MOFs based carbon dioxide adsorbent, preparation method and application thereof

A carbon dioxide and adsorbent technology, applied in the field of MOFs-based carbon dioxide adsorbent and its preparation, can solve the problems of weak adsorption and separation ability, and achieve the effect of strong adsorption ability, overcoming volatile and non-volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

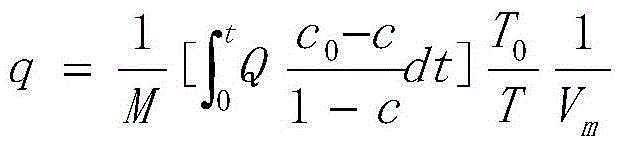

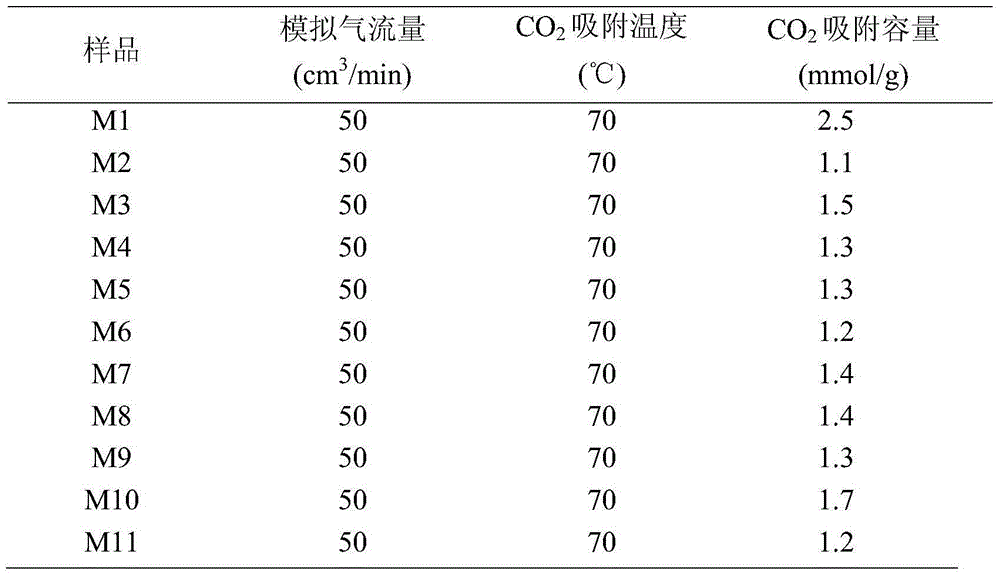

[0046] Dissolve 1g of tetraethylenepentamine in 100ml of absolute ethanol, stir for 0.5h, add 1g of MOF-74, stir for 4h, put the sample in an oven, dry at 80°C to remove ethanol, and then dry at 105°C, denoted as M1. In the obtained sample, the content of organic amine was 50 wt%. The adsorption data was measured by using a fixed bed, the adsorption temperature was 70°C, and the simulated gas flow rate was 50ml / min. The results are shown in Table 1.

Embodiment 2

[0048] Dissolve 1g of tetraethylenepentamine in 100ml of absolute ethanol, stir for 0.5h, add 1g of ZIF-8, stir for 4h, put the sample in an oven, dry at 80°C to remove ethanol, and then dry at 105°C, denoted as M2 . In the obtained sample, the content of organic amine was 50 wt%. The test conditions are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

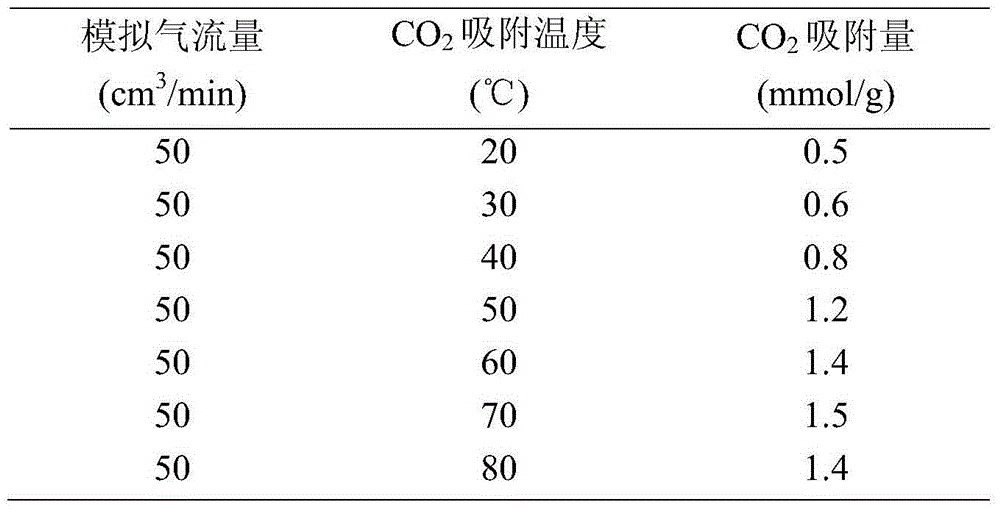

[0050] Dissolve 1g of tetraethylenepentamine in 100ml of absolute ethanol, stir for 0.5h, add 1g of MIL-101, stir for 4h, put the sample in an oven, dry at 80°C to remove ethanol, and then dry at 105°C, record as M3. In the obtained sample, the content of organic amine was 50 wt%. The adsorption capacity data was determined by using a fixed bed, and the results are shown in Table 1. When the adsorption temperature was adjusted to 20, 30, 40, 50, 60, 70, and 80°C, and the simulated gas flow rate was 50ml / min, the adsorption results of M3 are shown in Table 2. Adjust the adsorption temperature to 50°C, the simulated gas flow rate to 50ml / min; the desorption temperature to 150°C, the nitrogen purge flow rate to 50ml / min, and the desorption time to 30min. The cycle adsorption results of M3 are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com