Method for hydrolyzing carbonyl sulphide (COS)

A carbonyl sulfide and material technology, applied in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of narrow reaction temperature range, catalyst deactivation, low material space velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Catalyst preparation: Weigh 75g of powdered γ-Al respectively 2 o 3 and 20g powdered La 2 o 3 , add 800ml of deionized water, hydrothermally treat at 85°C for 4 hours, and let stand for 10 hours; then dry at 110°C for 18 hours, press, crush, and sieve a sample of 40 to 60 meshes as the required carrier; weigh 20gNa 2 CO 3 Dissolved in 180g of pure water to prepare a 10% solution, impregnated 50g of the solution onto 95g of the carrier, and then dried at 110°C for 10 hours to obtain the required catalyst.

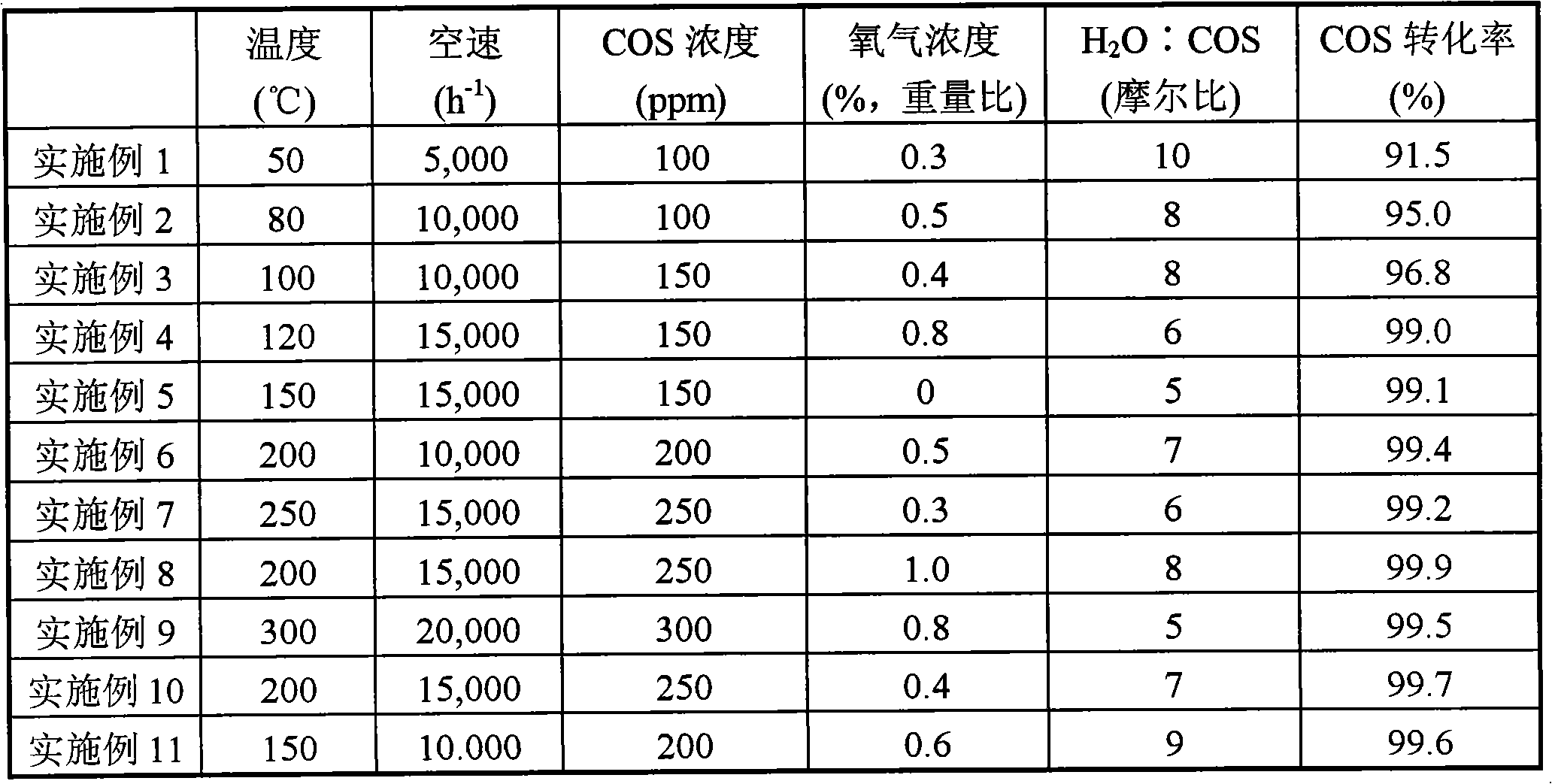

[0022] Carbonyl sulfide hydrolysis process experiment: according to the following process, the reaction was carried out in a Φ10×300 fixed bed quartz tube reactor, the temperature was 50°C, the COS content was 100ppm, the H 2 The molar ratio of O:COS is 10:1, and the space velocity is 5,000hr -1 , O in the material 2 The weight percent content is 0.3%. Evaluation results show that the COS conversion rate of the catalyst of the present invention is greater than...

Embodiment 2~11

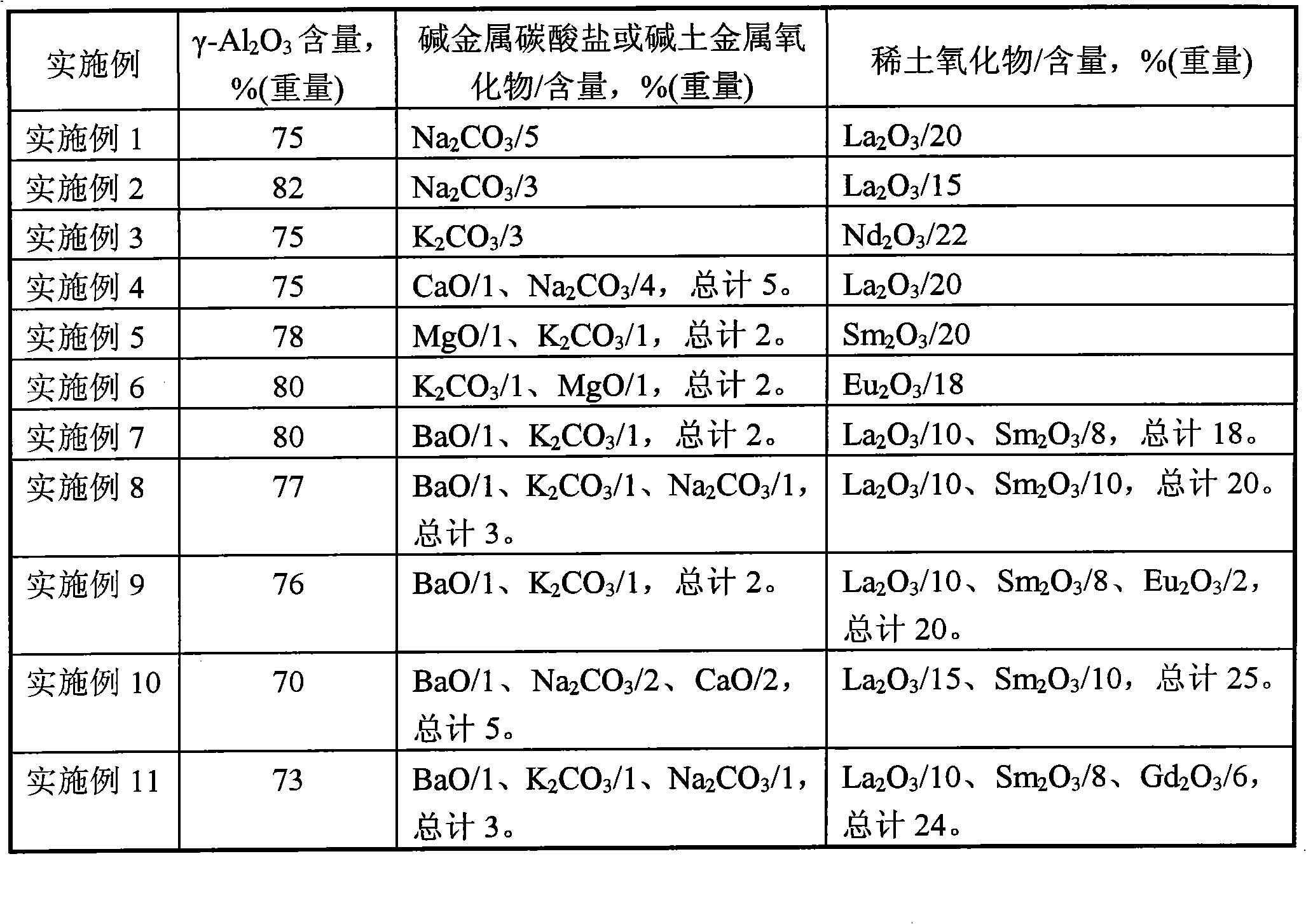

[0024] Catalyst preparation: except that the type or amount of specific rare earth oxide, the specific type or amount of alkali metal carbonate or alkaline earth metal oxide, and the specific amount of aluminum oxide have changed, the catalyst preparation process is the same as in Example 1. The specific composition is shown in Table 1.

[0025] Carbonyl sulfide hydrolysis process experiment: based on reaction temperature, COS concentration, space velocity, O in the material 2 content and H 2 O:COS molar ratio is a variable, and the rest are the same as in Example 1, and the specific data are shown in Table 2. The data shows that the temperature range of the method of the present invention is 50-300°C, and the material space velocity can be as high as 20000h -1 , and when the material contains ≤1% O by weight 2 can function normally.

Embodiment 12

[0027] Get the catalyst prepared by Example 1, at 50-300°C, the space velocity is 10,000hr -1 , COS content is 100ppm, H 2 O:COS molar ratio is 5:1, O in the material 2 Under the condition that the weight percent content is 0.5%, the COS conversion rate is shown in Table 3, and the result further shows that the method of the present invention has a good temperature operating range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com