Transparent layered film, process for producing same, and electrode for touch panel

A technology of transparent electrodes and laminated films, applied in other household appliances, chemical instruments and methods, coatings, etc., can solve the problems such as the relationship between the hard coating and the breakage of glass materials, glare and other problems, and achieve transparency Excellent, improves scratch resistance, and suppresses glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0220] A PET film (Mitsubishi Plastics Co., Ltd., PET, thickness 75 μm) was used as the transparent resin layer, and the AWM layer coating liquid AWM-1 was coated on the film with a wire bar coater #10, and then the coating was carried out at 80°C. Let dry for 1 minute. Pass the coating film through an ultraviolet irradiation device (manufactured by Ushio Co., Ltd., high-pressure mercury lamp, ultraviolet irradiation amount: 100mJ / cm 2 ) and UV-cured to form an AWM layer with a surface concave-convex structure. The thickness of the AWM layer in the obtained transparent laminated film was about 3 μm.

Embodiment 2~9 and comparative example 1~4

[0222] A transparent multilayer film was produced in the same manner as in Example 1 except that AWM-2 to 13 were respectively used instead of AWM-1 as the AWM layer coating liquid.

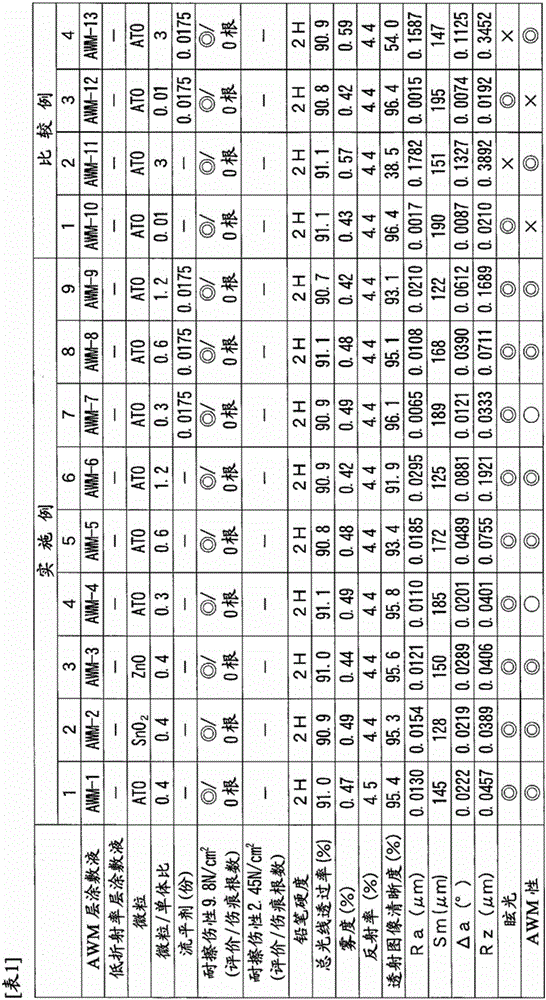

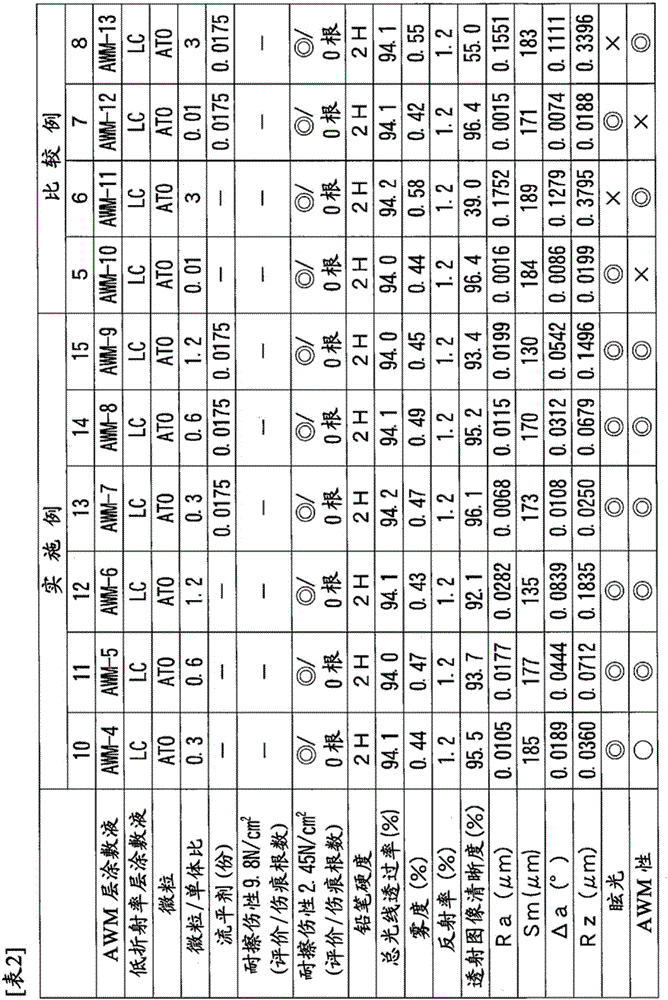

[0223] Table 1 shows the evaluation results of the transparent laminated films obtained in Examples 1-9 and Comparative Examples 1-4.

[0224]

Embodiment 10

[0226] On the AWM layer of the transparent laminate film obtained in Example 4, the low-refractive-index layer coating liquid LC was applied using a wire bar coater #4, and dried at 70° C. for 1 minute. Then, the coating film was passed through an ultraviolet irradiation device (manufactured by Ushio Co., Ltd., high-pressure mercury lamp, ultraviolet irradiation amount: 100mJ / cm 2 ) were subjected to UV curing to form a low refractive index layer. The thickness of the low-refractive index layer in the obtained low-reflection transparent laminated film was about 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com