Rounded glass cutting machine

A cutting machine and glass technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high labor consumption and poor safety, achieve convenient operation, improve safety, and reduce accidental scratches the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

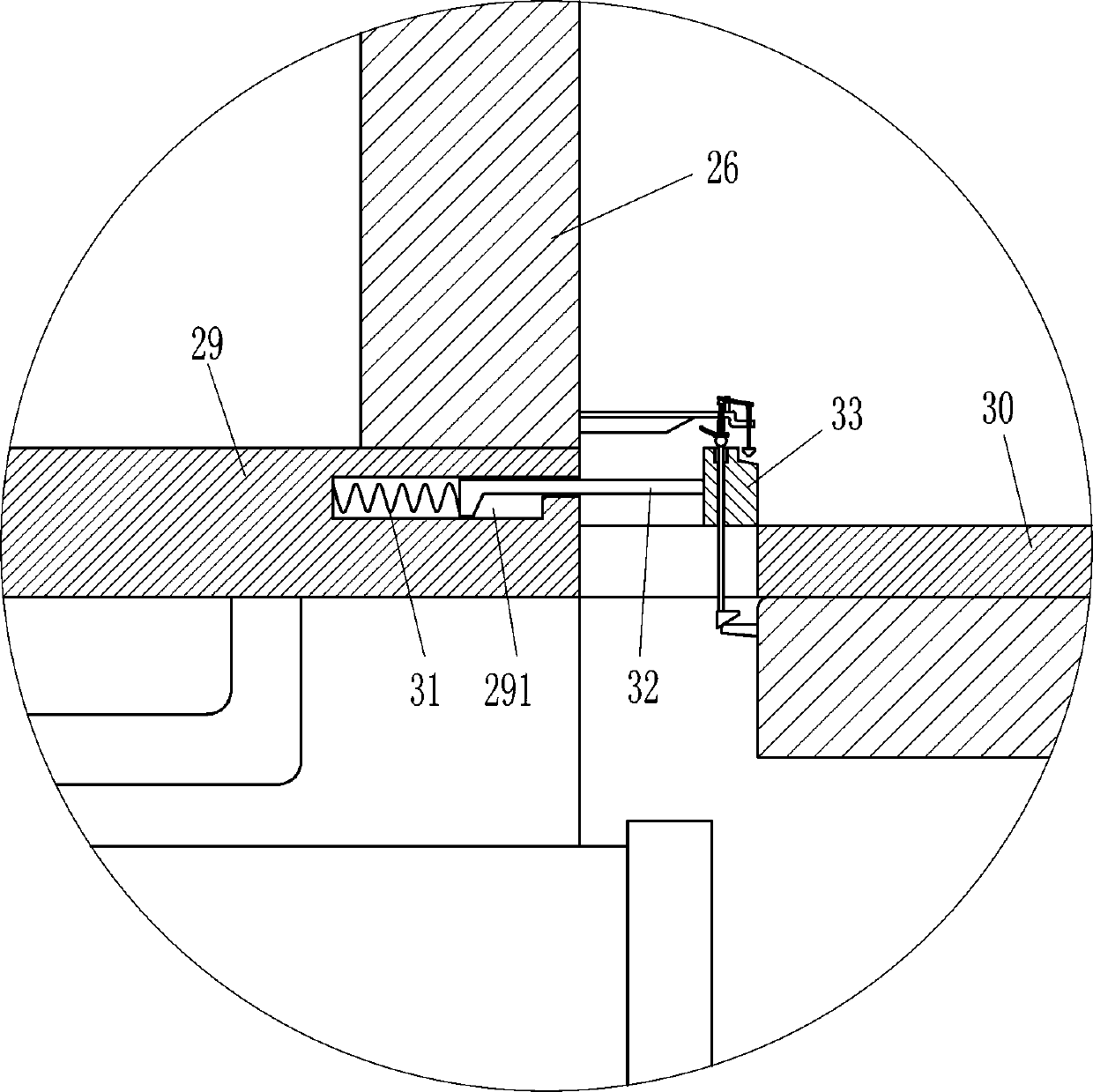

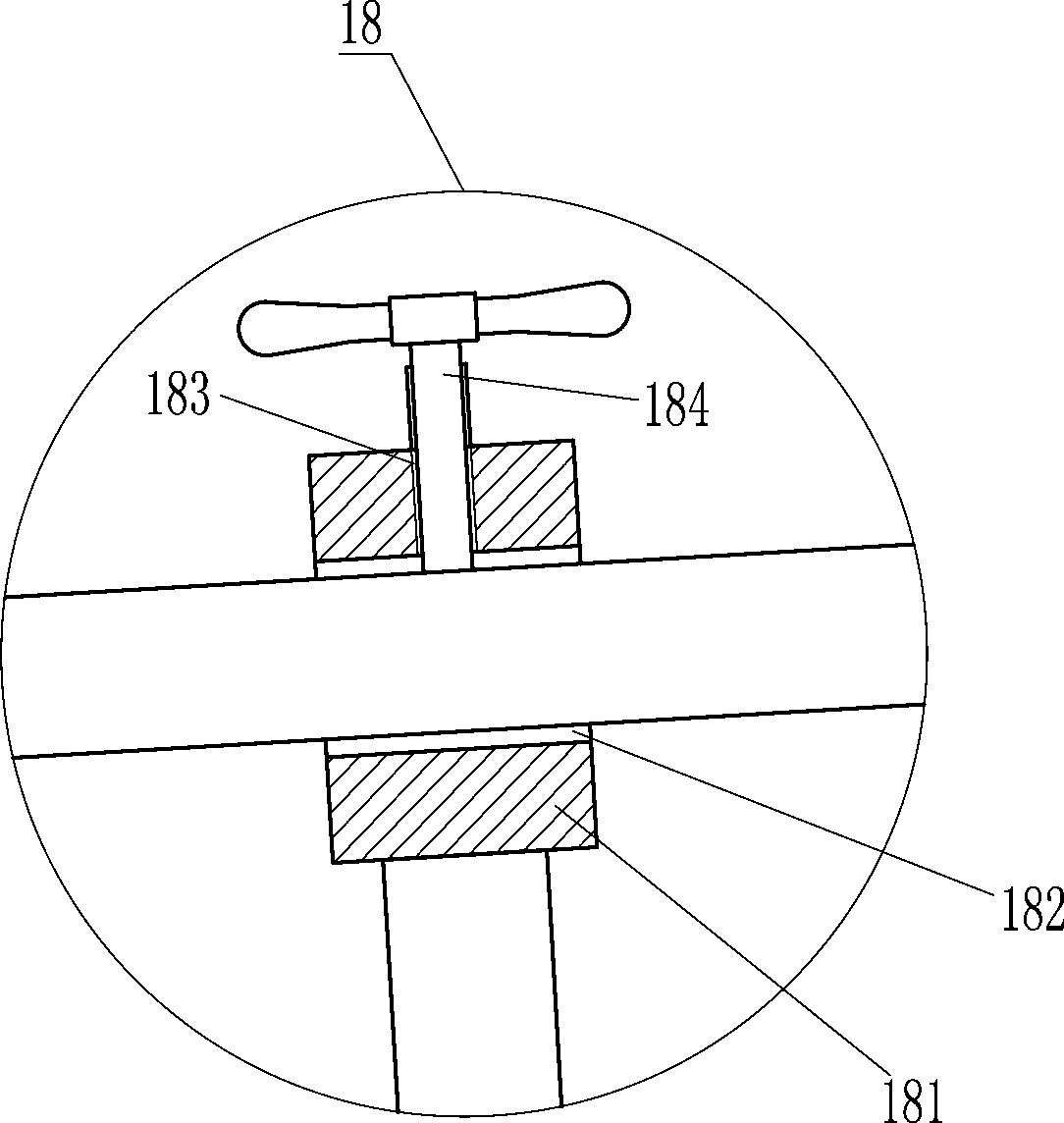

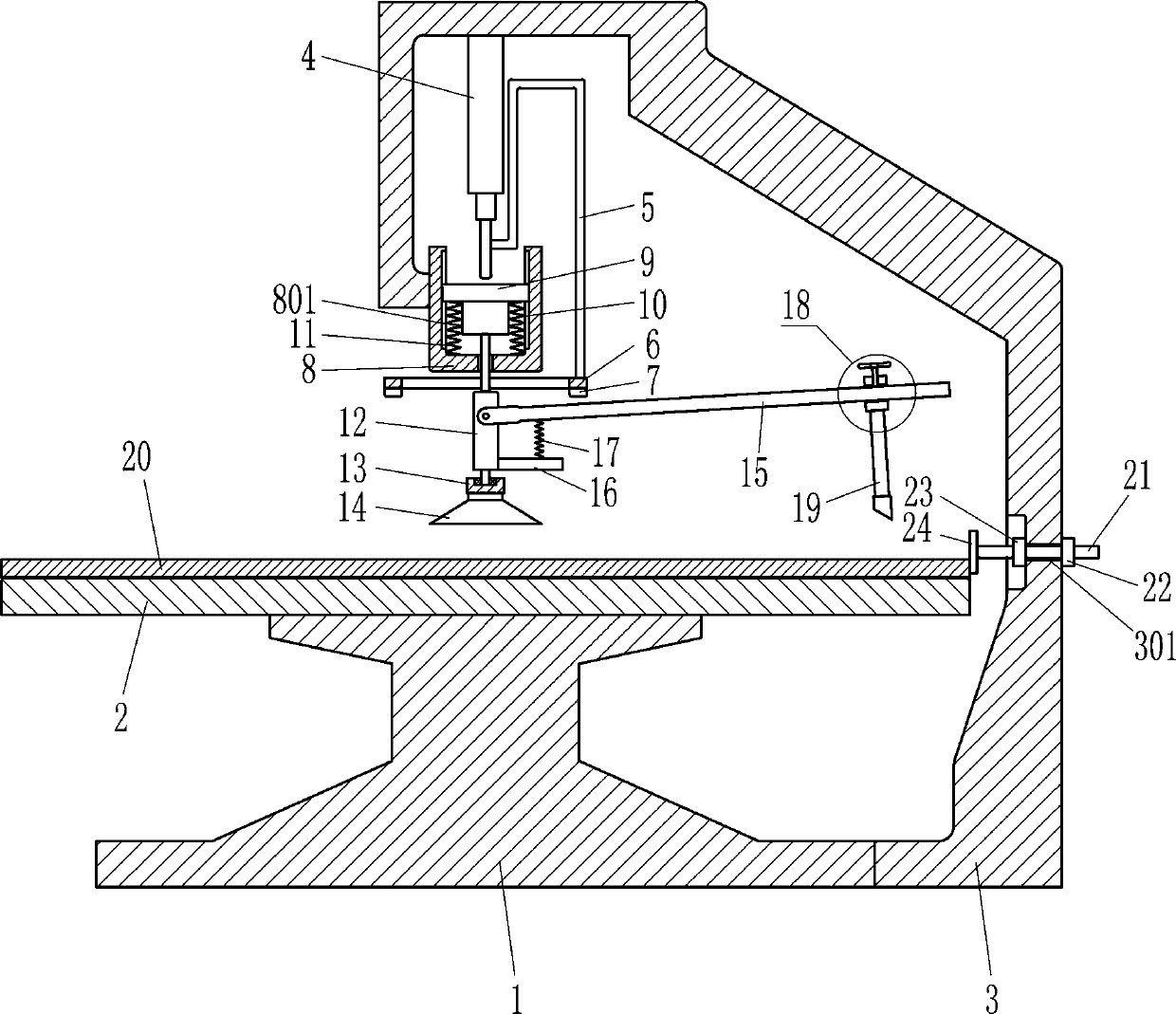

[0019] A round glass cutting machine such as Figure 1-2 As shown, it includes a base 1, a platform 2, a frame 3, a first cylinder 4, an N-shaped rod 5, an iron ring 6, a pressing block 7, a U-shaped frame 8, a first mounting plate 9, a motor 10, a first Spring 11, connecting plate 12, bearing seat 13, rubber pressure plate 14, scale rod 15, horizontal plate 16, second spring 17, adjustment mechanism 18 and glass cutter 19, platform 2 is connected to the upper part of base 1, and base 1 passes through The way of welding connection is connected with the platform 2, the lower part of the right side of the base 1 is connected with the frame 3, the first cylinder 4 is installed on the top of the inner side of the frame 3, and the telescopic rod of the first cylinder 4 is connected with the N-shaped rod 5. 3. A U-shaped frame 8 is connected to the lower part of the inner left side. The inner wall of the U-shaped frame 8 has a chute 801. The U-shaped frame 8 is slidably connected to...

Embodiment 2

[0021] A round glass cutting machine such as Figure 1-2 As shown, it includes a base 1, a platform 2, a frame 3, a first cylinder 4, an N-shaped rod 5, an iron ring 6, a pressing block 7, a U-shaped frame 8, a first mounting plate 9, a motor 10, a first Spring 11, connecting plate 12, bearing seat 13, rubber pressure plate 14, scale rod 15, horizontal plate 16, second spring 17, adjustment mechanism 18 and glass knife 19, platform 2 is connected to the upper part of base 1, base 1 right The lower part of the side is connected with a frame 3, the top of the inside of the frame 3 is equipped with a first cylinder 4, the telescopic rod of the first cylinder 4 is connected with an N-shaped rod 5, and the lower left side of the frame 3 is connected with a U-shaped frame 8. The inner wall of the type frame 8 has a chute 801, and the U-shaped frame 8 is slidingly connected with a first mounting plate 9, the first mounting plate 9 is matched with the chute 801, and a motor 10 is inst...

Embodiment 3

[0024] A round glass cutting machine such as Figure 1-2 As shown, it includes a base 1, a platform 2, a frame 3, a first cylinder 4, an N-shaped rod 5, an iron ring 6, a pressing block 7, a U-shaped frame 8, a first mounting plate 9, a motor 10, a first Spring 11, connecting plate 12, bearing seat 13, rubber pressure plate 14, scale rod 15, horizontal plate 16, second spring 17, adjustment mechanism 18 and glass knife 19, platform 2 is connected to the upper part of base 1, base 1 right The lower part of the side is connected with a frame 3, the top of the inside of the frame 3 is equipped with a first cylinder 4, the telescopic rod of the first cylinder 4 is connected with an N-shaped rod 5, and the lower left side of the frame 3 is connected with a U-shaped frame 8. The inner wall of the type frame 8 has a chute 801, and the U-shaped frame 8 is slidingly connected with a first mounting plate 9, the first mounting plate 9 is matched with the chute 801, and a motor 10 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com