Patents

Literature

98 results about "Glass knife" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A glass knife is a knife with a blade composed of glass. The cutting edge of a glass knife is formed from a fracture line, and is extremely sharp. Glass knives were used in antiquity due to their natural sharpness and the ease with which they could be manufactured. In modern electron microscopy, glass knives are used to make the ultrathin sections needed for imaging.

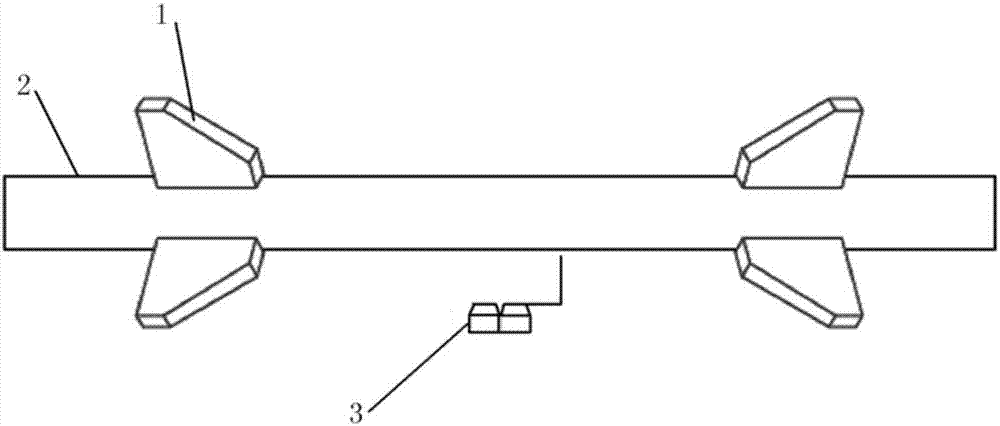

Glass-metal composite plate as well as manufacturing method and application thereof

InactiveCN103587161AImprove flexural strengthImprove securityLaminationLamination apparatusFlat glassThin metal

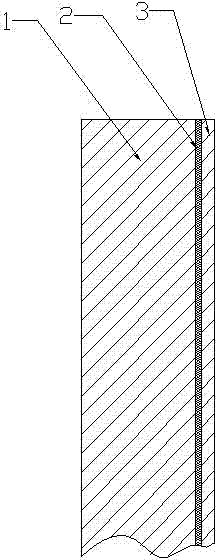

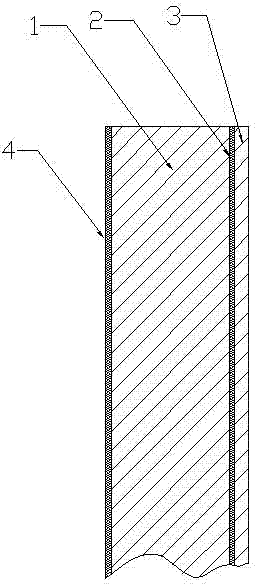

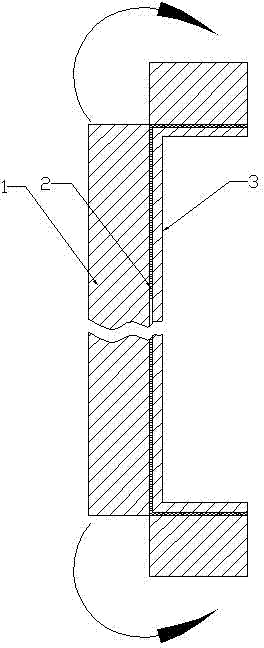

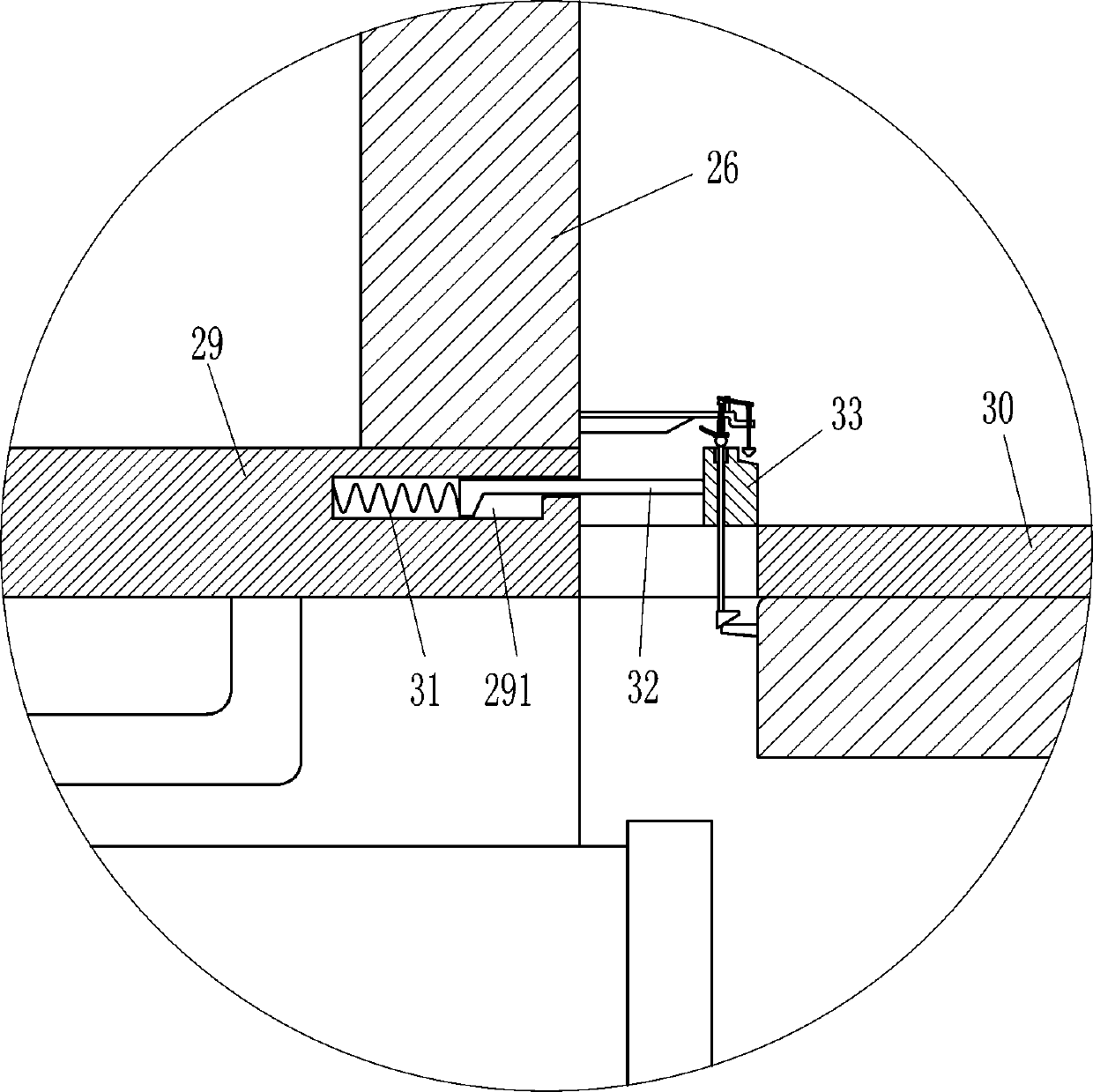

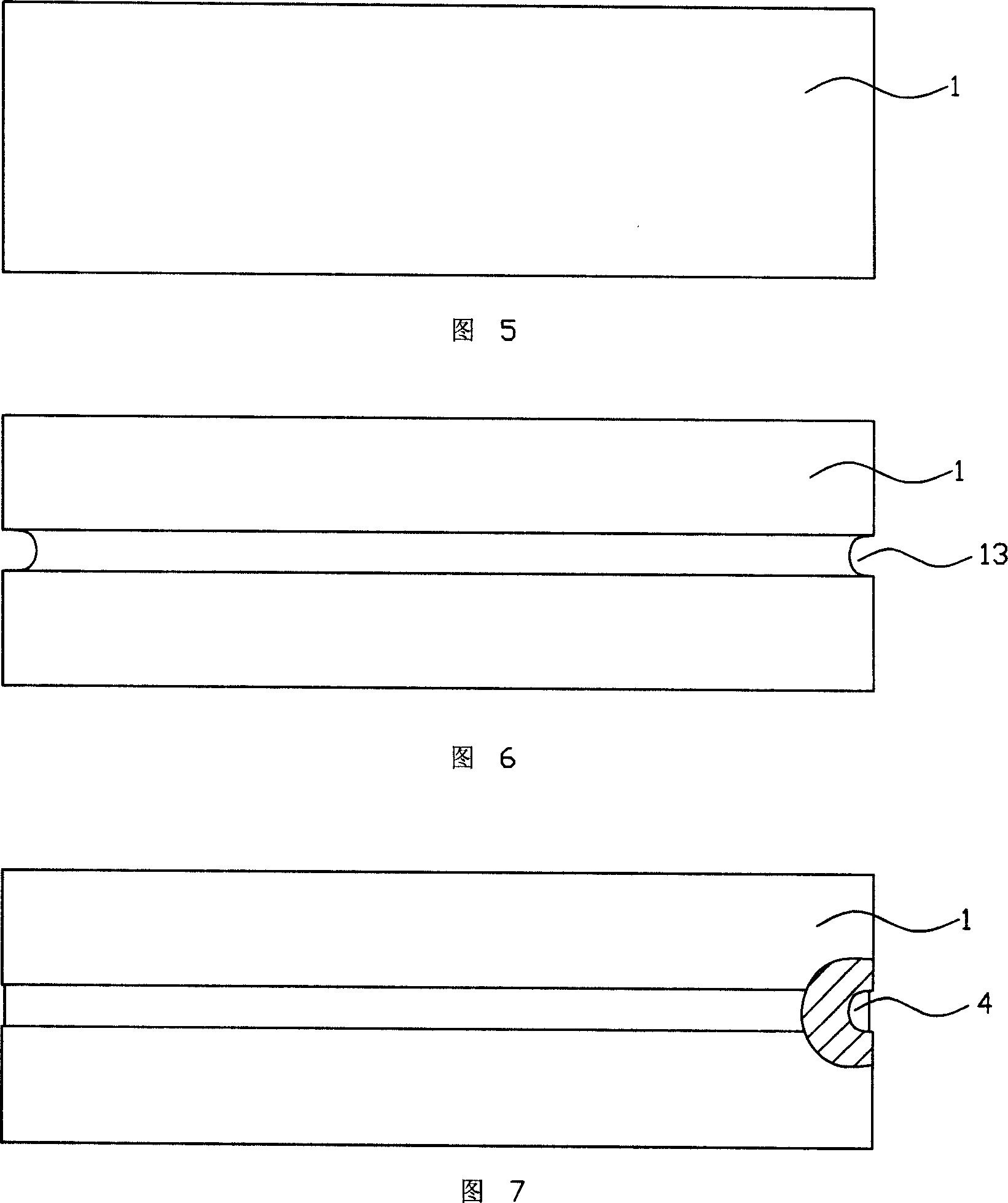

The invention discloses a glass-metal composite plate as well as a manufacturing method and application thereof. The glass-metal composite plate is characterized by being formed by compounding a glass plate (1) and a thin metal sheet (3) through an adhesive (2). A required part of the glass plate (1) of the glass-metal composite plate is broken and bent to manufacture various profiles and products. The glass-metal composite plate can be used for manufacturing hollow glass and vacuum glass which serve as lightproof heat preservation plates. The glass-metal composite plate is processed and manufactured at a cold end of a flat-plate glass production line. The manufacturing method mainly comprises the following steps: 1, cleaning the upper surface of an on-line glass plate according to a dry method; 2, coating the adhesive (UV (ultraviolet) glue or hot-melted glue) on the upper surface of the glass plate or the lower surface of the coiled thin metal sheet; 3, continuously pressing the glass plate and the thin metal sheet together through a pair of rollers; 4, solidifying the UV glue or the hot-melted glue; 5, cutting off the thin metal sheet and a glue layer on the upper surface of the glass-metal composite plate through a laser knife and correspondingly cutting off the glass plate on the lower surface of the glass-metal composite plate through a glass knife; 6, cutting off and stacking the glass-metal composite plate.

Owner:徐林波

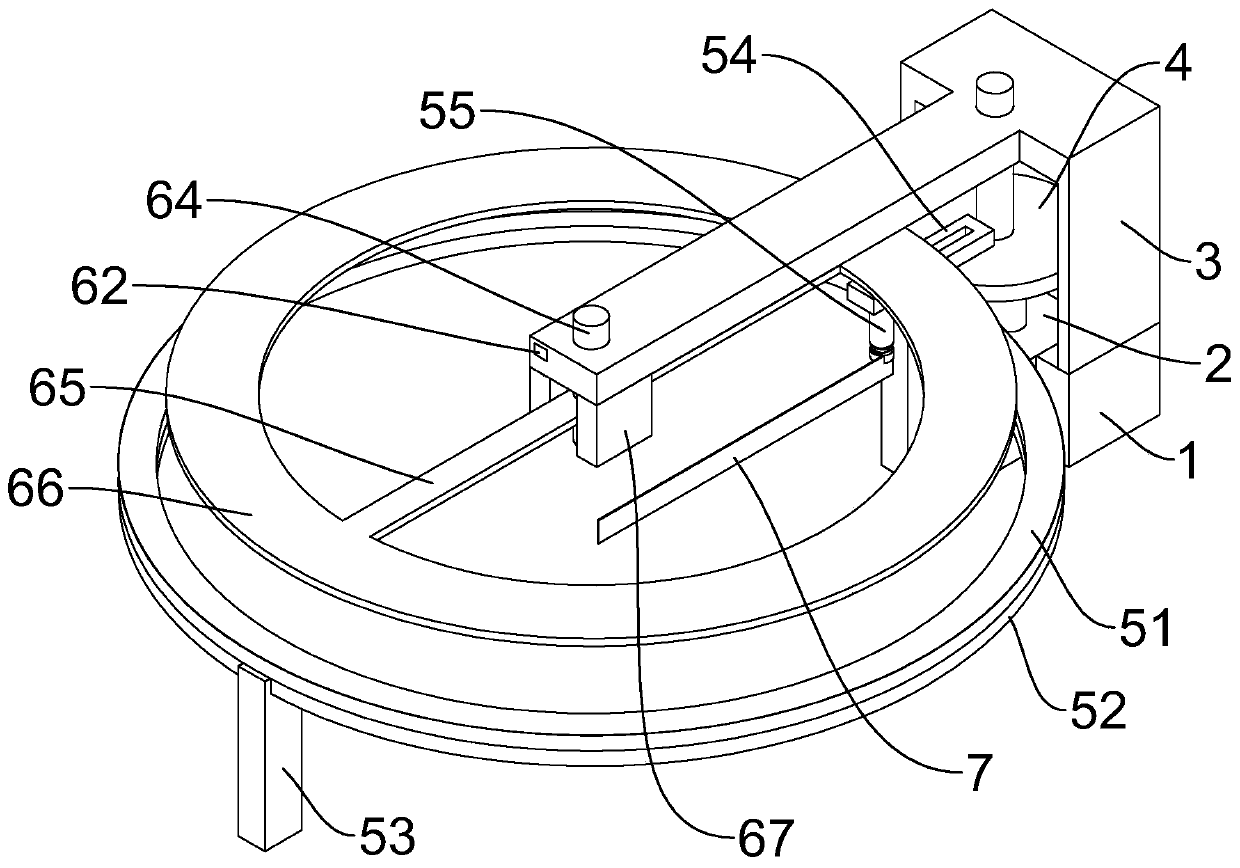

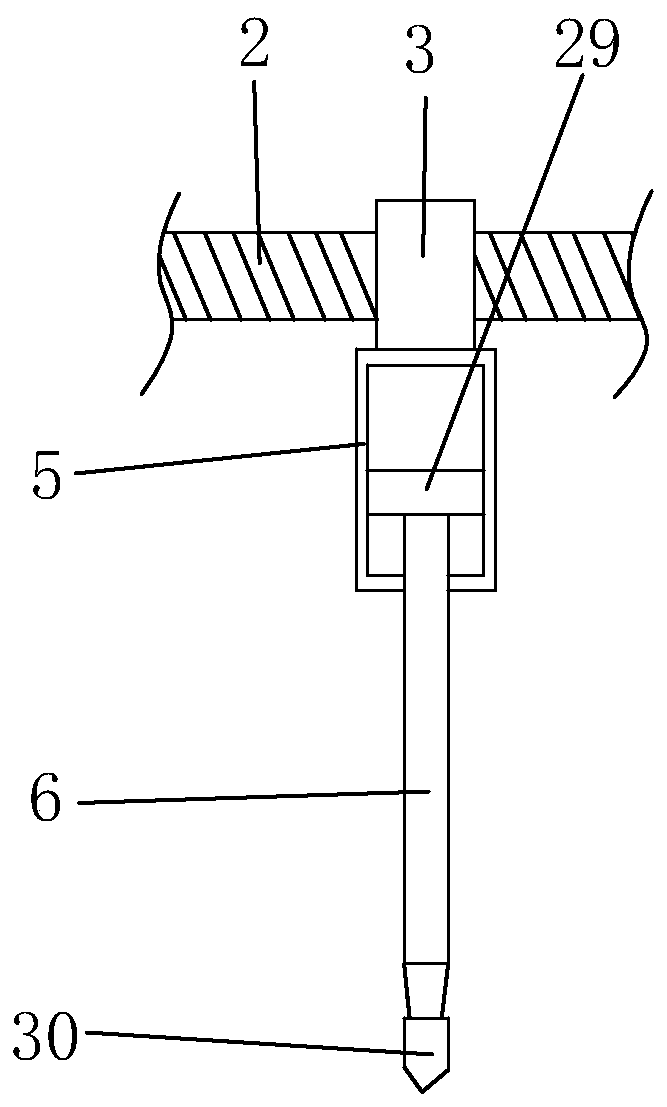

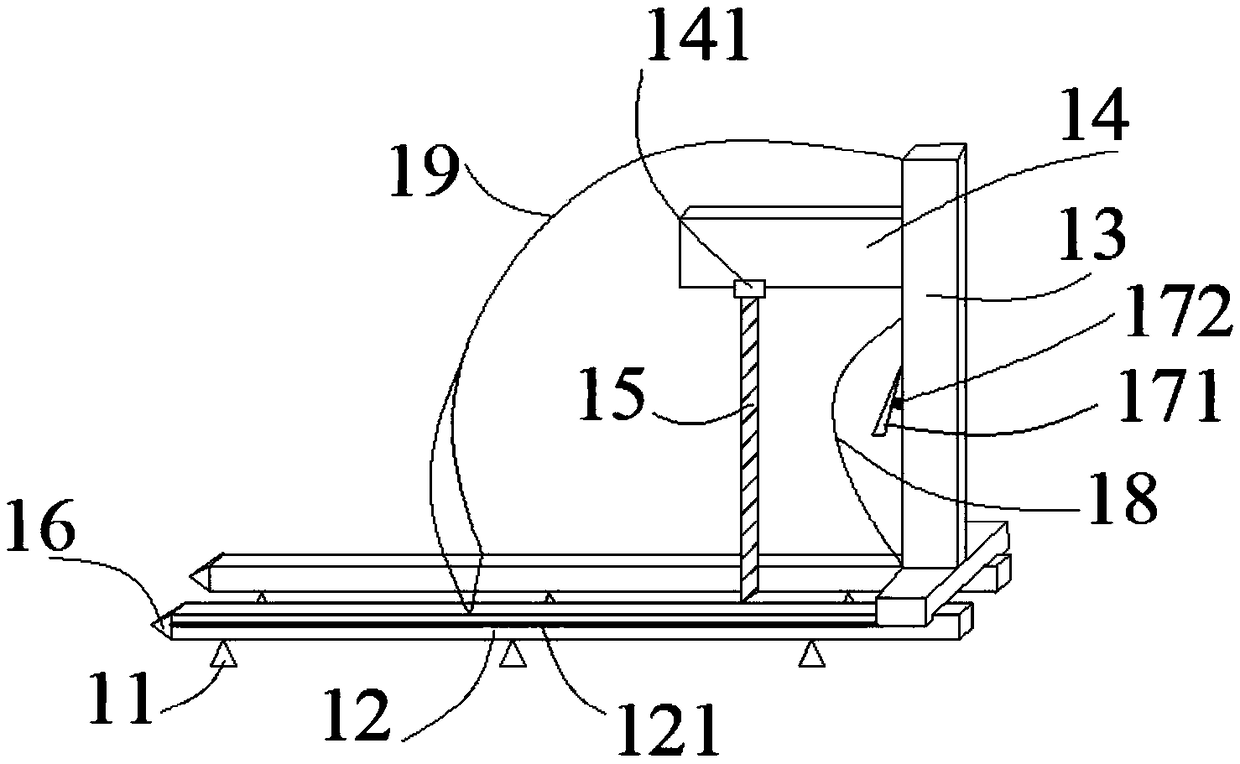

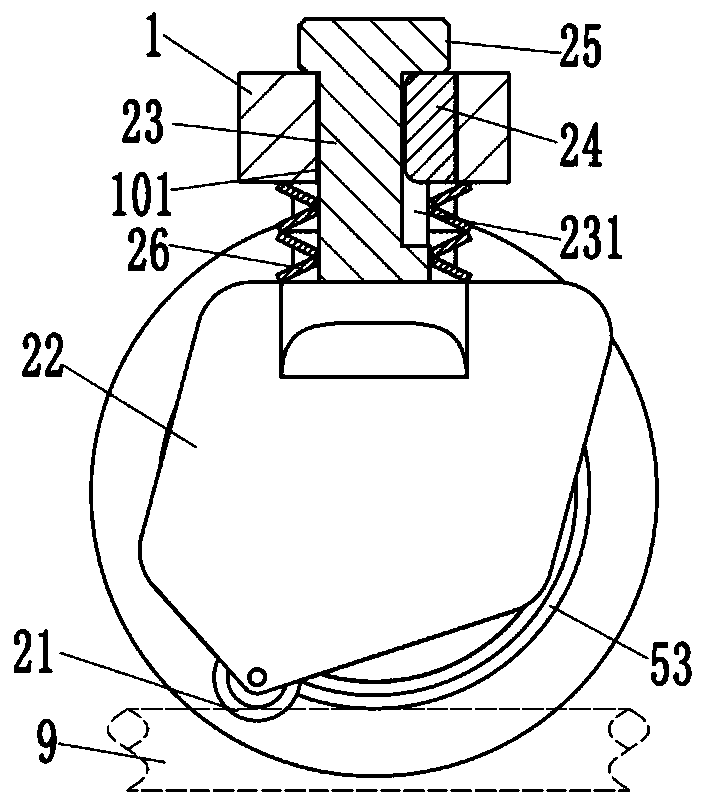

Rounded glass cutting machine

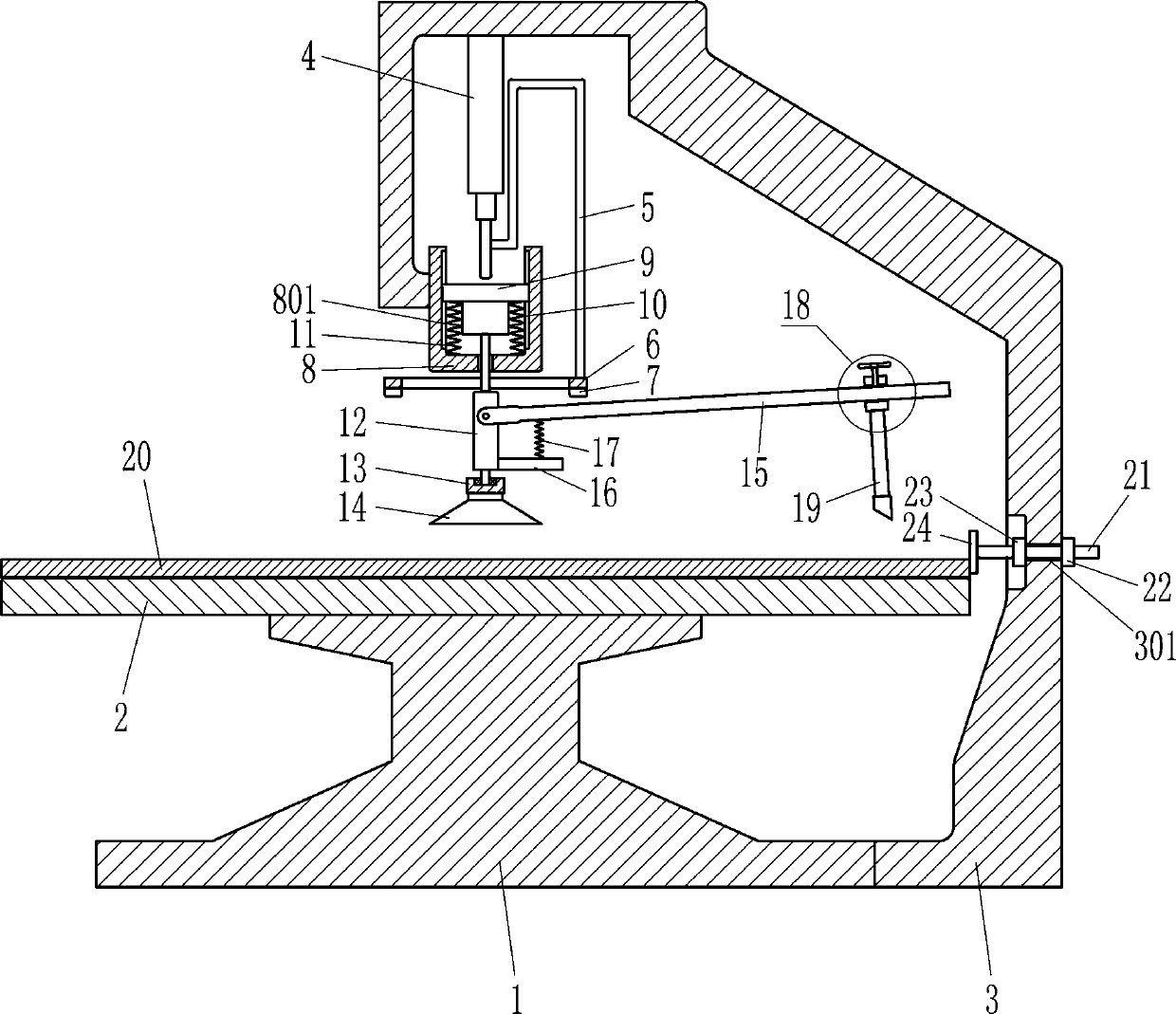

ActiveCN110395897AReduce direct contactFor precise cuttingGlass severing apparatusGlass cutterGlass knife

The invention relates to a glass cutting machine, in particular to a rounded glass cutting machine. The rounded glass cutting machine can accurately conduct round cutting, saves manpower and is high in safety. The rounded glass cutting machine comprises a base, a platform, a rack, a first air cylinder, an N-shaped rod, an iron ring, a pressing block, a U-shaped frame, a first mounting plate, a motor, a first spring, a connecting plate and the like. The upper part of the base is connected with a platform; the right lower part of the base is connected with a rack; a first cylinder is mounted atthe top inside the rack. The rounded glass cutting machine is provided with the adjusting mechanism and the glass cutter, the position of the glass cutter is adjusted through the adjusting mechanism,rounded glass of a certain size can be accurately cut, and the accurate cutting effect is achieved; meanwhile, the motor arranged on the rounded glass cutting machine drives the glass cutter to rotatethrough related parts to conduct round cutting, and operation is convenient; the rounded glass cutting machine is further provided with a material box and related components, so that the equipment can move glass blanks more conveniently.

Owner:威海烟华安全玻璃有限公司

High-toughness ultra-wear-resistant hard alloy and manufacturing method thereof

InactiveCN104911431AImprove wear resistanceImprove high temperature toughnessWear resistantHigh pressure

The invention discloses a high-toughness ultra-wear-resistant hard alloy and a manufacturing method thereof. The high-toughness ultra-wear-resistant hard alloy comprises the following raw materials in percentage by mass: 3.0-5.0% of Co, 0.6-1.0% of VC, 4.0-8.0% of (Ta, Nb) C, 5.0-7.0% of B4C, 0.4-0.8% of carbonyl Ni, 0.4-0.8% of Mo2C and the balance of WC; moreover, the carbon balance value of the proportioning is +0.17 to +0.21%. The manufacturing method comprises the procedures of proportioning, ball-milling, drying-granulating, shaping, and low-temperature carburizing-low-pressure sintering. The method provided by the invention is used for manufacturing the cutting tools of indexable inserts, end mills, micro-drills, glass knives and the like, and is suitable for cutting machining for the many materials of cast iron, carbon steel, alloy steel, stainless steel, glass, ceramics and the like. The method can be further used for manufacturing hard alloy wear-resistant parts, sealing parts, precise moulds, high-pressure nozzles and the like, and can improve the wear resistance and the toughness of the prepared hard alloys, prolong the service lives of the tools and increase the production efficiency.

Owner:HEYUAN ZHENGXIN HARDMETAL CARBIDE

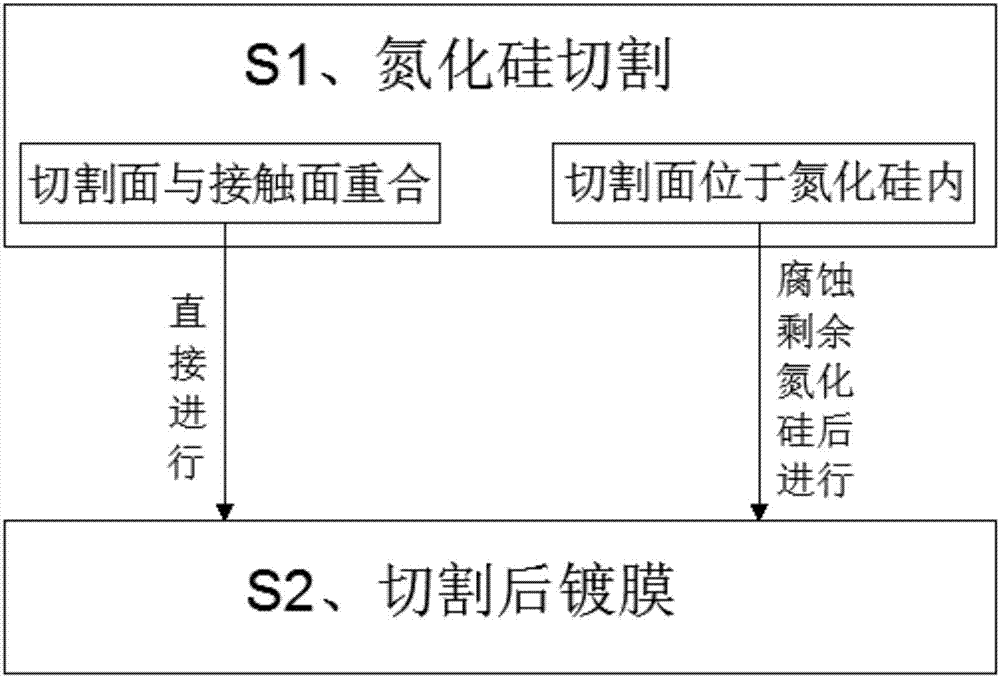

Battery piece PECVD post-plating film reworking piece processing method

ActiveCN107331734AExempt from usingReduce the use effectFinal product manufactureSemiconductor devicesGlass knifeEngineering

The invention discloses a battery piece PECVD post-plating film reworking piece processing method comprising the following steps: S1, silicon nitride cutting: using a glass knife to cut and remove the silicon nitride on the surface of the battery piece, specifically, if the glass knife cutting surface is located on the contact surface between the battery piece and the silicon nitride, directly entering step 2; S2, cutting and plating film: using a pipe type PECVD plating film process to re-plate films on the surface of the battery piece. The method can well remove the silicon nitride without using a HF acid solution or by using a little HF acid solution, and the texturization and PN node production cannot be affected; the method re-plate the PECVD film on the battery piece, thus effectively reducing battery piece damages and battery piece fragment rate, reducing raw material acid solution consumption, reducing production cost, improving work efficiency, and well processing aberration reworking pieces; the method is very effective.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

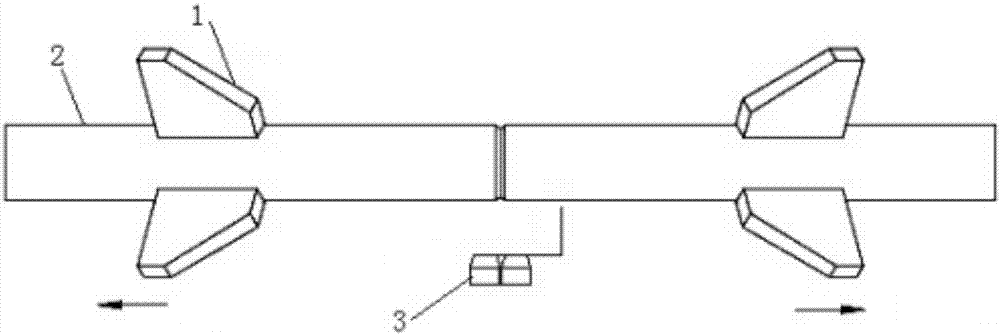

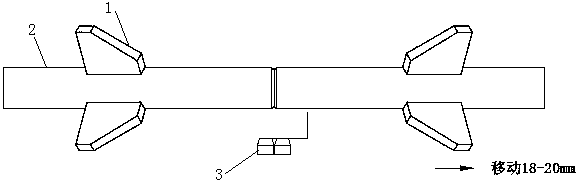

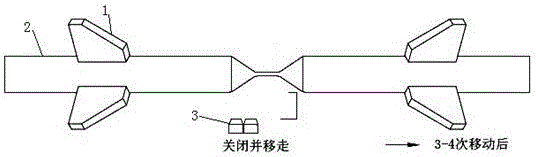

Method for drawing dual cones on preformed rod

InactiveCN107056041AHorizontal tension controllableThe magnitude of the horizontal tension is controllableGlass making apparatusBlow torchGlass cutter

The invention provides a method for drawing dual cones on a preformed rod. The method is characterized by including the steps of firstly, preheating, to be specific, fixing the preformed rod by two clamps on an operating platform to ensure that the preformed rod is arranged at the horizontal plane, and turning on a blow torch to burn positions where the cones are drawn out until surface glass is in a melting state; secondly, carrying out N drawing stages, to be specific, a first drawing stage, namely, slowly moving the clamps when the surface glass of the preformed rod is in the melting state and then stopping until the distance between the left clamp and the right clamp is increased to a set distance, a second drawing stage, namely continuing heating the positions, with the maximum reducing, of the preformed rod by the blow torch, and then moving the clamps to repeat the operation of the first step, repeating the previous steps until completing drawing of the Nth stage; further, turning off the blow torch, placing the position, to be drawn, of the preformed rod, in a holding furnace, cooling slowly for a certain time, cutting off from the finest drawing position by a glass cutter, moving the two sections of preformed rod with the cones formed by drawing out of the holding furnace, and cooling the same for stand-by application.

Owner:JIANGSU STERLITE TONGGUANG FIBER

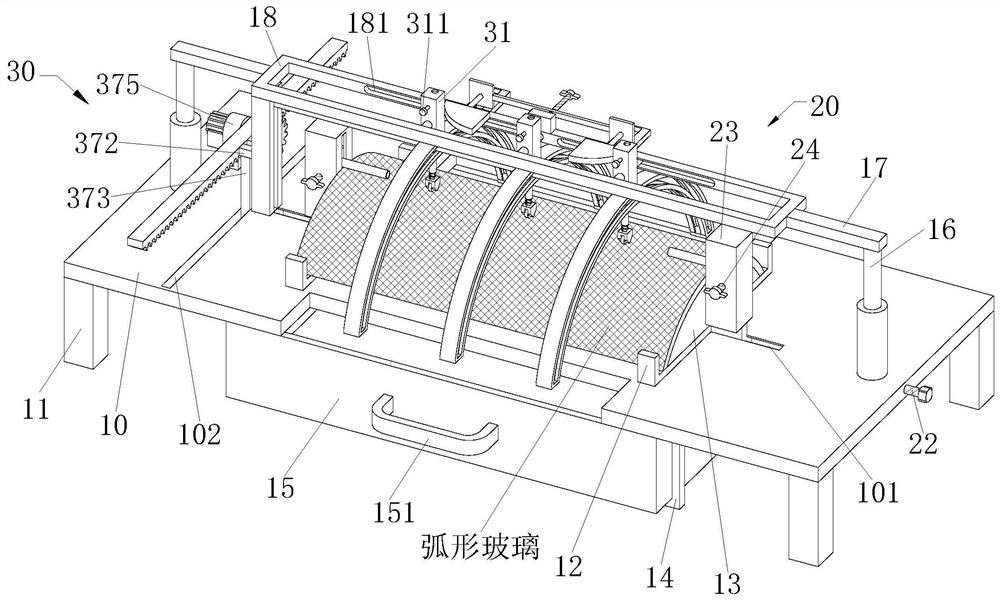

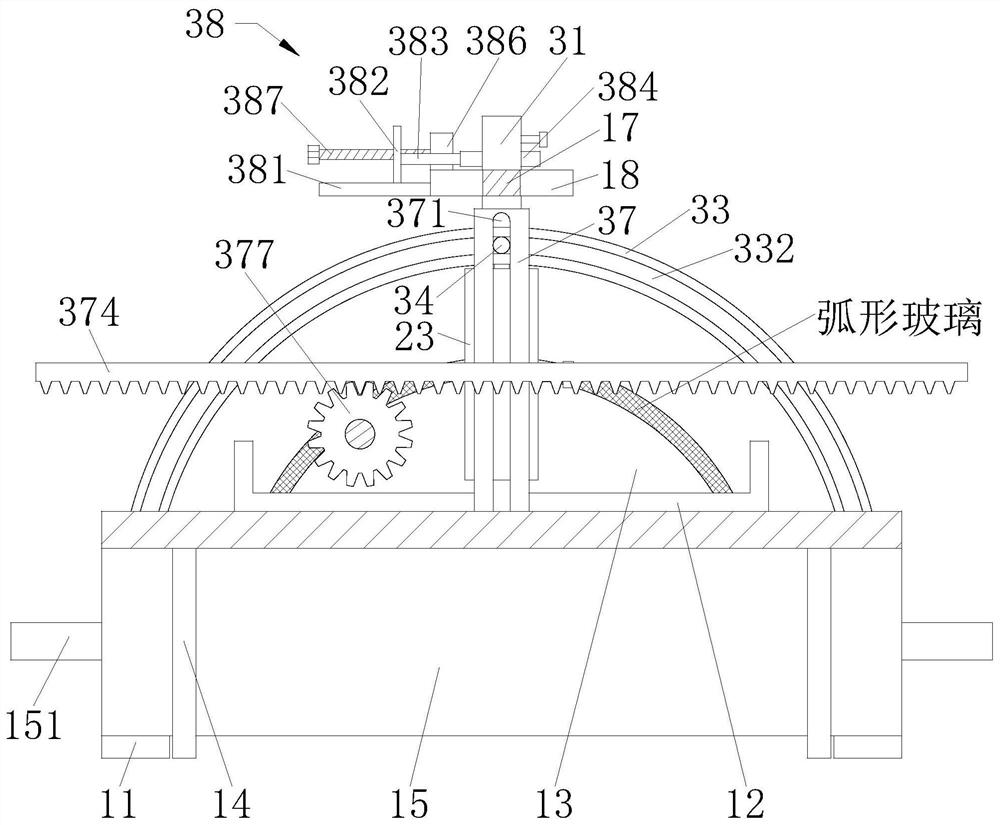

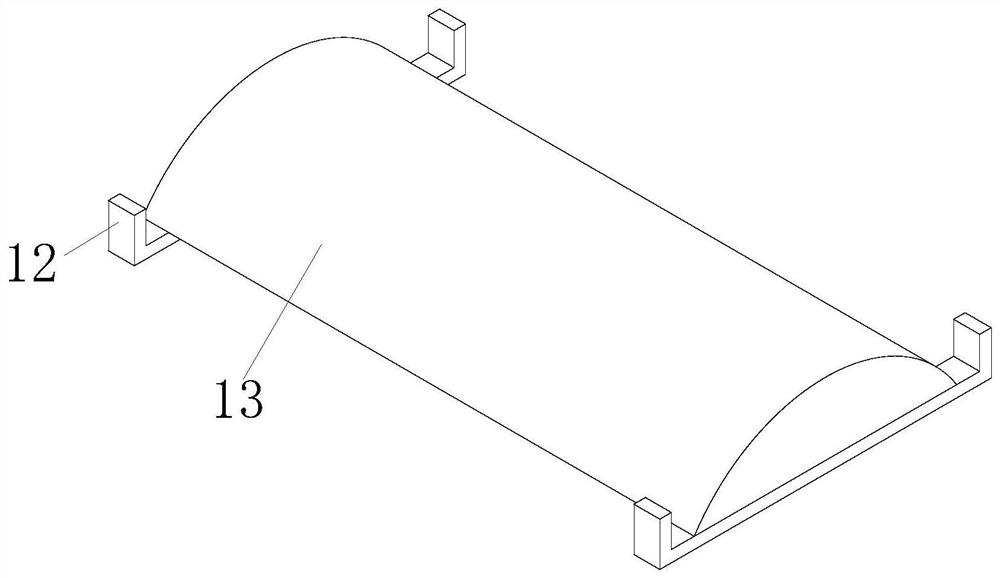

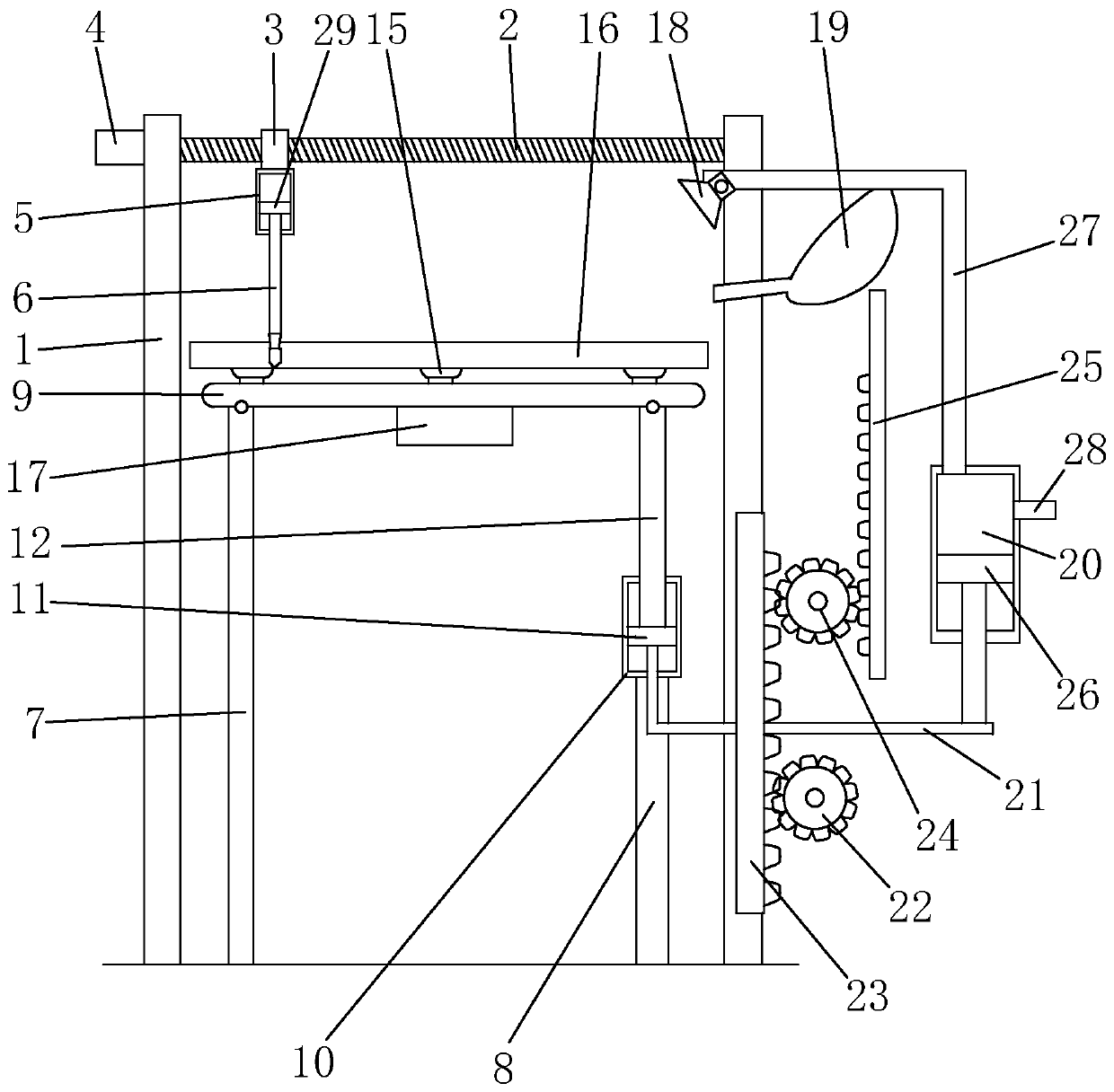

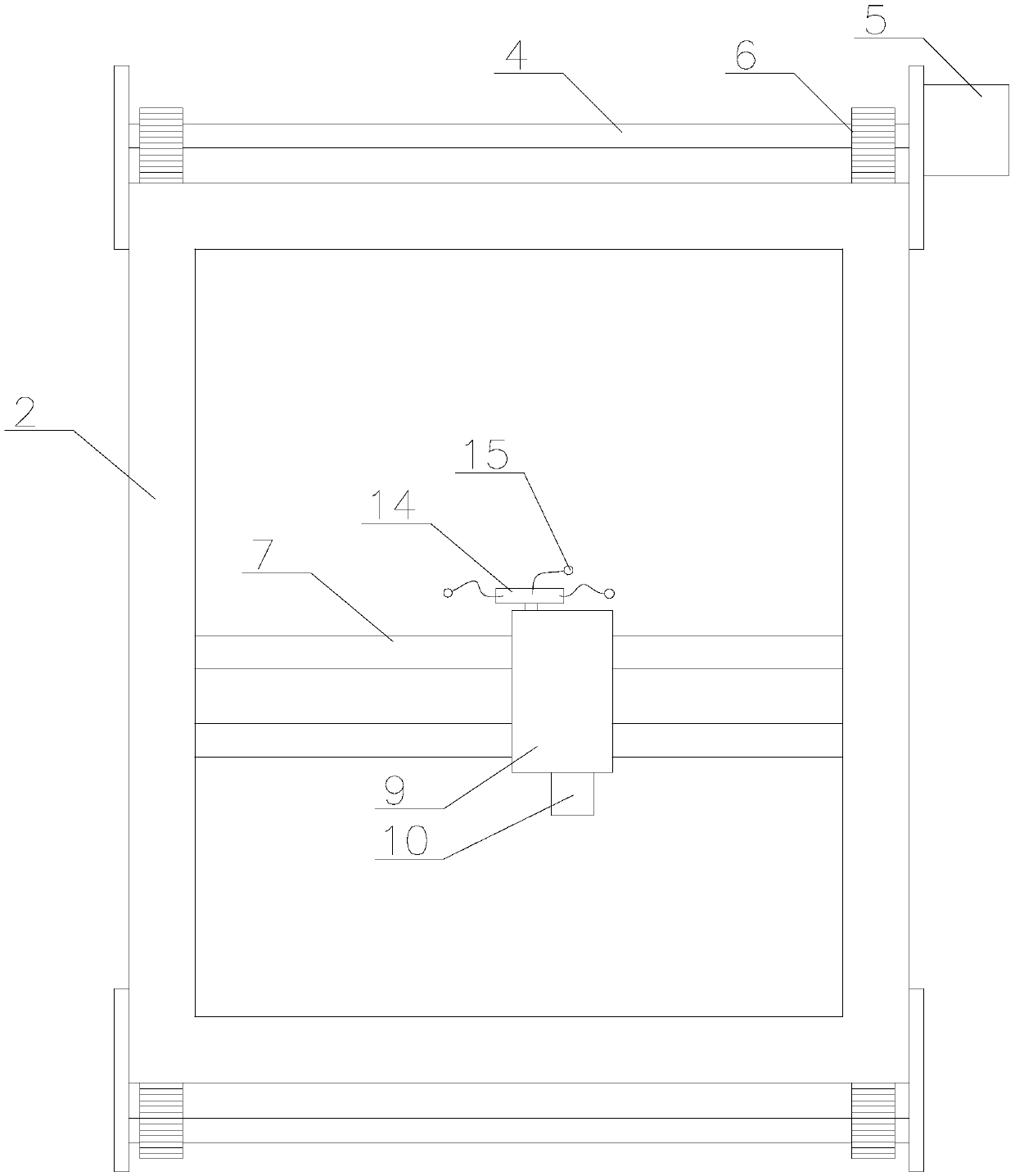

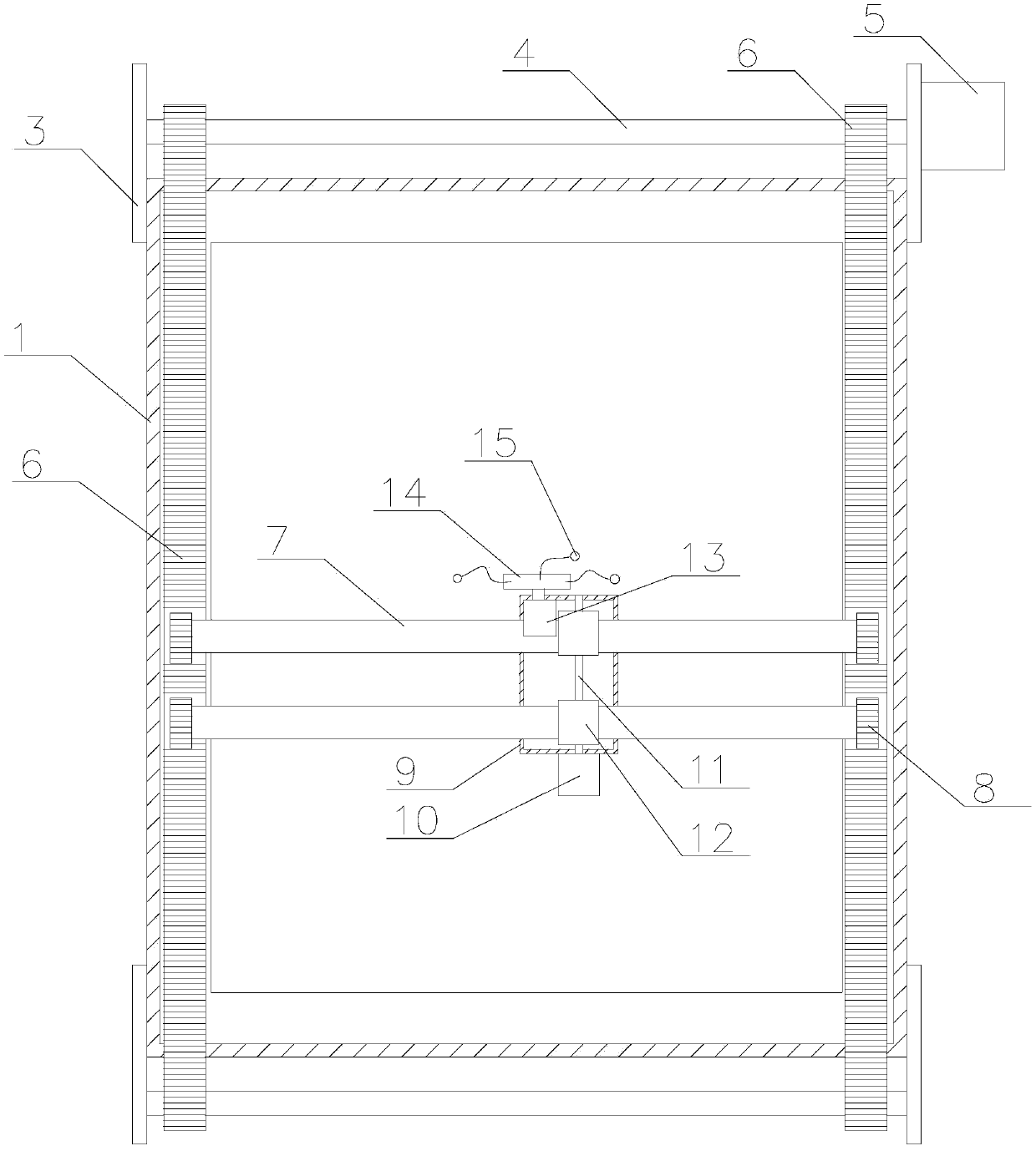

Automatic cutting machining machine and method for tempered glass

InactiveCN113173698AAvoid misalignmentAvoid scratchesGlass severing apparatusReciprocating motionGlass cutter

The invention relates to an automatic cutting machining machine and method for tempered glass. The machine comprises a workbench and a fixing device arranged above the workbench, wherein a cutting device is arranged above a curved base. According to the invention, a lifting rack is driven by a rotating gear to reciprocate up and down, so the lifting rack can drive an extrusion rod and a rubber sleeve to move to the topmost end of to-be-processed arc-shaped glass, the to-be-processed arc-shaped glass is fixed, and the phenomenon that the processing position of the to-be-processed arc-shaped glass is misplaced in the cutting process is prevented; a rubber sleeve is made of a flexible material, has compression performance and prevents the phenomenon that a hard material directly makes contact with the surface of glass to cause scratches; and the cutting position can be rapidly and accurately cooled through a water tank, and broken glass obtained after cutting is cleaned so as to prevent the cutting edge of the glass cutter from being abraded, so grinding force and friction heat are reduced, and the wear resistance and the cutting quality of the to-be-processed arc-shaped glass are improved.

Owner:王春红

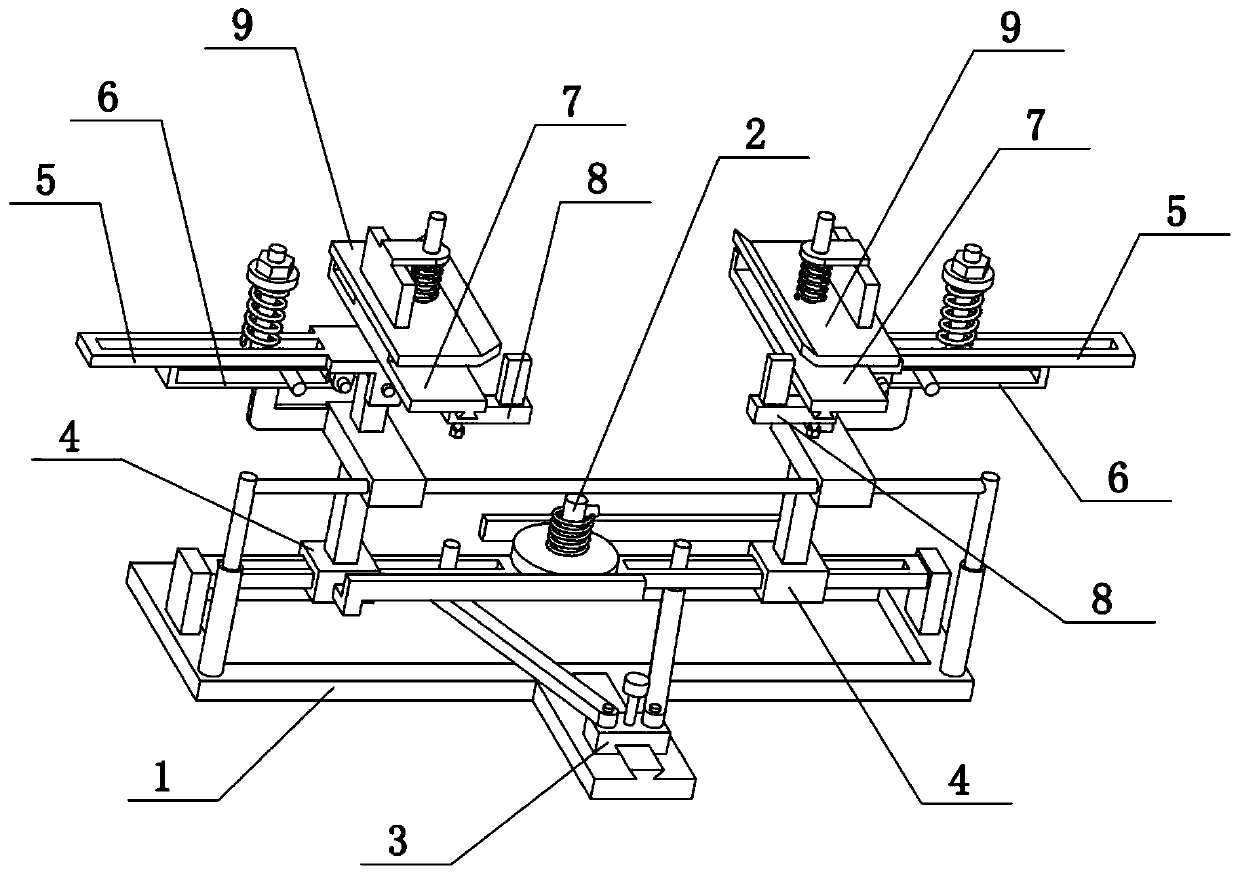

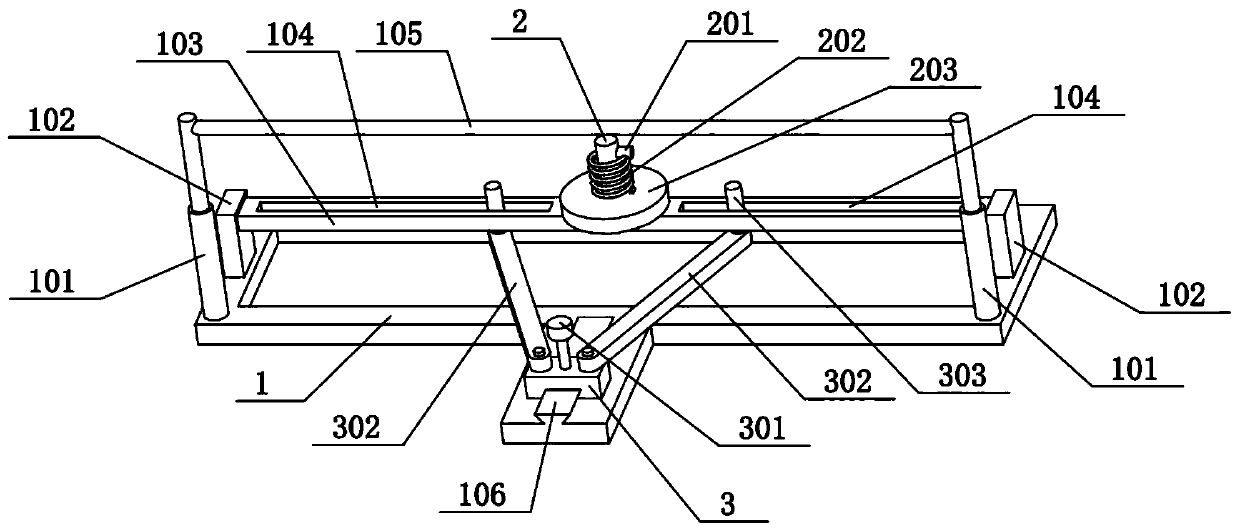

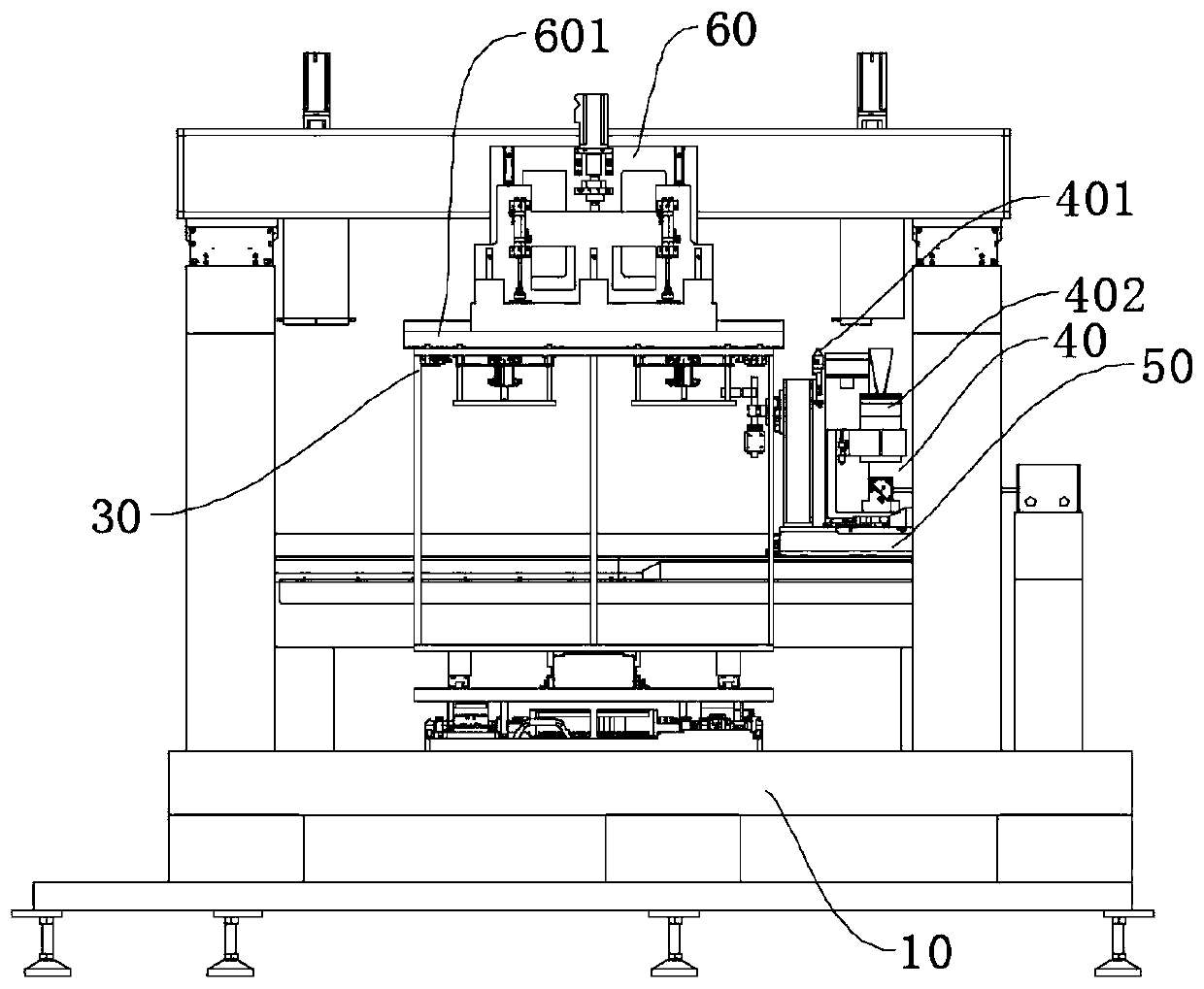

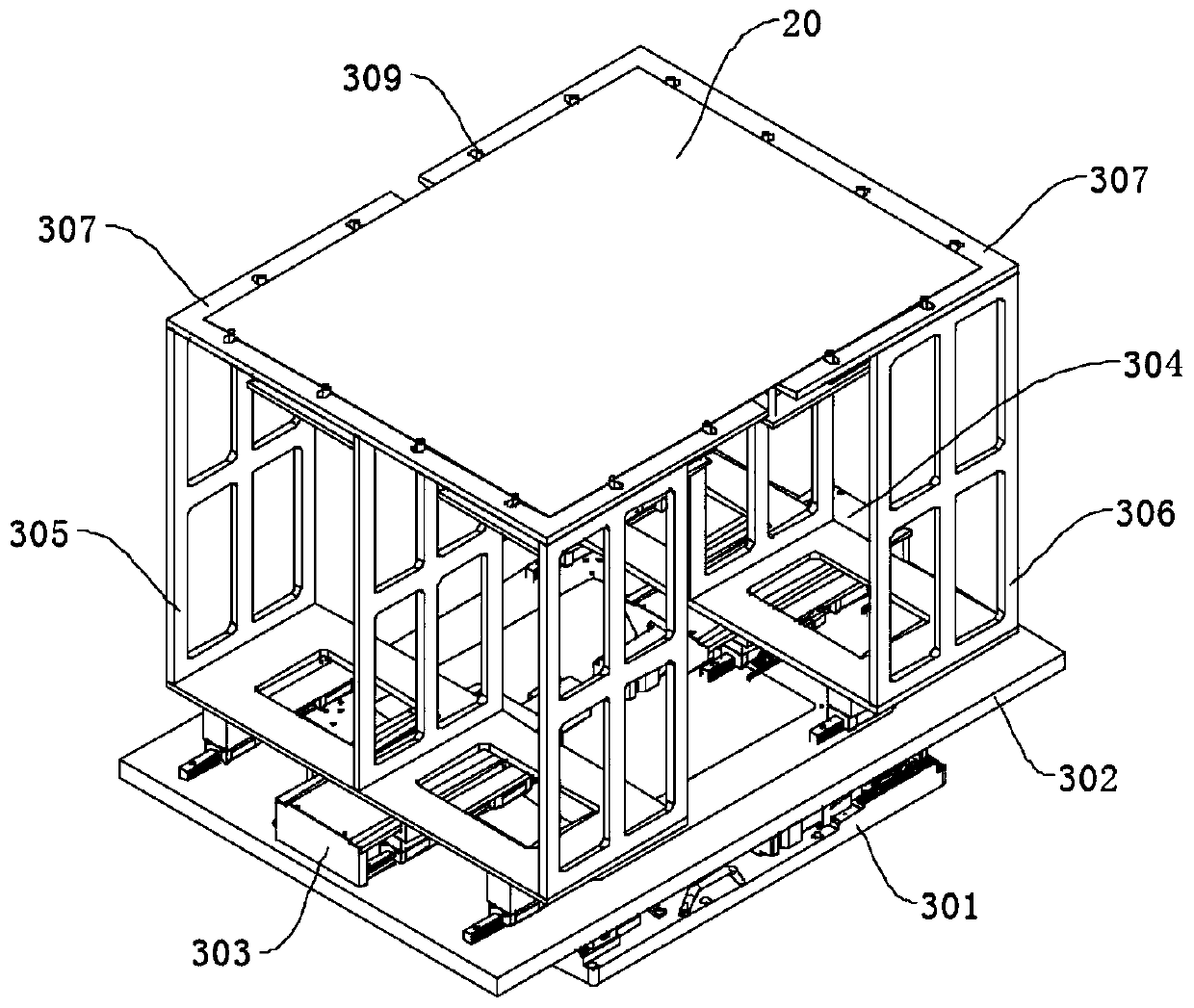

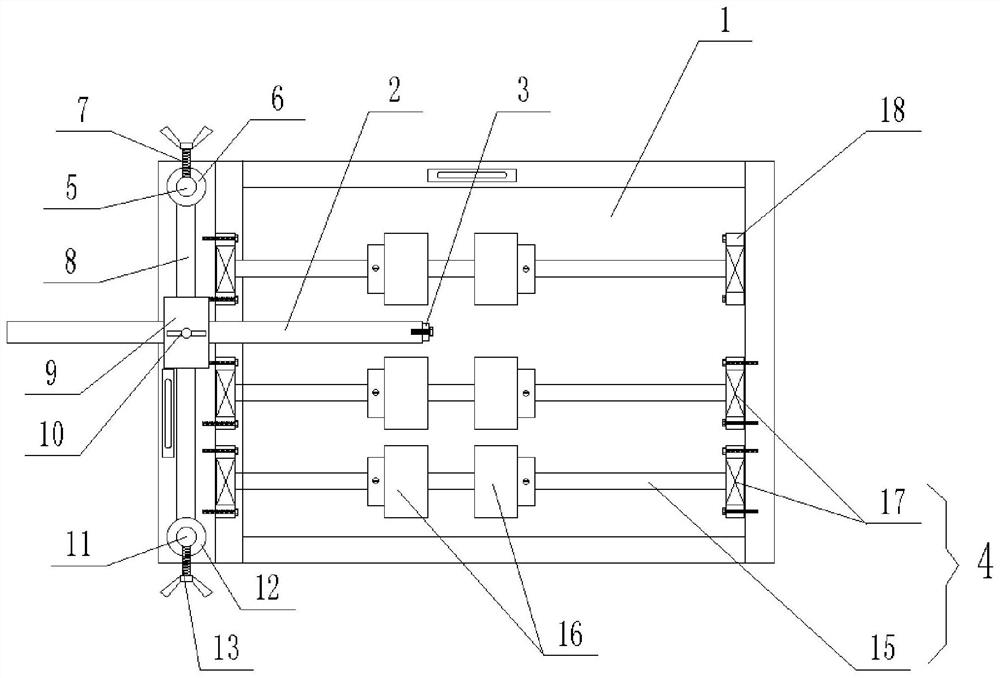

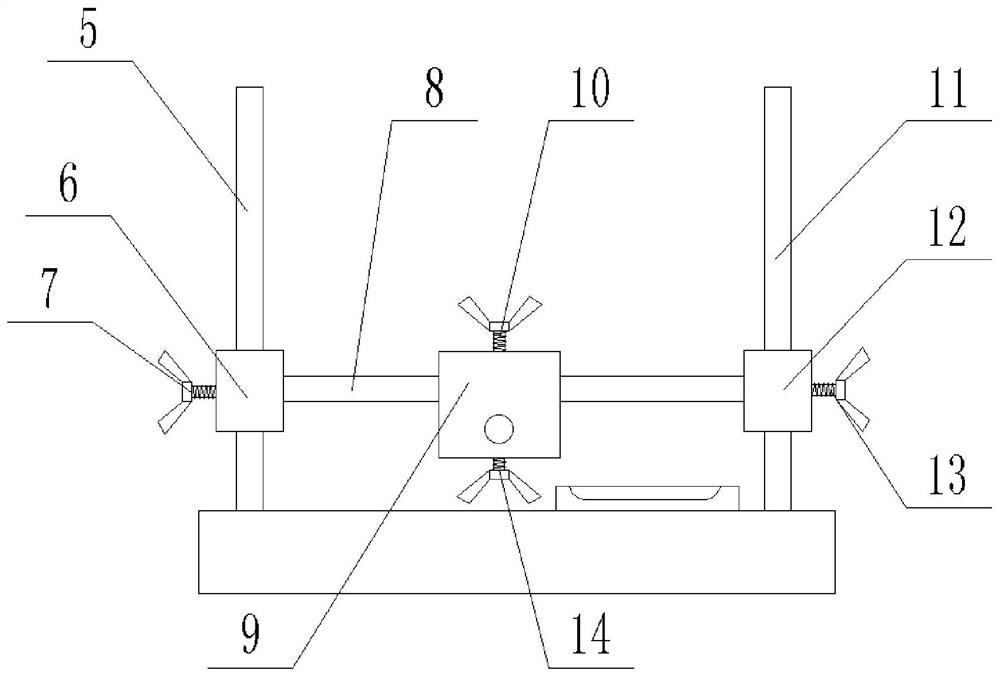

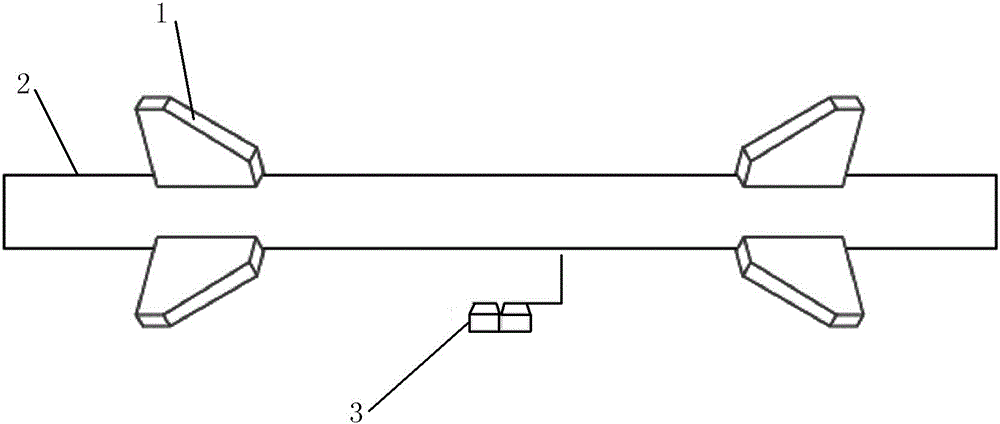

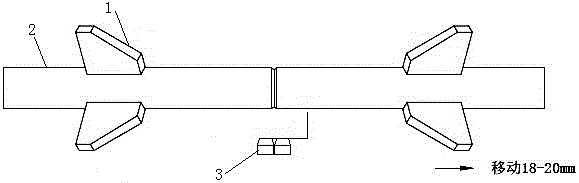

Glass machining device and method

The invention relates to a glass machining device and method. The method comprises the following steps: (1) the left and right ends of glass are placed at the upper ends of two lower clamping plates,so that two upper clamping plates press at the left and right ends of the glass to clamp the glass; (2) lines are marked at the middle parts of the glass by using a glass cutter; (3) two electric extension rods synchronously shrink to drive lifting rods to descend, and meanwhile, drive outer ends of two groove rods to synchronously rotate down; and (4) the two groove rods drive two thread columnsto rotate along with the groove rods; and two compression springs I are compressed, and drive outer ends of two rotating plates to rotate down so as to drive the two lower clamping plates to rotate tobreak off the glass.

Owner:江门市江海区金颖钢化玻璃有限公司

Glass cutter

InactiveCN104496163AConvenience for gluing workAvoid the hassle of frequently changing the position of the cutterGlass severing apparatusCutting glassGlass cutter

The invention provides a glass cutter. The glass cutter comprises a machine body, wherein the lower end of the machine body is provided with a rail, the machine body is provided with a slide rail, and the slide rail is internally provided with a slidable glass knife, and the slide rail is provided with a glass knife fixing block, the glass knife is fixedly arranged on the slide rail by virtue of the glass knife fixing block; the bottom end of the slide rail is provided with a telescopic cylinder, the left and right ends of the machine body are provided with clamping devices, and the glass knife moves on the slide rail by virtue of a moving motor at the bottom; the glass is transported by virtue of the slide rail, the glass is fixed by virtue of the clamping devices, the glass knife moves in the slide rail, and the work of the cutting the glass is carried out; manual cutting is replaced by mechanical cutting, so that the working efficiency is improved; as long as the moving track of the glass knife is changed so as to change the specification of cutting glass, the trouble of frequently changing the position of a cutter of a simple glass cutting machine is avoided, rejects caused by human errors are prevented, a glue brush is used for conveniently performing glue brushing operation on the cut glass, and the working efficiency is improved.

Owner:WUHU POWER TECH

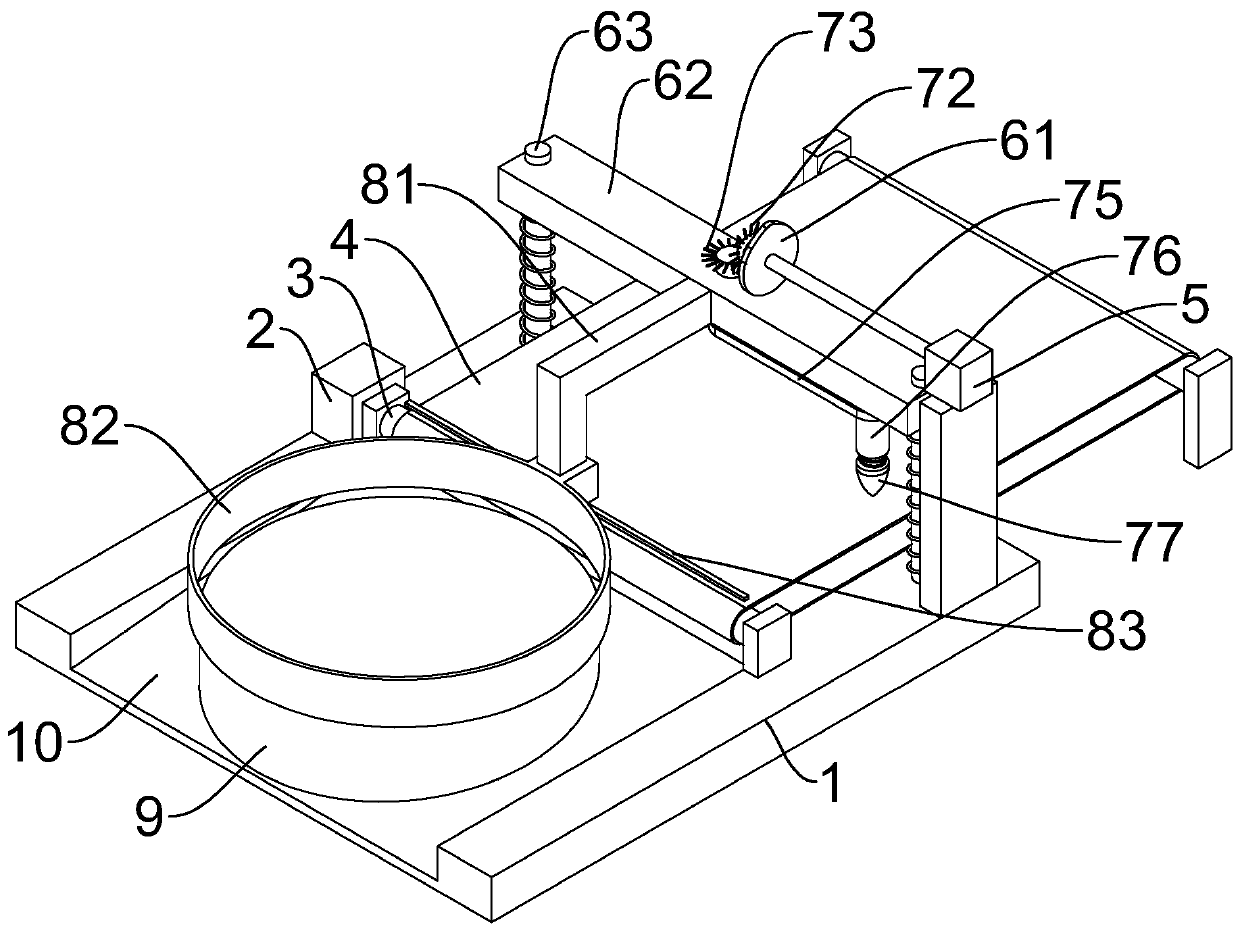

Glass processing device for forming round glass

InactiveCN110818243ASimple structureHigh degree of automationGlass severing apparatusCutting glassElectric machinery

The invention discloses a glass processing device for forming round glass. The glass processing device is used for cutting glass into round shape and comprises a bracket and a base; a circular cylinder, a first stepping motor and a supporting block are sequentially arranged at the upper end of the base from left to right; two conveying rollers are erected on the bracket; a conveying belt is connected between the two conveying rollers; the conveying roller on the left side is in key joint with an output shaft of the first stepping motor; a second stepping motor is arranged at the upper end of the supporting block; a lifting mechanism arranged on the base is connected to an output shaft of the second stepping motor; a cutting mechanism connected with the output shaft of the second stepping motor is arranged on the lifting mechanism, and a crushing mechanism matched with the circular cylinder is arranged on the lifting mechanism. The glass cutting device has the advantages that the structure is simple, a cutting knife can circle while descending, when a transverse plate descends to the bottom, a glass knife is pressed tightly on glass and conducts rotary cutting, meanwhile, the formedround glass is crushed, the glass moves leftwards by a section, the steps are continued, the automation degree is high, and time and labor are saved.

Owner:宁波爵盛科技有限公司

Chromosome flaking method of leymus hochst plant root tips

InactiveCN104006997AReduce physical damageHigh production success ratePreparing sample for investigationPlant rootsTableting

The invention relates to a chromosome flaking method of leymus hochst plant root tips. The method comprises the following steps that (1) in a step of preparing materials, after leymus hochst seeds are germinated for 5-7 days at constant temperature, white new roots of the potted leymussecalimus which grow vigorously are put into a centrifugal tube; (2) the centrifugal tube with root tips are placed into a high pressure container device, and N2O are introduced into the centrifugal tube for pretreatment to obtain pretreated new roots; (3) the pretreated new roots are dried and fixed by using Carnoy's fluid to obtain fixed new roots; (4) the fixed new roots are rinsed and dissociated by using glacial acetic acid after being dried to obtain dissociated new roots; (5) the dissociated new roots are dried and placed on a glass slide for manufacturing tablettings; (6) the tablettings are placed under an optical microscope for observing, dispersed and distinct cells of the chromosome are selected for taking photographs so as to perform fluorescence in situ hybridization, and finally, the positions of cover glasses are marked by using a glass knife, and the ready-made glasses are put into a refrigerator at minus 80 DEG C for storing. The method is efficient and safe.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Handheld glass cutting tool

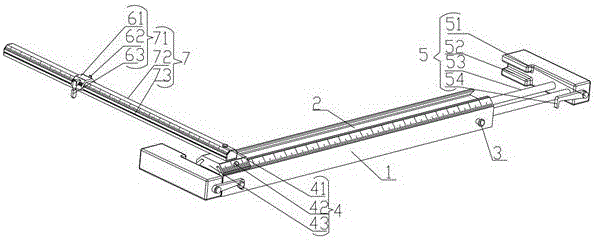

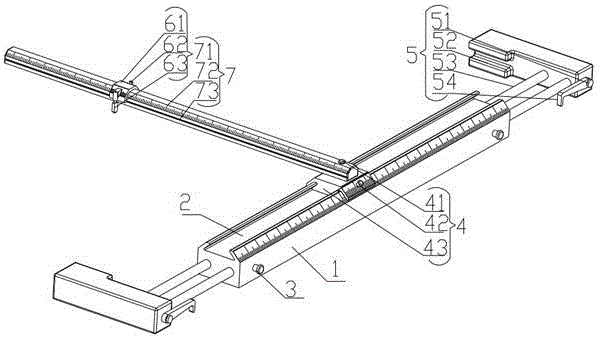

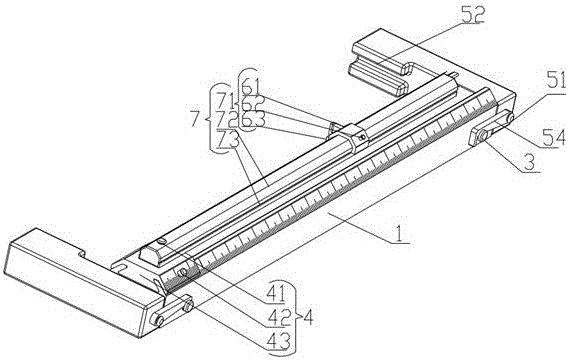

InactiveCN107867796AImprove cutting effectControl the depth of cutGlass severing apparatusCross cutHand held

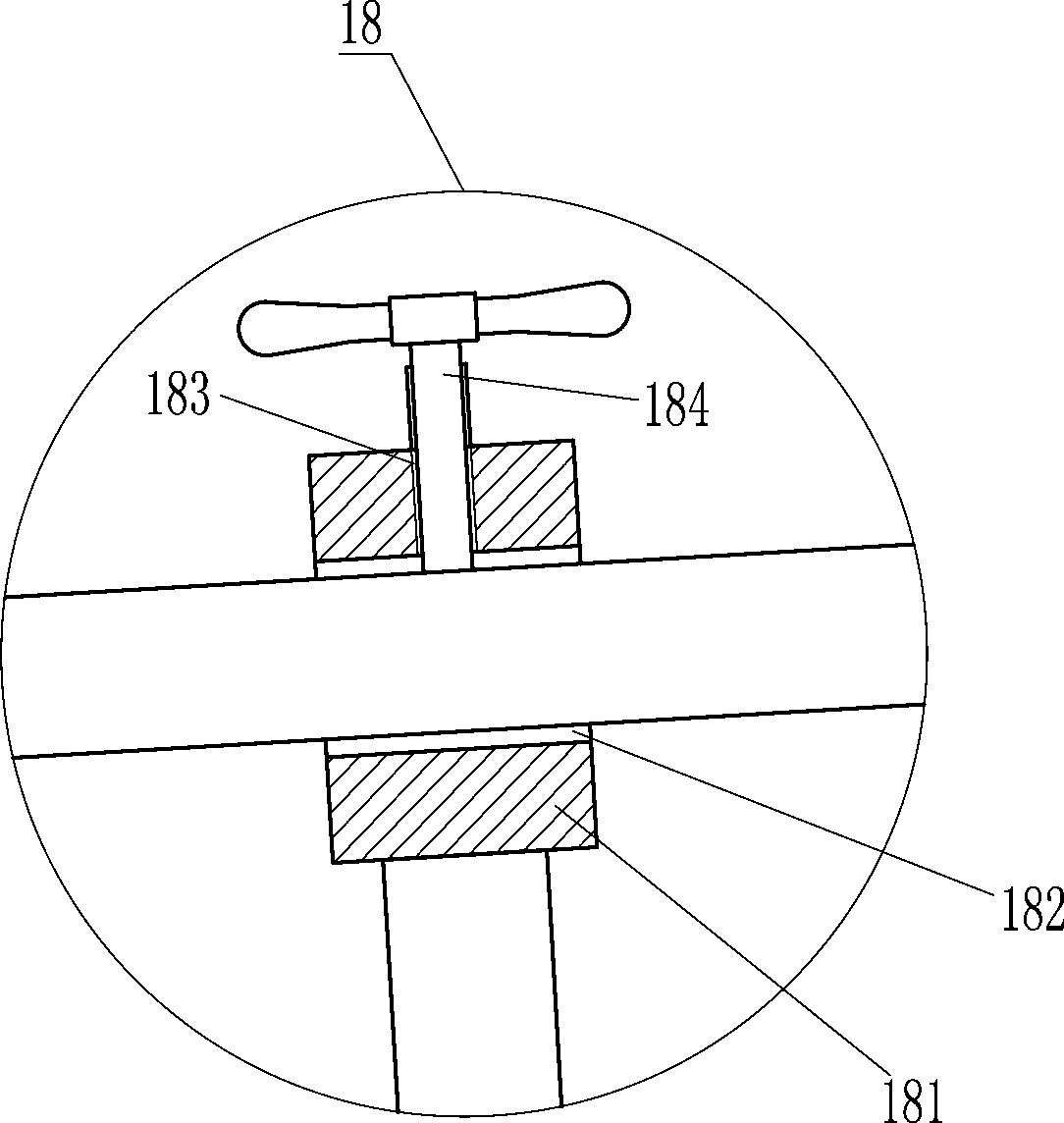

The invention provides a hand-held glass cutting tool, comprising a first base, a second base, a beam and a cutting knife, the bottoms of the first base and the second base are respectively provided with limit rollers and support rollers , the support roller is on the inner side of the plane formed by the limit roller and the crossbeam, one end of the crossbeam is provided with a thread, and the threaded end of the crossbeam passes through the second base and is fixed by bolts, and the other end of the crossbeam is connected to the first base Fixedly connected, the beam is provided with a groove between the first base and the second base, and the cutting knife moves left and right in the groove and is fixed on the beam through a fixing knob. The hand-held glass cutting tool created by the present invention has two limit rollers in contact with the glass side surfaces, and the beam is made of rigid material, so that the cutting path of the glass knife is parallel to the glass side, so that the quality of manual cutting is guaranteed. The tool is The detachable structure facilitates the replacement of damaged parts.

Owner:新昌县瑞宸机械有限公司

Glass cutter capable of cutting arcs on side face and right angle

ActiveCN105731780AImprove stabilityHigh precisionGlass severing apparatusElectrical conductorGlass knife

The invention discloses a glass cutter capable of cutting arcs on the side face and the right angle. The glass cutter mainly comprises a base, a dovetail groove sliding way, a fixing table, a main sliding guide body, a clamping arm and a cutting device. To achieve the purpose of cutting the arcs on the side face and the right angle, the clamping arm fixes glass or a tile from the side face, the main sliding guide body is moved to be precisely located at the position where a user wants to cut and fixed, then an auxiliary sliding guide body is moved to determine the radius of the cut arcs and fixed, and finally, by rotating the cutting device, the arcs can be cut on the side face conveniently. If the user wants to cut the arcs on the right angle, the arcs can be cut only by fixing the single side of the clamping arm. The effect of cutting the arcs on the side face and the right angle can be well integrated, the function of the cutting device is improved greatly, and the tediousness caused when multiple tools are carried during specific working is reduced; after cutting is finished, the clamping arm and the cutting device can be folded, space is saved, and carrying is convenient; the glass cutter is convenient to operate and adapts to market demands.

Owner:EAST CHINA JIAOTONG UNIVERSITY

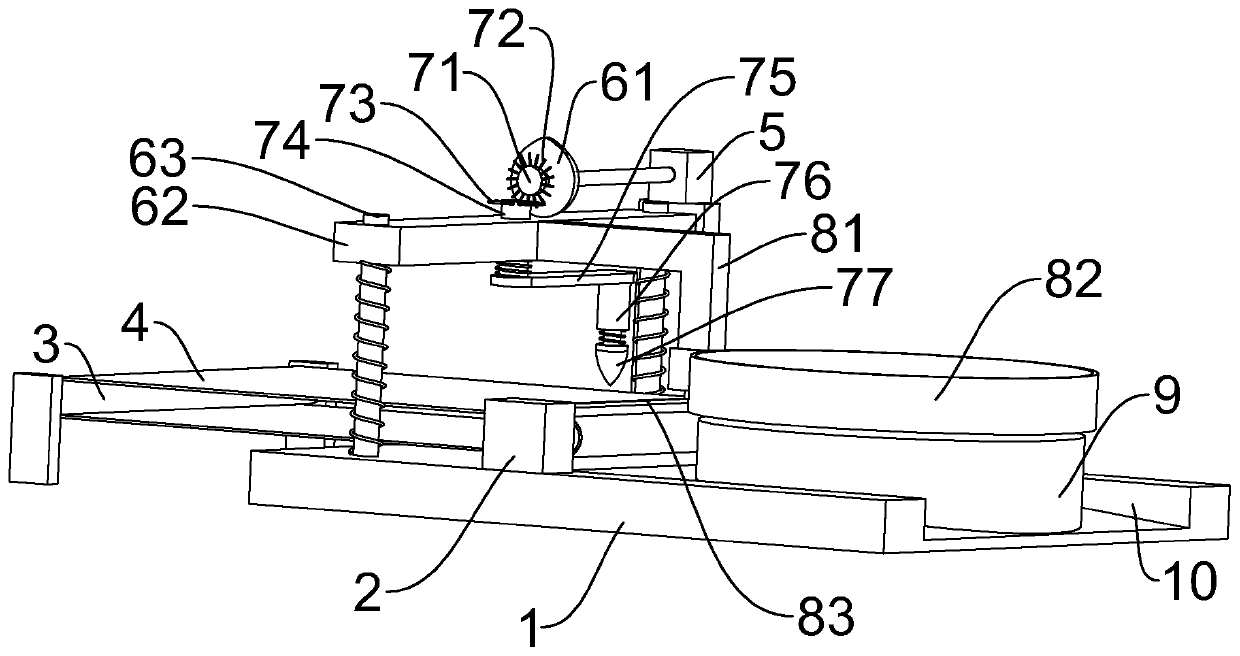

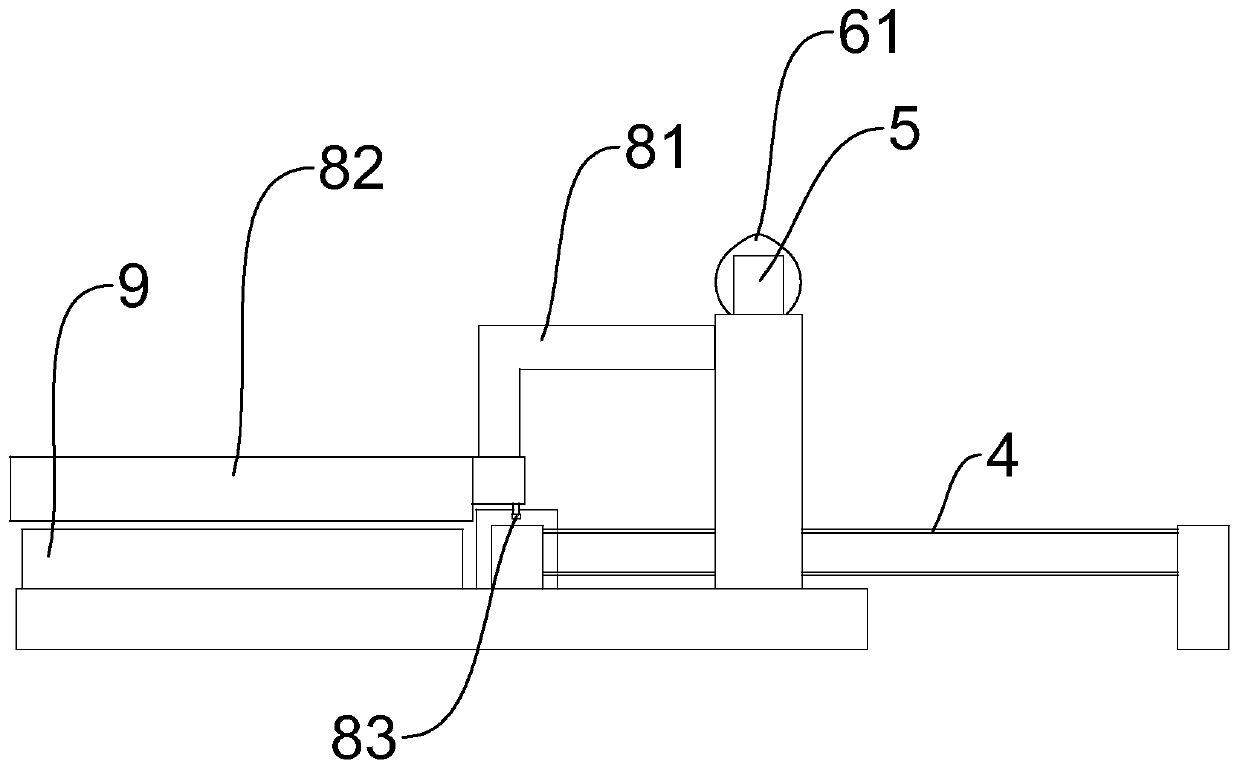

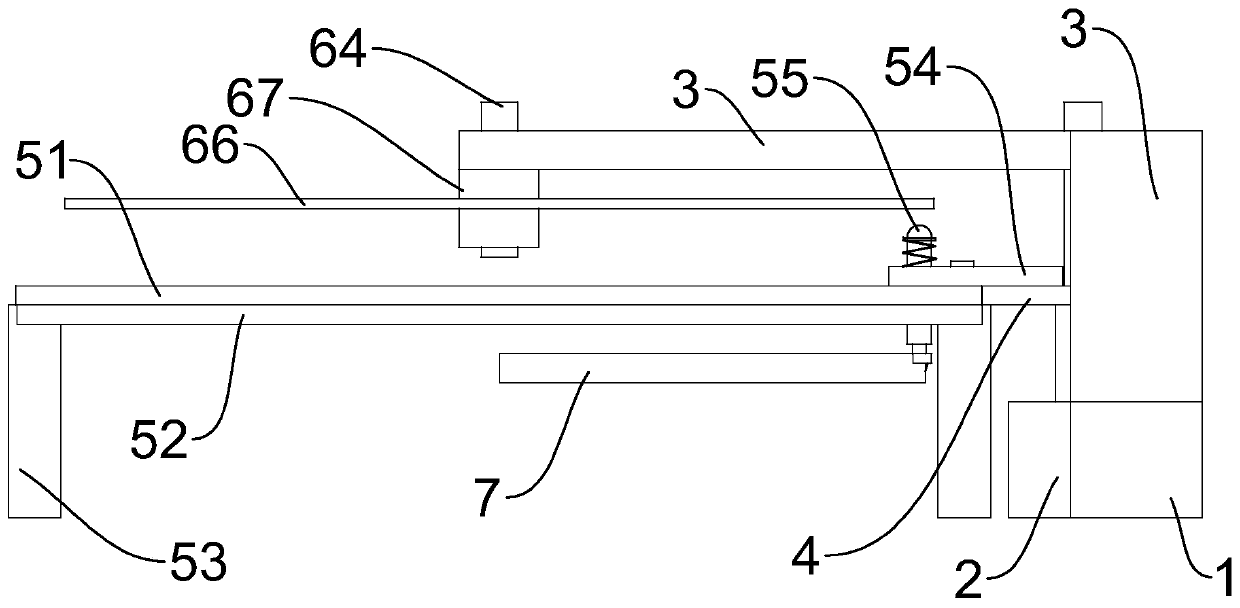

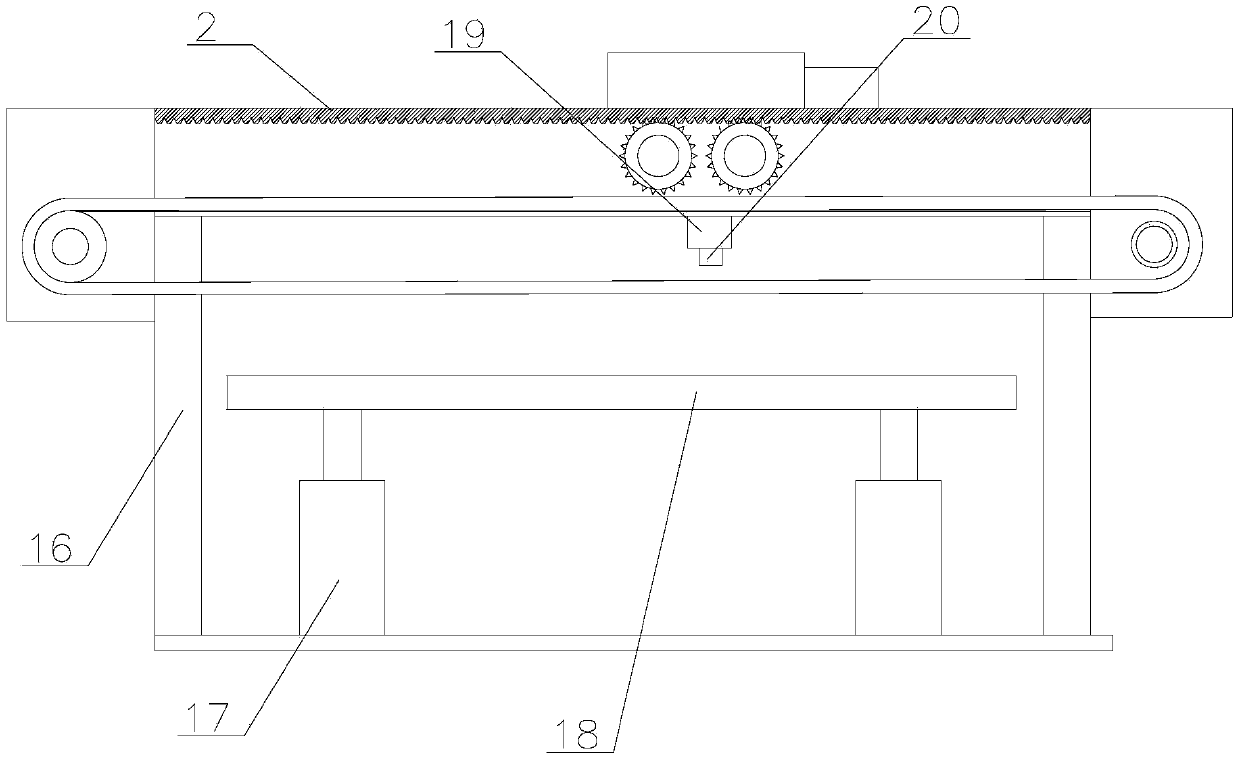

Round glass cutting device

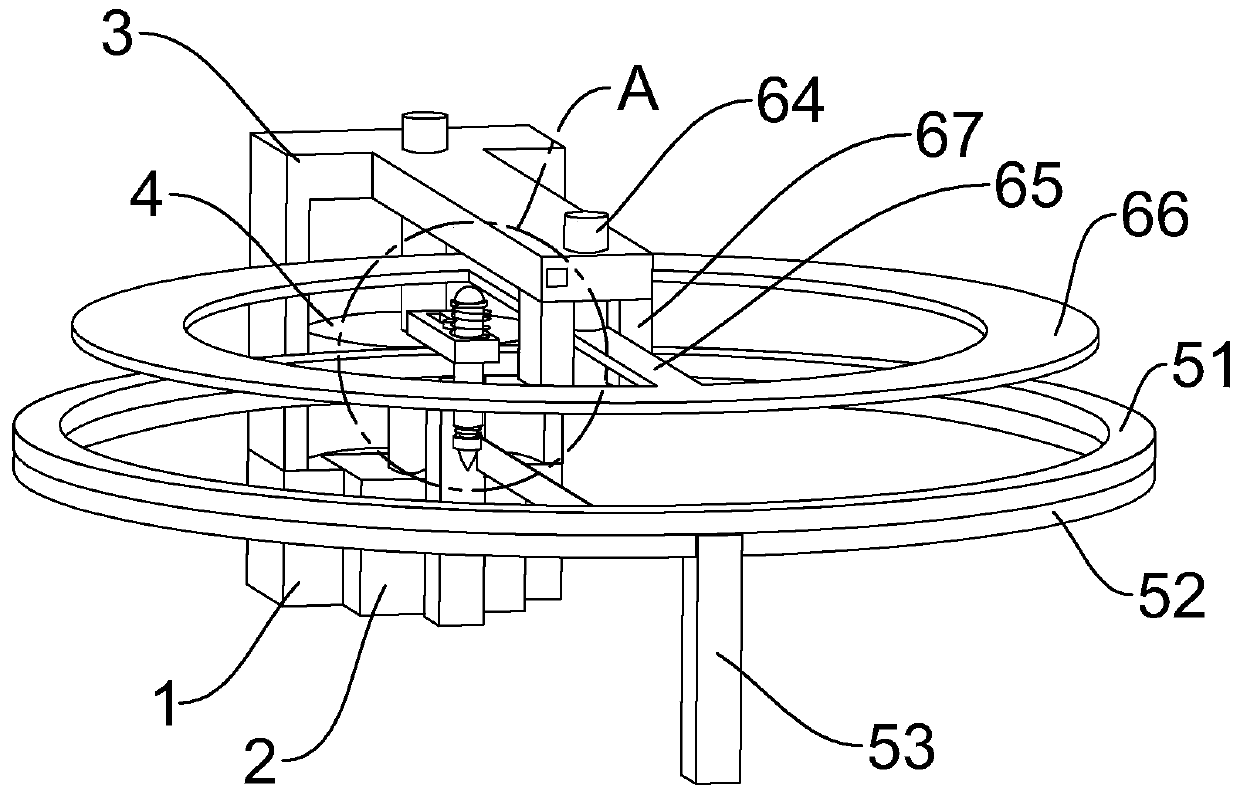

InactiveCN111018333ASimple structureHigh degree of automationGlass severing apparatusGear wheelElectric machinery

The invention discloses a round glass cutting device. The device comprises a base and a cutting mechanism, wherein a stepping motor is arranged in the base; a stabilizing piece is arranged at the upper end of the base; an output shaft of the stepping motor is in keyed joint with a first gear; the cutting mechanism comprises a gear ring engaged with the left end of the first gear; a circular ring is coaxially arranged at the lower end of the gear ring; two supports for erecting the circular ring are symmetrically arranged at the left end and the right end of the circular ring; an adjusting strip is arranged on the right side of the upper end of the gear ring; a lifting column is arranged at the left end of the adjusting strip; a first spring is arranged between the lifting column and the adjusting strip; and a glass cutter is telescopically arranged at the lower end of the lifting column. The round glass cutting device has the advantages that a structure is simple, the cutter can be pressed downwards through a pressing ring, the glass cutter rotates for cutting while pressing glass, an automation degree is high, and time and labor are saved.

Owner:宁波爵盛科技有限公司

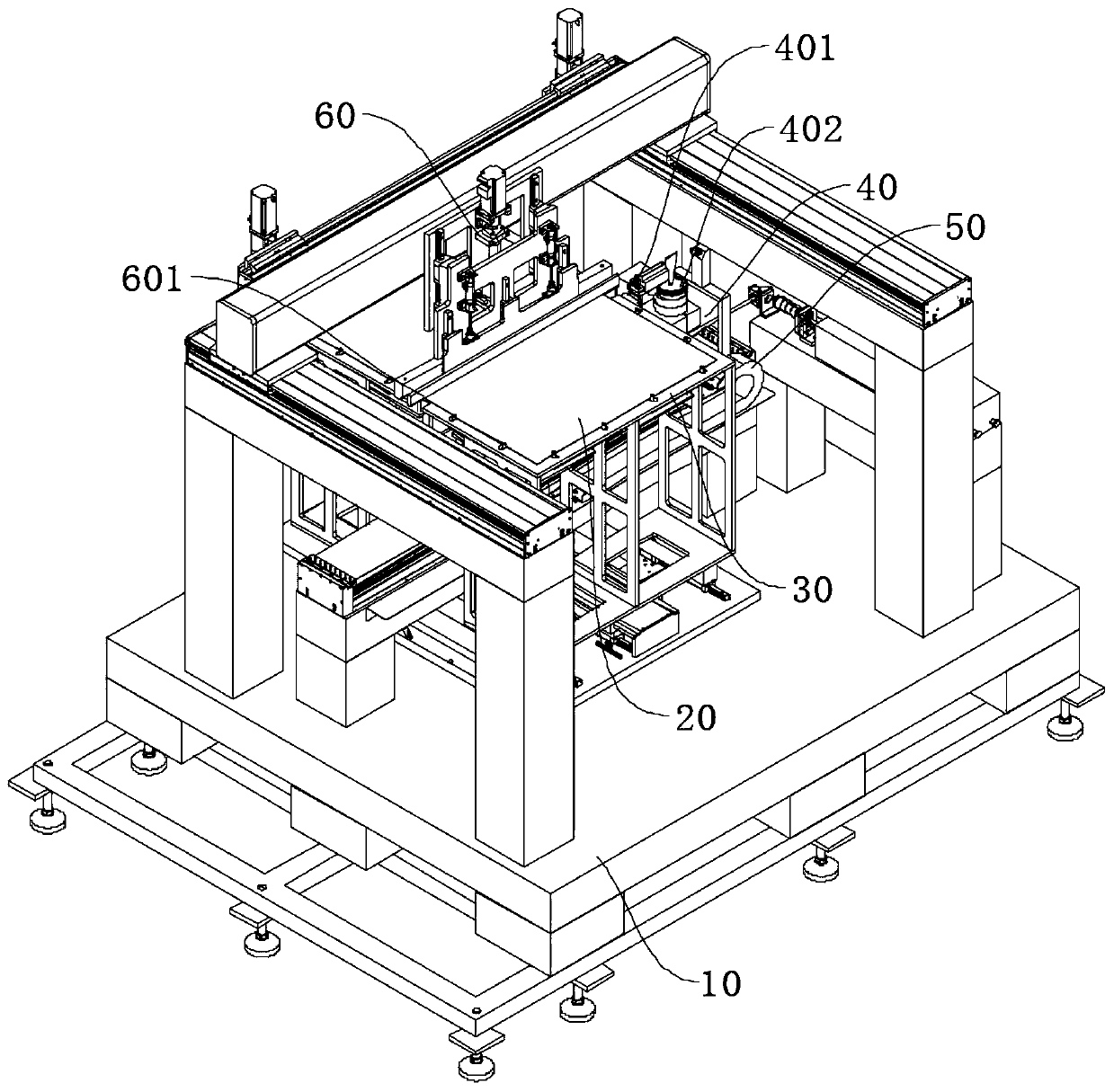

Glass cutting and cleaning integrated equipment and method

PendingCN110900850AImprove cleaning efficiencyHandling safetyWorking accessoriesStone-like material working toolsGlass chipElectric machinery

The invention discloses glass cutting and cleaning integrated equipment and method. The integrated equipment comprises a rack, and a cutting device and a cleaning device are arranged on the rack; thecutting device comprises a screw rod, a nut and a motor, the two ends of the screw rod are arranged on the rack, and the motor is fixedly arranged on the rack and connected with one end of the screw rod; the nut is movably arranged on the screw rod in a sleeving mode and matched with the screw rod, an air cylinder B is fixedly arranged at the lower end of the nut, and a glass cutter is fixedly connected to the lower end of a piston C in the air cylinder B. According to the working method for the integrated equipment, cutting and cleaning of the glass are completed through multiple steps. According to the glass cutting and cleaning integrated equipment, glass can be cut and cleaned, glass chips on the surface of the glass are cleaned and dried after the glass is cut, the cleaning efficiencyof the glass is improved, the hands of an operator cannot be scratched in the carrying process of the cleaned glass, and the carrying process of the glass is safer.

Owner:青岛港湾职业技术学院

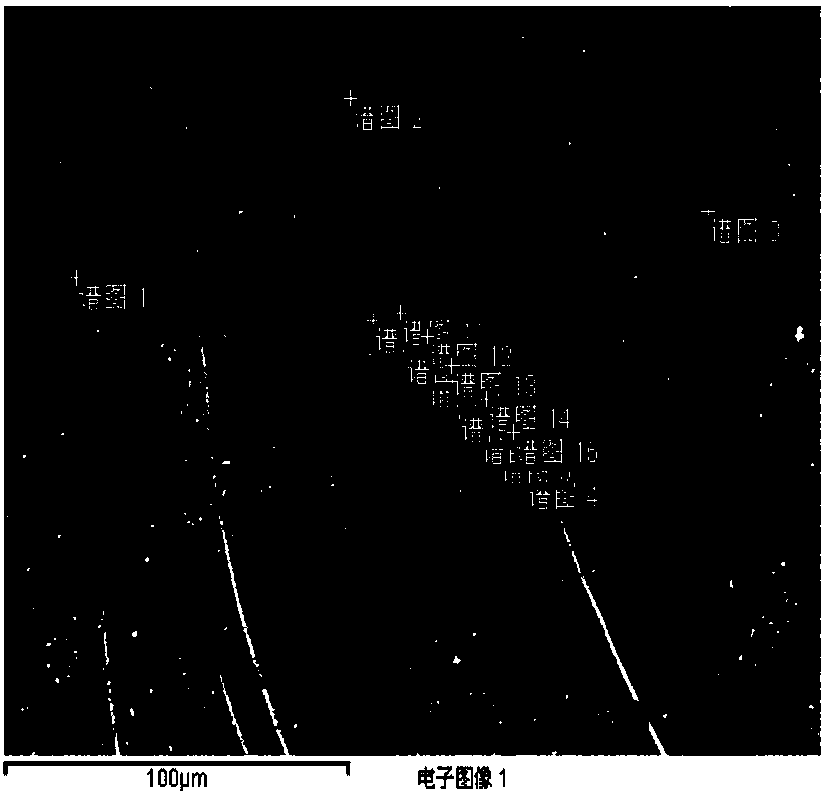

Method of using reflection electron probe to analyze glass defects

ActiveCN108061736AAccurate Defect AnalysisPrecise positioningMaterial analysis using radiation diffractionConventional transmission electron microscopeGlass cutter

The invention relates to a method of using a reflection electron probe to analyze glass defects. The method is characterized by comprising following steps: step one, labeling the position of a glass defect and measuring the distance between the glass defect and the glass surface; step two, taking the glass surface, which is closest to the glass defect, as the cutting surface, and cutting the cutting surface for many times by a glass cutter to obtain a sample with multiple cutting cracks; step three, observing the cut sample, and if the distance between the position of the glass defect and at least one cutting crack is 0-0.55 mm, taking the cutting crack as the characteristic crack for positioning the glass defect under a transmission electron microscope; and step four, taking the characteristic crack as a reference substance, and positioning and analyzing the glass defect by a reflection electron probe. The method solves the problem that in the prior art, the defect positioning is notaccurate, moreover, the method is simple and fast, and no extra cost is generated.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Glass cutting device

ActiveCN105753305BImprove cutting yieldNo deviation will occurGlass severing apparatusCutting glassGlass cutter

The invention provides a glass cutting device which comprises suckers, a guide track, a fixing rack and a glass cutter, wherein the suckers are arranged below the guide track; the suckers are used for sucking glass to be cut; the extending track of the guide track is identical to the cutting track of the glass to be cut; the fixing rack is connected with the guide track in a sliding manner; the fixing rack and the suckers are respectively arranged on two sides of the guide track; the fixing rack is provided with a cutter holder; the glass cutter is fixed on the cutter holder; the glass cutter faces to a plane where the guide track is placed. As the glass cutter is fixed on the fixing rack, the fixing rack is connected with the guide track in a sliding manner, the glass to be cut is fixed on the guide track through the suckers in a sucking manner, the glass cutter points to the glass to be cut, and the movement track of the glass cutter on the surface of the glass is limited through the guide track, the glass cutter is not deflected in the cutting process, and the cutting pass percent of the glass is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

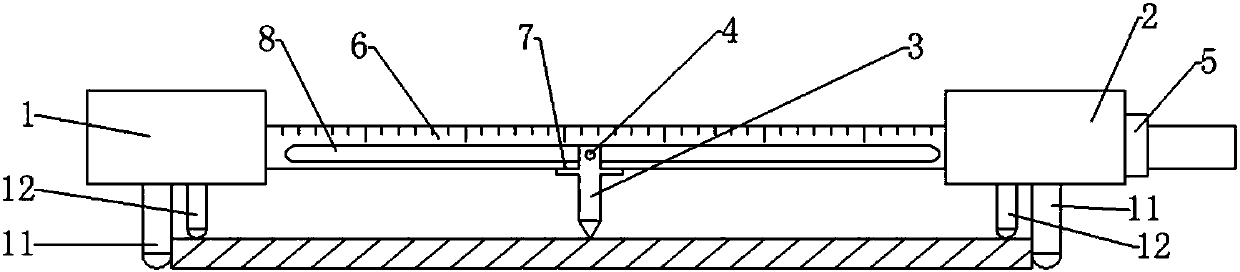

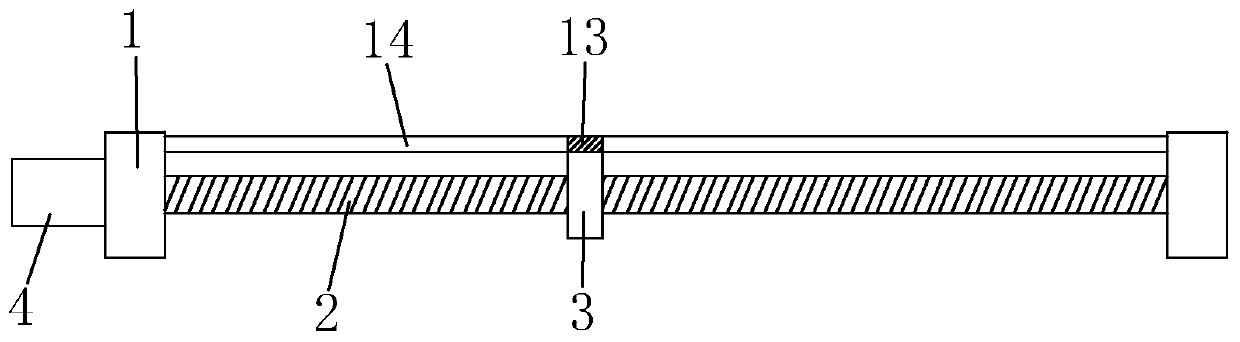

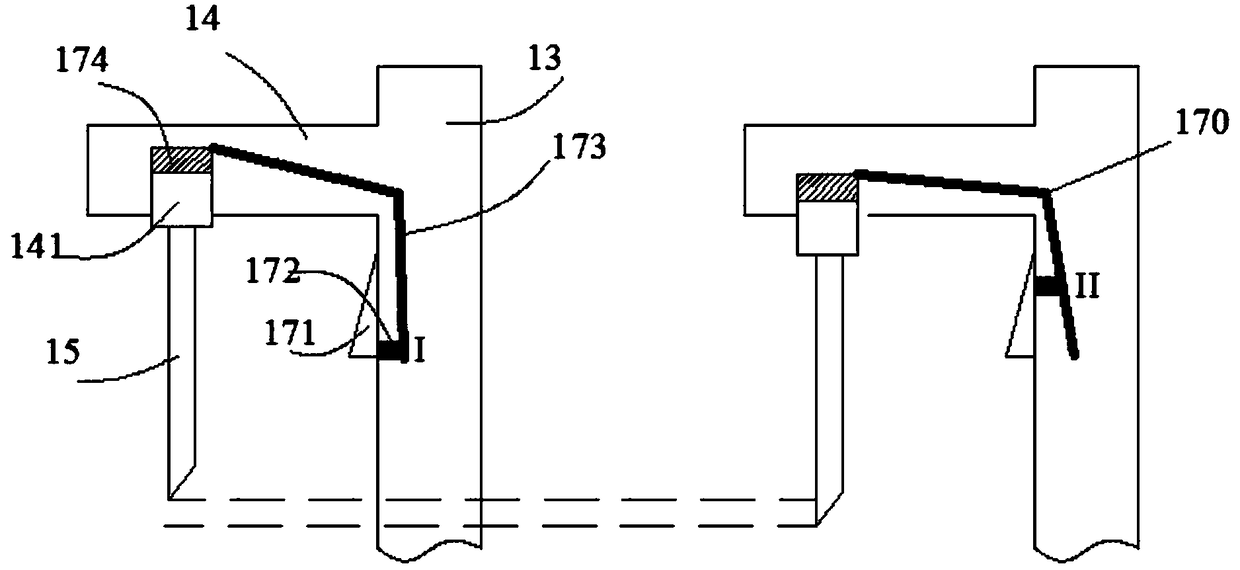

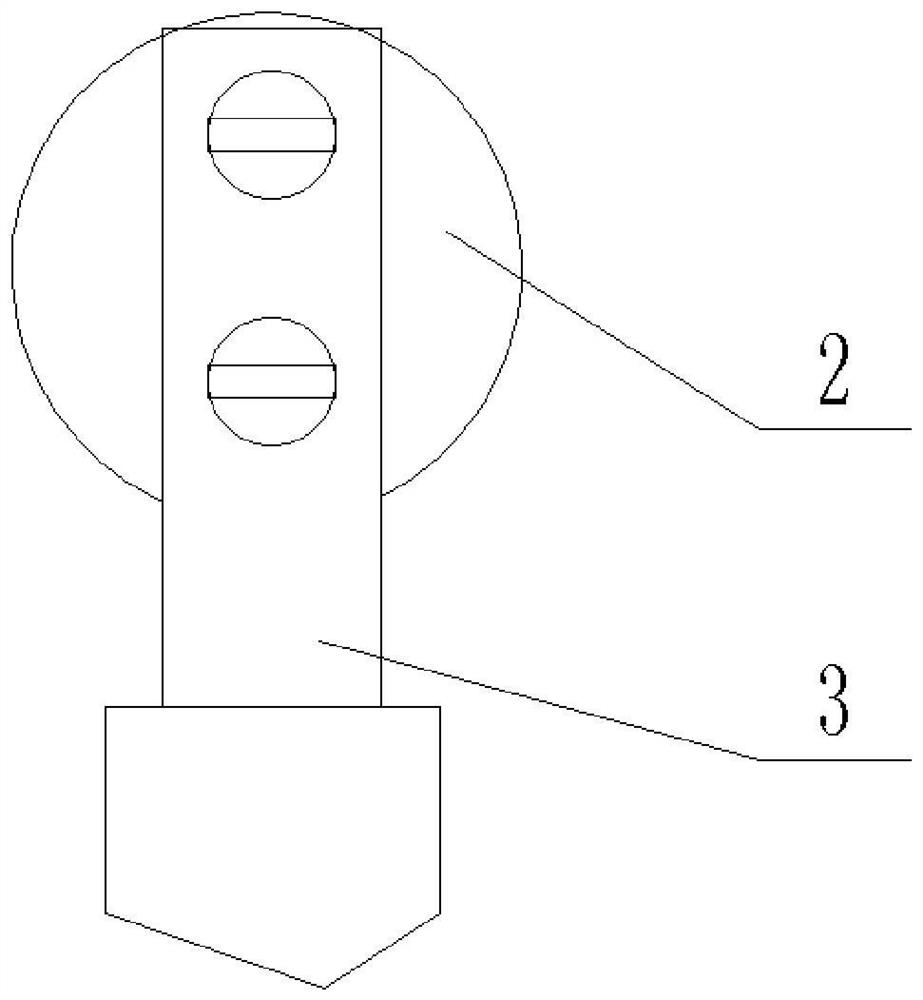

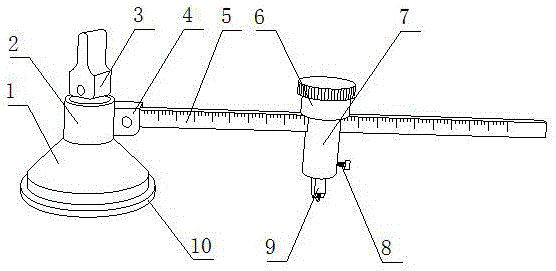

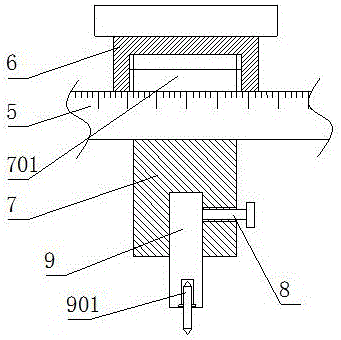

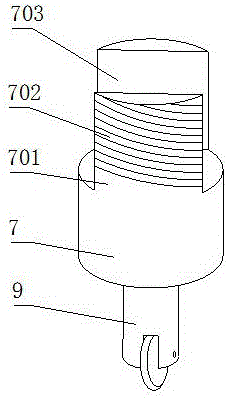

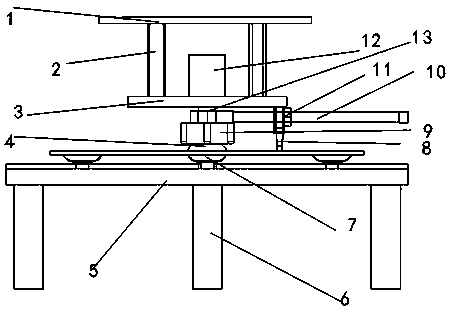

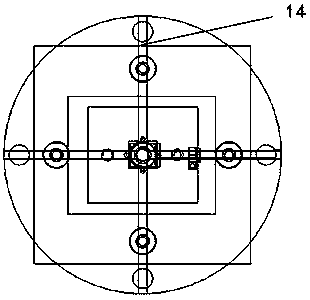

Glass knife with electronic level meter

InactiveCN103708715AHigh precisionImprove work efficiencyGlass severing apparatusEngineeringGlass knife

The invention belongs to a glass cutting tool, and concretely provides a glass knife with an electronic level meter. The glass knife comprises a glass backup plate, a push knife body and an electronic level meter. One end of the push knife body is fixed on the glass backup plate in the vertical direction. The electronic level meter is installed at the bottom surface of the push knife body. Glass levelness is transmitted to the electronic level meter through a sensor installed on the electronic level meter. The push knife body comprises a glass slide rail, a rotating disc and a six-rail knife bar. The glass knife changes the cutting method of a traditional glass knife that only one piece of glass can be cut once. That six pieces of glass with different sizes or the same size can be cut at the same time is achieved through one glass knife. Each knife head is independent, and no influences to glass cutting are generated among the knife heads. In addition, because the glass knife is equipped with an electronic level meter, the glass cutting precision is high, and the working efficiency is raised.

Owner:ZIBO VOCATIONAL INST

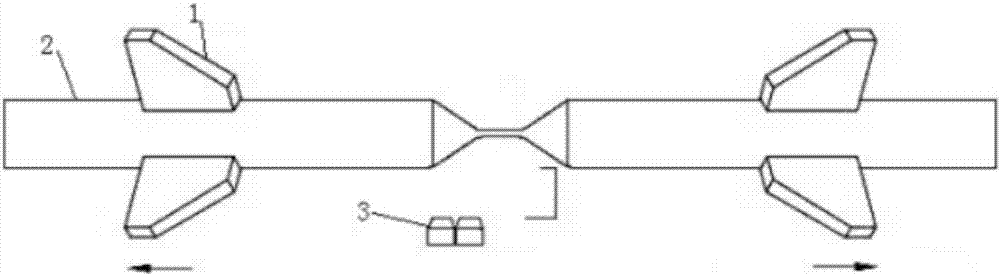

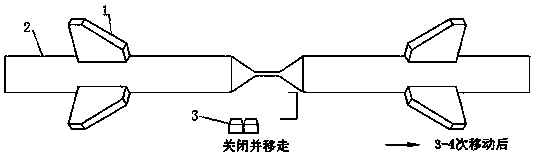

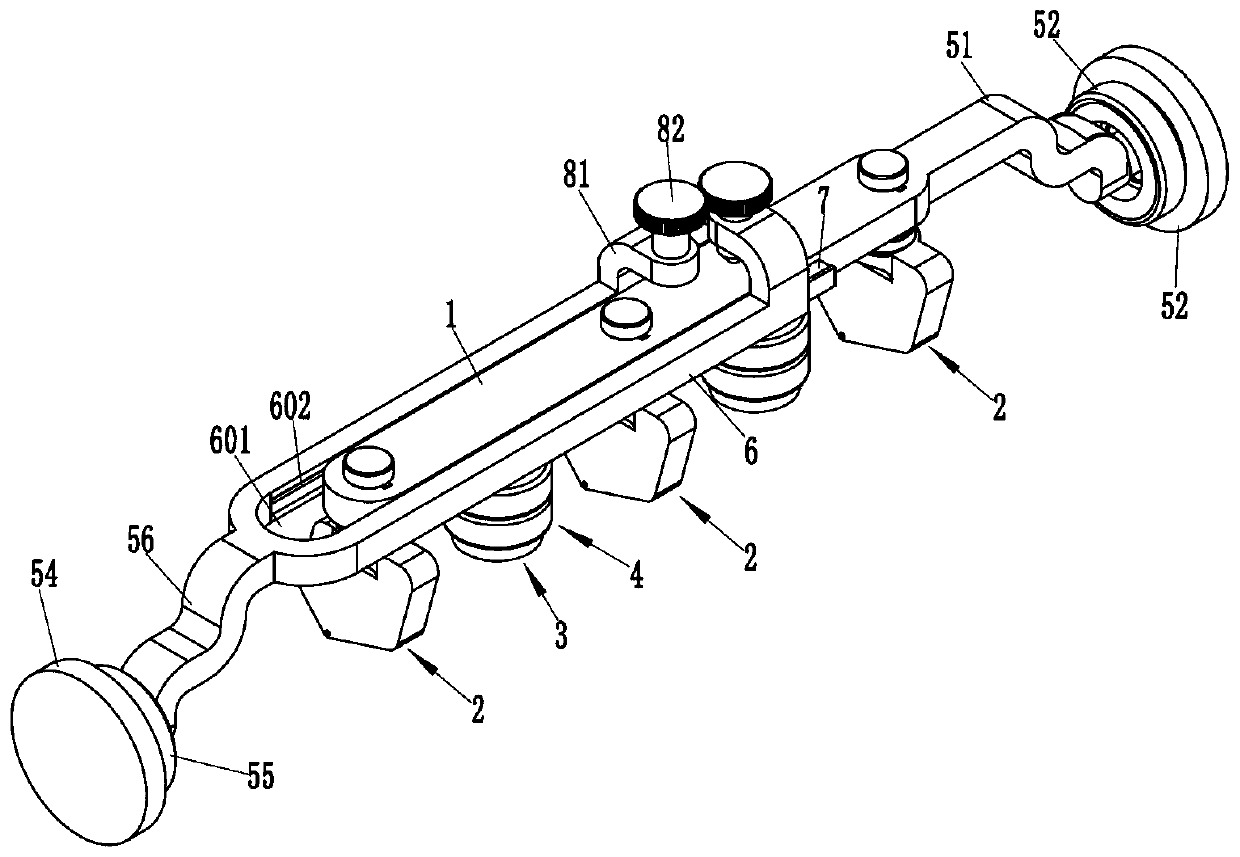

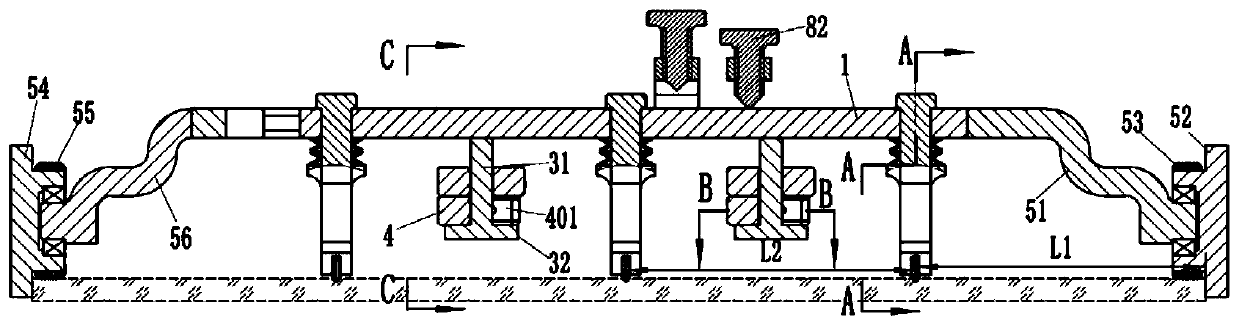

A method for drawing double cones of preform rods

The invention discloses a double tapering method for a preformed rod. The method comprises the steps: clamping the preformed rod on clamping claws at the two ends, aligning at the position needing to be tapered by using lamp caps, preheating the preformed rod, pre-burning by using one lamp cap firstly, starting the second lamp cap, continuously increasing the temperature of the preformed rod to enable the temperature to permeate gradually and starting to taper after determining that the surface layer glass of the preformed rod is in a molten state; fixing the clamping claw on the left side, moving the clamping claw on the right side, locking the clamping claws, continuously heating the maximal variable diameter position of the preformed rod by using the lamp caps, repeating the above operation again, enabling the rod diameter at the tapering position to reach 15 to 16 mm after moving for 3 to 4 times, turning off the lamp caps and moving away, putting the tapering part into a heat-insulating room, slowly cooling, cutting off the thinnest part of the tapering part by using a glass knife, moving the two sections of tapered preformed rod out of the heat-insulating room, and cooling for future use. No loss in the tapering process is guaranteed, scrap of other parameters caused by core cladding ratio change caused by tapering in the wire-drawing process is avoided, and the utilization rate of the preformed rod is effectively increased.

Owner:JIANGSU STERLITE TONGGUANG FIBER

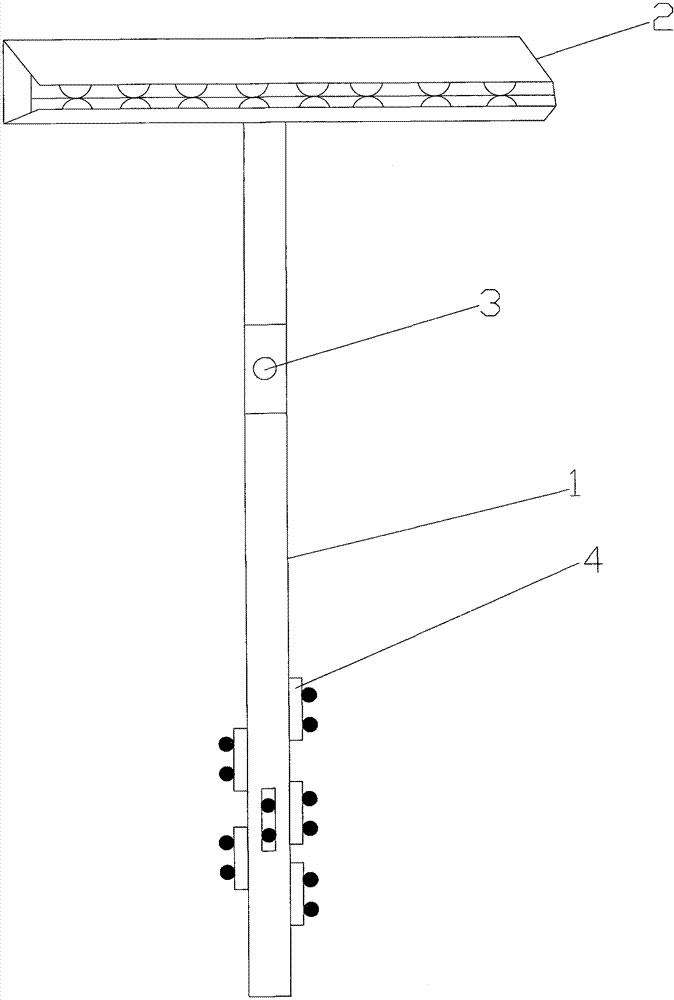

Glass micro-etching cutting device

ActiveCN110240396AImprove cutting efficiencyReduce labor intensityGlass severing apparatusGlass cutterEngineering

The invention discloses a glass micro-etching cutting device, comprising a walking cross beam; the walking cross beam is connected with a plurality of glass cutters which are evenly distributed in a linear way; a plurality of weight bearing block placement racks are fixed on the walking cross beam; a plurality of weight bearing blocks are arranged on the weight bearing block placement racks; a first connecting arm is fixed at the right end of the walking cross beam; the outer end of the first connecting arm is hinged with a positioning wheel; an auxiliary wheel is arranged at the right side of the walking cross beam and is hinged with a second connecting arm; the second connecting arm is fixed with a sliding block; a sliding rail can move left and right on the walking cross beam; the sliding block is provided with lock screws. The glass cutters, which are arranged at equal intervals, of the glass micro-etching cutting device can be used for etching multiple pieces of glass at a time, and the glass etching force of the glass cutters is increased by means of an auxiliary block, so that the glass cutting efficiency can be effectively increased, and the labor intensity is reduced.

Owner:卢明钗

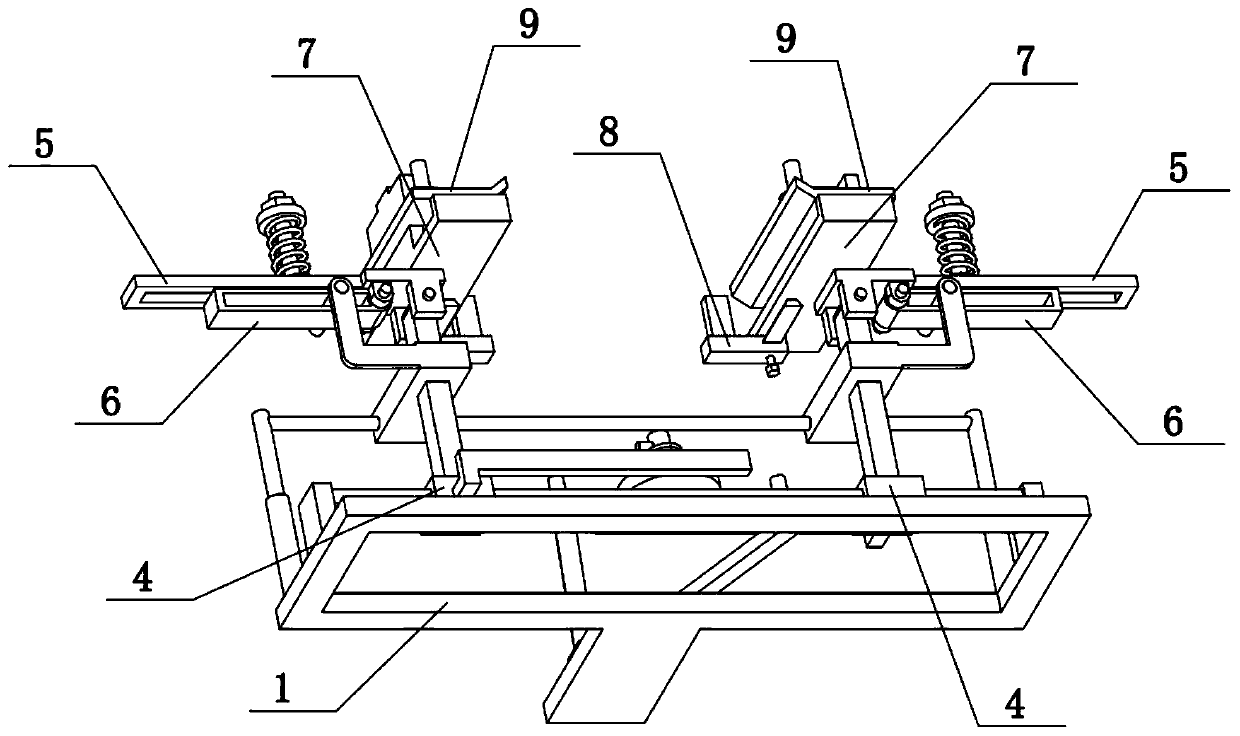

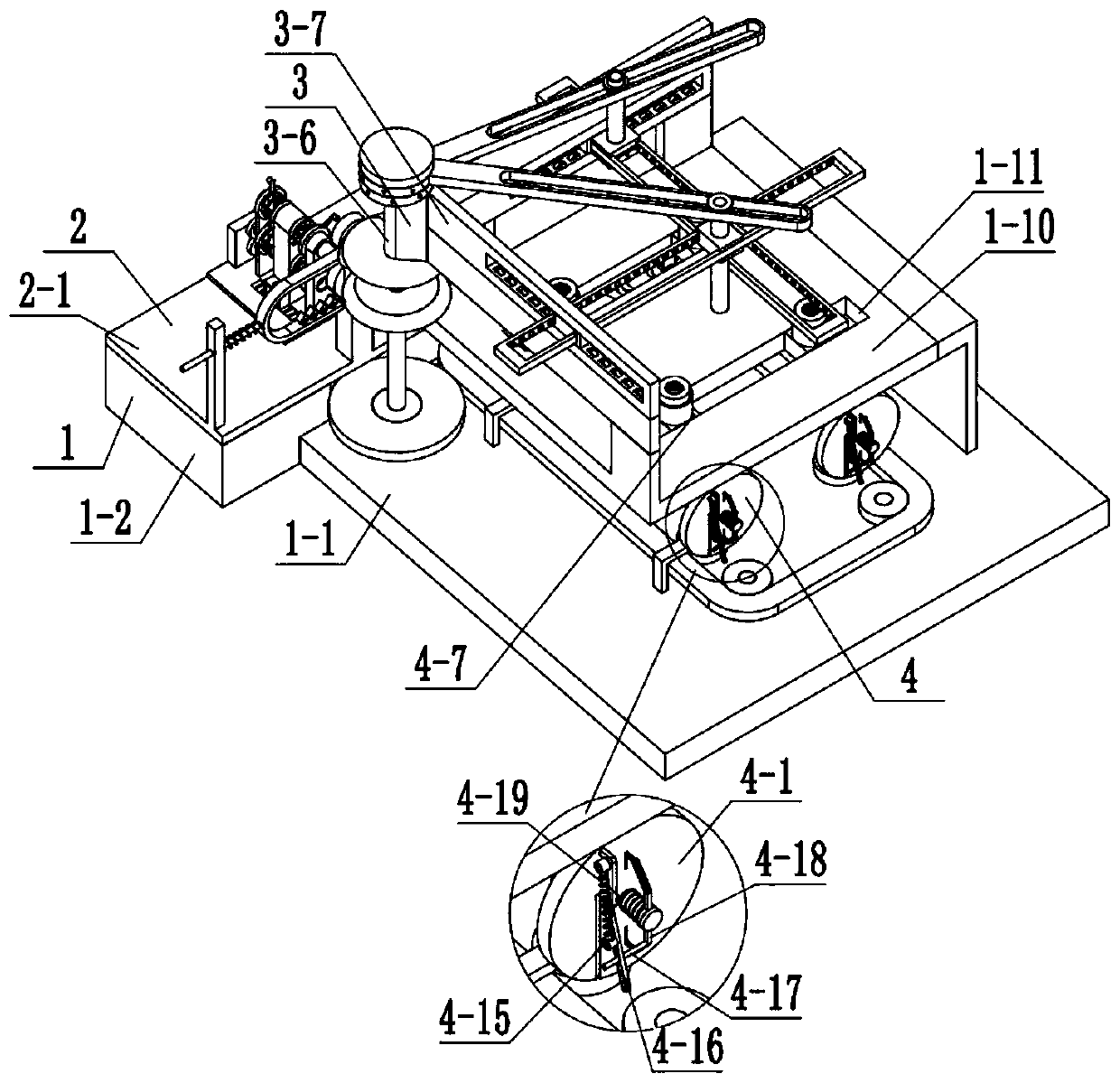

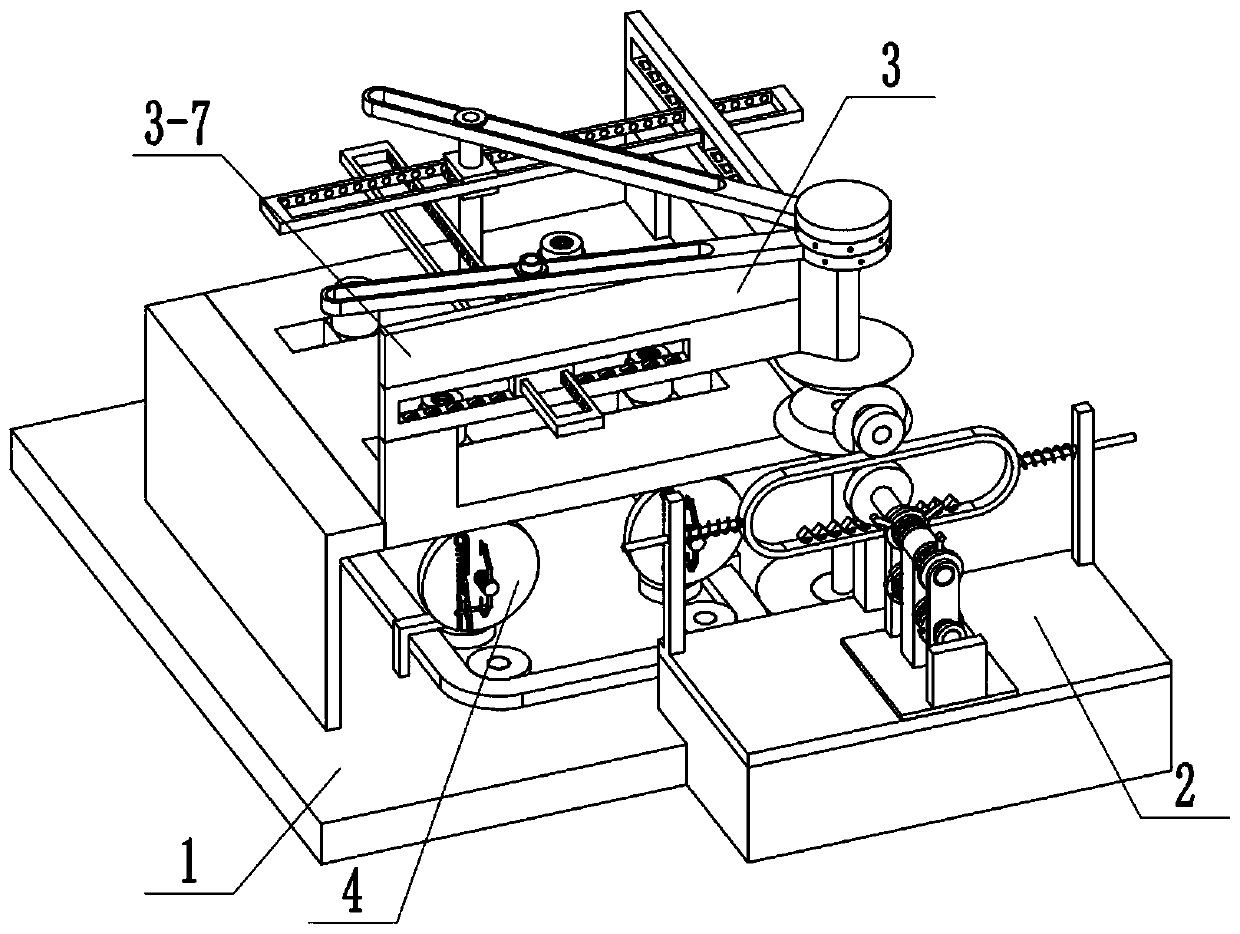

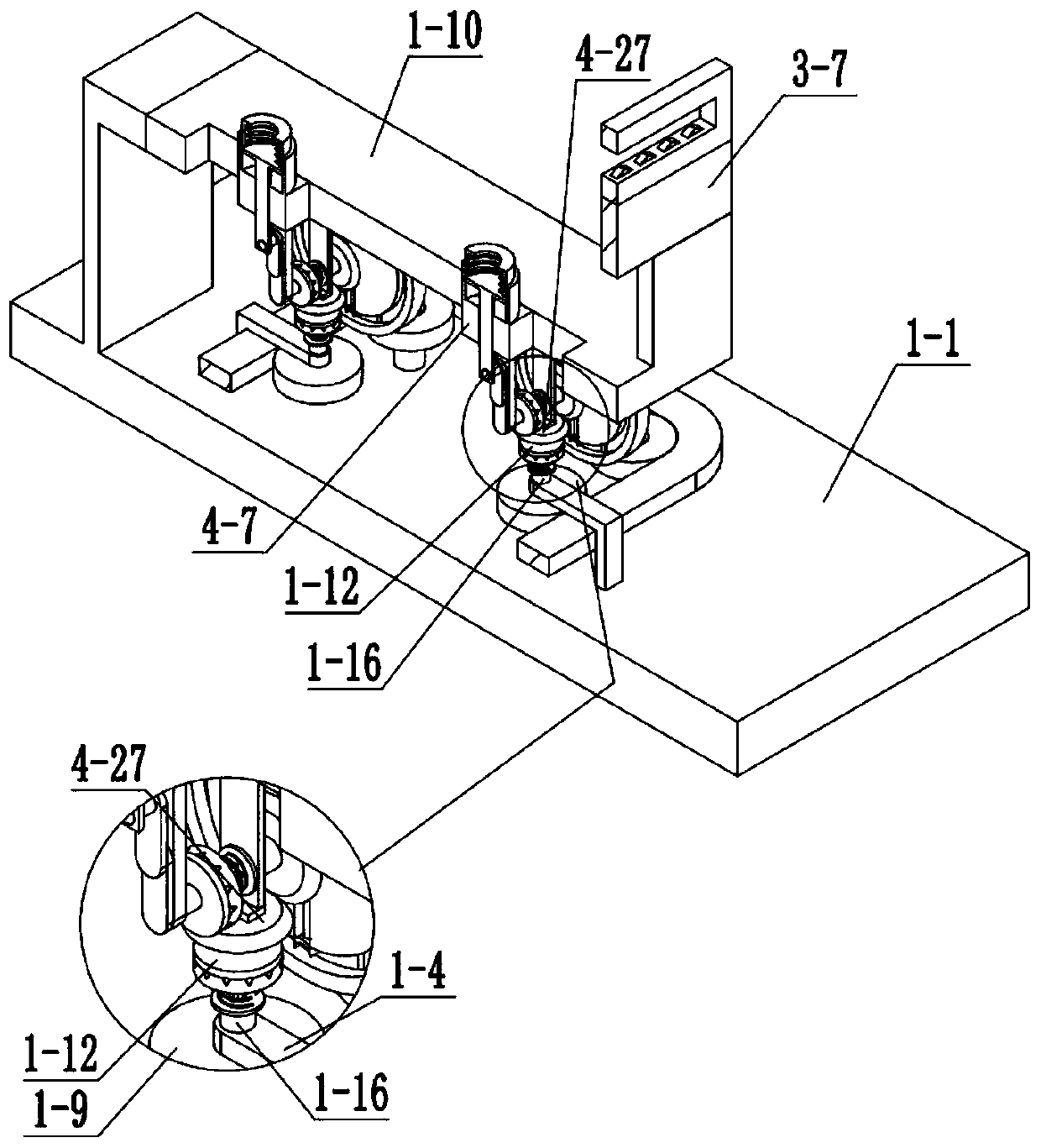

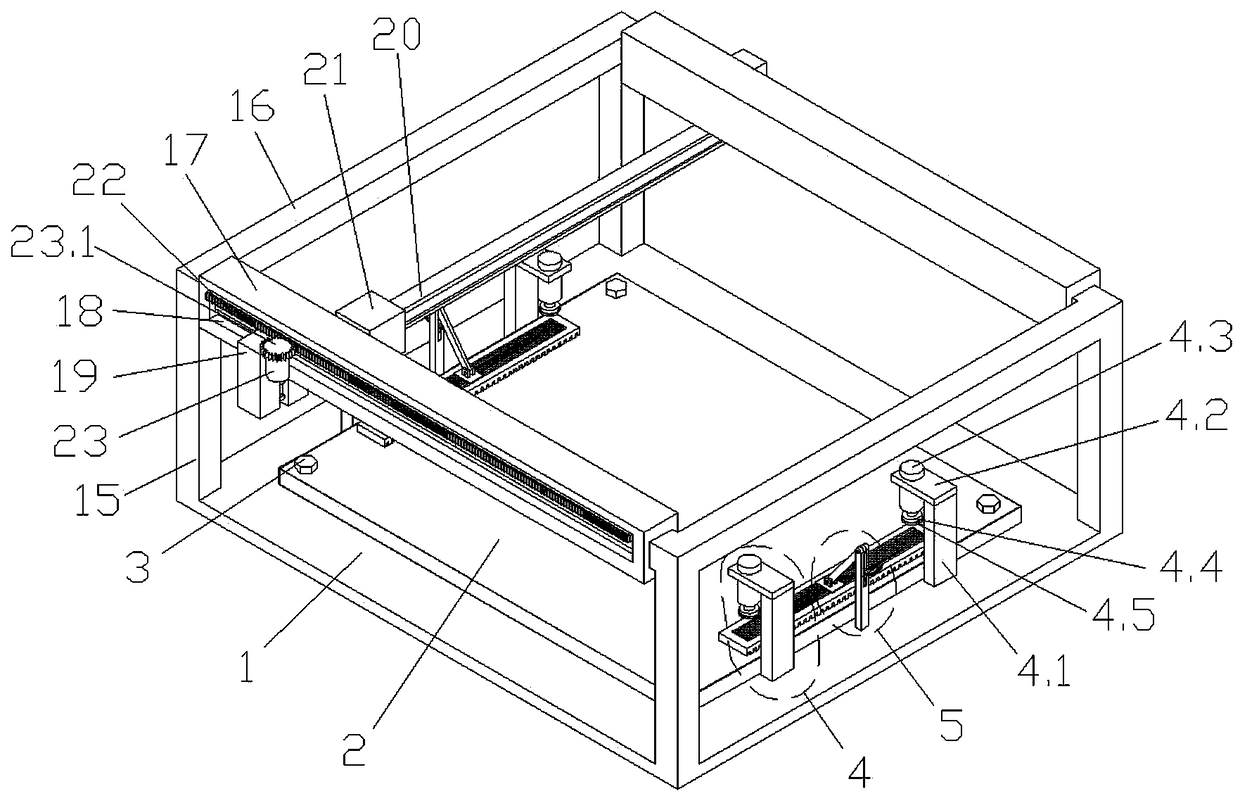

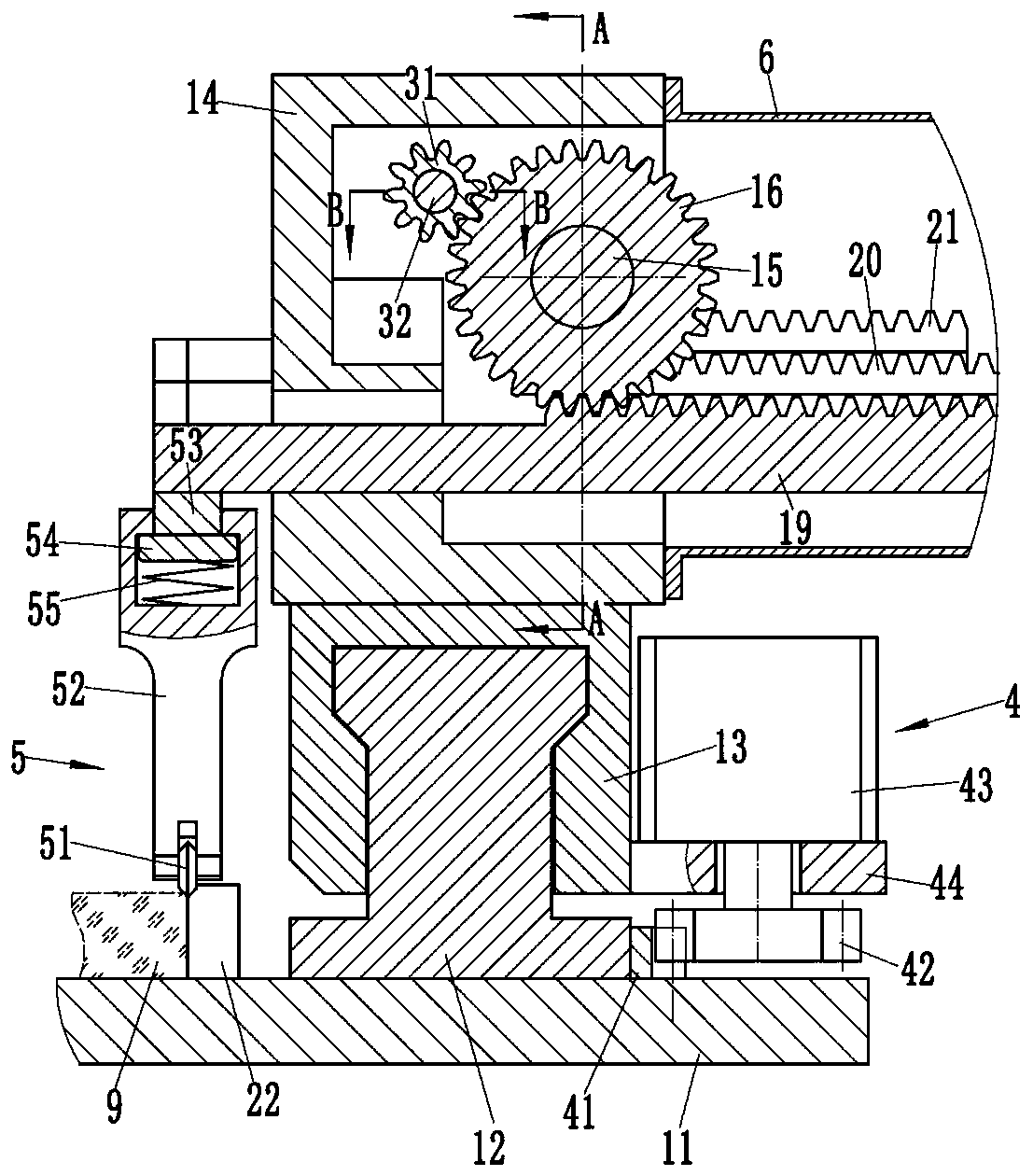

Glass cutting equipment for plastic steel windows

InactiveCN110776249AEasy to removeNo interferenceGlass severing apparatusCutting glassStructural engineering

The invention relates to the field of doors and windows, in particular to glass cutting equipment for plastic steel windows. The equipment can cut glass plates of different lengths and widths, can conveniently fix glass cutters of different specifications, and can improve the glass plate fixing stability. The equipment comprises an underframe combination, a power source, an XY cutting combinationand an adsorption combination. The downward movement amount of an inner end piston along a vertical plate casing pipe is maximum, so that the pressure difference of an external pressure and the pressure in a closed space is maximum, and a glass plate is tightly buckled to a rubber sealing sleeve; when a hinged sliding rod is located at a highest point MAX of a circular sliding groove, the inner end piston returns to an original position, so that the pressure difference between the external pressure and the pressure in the closed space is minimum, and meanwhile the glass plate can be conveniently removed; and when the locating point of the hinged sliding rod in the circular sliding groove has the highest point MAX of the circular sliding groove and a lowest point MIN of the circular slidinggroove, through relative rotation of an upper end clutch rod and a middle end clutch rod, transmission between a driving belt pulley 3 and a hinged rod bevel gear cannot be interfered.

Owner:刘培华

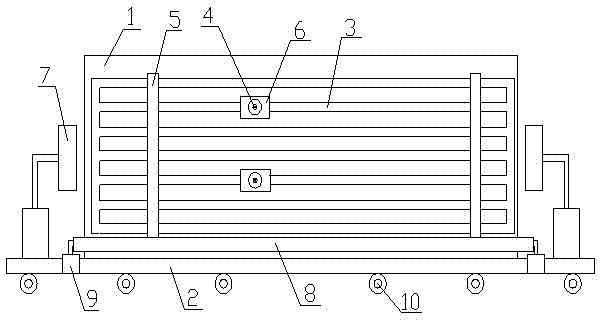

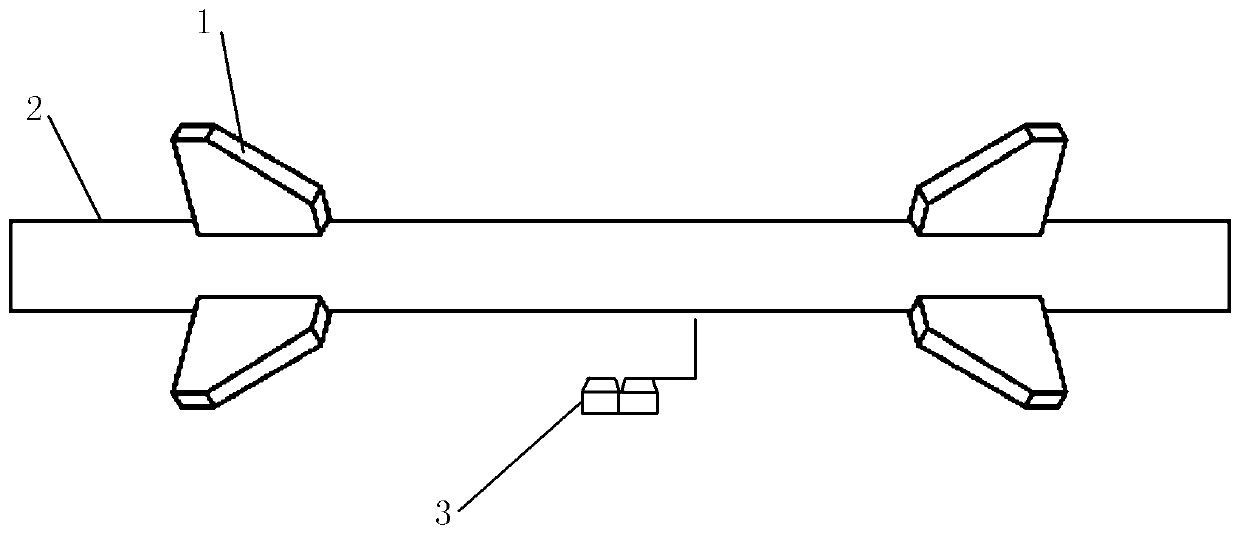

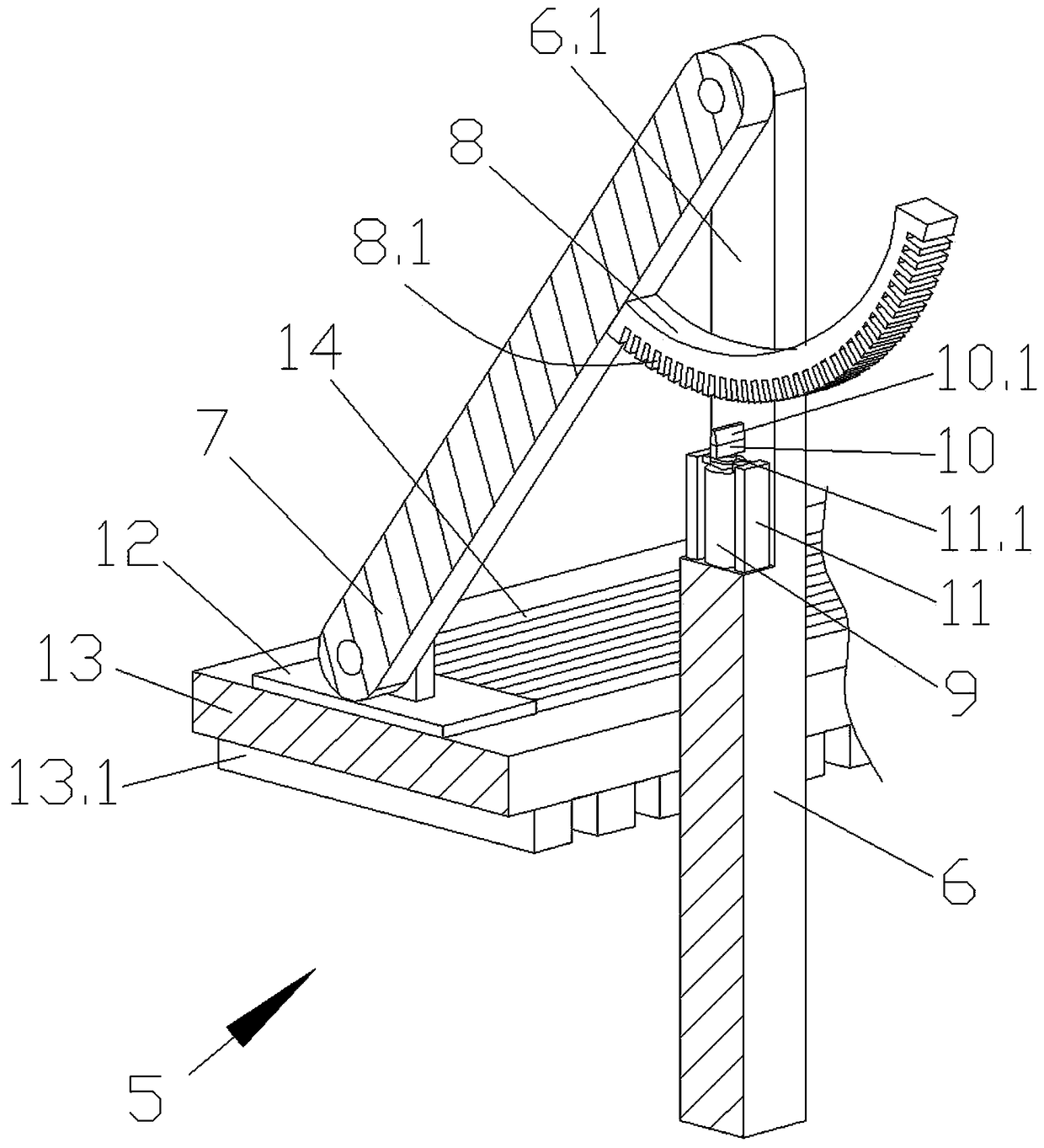

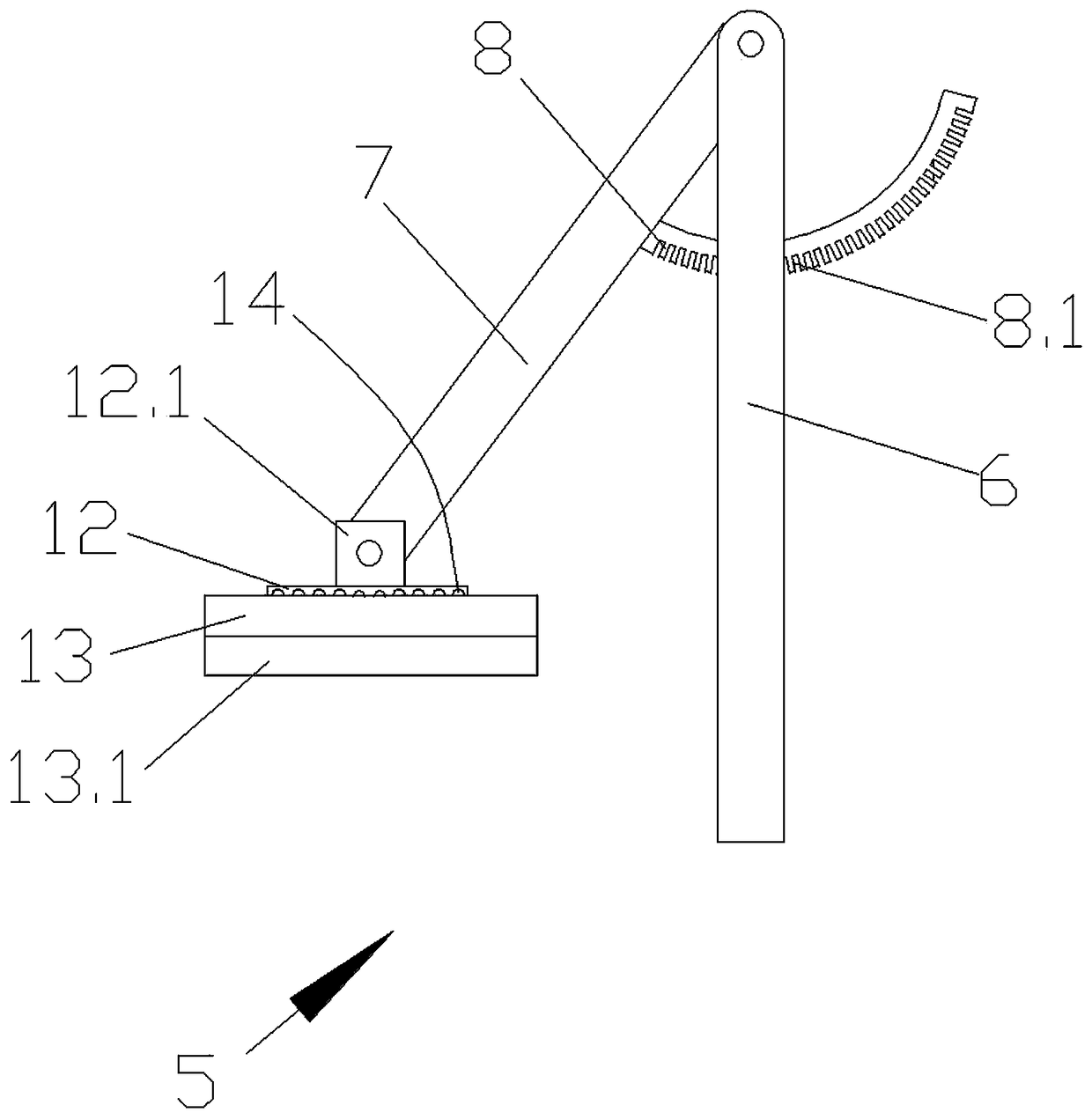

Glass cutting machine with pressing devices

The invention discloses a glass cutting machine with pressing devices. The glass cutting machine comprises a bottom plate, a base plate is arranged on the upper side of the bottom plate, and a group of bolts used for fixing the base plate to the bottom plate are arranged on the base plate; two pressing plates are arranged on the upper side of the base plate, and each pressing plate is fixed through one pressing device. Each pressing device comprises a stand column, wherein one end of a pressing rod is hinged to the stand column, an arc plate is arranged on one side of the pressing rod, a groupof square inserting grooves are formed in the lower side of the arc plate, and a hydraulic cylinder is arranged at the bottom of a groove. The glass cutting machine with the pressing devices has theadvantages that glass plates placed on the base plate can be fixed, the situation that the glass plates are moved due to friction between a glass knife and the glass plates when the cutting machine cuts the glass plates and accordingly cutting deviations are caused is avoided, and the hydraulic cylinders are used for pressing the plates downwards so that time and labor can be saved.

Owner:安徽锐利玻璃机械有限公司

Laser cutting device for noninvasive OLED glass substrate

The invention relates to the technical field of OLED panel processing, and discloses a laser cutting device for a noninvasive OLED glass substrate. The device comprises a stand, a vacuum adsorption type workbench for storing the glass substrate is arranged at the upper end of the stand, a cutting assembly is arranged on one side of the upper portion of the stand, the cutting assembly comprises a glass cutter used for conducting primary collision on the glass substrate and a laser lens used for cutting the glass substrate, the cutting assembly is fixed to the upper end of a first X-axis linearmodule, the first X-axis linear module drives the cutting assembly to penetrate through the lower portion of the vacuum adsorption type workbench, a breaking assembly is further arranged above the vacuum adsorption type workbench, the breaking assembly comprises a breaking knife arranged in a lifting mode, and the breaking knife is used for separating the cut glass substrate. The glass cutter andthe linear CO2 laser are combined to guide crack type scribing of the glass, and the breaking cutter is matched, so the cutting speed is high, and trimming is not needed after processing is completed.

Owner:AENEQ CO LTD

Glass bottle girdling method and device

PendingCN112456779ASmooth fracture surfaceReduce mistakesGlass severing apparatusEngineeringGlass cutter

The invention discloses a glass bottle girdling method and device, and the method comprises the steps: removing the bottom of a glass bottle, and enabling the lower end of the glass bottle to be opened, the glass cutter comprises an operation table, a glass cutter supporting rod is movably arranged on the operation table, a glass cutter is arranged at the end of the glass cutter supporting rod, and the axis of the glass cutter supporting rod is perpendicular to the cutter face of the glass cutter. A glass bottle placing frame used for limiting the glass bottle is further arranged on the operation table, when the glass bottle to be cut is placed on the glass bottle placing frame, the glass cutter supporting rod is moved to be placed in the glass bottle, the cutting edge of the glass cuttermakes contact with the interior of the glass bottle, the glass bottle is rotated, a circle of scratches are formed in the glass bottle through the glass cutter, the outer surface of the scratch of theglass bottle is heated, and the glass bottle is rotated during heating, so that the glass bottle is broken along the scratch. The scratches slide out of the glass bottle, so that the glass bottle explodes along the scratches due to the characteristics of the glass bottle, the fracture surface of the glass bottle is smooth and flat, and errors can be greatly reduced when the stress of a glass sheet is detected.

Owner:四川天马玻璃有限公司

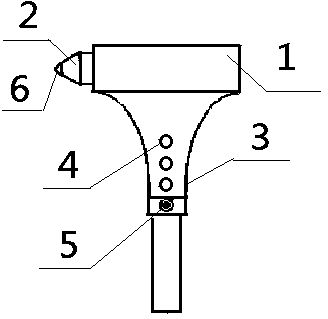

Extensible-handle multifunctional safety hammer

InactiveCN104339321ASave spaceEasy to smashPedestrian/occupant safety arrangementHand hammersExtensibilityGlass knife

The invention provides an extensible-handle multifunctional safety hammer which comprises a handle and a hammer head arranged at the front end of the handle. The handle comprises a front half section connected with a hammer body, and a rear half section capable of extending and contracting along the axial direction of the handle, and a glass knife is arranged in front of the tip of the hammer head. Due to extensibility of the handle, space is saved when the safety hammer is not in use at ordinary times; the glass knife is arranged, so that convenience is brought to passengers to smash or scratch glass during an emergency; a fluorescent coating is arranged on a spring button, so that convenience is brought to the passengers to find the safety hammer when an automobile is in a safety accident at night.

Owner:XIAN DASHENG FIRE DETECTION

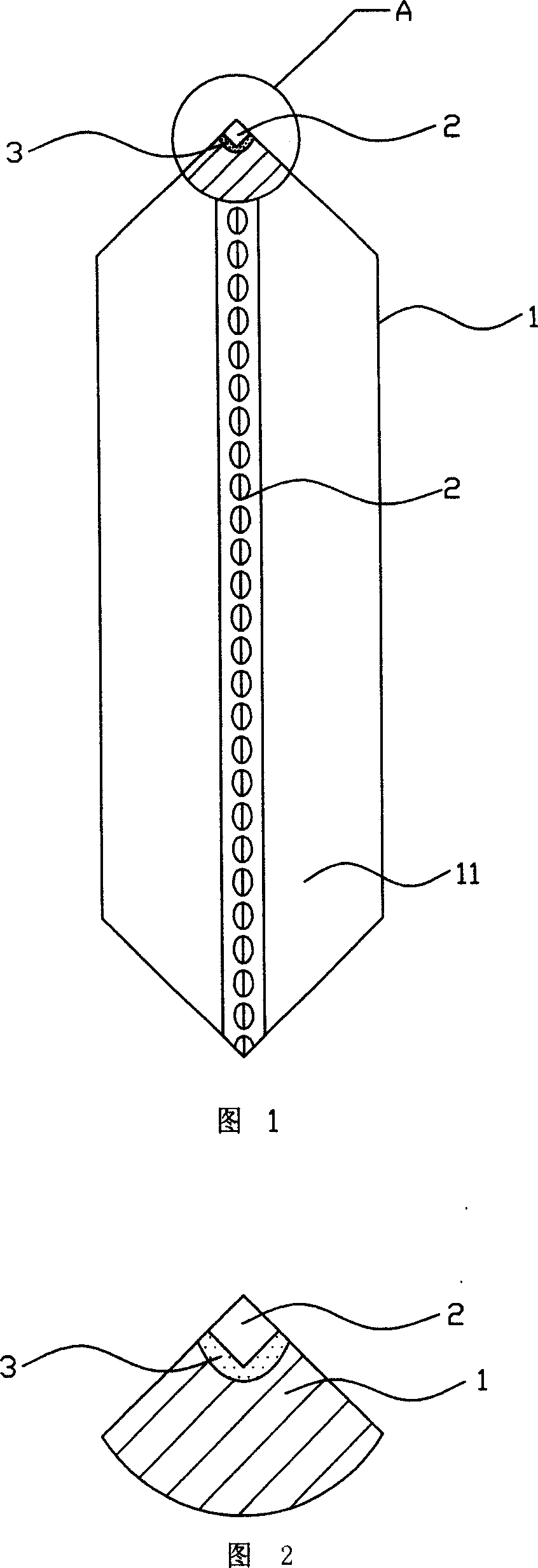

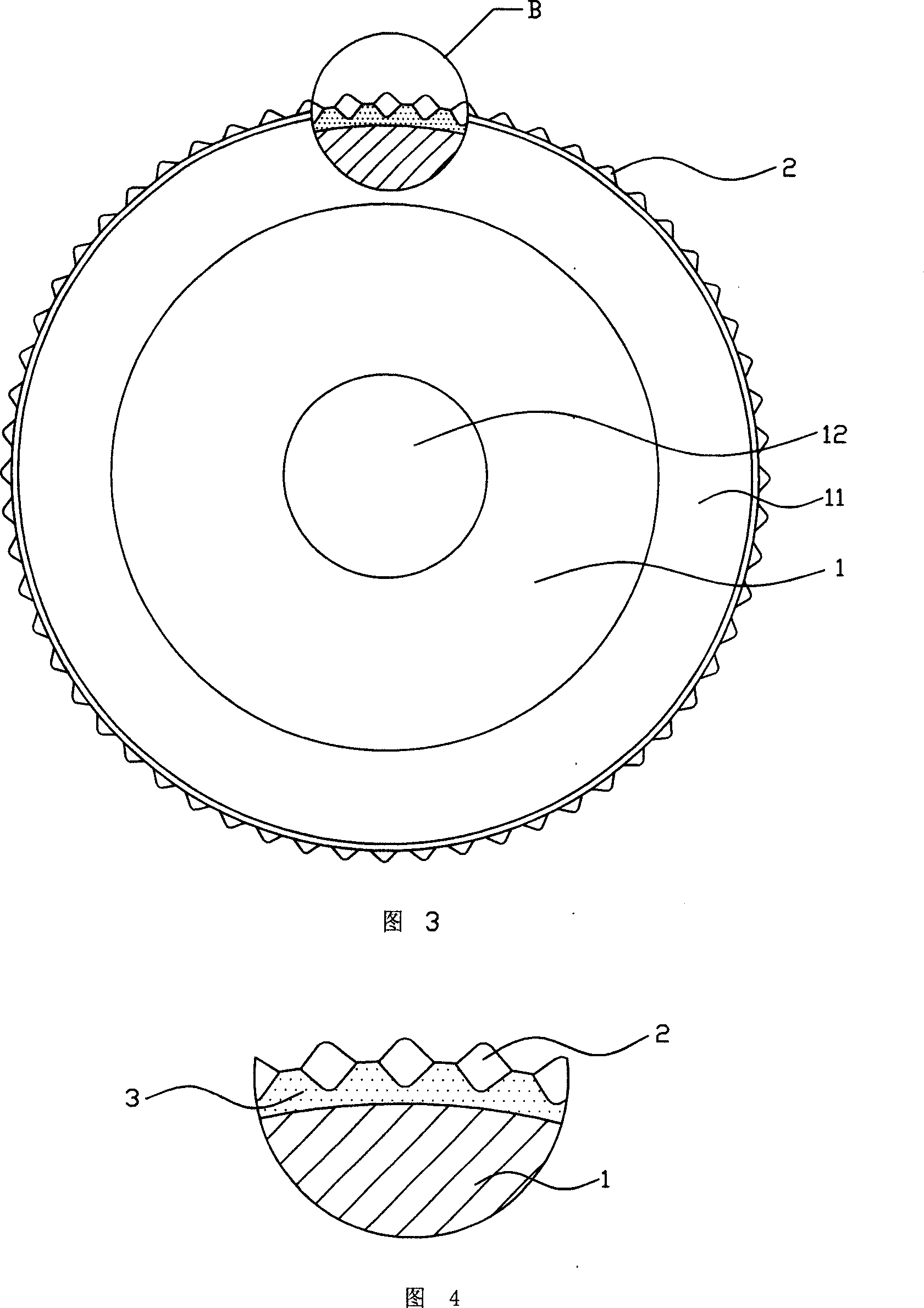

Glass knife disc and preparing method thereof

InactiveCN101143761AImprove welding strengthExtended service lifeGlass severing apparatusFlat glassLiquid-crystal display

A glass cutter disk is contrived to make scratches on glass. A tip of a blade portion of the disk is soldered with a row of highly-hard diamond particles to make deep scratches with less fractures and scraps, which is particular useful in cutting liquid crystal display panels. The disk is constructed in such a way that the diamonds are glued in place and secured by soldering, which can dramatically reduce the manufacturing cost plus simple and practical processing method.

Owner:XIAMEN CHIA PING DIAMOND IND CO LTD

Glass cutter

InactiveCN106630574AEasy to fixPrevent the opening from being out of roundGlass severing apparatusEngineeringGlass knife

The invention relates to a glass cutter. The glass cutter comprises a positioning device and a cutting device. The cutting device is rotated around the positioning device. The positioning device comprises a cone funnel. A sucking disc is installed under the cone funnel. The sucking disc is connected with a spanner above the cone funnel. The cutting device comprises a positioning rod and a cutter frame. One end of the positioning rod is provided with a sleeve. The sleeve is sheathed on the cone funnel. The cutter frame is provided with a cutter head. The cutter frame is cylinder-shaped. The upper end of the cutter frame is opened and provided with a groove along the axis. The width of the groove is 1-1.5 mm wider than that of the positioning rod. Two sides of the groove are provided with a clamping body. The outer side of the clamping body is provided with an external thread. The clamping body is matched with a fastening knob. The cutter frame is provided with a groove. The positioning rod passes through the groove, and is capable of fixing the cutter frame and the positioning rod by the fastening knob tightly. The aspheric tapping or failure caused by the sliding between the cutter frame and cutter rod in the feeding process can be prevented.

Owner:桐城市五强彩钢制品有限公司

Multifunctional glass cutting apparatus

InactiveCN105502907AImprove cutting efficiencyEasy to operateGlass severing apparatusDrive shaftGlass cutter

The invention discloses a multifunctional glass cutting apparatus, comprising a support, a transverse moving base, a transverse moving motor, a transverse moving transmission shaft, a compression wheel, a knocking motor, support legs, hydraulic cylinders, a glass carrier plate, a glass cutter holder and a glass cutter. The support legs are disposed on the lower portion of the support. A vertical moving motor is connected with a belt transmission shaft which is fitted with belt pulleys which are fitted with a transmission belt, a cover plate is fixedly mounted on the upper portion of the support, the lower portion of the cover plate is provided with fixed teeth, the transverse moving motor is fitted with the transverse moving transmission shaft which is fitted with the compression wheel, the knocking motor is mounted on the side of the compression wheel, the glass cutter holder is mounted on the lower portion of the transverse moving base, and the glass cutter is mounted on the glass cutter holder. The multifunctional glass cutting apparatus can cut various curvilinear edges, is high in cutting efficiency, is simple to operate, is suitable for glass different in thickness, and is convenient to adjust, simple in structure and low in investment cost.

Owner:江门市晶美玻璃制品有限公司

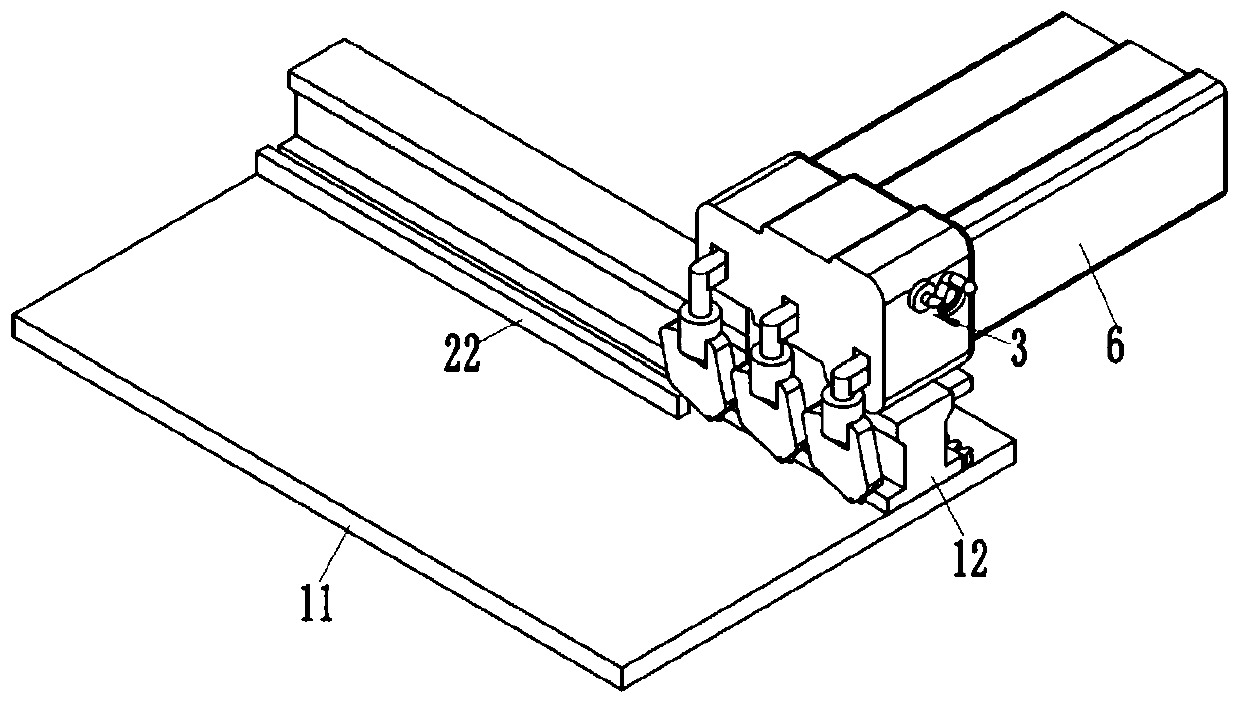

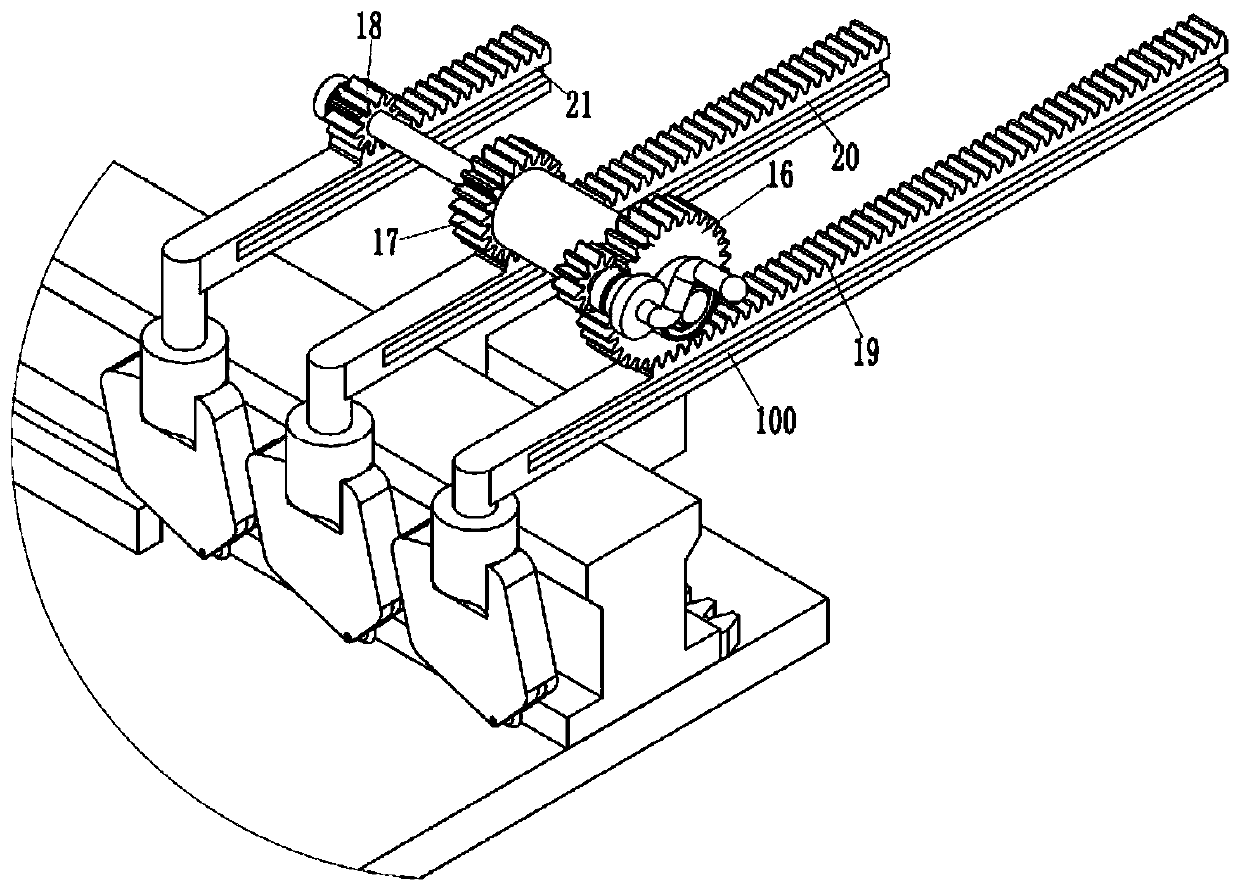

Interval-adjustable automatic micro-scribing glass cutting device

ActiveCN110015841AAdjust spacingImprove cutting efficiencyGlass severing apparatusGlass knifeGlass cutter

The invention discloses an interval-adjustable automatic micro-scribing glass cutting device. The device comprises a flat plate; a sliding rail which is arranged in the front-back direction is fixed at the right end of the flat plate; a sliding block sleeves the sliding rail; the sliding block is provided with a driving device for driving the sliding block to move back and forth; a case with a right opening is fixed on the sliding block; a rotating shaft is hinged to the interior of the case; a large gear, a middle gear and a small gear are fixed on the rotating shaft; the large gear is meshedwith a first rack; the middle gear is meshed with a second rack; the small gear is meshed with a third rack; the second rack, the third rack and the first rack are slidably connected to the left sidewall of the case; each of the left end of the second rack, the left end of the third rack and the left end the first rack is fixed with a glass cutter; the large gear is provided with a driving limiting device; and a rectangular positioning strip which is parallel to the sliding rail is fixed on the flat plate. According to the invention, glass can be cut into multiple pieces at one time, and thecutting distance can be adjusted, so that cutting efficiency can be effectively improved.

Owner:深圳市星昭晖光电科技有限公司

Double tapering method for preformed rod

Owner:江苏斯德雷特光纤科技有限公司

Circular glass cutting machine

InactiveCN108706864ASimple structureImprove cutting efficiencyGlass severing apparatusAgricultural engineeringGlass cutter

The invention discloses a circular glass cutting machine which comprises a mounting plate, wherein an upper fixing plate is arranged on the mounting plate; the mounting plate is fixed on the upper fixing plate by virtue of four connecting rods; a rotary handle is arranged below the mounting plate and connected onto a motor shaft of a stepping motor; the stepping motor is mounted at the central position on the mounting plate; a knife rest is arranged on the rotary handle; a glass cutter is arranged in the knife rest; a connector is arranged below the rotary handle; an upper sucker is arranged in the center of the connector and is used for adsorbing glass; in order to ensure stabilization during glass cutting, four telescopic lower suckers are arranged below the glass; the lower suckers aremounted on an operating platform; and the operating platform is fixed on the ground by virtue of a support frame. The circular glass cutting machine disclosed by the invention is novel in structure, reasonable in design and convenient to operate and can be widely used.

Owner:陈卫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com