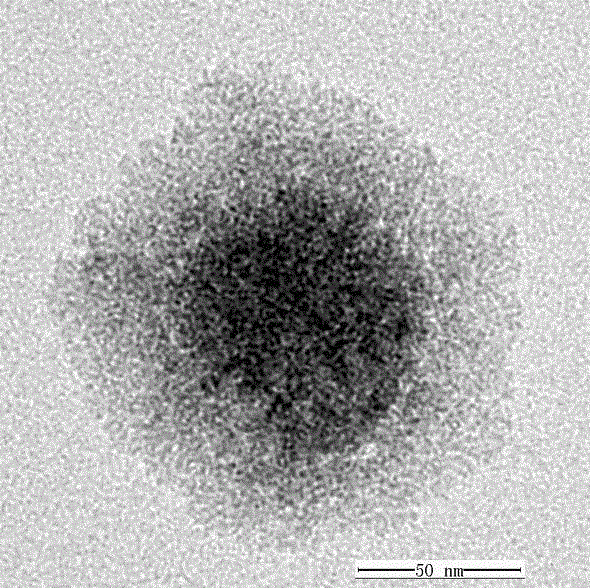

Preparation method for superparamagnetic nanoparticle photocatalyst with Fe3O4-PAMAM-TiO2 core-shell structure

A technology of fe3o4-pamam-tio2 and nanoparticles, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc. Reduce the size of the magnetic particle, reduce the dispersion of magnetic particles, etc., to avoid the reduction of the specific surface area, slow down the oxidation and dissolution, and avoid the effect of particle aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step (1): Superparamagnetic Fe 3 O 4 -Preparation of PAMAM nanoparticle colloidal solution: the concentration is 1×10 -5 The 6th-generation PAMAM dendrimers whose mol / L end groups are hydroxyl groups are filled with nitrogen and mechanically stirred for 60 minutes, then the iron salt mixture is added. The concentration of iron trichloride in the iron salt mixture is 1 mol / L , The concentration ratio of ferric chloride to ferric chloride is 2, and the amount of iron salt mixture added is Fe 3+ The ratio of the substance to the PAMAM dendrimer is 200:1 as the standard. Nitrogen is introduced at room temperature and stirred for 8 hours, then the temperature of the water bath is adjusted to 70℃, the stirring speed is increased to 800 rpm or more, and the concentration is 1 dropwise. ×10 -3 mol / L sodium hydroxide aqueous solution to pH 12, continue to stir for 60 min, then superparamagnetic Fe 3 O 4 -PAMAM nanoparticle colloidal solution.

[0022] Step (2): The surface is full...

Embodiment 2

[0026] Step (1): Superparamagnetic Fe 3 O 4 -Preparation of PAMAM nanoparticle colloidal solution: the concentration is 1×10 -5 The 6th-generation PAMAM dendrimer solution with the mol / L end group as ester group is filled with nitrogen and mechanically stirred for 40 minutes, and then the iron salt mixture is added. The concentration of iron trichloride in the iron salt mixture is 1 mol / L, the concentration ratio of ferric chloride to ferric chloride is 2, and the amount of iron salt mixture added is Fe 3+ The ratio of the substance to the PAMAM dendrimer is 120:1 as the standard. Nitrogen is introduced at room temperature and stirred for 6 hours, then the temperature of the water bath is adjusted to 80°C, the stirring speed is increased to 800 rpm or more, and the concentration is 1 dropwise. ×10 -2 mol / L sodium hydroxide aqueous solution to pH 11, continue to stir for 50 min, then superparamagnetic Fe 3 O 4 -PAMAM nanoparticle colloidal solution.

[0027] Step (2): The surfac...

Embodiment 3

[0031] Step (1): Superparamagnetic Fe 3 O 4 -Preparation of PAMAM nanoparticle colloidal solution: the concentration is 1×10 -4 The 5th-generation PAMAM dendrimer solution with carboxyl end groups in mol / L is filled with nitrogen and mechanically stirred for 30 minutes, then the iron salt mixture is added. The concentration of iron trichloride in the iron salt mixture is 1 mol / L , The concentration ratio of ferric chloride to ferric chloride is 1.5, and the amount of iron salt mixture added is Fe 3+ The ratio of the substance to the PAMAM dendrimer is 80:1 as the standard. Blow in nitrogen at room temperature and stir for 5 hours, then adjust the temperature of the water bath to 90℃, increase the stirring speed to 800 rpm or more, and drop the concentration to 1 ×10 -3 mol / L sodium hydroxide aqueous solution to pH 11, continue to stir for 40 min, then superparamagnetic Fe 3 O 4 -PAMAM nanoparticle colloidal solution.

[0032] Step (2): The surface is fully coated with Fe of PAMA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com