Waste glass crushing device

A technology of waste glass and crushing mechanism, which is applied in the direction of grain processing, etc., can solve the problem of low working efficiency of waste glass crusher, and achieve the effect of simple structure, high crushing efficiency and large working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be further described in detail through specific embodiments.

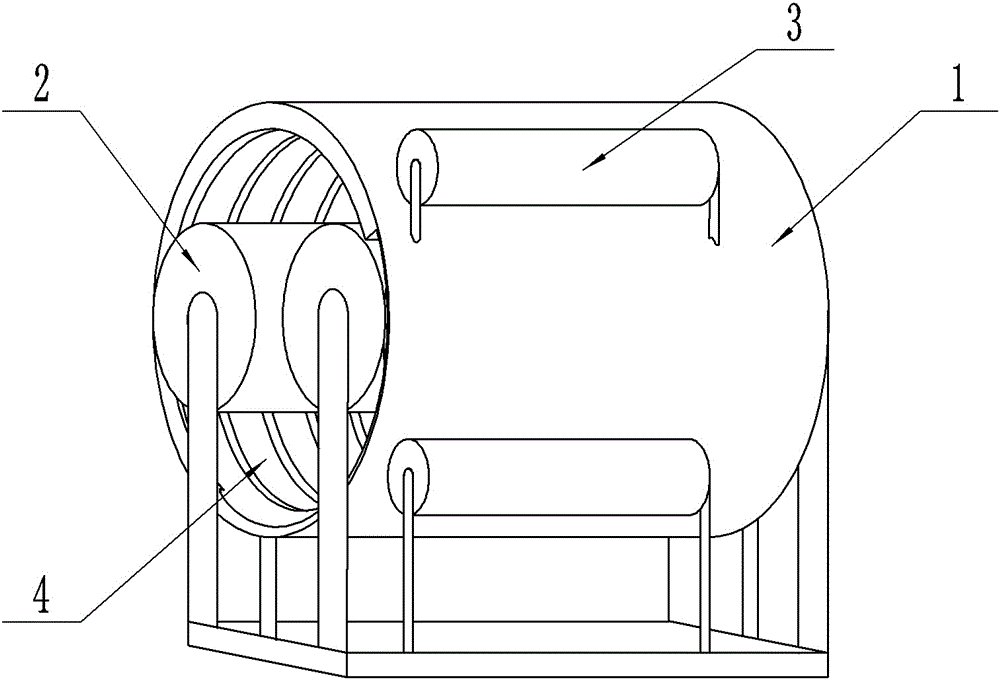

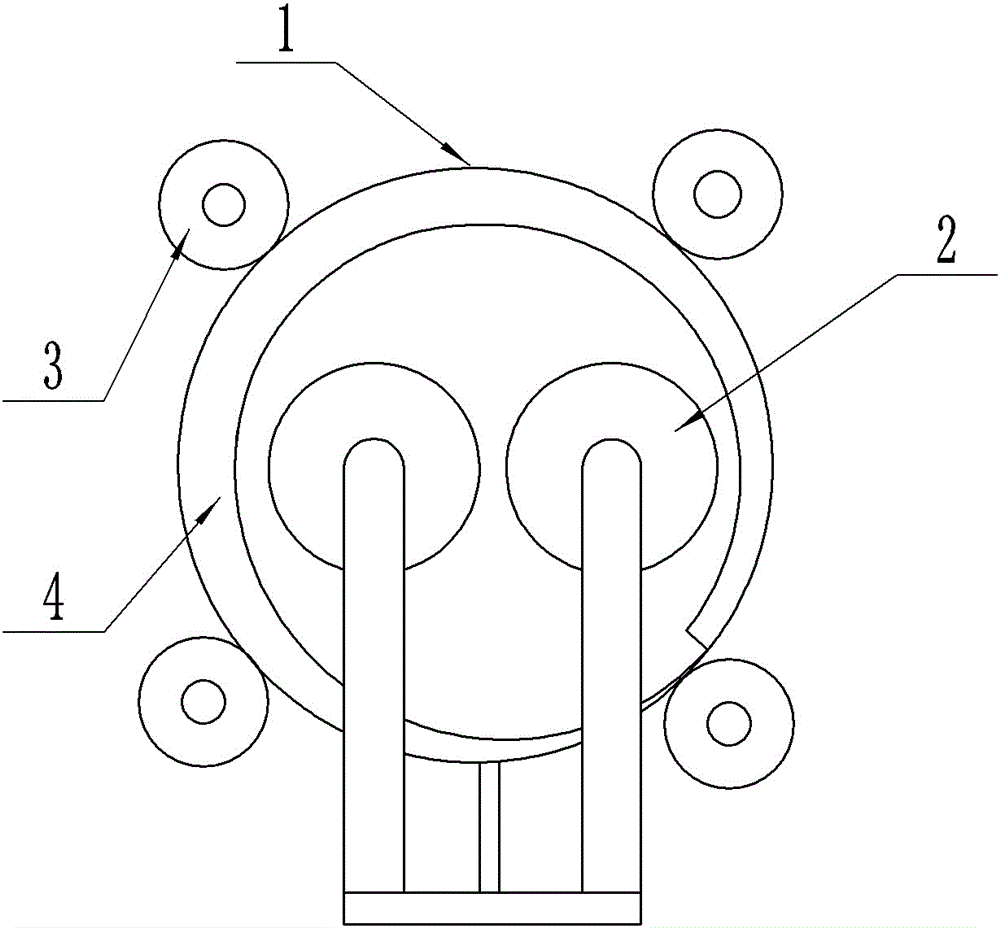

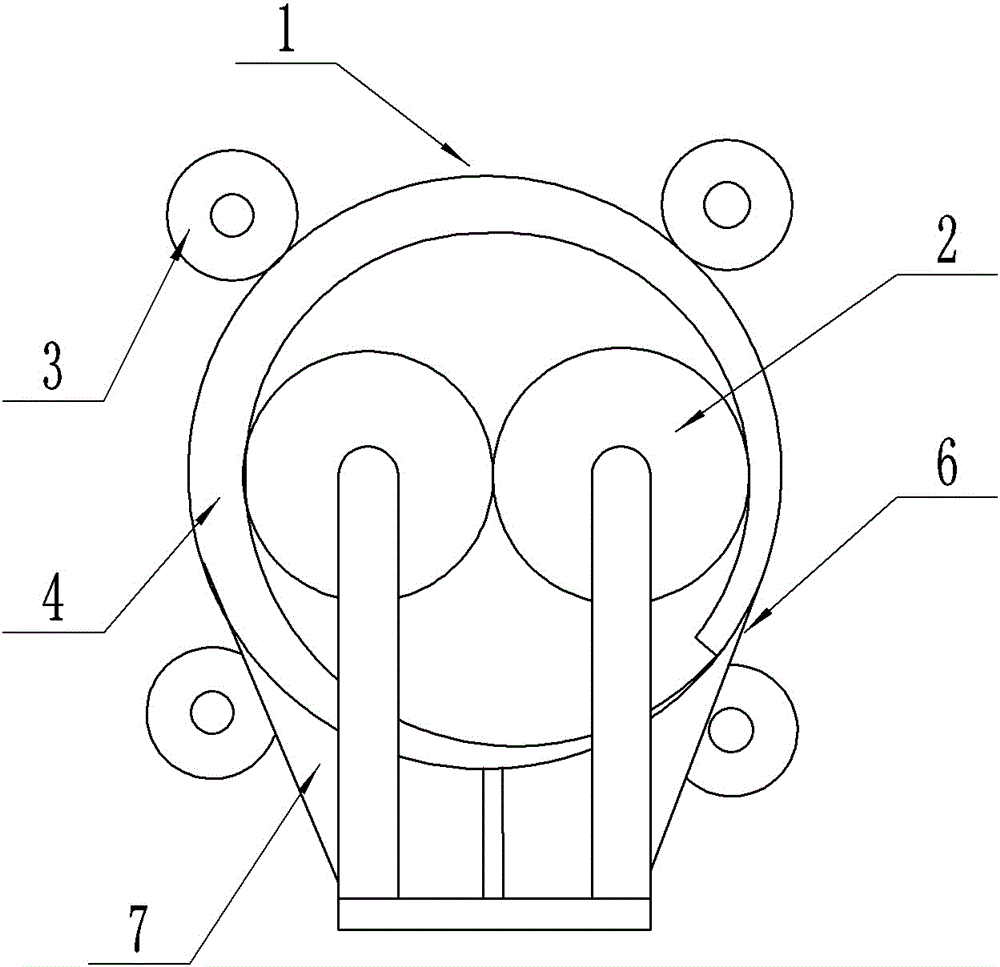

[0032] The reference numerals in the drawings of the specification include: rotating feeding barrel 1, crushing roller 2, driving wheel 3, spiral groove 4, feeding teeth 5, protective cover 6, and guide groove 7.

[0033] Example The waste glass crushing mechanism is basically as attached figure 1 And figure 2 As shown, it includes a control mechanism, a water pump, a machine frame, a rotating feeding barrel 1 and a pair of crushing rollers 2 arranged in the rotating feeding barrel 1. The crushing roller 2 is a cone roller, and the crushing roller 2 is at the feeding end of the rotating feeding barrel 1. The diameter of the position is smaller than the diameter of the crushing roller 2 at the discharge end of the rotating feeding drum 1, and the rotating feeding drum 1, the driving wheel 3 and the crushing roller 2 are all electrically connected to the control mechanism. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com