Patents

Literature

174results about How to "Large temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing multilevel porous carbon base composite phase change material

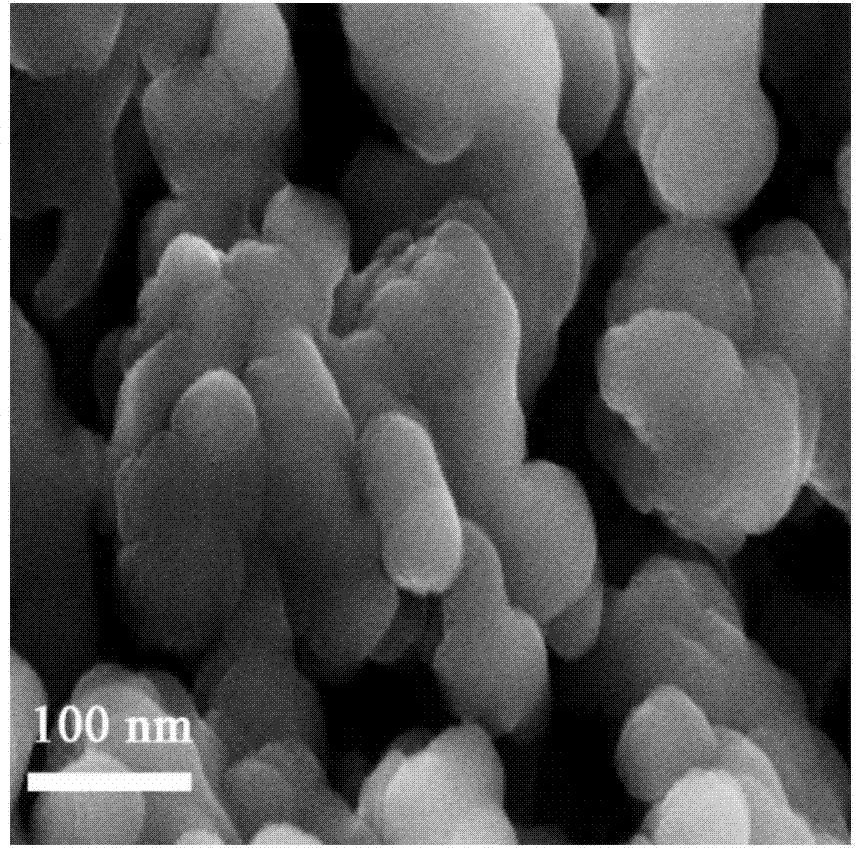

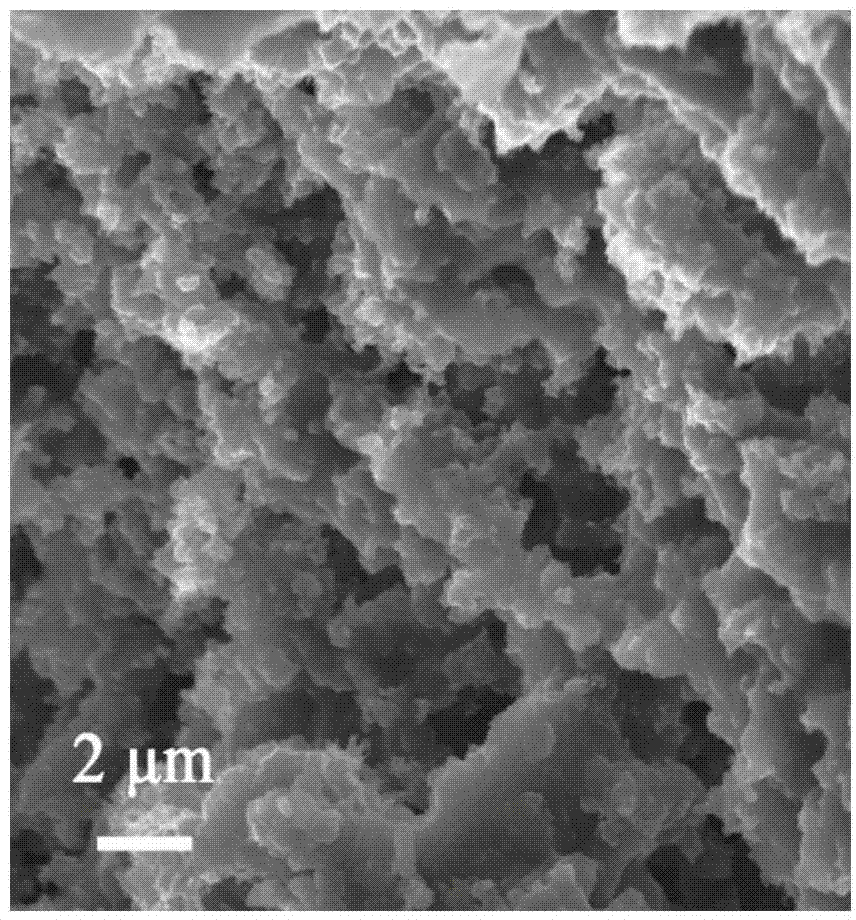

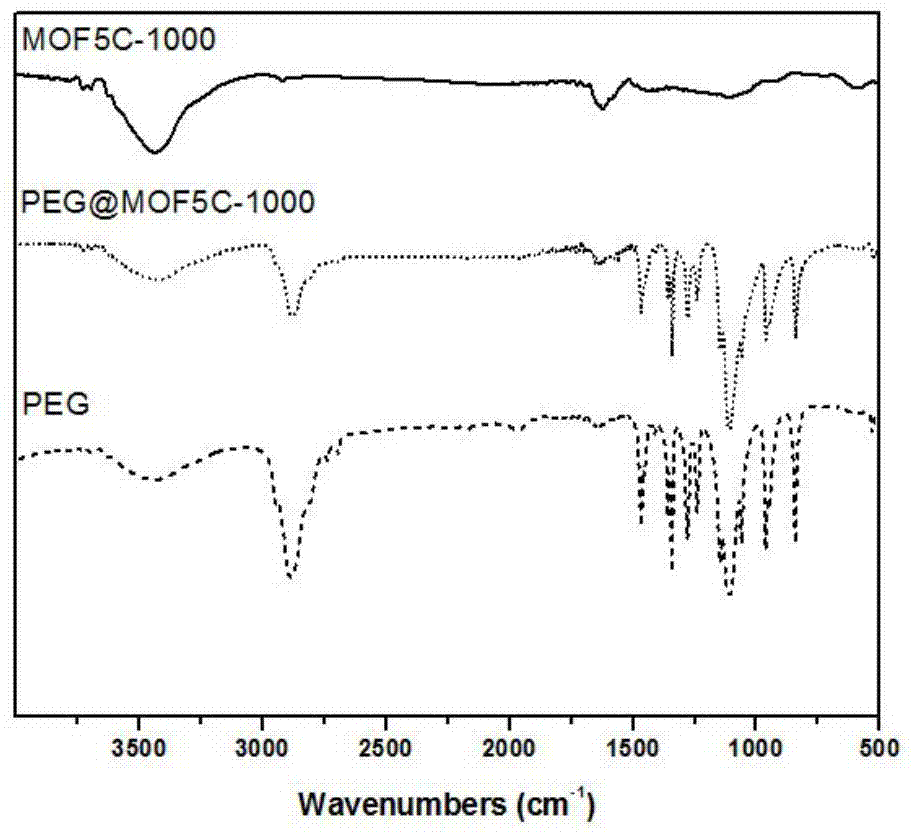

InactiveCN104710965AImprove heat storage capacityLarge temperature rangeProductsReagentsPorous carbonSynthesis methods

The invention provides a method for preparing a multilevel porous carbon base composite phase change material, and belongs to the field of composite phase change materials. The method comprises the following steps: at first, preparing an organic metal skeleton material by using such methods as a solution method, a solvothermal method or a stirring synthesis method; with the organic metal skeleton material as a template, high temperature carbonizing under the protection of an inert gas, and changing the carbonizing temperature and the post treatment manner to obtain a multilevel porous carbon material with a super-large specific surface area and a super-large pore volume; selecting proper solvents according to different kinds of phase change core materials, preparing the phase change core materials to a solution, dispersing the porous carbon material into the solution, removing the solvent by such manners as heating, and meanwhile the phase change core materials are adsorbed and limited in the porous carbon material. The composite phase change material prepared by the method provided by the invention has good thermal storage property, can effectively avoid the leakage problem of the phase change core material, and has the advantages of excellent heat transfer property, good cycling stability and wide application range, and the process is simple and is suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

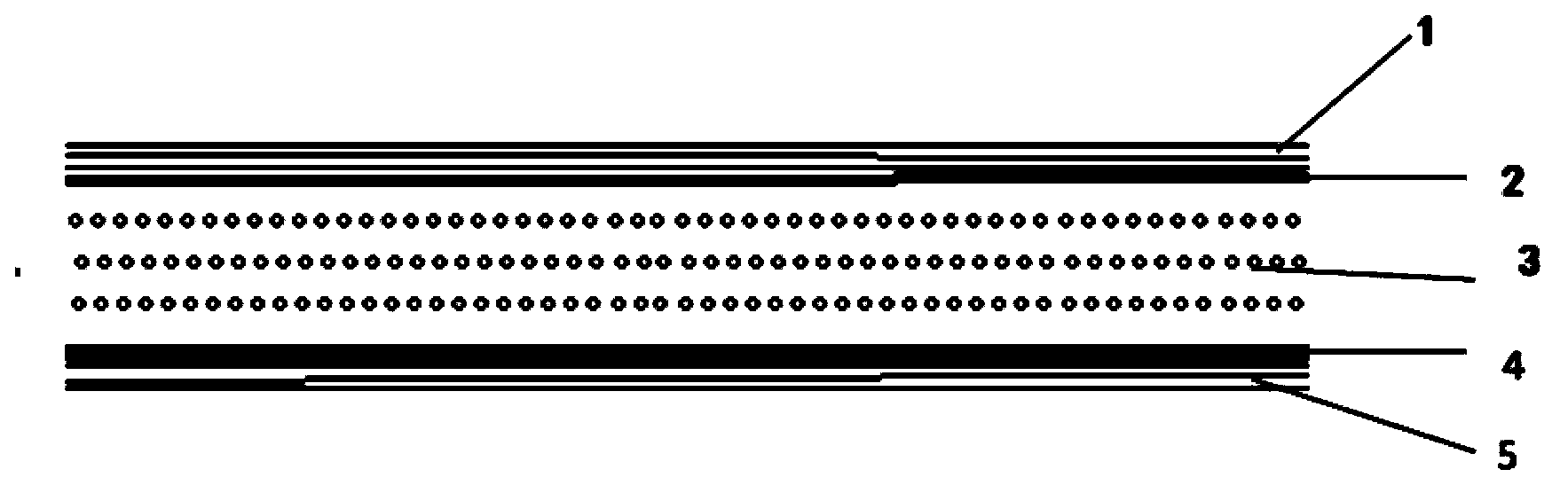

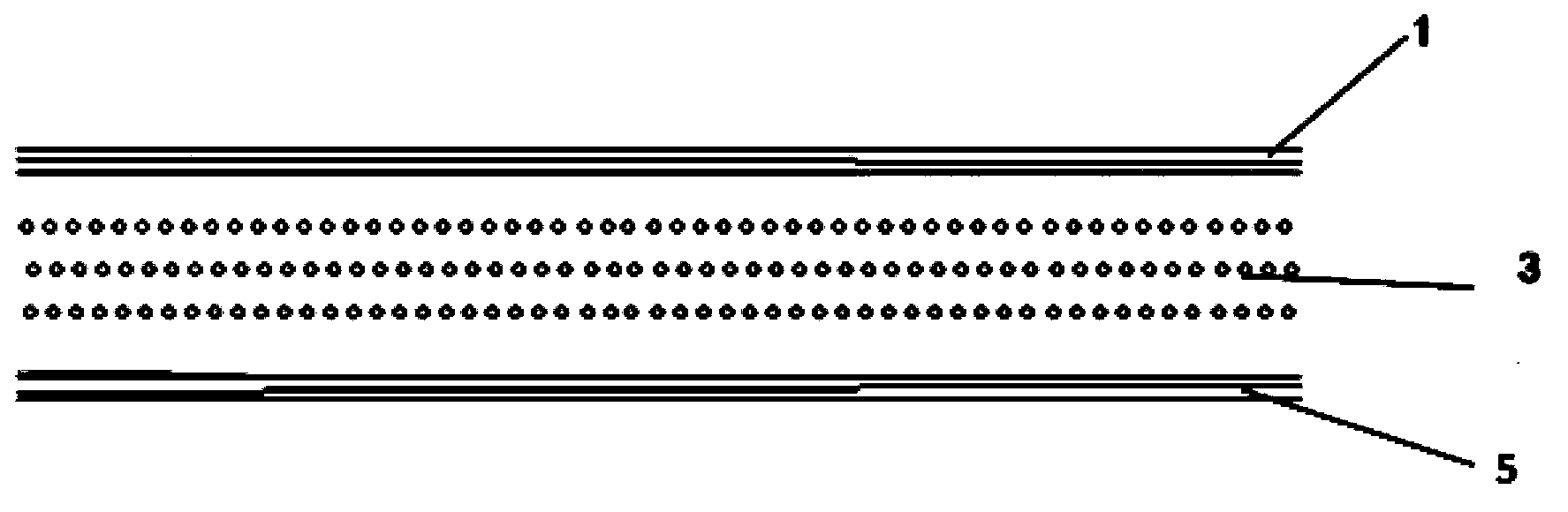

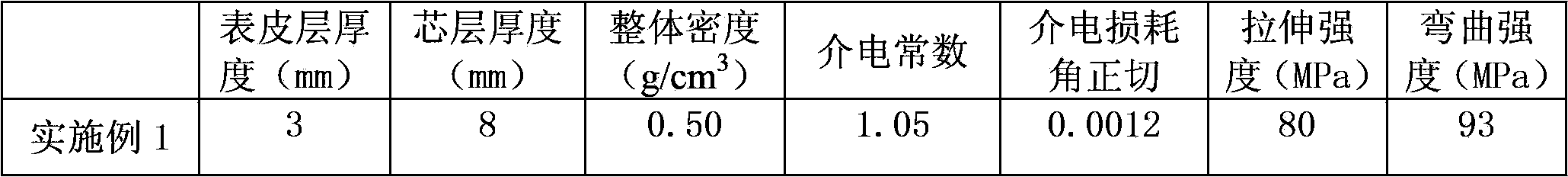

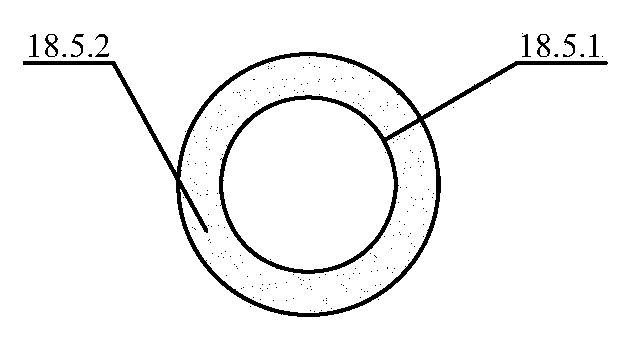

Wave-transmitting core clamping material of antenna cover and manufacturing method and application thereof

ActiveCN103660410AHigh mechanical strengthIncreased protectionSynthetic resin layered productsLaminationUltimate tensile strengthThermoplastic composites

The invention belongs to the technical field of materials, and relates to a wave-transmitting core clamping material and a manufacturing method and application thereof. The wave-transmitting core clamping material comprises an upper skin layer, a core layer and a lower skin layer, wherein the upper skin layer and the lower skin layer are bonded on the two sides of the core layer, respectively; the upper skin layer and the lower skin layer are made of a fiber-reinforced thermoplastic composite material or a laminated material of the fiber-reinforced thermoplastic composite material and a transition material. The prepared wave-transmitting core clamping material provided by the invention has the characteristics that the quality is light, the intensity is high, the wave-transmitting property is good, the adaptive temperature range is wide, and the core clamping material is manufactured to be in different shapes through different manners of hot pressing, vacuum forming and the like so as to meet the requirement on the shape of an antenna cover.

Owner:上海吒吒新材料科技有限公司

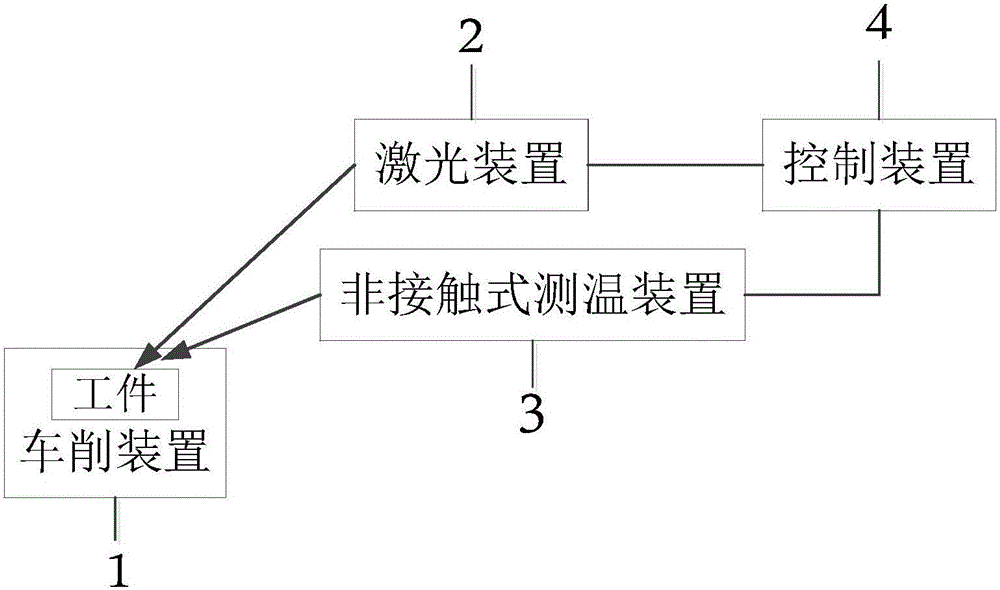

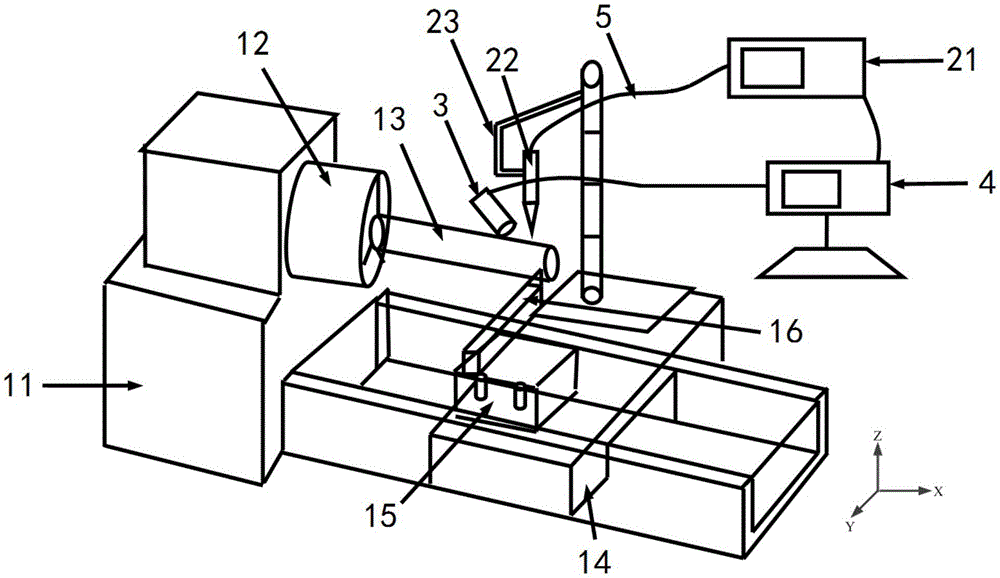

Laser heating assisted turning device and method

InactiveCN106001613ASolution to short lifeImprove surface qualityMeasurement/indication equipmentsMetal working apparatusData matchingMachined surface

The invention provides a laser heating assisted turning device and method. The laser heating assisted turning device comprises a turning device body, a laser device, a non-contact temperature measuring device and a control device, wherein a tool and a workpiece are fixed to the turning device body, the tool is detachably connected with the turning device body, the laser device is used for heating the workpiece through laser, the non-contact temperature measuring device is used for acquiring the temperature at the cutting position of the workpiece in real time, and the control device is used for comparing data of an optimum temperature field stored in the control device with temperature data acquired by the non-contact temperature measuring device in real time and controlling the laser device to adjust laser parameters so as to achieve the optimum temperature field if difference exists. The laser heating assisted turning device has the advantages that the laser parameters are adjusted in a data matching mode so that the temperature field at the cutting position of the workpiece can be always consistent to the optimum temperature field, the cutting performed in the temperature field makes the service life of the tool longest, the machined surface quality of the workpiece is the best, and the turning efficiency is the highest.

Owner:HARBIN INST OF TECH

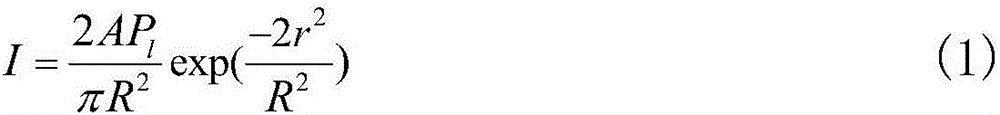

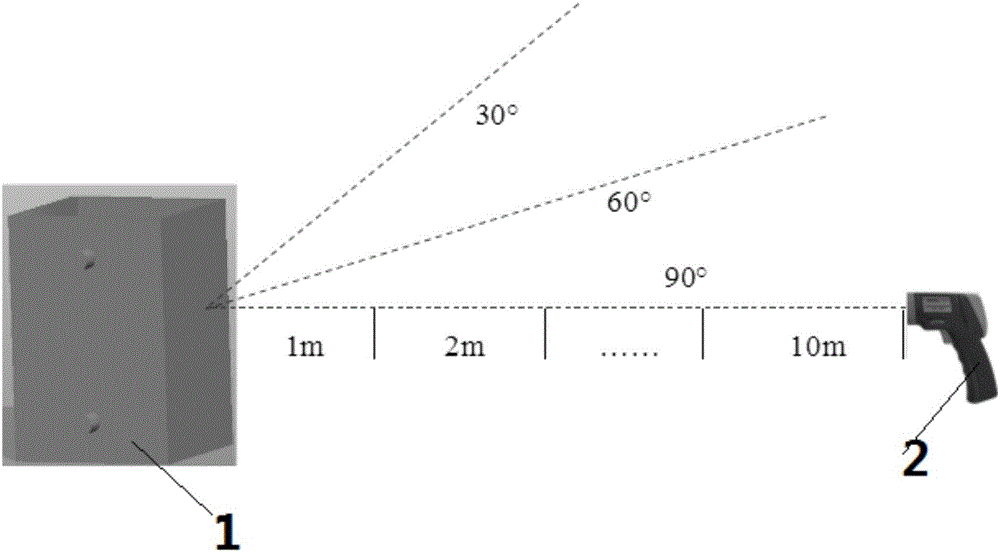

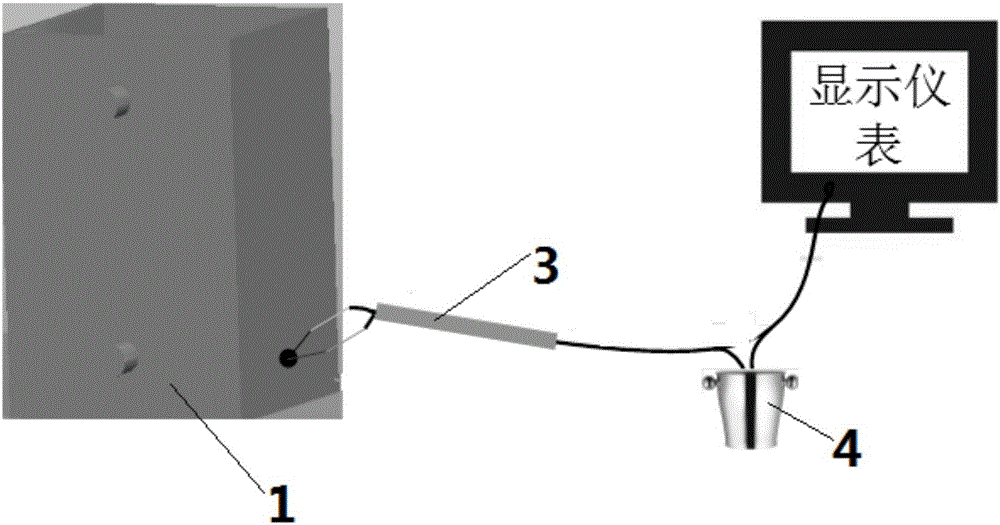

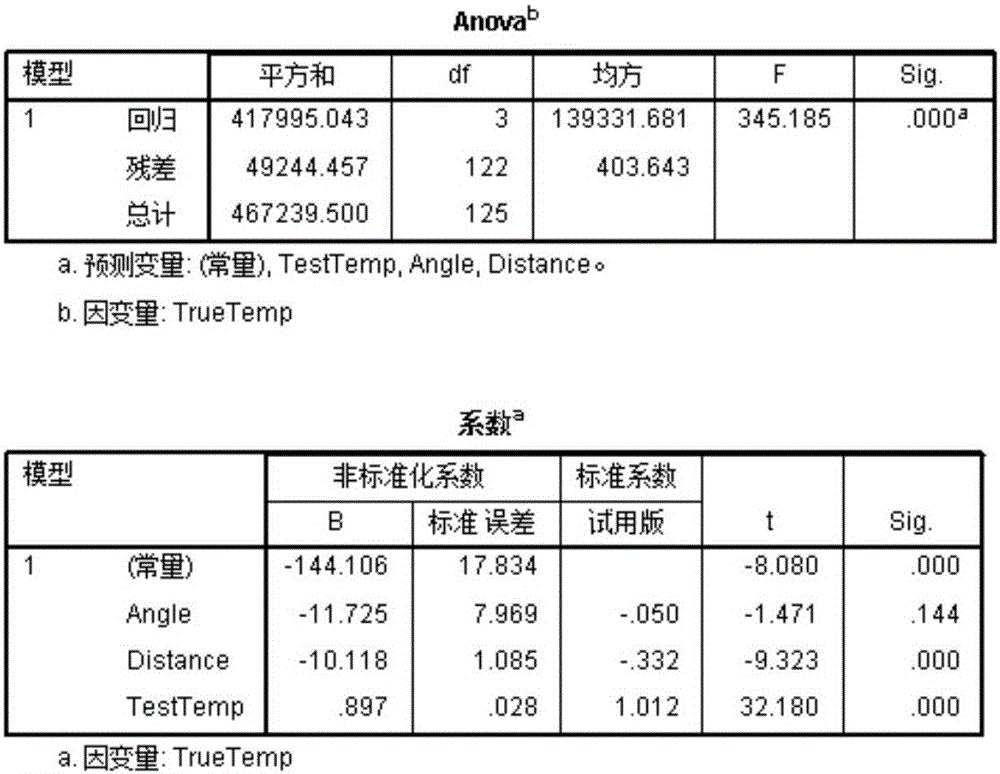

Method for correcting resting result of infrared temperature measurement equipment

ActiveCN106768380ACorrected temperatureLarge temperature rangeRadiation pyrometryThermometers using electric/magnetic elementsResearch ObjectIngot

The invention proposes a method for correcting the resting result of infrared temperature measurement equipment, and various types of infrared temperature measurement equipment as a research object. The data measured by the infrared temperature measurement equipment is corrected manually, and the corrected data is close to the real temperature of the object. The method comprises the steps: testing the function variables corresponding to a model and a formula through presetting a testing module and a calculation formula; carrying out the fitting of the measured data through software, determining the coefficient and multiplier of the calculation formula, and forming a complete calculation formula; and calculating the accurate temperature of the target under the same measurement condition no matter how the function variables change. The method is suitable for the correction of the target temperature of the infrared temperature measurement equipment with various types of precision and applicable temperature ranges under the complex conditions. The method has obvious advantages for the measurement of the temperature of steel ingot. The method can overcome the temperature errors, caused by the temperature, distance and angle changes, of the infrared temperature measurement equipment, and achieves the purpose of measuring temperature quickly, accurately and safely.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

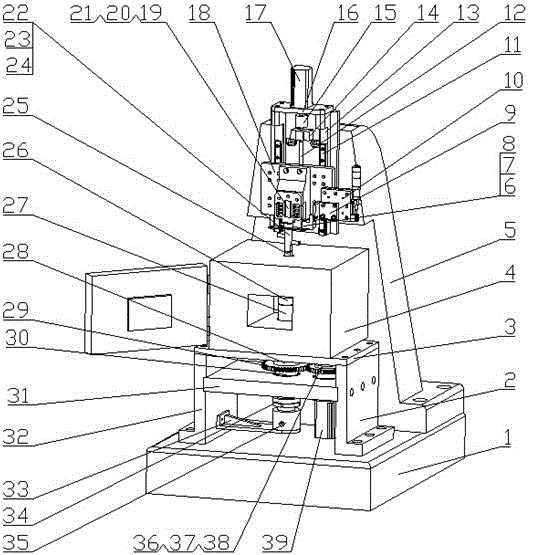

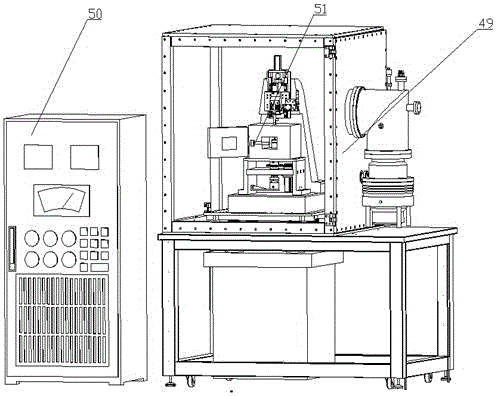

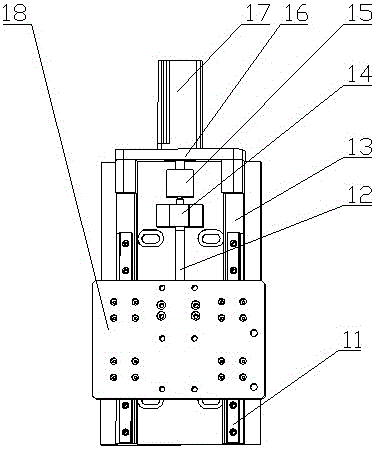

High-temperature micro-nano press mark test device and method in vacuum environment

PendingCN106404574AReduce the impact of collectionAvoid entanglementInvestigating material hardnessTest theoryMaterial hardness

The invention relates to a high-temperature micro-nano press mark test device and method in vacuum environment, and belongs to the field of mechanical and electronic integration precise instrument. The device can be used in vacuum environment; the oxidization caused by high-temperature environment on a press head and a test specimen can be prevented; the influence of air flowing on the test specimen heating is weakened; the stable heating temperature of the test specimen is ensured; further, the test analysis on the test specimen micro mechanical properties can be started; the characteristics parameters and the like of material hardness, elasticity modulus, creep properties and thermo-mechanical coupling effects are obtained so as to study the influence rule of variable-temperature and high-temperature environment on the material micro mechanical behaviors, deformation damage mechanisms and micro tissue structure evolution; the material and product design manufacturing, service prediction and reliability evaluation are guided. The structure of the device is compact; the measurement precision is high; the application range is wide; the wide application prospects are realized in the fields of material science, equipment manufacturing, ferrous metallurgy, national defense and military, aerospace and the like. According to the test method provided by the invention, the rich material micro mechanical property test theories and technical systems are combined.

Owner:JILIN UNIV

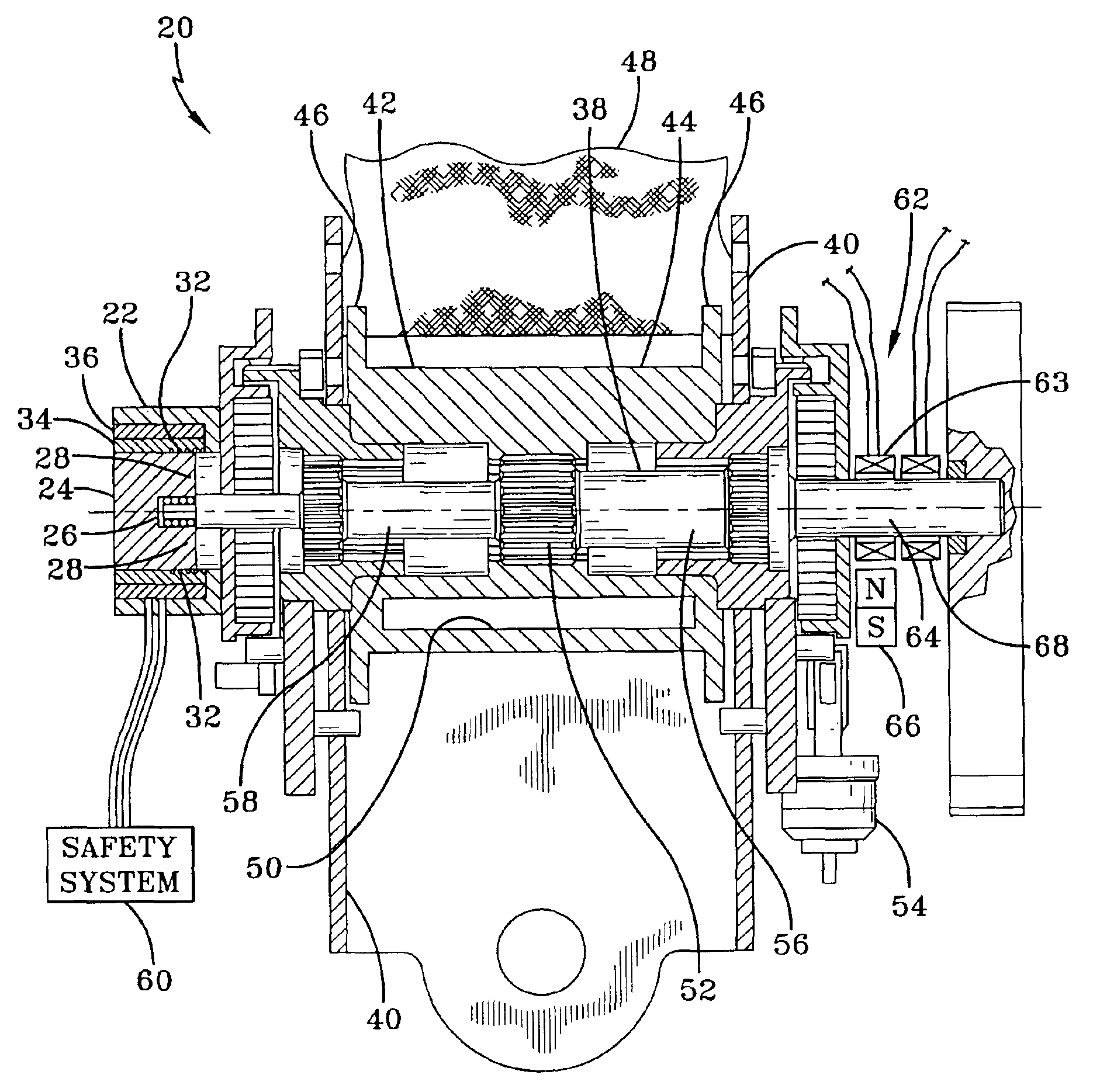

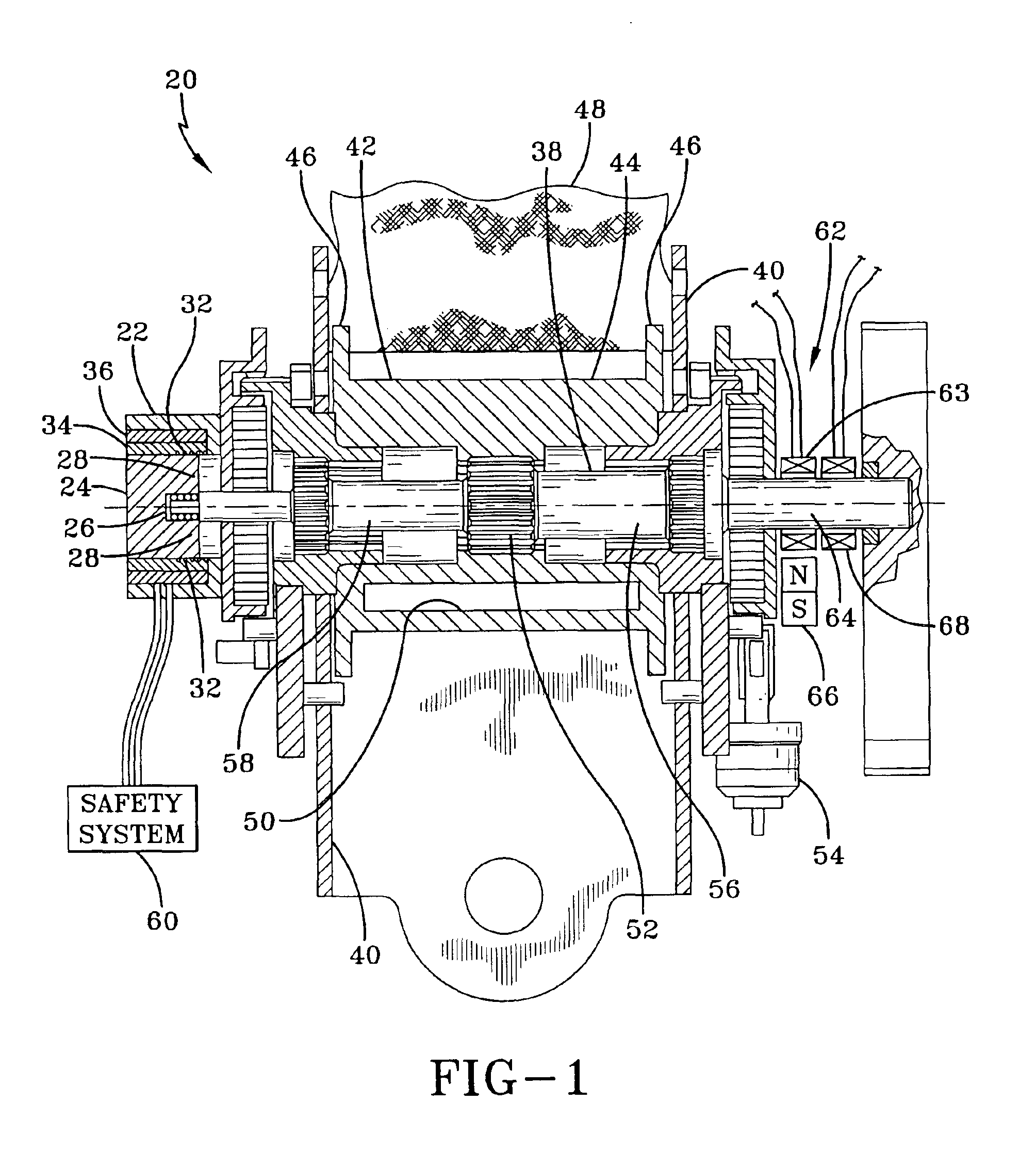

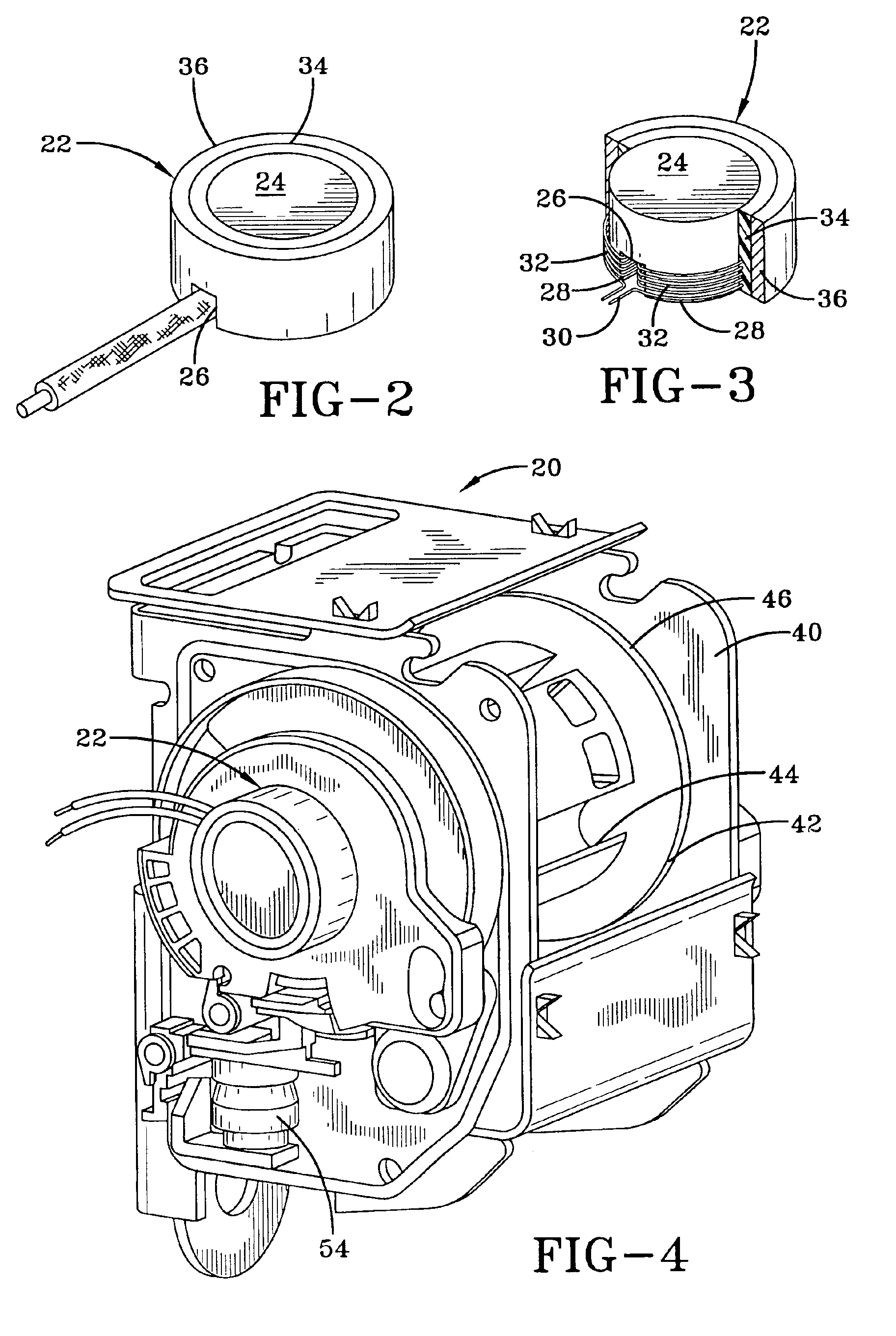

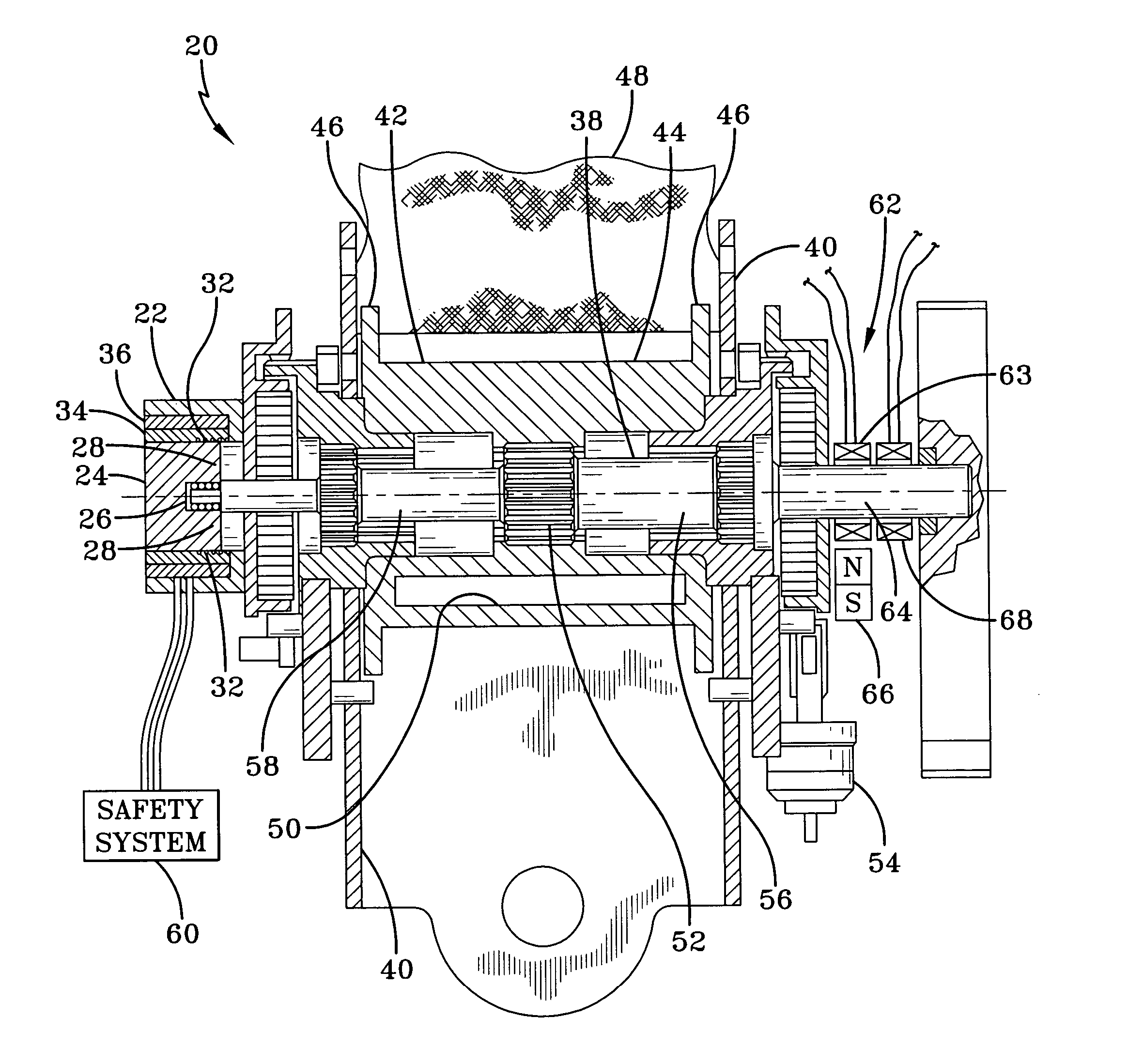

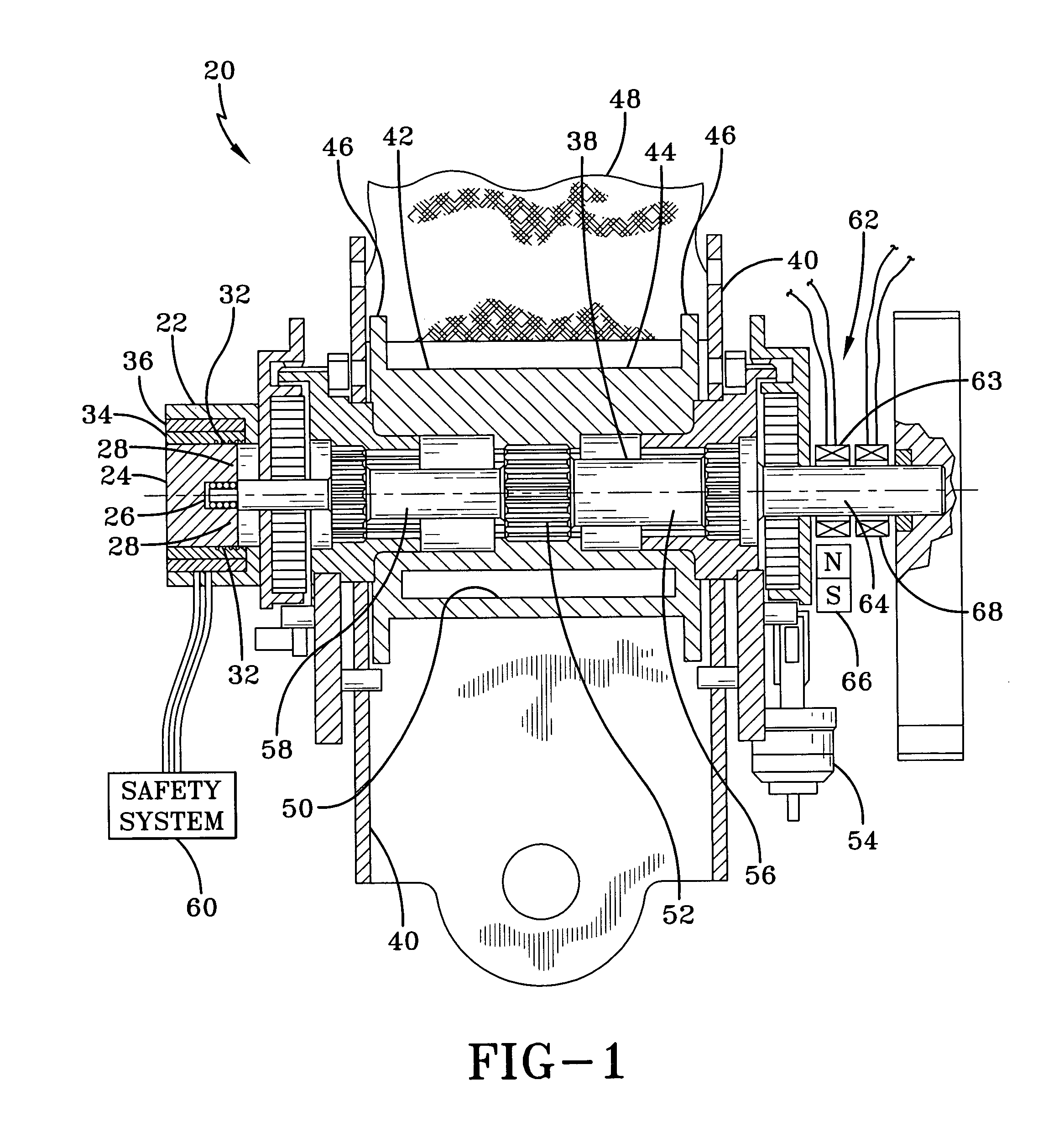

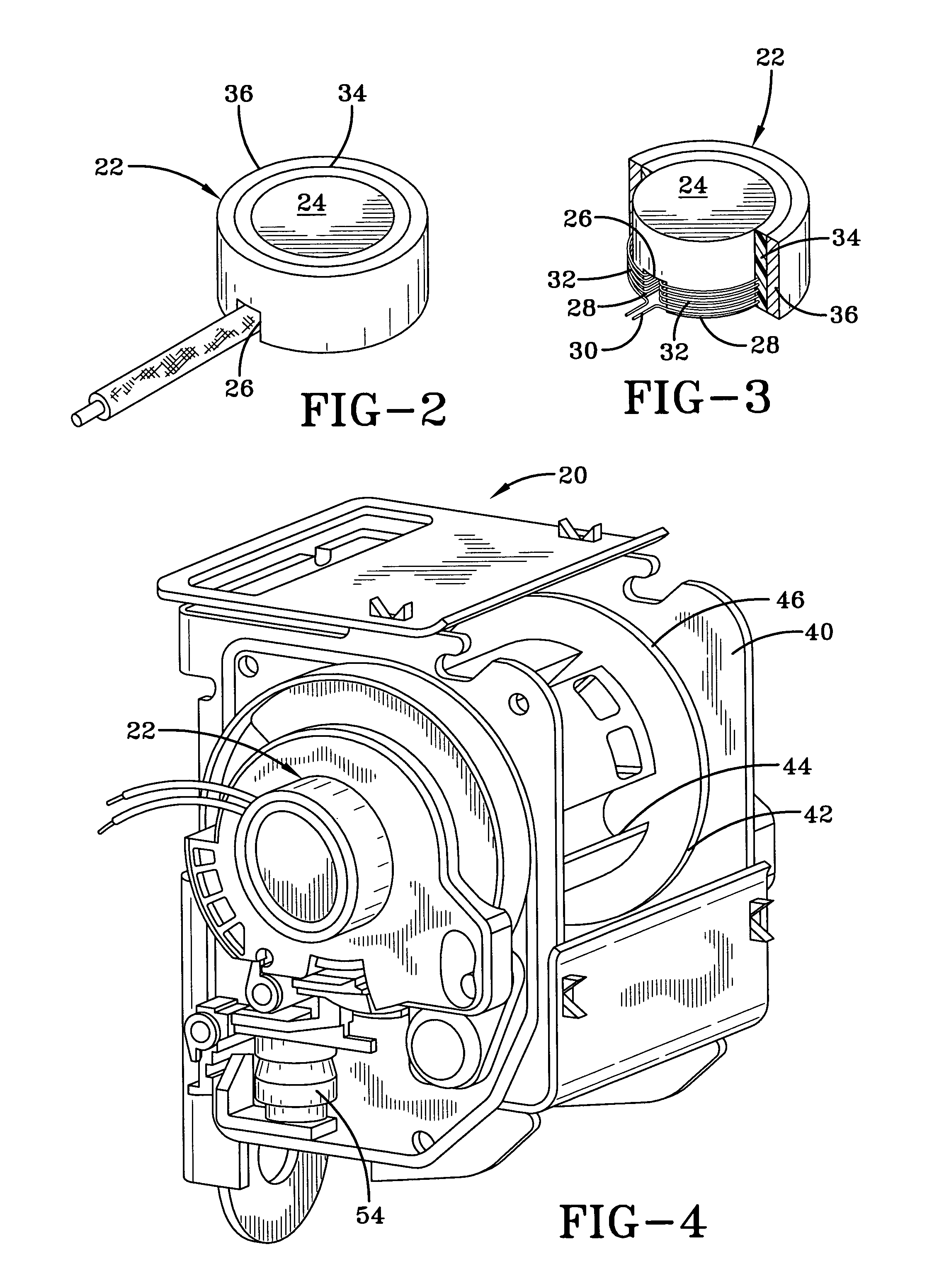

Seat belt retractor torsion rod activity sensor

InactiveUS6916045B2Large temperature rangeUse in some applicationBelt retractorsBelt control systemsSeat beltBelt safety

A seat belt load limiter employs a magnetostrictive sensor to detect the elastic loading and plastic deformation of a torsion rod forming part of a seat belt retractor. A magnet and a coil are placed about or adjacent to the torsion rod. When the torsion rod undergoes elastic or plastic strain, an electrical voltage is induced in the coil which is used to detect elastic or plastic strain of the torsion rod. A vehicle safety system uses the output of the magnetostrictive sensor to inform the vehicle operator when the seat belt load limiter is in need of replacement. The output of the magnetostrictive sensor as processed by the vehicle safety system can also be used to detect a situation where the seat occupant is not restrained by the seat belt and to make an airbag deployment decision.

Owner:KEY SAFETY SYST

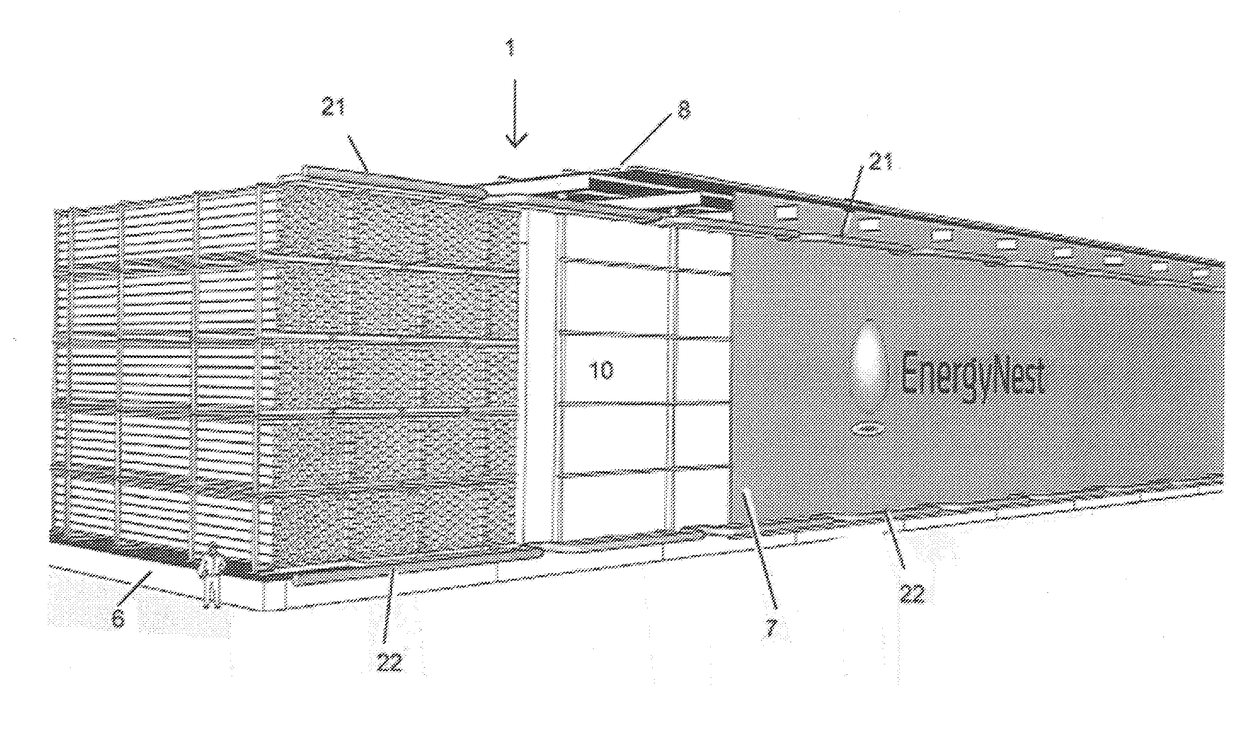

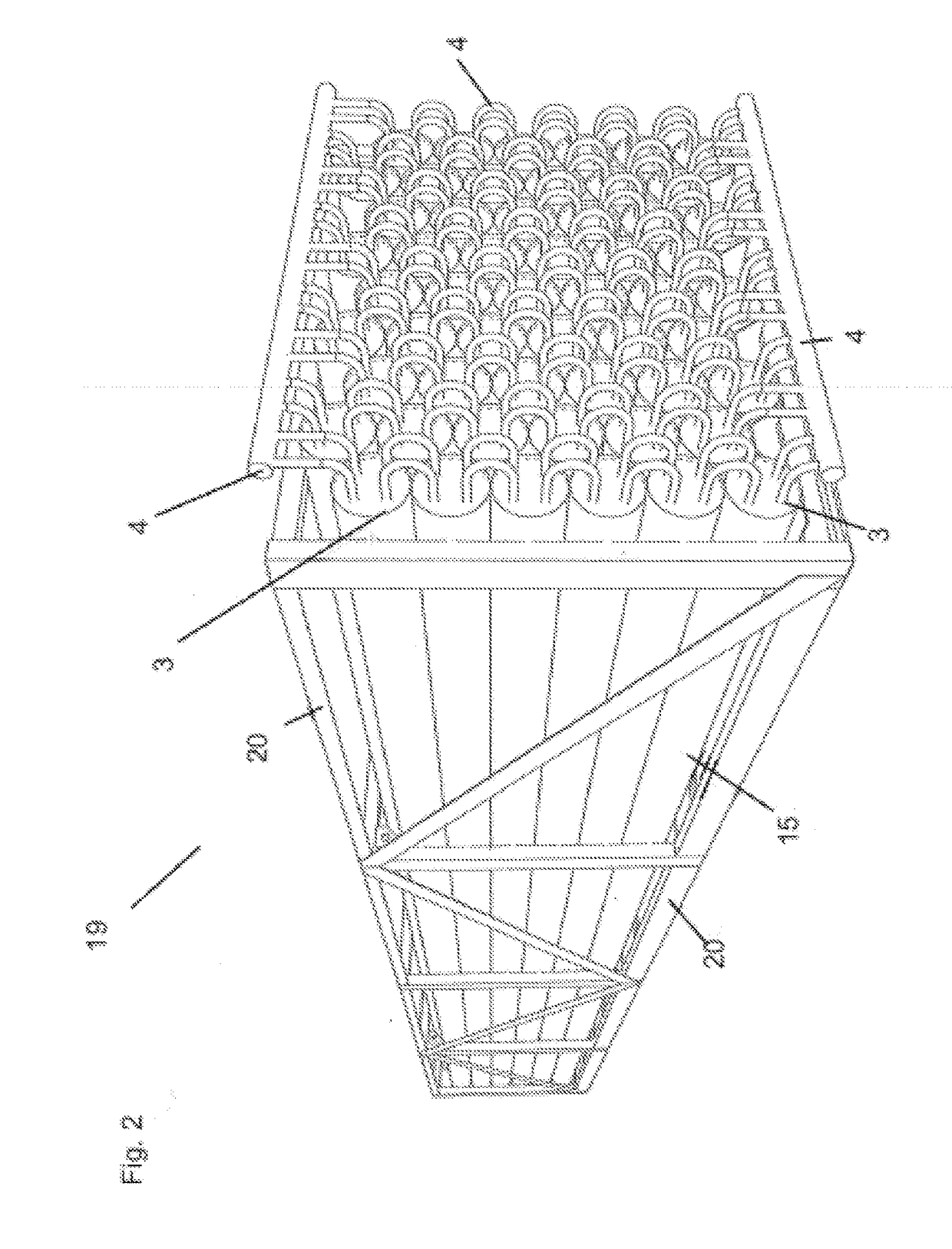

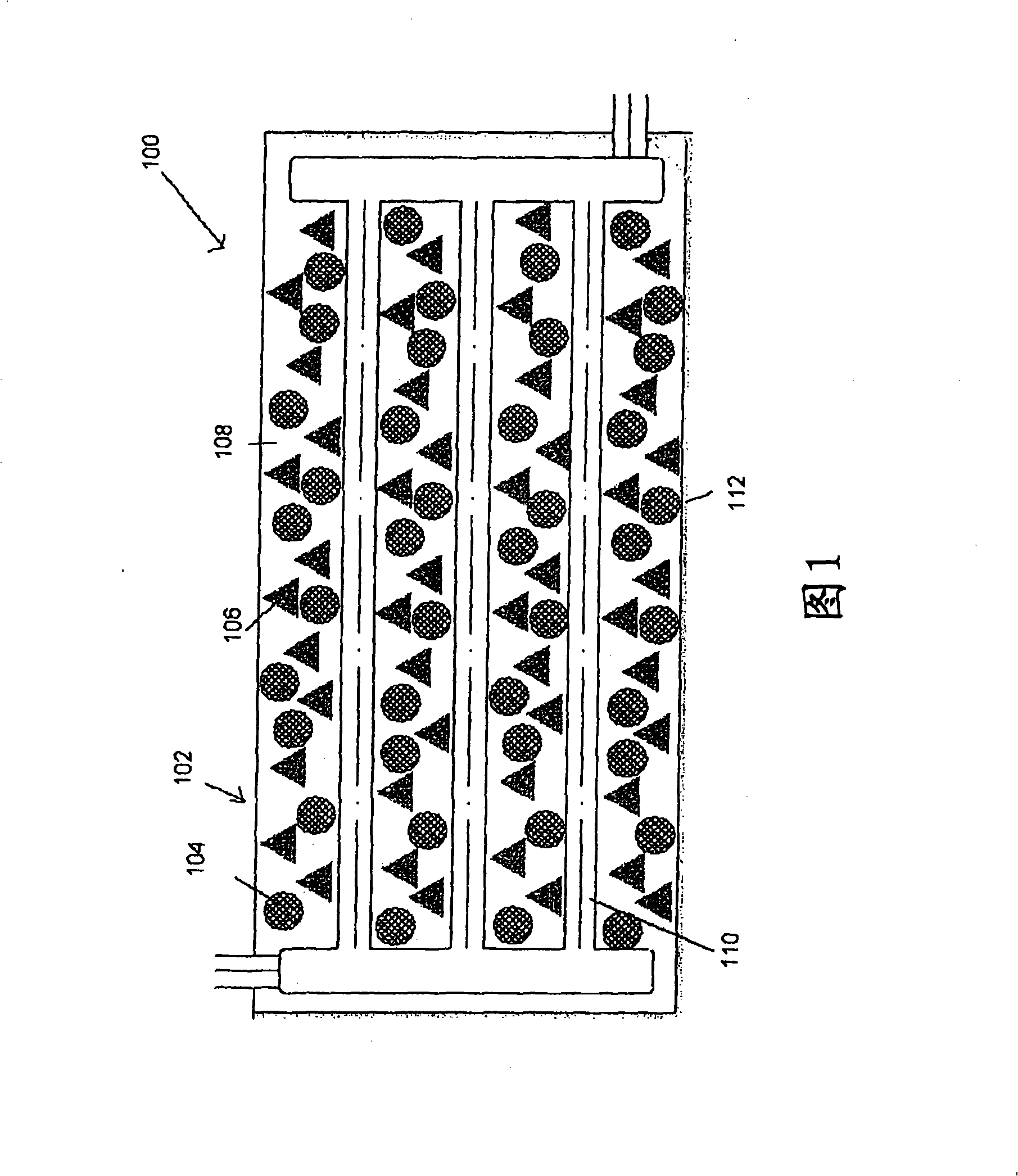

High temperature thermal energy storage, a method of building and a method of operating said storage

ActiveUS20180003445A1Easy to storeImproves cycled thermal energy/cost ratioHeat storage plantsStationary conduit assembliesThermal energyThermal energy storage

High temperature thermal energy storage, distinctive in that the storage comprises: a thermally insulated foundation, at least one self-supported cassette arranged on said foundation, which cassette is a self-supporting frame or structure containing a number of concrete thermal energy storage elements, some or all of said elements comprising embedded heat exchangers, a pipe system, the pipe system comprising an inlet and an outlet for thermal input to and output from the storage, respectively, and connections to said heat exchangers for circulating fluid through said heat exchangers for thermal energy input to or output from said thermal energy storage elements, and thermal insulation around and on top of the at least one self-supported cassette with concrete thermal storage elements. The invention also provides a method of building and methods of operating the storage.

Owner:NEST

Hot-seal functional stretch film

InactiveCN102190824ANo heat sealabilityAvoid warpingFlexible coversWrappersBlow moldingOptical property

The invention provides a functional stretch film with hot seal property, and in particular relates to a hot-seal unidirectional or bidirectional stretch film, which has the hot seal strength of more than or equal to 3N / 15mm and the thickness of more than or equal to 0.010mm and less than or equal to 0.150mm and which is formed by a single layer, two layers or more than two layers of polyolefine resin by an auxiliary co-mixing process and a blow molding, flow casting extrusion stretching or co-extrusion stretching process. The functional stretch film solves the technical problem that the effective hot seal cannot be achieved on an occasion with higher hot-seal requirements due to difficult obtaining of hot seal or serious hot-seal performance reduction when the polyolefin film is stretched. The product has the advantages of high mechanical strength, excellent optical property, obviously high water vapor resistance, anti-puncturing property and extremely good seal grease resistance and anti-pollution hot seal property, and can be widely applied to bags and automatic filling type sealed packages of foods, articles of daily use, cosmetics, chemicals, pesticides, military products and medical products as well as intaglio printing films and flexographic printing films, particularly various hot-seal materials under the dry-type lamination, wet-type lamination and extrusion lamination processing conditions.

Owner:江苏彩华包装集团公司 +1

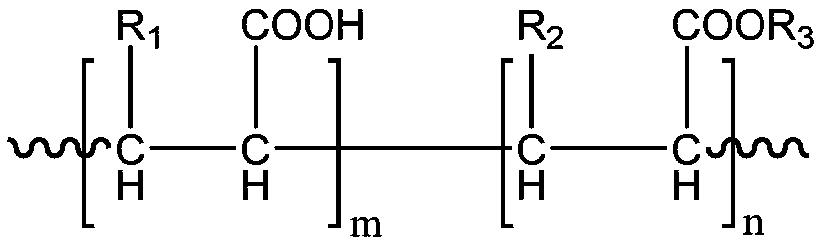

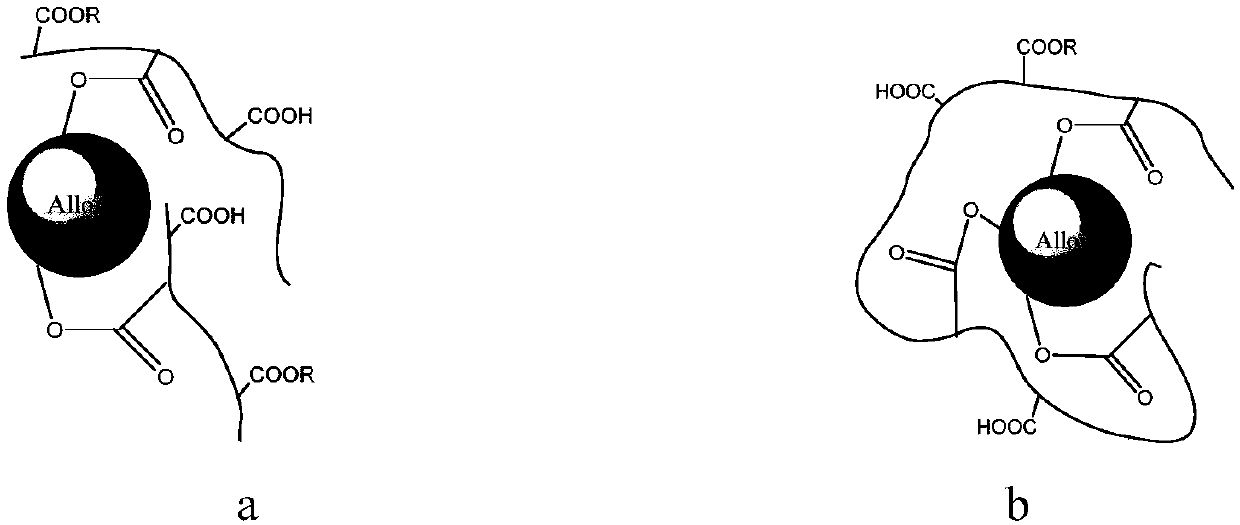

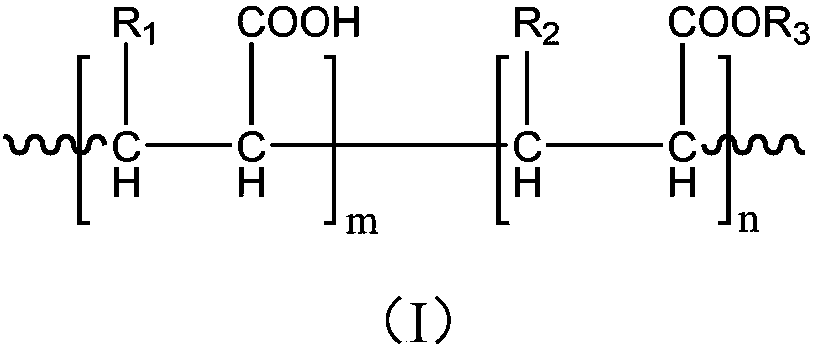

Solder paste scaling powder

ActiveCN107931891AImprove universalityLess corrosiveWelding/cutting media/materialsSoldering mediaAcrylic resinHeat stability

The invention discloses solder paste scaling powder. The solder paste scaling powder comprises a film forming agent. The film forming agent comprises acrylic resin. The acrylic resin comprises a repetition structure unit in a formula (I). The acrylic resin is adopted in the solder paste scaling powder for replacing rosin, corrosivity is weak, few residues exist, and tin powder is wrapped by the acrylic resin so that the tin powder can be prevented from being oxidized. Solder paste in which the solder paste scaling powder is added is provided with a wide process window, components in the solderpaste are stable in property, and the stability of the solder paste is good; and heat stability of the acrylic resin is good, and the reflow soldering temperature section is wide.

Owner:广东省先进陶瓷材料科技有限公司

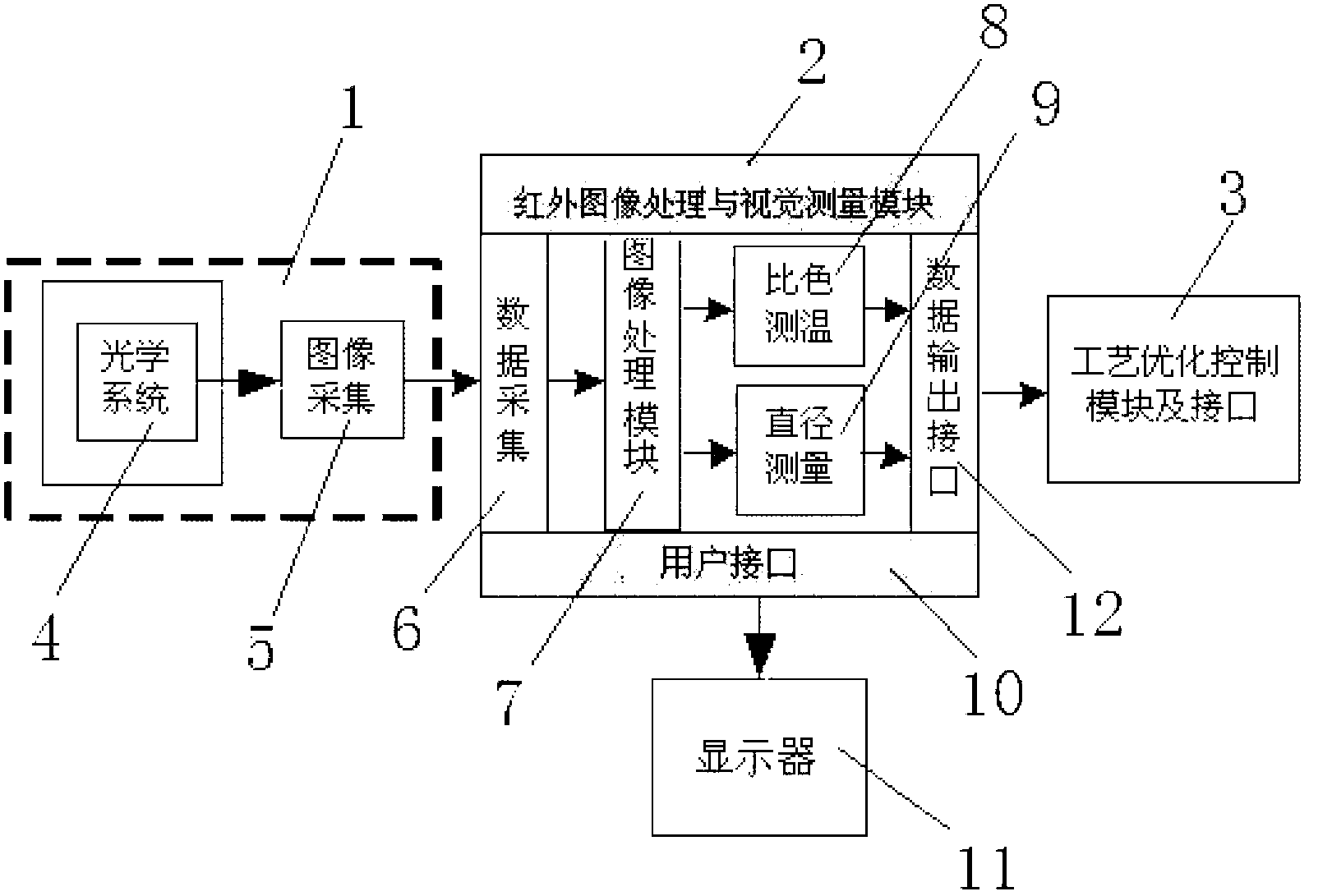

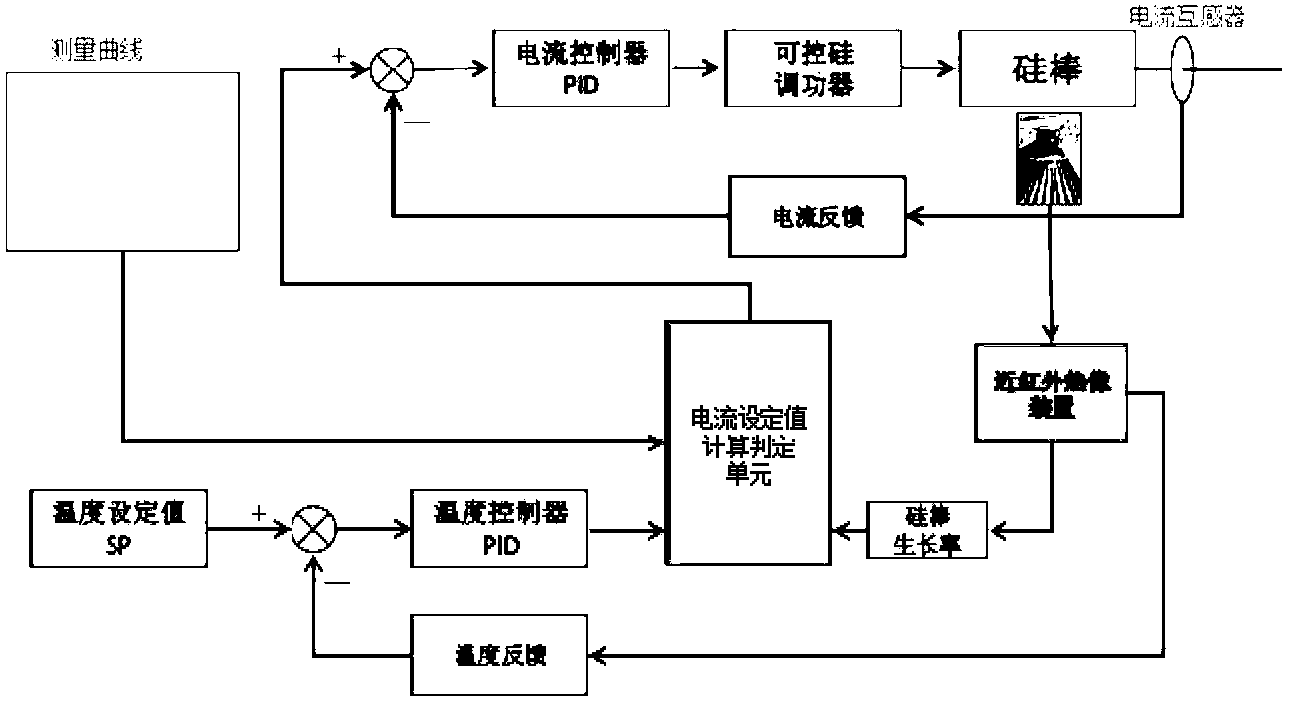

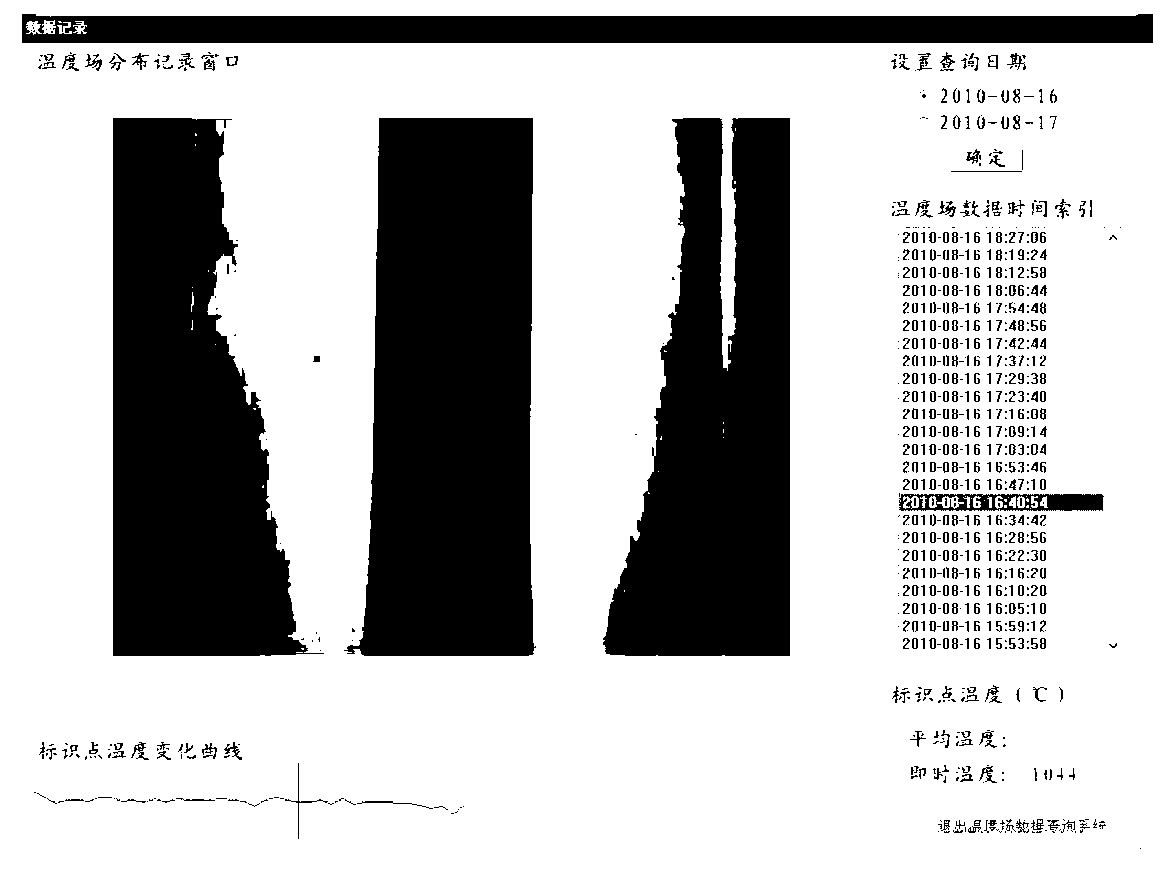

Multi-parameter online monitoring and optimizing control device and method of polycrystalline silicon reduction furnace

ActiveCN102795627ALarge temperature rangeHigh precisionChemical industryFrom chemically reactive gasesImaging processingDisplay device

The invention discloses a multi-parameter online monitoring and optimizing control device and method of a polycrystalline silicon reduction furnace. The device comprises a multi-parameter infrared monitoring probe, an infrared image processing and vision measuring module and a process optimizing control module, wherein the multi-parameter infrared monitoring probe obtains an infrared image of a silicon rod in the furnace; the infrared image is collected by a data collecting module and is converted into a digital image; the digital image is analyzed and processed by an image processing module, and the diameter and the growing rate of the silicon rod are obtained through a vision measuring technology; a colorimetric temperature measurement method is used for measuring temperature distribution on the surface of the silicon rod and obtained data is accessed to a display through a user interface; and an optimizing control module is established through measured data obtained by analyzing, and different polycrystalline silicon reduction furnace types are combined to carry out closed ring optimizing control. According to the multi-parameter online monitoring and optimizing control device and method, a silicon rod growing process can be optimally controlled; and the device and the method are of great importance of saving energy and reducing consumption, improving the production efficiency, guaranteeing the production safety and reducing the labor intensity.

Owner:HEFEI RUISHI MEASUREMENT & CONTROL ENG TECH +1

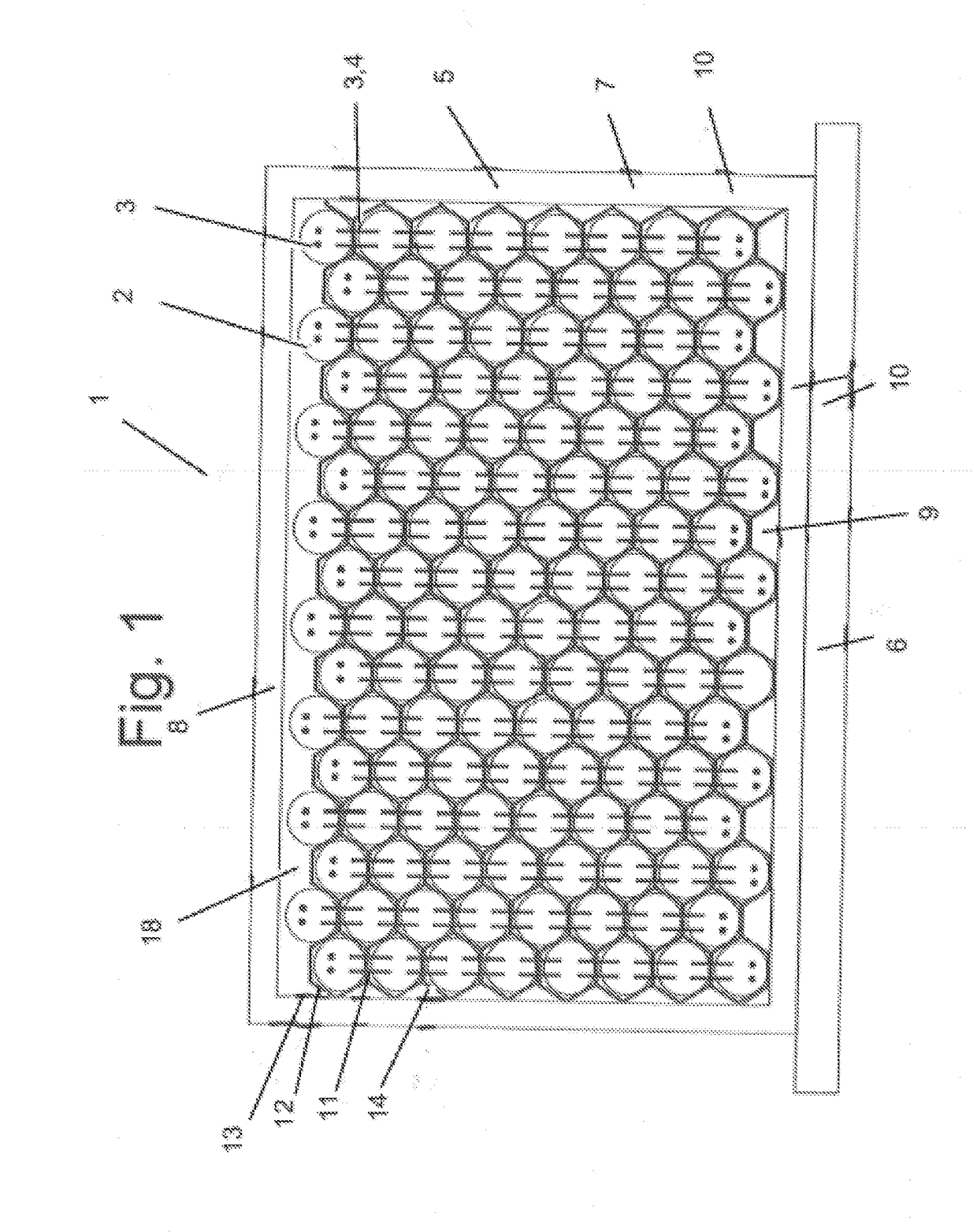

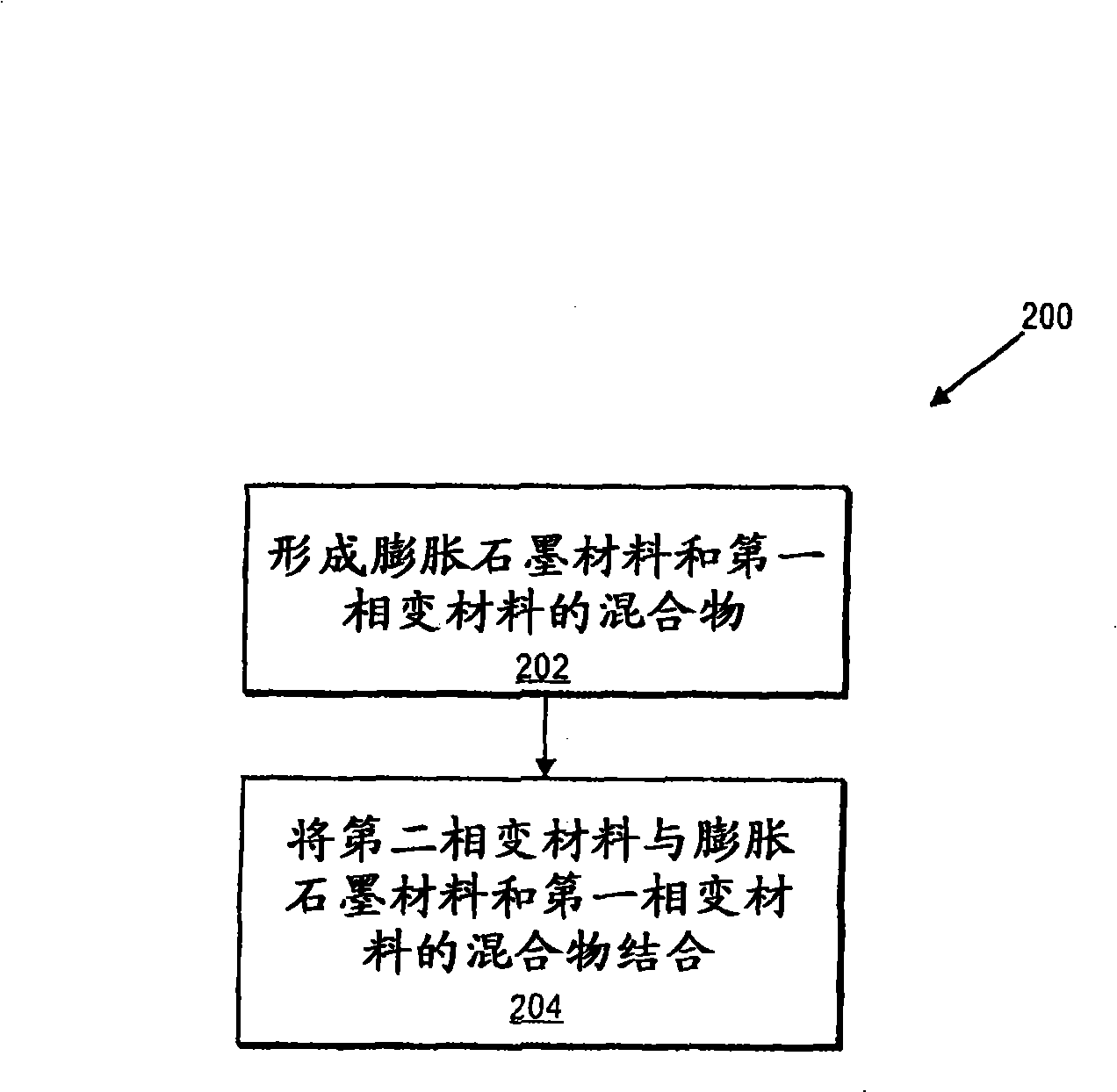

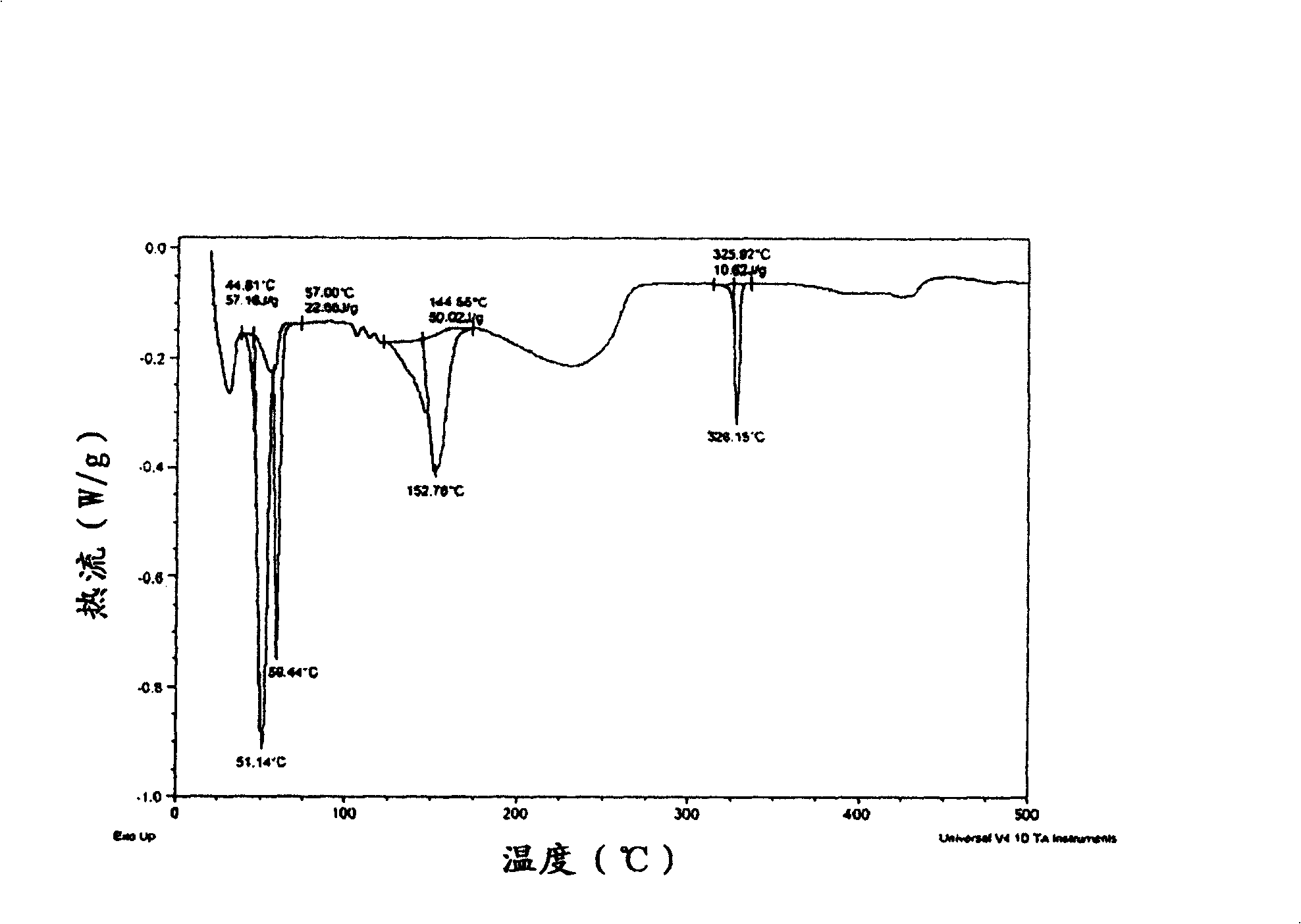

Latent heat storage material and preparation method of the latent heat storage material

InactiveCN101289611ALarge temperature rangeDomestic cooling apparatusLighting and heating apparatusLatent heat storageGraphite

The invention relates to a latent heat storage material comprising a first phase change material, at least one second phase change material different from the first phase change material, and an expanded graphite material wherein the first phase change material and the at least one second phase change material are intermixed and the latent heat storage material exhibits a phase transition over a range of temperatures. The invention also relates to a process for the preparation of a latent heat storage material comprising combining a mixture of an expanded graphite material and a first phase change material with at least one different second phase change material.

Owner:SGL CARBON SE

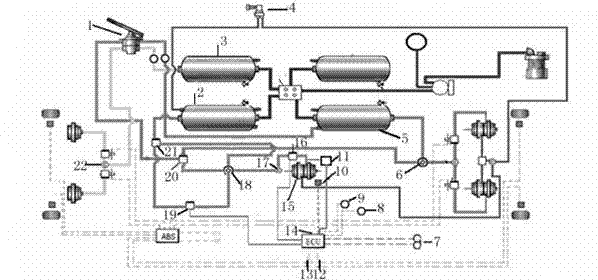

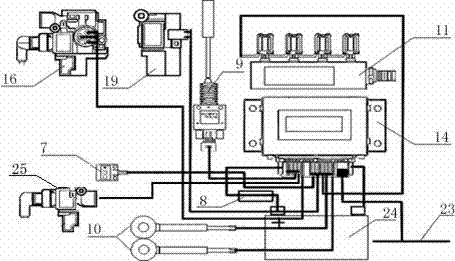

An electromechanical acbs automobile retarder control device and its control method

InactiveCN102294996ASolve the problem of overheatingImprove stabilityBrake coolingHand actuated initiationsMonitoring temperatureSolenoid valve

The invention relates to an electromechanical ACBS (Anti-lock Central Braking System) retarder control device and its control method, which mainly includes air circuit control and electronic control, and the air circuit is equipped with a PCV regulating valve (16) on the original air brake circuit. The normally closed solenoid valve (19) acts as a control valve to control the air pressure of the retarder air chamber, and uses the parking air reservoir to complete the retarder air supply without affecting the original braking performance of the vehicle. The retarder is cooled by circulating cooling water, and the cooling water is recycled by the electric water pump (25). The central retarder control system can judge the driver's operation, prevent misoperation, and realize the real-time monitoring of speed, temperature and pressure, retarder brake anti-lock, CAN bus communication, display and alarm and other functions. The control of the PCV regulating valve (16) and the normally closed solenoid valve (19) is realized through the high-power drive module, and the ECU of the control circuit adopts ISP programming method, power management, hardware watchdog and other methods to ensure better stability of the controller sex.

Owner:唐应时 +3

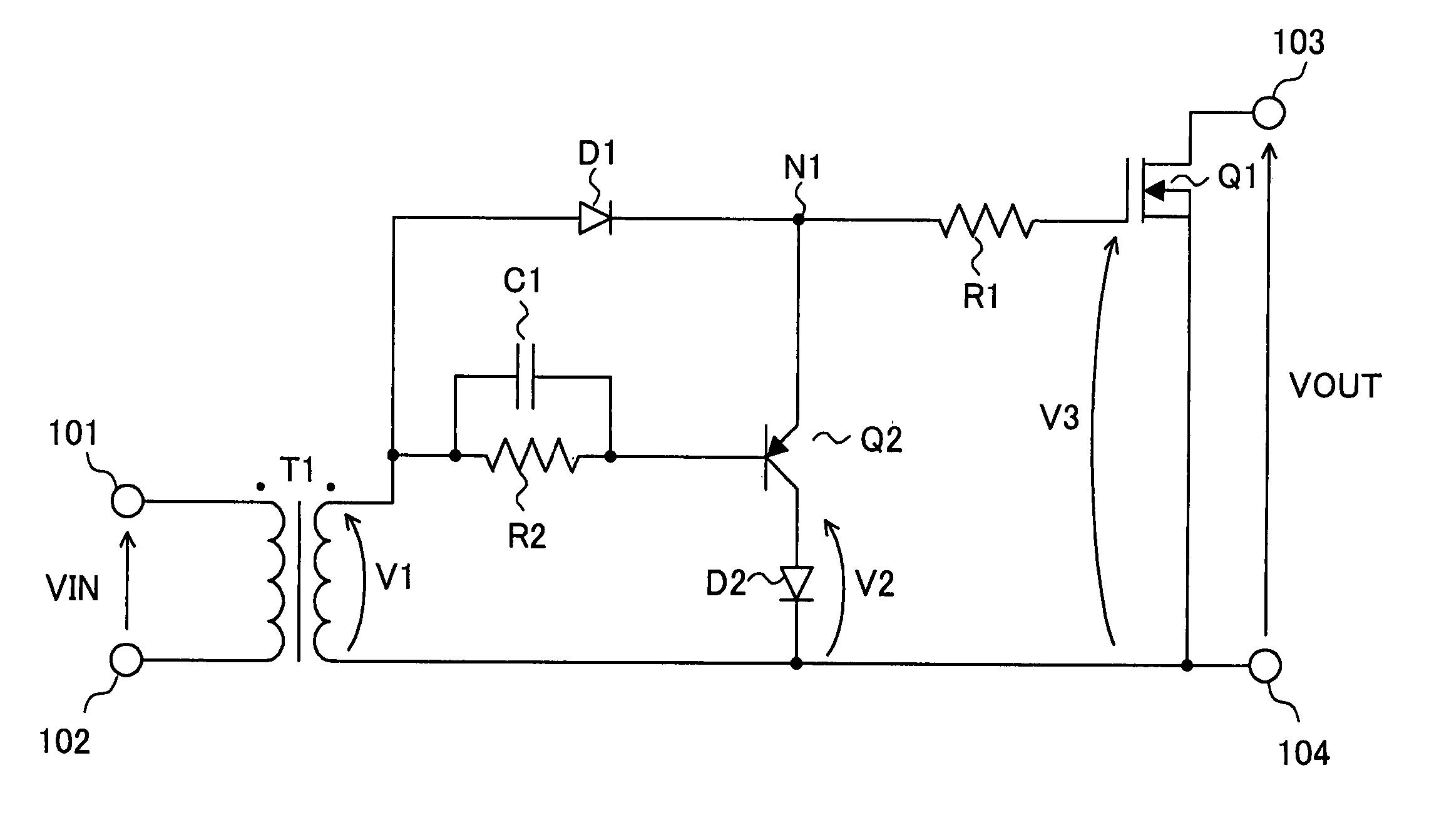

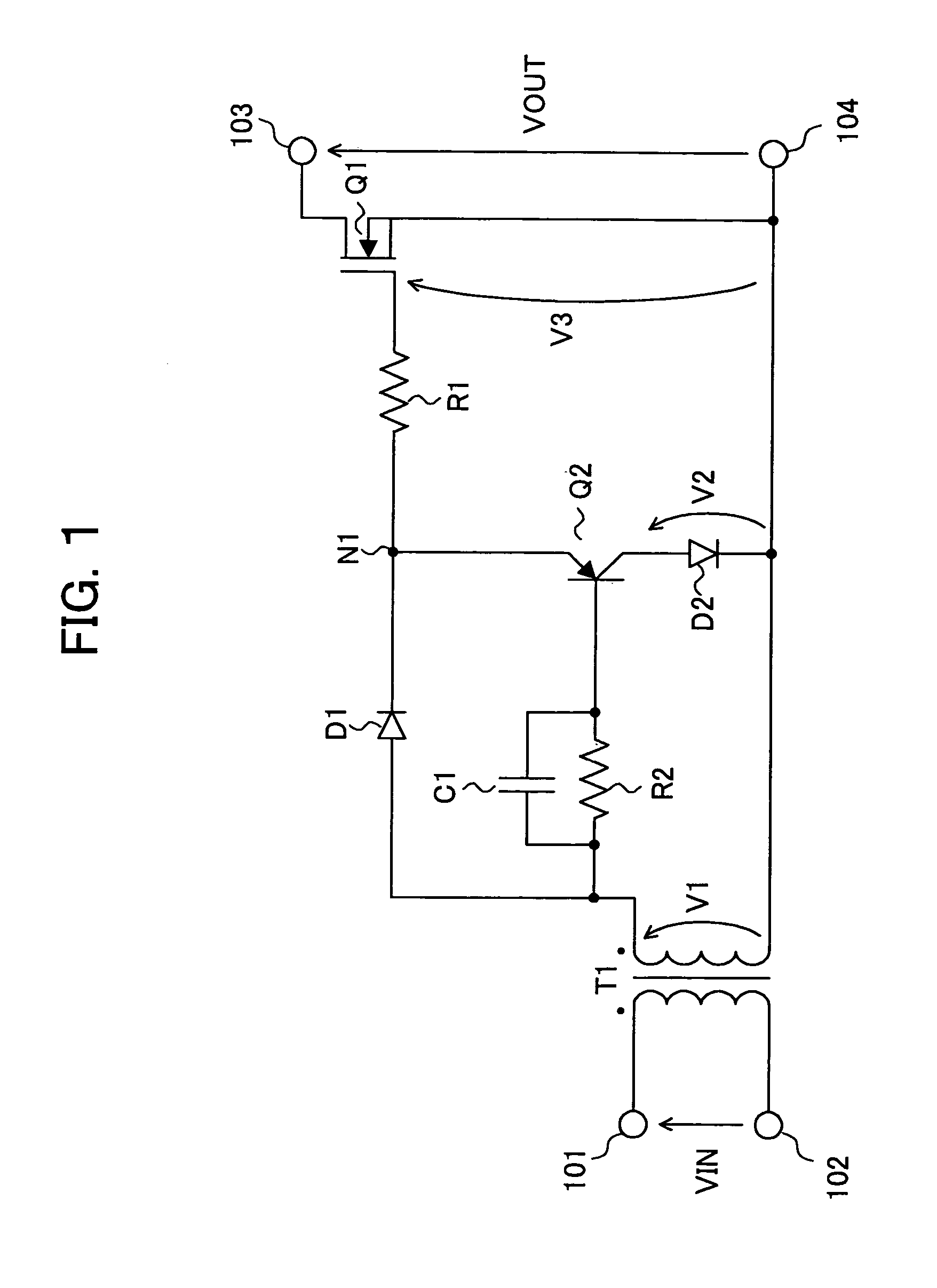

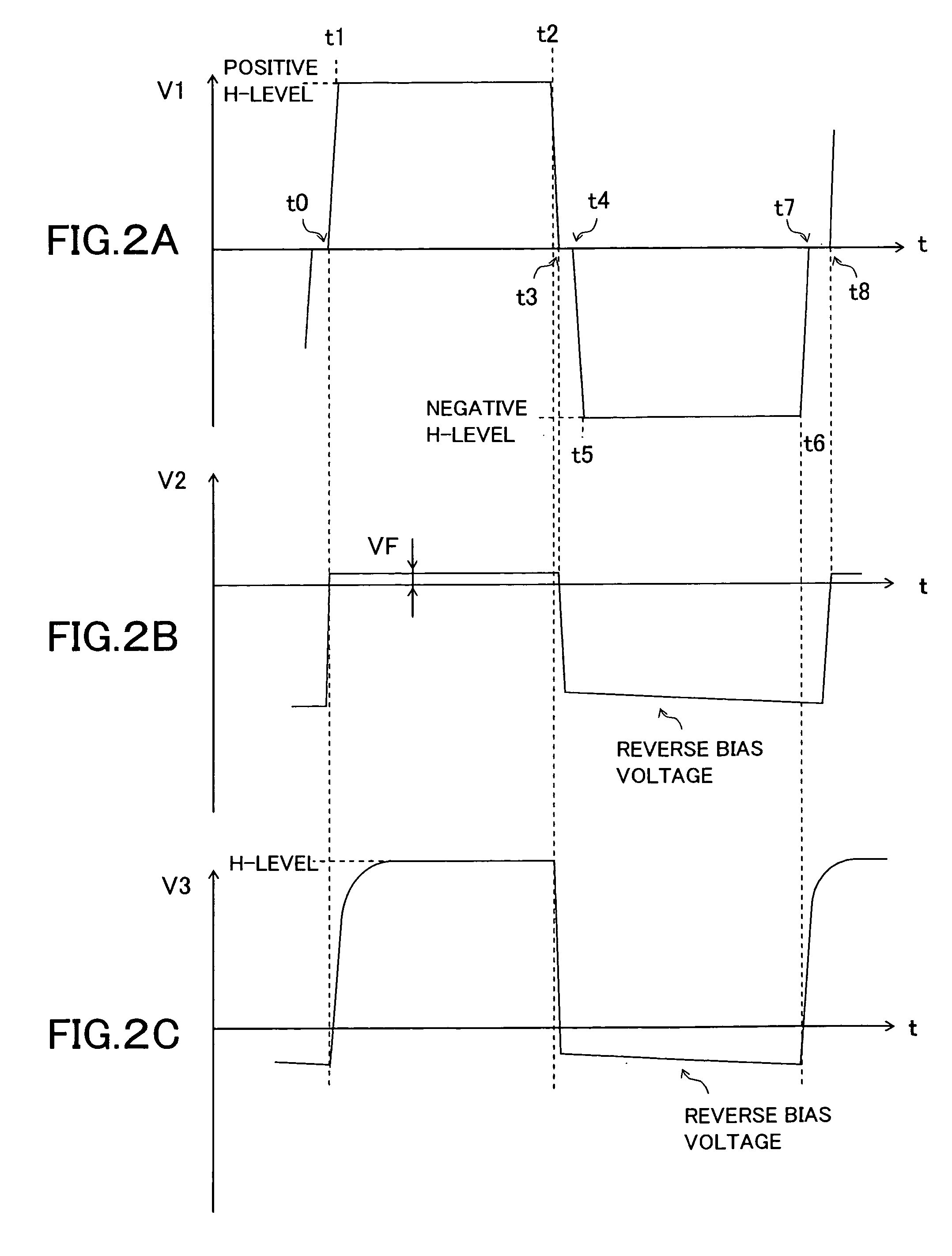

Drive circuit and power supply apparatus

InactiveUS7113412B2Little power dissipationLower Level RequirementsTransistorAc-dc conversionTransformerReverse bias

In charging a gate of a NMOS transistor Q1, the charging speed is adjustable by varying a resistor R1. When an inputted pulse signal VIN reverses to a negative voltage, a diode D2 turns off. Then, current flows along a discharging loop formed by the gate capacitor, the resistor R1, the emitter of the transistor Q2, the base of the transistor Q2, the resistor R2 and the capacitor C1, the transformer T1 and the source of the NMOS transistor Q1. A reverse bias voltage is applied to the gate of the NMOS transistor Q1, thereby keeping the NMOS transistor Q1off-state stably.

Owner:TAMURA KK

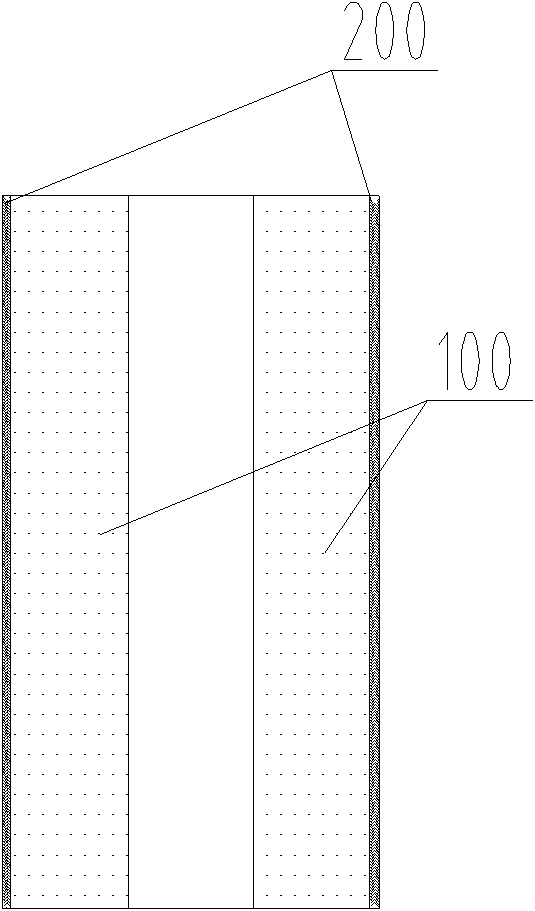

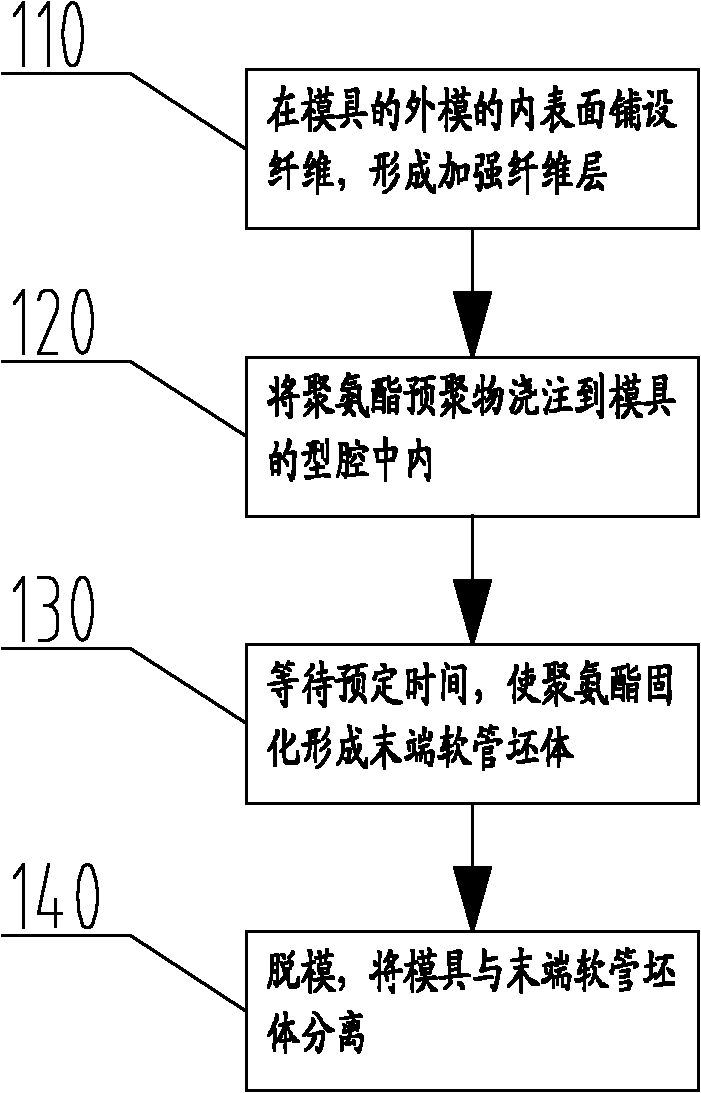

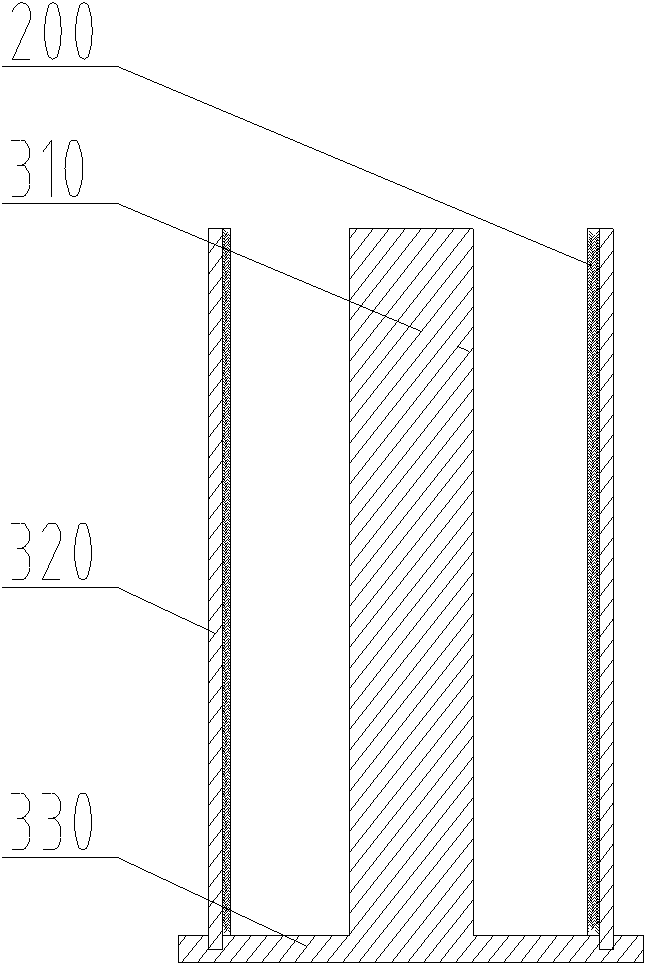

End hose of cantilever crane system, preparation method thereof and concrete transporting machine

ActiveCN102052527AExtended service lifeGuaranteed StrengthPipe elementsFlexible pipesFiberGlass fiber

The invention discloses a concrete transporting machine, an end hose of a cantilever crane system thereof and a preparation method of the end hose. The end hose of the cantilever crane system, which is disclosed by the invention, comprises a hose body and a fiber reinforcing layer compounded on the outer surface of the hose body; the material of the hose body comprises polyurethane, and the fiberreinforcing layer comprises glass fibers and / or carbon fibers; and preferentially, the fiber reinforcing layer is compounded on the outer surface of the hose body through a coupler. Because the polyurethane has stronger wear resistance, the wear rate of the hose body of the end hose is lower; moreover, the chemical property of the polyurethane is more stable, and influences due to external environment and temperature change on the properties of the end hose can be reduced, so that the end hose has longer service life; and in addition, the strength of the end hose is guaranteed through the fiber reinforcing layer consisting of the glass fibers and / or the carbon fibers to meet the requirements on transporting materials and controlling a delivery outlet, so that the end hose has lighter weight, which is also beneficial to controlling and operating the end hose.

Owner:SANY AUTOMOBILE MFG CO LTD

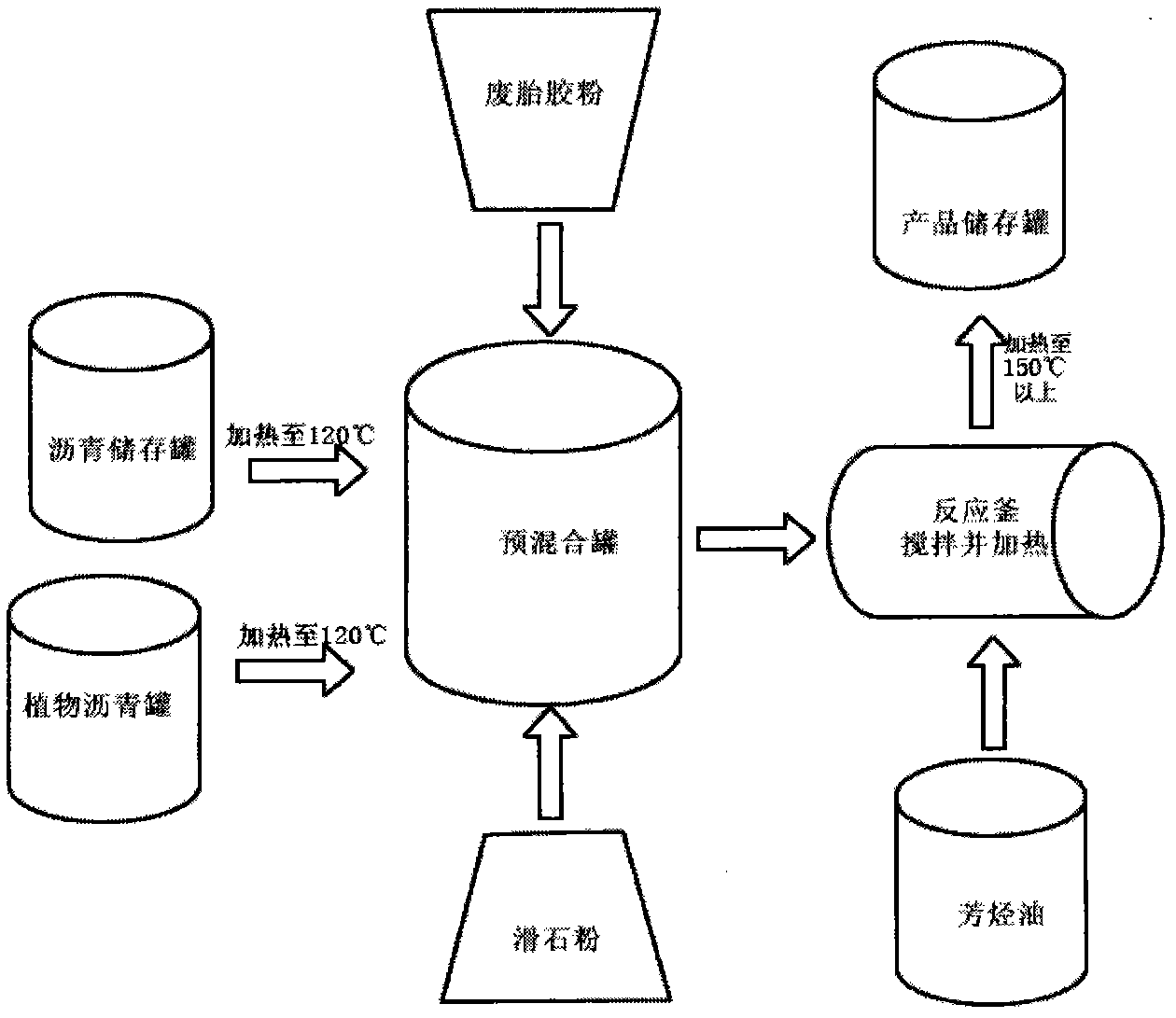

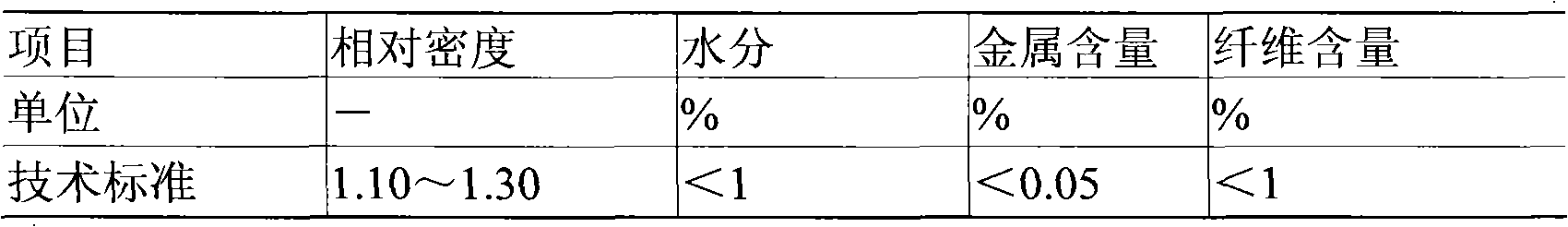

Waste tire rubber powder plant asphalt material and preparation method thereof

InactiveCN103013142AImprove performanceGood resistance to load deformationIn situ pavingsBuilding insulationsBituminous materialsRoad surface

The invention relates to the technical field of production and construction materials, and especially relates to a preparation method of modified asphalt produced under a certain condition by using waste residue produced during grain processing, waste tire rubber powder, petroleum asphalt, and other auxiliary materials. The material comprises 40-60% of petroleum asphalt, 25-50% of plant asphalt, 5-30% of waste tire rubber powder, 1 to 5% talcum powder, and 2-10% of base oil. The preparation method comprises the steps that: petroleum asphalt and plant asphalt are heated and are mixed according to the ratio; talcum powder (or cement and calcium powder) and waste tire rubber powder are added at the same time; the mixture is well mixed, and aromatic oil is added (the aromatic oil can also be added before the rubber powder and the talcum powder); the mixture is uniformly mixed and blended under a high-temperature condition; and reaction and development are carried out for 30-240min, such that the asphalt material is prepared. The asphalt material can be widely used in various levels of pavement for replacing other asphalt materials. With the asphalt material provided by the invention, pavement application performance is improved, petroleum resource is saved, environment is protected, and cost is reduced.

Owner:北京嘉格伟业筑路科技有限公司 +2

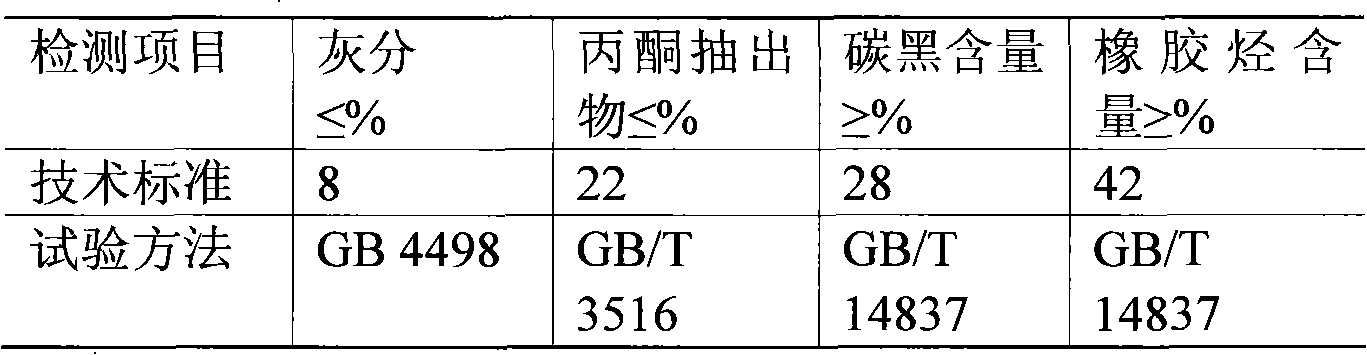

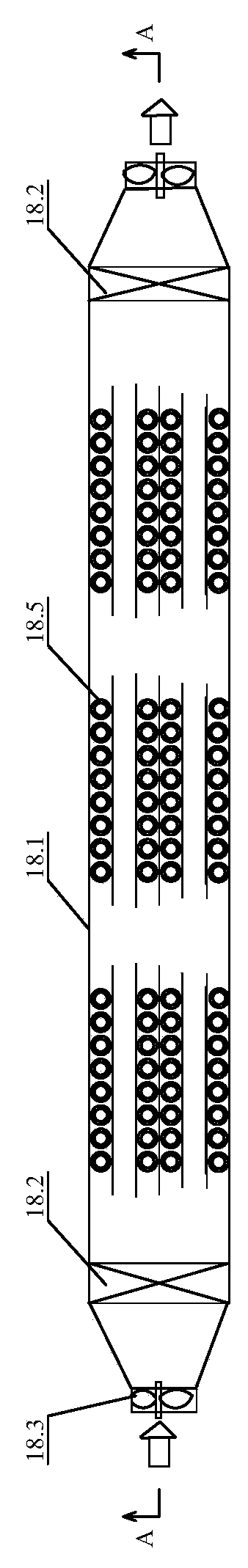

Solar hot water auxiliary heat storage device and power plant boiler solar hot water supply system constituted by same

ActiveCN104197310AEfficient use ofIncrease water temperatureSolar heating energySolar heat devicesMolecular sieveInstability

The invention discloses a solar hot water auxiliary heat storage device which comprises at least one molecular sieve heat storage bed and a heat storage water tank. The molecular sieve heat storage bed comprises a barrel-shaped heat storage bed outer shell, a plurality of heat storage tubes are arranged in the heat storage bed outer shell, and each heat storage tube is composed of a metal tube with meshes and an absorbent layer attached to the surface of the metal tube with the meshes and is used for heat storage. Absorption materials in the absorbent layer are molecular sieve absorption materials which are used as a heat storage working media pair together with water. The invention further discloses a power plant boiler solar hot water supply system constituted by the solar hot water auxiliary heat storage device. Solar energy can be fully used as the postcombustion of a power plant boiler, normal operation of the boiler is not influenced by the instability, the intermittence and the like of solar energy, and the cost of a power plant is obviously lowered.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

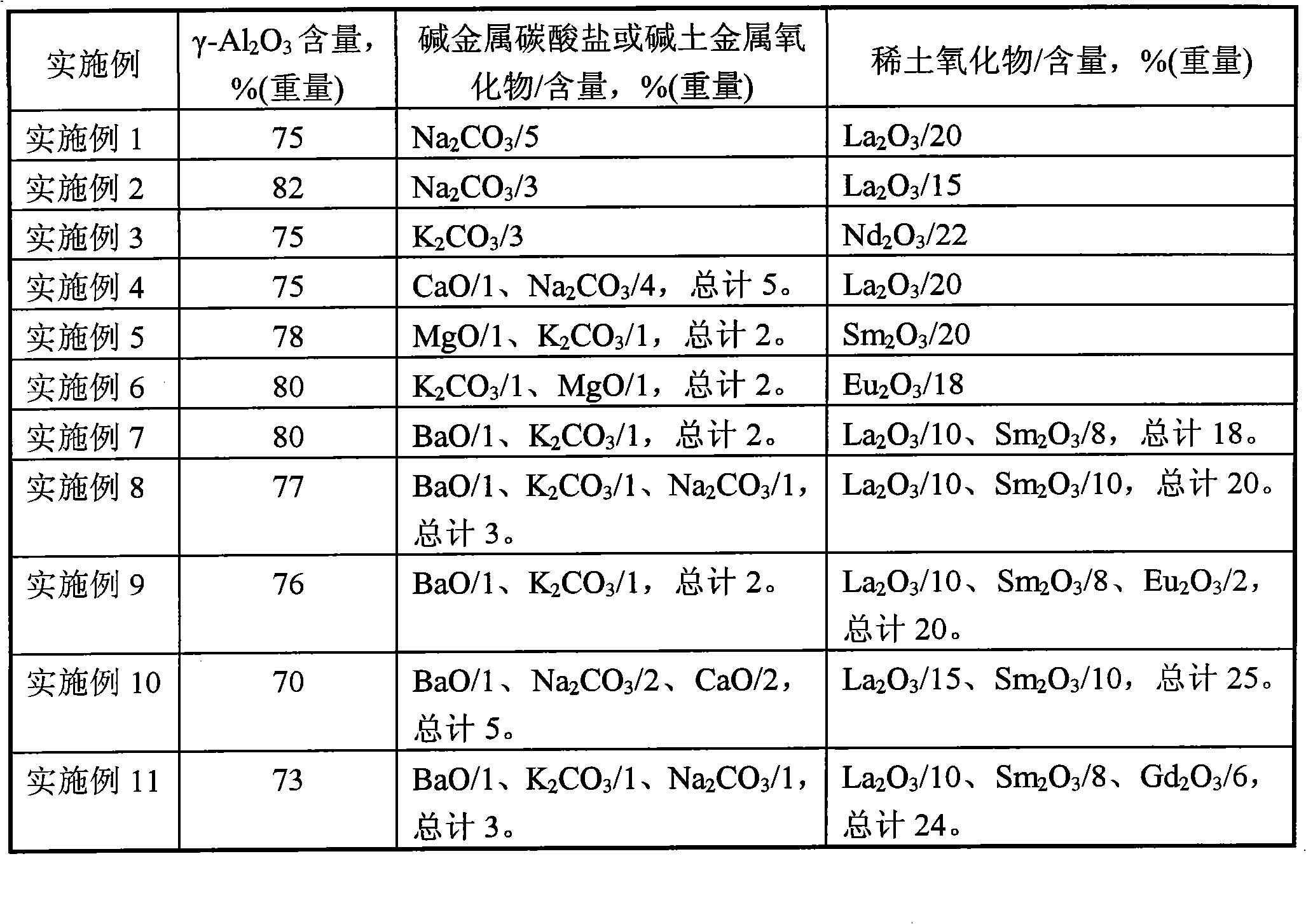

Method for hydrolyzing carbonyl sulphide (COS)

ActiveCN102463033AHigh airspeedPermalink will notDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthCarbonyl sulfide

The invention relates to a method for hydrolyzing carbonyl sulphide (COS), which is used for mainly solving the technical problems of narrower reaction temperature interval for COS hydrolysis, low applicative material airspeed and permanent inactivation of catalyst in the event of containing O2 in a material in the prior art. The technical problems are well solved by adopting the technical scheme as follows: the method for hydrolyzing the carbonyl sulphide comprises the step of reacting materials containing carbonyl sulphide and water in the presence of catalyst, wherein the catalyst comprises the following components in percentage by weight: (a) 1-5% of alkali carbonate, alkaline-earth metallic oxide or a mixture thereof; (b) 15-25% of rear-earth oxide in total; and (c) 70-82% of alumina. The method disclosed by the invention can be applied to industrial treatment of materials containing the carbonyl sulphide.

Owner:CHINA PETROLEUM & CHEM CORP +1

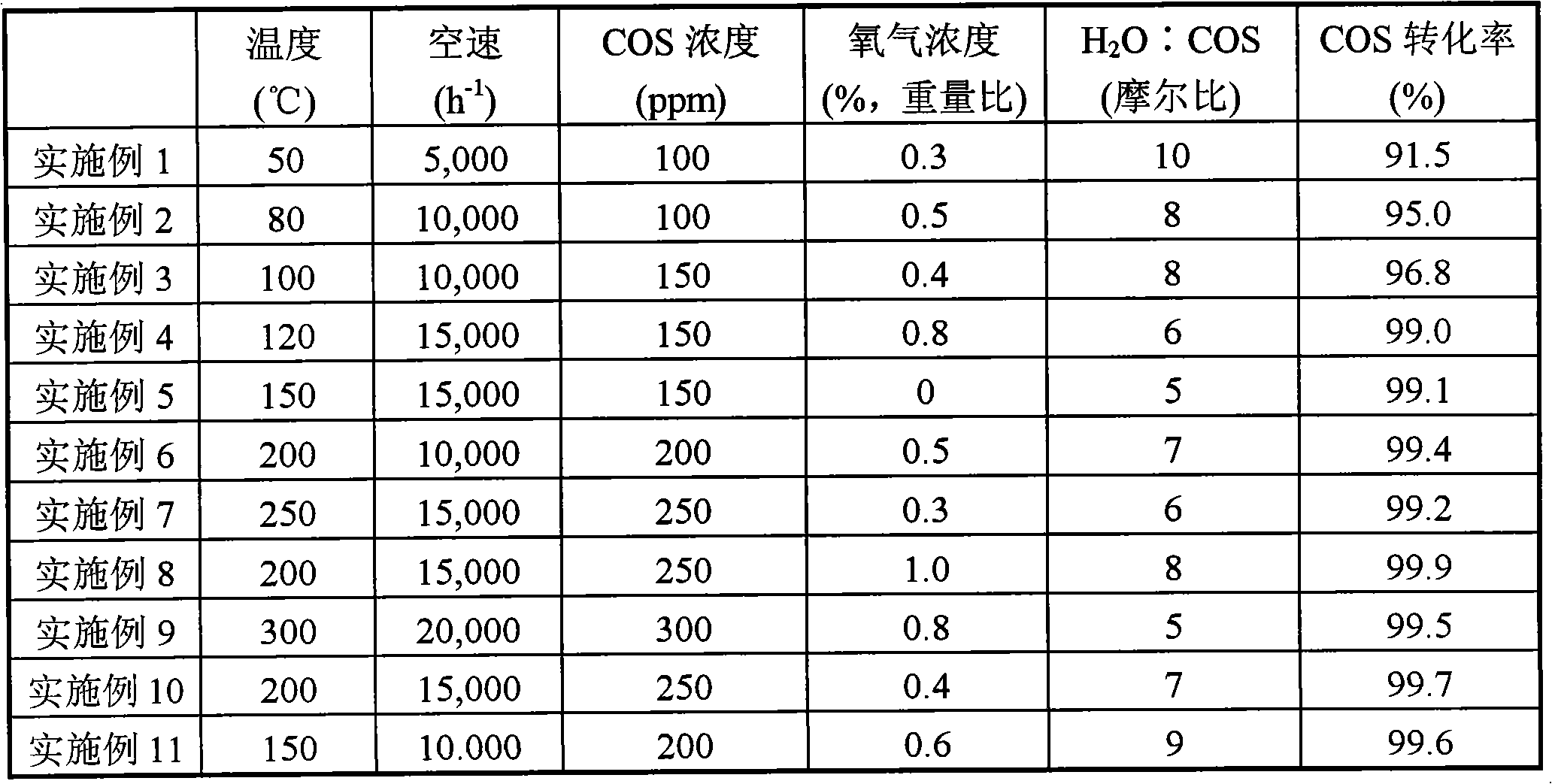

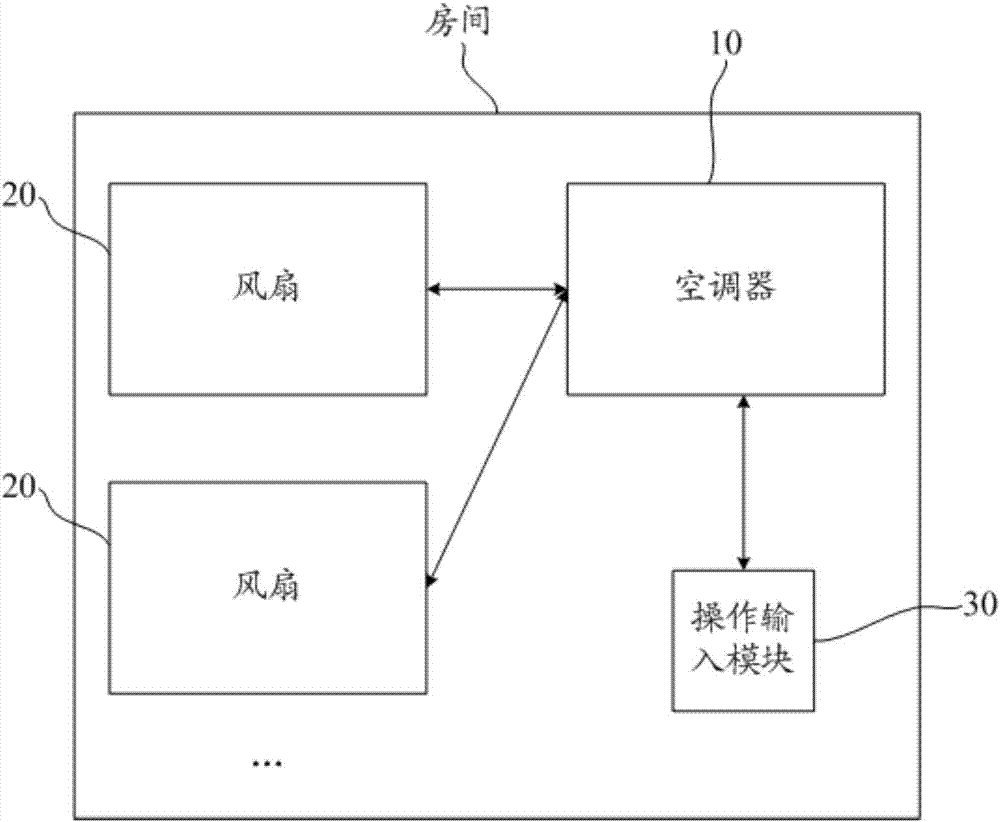

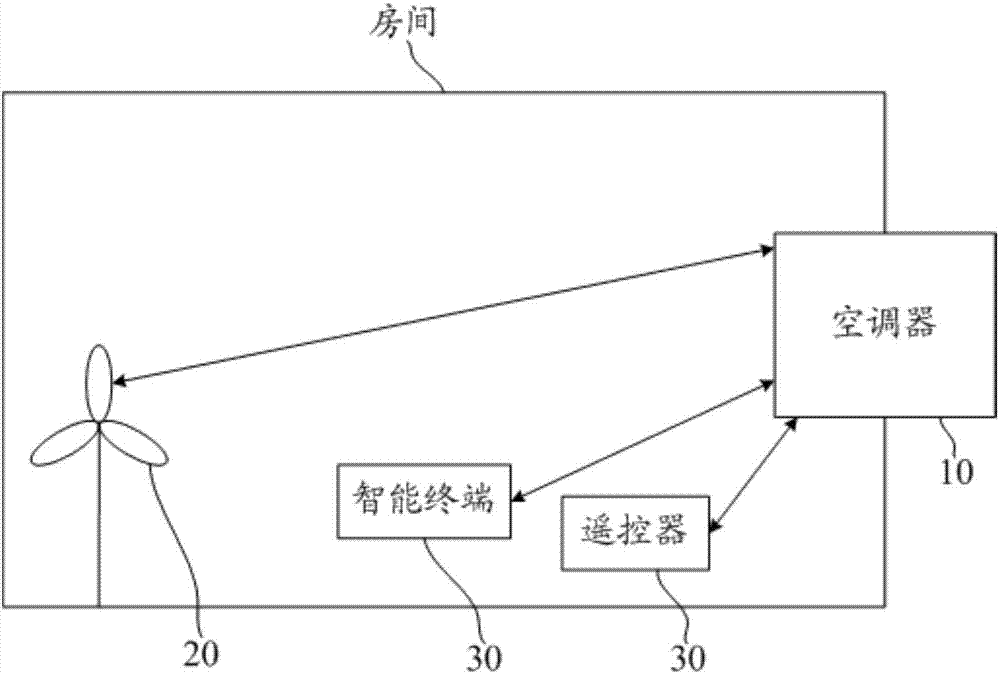

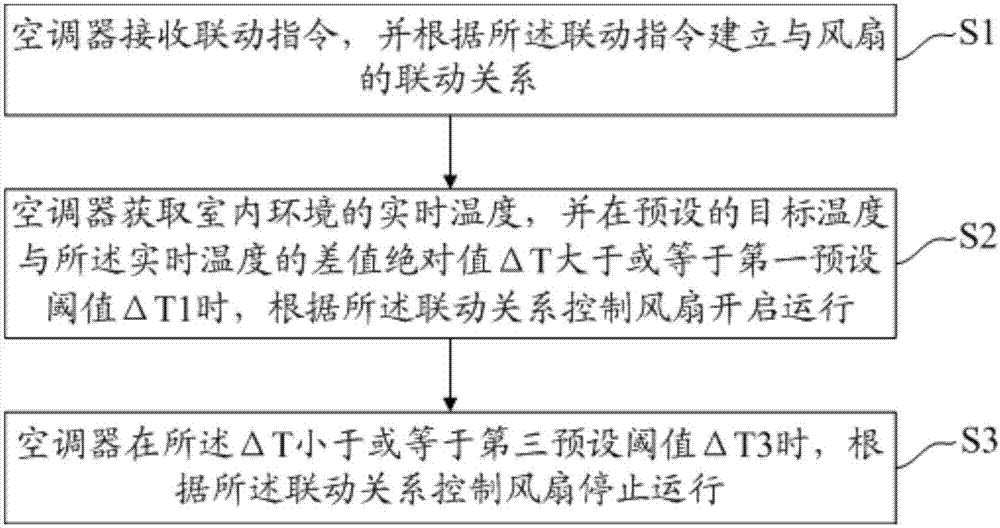

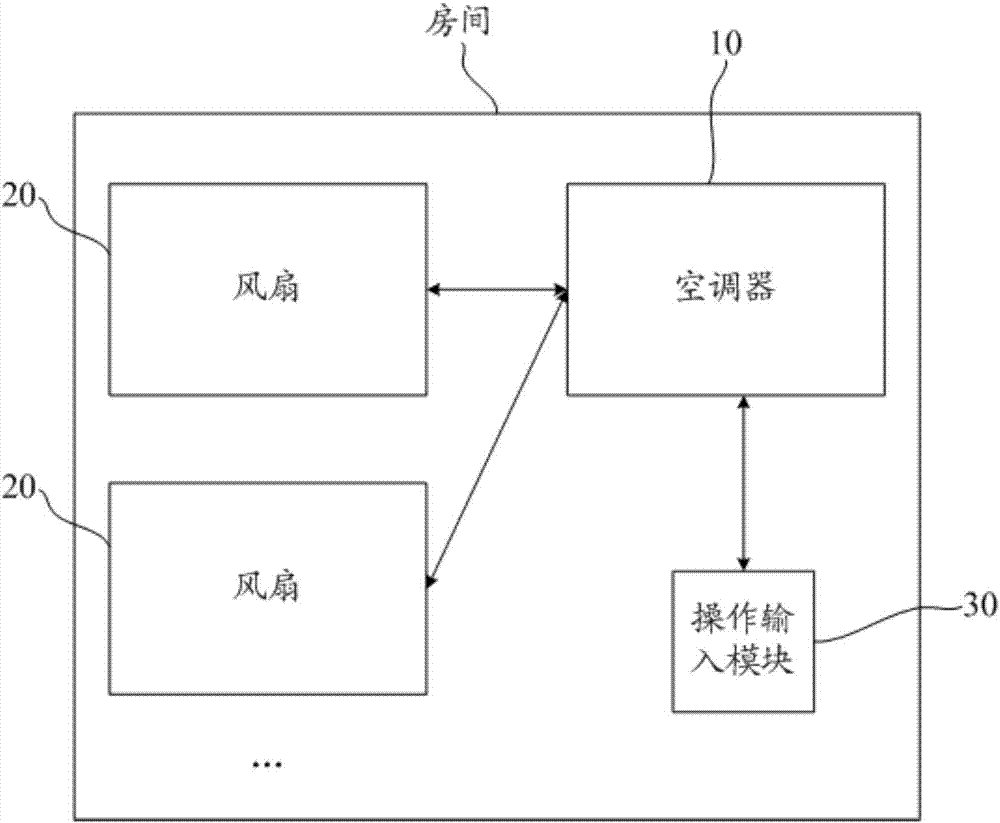

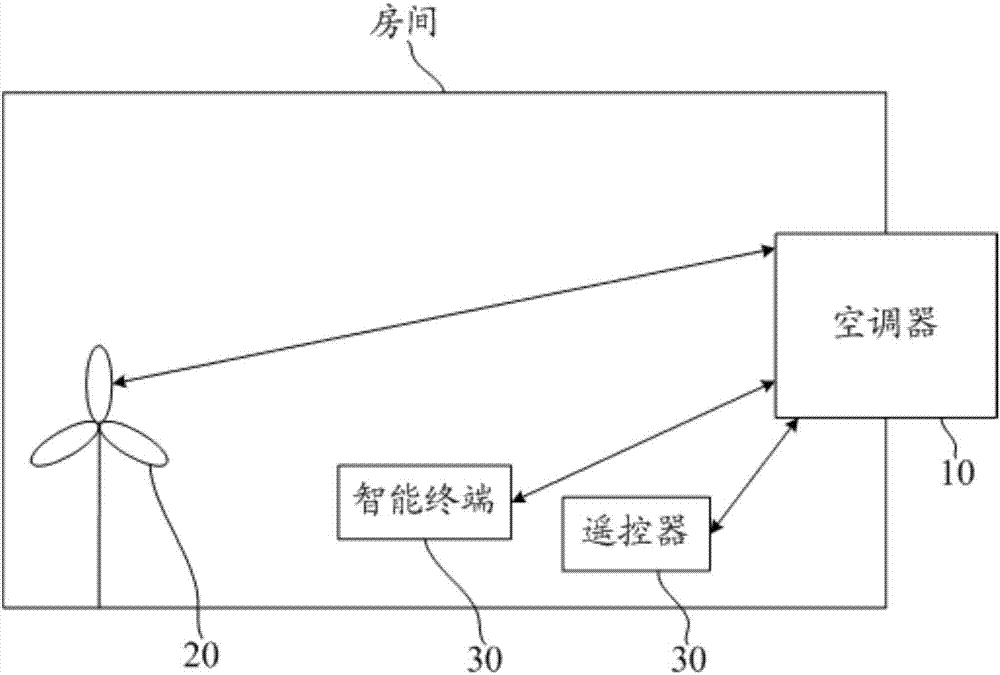

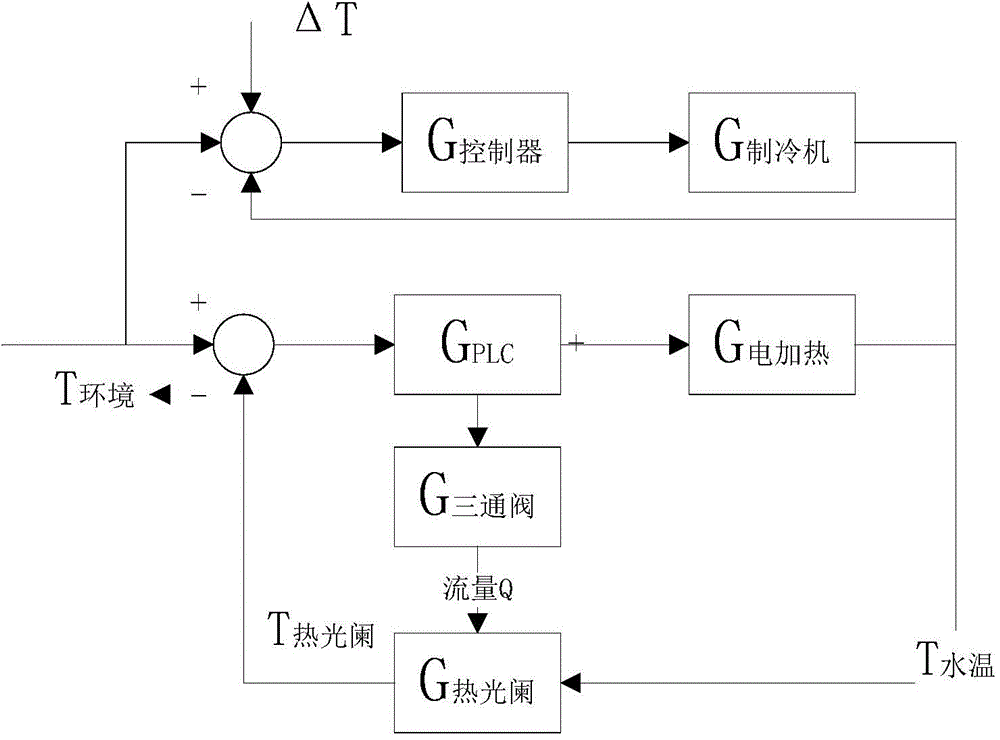

Air conditioner and fan ganged control method and system, and computer readable medium

ActiveCN107084505AIncreased temperature regulation rateLarge temperature rangeMechanical apparatusSpace heating and ventilation safety systemsControl theory

The invention discloses an air conditioner and fan ganged control method and system and a computer readable medium. The air conditioner and fan ganged control method comprises the following steps that S1, an air conditioner receives a ganged instruction and sets up a ganged relation with a fan according to the ganged instruction; and S2, the air conditioner obtains the real-time temperature of an indoor environment, and when the absolute value delta T of the difference value between the preset target temperature and the real-time temperature is larger than or equal to a fist preset threshold value delta T1, the fan rotation speed corresponding to the delta T is obtained according to a first preset rule, the fan is controlled according to the ganged relation to be started and operate at the obtained fan rotation speed, and the fan is controlled to open a cyclic swing mode, wherein the delta T corresponding to the larger fan rotation speed is larger. According to the technical scheme, the temperature adjusting rate of the air conditioner can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

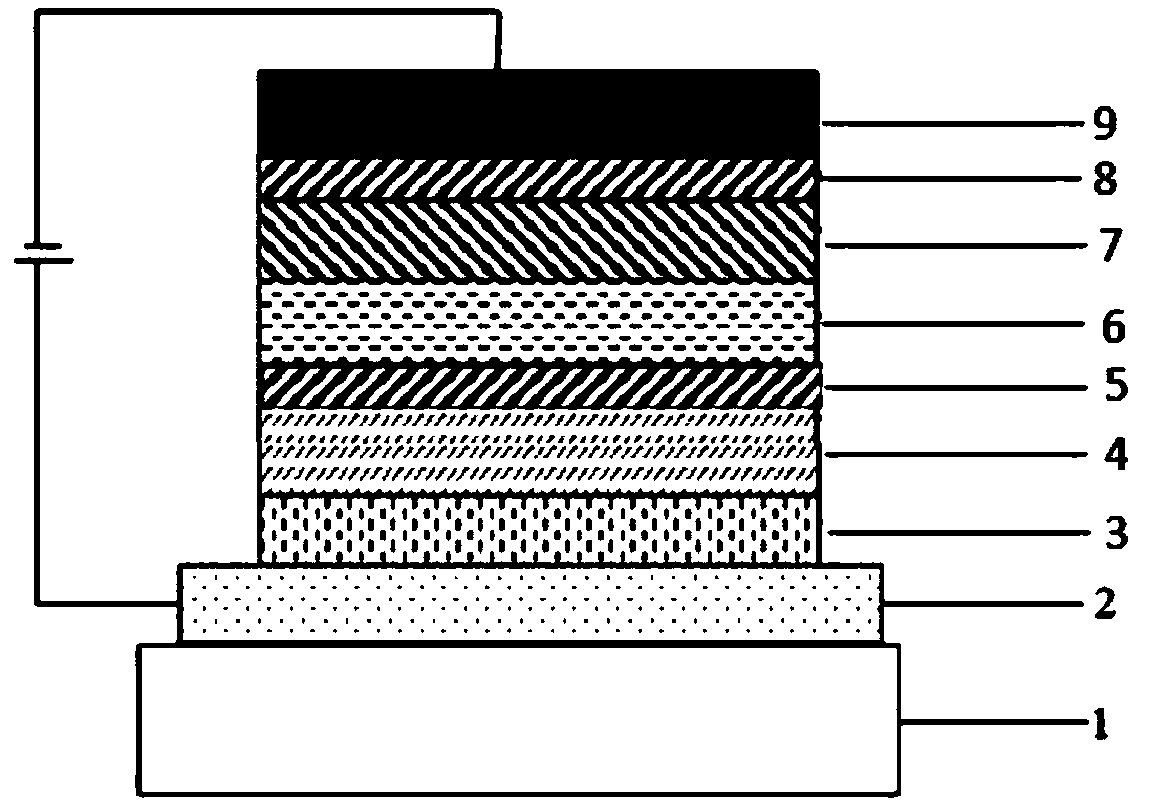

Compound taking fluorene as core, and preparation method and application thereof

InactiveCN110964021AThree-dimensional structure is stableImprove luminous efficiencyOrganic chemistrySolid-state devicesPerylene derivativesGlass transition

The invention discloses a compound taking fluorene as a core, and a preparation method and an application thereof, and belongs to the technical field of semiconductors. The compound provided by the invention has the structure represented by a general formula (I). The invention also discloses the preparation method and the application of the compound taking fluorene as the core. The compound provided by the invention contains fluorene derivatives and six-membered ring derivative structures, has relatively high glass transition temperature and molecular thermal stability, proper HOMO and LUMO energy levels and relatively high Eg, and can effectively improve the photoelectric property of an OLED device and prolong the service life of the OLED device through device structure optimization.

Owner:JIANGSU SUNERA TECH CO LTD

Temperature adjusting and controlling method for minitype experiment period and special apparatus therefor

InactiveCN1501038AHeatingFunctionalHeating or cooling apparatusMachines using electric/magnetic effectsTemperature controlElectricity

The present invention relates to temperature regulating and controlling method and special apparatus suitable for miniature experiment section. When the temperature of metal body is higher or lower than the temperature the temperature control instrument sets, the temperature controlling circuit will control the conversion of power supply polarity to make the temperature of the metal body within the range around the set temperature. The apparatus includes one metal body with experiment section flow channel, semiconductor refrigerator mounted on the metal body, heat sink set on the semiconductor refrigerator, heat isolating lay to cover the metal body except the part the semiconductor refrigerator is mounted; and temperature sensor fixed inside the hole in the metal body and connected to the temperature control instrument, with the heat sink being connected electrically to the DC power supply and the temperature control instrument via the temperature control circuit.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Seat belt retractor torsion rod activity sensor

InactiveUS20050040631A1Large temperature rangeUse in some applicationBelt retractorsBelt control systemsSeat beltEngineering

A seat belt load limiter employs a magnetostrictive sensor to detect the elastic loading and plastic deformation of a torsion rod forming part of a seat belt retractor. A magnet and a coil are placed about or adjacent to the torsion rod. When the torsion rod undergoes elastic or plastic strain, an electrical voltage is induced in the coil which is used to detect elastic or plastic strain of the torsion rod. A vehicle safety system uses the output of the magnetostrictive sensor to inform the vehicle operator when the seat belt load limiter is in need of replacement. The output of the magnetostrictive sensor as processed by the vehicle safety system can also be used to detect a situation where the seat occupant is not restrained by the seat belt and to make an airbag deployment decision.

Owner:KEY SAFETY SYST

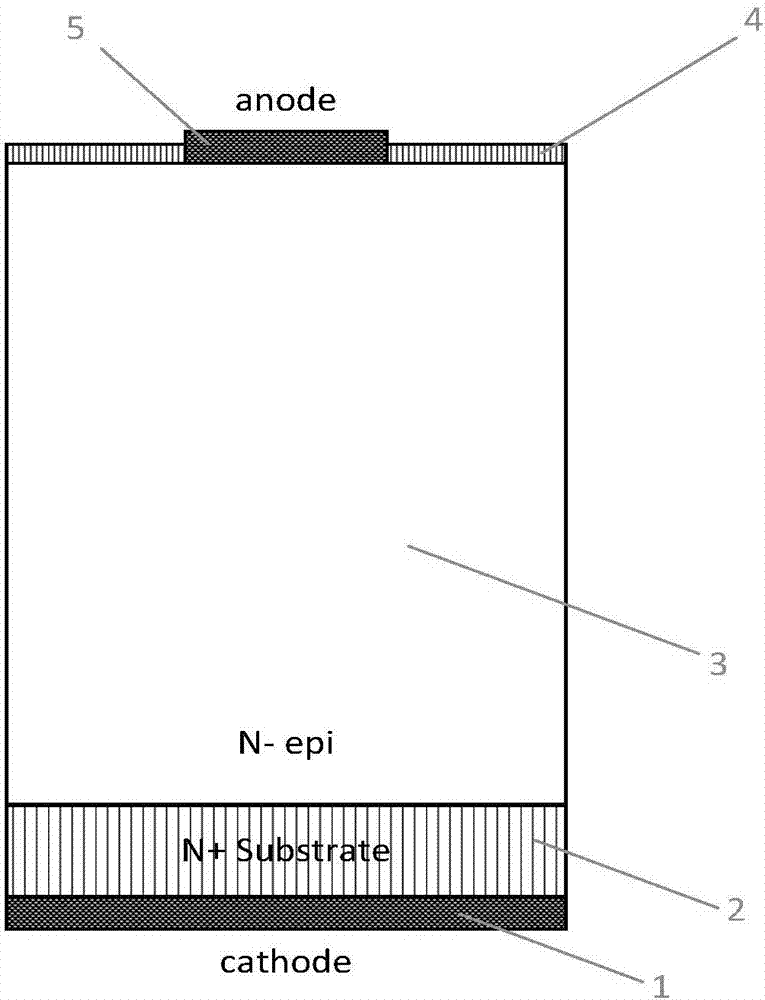

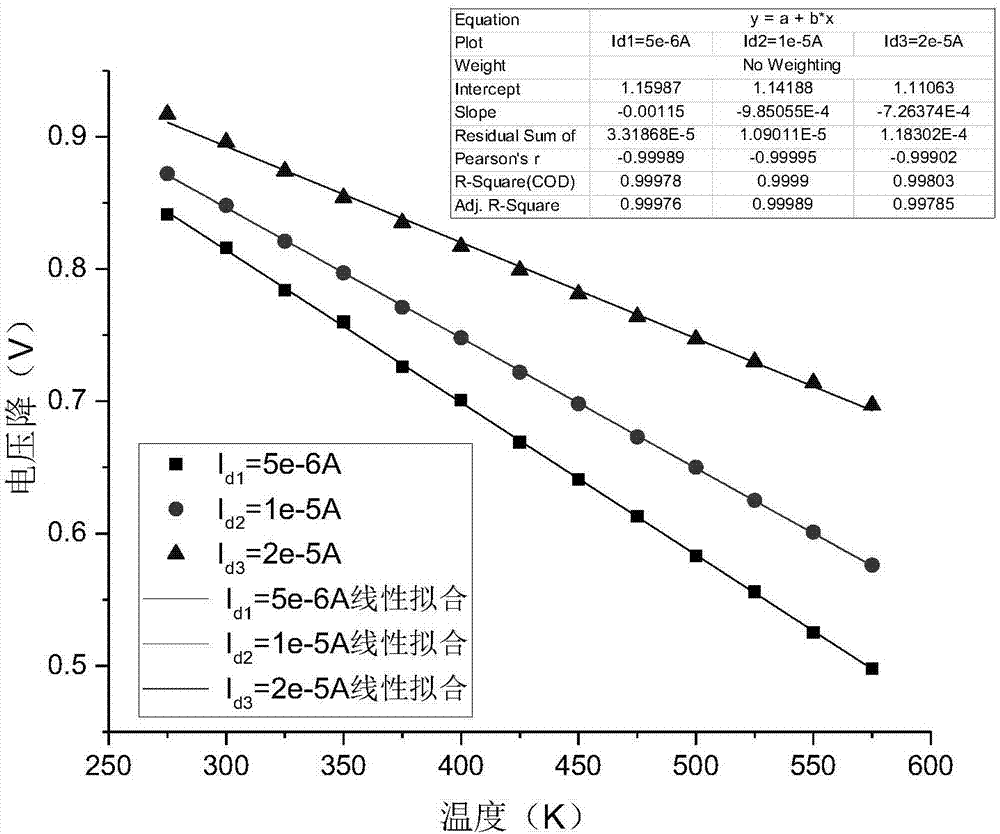

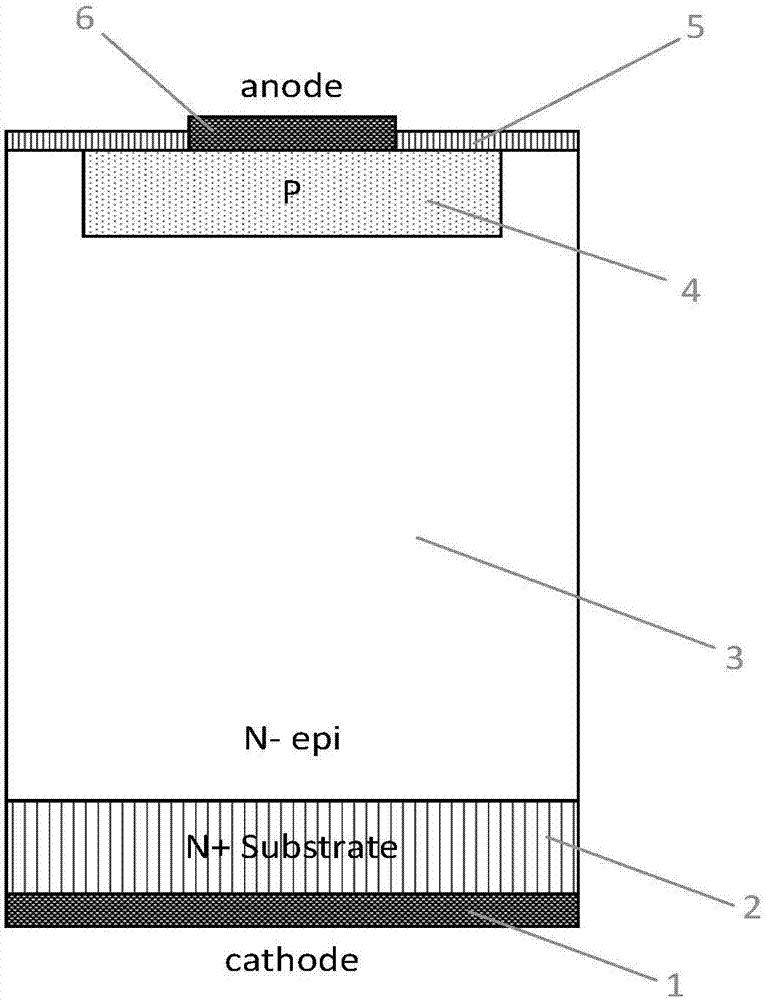

Silicon carbide linear temperature sensor, temperature measuring method thereof and manufacturing method thereof

ActiveCN107957299AEliminate adverse effectsLarge temperature rangeThermometers using electric/magnetic elementsUsing electrical meansN type siliconOhmic contact

The invention relates to a silicon carbide linear temperature sensor, a temperature measuring method thereof and a manufacturing method thereof and belongs to the technical field of semiconductor devices. The silicon carbide linear temperature sensor comprises a P well at the top layer of a silicon carbide N-epitaxial layer, an N well with a shallower central junction depth at the top of the P well, an N-type silicon carbide ohmic contact region at the center of the N well, an Ohmic contact electrode at the upper surface of the N-type silicon carbide ohmic contact region, N-type Schottky contact electrodes at two ends of the N well and a passivation layer at the surface of a device. According to the silicon carbide linear temperature sensor, the temperature measuring method and the manufacturing method, a lateral design is adopted to obtain the silicon carbide temperature sensor based on double Schottky diode structures, on one hand, the influence of reverse saturation current on the linearity of the sensor can be eliminated, the linearity is improved, on the other hand, a linear dependence relation between diffusion resistance Rs and temperature is introduced, and the sensitivityof the device is improved. At the same time, the device structure provided by the invention is a lateral structure, compared with an existing longitudinal structure, the structure of the invention iseasy to integrate, due to the isolation effect of the P well, the crosstalk between sensor main devices can be reduced, and the feasibility of integration with N-type epitaxial power devices is increased.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

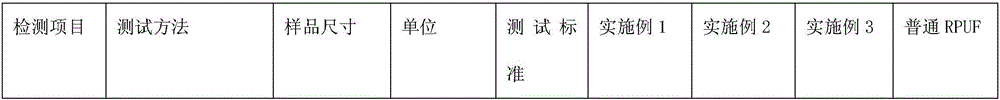

Environment-friendly flame-retardant hard polyurethane foaming plastic

The invention provides environment-friendly flame-retardant hard polyurethane foaming plastic. Polyisocyanates, polyether polyol, a foaming agent, a foam stabilizing agent, a catalyst, glycerinum and a flame retardant are taken as raw materials, wherein the flame retardant is synthesized novel halogen-free flame retardant 1-butyl-3-methylimidazole dibutyl ester ionic salt ([Bmim]DBP); the polyether polyol, the foaming agent, the foam stabilizing agent, the catalyst, the glycerinum and the flame retardant are uniformly stirred and mixed in a certain ratio at the room temperature in a high-speed dispersing machine, are further stirred and mixed uniformly with polyisocyanates added in a certain ratio, are subjected to foam molding in a mold, and are aged, so that the environment-friendly flame-retardant hard polyurethane foaming plastic can be obtained.

Owner:滕钜海

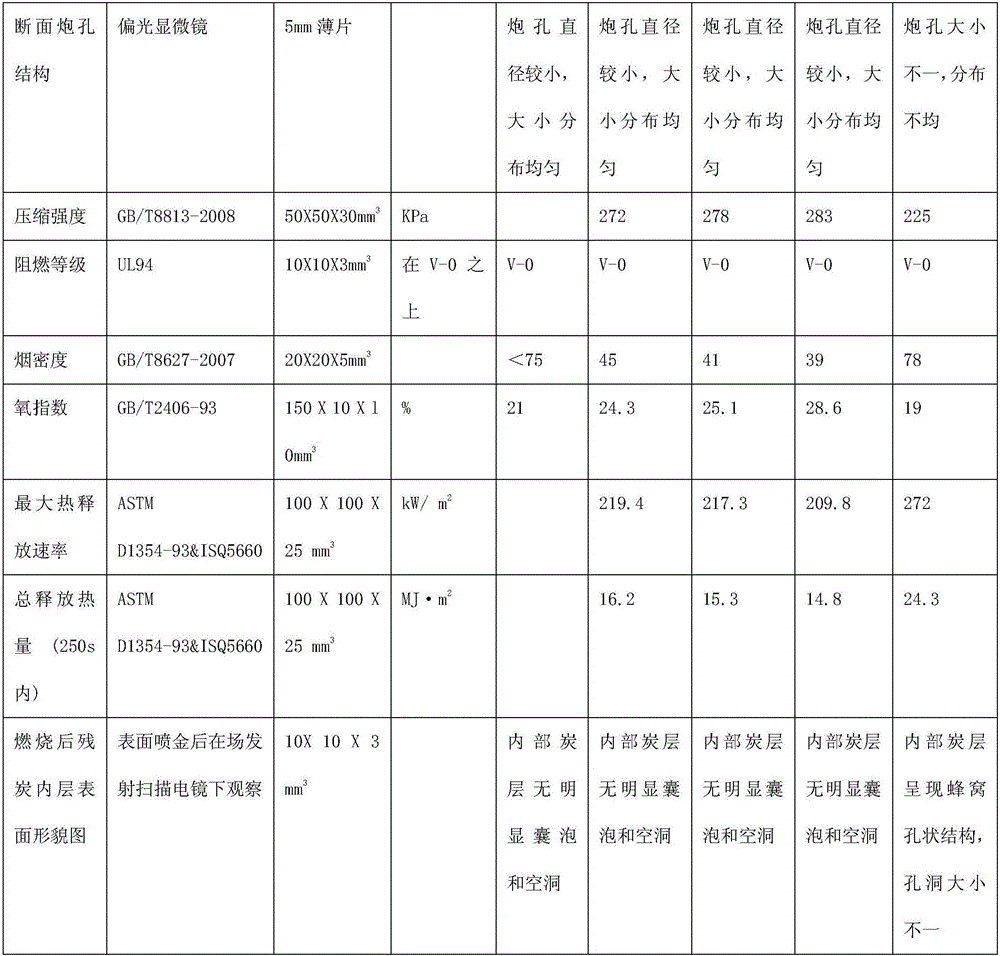

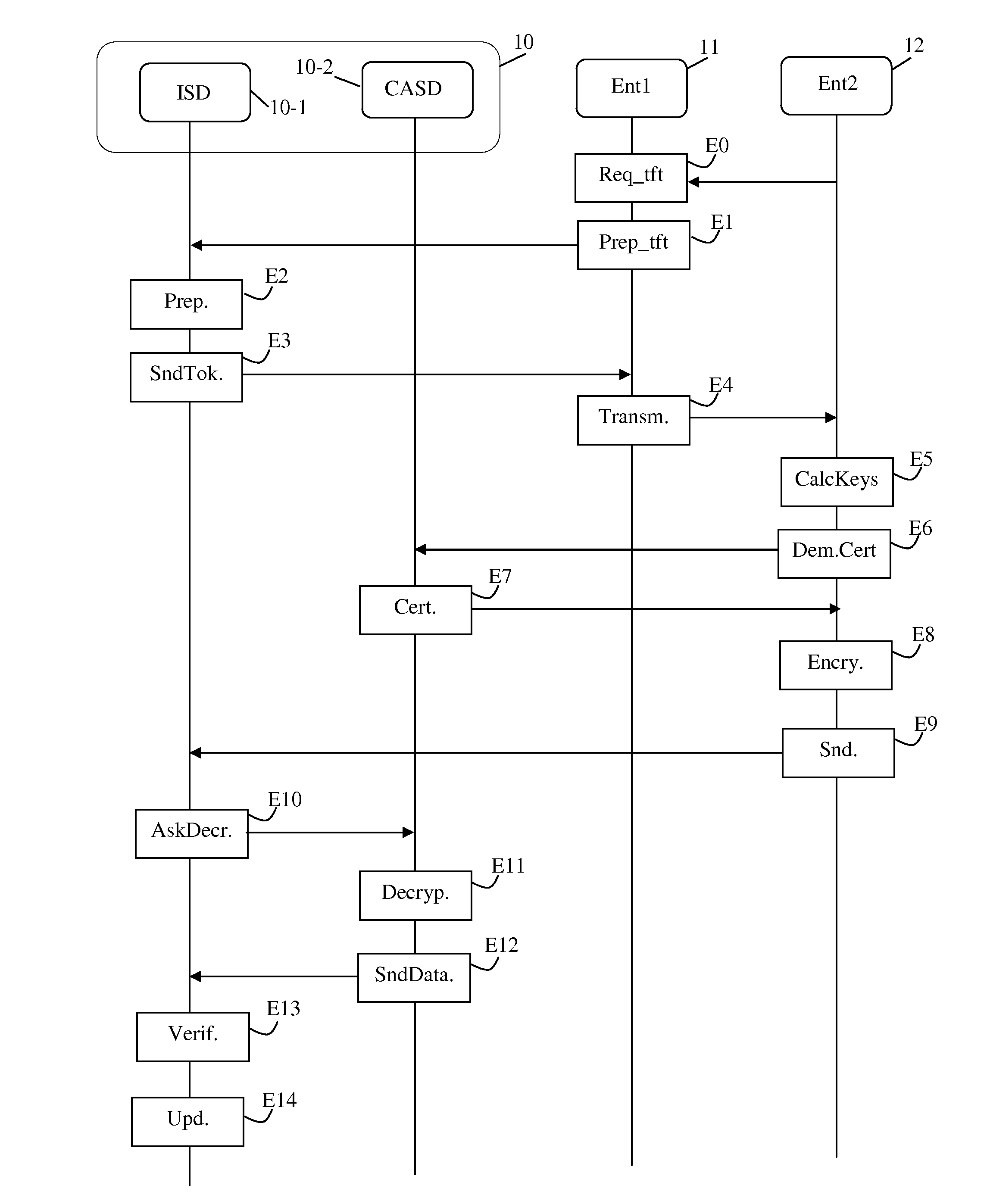

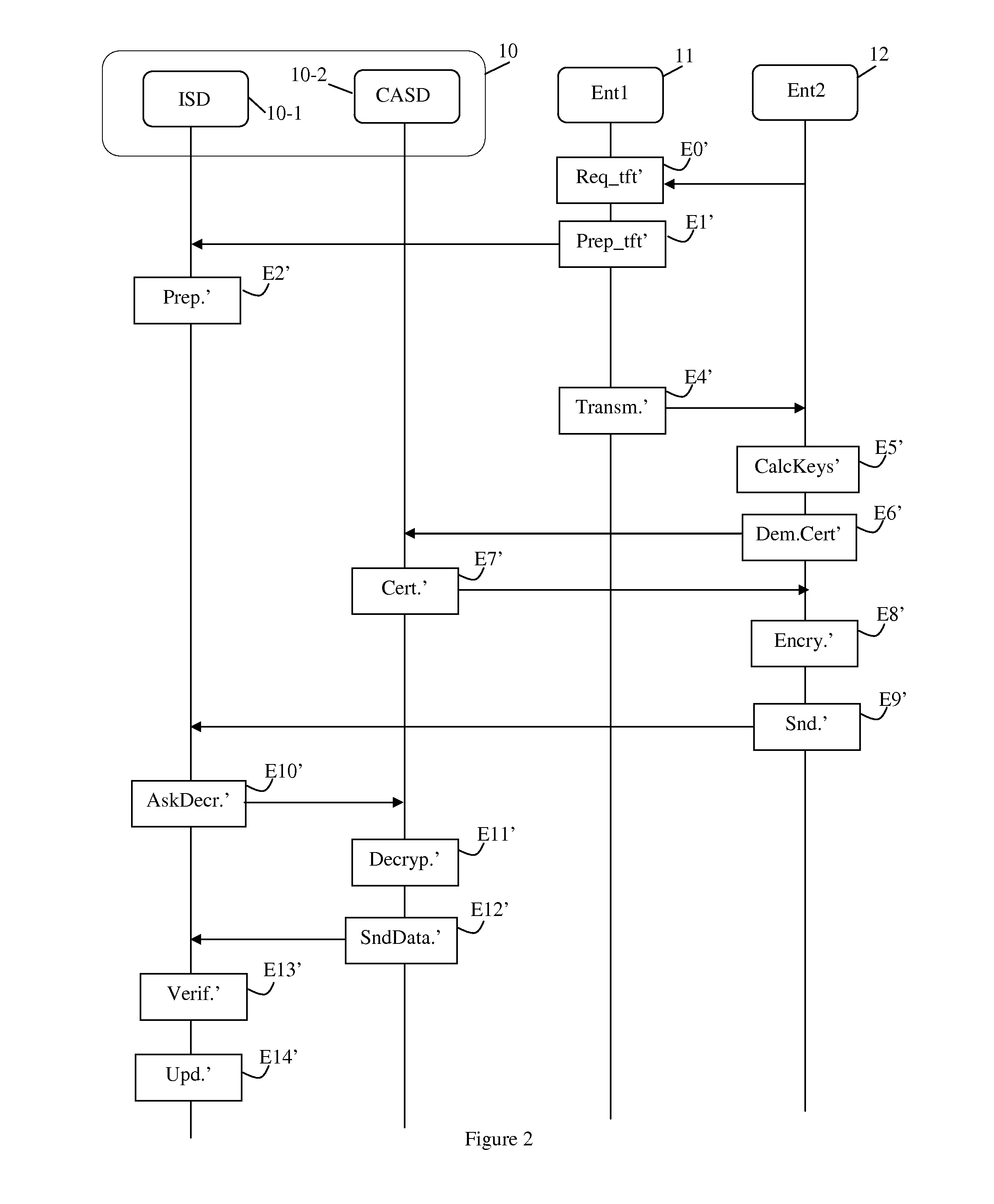

Method of transferring the control of a security module from a first entity to a second entity

ActiveUS20140359295A1Great mechanical strengthLarge temperature rangeUser identity/authority verificationSecurity arrangementSecurity domainComputer module

A method is provided for transferring control of a security module from a first entity to a second entity. The security module has a first security domain controlled by the first entity by at least one first secret control key specific to the first entity, and a second security domain, the second domain containing a private key and a certificate of a public key of a controlling authority. The method includes: receiving a request to obtain the certificate; sending the certificate; receiving data encrypted by the public key of the certificate, the data including at least one second secret control key specific to the second entity; decrypting the data; verifying the data; and if the verification is positive, replacing the at least one first secret control key by the at least one second secret control key.

Owner:ORANGE SA (FR)

Linkage control method and system of air conditioner and fan, and computer readable medium

InactiveCN107084506AIncreased temperature regulation rateLarge temperature rangeMechanical apparatusSpace heating and ventilation safety systemsComputer engineeringThermoregulation

The invention discloses a linkage control method and system of an air conditioner and a fan, and a computer readable medium, wherein the linkage control method of the air conditioner and the fan includes the following steps that S1, the air conditioner receives a linkage command and establishes linkage relationship with the fan according to the linkage command; S2, the air conditioner obtains a real-time temperature in a room, and when an absolute value deltaT of a difference value of a preset target temperature and the real-time temperature is larger than or equal to a first presupposed threshold value deltaT1, the fan is controlled to start and operate according to the linkage relationship. According to the technical scheme, the thermoregulation rate of the air conditioner can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Intermediate-phase asphalt and method for preparing intermediate-phase asphalt from coal liquefaction refined asphalt

ActiveCN103923682ALow viscosityImprove liquidityWorking-up pitch/asphalt/bitumen by chemical meansAlkyl transferReaction rate

The invention discloses an intermediate-phase asphalt and method for preparing the intermediate-phase asphalt from coal liquefaction refined asphalt. The method comprises the following steps: mixing coal liquefaction refined asphalt and additives to obtain a mixture; and carrying out co-carbonization polymerization reaction on the mixture to obtain the intermediate-phase asphalt, wherein the additives are high-molecular polymers. In the process of preparing the intermediate-phase asphalt from coal liquefaction refined asphalt, the high-molecular polymers can greatly inhibit excess carbonization through hydrogen transfer and alkyl transfer reactions in the medium and later reaction period of high-molecular polymers, and thus, can perform the functions of lowering the system viscosity and relieving the drastic reaction, thereby improving the system flowability, lowering the reaction rate, stabilizing and smoothing the reaction, and finally prolonging the carbonization temperature interval; and thus, the intermediate-phase asphalt with favorable fibrous structure is obtained.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

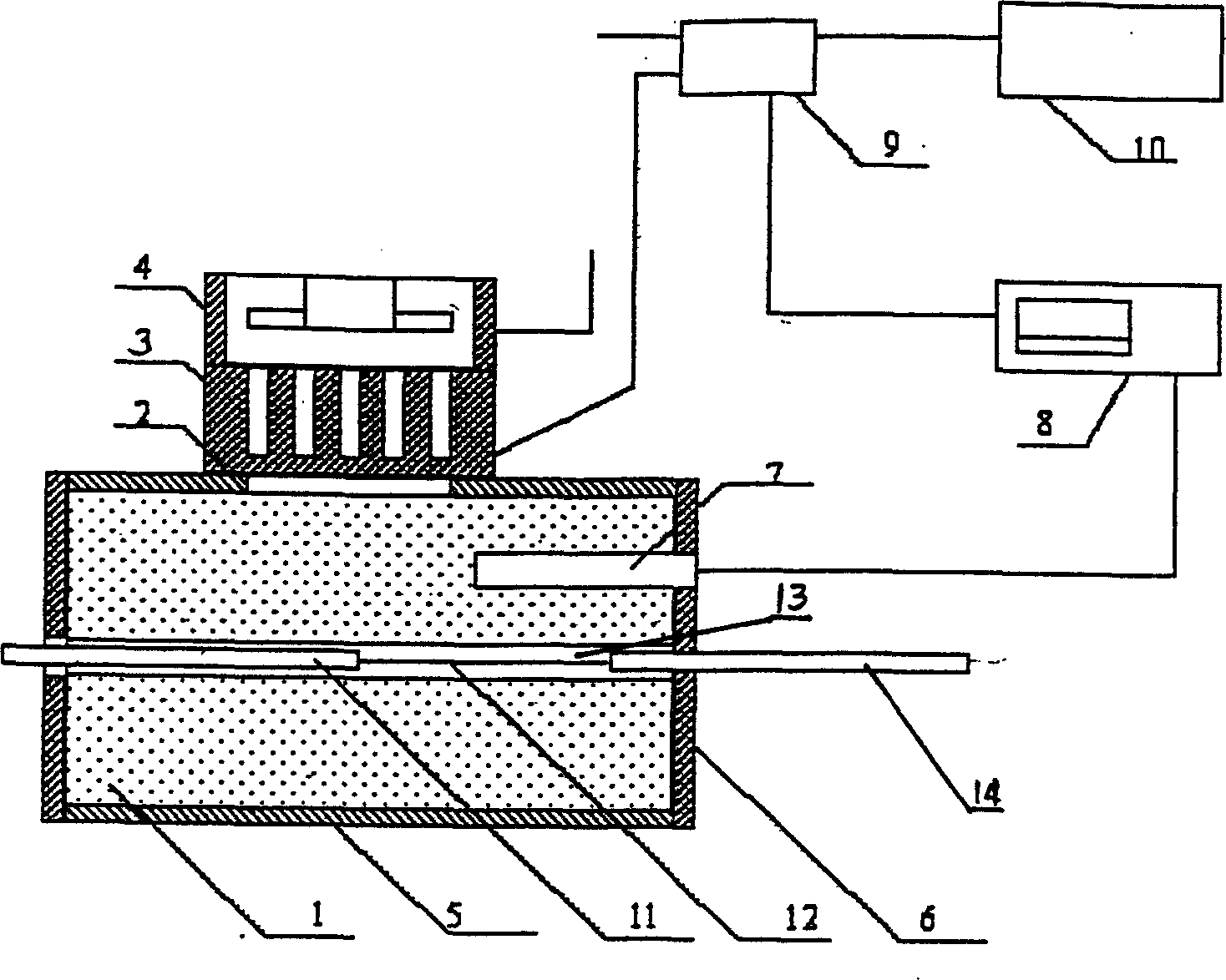

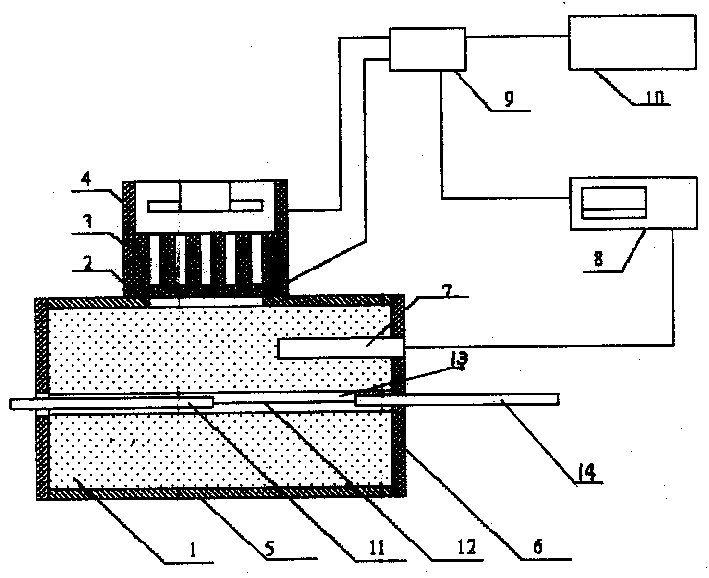

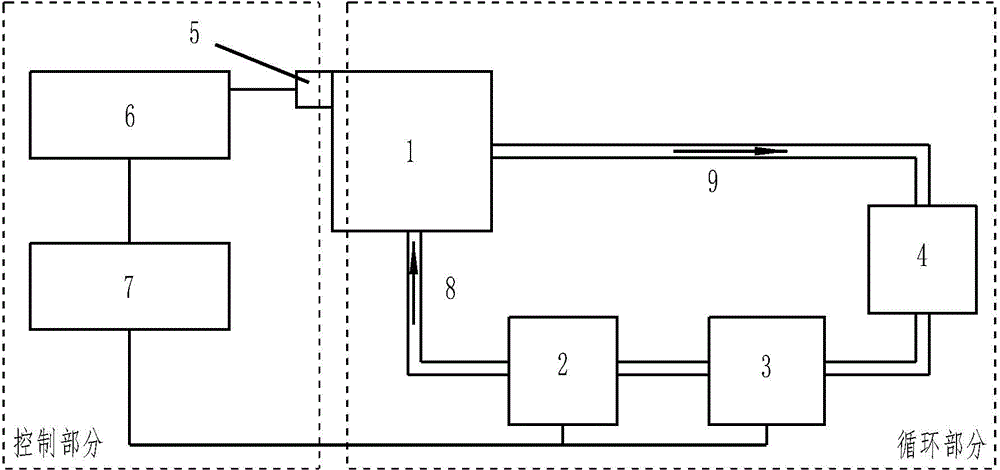

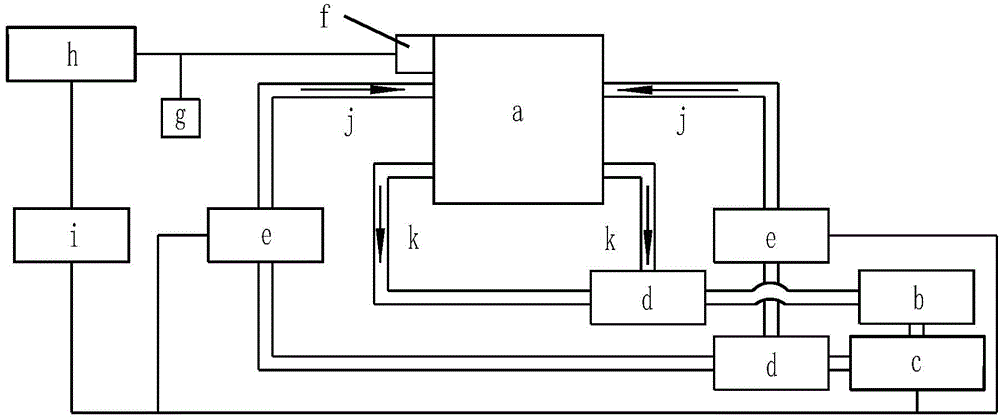

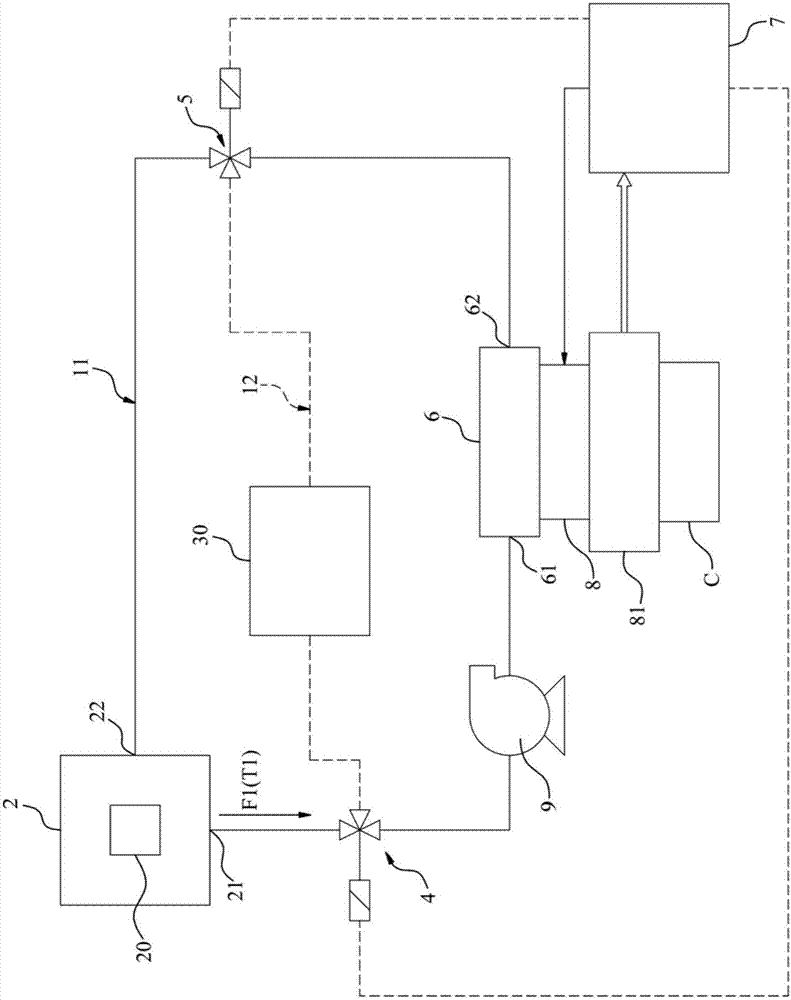

Thermal field diaphragm temperature control device capable of being used for large-diameter foundation solar telescope

InactiveCN104155749ALarge temperature rangeQuick responseTelescopesTemperature controlComputer module

The invention provides a thermal field diaphragm temperature control device capable of being used for a large-diameter foundation solar telescope. The thermal field diaphragm temperature control device comprises a thermal field diaphragm (1), a flow adjustment module (2), an air conditioner (3), a water collector (4), a temperature sensor (5), a temperature reading module (7), a water inlet pipe (8), a water outlet pipe (9) and the like. By means of the thermal field diaphragm temperature control device, control over the cooling medium flow and temperature can be controlled at the same time, temperature control over the thermal filed diaphragm can be conducted by adjusting the flow and temperature, the response speed and the temperature control range of the thermal field diaphragm temperature control device can be effectively increased and enlarged respectively, and vibration caused by the excessively large flow speed of the cooling media can be lowered at the same time.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Homo-polypropylene/carbon fiber/montmorillonite composite material and preparation method thereof

The invention relates to a homo-polypropylene / carbon fiber / montmorillonite composite material and a preparation method of the homo-polypropylene / carbon fiber / montmorillonite composite material. The homo-polypropylene / carbon fiber / montmorillonite composite material is prepared from the following raw materials in parts by weight: 85 to 95 parts of homo-polypropylene, 5 to 10 parts of carbon fibers, 2 to 3 parts of organic montmorillonite, and 3 to 5 parts of foaming masterbatches, the foaming masterbatches are prepared from the following raw materials in parts by weight: 60 to 70 parts of polyethylene, 20 to 30 parts of foaming agents, 1 to 3 parts of foam stabilizers, 3 to 5 parts of nucleating agents, 0.5 to 1.5 parts of zinc oxide, 0.5 to 1 part of a titanate coupling agent NDZ-201, 3 to 5 parts of PE wax and 0.5 to 1 part of zinc stearate. According to the homo-polypropylene / carbon fiber / montmorillonite composite material disclosed by the invention, the mechanical properties are excellent, the tensile strength reaches 36.9 MPa, the impact strength reaches 55.1 kJ / m<2>, and the flexural modulus reaches 1590 MPa. The foaming material has best foaming and biggest cell density, the cell density reaches 2.3*10<7> / cm3, and the porosity of the foaming material is 17.7%.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

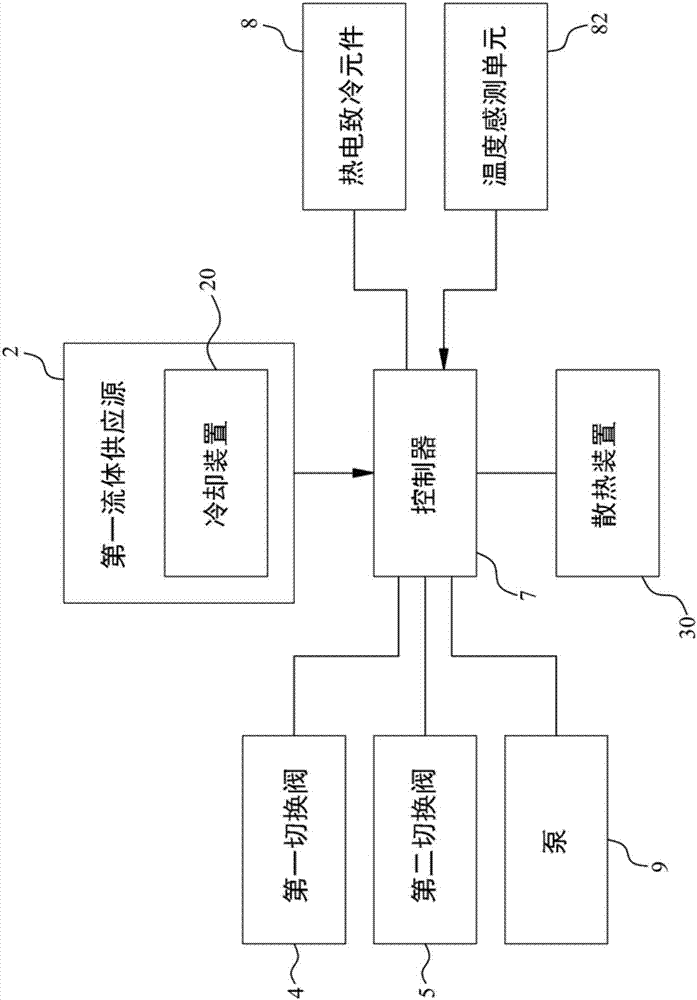

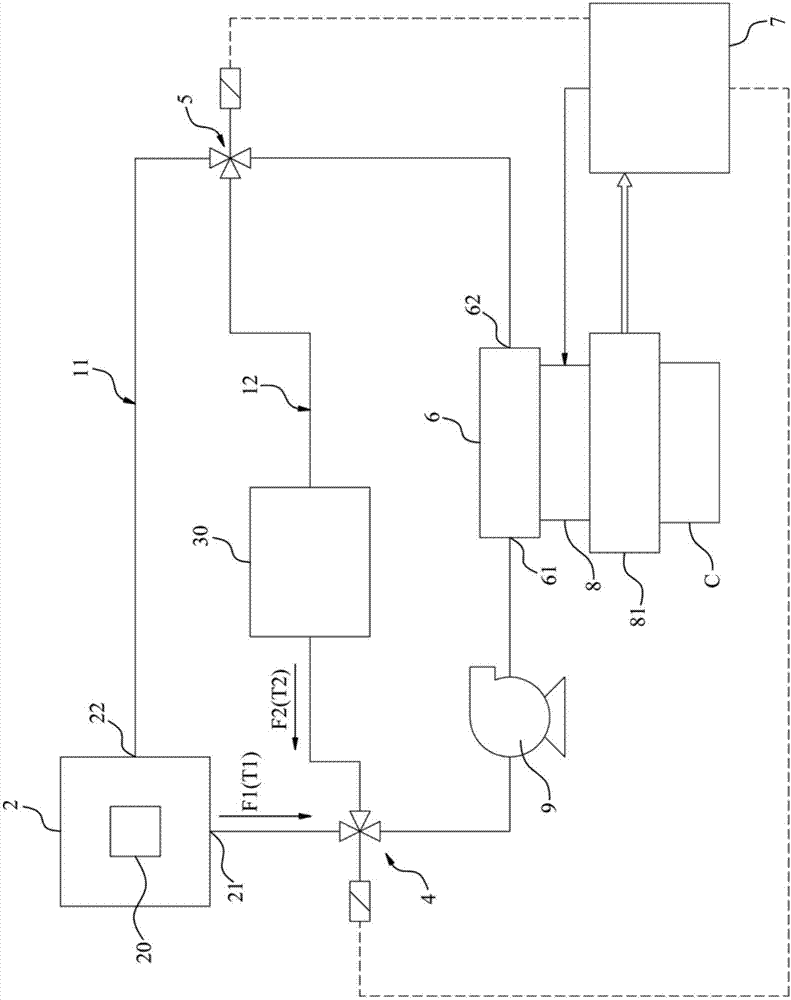

Dual loop type temperature control module and electronic device testing apparatus provided with the same

ActiveCN107045361AQuick switchReduce lossElectrical testingIndirect heat exchangersThermoelectric coolingTemperature control

The invention relates to a dual loop type temperature control module and an electronic device testing apparatus provided with the same. The temperature control module comprises a first loop through which a first working fluid of a first temperature flows, a second loop through which a second working fluid of a second temperature flows, a controller for controlling a first switching valve such that the first or second working fluid flows through a temperature regulating device, and a second switching valve such that the working fluid flowing through the temperature regulating device returns to the first or second loop. The temperature regulating device adjusts a thermoelectric cooling device to reach two different reference temperatures based on the rise / fall of its temperature dependent on the working fluid. The thermoelectric cooling device regulates the temperature of the tested object under a wide range of temperature difference and with accuracy based on the reference temperatures to facilitate the detection of high / low temperature.

Owner:CHROMA ATE

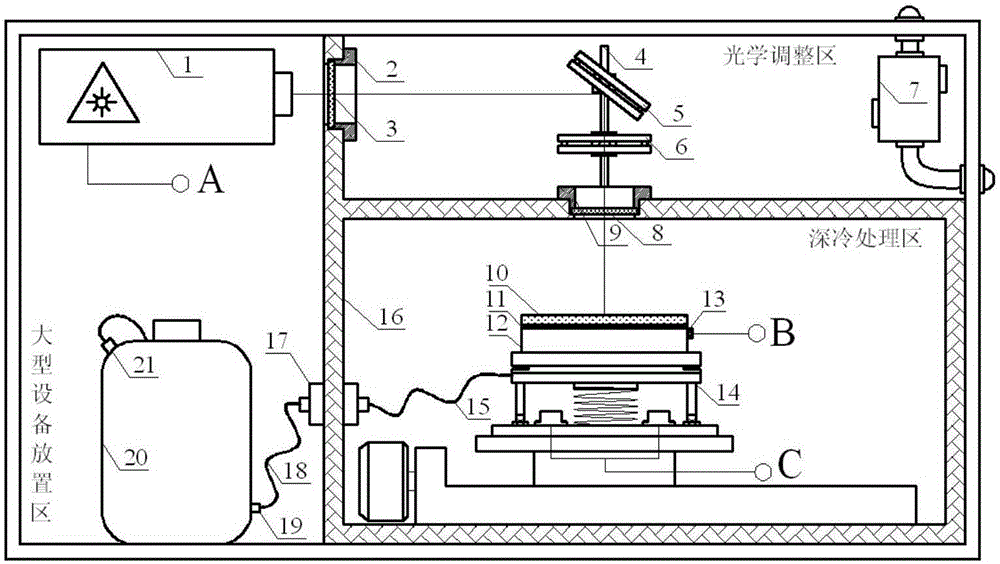

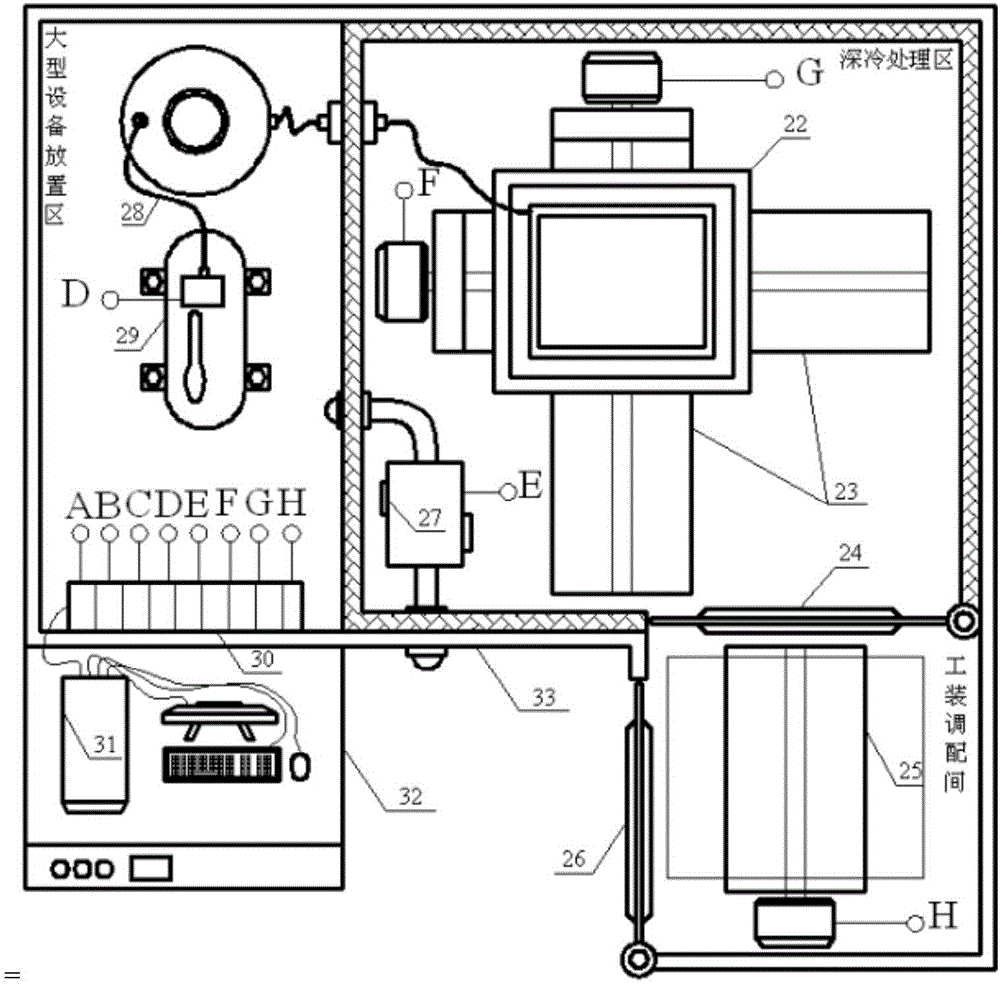

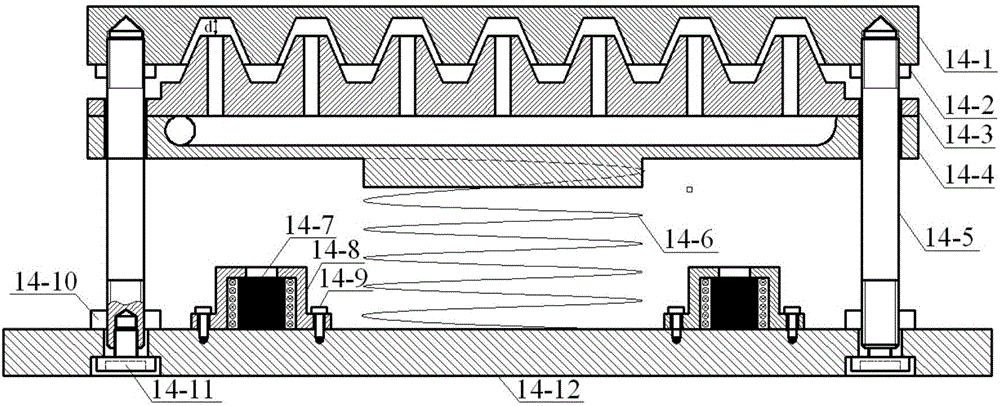

Copious cooling work table, copious cooling laser shock peening experiment system and control method thereof

ActiveCN106319176ALarge temperature rangeFast heating/cooling speedDomestic cooling apparatusLighting and heating apparatusLoop controlControl cell

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com