Method for synthesizing ethyl benzene and diethyl benzene

A synthesis method and technology of diethylbenzene, applied in the fields of condensation between hydrocarbons and non-hydrocarbons, organic chemistry, distillation purification/separation, etc., can solve complex process and equipment, low ethanol utilization rate, and comprehensive energy consumption reduction and other problems, to achieve the effect of comprehensive cost advantages, high utilization rate, and small loading volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

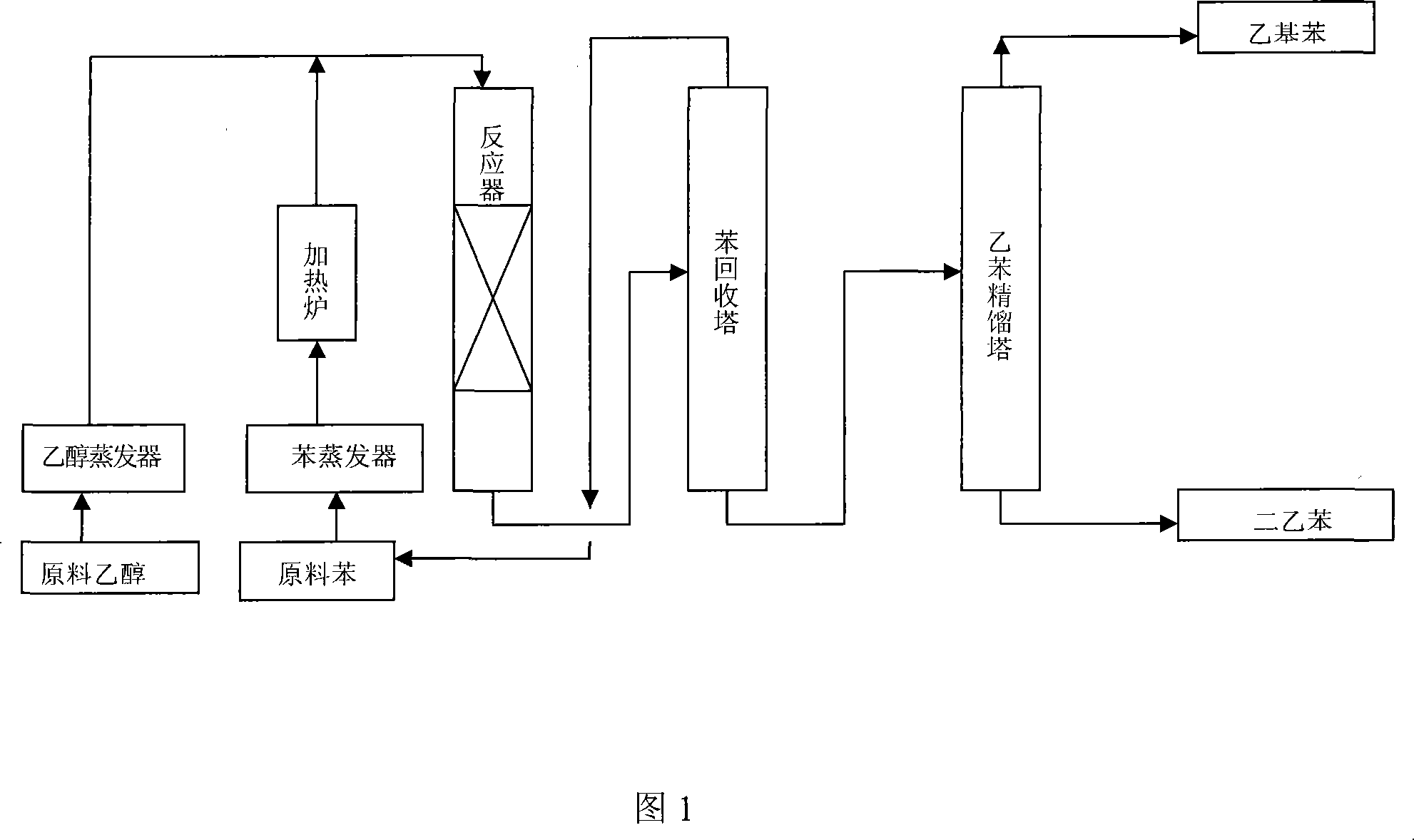

[0023] A kind of synthetic method of ethylbenzene, directly synthesizes ethylbenzene and diethylbenzene with ethanol and benzene as raw material, and its technological process is as shown in Figure 1.

[0024] Benzene and 95% ethanol are heated and vaporized, and sent to an adiabatic reactor filled with molecular sieve catalysts, the molar ratio of which is benzene:ethanol=5:1. The catalyst loaded in the reactor is SH-05 type alkylation molecular sieve, under the conditions of temperature 400°C, pressure 1.4MPa, and space velocity 1.2, the ethylation reaction is carried out. The molar percentage of ethylbenzene in the reaction product is about 18%, and the molar percentage of diethylbenzene is about 5%.

[0025] The ethylation reaction product is fed from the middle of the benzene recovery tower for rectification. The operating pressure of the benzene recovery tower is 1.2MPa, the temperature at the top of the tower is 180°C, the temperature at the bottom of the tower is 240°...

Embodiment 2

[0028] Benzene and 95% ethanol are heated and vaporized, and sent to an adiabatic reactor filled with molecular sieve catalysts, the molar ratio of which is benzene:ethanol=5:1. The catalyst loaded in the reactor is DL-405, and the ethylation reaction is carried out at a temperature of 420° C., a pressure of 2 MPa, and a space velocity of 1.5. The molar percentage of ethylbenzene in the reaction product is about 17%, and the molar percentage of diethylbenzene is about 5%.

[0029] According to the method described in Example 1, benzo was reclaimed and the product was separated and purified to obtain the product ethylbenzene with a purity of 99.65%.

Embodiment 3

[0031] Benzene and 95% ethanol are heated and vaporized, and sent to an adiabatic reactor filled with molecular sieve catalysts, the molar ratio of which is benzene:ethanol=4:1. The catalyst loaded in the reactor is SH-05, and the ethylation reaction is carried out under the conditions of a temperature of 380° C., a pressure of 0.7 MPa, and a space velocity of 1.6. The molar percentage of ethylbenzene in the reaction product is about 15%, and the molar percentage of diethylbenzene is about 23%.

[0032] According to the method described in Example 1, benzene is reclaimed and ethylbenzene is separated, diethylbenzene and heavy aromatics are directly produced in the bottom of the ethylbenzene rectification tower, and the product mixed diethylbenzene (containing polyethylbenzene) is obtained. Its purity is 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com