Method of removing multiple pollutants in flue gas through low-temperature gas-like phase catalytic oxidization

A gas-phase catalytic oxidation and catalytic oxidation technology, which is applied in the field of flue gas purification, can solve the problems of single liquid oxidant oxidation ability catalyst activity difference, oxidant consumption unsatisfactory removal efficiency, chlorine-containing oxidant consumption equipment corrosion, etc., to achieve electronic The effect of accelerating the transfer speed, saving investment and operating costs, and reducing catalyst costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

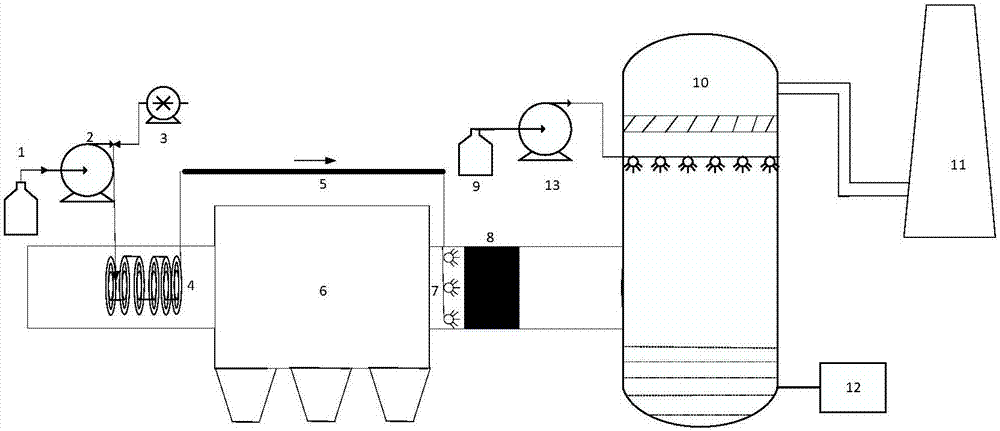

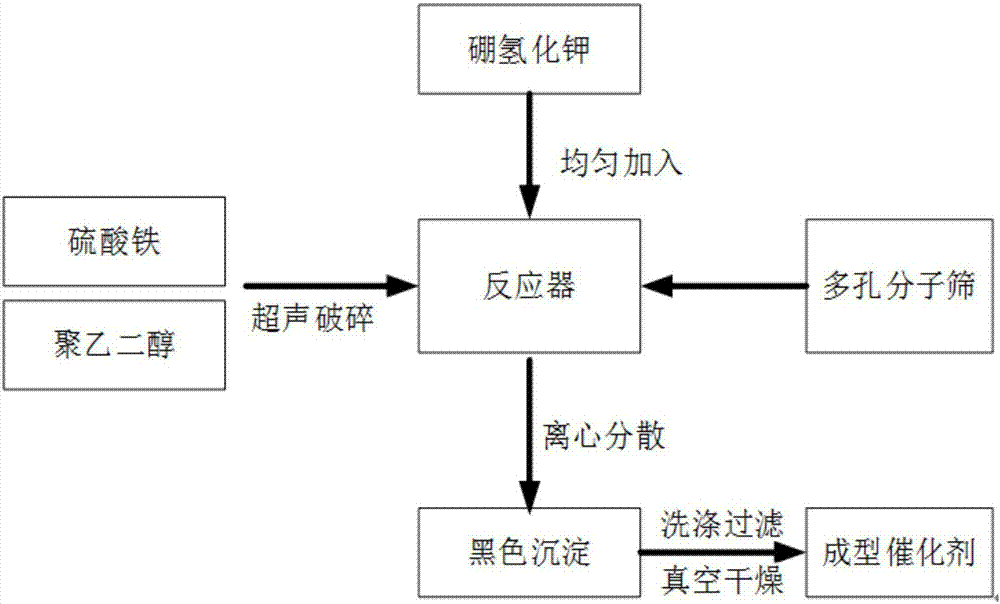

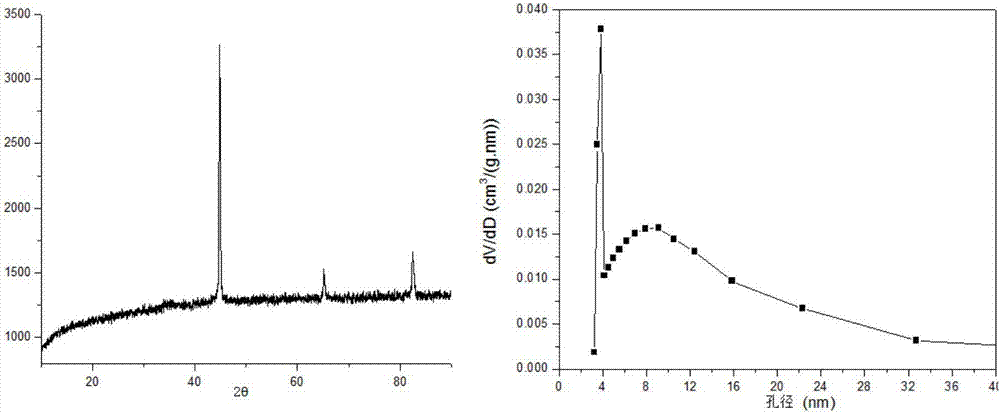

Method used

Image

Examples

Embodiment 1

[0069] With 5%wt hydrogen peroxide solution as oxidant, molecular sieve loaded with nanometer zero-valent iron as catalyst, the space velocity is 152866h -1 Under the conditions, the liquid-phase oxidant is injected into the generating device, and under the condition of controlling the temperature of the loop pipe and the catalyst bed at 120 and 110 °C respectively, the mixed solution of potassium humate and ammonia water is used as the absorption liquid to conduct simultaneous desulfurization, denitrification and demercuration experiments. Detected: SO 2 The removal efficiency is 98.8%, the denitrification efficiency is 90.2%, and the mercury removal efficiency is over 90.1%.

Embodiment 2

[0071] With 10%wt hydrogen peroxide and 0.1wt% peracetic acid solution as the oxidant, molecular sieve loaded with nanometer zero-valent iron as the catalyst, the space velocity is 198726h -1 Under the conditions, the liquid-phase oxidant is injected into the generating device, and the temperature of the loop pipe and the catalyst bed are controlled at 140 and 130 °C respectively, and the mixed solution of potassium humate and ammonia water is used as the absorption liquid to conduct simultaneous desulfurization, mercury and denitrification experiments. Detected: SO 2 The removal efficiency is 99.5%, the denitrification efficiency is 91.4%, and the mercury removal efficiency is over 92.7%.

Embodiment 3

[0073] With 15%wt hydrogen peroxide and 2wt% potassium hypochlorite solution as the oxidant, molecular sieve loaded with nanometer zero-valent iron as the catalyst, the space velocity is 229299h -1 Under the conditions, the liquid-phase oxidant is injected into the generating device, and under the condition of controlling the temperature of the loop pipe and the catalyst bed at 160 and 150 °C respectively, the mixed solution of potassium humate and ammonia water is used as the absorption liquid to conduct simultaneous desulfurization, mercury and denitrification experiments. Detected: SO 2 The removal efficiency is 99.8%, the denitrification efficiency is 93.2%, and the mercury removal efficiency is above 93.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com