Plasma etching method and plasma etching apparatus

A plasma and etching device technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as early exchange cycle, wafer W yttrium oxide pollution, and shortened lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

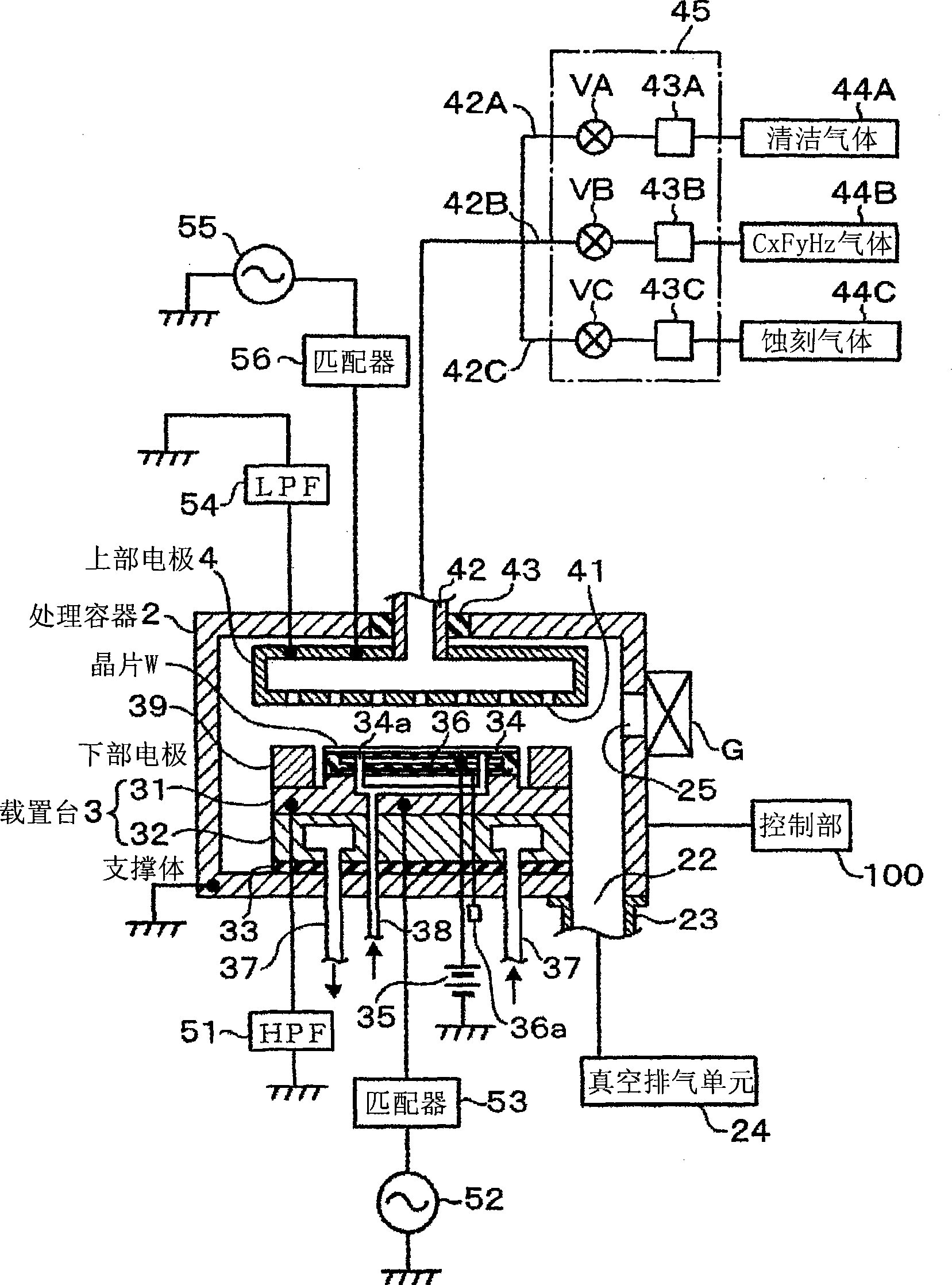

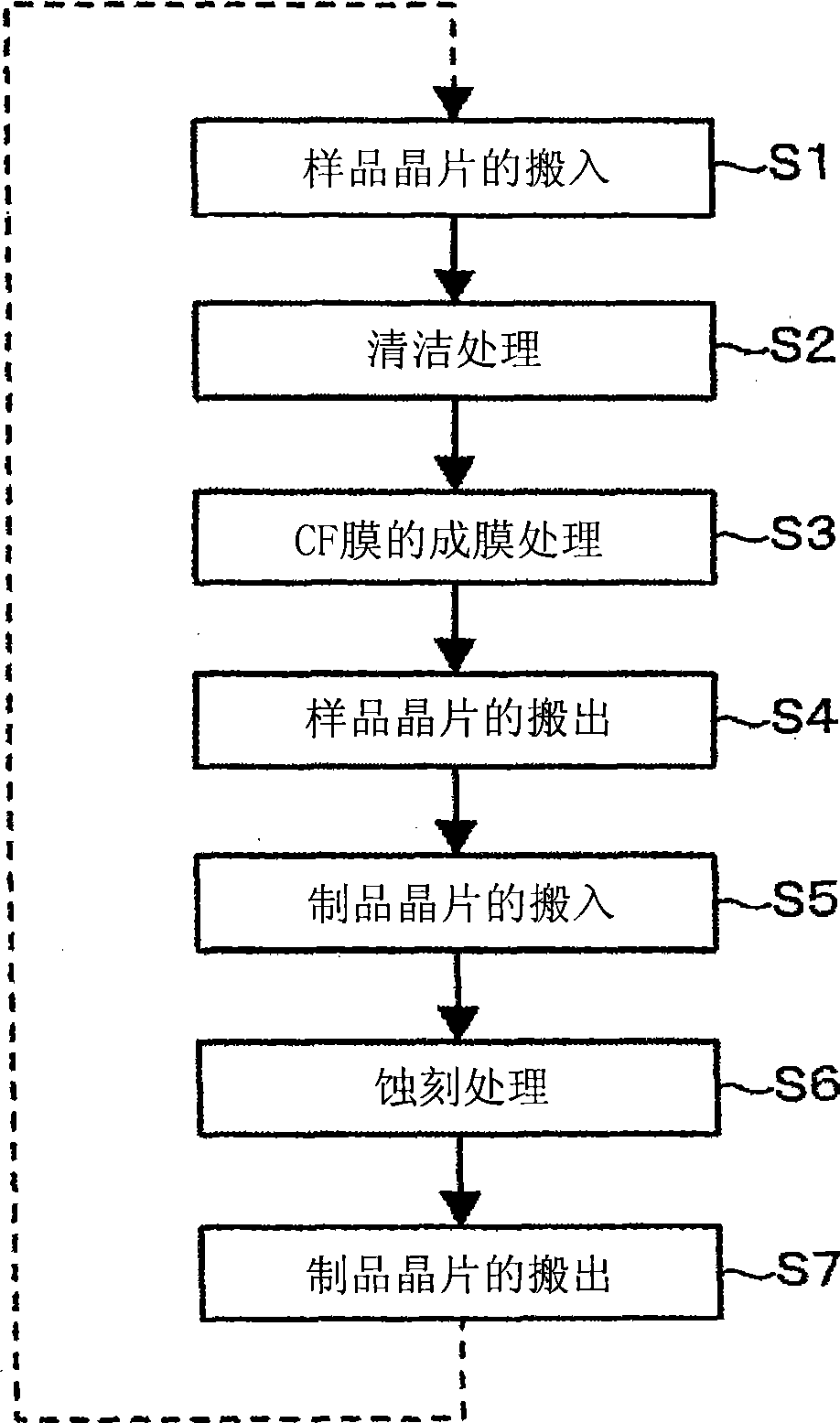

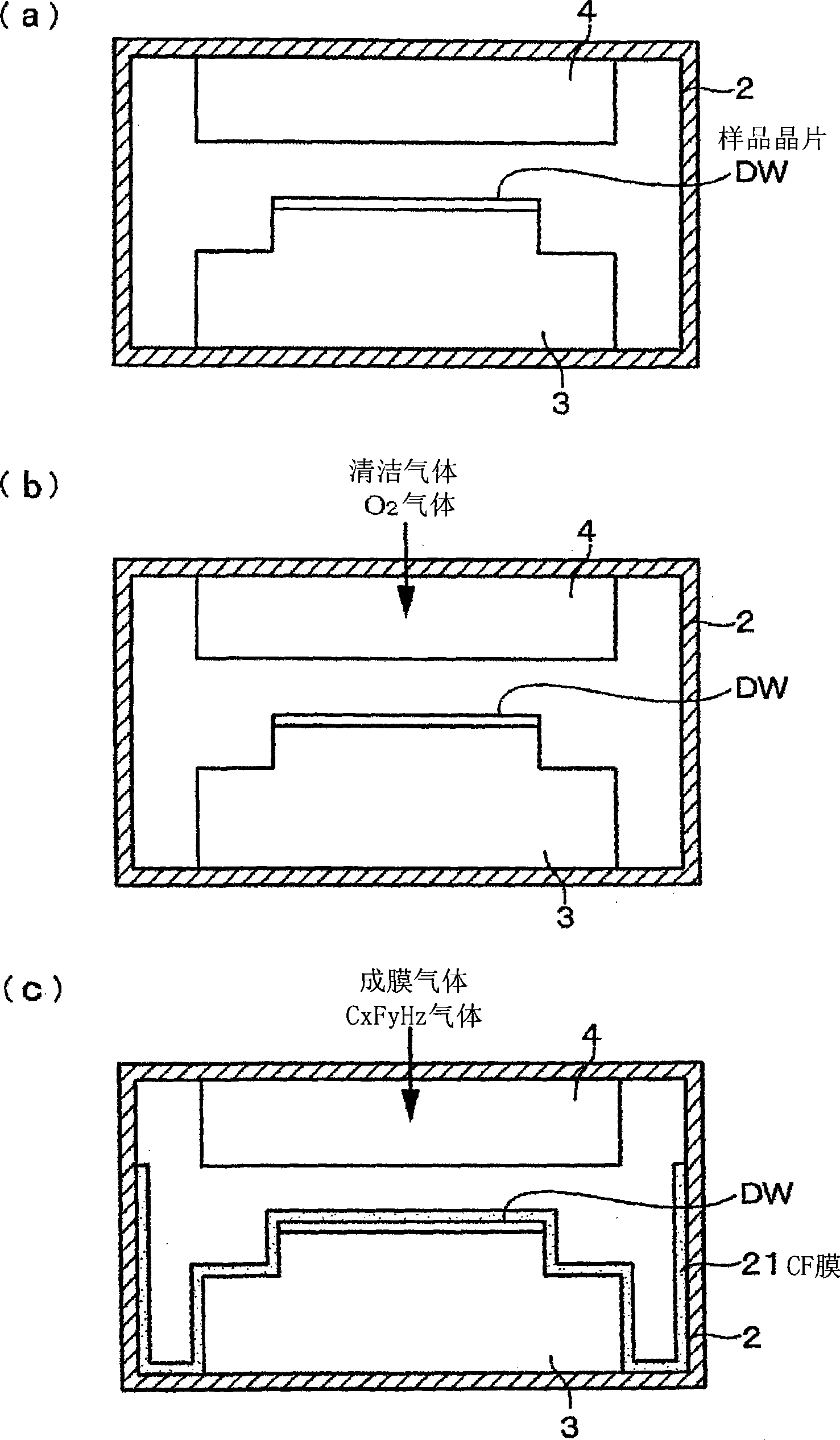

[0075] use figure 1 The plasma etching setup shown, according to figure 2 The shown steps S1 to S7 are processed in the order of cleaning treatment → CF film formation treatment → etching treatment, and the SiN film formed on the wafer W is etched. At this time, the cleaning process and the etching process were performed under the same conditions, and the film forming process of the CF film 21 was performed at a process pressure of 26.6 Pa, and the film forming gas, high frequency power, and process time were changed as described later. For the wafer W subjected to the etching process, the average value of the etching rate, the in-plane uniformity of the etching rate, and the amount of yttrium on the wafer were measured.

[0076] Here, the average value of the etching rate was measured at 33 measurement points in the radial direction of the wafer W, and calculated from the average value. In addition, the internal uniformity of the etching rate was calculated by Nano Spec 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com