Patents

Literature

242results about How to "High airspeed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

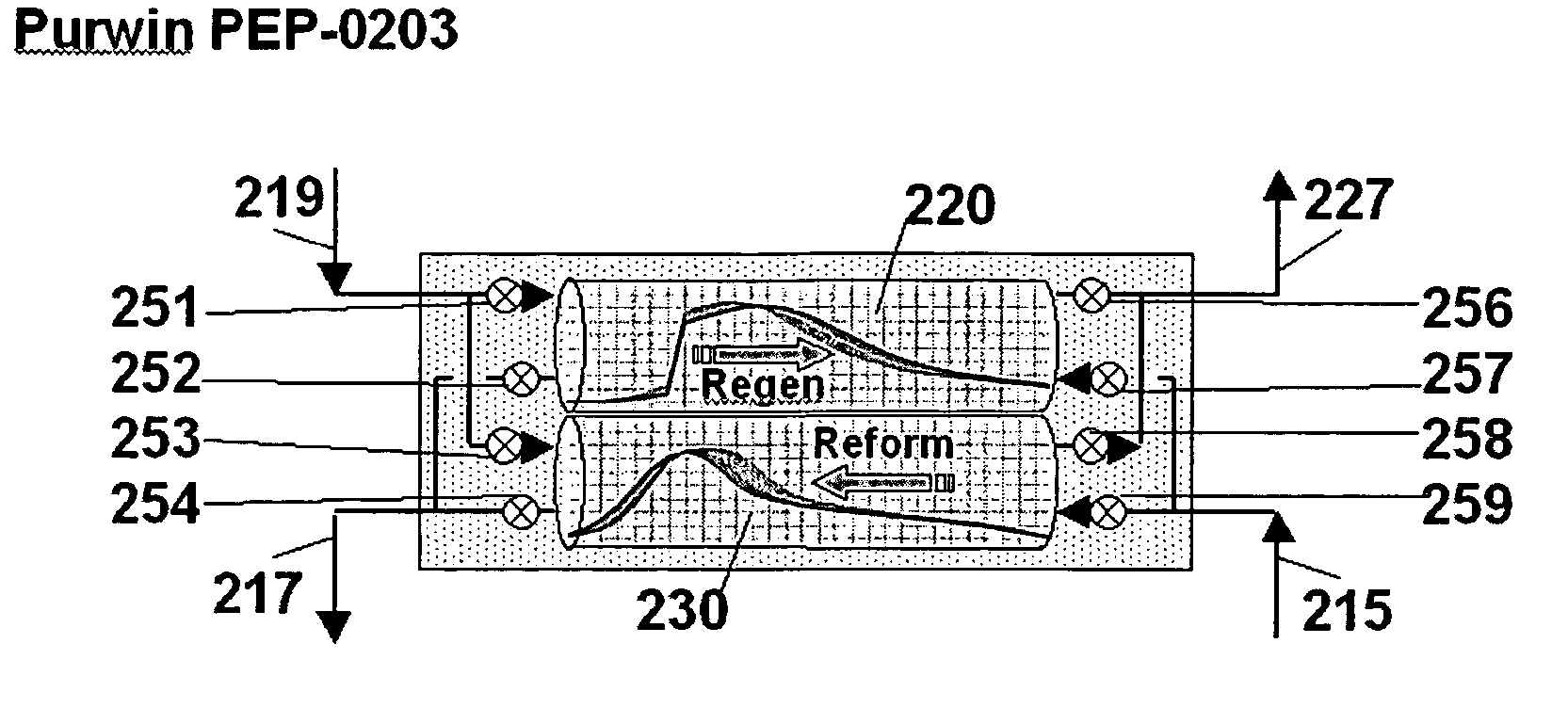

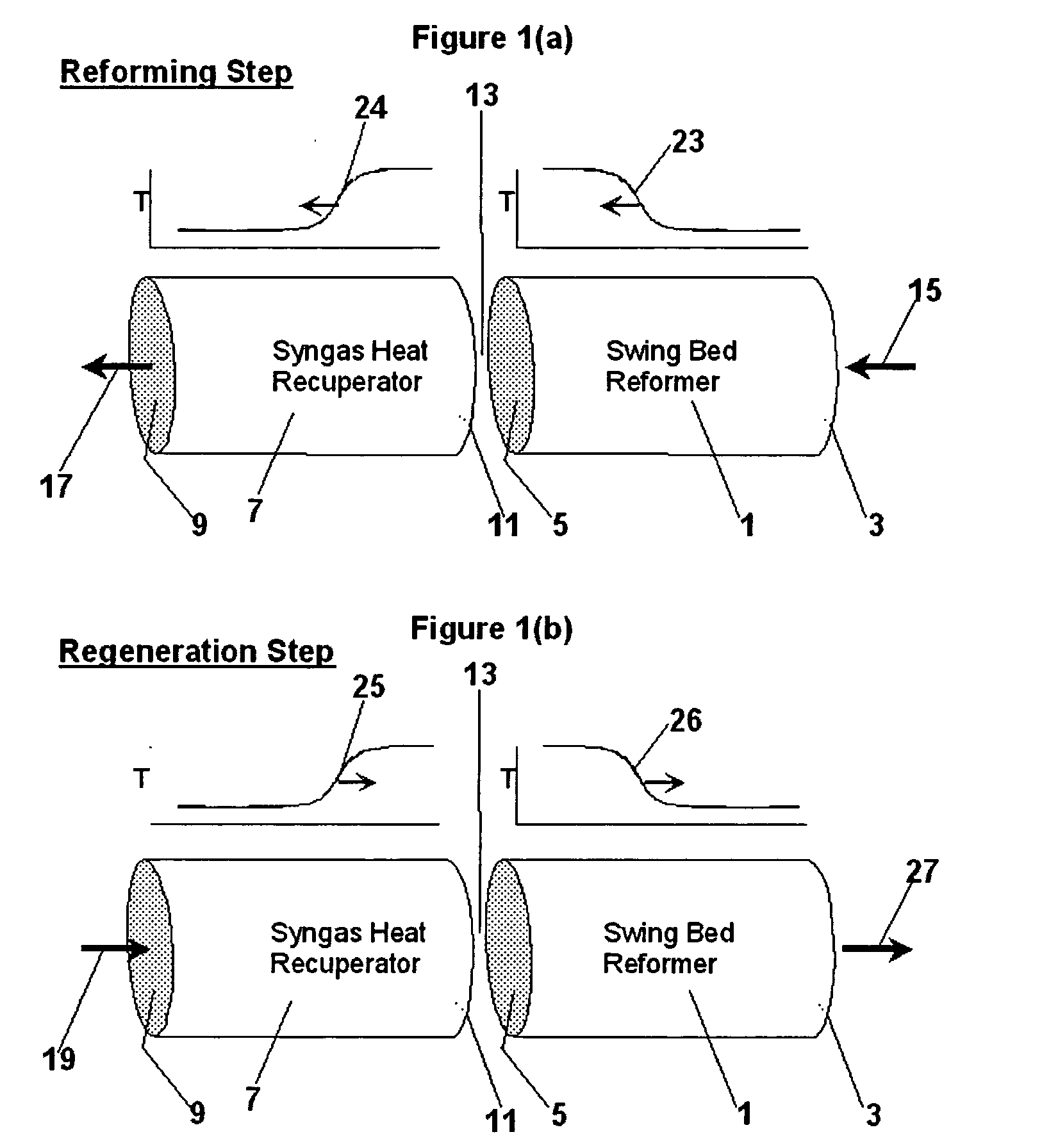

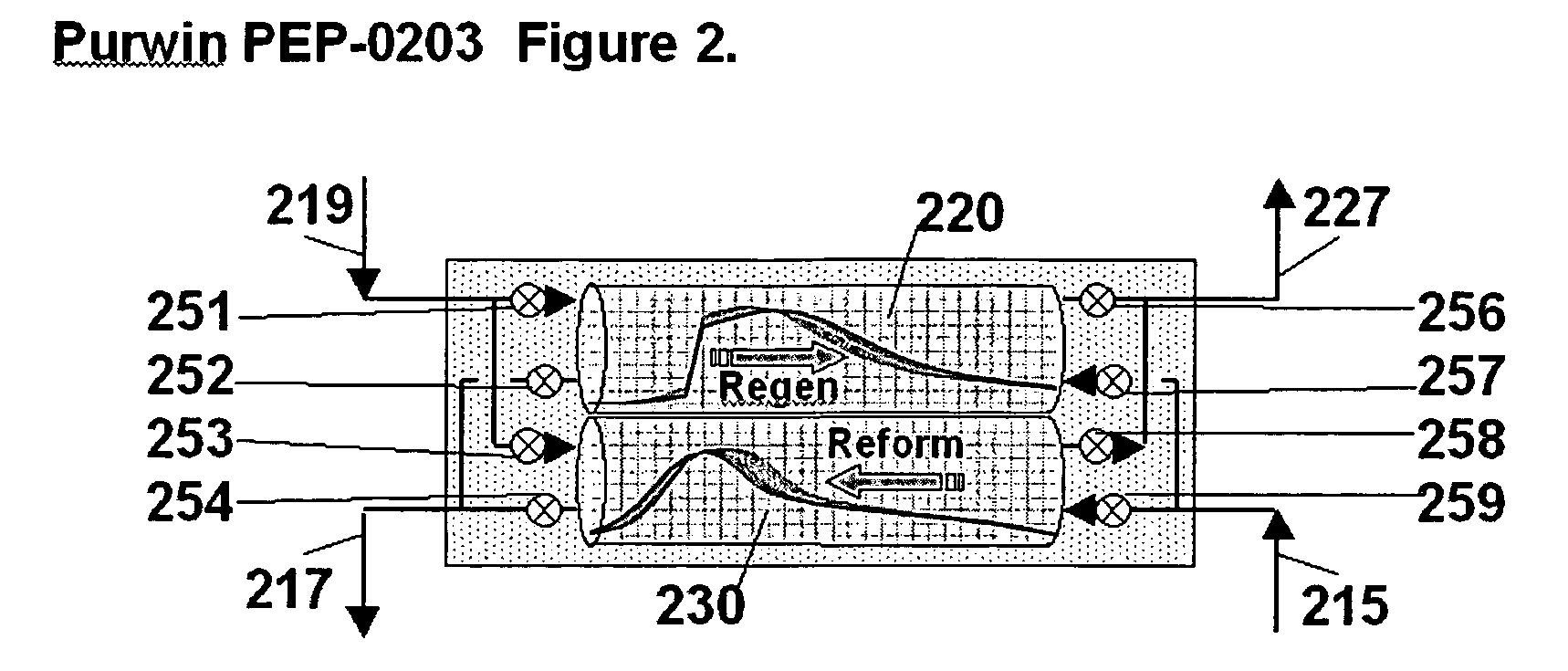

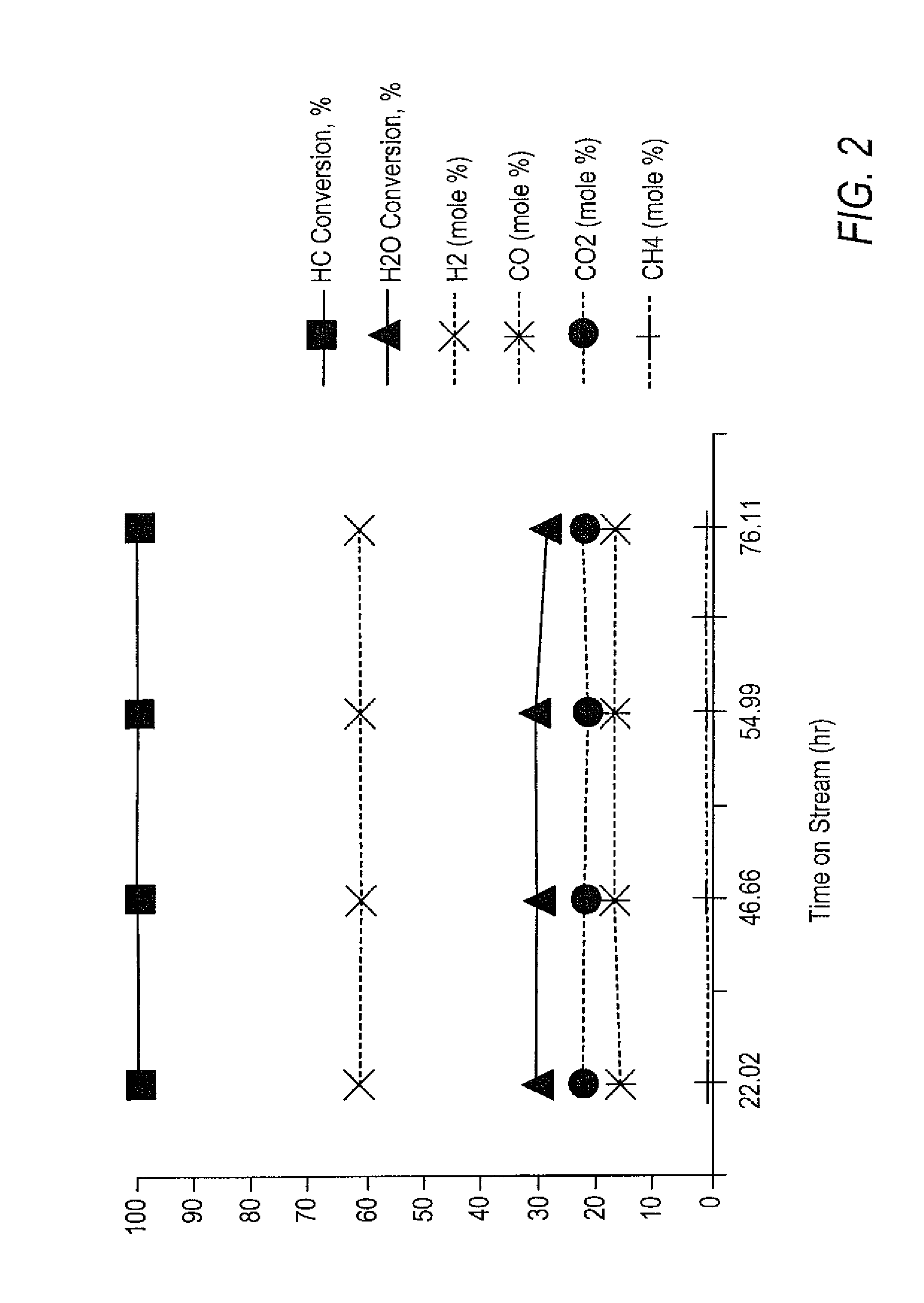

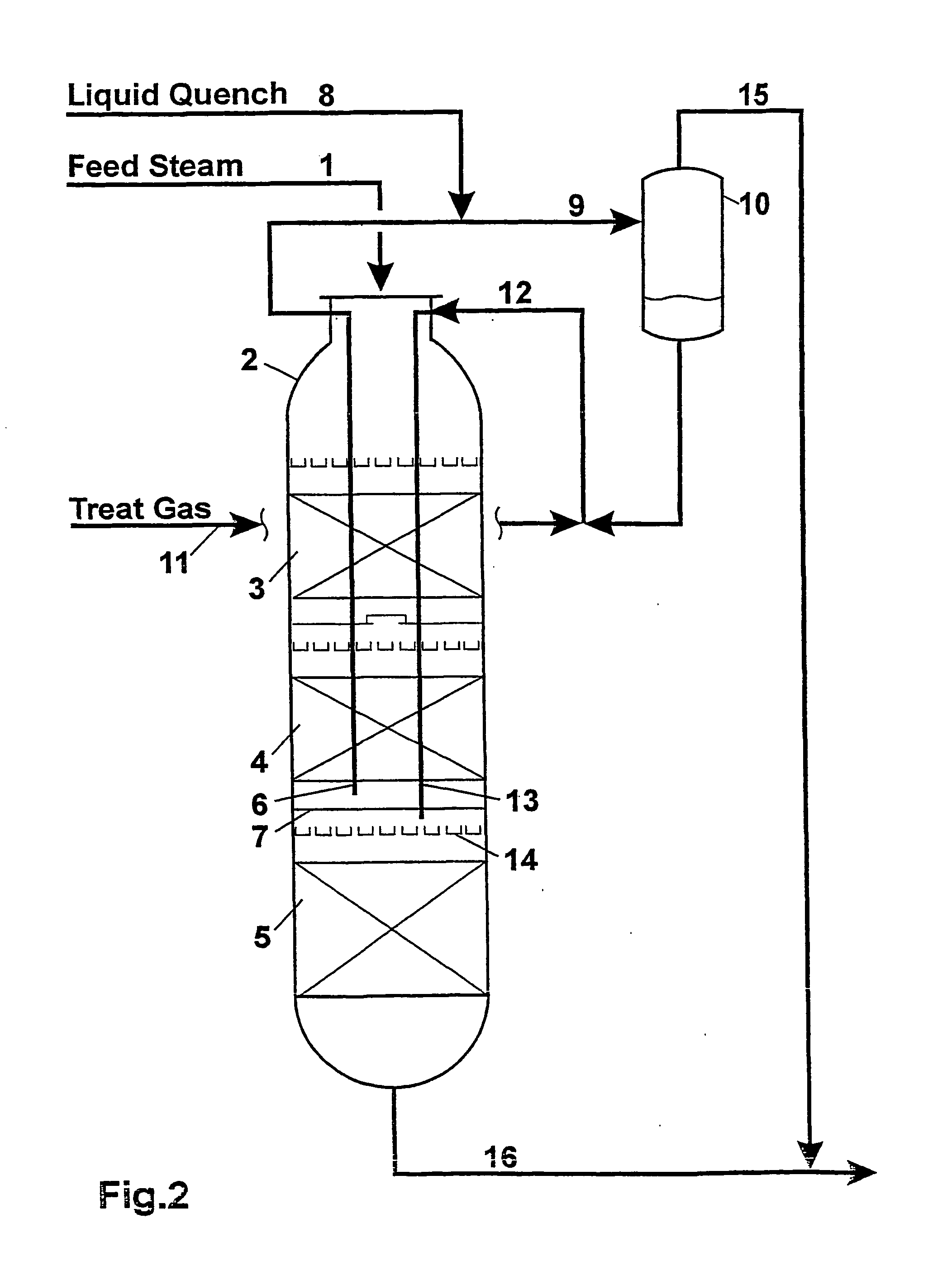

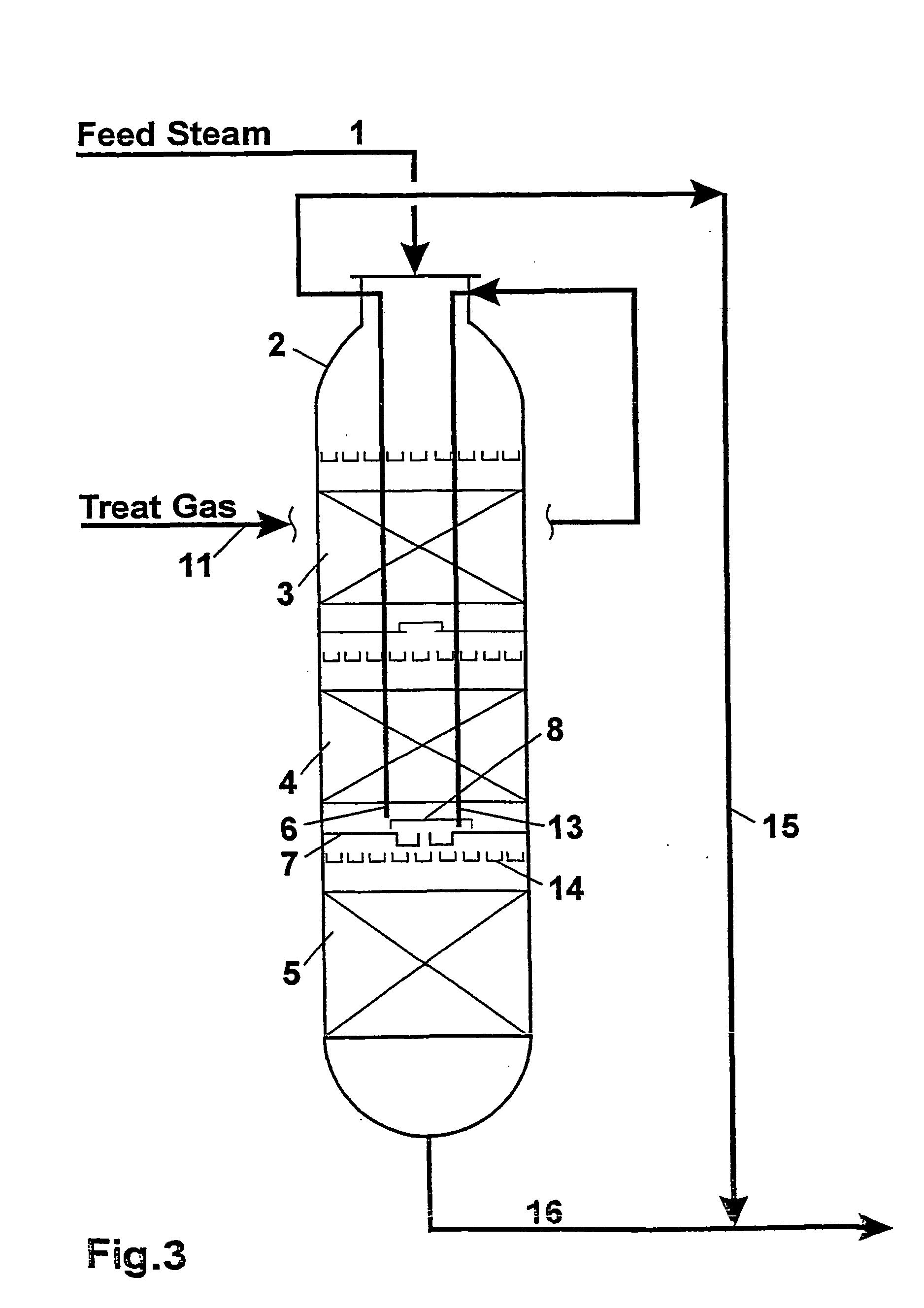

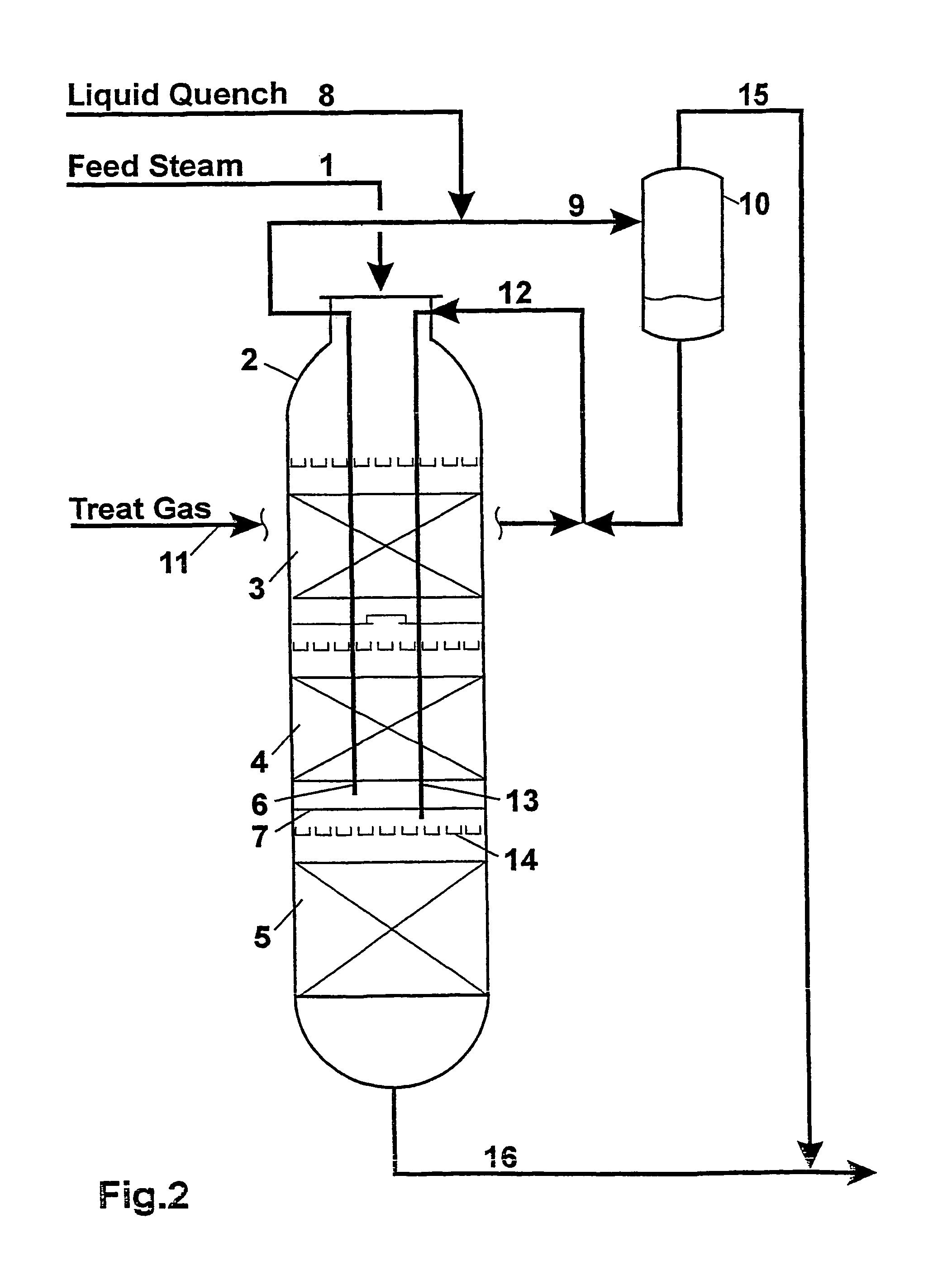

Pressure swing reforming for fuel cell systems

ActiveUS20040175326A1Efficient productionImprove permeabilityHydrogenChemical industrySyngasFuel cells

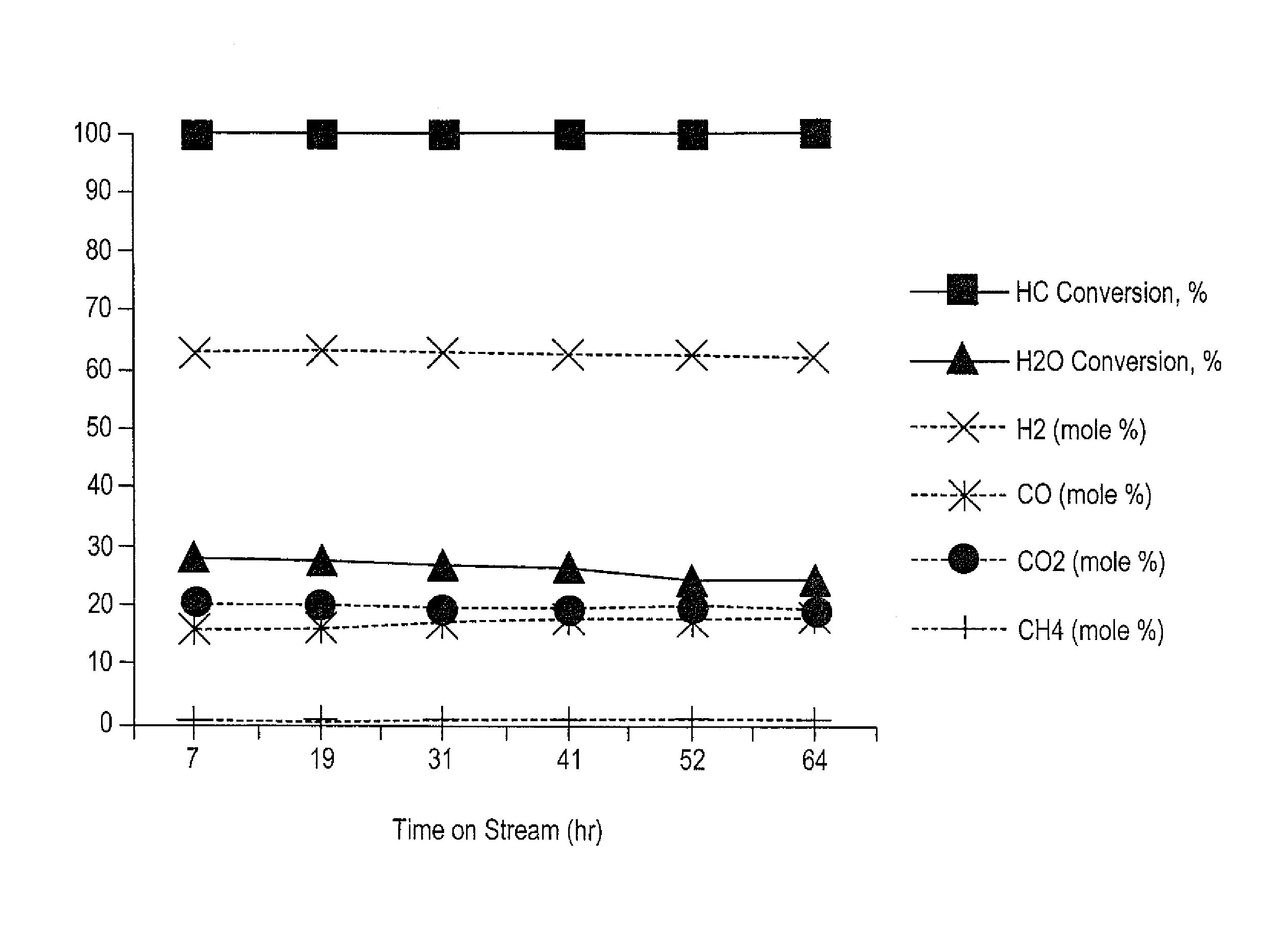

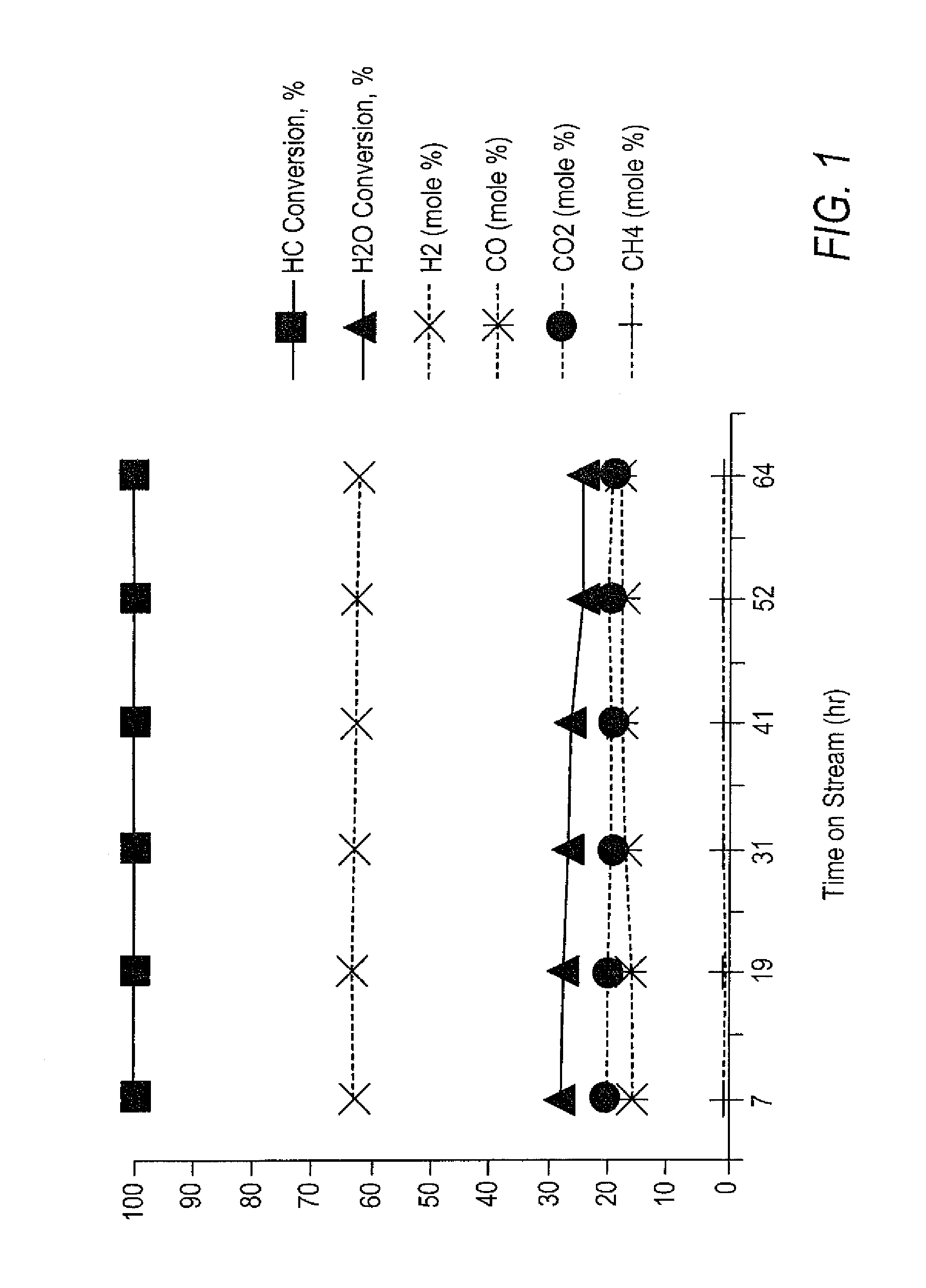

The present invention provides an improvement in the process of producing hydrogen from hydrocarbon-containing streams. A cyclic reforming process, referred to as pressure swing reforming, provides an efficient means for producing a hydrogen containing synthesis gas for fuel cell applications. Pressure swing reforming may be integrated with shift reactions, preferential oxidation, and membrane separation, achieving thermal and material efficiencies relative to conventional hydrogen production. In one embodiment, at least some synthesis gas which is first produced in the pressure swing reforming process is combusted with air to provide the heat for the regeneration step of the pressure swing reforming process.

Owner:EXXON RES & ENG CO

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickel-rhodium based catalysts for synthesis gas production

InactiveUS6878667B2High levelHigh selectivityHydrogenCatalyst activation/preparationPartial oxidationManganese

A nickel-rhodium alloy based catalyst for catalyzing the production of synthesis gas from a light hydrocarbon and O2 by a net catalytic partial oxidation process is disclosed. Preferred nickel-rhodium alloy based catalysts comprise about 1-50 weight percent nickel and about 0.01-10 weight percent rhodium on a porous refractory support structure. In certain embodiments, the catalyst also contains a lanthanide element, zirconium, cobalt, manganese or magnesium.

Owner:CONOCOPHILLIPS CO

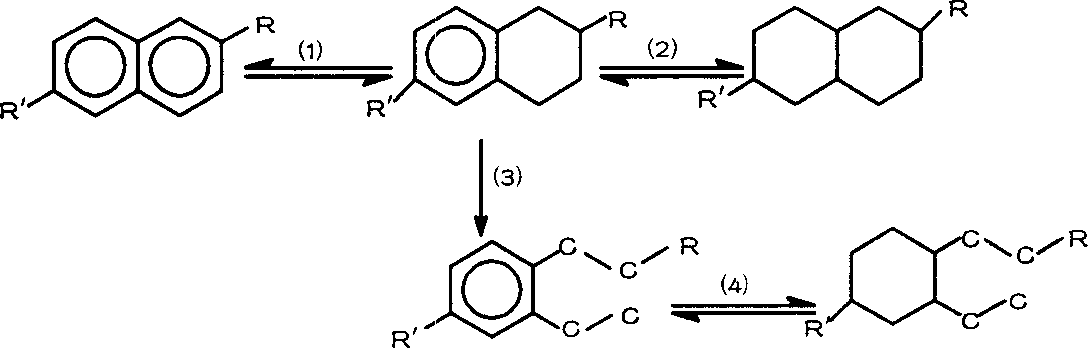

Catalysis conversion method for producing aromatic compounds

ActiveCN103923698ALess investmentReduce sulfur, nickelCatalytic crackingTreatment with hydrotreatment processesDistillationSlurry

The invention relates to a catalysis conversion method for producing aromatic compounds. According to the method, poor quality heavy cycle oil and residual oil are subjected to a hydrotreating reaction in the presence of hydrogen gas and a hydrogenation catalyst, and the reaction products are separated to obtain gas, naphtha, hydrogenated diesel oil and hydrogenated residue oil, wherein the hydrogenated diesel oil enters a catalysis cracking device and is subjected to a cracking reaction in the presence of a catalysis cracking catalyst, the reaction products are separated to obtain dry gas, liquefied gas, catalytic gasoline containing rich benzene, toluene and xylene, catalytic light diesel oil, distillates with a distillation range of 250-450 DEG C, and an oil slurry, and the distillates with the distillation range of 250-450 DEG C are conveyed to a residue oil hydrotreating device so as to be recycled. According to the present invention, the residue oil hydrogenation condition is completely utilized to achieve saturation of the aromatic ring in the poor quality heavy cycle oil to the maximal degree, such that the hydrogenated diesel oil maximally produce benzene, toluene and xylene during catalysis cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

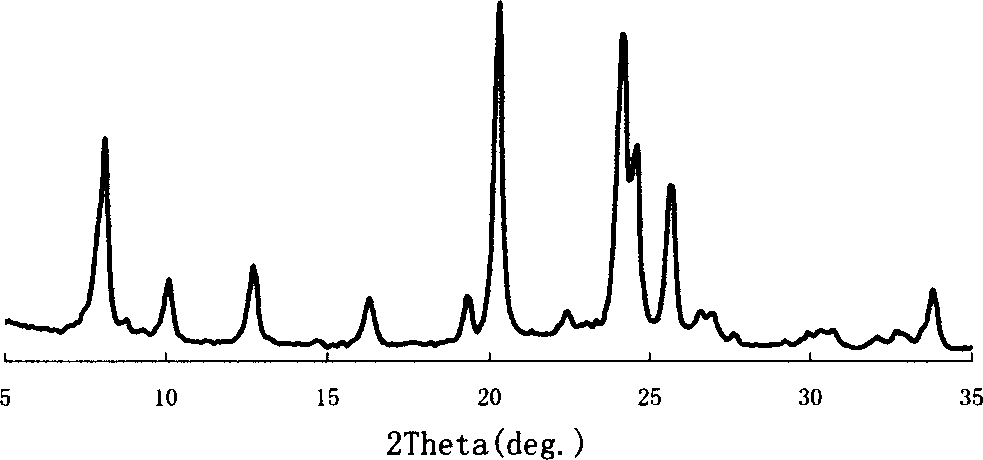

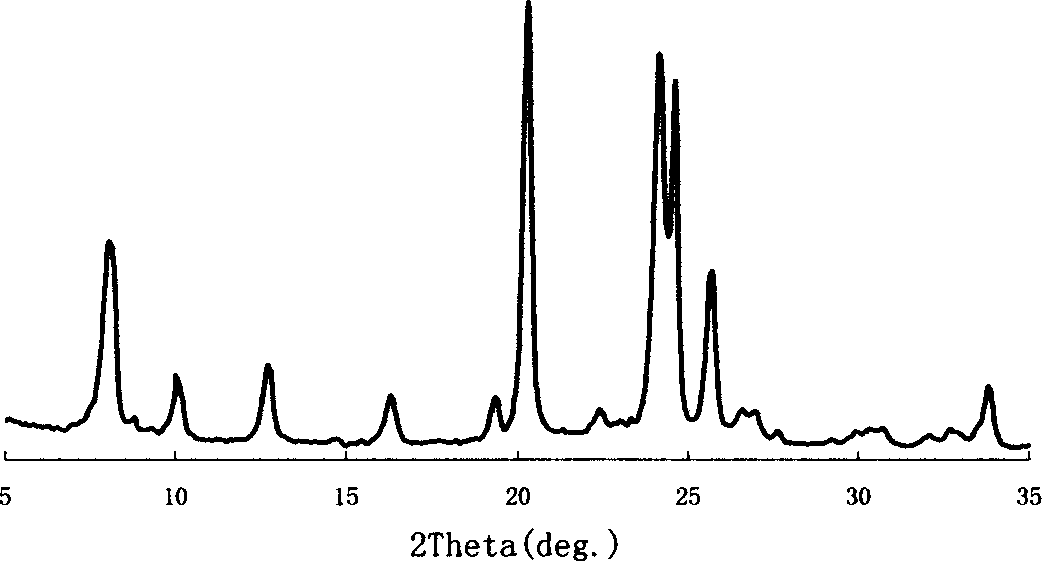

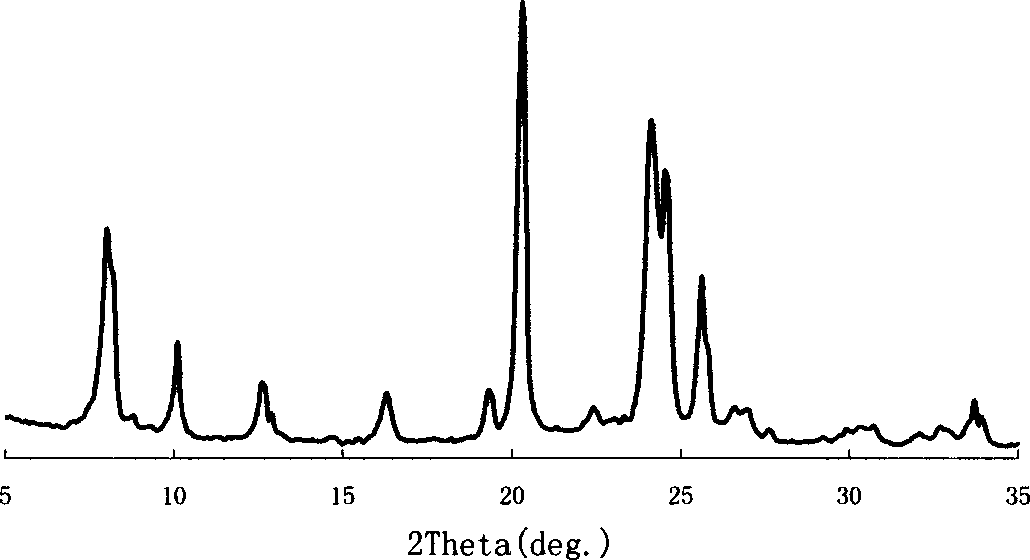

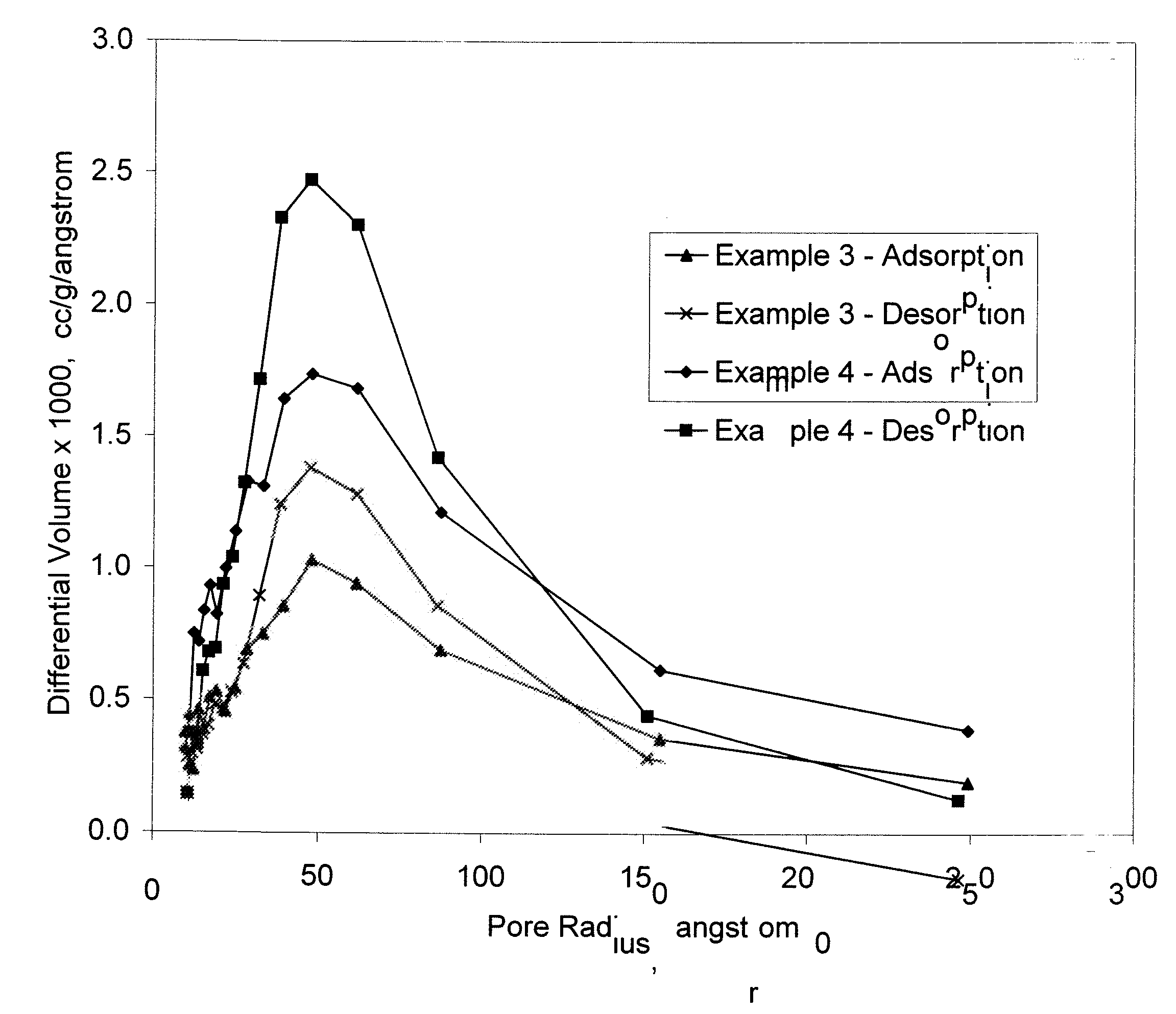

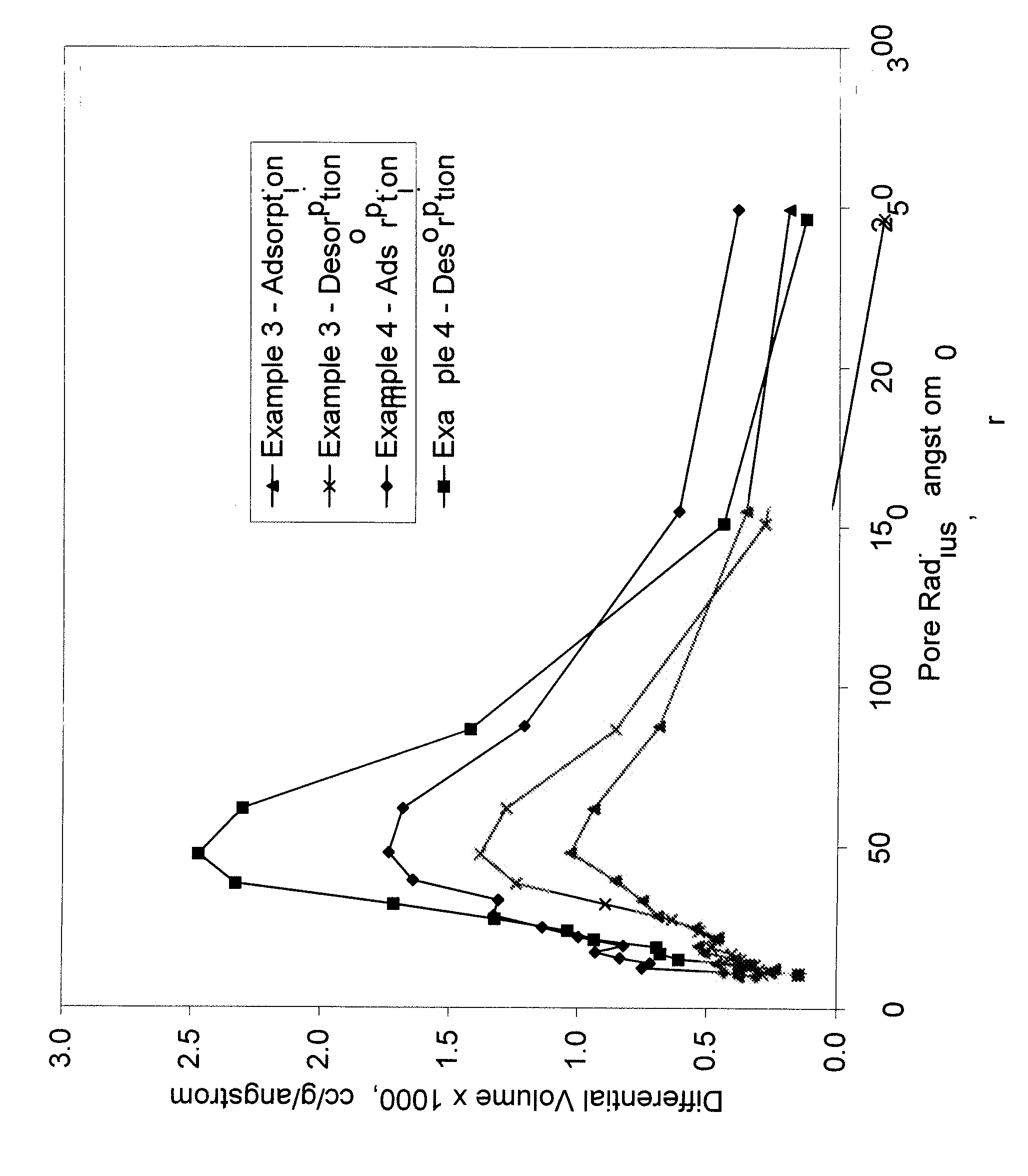

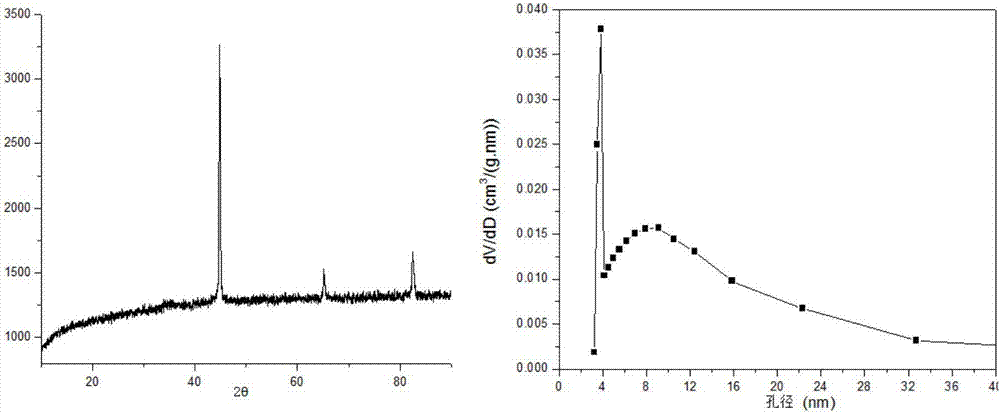

Hydroprocessing catalyst and its prepn process

The present invention is hydroprocessing catalyst and its preparation process. The catalyst includes one kind of molecular sieve with TON type structure and active metal component, and the molecular sieve has the features of surface Si / Al ratio higher than the bulk Si / Al ratio, proper acidity and channel structure for paraffin hydrocarbon to generate shape-selective cracking-isomerizing reaction, etc. The catalyst is used in hydroprocessing intermediate fraction oil and heavy fraction product, and has the features of high activity, high isomerizing selectivity, low cracking performance, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

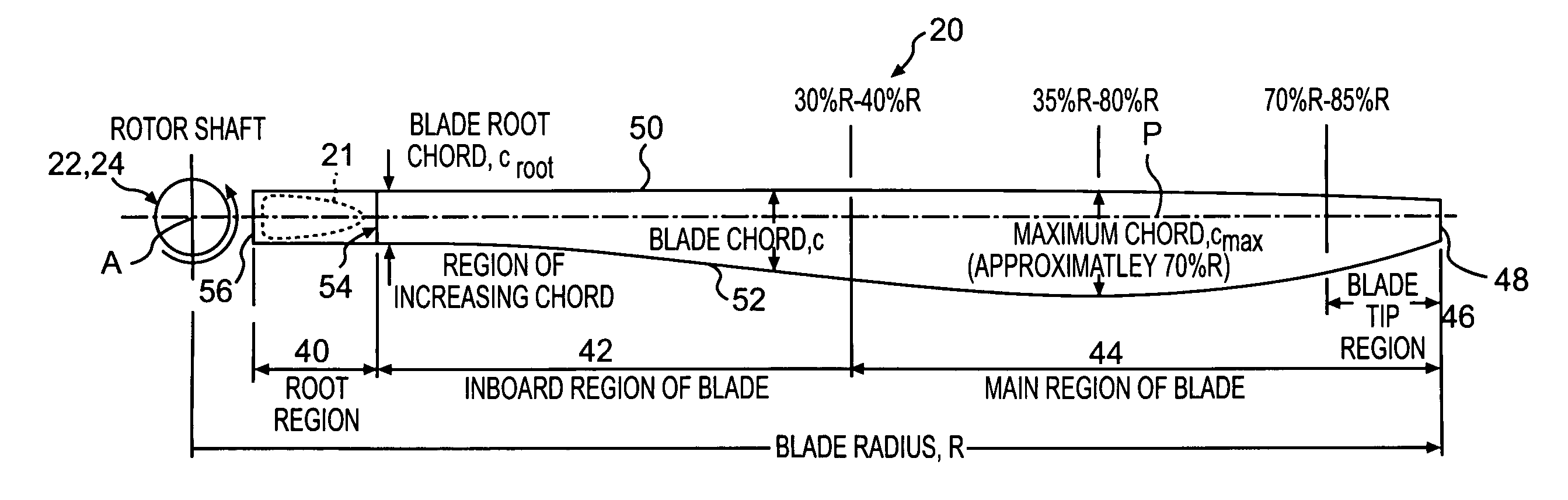

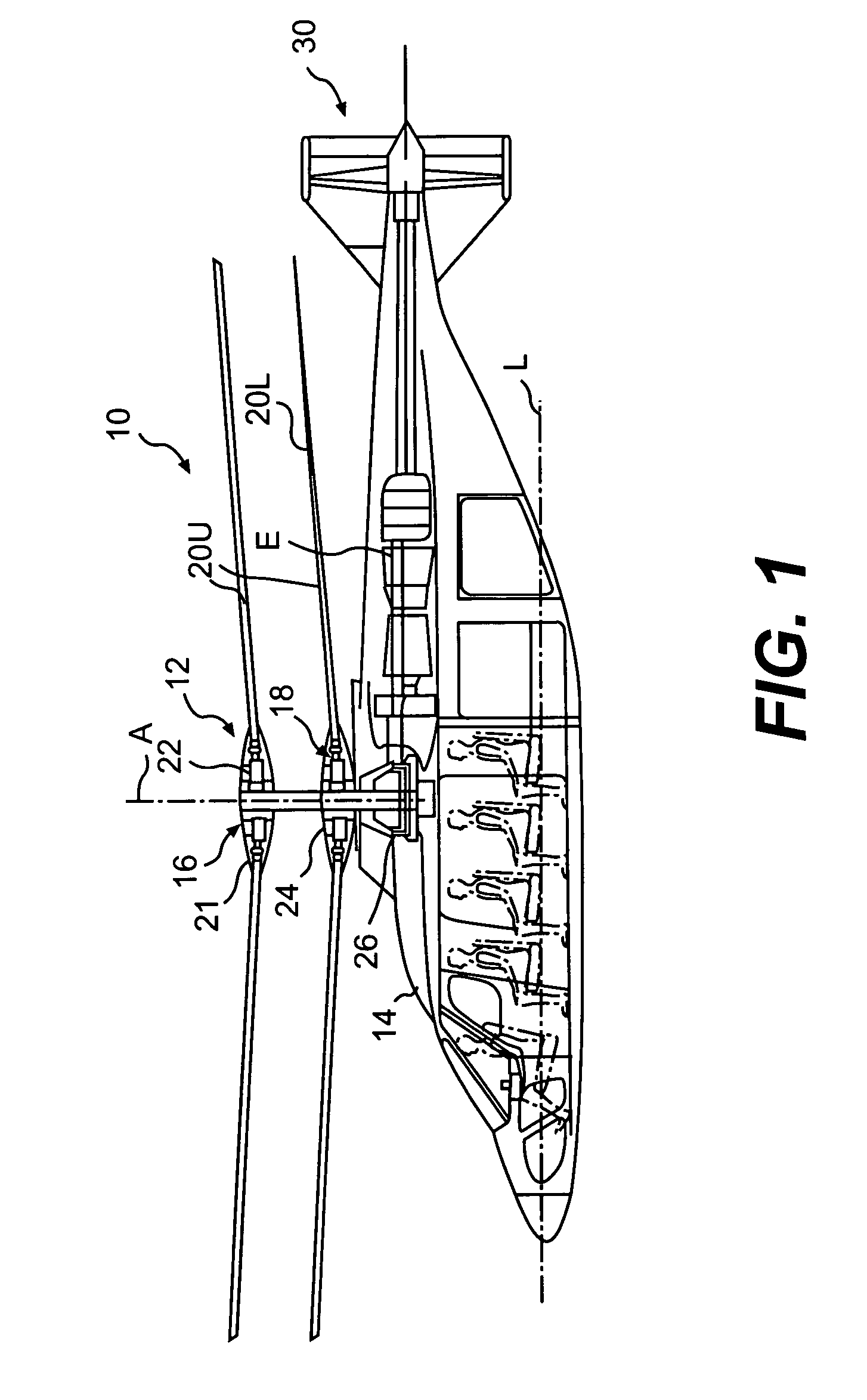

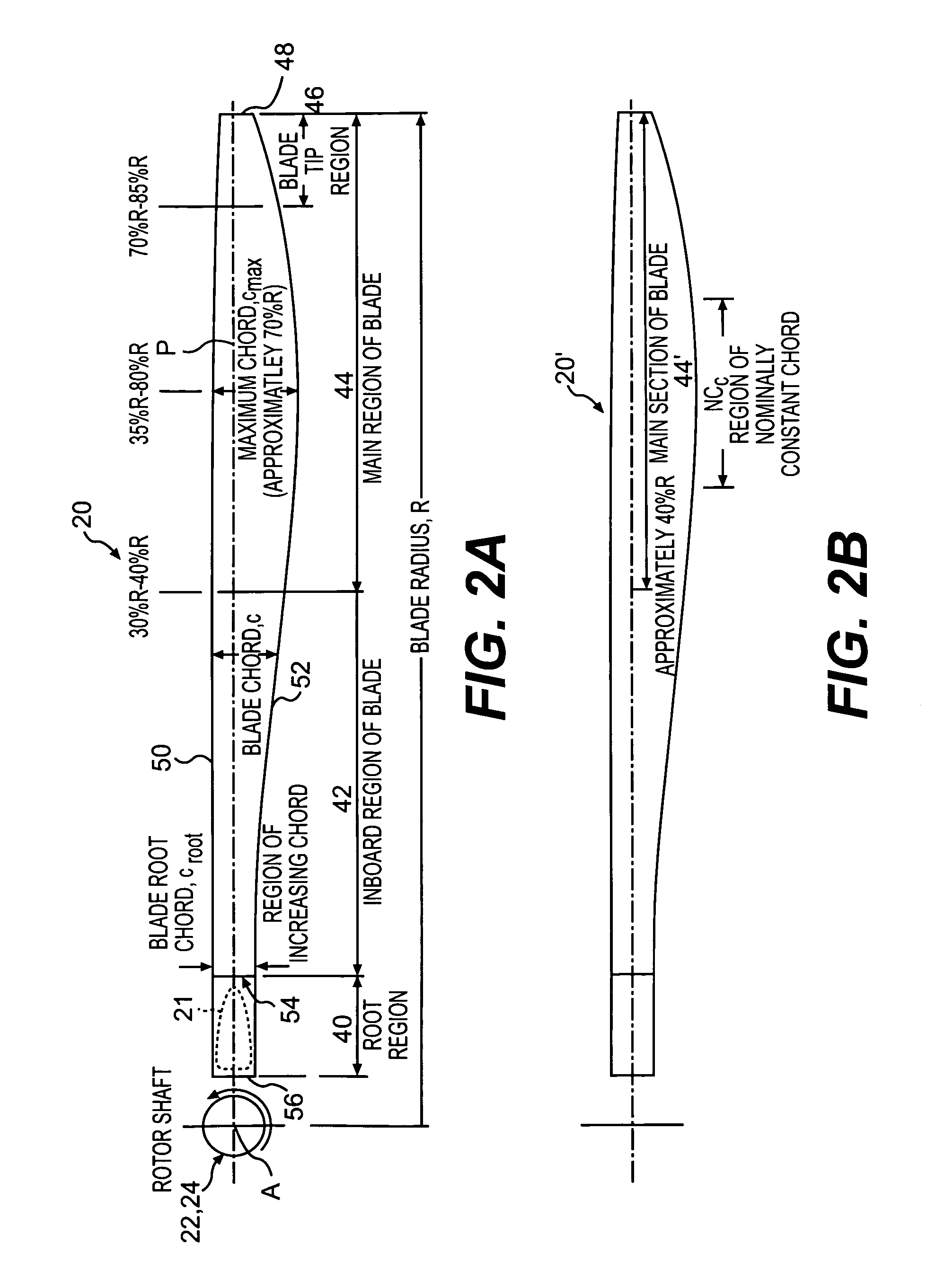

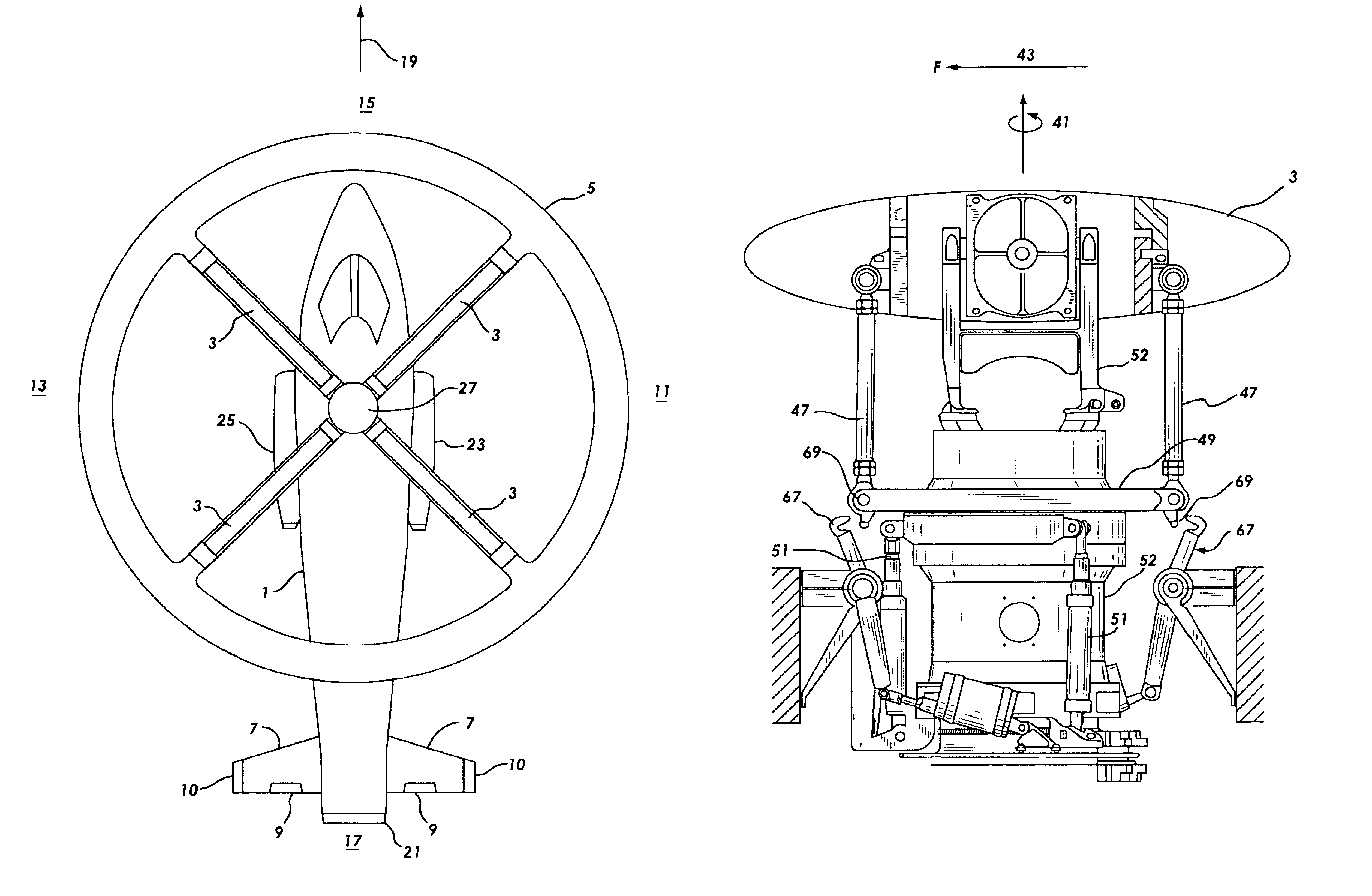

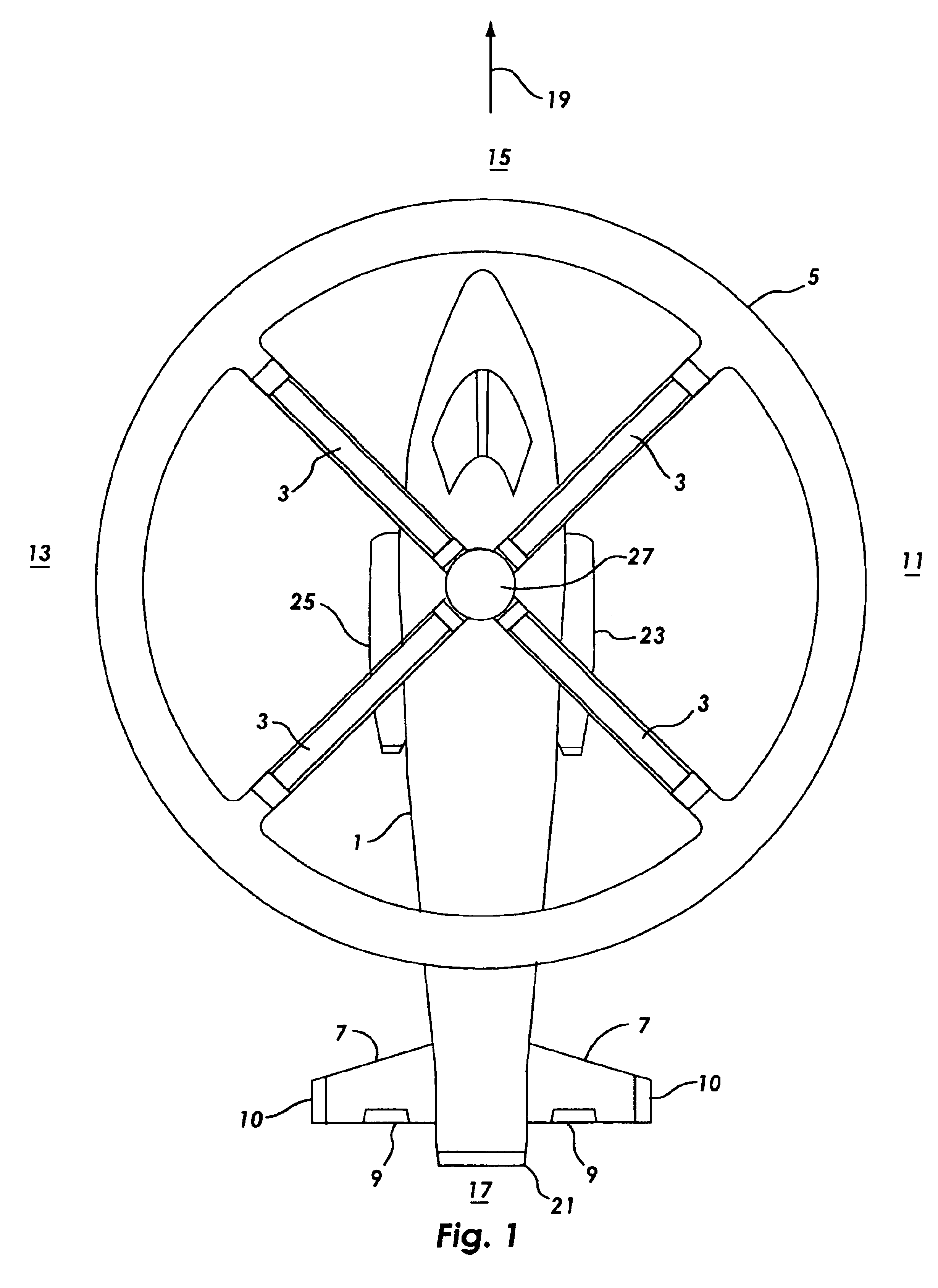

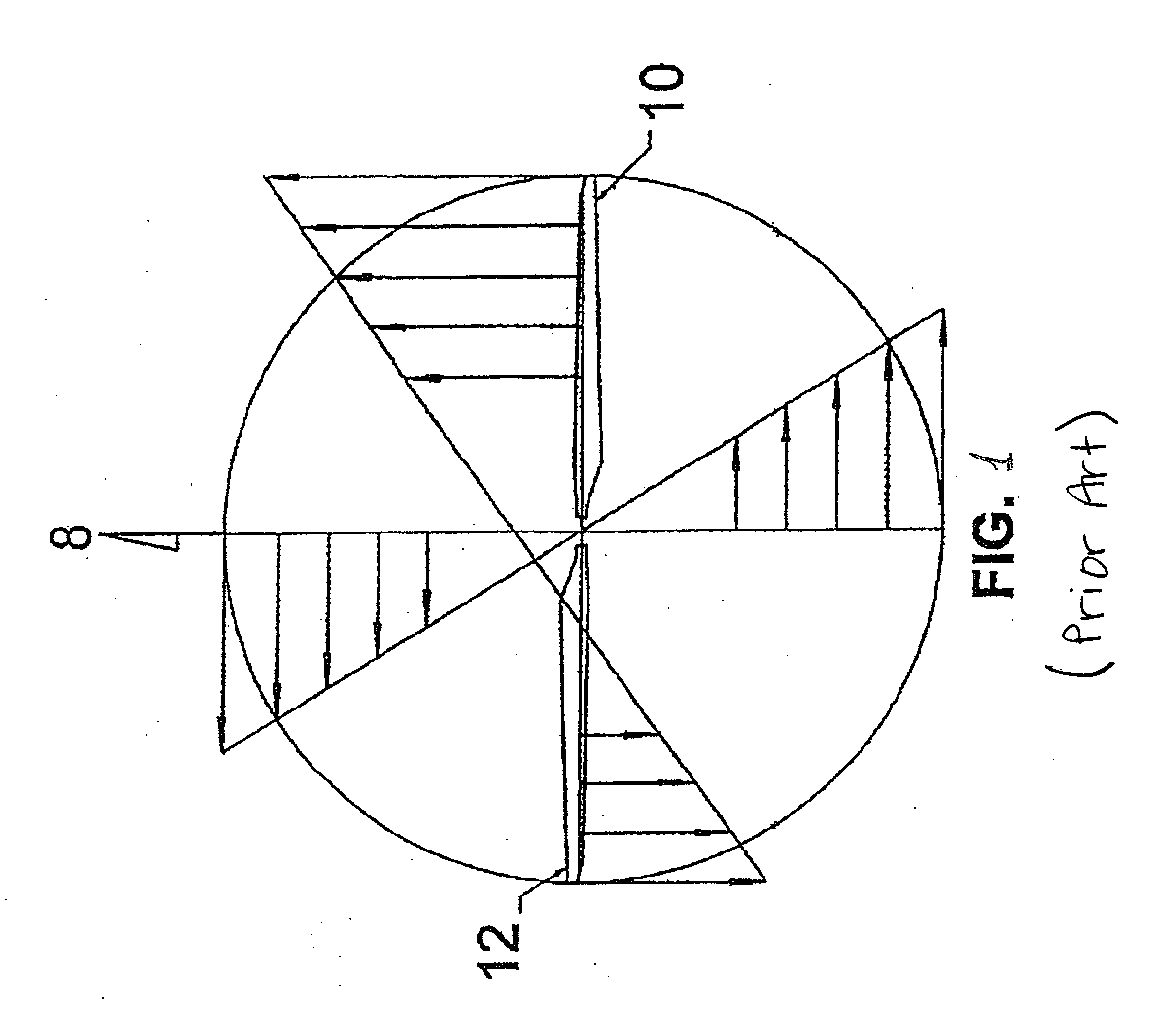

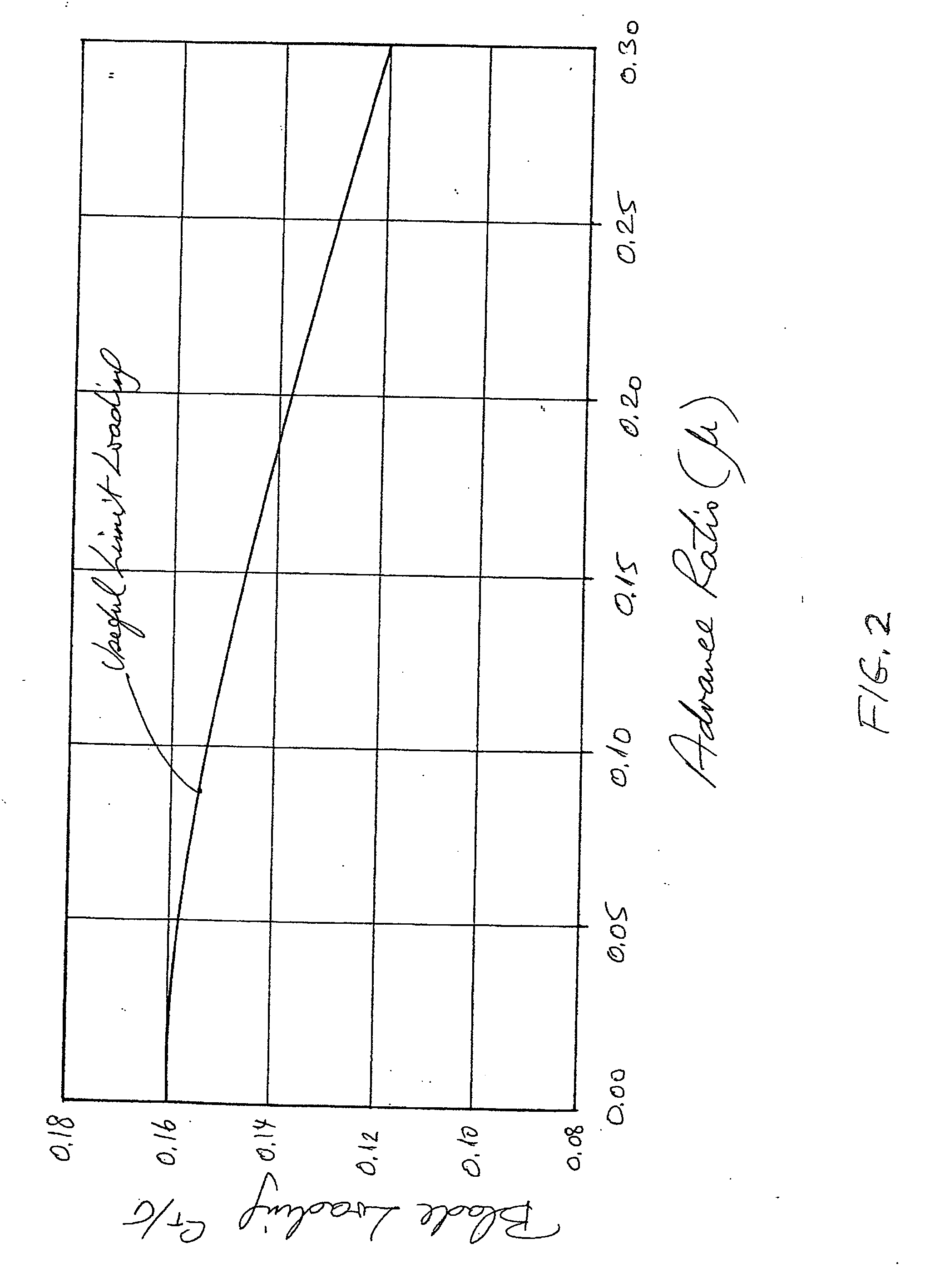

Rotor blade twist distribution for a high speed rotary-wing aircraft

ActiveUS20070110582A1Optimizing rotor performanceImprove flight efficiencyPropellersPump componentsFigure of meritRotary wing

Main rotor blades of the dual, counter-rotating, rigid coaxial rotor system exhibit a unique unconventional combination of positive and negative twist gradients in which the rotor system rotor Figure of Merit (hover efficiency) is improved by providing a dissimilar twist distribution between the lower rotor blade and the upper rotor blades. This improvement is specifically a result of reduced profile drag of the lower rotor system, achieved by driving the effective operating condition of the lower rotor blades to be similar to the upper rotor blade such that the tip drag losses of the lower main rotor have been reduced considerably using a mathematically vigorous approach. While minimal induced power consumption resulted due to the dissimilar lower main rotor twist, a significant profile power benefit is realized, resulting in the improved hover efficiency with essentially no reduction in rotor forward flight performance.

Owner:SIKORSKY AIRCRAFT CORP

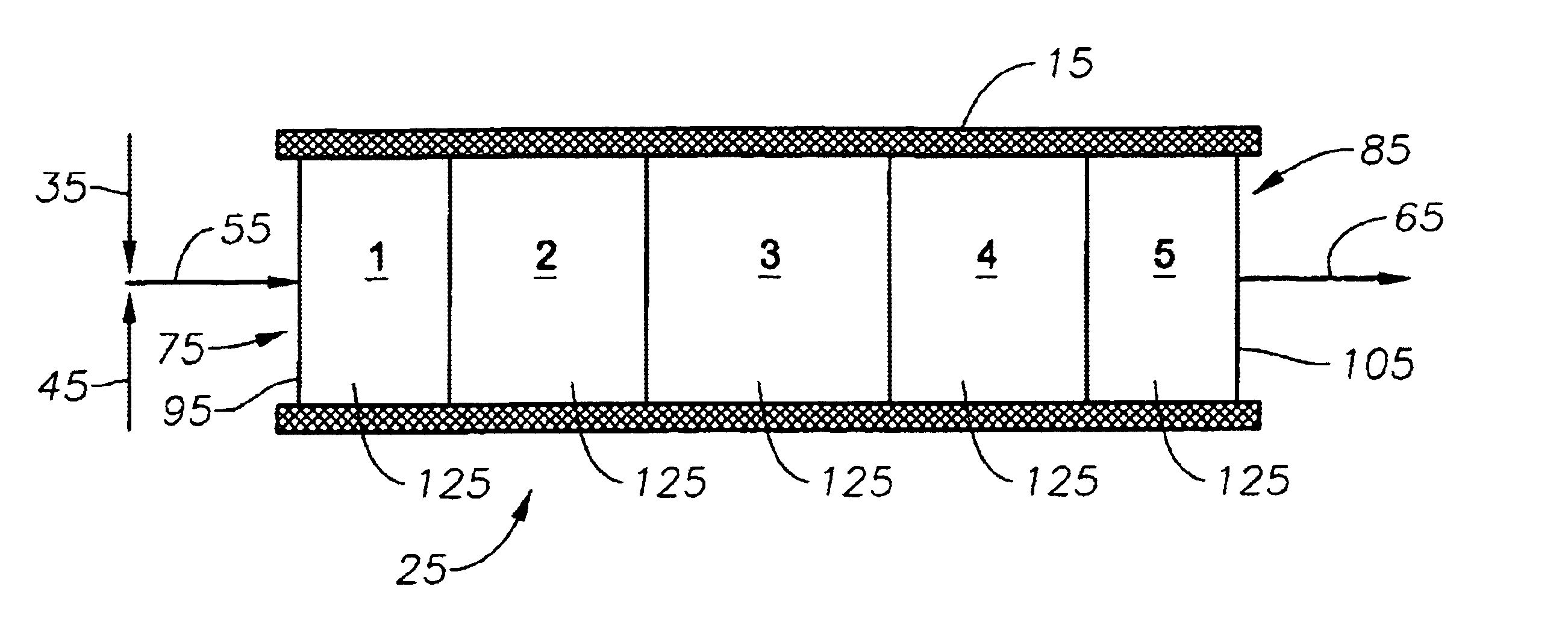

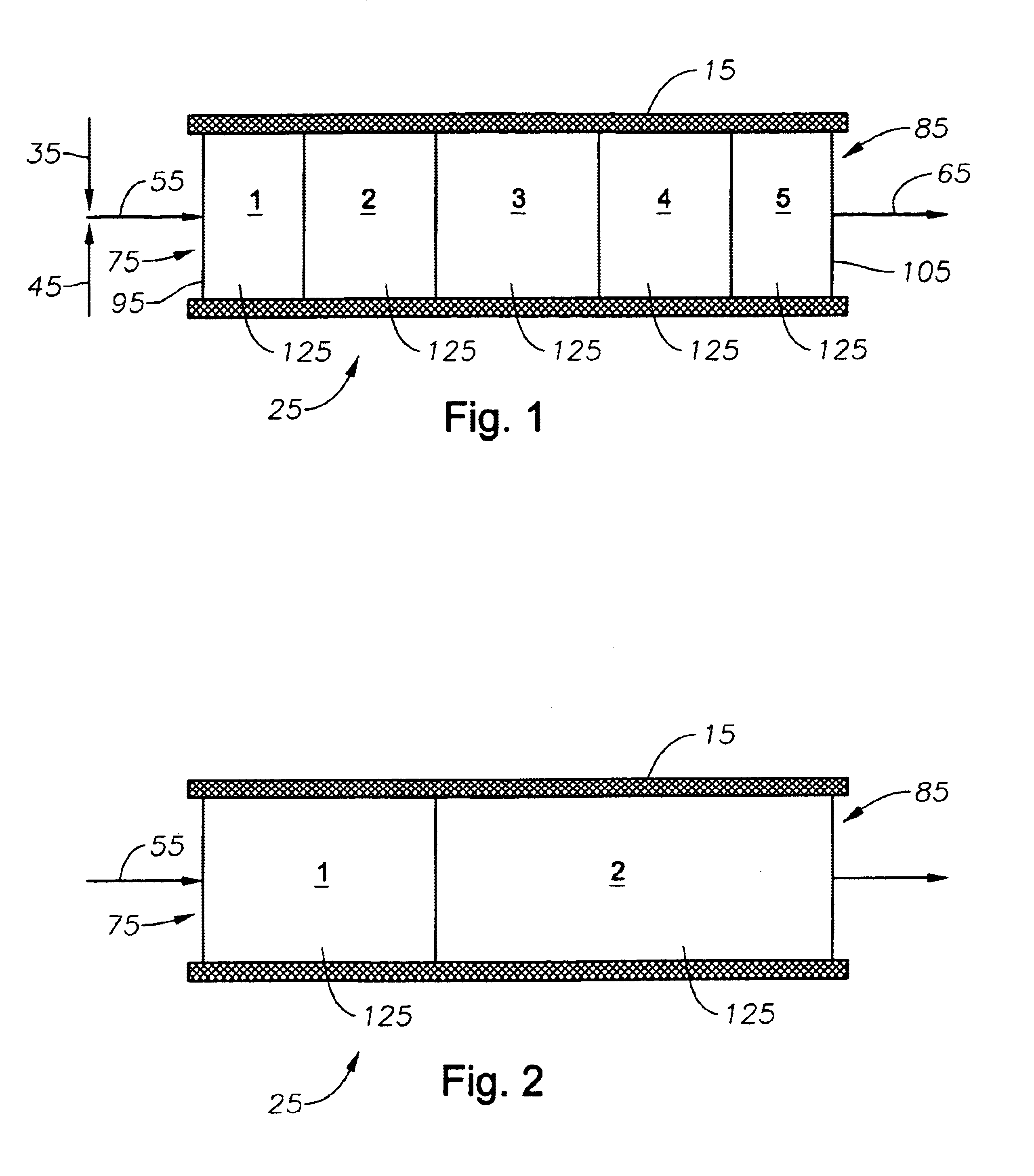

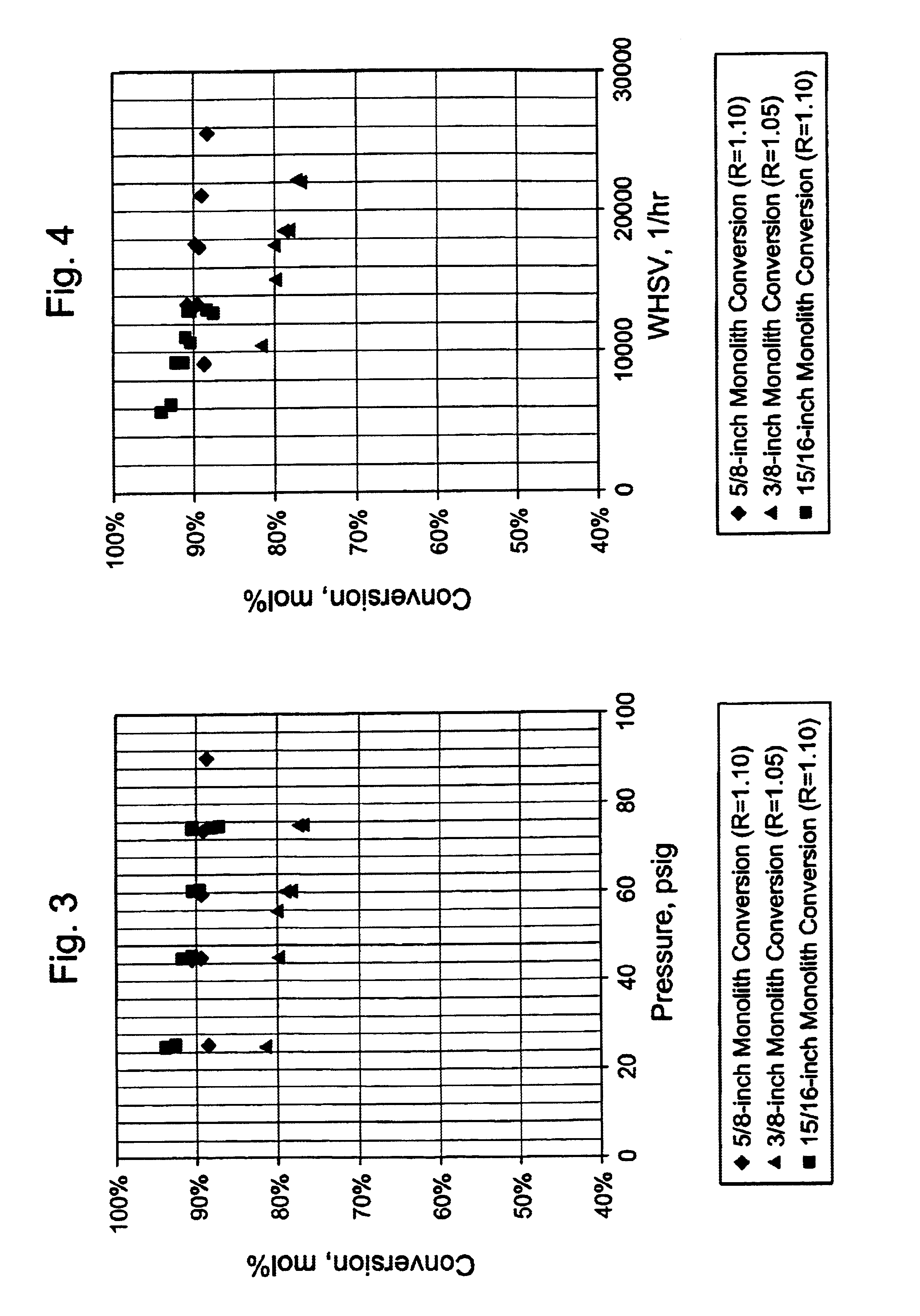

Catalyst system for enhanced flow syngas production

InactiveUS6887456B2Increase conversionsHigh selectivityHydrogen/synthetic gas productionBulk chemical productionSyngasProduct gas

A method and apparatus for converting a hydrocarbon and oxygen containing gas feed stream to a product stream, such as syngas, including catalytically partially oxidizing the hydrocarbon feed stream over a catalyst bed. The catalyst bed has a downstream section which is less resistant to flow than the upstream section.

Owner:PHILLIPS 66 CO

Catalyst for converting alcohols and ethers into aromatic hydrocarbons as well as preparation method and use method thereof

ActiveCN103007985ASmall particle sizeEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrogenAlcohol

The invention discloses a catalyst for converting alcohols and ethers into aromatic hydrocarbons, as well as a preparation method and a use method of the catalyst, and belongs to the technical field of chemical engineering. The preparation method comprises the steps as follows: at first, taking a template agent, kaolin, sodium hydroxide and water as raw materials for preparing a hydrogen type nanoscale ZSM-5 molecular sieve, and then directly preparing the catalyst; or based on the hydrogen type nanoscale ZSM-5 molecular sieve, preparing the two-component, three-component or four-component catalyst with metal and / or a structure enhancer and / or a stabilizing additive. The catalyst comprises the following components in percentage by mass: 30-100% of the needle-like nanoscale ZSM-5 molecular sieve, 0-10% of the metal, 0-50% of the structure enhancer and 0-10% of the stabilizing additive. The invention further provides a method for enabling the catalyst to be used for converting alcohols and ethers into aromatic hydrocarbons. The catalyst is small in particle size, high in catalytic efficiency and low in use cost; the preparation method is simple and efficient; and the use method is reasonable and efficient.

Owner:TSINGHUA UNIV

Petroleum hydrocarbon catalytic pyrolysis catalyst and its application

ActiveCN1955255AIncrease throughputHigh airspeedHydrocarbonsNaphtha reformingCatalytic pyrolysisAlkaline earth metal

This invention provides a petroleum hydrocarbon catalytic decomposition accelerant and its application. This accelerant includes following components: (1) lanthanide, its weight amount is 0.1-25%; (2) phosphorus or boron, its weight amount is 0.1-10%; (3) base metal, alkali metal and transition metal, their weight amount is 0.1-15%; (4) The others are ZSM-5,ZRP used as carrier. This accelerant used for production of low carbon alkenes by cracking heavy magnesium alkanes, with space velocity of gas 1-25hr-1, such as naphtha, diesel oil, educed pressure diesel and so on. The yield of ethylene, propylene, butylenes and butadiene will improve by 5%.

Owner:CHINA PETROLEUM & CHEM CORP +1

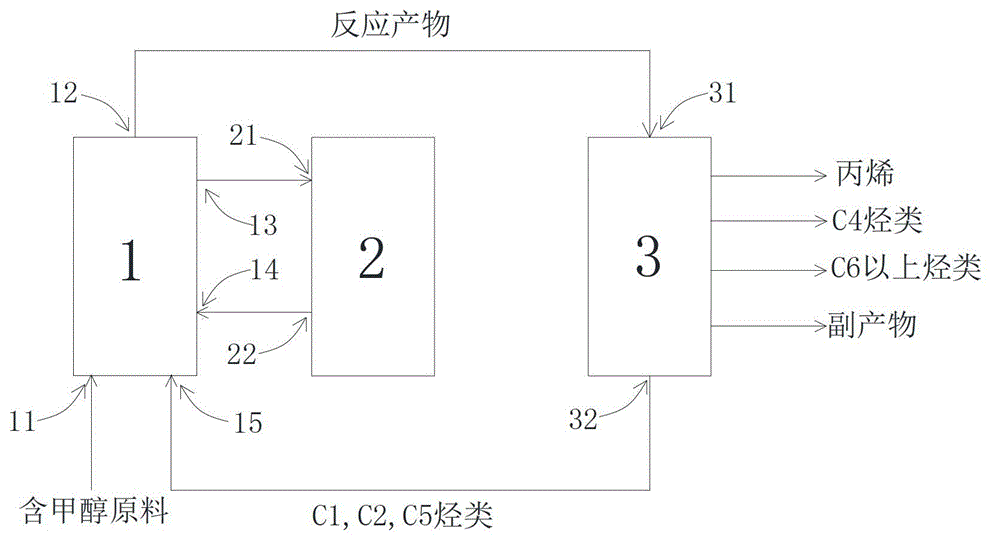

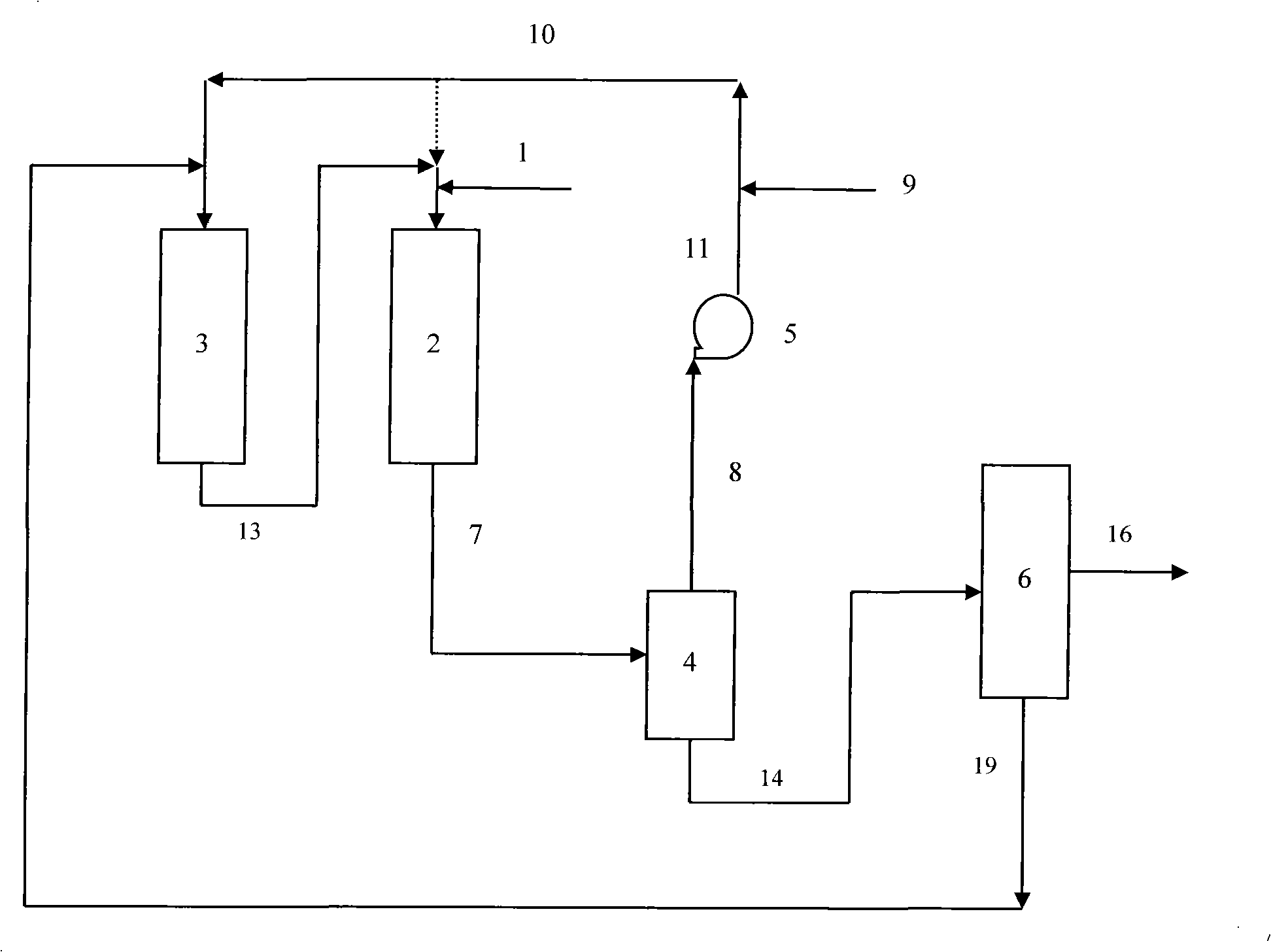

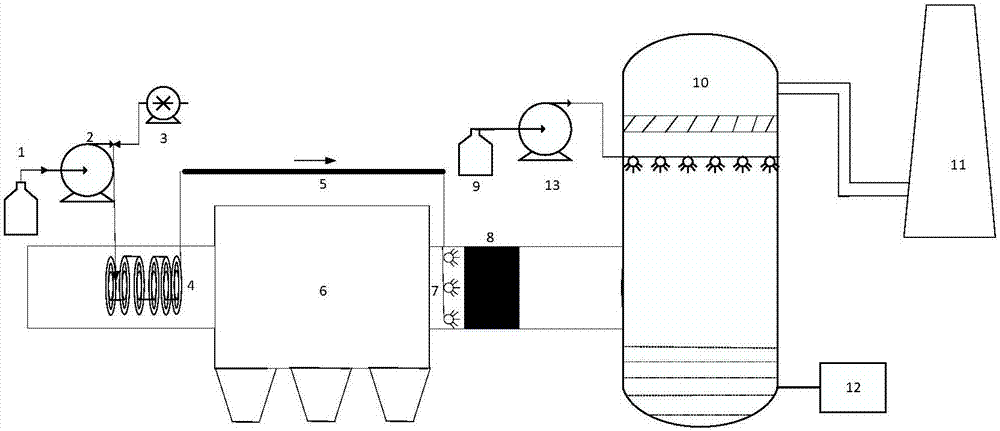

Method for utilizing circulating fluidized bed to prepare propylene and C4 hydrocarbons from methanol

InactiveCN104098429APromote regenerationLarge amount of processingCatalytic crackingMolecular sieve catalystsFluidized bedSeparation system

The invention provides a method for utilizing a circulating fluidized bed to prepare propylene and C4 hydrocarbons from methanol. The method comprises the following steps: 1) enabling a raw material containing methanol to enter a fluidized bed reactor, so as to generate a reaction product flow containing C1 hydrocarbon, C2 hydrocarbons, propylene, by-products, C4 hydrocarbons, C5 hydrocarbons, C6 hydrocarbons and hydrocarbons with more than six carbon atoms under the effect of a catalyst; and 2) enabling the reaction product flow obtained in the step 1) to enter a separation system to perform separation, so as to separate C1, C2 and C5 hydrocarbons, propylene, C4 hydrocarbons, C6 hydrocarbons, hydrocarbons with more than six carbon atoms and by products, returning C1, C2 and C5 hydrocarbons to the reactor to perform reaction, and recovering propylene, C4 hydrocarbons, C6 hydrocarbons, hydrocarbons with more than six carbon atoms and by-products as final products.

Owner:SHANGHAI BI KE CLEAN ENERGY TECH +1

Dual zone aromatic alkylation process

ActiveUS20080171900A1High selectivityLow molar ratioMolecular sieve catalystsMolecular sieve catalystAlkyl transferAlkylation

A process for the catalytic alkylation of an aromatic substrate with an alkylating agent is disclosed that comprises contacting the aromatic substrate and the alkylating agent in sequential alkylation zones to obtain an alkylaromatic. The first catalyst comprises UZM-8 zeolite and the second catalyst comprises beta zeolite. The process is particularly well suited for the alkylation of benzene with propylene to produce cumene.

Owner:UOP LLC

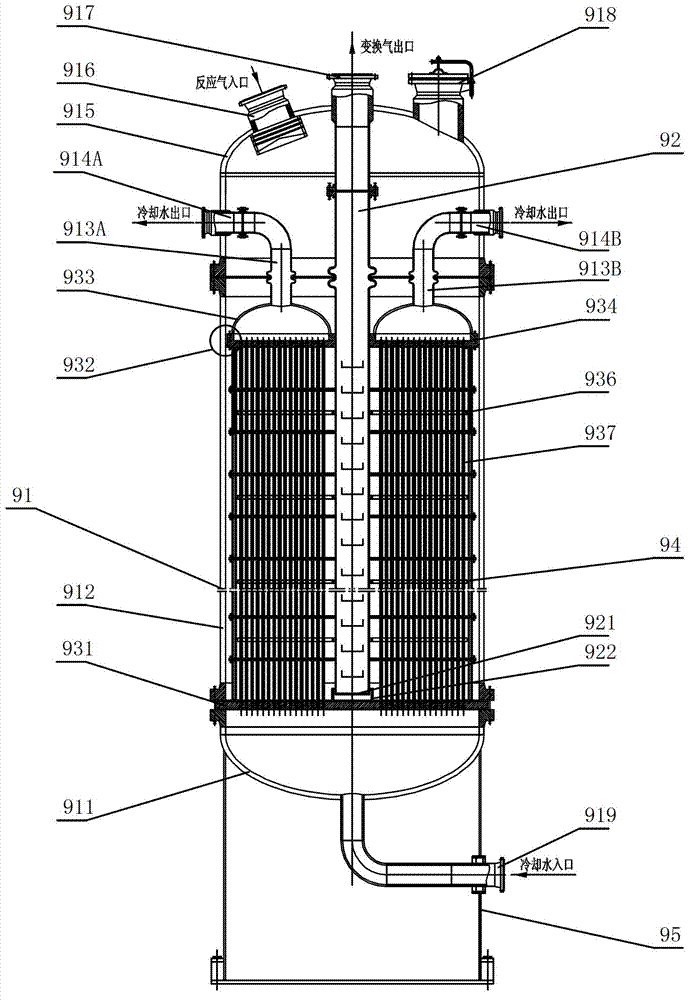

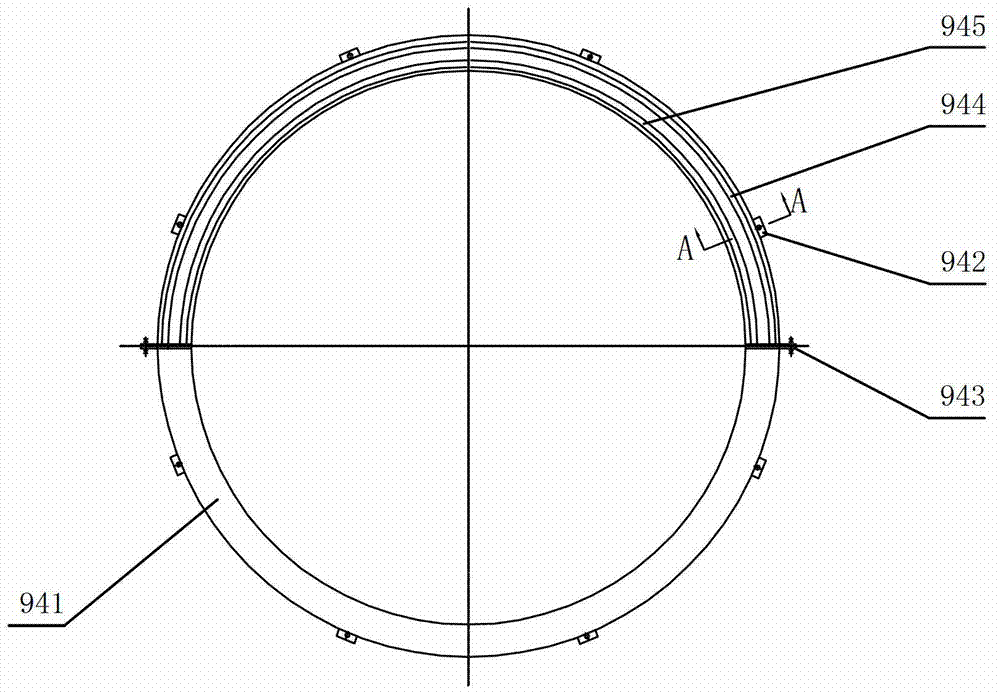

Low-moisture low-variable serial saturation tower thermal CO transformation technology

ActiveCN102888253AShort transformation processReduce resistanceHydrogenCombustible gas catalytic treatmentDry gasMoisture

Owner:CHINA PETROCHEMICAL CORP +2

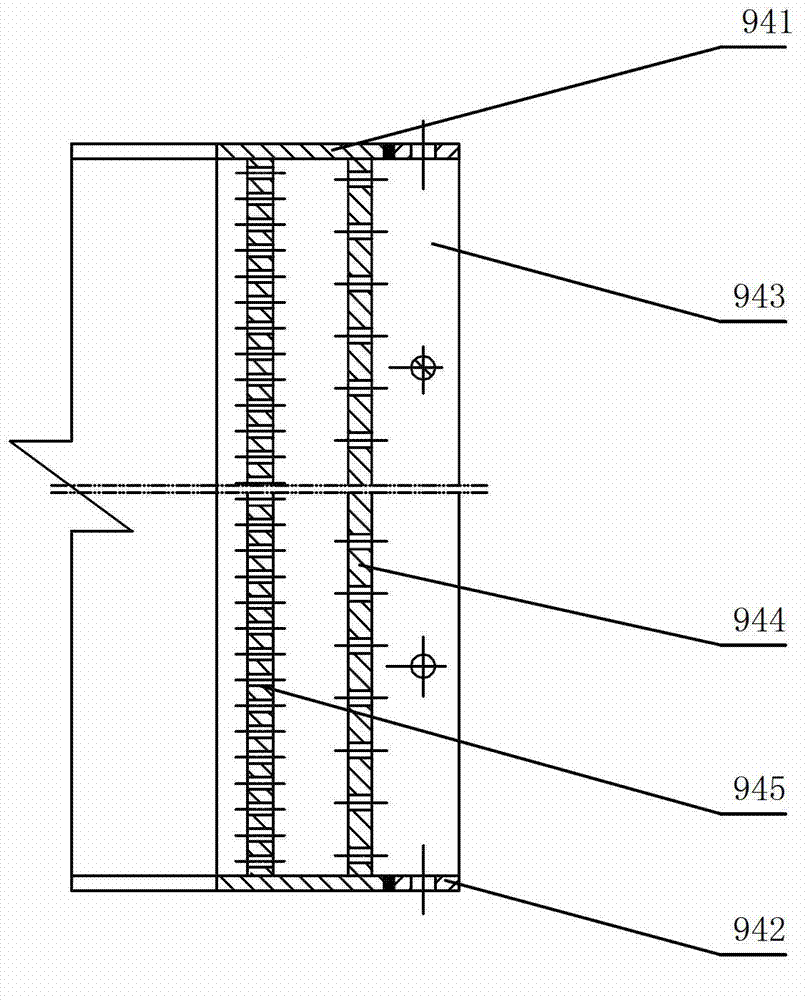

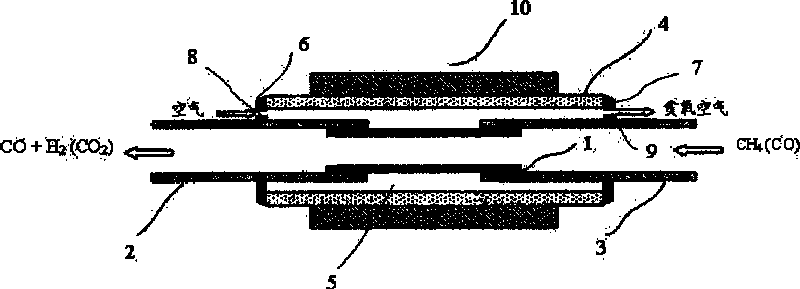

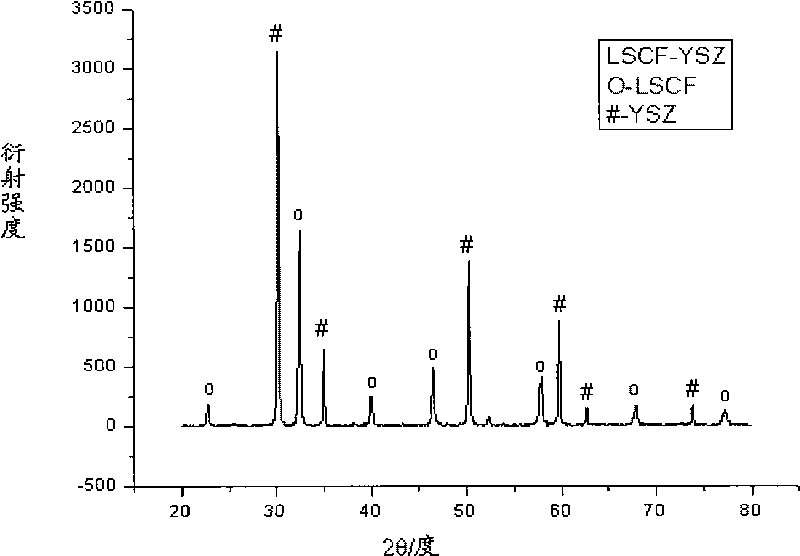

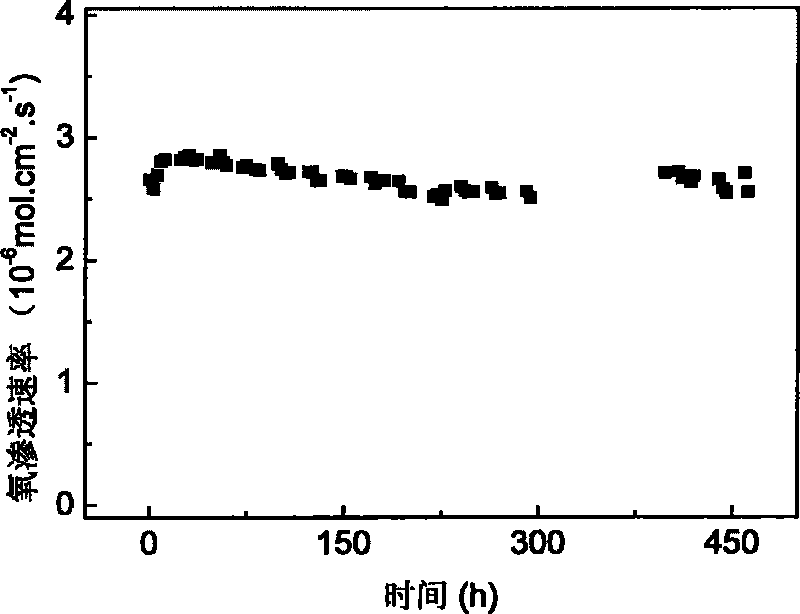

Hollow fiber membrane reactor for gaseous oxidation reaction, preparation and application thereof

InactiveCN101733048AImprove physicsImprove compatibilitySemi-permeable membranesHydrogenFiberComposite ceramic

The invention discloses a hollow fiber membrane reactor for gaseous oxidation reaction, a preparation method and application thereof. The membrane reactor is made of a compact hollow fiber oxygen permeation membrane, wherein the wall thickness of a pipe is between 0.1 and 0.3mm, and the outer pipe diameter is between 1 and 3mm; the oxygen permeation membrane is made of a dual-phase composite ceramic oxygen permeation membrane material which is prepared by mixing an electron conductive phase material and an ion conductive phase material in a volume ratio of 0.43-1.5:1; the electron conductive phase material is provskite-type chromic lanthanum composite oxide (Ln1-xAx)1-zCr1-yByO3 and / or strontium titanate-based composite oxide (LnxSr1-x)1-zTi1-yByO3; and the ion conductive phase material is stabilized fluorite type zirconium dioxide Zr1-x1Rx1O2-delta, or doped cerium dioxide R'z1Ce1-z1O2-delta. The method for preparing the membrane reactor comprises the following steps: mixing the electron conductive phase material and the ion conductive phase material in the volume ratio of 0.43-1.5:1 to prepare a hollow fiber membrane blank by adopting a wet phase inversion method; and sintering the blank at the temperature of between 1,300 and 1,600 DEG C for 10 to 18 hours. The membrane reactor has high oxygen permeation performance, excellent high temperature reduction resistance and long-term stability and low production cost.

Owner:UNIV OF SCI & TECH OF CHINA

Ferromanganese catalyst for Fischer-Tropsch synthesis and method for preparing the same

InactiveCN1463793ALarge specific surface areaHigh mechanical strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsFerricHigh selectivity

The catalyst for Fischer-Tropsch synthesis has the atom makeup of Fe 100, Mn 4-100, Ca 2-50 and K 0.2-10; and is prepared with precursors and through precipitation process. The present invention hasthe advantages of large specific surface area, high strengthen, low cost, high conversion rate and high selectivity.

Owner:SYNFUELS CHINA TECH CO LTD

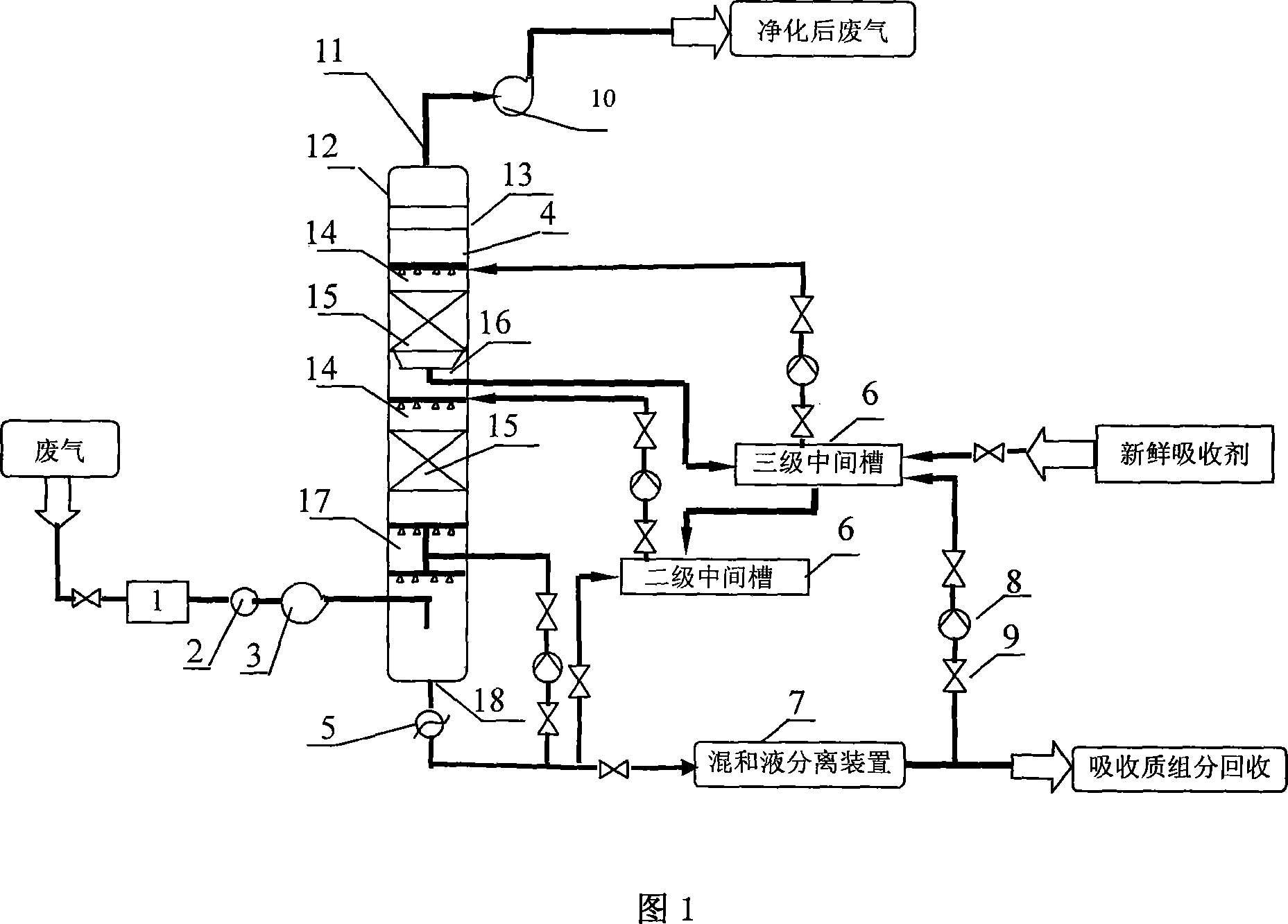

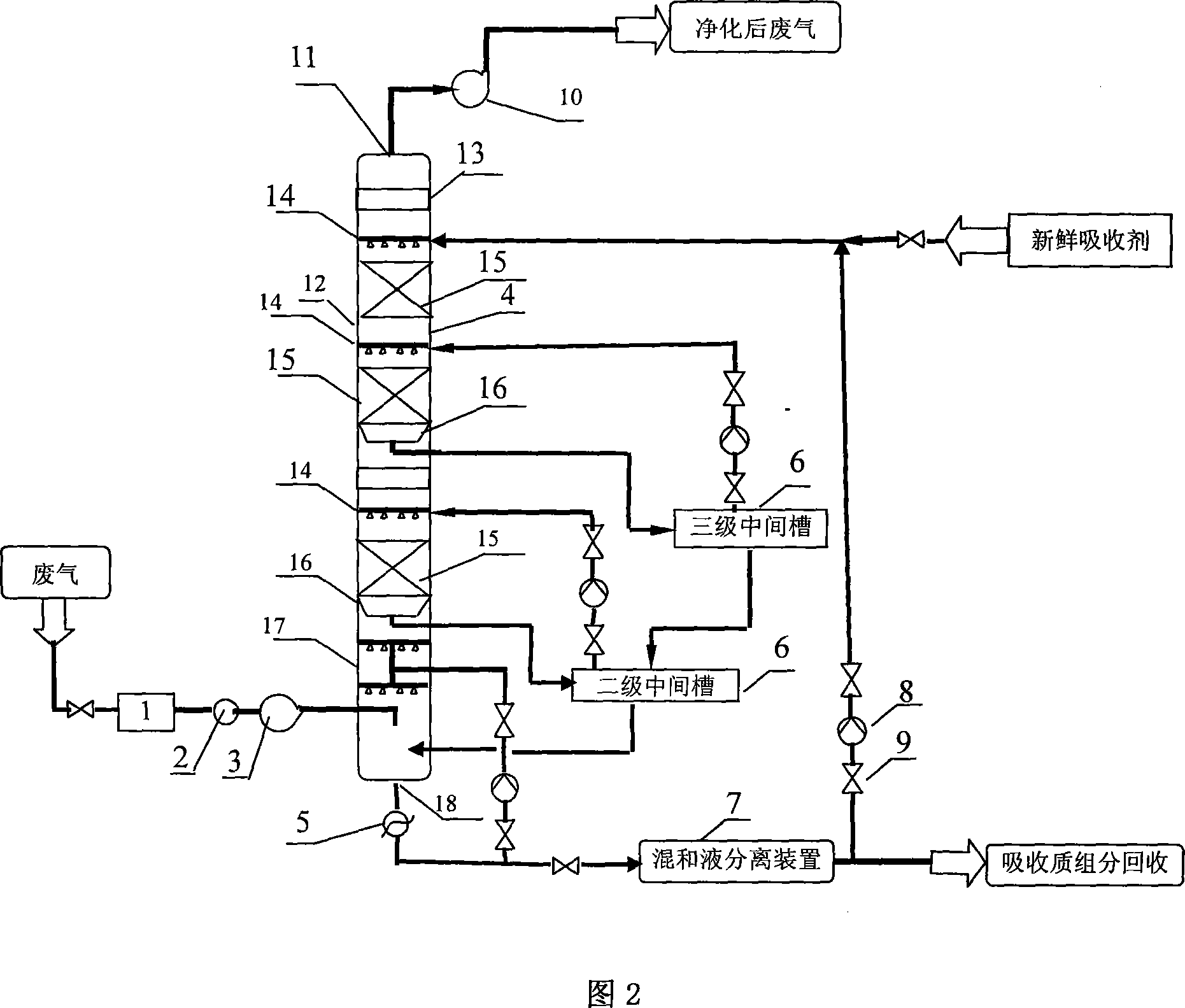

Process method of purifying and recycling mixed organic waste gas

InactiveCN101108296APromote absorptionHigh flash pointDispersed particle separationChemical industryOrganic solvent

The invention belongs to chemical industry and waste gas process field, in particular providing a process method which mixes organic waste gas purifying and resource recovery. The specific procedure is that: make the mixed waste gas pass through a filter to be filtered, and then enters into a single-seat multilevel absorption tower and contacts with a packing layer and a liquid distribution device; when the series of the single-seat tower is 3, the second-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising the mixing liquid which is pumped in after cooled by a heat interchanger at the bottom of the adsorption tower and the mixing liquid which generates in the middle groove of the third-grade; the third-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising fresh absorbent, the regenerating liquid recycled by a mixing liquid separation device and the collecting liquid collected by a collecting hopper of third-grade; when the series of the single-seat tower is N and is larger than 3, all grades of absorbent from the second grade to the N minus 2 is a mixing liquid comprising a mixing liquid generated in the middle groove of the next grade and a collecting liquid collected by the collecting hopper on the same grade, the absorbent of the N minus grade is the colleting liquid collected by the collecting hopper of the N minus 1 grade, the absorbent of the N grade is a mixing liquid comprising of pumped fresh absorbent and the regenerating liquid recycled by the mixing liquid separation device. The fresh absorbent is an environment-protected organic solvent with high boiling point, strong lipophilicity and low volatility. The invention can recycle a plurality of organic infectant in waste gas, the technics procedure is simple, practical, and the operation cost is low.

Owner:上海同济华康环境科技有限公司

Catalyst and process for thermo-neutral reforming of liquid hydrocarbons

ActiveUS9499403B2Long catalyst lifeSmall sizeProductsHydrogen separationLiquid hydrocarbonsFour component

The invention relates to a four-component catalyst and a seven-component catalyst and refractory supports for use in the thermoneutral reforming of petroleum-based liquid hydrocarbon fuels.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS) +2

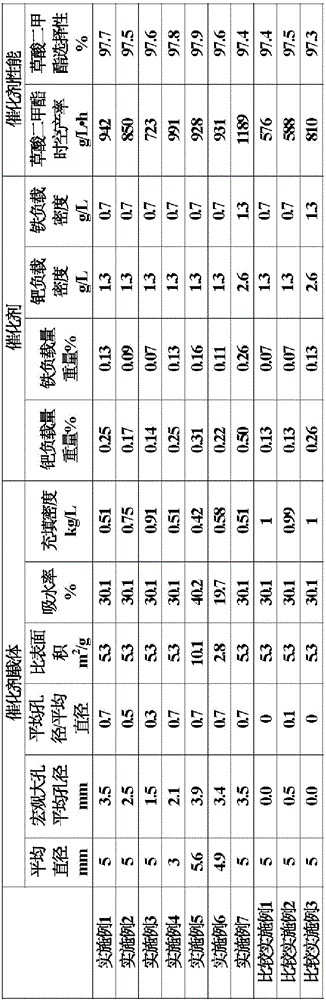

Catalyst carrier and catalyst comprising the same

ActiveCN106457227AEasy to fillEvenly stackedCatalyst carriersCatalyst activation/preparationOxalateGas phase

The invention relates to a catalyst carrier used in a process of coupling and synthesizing dialkyl oxalates through gas phase catalysis of carbon monoxide, the catalyst carrier comprises micro pores and one or more macro pores which can pass through the catalyst carrier, wherein the ratio of the average pore size of the macro pores and the average diameter of the catalyst carrier is more than 0.2. The invention also relates to the catalyst carrier and a catalyst which comprises activated components and an optional additive and is loaded on the catalyst carrier. The catalyst can effectively perform gas phase catalysis on carbon monoxide to couple and generate the dialkyl oxalates, the heat dissipation is improved, the pressure drop is reduced, the usage amount of precious metal such as palladium is reduced, the usage cost of the catalyst and the production cost of the dialkyl oxalates are reduced, so that the industrial mass production of the dialkyl oxalates can be contributed to realize.

Owner:HIGHCHEM

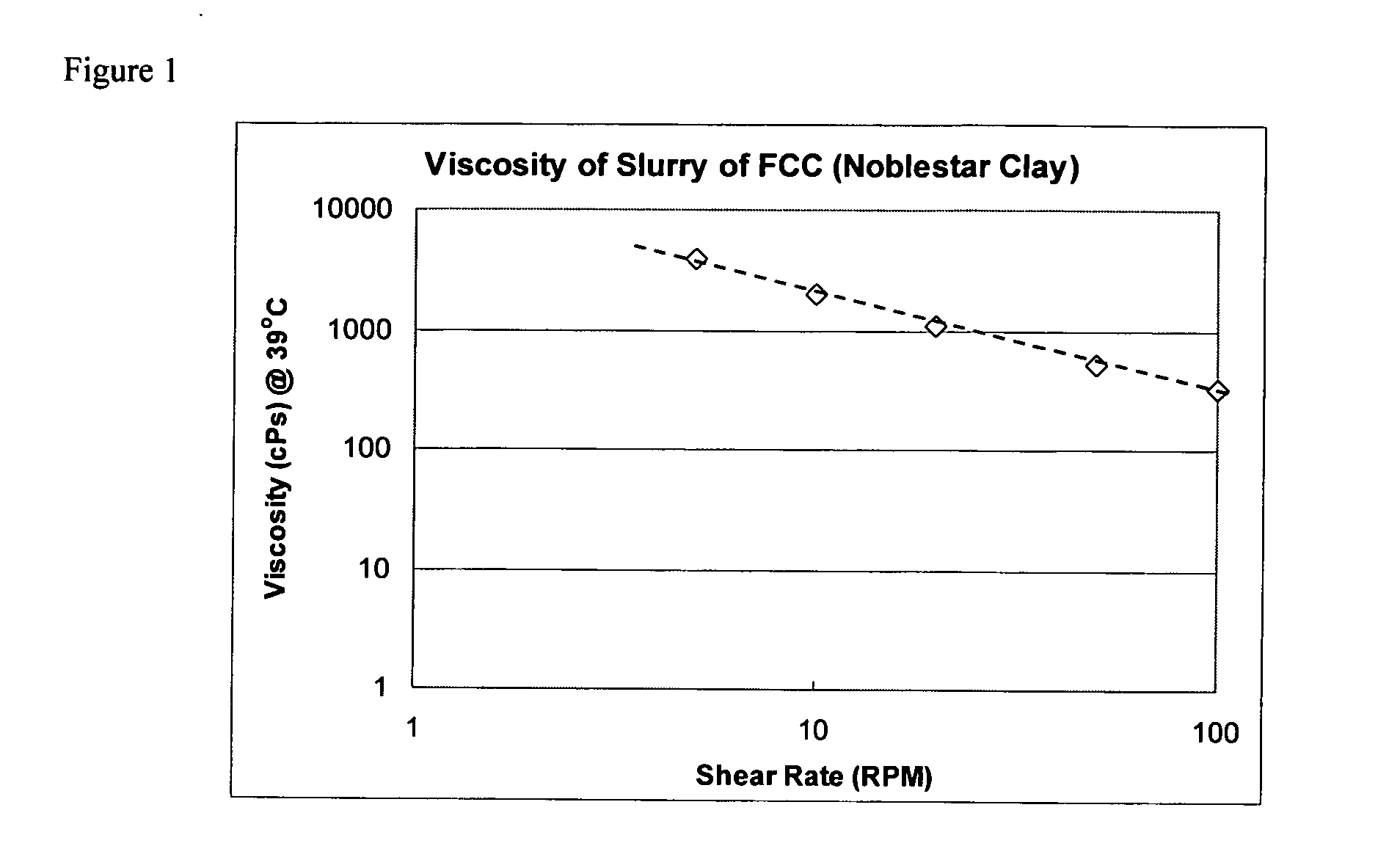

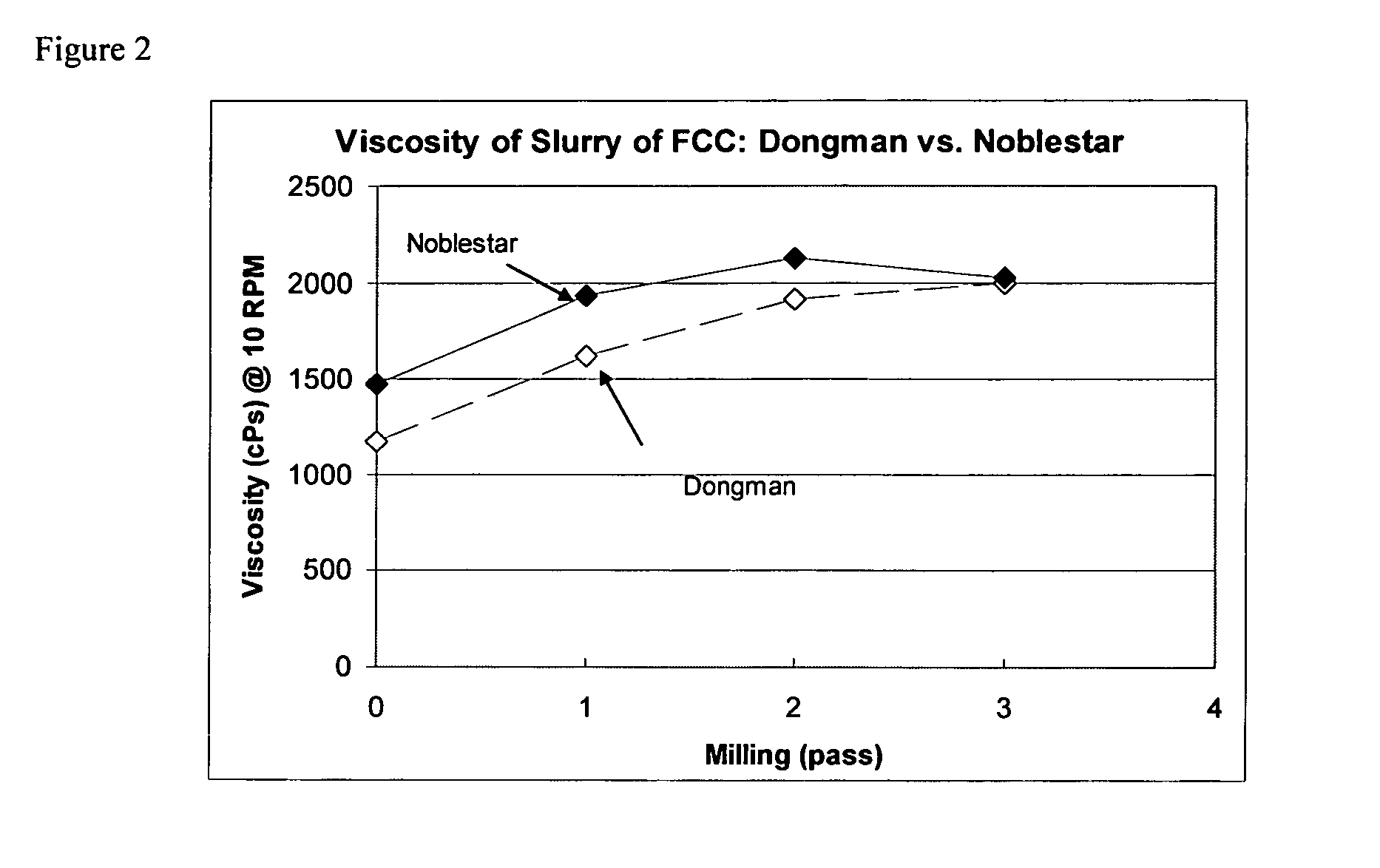

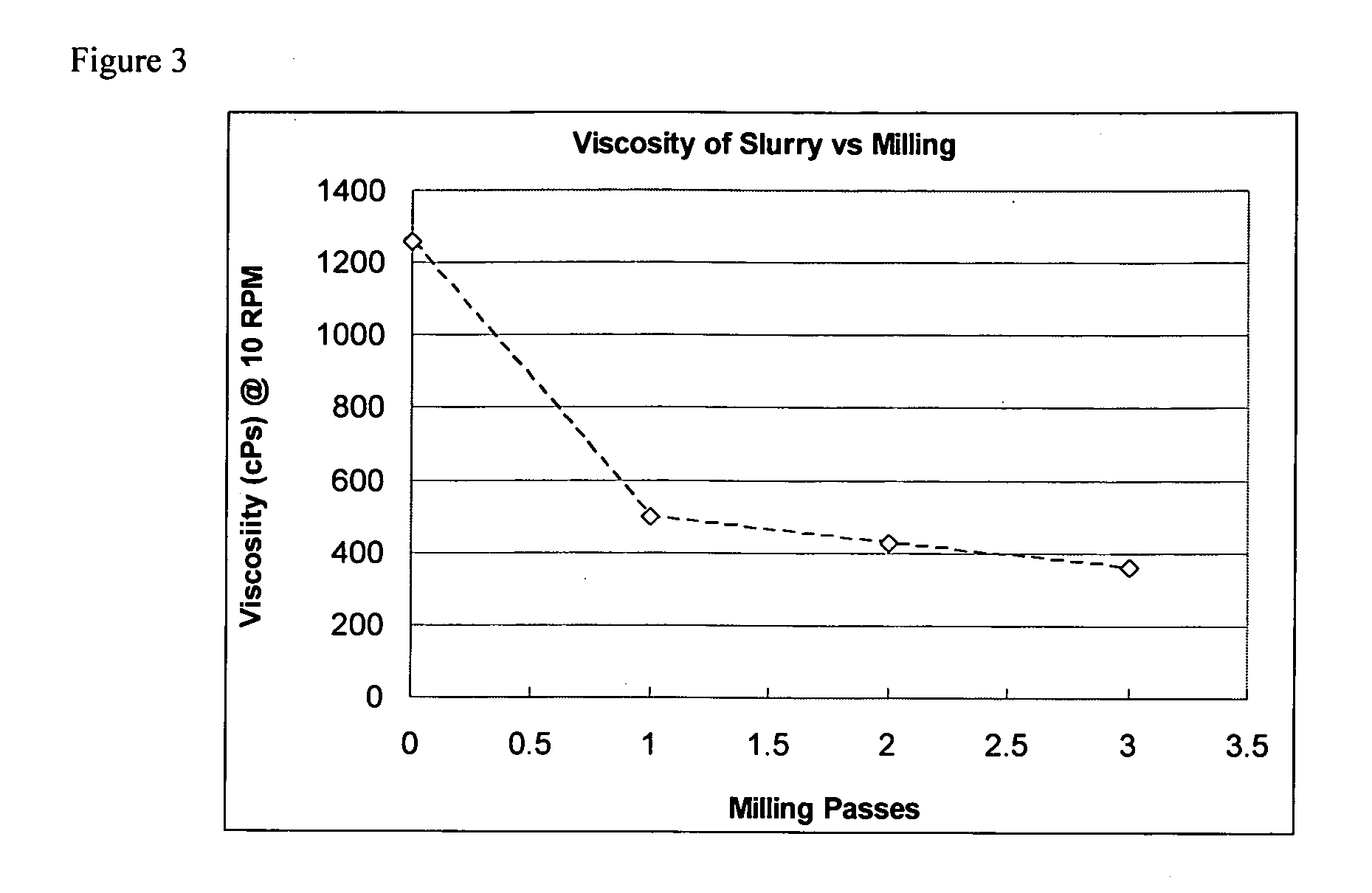

High solids catalyst formulation and spry drying

InactiveUS20110108462A1Increase line speedIncrease severityCatalytic crackingMolecular sieve catalystsPolymer scienceGasoline

A catalyst composition prepared based on high solids formulation containing a zeolite, a binder precursor, a matrix and a slurring agent and a process for preparing a shaped catalyst product to be used in fluid catalytic cracking process for converting a heavier hydrocarbon fraction into a lighter hydrocarbons, particularly gasoline and light olefins.

Owner:CHANG YUN FENG

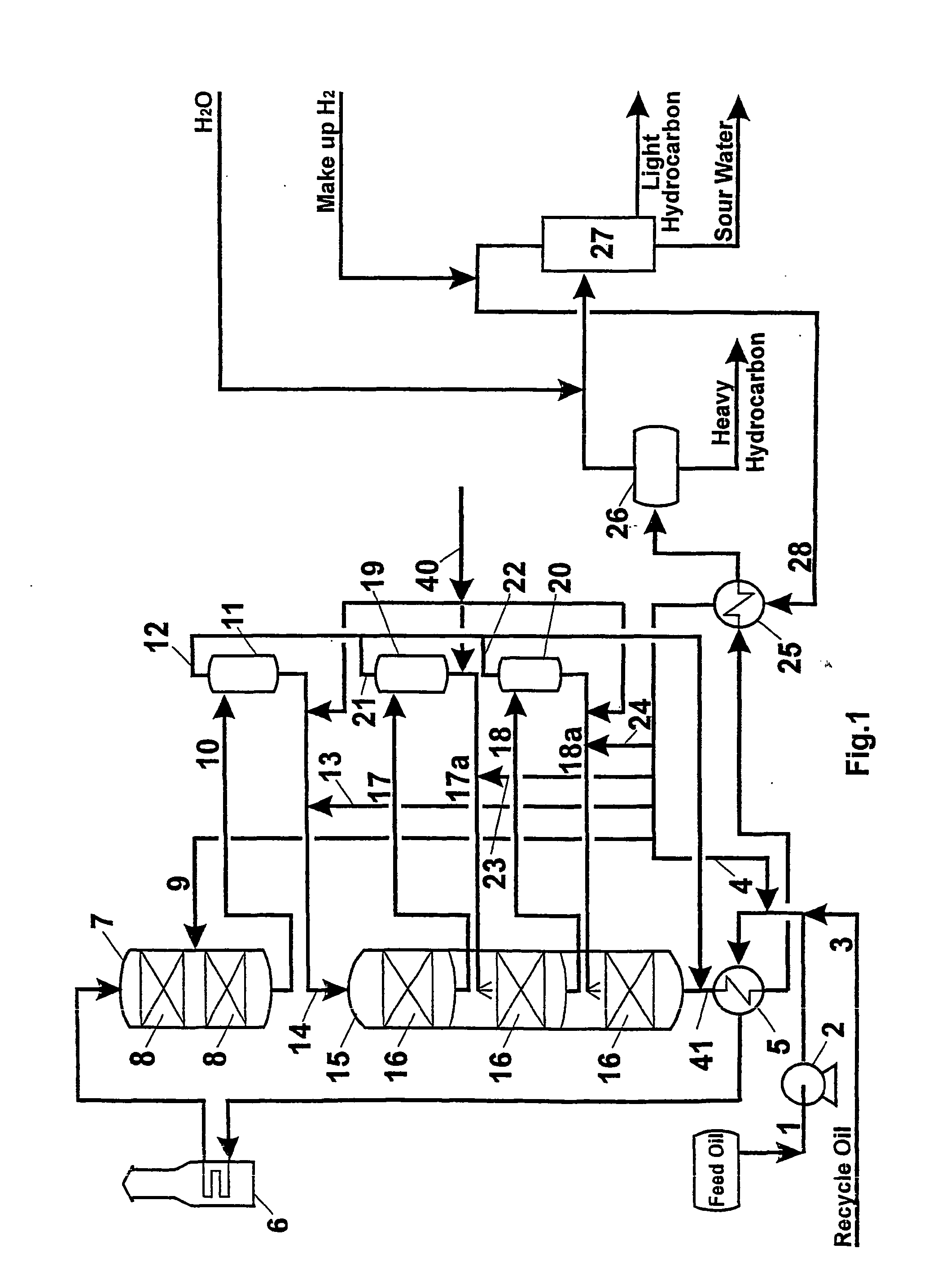

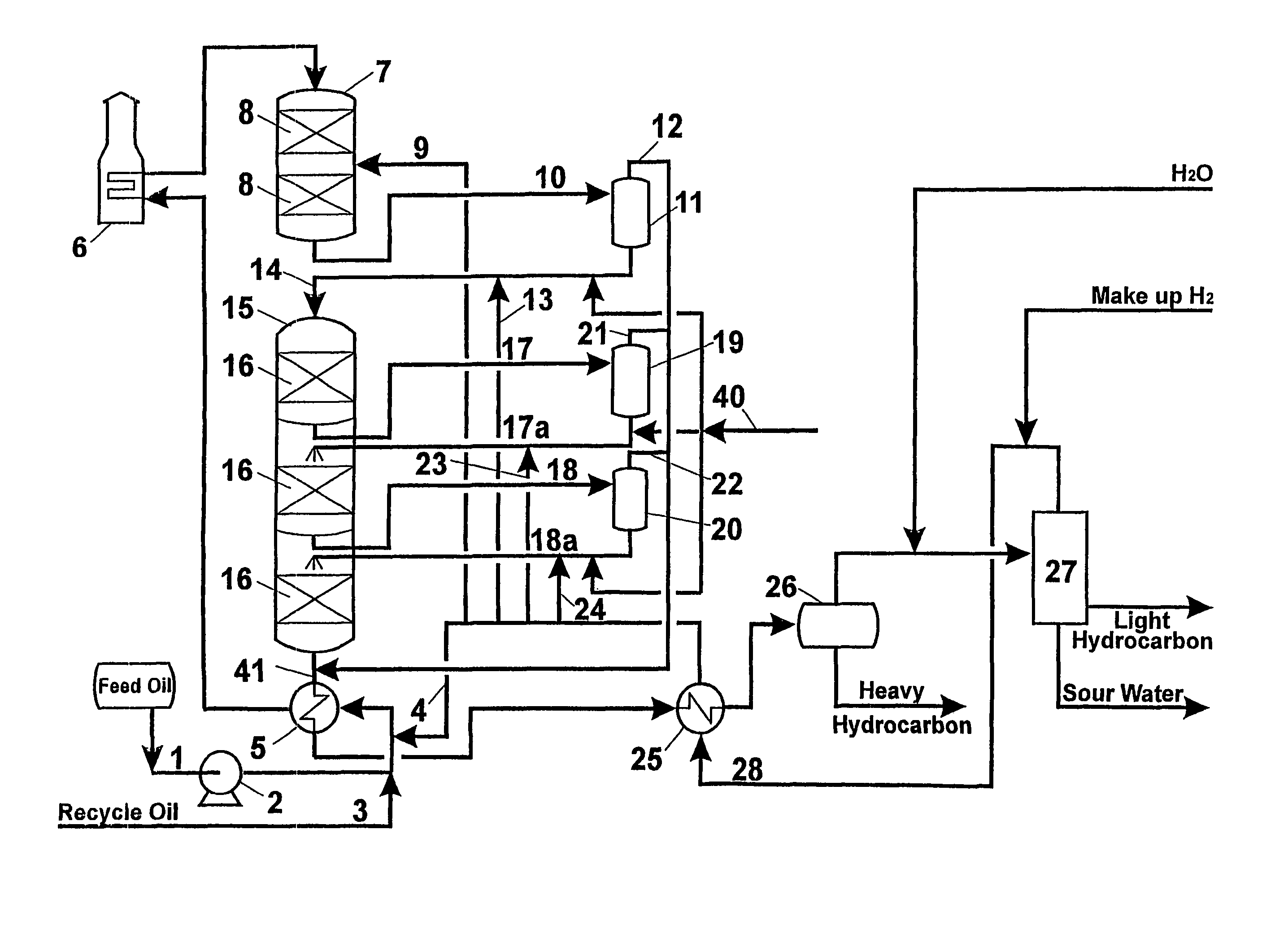

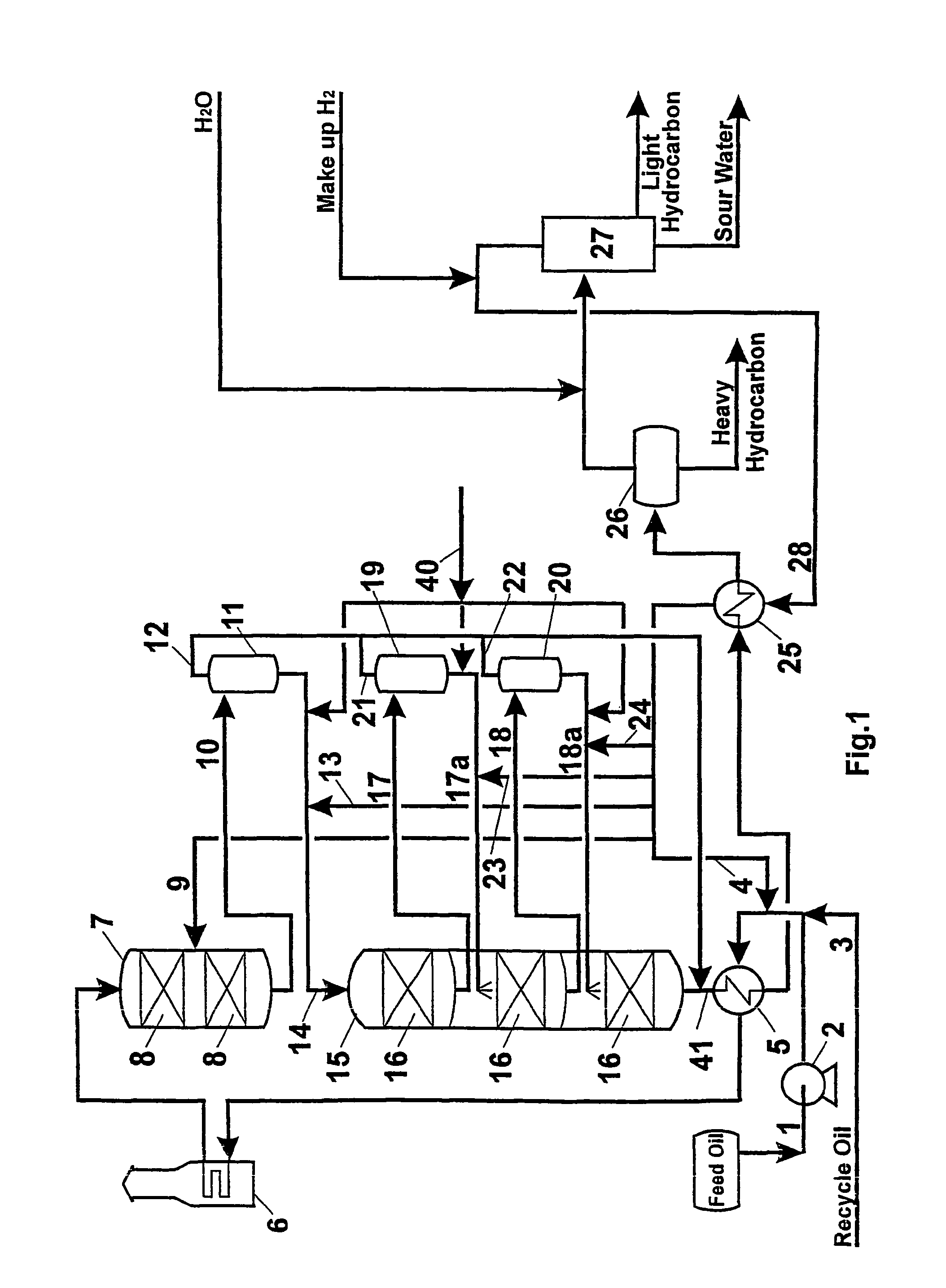

Hydroprocessing process and method of retrofitting existing hydroprocessing reactors

InactiveUS20040045870A1High airspeedExtended service lifeHydrocarbon oil crackingTreatment with hydrotreatment processesPtru catalystFluid phase

A process for hydroprocessing a hydrocarbon feed comprising the steps of (a) admixing the feed with a hydrogen rich gas and obtaining a first admixed process stream; (b) contacting the first admixed process stream with a first catalyst being active in hydrocracking of hydrocarbon compounds and obtaining a first catalyst effluent process stream; (c) separating the first catalyst effluent process stream in a gas phase stream and a liquid phase stream, and withdrawing the gas phase stream; (d) admixing the liquid phase stream with a hydrogen rich gas and obtaining a second admixed process stream; (e) contacting the second admixed process gas stream with a second catalyst being active in hydrocracking of hydrocarbon compounds and obtaining a second catalyst effluent process stream; (f) withdrawing and admixing the second catalyst effluent process stream with the gas phase stream obtained in step (c); and (g) withdrawing the admixed process stream provided in step (f).

Owner:HALDOR TOPSOE AS

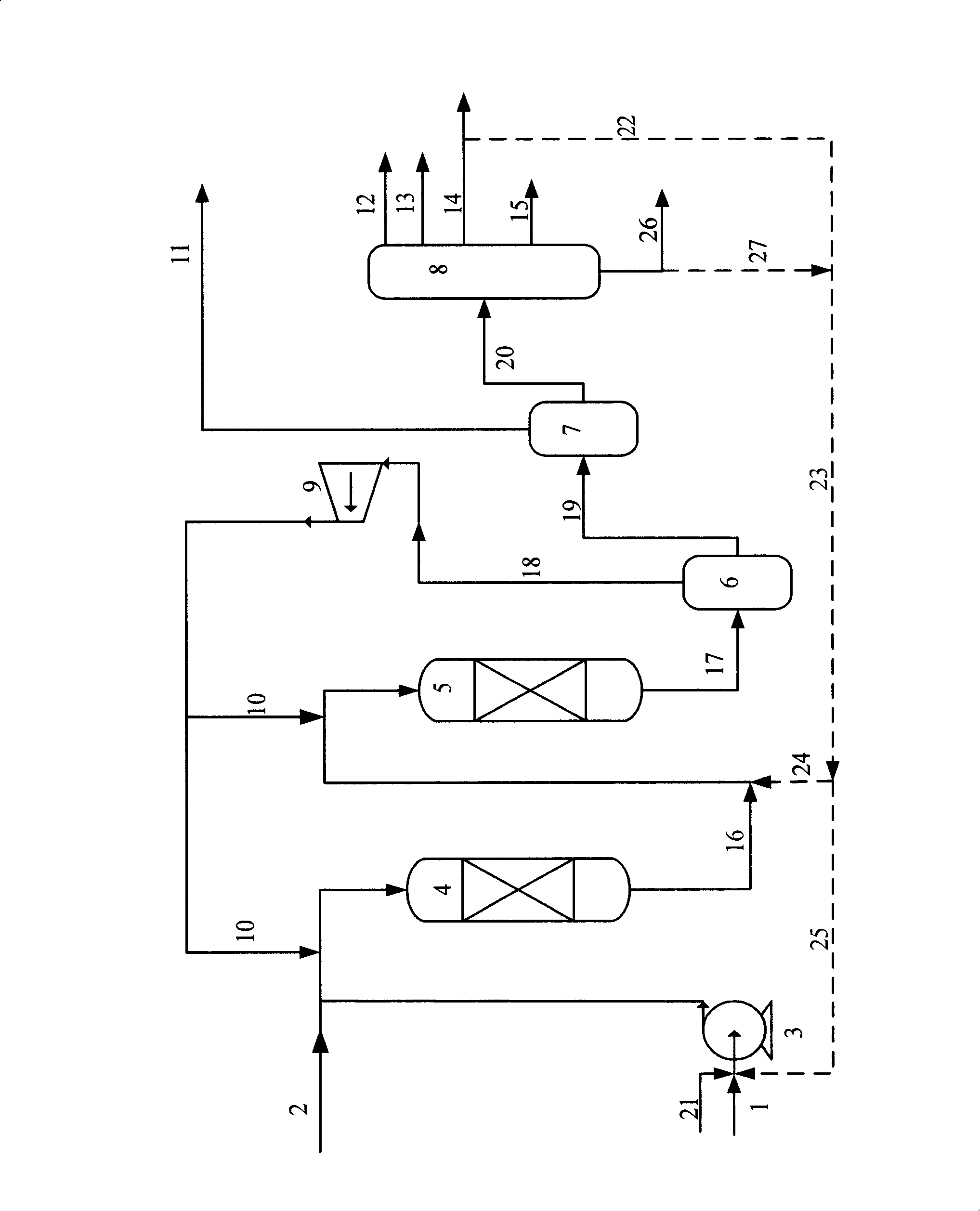

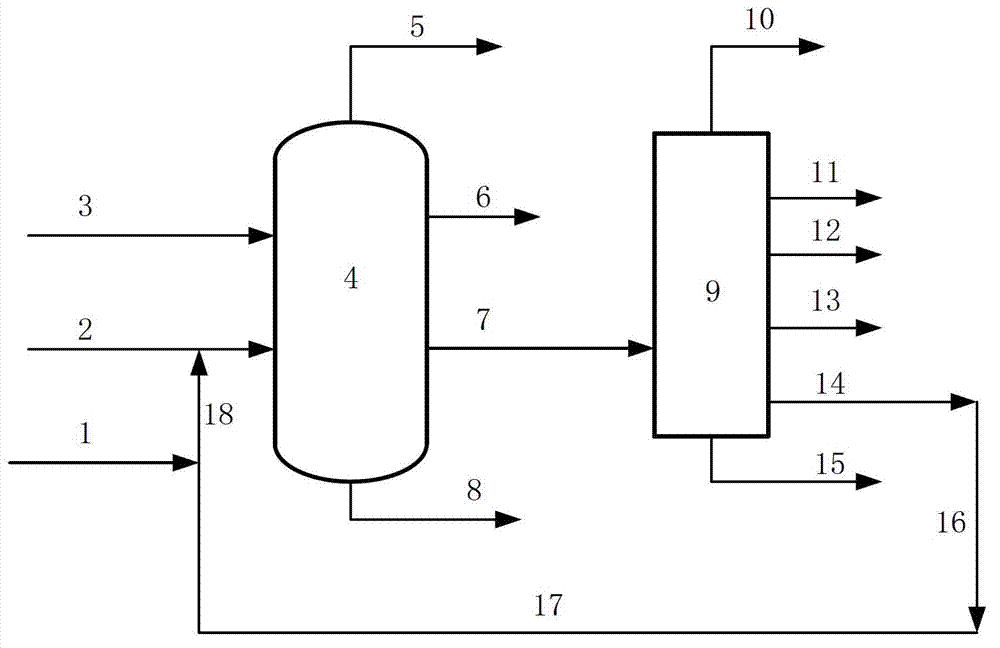

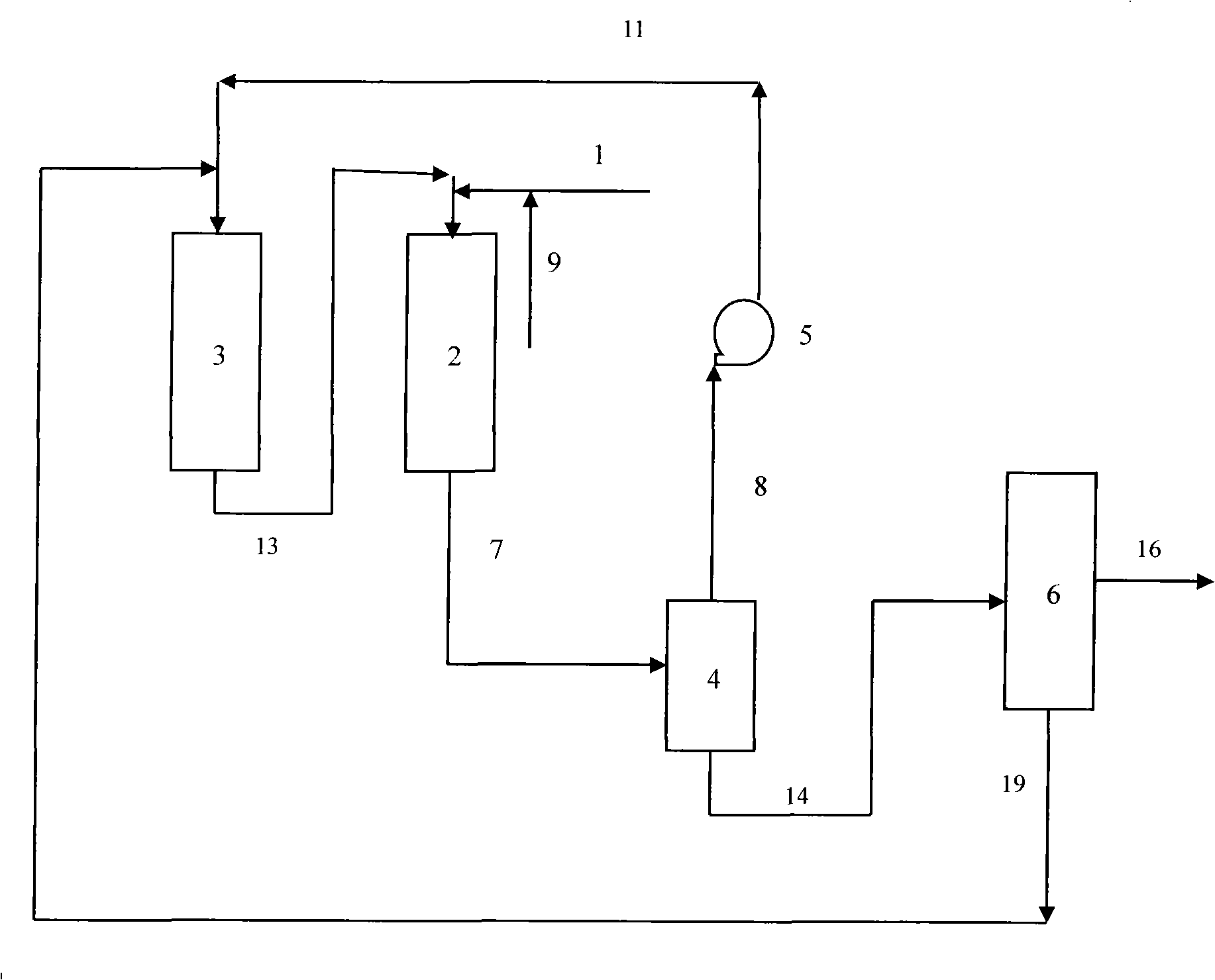

Hydrogenation conversion process

ActiveCN101333459AHigh airspeedReduce volume ratioTreatment with hydrotreatment processesHydrogenation reactionFractionation

The invention discloses a hydro-conversion method, in particular to a long distillate raw oil hydro-cracking method. The method comprises: mixing a long distillate raw oil with the generated stream in a second hydrogenation reaction zone to enter a first hydrogenation reaction zone, separating the generated stream after the hydro-treating reaction to obtain hydrogen-rich gas and liquid, recycling the hydrogen-rich gas, putting the liquid into a fractionating tower for fractionation to obtain light-end products and tail oil, mixing the tail oil with hydrogen to enter the second hydrogenation reaction zone, and putting the generated stream in the second hydrogenation reaction zone into the first hydrogenation reaction zone. Compared with the prior art, the method realizes the direct production of clean automotive fuel and high quality chemical raw materials by long distillate raw materials in a set of hydrogenation systems, thereby reducing the equipment investment and operating cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethyl methyl ketone by dehydrating 2,3-butanediol efficiently

InactiveCN101580462AAvoid dependenceHigh activityMolecular sieve catalystsOrganic compound preparationMolecular sieveSolid acid

The invention discloses a method for preparing an ethyl methyl ketone by dehydrating a 2,3-butanediol, belonging to the technical field of chemical product preparation. The method is to prepare the ethyl methyl ketone by dehydrating the 2,3-butanediol under the action of molecular sieve solid acid catalyst. The method comprises the following steps: taking the 2,3-butanediol of 10-90 wt% as a raw material, pre-heating and vaporizing the raw material at a reaction temperature of 200-300 DEG C, the raw material gas after being aerified reacting through a catalyst layer with the 2,3-butanediol mass airspeed of 1.5-3.4h, and separating reactor outlet materiels by liquid-vapor separation to obtain the ethyl methyl ketone. The conversion rate of the 2,3-butanediol is 94.2-100%, and the selectivity of the ethyl methyl ketone can reach 70.1-94.2%. The catalyst adopted in the invention has high activity and high airspeed, thereby having high conversion rate of 2,3-butanediol with different concentration; the ethyl methyl ketone has high selectivity and productivity and is environmentally friendly, the process is simple and the catalyst has good stability.

Owner:TSINGHUA UNIV

Hydroprocessing process and method of retrofitting existing hydroprocessing reactors

InactiveUS7156977B2Avoid crackingHigh airspeedTreatment with plural serial cracking stages onlyCoke ovensHydrogenGas phase

Owner:HALDOR TOPSOE AS

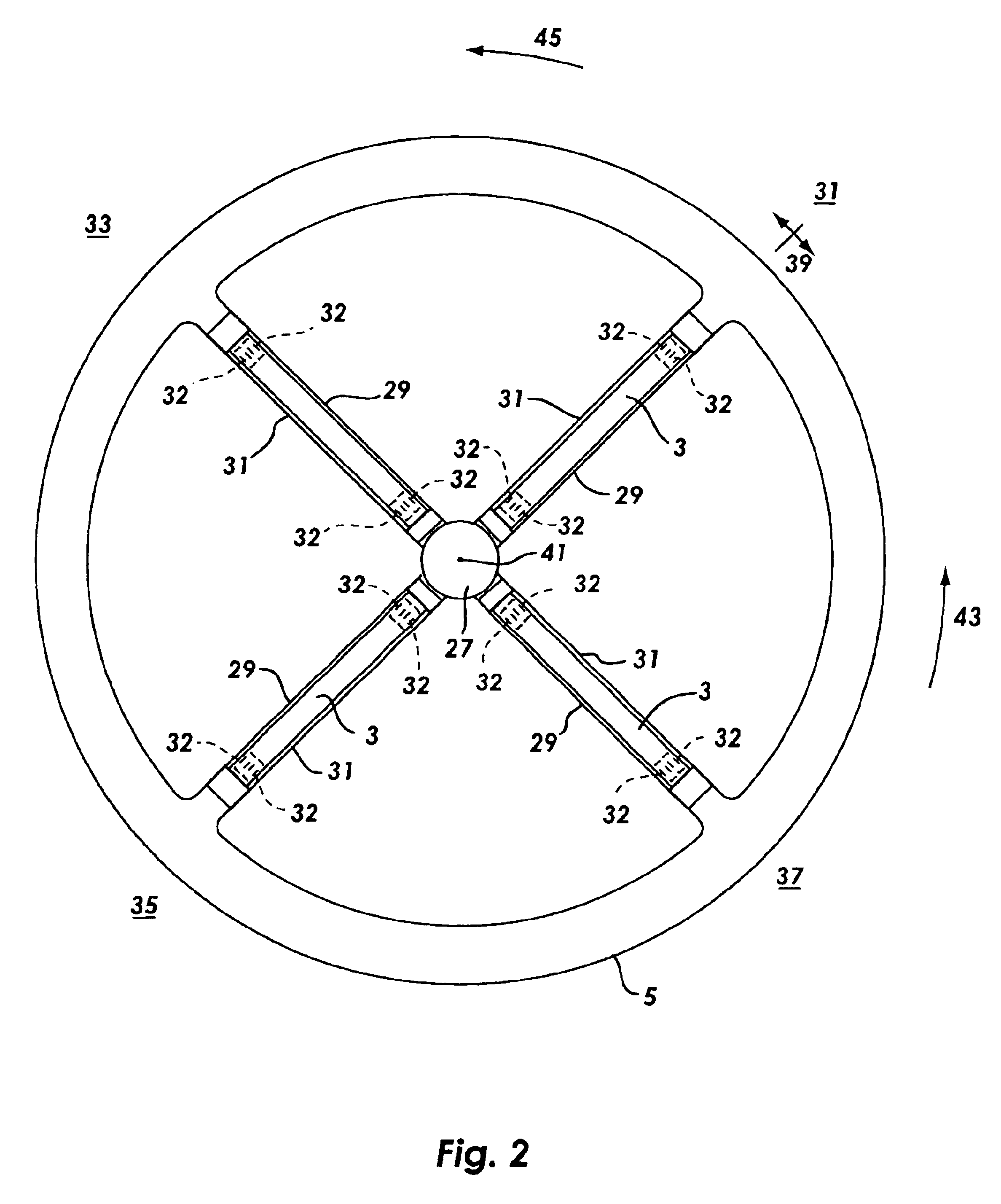

Rotary/fixed wing aircraft

A rotor system that allows an aircraft to operate as a helicopter and as an airplane is disclosed. The invention incorporates an annular airfoil attached at the tips of the rotor blades. The rotor system stops and is secured from rotation for operation at high forward speeds. The annulus acts as the primary lifting surface in airplane mode at high speed. The rotor blades incorporate leading and trailing edge flaps for control in transitional and fixed wing flight modes.

Owner:PICA BRET D

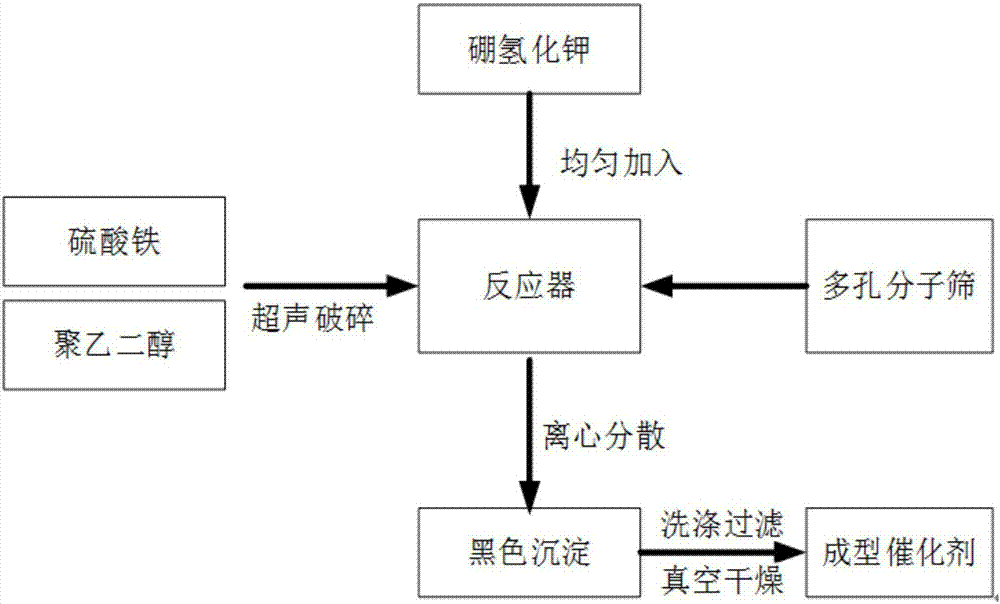

Metal modified SAPO-34 zeolite catalyst, preparation method thereof and use method thereof

InactiveCN102744102AGood choiceImprove conversion rateMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHigh concentrationMetal nitrate

The invention relates to the field of technologies for preparing ethylene through dehydrating ethanol, and concretely relates to a metal modified SAPO-34 zeolite catalyst, a preparation method thereof and a use method thereof. The preparation method of the modified SAPO-34 zeolite catalyst comprises the following steps: adding a metal nitrate to deionized water to prepare a dipping solution having a percentage of the metal nitrate being 1.67-7.93wt%, adding 10g of an SAPO-34 zeolite carrier, and uniformly stirring to obtain a mixed solution. According to the invention, the metal modified SAPO-34 zeolite catalyst is prepared through dipping and modifying SAPO-34 zeolite by above metal salt, and is used for catalyzing the dehydration of ethanol to produce ethylene, so the production of ethylene through dehydrating ethanol by using the metal modified SAPO-34 zeolite catalyst has the characteristics of high ethanol conversion rate, good ethylene selectivity, high concentration of the raw material ethanol in the reaction, high ethanol air speed and low reaction temperature, thereby the ethylene yield is improved.

Owner:XINJIANG UNIVERSITY

CO low-temperature oxidation catalyst and preparation method thereof

ActiveCN101485984AHigh activityHigh selectivityCarbon compoundsDispersed particle separationActive componentCerium

The invention provides a CO low-temperature oxidation catalyst. The catalyst is characterized in that the catalyst consists of a CeO2-TiO2 compound oxide carrier and an active component of CuO, and the loading capacity of the active component of CuO is 1 to 20 weight percent, wherein the range of the mol ratio of TiO2 to CeO2 is 0.1-4. The coprecipitation method is adopted to prepare the cerium-titanium compound oxide carrier, and a copper nitrate solution is steeped on the carrier. The catalyst prepared by the method has highly efficient catalytic activity, and can realize the complete removal of CO in the temperature range of between 80 and 170 DEG C, and the highest selectivity reaches 100 percent; moreover, the catalyst also has good waterproof and CO2 resistant performances. The method has the advantages of simple preparation conditions, low production cost, and the like.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

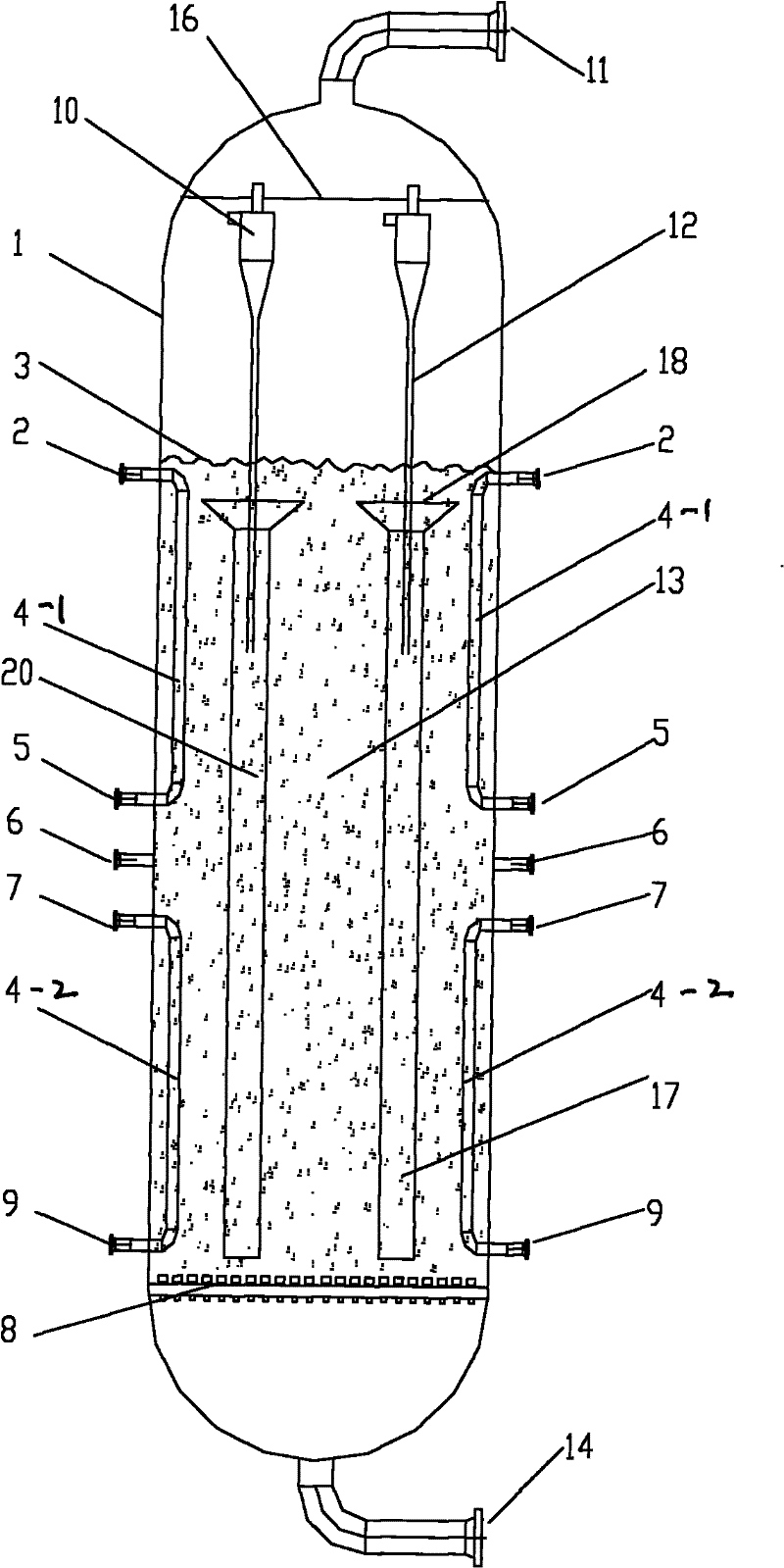

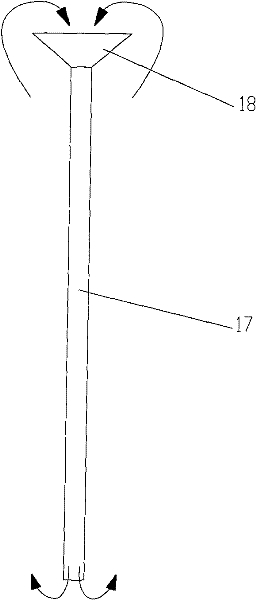

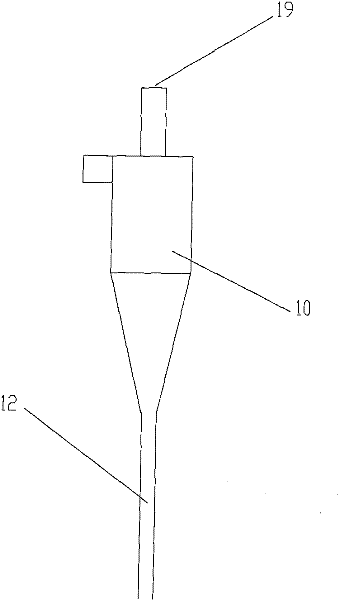

FischerTropsch synthesis slurry bed reactor

ActiveCN102188938AHigh airspeedImprove space utilizationHydrocarbon from carbon oxidesChemical/physical processesCycloneProcess engineering

The invention provides a slurry bed reactor for FischerTropsch synthesis, comprising a shell, a group of gas-liquid cyclone separators, a baffle, a coil and a synthesis gas distribution plate, wherein the shell is provided with a slurry bed layer; the reactor is provided with a group of circulation cups (20) and a group of gas-liquid cyclone separators (10); bubble cap distributors are evenly arranged on the synthesis gas distribution plate; the cyclone separator diplegs (12) of the gas-liquid cyclone separators (10) extend into an expanded port (18); and a slurry bed layer (13) is positioned above the synthesis gas distribution plate (8). The number of the gas-liquid cyclone separators (10) is not larger than that of the circulation cups (20), and each gas-liquid cyclone separator (10) and the corresponding circulation cup (20) are coaxially arranged. Fluid in and out of the circulation cups (20) circularly flows to improve the reactor airspeed and space utilization ratio; and the cyclone separator diplegs (12) extend into the expanded port (18) to accelerate the circulation of the fluid in and out of the circulation cups (20).

Owner:CHINA PETROCHEMICAL CORP +1

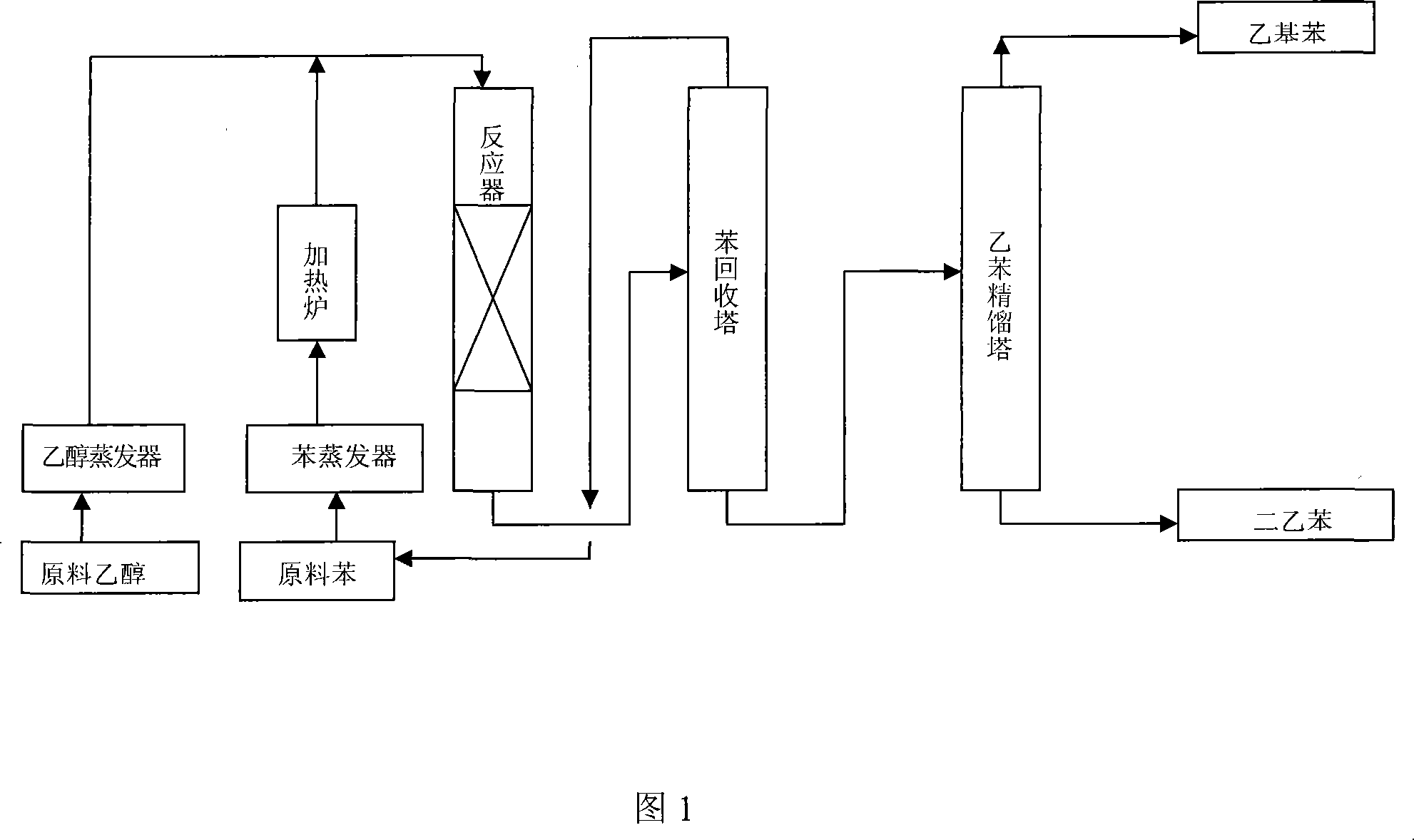

Method for synthesizing ethyl benzene and diethyl benzene

InactiveCN101085711AEliminate the dehydration stepIncrease profitDistillation purification/separationHydrocarbon by hydrocarbon and non-hydrocarbon condensationOperational costsDiethyl benzene

The invention discloses a method for synthesizing ethyl benzene and diethyl. It takes benzene and ethanol as raw material and comprises following steps: (A) benzene ethylization: heating benzene and ethanol for gasification, feeding them into reactor filled with molecular screen catalyst, the molar ratio between benzene and ethanol is 4- 8: 1, and the condition is at 350- 420 Deg. C and 0.7- 2 MPa; (B) recovering benzene: distilling reactant of ethylization, separating and getting mixture of benzene and ethyl benzene and diethyl; dewatering recovered benzene and using it as material for ethylization in step (A); (C) separating and refining: distilling said mixture, separating and getting ethyl benzene and diethyl. The invention replaces ethane with ethanol and finishes ethylization with one step. It is characterized by simnple process, high utilization rate of ethanol and saved investment and operational cost.

Owner:常州世鑫化工有限公司

Selective Hydrogenation Process Using Layered Catalyst Composition and Preparation of Said Catalyst

InactiveUS20080248199A1High airspeedLower cost of capitalMolecular sieve catalystsPretreated surfacesHydrogenation processOrganic chemistry

A selective hydrogenation process and a layered catalyst composition for use in the selective hydrogenation process are disclosed. The process is useful for the selective hydrogenation of diolefins having from about 8 to about 19 carbon atoms per molecule to monoolefins.

Owner:UOP LLC

Method of removing multiple pollutants in flue gas through low-temperature gas-like phase catalytic oxidization

ActiveCN106943871AIncrease profitReduce consumptionGas treatmentDispersed particle separationGas phaseFlue gas

The invention discloses a method of removing multiple pollutants in flue gas through low-temperature gas-like phase catalytic oxidization and belongs to the technical field of flue gas purification. According to the method, a liquid-phase oxidant is activated into a gas-like phase by means of flue gas temperature, and the gas-like phase oxidant generates strong-oxidizing free radicals under effects of a catalyst; the multiple pollutants in flue gas are catalytically oxidized into soluble valences by the strong-oxidizing free radicals, wherein an oxidizing product is absorbed by an absorbent in a spray column, thereby achieving integrated removal of the soluble multiple pollutants. A high-active low-temperature catalyst is prolonged in service life, reduces consumption on the oxidant and saves investment and operation cost. The absorption product is high in content of nitrogen and sulfur, so that the product can be processed into a compound fertilizer raw material. The method can reach 99-100%, 90-95% and 90-95% in removal rates respectively on SO2, NO and Hg<0>, is suitable for boilers in various types and other flue gas purification fields, and has excellent economic and promotion value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

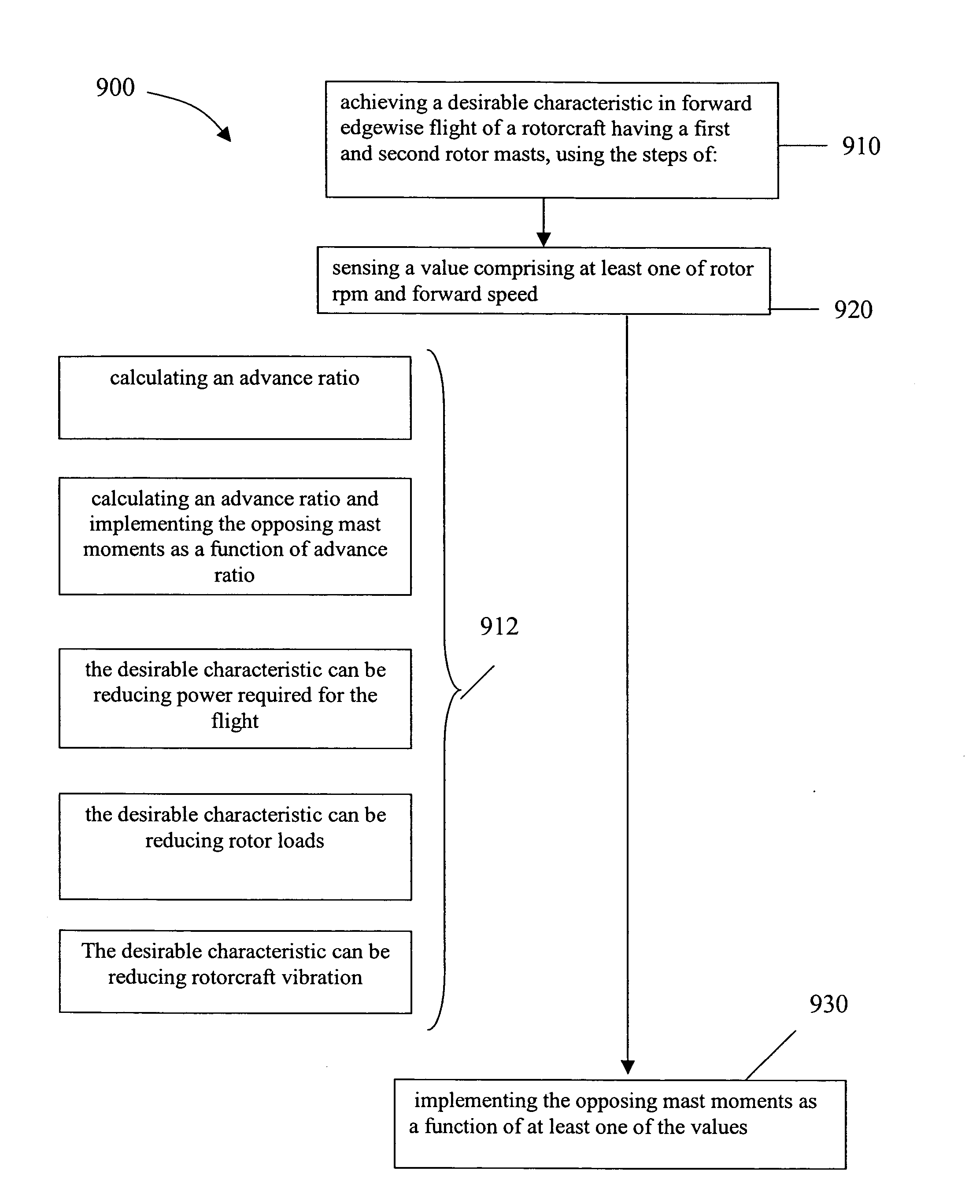

Rotorcraft with opposing roll mast moments, and related methods

ActiveUS20100270422A1High rotor gearboxHigh airframe reliabilityPropellersDigital data processing detailsRolling momentRotary wing

In rotorcraft having rotors on multiple masts, a controller causes opposing roll mast moments to be applied to the different rotors. In preferred embodiments, the opposing roll moment is the result of increasing the lift on the advancing blade and reducing the lift on the retreating blade on the second rotor. This can be accomplished in any suitable manner, such as by applying differential cyclic roll control to the two rotors by tilting the two Swashplates of the two rotors or by using Individual Blade Control (IBC).

Owner:KAREM ABE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com