Coated ternary positive electrode material and preparation method and application thereof

A cathode material and a coating type technology, which is applied in the field of cathode materials for lithium ion batteries, can solve the problems of complex procedures, decreased structural stability, unfavorable industrial production, etc., and achieves the effect of reducing the mixed discharge of lithium and nickel and reducing the residual alkali on the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

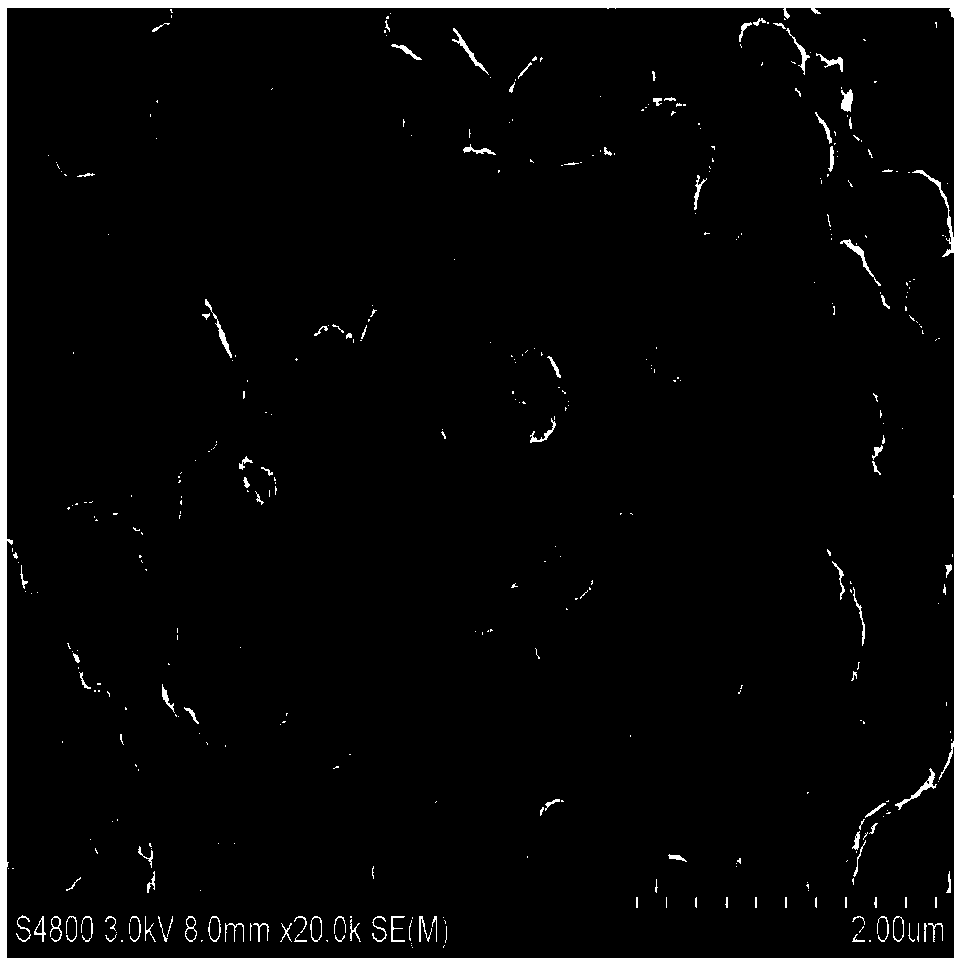

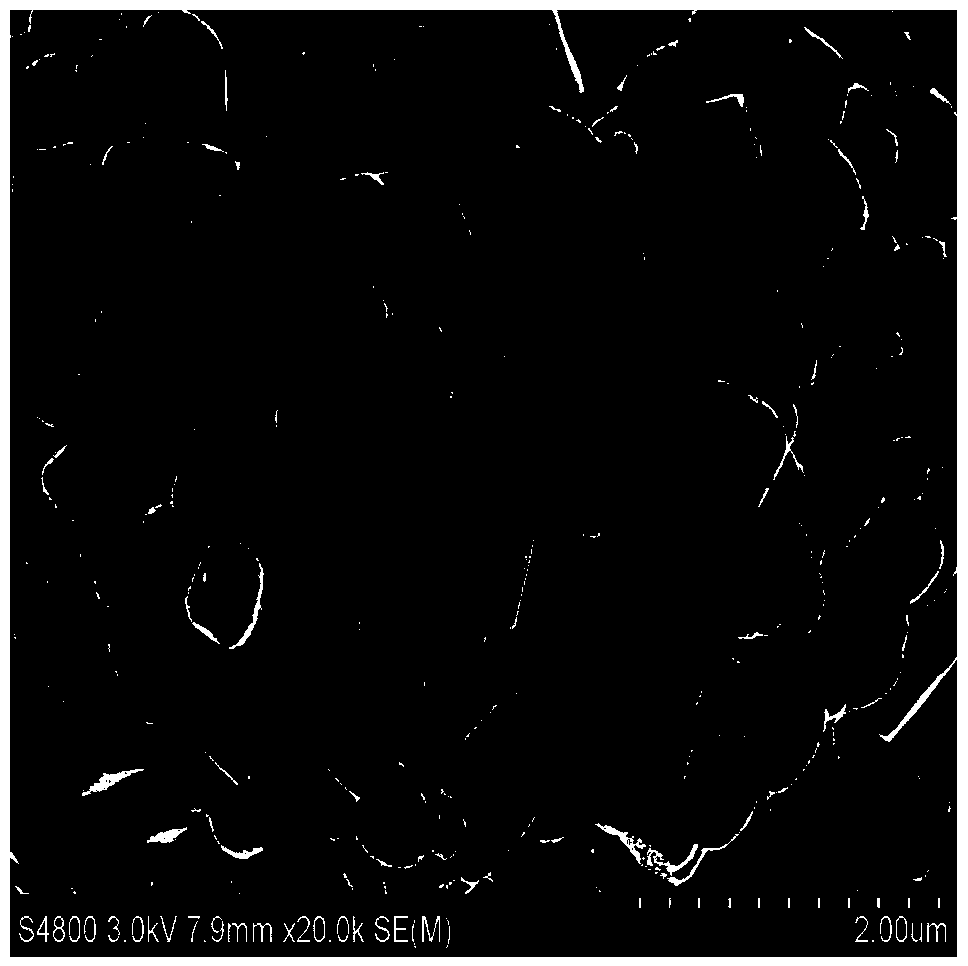

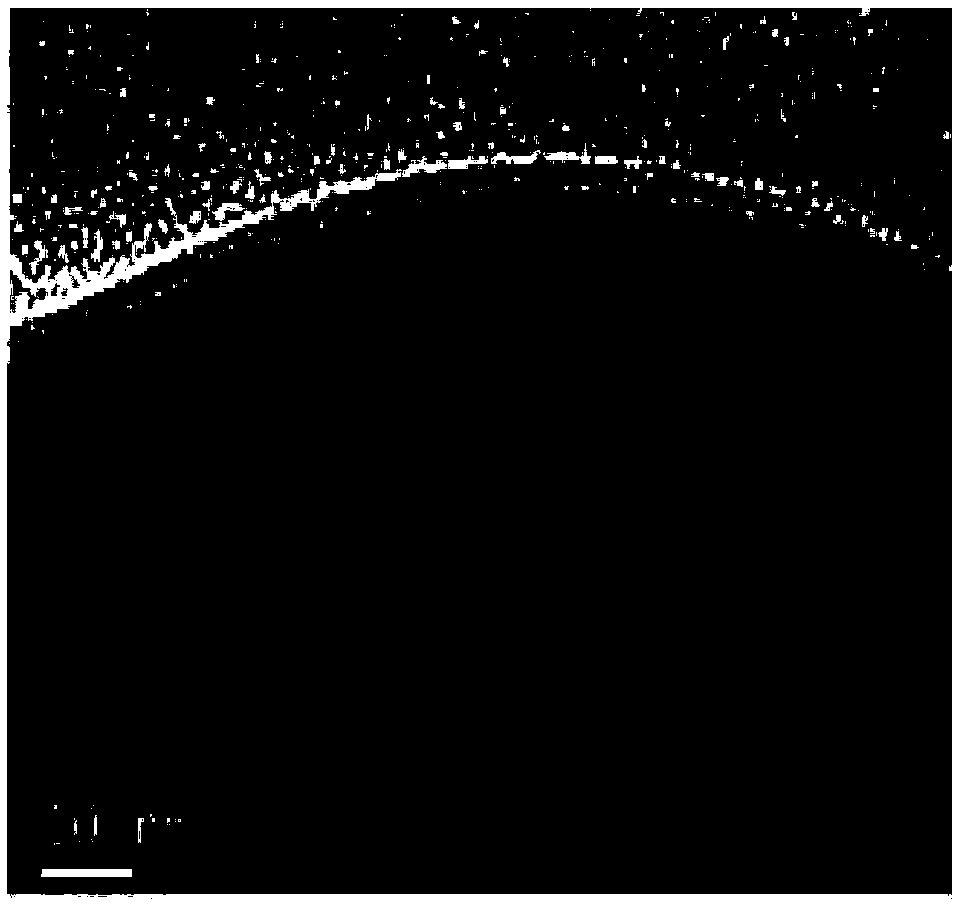

Image

Examples

Embodiment 1

[0059] Preparation of ternary cathode material Li 1.01 Ni 0.5 co 0.2 mn 0.25 Ge 0.05 o 2 , then using TaF 5 Coating the ternary material while reducing the residual alkali includes the following steps:

[0060] Preparation of ternary cathode material:

[0061] (1) According to the stoichiometric ratio Li 1.01 Ni 0.5 co 0.2 mn 0.25 Ge 0.05 o 2 , weighed 18.66g lithium carbonate and 22.7g lithium hydroxide, 91.61g Ni 0.5 co 0.2 mn 0.3 (OH) 2 Precursor, 5.23g GeO 2 Put it in a three-dimensional mixer, add polyurethane balls, and mix well.

[0062] (2) Put the uniformly mixed material in a sagger for heat treatment, calcined in an oxygen atmosphere, first raise the temperature to 350°C at a rate of 2°C / min and keep it for 2h, then raise the temperature to 900°C and keep it for 15h, and then heat it at 7.5°C / min rate to cool to room temperature to obtain a ternary cathode material without post-treatment such as washing, and the residual alkali on the surface is r...

Embodiment 2

[0067] Preparation of ternary cathode material Li 1.02 Ni 0.6 co 0.2 mn 0.18 In 0.02 o 2 , then using TaF 5 Coating the ternary cathode material while reducing the residual alkali includes the following steps:

[0068] Preparation of ternary cathode material:

[0069] (1) According to the stoichiometric ratio Li 1.02 Ni 0.6 co 0.2 mn 0.18 In 0.02 o 2 , weighed 19.02g lithium carbonate and 33.96g lithium acetate, 91.99g Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor, 2.78g In 2 o 3 Put it in a three-dimensional mixer, add polyurethane balls, and mix well.

[0070] (2) Put the uniformly mixed material in a sagger for heat treatment, and calcinate it in an oxygen atmosphere. At a rate of 8°C / min, first raise the temperature to 500°C and keep it for 1h, then raise the temperature to 880°C and keep it for 10h, and then heat it at 5°C The rate of / min is cooled to room temperature to obtain a ternary positive electrode material without post-treatment such as washing, and t...

Embodiment 3

[0075] Preparation of ternary cathode material Li 1.04 Ni 0.65 co 0.15 mn 0.17 Ca 0.03 o 2 , then using TaF 5 Coating the ternary cathode material while reducing the residual alkali includes the following steps:

[0076] Preparation of ternary cathode material:

[0077] (1) According to the stoichiometric ratio Li 1.04 Ni 0.65 co 0.15 mn 0.27 Ca 0.03 o 2 , weighed 23.37g lithium hydroxide and 35.85g lithium nitrate, 91.98g Ni 0.65 co 0.15 mn 0.2 (OH) 2 The precursor and 1.68g CaO were placed in a three-dimensional mixer, and polyurethane balls were added and mixed evenly.

[0078] (2) Put the uniformly mixed material in a sagger for heat treatment, calcined in an oxygen atmosphere, first raise the temperature to 400°C for 3 hours at a rate of 5°C / min, then raise the temperature to 860°C for 12.5h, and then heat it at 10°C The rate of °C / min is cooled to room temperature to obtain a ternary cathode material without post-treatment such as washing, and the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com