Patents

Literature

2811 results about "Glass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers.

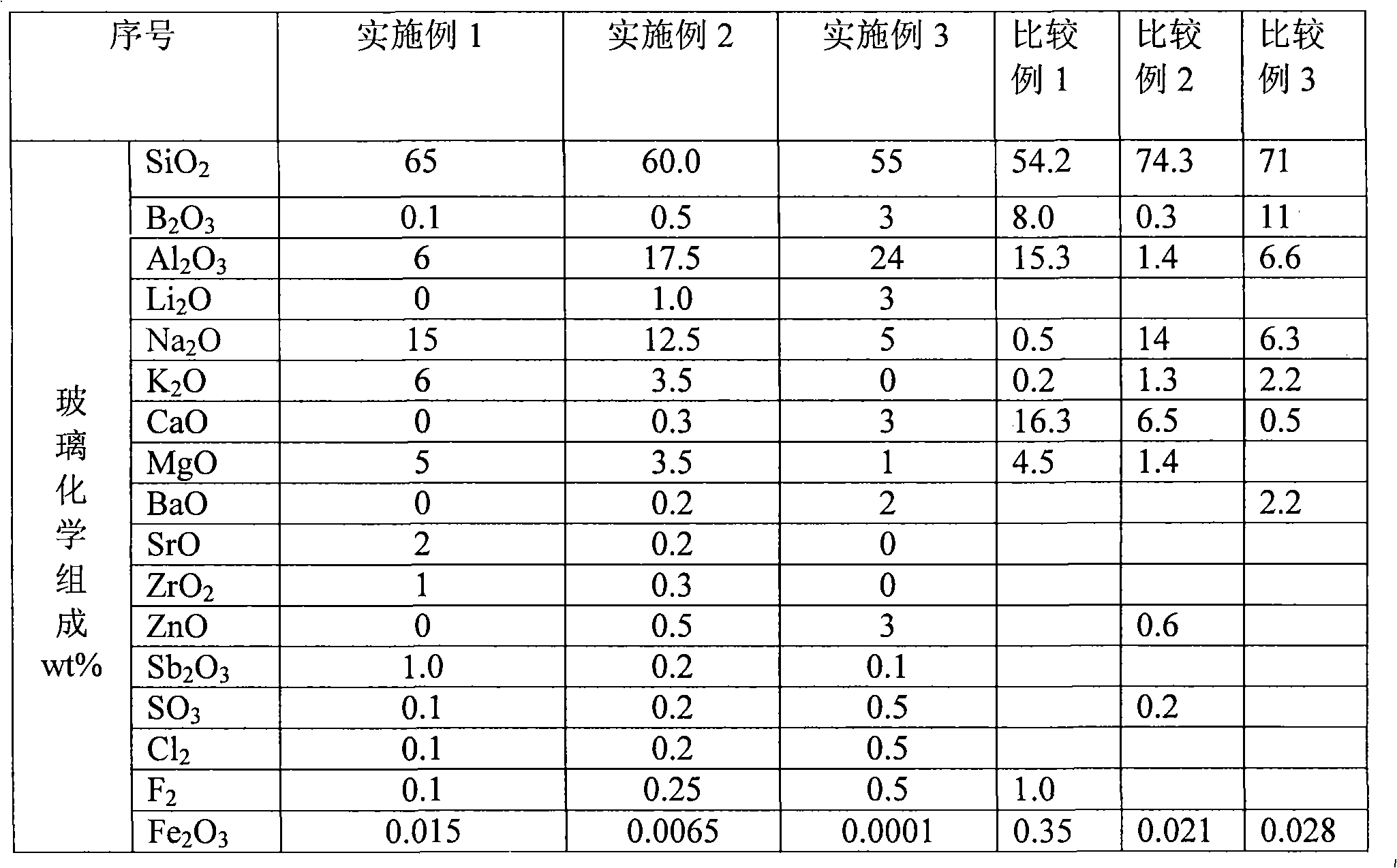

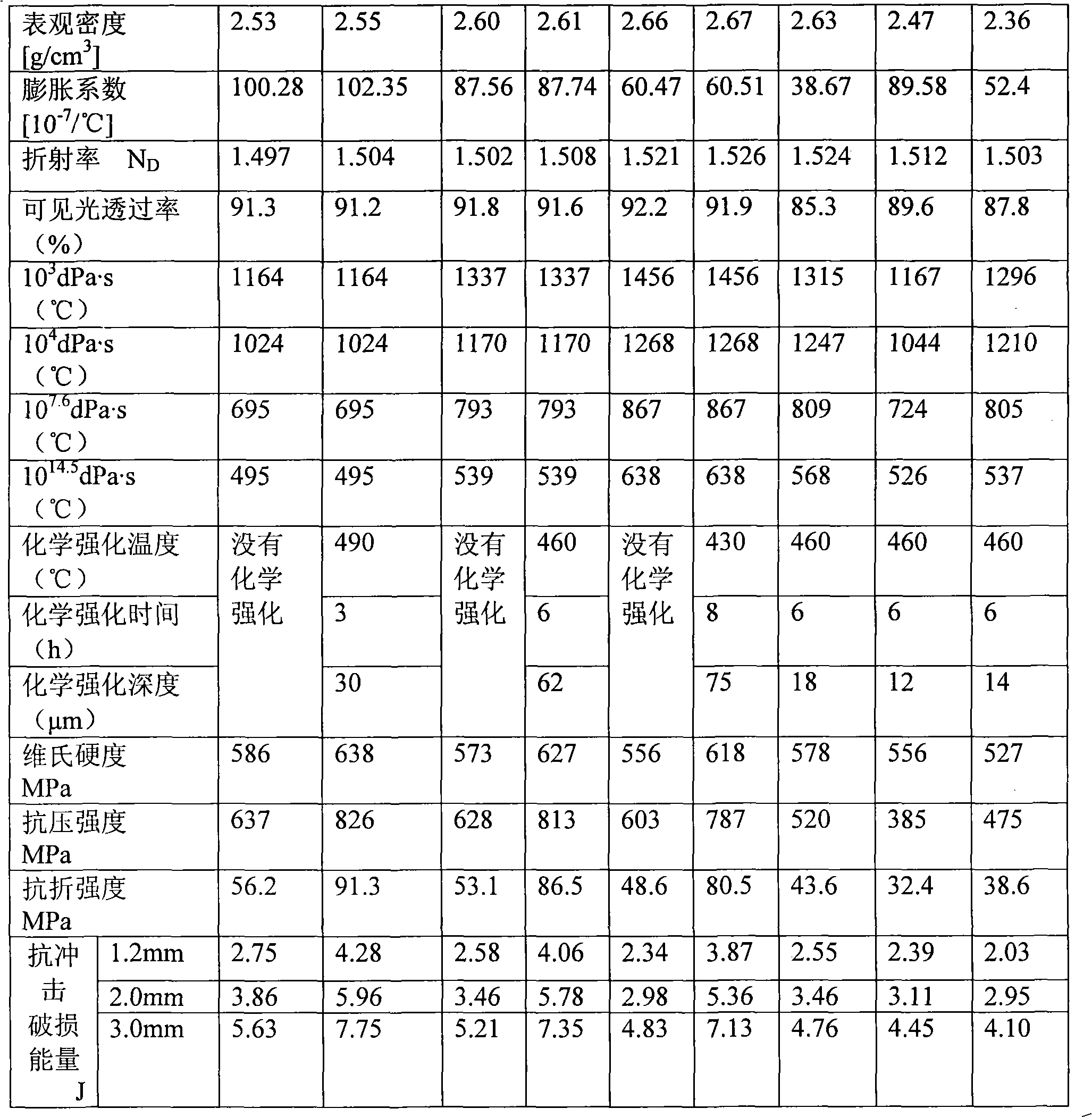

High strength aluminosilicate glass and chemically toughening process thereof

ActiveCN101337770AMeet the screen saver functionProtective functionGlass tempering apparatusAlkali freeShock resistance

The invention relates to a high-strength aluminate silicate glass and a chemical toughening method thereof, and belongs to the silicate glass field. The glass comprises the following chemical components (weight percent): 55 to 65 weight percent of SiO2, 0.1 to 3 weight percent of B2O3, 6 to 24 weight percent of Al2O3, 3 to 9 weight percent of MgO plus CaO plus BaO plus SrO, 0 to 1 weight percent of ZrO2, 0 to 2 weight percent of ZnO, 0.1 to 0.5 weight percent of Cl2, 0.1 to 1.0 weight percent of Sb2O3, 0.1 to 0.5 weight percent of SO3 and 0.1 to 0.5 weight percent of F2, and belongs to a aluminate silicate glass system. The high-strength aluminate silicate glass is prepared through a known plate glass production method, and then is subjected to the strengthening treatment by adopting the chemical toughening method. The glass has high permeability of visible light, and relatively common soda lime glass, neutral medicine glass and alkali-free high-aluminum glass have good shock resistance property, high scratch resistance property and high durability. The high-strength aluminate silicate glass is applied to the screen surface protection of plasma display products and liquid crystal display products, the protection of touch screens, the screen protection of automated teller machines, and the screen protection of other electronic products (Mobile phones, PDAs and media machines, etc.), thereby effectively preventing the impact and the scratch damage to the glass surface of display products. The high-strength aluminate silicate glass contains no harmful elements.

Owner:SUZHOU SHINWU OPTRONICS TECH

Process for producing anti-glare glass by using high-boron silicon and high-aluminium silicon glasses

The invention discloses a process for producing anti-glare glass by using high-boron silicon and high-aluminium silicon glasses, wherein the method comprises the following steps: (1) weighing the raw materials according to the formula of a frosting liquid, mixing and stirring the raw materials evenly, curing the mixture for 24 -30 hours to prepare the frosting liquid; (2) after cleaning the glass to be frosted, carrying out protective treatment on one surface that is not needed to be frosted; (3) placing the protected glass into a pre-treatment liquor for further cleaning; (4) placing the treated glass into the cured frosting liquid to frost the glass for 30 -200 seconds, taking out the glass and cleaning the glass with water; and (5) placing the frosted glass into a polishing liquid to etch to obtain the anti-glare glass finished product. The invention solves the problem that the high-boron silicon and high-aluminium silicon glasses have large hardness and are difficult to be frosted; the process provided by the invention improves the hardness of the glass while guaranteeing the even frosting degree and good anti-glare effect; the product produced by the process provided by the invention has advantages of acid and alkali resistance and corrosion resistance.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

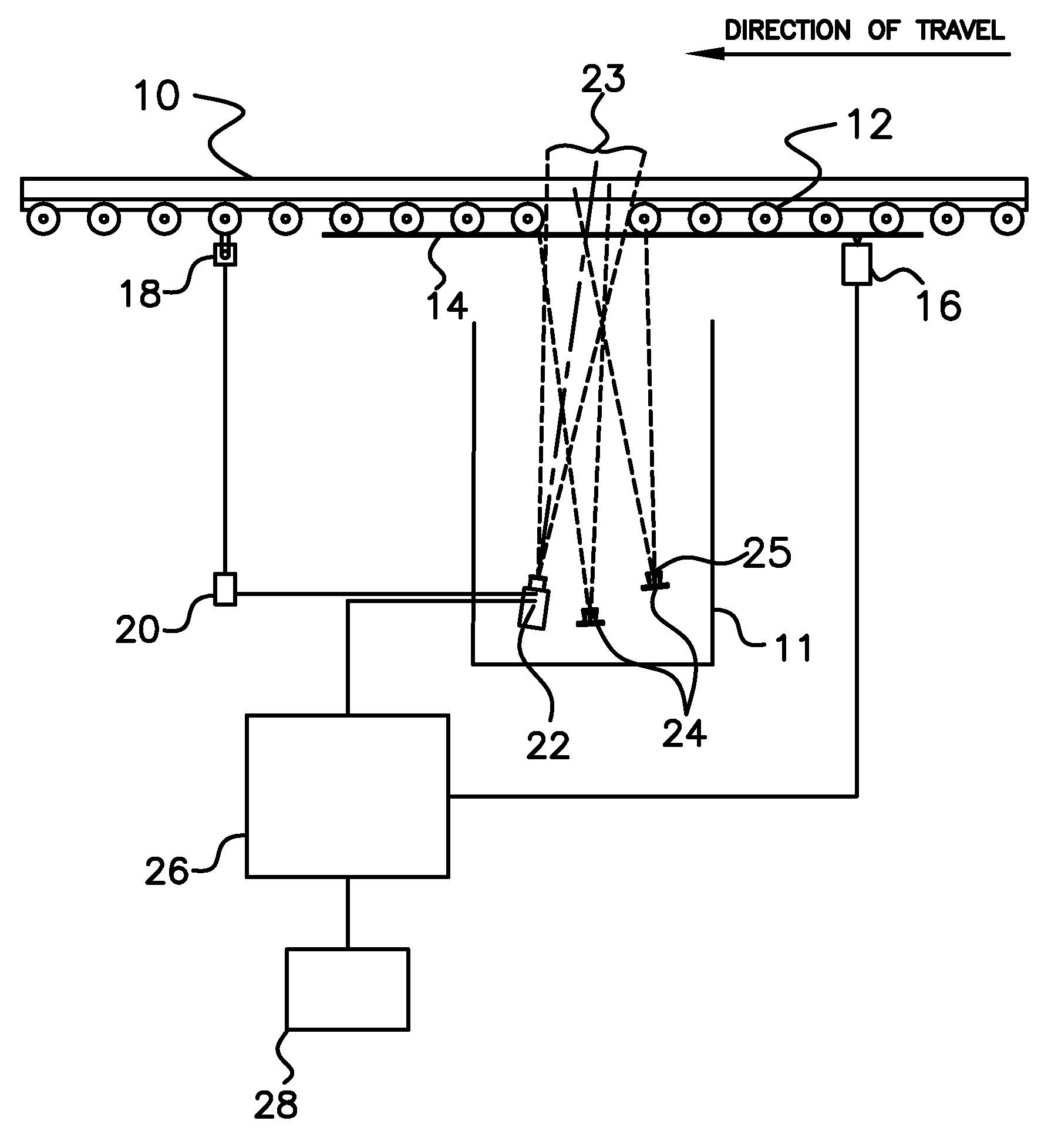

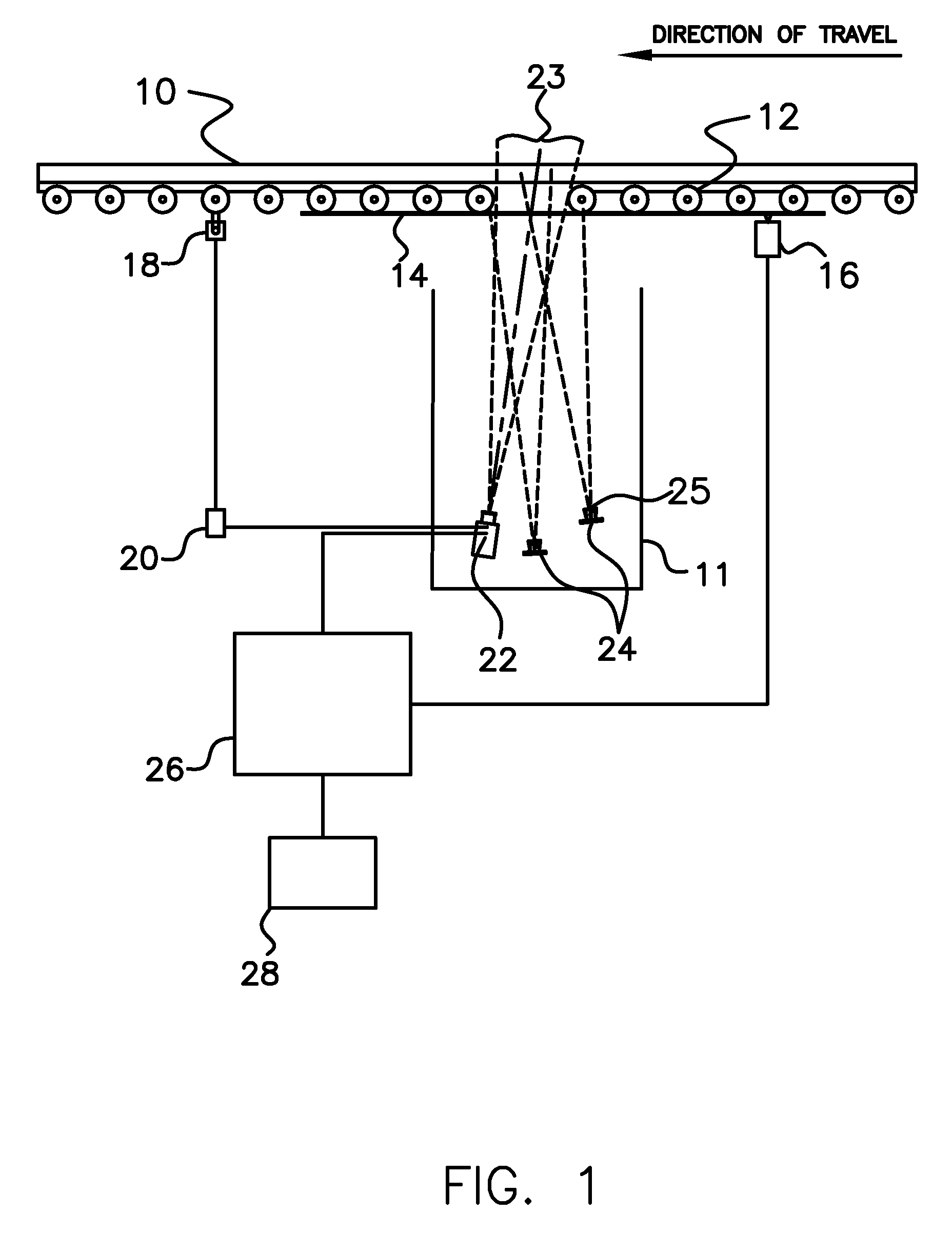

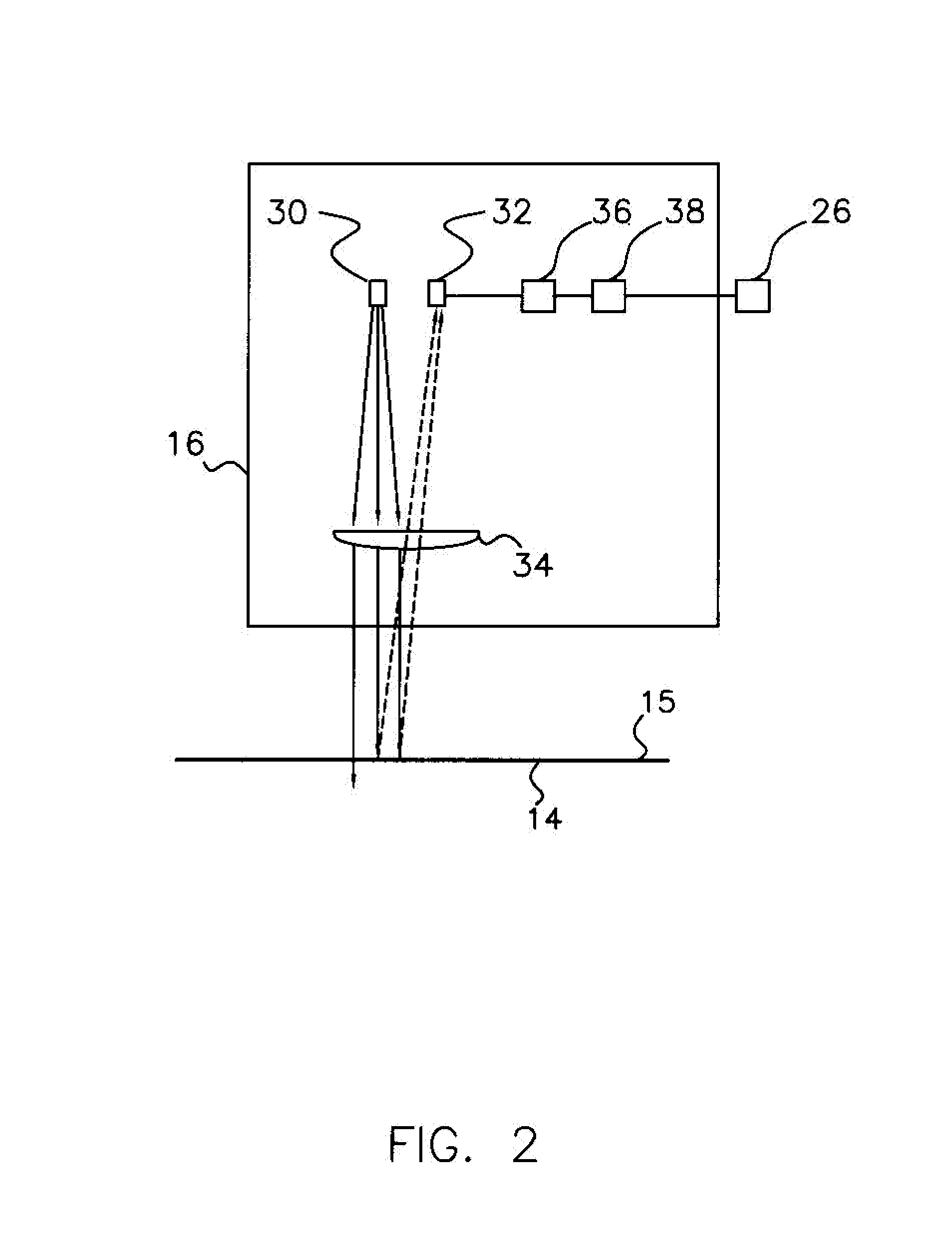

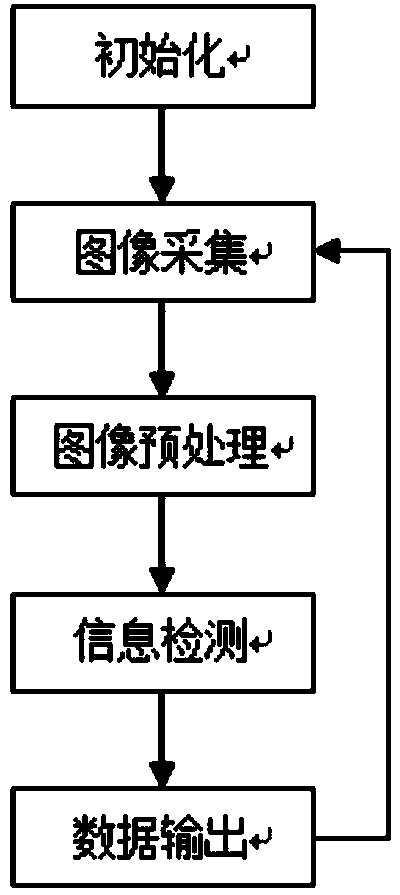

Apparatus and methods for real-time adaptive inspection for glass production

ActiveUS7369240B1Easy to adjustAvoid corrosionMaterial analysis by optical meansImaging processingEngineering

An apparatus and methods for the real-time inspection for defects in and on transparent sheets, such as a sheet of glass, are described. A sensor detects a transparent light reflective coating on a transparent sheet and defines a sample profile. An optical inspection system utilizes an illumination source and an imaging device to obtain images of the transparent sheets. An image processing system analyzes for defects in the transparent sheets, including coating defects and defects in edge deleted perimeters. Inspection variables which correspond to the sample profile are used by the optical inspection system and image processing system for real-time inspection.

Owner:LITESENTRY LLC

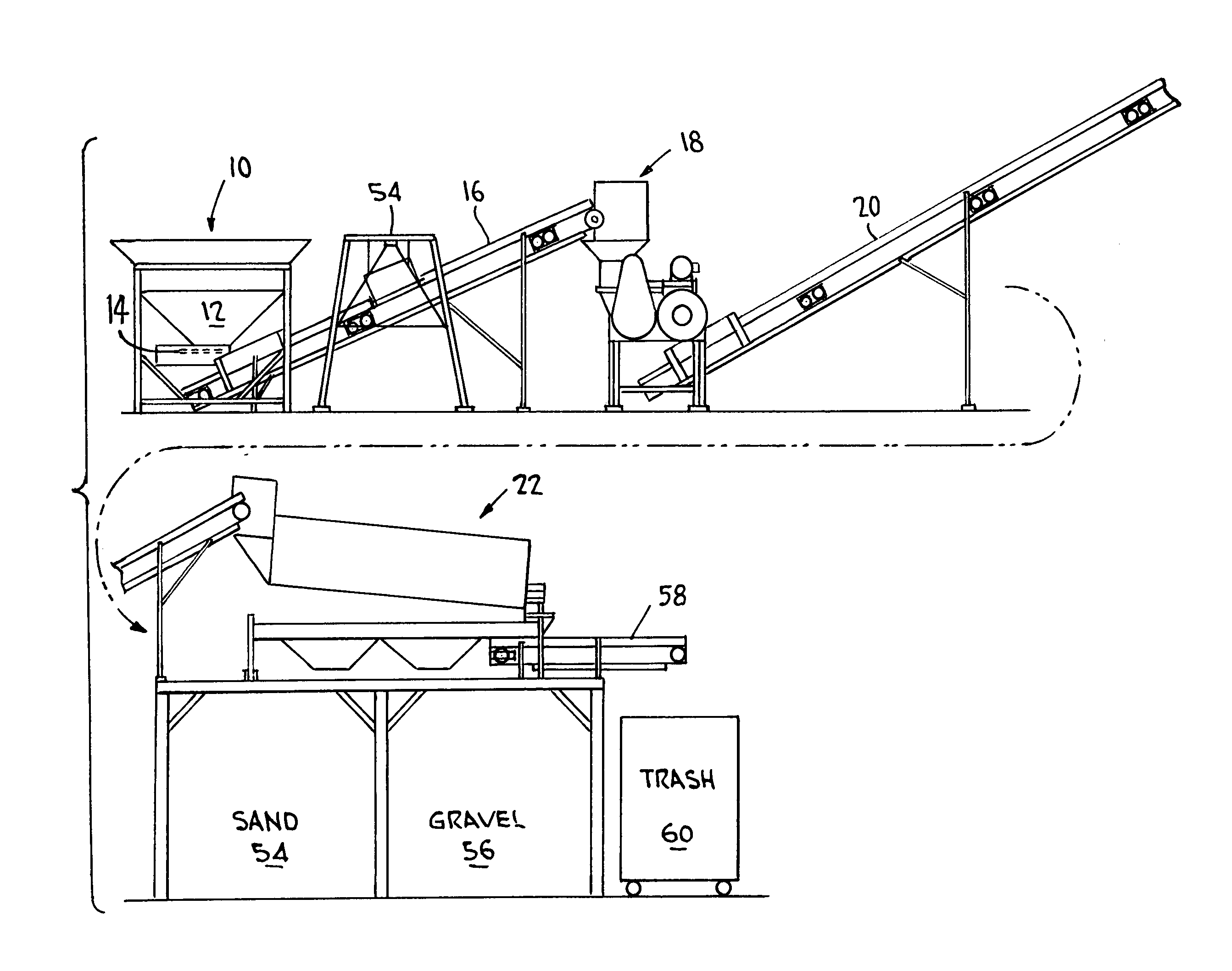

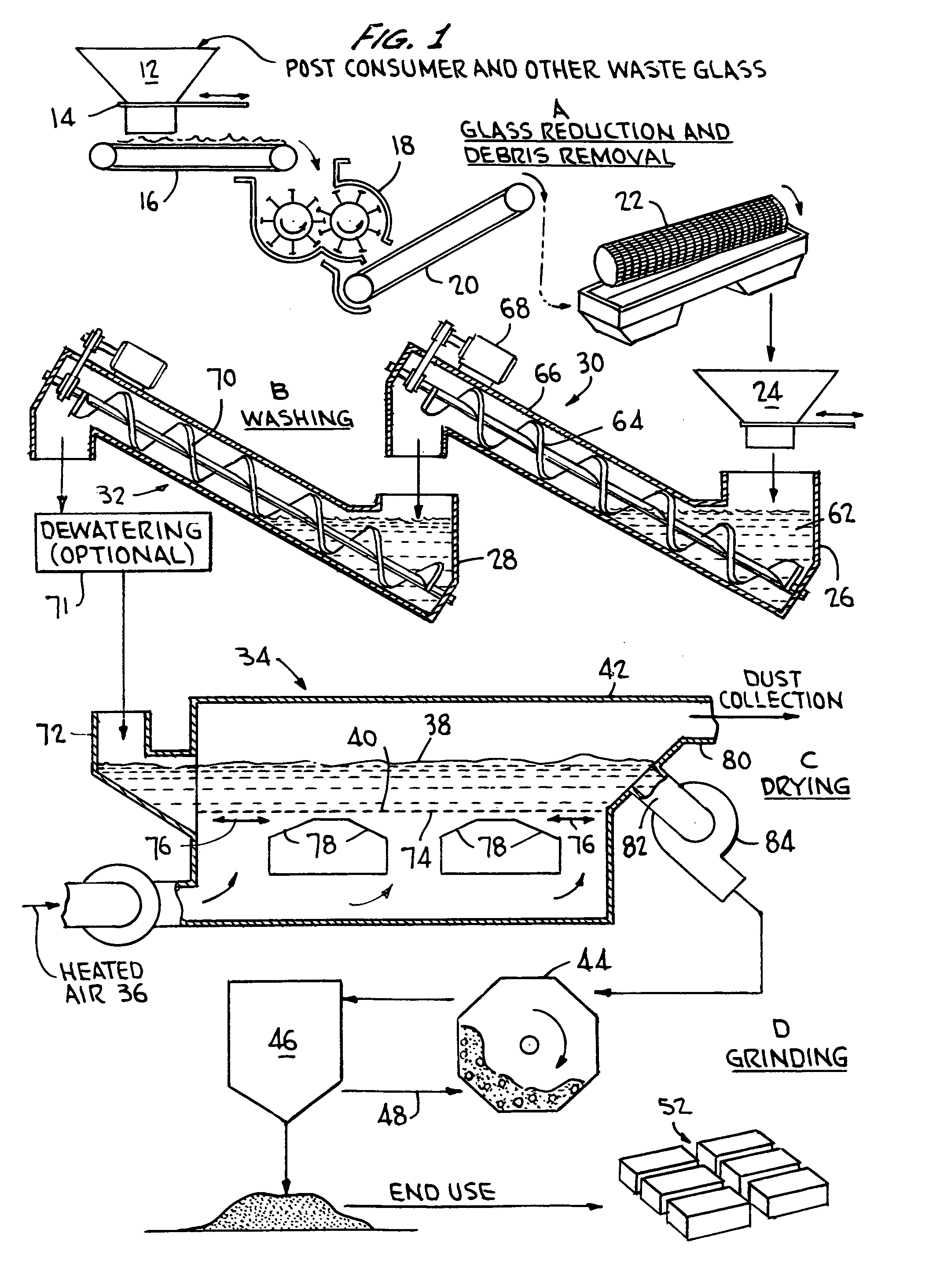

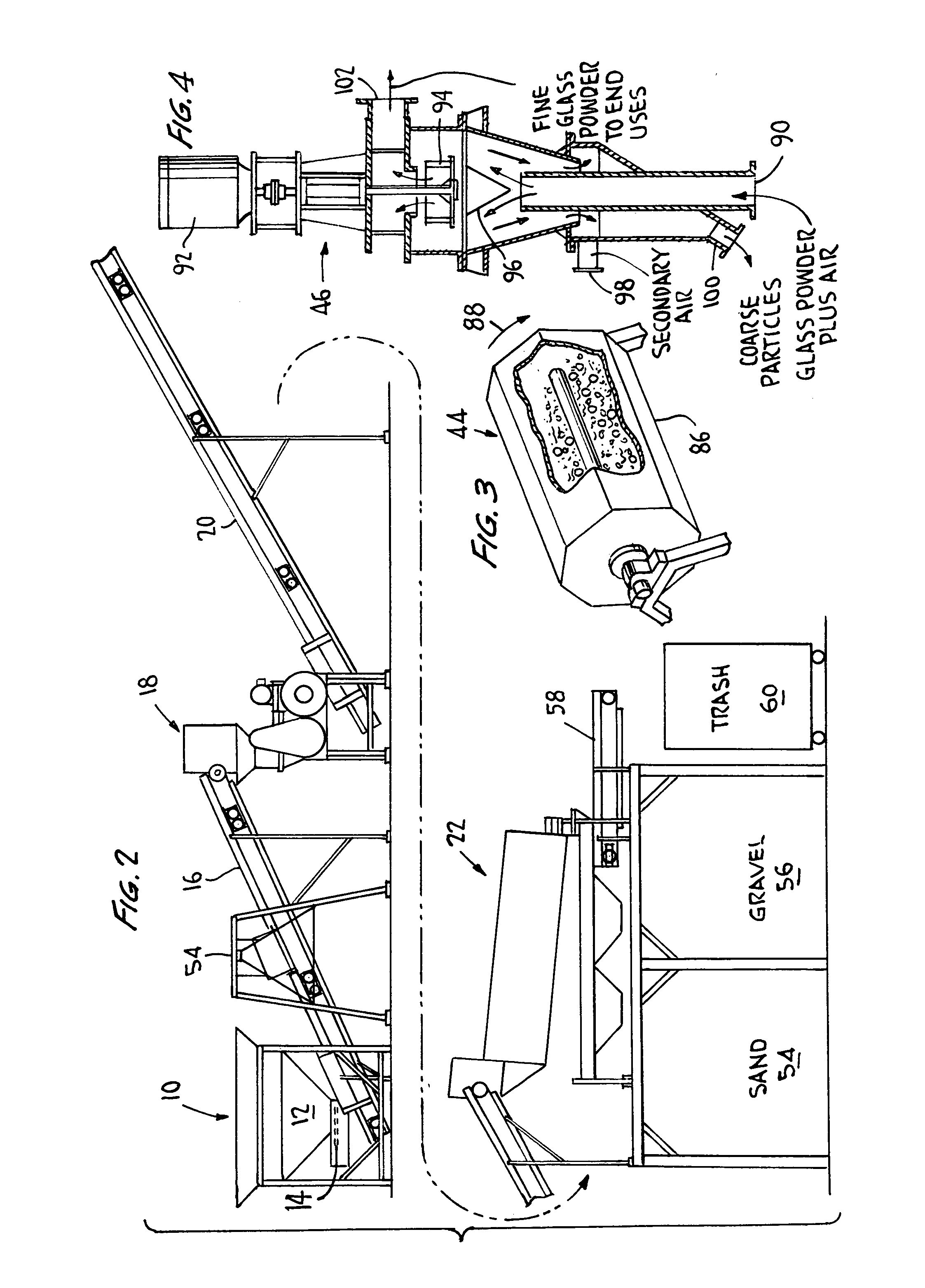

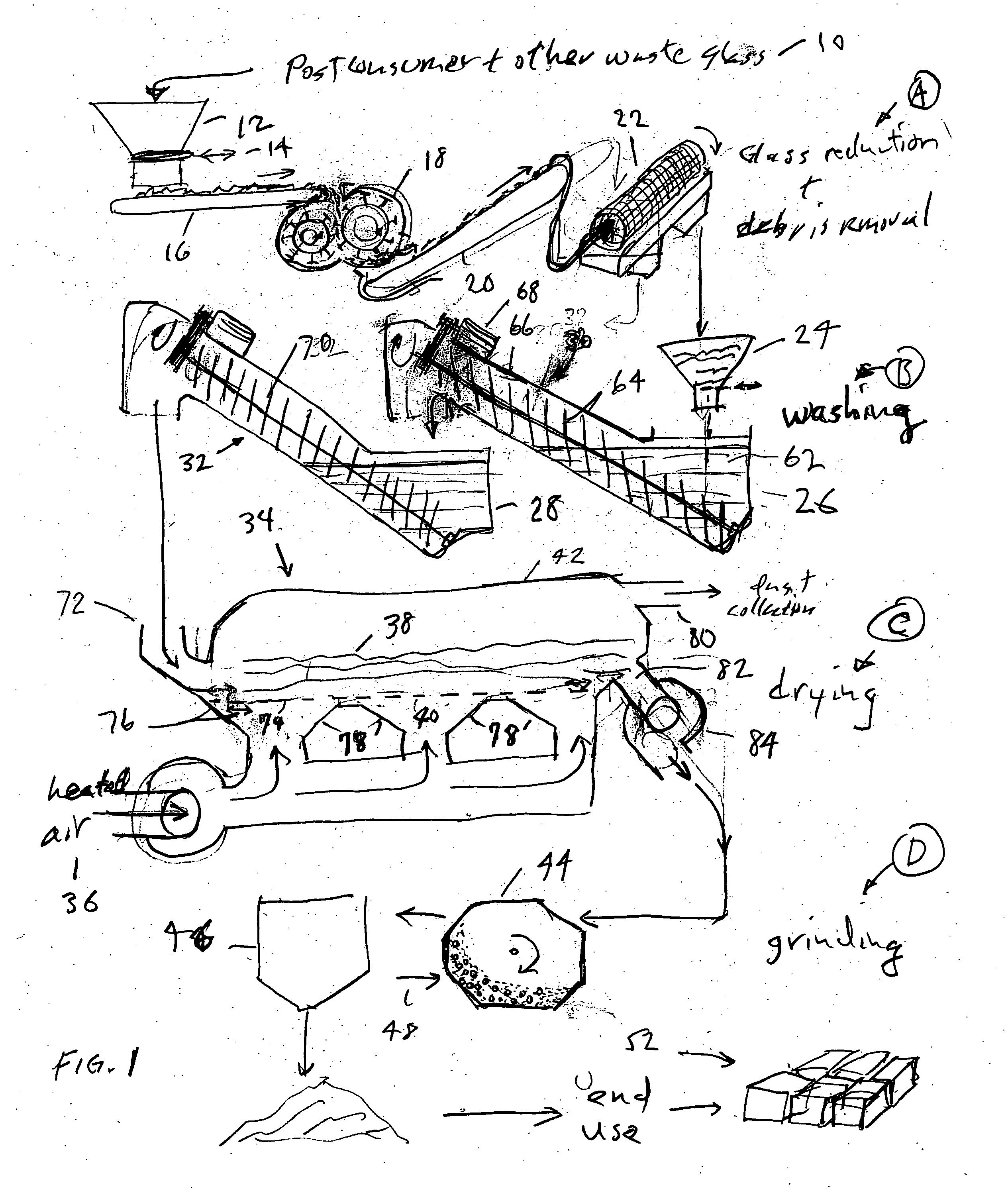

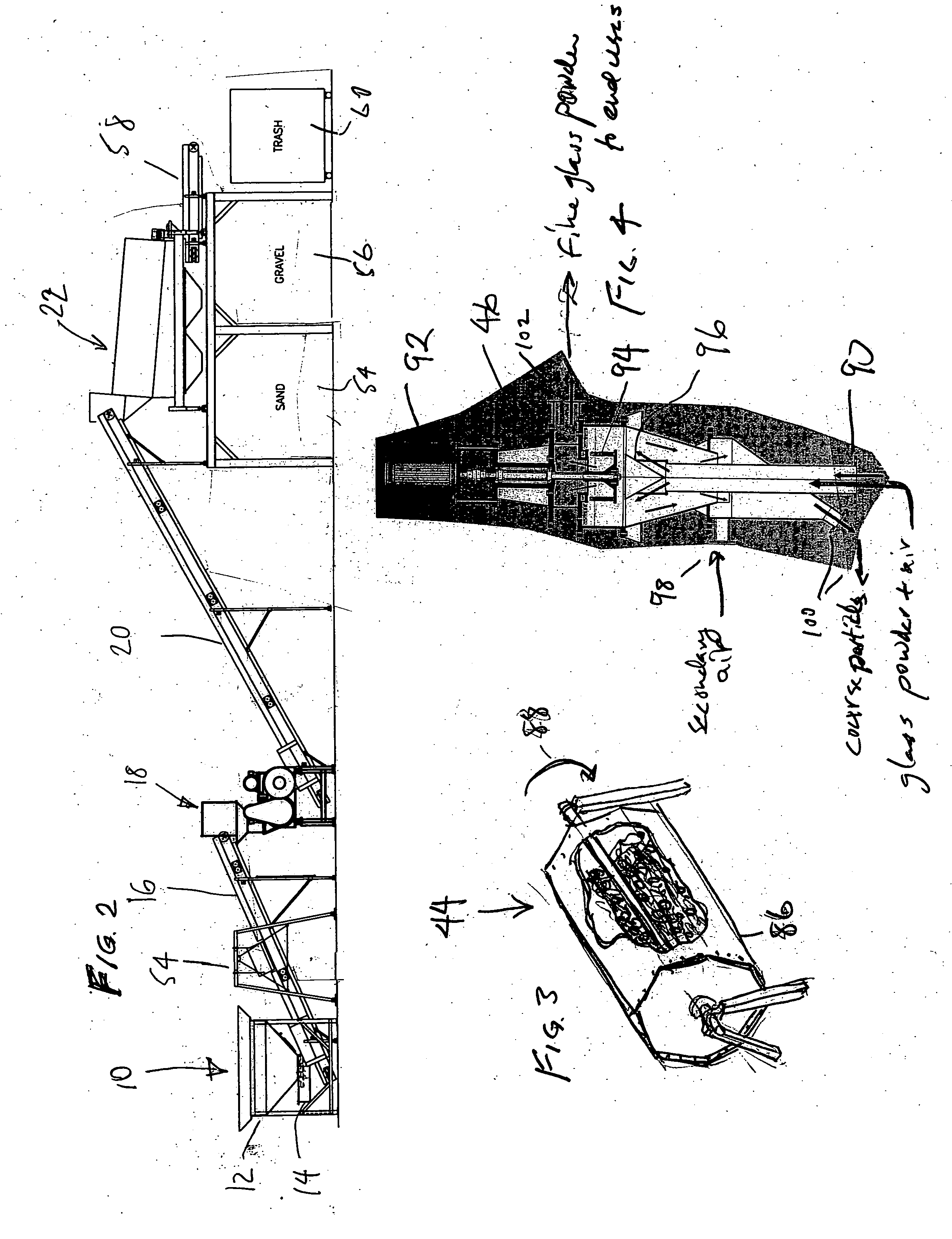

Production of glass powder from waste glass, and products made using the same, especially concrete

ActiveUS7413602B2Suppress the alkali-silica reactionCocoaGrain treatmentsFluidized bedSmall fragment

A clean dry glass powder useful as a substitute for Portland cement in concrete, in paints, and for other known uses for glass powder produced conventionally can be produced from unsorted post-consumer waste glass, including a subsatantial fraction of non-glass items, by employing glass pulverizing equipment to reduce waste glass to small fragments, allowing removal of trash, employing a multistep washing process to clean the glass fragments, in the preferred embodiment using aggregate cleaning equipment, drying the fragments, preferably using fluidized bed techniques, and grinding the glass to a desired particle size, preferably using a ball mill, in combination with an air classification step to produce a glass powder of uniform particle size.

Owner:URBAN MINING NORTHEAST

Production raw material of foamed glass and process for producing foamed glass

The invention relates to raw materials for producing foam glass and a method for applying the same to produce the foam glass. The compositions by weight portion of the raw materials are: 380 to 580 portions of quartz sand, 105 to 250 portions of potassium feldspar, 130 to 270 portions of albite, 115 to 200 portions of dolomite, 5 to 25 portions of calcite, 150 to 250 portions of calcined soda, 0.5 to 30 portions of glauber salt, 1.0 to 12 portions of magnesium carbonate and 1.0 to 8.5 percent of potassium carbonate. The method comprises the following steps that: firstly, various raw material compositions are mixed into uniform glass mixture; secondly, the glass mixture is melted and cooled into cullet; thirdly, ball milling, foaming and annealing of the cullet are performed, and then foam glass is obtained. The method can automatically control and adjust the chemical compositions of the glass and add various functional compositions as required to meet the demand of producing the foam glass with different performances by adoption of common mineral and chemical raw materials of the natural world.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

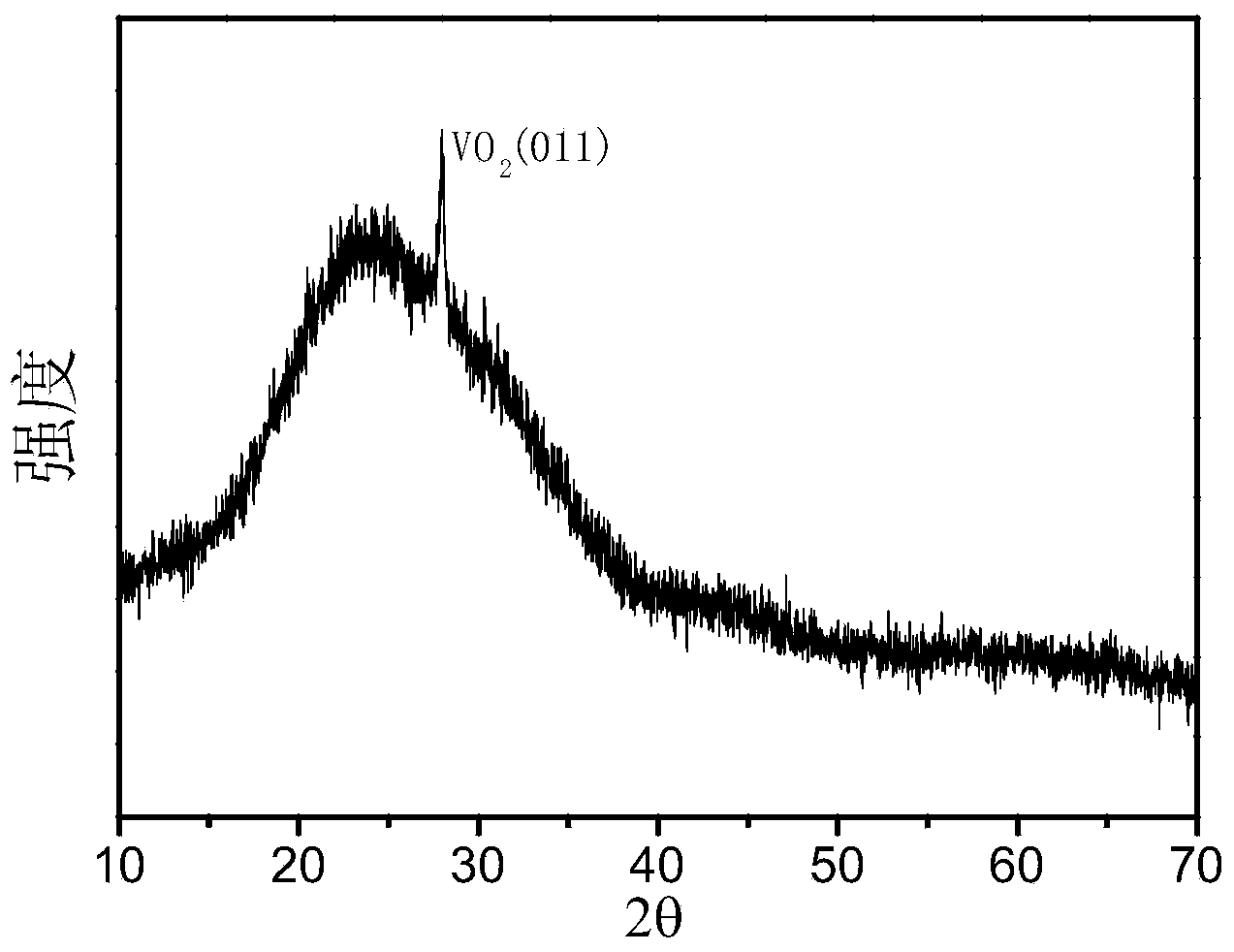

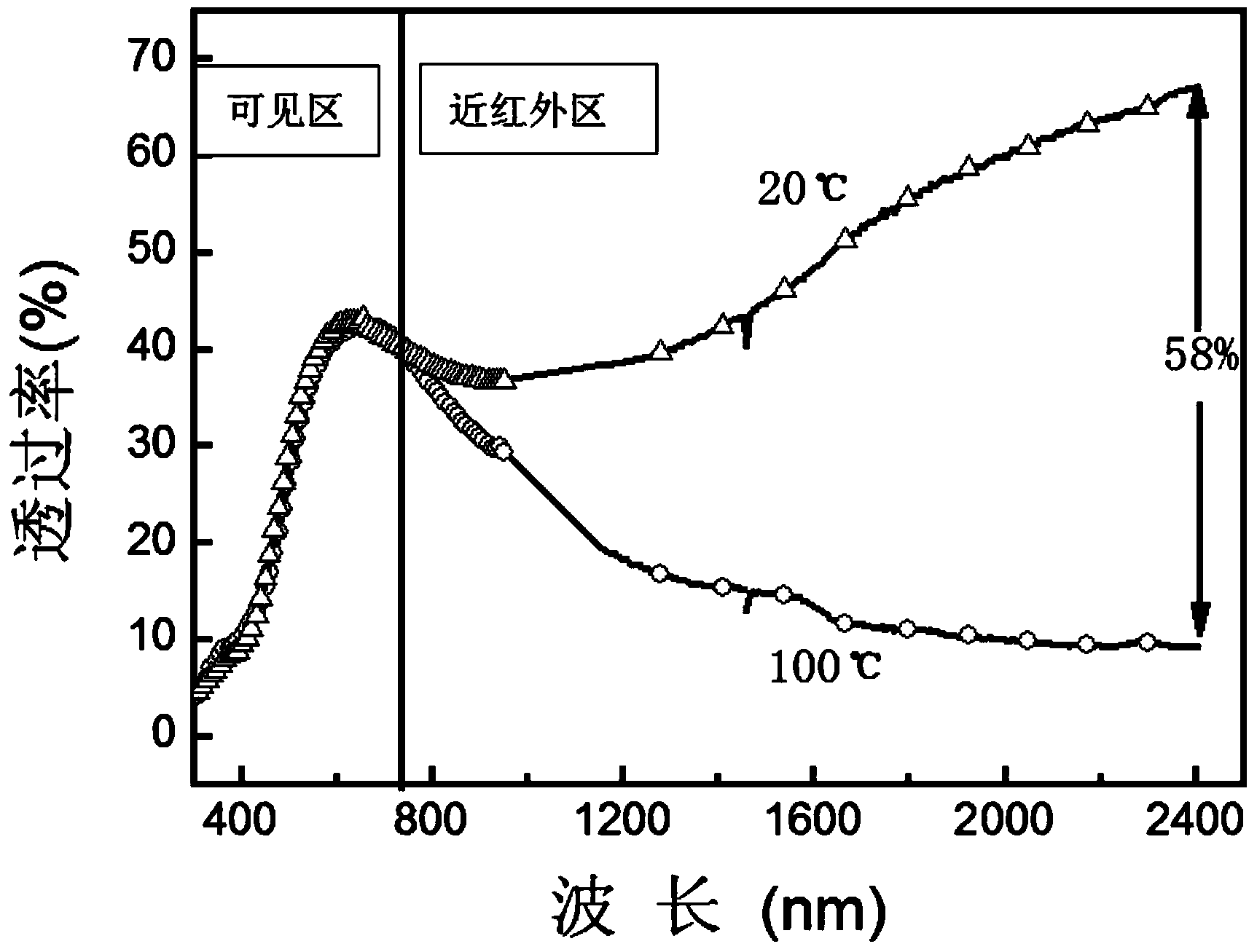

Method for preparing vanadium dioxide film

InactiveCN104032278AImprove performanceGood repeatabilityVacuum evaporation coatingSputtering coatingVanadium dioxideTransmittance

The invention discloses a method for preparing a vanadium dioxide film. According to the method, metal vanadium or low-valence vanadium oxide film is annealed in oxygen and vacuum to obtain a phase-transition vanadium dioxide film; the most proper oxygen partial pressure, the annealing temperature and the annealing time are selected according to the type and thickness of the low-valence vanadium oxide to obtain a vanadium dioxide film with excellent performance, wherein the infrared regulation rate at 2,400nm can be 58 percent, and the visible light transmittance can be 43 percent; the doped low-valence vanadium oxide film is oxidized to obtain the doped vanadium dioxide film, and the phase transition temperature of the vanadium dioxide can be regulated by means of doping to adapt to different requirements. The vanadium dioxide film can be applied to optical information storage, photoelectric switches, intelligent windows and uncooled infrared focal plane imaging; the method is compatible with large-scale coated glass production process, and a vanadium dioxide film with excellent performance can grow on amorphous glass.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Production of glass powder from waste glass, and products made using the same, especially concrete

ActiveUS20060130707A1Many applicationsSuppress the alkali-silica reactionCocoaGrain treatmentsFluidized bedSmall fragment

A clean dry glass powder useful as a substitute for Portland cement in concrete, in paints, and for other known uses for glass powder produced conventionally can be produced from unsorted post-consumer waste glass, including a subsatantial fraction of non-glass items, by employing glass pulverizing equipment to reduce waste glass to small fragments, allowing removal of trash, employing a multistep washing process to clean the glass fragments, in the preferred embodiment using aggregate cleaning equipment, drying the fragments, preferably using fluidized bed techniques, and grinding the glass to a desired particle size, preferably using a ball mill, in combination with an air classification step to produce a glass powder of uniform particle size.

Owner:URBAN MINING NORTHEAST

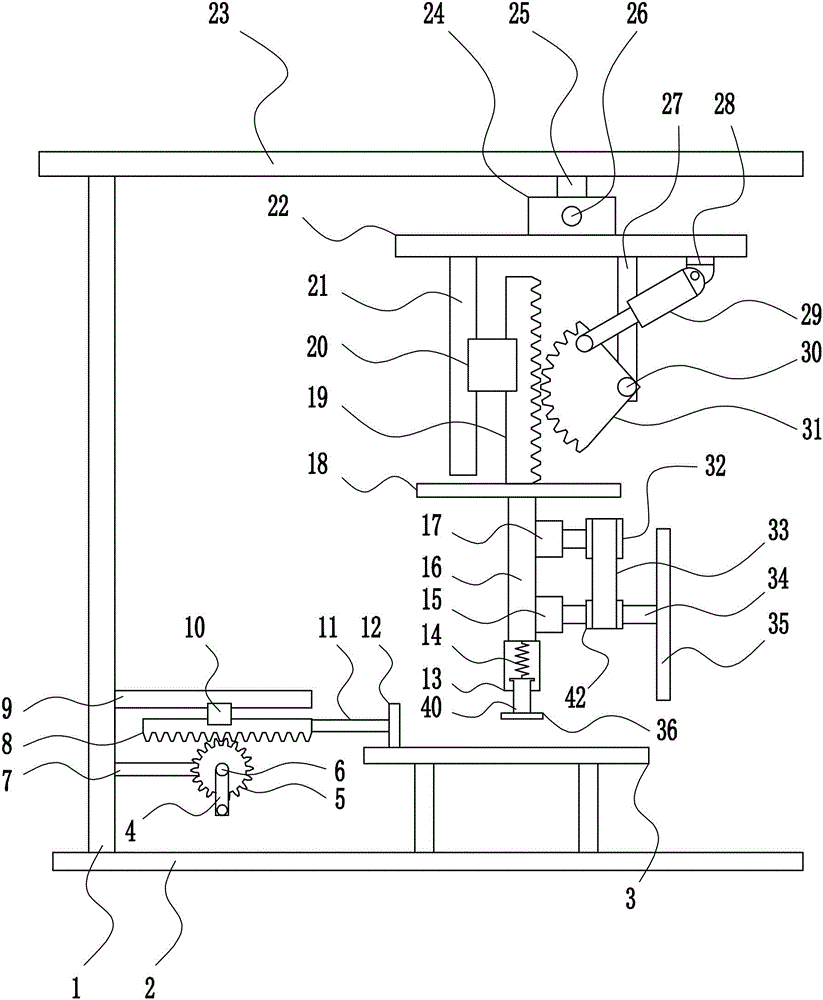

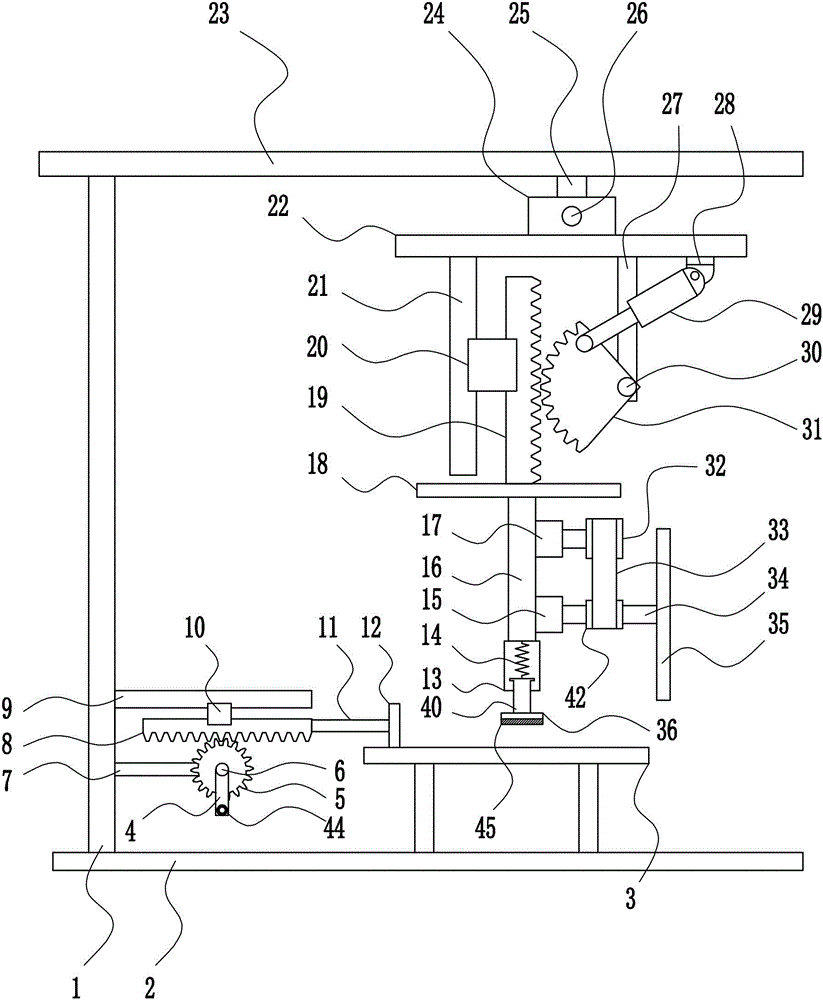

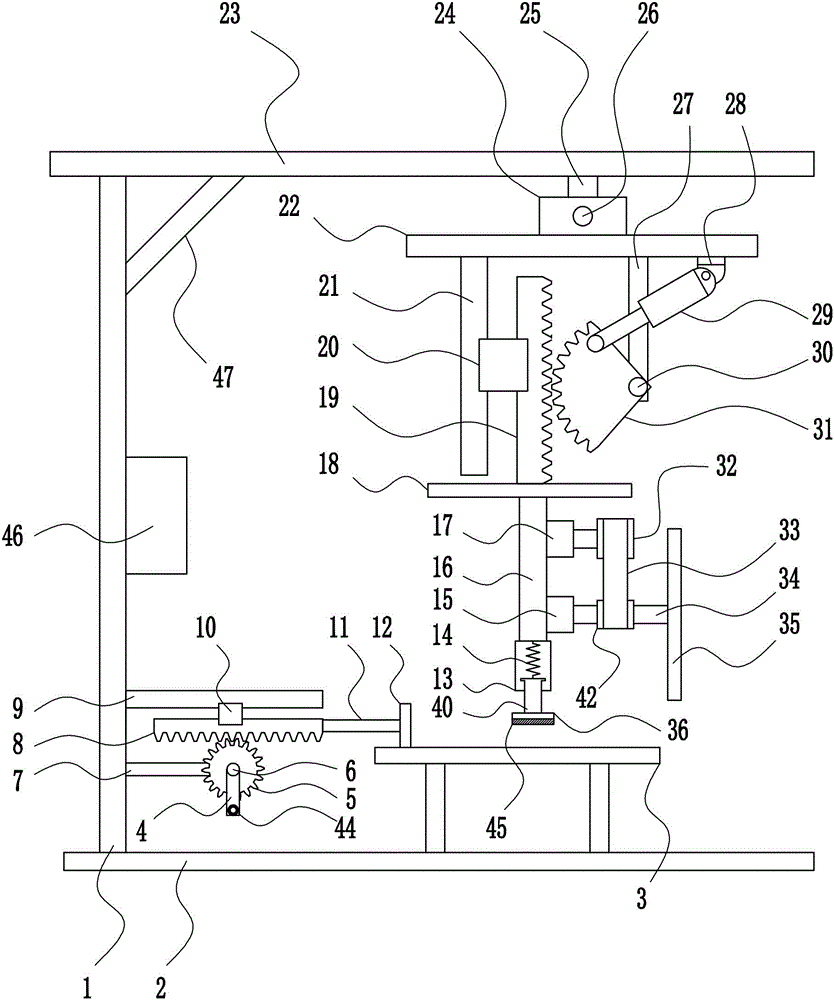

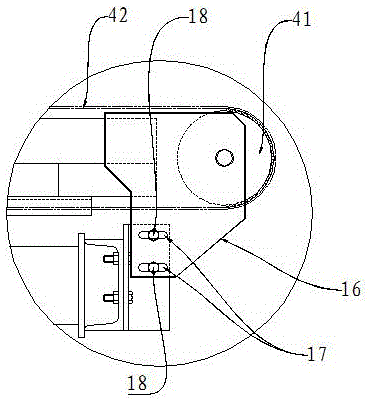

Cutting device for nano-glass production

The invention relates to a cutting device, in particular to a cutting device for nano-glass production, wherein the cutting device is convenient to operate, low in energy consumption and uniform in cutting. The cutting device for nano-glass production comprises a left frame, a bottom plate, a placement table, a rocking handle, a circular gear, a first rotating shaft, a first bearing block, a first rack, a first sliding rail, a first slider, an ejector rod and the like, the left side of the top of the bottom plate is welded with the left frame, the right side of the top of the bottom plate is connected with the placement table in a bolted manner, the lower portion of the right side of the left frame is connected with the first bearing block and the first sliding rail in a bolted manner. An electric push rod drives a sector gear to swing, the sector gear drives a second rack to move downwards, and vertical movement of a blade is realized through matching of a second motor with a lead screw and a nut.

Owner:麻城小龟龟机械科技有限公司

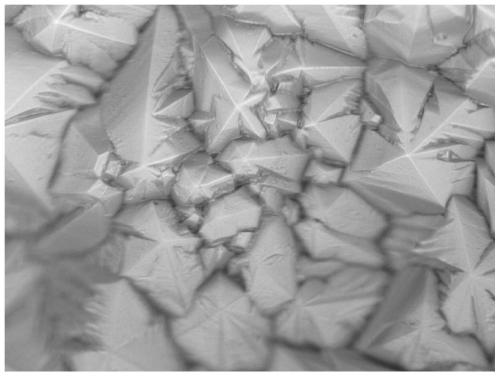

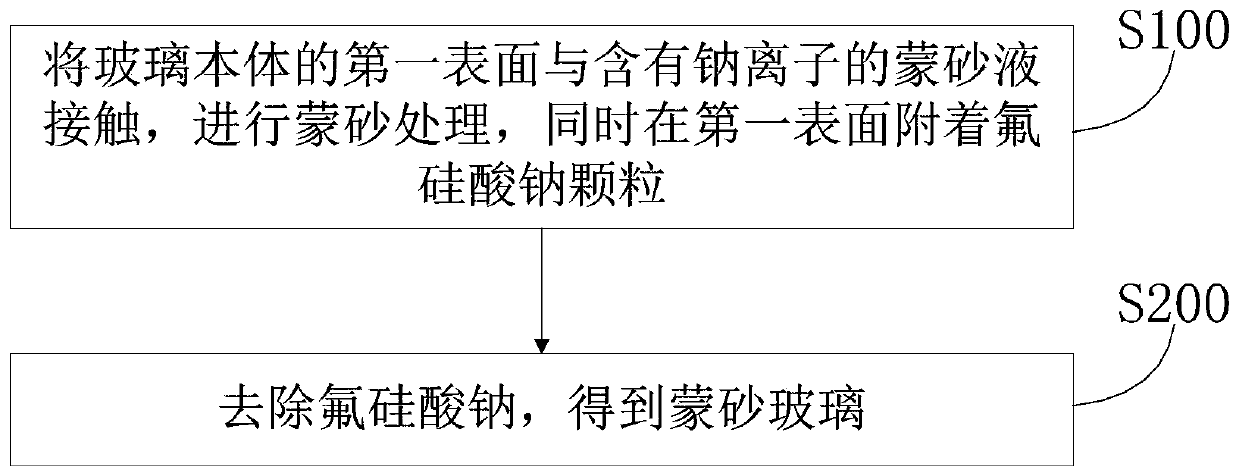

Frosted glass and preparation method thereof, glass back cover and electronic device

ActiveCN110467354ACasings with display/control unitsCasings/cabinets/drawers detailsSpecular reflectionPoint projection

The invention provides a frosted glass and a preparation method thereof, a glass back cover and an electronic device, wherein the frosted surface of frosted glass has a pointed projection structure. According to the present invention, based on the pointed projection structure of the frosted glass, the frosted glass has a frosted effect and achieves anti-fingerprint and anti-glare effect, and lightcan be subjected to mirror reflection on the surface having the pointed projection structure to form pearlescent effect, such that the frosted glass simultaneously has effects of fingerprint resistance, glare resistance and pearlescent effect, and pearlescent ink printing on the glass is not required so as to save the frosted glass production process and the frosted glass production cost.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

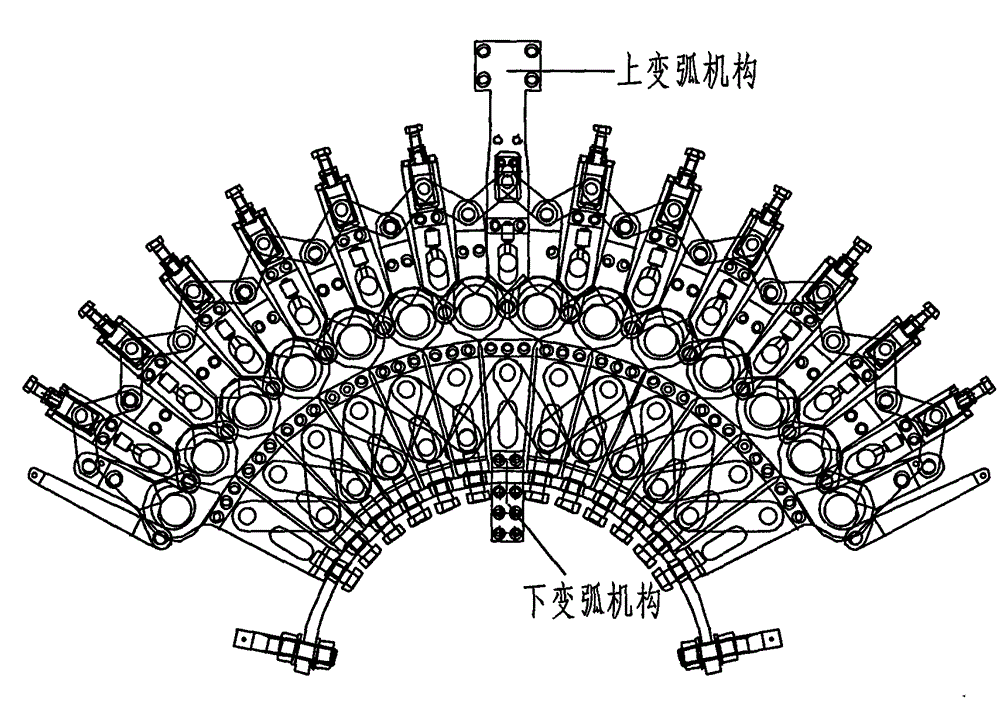

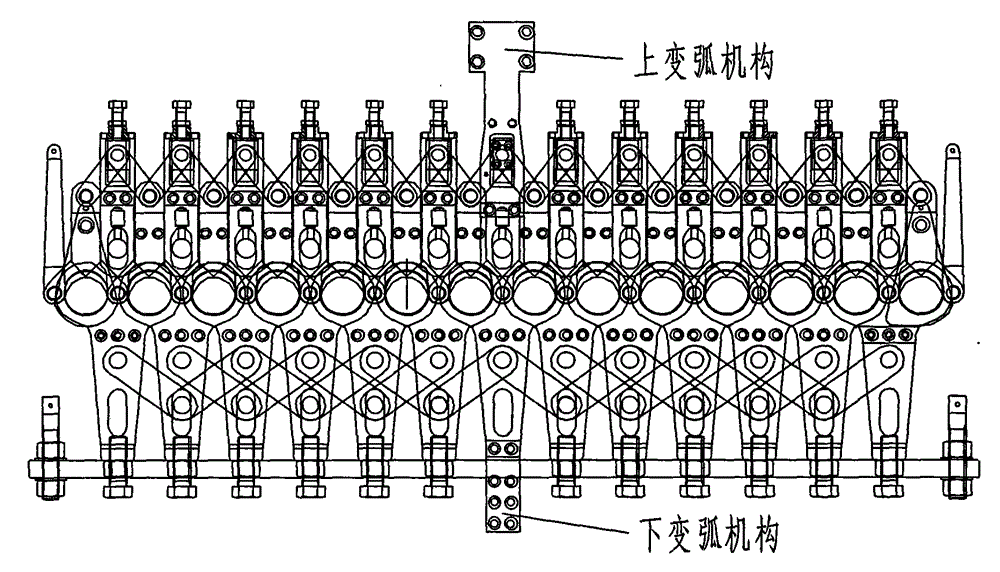

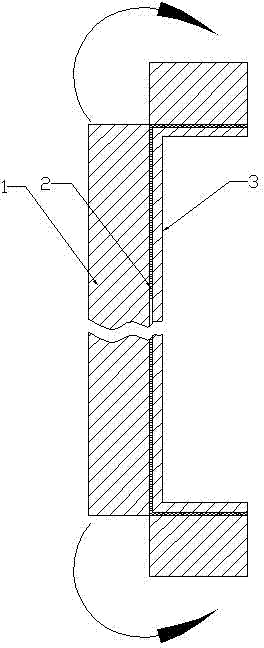

Forming device for reversely bending tempered glass and operating method thereof

ActiveCN104086075AAccurate arcImprove protectionGlass reforming apparatusGlass tempering apparatusScreen printingEngineering

The invention relates to a forming device for reversely bending tempered glass and an operating method thereof. The forming device is convenient and quick to use, and has the advantages of high glass production efficiency, energy saving and environmental protection. The forming device has favorable working effect for glass of which the outer cambered surface is a screen printing ink surface or any other film surface, and well protects the screen printing ink surface or any other film surface. Meanwhile, due to the special up-and-down variable-camber structure and pressure roller structure, the forming radian of the glass can reach the set standard, and the goodness of fit can be controlled within 0.5mm. The forming device ensures the radian accuracy of the finished tempered glass, and improves the external quality and internal quality of the product.

Owner:MOUNTAIN GLASS TECH

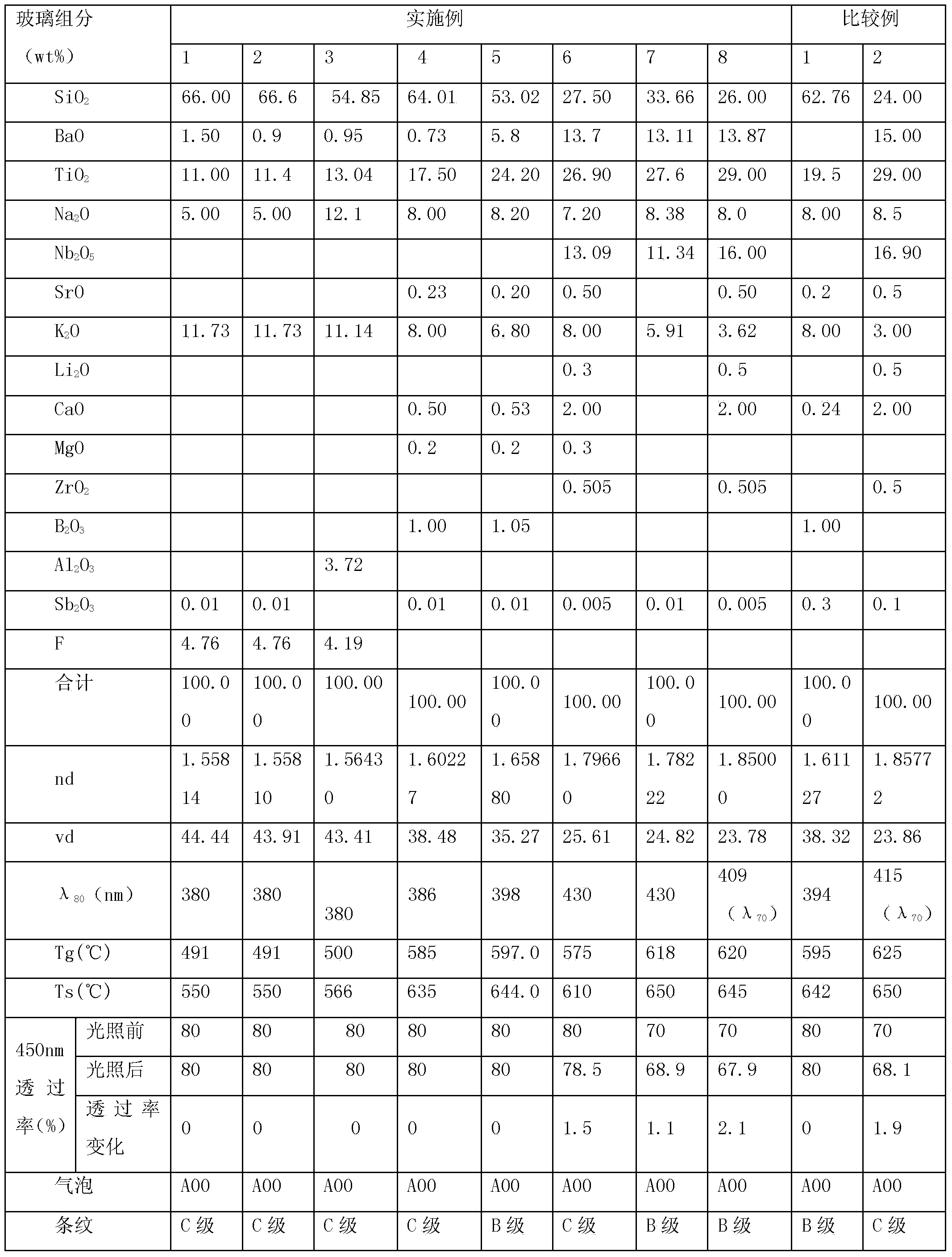

Environment-friendly flint optical glass and optical element

The invention provides an environment-friendly flint optical glass with a refractive index of 1.55 to 1.85 and abbe number of 23 to 45. The optical glass has an ideal bubble quality and chroma quality. The transmittance of a wave, which is triggered by irradiating UV on the environment-friendly optical glass and has a wave length of 450 nm, is less than 2.1%. The optical glass is composed of the following components in percentage by weight: 20 to 70% of SiO2, 5 to 35% of TiO2, 0 to 20% of RO, 5 to 25% of R2O, wherein the RO represents the total amount of MgO, BaO, CaO, and SrO, and the R2O represents the total amount of K2O, Na2O, and Li2O. The provided optical glass has a qualified optical performance, has an ideal bubble quality and chroma quality, and moreover has an easier glass production difficulty and raw material production difficulty. The provided optical glass can meet the requirements of high-class optoelectronic digital products and high definition (HD) imaging equipment.

Owner:CDGM OPTICAL GLASS

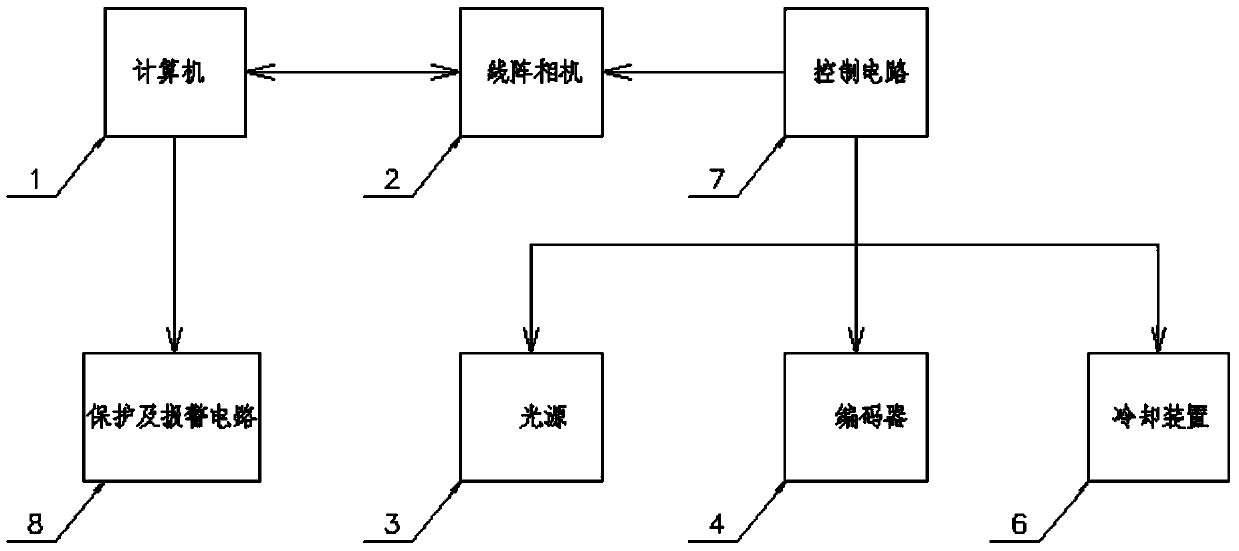

Glass plate width detection system based on machine vision

ActiveCN103471512AFast image processingProcessing speedUsing optical meansImaging processingMachine vision

The invention relates to the technical field of glass production, in particular to a glass plate width detection system based on machine vision. The system comprises a line-scan digital camera, an encoder, a light source and a light-shielding cover, and is characterized in that the line-scan digital camera and the light source are located above a to-be-detected glass plate, the light source and the line-scan digital camera are not on the same vertical plane, the light-shielding cover is arranged on the outside of the light source, the line-scan digital camera is arranged on the outer side of the light-shielding cover, the two ends of the light-shielding cover are sealed, the upper portion of the light-shielding cover is provided with a hole, imaging of the light source on the to-be-detected glass plate can be seen in the hole through the line-scan digital camera, the to-be-detected glass plate is arranged on a roller bed, the roller bed is provided with the encoder, and the encoder collects the speed of the roller bed to control the speed of the line-scan digital camera in catching an image. Compared with the prior art, the system has the advantages that the image can be directly processed, information on the left side and the right side of the glass plate is information at the same moment, and consistency of data is achieved; the image processing speed is high, information of the glass plate is detected in real time, measured data are high in precision and high instantaneity and accuracy are achieved.

Owner:CHINA TRIUMPH INT ENG

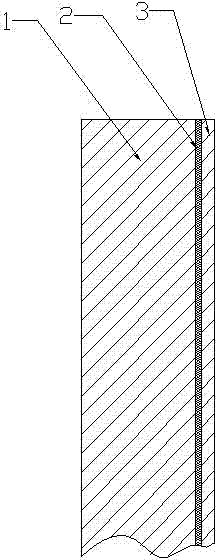

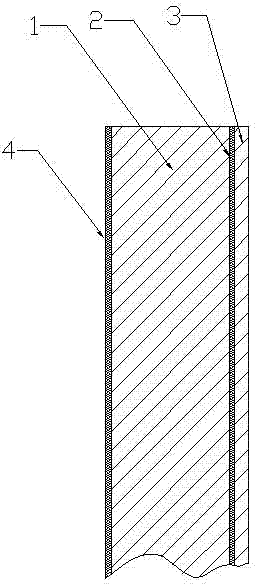

Glass-metal composite plate as well as manufacturing method and application thereof

InactiveCN103587161AImprove flexural strengthImprove securityLaminationLamination apparatusFlat glassThin metal

The invention discloses a glass-metal composite plate as well as a manufacturing method and application thereof. The glass-metal composite plate is characterized by being formed by compounding a glass plate (1) and a thin metal sheet (3) through an adhesive (2). A required part of the glass plate (1) of the glass-metal composite plate is broken and bent to manufacture various profiles and products. The glass-metal composite plate can be used for manufacturing hollow glass and vacuum glass which serve as lightproof heat preservation plates. The glass-metal composite plate is processed and manufactured at a cold end of a flat-plate glass production line. The manufacturing method mainly comprises the following steps: 1, cleaning the upper surface of an on-line glass plate according to a dry method; 2, coating the adhesive (UV (ultraviolet) glue or hot-melted glue) on the upper surface of the glass plate or the lower surface of the coiled thin metal sheet; 3, continuously pressing the glass plate and the thin metal sheet together through a pair of rollers; 4, solidifying the UV glue or the hot-melted glue; 5, cutting off the thin metal sheet and a glue layer on the upper surface of the glass-metal composite plate through a laser knife and correspondingly cutting off the glass plate on the lower surface of the glass-metal composite plate through a glass knife; 6, cutting off and stacking the glass-metal composite plate.

Owner:徐林波

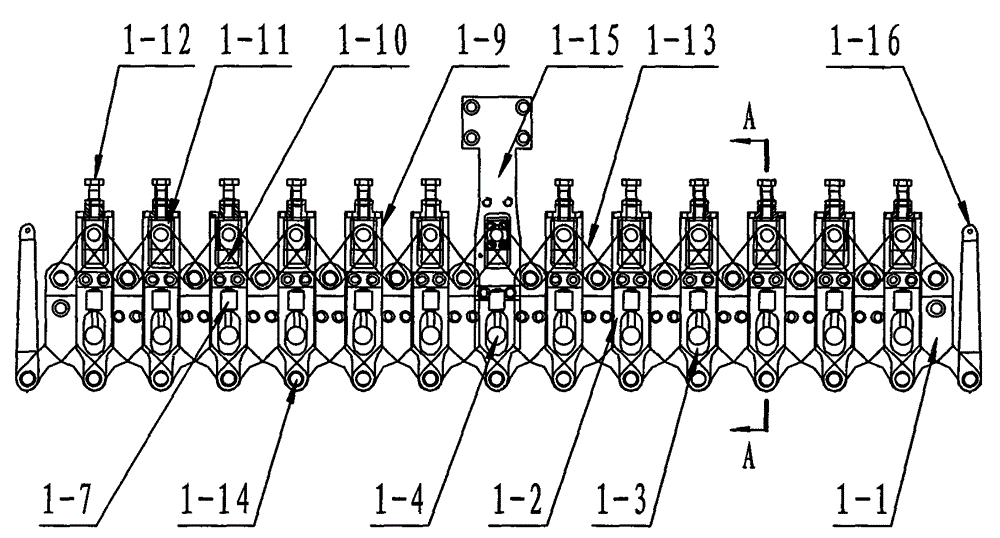

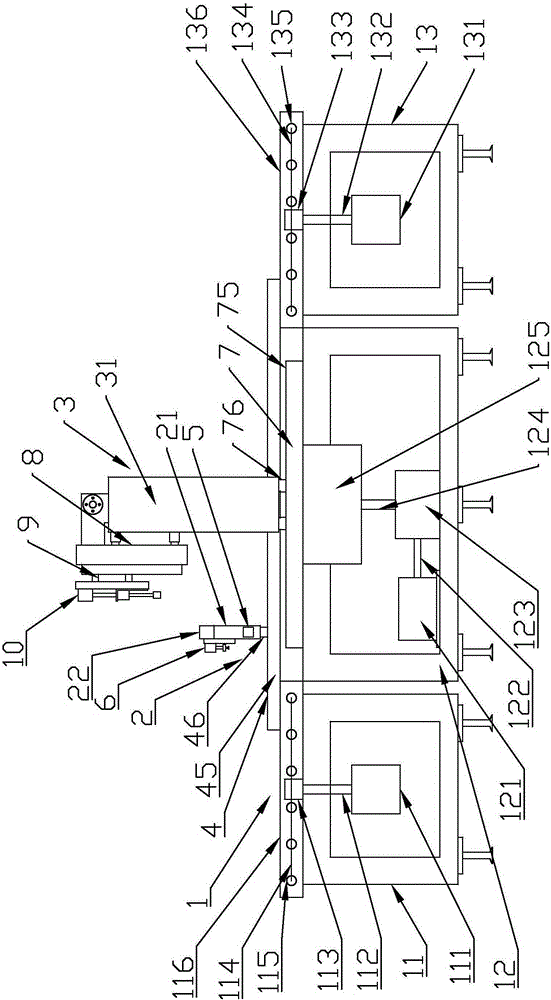

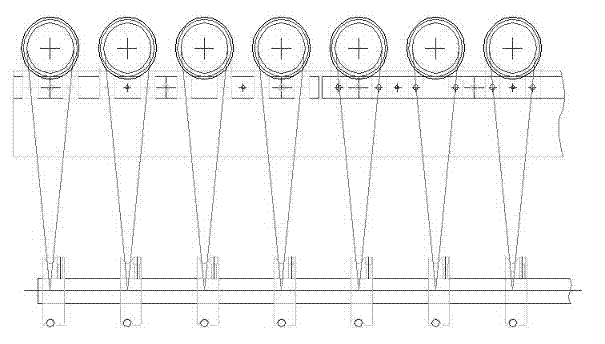

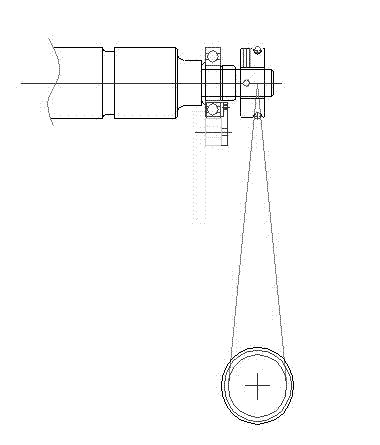

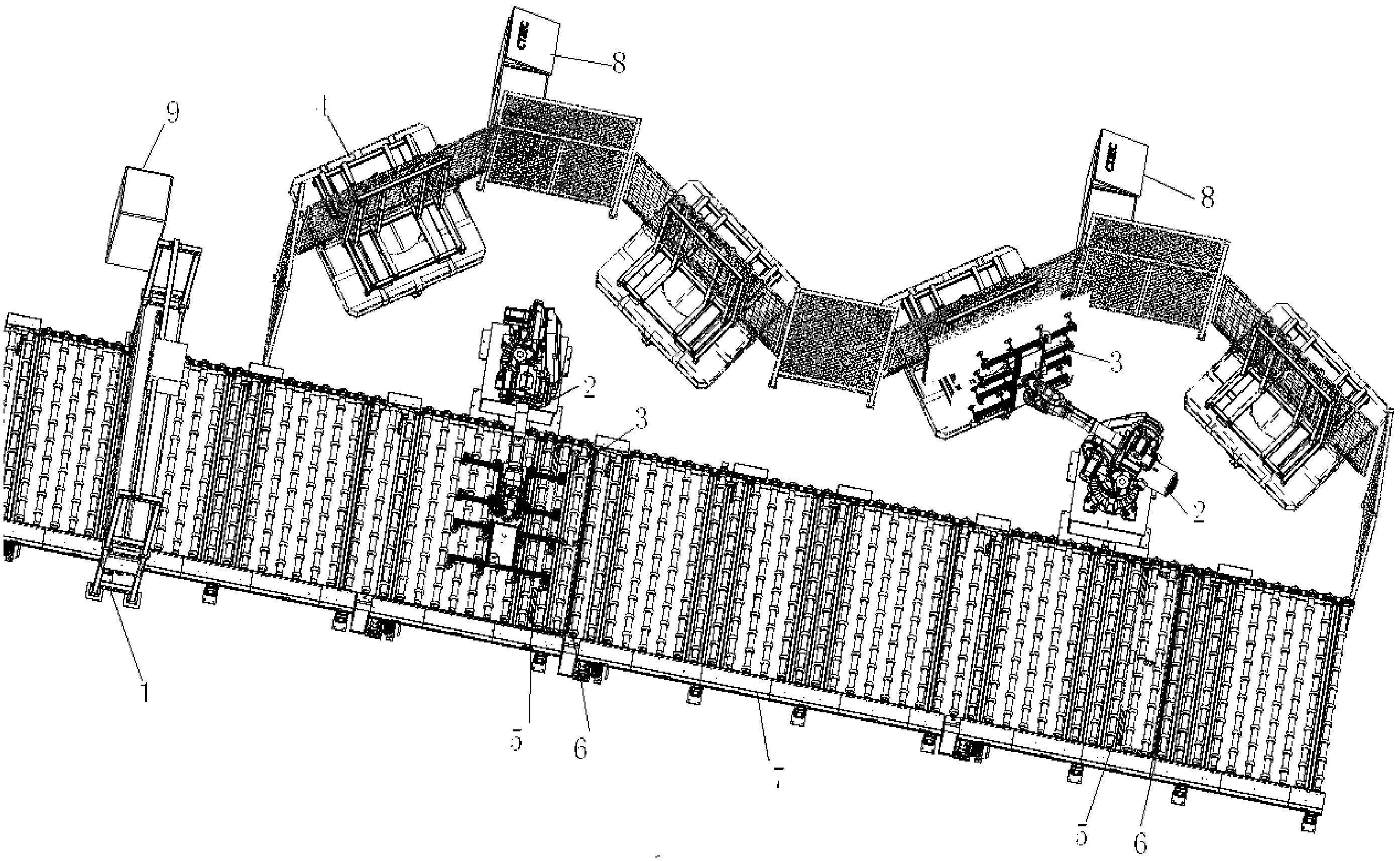

Full-automatic linear edge grinding machine for glass production

InactiveCN105215812ASolve the edging problemSimple structureEdge grinding machinesGrinding carriagesEngineeringPortal frame

The invention discloses a full-automatic linear edge grinding machine for glass production. The full-automatic linear edge grinding machine comprises machine frames which comprise the feeding machine frame, the main machine frame and the discharging machine frame. A conveying mechanical hand and an edge grinding device are arranged on the main machine frame, and an edge grinding workbench is arranged in the main machine frame; the conveying mechanical hand comprises an X-direction conveying mechanism, a Y-direction clamping mechanism and a suction cup mechanism. The X-direction conveying mechanism is fixedly mounted on the main machine frame and provided with a vertical conveying frame. The Y-direction clamping mechanism is fixedly mounted on the side face of the vertical conveying frame. The suction cup mechanism is fixedly mounted at the upper end of the vertical conveying frame. The edge grinding device comprises an X-direction moving mechanism, a Y-direction moving mechanism, a lifting mechanism and a grinding mechanism. The X-direction moving mechanism is fixedly mounted on the main machine frame and provided with a portal frame. The Y-direction moving mechanism, the lifting mechanism and the grinding mechanism are all fixedly mounted on the portal frame. The full-automatic linear edge grinding machine is simple in structure, high in automation degree and capable of precisely positioning glass to greatly improve the smoothness of ground glass workpieces.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

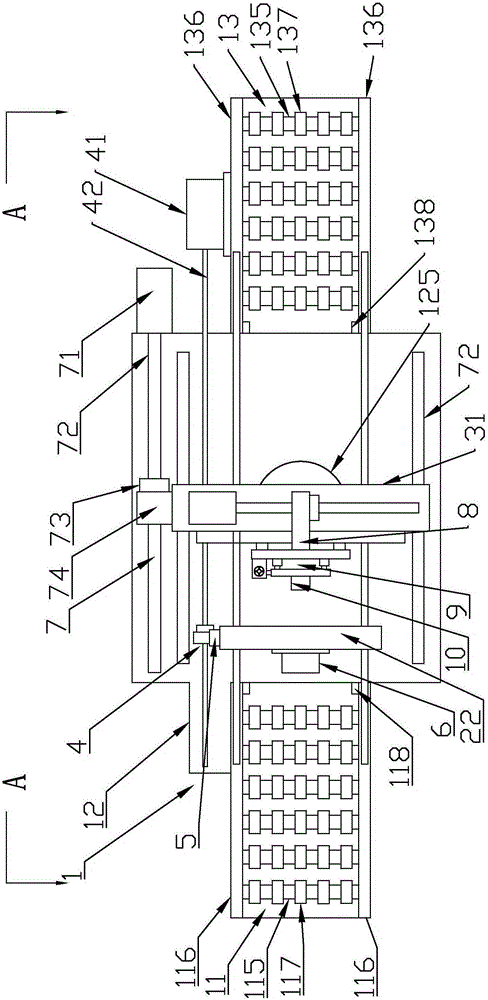

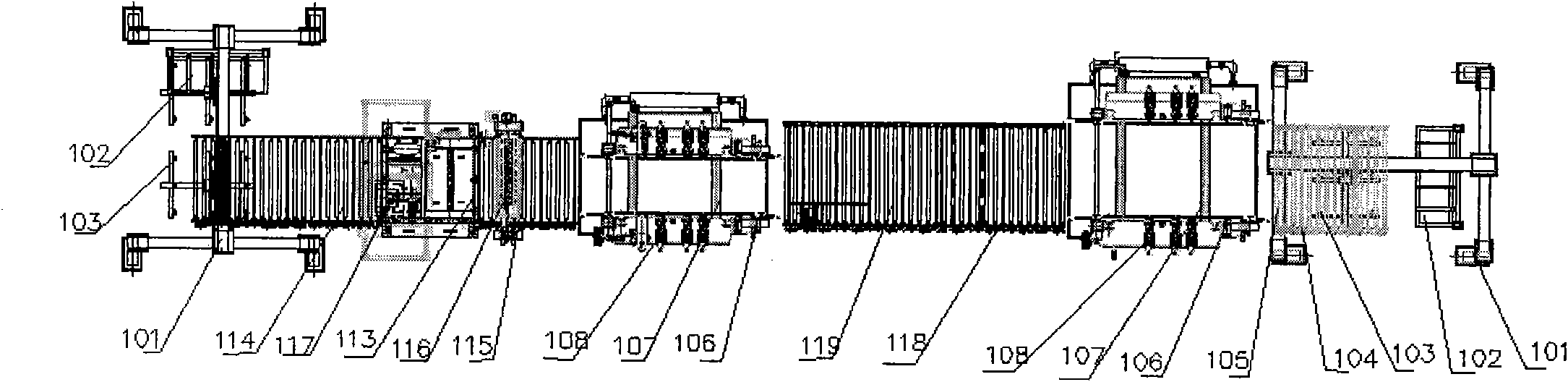

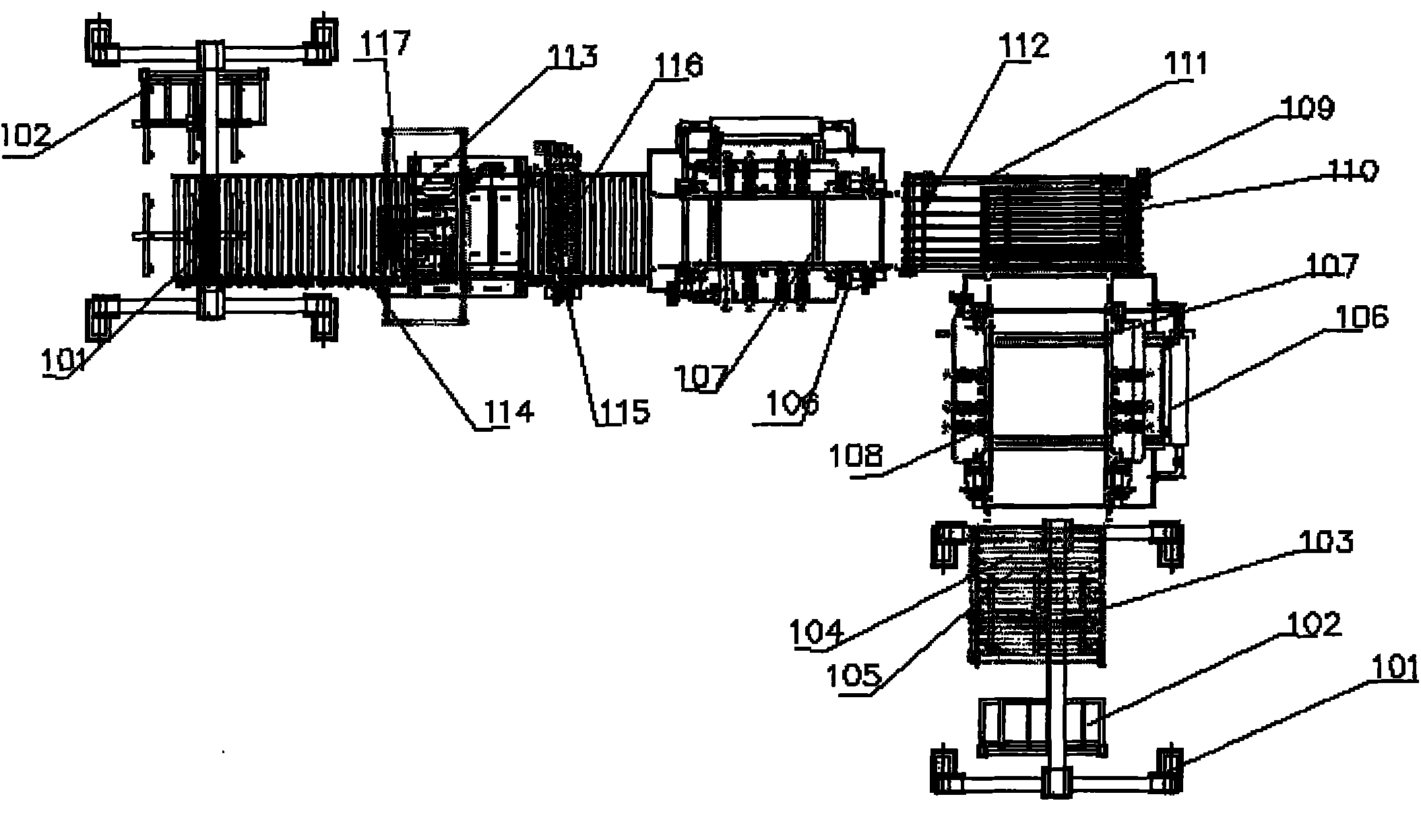

Glass producing system

InactiveCN102139466AImprove processing efficiencyReduce operating costsEdge grinding machinesTurn angleAssembly line

The invention discloses a glass producing system, which is a turning-angle assembly line. The glass producing system comprises two automatic loading and unloading machines, two double-sided edge finishing machines, an assembly line transmission platform, a right-angle turning table and a glass cleaning table; and the connection relation is that: the automatic loading and unloading machine, the assembly line transmission platform, the double-sided edge finishing machine, the right-angle turning table, the double-sided edge finishing machine, the glass cleaning table and the automatic loading and unloading machine are sequentially connected. With the adoption of the glass producing system, the glass automation assembly line production is realized, and the automatic operation of the whole process is realized by one person.

Owner:尹青

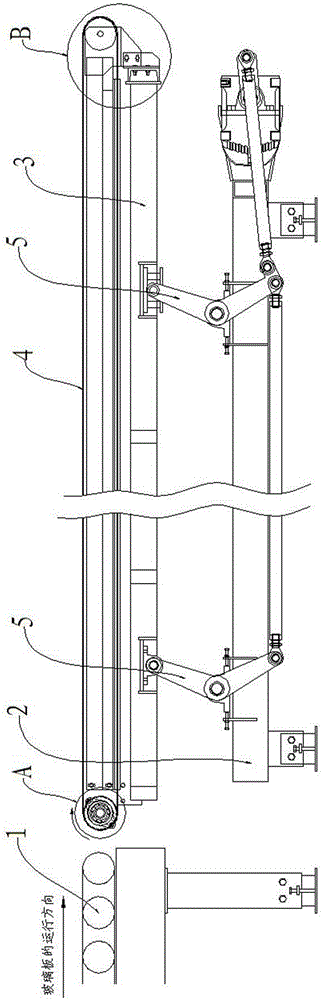

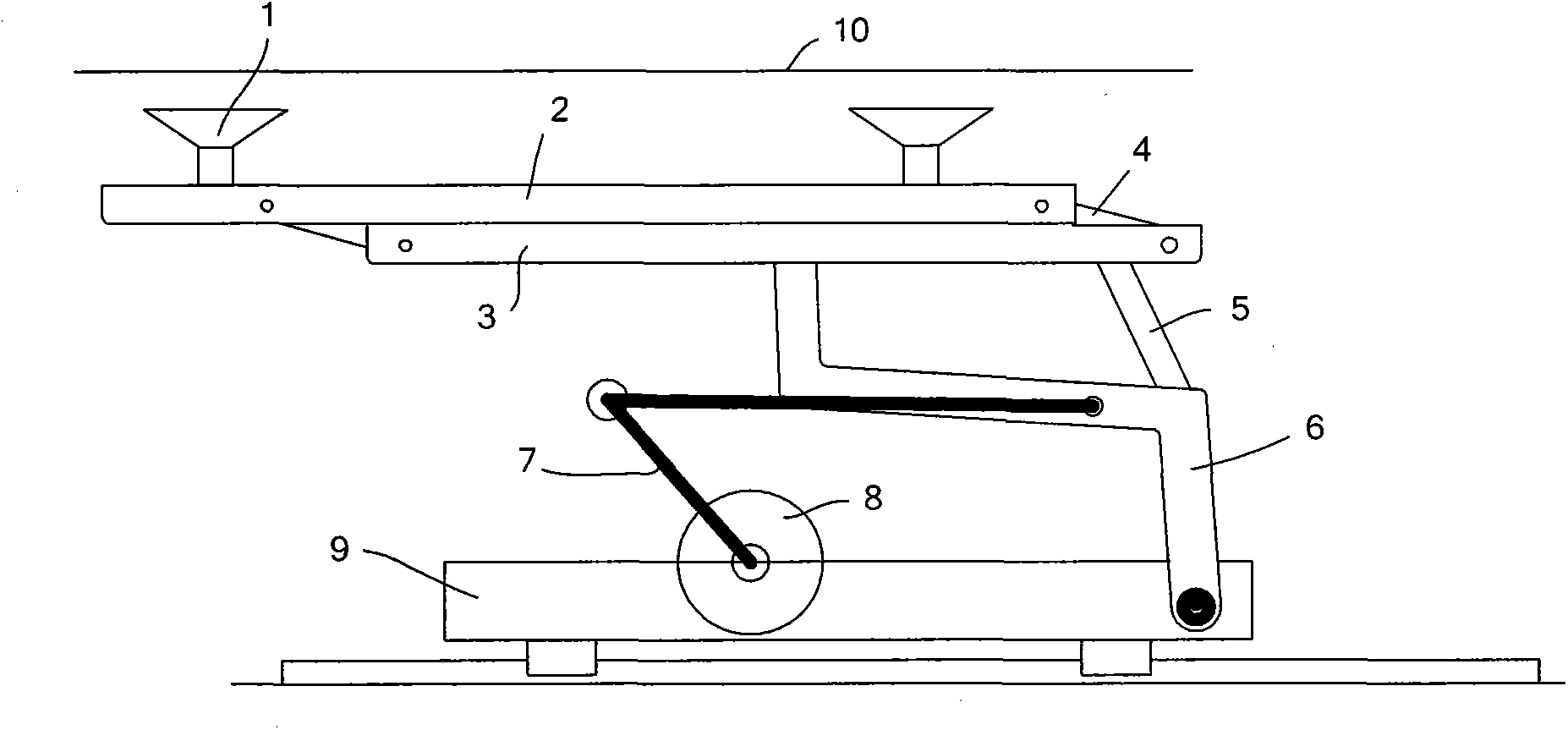

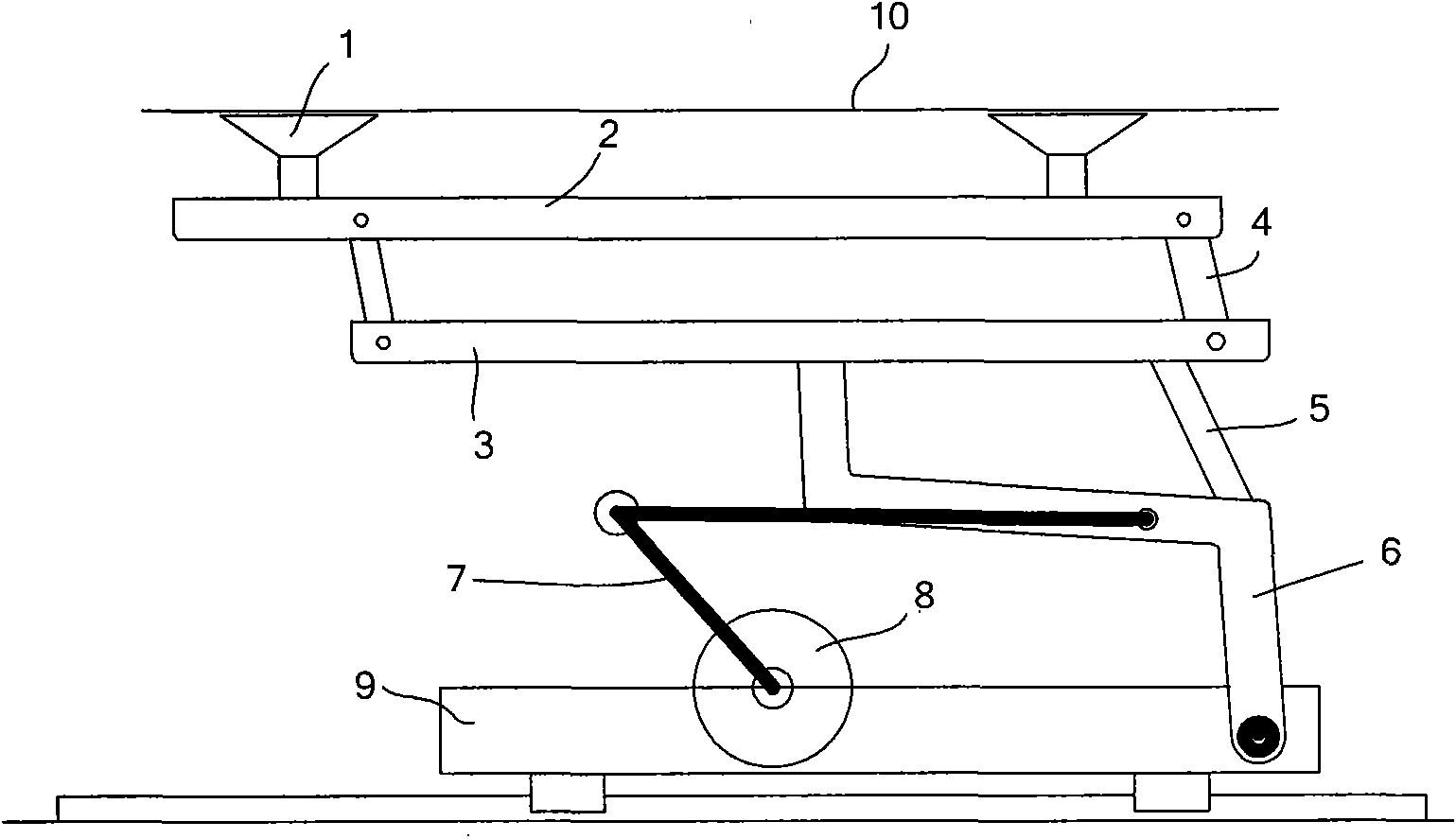

Lifting type belt plate fetching machine

ActiveCN105059896ASmooth entryEntry does not produceConveyorsConveyor partsRelative motionManufacturing line

The invention discloses a lifting type belt plate fetching machine. The lifting type belt plate fetching machine is correspondingly arranged at the tail end of a roller way used for conveying glass plates in a glass production line. The lifting type belt plate fetching machine comprises a base, a belt conveying rack, a lifting mechanism and a belt conveying mechanism horizontally mounted on the belt conveying rack. A belt conveying motor used for driving the belt conveying mechanism to operate is arranged at one end of the belt conveying rack. The belt conveying rack is horizontally mounted on the lifting mechanism. The lifting mechanism is fixed to a base. A lifting mechanism transmission station in transmission connection with the lifting mechanism is arranged on one side of the base. The lifting mechanism transmission station drives the belt conveying rack to act through the lifting mechanism so that the belt conveying mechanism can have certain displacement in the horizontal direction while the vertical height of the belt conveying mechanism is changed, and accordingly the glass plate at the tail end of the roller way is transferred onto the belt conveying mechanism. According to the lifting type belt plate fetching machine, the conveying speed of the belt conveying mechanism is the same as that of the roller way, in this way, it is guaranteed that the glass plate enters a belt of the belt conveying mechanism smoothly, relative movement is avoided, the quality of glass is improved, and the rate of finished products is increased.

Owner:HENAN HAICHUAN ELECTRONICS GLASS CO LTD

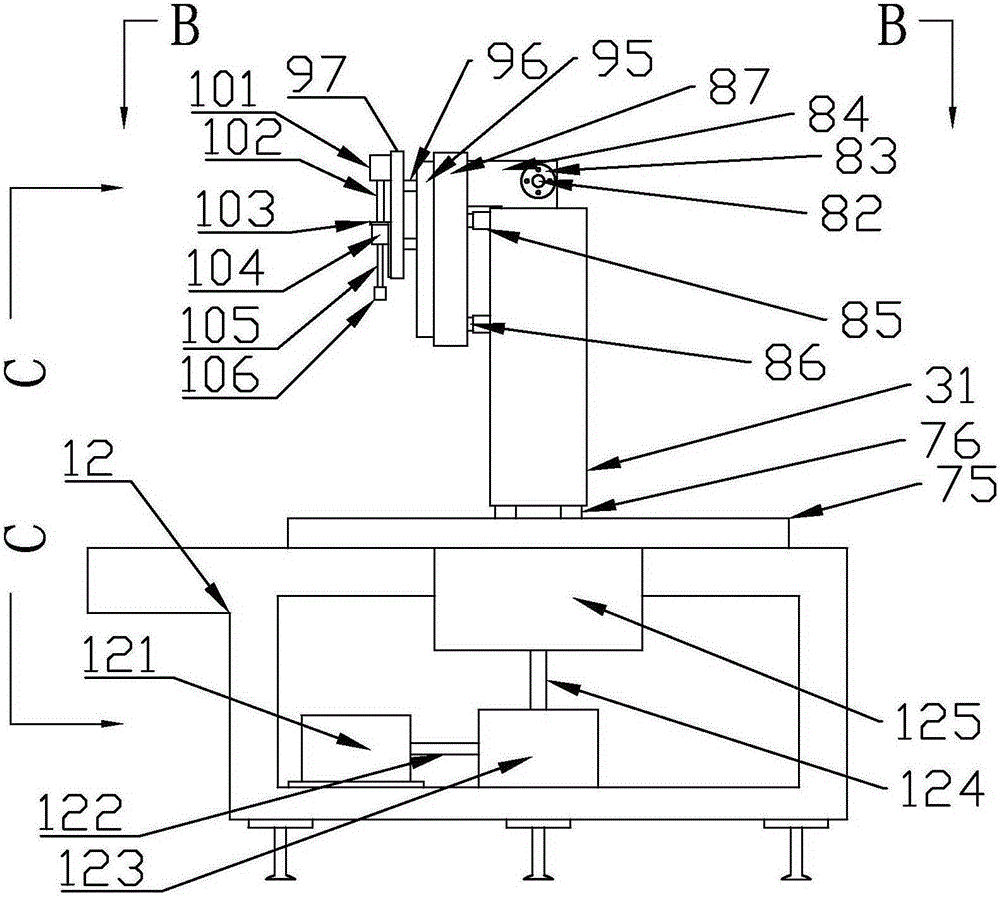

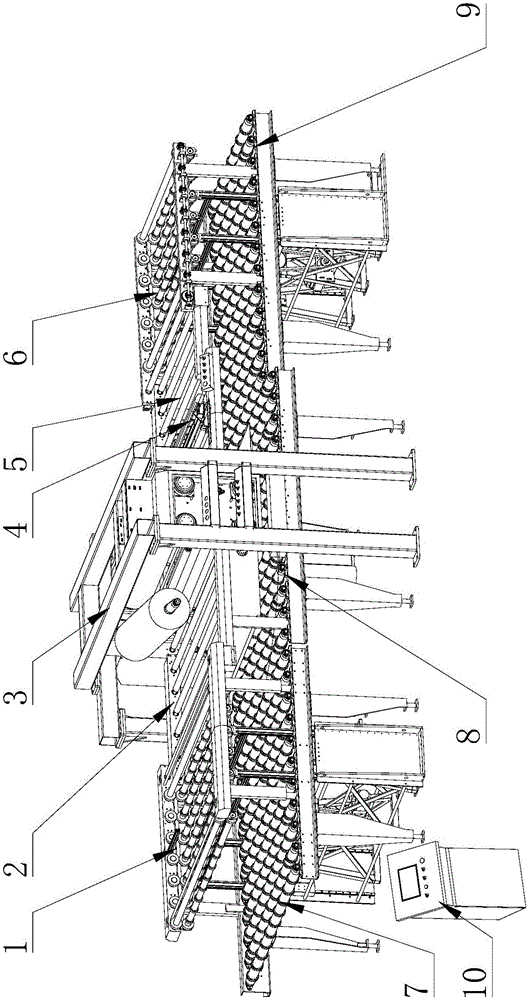

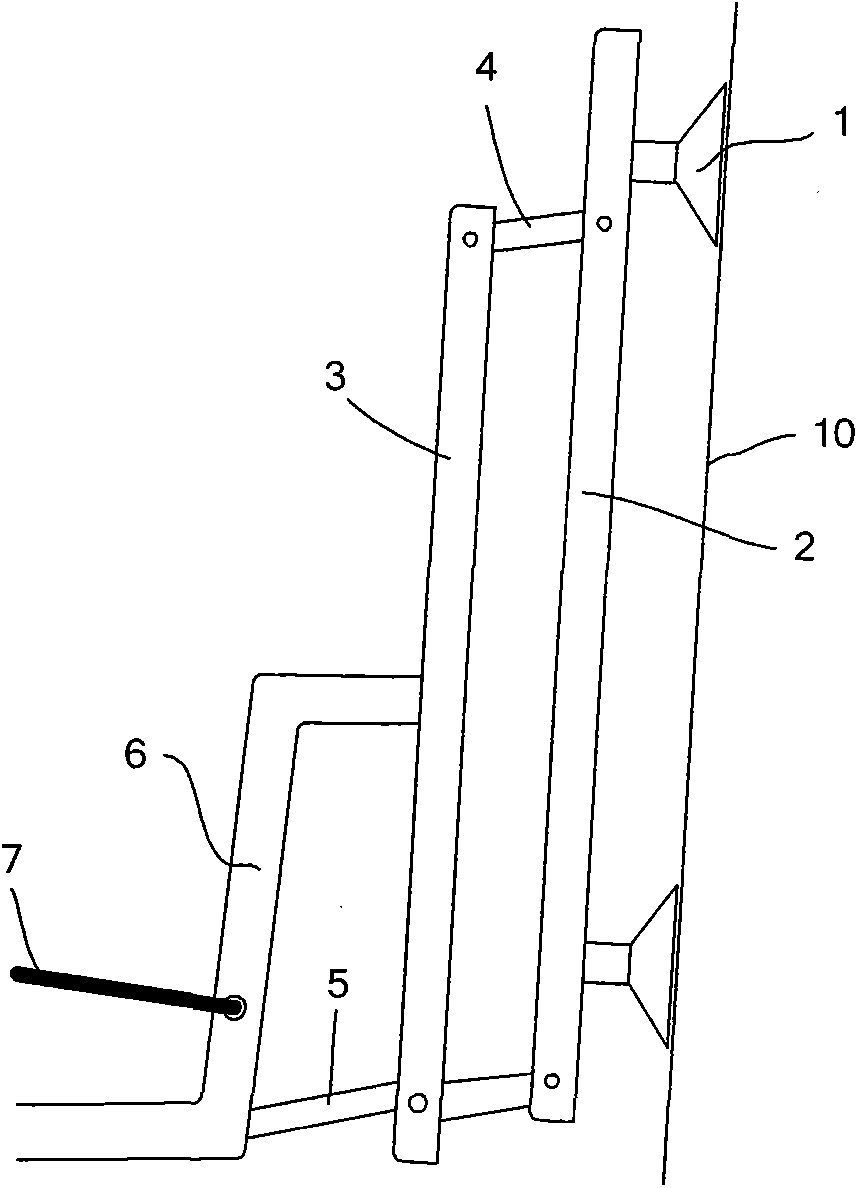

Online automatic laminating system of glass production line

The invention discloses an online automatic laminating system of a glass production line, and relates to online glass laminating equipment. The online automatic laminating system of the glass production line comprises the glass production line, feeding and discharging lifting frames, a laminating device (3), a film cutting mechanism (4) and a control table (10) are arranged, one feeding and discharging lifting frame is connected with the feeding end of the laminating device (3), the film cutting mechanism (4) is arranged on the laminating device (3), and the discharging end of the laminating device (3) is connected with the other feeding and discharging lifting frame. The laminating device (3) and the film cutting mechanism (4) are erected above the glass production line. According to the online automatic laminating system, glass can be selectively received to be laminated while normal production of the glass production line is not influenced.

Owner:深圳市龙锋泰自动化有限公司

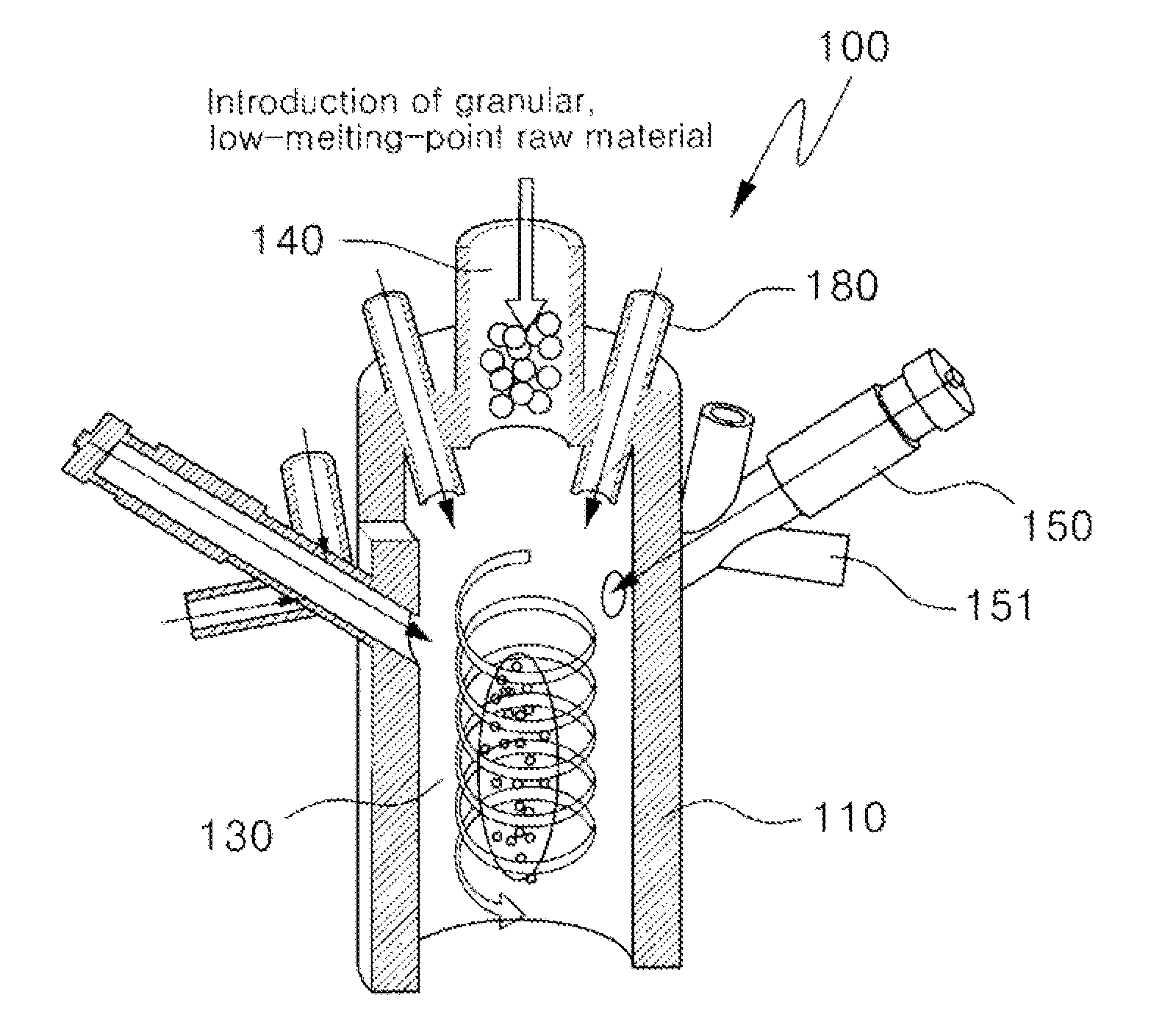

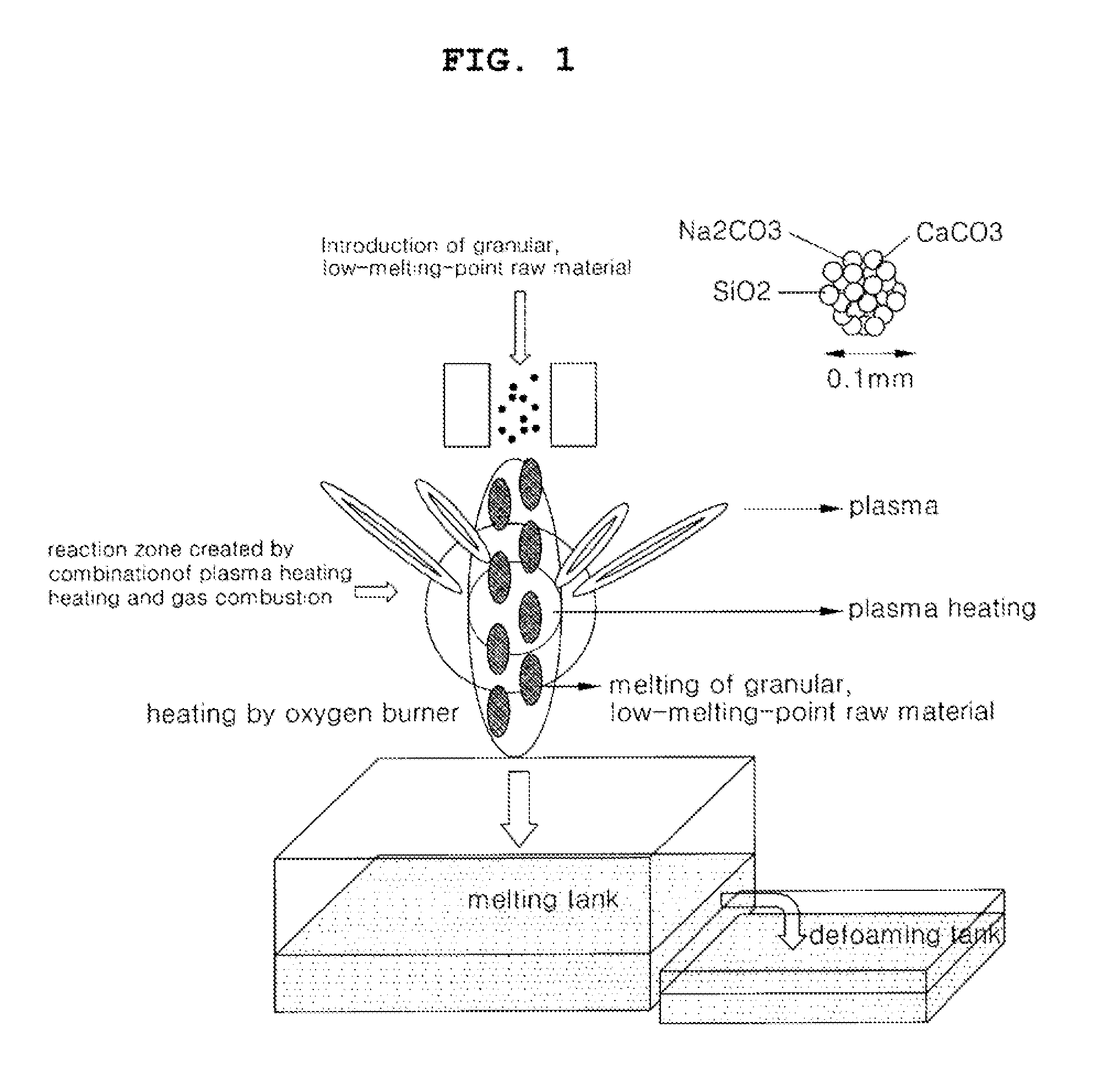

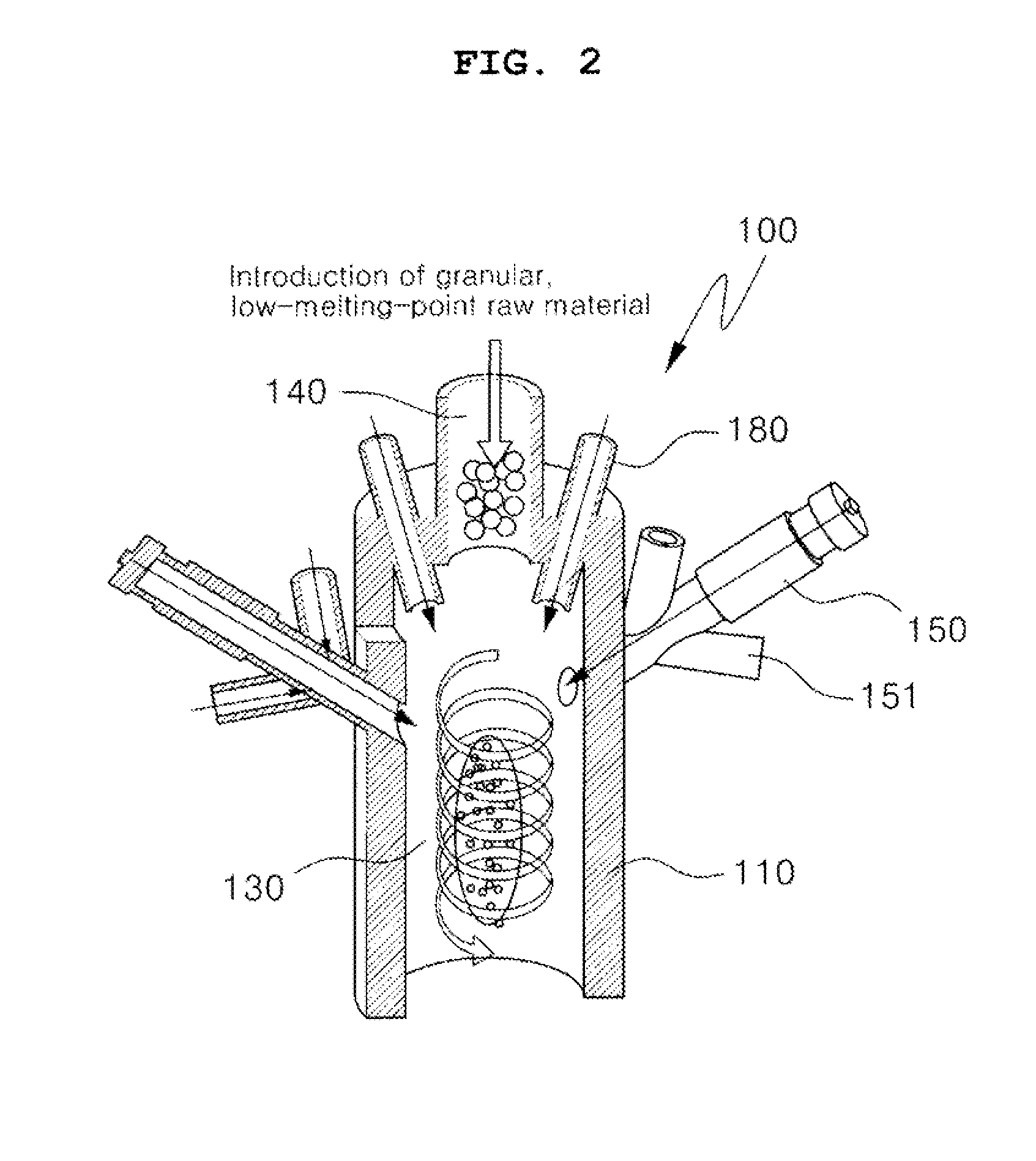

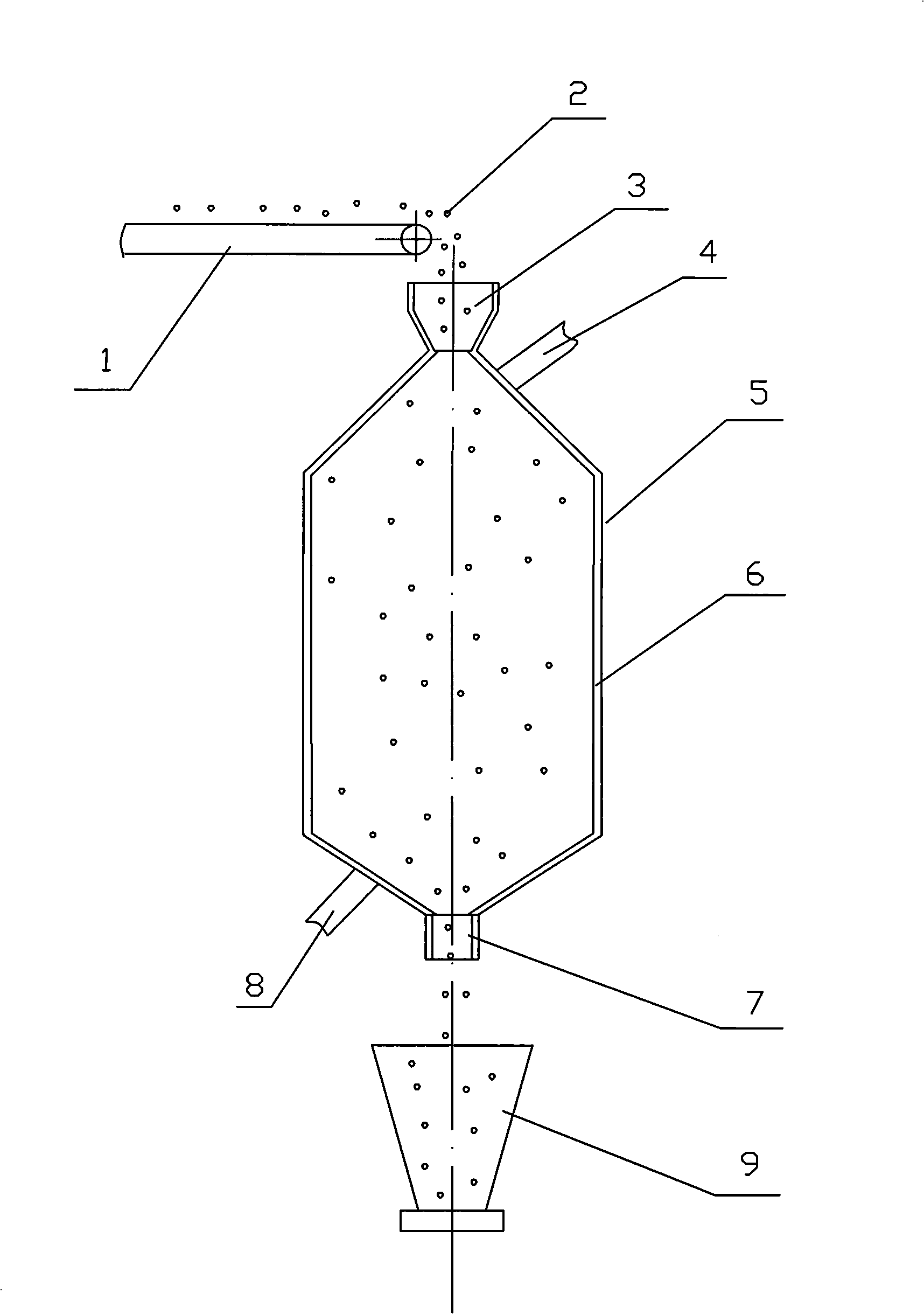

Low-carbon-type in-flight melting furnace utilizing combination of plasma heating and gas combustion, melting method utilizing the same and melting system utilizing the same

InactiveUS20120125052A1Maximizing residence timeCharging furnaceGlass furnace apparatusMelting tankCombustion

A low-carbon-type in-flight melting furnace for melting granular raw material for glass production in in-flight state using plasma heating and gas combustion, a melting method using the same and a melting system utilizing the same are provided. The low-carbon-type in-flight melting furnace includes a melting furnace body unit; a melting tank in the melting furnace body unit; a melting unit provided above the melting tank and serving to melt raw material; a raw material feeding unit provided outside the melting unit; a plasma / gas melting device provided around the melting unit and serving to spray high-temperature flames produced by plasma and gas; an exhaust tube provided at one side of the melting tank and serving to discharge exhaust gas; and a tap hole for tapping the melt, formed in the melting unit, through the melting tank, in the form of a slag.

Owner:KOREA INST OF ENERGY RES

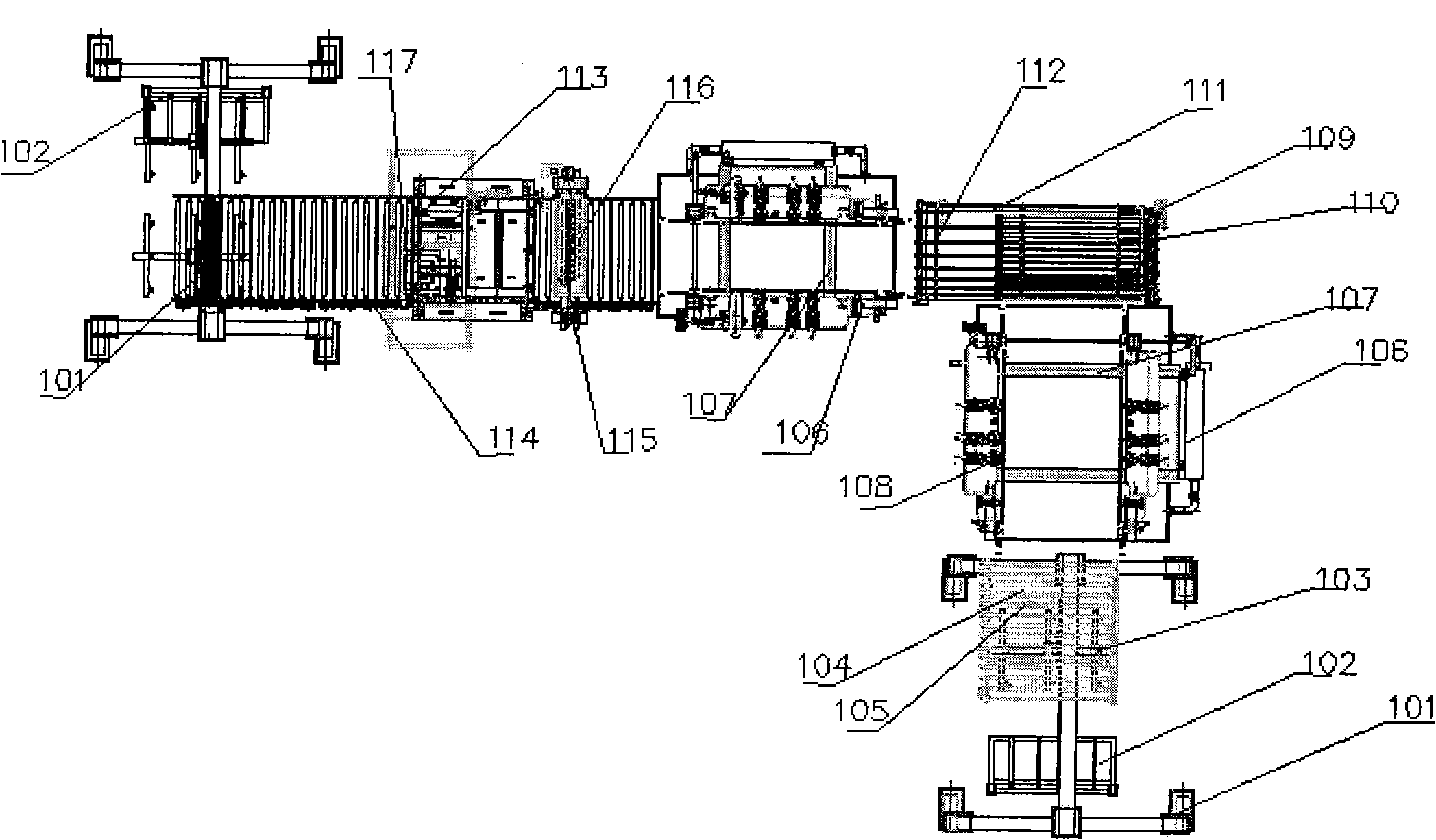

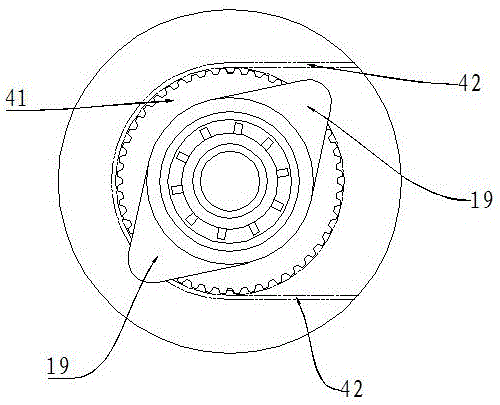

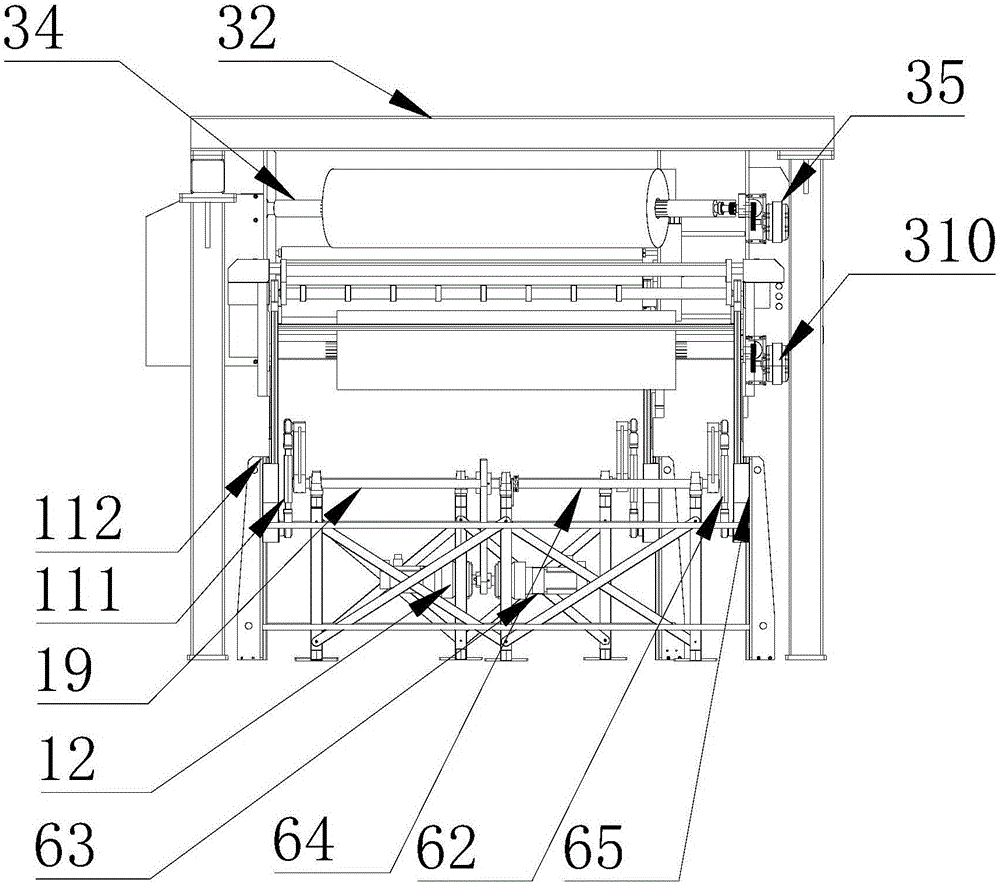

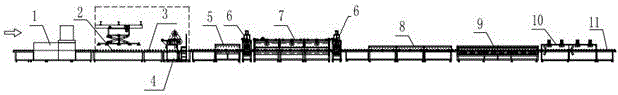

Ultrathin toughened glass production line and production method

ActiveCN102757173ASmooth and precise transmissionSolve the problem of different heating degreesGlass tempering apparatusDrive wheelEngineering

The invention relates to an ultrathin toughened glass production line and a production method. According to the ultrathin toughened glass production line and the production method, driven wheels are fixed to one of the ends of a plurality of rollers placed on the driving shaft on which a plurality of driving wheels in a glass conveying mechanism are fixed at equal intervals, respectively; the faces of the driven wheels are vertical to the faces of the driving wheels; a plurality of photoelectric tubes in a glass measuring device are transversely and densely distributed below an inlet of a heating furnace body; the signal output ends of the photoelectric tubes are connected with the signal input ends of a photoelectric controller in the glass measuring device; the length and the width of the glass are calculated through an optical-electricity encoder; a plurality of high-temperature gas spraying tubes are arranged at equal intervals or unequal intervals on roller conveying channels in the heating furnace body; wind ports are arranged between the rollers in the roller conveying channels in the heating furnace body; air blasting pipes serving as convex nozzle type channels are arranged in an outlet of the heating furnace body; and the outlets of the convex nozzle type channels are opposite to inserting inlets of a quenching device. According to the ultrathin toughened glass production line and the production method, the cooling medium is replaced, thus greater cooling performance is achieved.

Owner:杭州精工机械有限公司

Automatic sheet fetching sheet fetching and stacking equipment of photovoltaic thin glass production line

ActiveCN103935765AEasy to moveRealize the function of picking and palletizingStacking articlesConveyor partsProduction lineThin glass

The invention discloses automatic sheet fetching sheet fetching and stacking equipment of a photovoltaic thin glass production line. The automatic sheet fetching sheet fetching and stacking equipment of the photovoltaic thin glass production line comprises a suction cup rack, a landing gear, a roll-over rack and a moving device. The roll-over rack can be arranged on the moving device in a rolling over mode, the landing gear can be arranged on the roll-over rack in a lifting mode, the suction cup rack is arranged on the landing gear, and the top of the suction cup rack is provided with a sucker cup. According to the equipment, the suction cup rack, the landing gear, the roll-over rack and the moving device can conduct sheet fetching on the photovoltaic glass from the bottom, and movement is convenient, roll-over sheet fetching and stacking is conducted, so that the sheet fetching sheet fetching and stacking function is reliably achieved.

Owner:山东元凯恒盛玻璃科技有限公司

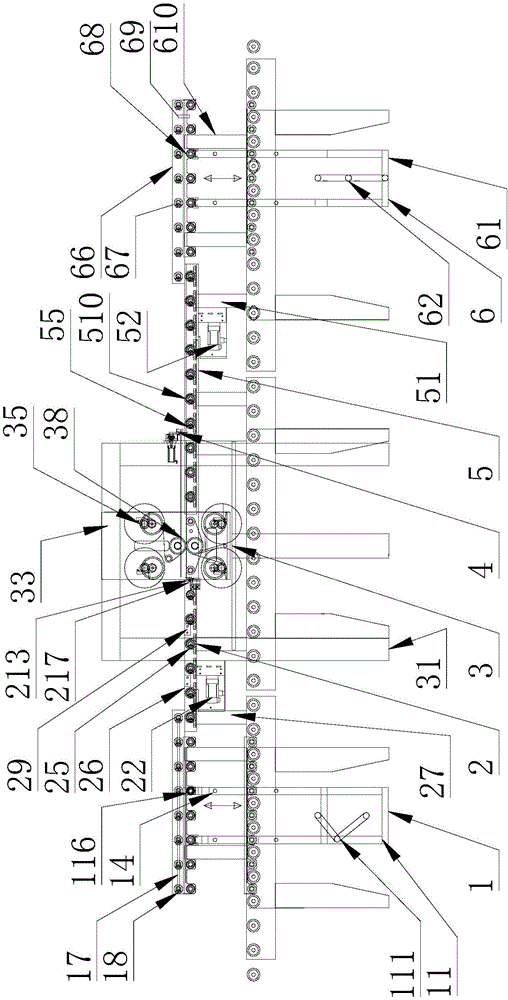

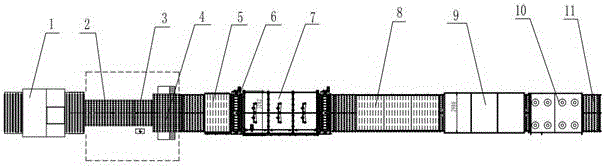

Continuous laminated glass production line

The invention discloses a continuous laminated glass production line. The glass production line, from a feeding part to a discharging part, comprises a sheet loading section, a cleaning section, a sheet taking section, a sheet combining section, a transition section, a rolling section, a constant temperature section, a vacuum section, an air cooling section, and a sheet unloading section, each of which is provided with a conveyance roller way; the power required by rotation of an upper press roll and a lower press roll in a rolling machine of the production line disclosed by the invention is provided separately by two groups of independent motors cooperating with a speed reducer, the smoothness of laminated glass in a rolling process is enhanced to enable glass to smoothly pass through the rolling process; the constant temperature section, the vacuum section and the air cooling section of the production line disclosed by the invention replace heating, pressurizing and cooling processes of a conventional glass autoclave, continuous production can be performed, the heat on glass in a pre-laminating process can be fully used, and a qualified product can be produced continuously and quickly, so that the production cost is fully reduced; and meanwhile, the production line does not have safety risks of high temperature, high pressure and the like caused by the conventional glass autoclave, and enables glass deep processing enterprises to achieve an effect of safety production more easily.

Owner:深圳市华彩玻璃机械有限公司

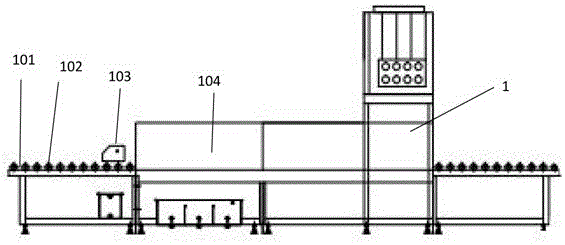

Preheating method and apparatus for glass batch

InactiveCN101328005AWill not polluteReduce manufacturing costGlass productionThermal insulationFlue gas

The invention relates to a pre-heating method and a device especially for glass batch oxy fuel combustion comprising a vessel with an interlayer composed of an inner shell(6) and an outer shell(5), wherein the batch(2) is transported into the inner shell(6) through a belt conveyer(1), while the flue gas from the melting furnace enters into the interlayer of the pre-heating device through an inferior flue gas inlet(8) and is discharged from a flue gas outlet(4) by the draught of the chimney hot air flow. The high temperature flue gas heats the batch to 300-600 DEG C in the interlayer through radiation conduction heat exchange, the pre-heated batch enters into a high temperature heat-resistant sealing pushing batch feeder through a thermal insulation bucket(9) and finally enters into the melting furnace. The advantages of the invention are as follows: pre-heating the batch by flue gas can reach the saving energy purpose and reduce the production cost of the glass production enterprises. The batch can not be polluted by the flue gas because of the radiation conduction heat exchange between the batch and the flue gas.

Owner:CHINA TRIUMPH INT ENG +1

Glass refining agent, production method and application

ActiveCN102659311AQuality improvementReduce iron contentGlass furnace apparatusSpray GranulationAlkaline earth metal

The invention discloses a glass refining agent for forming an echelon refining effect in glass melt so as to eliminate bubbles in melted glass liquid, a production method of the glass refining agent and application of the glass refining agent to glass production. The glass refining agent comprises one or a combination of an oxide refining agent, an alkaline-earth metal salt refining agent and a halide refining agent, and is characterized in that the glass refining agent is prepared by raw material via procedures of distribution, ball milling, sieving, spray granulation and mixing, and comprises three particle groups with different specific surface areas, the first particle group accounts for 20%-30% by weight, the grain size of the first particle group is larger than 1.5mm and smaller than or equal to 2.0mm, the second particle group accounts for 40%-50% by weight, the grain size of the second particle group is larger than 0.5mm and smaller than or equal to 1.5mm, the third particle group accounts for 25%-35%, the grain size of the third particle group is larger than or equal to 0.5mm, and the sum of the three particle groups is 100%. The glass refining agent is not made of arsenic trioxide, is non-toxic, is safe in use and favorable for environmental protection and human health, plays an active role in developing green glass products, and can be applied to production of ultra-white glass as the iron content of the refining agent is low.

Owner:YIYANG SHENGLI CHEM IND

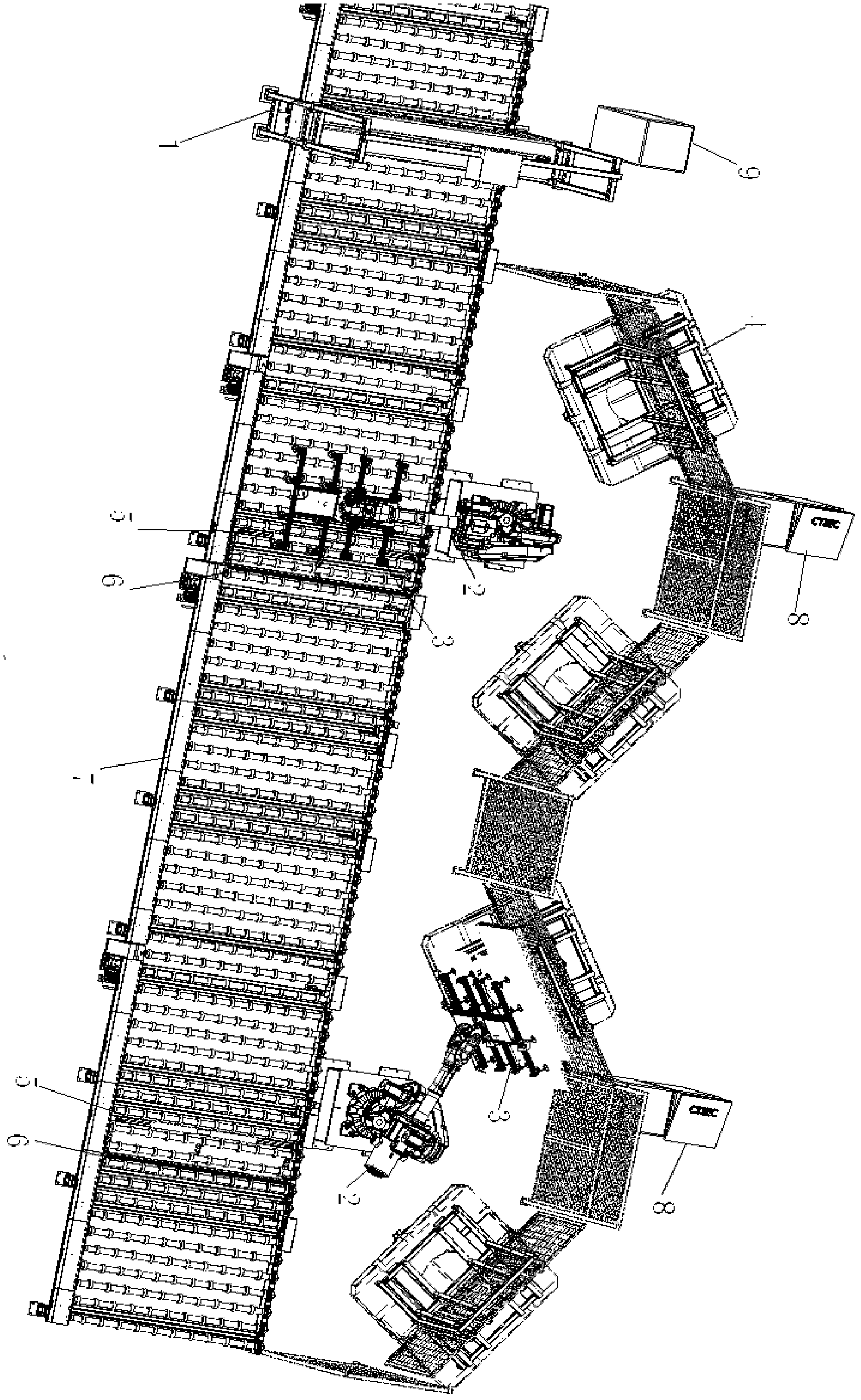

Method of manipulator stacking system for glass

ActiveCN102491091ALittle external interferenceHigh precision of Y valueCharge manipulationStacking articlesProduction lineControl system

The invention relates to the technical field of glass production lines, in particular to a method of a manipulator stacking system for glass. A vision detecting system 1 is arranged on a support at the tail end of a conveying belt, acquires information such as the size, the position, the speed, the grade and the like of glass, and transmits the information to a management system 9 in real time; the management system 9 which is communicated with one-machine electric control systems 8 acquires working states and waiting states of the one-machine electric control systems, then distributed tasks according to states of various manipulators 2, and transmits glass distribution information to the one-machine electric control system 8 which receives the tasks; the one-machine electric control system 8 receiving the tasks controls a rib mechanism 6 thereof to ascend by the aid of the acquired information when the glass is conveyed to a grabbing area of the one-machine electric control system 8, an edge measuring device 5 operates to acquire a Y-direction coordinate value of glass after the glass is positioned, an X coordinate of the glass is acquired and the rib mechanism completes operation, and at the moment, position information of the glass is acquired completely. The manipulator stacking system can be used for grabbing a plurality of pieces of glass in various specifications.

Owner:CHINA TRIUMPH INT ENG

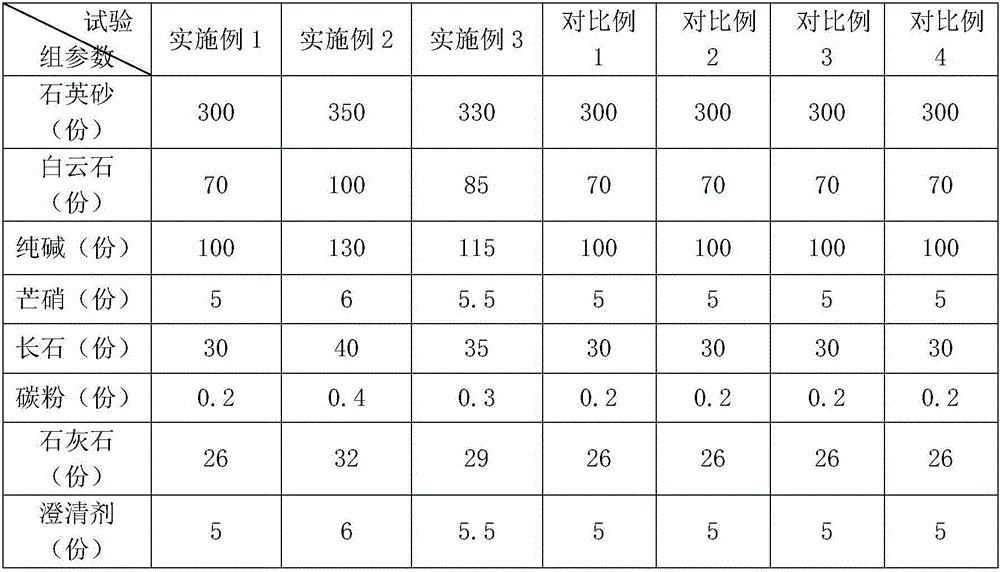

Tempered glass manufacturing technique

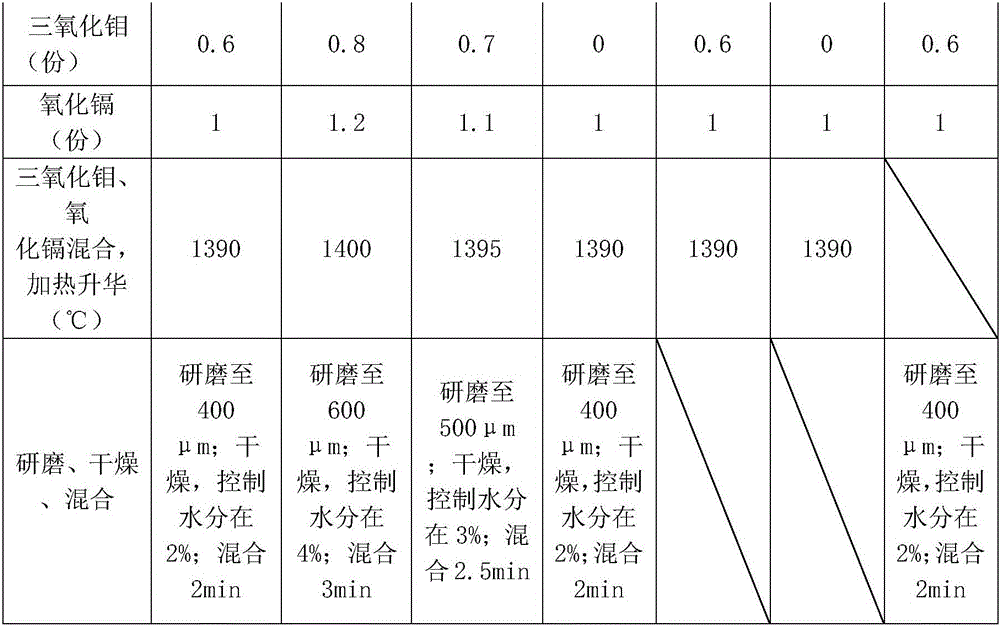

ActiveCN106587606AHigh transparencyAvoid poor resultsGlass tempering apparatusGlass productionDolomiteToughened glass

The application of the invention belongs to the field of glass manufacturing techniques, and particularly discloses a tempered glass manufacturing technique which comprises the following processing steps: (1) burdening: in parts by weight, taking 300-350 parts of quartz sand, 26-32 parts of limestone, 70-100 parts of dolomite, 100-130 parts of sodium carbonate, 5-6 parts of mirabilite, 30-40 parts of feldspar, 0.2-0.4 parts of carbon powder, 5-6 parts of a clarifying agent, 0.6-0.8 parts of molybdenum trioxide, and 1.0-1.2 parts of cadmium oxide; (2) grinding, drying and mixing: grinding raw materials in step (1) to 400-600 mu m, drying powder after grinding, and controlling the water content at 2-4%; put dried raw materials into a mixer and mixing the materials for 1.5-2 min; (3) melting; (4) molding; (5) preheating; (6) preheating; (7) rapid heating; (8) cooling; (9) cooling again; (10) homogeneous processing. Tempered glass manufactured by adopting the tempered glass manufacturing technique has excellent quality, the spontaneous explosion rate of the tempered glass is effectively reduced, and the safety is good.

Owner:CHONGQING SANXING JINGYI GLASS CO LTD

Low-expansion lithium aluminum silicon transparent glass ceramic

The invention belongs to the technical field of special glass production and manufacturing and provides low-expansion lithium aluminum silicon transparent glass ceramic. The low-expansion lithium aluminum silicon transparent glass ceramic comprises the following basic ingredients by mass percentage: 6-9% of B2O3, 5-10% of K2O+Na2O, 56-64% of SiO2, 13-18% of Al2O3, 2-4% of Li2O, and 1-3.5% of MgO, wherein clarifiers and nucleation agents are added into the basic ingredients of the transparent nucleated glass; the clarifiers are Sb2O3 and CeO2; the additions of Sb2O3 and CeO2 are 1.6% and 0.35% respectively; the nucleation agents are TiO2 and ZrO2; and the additions of TiO2 and ZrO2 are 2.5% and 0.8% respectively. The transparent nucleated glass has excellent light transmittance and chemical stability, high strength and low expansion coefficient.

Owner:AVIC (HAINAN) SPECIAL GLASS MATERIALS CO LTD

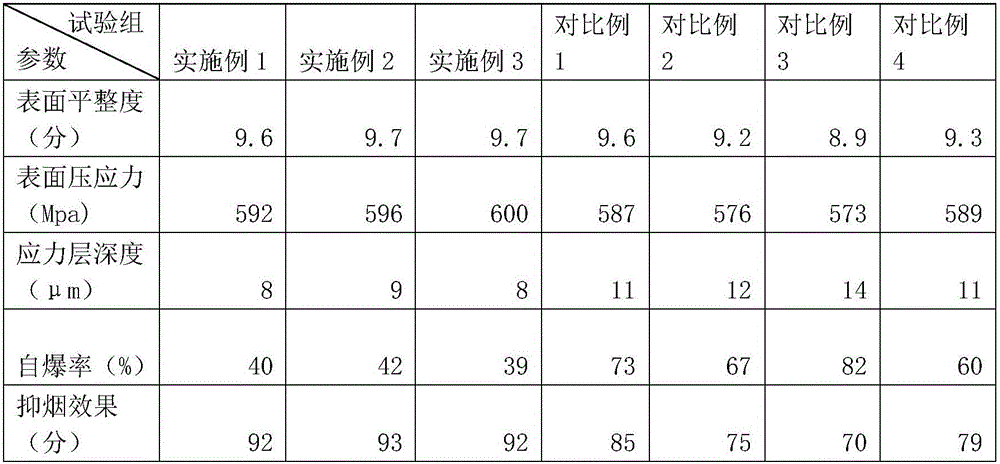

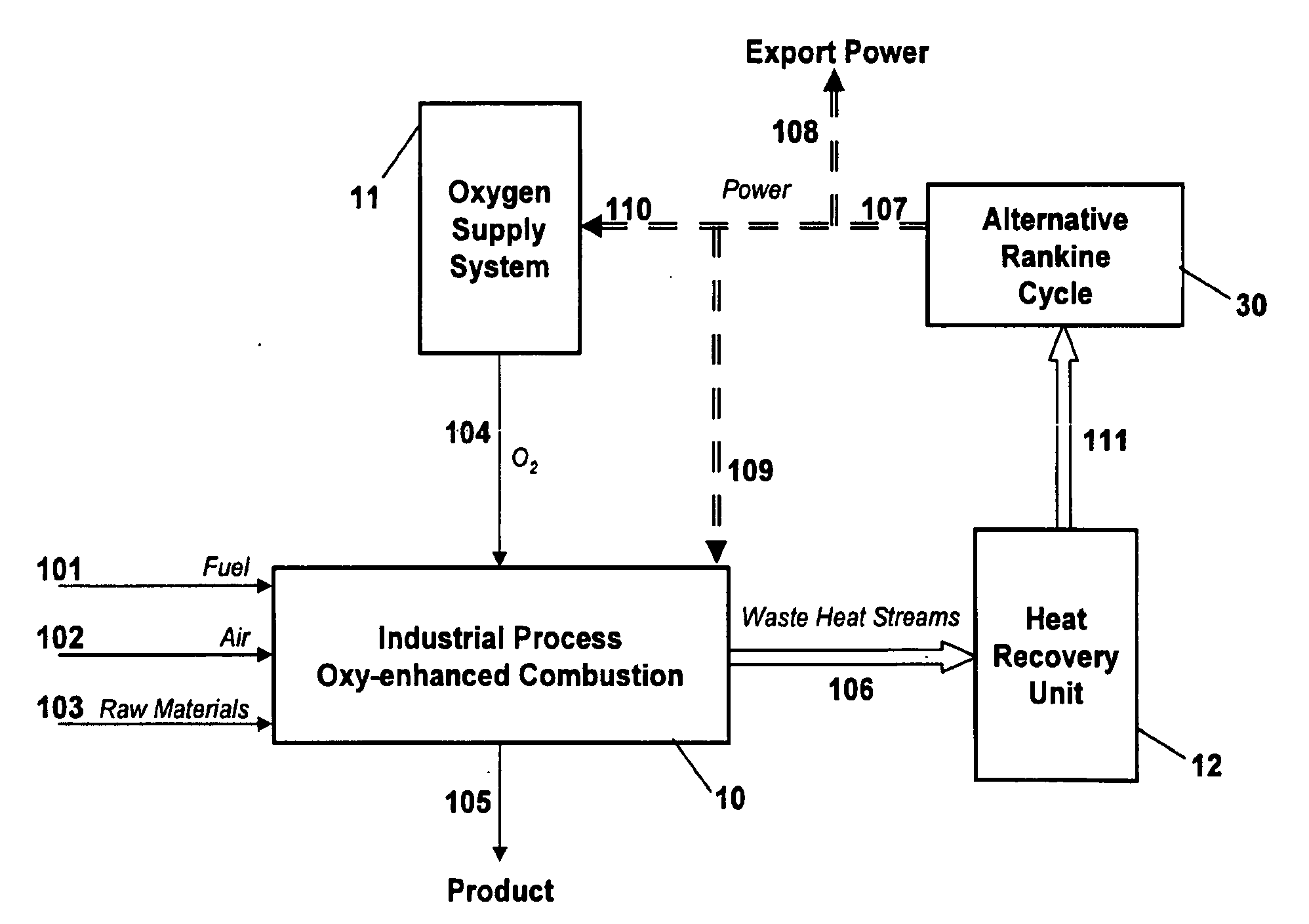

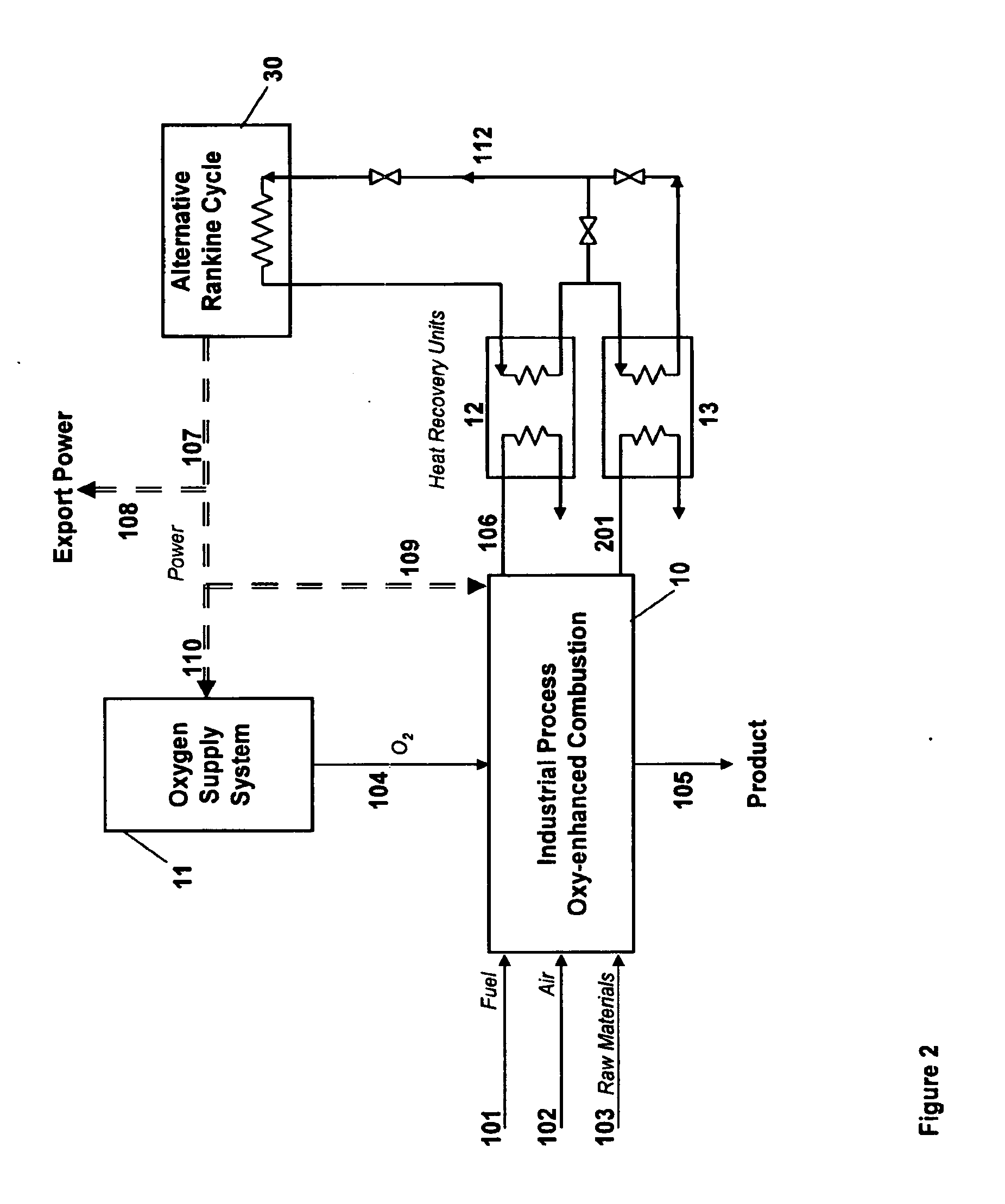

Oxygen enhanced combustion in industrial processes

InactiveUS20090308073A1Reduce equipment costsProvide such operationSolidificationLiquefactionWorking fluidCombustion

The present invention relates to a system for carrying out oxygen-enhanced combustion in an industrial process wherein the industrial process, an oxygen supply system or a source of oxygen, a heat recovery network, and an alternative Rankine cycle system based on a working fluid other than steam are integrated to achieve improved throughput and efficiency, and a method for oxygen-enhanced combustion in an industrial process using said system. Examples of industrial processes include cement production, steel reheat applications, glass production, aluminum and copper melting, as well as any industrial process that uses process heater, furnaces where combustion is carried out using an oxidant stream with oxygen content higher’ than that in ambient air and up to 100%.

Owner:PRAXAIR TECH INC

Ultra clear float solar battery glass production process and product thereof

ActiveCN103253864AHigh light transmittanceReduce reflectivityGlass severing apparatusPhotovoltaic industryEngineering

The invention belongs to the technical field of special glass production, and provides an ultra clear float solar battery glass production process and a product thereof. The process comprises the following steps: (1) preparing raw materials, (2) feeding and melting, (3) carrying out clarification, (4) carrying out homogenization, (5) carrying out tin stripping molding, (6) annealing, and (7) cutting. With the ultra clear float solar battery glass production process, ultra clear float solar battery glass with a thickness of 2.5 mm can be produced, wherein the glass has characteristics of high transmittance, low reflectivity and light unit weight, and is applicable for photovoltaic industry to be adopted as a photoelectric conversion substrate and a light-heat conversion panel so as to be used for solar battery manufacturing. In addition, with application of the process to produce the ultra clear float solar battery glass, the production cost is low so as to reduce a production cost of the whole photovoltaic industry chain.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

Frosting liquid used in production line of frosted glass

A frosting liquid used in a production line of frosted glass includes following components, by weight, 5-10 parts of ammonium fluoride, 5-10 parts of inorganic acid, 5-10 parts of organic acid, 5-10 parts of inorganic salt, 3-5 parts of solid dispersed particles, 0.2-0.3 parts of a surfactant, 0.2-0.3 parts of a dispersing agent and 76.6-80 parts of water. The frosting liquid can enhance the strength of frosted glass and reduce fragment rate.

Owner:HUBEI HCT

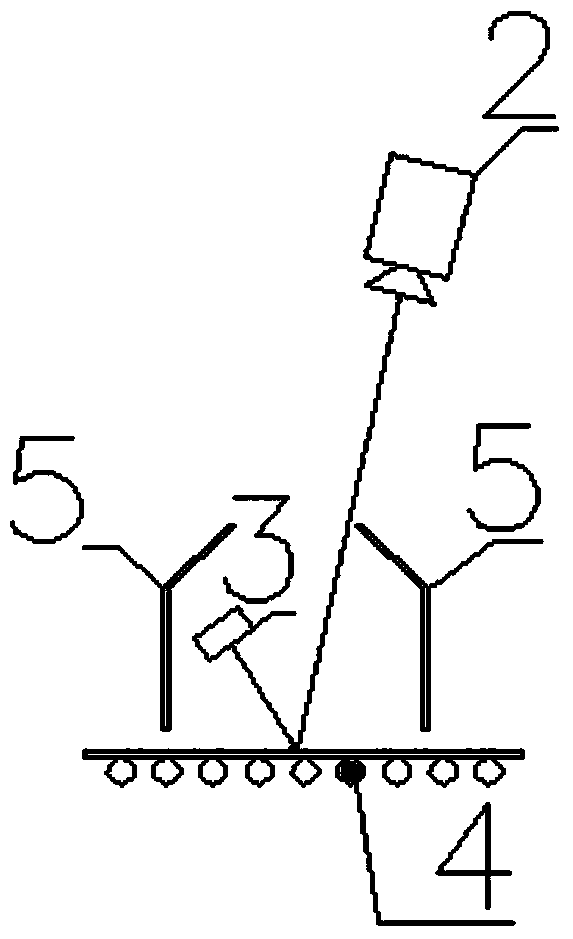

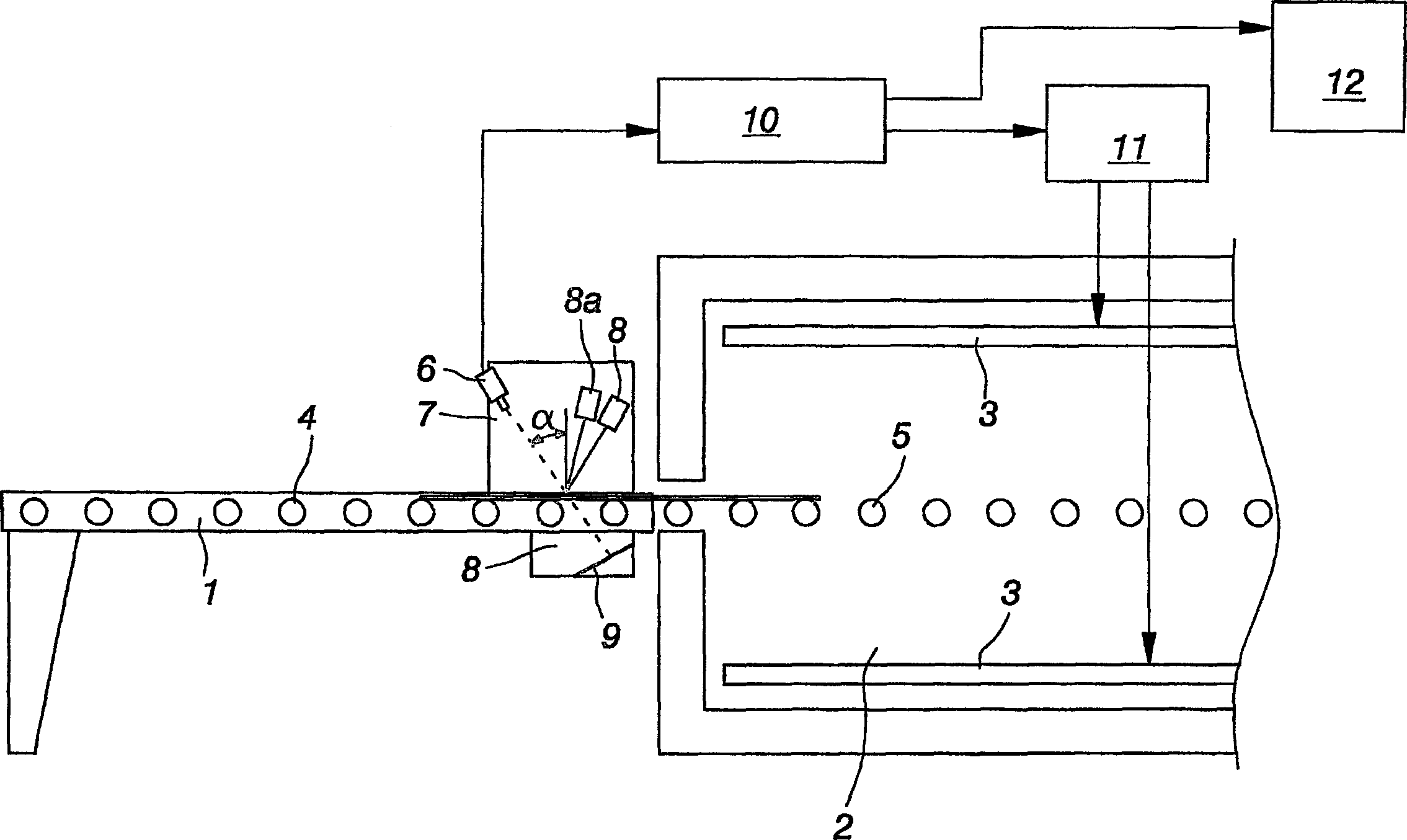

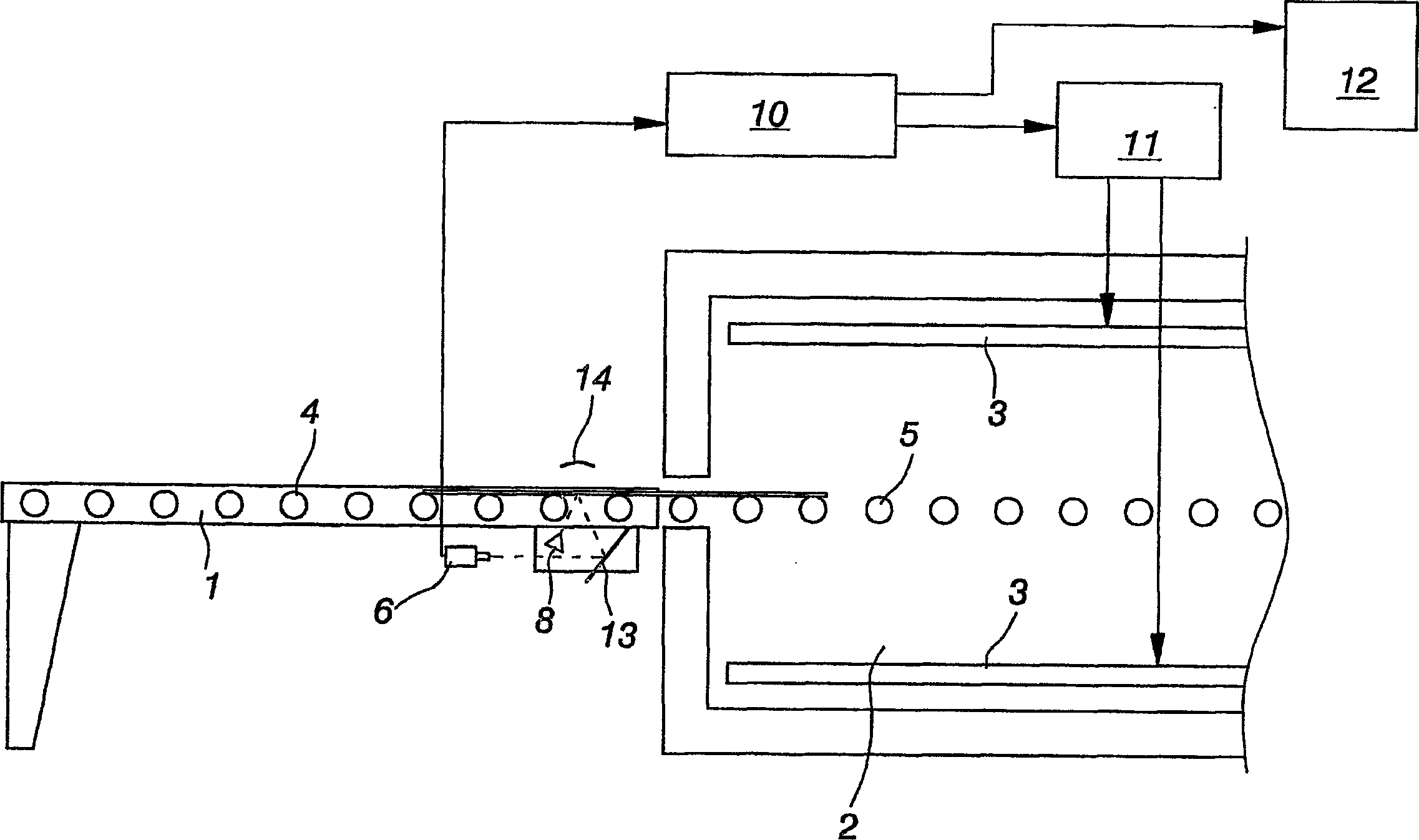

Method and apparatus for monitoring safety glass production or controlling a treatment process

The invention relates to a method and apparatus for monitoring safety glass production or controlling a treatment process, such as a tempering process. Information representing a load of glass panels is used in controlling a treatment process, such as heating of glass panels, or in monitoring production. The information, which includes at least one of the following: shape, size, and position, is read with one or more cameras ( 6 ). This is possible as glass is made visible by means of reflected light as high intensity light is applied to the glass surface. The line camera ( 6 ) is used for receiving low intensity background light radiation incident through the glass conveying plane, a substantial increase in its intensity, as light is reflected by glass, being deciphered as glass.

Owner:玻石服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com