Patents

Literature

452 results about "Glass fragment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TRACES OF GLASS can often become a source of forensic evidence. Glass fragments are regularly encountered at crime scenes, particularly those involving motor-vehicle accidents, car theft, and burglaries. Windows are a common point of entry into buildings for burglars, and large quantities of broken glass may be produced.

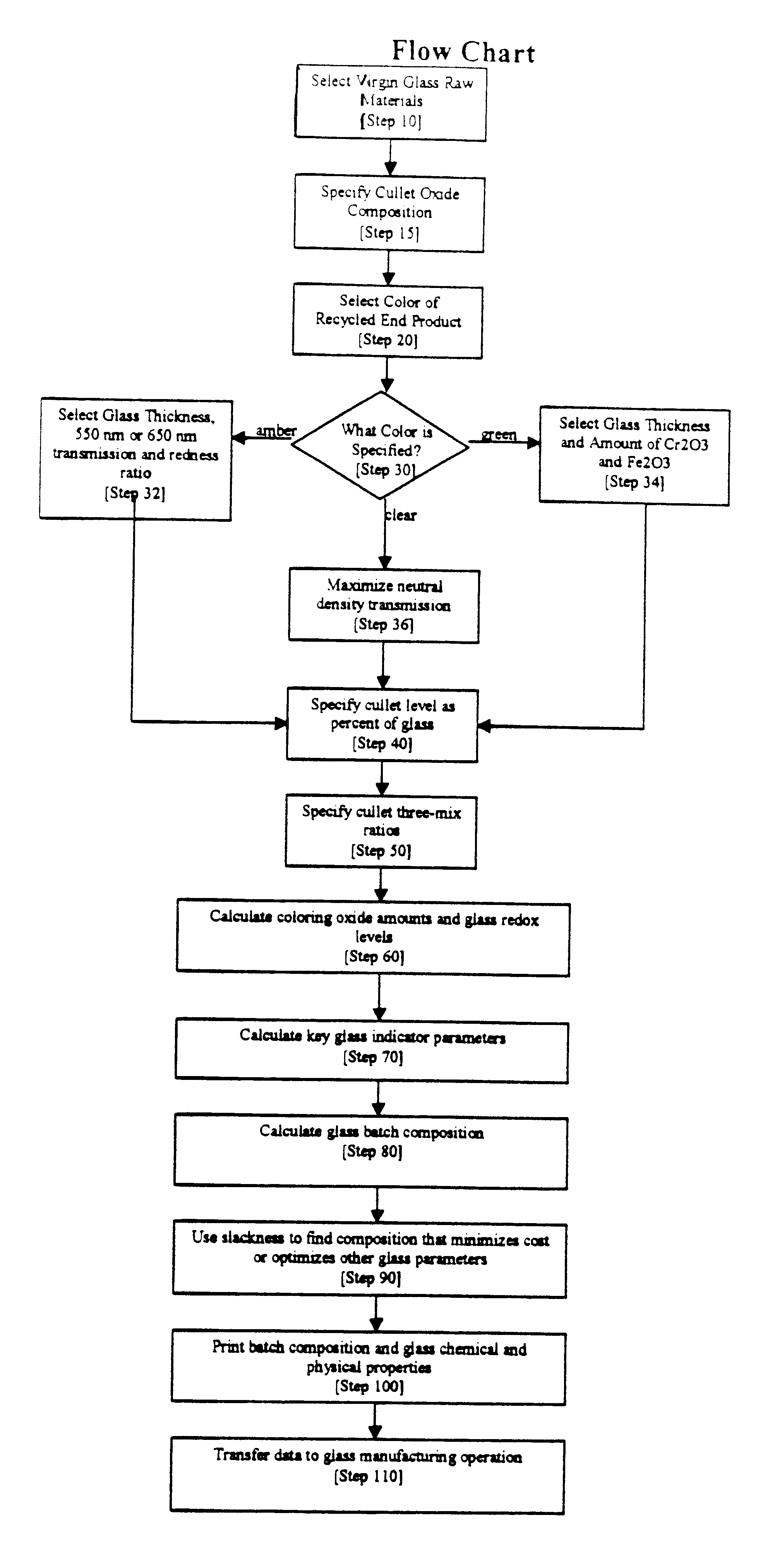

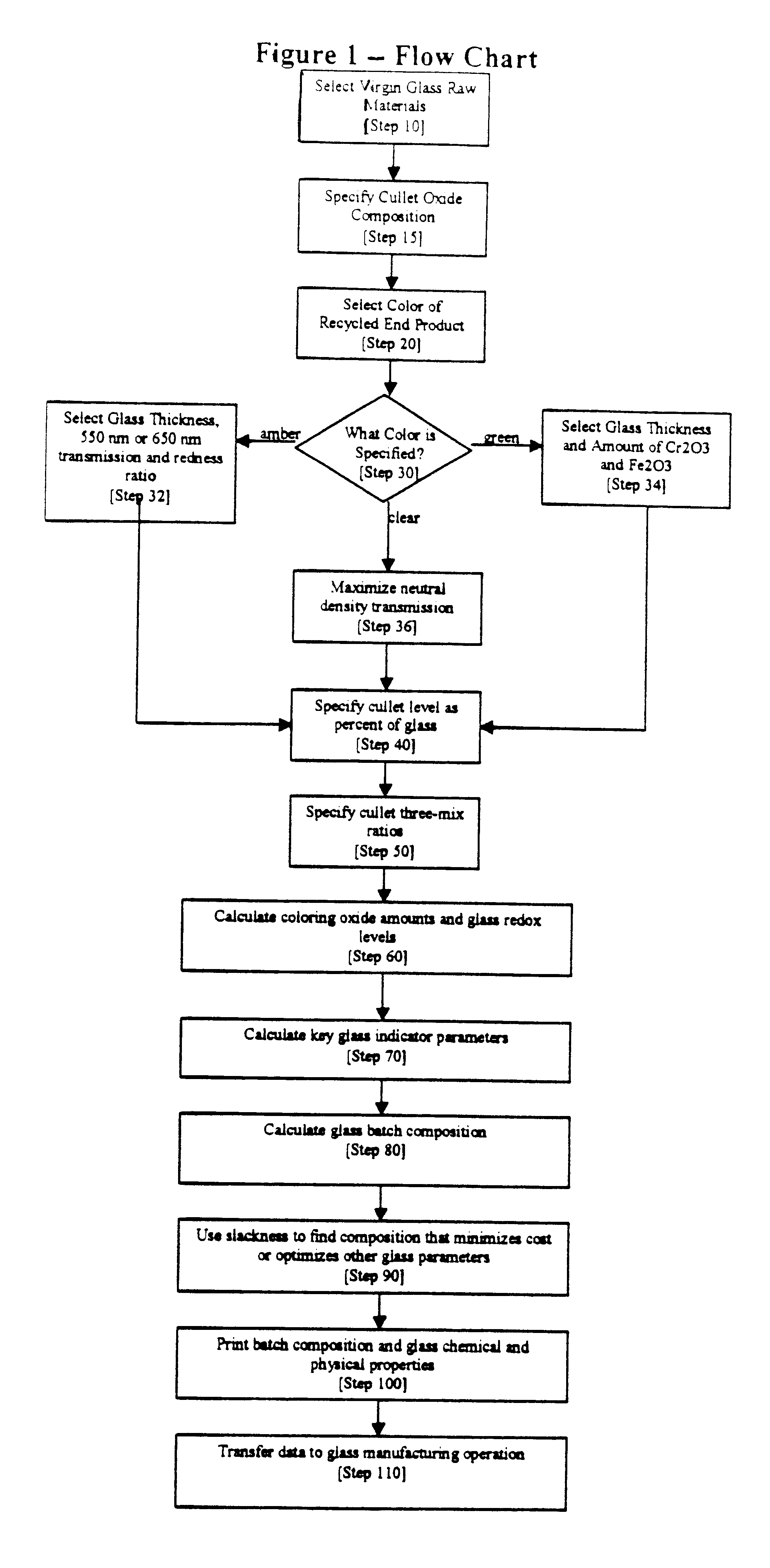

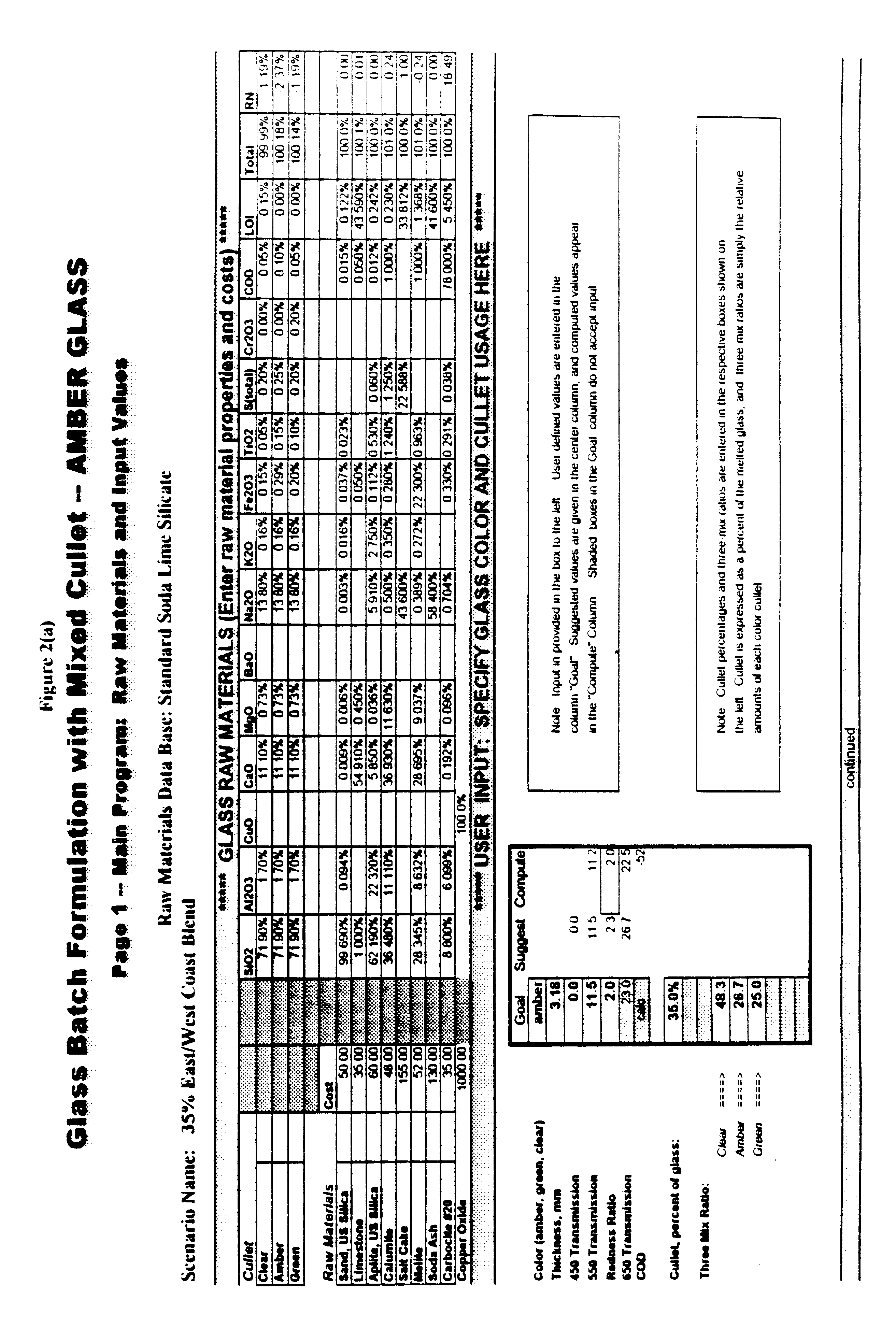

Automated process for recycling batches of mixed color cullet into amber, green, or flint glass with selected properties

InactiveUS6763280B1Low costMinimize iron levelCharging furnaceBlowing machine gearingsManufactured materialRedox

An automated method for recycling mixed colored cullet glass (i.e., broken pieces of glass of mixed colors and types) into new glass products. A computer controlled process identifies the virgin glass raw materials, the desired target glass properties, the composition of a batch of mixed colored cullet, and the quantity of cullet to be used in the glass melt, and the computer controlled process automatically determines the proper amounts of raw materials to add to the batch of mixed colored cullet so that recycled glass is produced having the desired coloring oxides, redox agents, and glass structural oxides in the proper proportion. The recycled glass is then used to make glass products such as beer bottles.

Owner:CULCHROME LLC

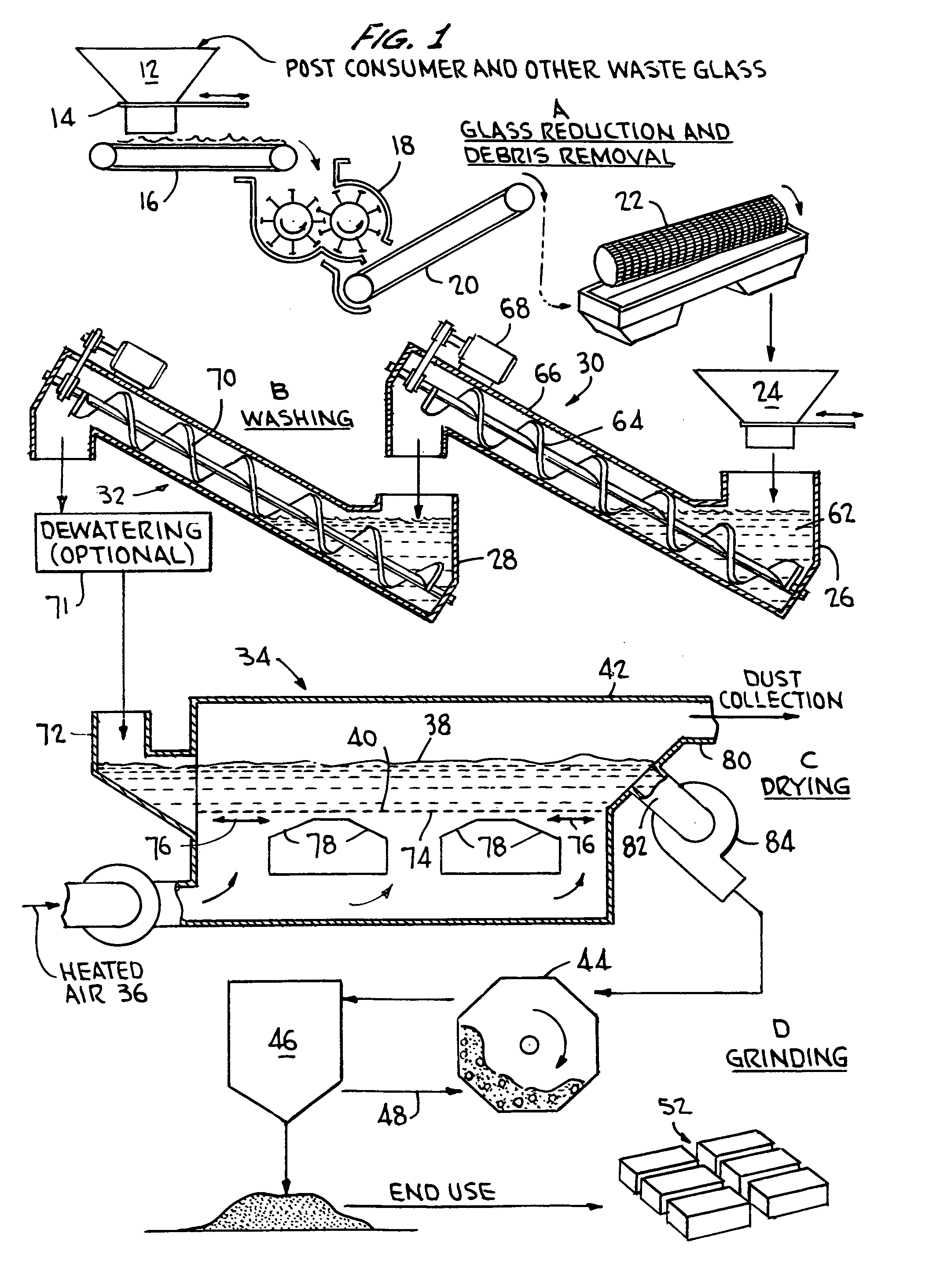

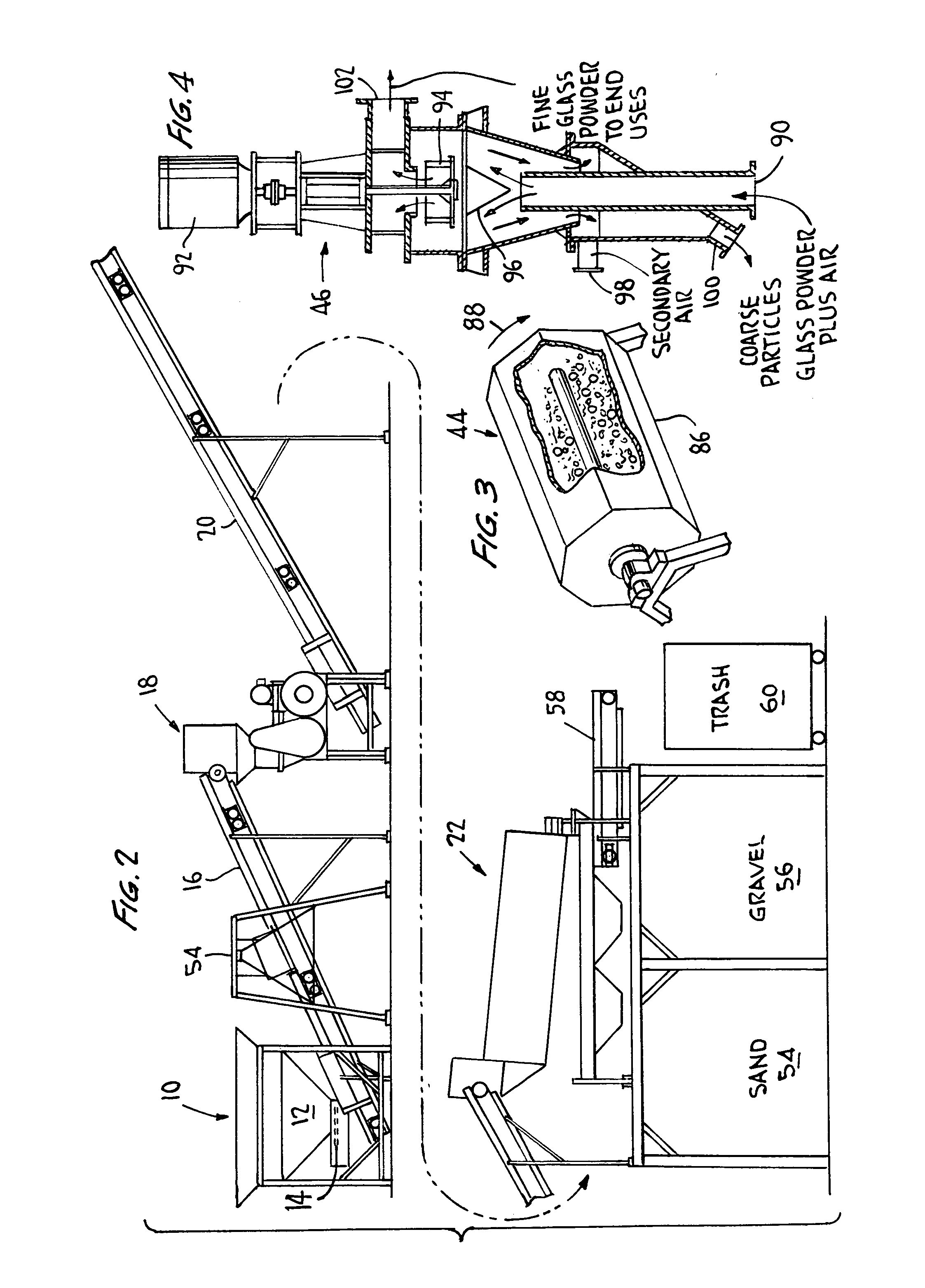

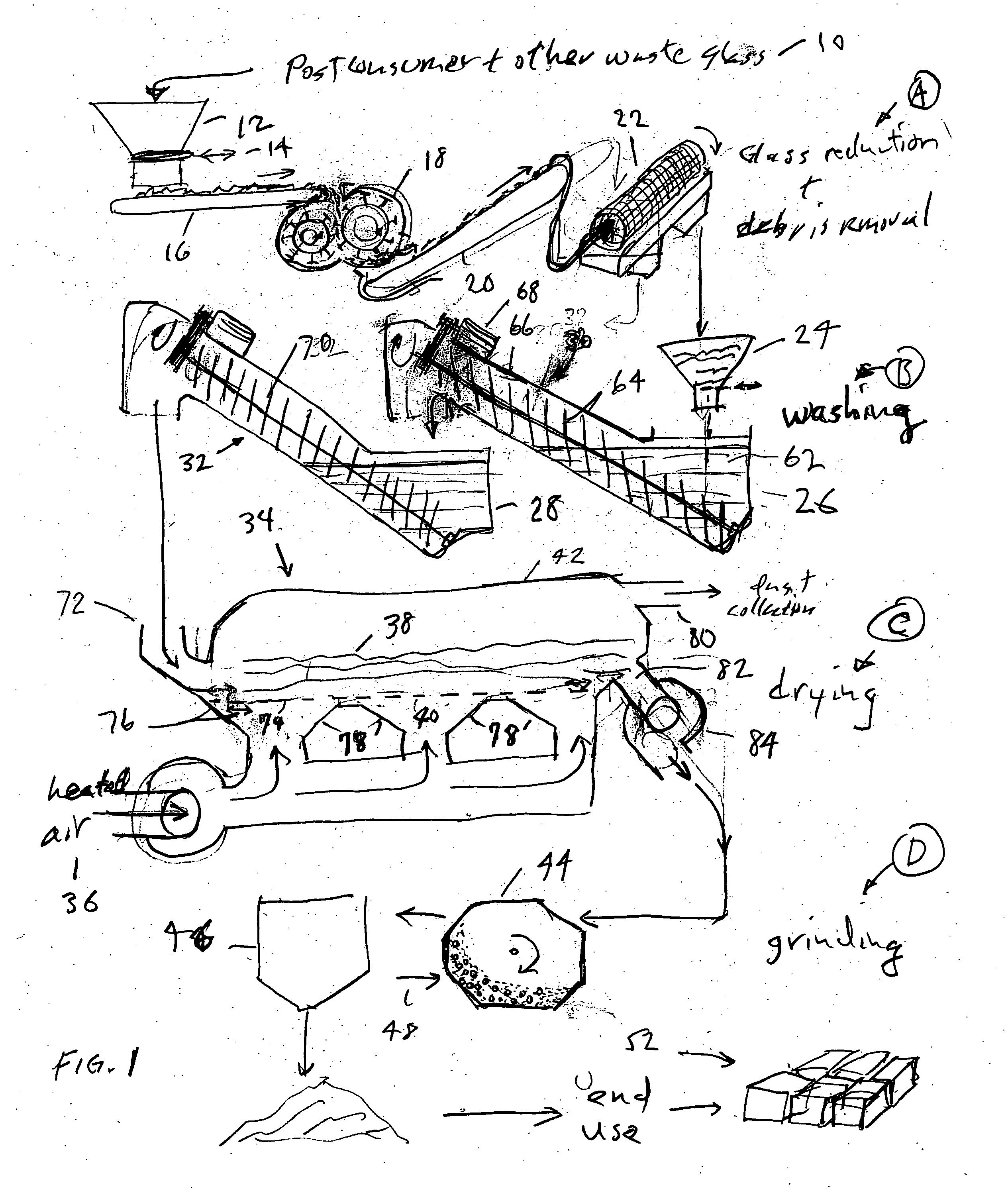

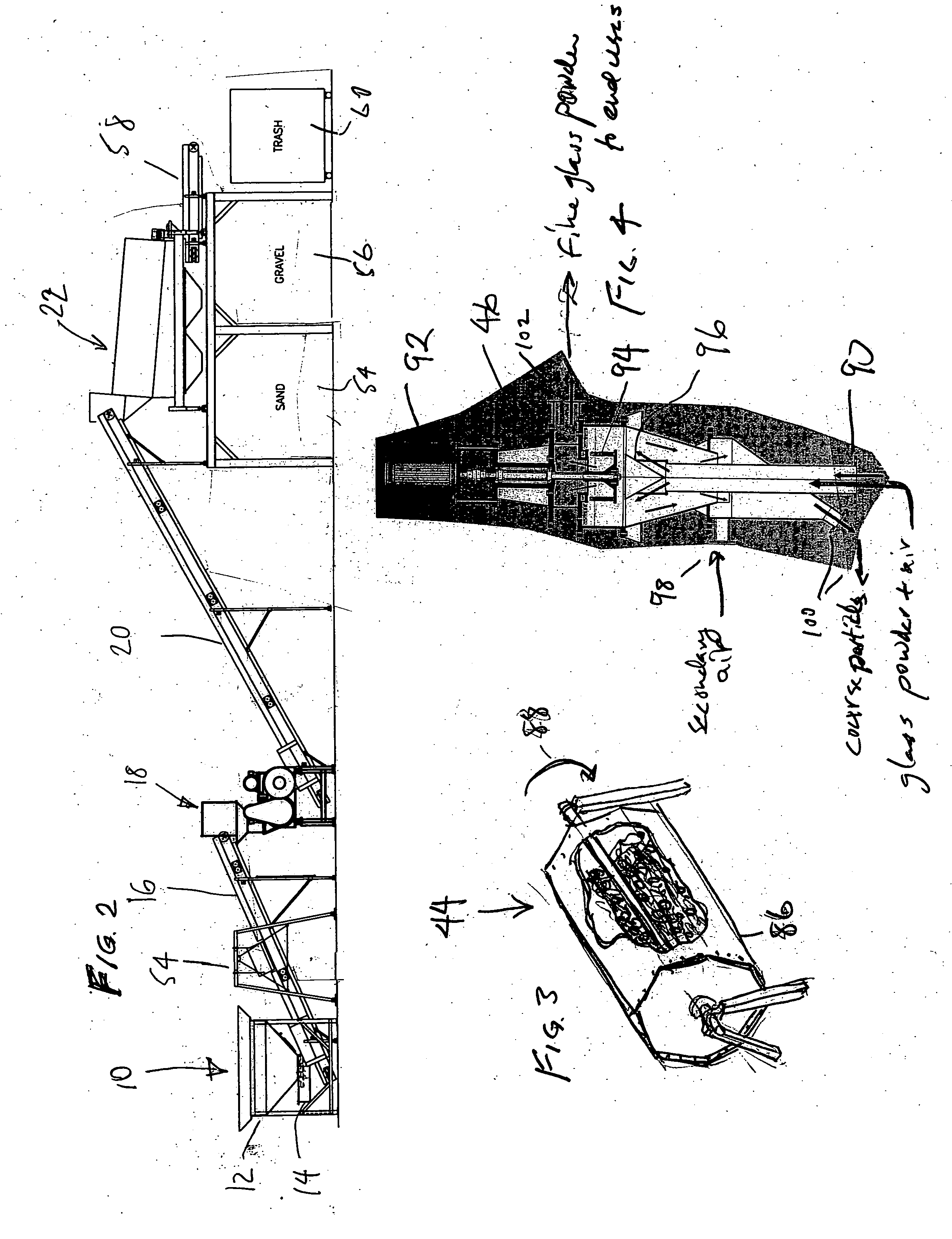

Production of glass powder from waste glass, and products made using the same, especially concrete

ActiveUS7413602B2Suppress the alkali-silica reactionCocoaGrain treatmentsFluidized bedSmall fragment

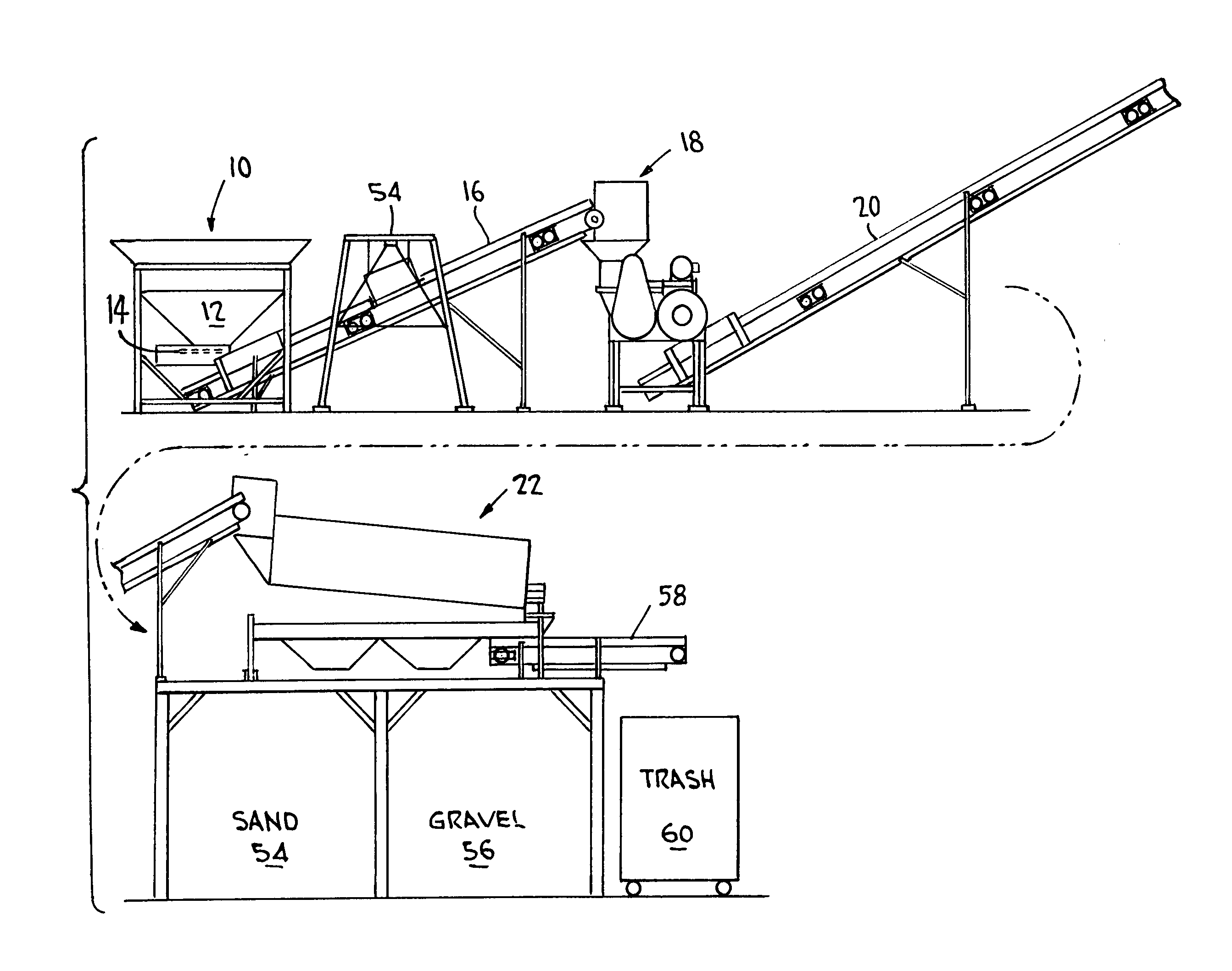

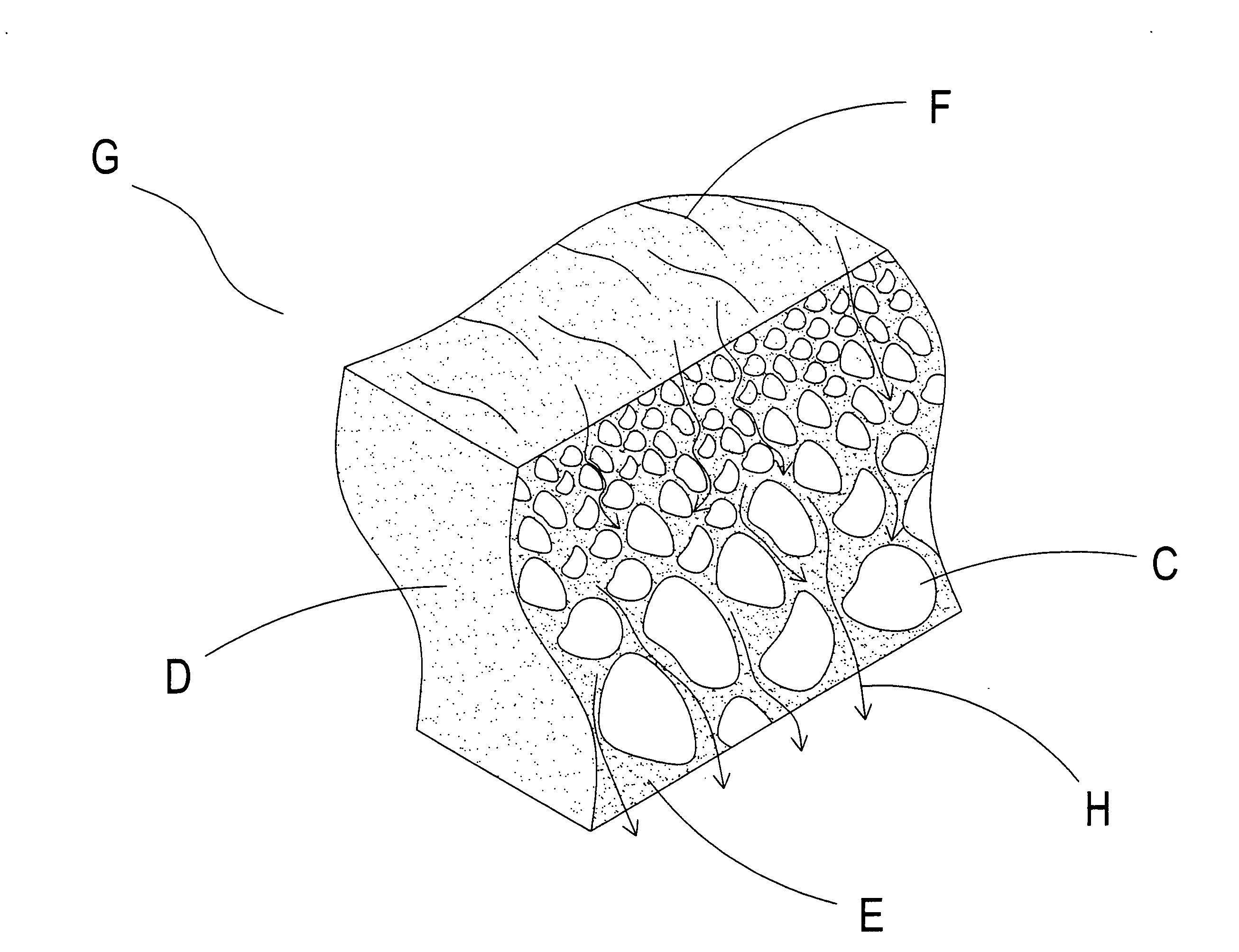

A clean dry glass powder useful as a substitute for Portland cement in concrete, in paints, and for other known uses for glass powder produced conventionally can be produced from unsorted post-consumer waste glass, including a subsatantial fraction of non-glass items, by employing glass pulverizing equipment to reduce waste glass to small fragments, allowing removal of trash, employing a multistep washing process to clean the glass fragments, in the preferred embodiment using aggregate cleaning equipment, drying the fragments, preferably using fluidized bed techniques, and grinding the glass to a desired particle size, preferably using a ball mill, in combination with an air classification step to produce a glass powder of uniform particle size.

Owner:URBAN MINING NORTHEAST

Production of glass powder from waste glass, and products made using the same, especially concrete

ActiveUS20060130707A1Many applicationsSuppress the alkali-silica reactionCocoaGrain treatmentsFluidized bedSmall fragment

A clean dry glass powder useful as a substitute for Portland cement in concrete, in paints, and for other known uses for glass powder produced conventionally can be produced from unsorted post-consumer waste glass, including a subsatantial fraction of non-glass items, by employing glass pulverizing equipment to reduce waste glass to small fragments, allowing removal of trash, employing a multistep washing process to clean the glass fragments, in the preferred embodiment using aggregate cleaning equipment, drying the fragments, preferably using fluidized bed techniques, and grinding the glass to a desired particle size, preferably using a ball mill, in combination with an air classification step to produce a glass powder of uniform particle size.

Owner:URBAN MINING NORTHEAST

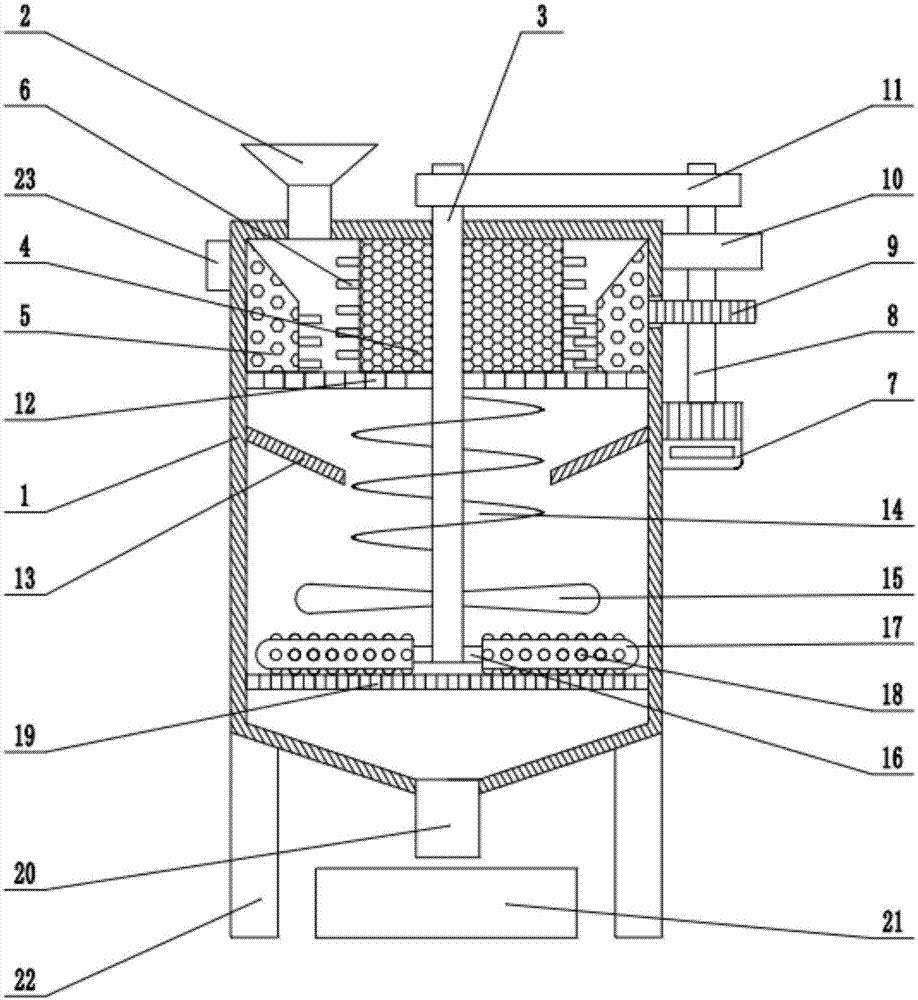

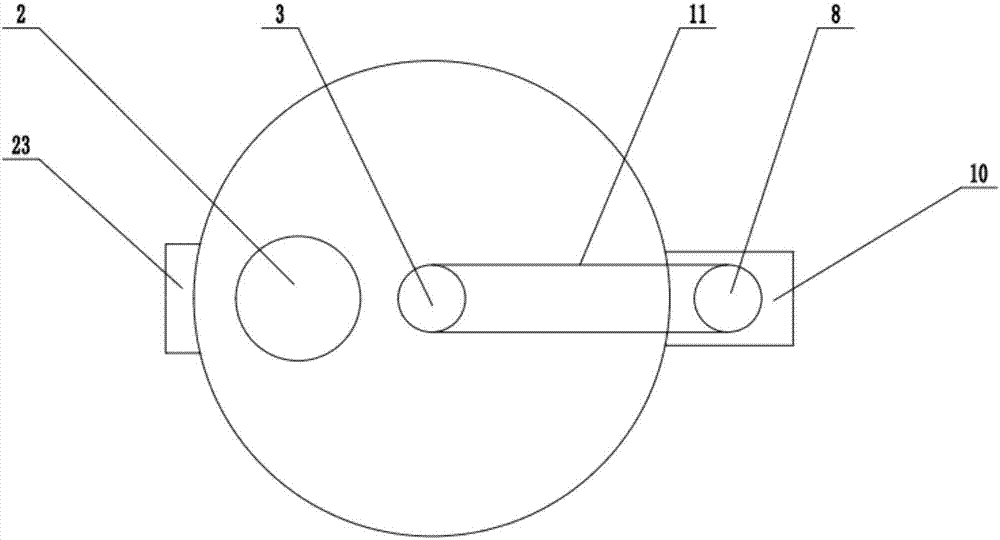

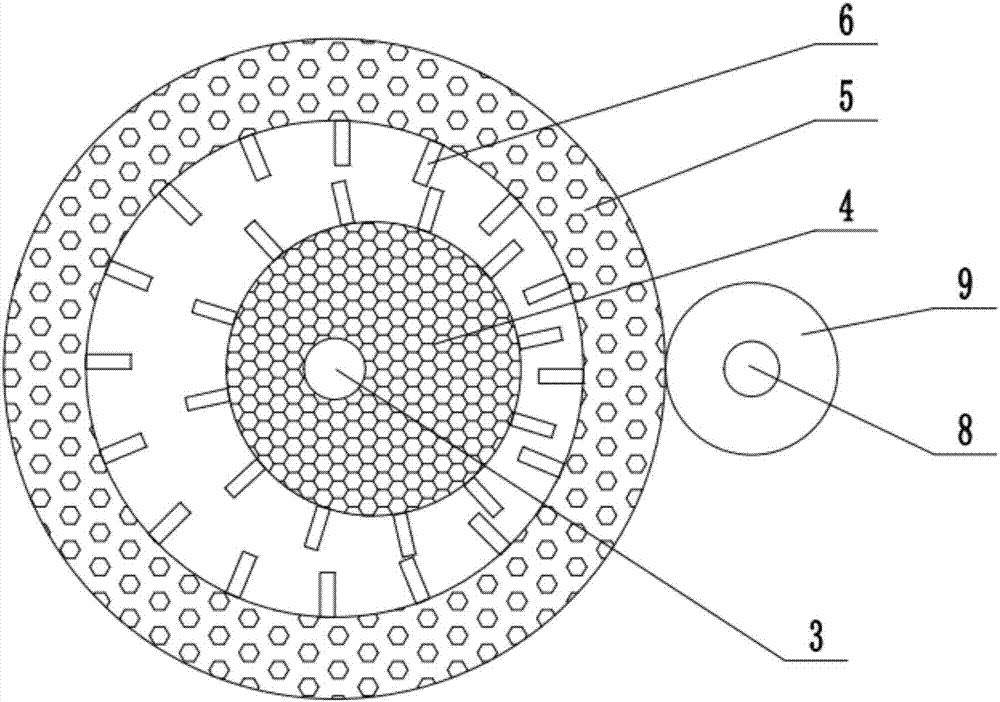

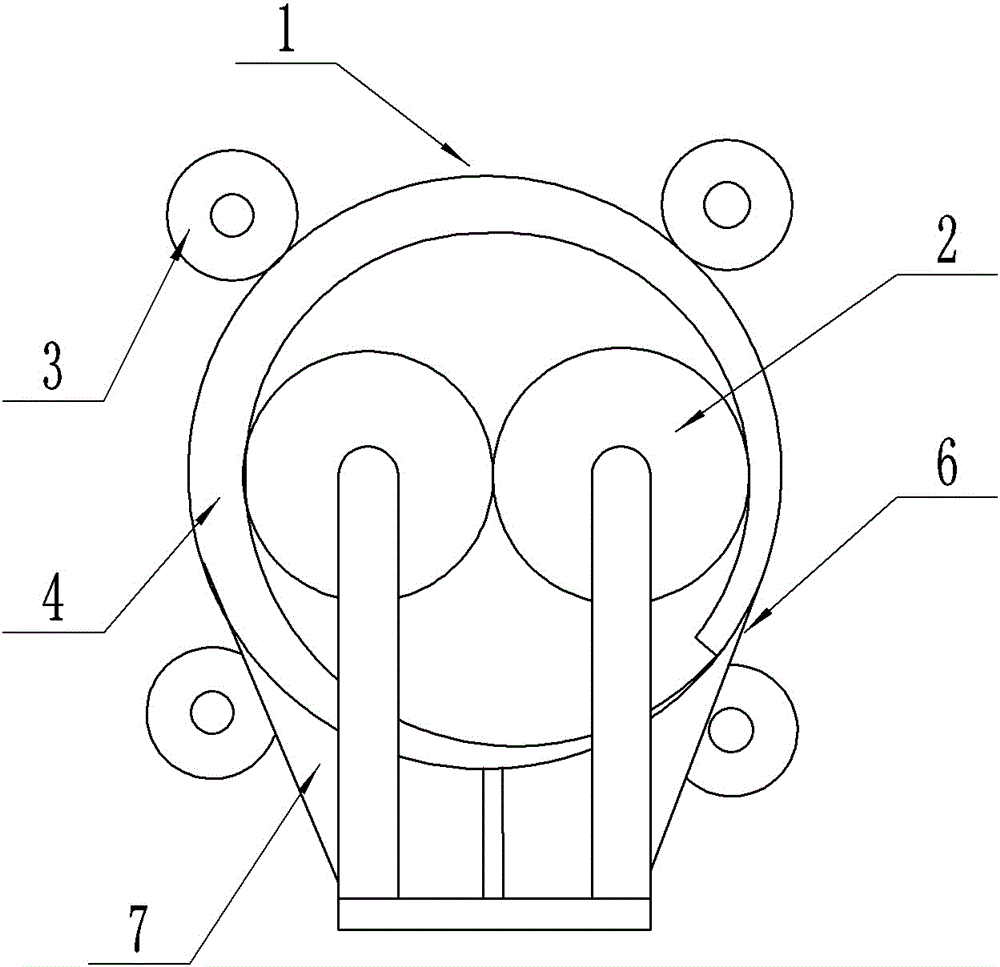

Glass waste grading crushing device

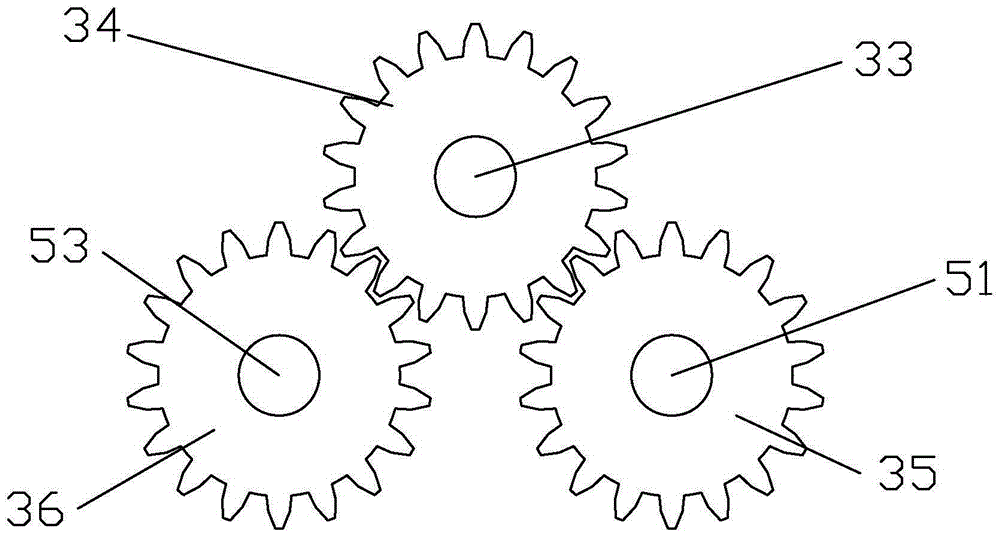

InactiveCN107282259AImprove crushing effectRealize graded crushingGrain treatmentsDrive shaftGear wheel

The invention discloses a glass waste grading crushing device comprising a shell, a feed port, a motor, a discharge port, a collection box and support pillars; the shell is internally provided with a rotating shaft sheathed with an inner crushing barrel, and an outer crushing barrel; the outer wall of the outer crushing barrel is fixedly connected to the motor; the shaft-extension end of the motor is fixedly connected to the rotating shaft which is sheathed with a gear, and a rack is machined at the outside wall of the outer crushing barrel; the upper end of the rotating shaft is connected to the upper end of the rotating shaft through a transmission mechanism, and a first sieve plate is arranged below the inner crushing barrel; and the rotating shaft is fixedly connected to a helical plate below which agitating blades are arranged. Glass waste is extruded by the inner crushing barrel and the outer crushing barrel, and crushed by crushing blades at the same time, so that the crushing effect is good; glass fragments on the surface of a second sieve plate are ground by grinding protrusions to a certain extent, and then the broken glass falls onto the bottom of the shell through the second sieve plate; and thus, the grading crushing of the glass waste is achieved.

Owner:邹铁梅

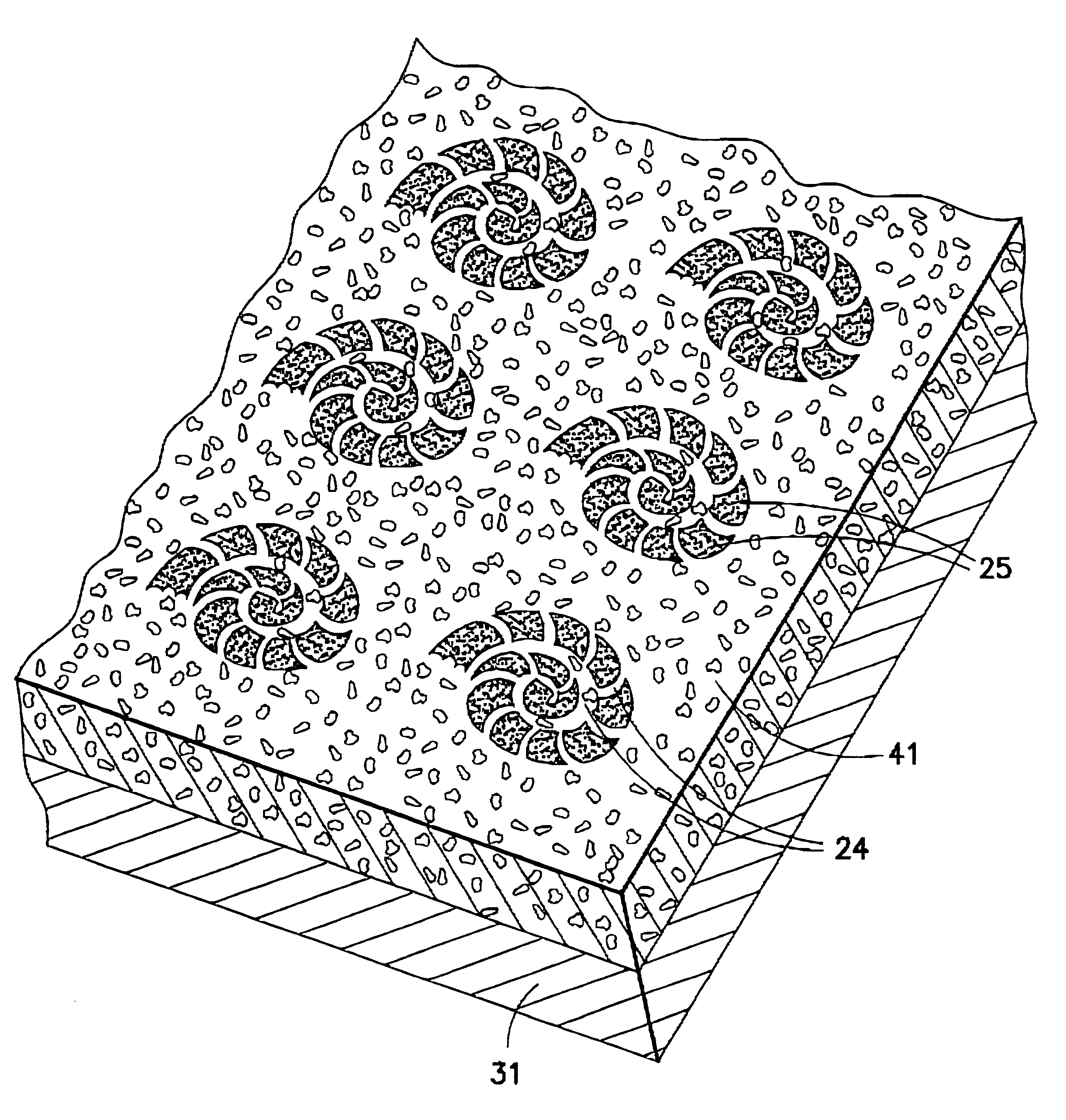

High ornamental environment-friendly type integral seamless grinding stone terrace and manufacturing technique thereof

ActiveCN101168997AImprove wear resistanceExtended service lifeSolid waste managementOrnamental structuresEpoxyWax

The invention discloses a highly decorative environment-friendly integral seamless burrstone terrace and a manufacturing process thereof. After the ground is pretreated through burnishing, etc., epoxy resin varnish is used for bottoming and then epoxy mortar paint is used for basal plane alignment; a die is positioned according to pre-designed patterns, then epoxy burrstone terrace pulp including burrstone aggregate such as shell chips, glass fragments, plastic chips, stained stone chips, etc. is poured into the die, after the pulp is solidified, epoxy burrstone terrace pulp, the colors and (or) the burrstone aggregate of which is obviously different from the pattern layer, is poured outside the pattern layer; after the pulp is solidified, a buffing machine is used for buffing; epoxy resin clear lacquer is coated integrally; finally floor wax is applied all over for maintenance. The process can enable that almost any pattern can be presented on the terrace unrestrictedly, thereby high-lighting the decorative effect of the terrace. The terrace has the advantages of environmental protection, firmness, wear resistance, long service life and chemicals resistance, etc., thereby being widely applied to the decoration and the fitment of the ground of large public buildings and exclusive private residences such as airports, guesthouses, hotels, conference centre, exhibition halls, etc.

Owner:广州秀拍化工涂料有限公司

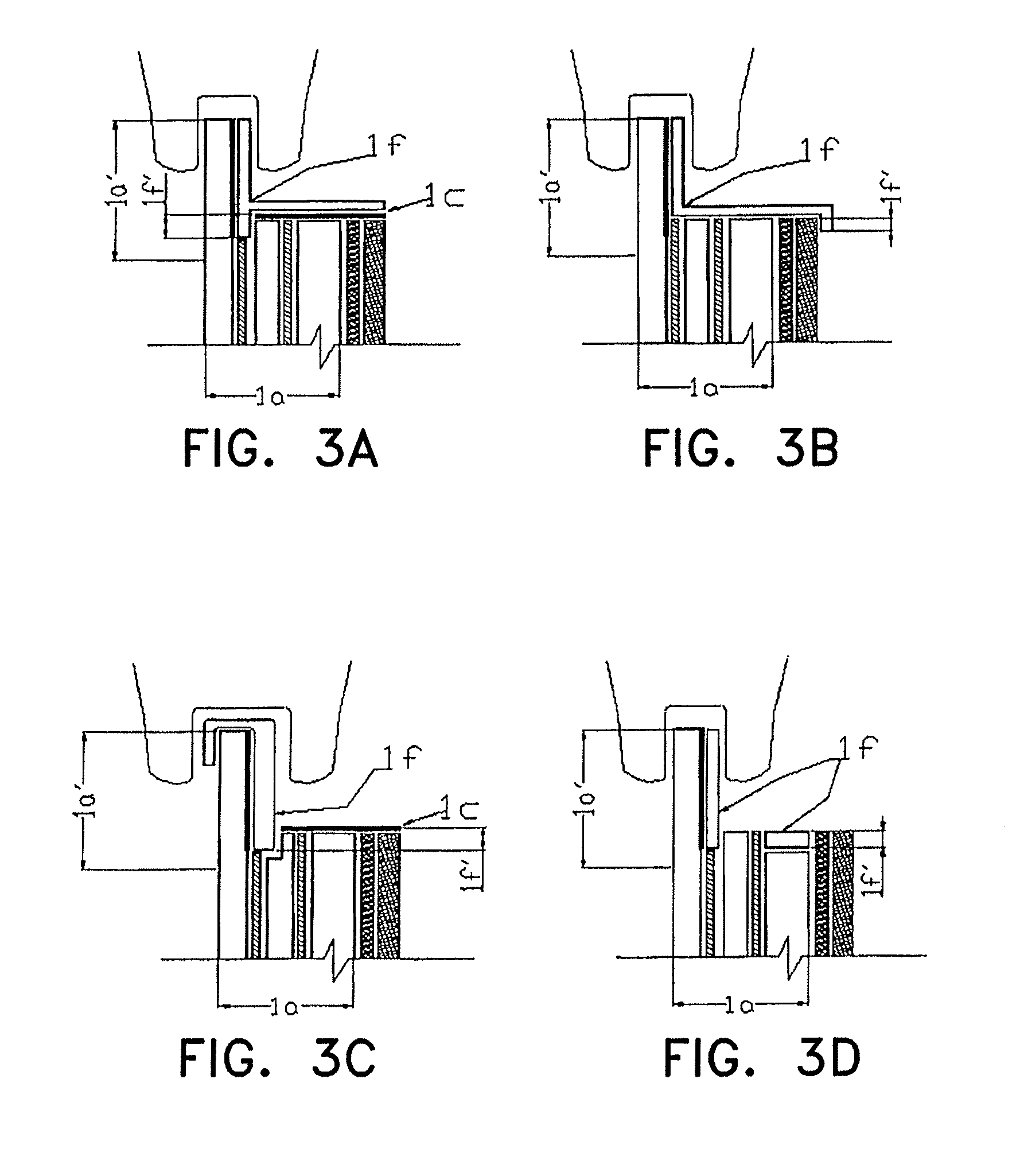

Method of making monolithic terrazzo floors having seamlessly integrated inlays

A method of making terrazzo floors with design inlays. The method utilizes pre-molded inserts as inlays in the finished floor, and generally includes four steps. First, inserts are pre-molded, which has design elements in terms of their color, nature of inclusions (chips, glass fragments, etc. and their colors), shape and / or a pattern of grooves in their upper surfaces. Second, the pre-molded inserts are placed on and affixed to the sub-flooring in a predetermined arrangement. Third, epoxy flooring mixture is poured to a height that fills the grooves in the inserts' upper surfaces and preferably cover the inserts. Fourth, the floor, after cured and hardened, is ground and polished to expose the upper surfaces of the inserts, which now become seamlessly integrated inlays within the overall finished floor. The designs in the inlays are viewable because the inserts contain different visual ingredients (pigments, colored plastic or glass chips, etc) in contrast with the overall floor and they are outlined by the filled grooves.

Owner:SEDAKA ALEN

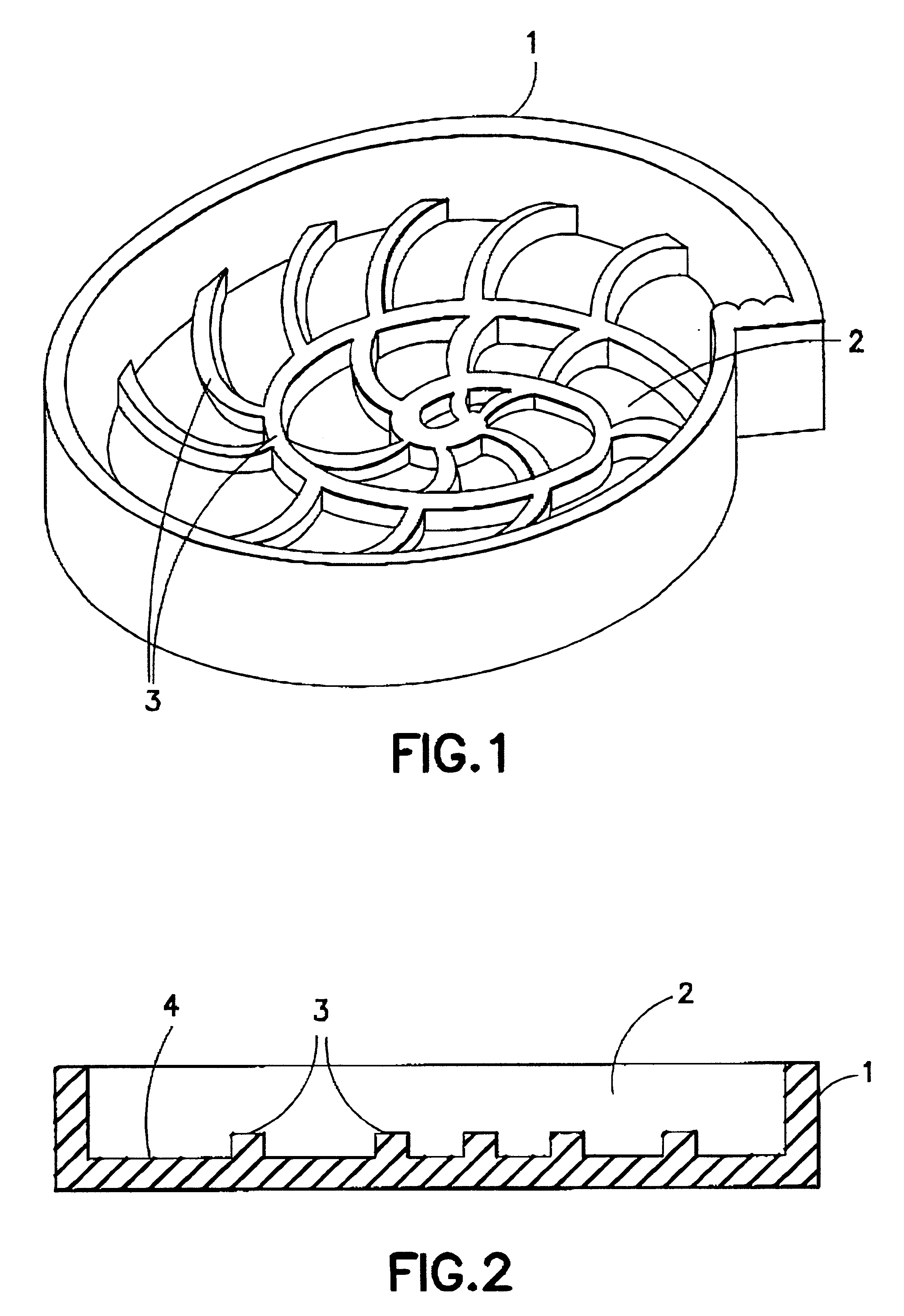

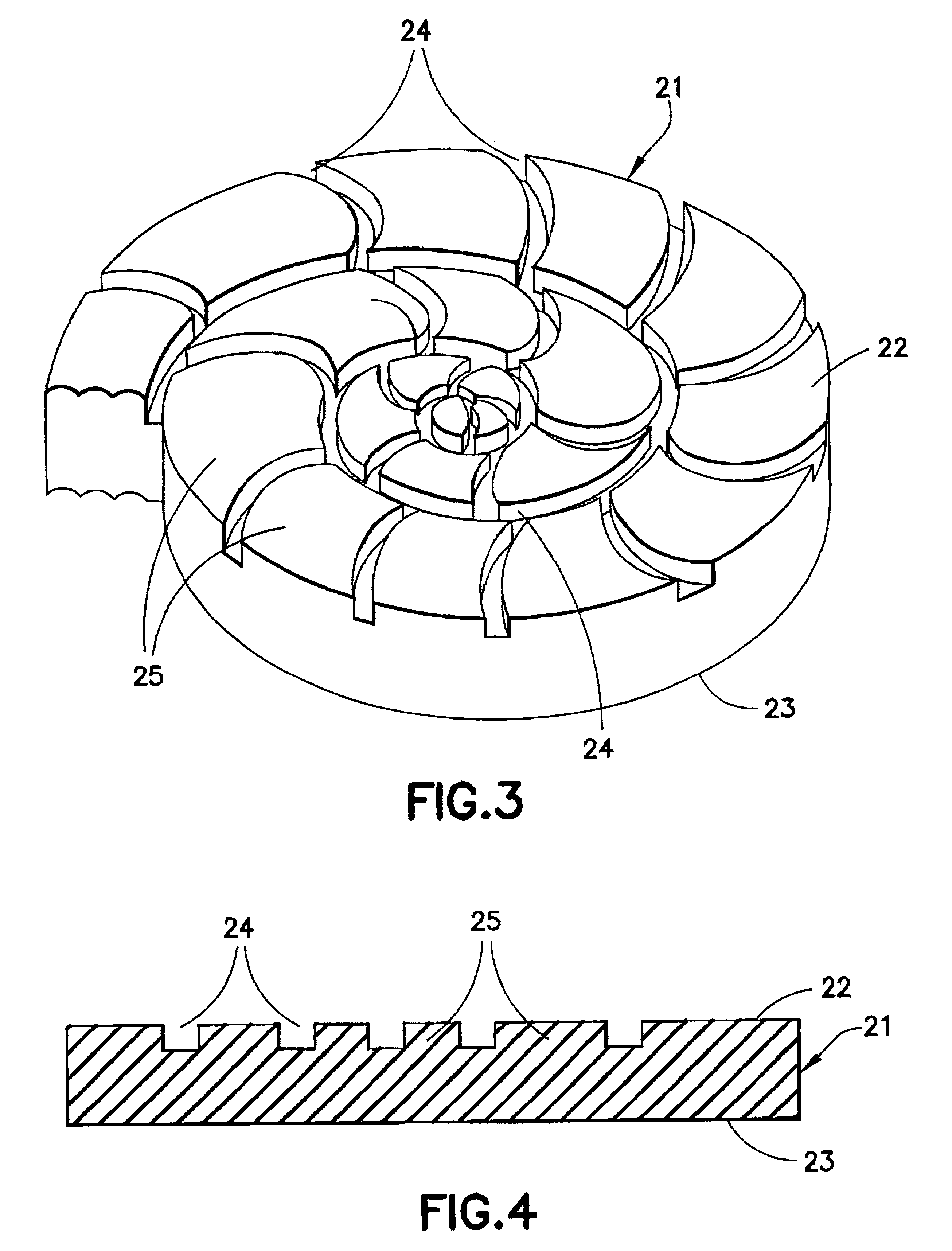

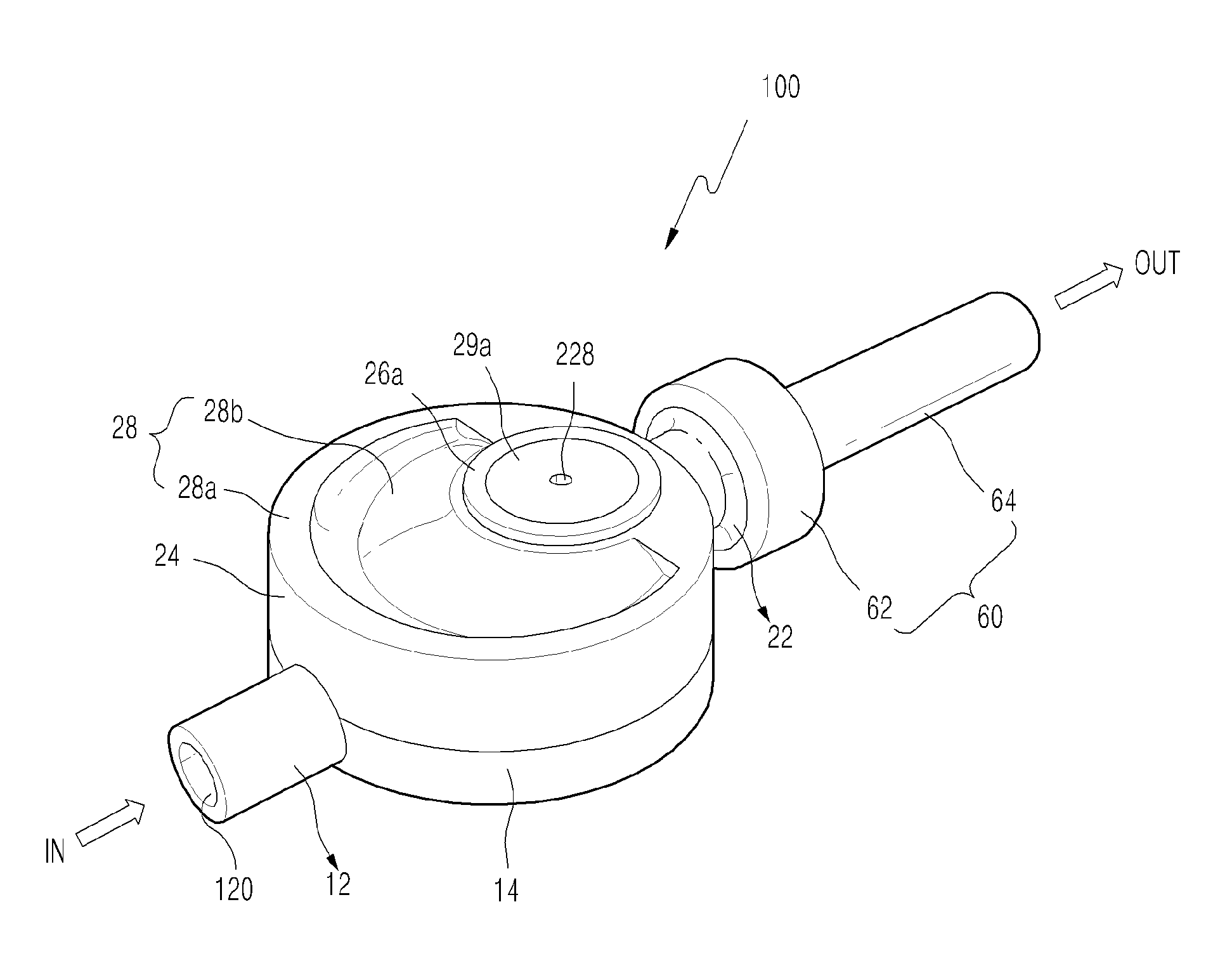

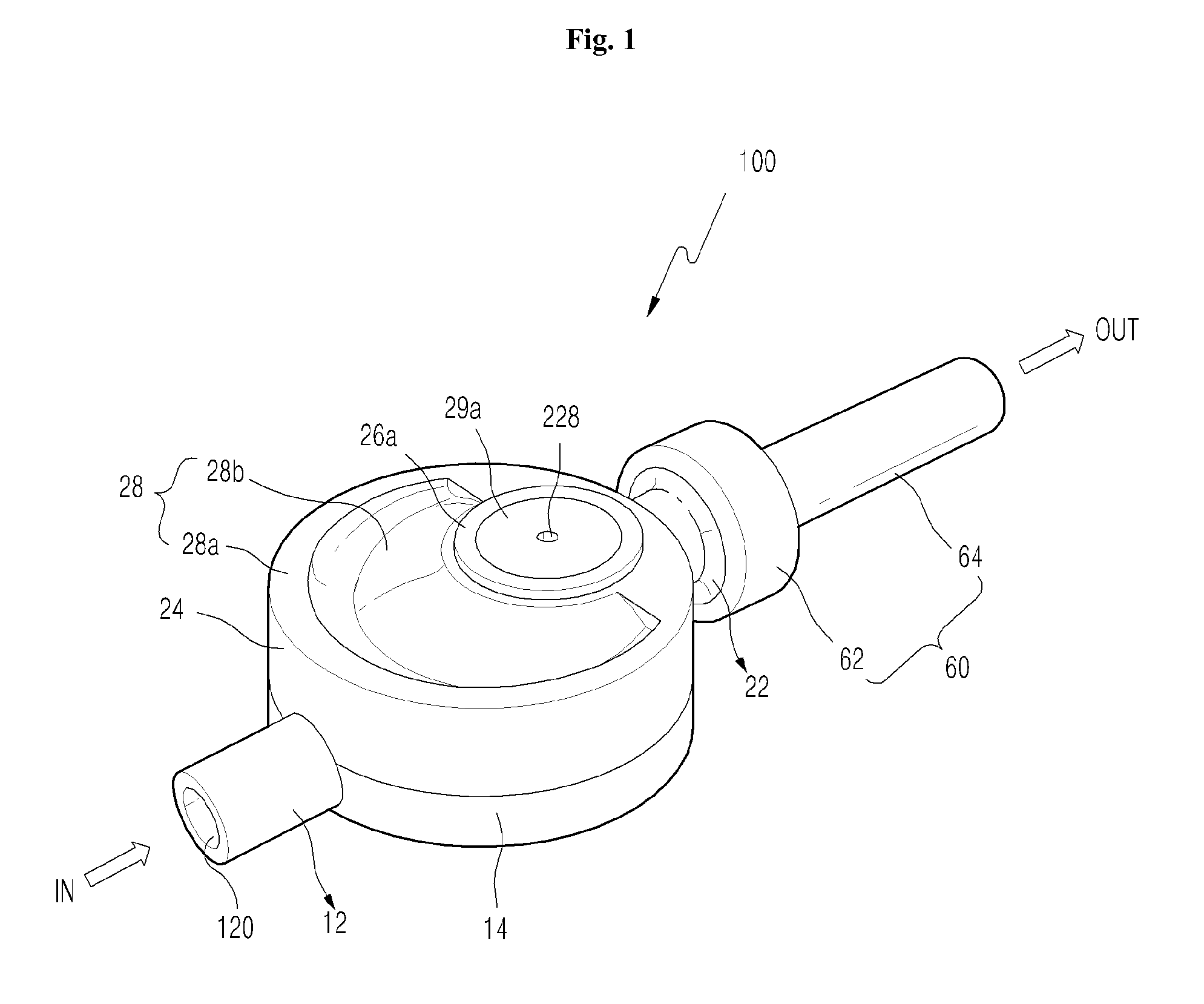

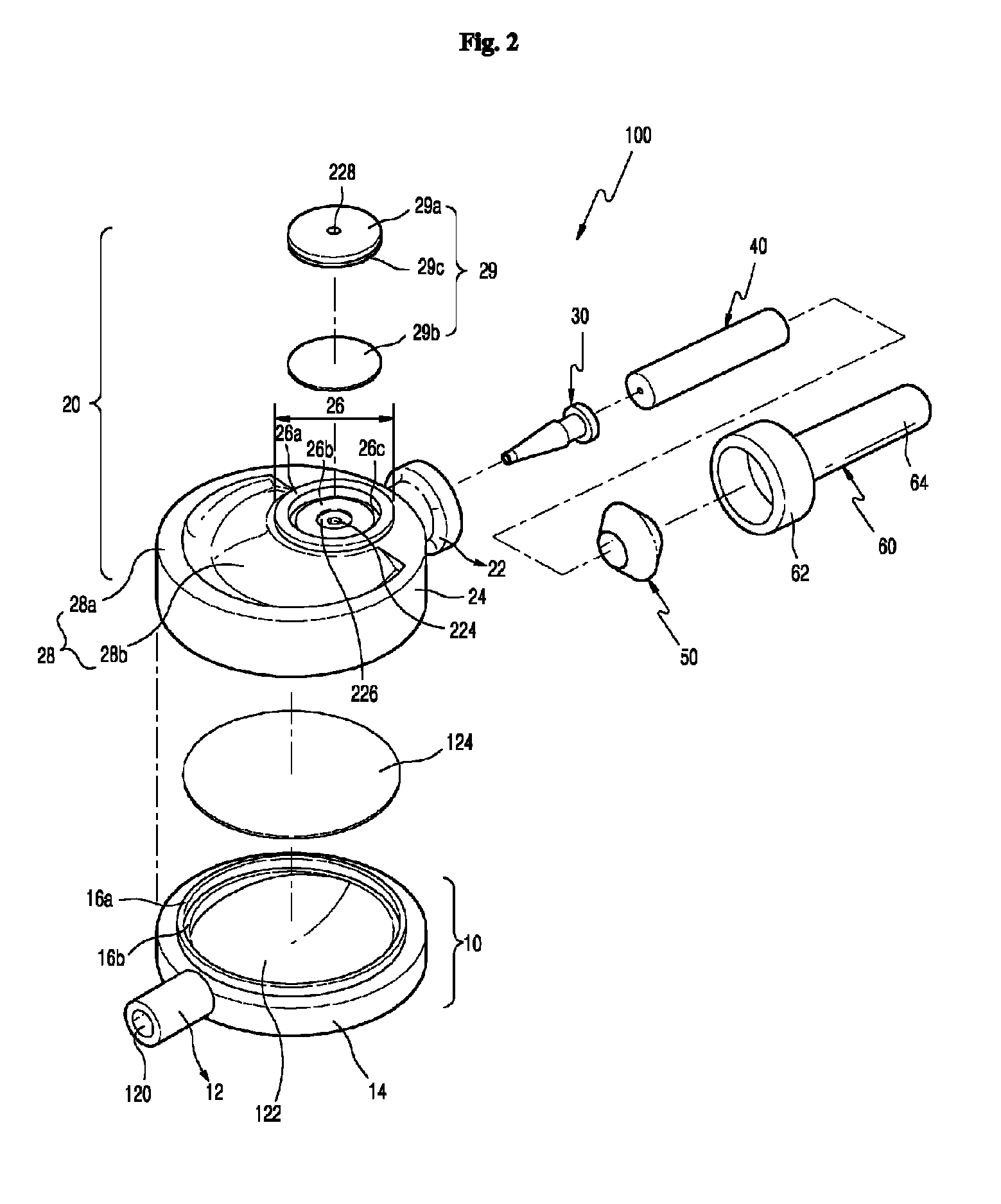

Filter device and liquid injection apparatus having the same

InactiveUS8382712B2Efficient removalAvoid airLiquid degasificationFiltering accessoriesSolid particleGlass fragment

Owner:E WHA FRESENIUS KABI

Drain cover

InactiveUS20070131597A1Improve securityFatty/oily/floating substances removal devicesGround-workGlass fiberYarn

A drain cover is primarily composed of a layer of eco-material paved on the drain cover. The eco-material is made by stirring wastes of irregular shapes (e.g., slag, glass fragments, ceramic or waste gravels) with an adhesive agent and fiber glass yarns. By paving the eco-material on drain holes of the drain cover, trashes and grits can be prevented from flowing into a drain to cause an imperfect draining and a clogging. The wastes after being stirred with the adhesive agent and the fiber glass yarns can prevent insects from crawling out of the drain holes, and can reduce a drifting of odor in the drain. In addition, the wastes of irregular shapes can also increase a slip-proof effect to the drain cover, such that a pedestrian will not be tripped by the drain holes, thereby increasing a safety of walking of the pedestrian.

Owner:CHEN LI HUAN

Artificial quartz plate and production method thereof

The invention discloses an artificial quartz plate and a production method thereof. According to the plate, an artificial stone product is obtained by taking quartz sand, quartz powder and broken glass pieces as main raw materials, adding a coupling agent, an accelerator and a curing agent and bonding and curing by organic resin, wherein the addition proportion of the broken glass pieces can achieve more than 25%. The production method comprises the steps: (1) determining a formula; (2) preparing production equipment; (3) mixing raw materials; (4) paving raw materials; (5) carrying out extrusion forming; (6) performing constant-temperature drying; (7) polishing, cutting, laminating and packaging. The artificial quartz plate product produced by using the method is hard and compact in texture, indeformable, non-cracking, non-discoloring, free from color fading, durable, and simple to maintain. Due to the use of a great amount of broken glass pieces, the influence of waste glass on the environment can be reduced, the produced plate does not contain any pollutant source and radiation source, and is wide in applications, thus being a novel environment-friendly and green building decoration material which has no radiation pollution and can be recycled.

Owner:CENGONG COUNTY HONGYU NEW MATERIALS

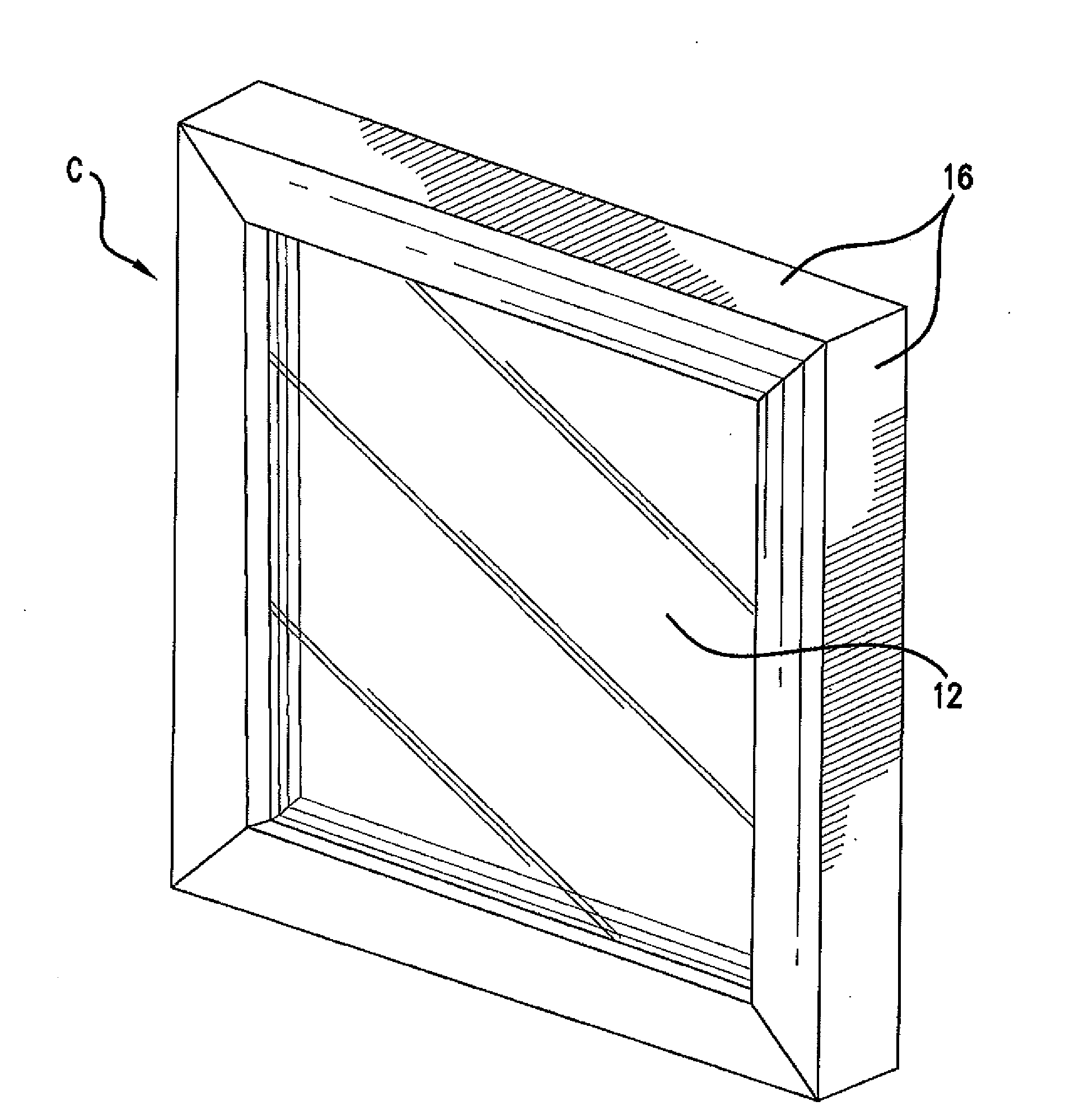

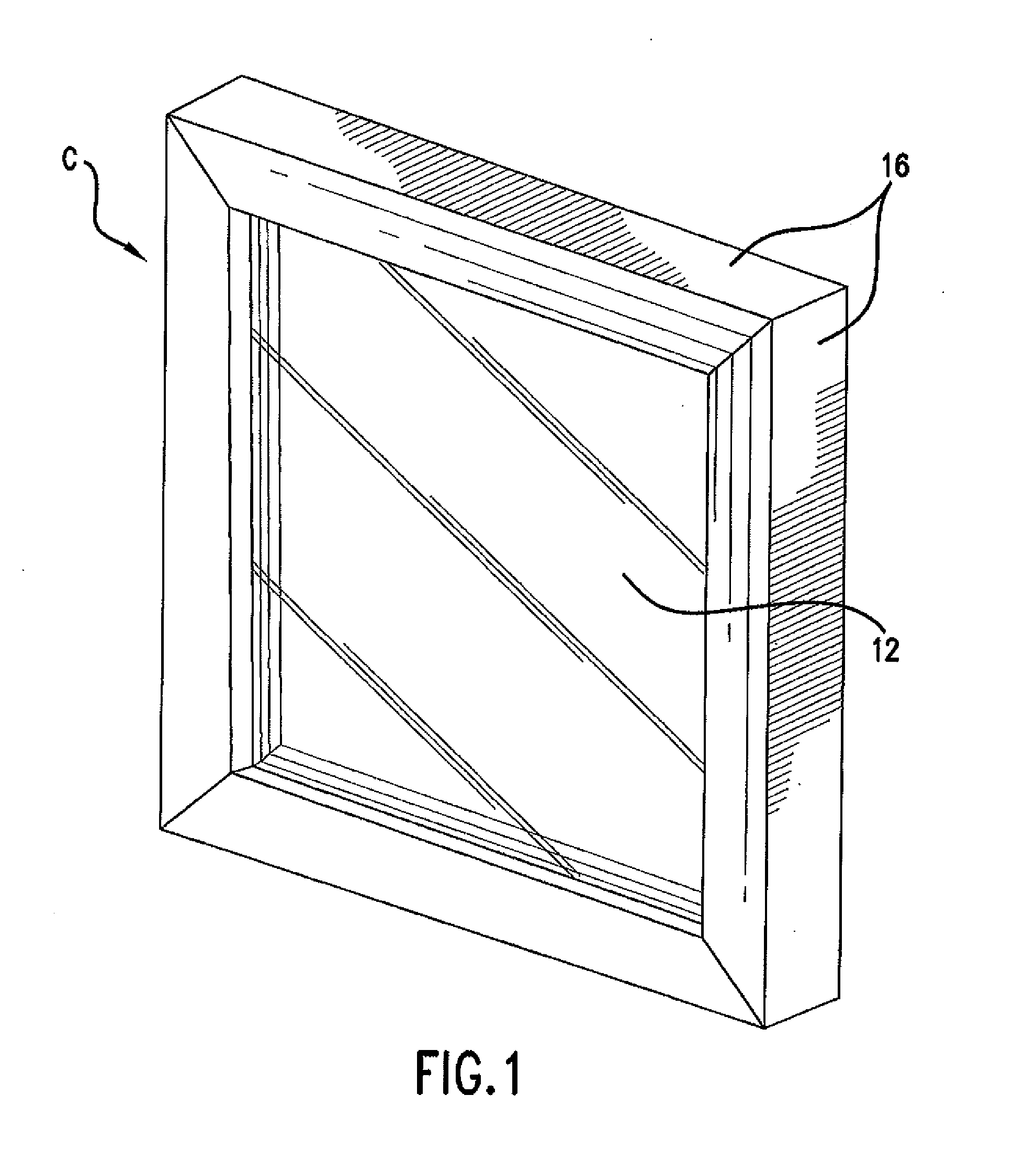

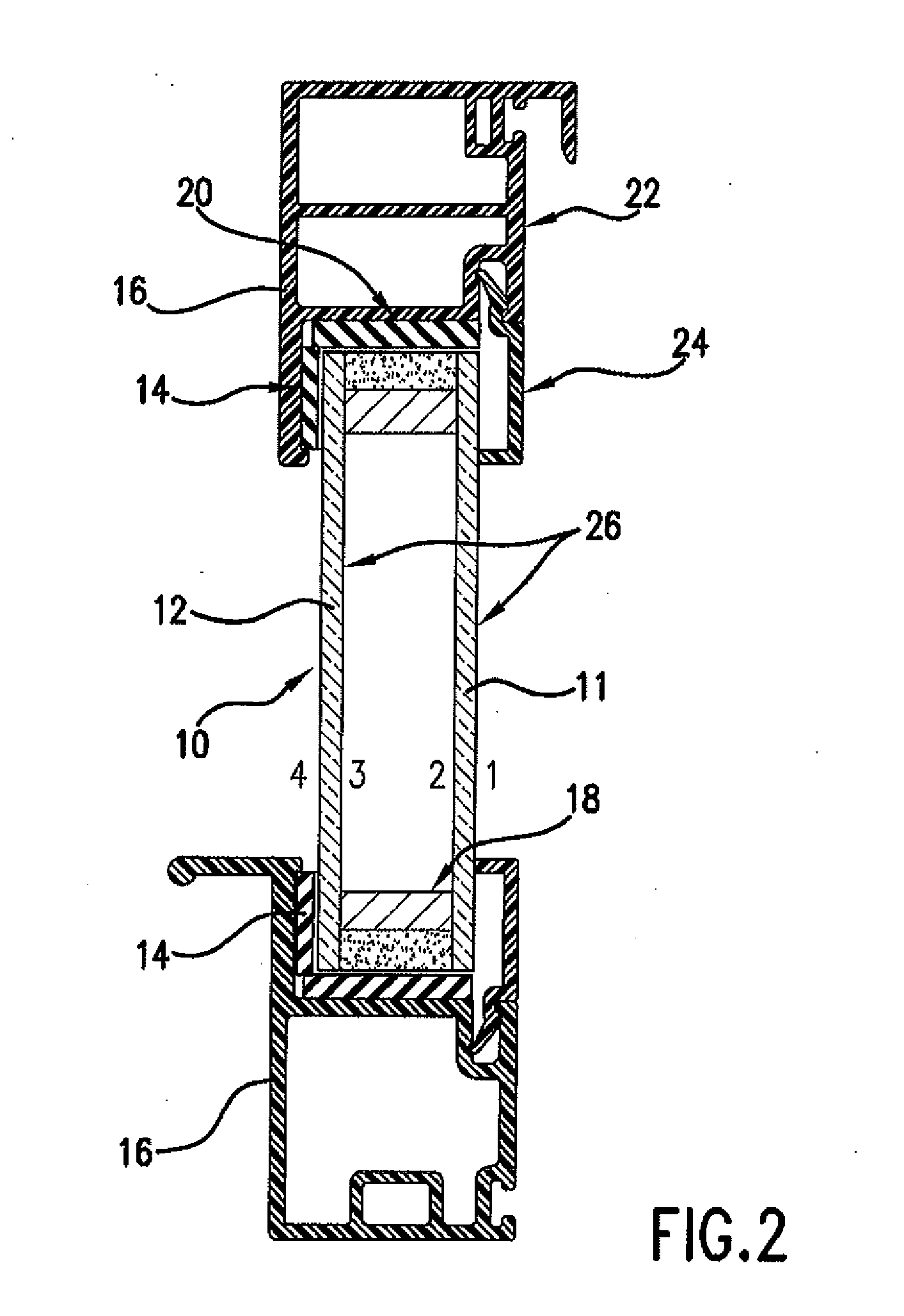

Impact resistant window

A novel impact and blast resistant window is presented. A surface of a glazing pane has a durable transparent polymer film coated or adhered thereto. The surface of the window pane having the film is sealed to the sash by double sided tape. The resulting window produces an unexpected ability for the durable transparent polymer film to retain pieces of broken glass driven toward the interior of the building by a missile striking an exterior of the window, without the durable transparent polymer film pulling loose from the window sash.

Owner:HAWKES DESIGN & CONSULTING

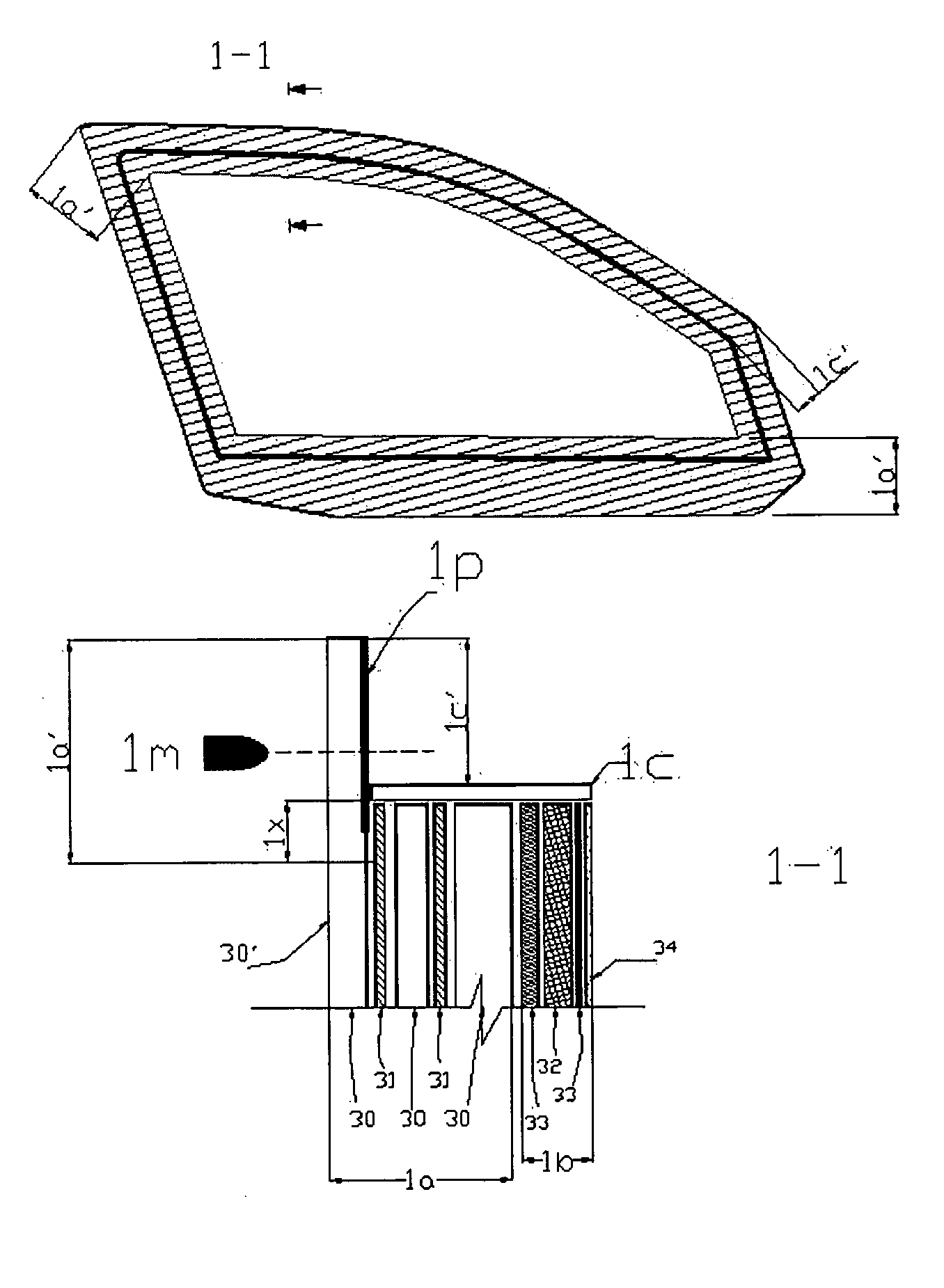

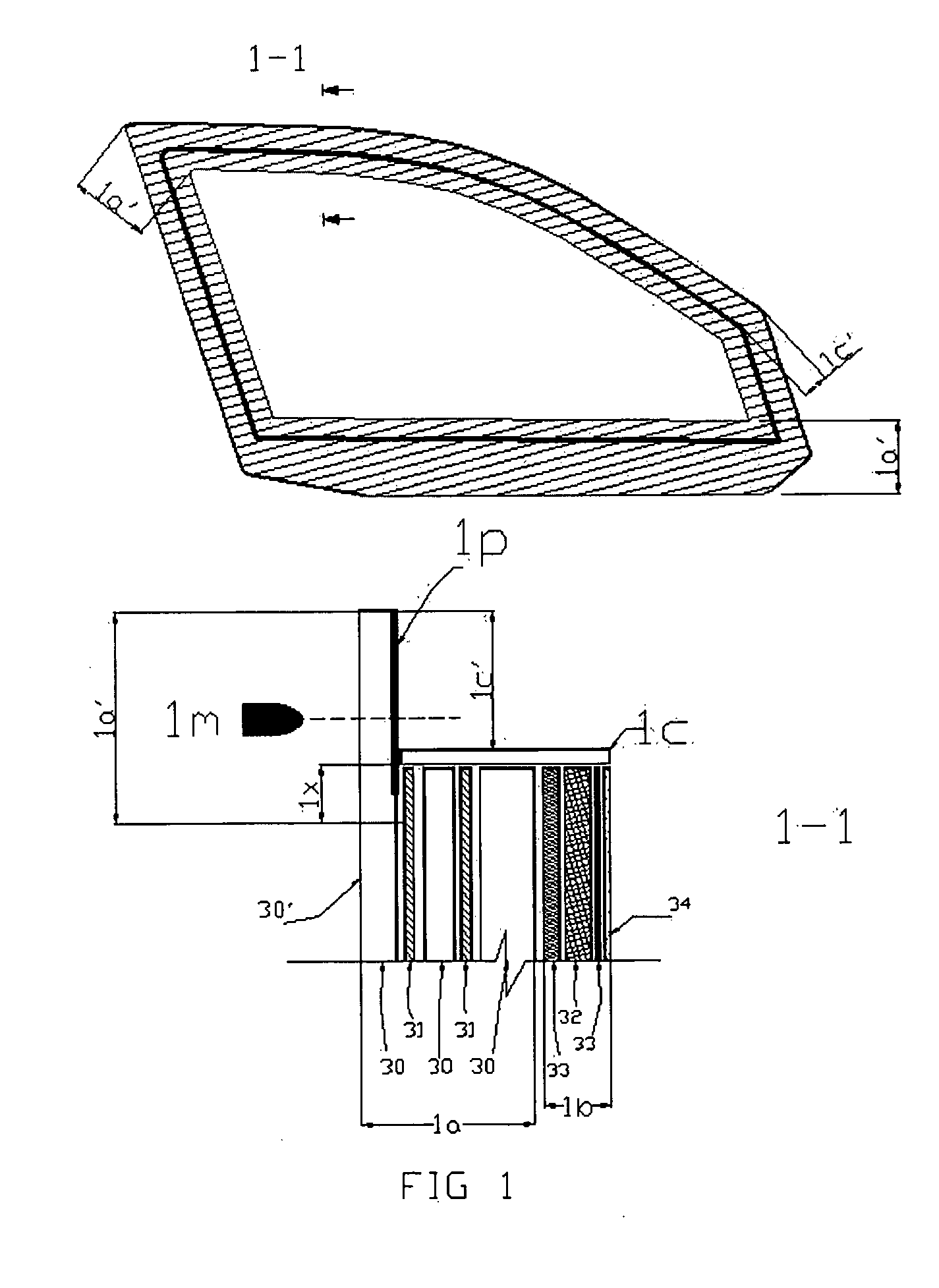

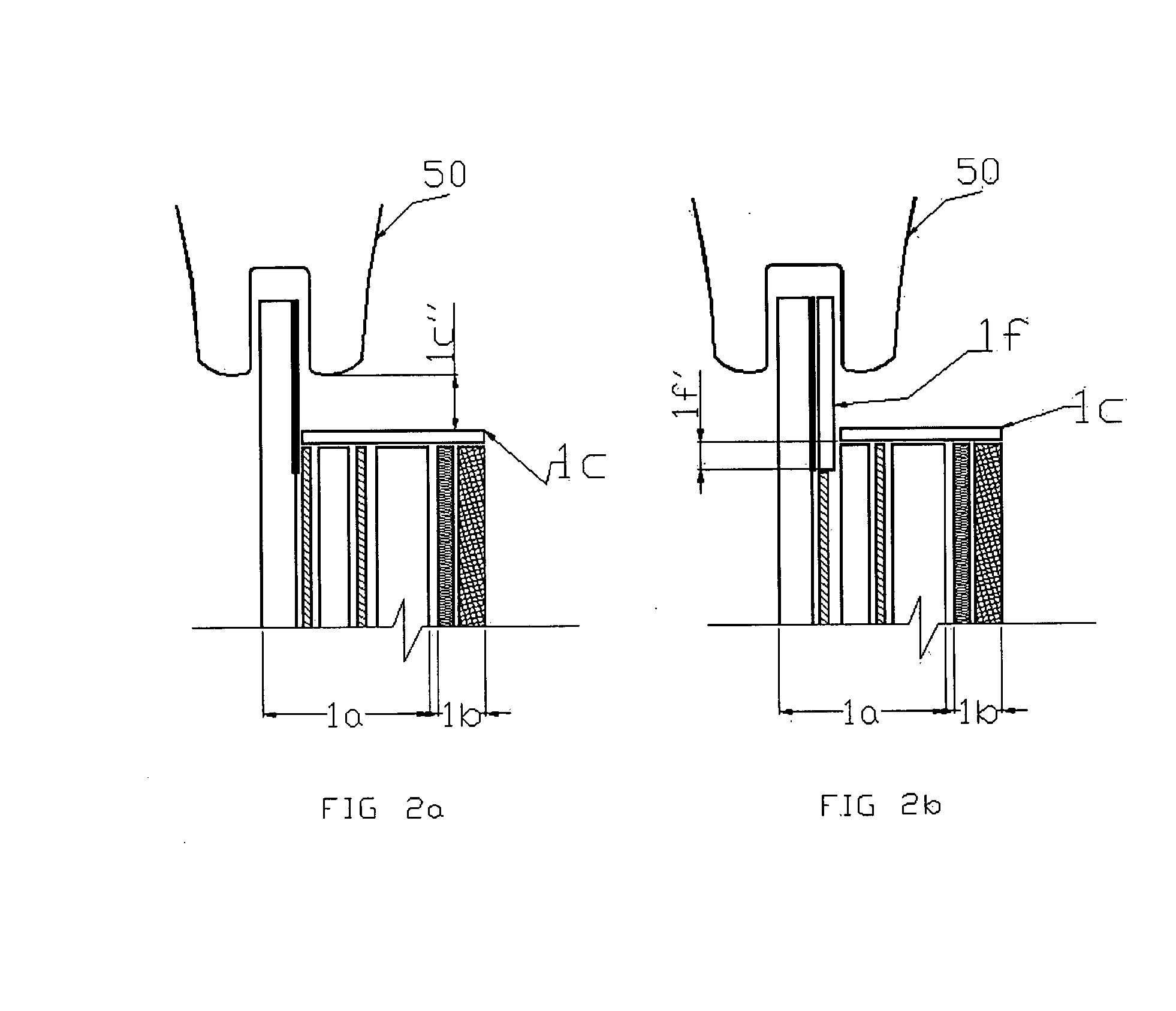

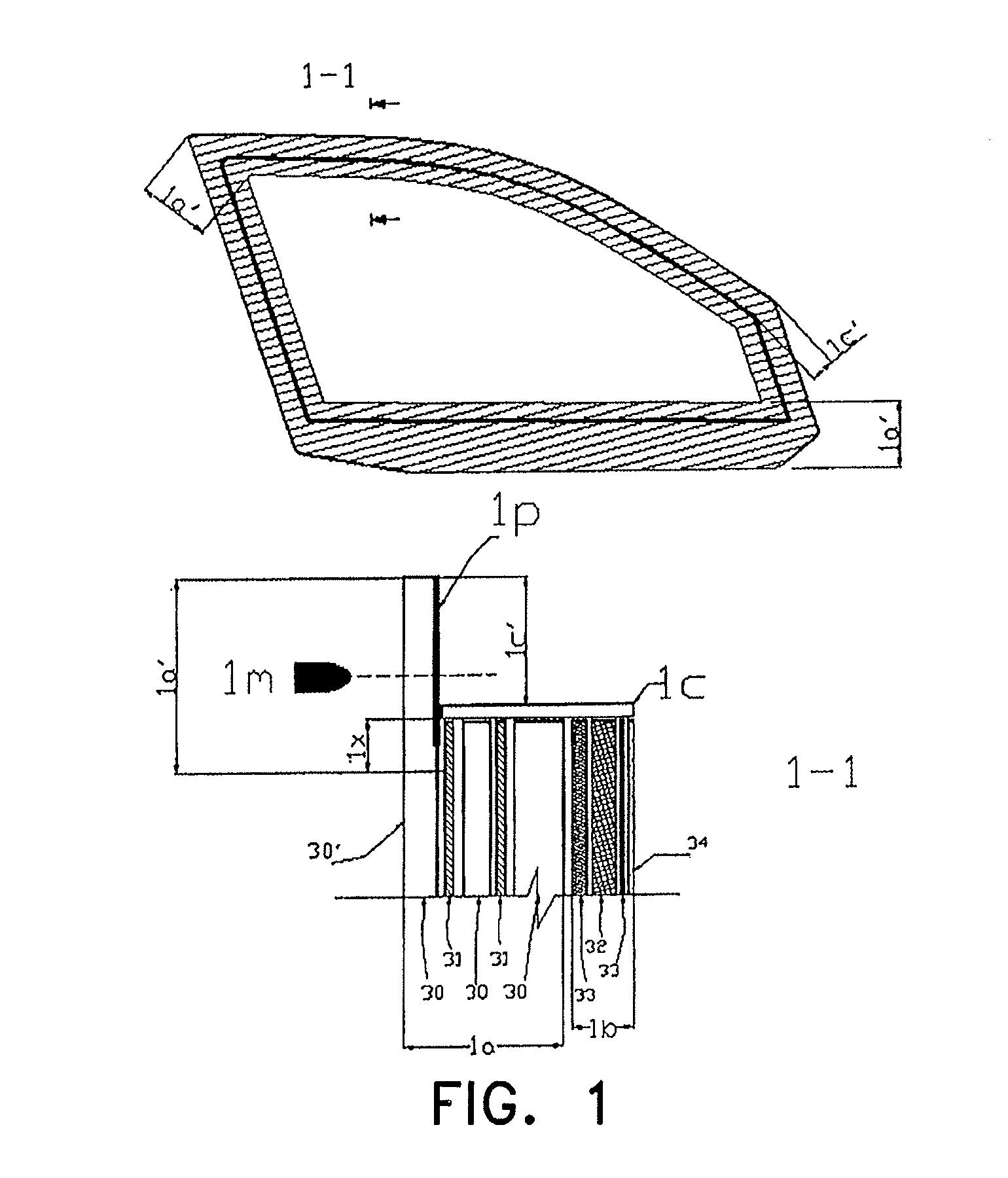

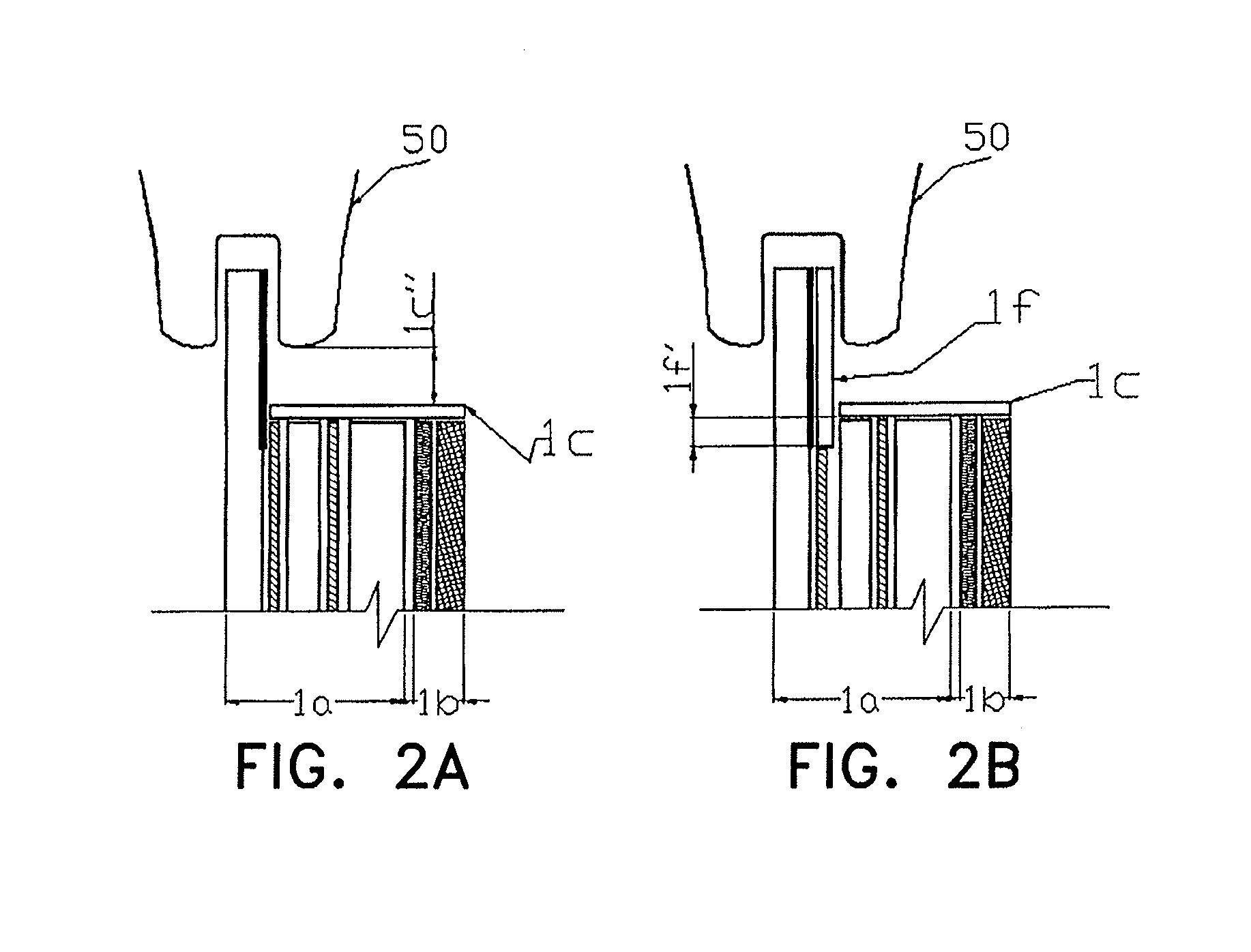

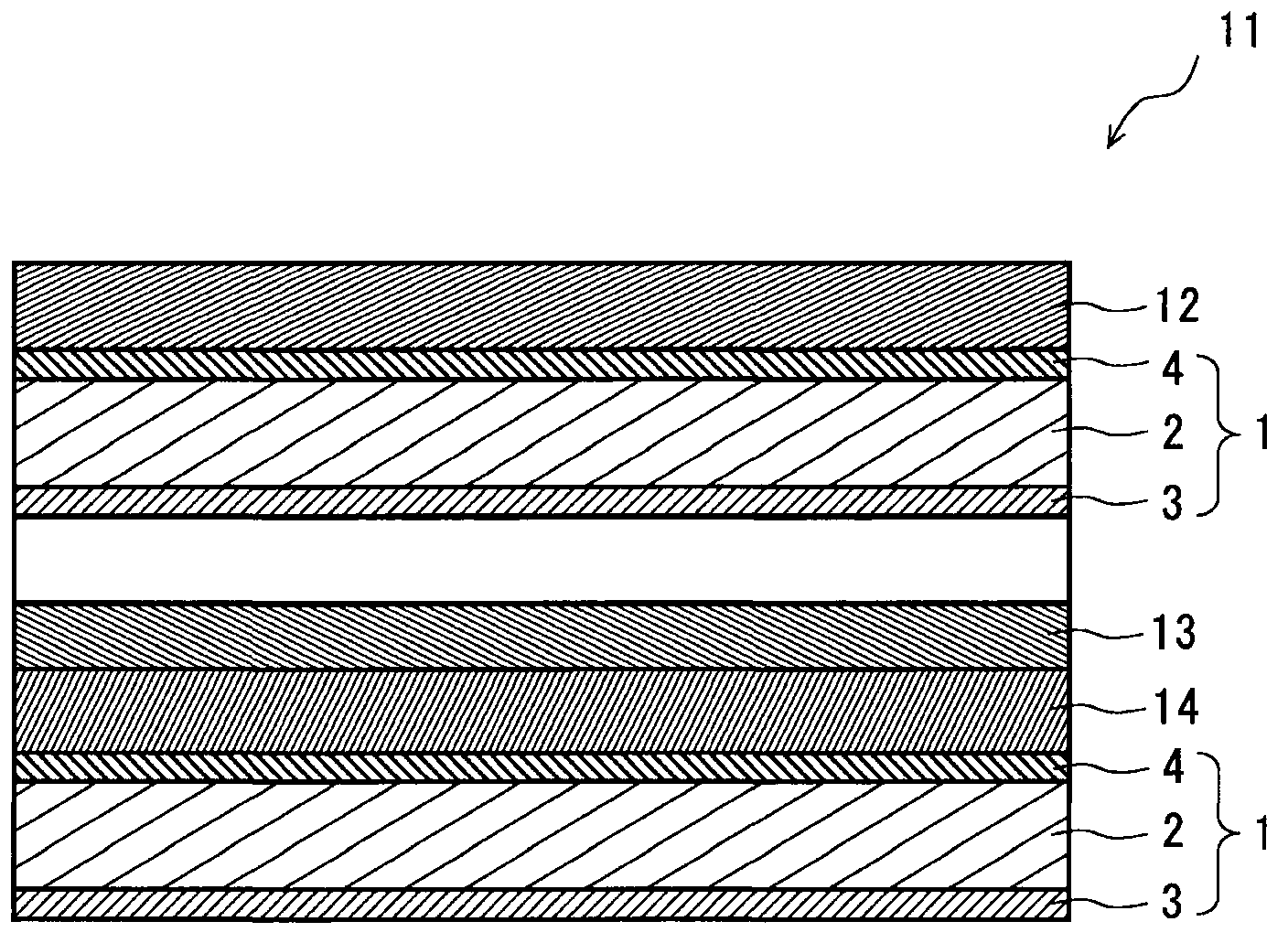

Armored Glass Composition with Perimeter Reinforcement

ActiveUS20080032104A1Effective ballistic solutionEffective ballistic protectionArmourGlass/slag layered productsEngineeringGlass fragment

The invention relates to a special array of materials located on the periphery of a glass armored composition (BRG), with the purpose of having a controlled deformation zone being able to absorb residual energy of impacts made on the edge of the armored piece, therefore providing an effective retention of the projectile and of the glass fragments generated by the impact. The invention provides superior ballistic protection for BRGs destined for automobile applications, for fixed and mobile pieces.

Owner:AGP AMERICA

Protective film for glass

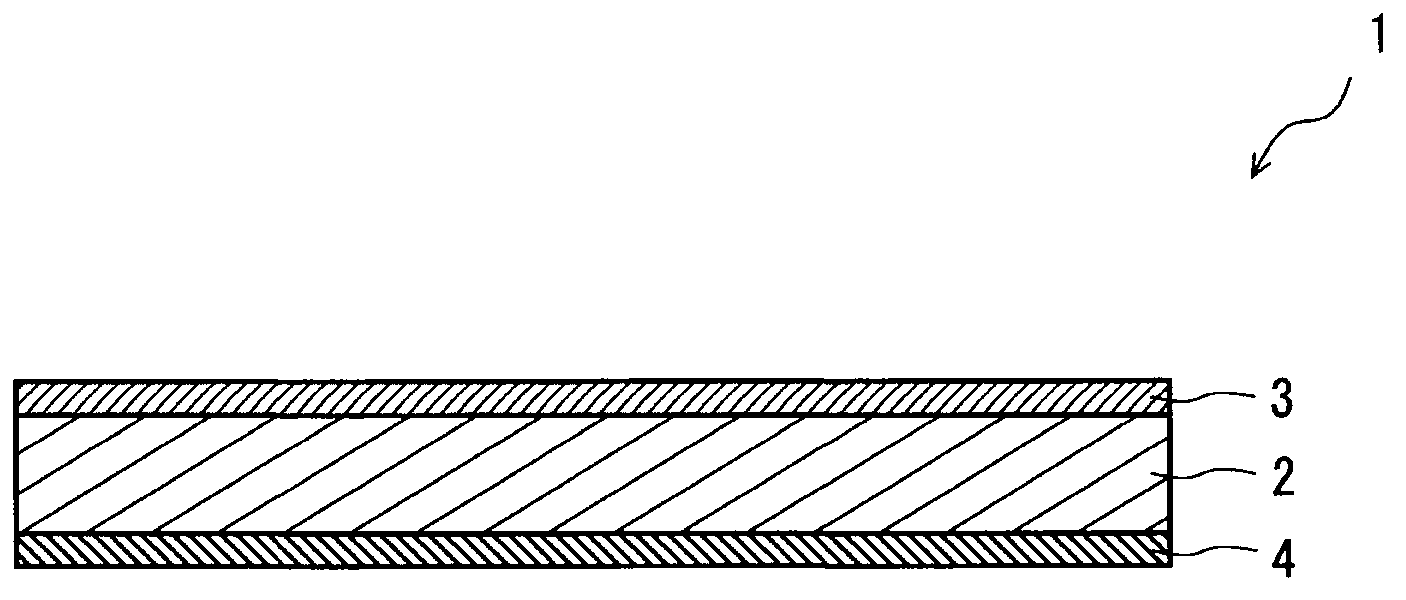

InactiveUS20040247879A1Excels in transparencyExcels in tear resistanceProtective equipmentSynthetic resin layered productsVitrificationTectorial membrane

A glass protecting film comprising at least 5 or more layers, of which at least one layer is the layer which comprises polyester having 1,4-cyclohexane dimethanol is one of the components, and a glass protecting comprising a multi-layer structure which comprises at least two kinds of thermoplastic resin, of which the difference of glass transition temperature is 40° C. or less, the face-impact strength is 18 J / mm or more, haze is 3% or less, are films which excel in transparency, tear resistance, and impact resistance, and are suitable for protecting glass and preventing damaged glass fragments.

Owner:TORAY IND INC

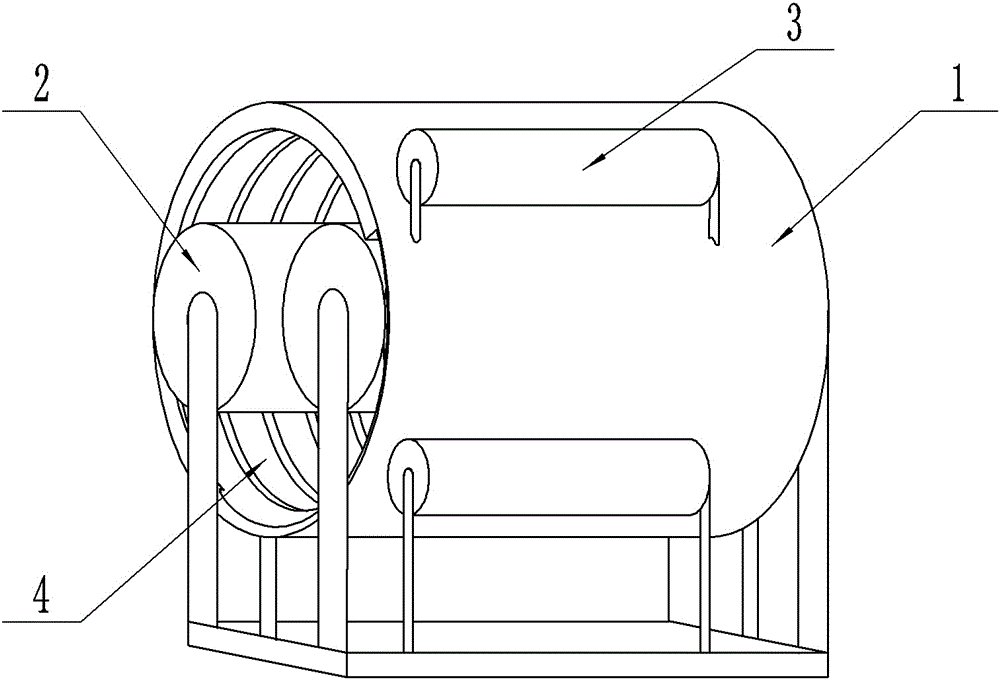

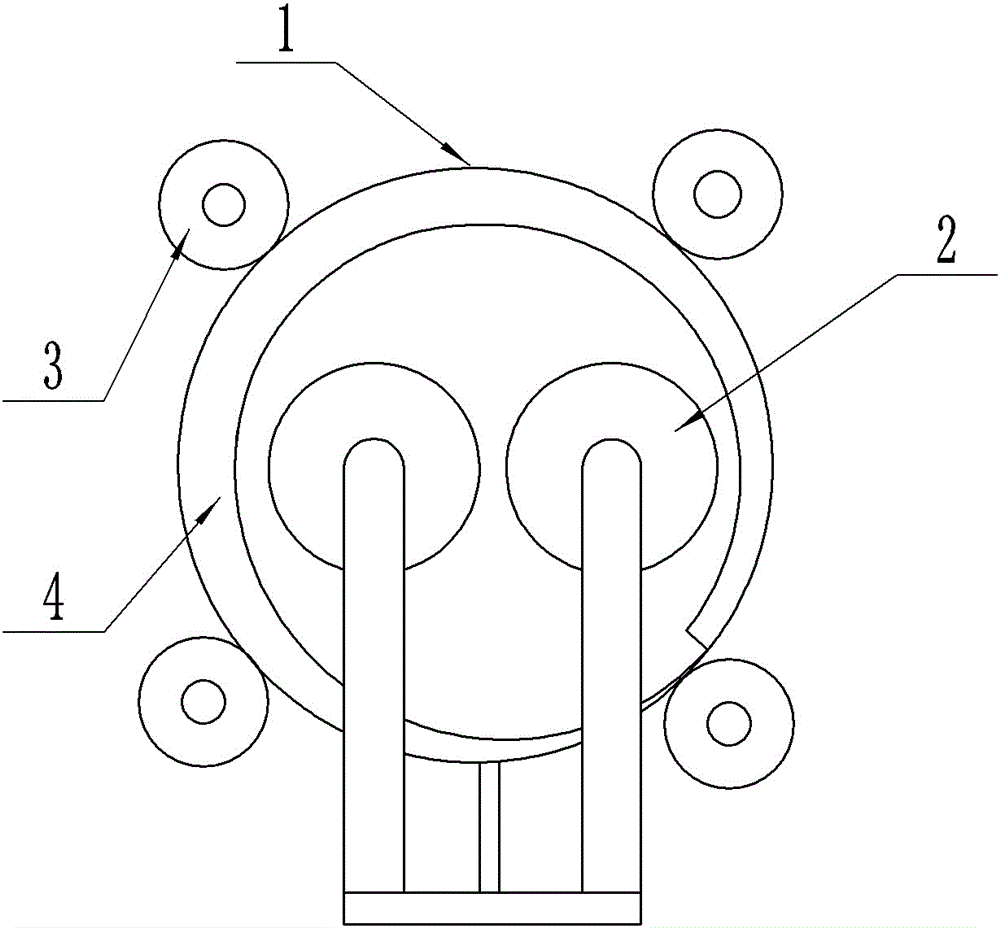

Waste glass crushing device

ActiveCN106694096AOvercome the problem of low crushing efficiencyCompletely brokenGrain treatmentsDrive wheelEngineering

The invention belongs to the technical field of glass processing, and particularly discloses a waste glass crushing mechanism. The waste glass crushing mechanism comprises a control mechanism and further comprises a rack, a rotation feeding barrel and a pair of crushing rollers arranged in the rotation feeding barrel. Drive wheels driving the rotation feeding barrel are arranged on the outer wall of the rotation feeding barrel in the circumferential direction. The rotation feeding barrel, the drive wheels and the crushing rollers are all connected to the rack. A spiral groove is formed in the inner wall of the rotation feeding barrel. The crushing rollers are conical rollers. The diameter of the parts, at the feeding end position of the rotation feeding barrel, of the crushing rollers is smaller than the diameter of the parts, at the discharging end position of the rotation feeding barrel, of the crushing rollers. The rotation feeding barrel, the drive wheels and the crushing rollers are all electrically connected with the control mechanism. Through the arrangement of the device, the problem that in the prior art, the glass crushing efficiency is low is solved, and crushing is more thorough; and meanwhile the quality of regenerated glass manufactured through recycled glass fragments is improved.

Owner:CHONGQING CONGBO ENERGY SAVING GLASS CO LTD

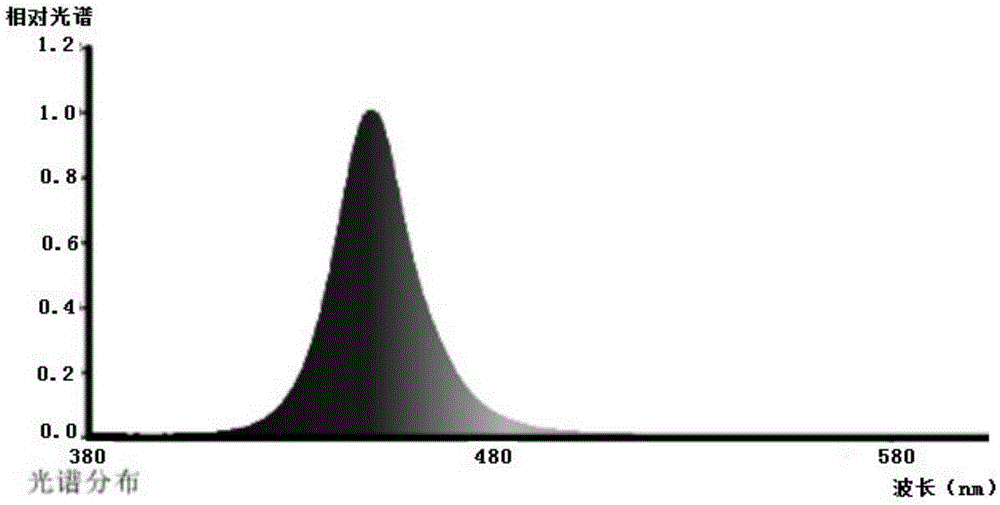

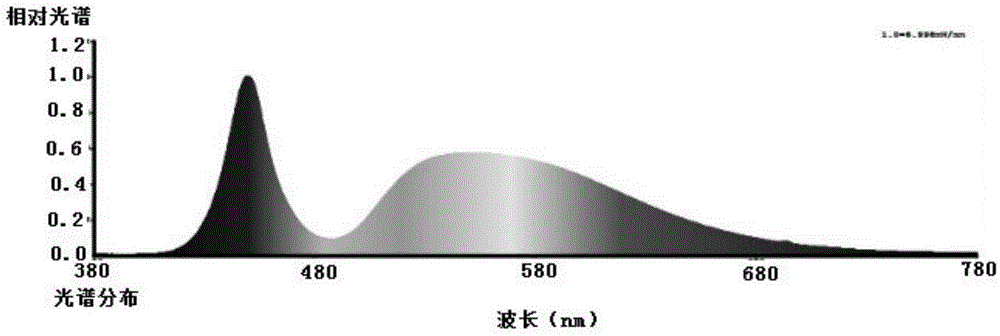

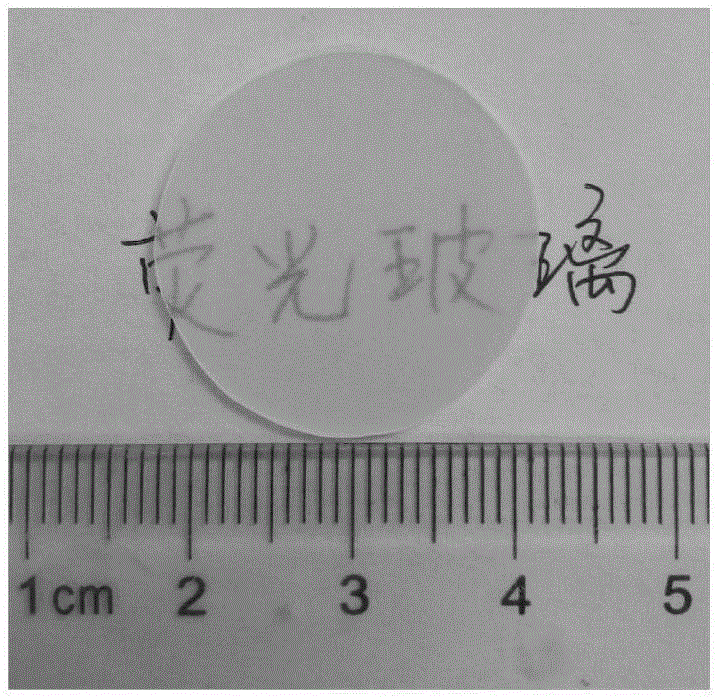

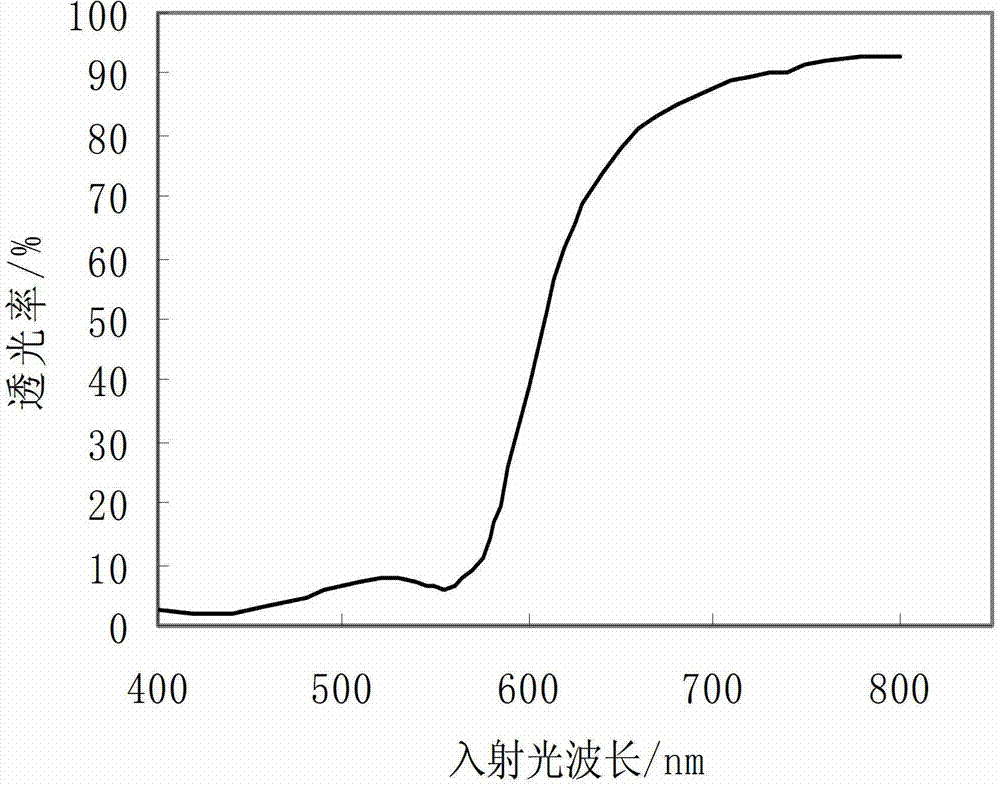

Ce:YAG fluorescent glass for white-light LED and preparation method of Ce:YAG fluorescent glass

The invention provides low-softening-point Ce:YAG fluorescent glass for white-light LED and a preparation method of the Ce:YAG fluorescent glass. According to the Ce:YAG fluorescent glass, Ce:YAG microcrystals are uniformly dispersed in an oxide glass matrix, and the addition amount of the Ce:YAG microcrystals is 1%-20% of the weight of the oxide glass matrix. The preparation method of the Ce:YAG fluorescent glass comprises the following steps: after uniformly mixing multiple oxide powder, and melting, so as to obtain a glass melt; rapidly pouring the glass melt into cold water, so as to obtain glass fragments; crushing and milling the glass fragments into uniform powder, and sieving; uniformly mixing sieved glass powder with Ce:YAG fluorescent microcrystals, heating, taking out the mixture, and forming, so as to obtain a green body; and annealing the green body, so as to obtain the low-softening-point Ce:YAG fluorescent glass for the white-light LED. The Ce:YAG fluorescent glass has the beneficial effects that formula components are few, the raw materials are cheap, the softening point is low, and the preparation process is simple; the Ce:YAG fluorescent glass is applicable to mass production; the obtained fluorescent glass material is high in transparency.

Owner:中科皓烨(东莞)材料科技有限责任公司

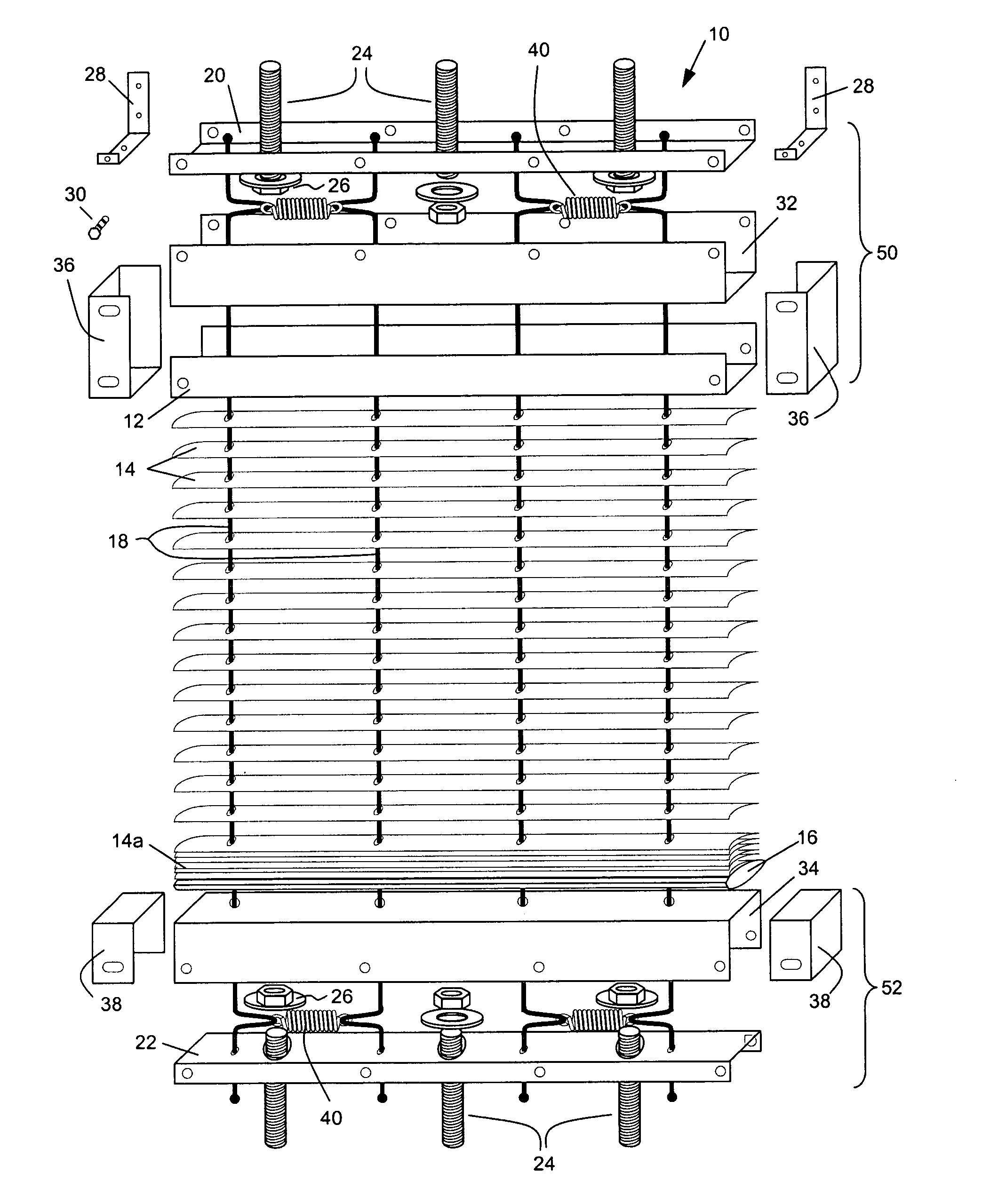

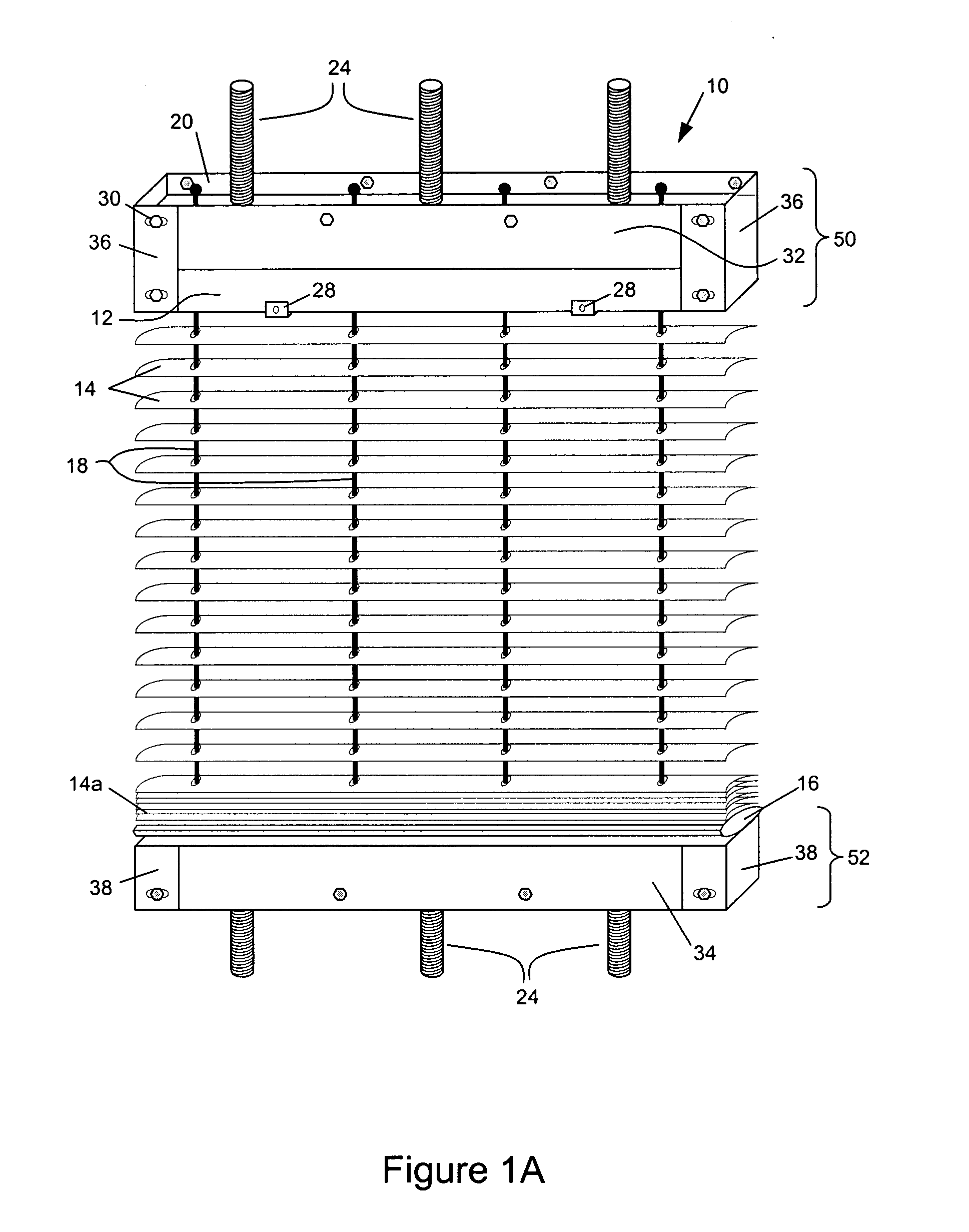

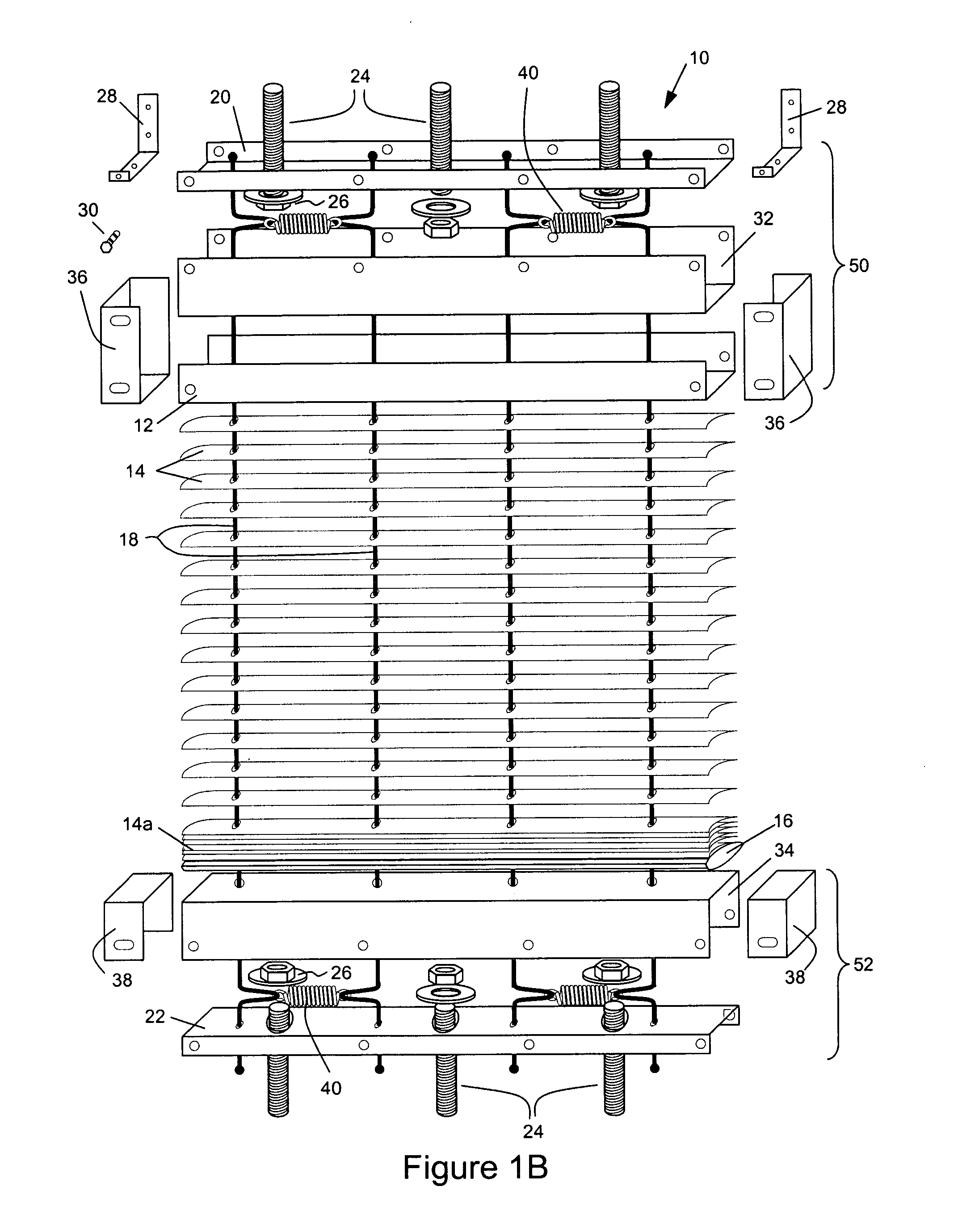

Retrofit glass fragment catching system

A blast resistant window blind system includes a blind system comprising a plurality of parallel blind slats, a plurality of spaced pane engaging members, and first and second mounting bodies coupled to the pane engaging members and anchor members disposed at first and second opposite ends of said opening, wherein the pane engaging members are secured to the mounting bodies and coupled thereby to the structure. At least one energy dampening device is coupled to the pane engaging members, allowing the pane engaging members to extend a selected amount toward the inside of the structure upon impact of the window pane, wherein the blind system and pane engaging members cooperate to restrain the window pane from being blown into the inside of the structure and conform to the inside surface of the window pane during impact therewith to distribute the restraining force across the window pane.

Owner:V GAZAWAY LIVING TRUST A CALIFORNIA TRUST +1

Regenerative ceramic tile and producing method thereof

The invention discloses a regenerative ceramic tile and a producing method thereof, which belongs to the field of building materials. The regenerative ceramic tile is prepared by mainly comprising the steps that discarded electrolytic manganese waste-residues of electrolytic manganese factories, discarded porcelain tile polishing waste residues of ceramics factories and waste glass fragments are taken as raw materials, after electrolytic manganese waste-residues, porcelain tile polishing waste residues and waste glass dust subjected to natural air-drying are uniformly mixed according to certain proportion, the obtained mixture is subjected to compression molding, and then a regenerative ceramic tile is produced by using a high-temperature fast burning process. By using the technical scheme of the invention, because all the product raw materials come from industrial waste residues, the regenerative ceramic tile is an effective way for carrying out recycling reutilization on industrial solid wastes and solving the environment pollution problem of the regenerative ceramic tile. The regenerative ceramic tile disclosed by the invention is simple in production technique and high in product quality, can be widely applied to the laying of building walls, roads and squares, and has good social, economic and environmental benefits.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method for colored glass beads

InactiveCN102898003AAvoid the disadvantages of single color, unstable color, high production cost, etc.Improve efficiencyGlass shaping apparatusGlass productionGlycerolSlurry

The invention provides a preparation method for colored glass beads; and the preparation method comprises the following steps of: after uniformly mixing SiO2 powder, CaO powder, Na2O powder, K2O powder, Al2O3 powder, ZnO powder and Sb2O3 powder, forming a batch material; pouring a glass liquid after the batch material is melted into water, quenching the glass liquid in the water; grinding water-quenched glass fragments to a particle size of 10-200 microns; and then nodulizing the ground glass fragments in a bead forming furnace, so as to obtain a parent glass bead; pouring water, glycerol and dextrin into a beaker; after uniformly mixing the water, the glycerol and the dextrin, adding a mixture to a mixture of AgNO3, CuCl, Cu2O, SnO, FeSO4.7H2O, zinc powder and pulverized coal; uniformly mixing the two mixtures; and ball-milling the mixtures so as to obtain a coloring ion diffusion slurry for a colored glass bead; and mixing the parent glass bead and the coloring ion diffusion slurry so as to form a mixed material; pouring the mixed material into a stainless steel mold; heating the stainless steel mold to 550-650 DEG C; preserving the heat of the stainless steel mold for 5-10 minutes; and cooling the stainless steel mold so as to obtain ion diffused and colored glass bead. According to the invention, defects of single color, instable color, high production cost and the like in the traditional preparation method are avoided.

Owner:SHAANXI UNIV OF SCI & TECH

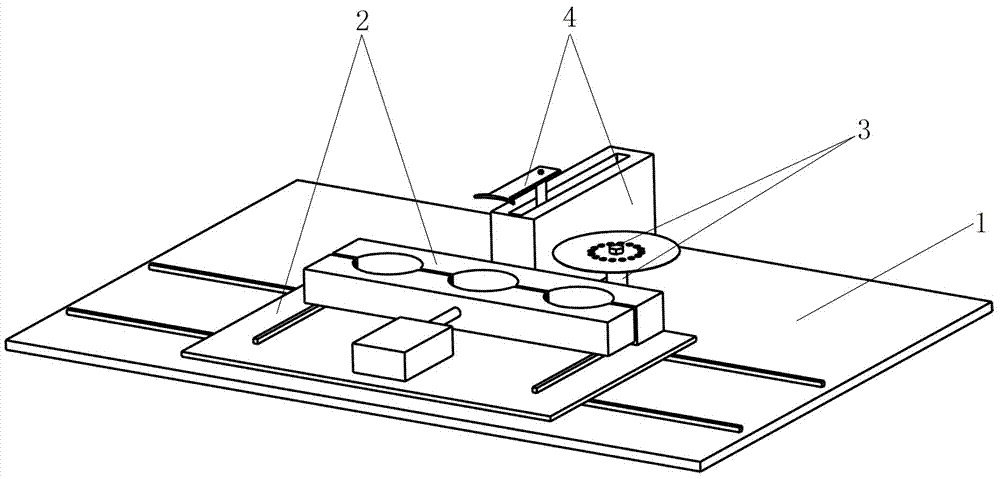

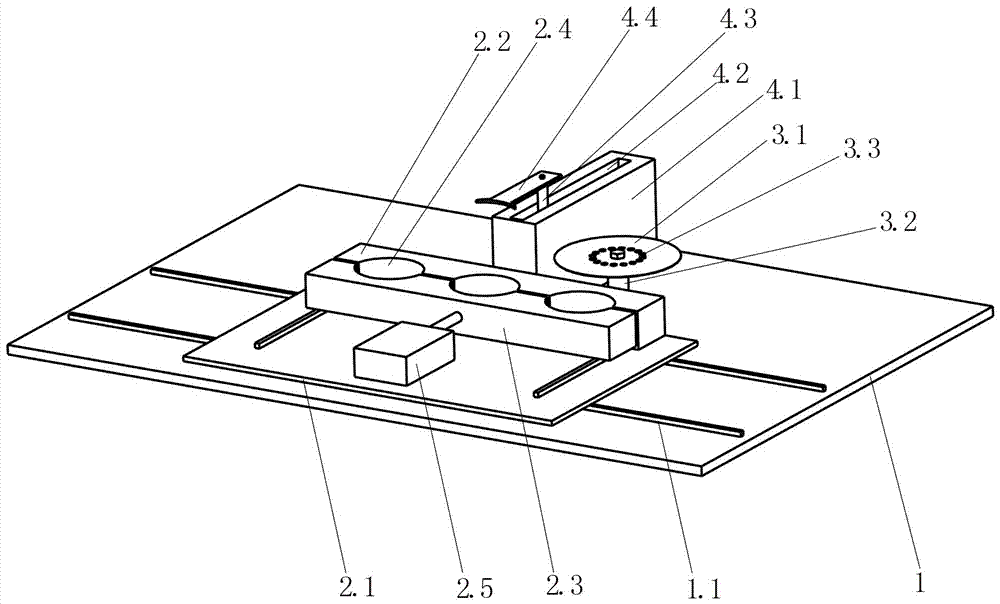

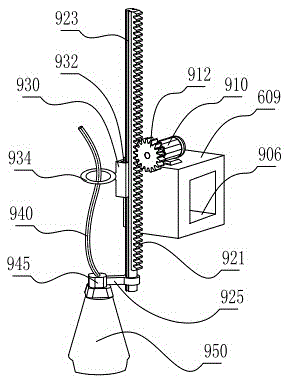

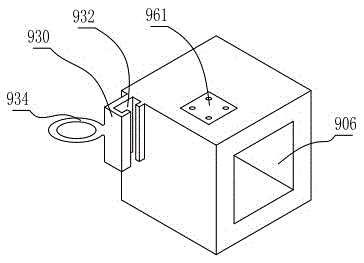

Ampoule bottle opening device

InactiveCN107161929AAvoid harmReasonable designBottle/container closurePower operated devicesLeft halfSlide plate

The invention relates to a bottle opening device, in particular to an ampoule bottle opening device. The ampoule bottle opening device comprises a bottom plate and is characterized in that a bottle body fixing device is arranged at the left half part of the bottom plate in a transverse sliding mode; a bottleneck dull polish mechanism and a bottleneck striking mechanism are arranged at the right half part of the bottom plate; the bottle body fixing device comprises sliding plates, a right splicing piece, a left splicing piece, bottle body clamping grooves and an air cylinder; the bottleneck dull polish mechanism comprises a disk sand wheel, a rotating shaft and a tightness-degree adjusting knob; and the striking mechanism comprises a rectangular machine seat, a sliding groove, a sliding rod and a striking punch. Due to the fact that when an ampoule bottle is opened by the ampoule bottle opening device, double hands of an operator do not directly make contact with a bottle body, the situation that a medical worker is damaged by glass fragments can be effectively avoided.

Owner:王中杰

Armored glass composition with perimeter reinforcement

ActiveUS8088472B2Efficient solutionEffective protectionArmourGlass/slag layered productsEngineeringGlass fragment

The invention relates to a special array of materials located on the periphery of a glass armored composition (BRG), with the purpose of having a controlled deformation zone being able to absorb residual energy of impacts made on the edge of the armored piece, therefore providing an effective retention of the projectile and of the glass fragments generated by the impact. The invention provides superior ballistic protection for BRGs destined for automobile applications, for fixed and mobile pieces.

Owner:AGP AMERICA

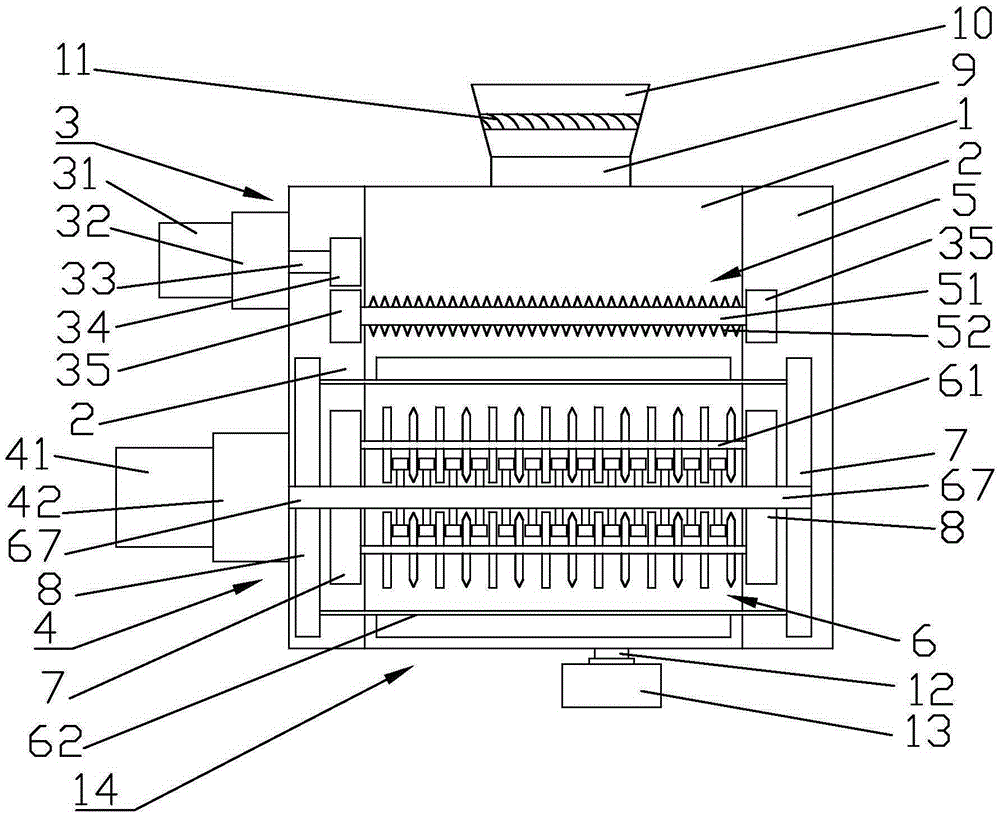

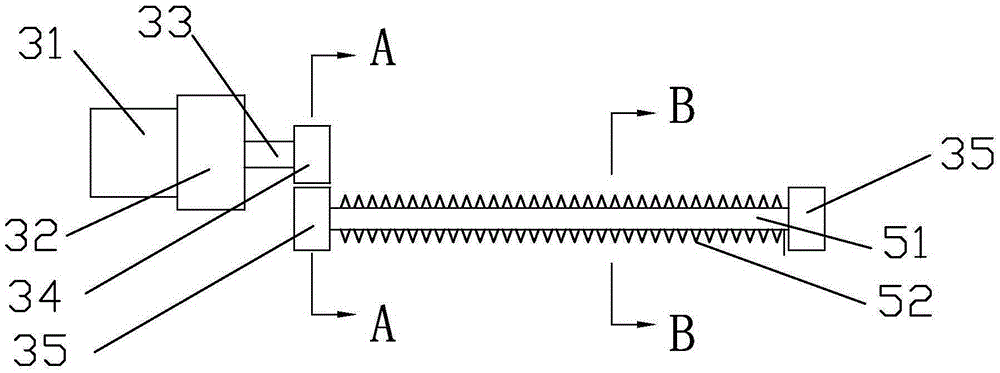

Method for testing glass by using worm wheel turntable rack photography and circular corner clamp plates

InactiveCN105651629AChange labor intensityAvoid accidental splash damageStrength propertiesEngineeringGlass fragment

The invention relates to a tempered glass testing method, in particular to a method for testing glass by using worm wheel turntable rack photography and circular corner clamp plates. Modifications include: one, an assembly process includes a clamp plate assembly process and a machine assembly process; two, a tempered glass fragmentation test includes the following steps: (one), a worm cranking handle at one end of a worm shaft is cranked by hand so that a test top plate is horizontal; (two), first, second, third and fourth clamp plates equal in structural size are placed on the test top plate; (three), a trapezoidal glass plate to be tested is placed on the test top plate within a surrounded space; (four), an impact motor is started to break the trapezoidal glass plate; (five), a photography motor is started to take photos and send fragment photos to a computer processing center; (six), the second and third clamp plates are moved so that tempered glass fragments can be conveniently cleared and dropped into a glass fragment recycling container.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

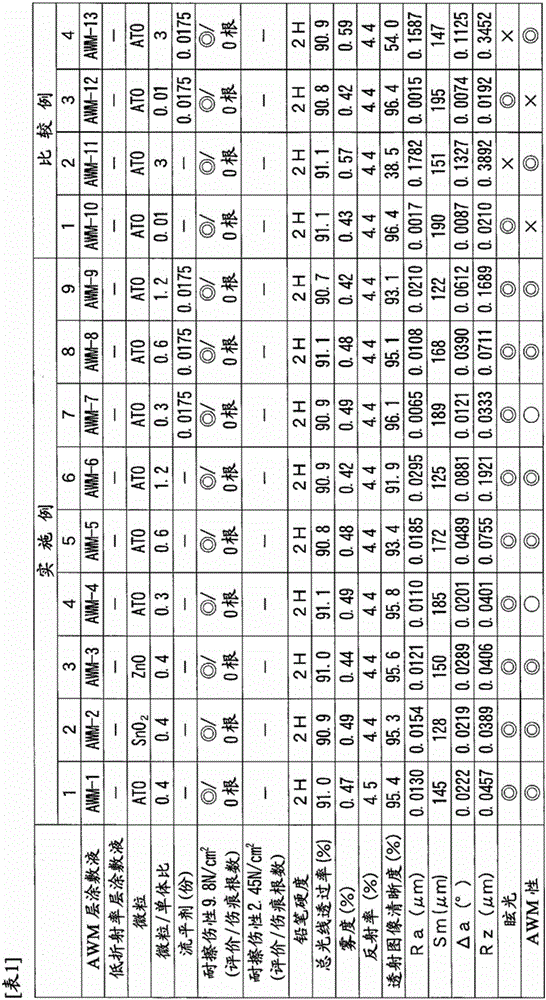

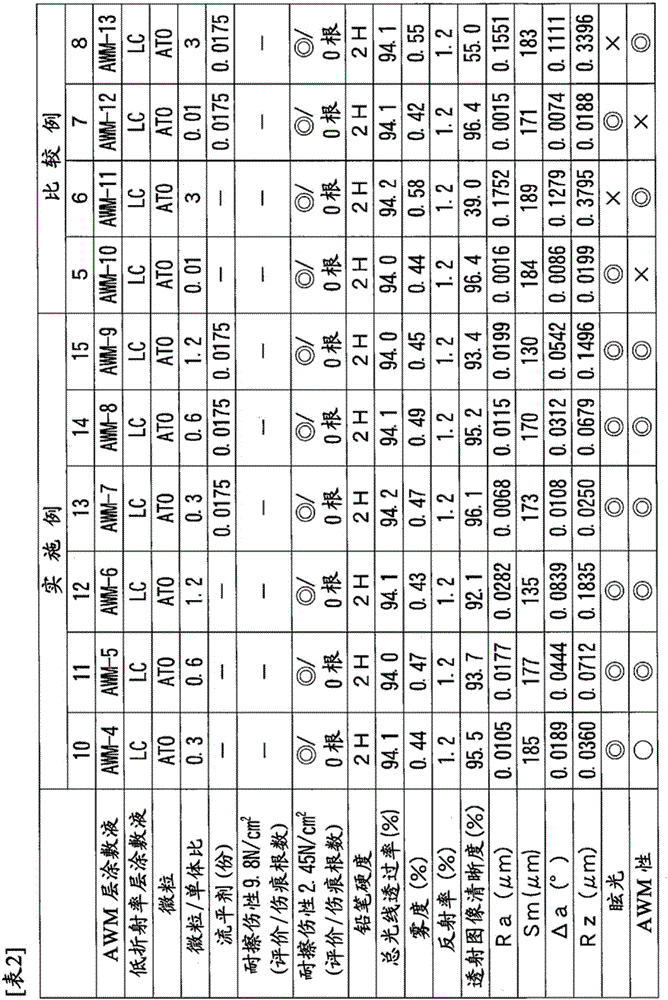

Transparent layered film, process for producing same, and electrode for touch panel

ActiveUS20170022343A1Prevents and reduces sparkling high-definitionLow hazeSynthetic resin layered productsElectrical equipmentDisplay deviceGlass fragment

A transparent layered film is produced by forming an anti-water-mark layer on a first side of a transparent resin layer and forming an uneven structure on a surface of the anti-water-mark layer, wherein the anti-water-mark layer comprises a cured product of a curable composition containing a curable resin, a thermoplastic resin, and a metal oxide particle having an average primary particle size of 1 to 100 nm, and the uneven structure has a roughness average Ra of not less than 0.005 and less than 0.03 μm, a mean spacing of profile irregularities Sm of 50 to 300 μm, an average absolute slope Δa of less than 0.1°, and a ten-point average roughness Rz of less than 0.2 μm. Lamination of the film on a glass-containing upper electrode of a touch screen display prevents scattering of glass fragments produced by breakage of the upper electrode, occurrence of water marks, and sparkling on a high-definition display provided with the film.

Owner:DAICEL CHEM IND LTD

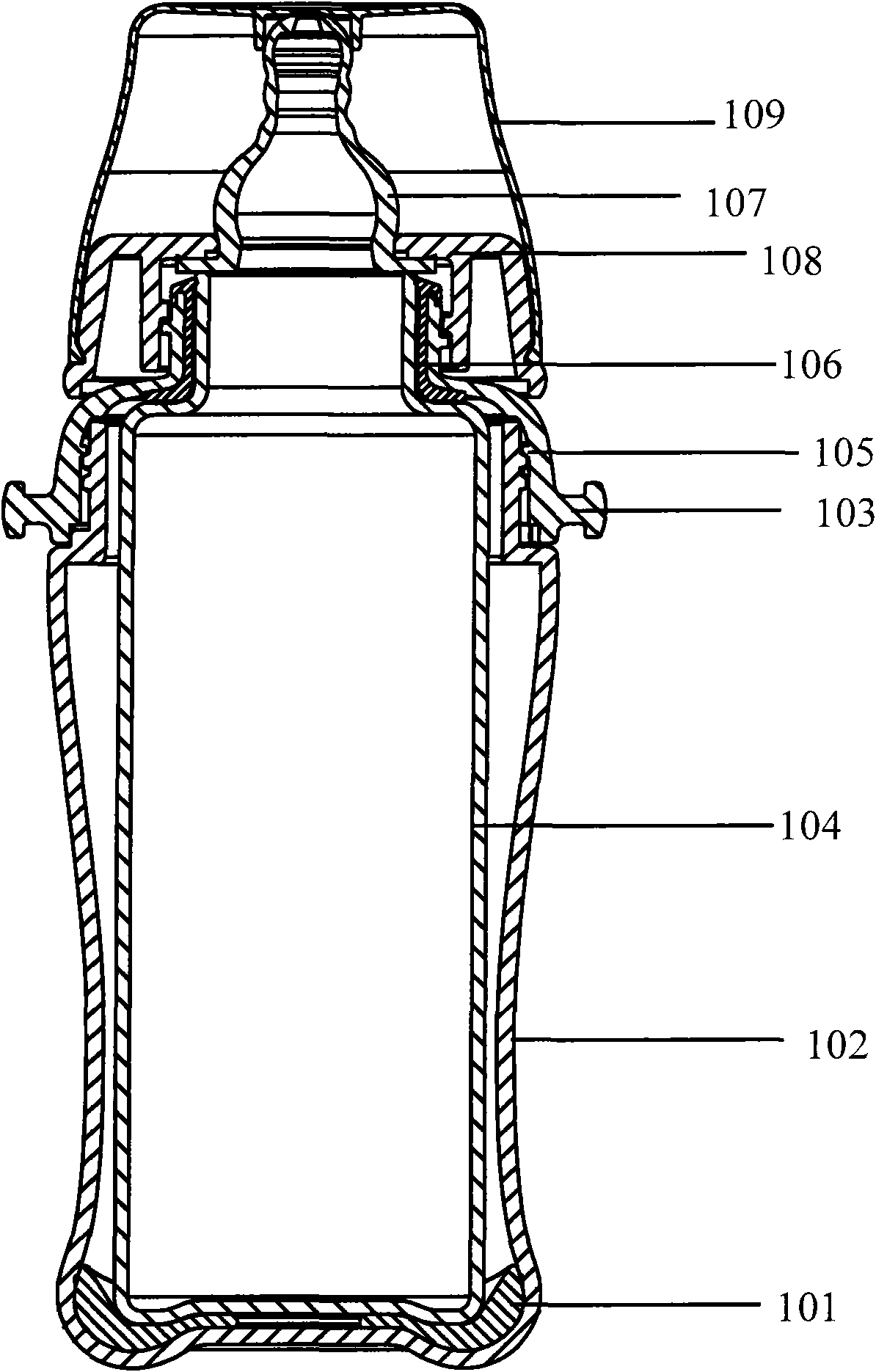

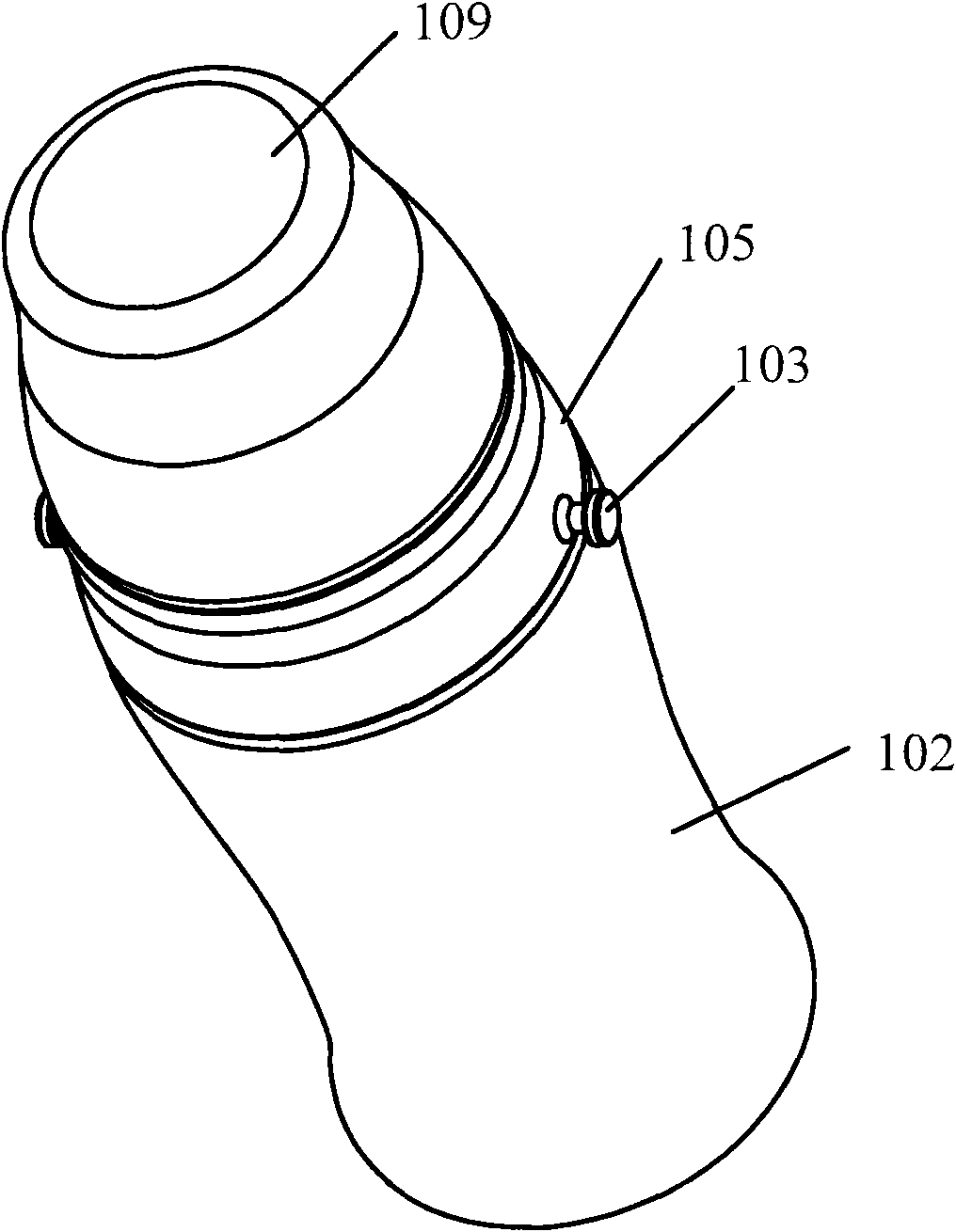

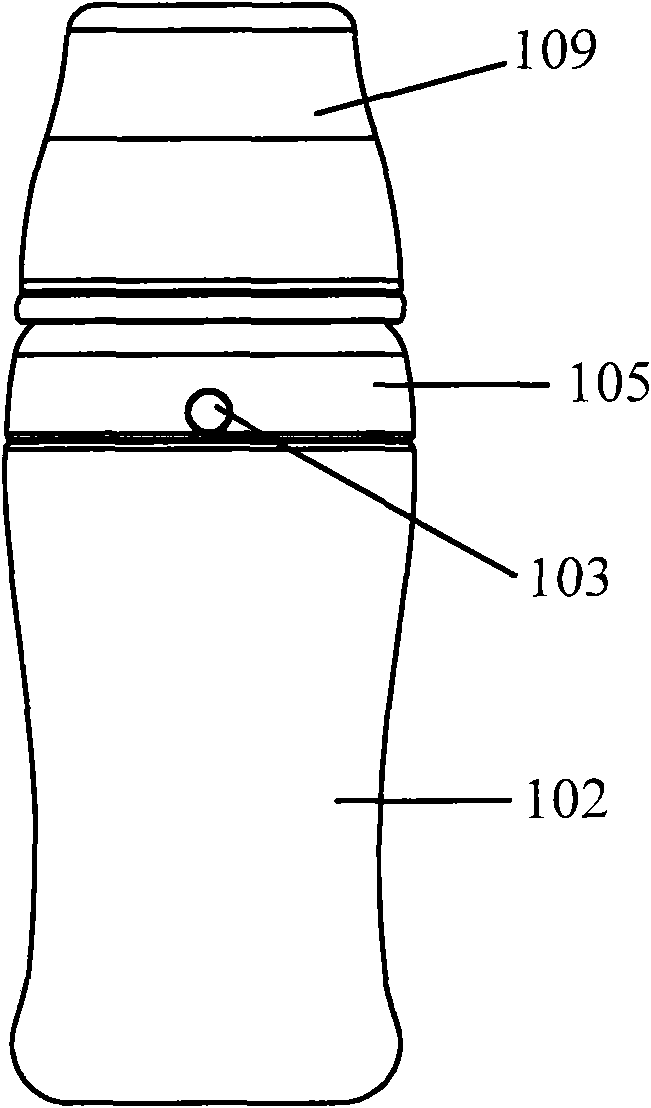

Safe glass drinking bottle

InactiveCN101579170APlay the role of heat insulationAvoid spillingTravelling sacksFeeding-bottlesEngineeringGlass fragment

The invention relates to the technical field of daily article, in particular to a safe glass drinking bottle. The safe glass drinking bottle comprises a glass bottle body that is sheathed in a shell with opened upper end and closed bottom; a lining cushion is embedded in the bottom of the shell; and a bottle cap assembly connected on the glass bottle mouth is connected with the top of the shell in a threaded way. The safe glass drinking bottle has the advantages of general glass drinking bottles, and can be effectively prevented from falling off or breaking suddenly by the plastic shell attached on the surface of the glass bottle body and the soft rubber lining cushion attached to the bottom of the shell; when even the drinking bottle is broken down, all fragments of the glass bottle body can be wrapped in the plastic shell, thus avoiding the harm of the glass fragments to the human body; and the safe glass drinking bottle has reasonable structure, safe use and more humanized design.

Owner:新文越实业集团有限公司

Modified tyre stock containing crushed curtain cloth

ActiveCN101812192AImprove puncture resistanceReduce delaminationSpecial tyresForeign matterGlass fragment

The invention discloses a modified tyre stock containing crushed curtain cloth, which comprises the following main components of natural rubber, butadiene styrene rubber, butadiene rubber, carbon black, zinc oxide, stearic acid, an anti-aging agent, sulphur powder, aromatic oil, an accelerator, binding agent, resorcinol, methylene melamine, resin, tackifier and the like. The modified tyre stock is mainly characterized by being prepared by mixing the modified crushed curtain cloth and the components in an internal mixer and an open mill. In the invention, the crushed curtain cloth is added into the stock to form a mesh structure, so that sharp objects are prevented from penetrating; the tyre with high strength and puncture resistance not only can resist the puncture and the cutting of gravels, iron nails, glass fragments and other foreign bodies, but also has favorable resisting effect for knife tabbing, needle puncture and the like as well as can be widely used for special vehicles, locomotive cars, electric vehicles, bicycles and motor cycles.

Owner:SICHUAN YUANXING RUBBER

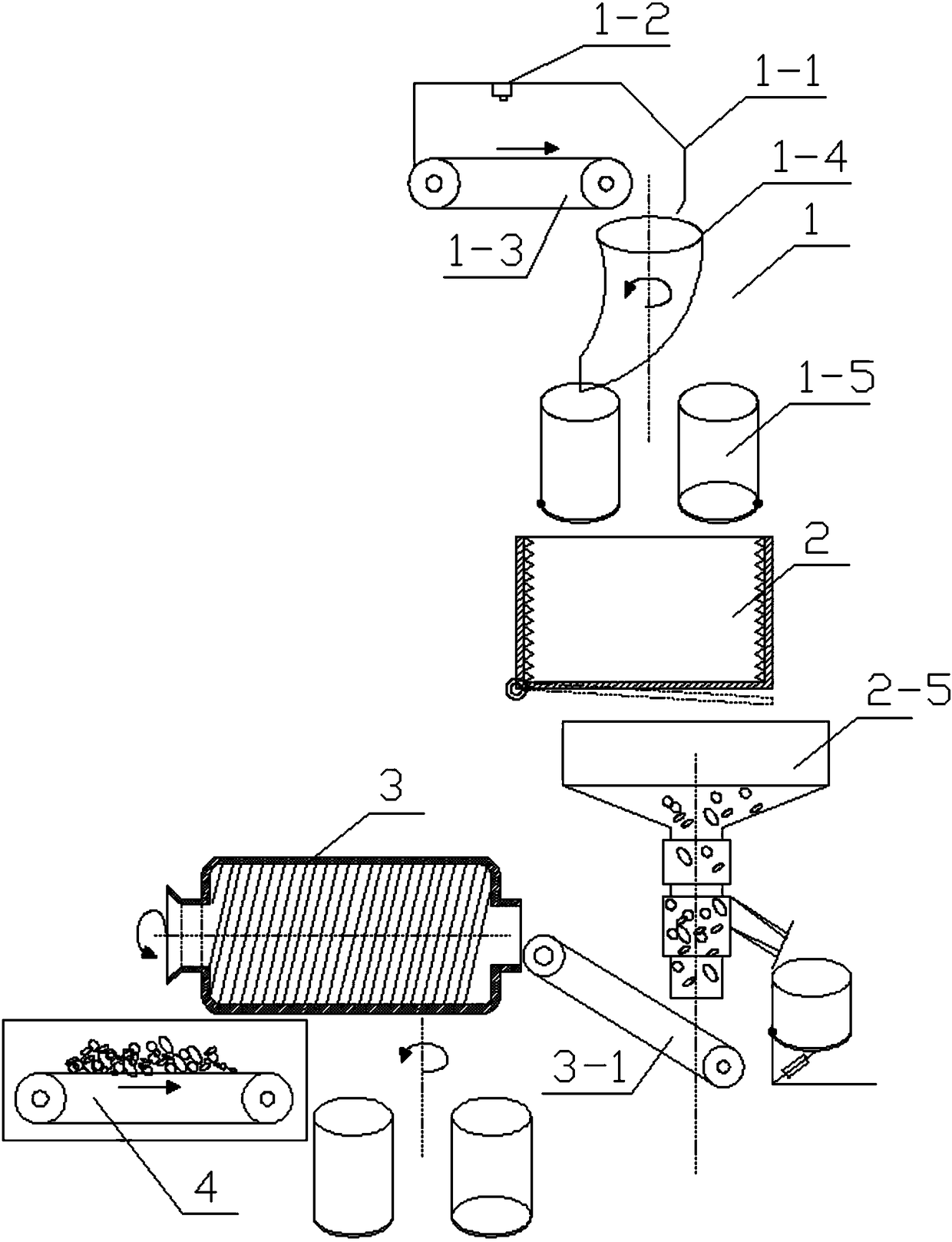

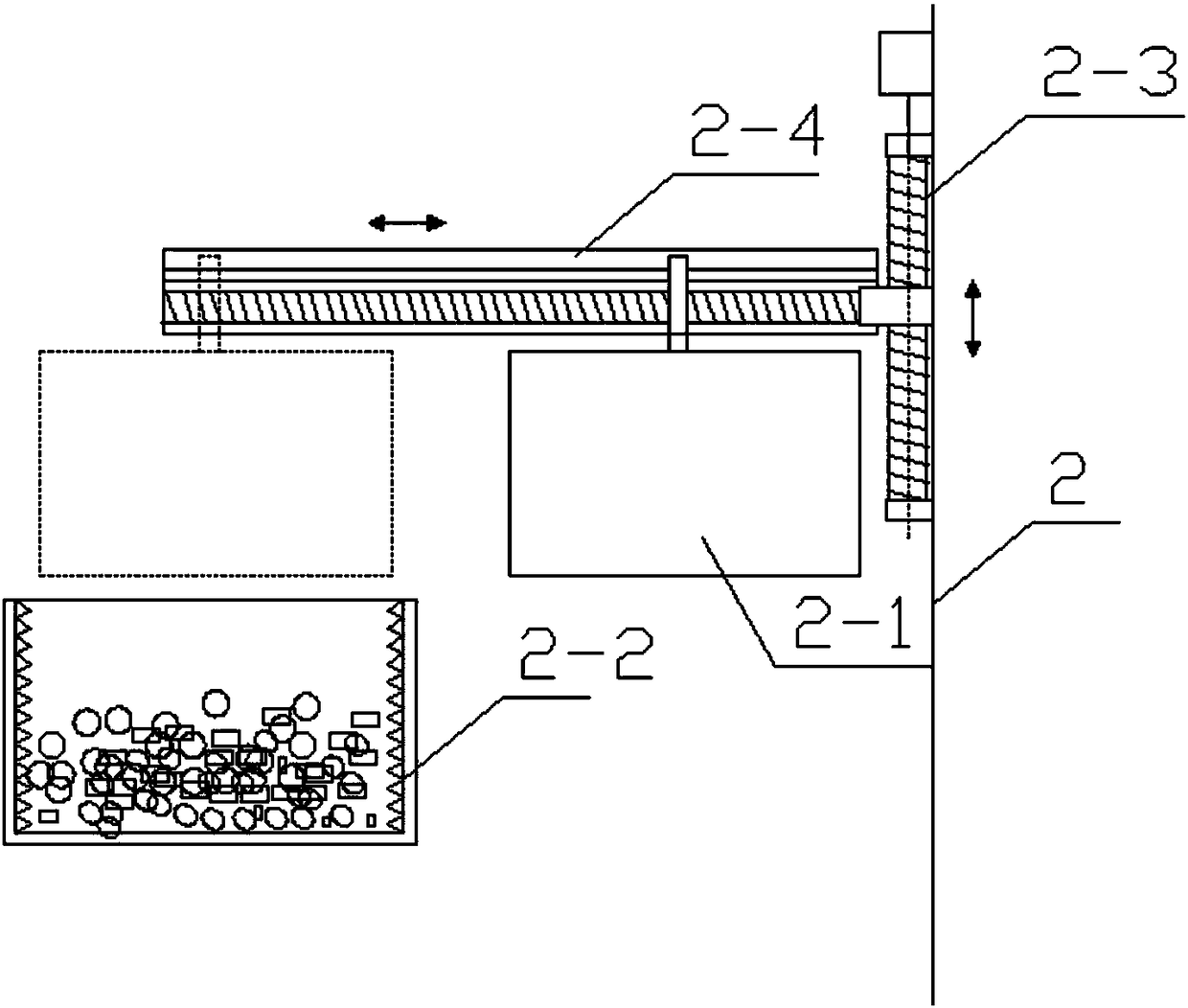

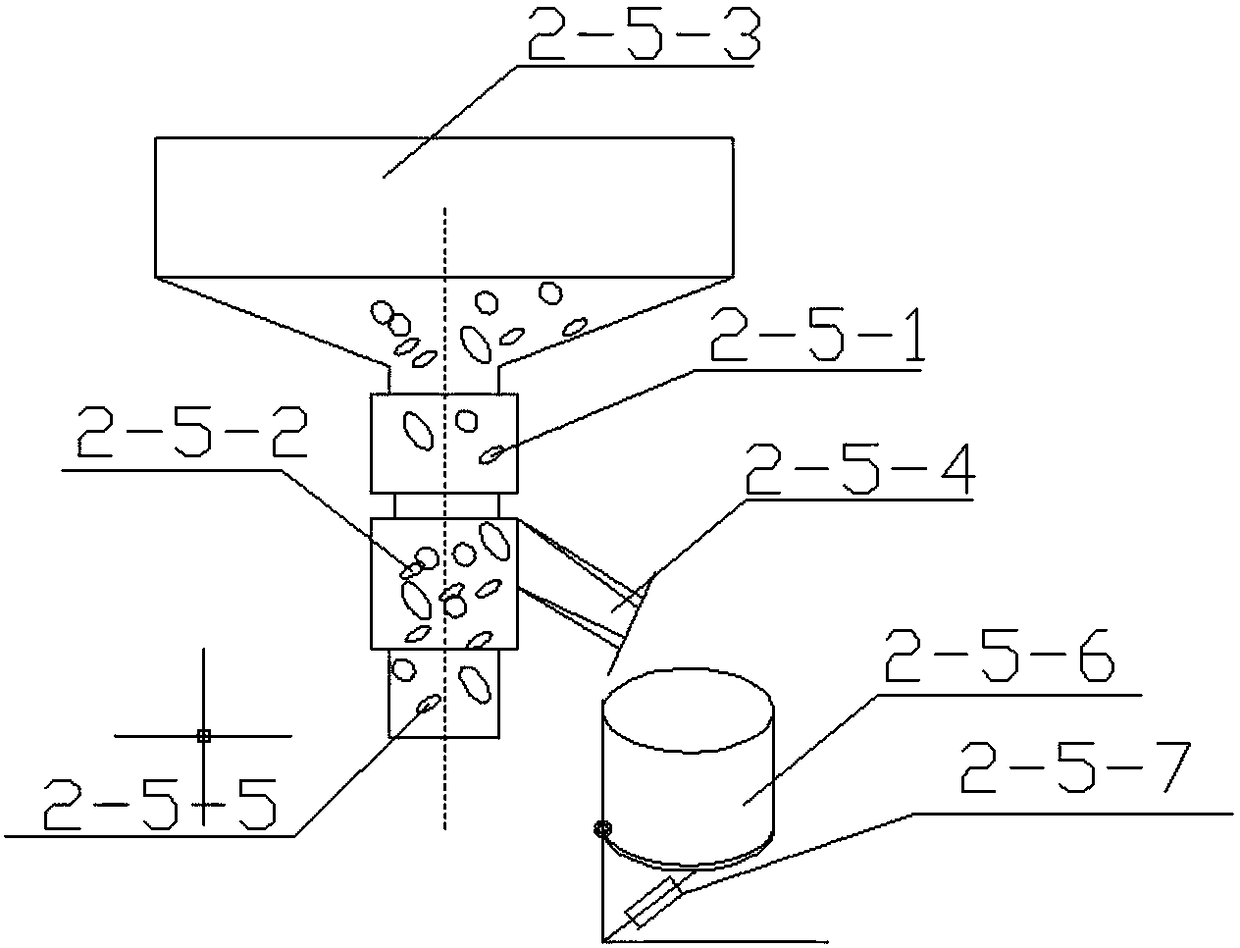

Intelligent waste glass treatment device

The invention provides an intelligent waste glass treatment device. The intelligent waste glass treatment device comprises a glass putting recognizing and sorting device, a glass coarse crushing device, a cleaning device, a drying device and a control system. Waste glass in different colors is screened through the glass putting recognizing and sorting device, the glass coarse crushing device crushes waste glass in the same color into large-particle glass and removes metal among glass, and glass fragments with metal being removed are cleaned and dried. The waste glass treatment device capable of achieving color sorting, cleaning and recovery integrally is improved and is intelligent, simple in process, convenient to operate, capable of mass treatment easily and low in energy consumption, and the treated waste glass can be used for producing high-quality glass products.

Owner:李奕菲

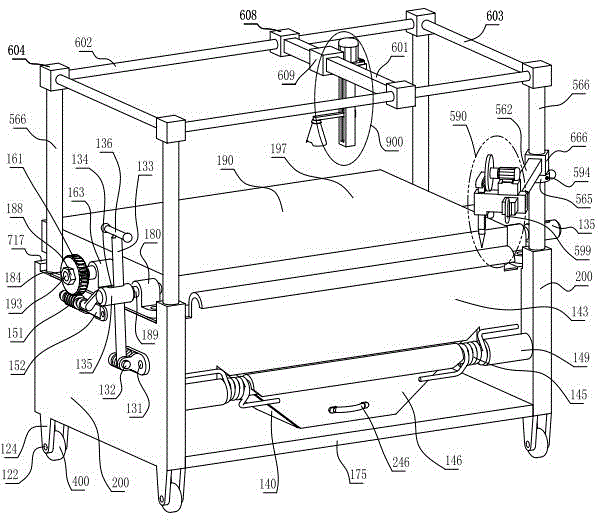

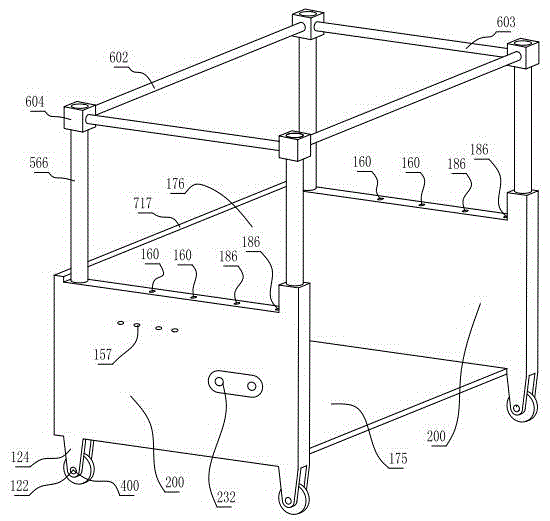

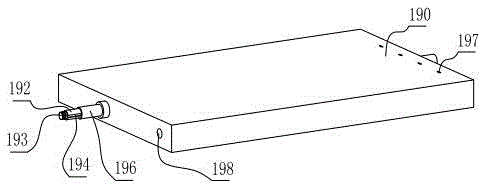

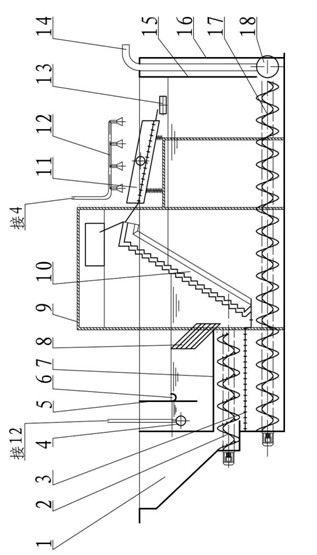

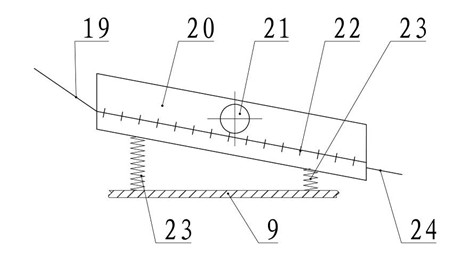

Food waste pretreatment equipment

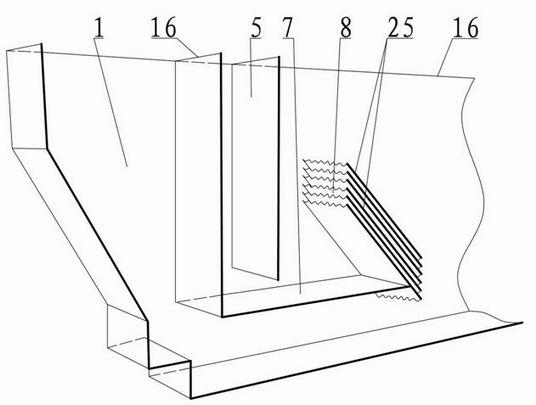

The invention provides food waste pretreatment equipment which belongs to waste treatment equipment and is used for solving the problems of too violent crushing and too many adhesive materials contained in separated impurities of the traditional waste pretreatment equipment. The food waste pretreatment equipment is characterized in that a first partition board and a second partition board are arranged in a shell; the shell is partitioned into a left space, a middle space and a right space by the first partition board and the second partition board partition, wherein the bottoms of the left space, the middle space and the right space are communicated; a rack is arranged in the middle space, and a lifting mechanism is obliquely fixed on the rack; a horizontal partition board is fixed below the first partition board, a spiral bag breaking device and a mesh screen are arranged below the horizontal partition board in sequence, the mesh screen is connected with the lifting mechanism and a vibrating screen in sequence, a flusher is arranged above the vibrating screen, a spiral transmitter is arranged below the mesh screen, and a feeding pump is arranged at the bottom of the right inner space of the shell; the left inner space of the shell is provided with a booster pump connected with the flusher; and a bevel board group which is obliquely arranged is fixed between the first partition board and the rack. The food waste pretreatment equipment has a compact structure and universal parts and integrates the functions of bag breaking, oil removing and impurity removing; and food residues subjected to impurity removal do not contain glass fragments and are homogeneous and fluidized, thereby being convenient for post-treatment.

Owner:HUAZHONG UNIV OF SCI & TECH

Hard coating film and touch panel using the same

InactiveCN102922805APrevent splashSynthetic resin layered productsNon-linear opticsIn planeAcrylic resin

The purpose of the invention is to provide a hard coating film and a touch panel using the same. The hard coating film effectively prevents glass fragment from splashing when a glass substrate is damaged. The hard coating film of the invention comprises a transparent basis material layer, a hard coating layer which is bonded on one surface of the transparent basis material layer, and a bonding layer which is bonded on the other surface of the basis material layer. A delay value in plane (Ro) is less than 100 nm. And delay value (Rth) in thickness direction is less than 200 nm. In the hard coating film, the basis material layer preferably uses polycarbonate resin, cycloolefin copolymer, or acrylic acid series resin as main ingredient. The average thickness of the basis material layer of the hard coating layer is more than 10 [mu] m but less than 500 [mu] m. Preferably, the haze degree of the hard coating film is less than 2%.

Owner:KEIWA INCORPORATED

Method for detecting glass through gear turntable rack shooting V-shaped clamping plate

InactiveCN105606470AEasy to removeOvercome the defect that the fit does not have self-lockingStrength propertiesEngineeringGlass fragment

The invention relates to a method for testing and inspecting tempered glass, in particular to a method for detecting glass through a gear turntable rack shooting V-shaped clamping plate. As an improvement: the steps for performing fragmentation testing on tempered glass are as follows: firstly, turning a hand wheel crank handle with a hand to enable a cylindrical bulb at one end of bolt lock pin to enter lock pin positioning holes in the two sides of a testing platform plate so as to be locked and positioned, and to enable the testing platform plate to be fastened horizontally; secondly, forming a surrounding space among a clamping plate fixed side, a clamping plate left side, a clamping plate opposite side and a clamping plate right side with the same structural sizes; thirdly, putting a tempered glass plate to be tested on the testing platform plate in the surrounding space; fourthly, ensuring that a cylinder impactor rotates around the excircle of an upper pillar type column with an impacting cross rod, so as to be deviated from the upper part of the tempered glass plate; sixthly, cleaning tempered glass fragments, and enabling the tempered glass fragments to fall into a broken glass recovery container.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Pulverizer applied to recycling of waste glass

InactiveCN105413798ASolve the crushing problemSimple structureGrain treatmentsGlass fragmentGlass recycling

The invention discloses a pulverizer applied to recycling of waste glass. The pulverizer comprises a pulverizing cavity. The pulverizing cavity comprises a transmission room and a pulverizing room. A transmission device is arranged in the transmission room. A pulverizing device is arranged in the pulverizing room. The transmission device comprises a first transmission device body and a second transmission device body. The pulverizing device comprises a first pulverizing device body and a second pulverizing device body. The first pulverizing device body comprises a pulverizing roller which is connected with the first transmission device body. The pulverizing roller comprises a first pulverizing roller body and a second pulverizing roller body. The second pulverizing device body comprises a center pulverizing main shaft which is connected with the second transmission device body. According to the pulverizer, the two levels of pulverizing device bodies are adopted, the first pulverizing device body, the first pulverizing roller and the second pulverizing roller are used for conducting primary pulverizing on waste glass, and then the second pulverizing device body is used. Small glass fragments can be pulverized further, and in addition, the glass fragments is evenly pulverized further to become aggregate capable of being used for concrete.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

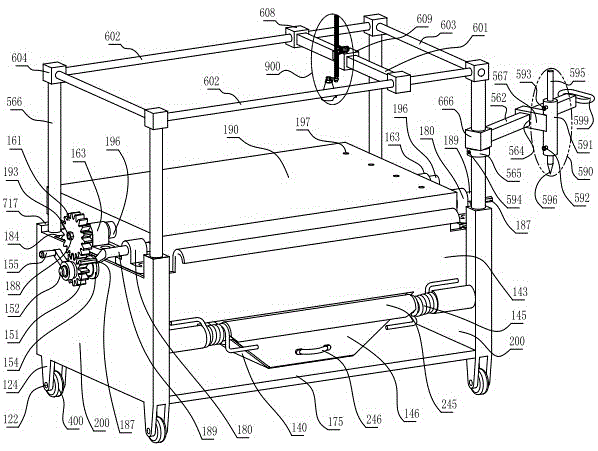

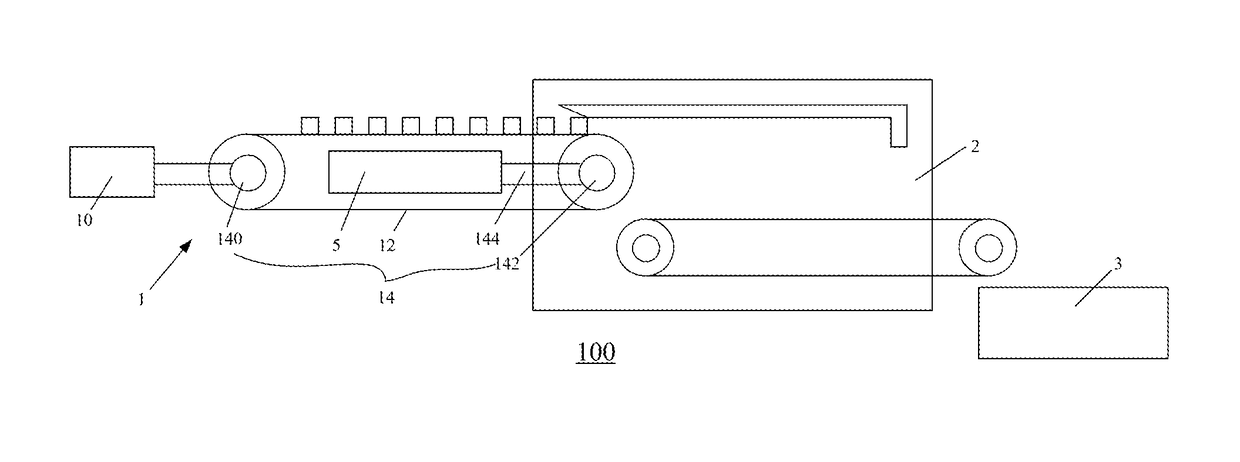

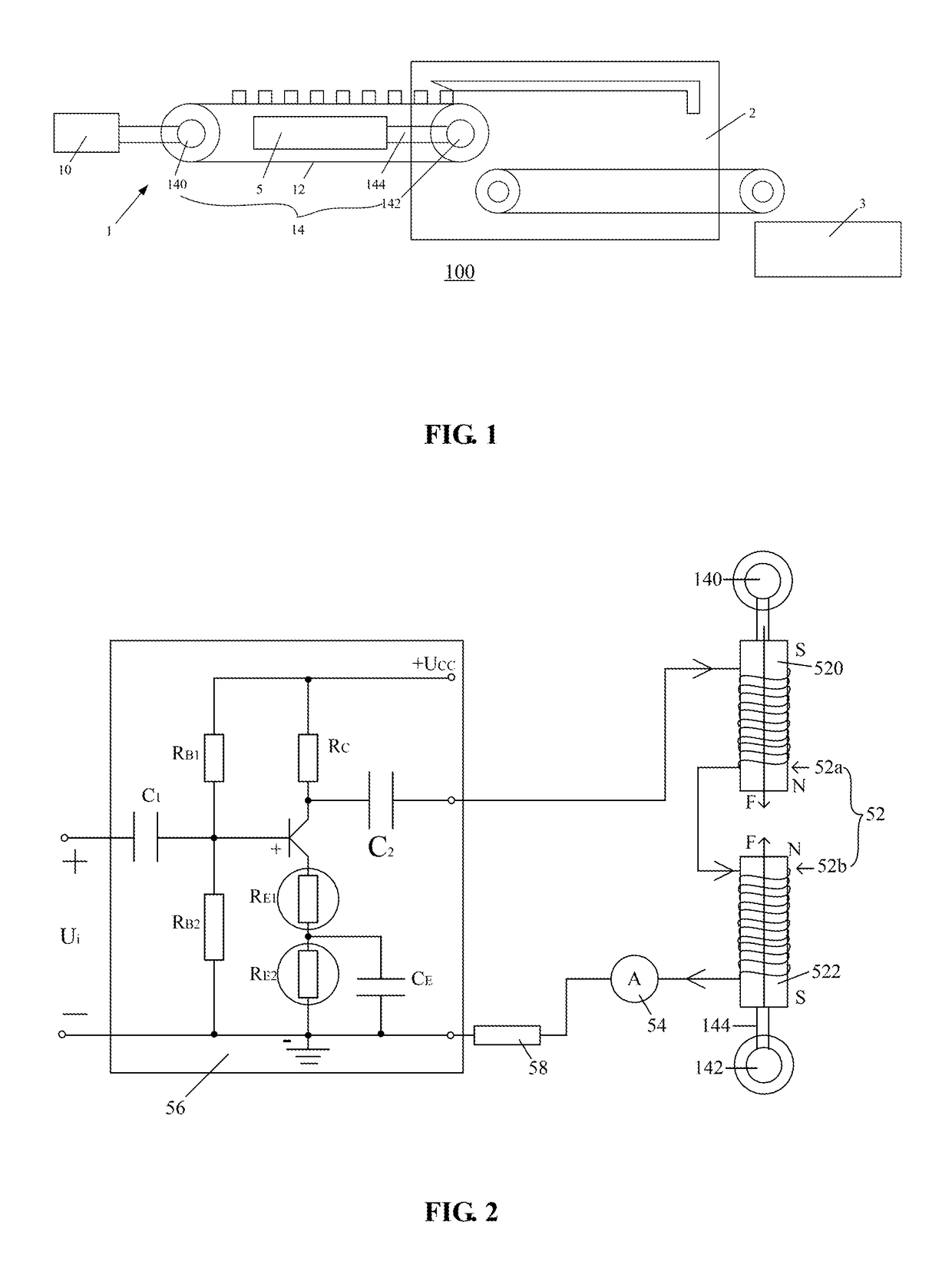

System for automatic feedback and adjust transmittal pulling force of the glass fragment

ActiveUS20170183168A1Reduce tensionReduce distanceConveyorsGlass transportation apparatusAuto regulationPull force

A system for automatic feedback and adjust transmittal pulling force of the glass fragment comprises a delivery machine, a glass broken machine and a recycle box, the glass fragment is transmitted by the delivery machine and triturated by the glass broken machine, and then transported them to the recycle box, the delivery machine comprises a driving motor, a conveyer belt and a driving roller, the conveyer belt is surrounded between the driving rollers, the driving roller is turn round by the driving of the driving motor to lead the conveyer belt rotating at the same time, and then the glass fragment on the conveyer belt could be transported into the glass broken machine for triturating and recycling. Additional, an electromagnetic control system is provided for automatic adjusting transmittal pulling force of the conveyer belt depends on the distance between the two driving rollers, which is connecting with the driving roller.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Transparent layered film, process for producing same, and electrode for touch panel

ActiveCN106163804ASuppression of scatteringAvoid flyingSynthetic resin layered productsPretreated surfacesDisplay deviceGlass fragment

A transparent layered film produced by forming, on one surface of a transparent resin layer, an anti-water-mark layer that is constituted of a cured object of a curable composition comprising a curable resin, a thermoplastic resin, and metal oxide particles with an average primary-particle diameter of 1-100 nm and forming, in the surface of the anti-water-mark layer, a rugged structure which has an arithmetic average roughness (Ra) of 0.005 [mu]m or greater but less than 0.03 [mu]m, an average distance (Sm) between the irregularities of 50-300 [mu]m, an arithmetic average inclination (delta a) less than 0.1 DEG, and a ten-point average roughness (Rz) less than 0.2 [mu]m. When a glass to which the film has been laminated is used in the upper electrode of a touch panel display, not only glass fragment scattering due to breakage of the upper electrode can be inhibited, but also the generation of water marks is prevented and the display device even with high resolution can be inhibited from glittering.

Owner:DAICEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com