Patents

Literature

319 results about "Glass manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reinforced plate glass and method for manufacturing the same

InactiveUS20100119846A1Quality improvementStrength of plate glass surfaces opposed to each otherGlass/slag layered productsGlass severing apparatusFlat glassUltimate tensile strength

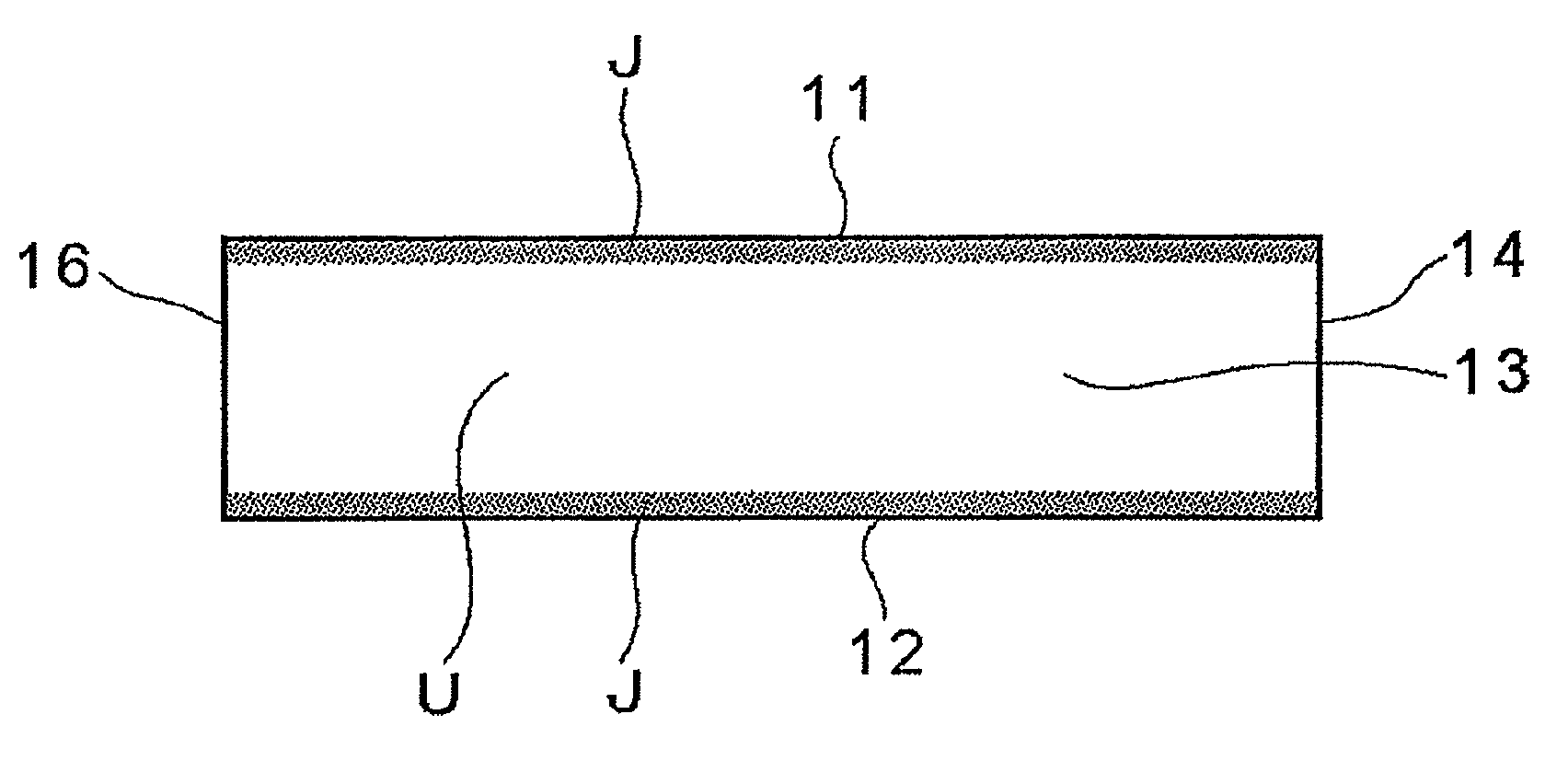

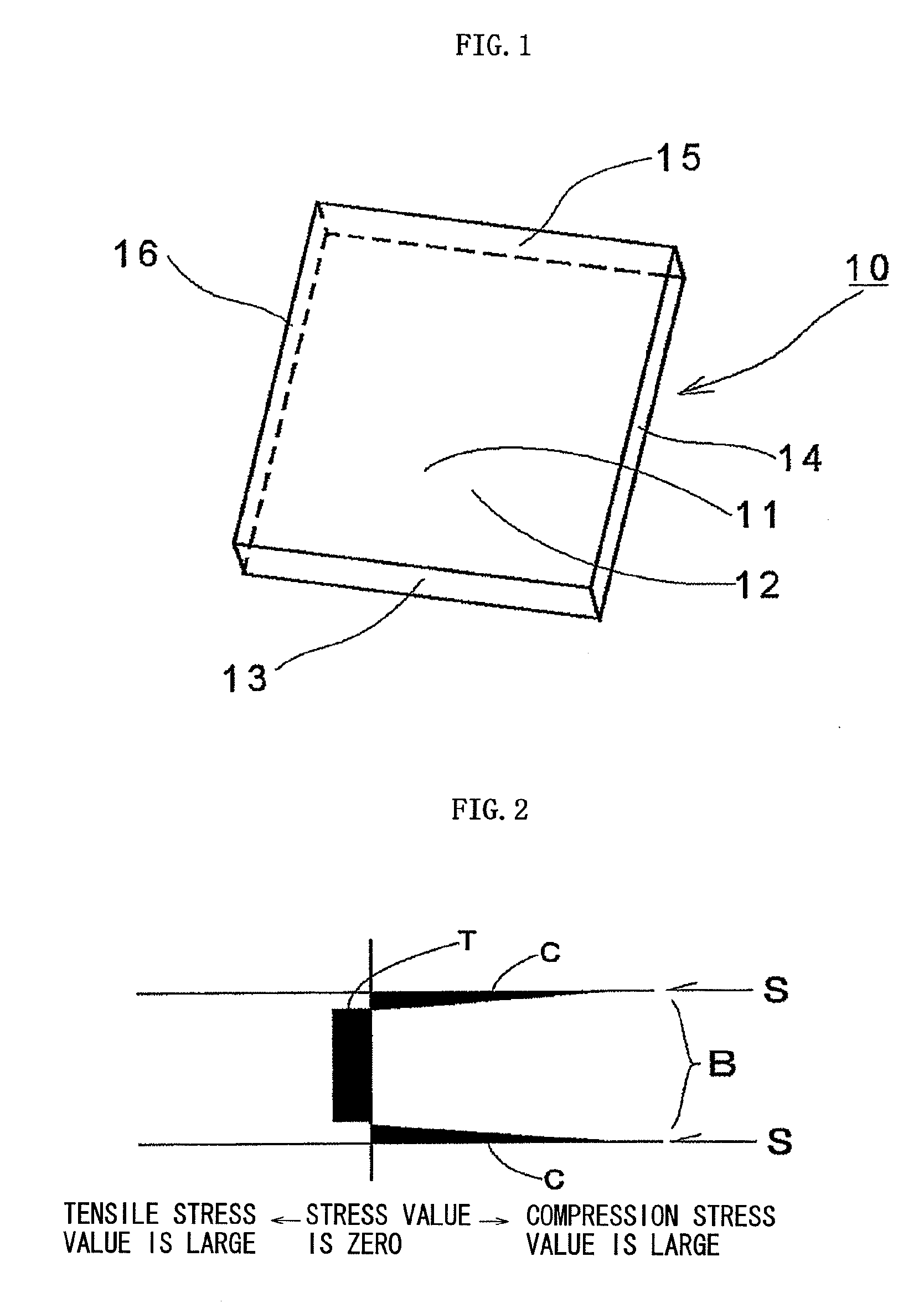

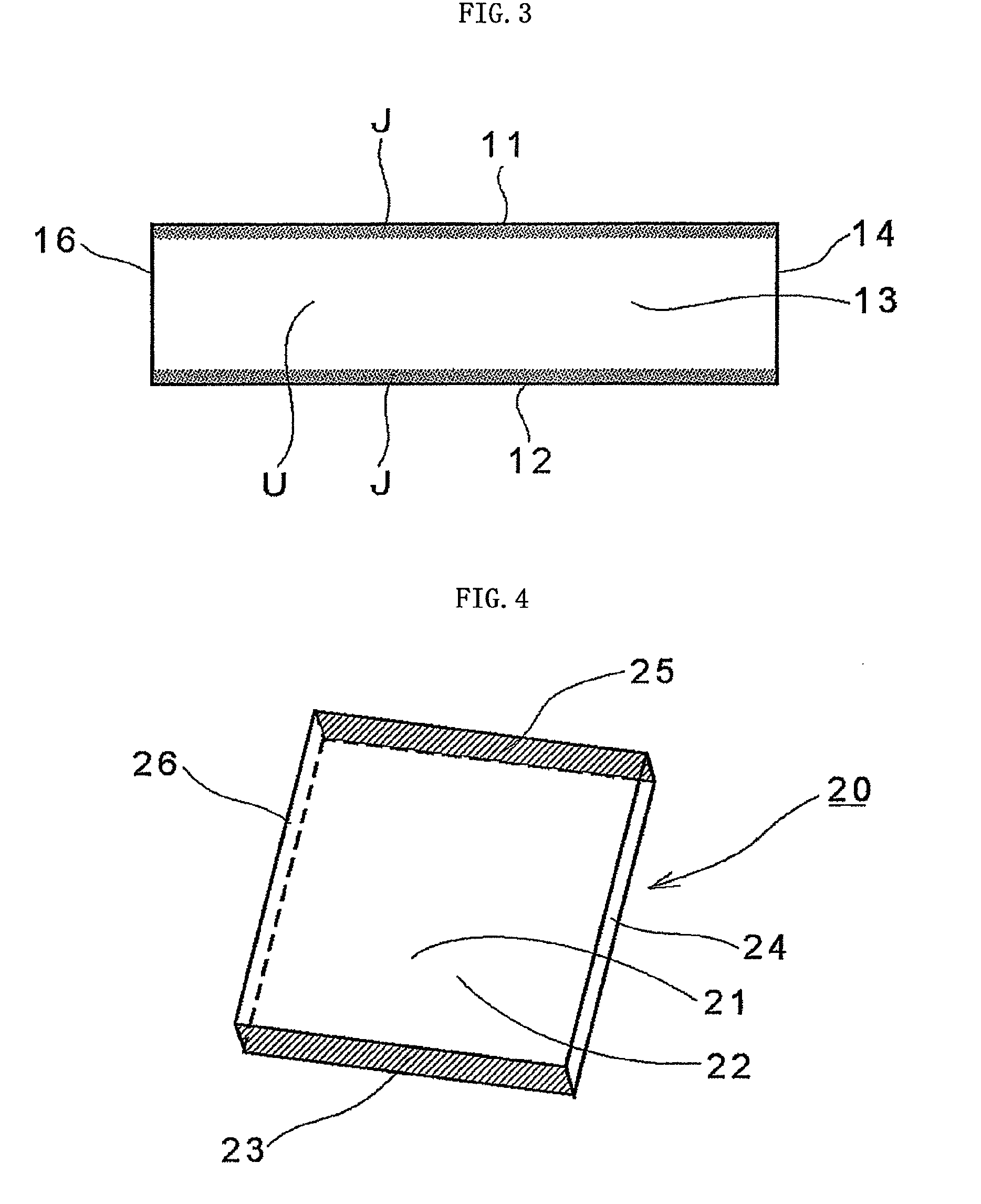

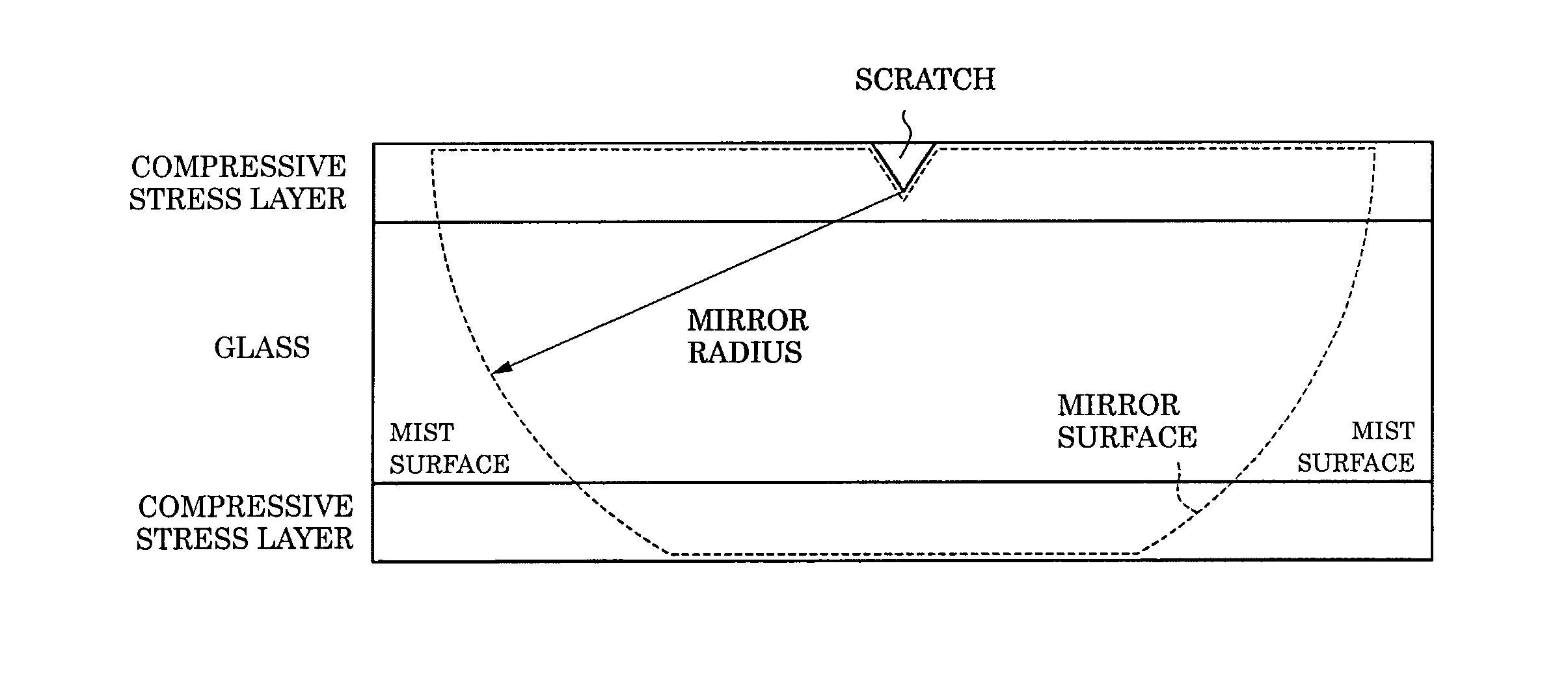

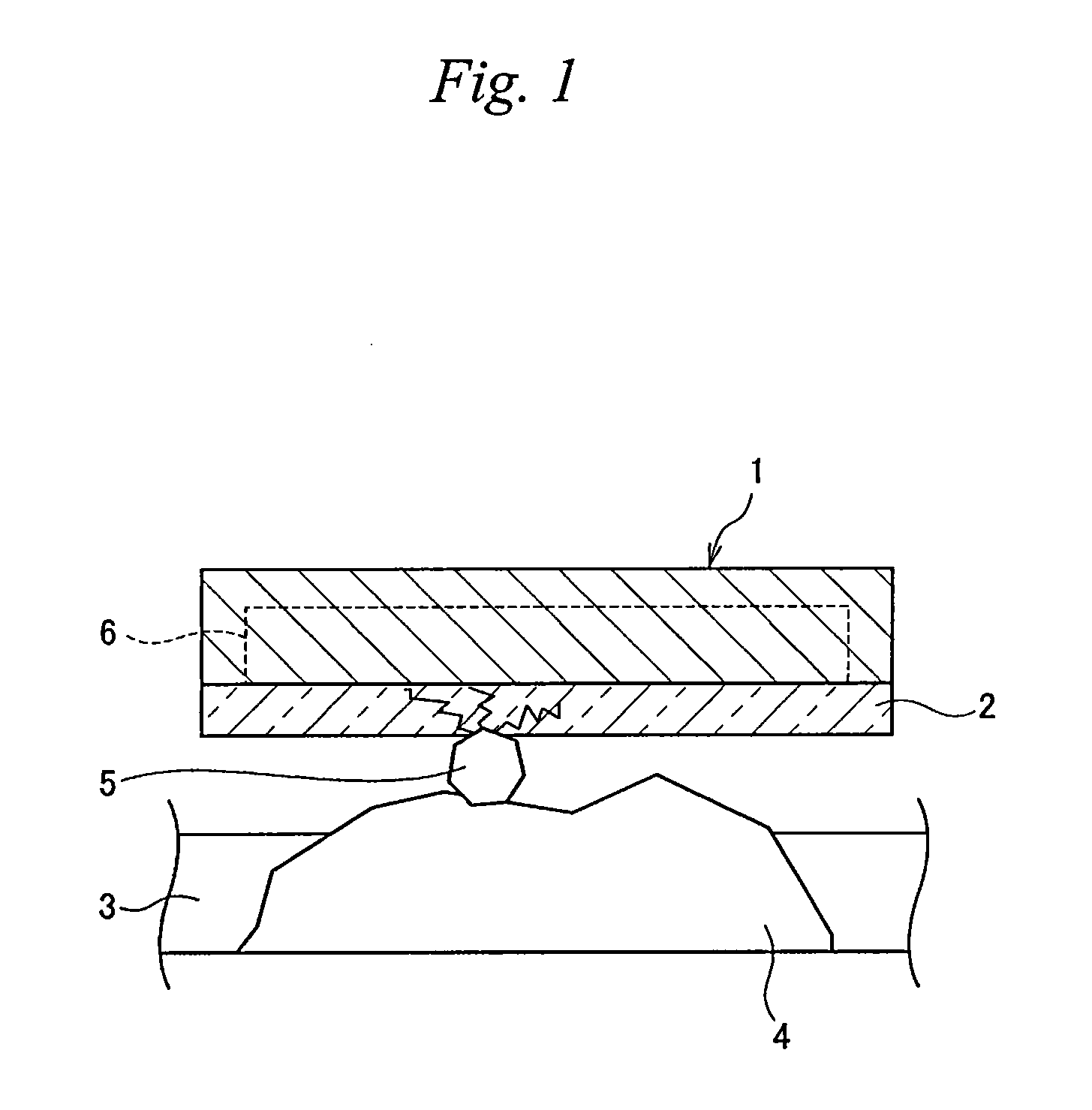

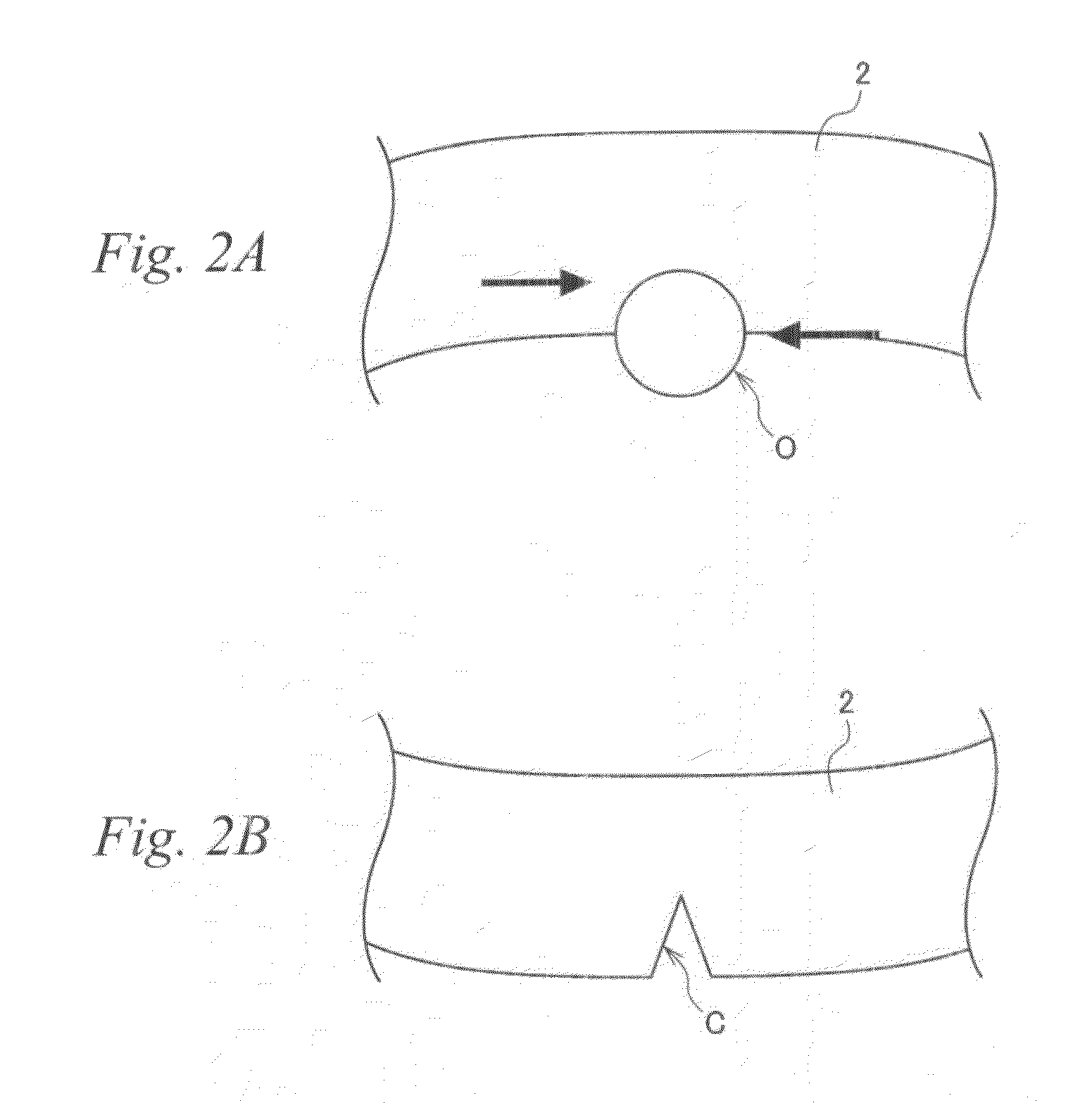

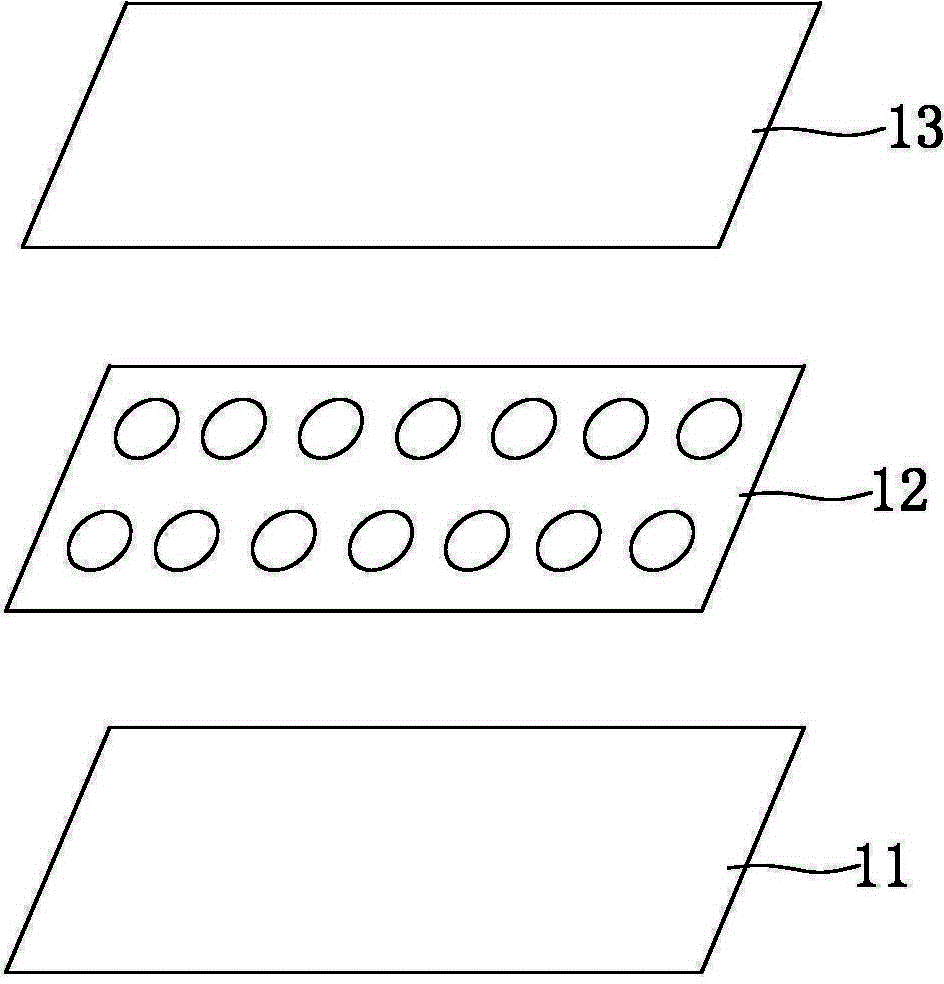

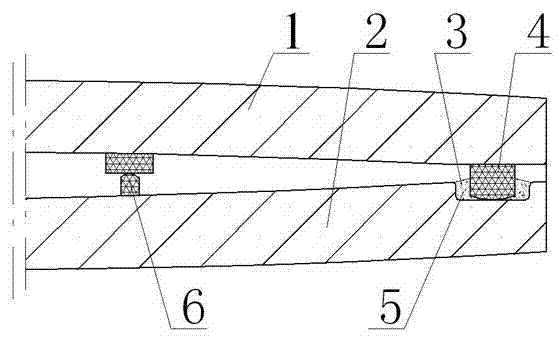

[Object] To provide a method of manufacturing a reinforced plate glass by which glass surface strength can be sufficiently increased, and a stable quality reinforced plate glass is manufactured at high production efficiency, and to provide a reinforced plate glass manufactured by the manufacturing method.[Solving Means] A reinforced plate glass (10) is formed of an inorganic oxide glass, and is provided with a compression stress layer by chemical reinforcement on plate surfaces (11, 12) opposed to each other in a plate thickness direction. Plate end faces (13, 14, 15, 16) have regions where a compression stress is formed and regions where no compression stress is formed.

Owner:NIPPON ELECTRIC GLASS CO LTD

Display cover glass and display cover glass fabrication method

ActiveUS20140370264A1Increase the surface compressive stressGood wear resistanceDigital data processing detailsSynthetic resin layered productsDisplay deviceCompressive strength

The present invention provides a cover glass for a display, having high durability to slow cracking and strong abraded strength even though a compressive stress is large and a depth of a compressive stress layer is deep. The present invention relates to a cover glass for a display, in which a depth of a compressive stress layer (DOL) is 30 μm or more, a surface compressive stress is 300 MPa or more, a position (HW) at which a compressive stress is half of a value of the surface compressive stress is a position of 8 μm or more from a glass surface, and the depth of the compressive stress layer (DOL) and the position (HW) at which the compressive stress is half of the value of the surface compressive stress satisfy the following formula:0.05≦HW / DOL≦0.23 (1).

Owner:ASAHI GLASS CO LTD

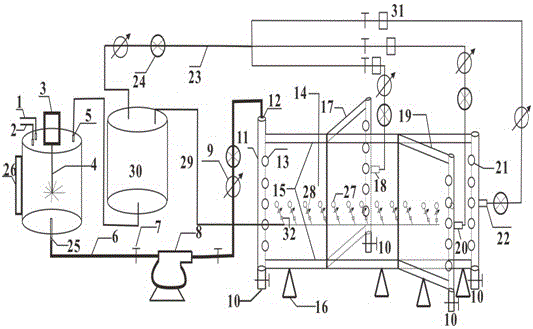

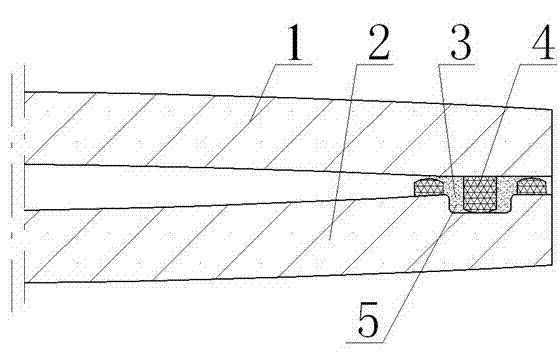

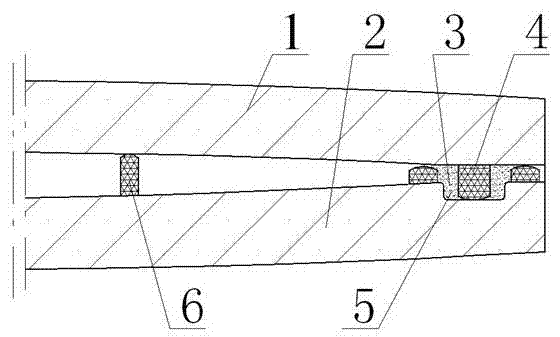

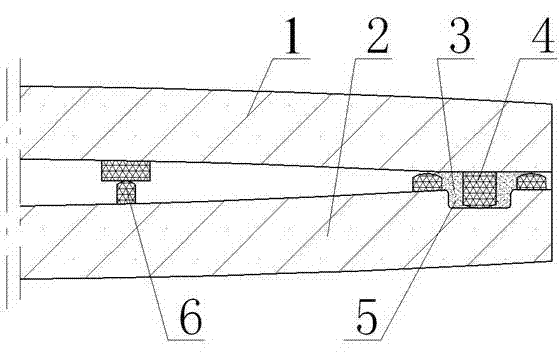

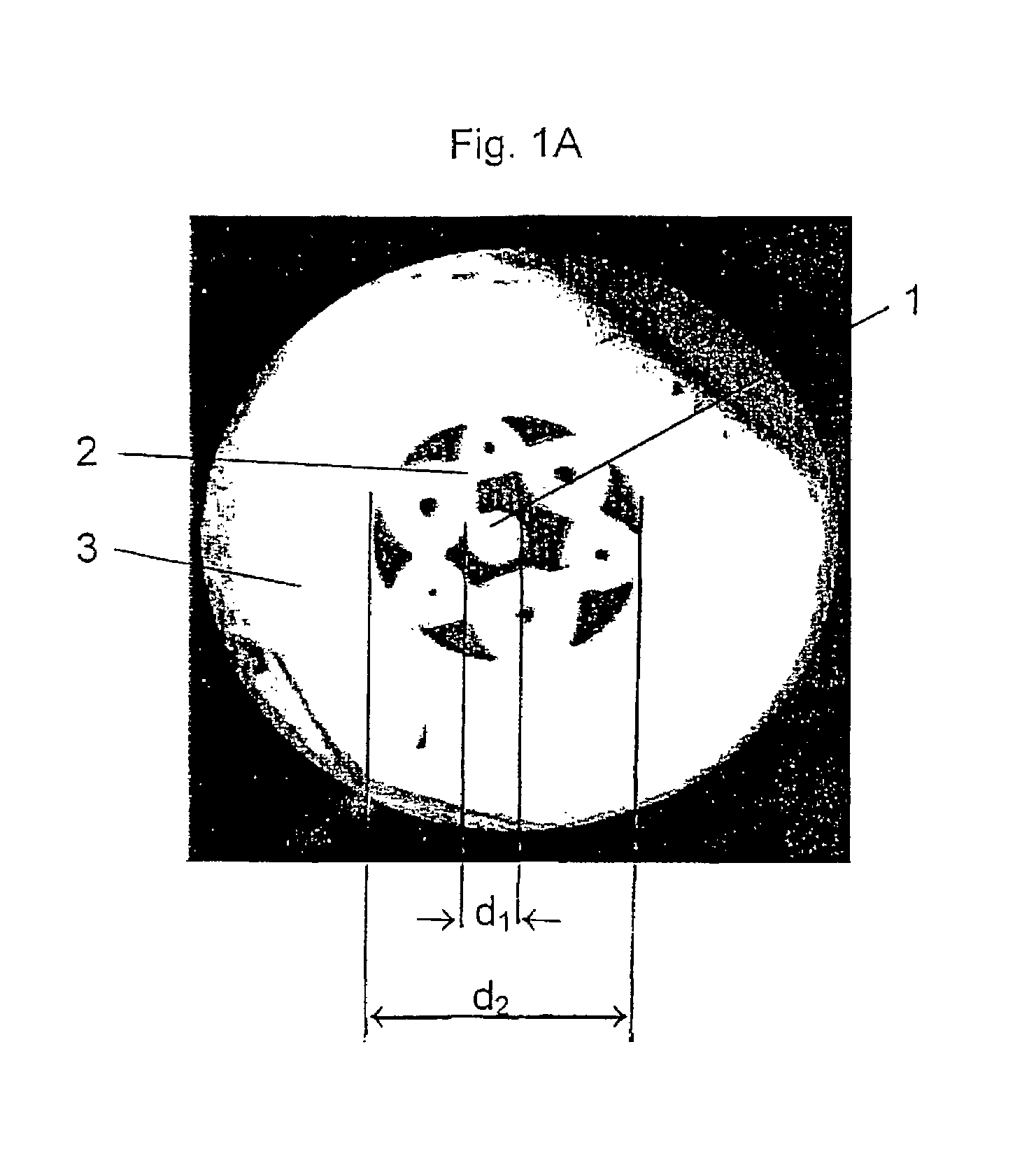

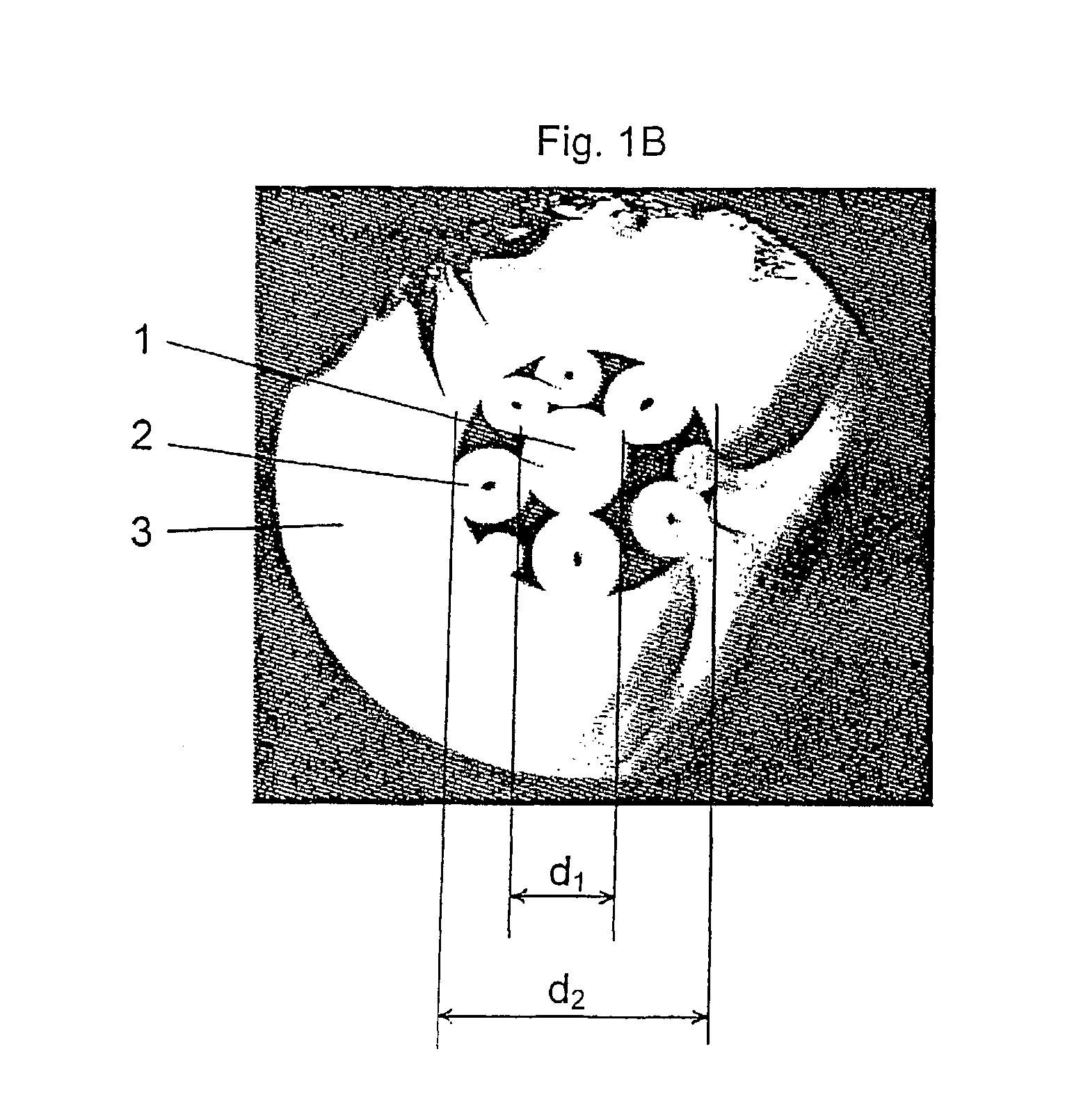

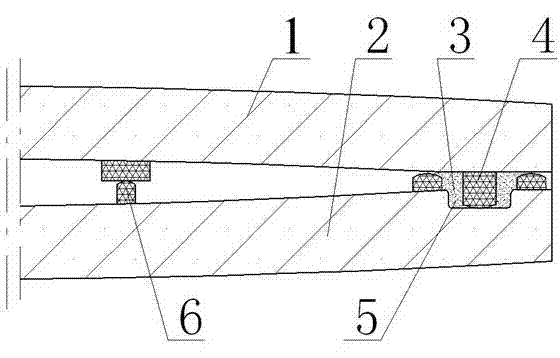

Device and method for simulating shale complex crack sand pavement

The invention relates to a testing device and method for simulating pavement of propping agents in a complex manual crack. The testing device is composed of a fracturing fluid preparing tank, a fluid injection pump, a simulation shaft, a plurality of adjustment valves, a flow meter, a pressure meter and the complex manual crack. The manual crack is composed of a primary crack body and a plurality of secondary crack bodies on the periphery of the primary crack body. Different crack states can be simulated. The manual crack is made of transparent organic glass, and the width and the complex degree can be manually arranged. By means of the testing device and method, the flow conditions of sand carrying fluid in the complex manual crack and the pavement conditions of the popping agents under the conditions of different crack widths, different sand carrying fluid sand proportions, different fracturing fluid leak-off rates, different crack complex degrees and the like can be simulated, and the visualization of migration and sedimentation of the propping agents in the complex manual crack can be achieved in the test process.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

Pulling roll material for manufacture of sheet glass

A pulling roll for glass manufacture comprised of a high-temperature millboard material. The millboard comprises aluminosilicate refractory fiber, silicate, mica, and kaolin clay. A method of manufacturing a pulling roll is disclosed, together with a roll produced by the methods disclosed herein. The method comprises forming a pulling roll and densifying at least a portion of the pulling roll by exposing to the pulling roll to high temperatures.

Owner:CORNING INC

Pulling roll material for manufacture of sheet glass

Owner:CORNING INC

Convex low-altitude glass welded by metal solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951814AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideAlloy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper glass and the lower glass are respectively provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

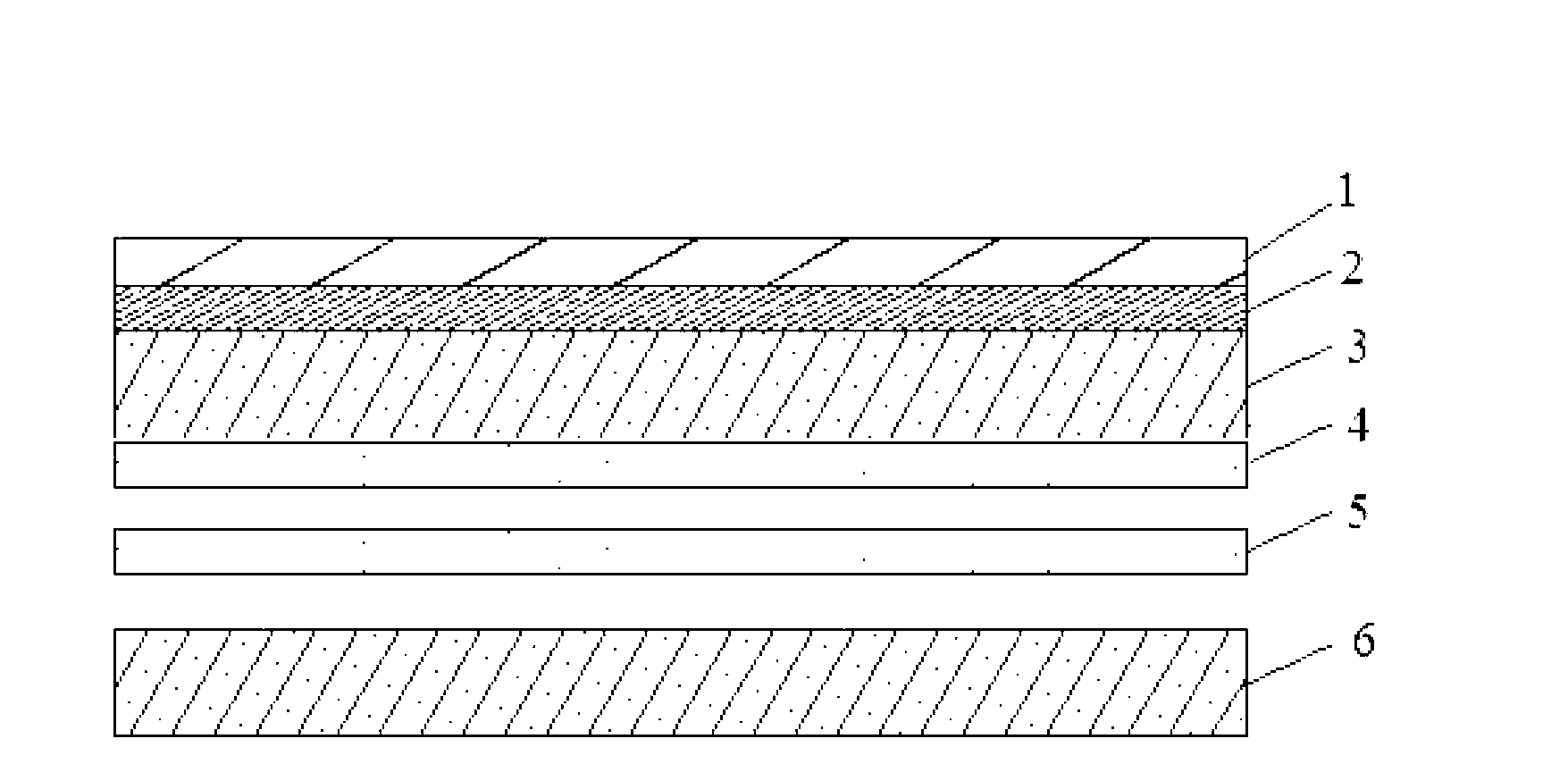

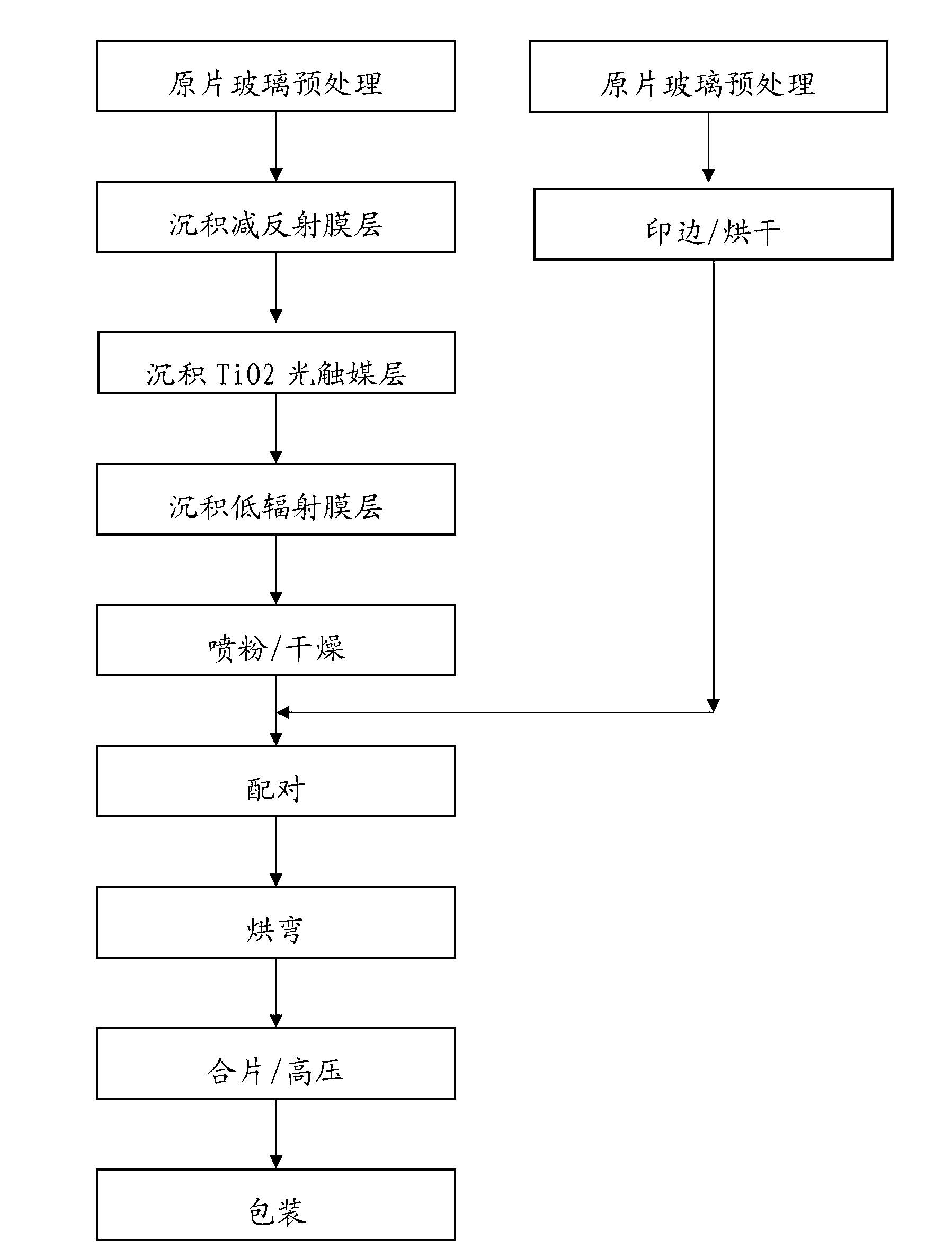

Anti-reflection, low-radiation and easy-cleaning coated glass capable of roasting and bending and manufacture method thereof

InactiveCN103241961AKeep it clean and shinyImprove transmittanceGlass/slag layered productsPolyvinyl butyralTransmittance

The invention relates to an anti-reflection, low-radiation and easy-cleaning coated glass capable of roasting and bending and a manufacture method of the coated glass. The glass is an anti-reflection, low-radiation and easy-cleaning coated laminated glass capable of roasting and bending, and the anti-reflection, low-radiation and easy-cleaning coated laminated glass capable of roasting and bending is formed by sequentially overlapping anti-reflection and low-radiation coated glass with polyvinyl butyral and a glass plate B, wherein the anti-reflection and low-radiation coated glass is structured by comprising a TiO2 photocatalyst layer, an anti-reflection film layer, a glass plate A and a low-radiation film layer which are overlapped from top to bottom in sequence. Compared with the prior art, the laminated glass manufactured from the anti-reflection, low-radiation and easy-cleaning coated glass has an easy-cleaning characteristic, also has the effects of increasing the visible light transmittance by 3 to 4% and reducing the visible light reflectance from 12 to 15% to 3 to 4%, can prevent the sight from being interfered by a projection of a matter in a car on the glass during driving, and has the visible light transmittance not less than 70% and sun light transmittance not greater than 50%; and the anti-reflection, low-radiation and easy-cleaning coated glass capable of roasting and bending is particularly suitable for a front windshield of the car.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

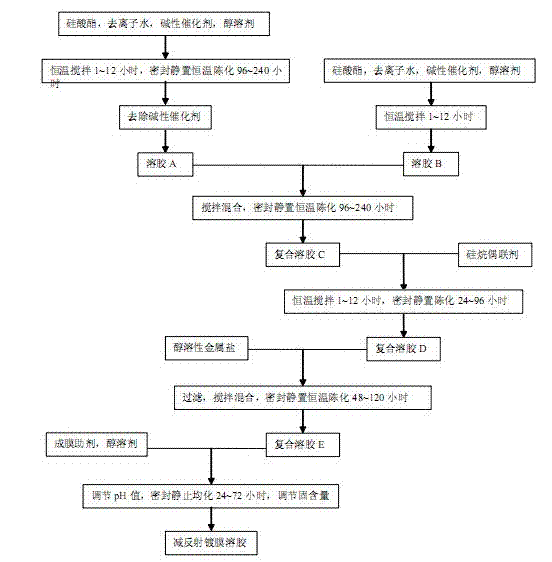

Composite sol for anti-reflection coating and anti-reflection coated photovoltaic glass

InactiveCN102850894AHigh mechanical strengthImprove smoothnessCoatingsColloidal chemistry detailsWeather resistanceSolar cell

The invention relates to the field of manufacture of packaging glass for solar cells, and especially relates to a multi-step catalyzed composite sol for anti-reflection coating, and anti-reflection coated photovoltaic glass manufactured by the composite sol. The composite sol for anti-reflection coating is prepared from the following raw materials by the following method which comprises steps of: preparing sol A, preparing sol B, preparing composite sol C, preparing composite sol D, preparing composite sol E, and preparing the composite sol for anti-reflection coating. An anti-reflection film coated by the sol only needs coating once; therefore the production cost is low, and the process is high-efficient and easily-controlled; the composite sol of the invention is suitable for large-area coating production of photovoltaic glass; the coated product can pass related examinations, such as film hardness, adhesion, and weatherability.

Owner:杭州美格玻璃有限公司

Pulling roll material for manufacture of sheet glass

A pulling roll for glass manufacture made of a high-temperature millboard material. The millboard includes aluminosilicate refractory fiber, silicate, mica, and kaolin clay. A method of manufacturing a pulling roll also is disclosed, together with a roll produced by the methods disclosed herein. The method includes forming a pulling roll and densifying at least a portion of the pulling roll by exposing the pulling roll to high temperatures.

Owner:CORNING INC

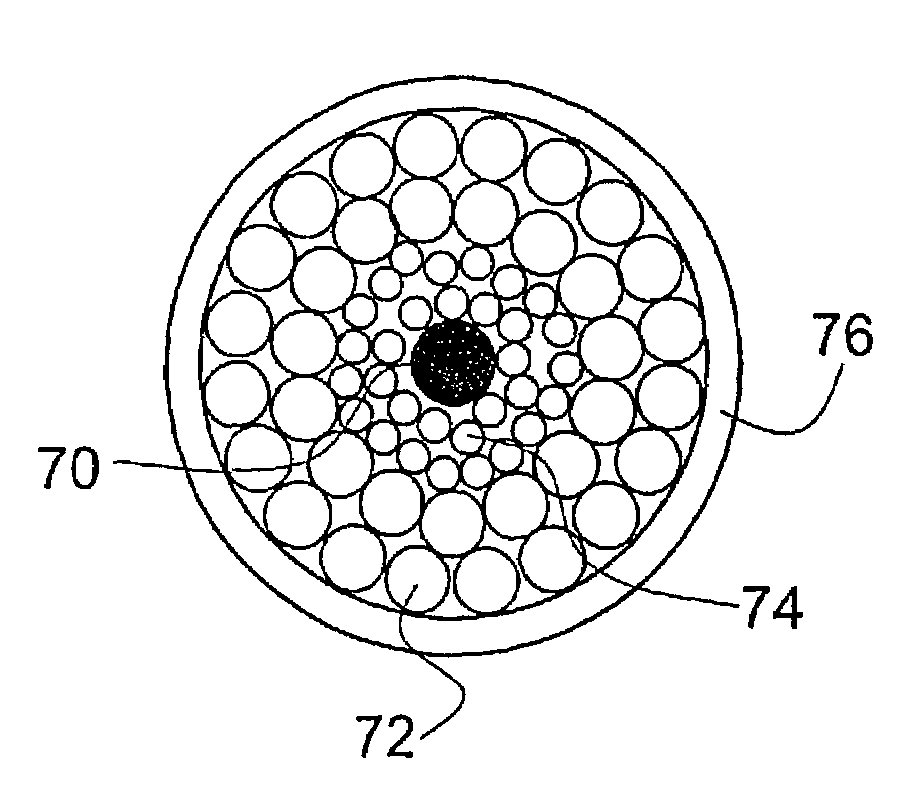

Holey optical fibres of non-silica based glass

InactiveUS7155099B2Mismatch problemMinimal numberGlass making apparatusOptical fibre with multilayer core/claddingFibre typeRare earth

To overcome problems of fabricating conventional core-clad optical fibre from non-silica based (compound) glass, it is proposed to fabricate non-silica based (compound) glass optical fibre as holey fibre i.e. one contining Longitudinal holes in the cladding. This removes the conventional problems associated with mismatch of the physical properties of the core and clad compound glasses, since a holey fibre can be made of a single glass composition. With a holey fibre, it is not necessary to have different glasses for the core and cladding, since the necessary refractive index modulation between core and cladding is provided by the microstructure of the clad, i.e. its holes, rather than by a difference in materials properties between the clad and core glasses. Specifically, the conventional thermal mismatch problems between core and clad are circumvented. A variety of fibre types can be fabricated from non-silica based (compounds) glasses, for example: single-mode fibre; photonic band gap fibre; highly non-linear fibre; fibre with photosensitivity written gratings and other refractive index profile structures; and rare-earth doped fibres (e.g. Er, Nd, Pr) to provide gain media for fibre amplifiers and lasers.

Owner:UNIV OF SOUTHAMPTON

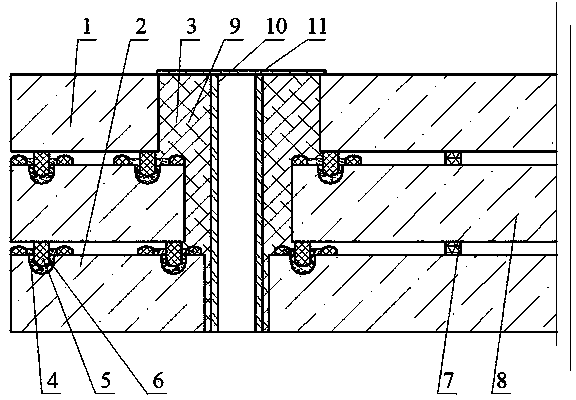

Plane double-vacuum-layer glass with sealing strips and grooves and mounting holes through metal welding

The invention provides plane double-vacuum-layer glass provided with sealing strips and grooves and mounting holes through metal welding. The plane vacuum glass comprises upper glass, lower glass and middle glass, and is characterized in that the plane double-vacuum-layer glass is provided with mounting holes; sealing strips are arranged at the peripheries of lower surfaces of the upper glass and the middle glass, and the mounting holes; sealing strips and sealing grooves are formed in the peripheries of the upper surfaces of the middle glass and the lower glass, and the mounting holes; the peripheries of three blocks of glass are automatically welded together through metal welding material in a vacuum furnace; the mounting holes are sealed automatically by adopting metal welding material; two closed vacuum layers are formed among three blocks of glass; supporting materials arranged in a dot matrix manner are arranged in the vacuum layers. The manufacturing method and technology of the vacuum glass provided by the invention are simple, the vacuum glass and tempered vacuum glass manufactured through the manufacturing method and technology has the advantages that the mounting and use are convenient, the air tightness of the vacuum glass can be guaranteed, and the strength, heat insulation performance and sound insulation performance of the vacuum glass are increased.

Owner:戴长虹

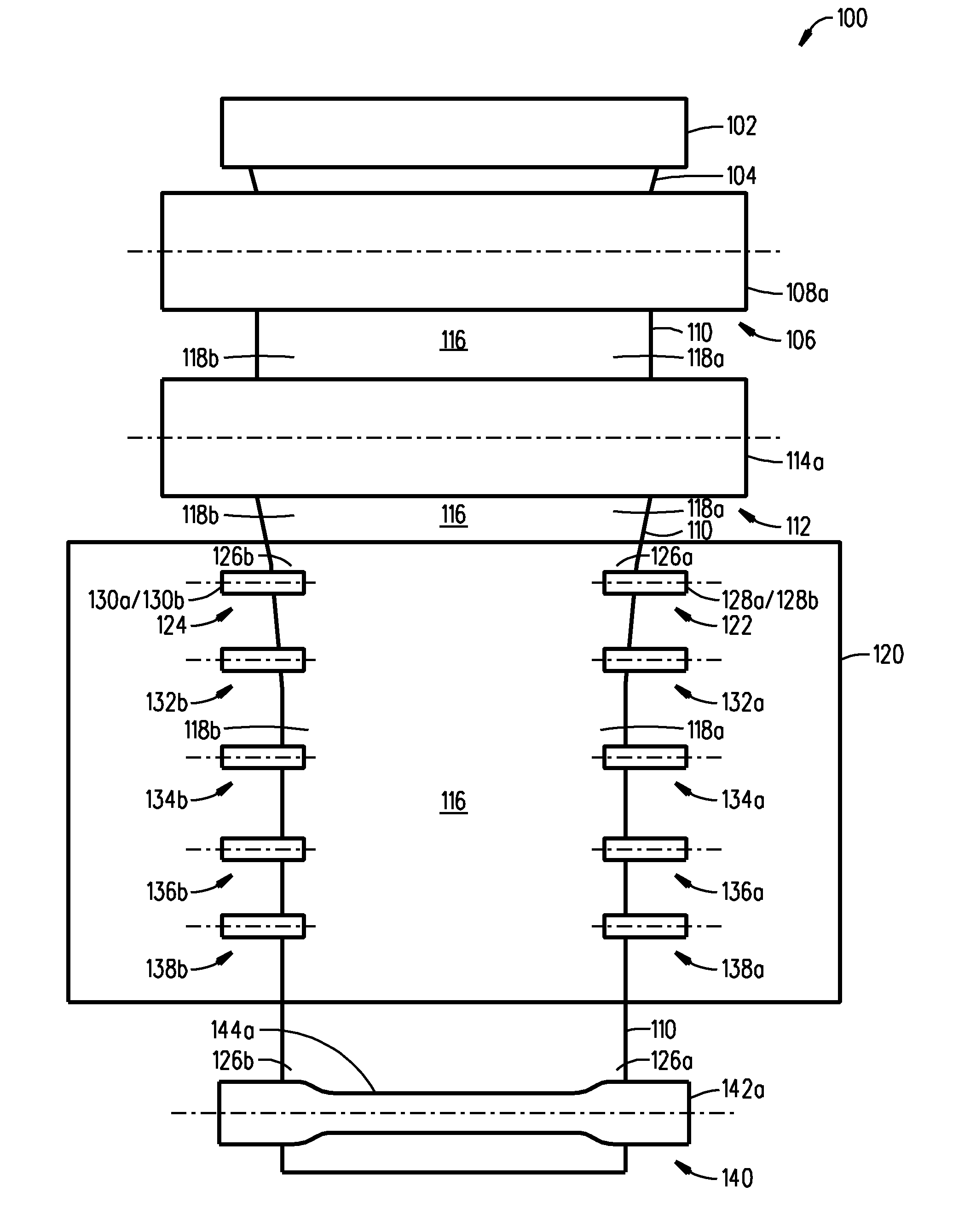

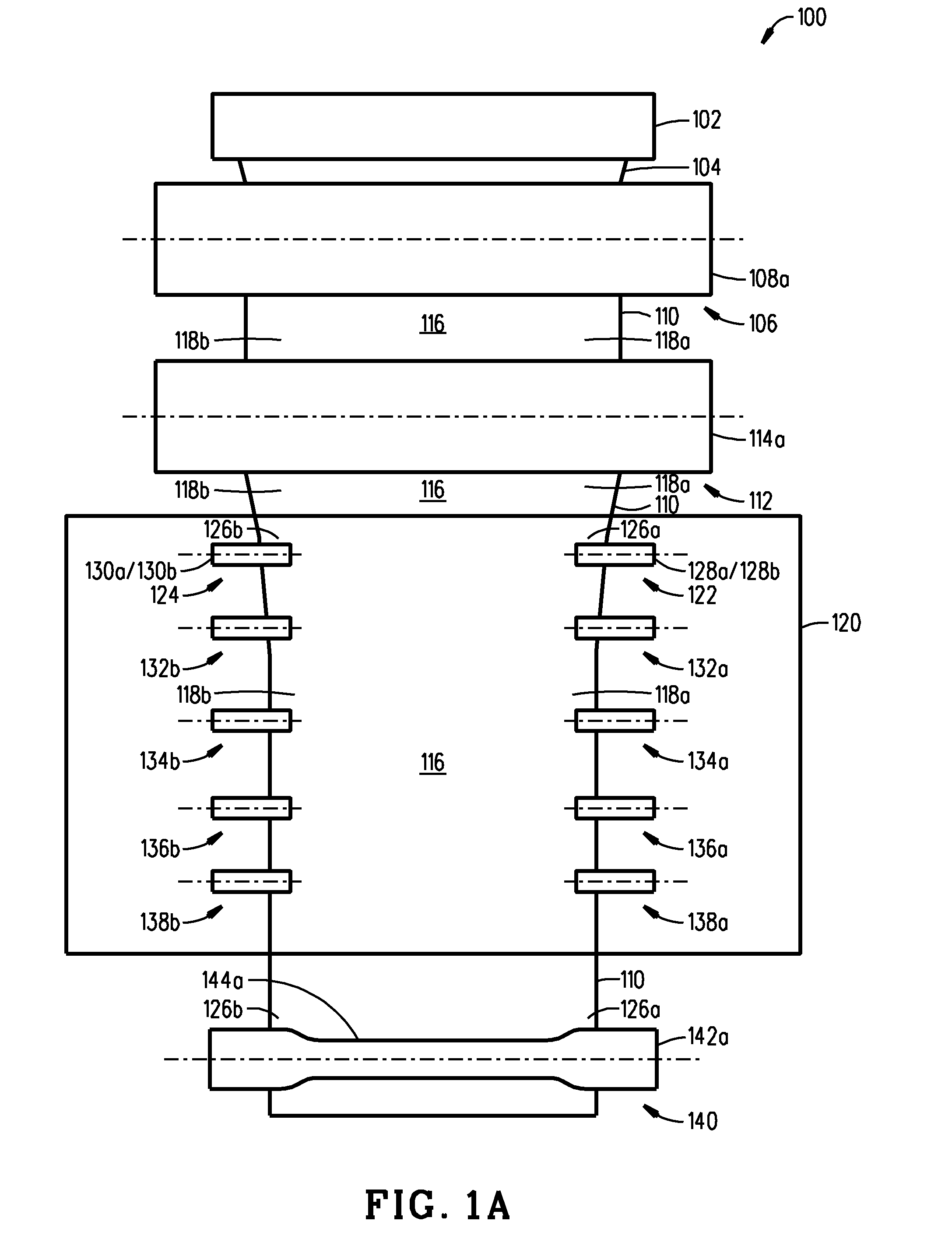

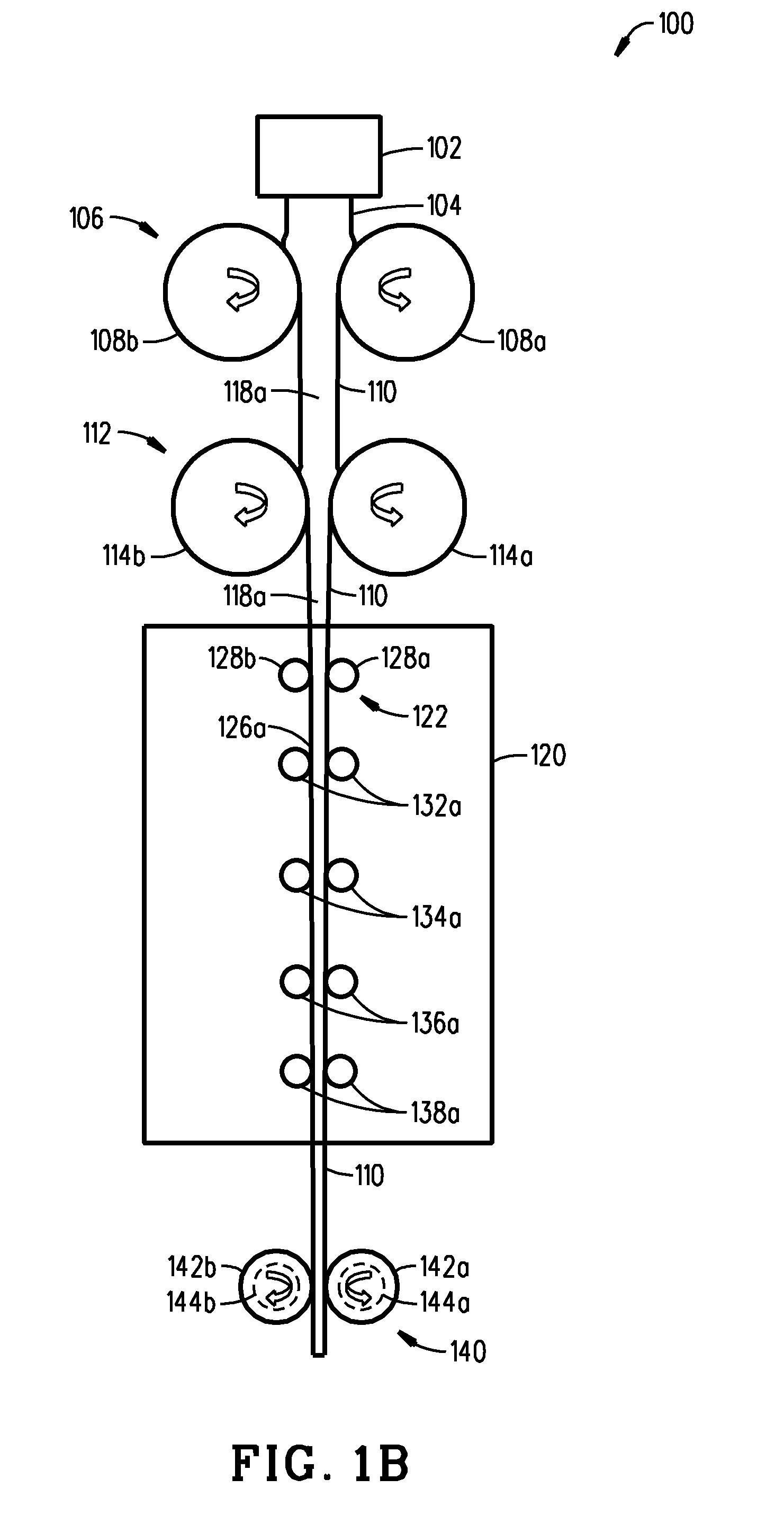

Glass manufacturing system and method for forming a high quality thin glass sheet

A glass manufacturing system (100, 100′, 100″) and method are described herein for forming a high quality thin glass sheet (110). In one embodiment, the glass manufacturing system and method use at least one of a compensated rolling roll (108a), a temperature controlled environment (120) and edge rolls (122, 124) to form a high quality thin glass sheet that has a thickness less than about 2 mm and more preferably less than about 100 μm.

Owner:CORNING INC

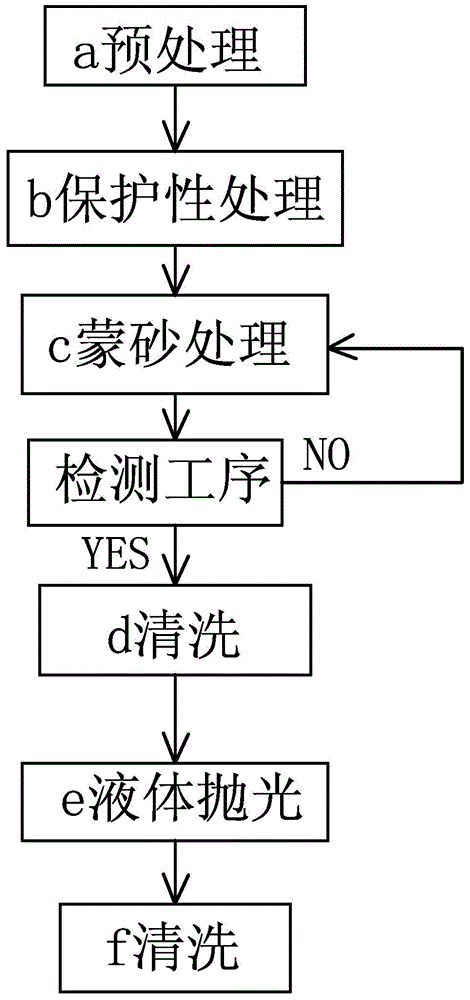

Anti-dazzle processing method for electronic product glass display screen

ActiveCN104829140AEliminate sharp cornersGood optical performanceFlexible article cleaningCleaning using toolsMegasonic cleaningEngineering

The invention provides an anti-dazzle processing method for an electronic product glass display screen and belongs to the technical field of display screen processing technology. The anti-dazzle processing method includes rinsing and dedusting the glass display screen in a rinsing tank and subjecting the rinsed and dedusted glass display screen to ultrasonic cleaning in an ultrasonic cleaner; sticking corrosion-resistant plastic protective films on four side faces and the back face of the glass display screen; heating frosting liquid to 20-26 DEG C, and soaking the glass display screen in the heated frosting liquid for 60-120 seconds; removing the protective films on the glass display screen; filling a jetting machine with a polishing solution, fixing the glass display screen, and jetting the polishing solution to the front face of the glass display screen through a spray head of the jetting machine for 180-300 seconds. The anti-dazzle processing method for the electronic product glass display screen has the advantages that the anti-dazzle processing method solves the technical problems of poor surface quality, bad hand feeling, weak anti-dazzle capability and the like of anti-dazzle glass manufactured by an existing anti-dazzle processing method for the display screen; microcosmic sharp corners are eliminated by means of adopting a unique high-pressure jetting and polishing mode, so that anti-dazzle capability is improved.

Owner:ZHEJIANG XINGXING TECH CO LTD

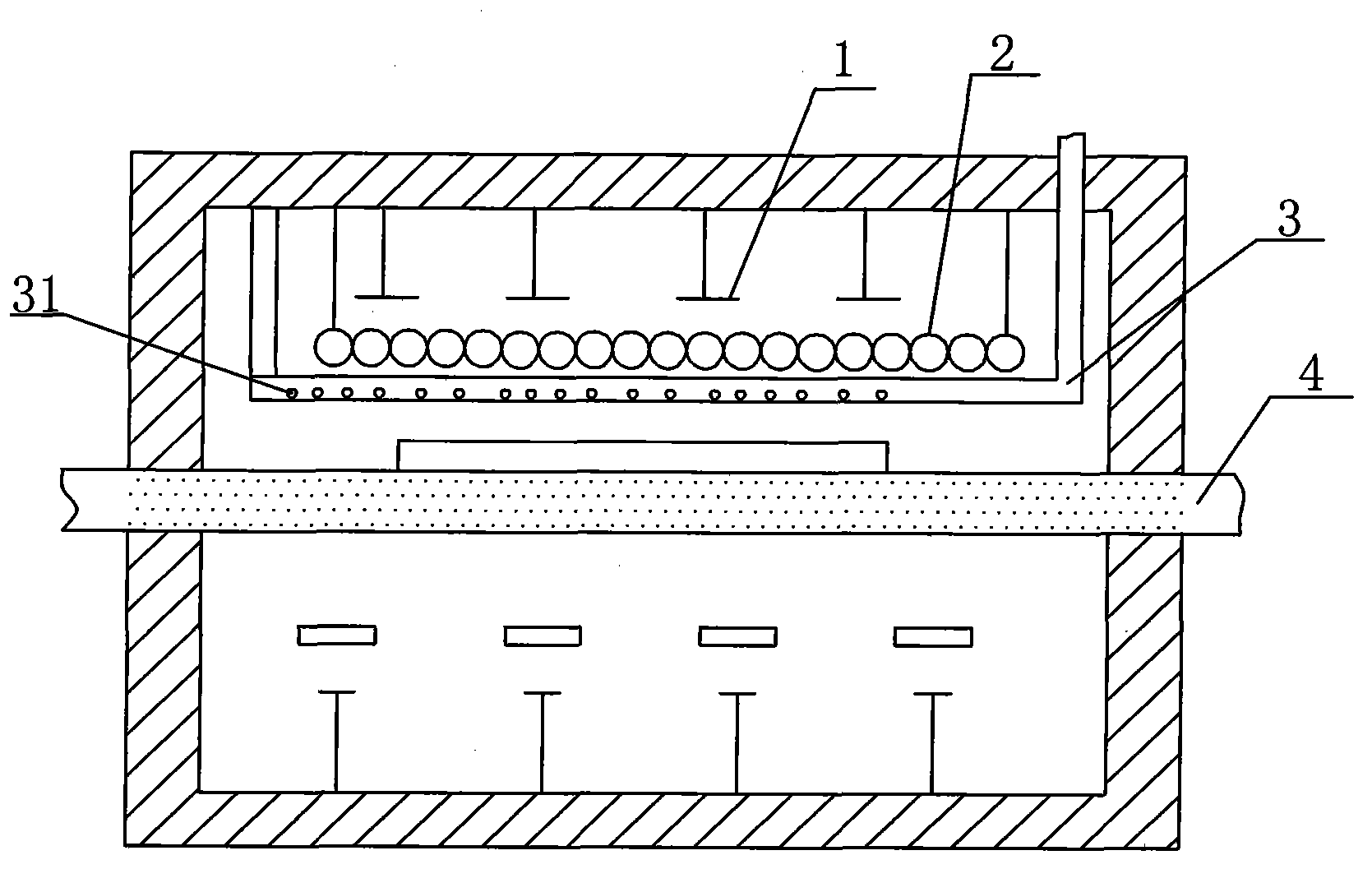

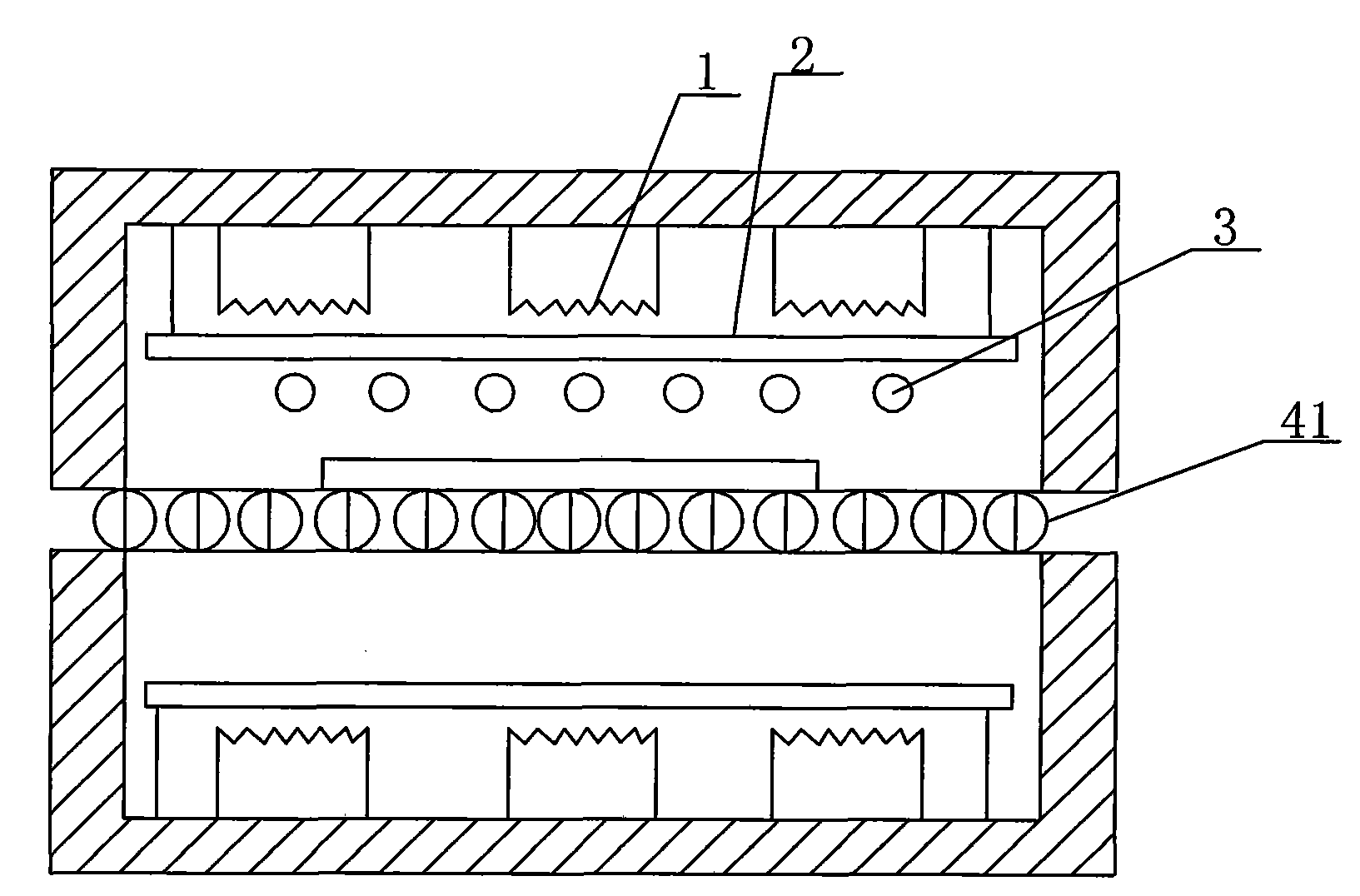

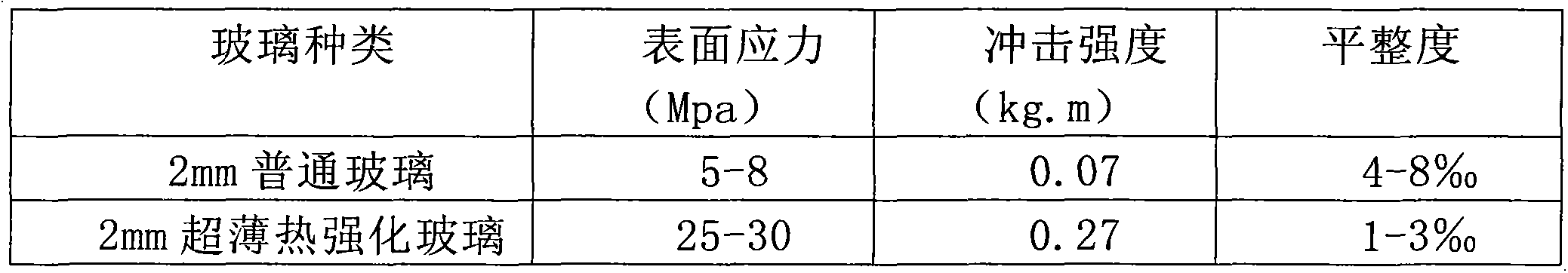

Manufacturing method of ultrathin heat-reinforced glass

InactiveCN103319082AHeating fastRadiation area is largeGlass tempering apparatusGlass manufactureToughness

The invention discloses a manufacturing method of ultrathin heat-reinforced glass. The manufacturing method comprises the following steps of: flatly placing ultrathin glass with the thickness of 1.8-2.2mm on a rolling way, adjusting the pressure of convection air in a toughening furnace to be 2000-4000pa / cm<2> with the convection time of 30-50s, simultaneously using the rolling way to drive the glass to do reciprocating movement for 40-50S in the toughening furnace at a speed of 20-30mm / s, and then adjusting the operating speed of the rolling way to be 160-175mm / s till the glass is heated to be 623-630 degrees. The glass manufactured by utilizing the method has the advantages that the generation of 'white mist' is avoided, and the glass is good in flatness, high in strength and good in toughness.

Owner:CHANGZHI SHENGLONG IND

Luminous glass film

InactiveCN102618180AImprove luminous brightnessGood luminous effectNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer resinPolyresin

The invention belongs to the technical field of interlayers in interlayer glass, and particularly relates to a luminous glass film. The layer structure of the luminous glass film comprises a luminous layer, wherein the luminous layer comprises the following components in parts by weight: 100 parts of polymer resin, 5-50 parts of light-storing long-afterglow lightening paint, 0-10 parts by weight of a dispersing agent and 0-5 parts by weight of a coupling agent. The glass film has high luminous performance, the interlayer glass manufactured by using the glass film can be applied to decoration, safety indication, display function and the like, and has the safety of interlayer glass.

Owner:TIANJIN SUNRAY PLASTIC PROD

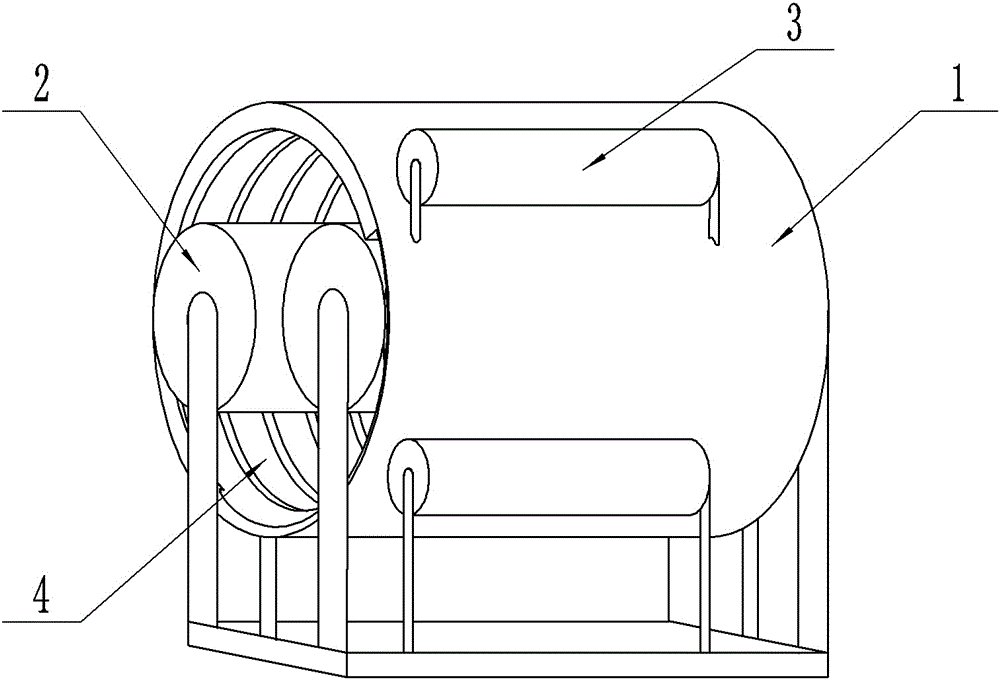

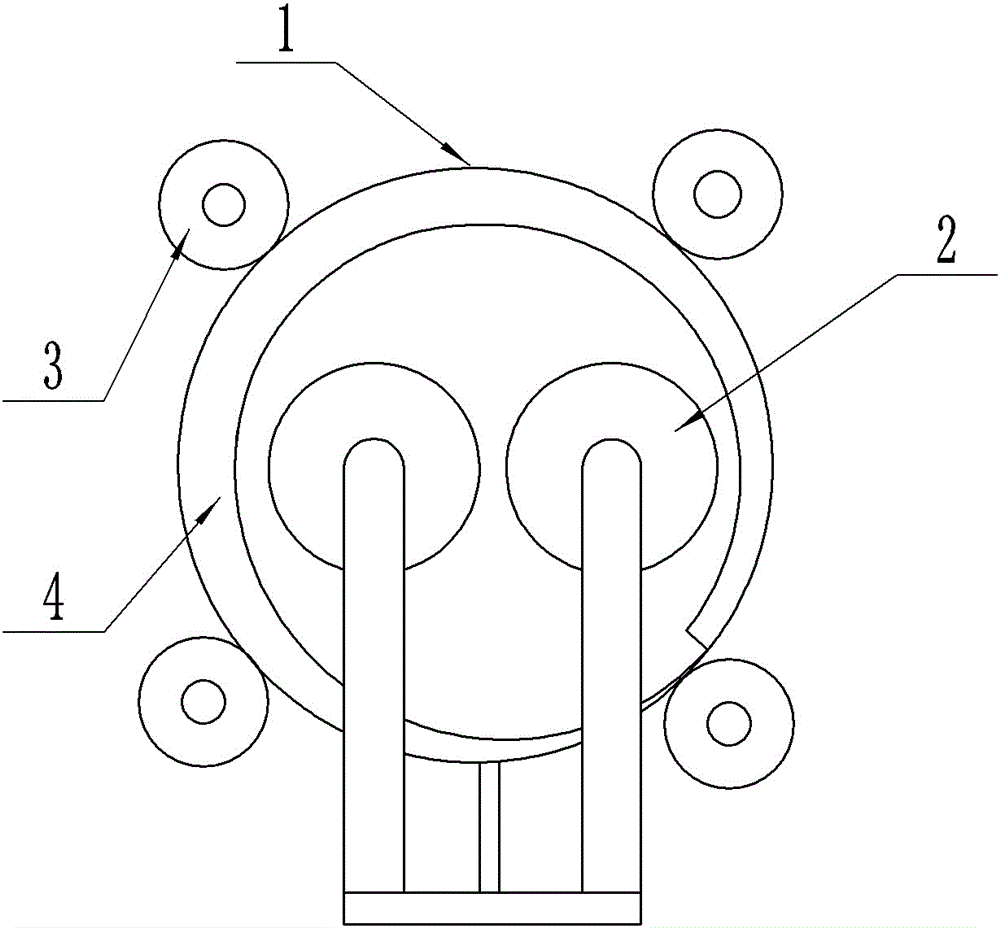

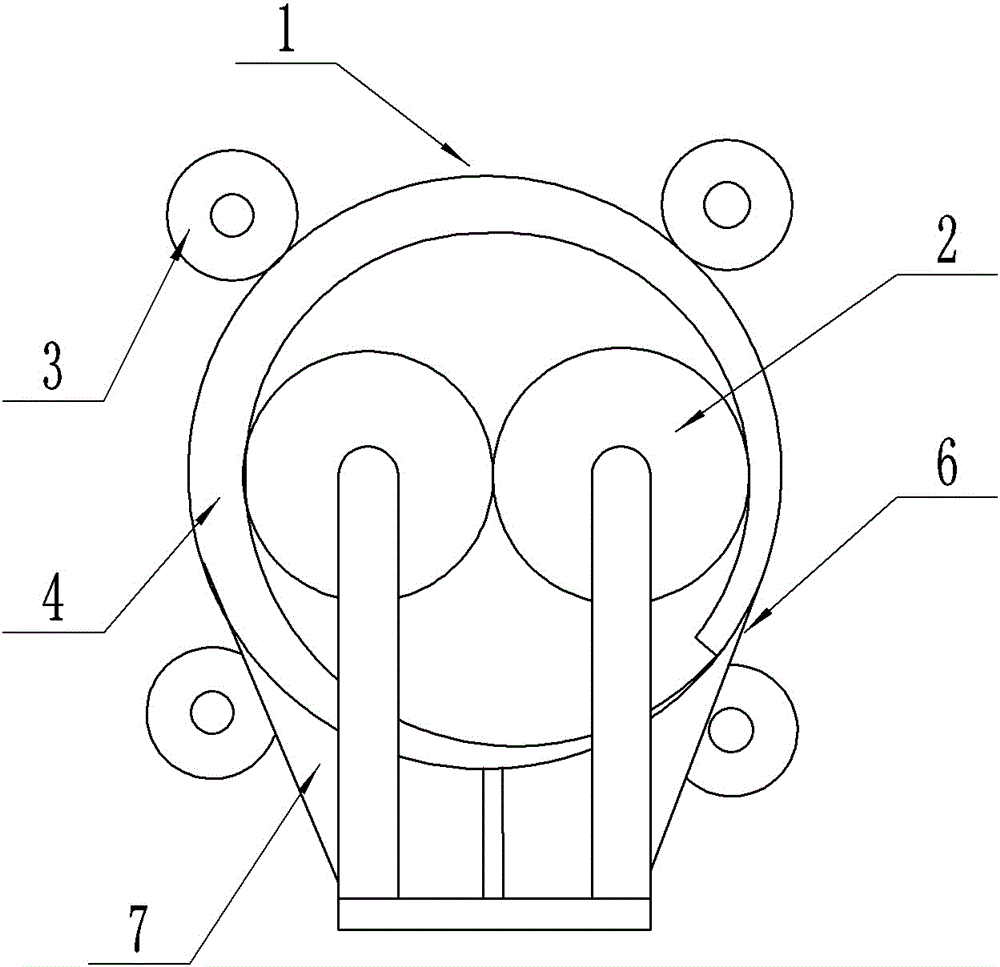

Waste glass crushing device

ActiveCN106694096AOvercome the problem of low crushing efficiencyCompletely brokenGrain treatmentsDrive wheelEngineering

The invention belongs to the technical field of glass processing, and particularly discloses a waste glass crushing mechanism. The waste glass crushing mechanism comprises a control mechanism and further comprises a rack, a rotation feeding barrel and a pair of crushing rollers arranged in the rotation feeding barrel. Drive wheels driving the rotation feeding barrel are arranged on the outer wall of the rotation feeding barrel in the circumferential direction. The rotation feeding barrel, the drive wheels and the crushing rollers are all connected to the rack. A spiral groove is formed in the inner wall of the rotation feeding barrel. The crushing rollers are conical rollers. The diameter of the parts, at the feeding end position of the rotation feeding barrel, of the crushing rollers is smaller than the diameter of the parts, at the discharging end position of the rotation feeding barrel, of the crushing rollers. The rotation feeding barrel, the drive wheels and the crushing rollers are all electrically connected with the control mechanism. Through the arrangement of the device, the problem that in the prior art, the glass crushing efficiency is low is solved, and crushing is more thorough; and meanwhile the quality of regenerated glass manufactured through recycled glass fragments is improved.

Owner:CHONGQING CONGBO ENERGY SAVING GLASS CO LTD

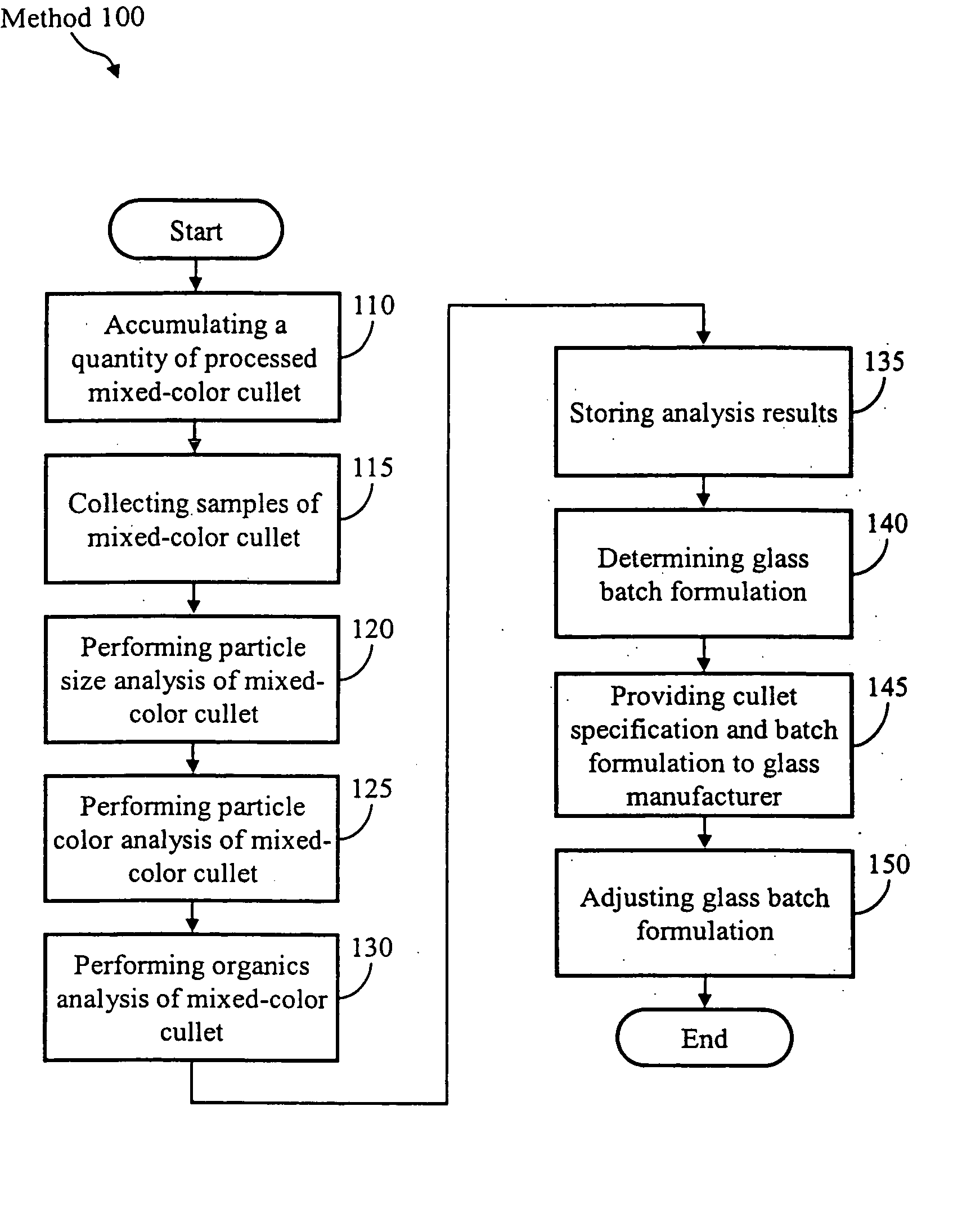

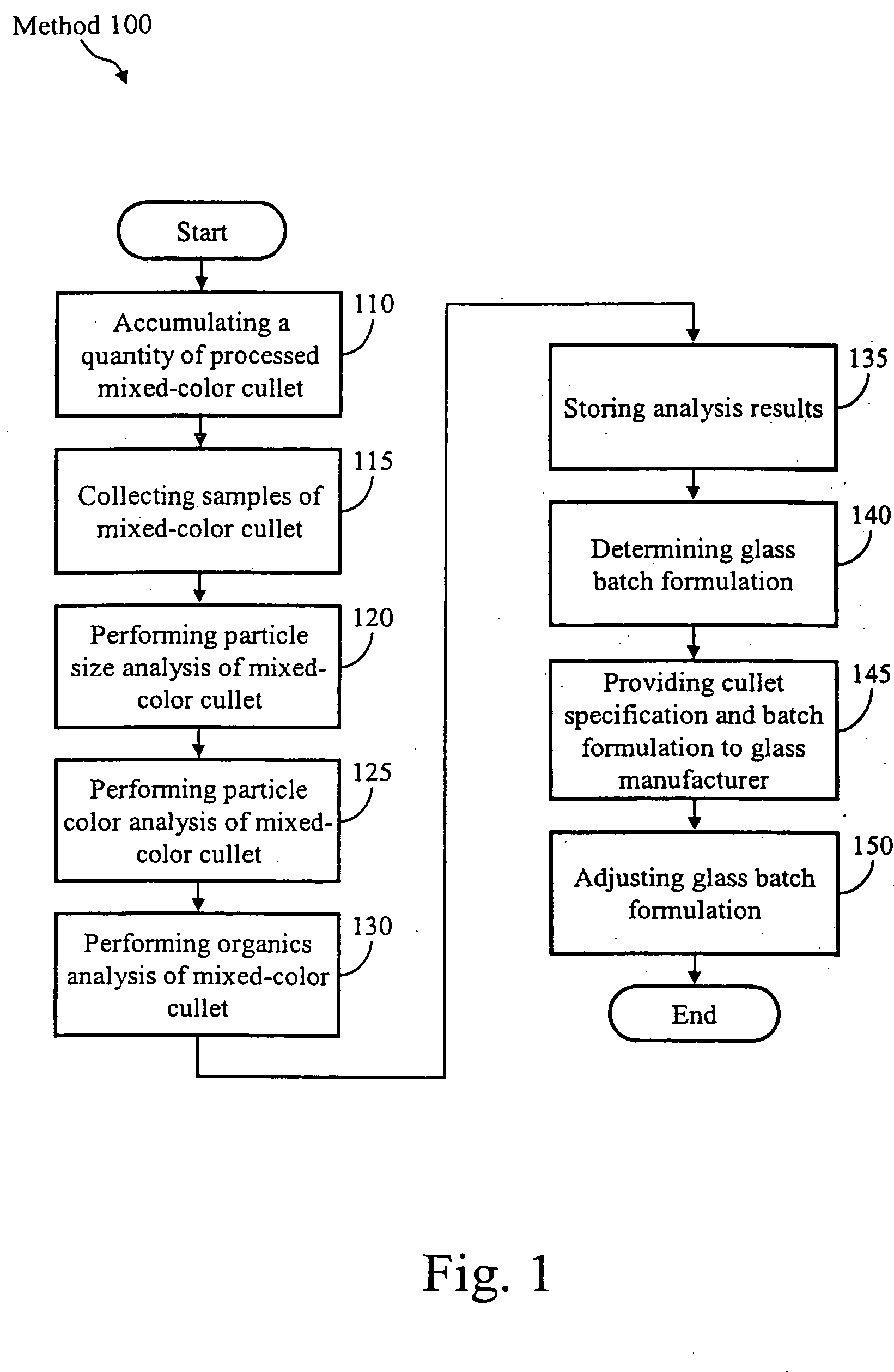

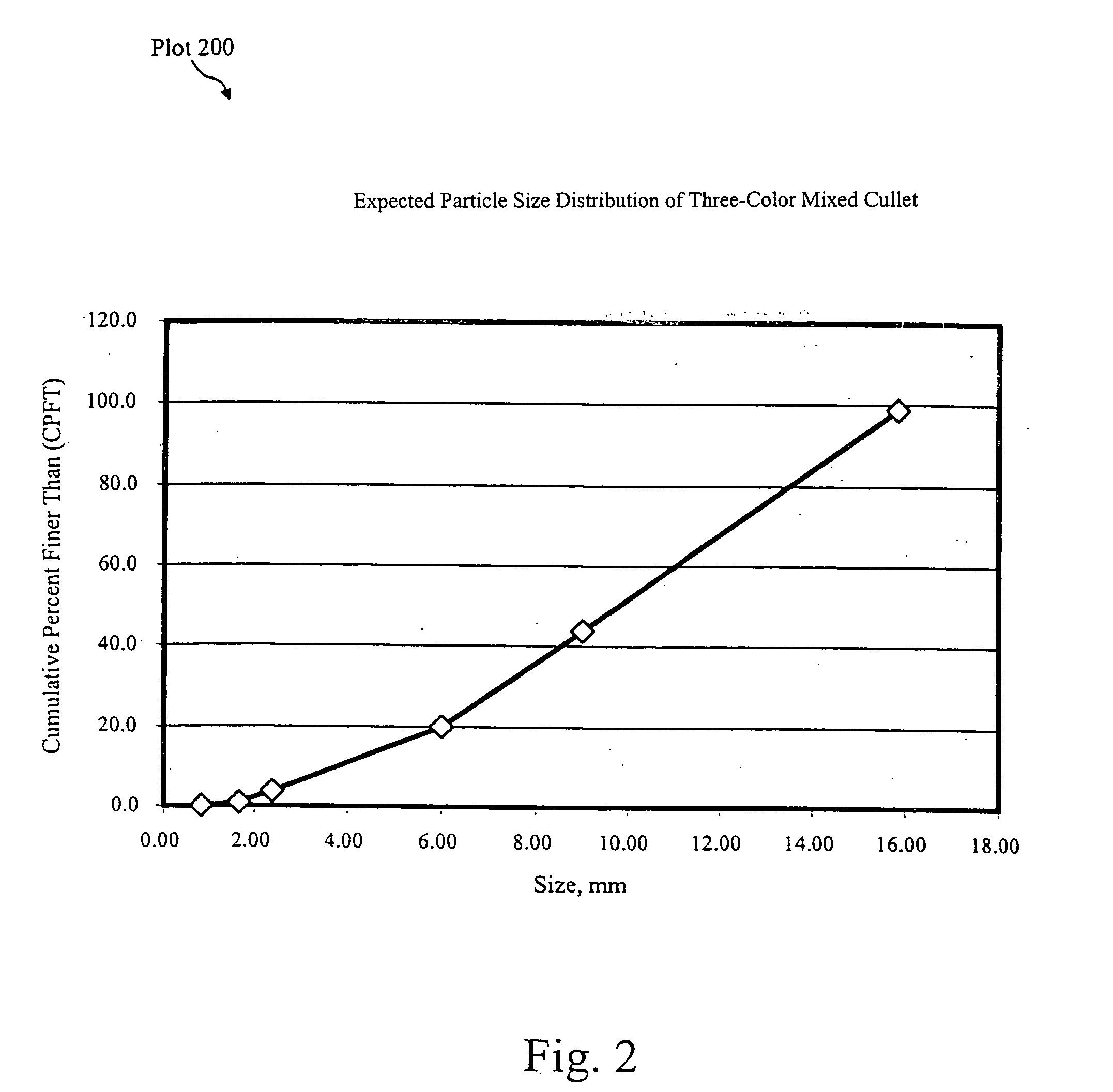

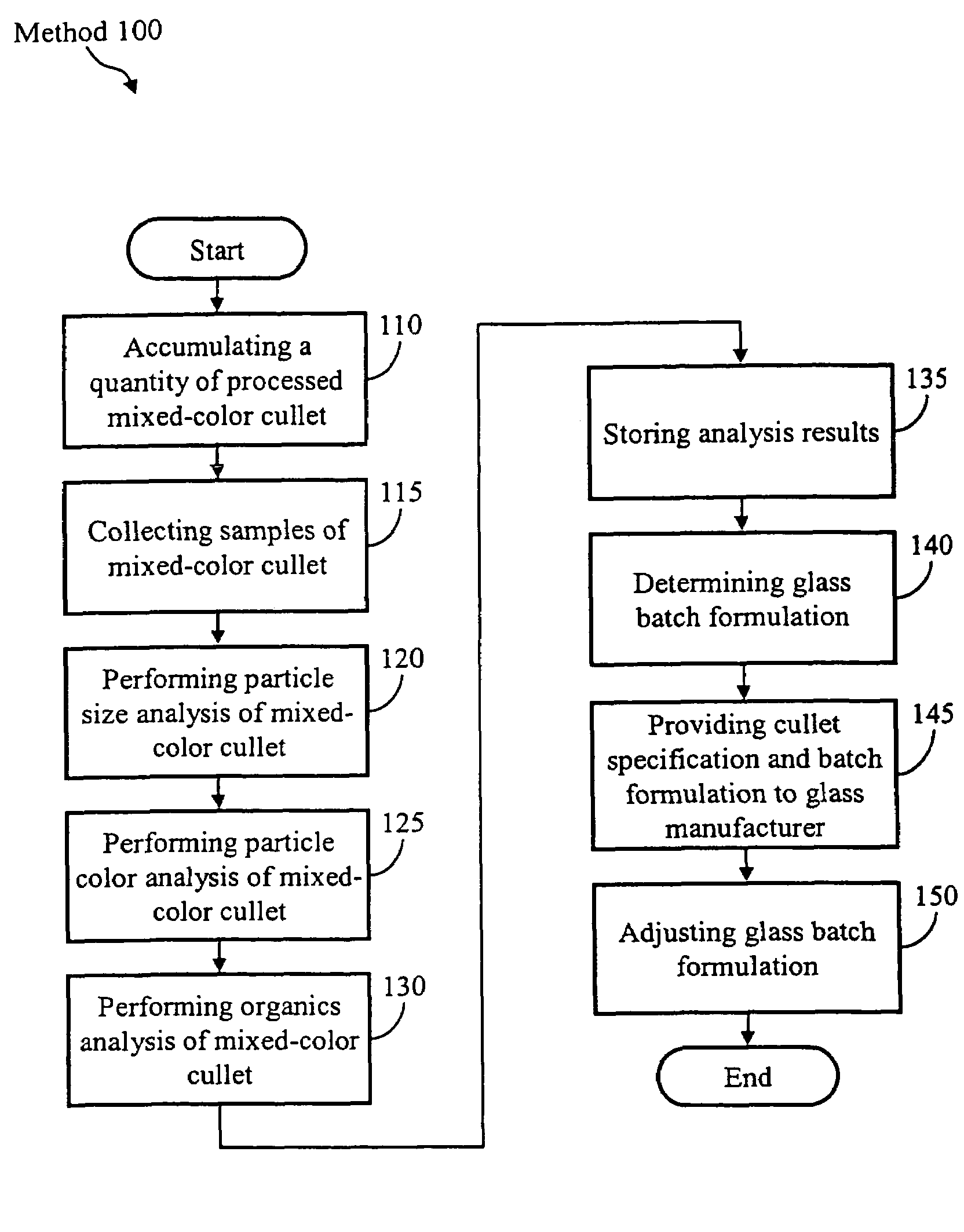

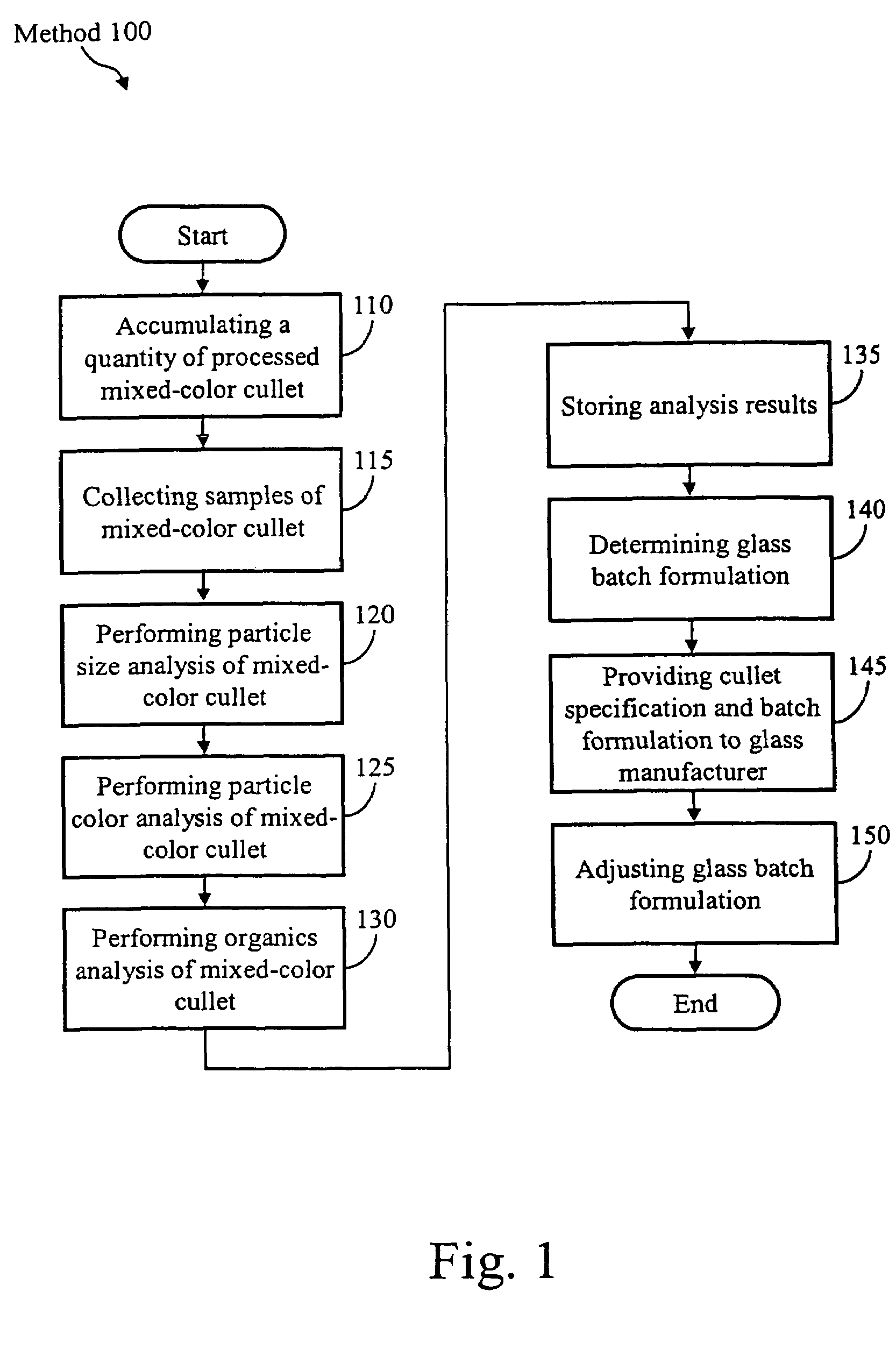

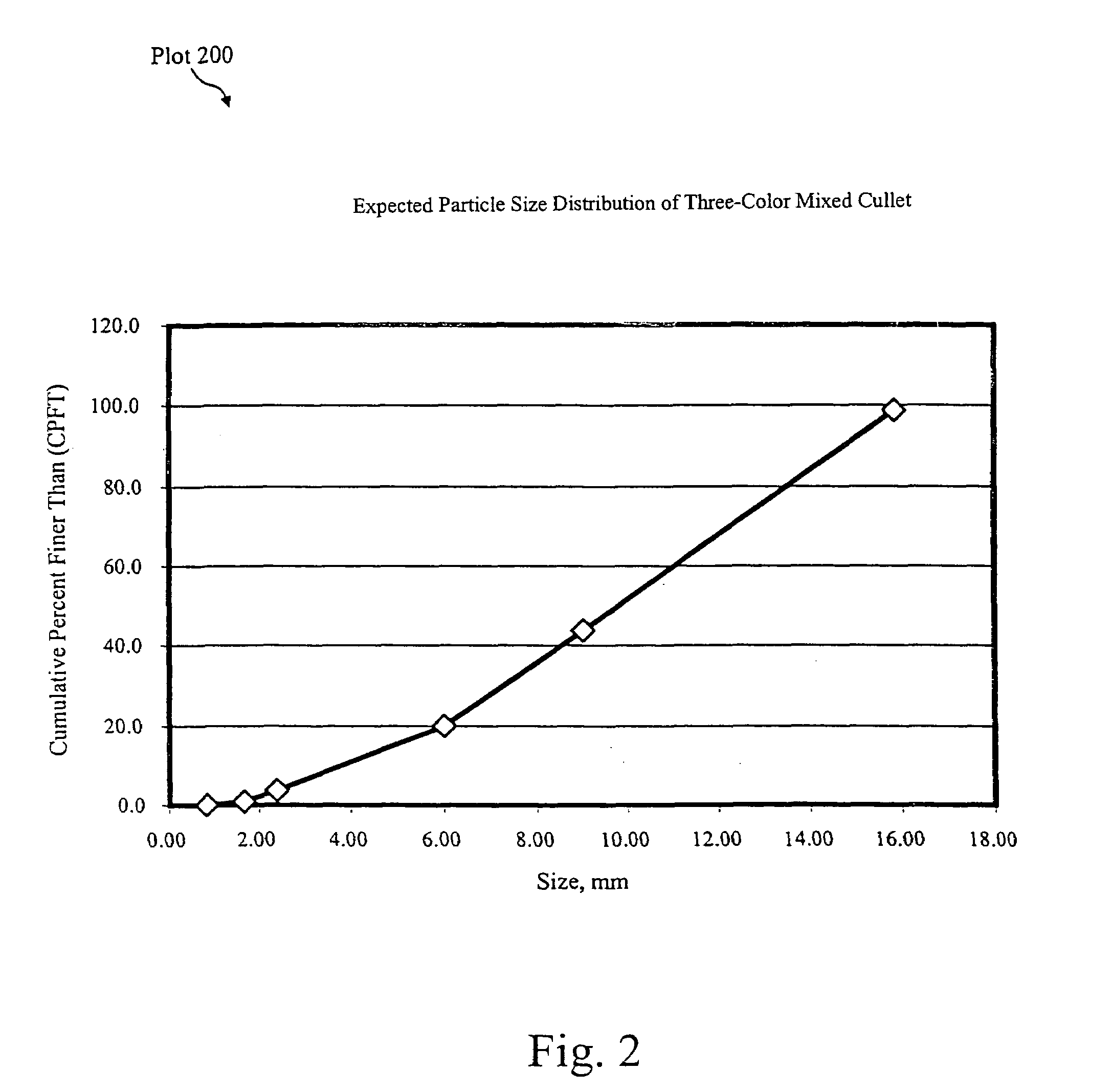

Method of analyzing mixed-color cullet to facilitate its use in glass manufacture

A method of determining the constituents and impurities in mixed-color cullet to facilitate use of mixed-color cullet in glass manufacture is provided. A glass batch formulation is adjusted based on the measured characteristics of supplied mixed-color cullet. More specifically, certain preferred aspects of the present invention include the steps of providing quantity of mixed-color cullet, collecting at least one sample of the mixed-color cullet, performing, either singularly or in combination, particle size analysis, particle color analysis, or organics analysis of the mixed-color cullet, optionally storing the analysis results, determining a glass batch formulation, providing the cullet specification and the batch formulation to a glass manufacturer, and adjusting glass batch formulation based on the cullet specification to ensure consistent glass quality.

Owner:CULCHROME LLC

Method of analyzing mixed-color cullet to facilitate its use in glass manufacture

Owner:CULCHROME LLC

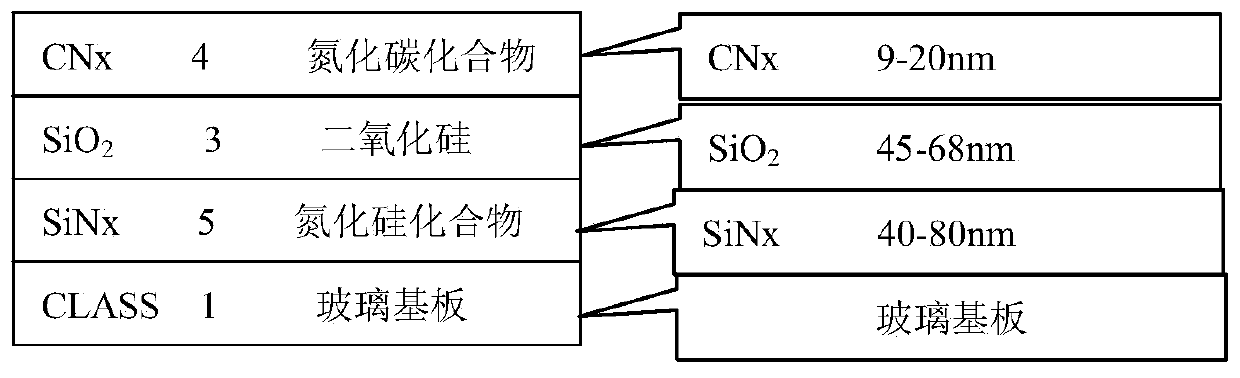

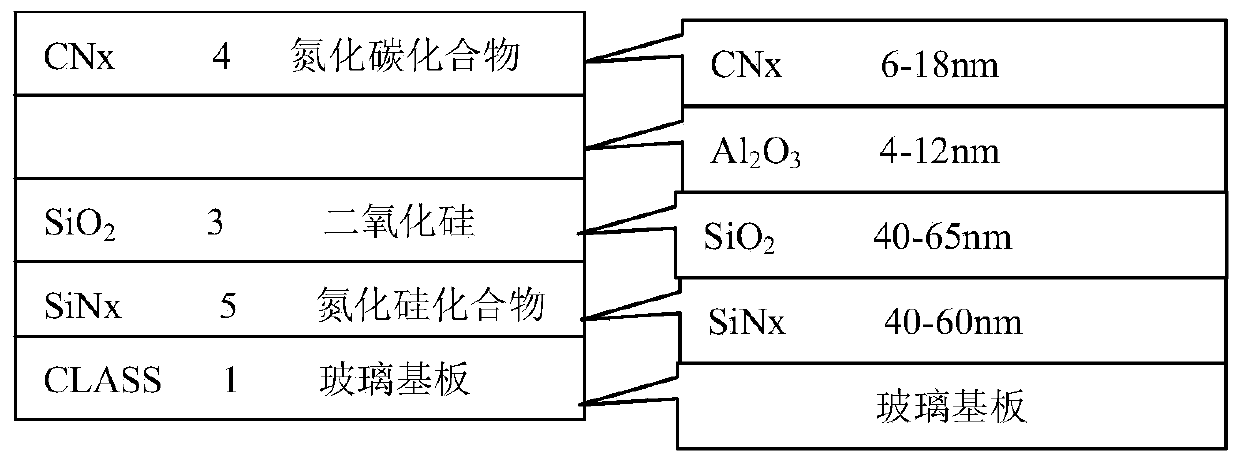

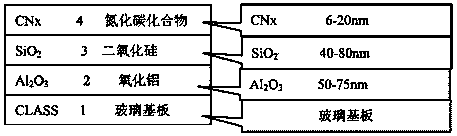

Anti-scratching extra-hard glass and preparation method thereof

ActiveCN104044313AImprove adhesionHigh hardnessVacuum evaporation coatingSputtering coatingCarbon layerGlass manufacture

The invention discloses anti-scratching extra-hard glass and a preparation method thereof, relating to the improvement and development of amorphous carbon nitride in the manufacturing field of glass. The anti-scratching extra-hard glass comprises a glass substrate, wherein a buffer nanolayer is arranged on the glass substrate, a nanometer transition layer is arranged on the buffer nanolayer, and a carbon nitride nanolayer is arranged on the nanometer transition layer. According to the anti-scratching extra-hard glass, as aluminum oxide and carbon nitride are taken as the transition layer of the glass substrate, the adhesive force of a membrane layer is increased; by buffering the internal stress of aluminum oxide or carbon nitride by virtue of silicon dioxide, the stress difference between the membrane layer in the front part and a carbon nitride layer can be decreased, the rigidity and the adhesive force of the membrane layer are improved, and the abrasive resistance of the membrane is enhanced; the phenomena that a thin layer is broken and falls off and the transmittance of a carbon nitride structural layer system is low caused by the large stress difference between a substrate and layer materials after the carbon nitride structural layer system is plated are solved; the Moh's hardness measurement reaches a level 6.5, and good anti-reflection and anti-scratching effects are achieved.

Owner:SHENZHEN SANXIN JMT GLASS

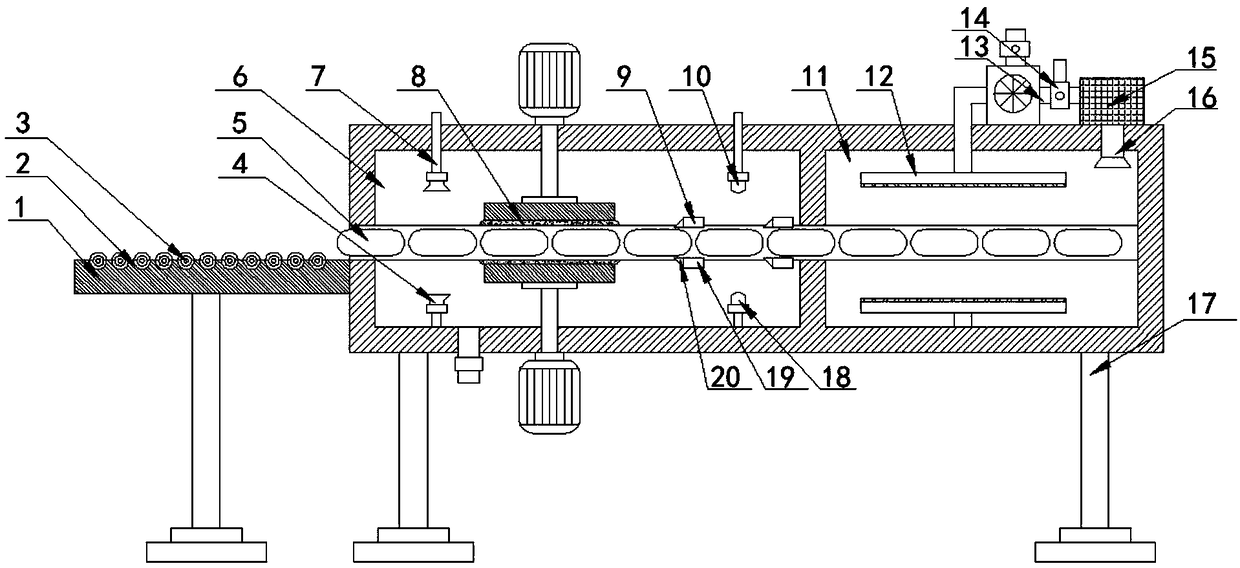

Vertical glass cleaning device with drying function

InactiveCN108114959AAvoid secondary pollutionAvoid stickingDrying solid materials without heatDrying gas arrangementsEngineeringMechanical engineering

The invention provides a vertical glass cleaning device with a drying function, and belongs to the field of glass manufacture. The vertical glass cleaning device comprises a glass placement propulsiondevice, a transverse conveying device, a water spraying device, a rotary cleaning device, a scraping rod device, a secondary spraying and cleaning device and a drying device. According to the vertical glass cleaning device, glass is driven by a conveying roller in the transverse conveying device, the problem of pollution to glass surfaces due to contamination of the roller in traditional roller-type transmission is solved, the glass is conveyed from the side face of the glass, and secondary pollution caused by direct conveying from the surface of the glass by the roller is avoided. The glasscan be effectively dried by the drying device inside a drying cavity, secondary pollution caused by remaining of water stains on the surface of the glass is avoided, and glass adhesion is avoided.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

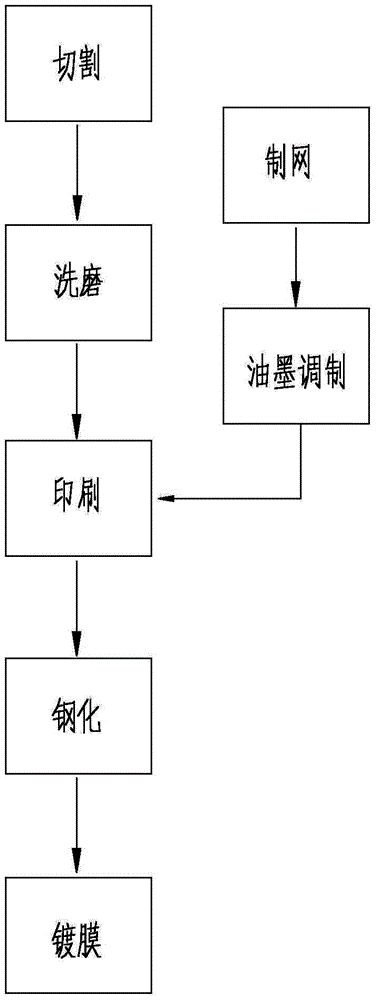

Manufacturing method for color glaze coated glass and color glaze coated glass

ActiveCN105271808AIncrease tightnessSimple processGlass tempering apparatusGlass productionScreen printingWear resistant

The invention belongs to the glass manufacturing technology field, and discloses a manufacturing method for color glaze coated glass and color glaze coated glass. The manufacturing method comprises steps: a cutting procedure is carried out, namely, a glass original sheet is selected and cut; a washing and grinding procedure is carried out, namely, the glass original sheet is ground and washed; a printing procedure is carried out, namely, a screen printing plate is selected and washed, printing oil is blended, and a pattern is printed on the surface of the glass original sheet; a toughening procedure is carried out, namely, the surface of the glass original sheet is cleaned, the glass original sheet is conveyed to a toughening furnace and heated, then is outputted after heating and cooled rapidly to a normal temperature, and glaze layer is formed; a coating procedure is carried out, namely, coating layers with different colors are plated on the glaze layer according to needs. The color glaze coated glass is manufactured through the above manufacturing method. The manufacturing method is simple, and the production efficiency is high. The color glaze coated glass manufactured through the method has good acid-base resistance, has a good adhesive force, and is durable and wear-resistant. The color is changeable, the sunshade effect is raised, and usage requirement of the coated glass are met.

Owner:XINYI GLASS ENG (DONGGUAN) CO LTD

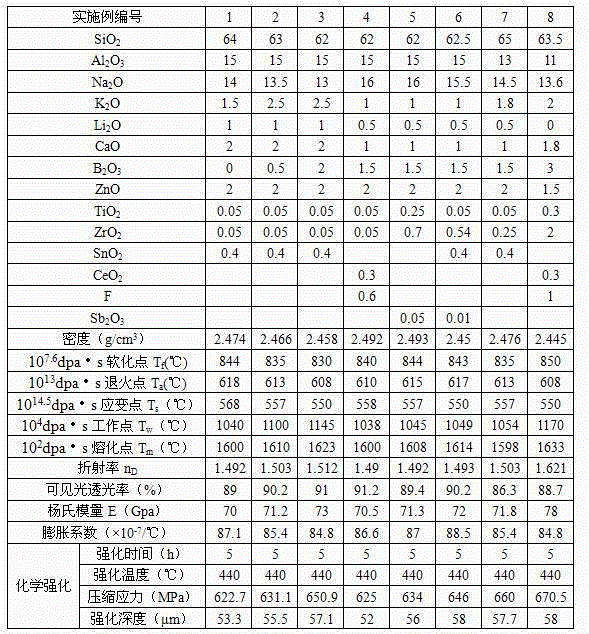

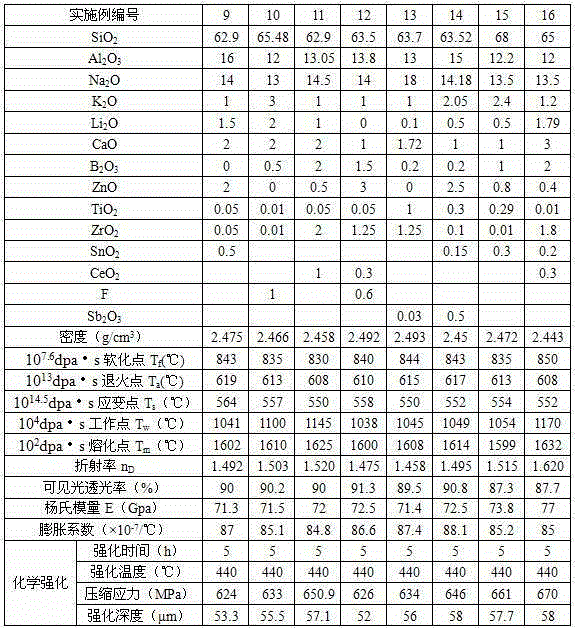

High-alkali high-alumina silicate glass suitable for chemical enhanced treatment

The invention discloses high-alkali high-alumina silicate glass suitable for chemical enhanced treatment. The glass comprises the following chemical ingredients, by weight, 62-68% of SiO2, 11-16% of Al2O3, 13-18% of Na2O, 1-3% of K2O, 0-2% of Li2O, 1-3% of CaO, 0-3% of B2O3, 0-3% of ZnO, 0.01-1% of TiO2, 0.01-2% of ZrO2 and at least a clarifying agent. The clarifying agent is selected from 0-0.5 wt% of SnO2, 0-0.5 wt% of Sb2O3, 0-1 wt% of F and 0-1 wt% of CeO2. The glass manufactured by the above formula undergoes chemical enhanced treatment in KNO3 molten salt of 420-460 DEG C for more than 5 hours so as to form protective glass with more than 600 MPa of pressure stress formed on the surface and a pressure stress layer of more than 50 microns thick. The protective glass can be applied to mobile devices such as a mobile telephone, a smart phone, a flat computer, a notebook computer and a PDA.

Owner:WUHU DONGXU OPTOELECTRONICS EQUIP TECH

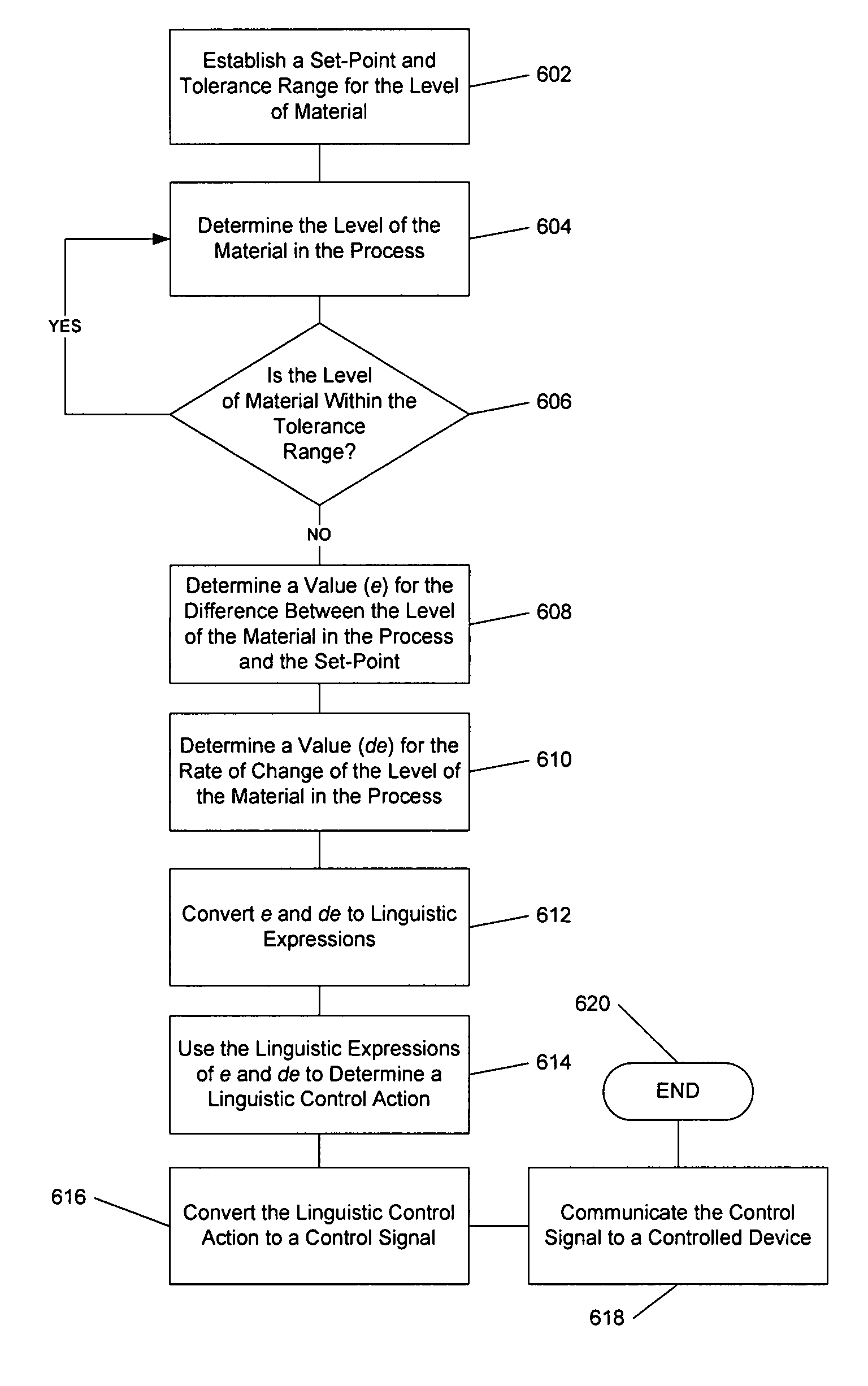

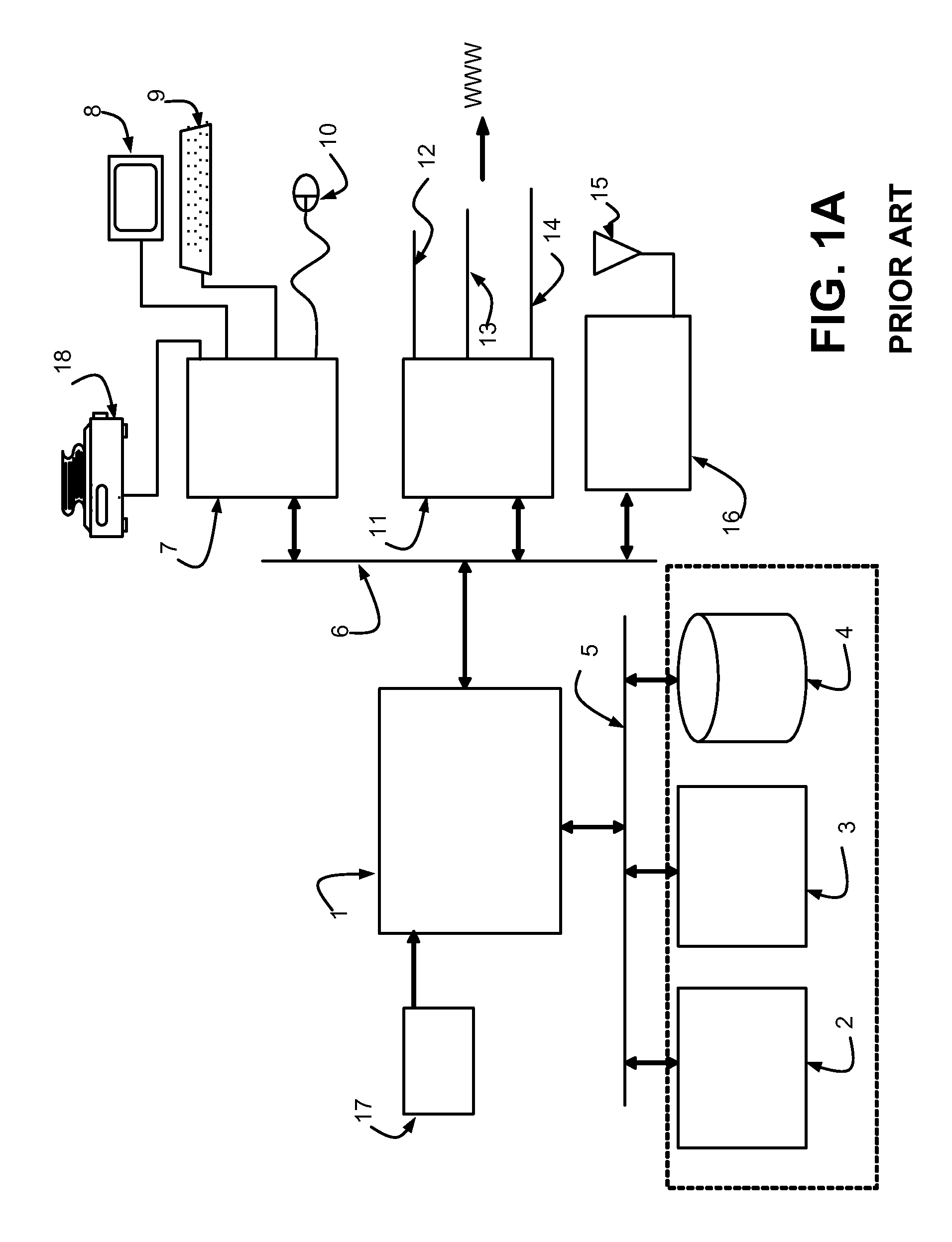

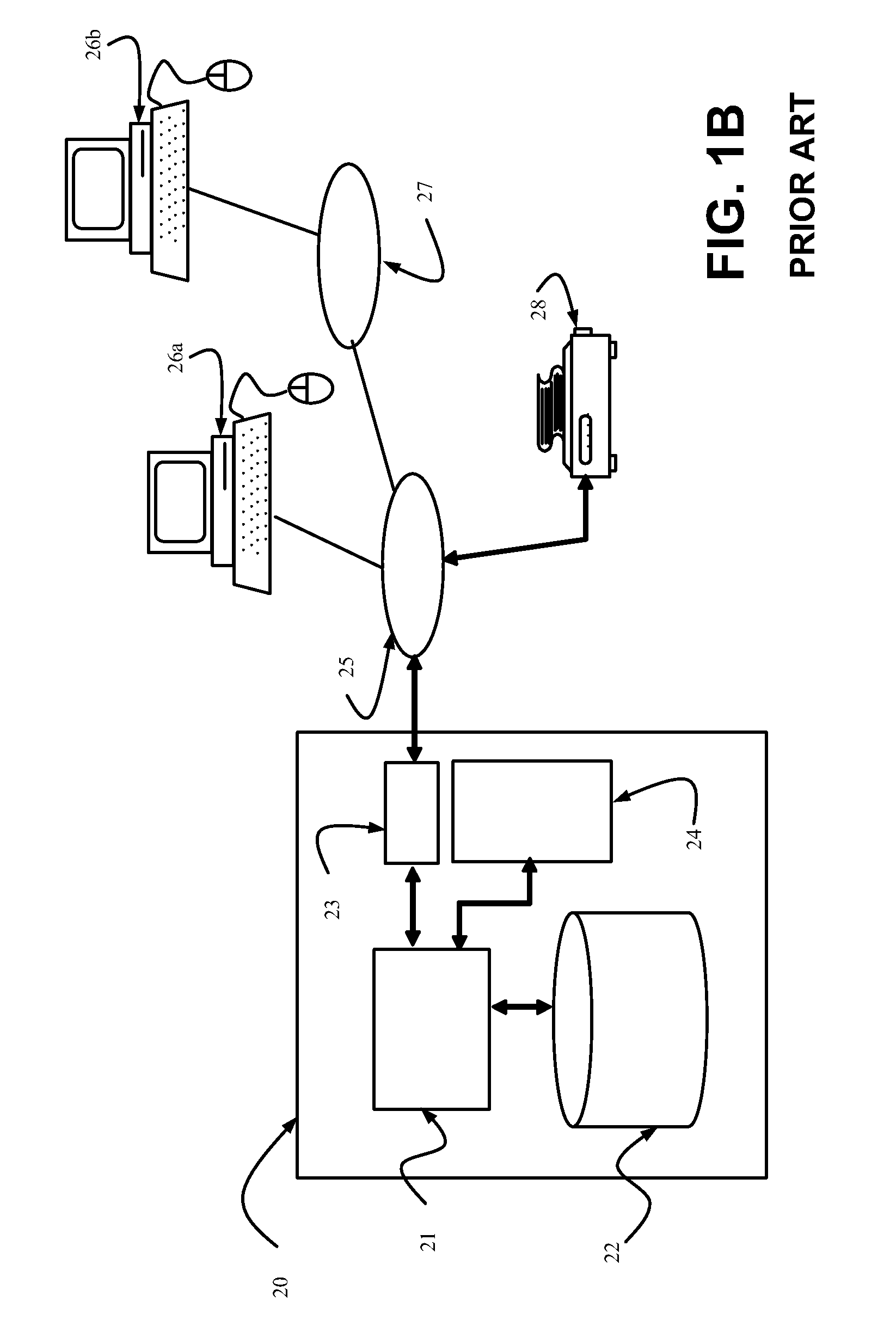

Fuzzy logic control for process with large dead time

The present invention relates to a control system, method and computer program product to control a process having a large dead time. An exemplary process controllable by embodiments according to the invention is the glass manufacturing process, where fuzzy logic is used to control a level of molten and melting raw materials in a furnace during a glass-manufacturing process by controlling the rate at which raw materials enter the furnace.

Owner:CORNING INC

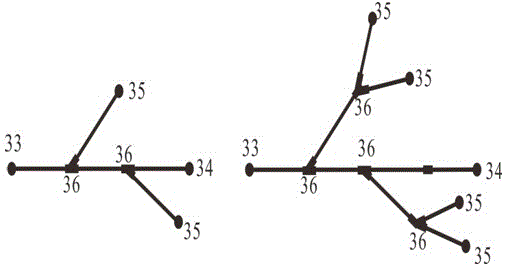

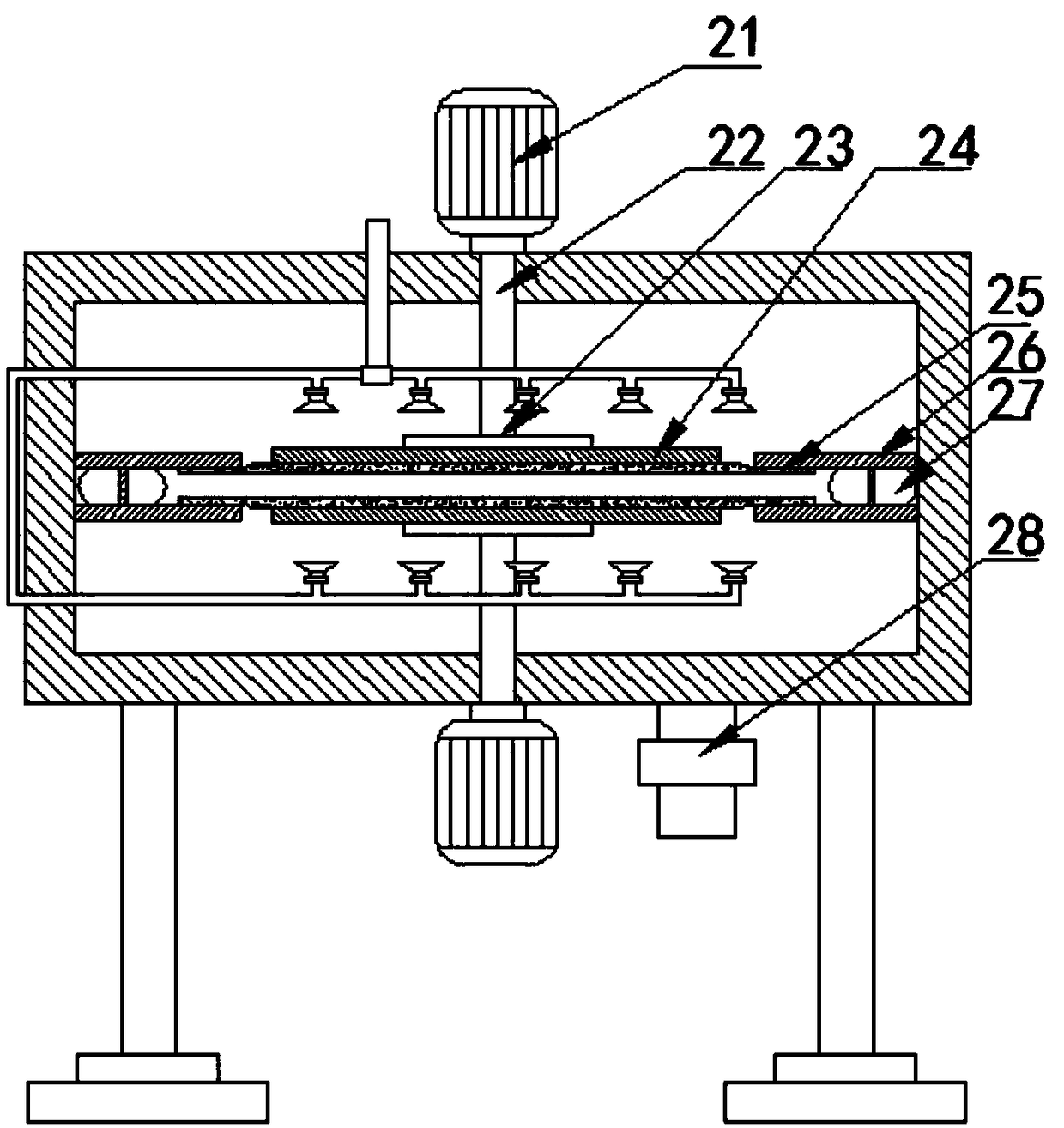

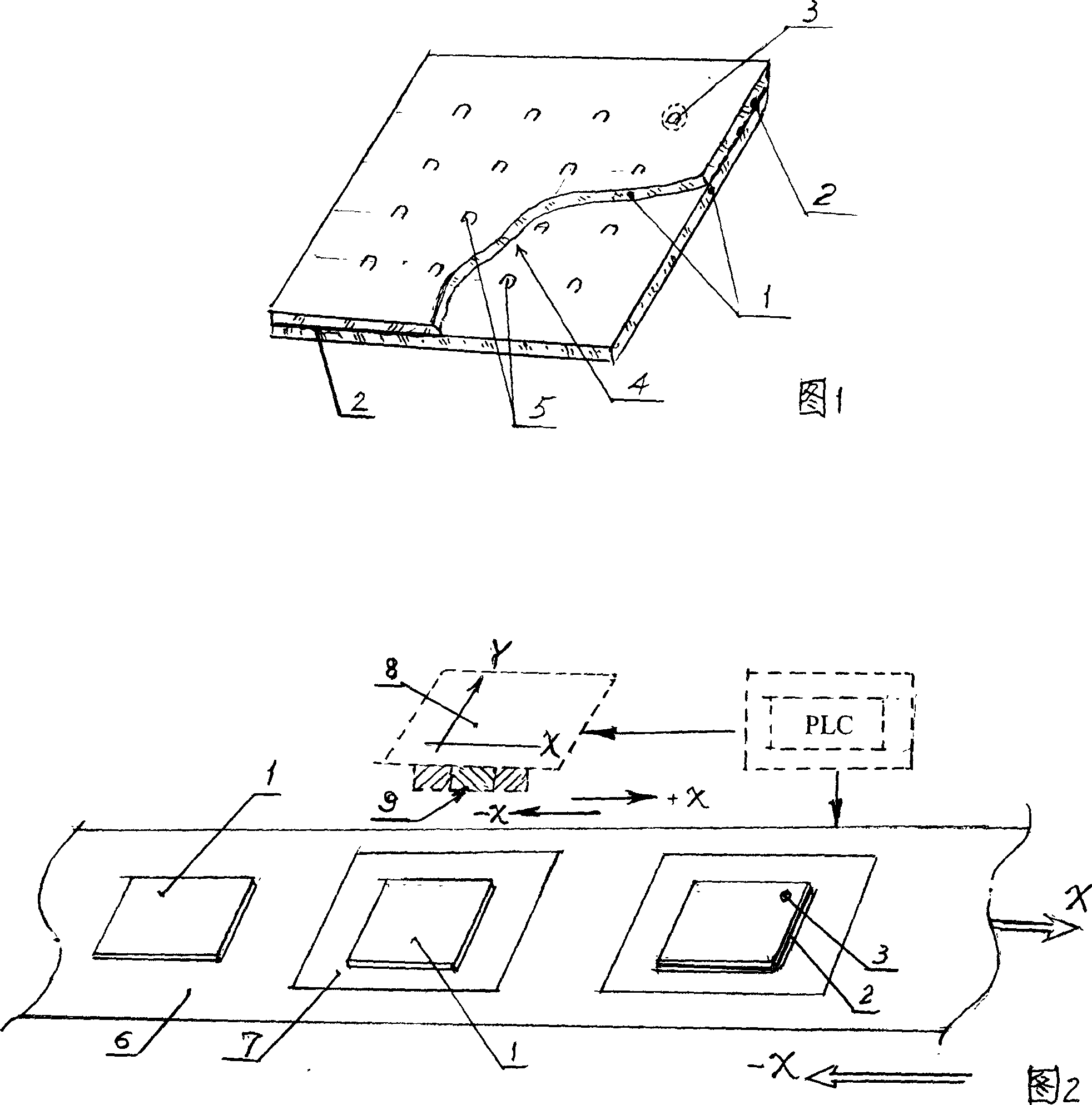

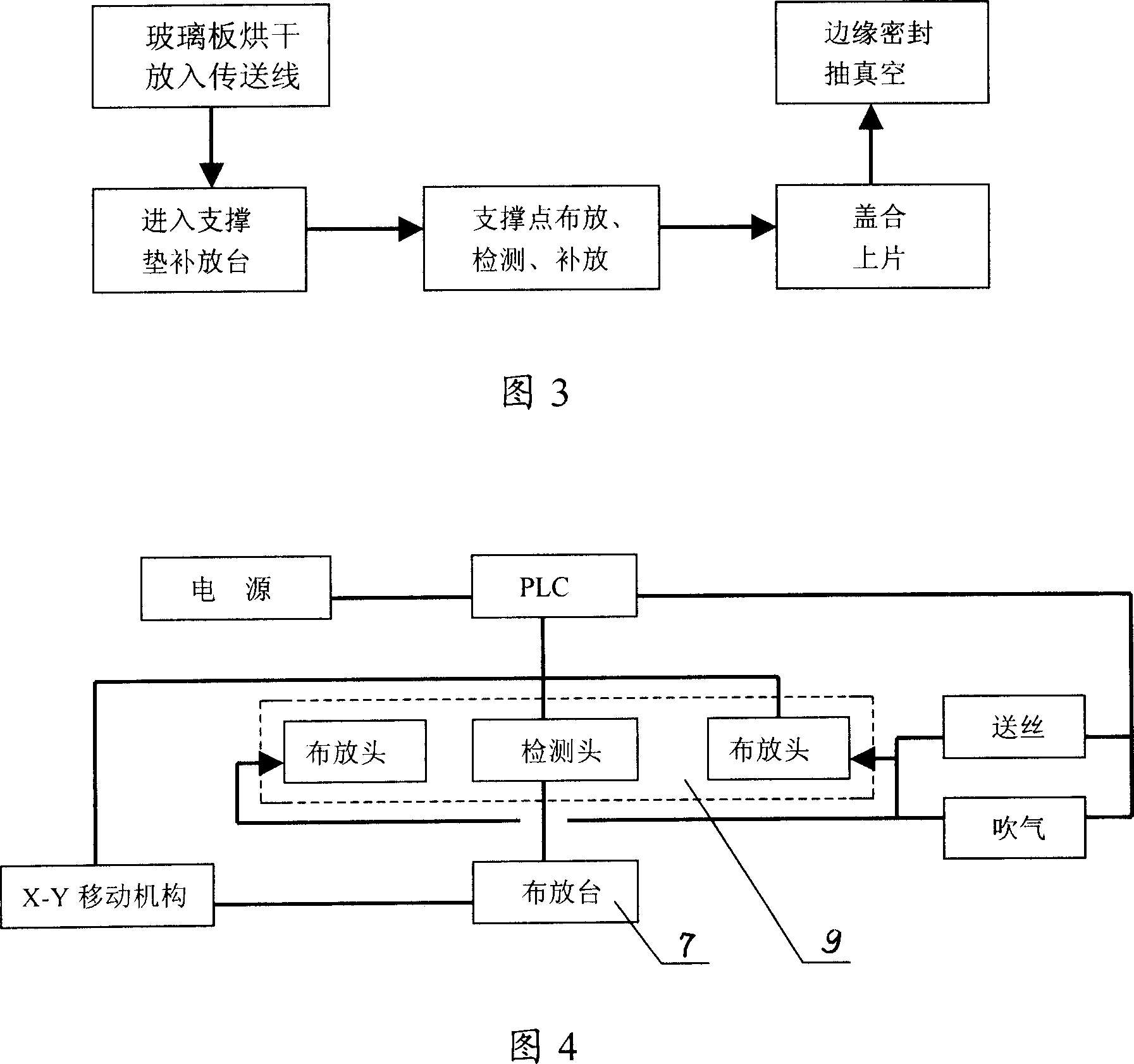

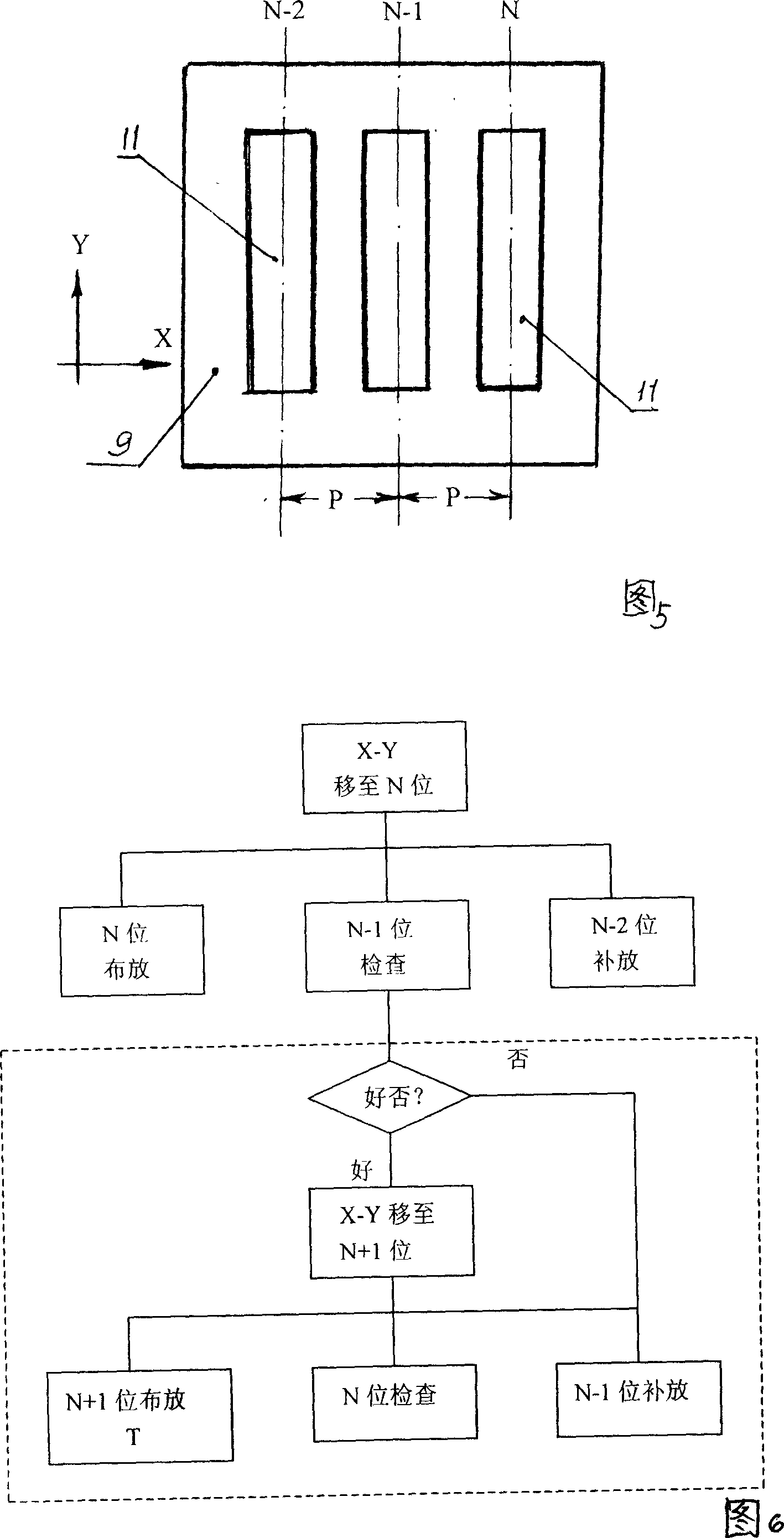

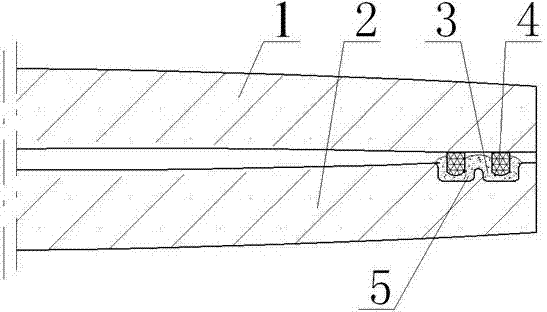

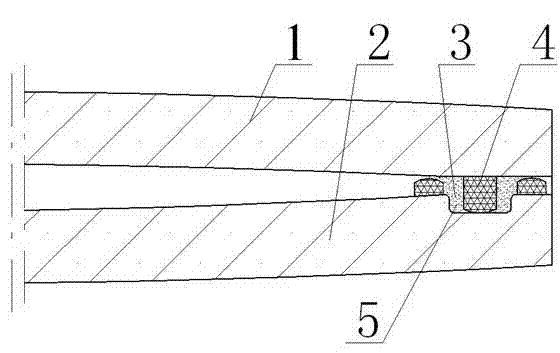

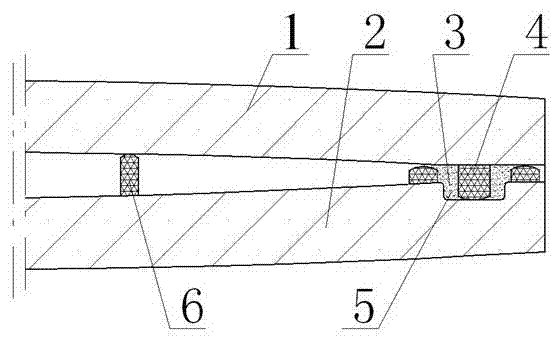

Vacuum glass supporting point distribution method and system

InactiveCN1951845ACompact structureEasy to replaceDoors/windowsClimate change adaptationYarnDistribution method

The invention discloses a distributing method and system of support point in the vacuum glass in the preparing domain of vacuum glass, which comprises the following steps: transmitting glass to distribute; distributing support point; proceeding photoelectric examination; supplementing; distributing point by point according to negative-X direction; covering the upper glass. The distributing system contains a distributing component and transmitting line anchored by X-Y step-by-step motor, wherein the distributing component consists of two distributing heads and a photoelectric detecting head; the distributing head possesses one case with drift pin in the center of case and cutting head of yarn on the bottom; the yarn inlet is set on one side of cutting head; the yarn transmitting wheel is set on the exterior of step-by-step motor; the blowing spraying pipe is set on the other side of yarn inlet; the driving electromagnetic coil and armature iron are set on the exterior of punching channel.

Owner:王基奎

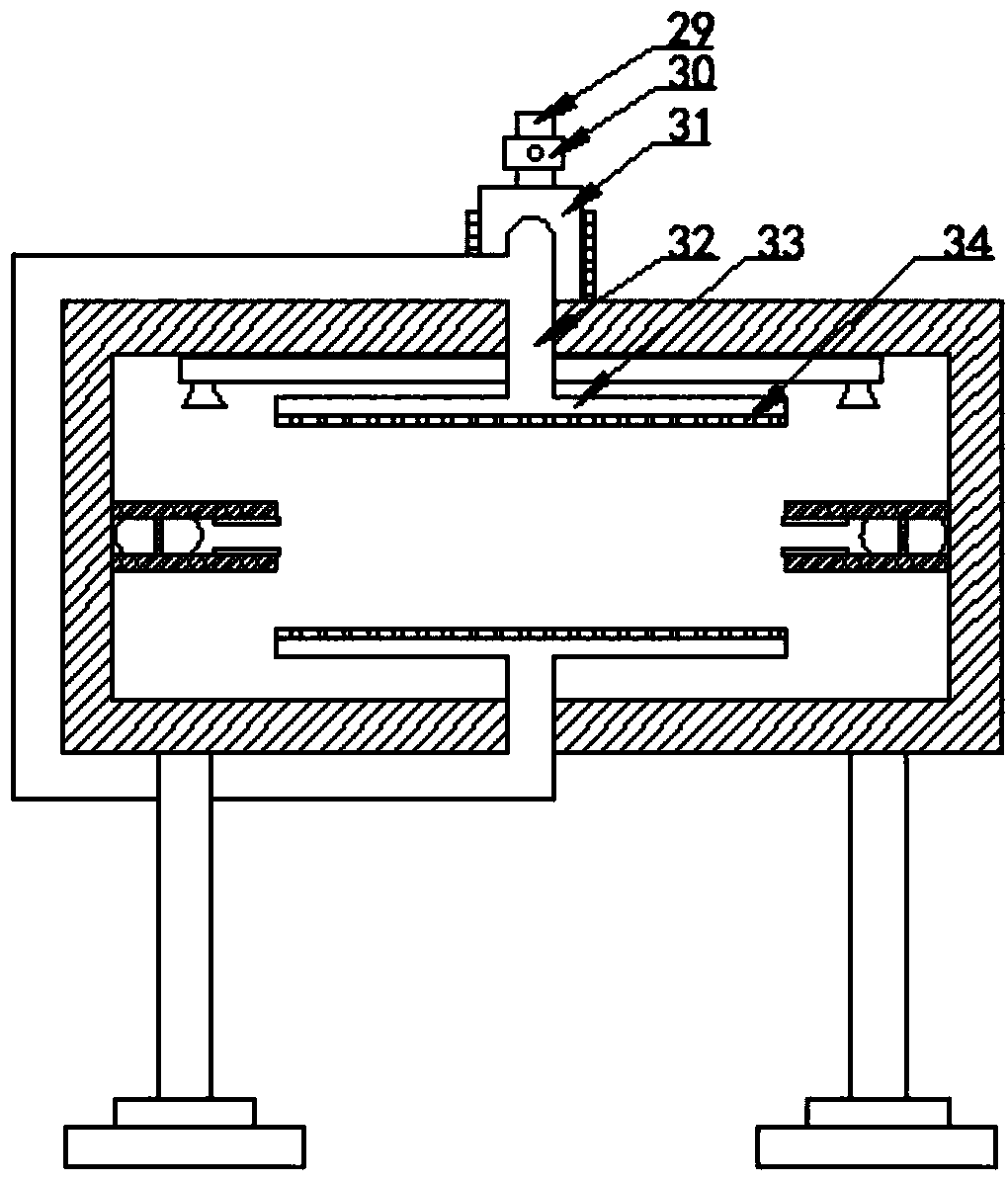

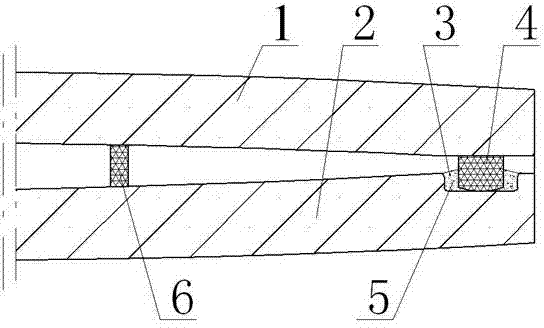

Convex vacuum glass welded by glass solders and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951803AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideEngineering

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by glass solders in a vacuum edge sealing furnace, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and not only can be used for manufacturing common vacuum glass, but also is particularly suitable for manufacturing of tempered vacuum glass; and the vacuum glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

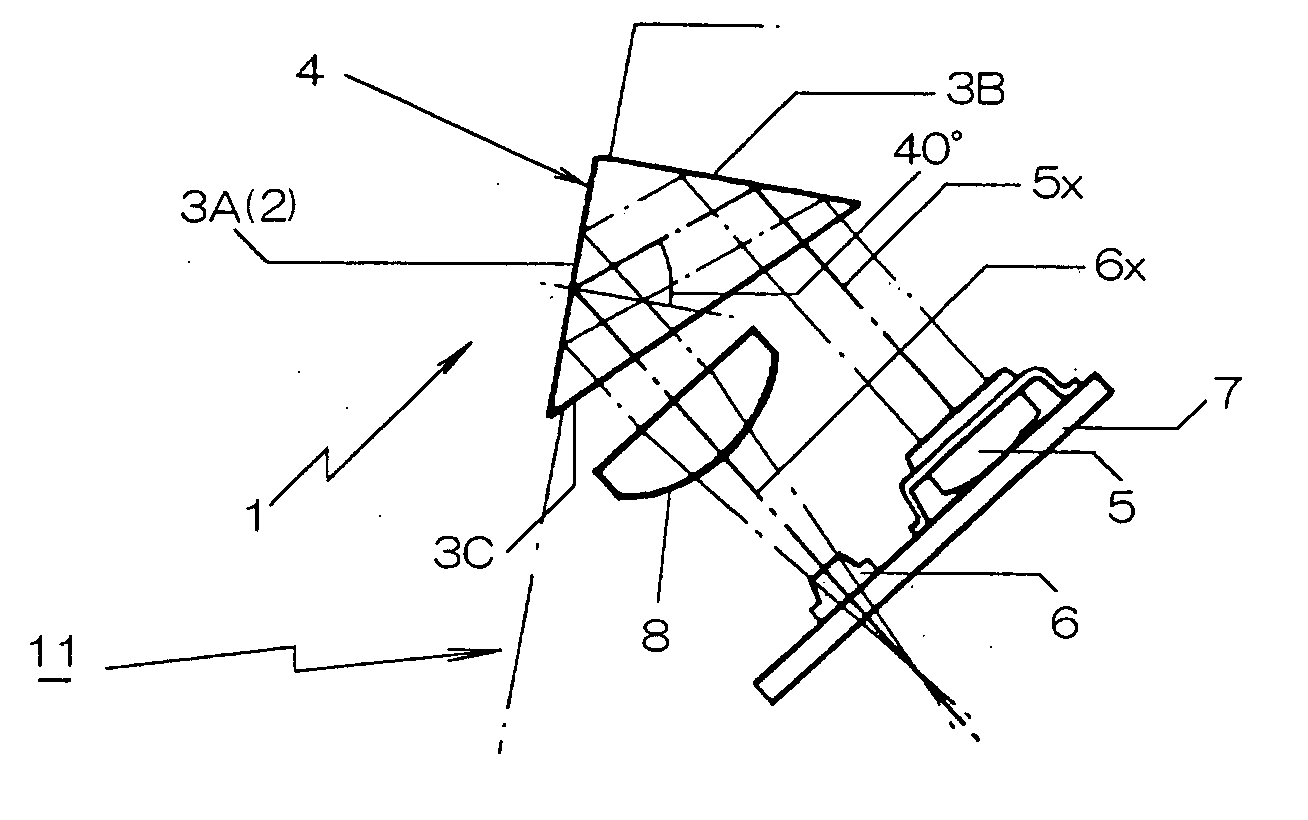

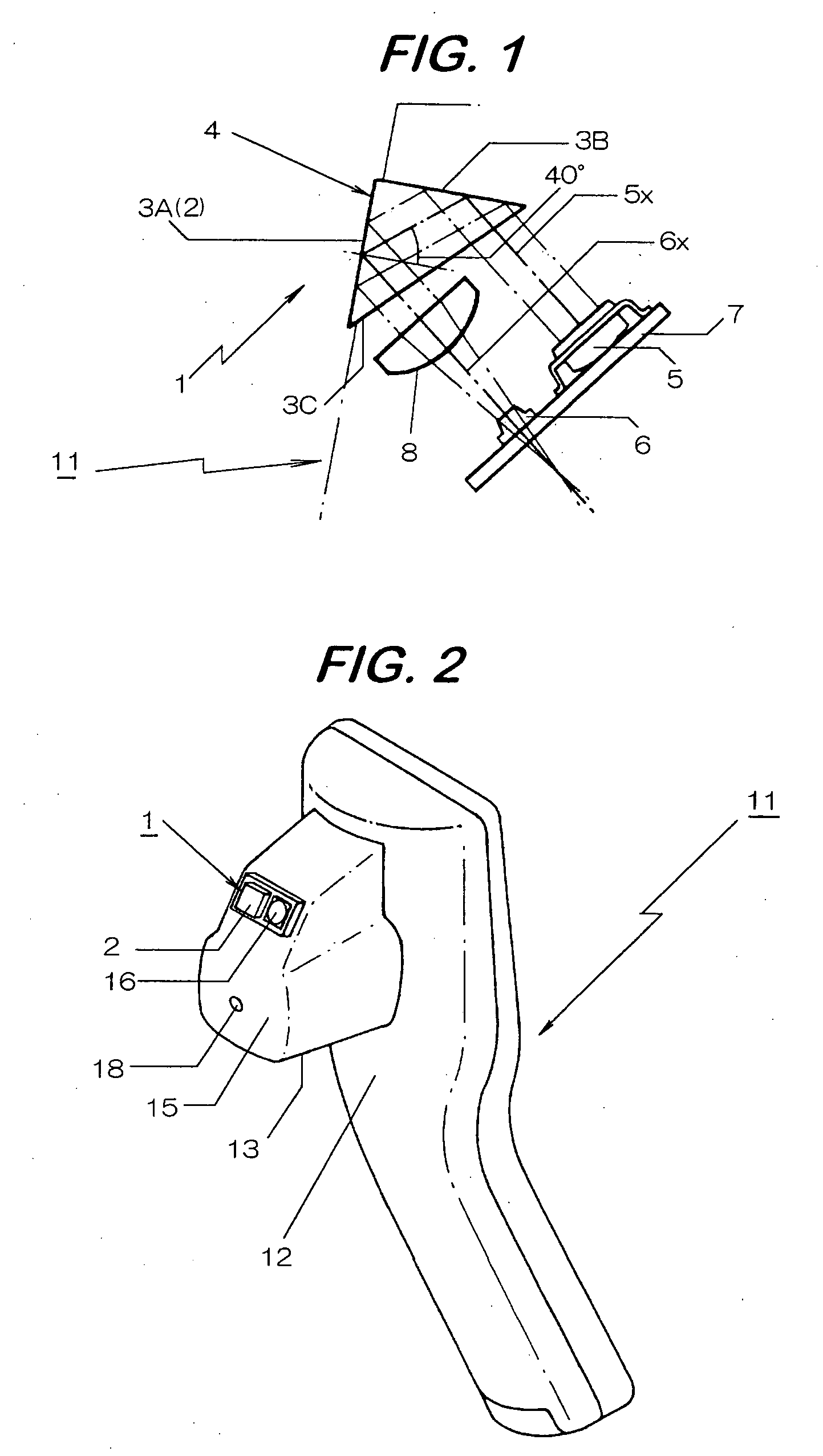

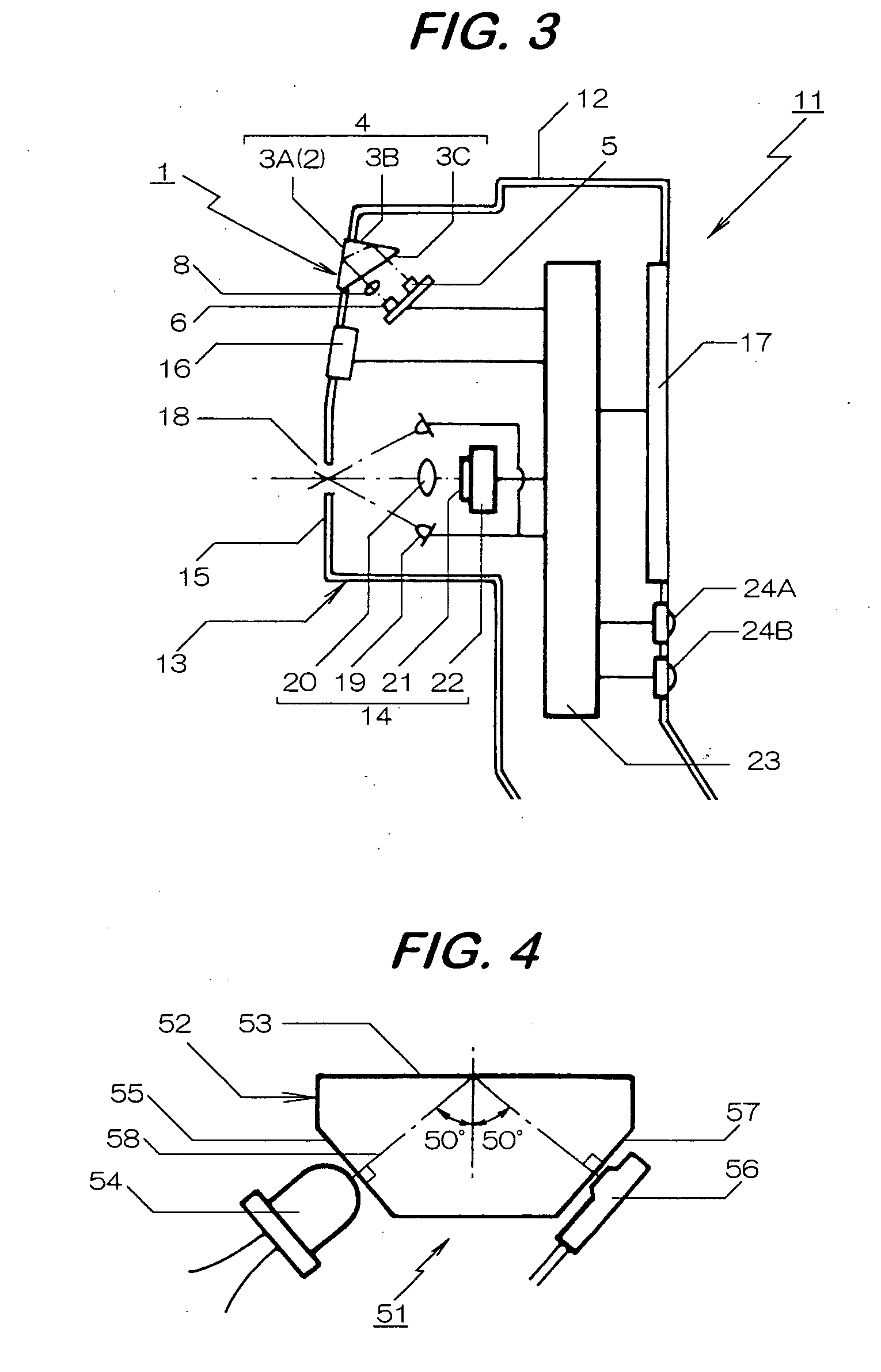

Skin condition observation apparatus

ActiveUS20040086456A1Compounds screening/testingDiagnostics using lightMeasurement deviceOptical axis

A skin condition observation apparatus having a sebum amount measuring device adapted for bringing a sebum sampling surface into contact with skins and optically measuring the amount of deposited sebum, wherein the sebum amount measuring device comprises an orthogonal prism having two reflection surfaces orthogonal with each other in which one reflection surface is exposed as the sebum sampling surface, and a light emitting element for illuminating a light to one of the reflection surfaces and a photoreceiving element for detecting the intensity of a reflection light reflected on the two reflection surfaces and returned therefrom are located being opposed to the hypotenuse surface at the back of the orthogonal prism, with their optical axes being in parallel with each other, whereby the sebum amount measuring device of the skin condition observation apparatus can be manufactured with no requirement for glass fabrication at high accuracy, troublesome and delicate alignment for optical axes with respect to the angle, at a low cost and in a reduced-size.

Owner:MORITEX CORP

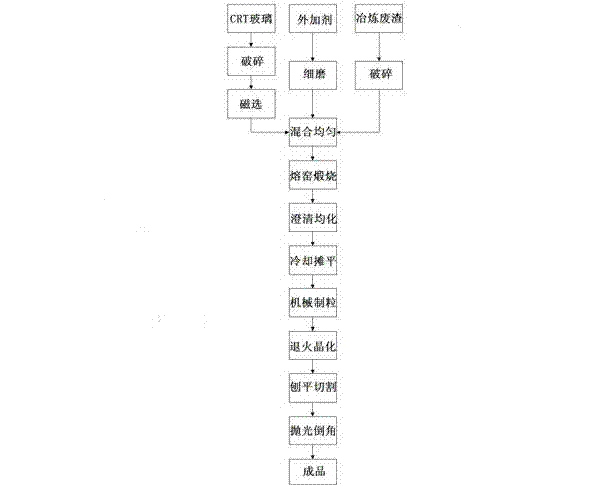

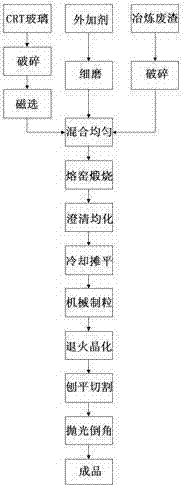

Method for manufacturing microcrystalline glass utilizing smelting waste slag and CRT (Cathode Ray Tube) waste glass

The invention relates to microcrystalline glass manufactured utilizing smelting waste slag and CRT (Cathode Ray Tube) waste glass. The microcrystalline glass is characterized in that: the process formula is designed according to the product requirements, and the raw materials comprise the following components according to a weight ratio: 45% of smelting waste slag, 45% of CRT waste glass, 3-5% of calcite ash, 5% of quartz sand and 0.5-1% of additive; and the process can be properly adjusted according to the process requirements, chemical composition of the raw materials, color and the like. According to the invention, industrial smelting waste slag and CRT waste glass are sufficiently utilized to replace natural stones and clay mineral resources, thus the mine exploitation is avoided, resources are saved, wastes are changed into valuable, pollution is prevented, environment is protected, building material products with high added value are produced and social wealth is created.

Owner:CHENZHOU WANRONG METAL PROCESSING

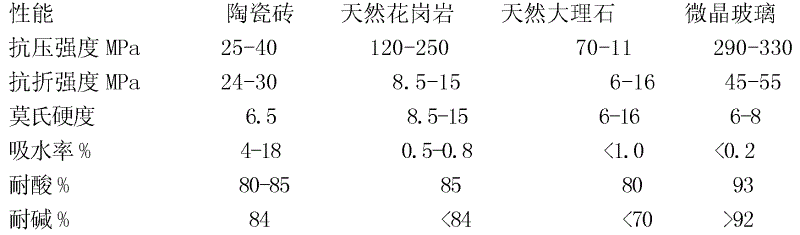

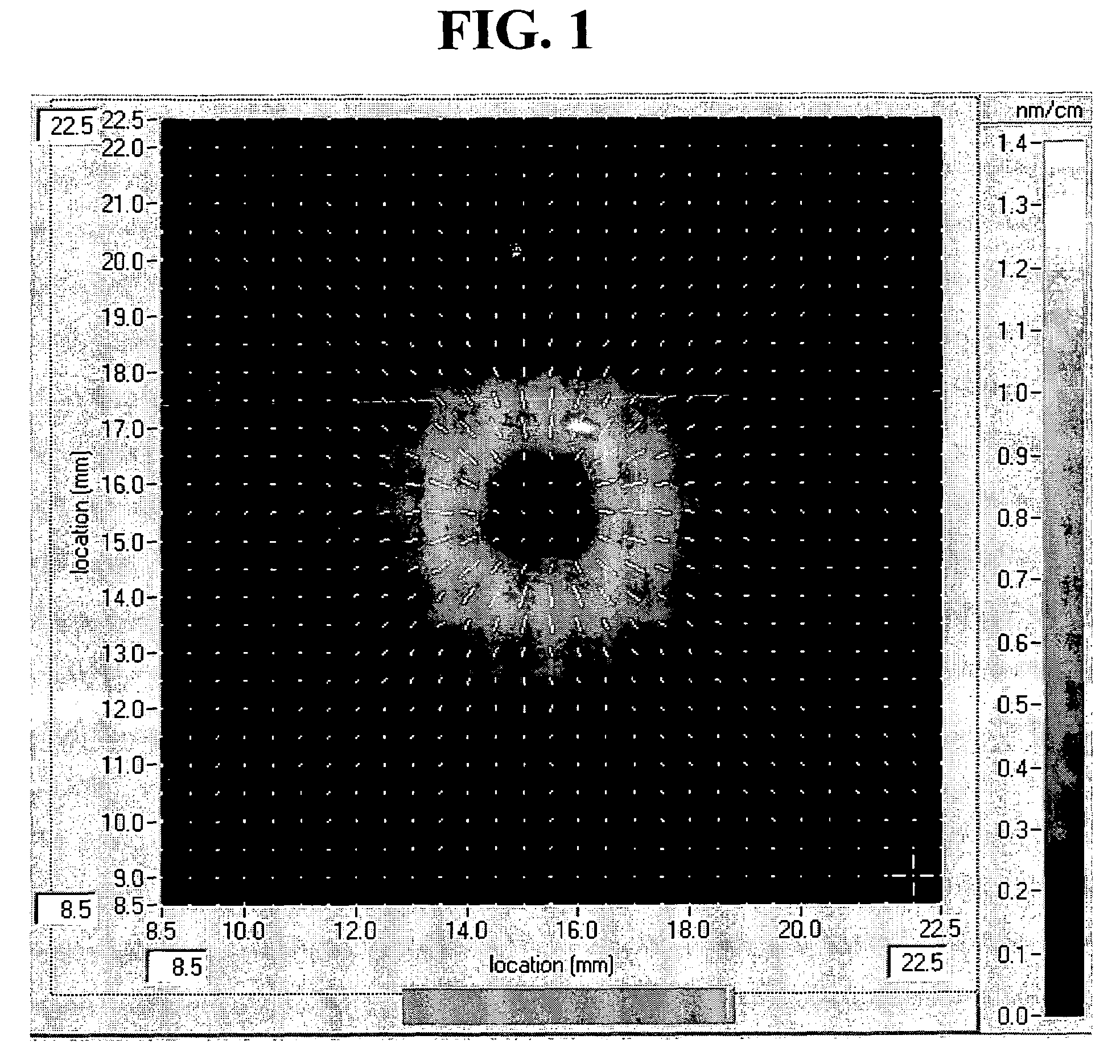

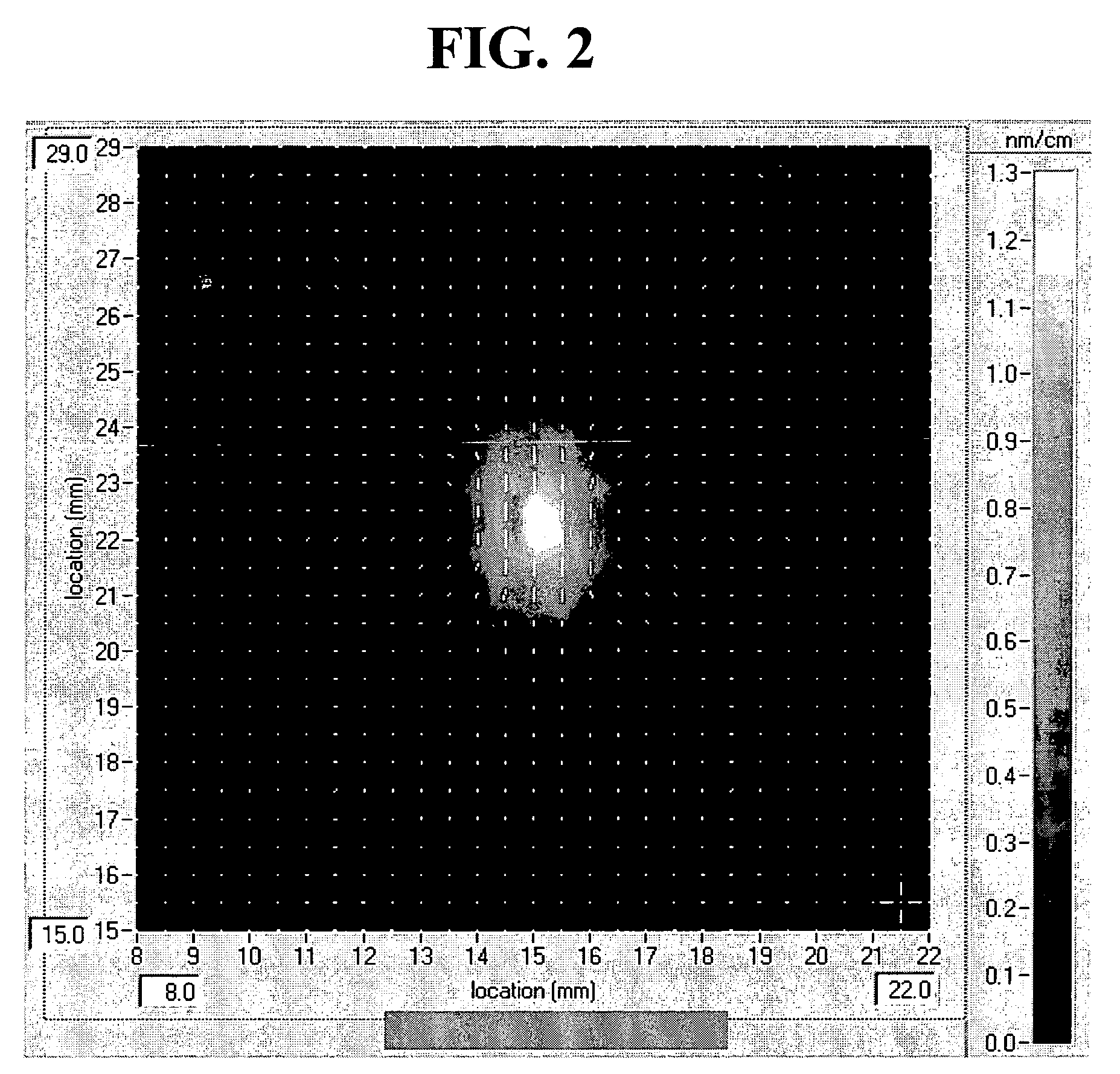

Synthetic silica having low polarization-induced birefringence, method of making same and lithographic device comprising same

Disclosed are synthetic silica glass having a low polarization-induced birefringence, process for making the glass and lithography system comprising optical element made of the glass. The silica glass has a polarization-induced birefringence measured at 633 nm of less than about 0.1 nm / cm when subjected to excimer laser pulses at about 193 nm having a fluence of about 40 μJ·cm−2·pulse−1 and a pulse length of about 25 ns for 5×109 pulses.

Owner:CORNING INC

Clarifying agent for TFT-LCD (Thin Film Transistor Liquid Crystal Display) glass, application and use method thereof

InactiveCN102584002AReduce contentPerformance is not affectedGlass furnace apparatusEngineeringThin-film-transistor liquid-crystal display

The invention belongs to the field of glass manufacturing and discloses a clarifying agent for TFT-LCD (Thin Film Transistor Liquid Crystal Display) glass. The clarifying agent is strontium chloride of which the weight percent is 0.12-0.36% of the weight of the TFT-LCD glass raw materials. Due to the adoption of the clarifying agent, the weight percent of the strontium oxide correspondingly generated in the TFT-LCD glass is 0.5-1.5%. The invention also discloses a use method of the clarifying agent. The use method comprises the steps of mixing, founding and annealing. The invention also discloses an application of the strontium chloride which is used as the clarifying agent for the TFT-LCD glass. The invention provides a new application of the strontium chloride, which is the clarifying agent for manufacturing a TFT-LCD glass substrate; the content of hydroxyl in liquid glass is reduced; a clarifying effect is achieved; the air bubbles are reduced; and according to the use method, the optimal effect of the clarifying agent is achieved and the optimal classifying effect is achieved.

Owner:成都中光电科技有限公司 +1

Convex low-altitude glass welded by glass solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951813AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionGlass manufactureLow altitude

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper and lower glass are provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by glass solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com