Manufacturing apparatus of electric part, manufacturing method of electric part and manufacturing method of LED illumination

A technology for electronic components and manufacturing methods, applied in the direction of assembling printed circuits with electrical components, printed circuit manufacturing, electrical components, etc., can solve the problems of deterioration of fluorescent agents, deformation of substrates, adverse effects of electronic components, etc., and achieve the effect of suppressing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] In Example 1, a substrate made of PET was used, and in Example 2, a substrate made of PEN was used. First, on each substrate, a copper foil is etched by a known method to form a wiring pattern, thereby producing a printed circuit board. Both the substrates used in Example 1 and Example 2 had a thickness of 50 μm and were flexible.

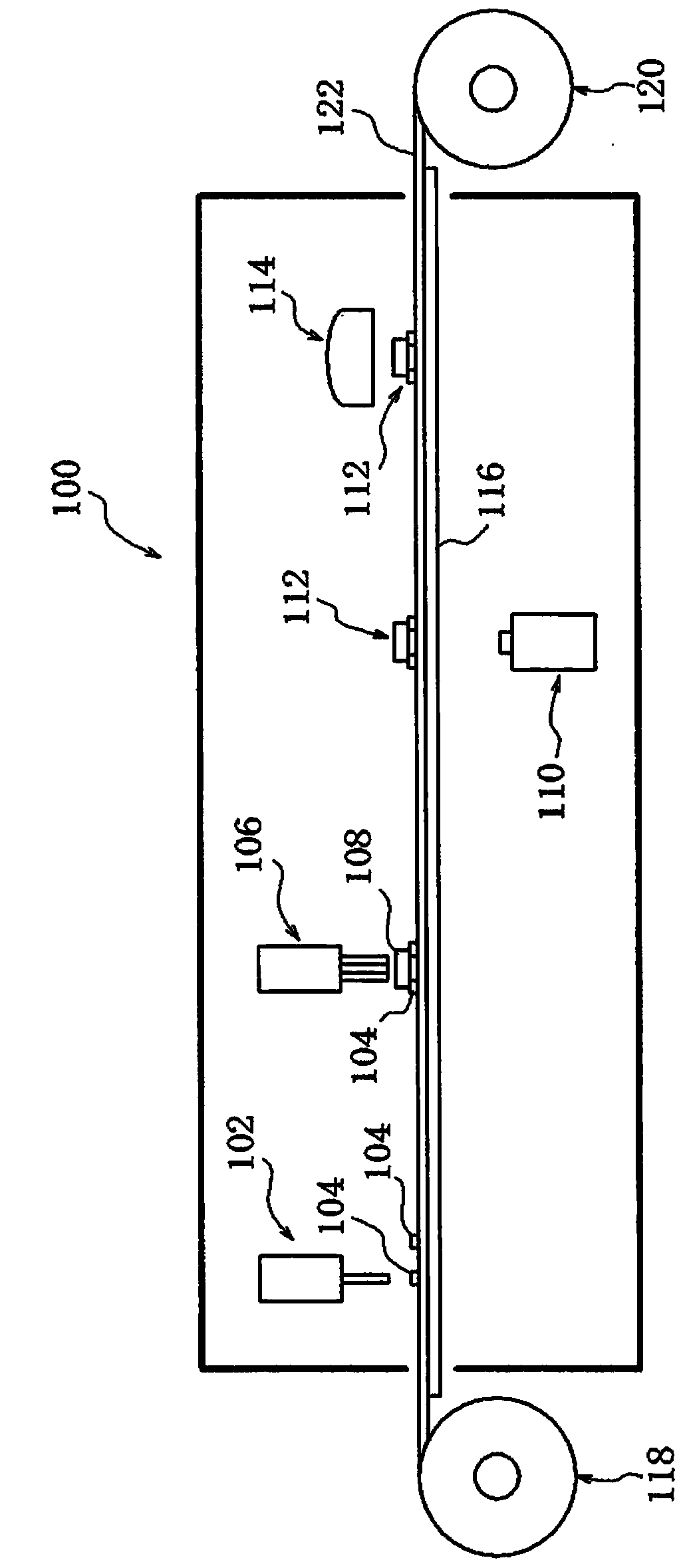

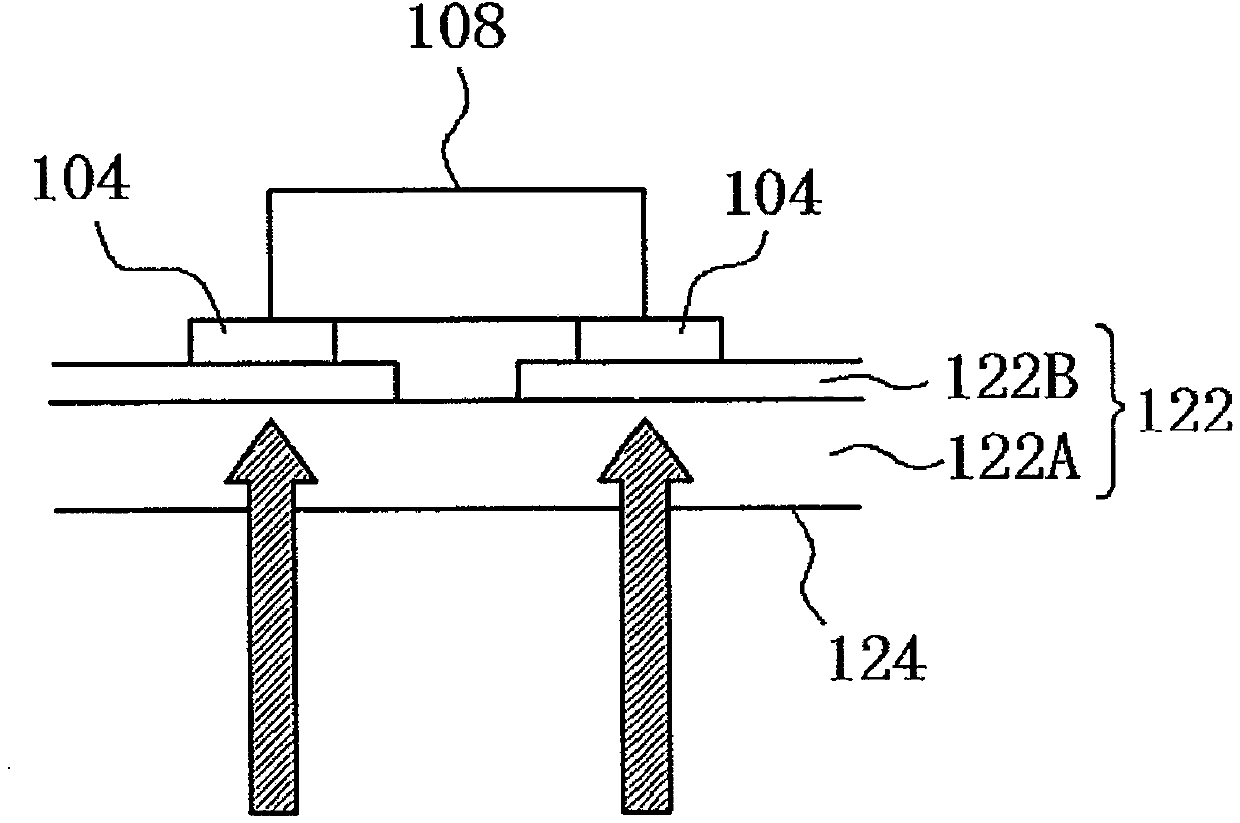

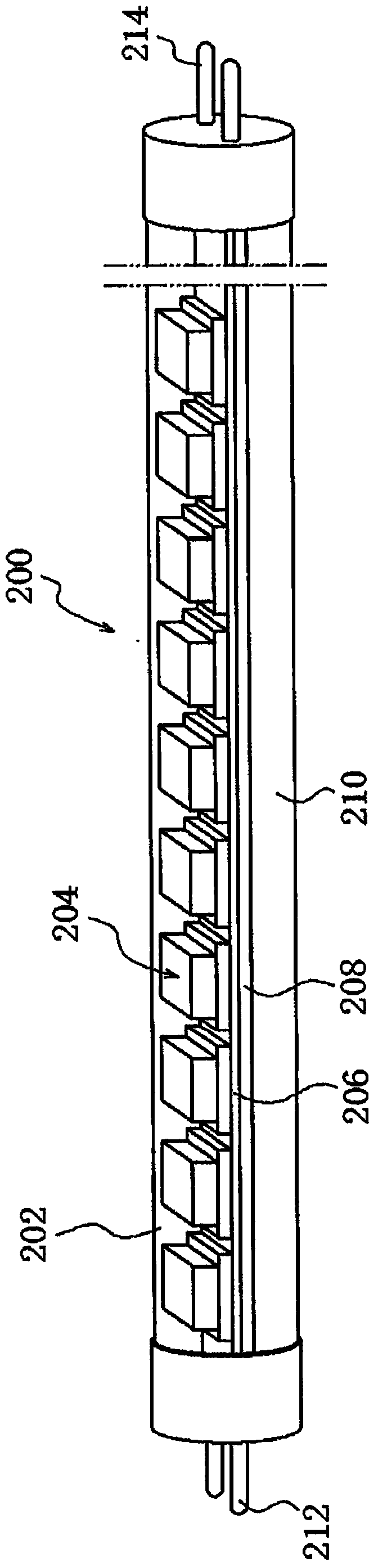

[0099] Second, use figure 1 In the illustrated reel-to-reel electronic component manufacturing apparatus, LEDs are mounted while winding a substrate from one reel to the other reel. Using a non-contact jet applicator (JetMaster: manufactured by Musashi High-Tech Co., Ltd.), paste solder was supplied onto the wiring pattern of the printed circuit board. Then, an LED element was mounted on the cream solder using a mounter (desk mounter: manufactured by Okuhara Electric Co., Ltd.). Secondly, use a semiconductor laser device with a luminous center wavelength of 920nm (LD irradiation device 15W type: manufactured by Japan Hamamatsu Photonics ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com