High-alkali high-alumina silicate glass suitable for chemical enhanced treatment

A high-aluminosilicate, chemical technology, applied in the field of glass production, can solve the problems of low hardness and mechanical strength, poor display, low Young's modulus, etc., to improve ion exchange performance, improve chemical stability, improve The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

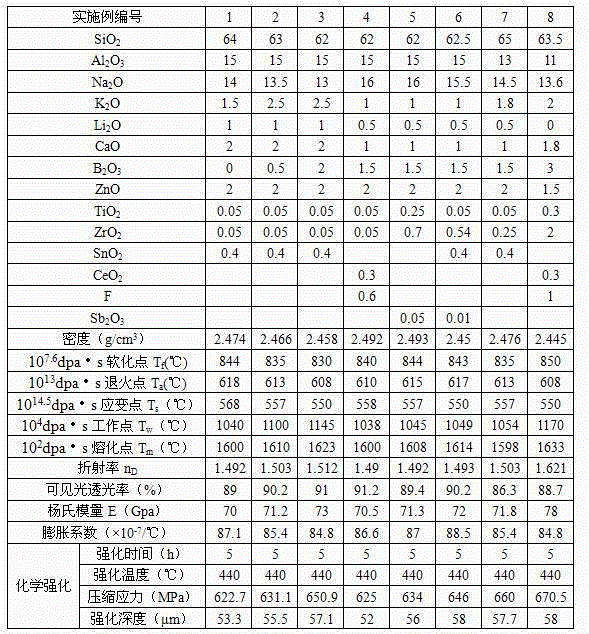

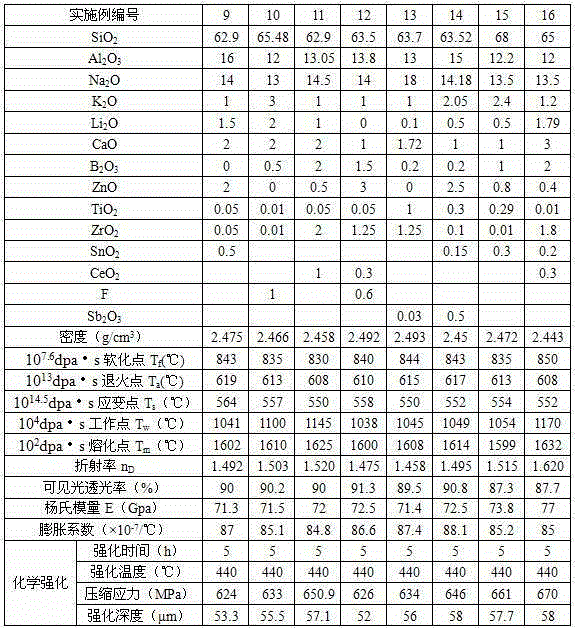

Examples

Embodiment Construction

[0032] The components that can be contained in the glass formulation of the present invention will be described below, and the content of each component is expressed in weight percent.

[0033] SiO 2 It is the main component of the glass skeleton, which can improve the glass strain point, chemical stability and mechanical strength of the glass, and reduce the thermal expansion coefficient and density of the glass. When the content is below 60%, the chemical stability of the glass is not good, but when the content exceeds 68%, the high-temperature viscosity of the glass increases, making the glass melting temperature too high and difficult to melt. In order to obtain a glass with high Young's modulus and suitable for rapid chemical strengthening, SiO 2 The ratio is limited to 62-68%.

[0034] Al 2 o 3 It is an intermediate oxide, which improves the hardness and mechanical strength of the glass, improves the chemical stability of the glass and can accelerate the ion exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com