Patents

Literature

195results about How to "Suppression of scattering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

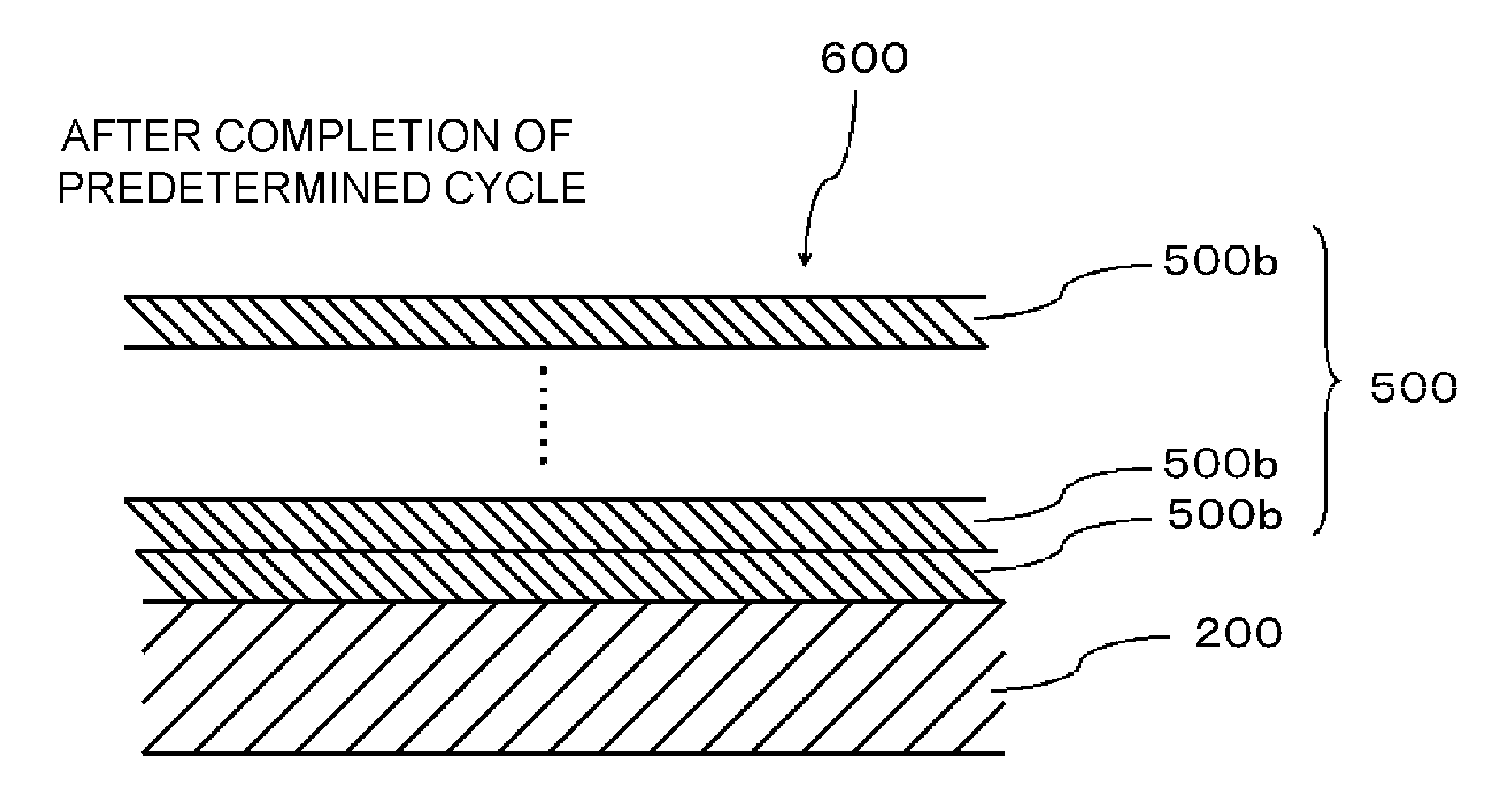

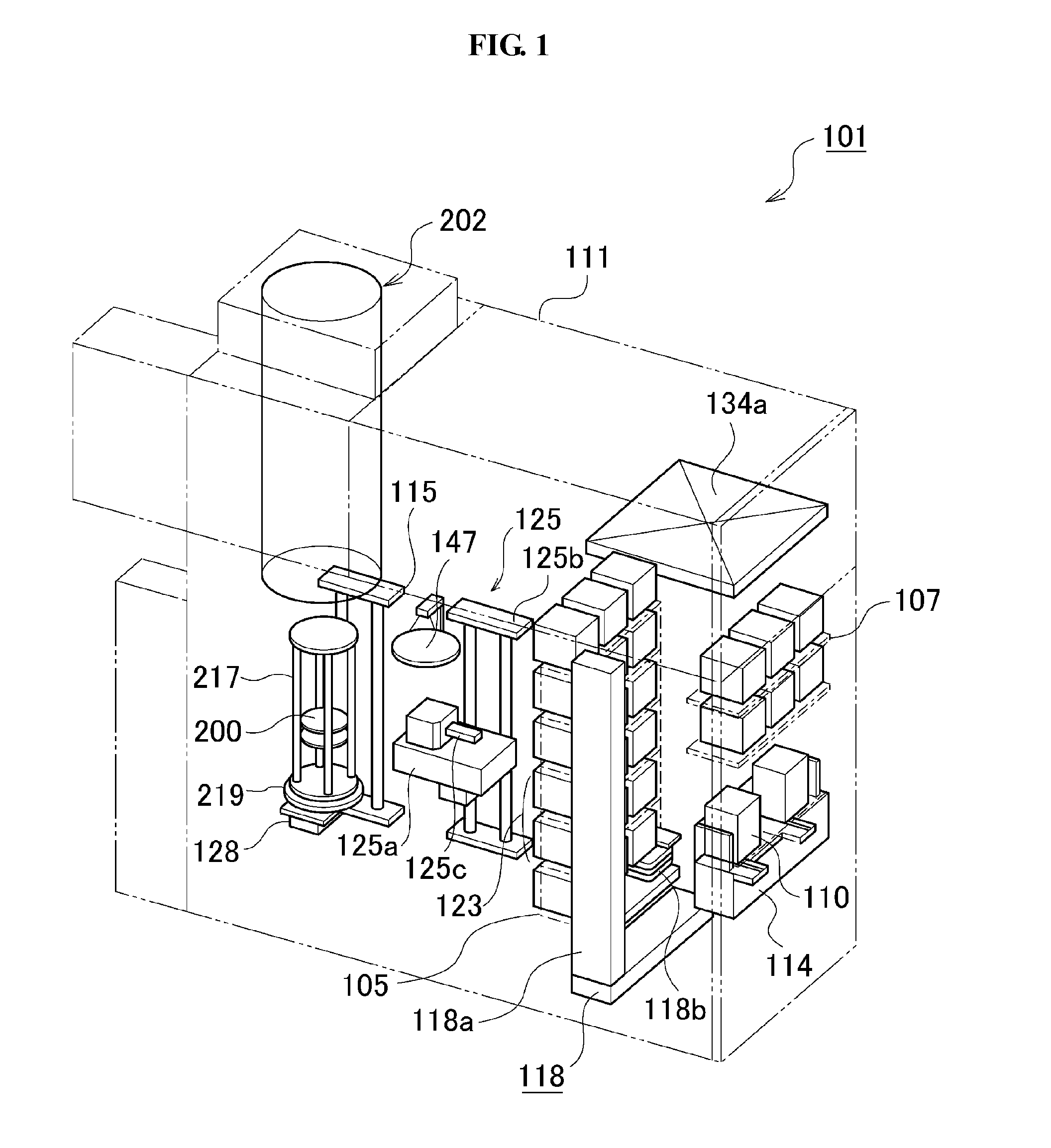

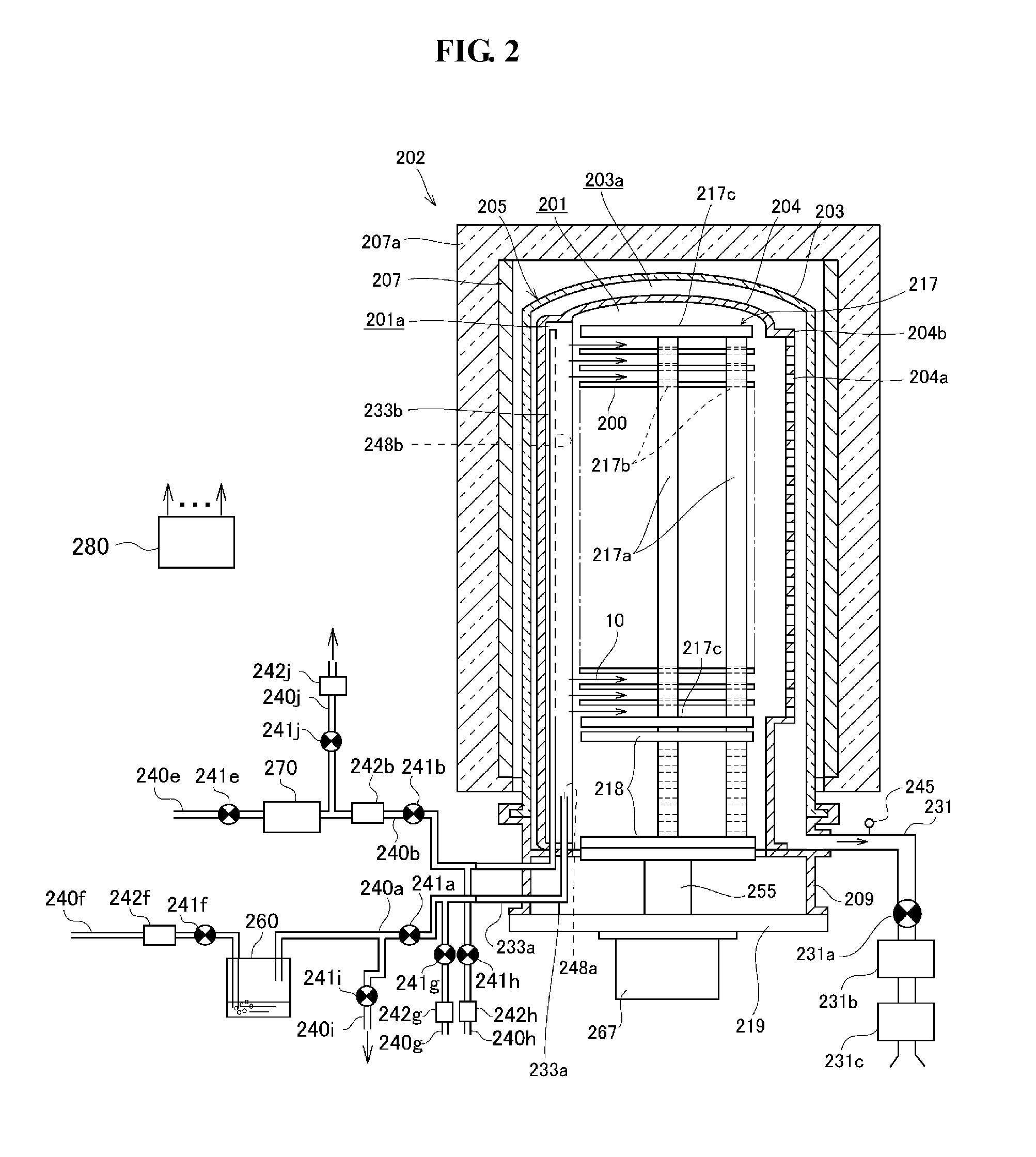

Substrate processing apparatus, method of manufacturing semiconductor device and semiconductor device

ActiveUS20120119337A1Avoid processing qualitySuppress scatterLiquid surface applicatorsSemiconductor/solid-state device detailsForeign matterThermodynamics

Provided is a substrate processing apparatus capable of suppressing accumulation of reaction products or decomposed matters on an inner wall of a nozzle and suppressing scattering of foreign substances in a process chamber. The substrate processing apparatus includes a process chamber, a heating unit, a source gas supply unit, a source gas nozzle, an exhaust unit, and a control unit configured to control at least the heating unit, the source gas supply unit and the exhaust unit. The source gas nozzle is disposed at a region in the process chamber, in which a first process gas is not decomposed even under a temperature in the process chamber higher than a pyrolysis temperature of the first process gas, and the control unit supplies the first process gas into the process chamber two or more times at different flow velocities to prevent the first process gas from being mixed.

Owner:KOKUSA ELECTRIC CO LTD

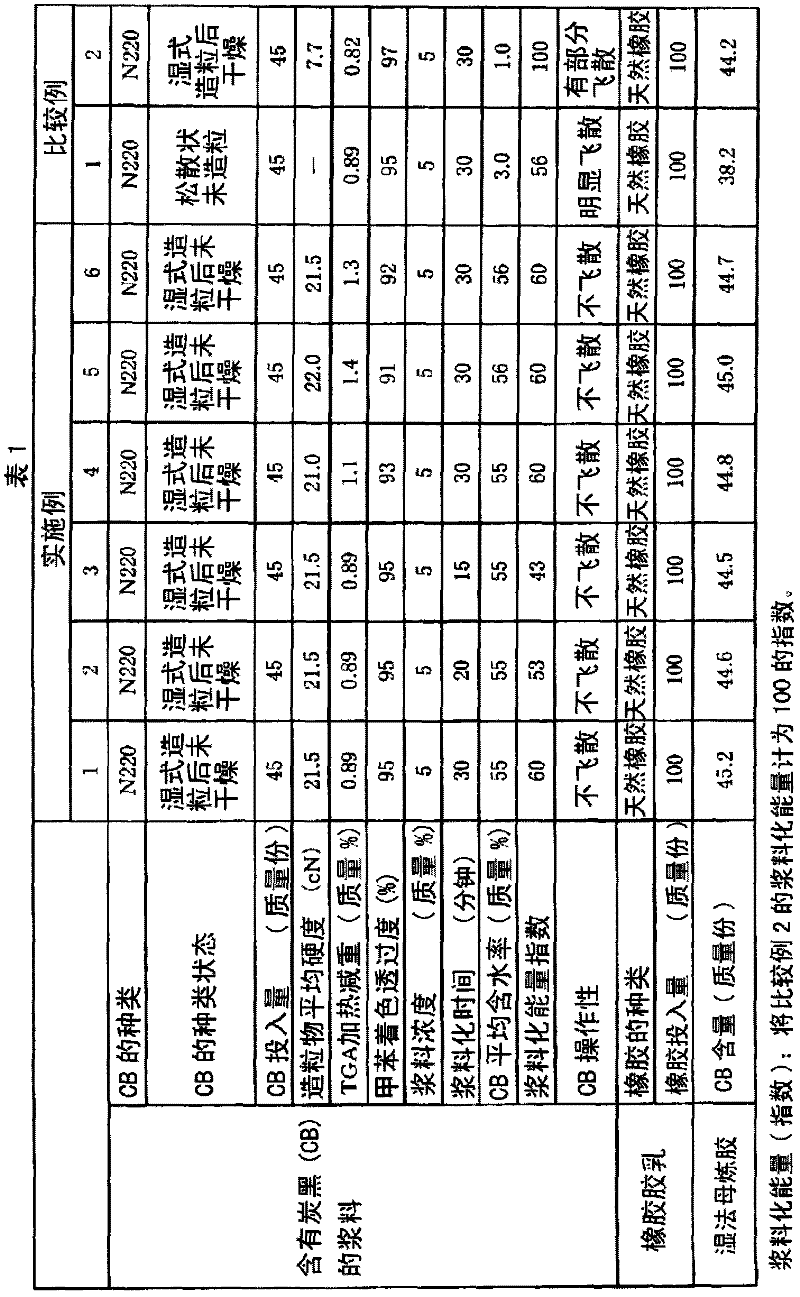

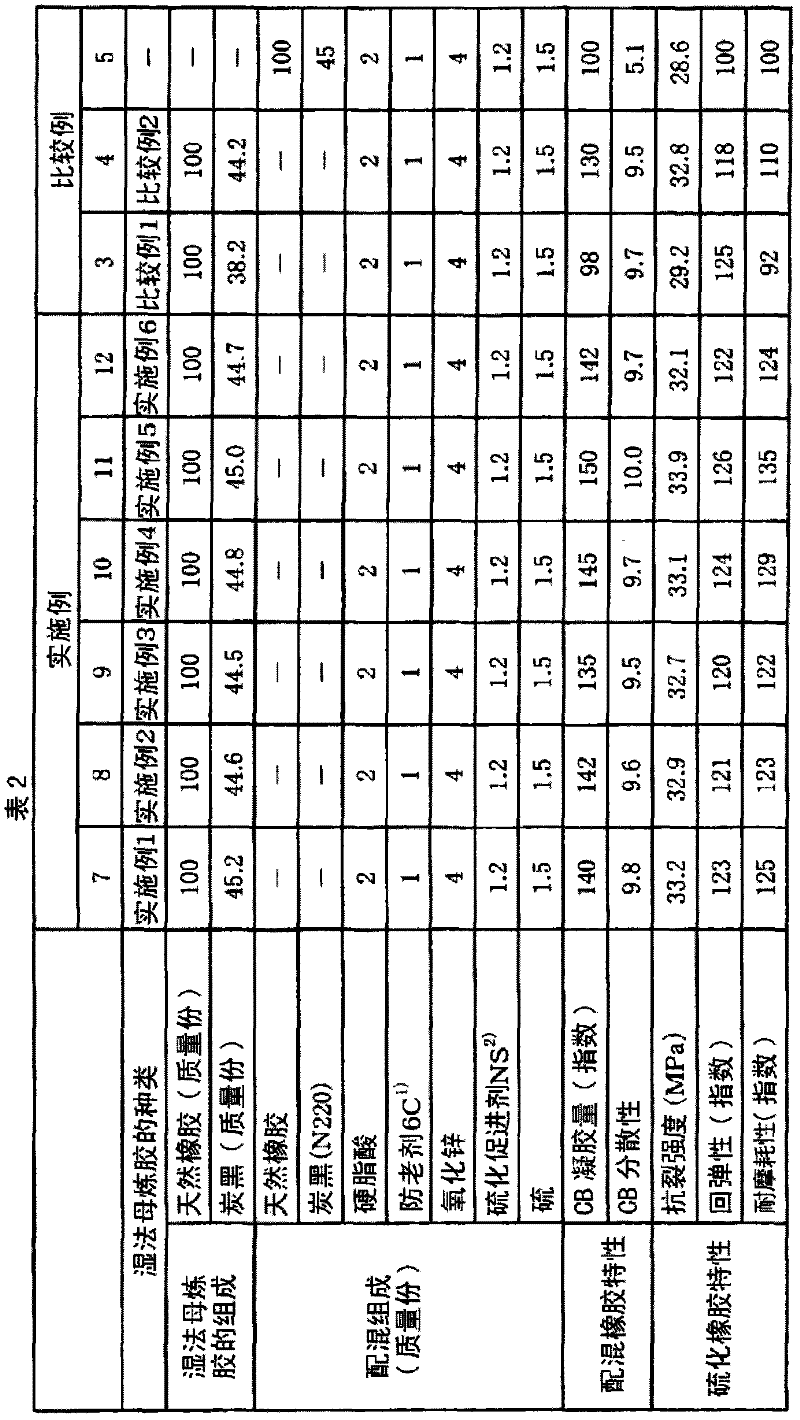

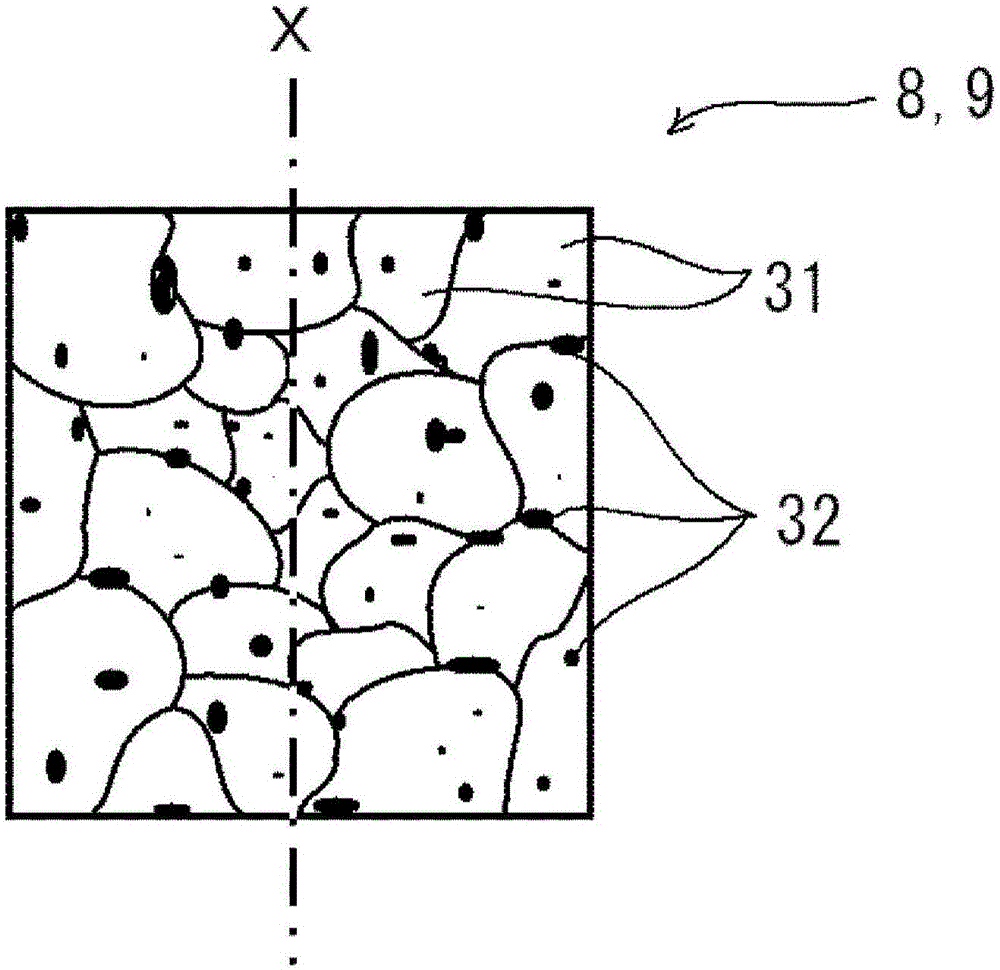

Process for producing rubber-wet masterbatch, rubber composition, and tire

A process for efficiently producing a rubber-wet masterbatch which contains carbon black having improved dispersability in a rubber as compared with granulated dry carbon black products obtained by an ordinary wet process or with ungranulated carbon black. By using carbon black having high surface activity, rubber-reinforcing properties, wear resistance, and other properties can be improved. The wet masterbatch obtained has an intact yield of carbon black, and the carbon black has satisfactory handleability. Provided are a carbon black-containing rubber-wet masterbatch obtained by the process, and a rubber composition and a tire each obtained using the masterbatch. The process for producing a carbon black-containing rubber-wet masterbatch comprises the step of mixing a slurry (A) obtainedby dispersing a filler comprising carbon black with a rubber liquid (B) obtained by dispersing or dissolving a rubber ingredient, wherein the slurry (A) is prepared using a filler comprising undried carbon black granulated by a wet process.

Owner:BRIDGESTONE CORP

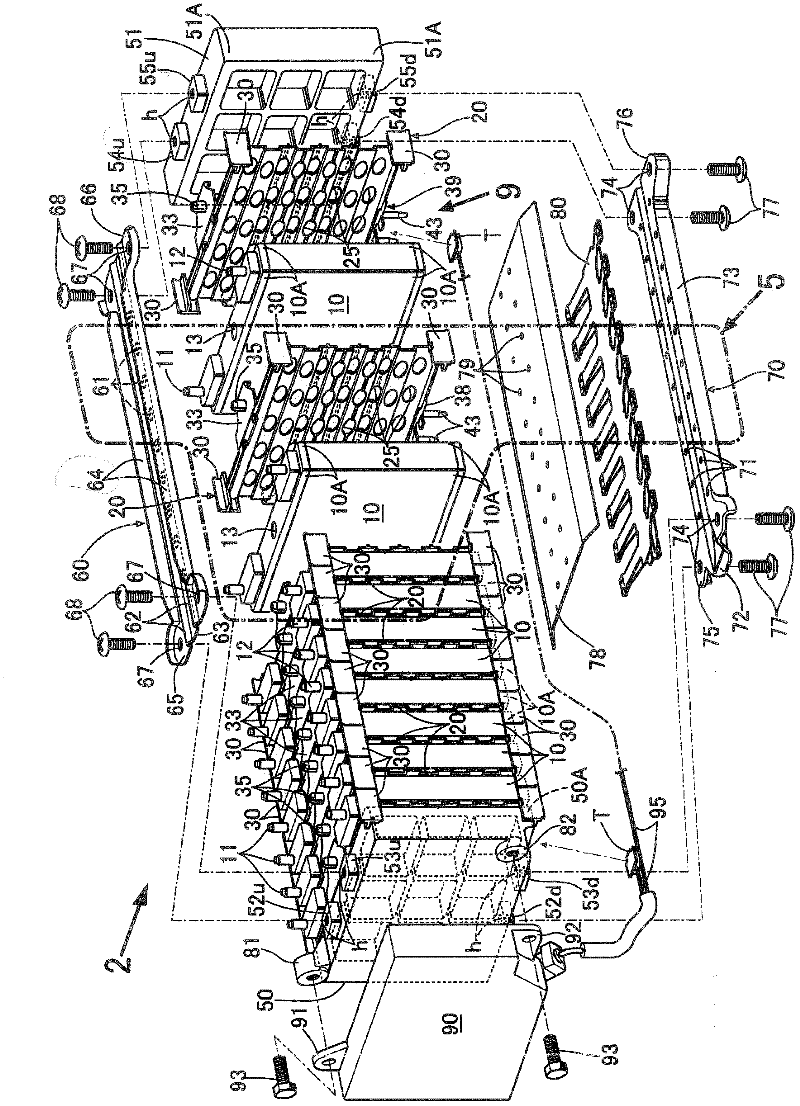

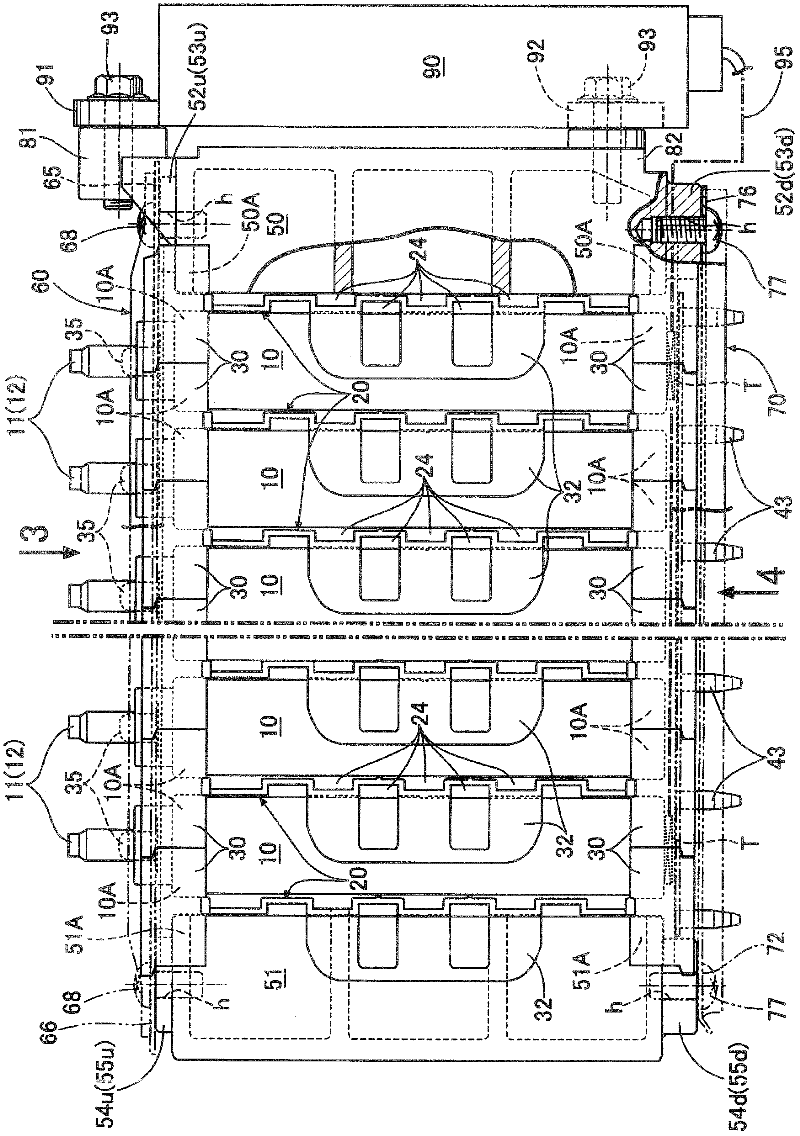

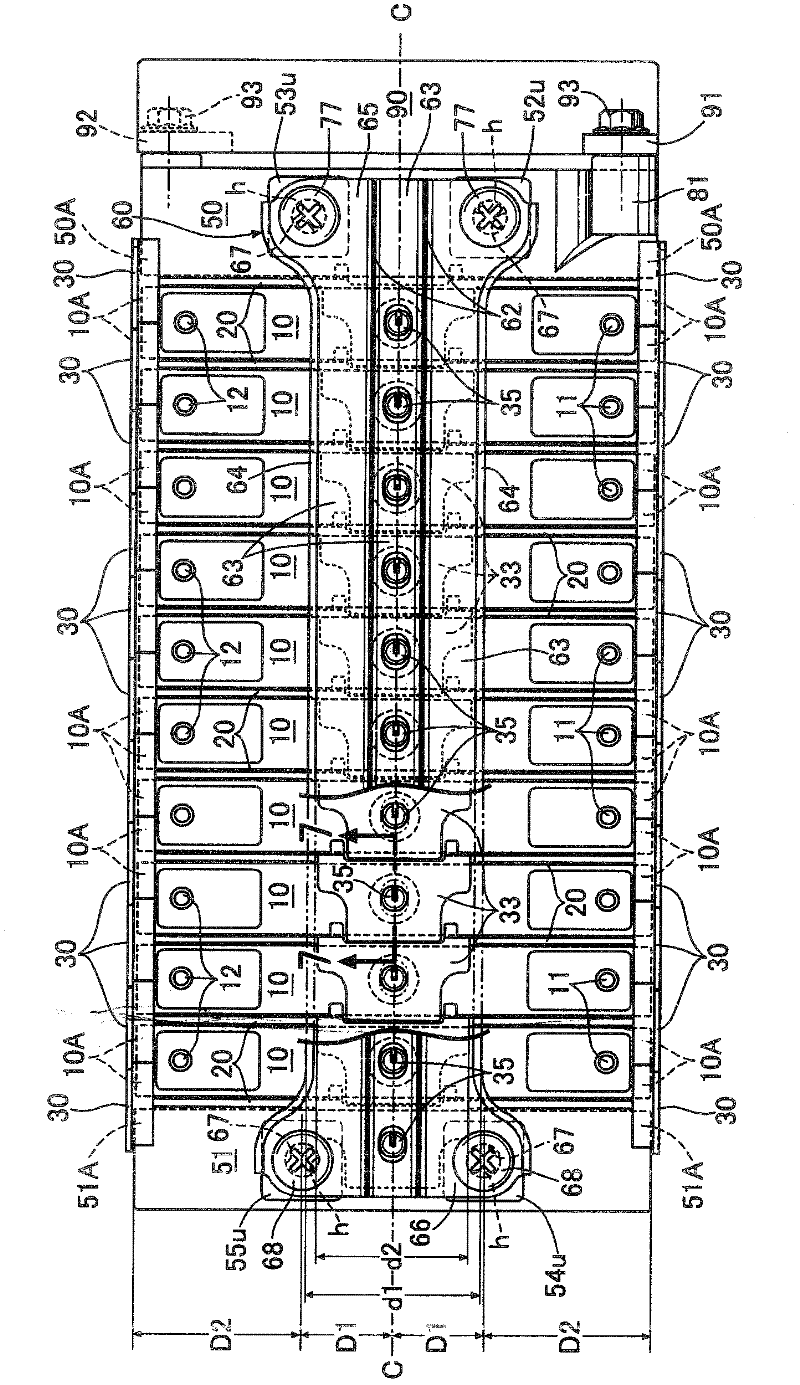

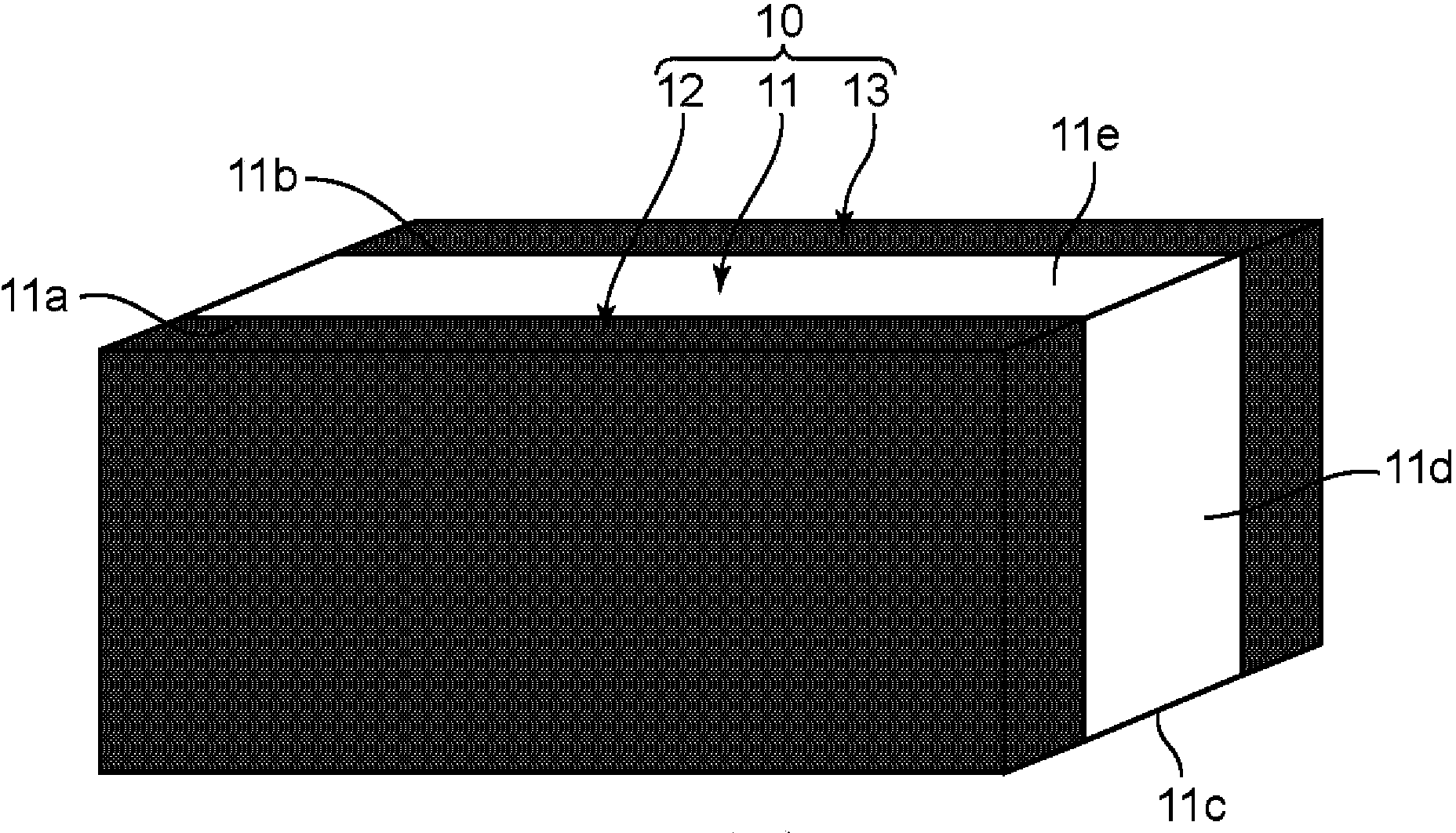

Battery module

ActiveCN102403474AAvoid flyingRestricted movementCell temperature controlBattery isolationInternal pressureEngineering

Owner:HONDA MOTOR CO LTD

Adhesive composition, filmy adhesive, adhesive sheet, and semiconductor device made with the same

InactiveCN101365765ASuppression of scatteringSimplify the manufacturing processNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsMeth-Adhesive

Owner:RESONAC CORPORATION

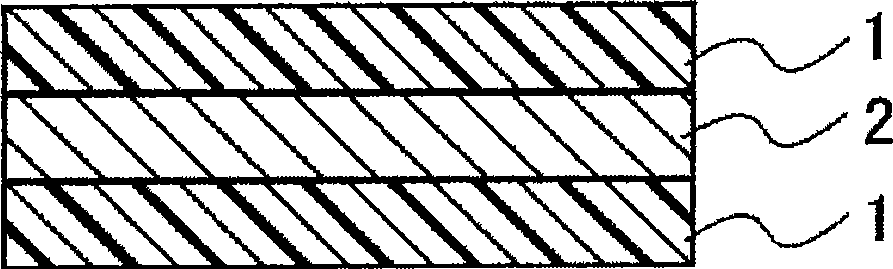

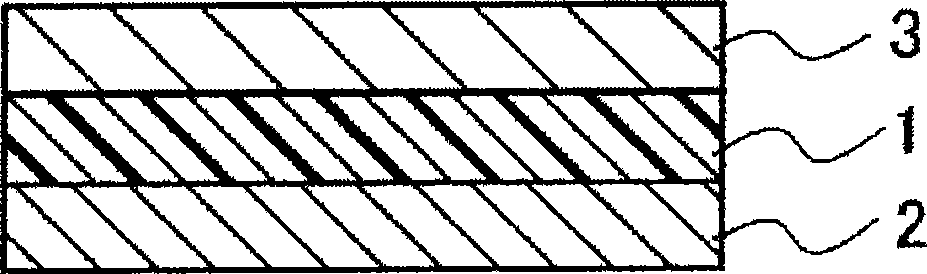

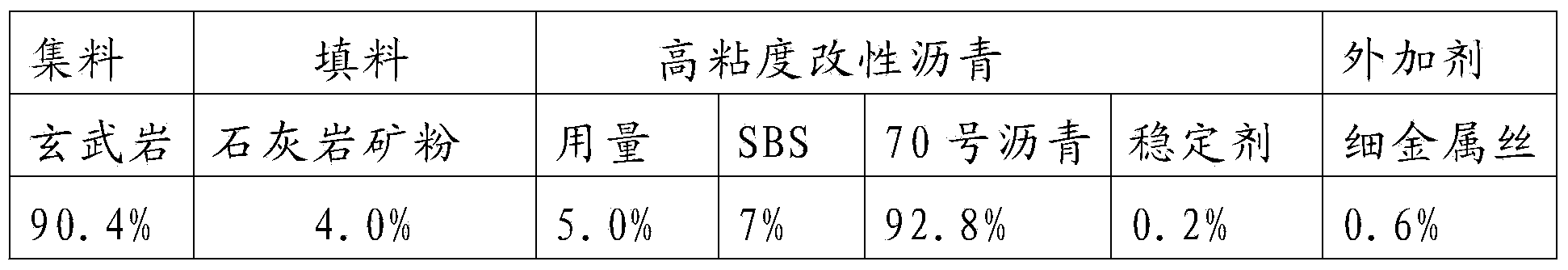

Special asphalt mixture capable of inhibiting flying of drainage asphalt pavement stones and preparation method thereof

ActiveCN104030609AStrengthen anti-scattering abilitySuppression of scatteringVoid ratioMetal filament

The invention discloses a special asphalt mixture capable of inhibiting flying of drainage asphalt pavement stones and a preparation method of the mixture. The special asphalt mixture capable of inhibiting the flying of the drainage asphalt pavement stones comprises aggregate, filler, high viscosity modified asphalt and an external additive, wherein the aggregate comprises basalt, diabase and / or limestone; the filler is limestone mineral powder; the high viscosity modified asphalt is made from SBS (styrene butadiene styrene), No.70 petroleum asphalt and a stabilizer through stirring and high shearing at high temperature; the external additive is a plurality of fine metal filaments. The preparation method of the special asphalt mixture comprises the following steps: adding the fine metal filaments into the aggregate, mixing, spraying the high viscosity modified asphalt and the filler at the same time, and continuously mixing, so that the special asphalt mixture is formed. The special asphalt mixture disclosed by the invention has the advantages that the fine metal filaments are creatively added, the problem of flying of stones is effectively inhibited, void ratio is reduced as a skeleton space is filled or blocked, and drainage and noise reduction functions of the drainage asphalt pavement can not be influenced.

Owner:SHANGHAI PUDONG ROAD & BRIDGE CONSTR +2

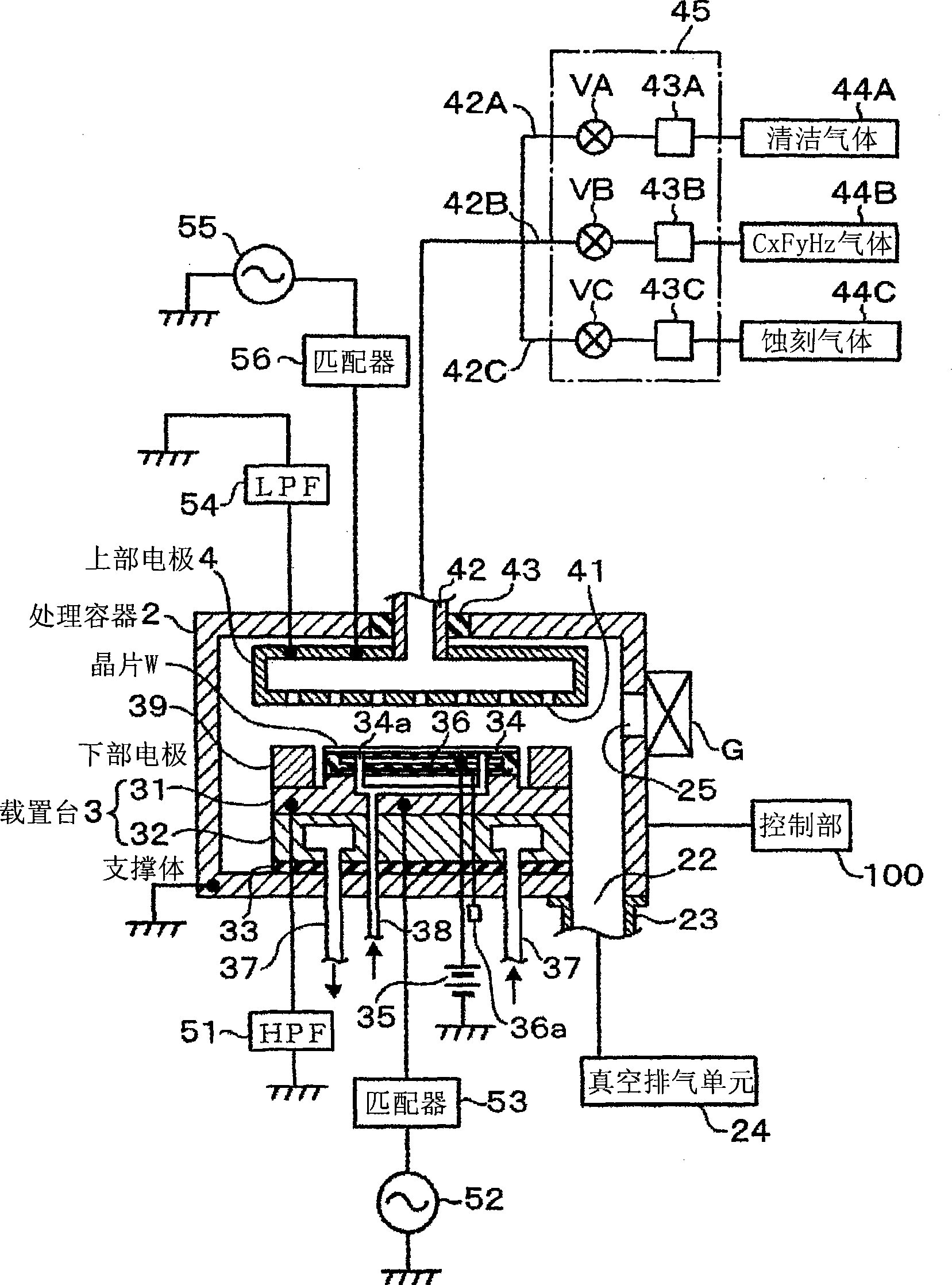

Plasma etching method and plasma etching apparatus

ActiveCN101504915ALess quantityImprove in-plane uniformityGas treatmentSemiconductor/solid-state device manufacturingGas plasmaMaterials science

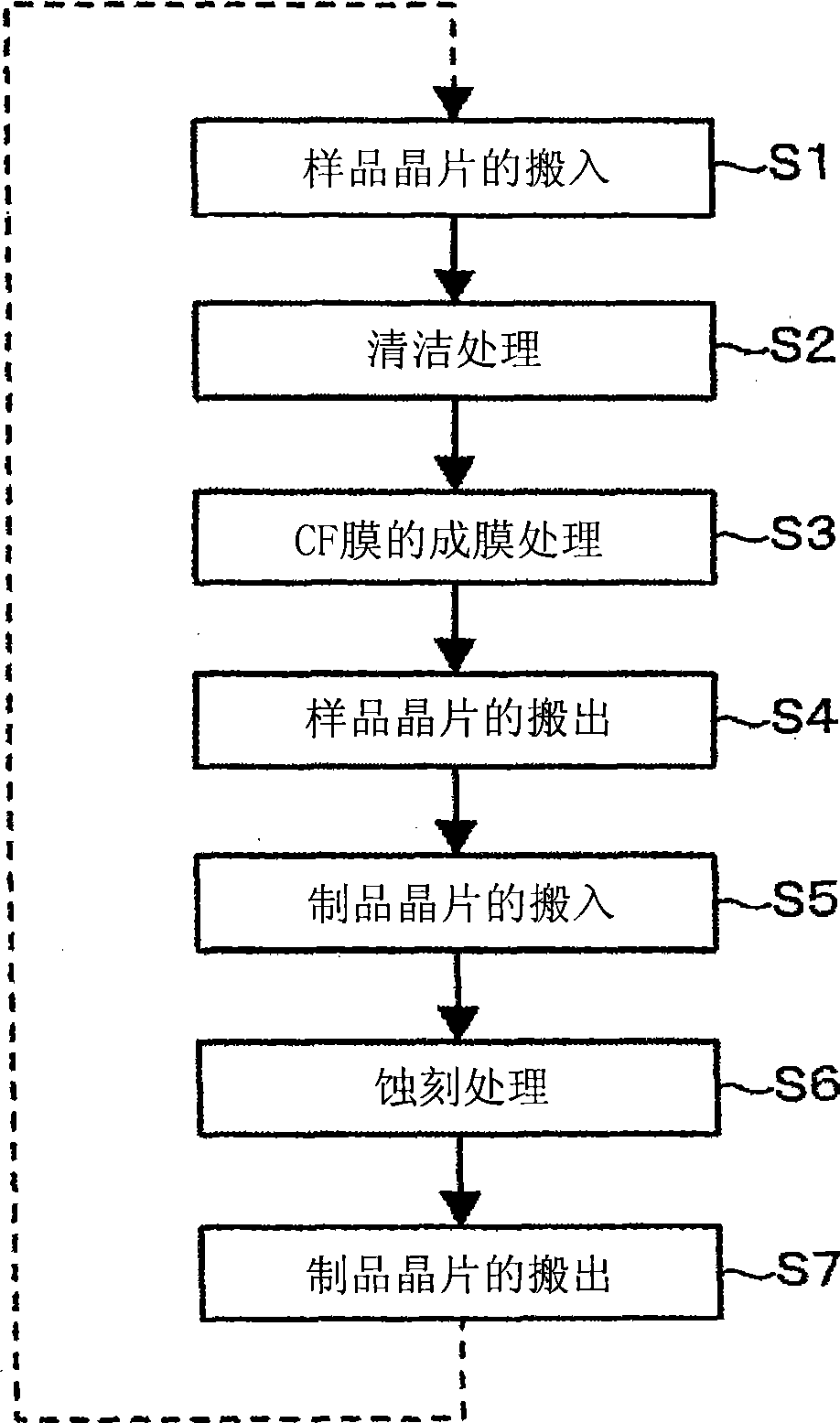

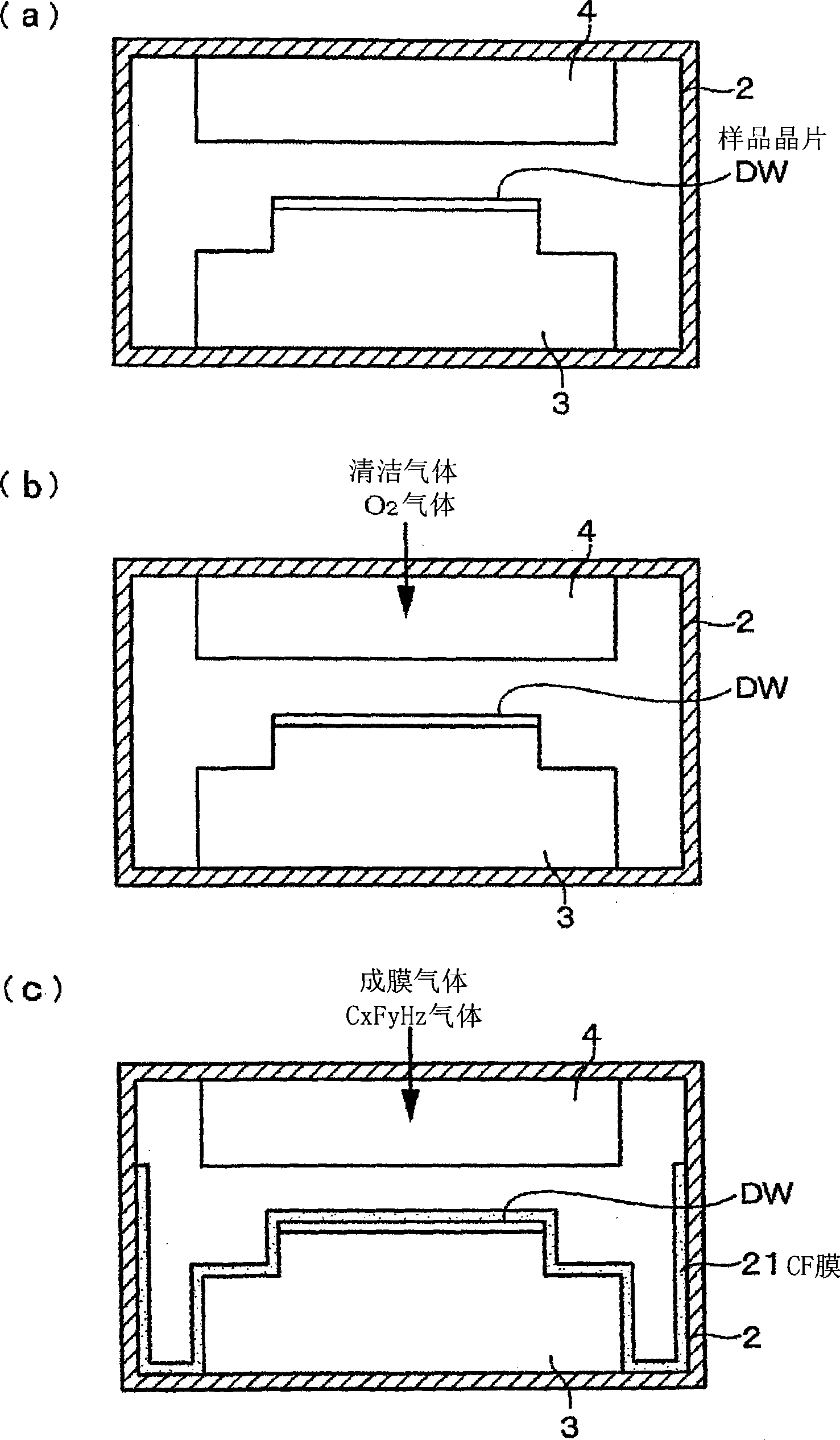

The invention provides a plasma etching method and a plasma etching device, which are capable of controlling profile of the etching and prohibiting the generation of particles resulted from etching a treatment vessel and the like. Once a cleaning procedure (a) is implemented, the plasma, which is obtained by subjecting the cleaning gas to plasma treatment, is utilized to remove adhesions adhered to the treatment vessel (2); once a filming procedure (b) is implemented, the plasma, which subjects a filming gas containing carbon and fluorine to plasma treatment, is utilized to form a CF film at a part exposed to the plasma inside the treatment vessel; once an etching procedure (c) is implemented, a wafer W is carried on a carrying table inside the treatment vessel and the plasma subjecting an etching gas to plasma treatment is utilized to etch the wafer W; and once a procedure (d) of moving the wafer W out of the treatment vessel after the etching procedure (c) is implemented, the procedures (a)-(d) are implemented upon the end of the procedure (d).

Owner:TOKYO ELECTRON LTD

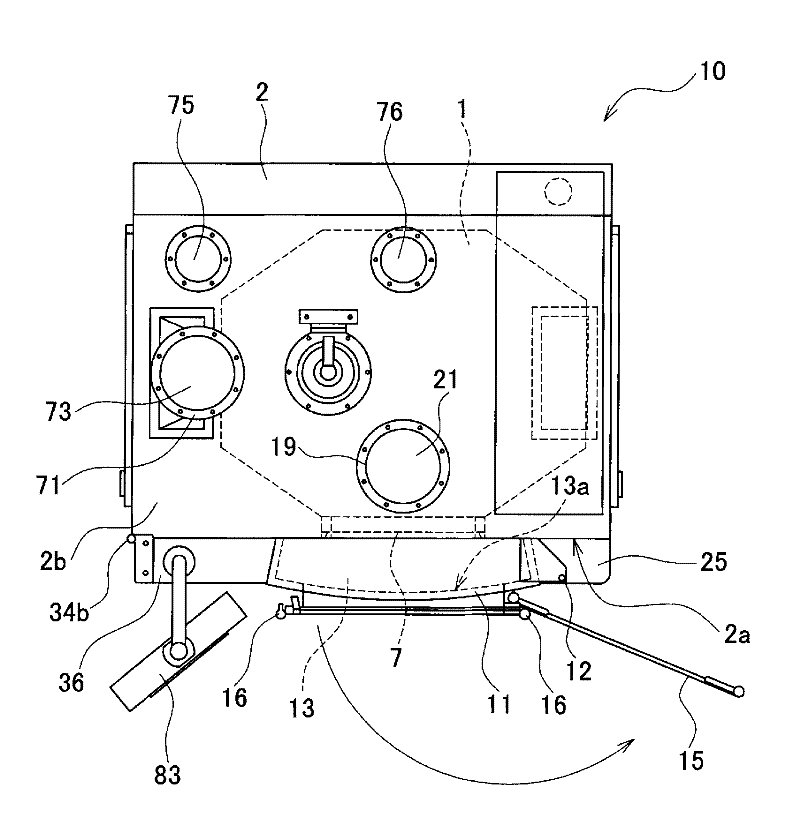

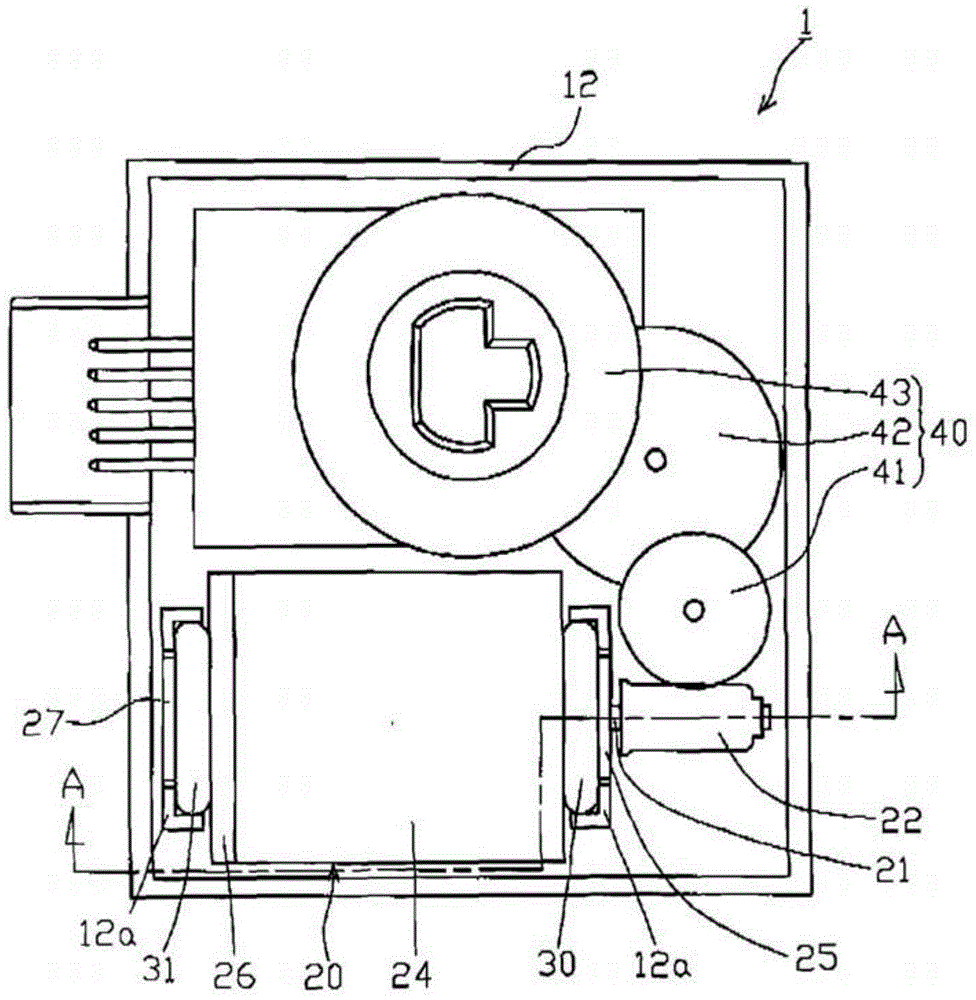

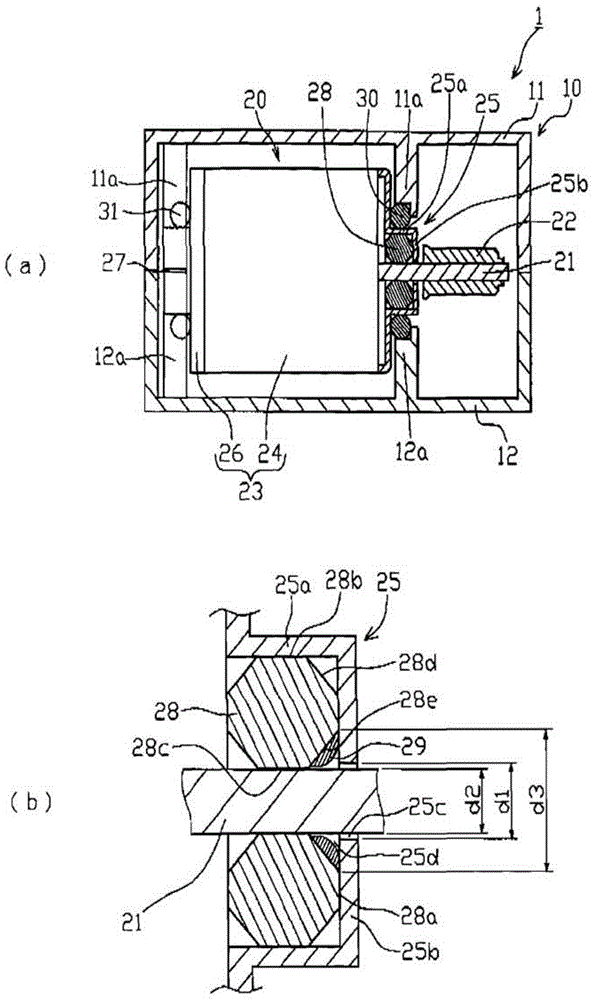

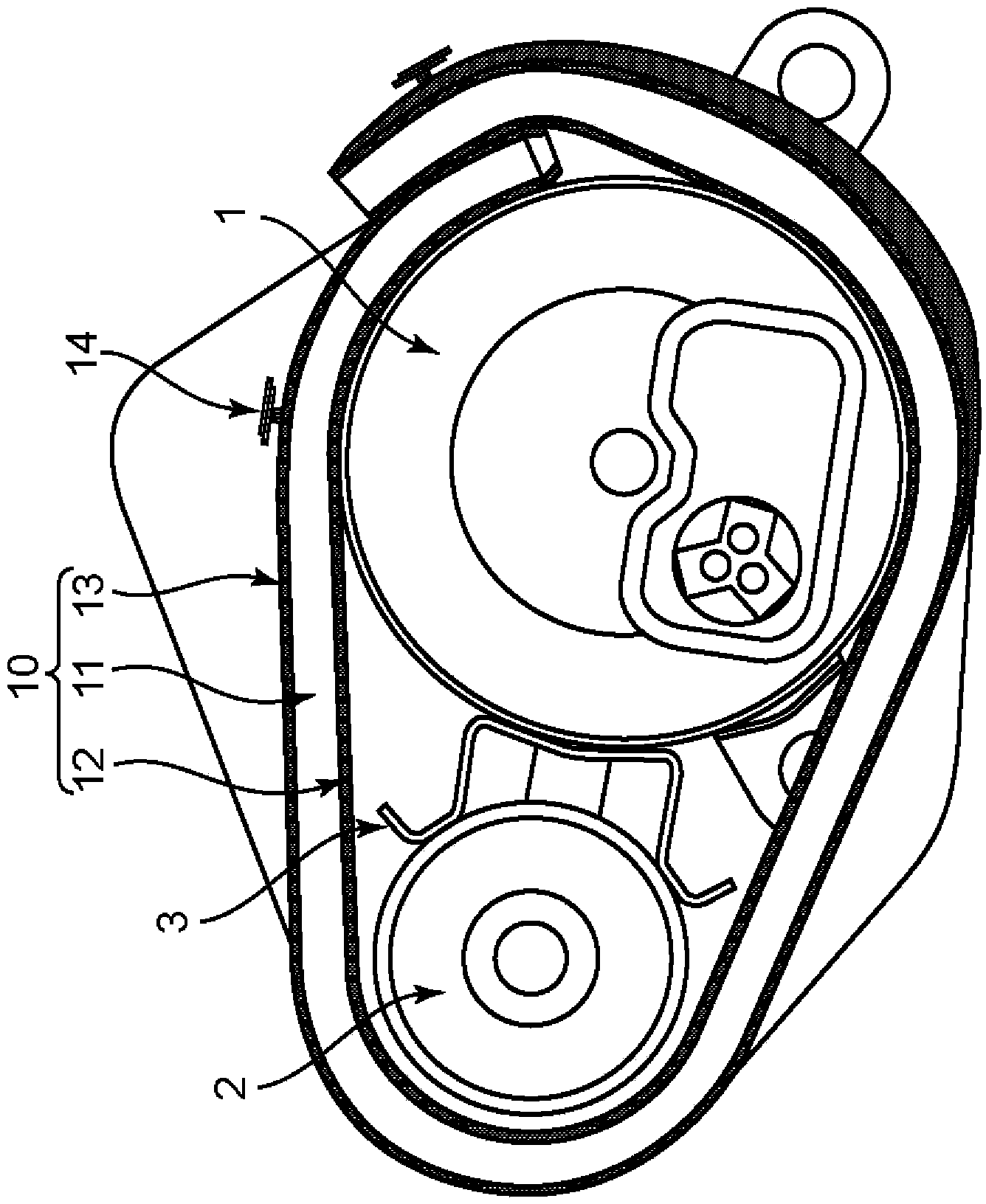

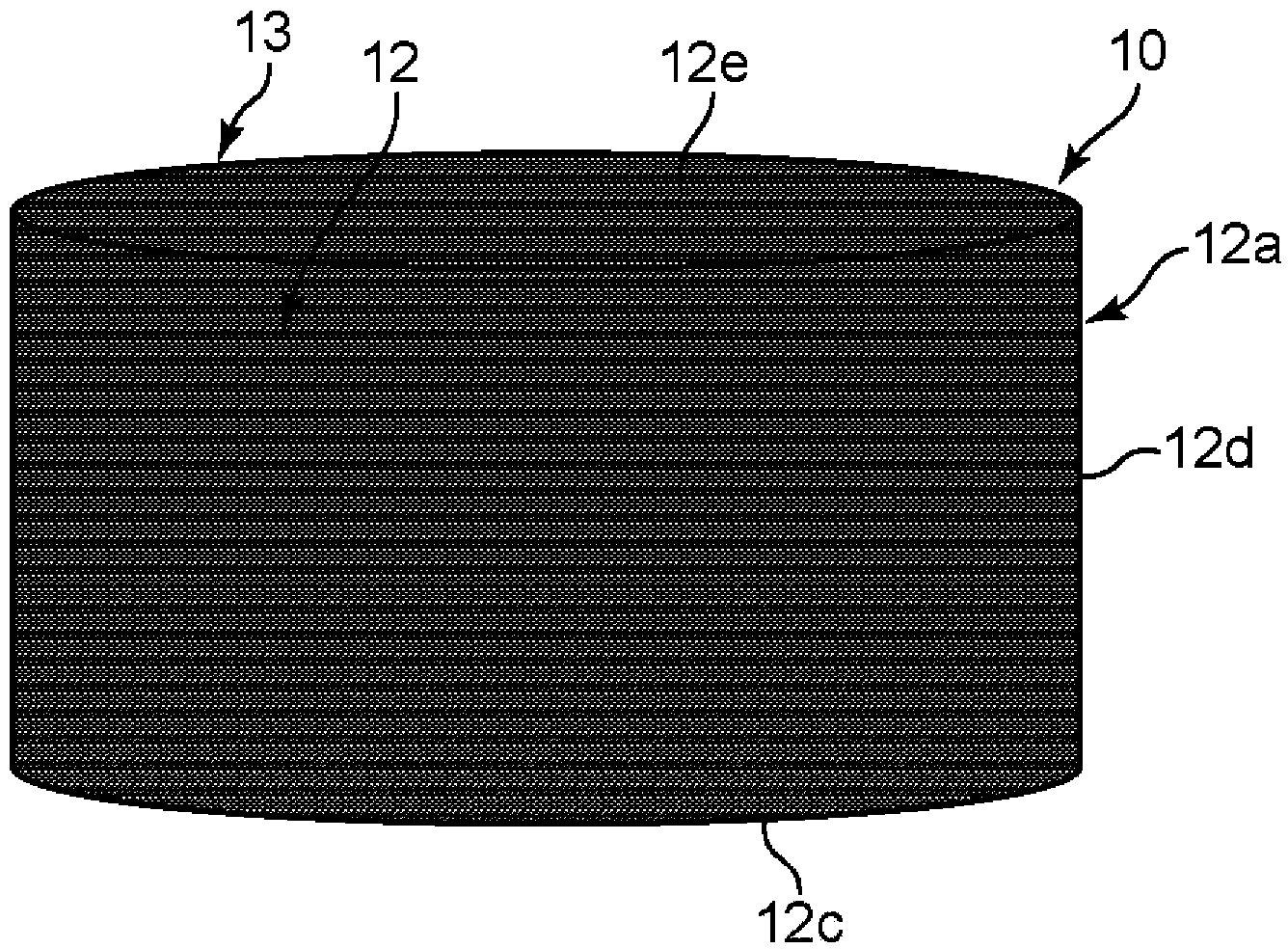

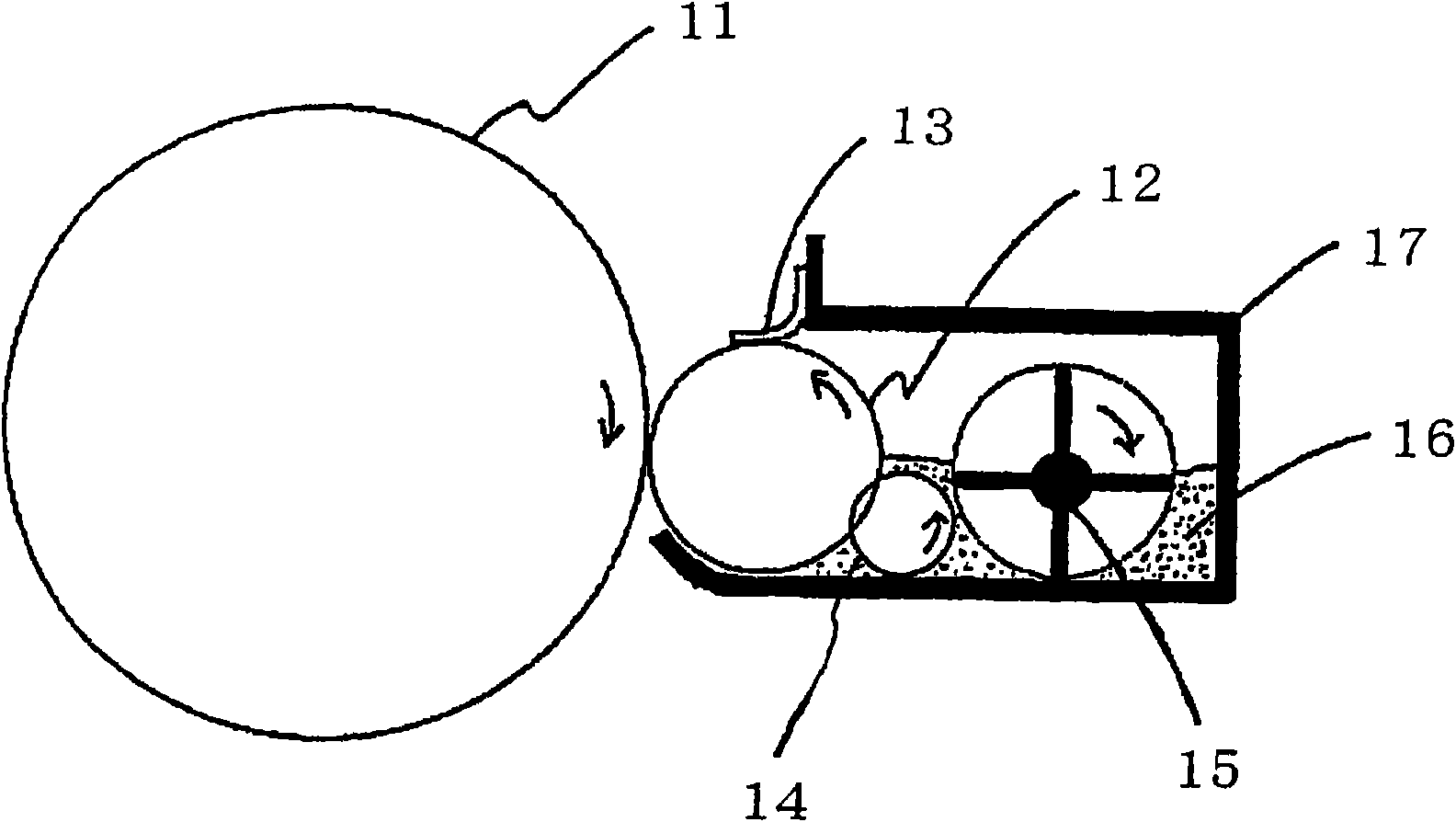

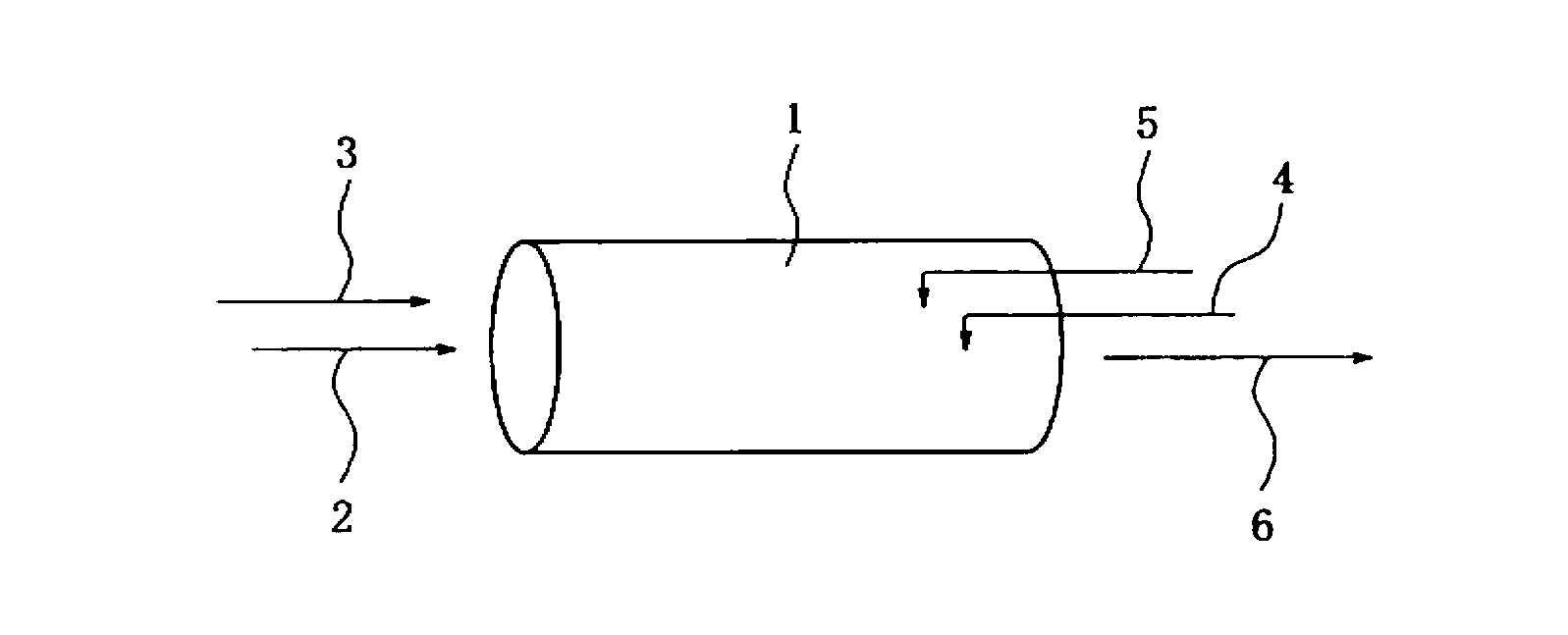

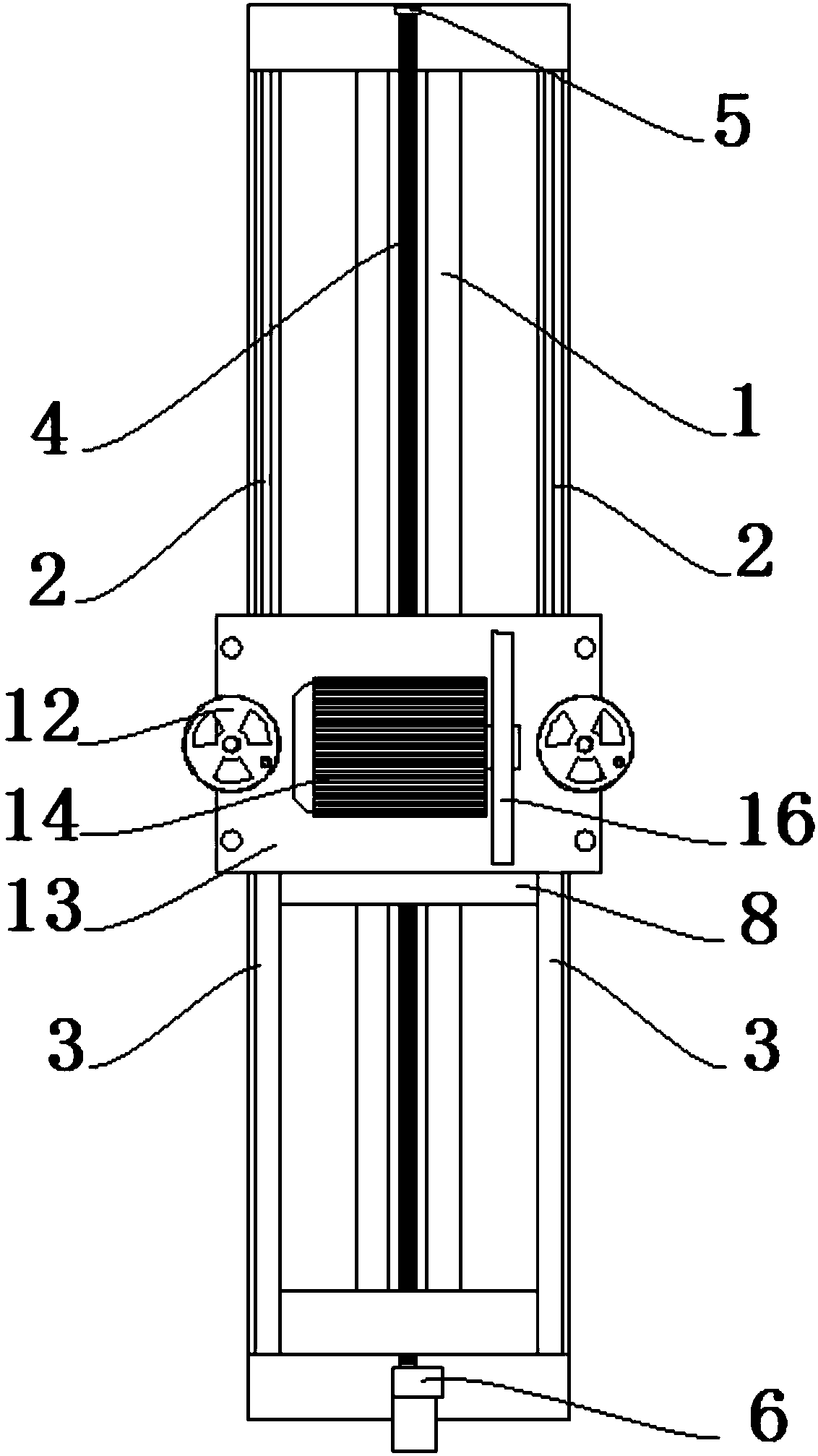

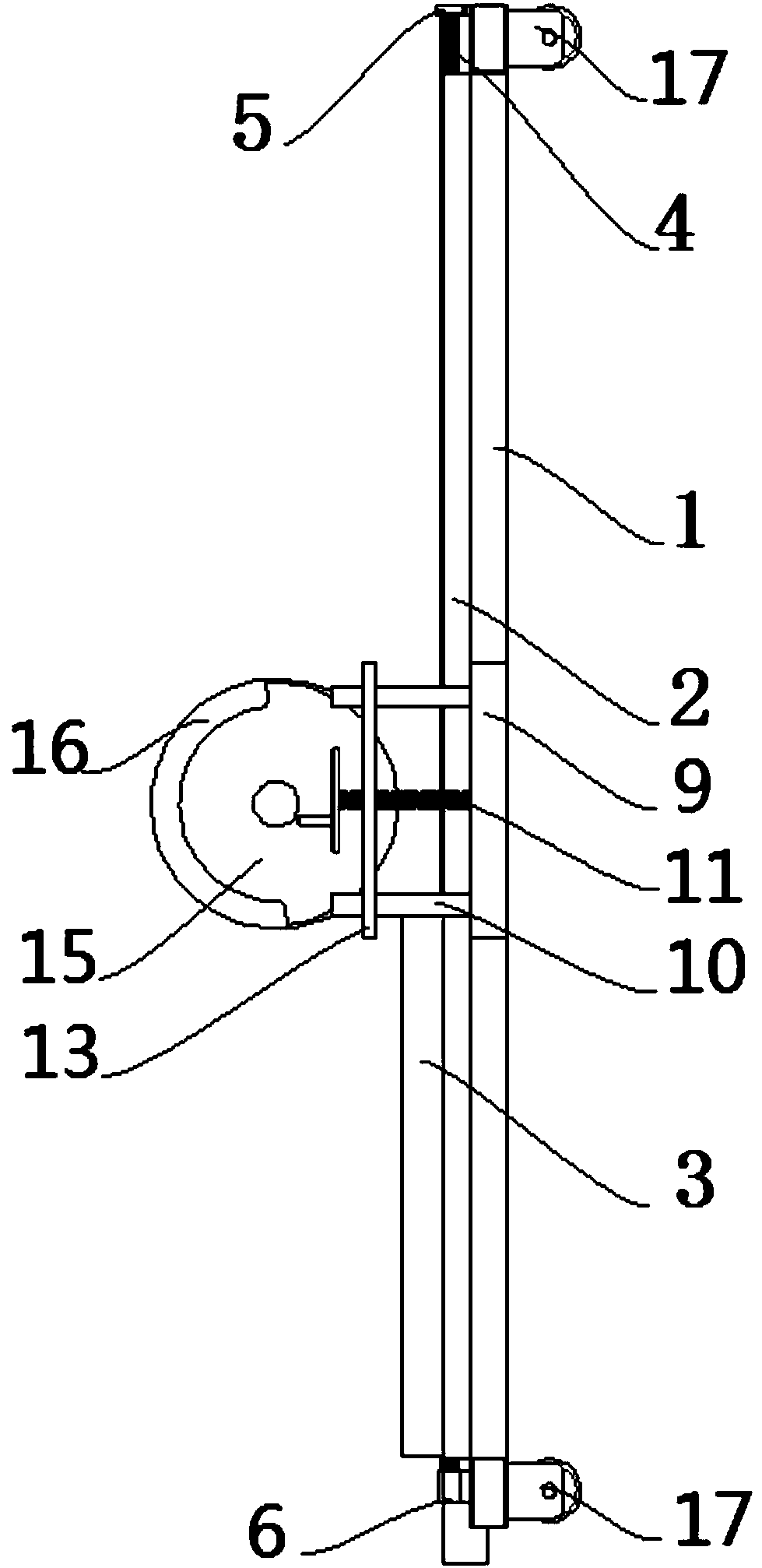

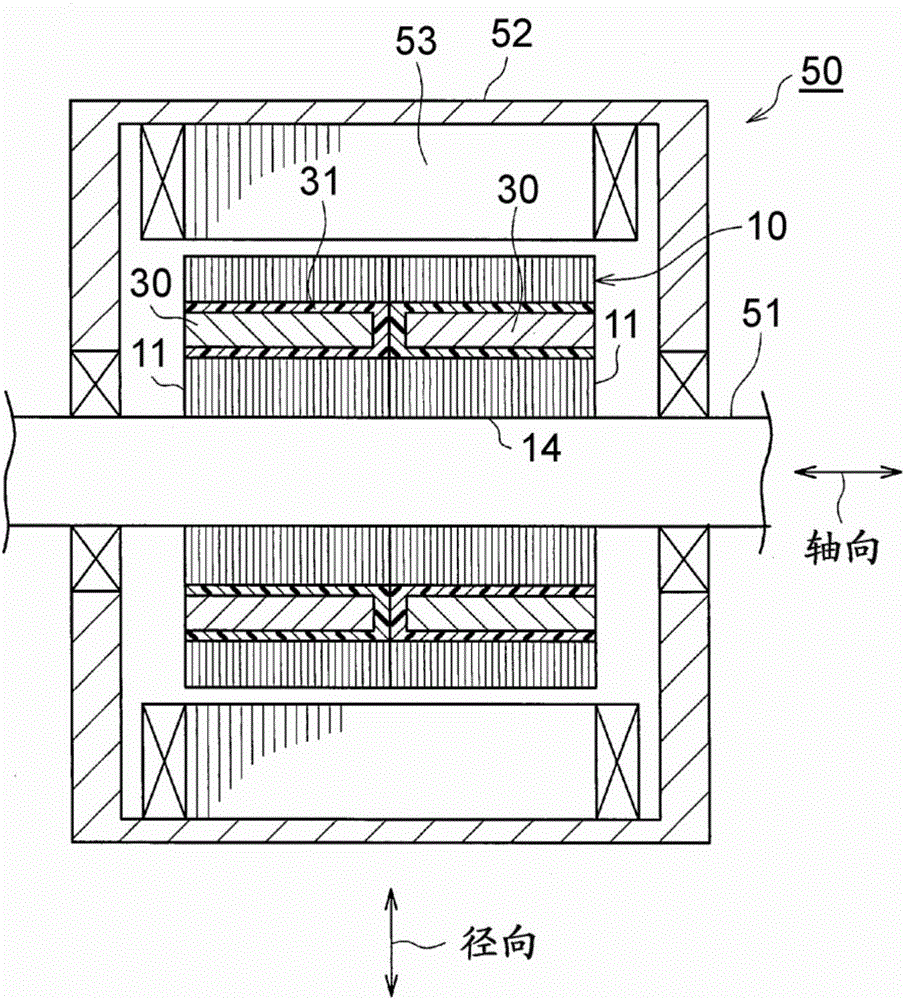

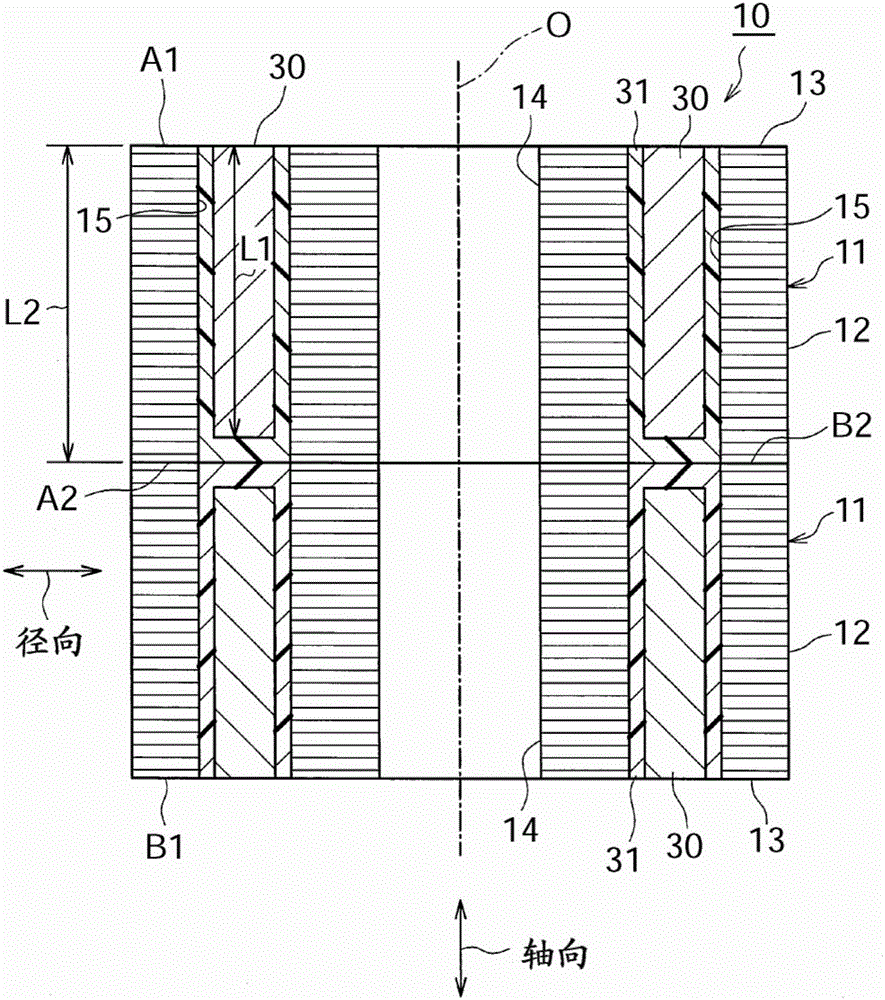

Pan coating device

ActiveCN102202778AReduce cleanup workloadReduce flow rateMaterial granulation and coatingLiquid surface applicatorsStable stateRotational axis

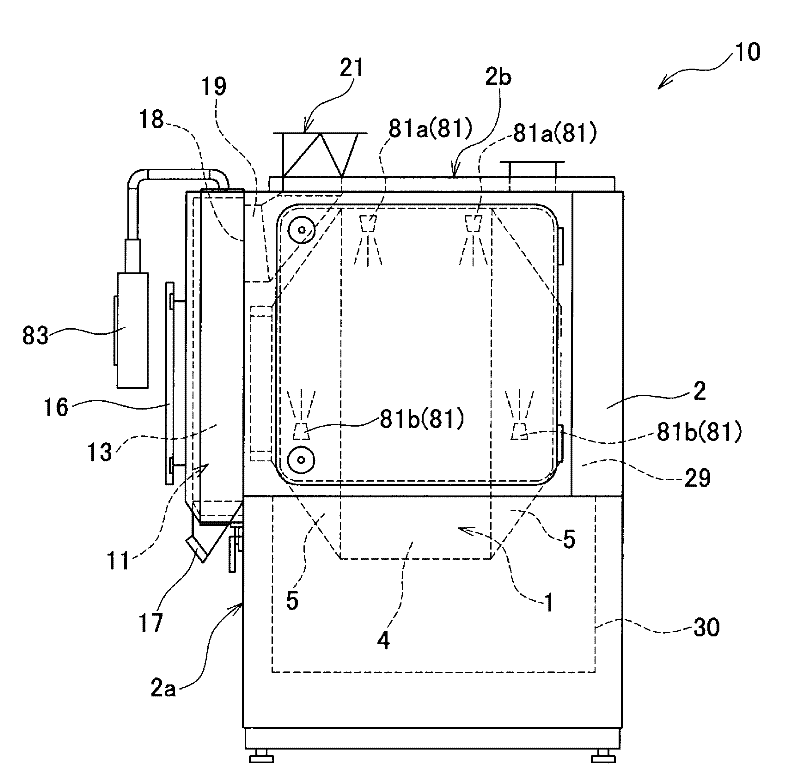

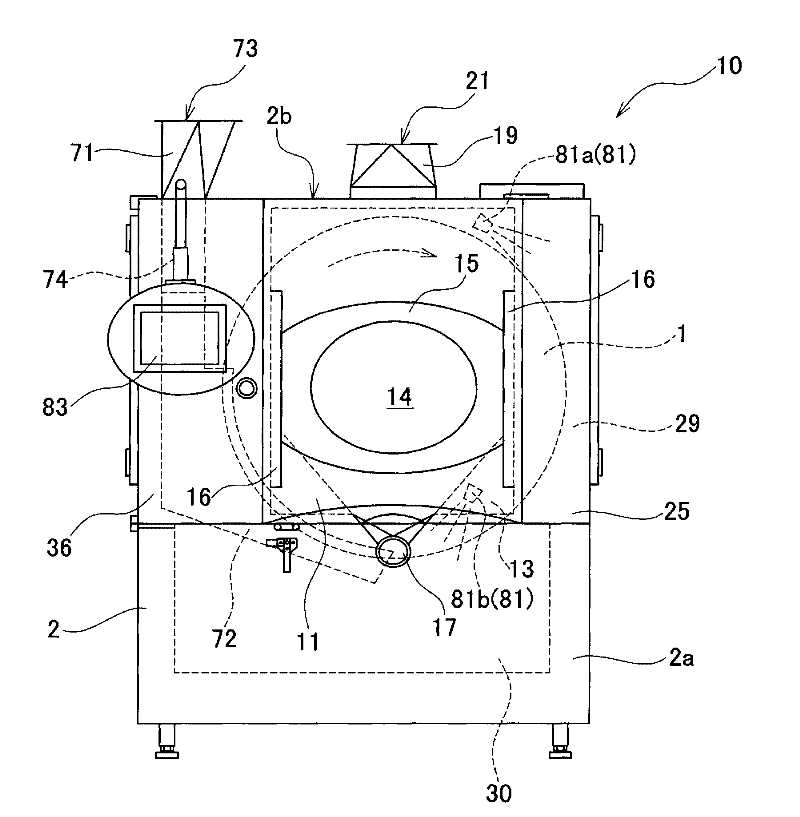

In a pan coating device (10) provided with a rotating drum (1) which rotates about a horizontal rotational axis line (O), an air supply chamber (13) with a larger cross-sectional area than that of an opening (7) in the front surface of the rotating drum is provided at the preceding stage of the opening (7). The air supply chamber (13) is formed inside a chamber door (11) attached to the front of a housing (2) with one end thereof communicating with the opening (7) and the other end thereof connected to an air supply duct (19) via an air supply hole (18). Air flowing into the air supply chamber (13) from the air supply duct (19) is reduced in flow velocity in the air supply chamber (13) and supplied from the opening (7) into the rotating drum (1) with the current thereof in a stable state.

Owner:FREUNT IND

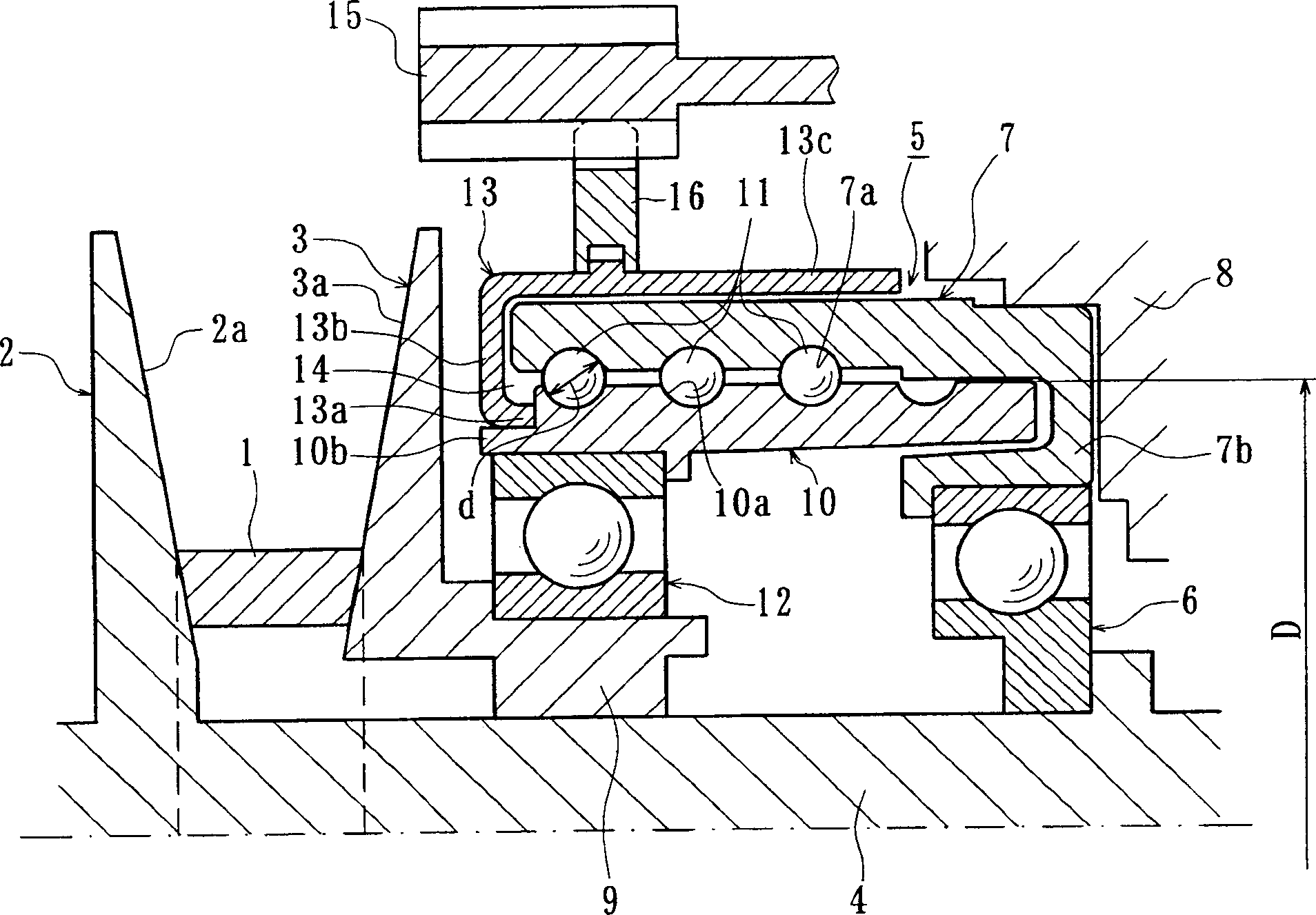

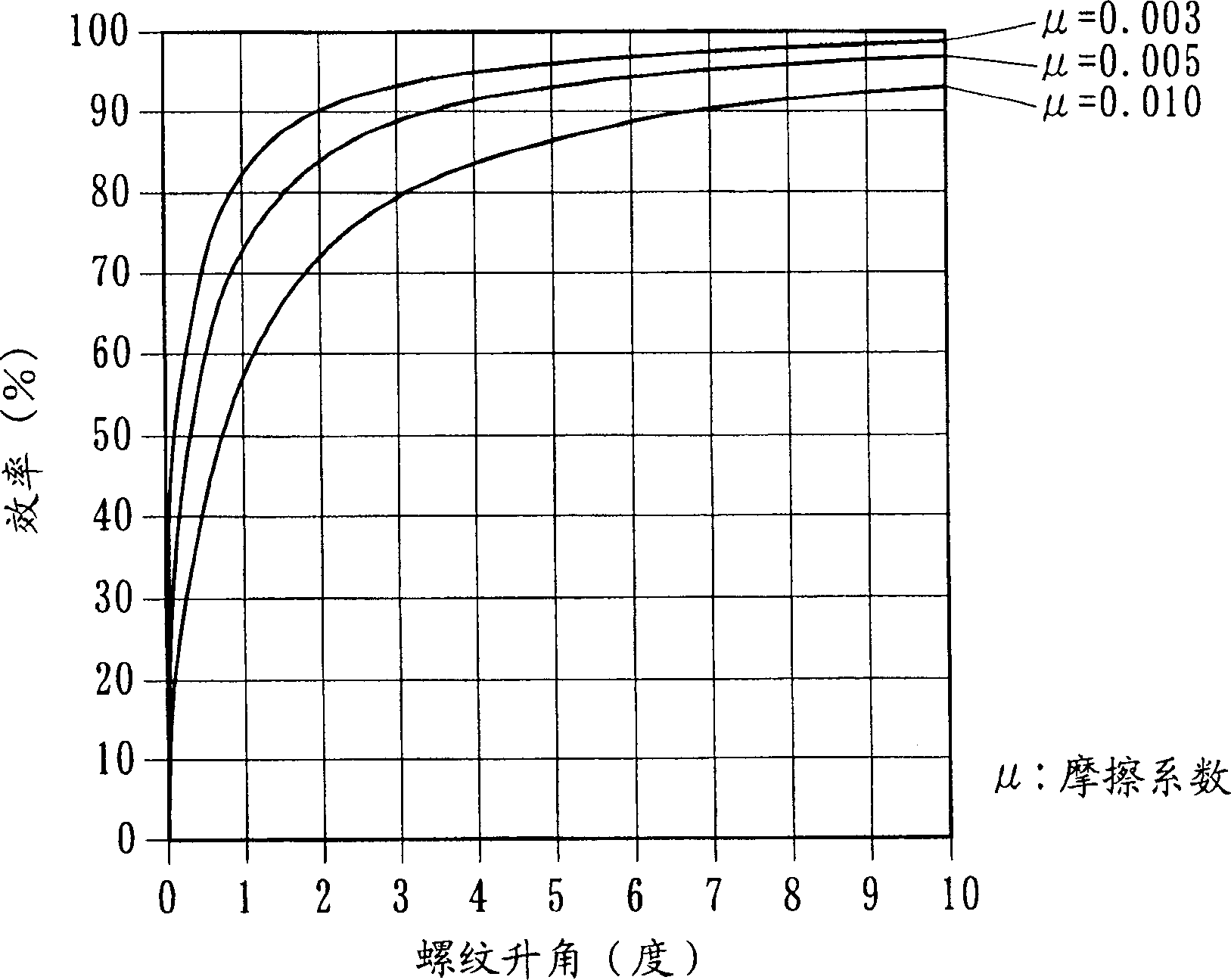

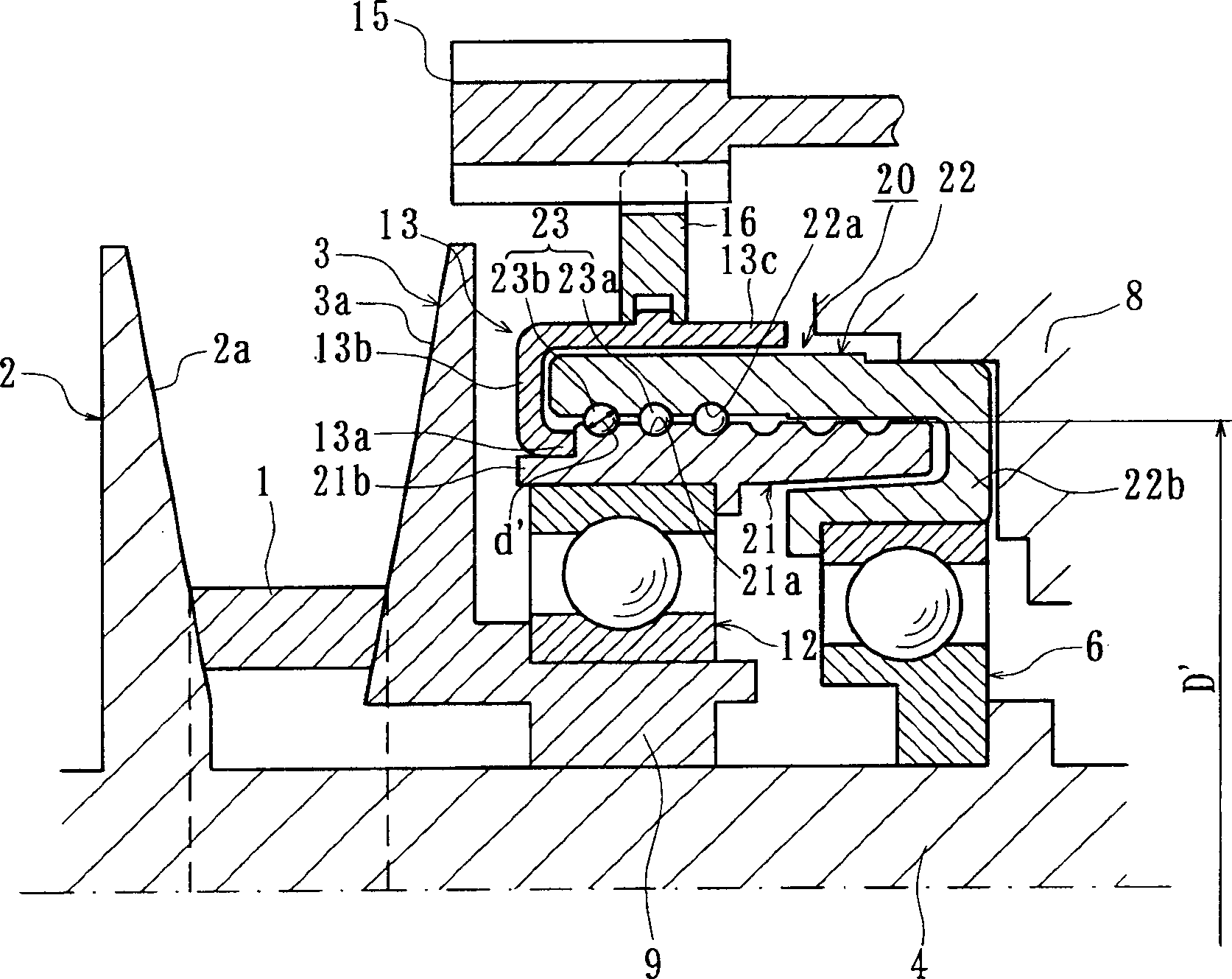

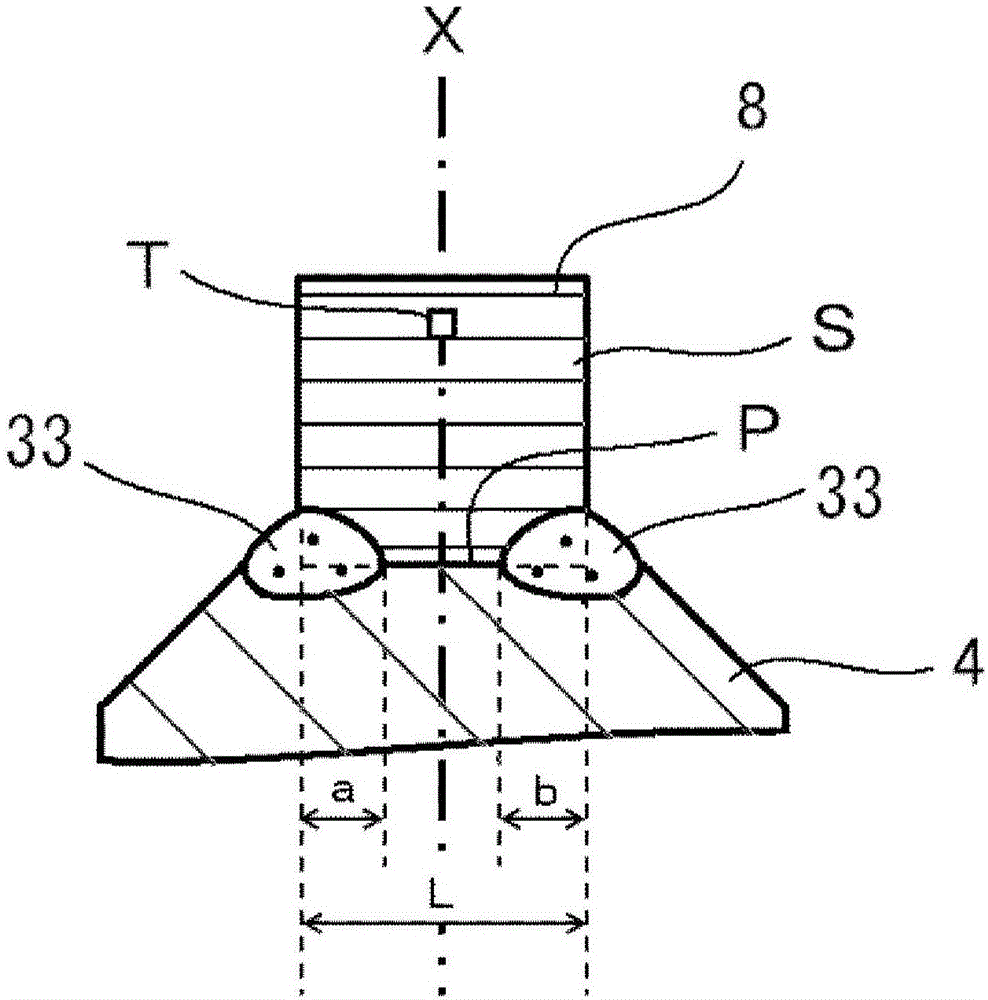

Ball screw and belt stepless variable speed devcie with same

InactiveCN1420293AShorten the overall lengthEliminate relative slidingGearing controlBearing componentsBall screwPulley

There are provided a ball screw enabling the reduction of weight and size of a CVT without reduction of the transmission efficiency as well as a CVT in which the ball screw is incorporated. A CVT of the present invention comprises an axially immovable pulley half 2 and axially movable pulley half 3 both mounted on a rotary shaft 4, and the axially movable pulley half 3 being moved by a ball screw 20 so as to infinitely vary the belt wrapping radius and thus the transmission speed, and is characterized in that a nut 22 forming one part of the ball screw 20 is immovably secured both in axial and rotational directions, a screw shaft 21 forming the other part of the ball screw 20 is movable both in axial and rotational directions and connected to the axially movable pulley half 3, and the axially movable pulley half 3 is axially moved by rotating the screw shaft 21.

Owner:NTN CORP

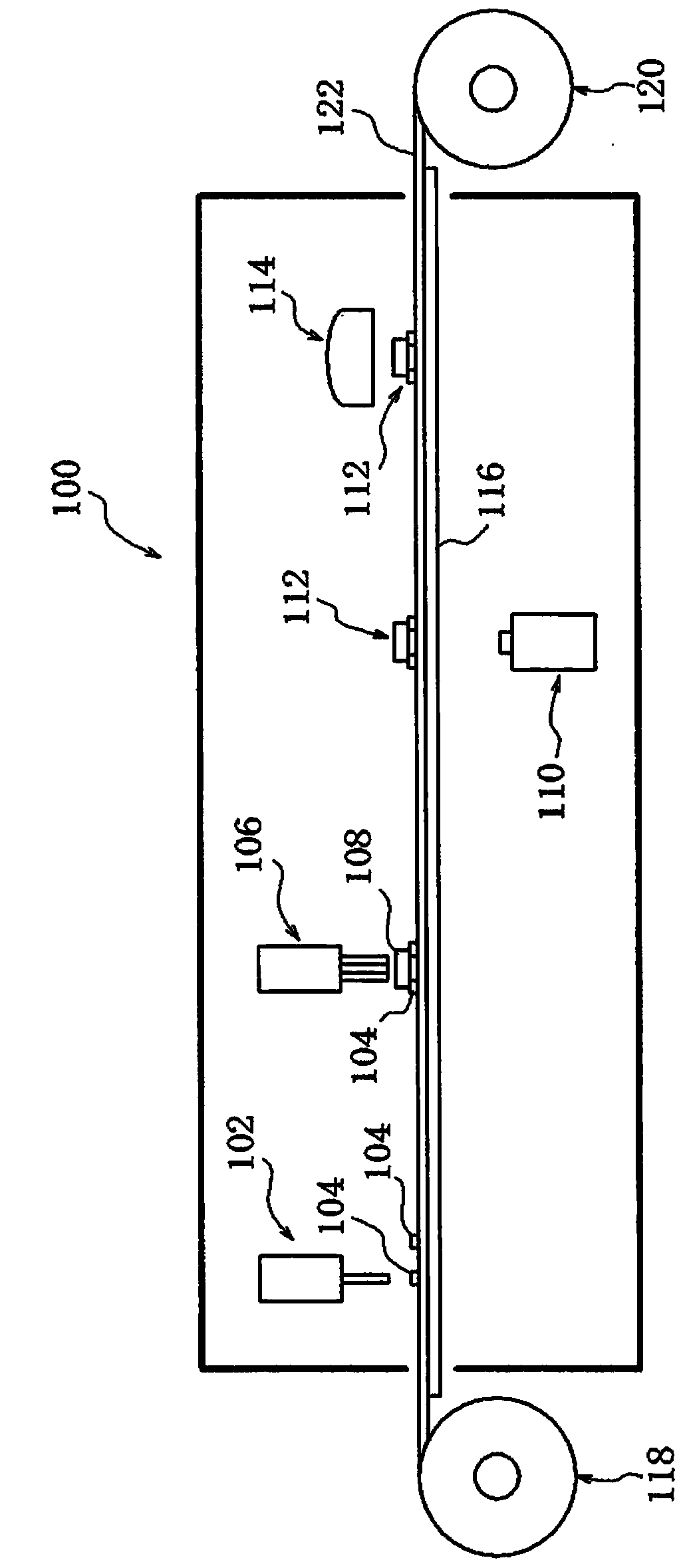

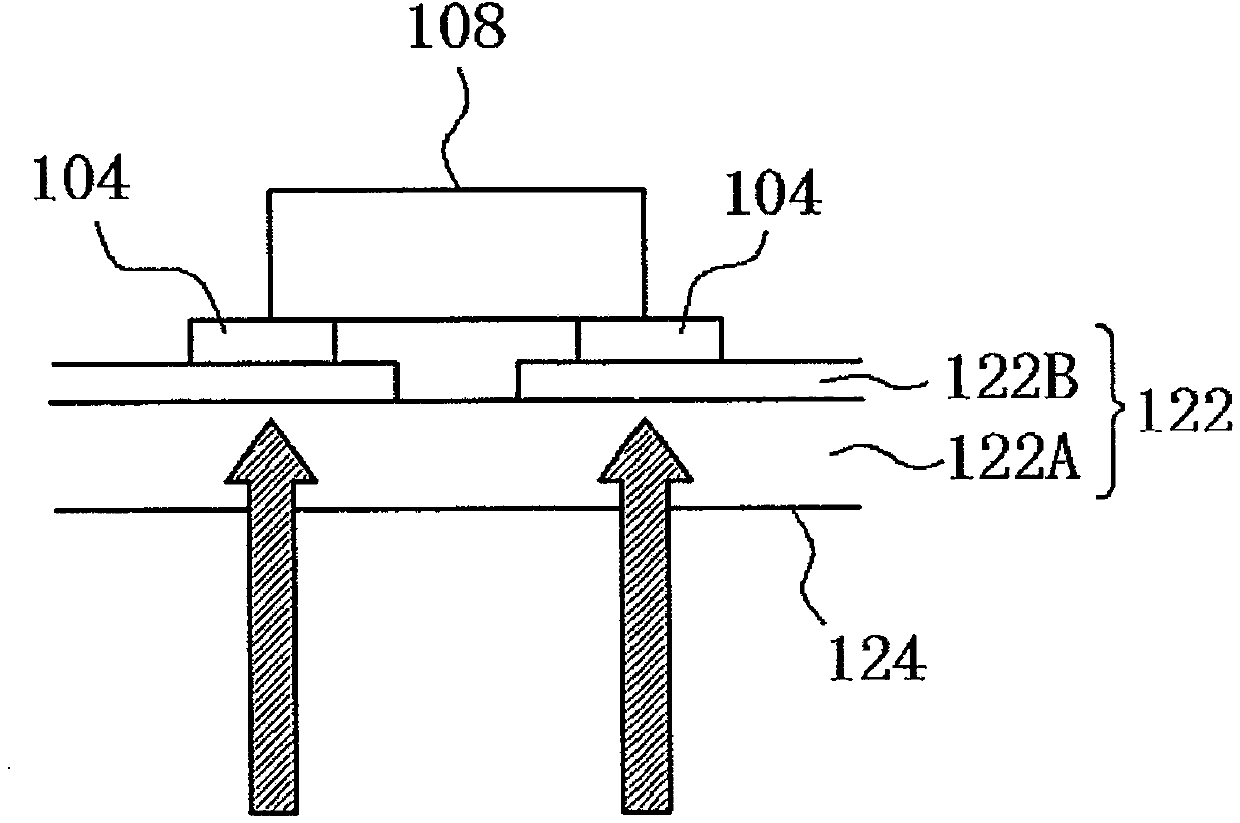

Manufacturing apparatus of electric part, manufacturing method of electric part and manufacturing method of LED illumination

InactiveCN103999560AAvoid damageSuppression of scatteringPrinted circuit assemblingPrinted circuit aspectsManufactured apparatusEngineering

Provided are an apparatus for manufacturing an electronic part and a method of manufacturing the electronic part, wherein an electronic element can be soldered to a printed circuit board in a shorter time than conventional methods, and wherein damage to the electronic element, spattering of solder, and damage to the circuit board can be inhibited. An apparatus (100) for manufacturing an electronic part (112) according to the present invention, which mounts an electronic element (108) on a printed circuit board (122) comprising a substrate (122A) and a wiring pattern (122B) disposed thereon, comprises: a supplying apparatus (102) that supplies solder (104) onto the wiring pattern (122B) of the printed circuit board (122); a placing apparatus (106) that places the electronic element (108) on the solder (104); a laser (112) that radiates light having the center wavelength of the light-emission thereof within a range of 700 nm - 1100 nm, towards the solder (104) upon which the electronic element (108) is mounted, from the back face (124) side of the printed circuit board. The apparatus (100) for manufacturing an electronic part (112) is characterized in that the light transmits through the substrate (122A) to reach the wiring pattern (122B), heats the wiring pattern (122B) and melts the solder (104), so that the electronic element (108) is soldered to the printed circuit board (122).

Owner:NISSHINBO MECHATRONICS

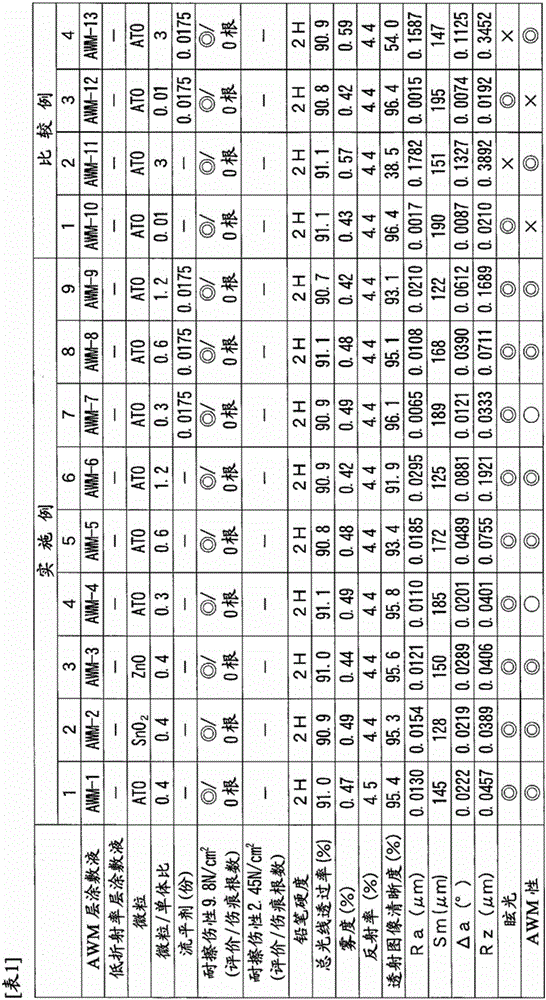

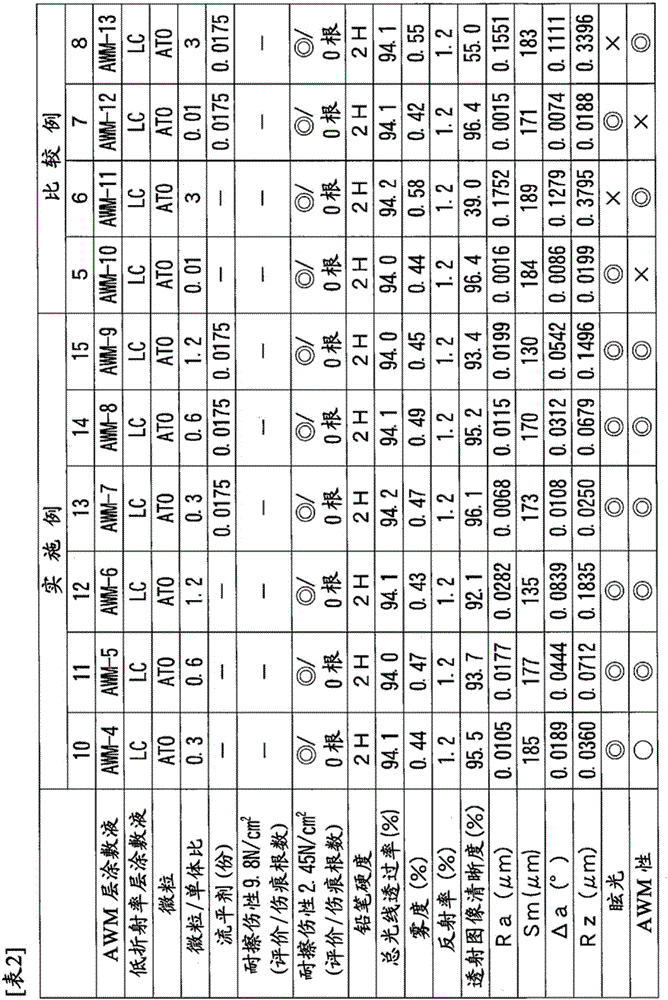

Transparent layered film, process for producing same, and electrode for touch panel

ActiveCN106163804ASuppression of scatteringAvoid flyingSynthetic resin layered productsPretreated surfacesDisplay deviceGlass fragment

A transparent layered film produced by forming, on one surface of a transparent resin layer, an anti-water-mark layer that is constituted of a cured object of a curable composition comprising a curable resin, a thermoplastic resin, and metal oxide particles with an average primary-particle diameter of 1-100 nm and forming, in the surface of the anti-water-mark layer, a rugged structure which has an arithmetic average roughness (Ra) of 0.005 [mu]m or greater but less than 0.03 [mu]m, an average distance (Sm) between the irregularities of 50-300 [mu]m, an arithmetic average inclination (delta a) less than 0.1 DEG, and a ten-point average roughness (Rz) less than 0.2 [mu]m. When a glass to which the film has been laminated is used in the upper electrode of a touch panel display, not only glass fragment scattering due to breakage of the upper electrode can be inhibited, but also the generation of water marks is prevented and the display device even with high resolution can be inhibited from glittering.

Owner:DAICEL CORP

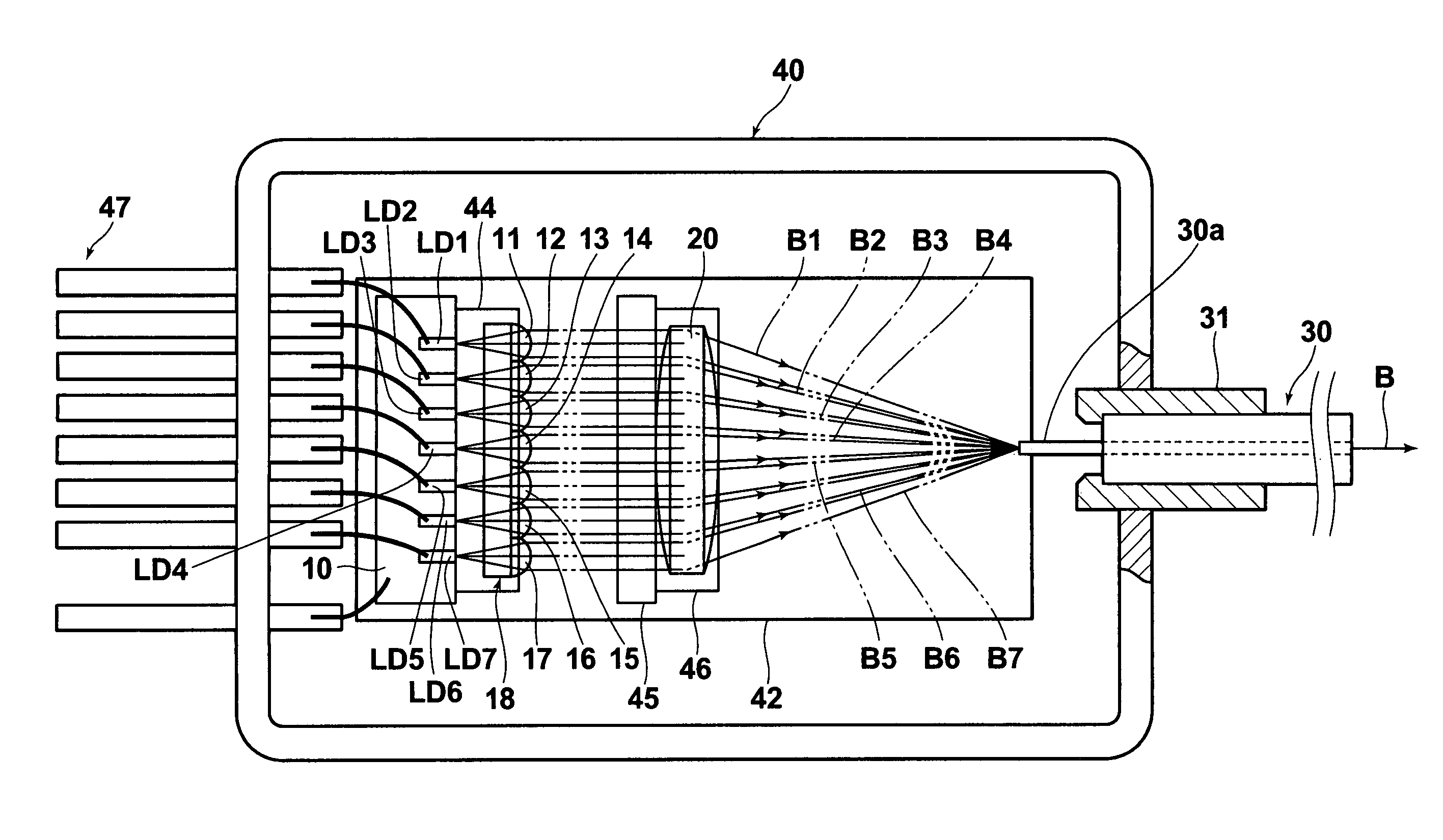

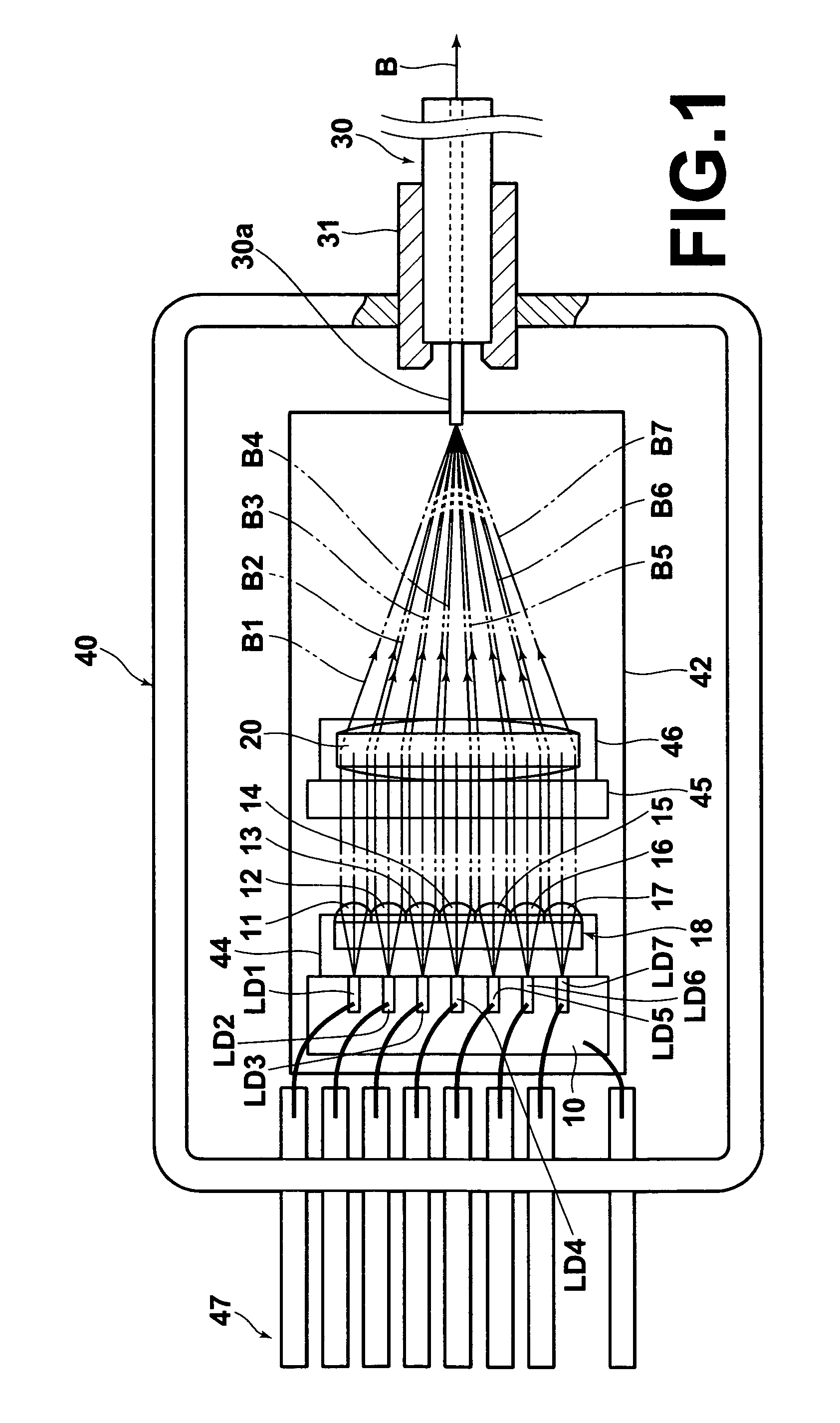

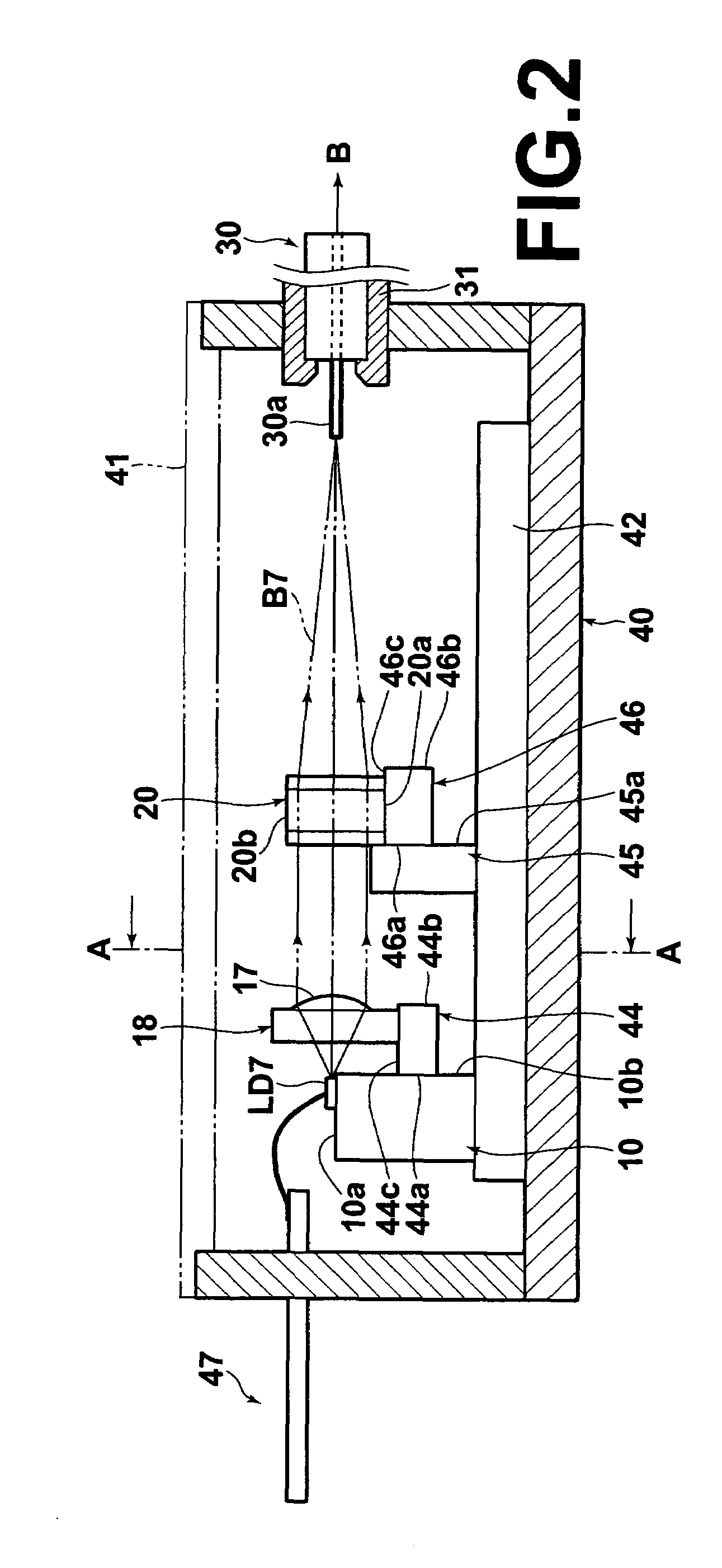

Laser apparatus and method for assembling the laser apparatus

In a laser apparatus: an adhesion surface and a first reference surface making a first predetermined angle with the adhesion surface are formed on an attachment part, and a mounting surface and a second reference surface making a second predetermined angle with the mounting surface are formed on a fixing member which is directly or indirectly fixed to a main body and arranged to adhesively hold the attachment part. In a method for assembling the laser apparatus: a first angle between the second reference surface and a reference direction is measured; the orientation of the attachment part is adjusted while measuring a second angle between the first reference surface and the reference direction; and the attachment part is adhesively fixed to the fixing member when the second angle is equal to an angle predetermined based on the first angle and the first and second predetermined angles.

Owner:ADTEC ENG +1

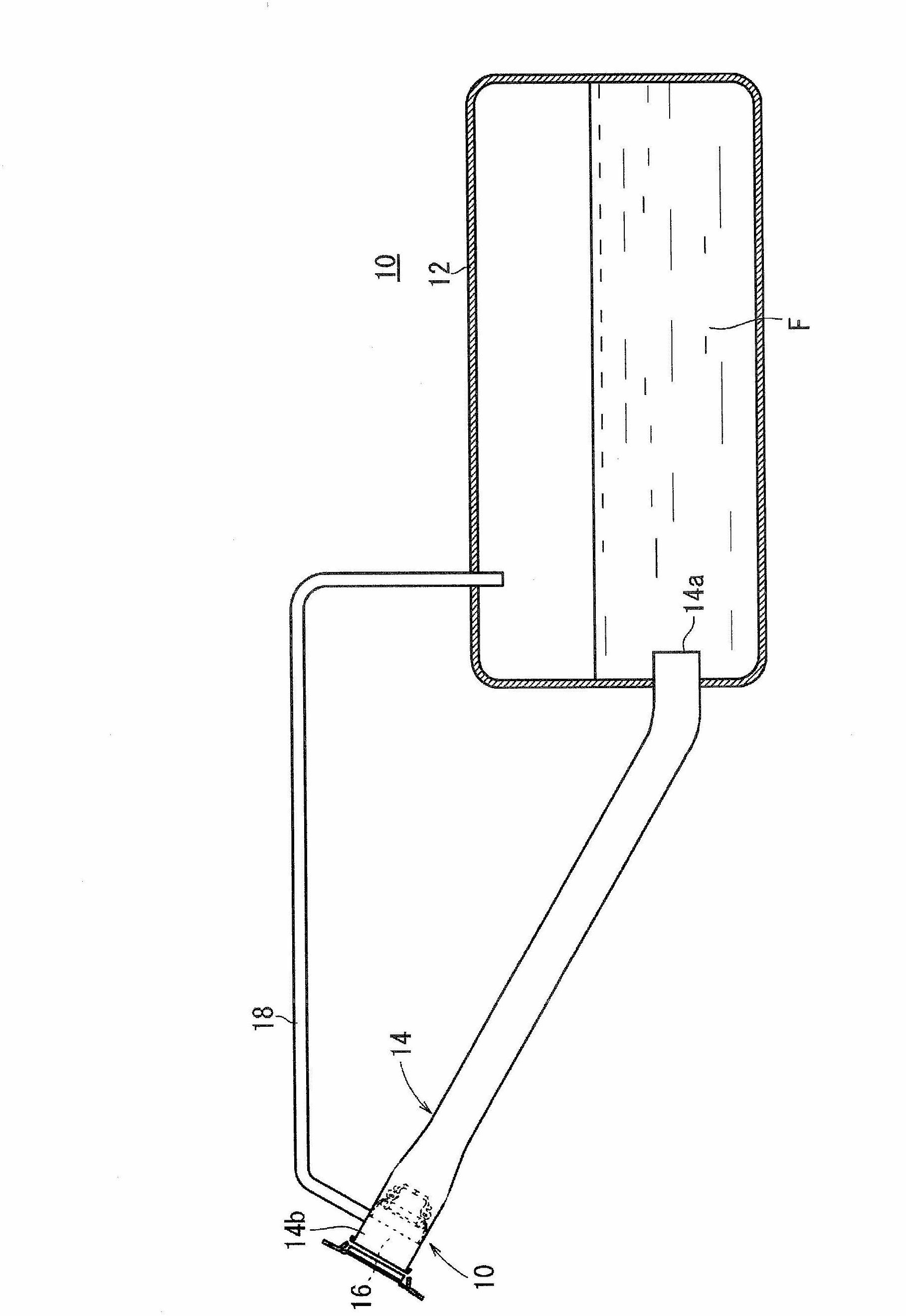

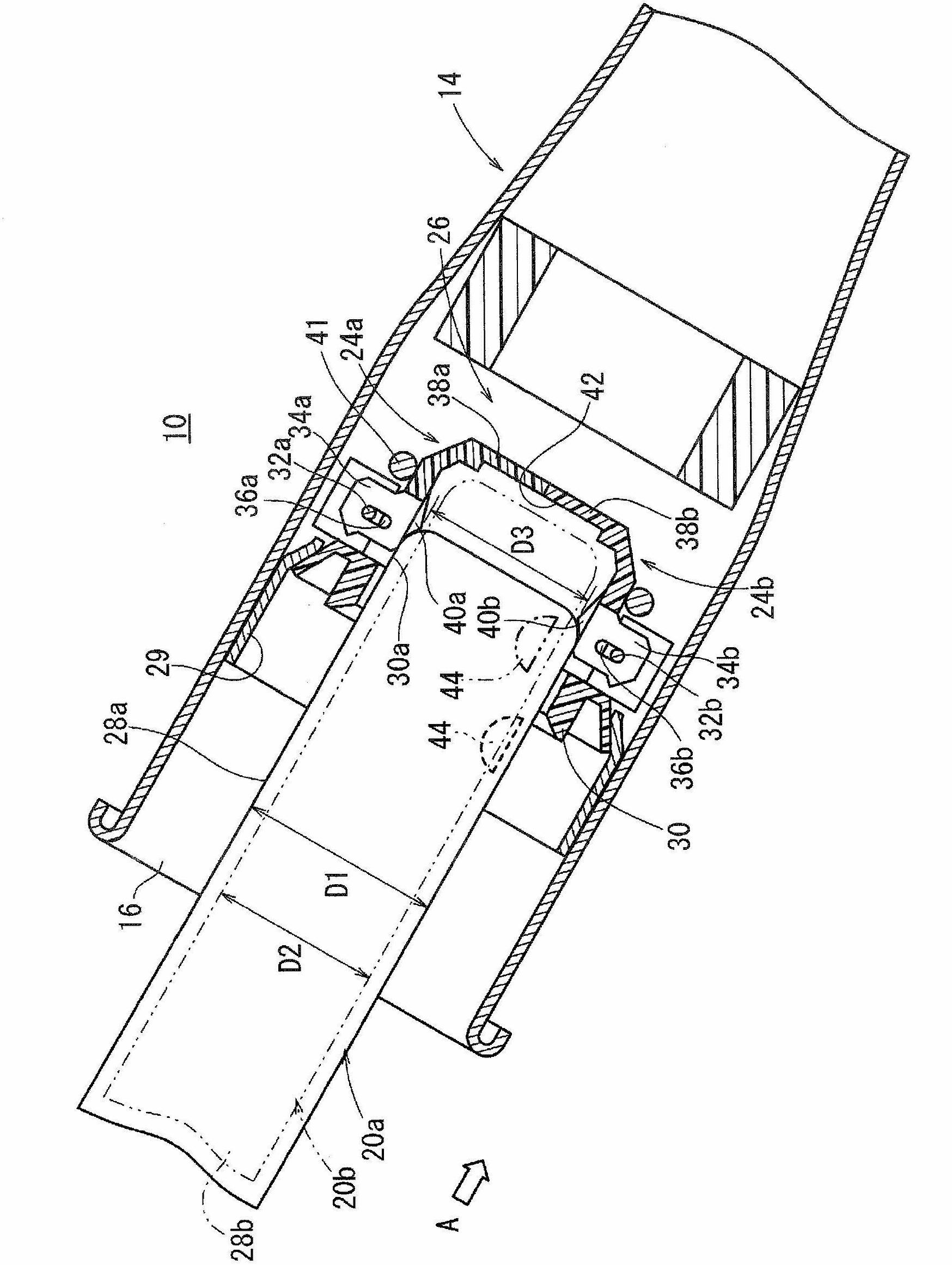

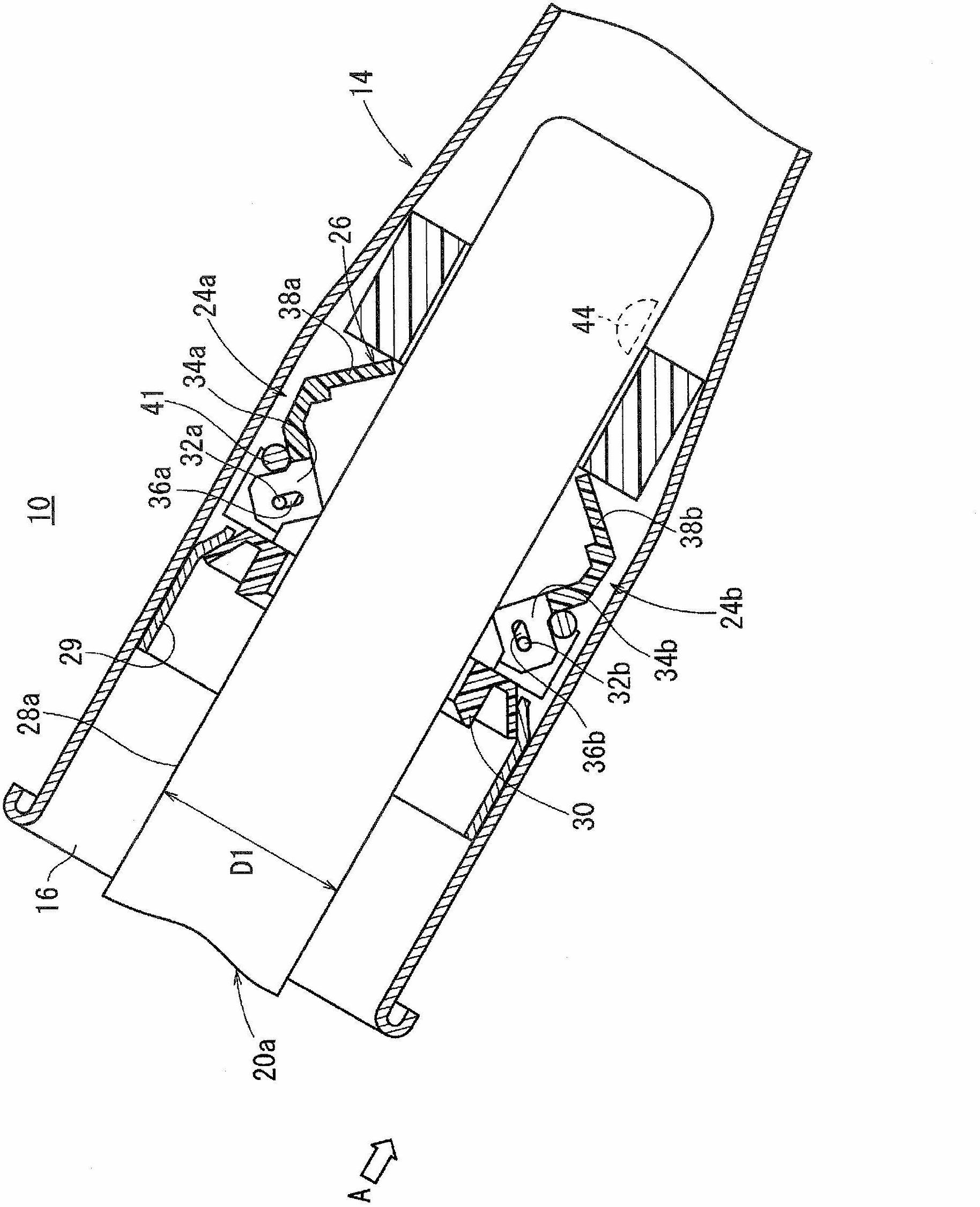

Fuel filling pipe device for vehicle

InactiveCN102656043ASuppression of scatteringMachines/enginesLiquid fuel feedersMechanical engineering

Provided is a fuel filling pipe device for a vehicle, configured so that fuel discharged from a fuel filling gun with shutter members closed can be prevented from spurting to the outside from the fuel filling opening. The fuel filling pipe device (10) for a vehicle comprises a filling pipe (14), a fuel filling opening (16) which is provided to the filling pipe (14) and into which a fuel filling gun (20a) is inserted, and a shutter mechanism (26) which is provided inside the fuel filling opening (16) and is provided with openable and closable shutter members (24a, 24b) opened when the fuel filling gun (20a) is pushed therein. The shutter mechanism (26) is provided with a spurt prevention section for preventing fuel, which is discharged from the fuel filling gun (20a) with the shutter members (24a, 24b) closed, from spurting to the outside from the fuel filling opening (16).

Owner:HONDA MOTOR CO LTD

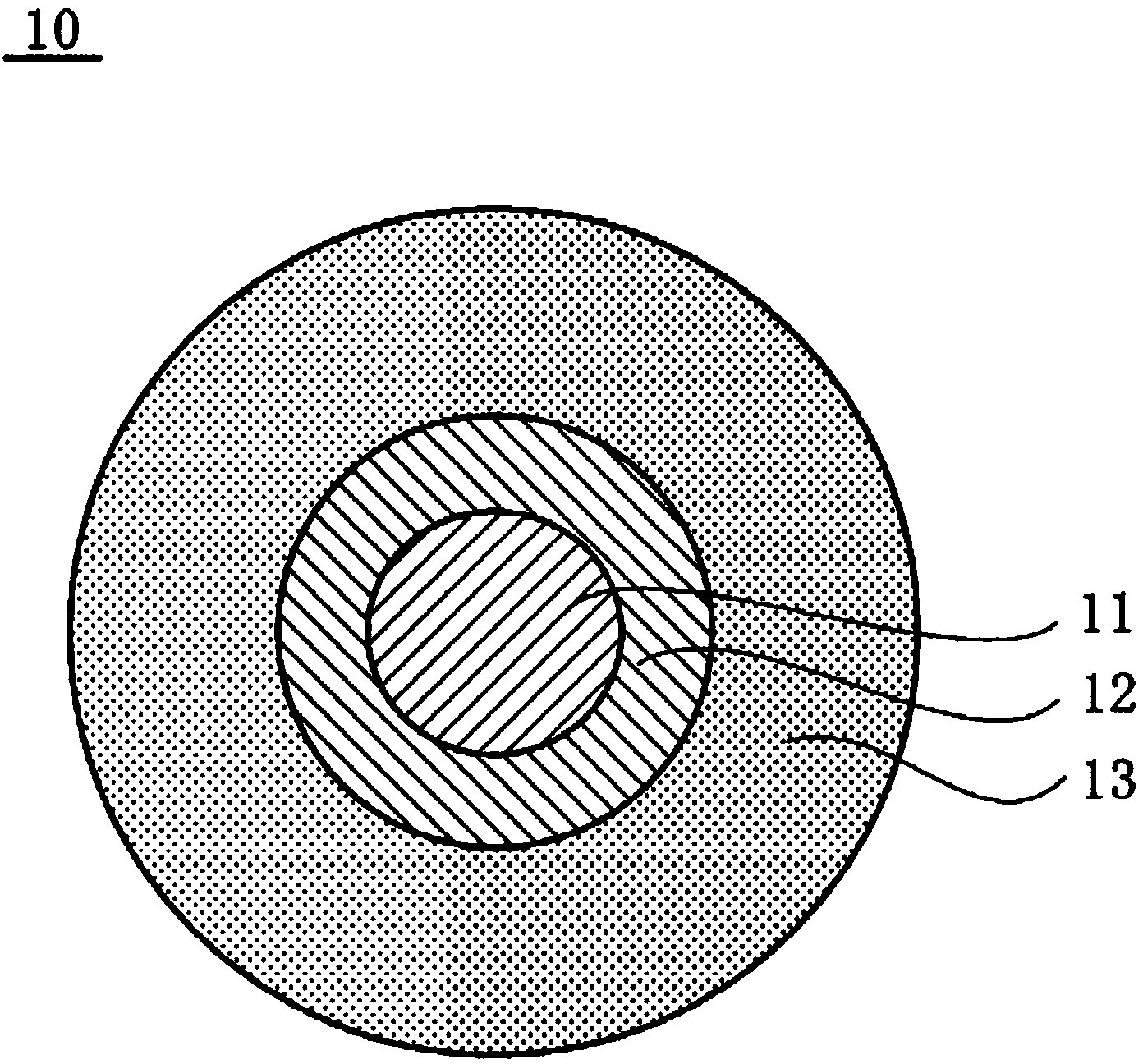

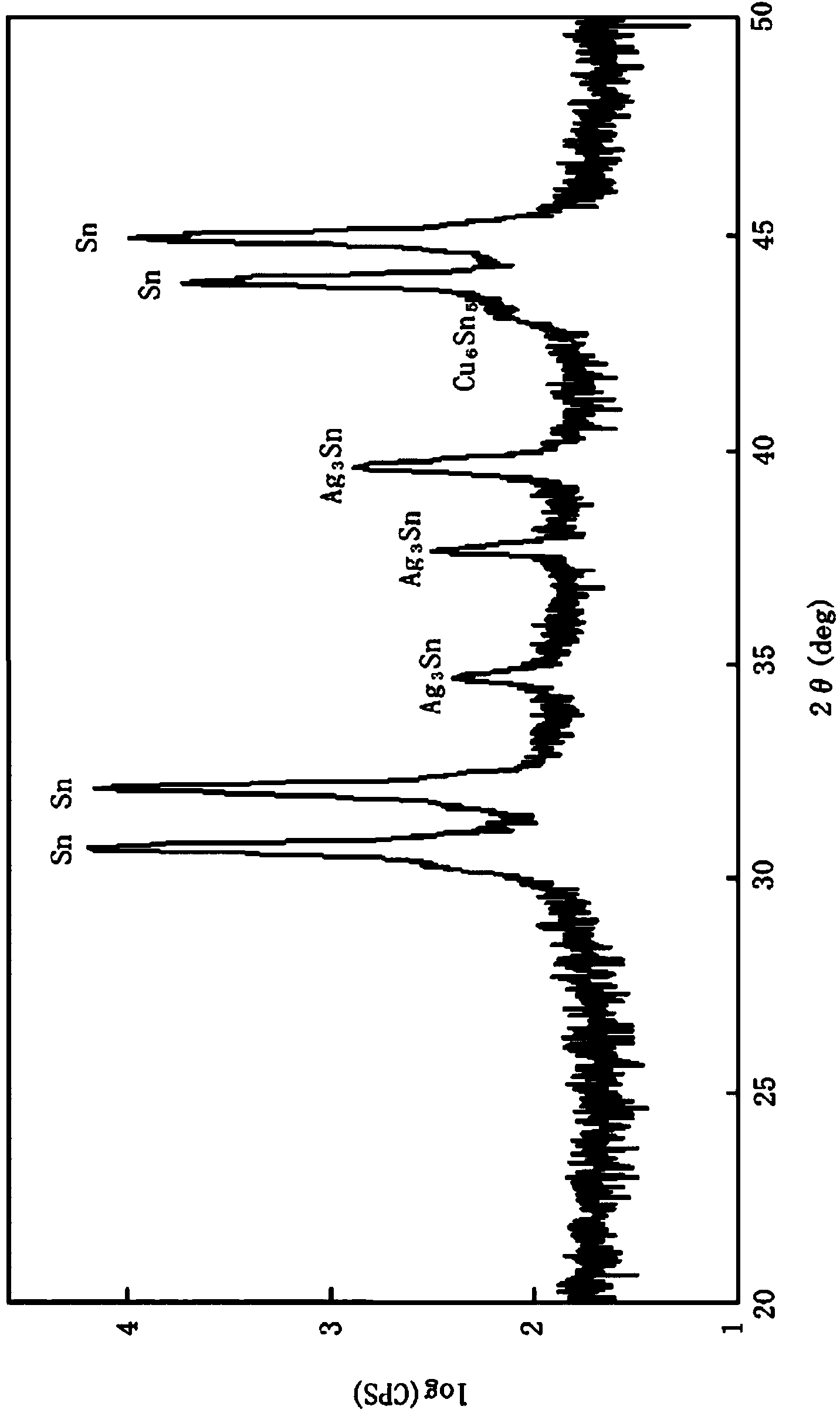

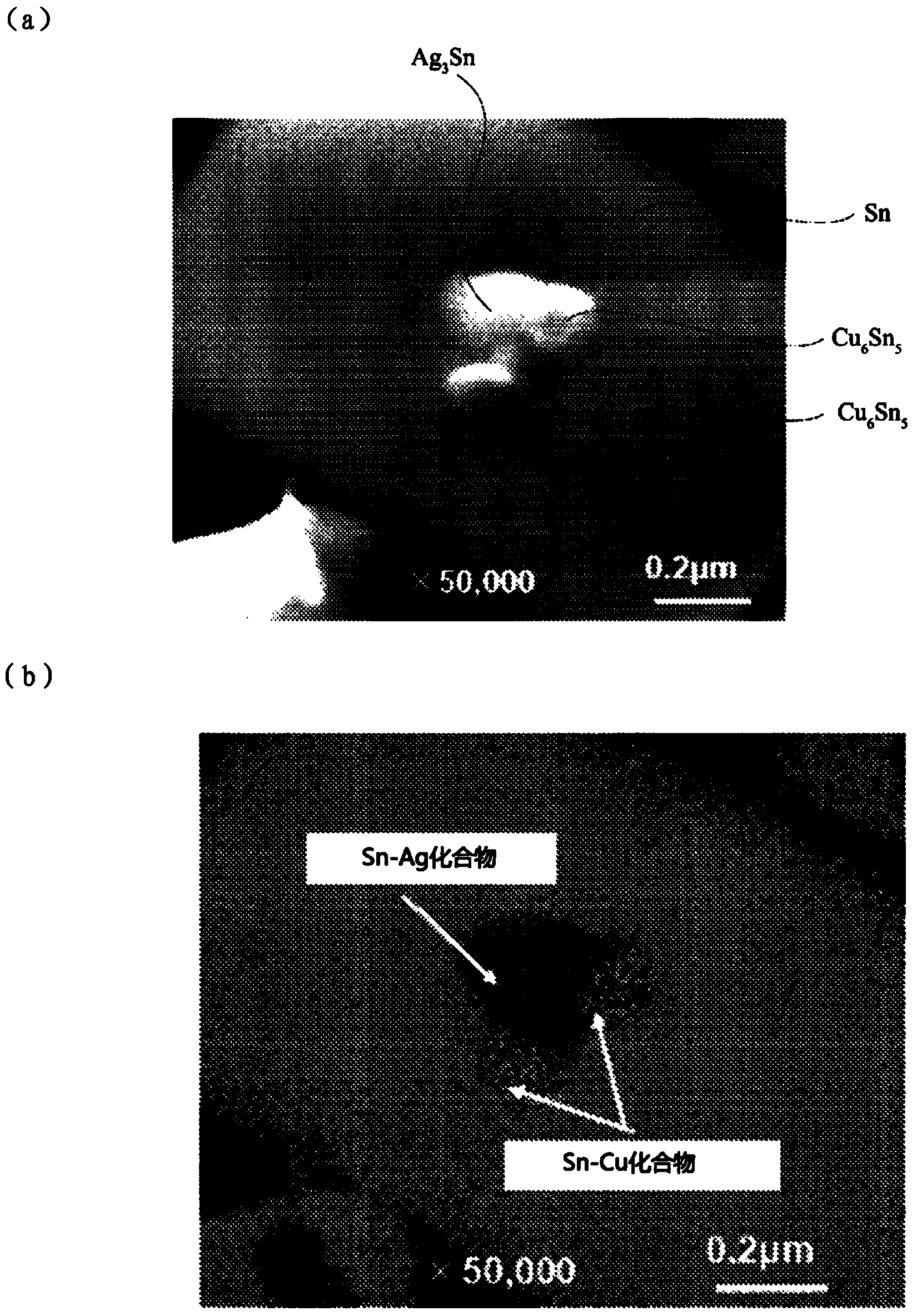

Solder powder, and solder paste using solder powder

ActiveCN103619529AGood melt diffusibilityEasy to controlWelding/cutting media/materialsCoatingsSolder pasteCopper

A particle of this solder powder is configured of a core and a coat layer applied on the core, and has an average particle diameter of 5 [mu]m or less. The solder powder is characterized in that: the core is composed of an intermetallic compound of silver and tin or is composed of silver and an intermetallic compound of silver and tin; the coat layer is composed of tin; and an intermediate layer composed of an intermetallic compound of copper and tin is provided between the core and the coat layer such that at least a part of the core is covered.

Owner:MITSUBISHI MATERIALS CORP

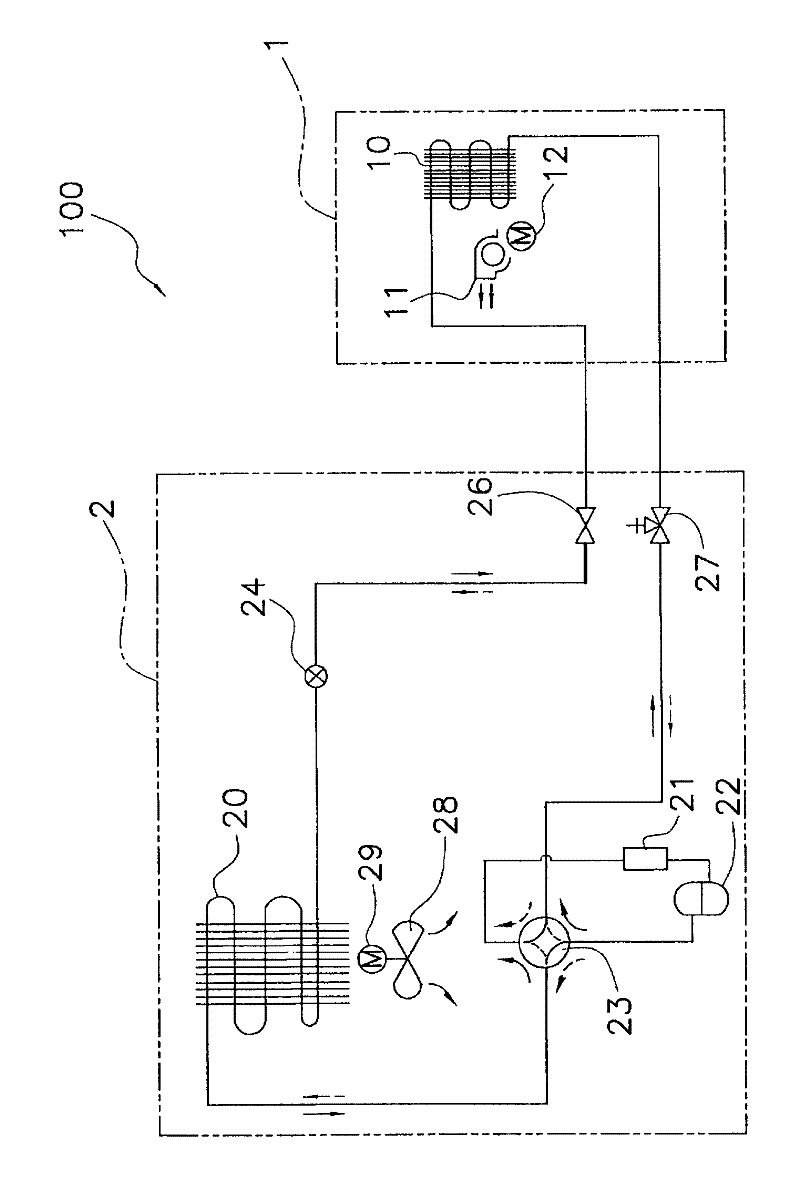

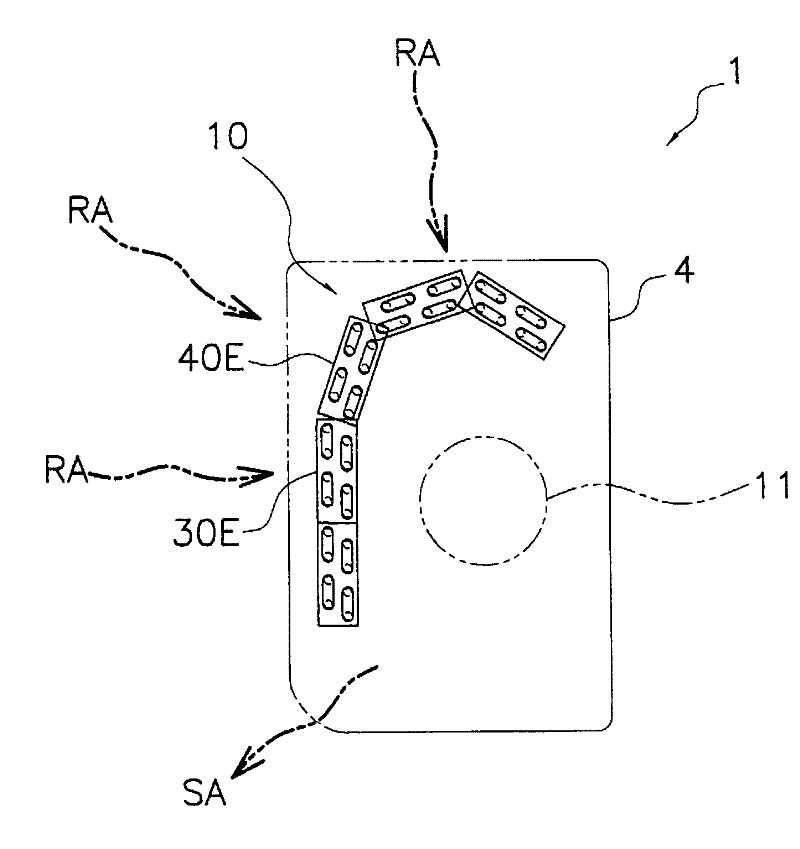

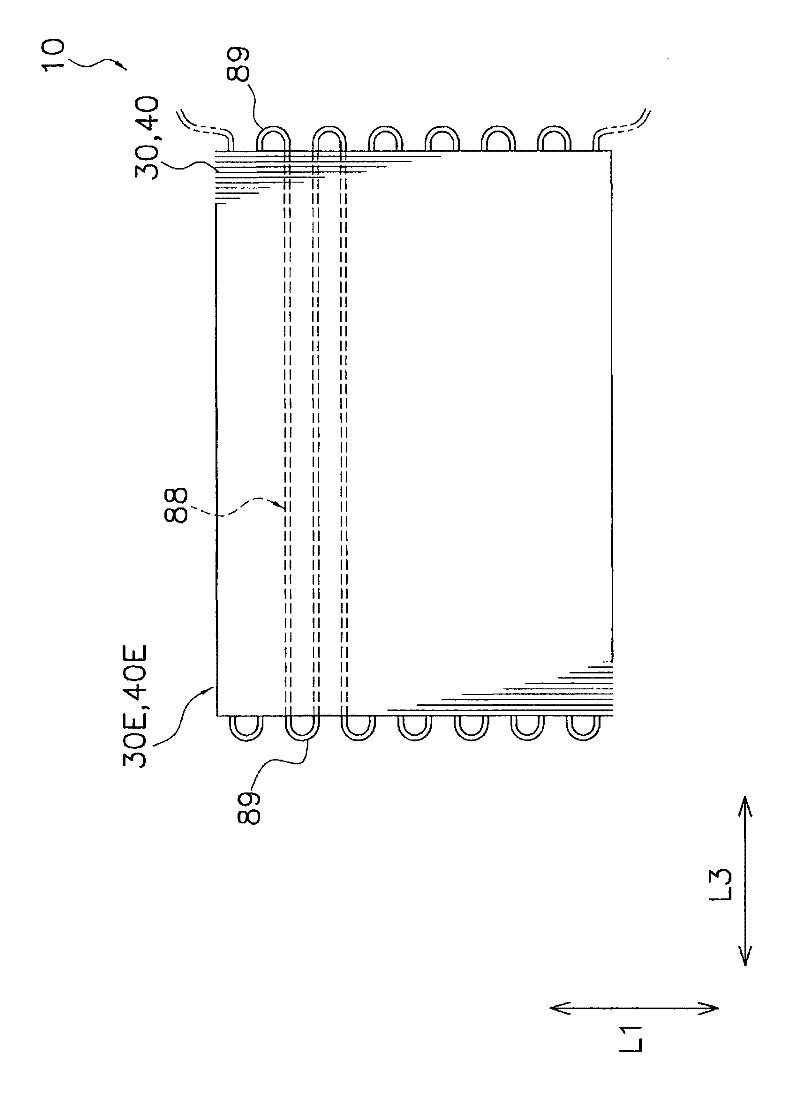

Heat exchanger, air conditioner, and method for manufacturing heat exchanger

ActiveCN102297625ASuppression of scatteringPromote sheddingEvaporators/condensersSpace heating and ventilation detailsEngineeringAir conditioning

The present invention provides a heat exchanger, an air conditioner, and a method for manufacturing the heat exchanger capable of suppressing scattering of condensed water toward the downstream side in the air flow direction from the bent portion. The indoor heat exchanger (10) has lower fins (30) and upper fins (40). The upper fins (40) are inclined so that: the angle of the length direction of the upper fins (40) relative to the vertical direction and on the side of the air flow direction (F) is greater than or equal to the length direction of the lower fins (30) The angle with respect to the vertical direction, and the upper end portion of the upper fin (40) and the lower fin (30) are arranged adjacent to each other. Furthermore, the upper fin (40) has a curved bent portion (R) provided near the upper end of the lower fin (30) on the downstream side in the air flow direction (F).

Owner:DAIKIN IND LTD

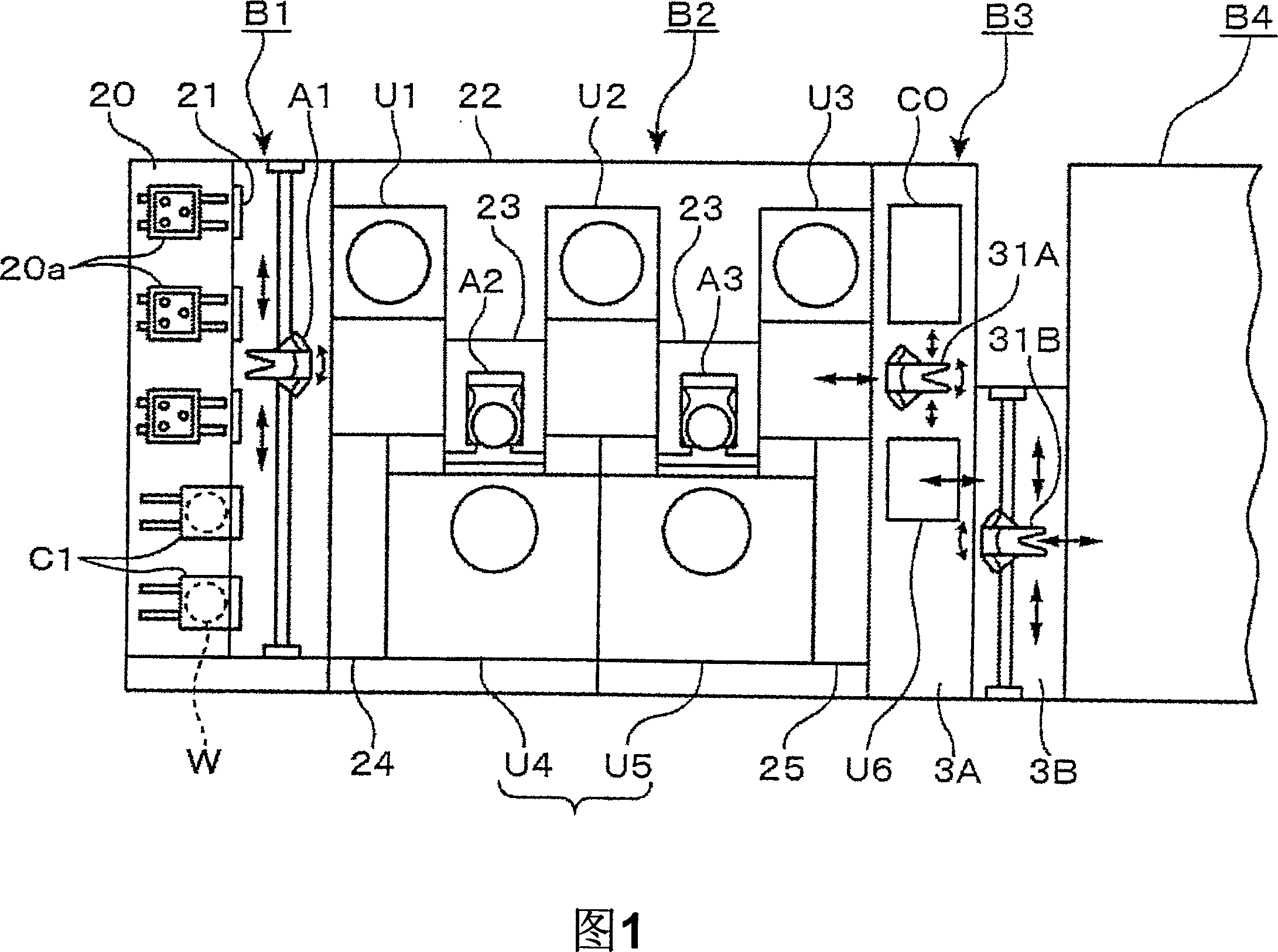

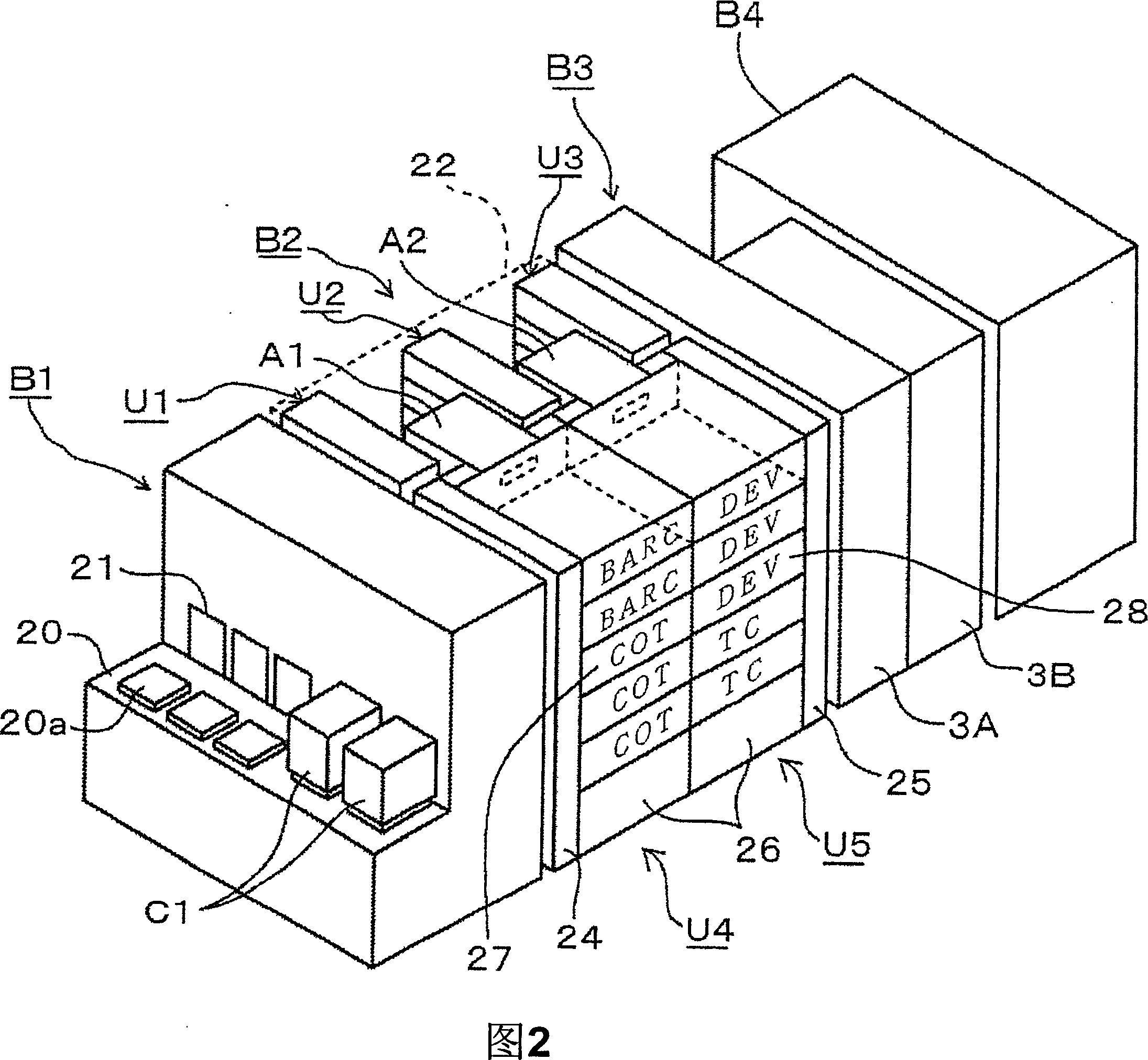

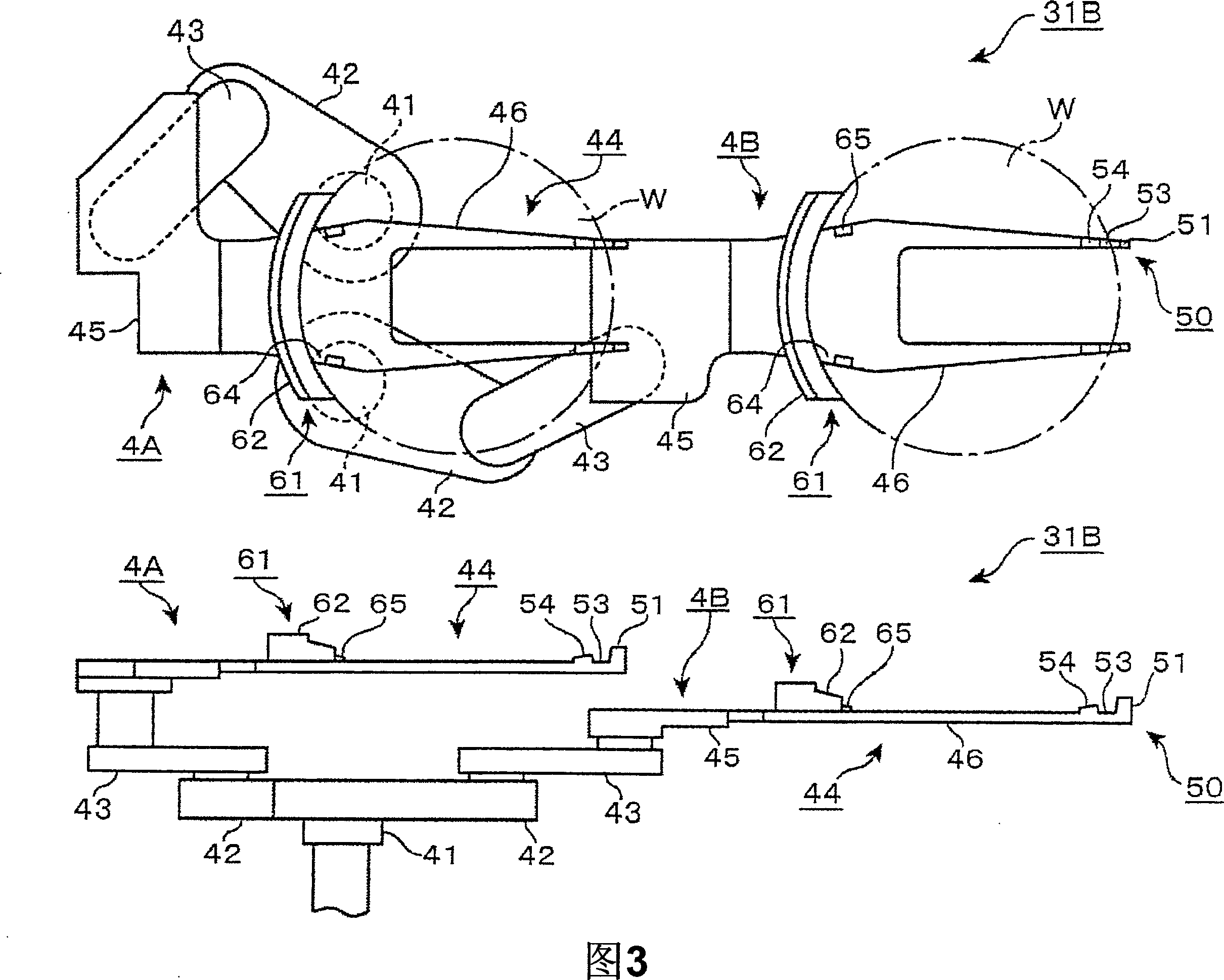

Substrate conveyer, substrate conveying method and coating, developing apparatus

InactiveCN1925125ASuppression of scatteringReliable handlingSemiconductor/solid-state device manufacturingLiquid processing with progressive mechanical movementMechanical engineeringContamination

Owner:TOKYO ELECTRON LTD

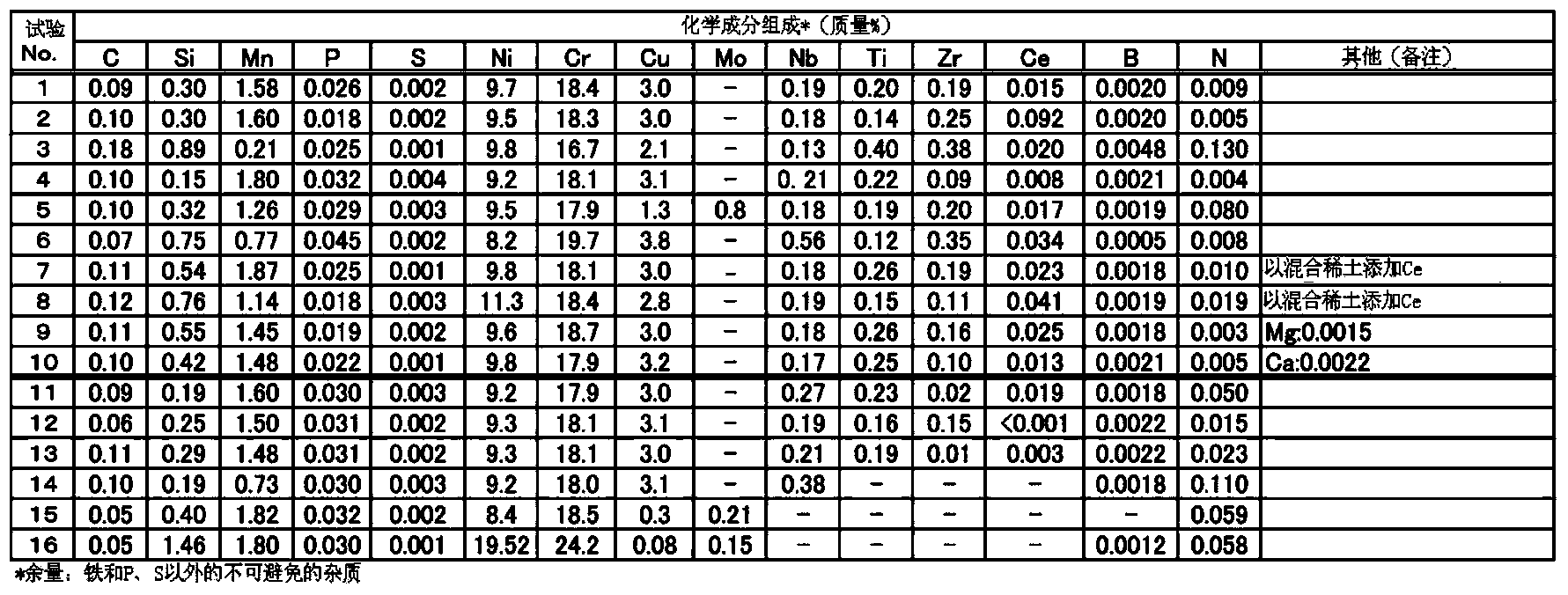

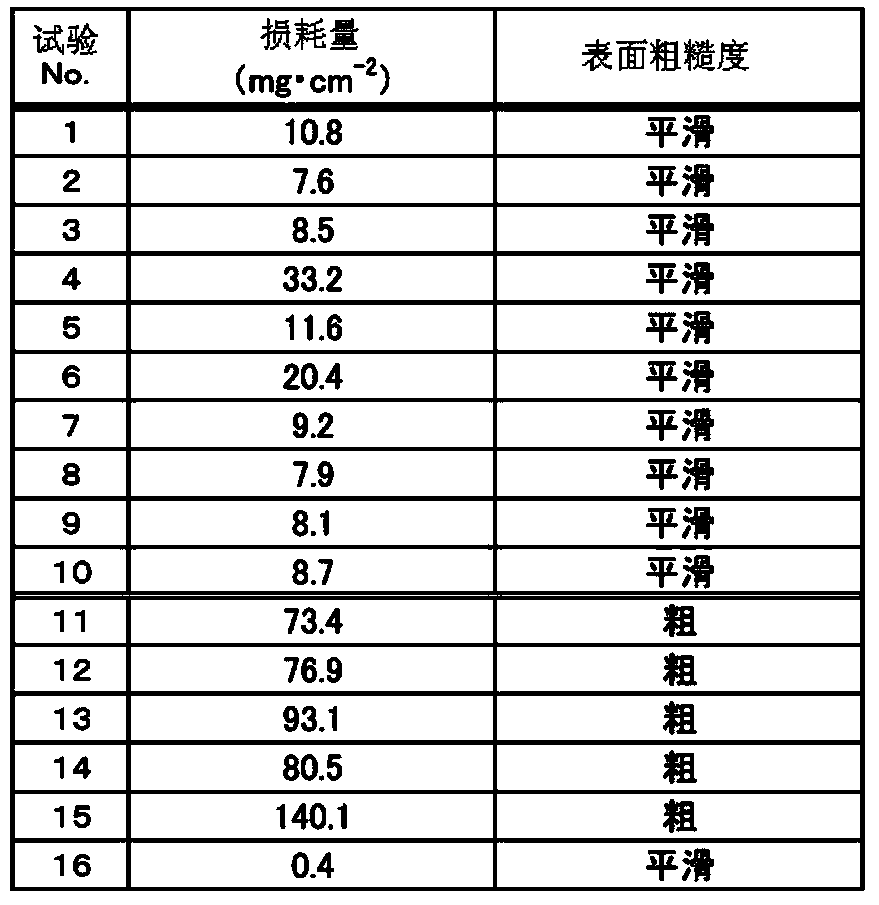

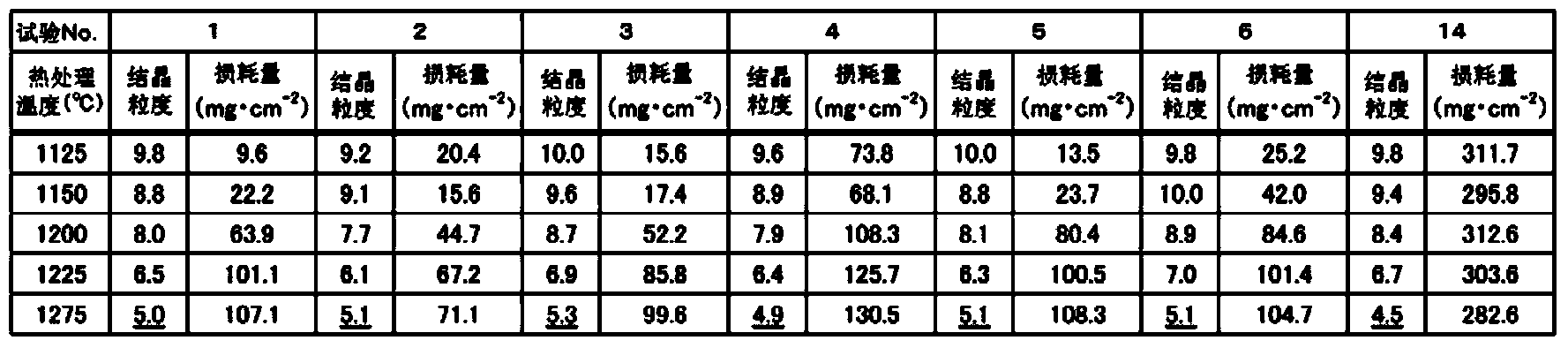

Heat-resistant austenitic stainless steel having excellent cyclic oxidation resistance

Owner:KOBE STEEL LTD

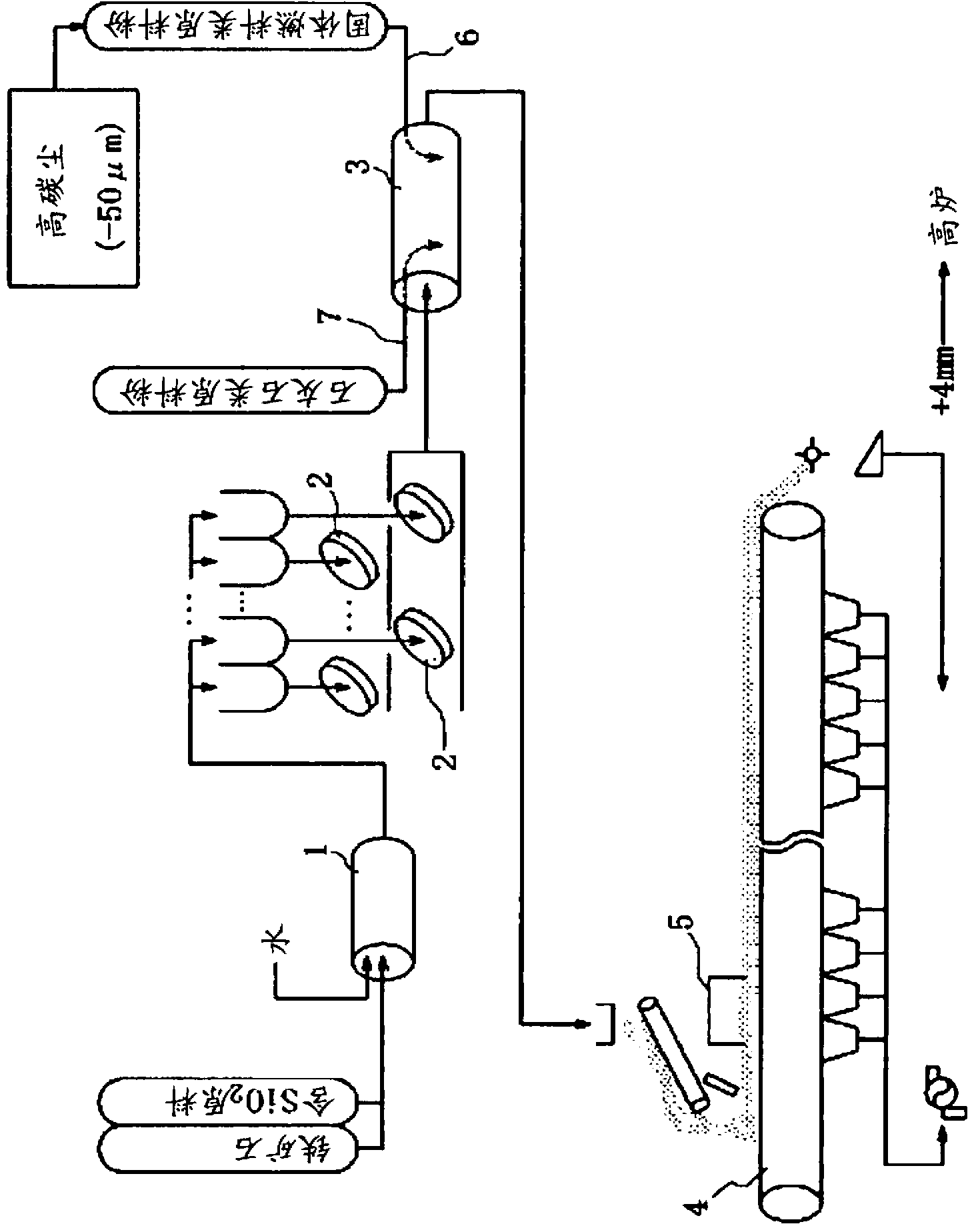

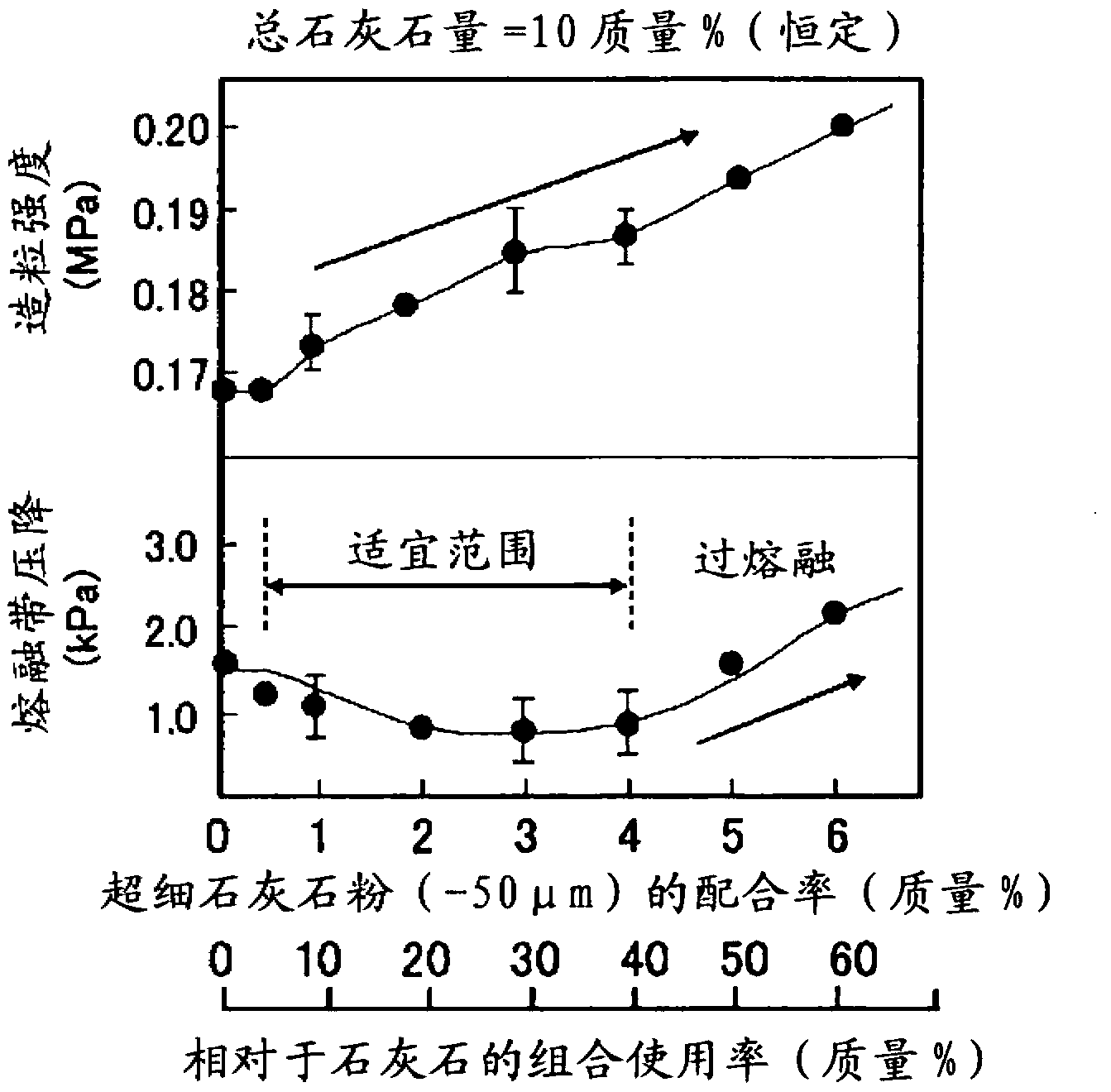

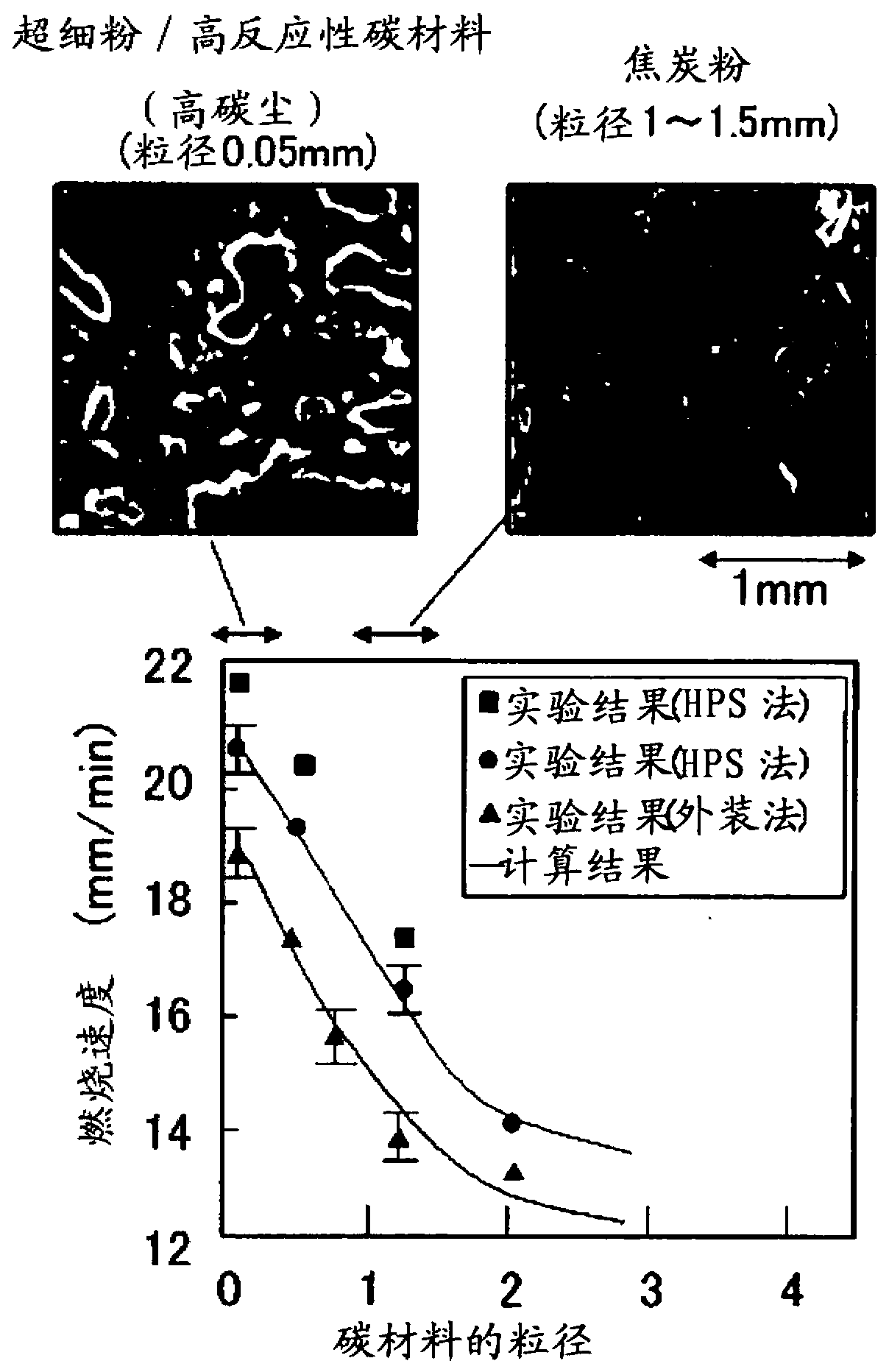

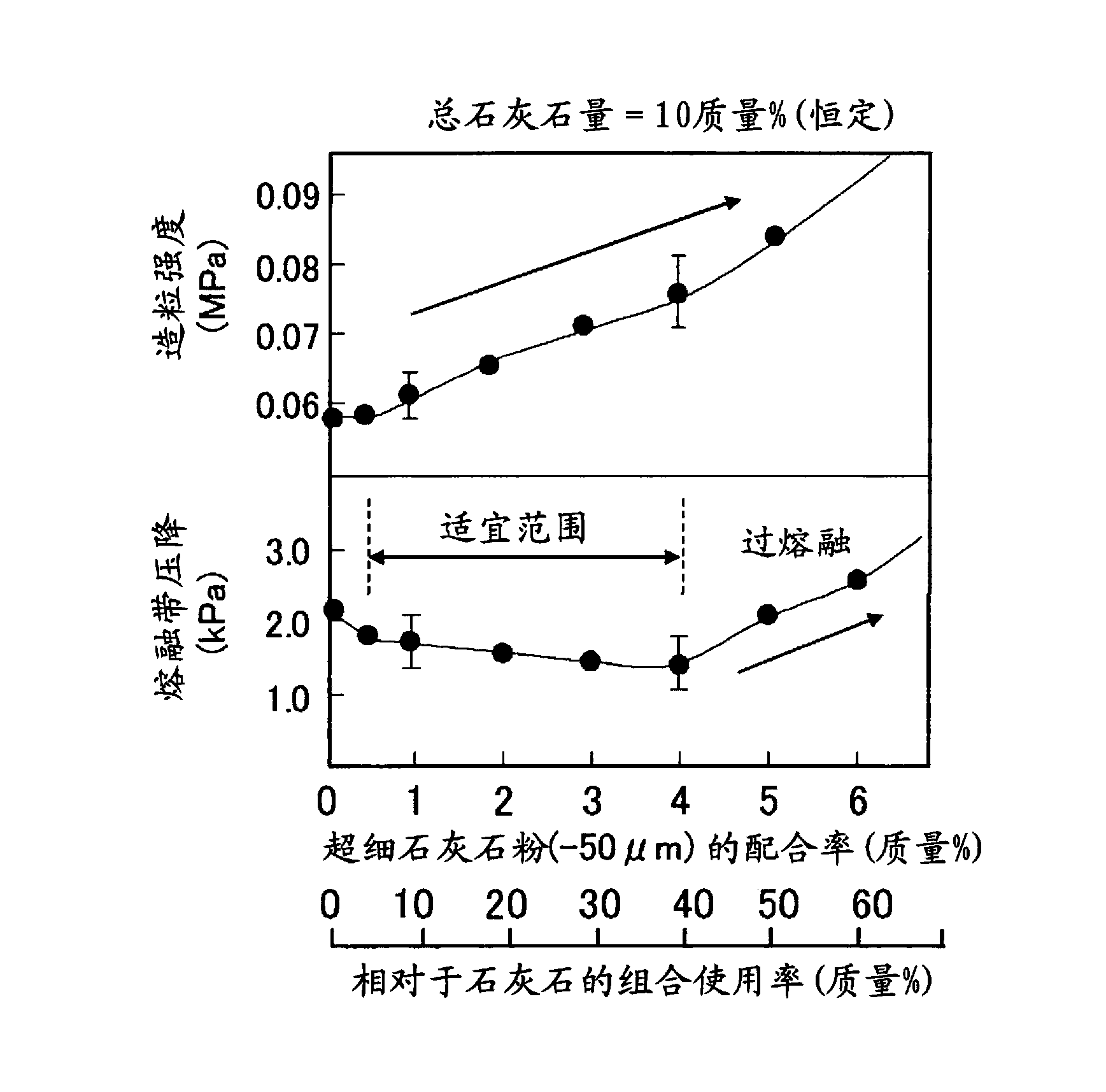

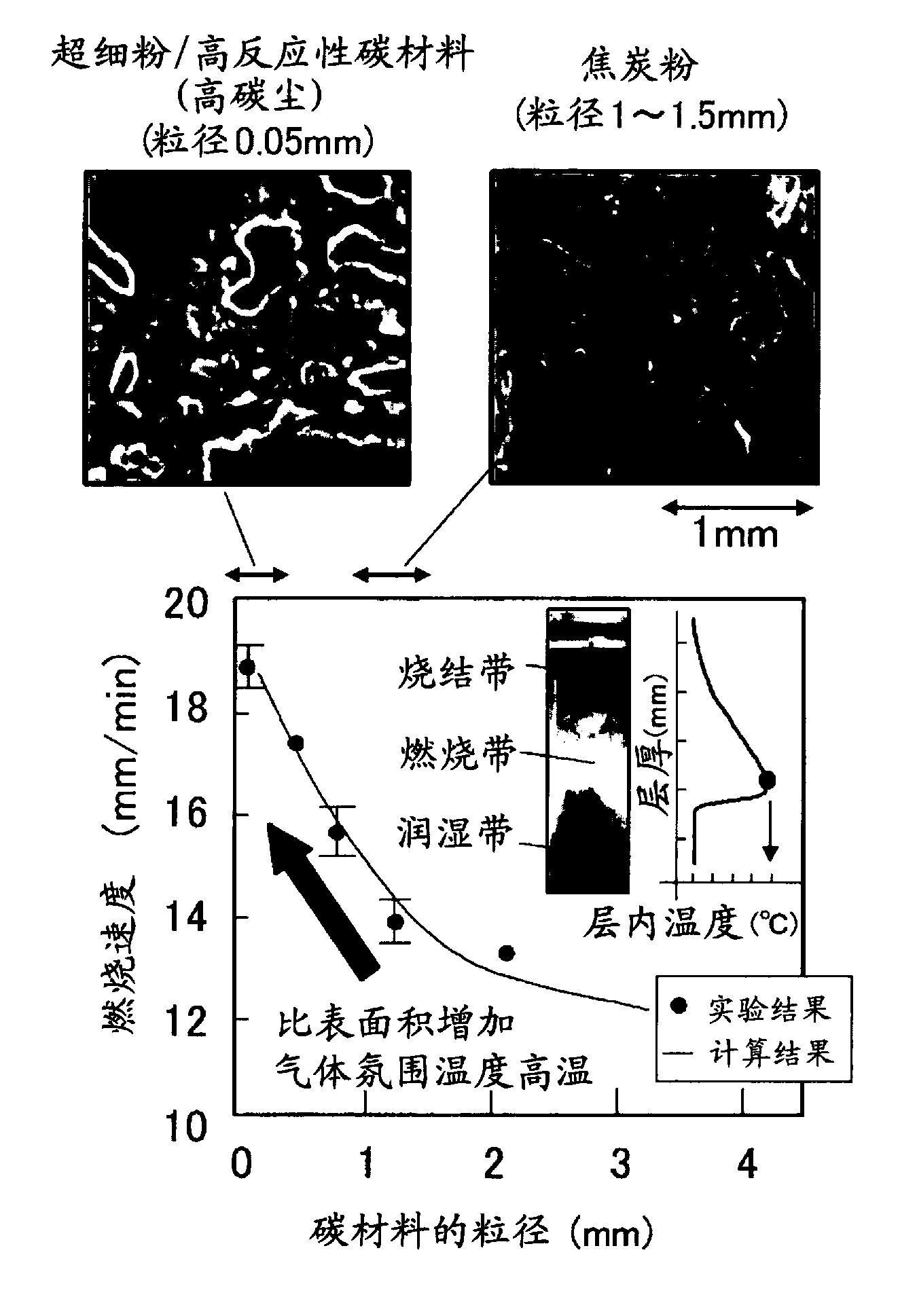

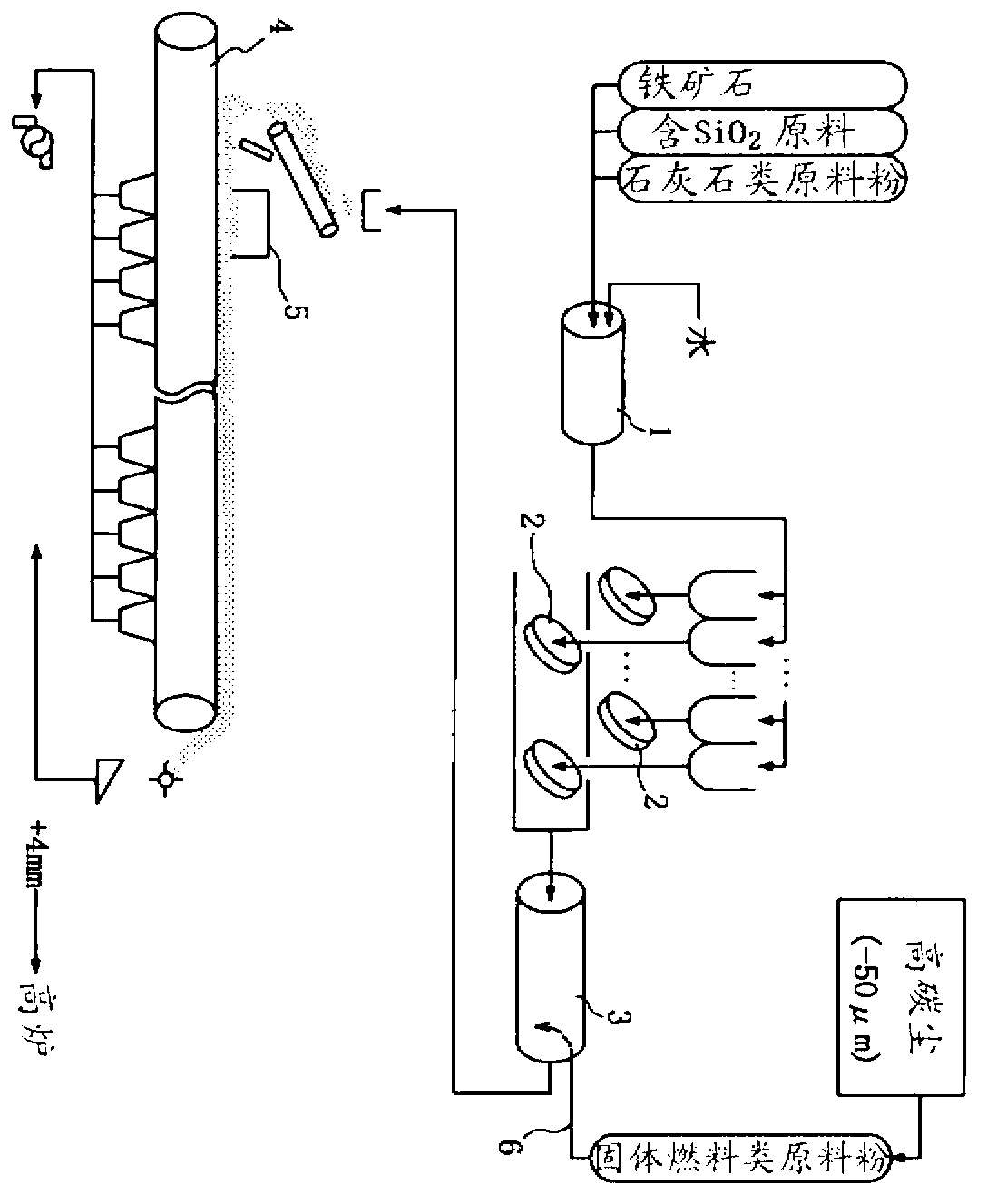

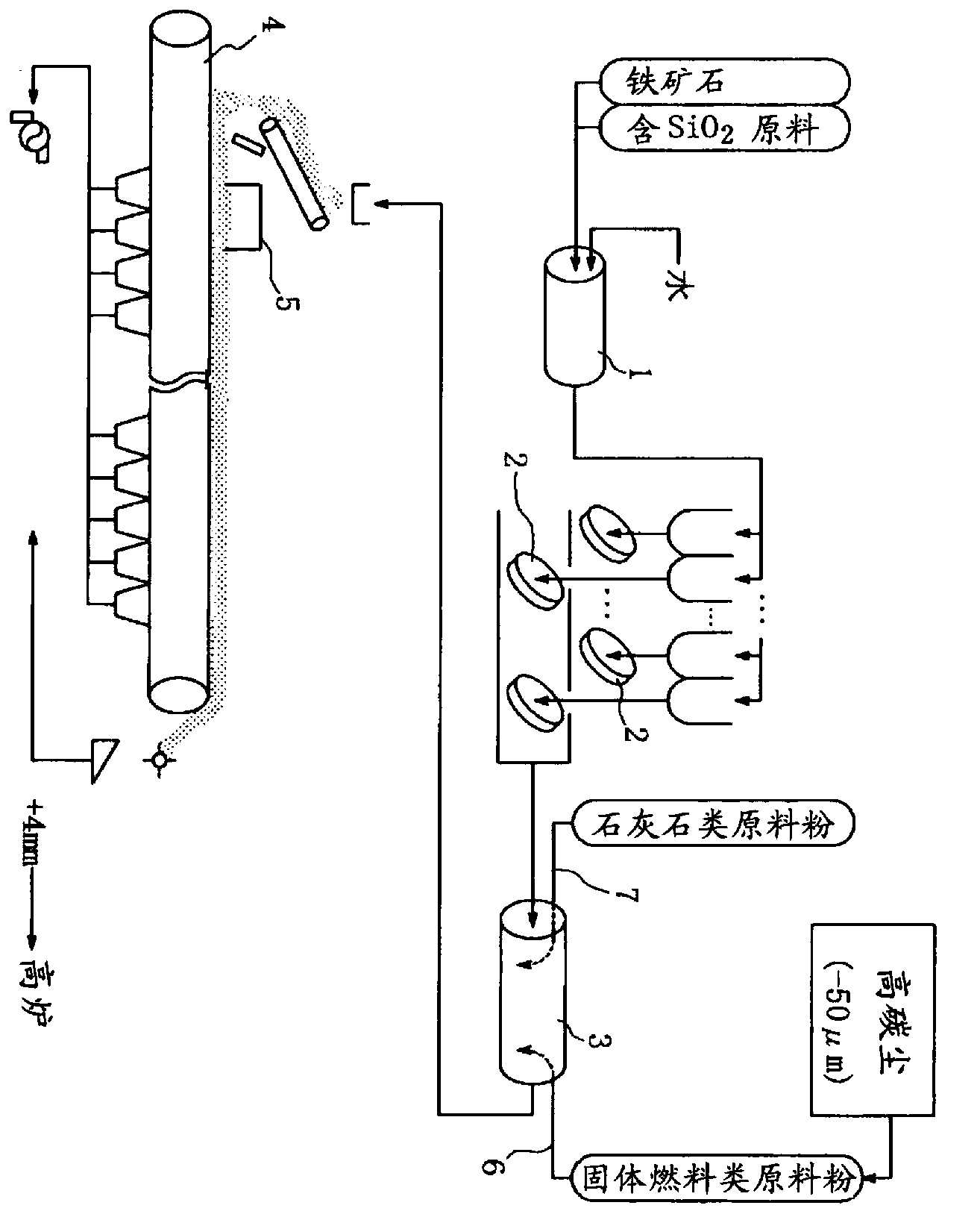

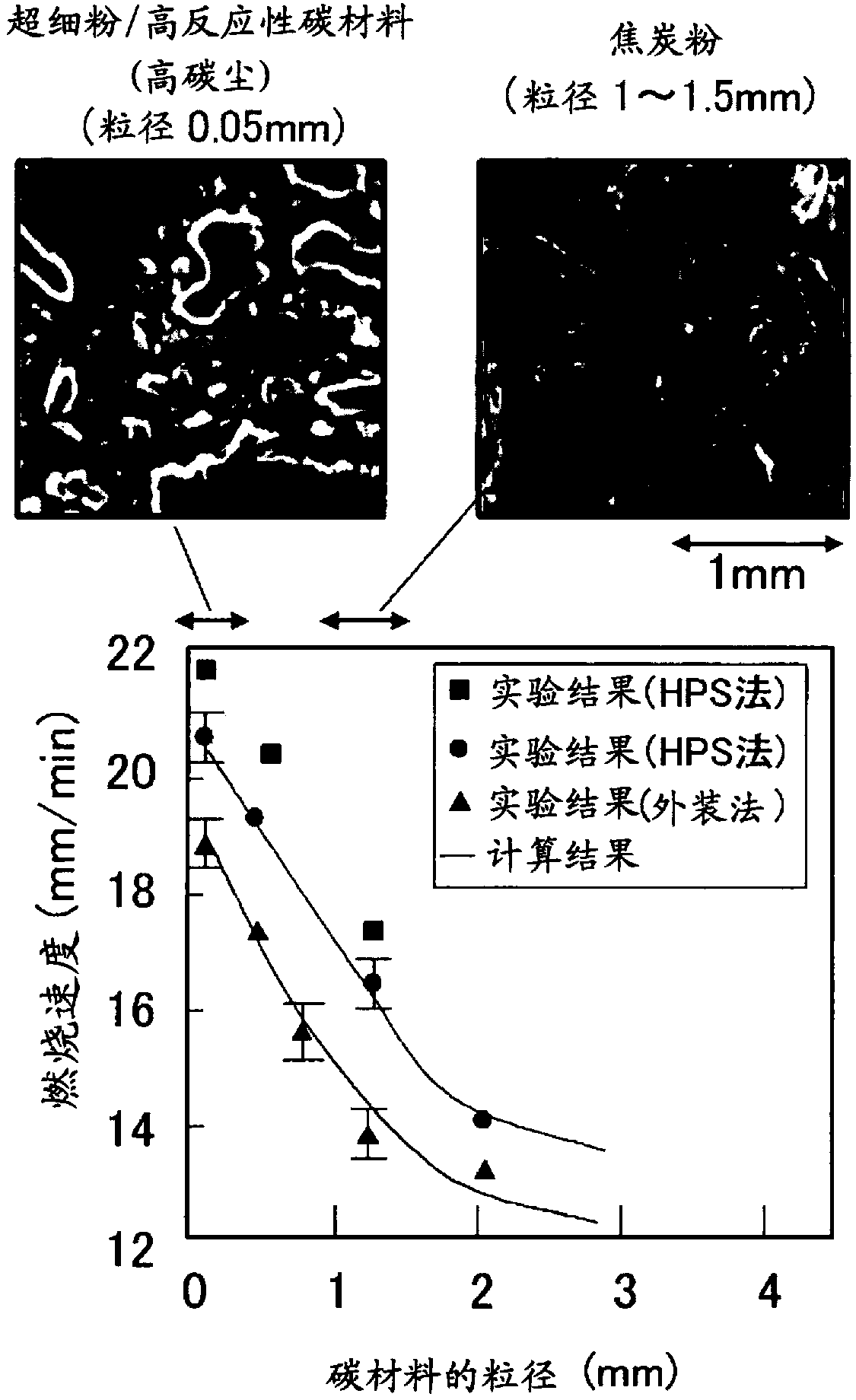

Method for producing starting material for sintering

Provided is a method for producing a starting material for sintering, wherein it is possible to improve productivity compared to conventional methods by effectively using ultrafine limestone powder and high-carbon dust during the process in which the surface of pseudo particles is being covered with a limestone-based powder starting material and a solid-fuel-based powder starting material. When forming a limestone-based powder starting material inner layer by supplying a limestone-based powder starting material to the surface of pseudo particles obtained by granulating a material containing SiO2 and iron ore and when forming a solid-fuel-based powder starting material outer layer by supplying a solid-fuel-based powder starting material on the limestone-based powder starting material inner layer, a limestone-based powder starting material containing 5 to 40 mass% of ultrafine limestone particles is used as the limestone-based powder starting material and a solid-fuel-based powder starting material containing 5 to 40 mass% of high-carbon dust is used as the solid-fuel-based powder starting material.

Owner:JFE STEEL CORP

Concrete aggregate prepared by utilizing coal gangue and preparation method thereof

The invention relates to concrete aggregate prepared by utilizing coal gangue and a preparation method thereof. The concrete aggregate is prepared from the following raw materials in parts by weight: 110-150 parts of broken coal gangue, 50-70 parts of foundry waste sand, 10-20 parts of copper sludge, 10-20 parts of red mud, 50-70 parts of regenerated diatomite broken pieces, 5-9 parts of additives, 6-10 parts of calcium hydroxide and 5-9 parts of sodium hydroxide solution with the mass concentration of 0.5mol / L, wherein the regenerated diatomite broken pieces are prepared from the following components in parts by weight: 40-60 parts of waste diatomite slurry, 20-30 parts of modified steel slag micro-powder, 6-11 parts of a surface modifier and 0.04-0.06 part of a foaming agent; and the modified steel slag micro-powder is prepared from steel slag and sodium metaborate which accounts for 1 / 10 to 1 / 2 of the weight of the steel slag. According to the invention, a large-scale application direction is found for the coal gangue, foundry waste sand, copper sludge, red mud, steel slag and waste diatomite, the waste materials are changed into things of value, and the environmental pollution and land occupation caused by solid wastes are reduced, so that the resources are further utilized, and energy conservation and environment friendliness are achieved.

Owner:重庆交院和瑞工程检测技术有限公司

Motor actuator

ActiveCN104426286AAvoid flyingSuppression of scatteringMechanical energy handlingSupports/enclosures/casingsEngineeringActuator

The invention provides a motor actuator which can effectively prevent lubricating grease from being sprayed out. The motor (20) comprises a motor housing (23), which comprises a bearing accommodating part (25), wherein an oil-containing bearing is fixedly arranged in the bearing accommodating part (25); and a rotation shaft (21) which stretches out from the bearing accommodation part (25) to the motor housing (23). The motor housing (23) is elastically supported on a shell (10) by O-shaped rings (30,31). The bearing accommodating part (25) comprises a cylindrical part (25a), an accommodated oil-containing bearing, and a flange part which is opposite to the external end surface (28a) of the oil-containing bearing in the axial direction, and an opening part (25c) for inserting a rotation shaft is formed. The oil-containing bearing is provided with a second chamfering part (28e), which is coated by lubricating grease (29), in the inner circumferential side of the external end surface in the axial direction. The inner diameter (d1) of the opening part is arranged to be larger than the external diameter (d2) of the rotation shaft, and smaller than the external diameter (d3) of the second chamfering part.

Owner:TOKYO PARTS IND CO LTD

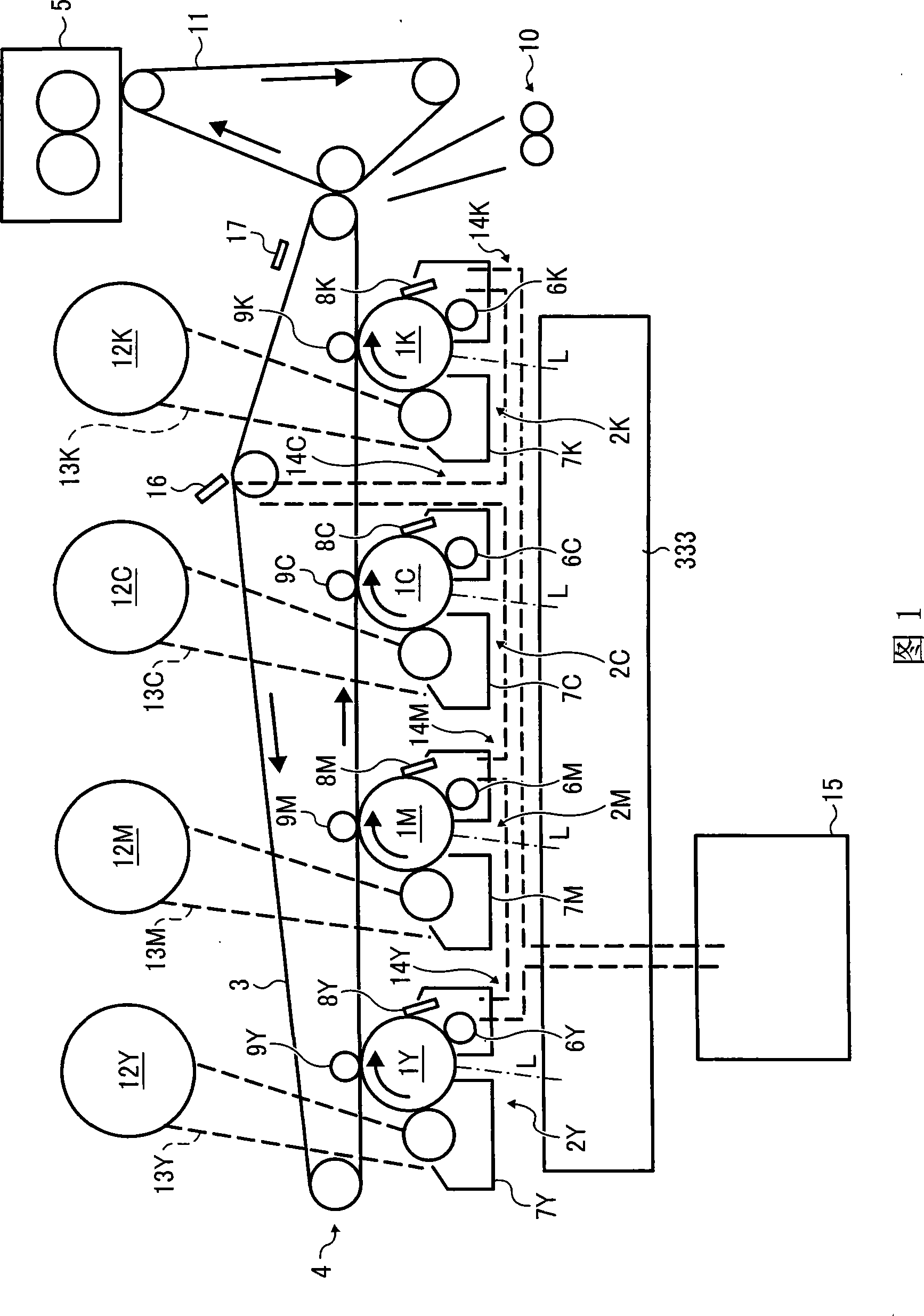

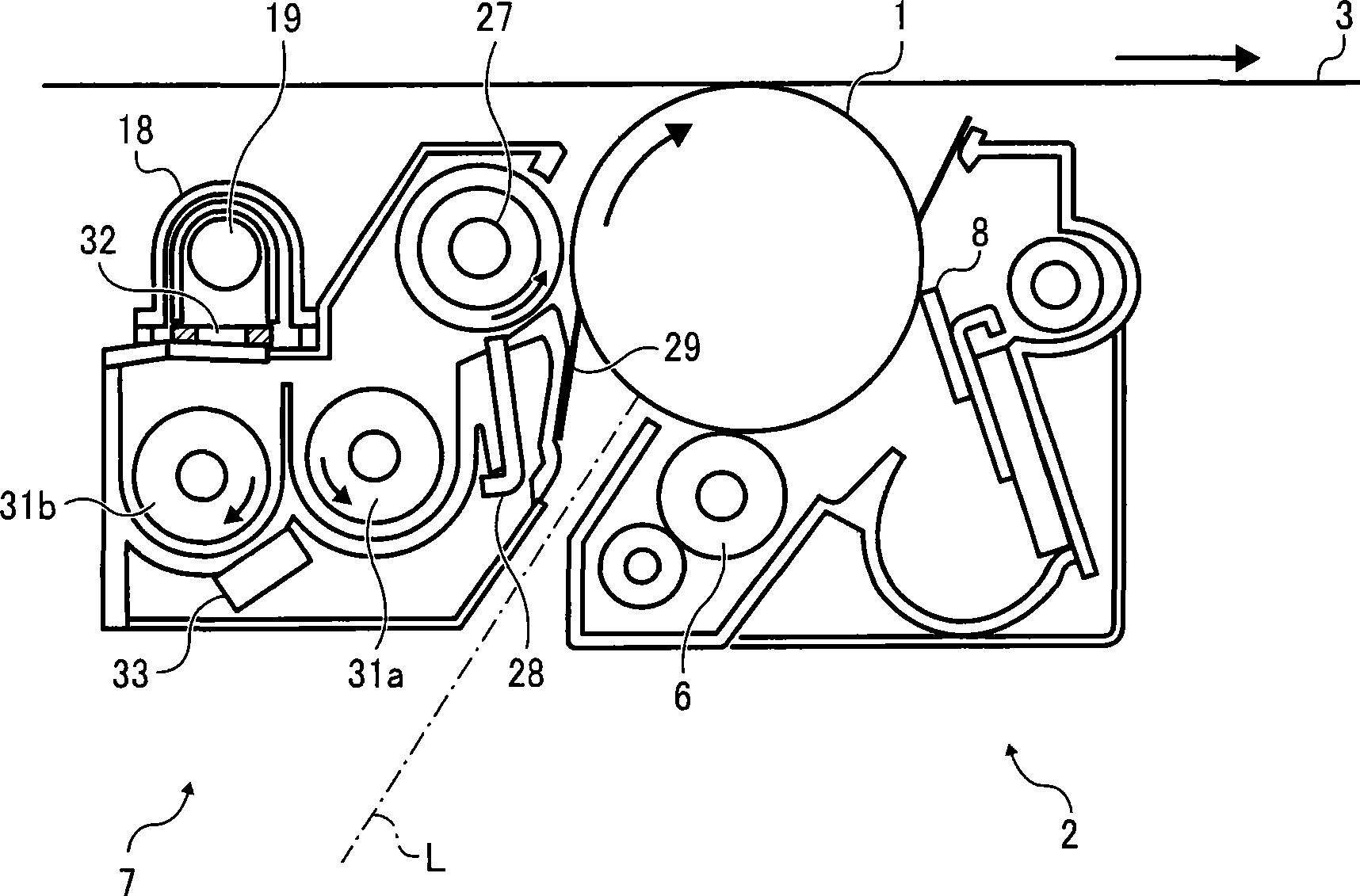

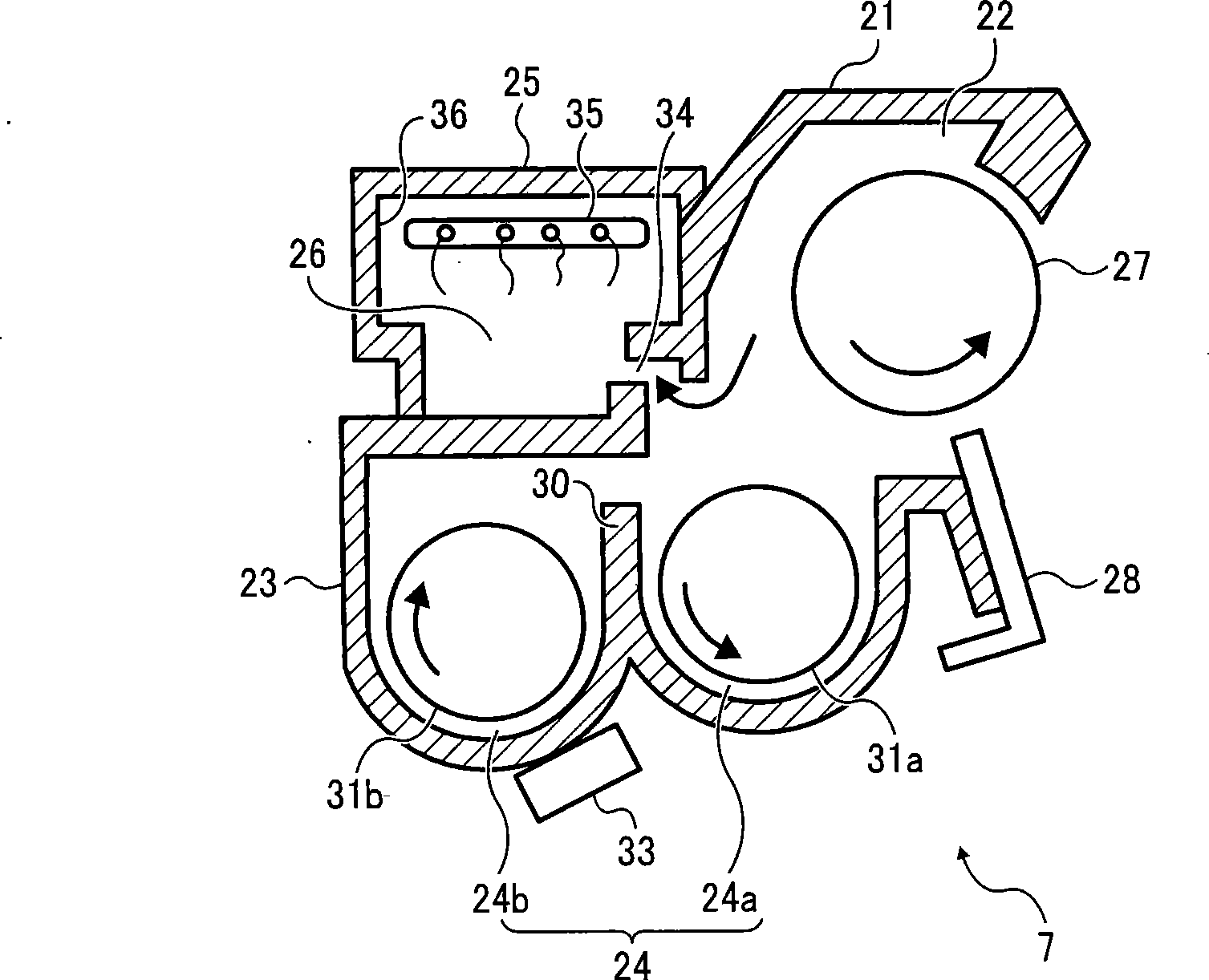

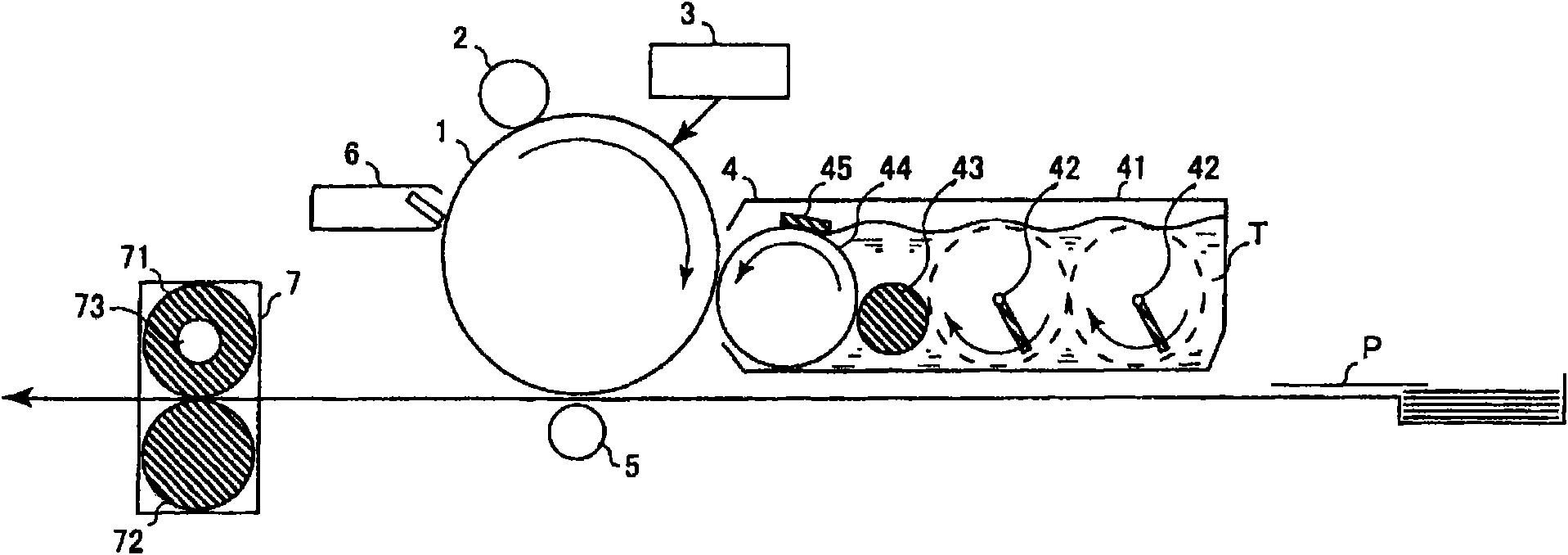

Development device, process cartridge, and image forming apparatus

InactiveCN101446792AHigh speedSuppression of scatteringElectrographic process apparatusMaintainabilityImage formation

The invention provides a development device capable of separating a flyheaded toner from a part contacting with an user with good maintainability performance, and a process cartridge using the development device and image forming apparatus. The development device comprises: a development roller 27 configured to carry developer and disposed in a development case, partly exposed from an opening of the development case facing a sensitizatoon body 1, a developer-transporting screw 31a configured to transport the developer to the developer roller 27, and a discharging space 26 for discharging air from a communication port 34 in ralative area for communicating the development roller 27 and the developer-transporting screw 31a through a discharging port 35 that opens in a longitudinal direction of the developer-transporting screw 31a.

Owner:RICOH KK

Outdoor unit

ActiveCN103765110ASuppression of scatteringCompressorPositive displacement pump componentsGlass fiberFiber

Owner:DAIKIN IND LTD

Image-forming apparatus and cartridge

ActiveCN101681135AExcellent image stabilityExcellent thin line reproducibilityElectrographic process apparatusDevelopersImaging qualityImage formation

The invention provides an image-forming apparatus and a cartridge which inhibit troubles attributable to toner particle size distribution or toner / photoreceptor matching, such as a white-background fouling, afterimage, scattering, streaks, blurring, and blind spots, and are satisfactory with respect to image quality, thin-line reproducibility, and cleanability. Even when applied to a high-speed printer, the apparatus and cartridge can prevent fouling and selective development in long-term use and can stably form high-resolution images. The image-forming apparatus has an electrophotographic photoreceptor which includes a photosensitive layer containing an oxytitanium phthalocyanine which has major diffraction peaks for a CuK alpha line at Bragg angles (2 theta) of 9.0 DEG and 27.2 DEG andhas at least one major diffraction peak for the line in the range of from 9.3 DEG to 9.8 DEG . It employs a toner satisfying all of the following requirements: (1) the volume median diameter (Dv50)is 4.0-7.0 mu m; (2) the average roundness is 0.93 or higher; and (3) the volume median diameter (Dv50) and the percentage by number of toner particles having a size of 2.00-3.56 mu m (Dns) satisfy the relationship Dns<=0.233EXP(17.3 / Dv50).

Owner:MITSUBISHI RAYON CO LTD

Method for producing starting material for sintering

Provided is an advantageous method for producing a starting material for sintering, wherein it is possible to improve productivity compared to conventional methods by effectively using ultrafine limestone powder and high-carbon dust during the process in which the surface of pseudo particles is being covered with a limestone-based powder starting material and a solid-fuel-based powder starting material. When the surface of pseudo particles is being covered with a limestone-based powder starting material and a solid-fuel-based powder starting material, a limestone-based powder starting material containing 5 to 40 mass% of ultrafine limestone particles is used as the limestone-based powder starting material and a solid-fuel-based powder starting material containing 5 to 40 mass% of high-carbon dust is used as the solid-fuel-based powder starting material.

Owner:JFE STEEL CORP

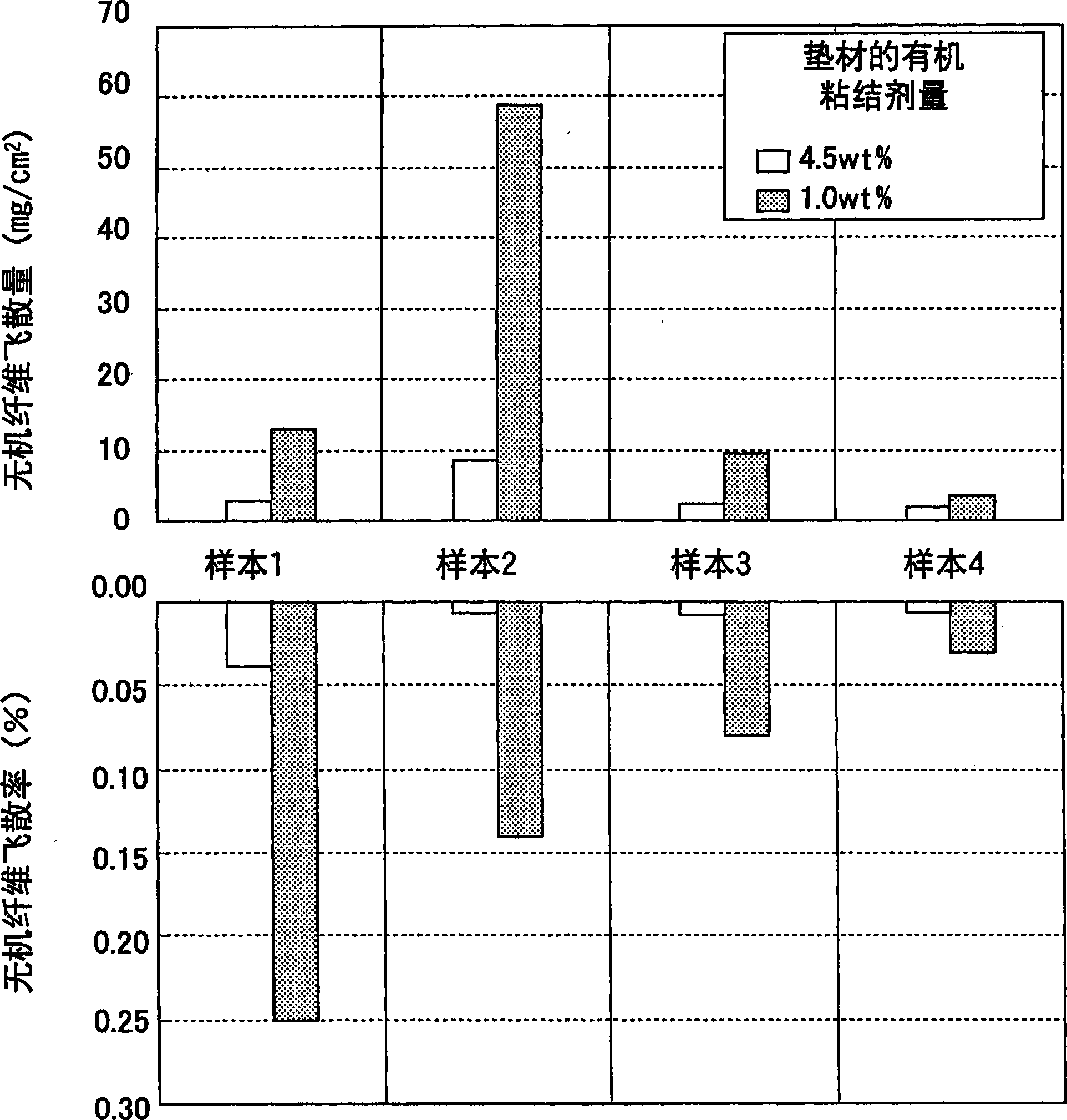

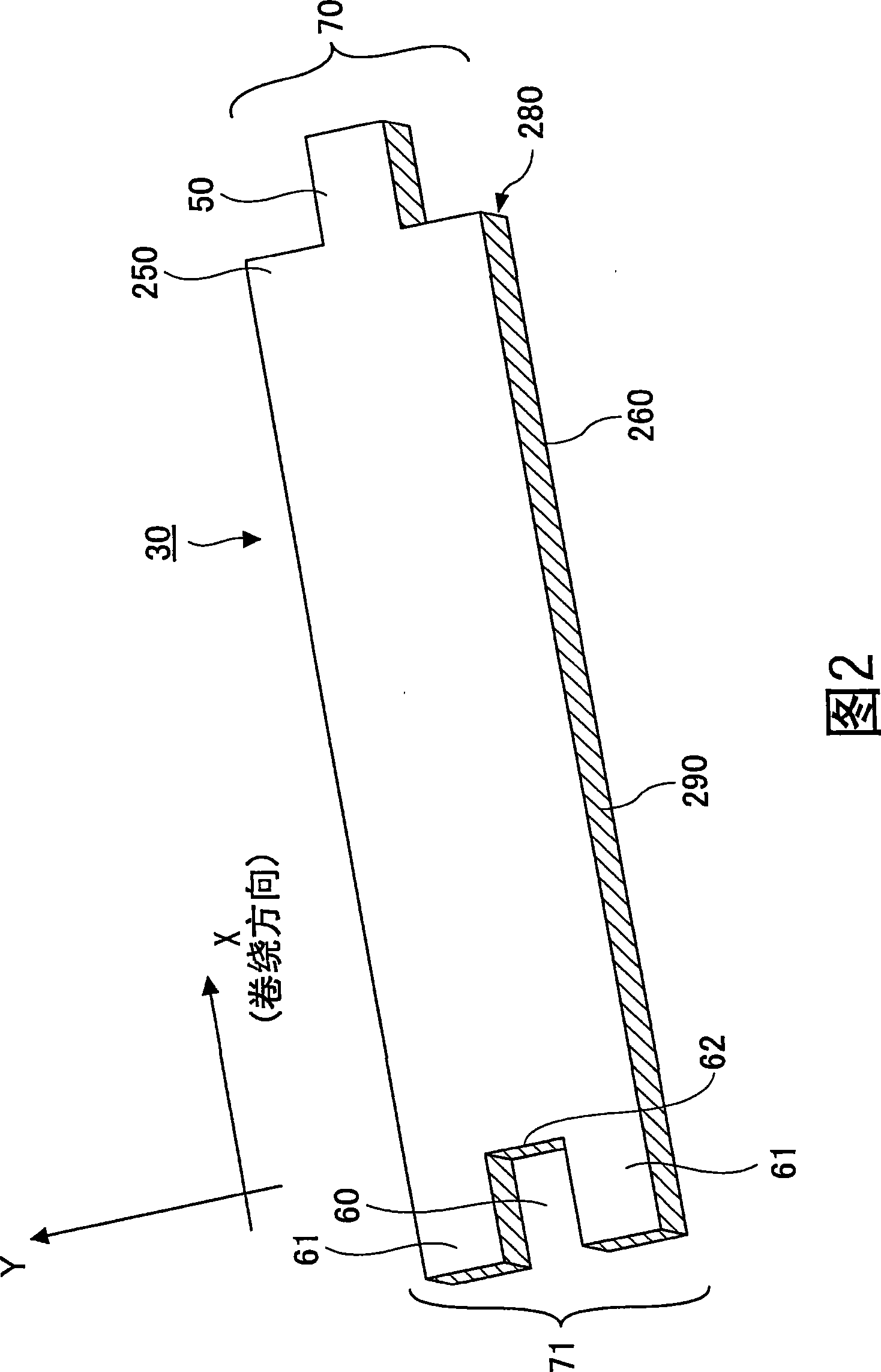

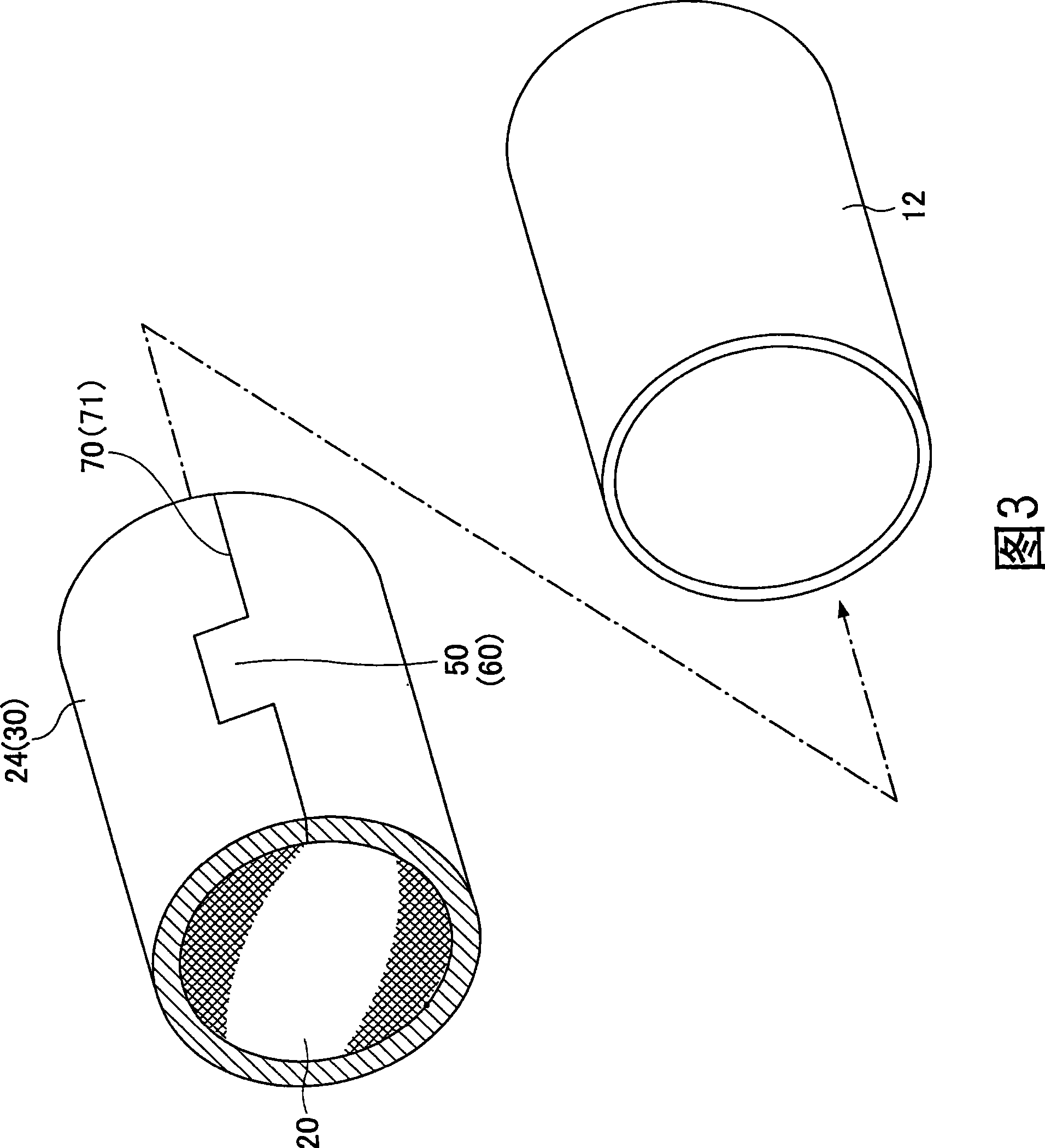

Mat member, method of fabrication mat member, exhaust gas treating apparatus, and silencing device

ActiveCN101397927ASuppression of scatteringExhaust apparatusDispersed particle separationFiberEdge surface

A mat member includes inorganic fibers, a first main surface, a second main surface opposite to the first main surface, an edge surface surrounding the first main surface and the second main surface, and an inorganic fiber scattering reduction unit. The inorganic fiber scattering reduction unit is provided on at least a part of the edge surface of the mat member and configured to reduce scattering of the inorganic fibers.

Owner:IBIDEN CO LTD

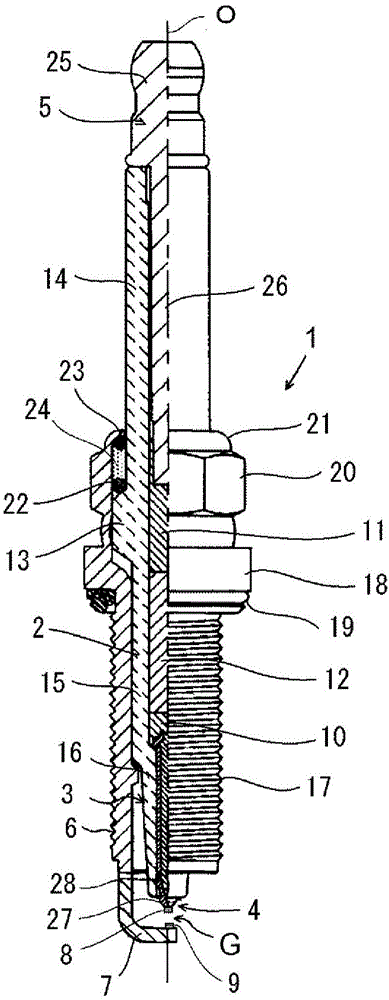

Spark plug

ActiveCN106030942AExcellent consumptionIncreased durabilitySparking plugs manufactureEngineeringPerovskite

The objective of the present invention is to provide a spark plug having excellent durability by providing a central electrode and / or a grounding electrode with a tip having excellent resistance to spark-wear under high-temperature environment. The spark plug is provided with a central electrode and a grounding electrode disposed with a gap from the central electrode, said spark plug being characterized in that: there is a tip forming the gap on the central electrode and / or the grounding electrode; the tip has a metal matrix, whereof the main constituent is Ir, and oxide particles containing at least one species of oxide having a perovskite structure represented by the general formula ABO3 (where A is at least one species selected from the group 2 elements of the periodic table, and B is at least one species selected from the metal elements); and the proportion of the surface area occupied by the oxide particles upon observation of the cross section of the tip is 1% to 13% inclusive.

Owner:NGK SPARK PLUG CO LTD

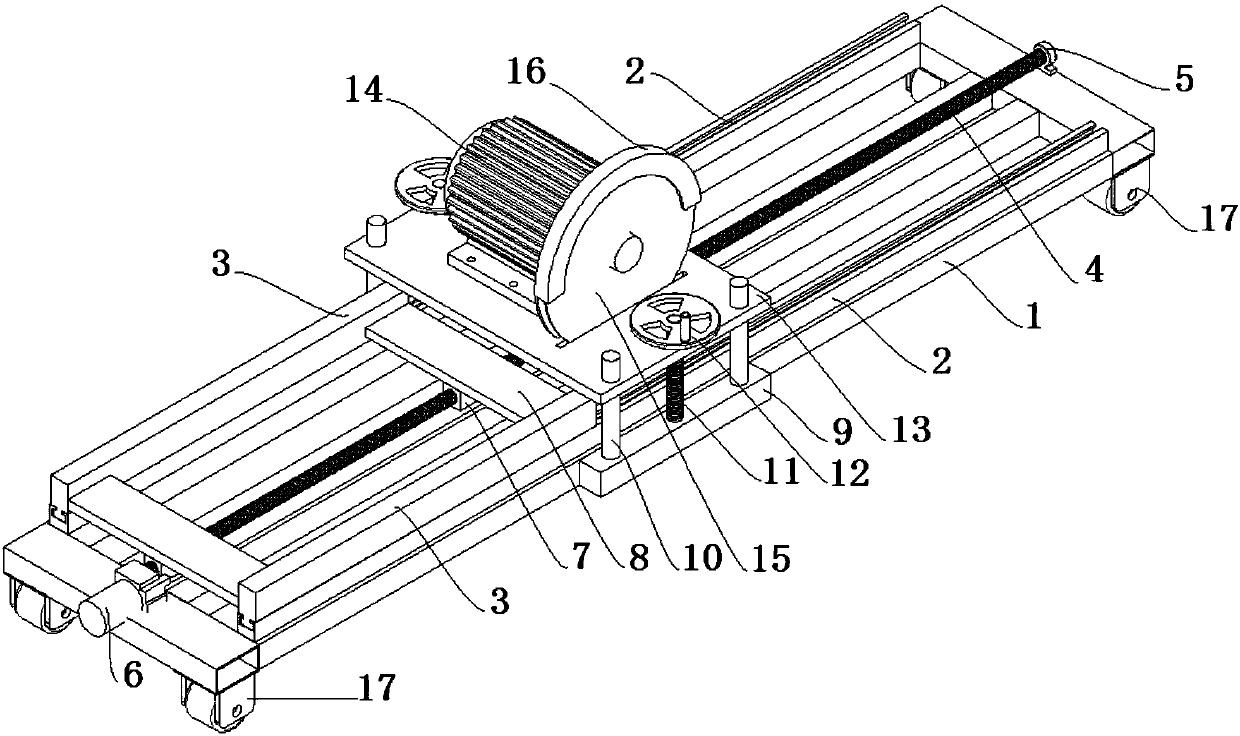

Automatic cutting device for building plate

The invention discloses an automatic cutting device for building boards, which comprises a base and cutting equipment. Guide rails are fixedly installed on the left and right sides of the base respectively. Slide blocks are respectively matched at the upper ends of the guide rails. Screw rods are arranged between the guide rails, and one end of the screw rod passes through The bearing seat of the screw rod is fixedly connected with the base, the other end of the screw rod is connected with the DC motor through a coupling, the DC motor is fixed on the base, the screw rod is matched with a screw nut, and the screw nut is fixedly connected with a slider drive The two ends of the drive plate and the slider drive plate are respectively fixedly connected with the slider on the guide rail. The top of the base is equipped with a cutting device. The cutting device includes a motor and a cutting blade. The cutting blade is fixedly installed on the rotor output shaft of the motor, and the motor is fixed. Installed on the motor mounting plate, the motor mounting plate is fixedly connected to the base through the motor lifting frame, and the motor mounting plate can move vertically on the motor lifting frame. The invention ensures that the incision of the building board is smooth, the cutting effect is good, and the cutting speed is improved at the same time.

Owner:罗艳春

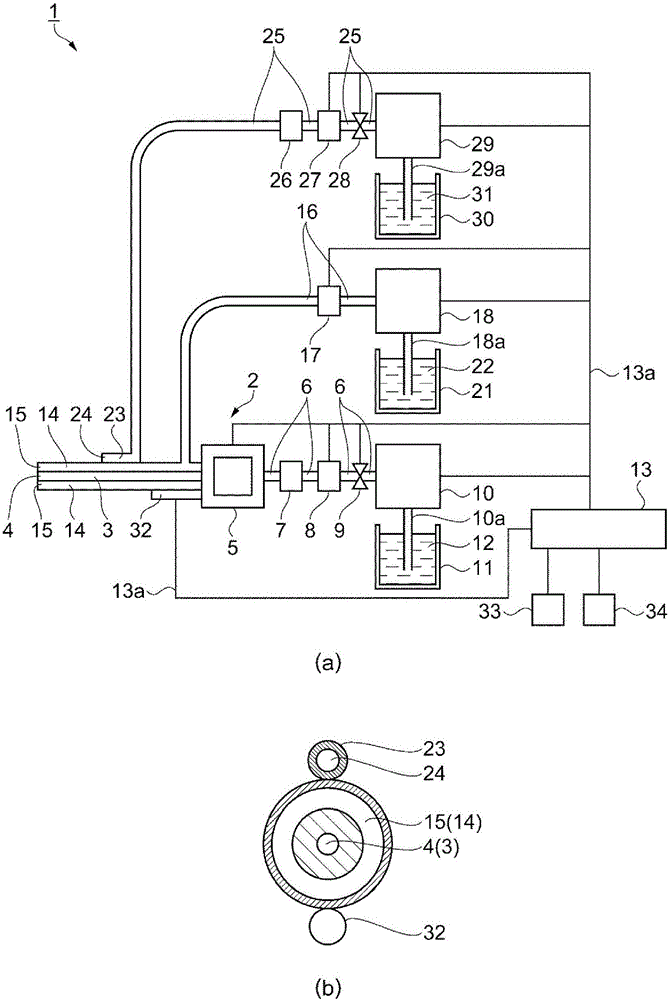

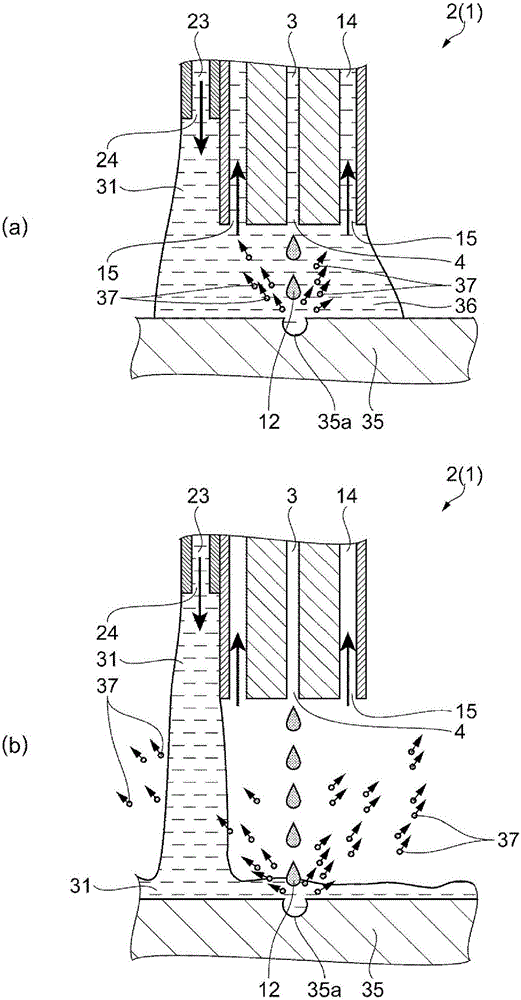

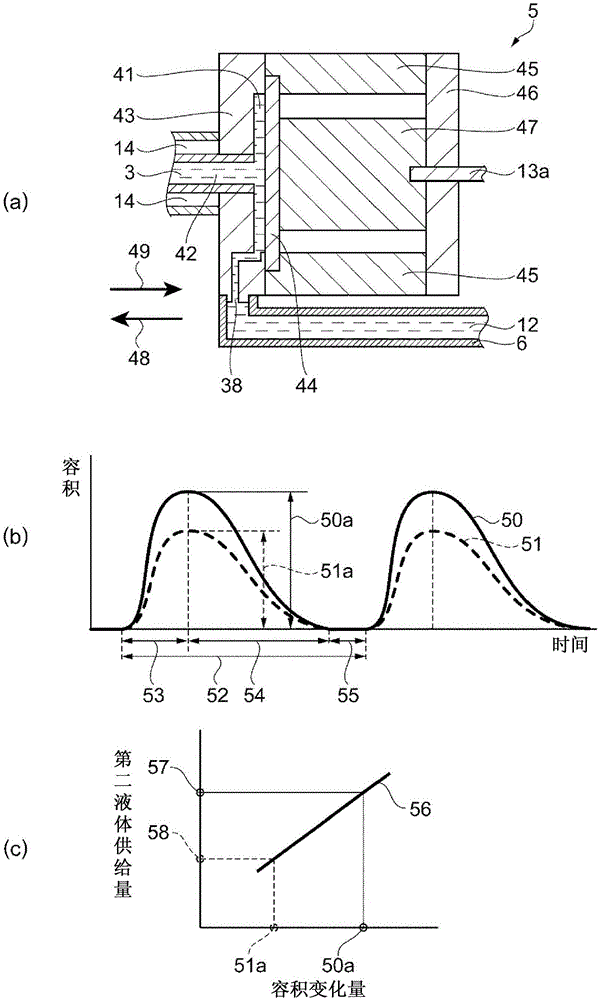

Liquid spray device and surgical device

InactiveCN106102607ASuppression of scatteringFlexible member pumpsFluid jet surgical cuttersBiological bodyLiquid jet

Provided is a liquid spray device with which the scattering of biological tissue, such as cells, which has been excised or disintegrated by means of a sprayed pulse flow, can be prevented. The invention is provided with a supply pipe 23 that sprays, from a nozzle 4, a pulse-like first liquid 12 that is supplied from a spray pipe 3, and supplies a second liquid 31 from the supply pipe 23 to the vicinity of the nozzle 4. The invention is further provided with a suction opening 15 that is disposed near the nozzle 4, and a suction pump 18 that is connected to the suction opening 15 via a suction pipe 14 and suctions in the first liquid 12 and the second liquid 31.

Owner:SEIKO EPSON CORP

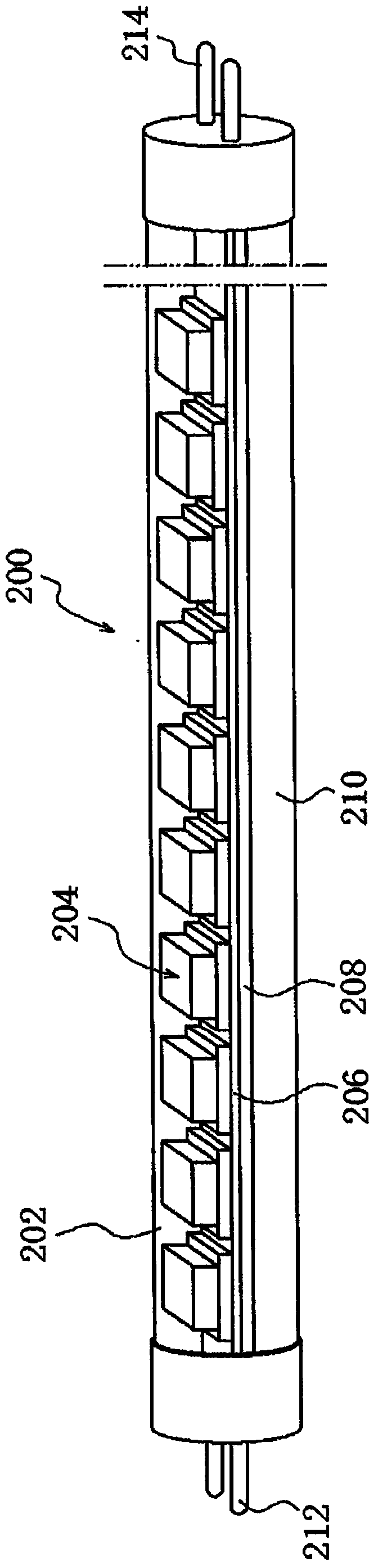

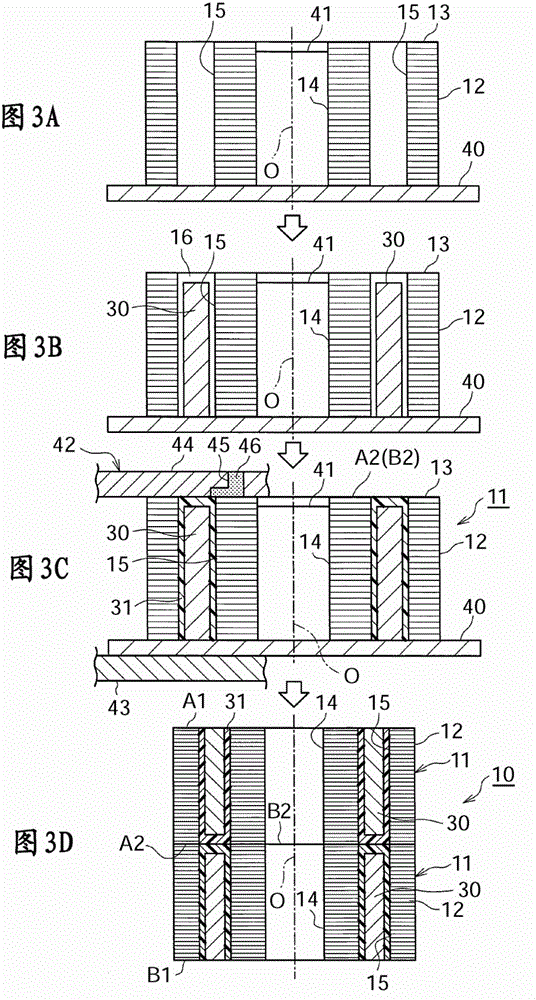

Method for manufacturing a rotary electric machine rotor

InactiveCN106340984AImprove productivitySuppression of scatteringMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineMaterials science

The invention relates to a method for manufacturing a rotary electric machine rotor. The method for manufacturing the rotary electric machine rotor includes: forming core block elements; inserting magnets in corresponding one of magnet holes; forming magnet core blocks by injecting a molten resin into each of the magnet holes from above the magnet, solidifying the molten resin, and thereby forming a resin portion so as to integrate each of the core block elements and the magnets, the molten resin is injected at a second end surface, and end surfaces of the magnets being exposed on a first end surface; forming the rotary electric machine rotor by stacking and integrating plural magnet core blocks, the plural magnet core blocks being stacked such that the first end surfaces of two magnet core blocks that are disposed at both ends in an axial direction constitute end surfaces at both ends of the rotary electric machine rotor in the axial direction.

Owner:TOYOTA JIDOSHA KK

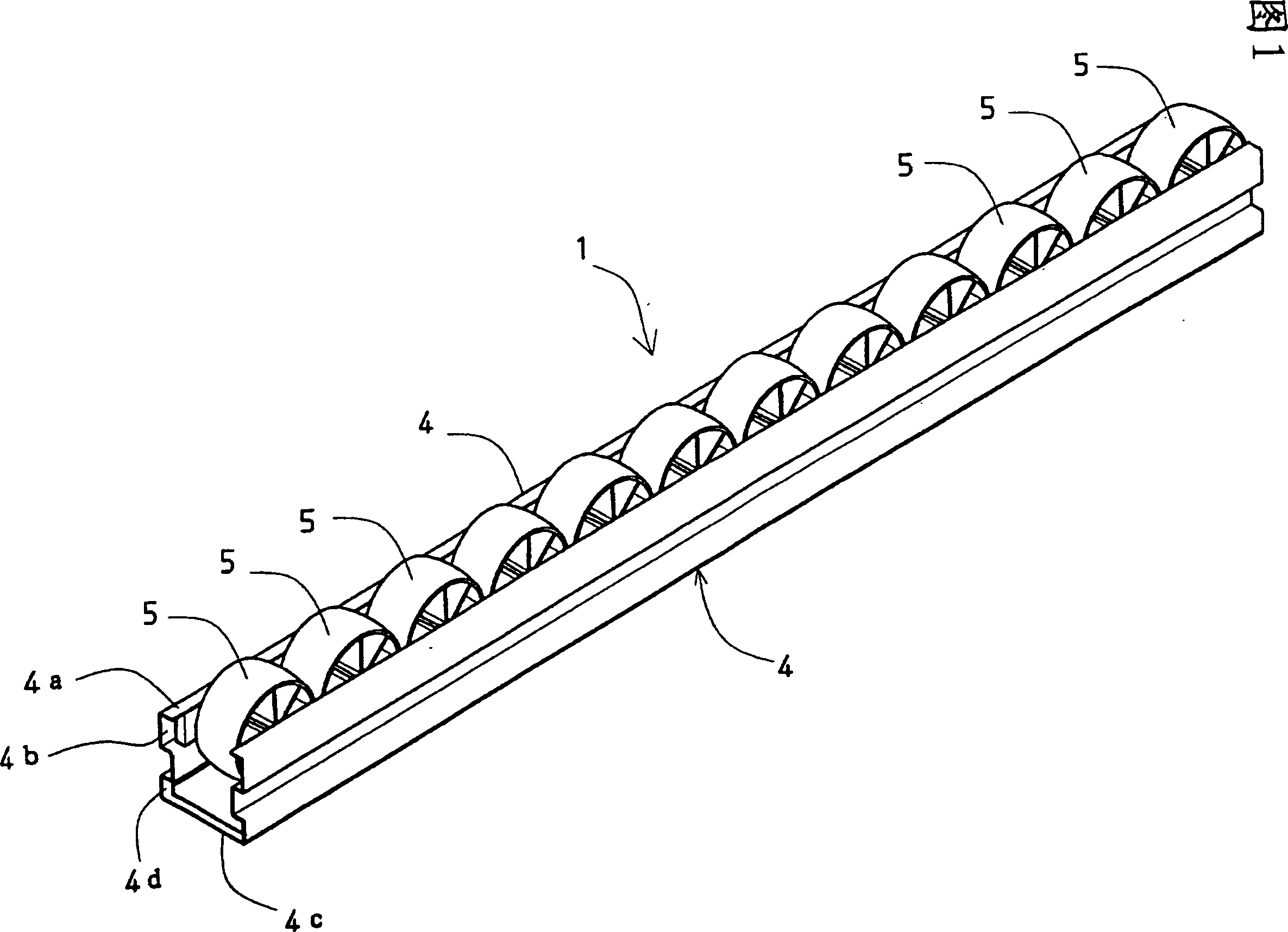

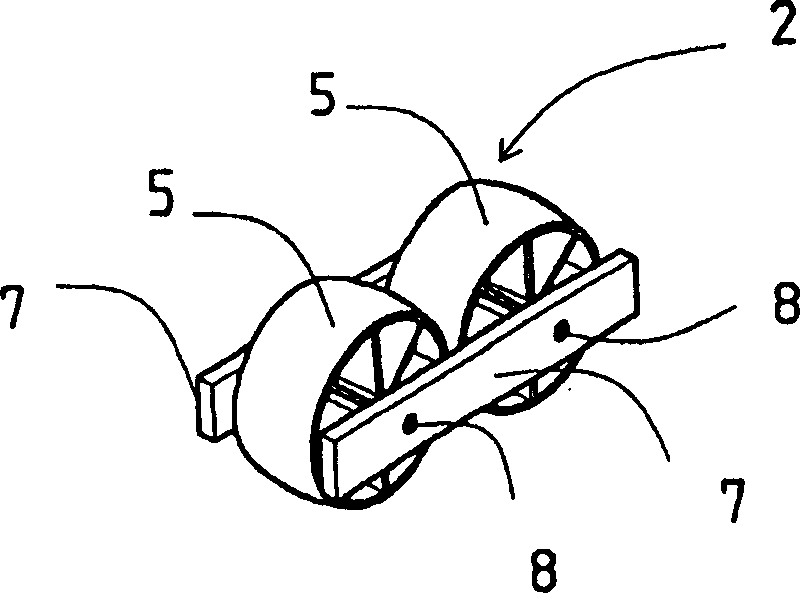

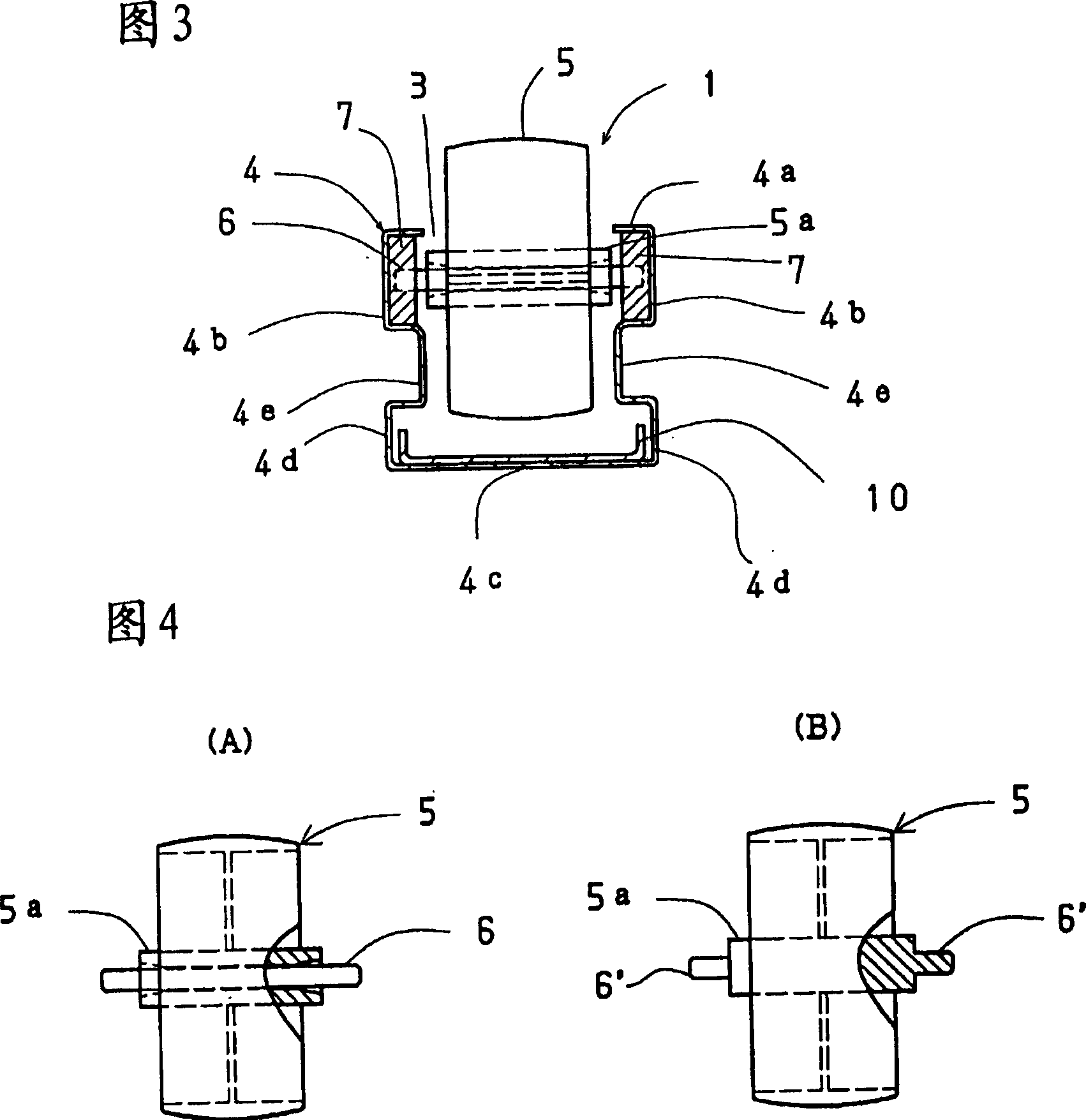

Wheel conveyor

InactiveCN1910098AEasy to disassembleImprove cleanlinessRollersRoller-waysEngineeringMechanical engineering

A wheel conveyer formed by installing a wheel assembly having wheels and support plates disposed on both sides thereof and rotatably supporting the axles of the wheels in the grooves of frame materials, easily disassembled and cleaned, and having vibration damping function and dust collecting function. In the wheel assembly (2), the wheels (5) comprise axle pins (6), pin holes (8) are formed in the support plates (7), and the axle pins (6) are inserted into the pin holes (8) and rotatably supported on the pin holes. The shape of the frame material (4) in cross section is such that a first groove-shaped part (4b) formed continuously with a lip part (4a) supports the support plate (7) movably in the longitudinal direction, and a bottom part groove-shaped part (4d) formed continuously with a bottom wall (4c) is swelled outward from the mouth edge of the lip (4a). These two groove-shaped parts (4b) and (4d) are joined continuously to each other through a joining parts (4b) of the frame materials (4), and the plurality of wheels (5) are arranged in a row.

Owner:YAZAKI IND CHEM CO LTD

Method for producing starting material for sintering

ActiveCN103038368ASuppression of scatteringLarge particle sizeProcess efficiency improvementSolid fuelIron ore

Provided is a method for producing a starting material for sintering, wherein it is possible to improve productivity compared to conventional methods by effectively using high-carbon dust during the process in which the surface of pseudo particles is being covered with a solid-fuel-based powder starting material. When forming a limestone-based powder starting material base layer by supplying a limestone-based powder starting material to the surface of pseudo particles obtained by granulating a material containing SiO2 and iron ore and when forming a solid-fuel-based powder starting material outermost layer by supplying a solid-fuel-based powder starting material on the limestone-based powder starting material base layer, a solid-fuel-based powder starting material containing 5 to 40 mass% of high-carbon dust is used as the solid-fuel-based powder starting material.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com