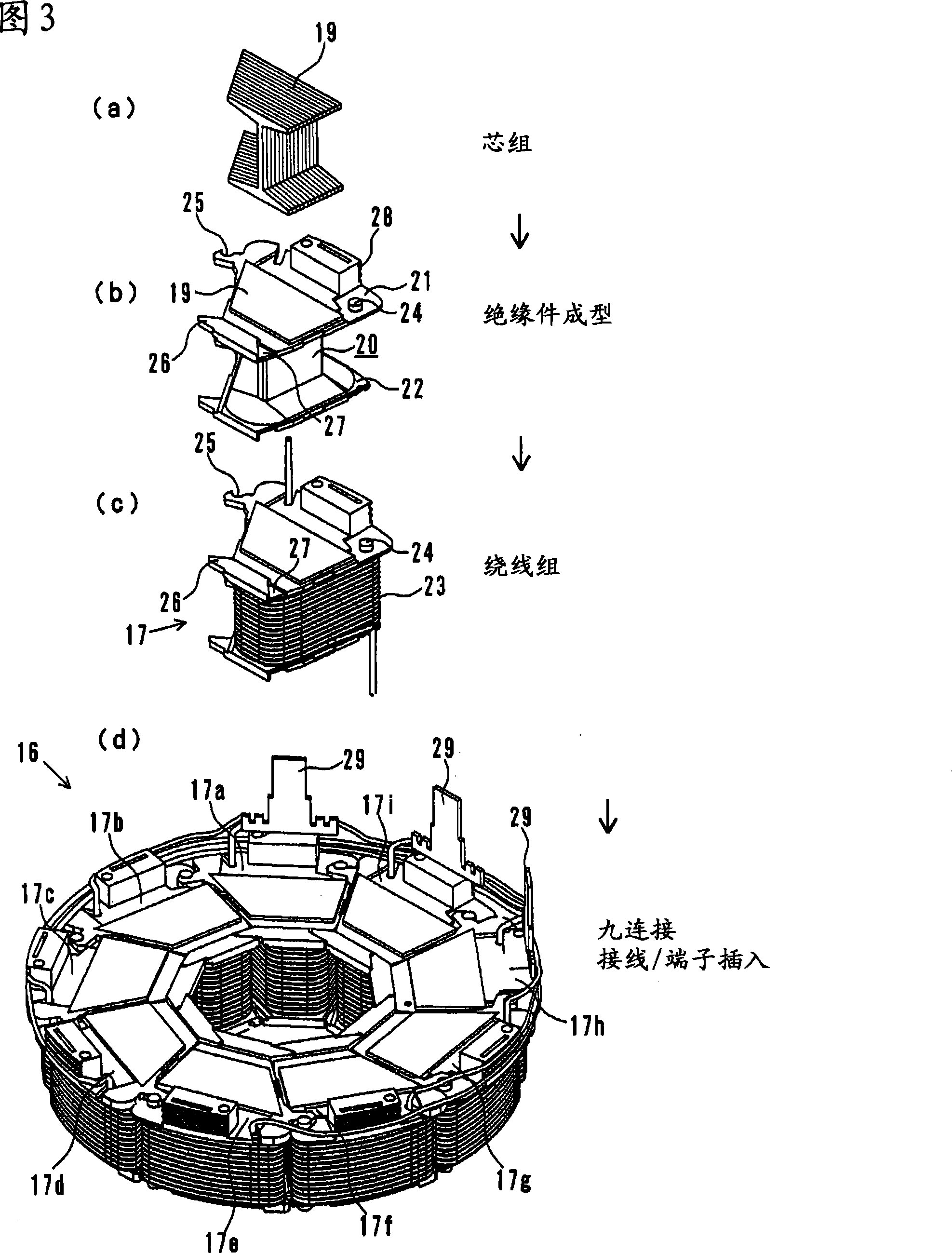

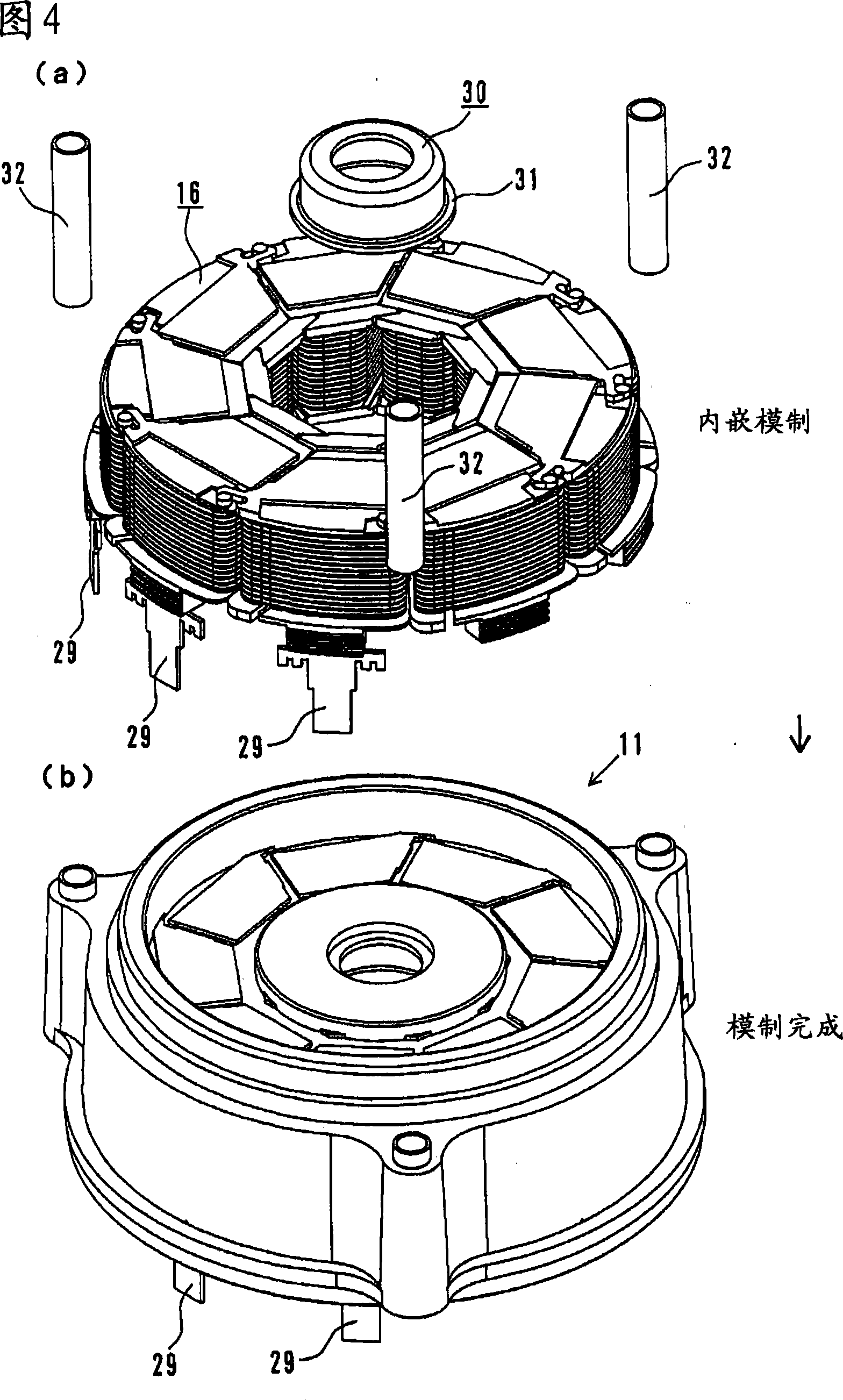

Axial air gap type electric motor

ActiveCN101183821AWon't breakAvoid breakingWindingsMagnetic circuit rotating partsEngineeringElectric motor

The object is to provide an axial air gap type electric motor in which even if a large force to some extent is added to the vertical direction to the rotor output axis, the bearings don't damage and its long lifetime is realized. The axial air gap type electric motor comprises a stator and two rotors each of which is configured almost with a discoid shape and which are arranged as facing an identical rotation axis (rotor output axis) with a fixed gap. Said stator has a stator core comprising multiple pole members connected annually and one of the bearings for fixing the rotor output axis is installed inside said stator configured annually and another bearing is installed on the rotor output axis between the outside of said rotor and the load connected.

Owner:FUJITSU GENERAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com