Patents

Literature

59 results about "Diethyl benzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective absorption method for reducing propylene in catalytic cracking dry gas

InactiveCN1689688ANo decontamination requiredNo refinementChemical industryDispersed particle separationDesorptionDiethyl benzene

The propylene absorbing process is to eliminate propylene from catalytically cracked dry gas from oil refinery without any purifying and refining in a propylene selectively absorber. The dry gas and the absorbent are contacted through convection. The absorbent may be benzene, ethyl benzene, diethyl benzene, triethyl benzene, polyethyl benzene, diesel oil, gasoline, etc. or their mixture. The absorption conditions include operation temperature of -10 deg.c to +40 deg.c, pressure of 0.1-3.5 MPa, and the absorbent / dry gas volume ratio of 3-25 ml / L. The desorption conditions for the absorbed absorbent include temperature of 20-300 deg.c, pressure of 0.1-3.5 MPa, the sweeping gas / absorbent volume ratio of 1-15, and the sweeping time of 1-10 hr. The sweeping gas may be N2, H2, methane, ethane, etc. or their mixture. The desorbed absorbent may be reused.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

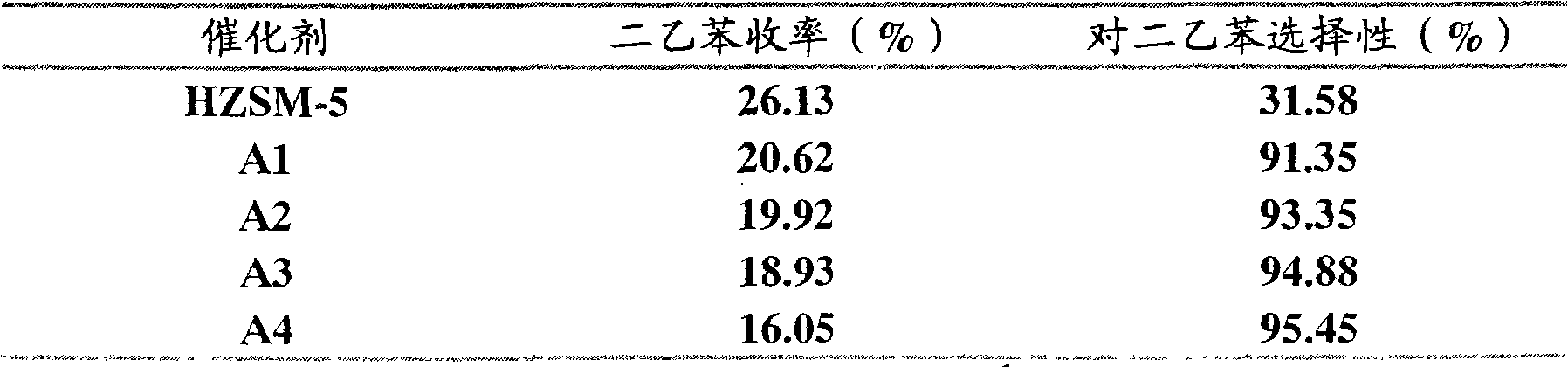

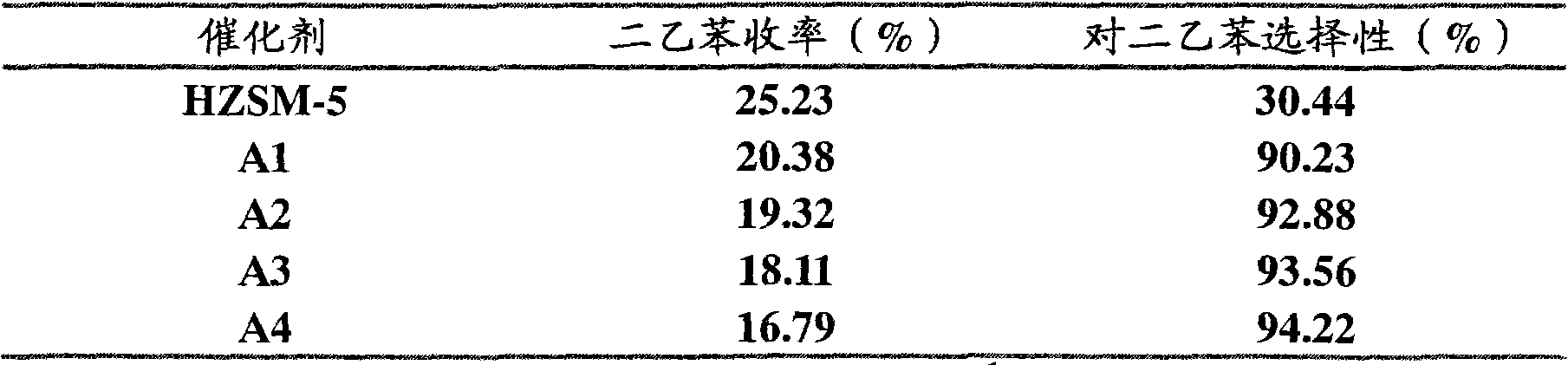

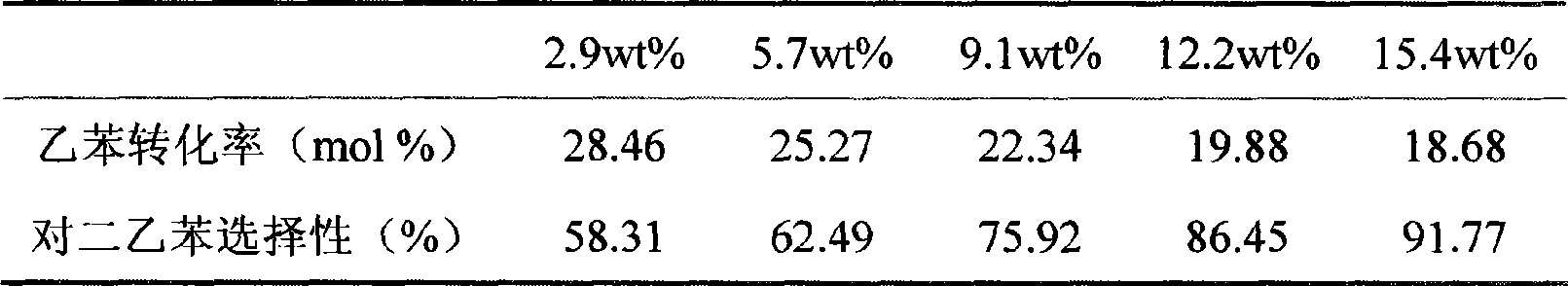

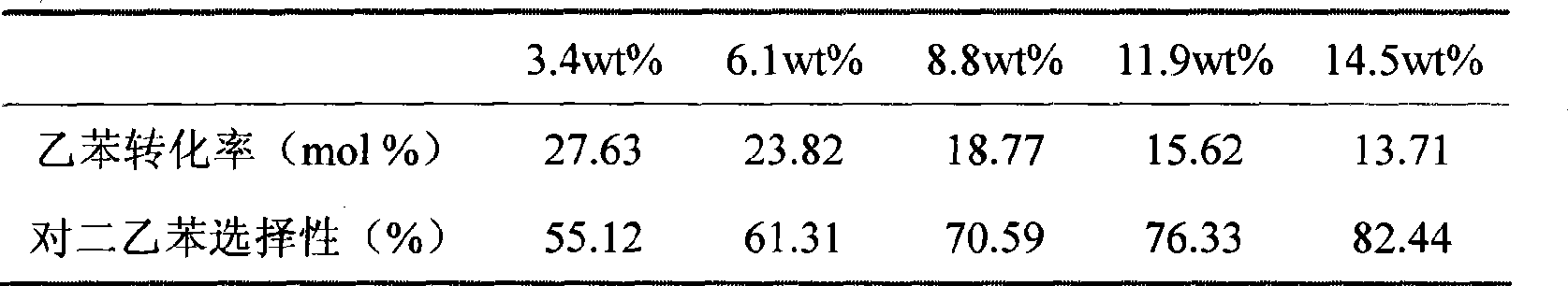

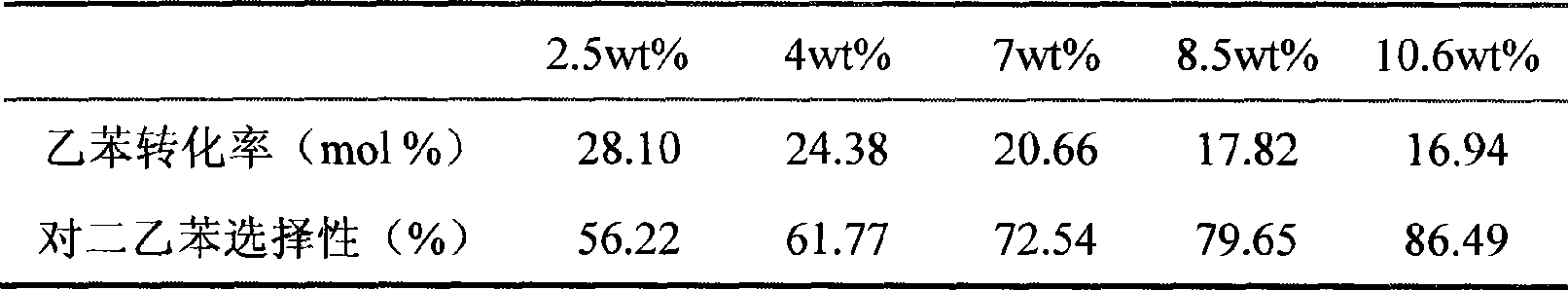

Catalyst for synthesizing para diethyl benzene by ethanol and ethyl benzene combination reaction and its preparation method

InactiveCN1605390AHigh yieldGood choiceOrganic chemistryMolecular sieve catalystsMolecular sievePtru catalyst

The present invention relates to catalyst for alkylating ethanol and ethyl benzene into p-diethylbenzene and its preparation process. The industrial catalyst for efficient synthesis of p-diethylbenzene is prepared with the H-ZSM-5 molecular sieve with Si / Al ratio of 50 as basic matter and through surface acidity and tunnel regulation with B, Mg and Co, and has ideal pore size distribution and in-tunnel acidity distribution and strong coking resisting capacity. The precursor of B is boric acid, that of Mg is magnesium nitrate and that of Co is cobalt nitrate. The mass ratio between B and H-ZSM-5 molecular sieve is 1-3 %, that between Mg and H-ZSM-5 molecular sieve is 0.1-1 % and that between Co and H-ZSM-5 molecular sieve is 1-3 %. Compared with available similar catalyst, the present invention has the features one simple preparation process, low cost, high selectivity and yield of p-diethylbenzene, etc.

Owner:NANKAI UNIV

Preparation and use of nano HZSM-5 zeolite metallic ion composite modified catalyst

InactiveCN1546236AImprove stabilityLarge specific surface areaMolecular sieve catalystsCooking & bakingLanthanum

The invention provides a kind of nano HZSM-5 zeolite metal ion compound modified catalyst and the manufacturing method, which uses ethylbenzene and ethyolene as materials to produce diethylbenzene through alkylation. The catalyst uses nano HZSM-5 molecular sift and carrier Al2O3 as parent, carries 1-2 kinds of lanthanum, silicon, phosphorus and magnesium and so on active component, the modified catalyst can be produced through immersing, drying, baking. The invention has a large specific area, the channel is short, and the catalyst has high reaction activity and stability, and high para-selectivity.

Owner:DALIAN UNIV OF TECH

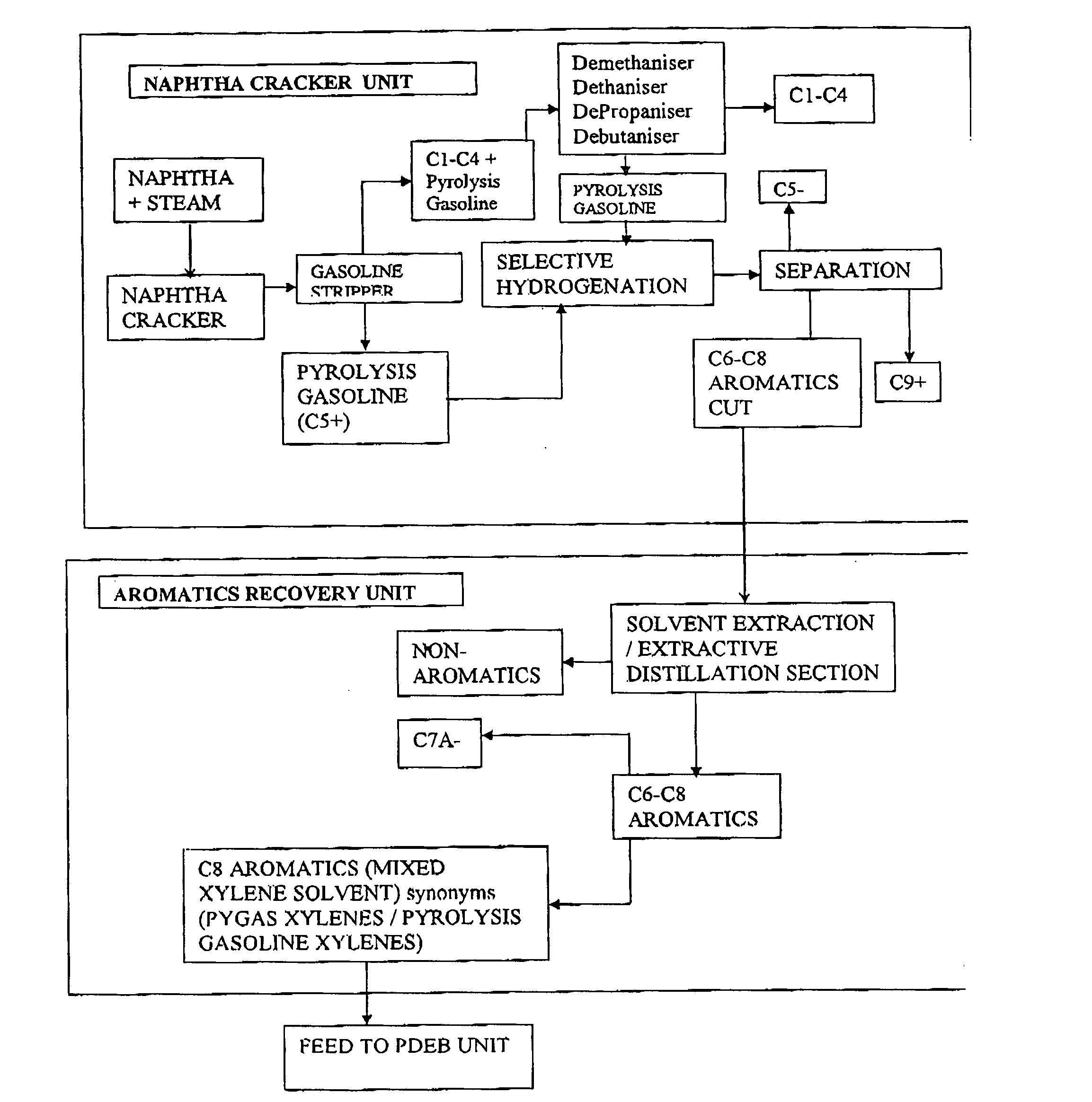

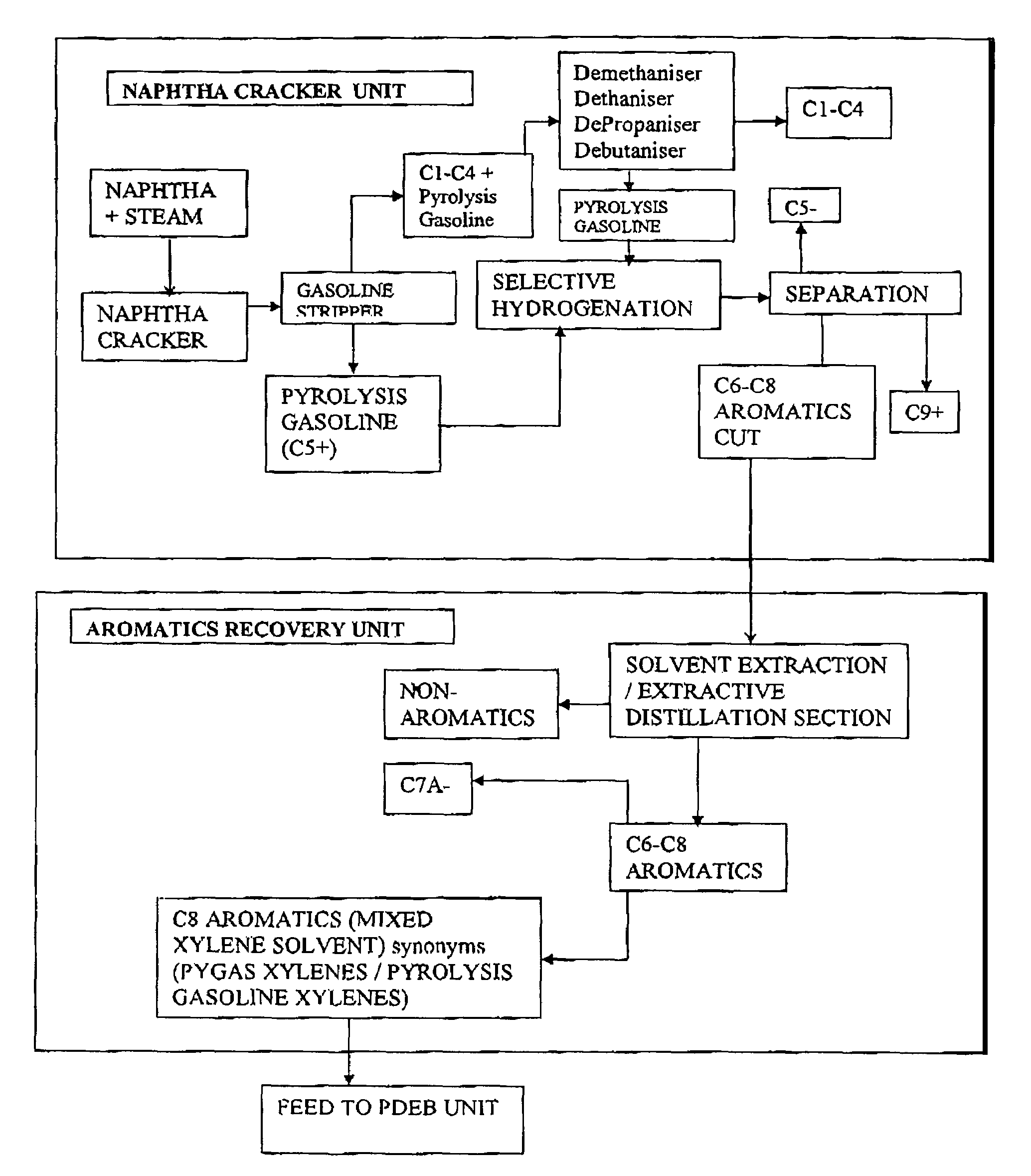

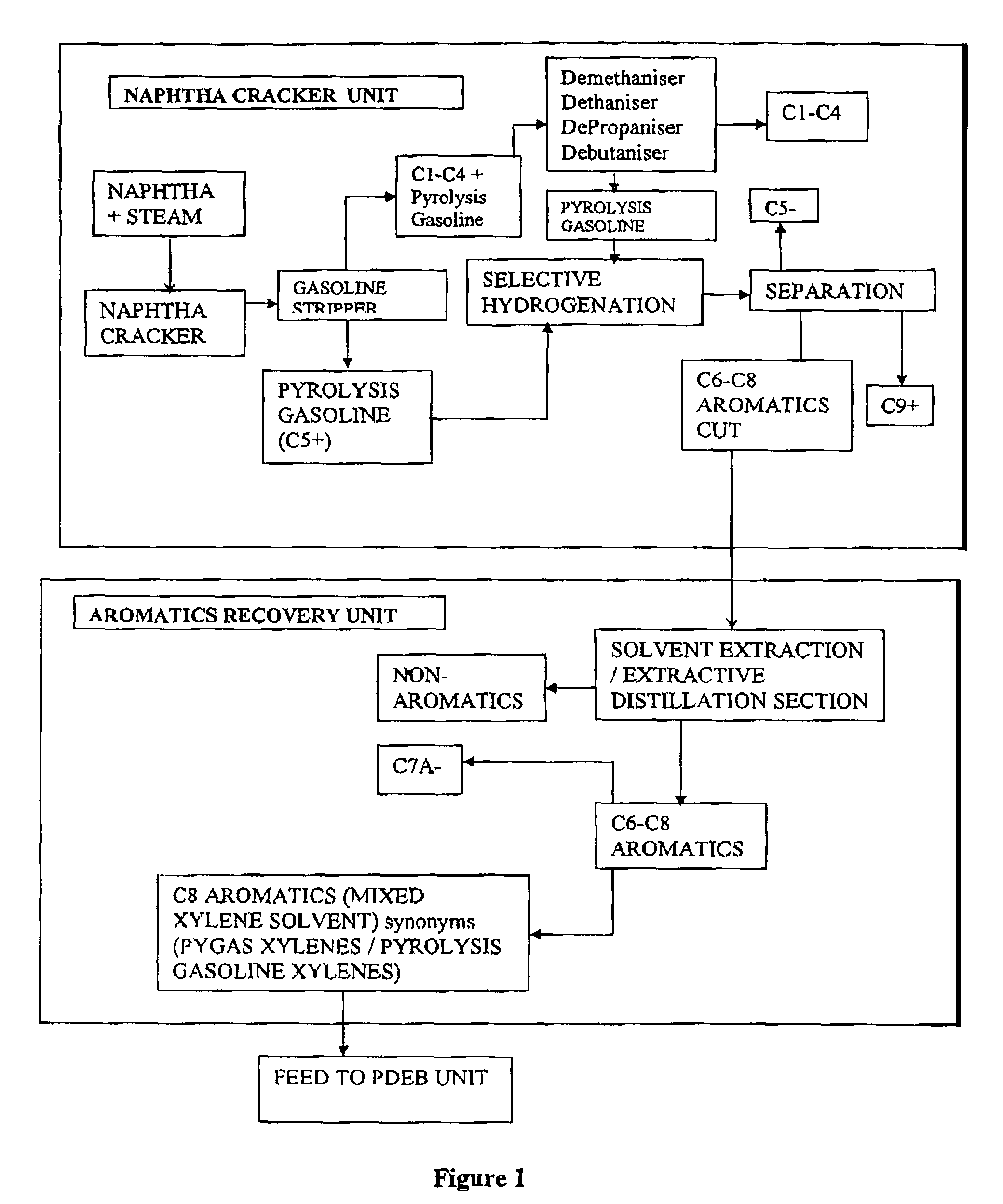

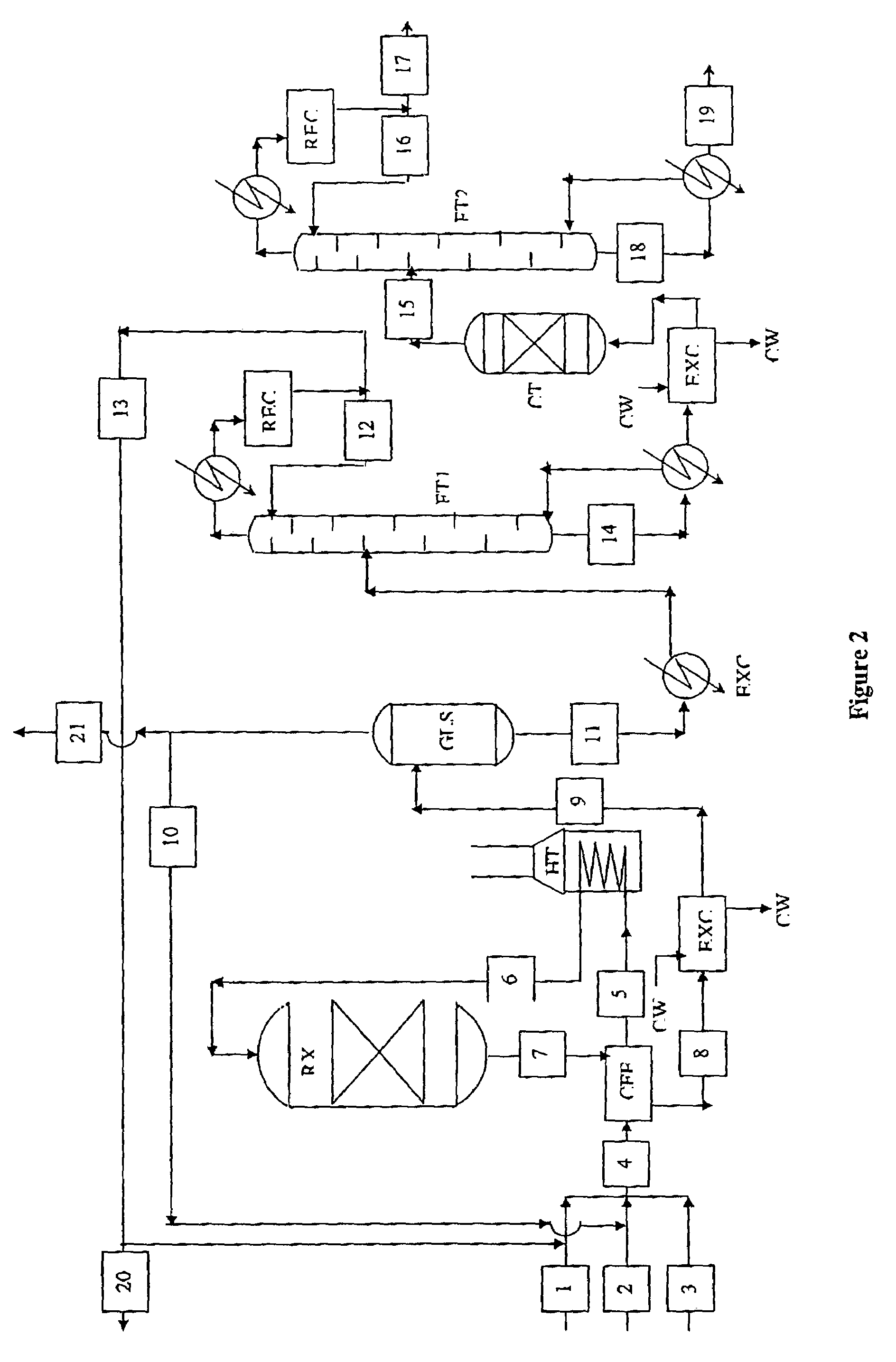

Process for the production of para-diethylbenzene

InactiveUS20060173225A1Speed up the processHydrocarbon by isomerisationMolecular sieve catalystPtru catalystDiethyl benzene

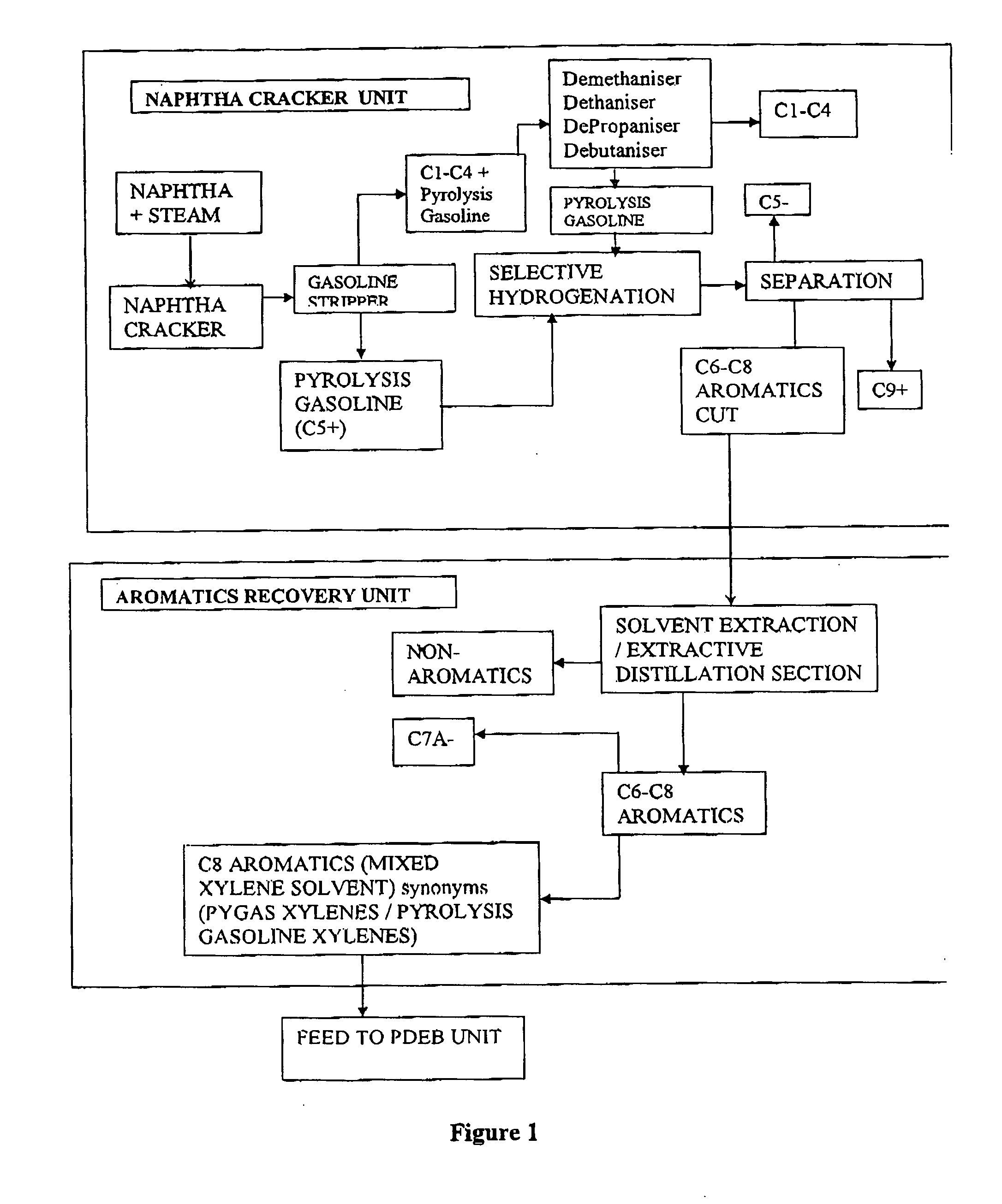

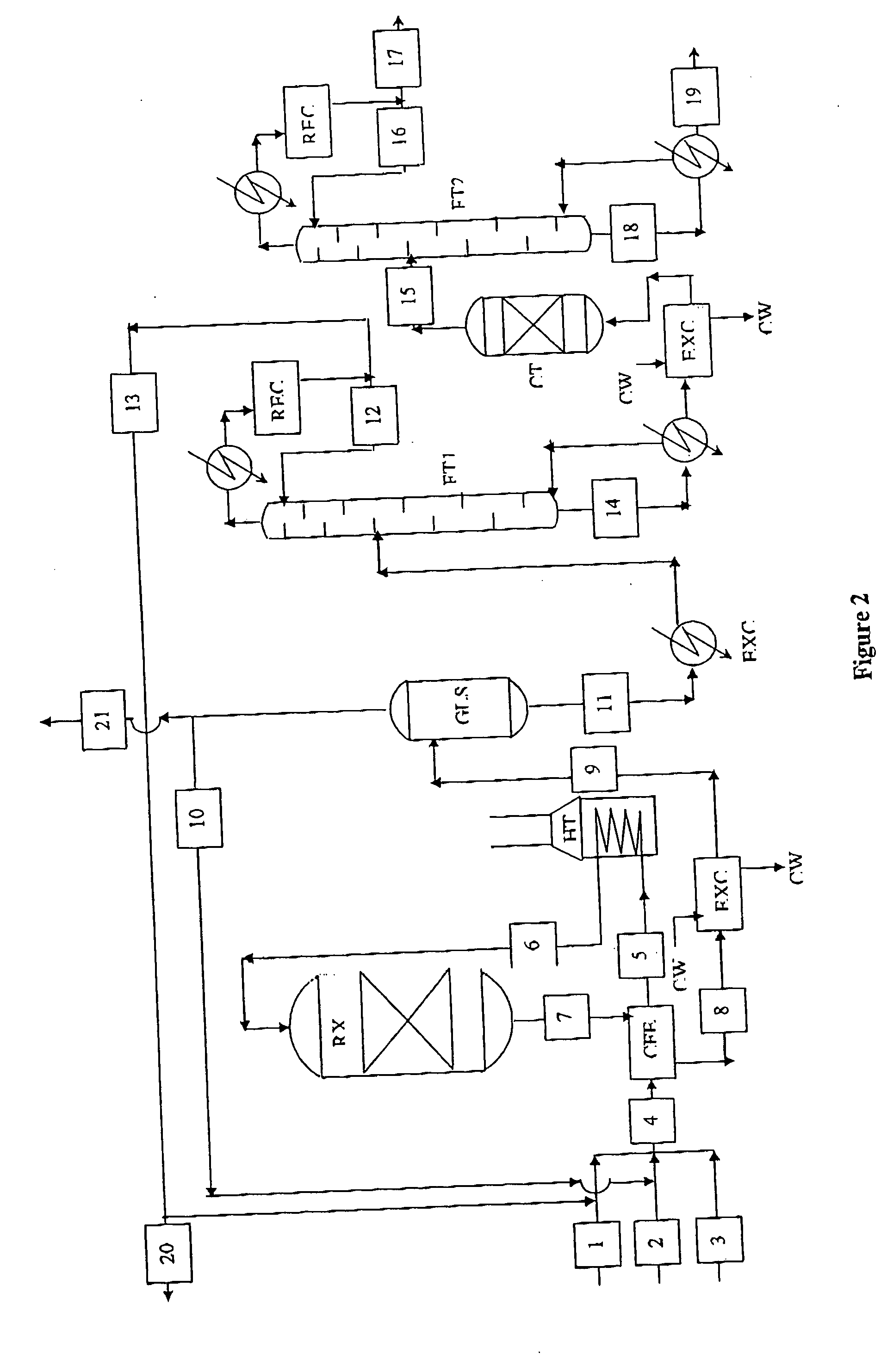

The present invention relates to a process for the selective production of para-diethyl benzene from a mixed aromatic feedstock containing ethyl benzene and at least one other aromatic compound selected from benzene, alkylated benzene having alkyl group with carbon number 1 to 6, mono-alkyl aromatics, dialkyl aromatics, trialkyl aromatics, tetraalkyl aromatics, pentaalkyl aromatics, hexaalkyl aromatics, containing side chains having 1 to 6 carbon atoms, and any mixtures thereof the process comprising of (a) alkylating the feedstock under alkylating conditions, over a selectivated metallosilicate composite catalyst; and (b) recovering a product stream containing at least 95 wt % paradiethyl benzene, the product stream being substantially free from other isomers of diethylbenzene, Ca aromatics, C9 aromatics, C10+ heavy aromatics other than diethyl beizene isomers, sulphur, halogen, olefinc compound and carbonyl compounds.

Owner:INDIAN PETROCHEMICALS CORPORATION LIMITED

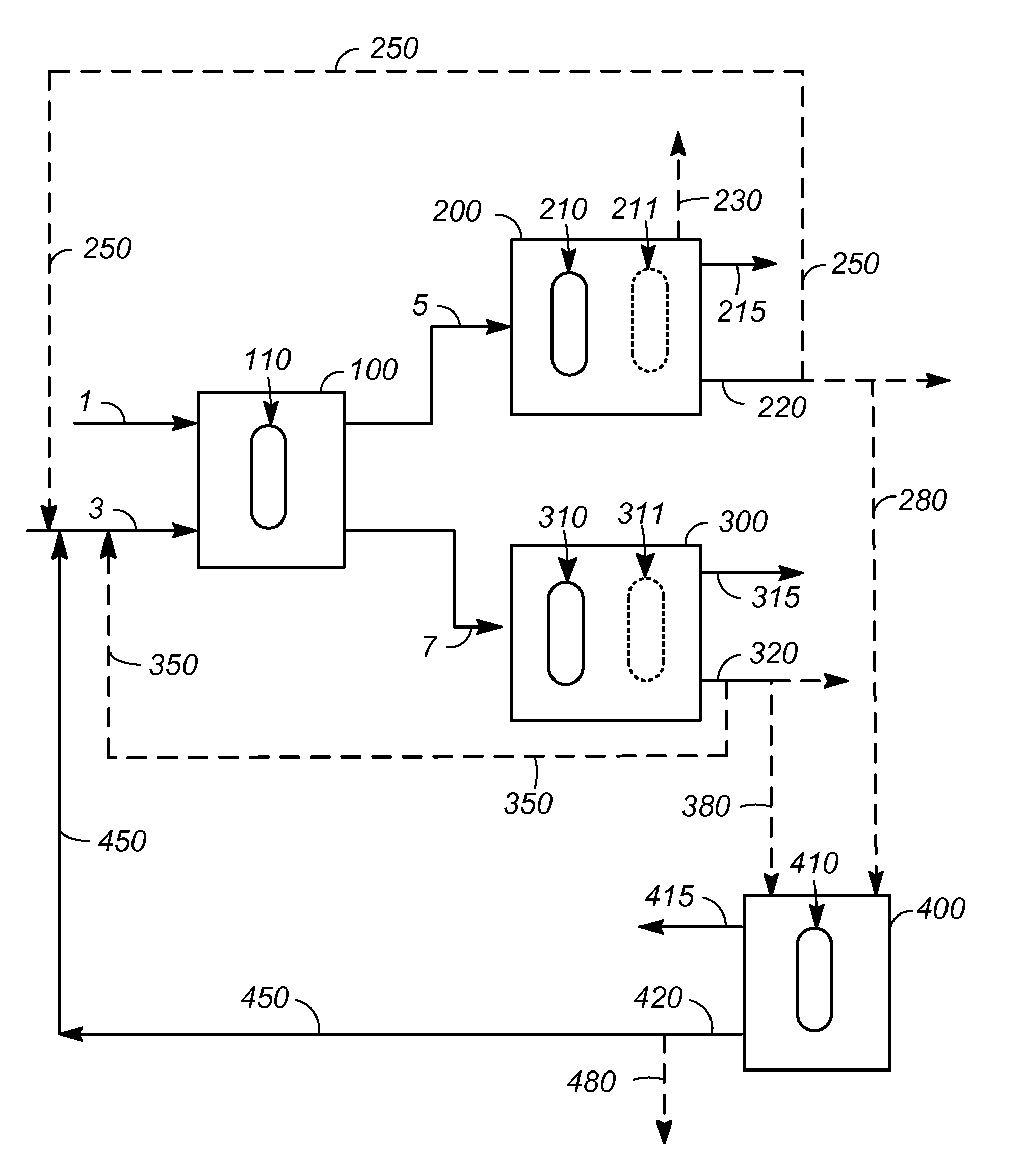

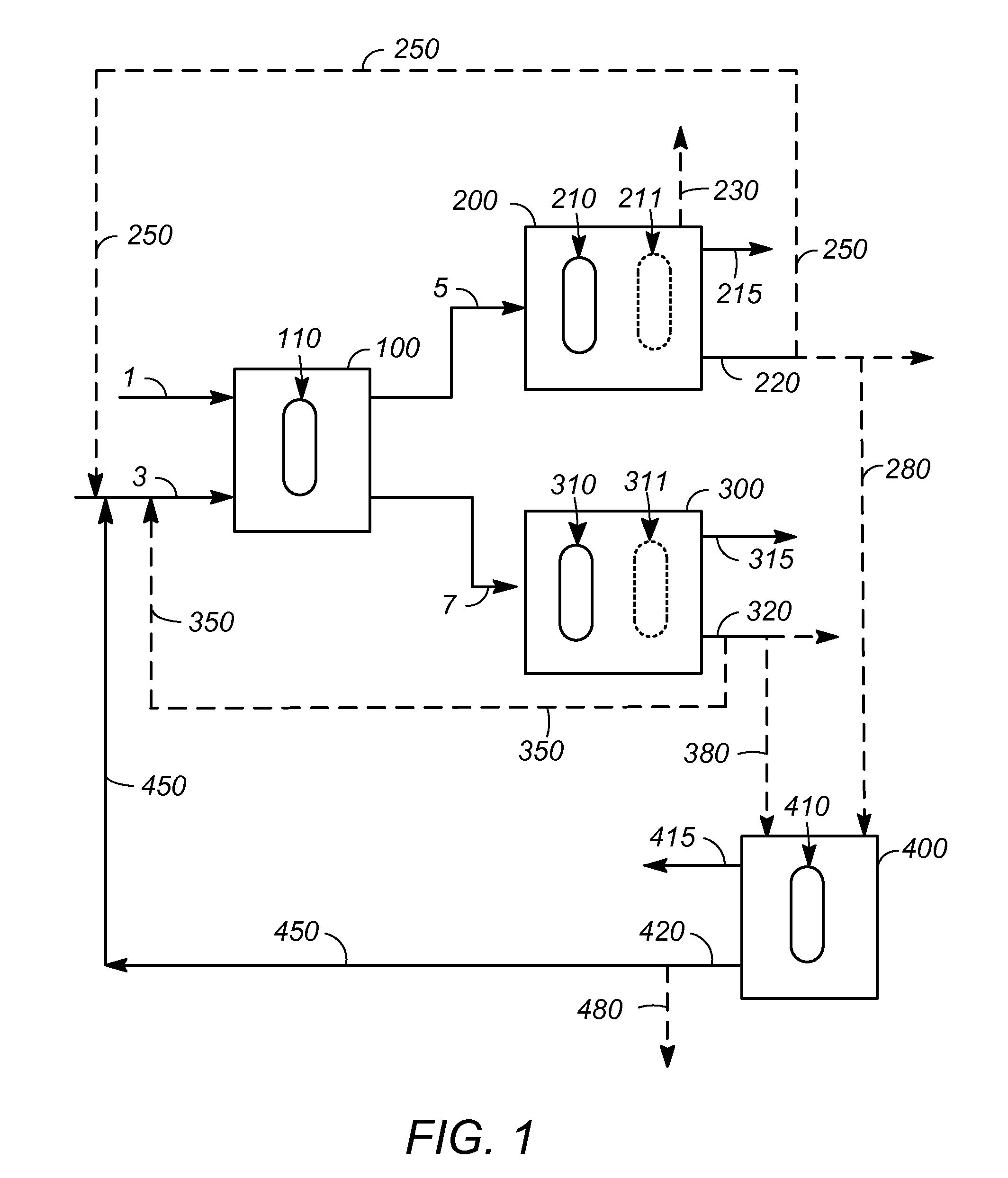

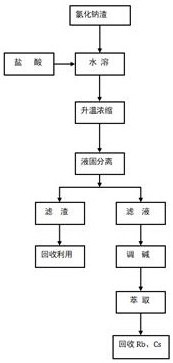

Process for separating para-xylene from a mixture of C8 and C9 aromatic hydrocarbons

ActiveUS8198502B2HydrocarbonsAdsorption purification/separationExtractive distillationAromatic hydrocarbon

The invention is an adsorptive separation process for producing a para-xylene product from a feed stream comprising para-xylene, at least one other C8 aromatic, and a C9 aromatic. An adsorbent comprising X or Y zeolite and a desorbent comprising para-diethylbenzene (p-DEB) are used in an adsorptive separation zone to produce an extract stream comprising para-xylene, p-DEB, and the C9 aromatic and a raffinate stream comprising the at least one other C8 aromatic, the C9 aromatic, and p-DEB. The extract stream is separated in an extract distillation zone to produce a second desorbent stream comprising the C9 aromatic and p-DEB and the raffinate stream is separated in a raffinate distillation zone to produce a third desorbent stream comprising the C9 aromatic and p-DEB. At least a portion of at least one of the second desorbent stream and the third desorbent stream is further separated in a desorbent distillation zone to produce a stream comprising the C9 aromatic.

Owner:UOP LLC

Method for preparing catalyst for compounding p-diethylbenzene by alkylation reaction of ethylbenzene and ethane or alcohol

ActiveCN101618335ASimple preparation processLow costMolecular sieve catalystsHydrocarbonsAlkyl transferMolecular sieve

The invention relates to a method for preparing catalyst for compounding p-diethylbenzene by the alkylation reaction of ethylbenzene and ethane or alcohol, and the obtained catalyst can be used for compounding p-diethylbenzene by the alkylation reaction of ethylbenzene and ethane or compounding p-diethylbenzene by the alkylation reaction of the ethylbenzene and alcohol. The catalyst is formed in such a way that an HZSM-5 molecular sieve of SiO2 / Al2O3 molar ratio=16-200 as a matrix to be loaded with silicon dioxide and then roasted and passivated by air and water vapor. The preparation of the catalyst only needs three-step operation; and compared with the prior method for preparing the similar catalyst, the invention greatly simplifies the preparation process. The method does not need to add other substances to further modify the HZSM-5 molecular sieve, thereby having low raw material cost and production energy consumption as well as less environmental pollution and obtaining favorable p-diethylbenzene selectivity and yield.

Owner:SHANGHAI NOVEL CHEM TECH

Method for separating acetonitrile-methylbenzene azeotropic mixture by continuous extractive distillation

InactiveCN1736530AEasy to realize automatic controlScale upExtractive distillationRefluxExtractive distillation

The invention discloses a method for continuous extraction and distillation and separation of acetonitrile- toluene azeotrope. The method is described as the following: using propyl benzene, butylbenzene, isobutylbenzene, sec- butylbenzene, tertiarybutyl phenol, mesitylene, p- diethyl benzene or tertiary-butyl toluene as the extractant, operating in a extracting- fractionating tower at a normal pressure or reduced pressure with a mass ratio of extractant in extracting- fractionating tower to overhead being 2: 1- 10: 1 and a feeding temperature of extractant of 25- 80 Deg. C, the acetonitrile- toluene azeotrope entering from the middle of extracting- fractionating tower, picking the qualified content of acetonitrile from the head of tower with a reflux ratio of 1: 1- 5: 1, toluene and solvent from the bottom of the tower flowing into the middle of the extractant recovery tower, the toluene being picked from the head of extractant recovery tower with a reflux ratio of 2: 1- 10: 1, and the high-purity extractant which can be circularly used being picked from the bottom of the extractant recovery tower. The merit of the invention is that using extractant to destroy acetonitrile- toluene azeotrope,the high purity acetonitrile and toluene are prepared.

Owner:TIANJIN UNIV

Styrene system ion exchange resin as well as preparation method and application thereof

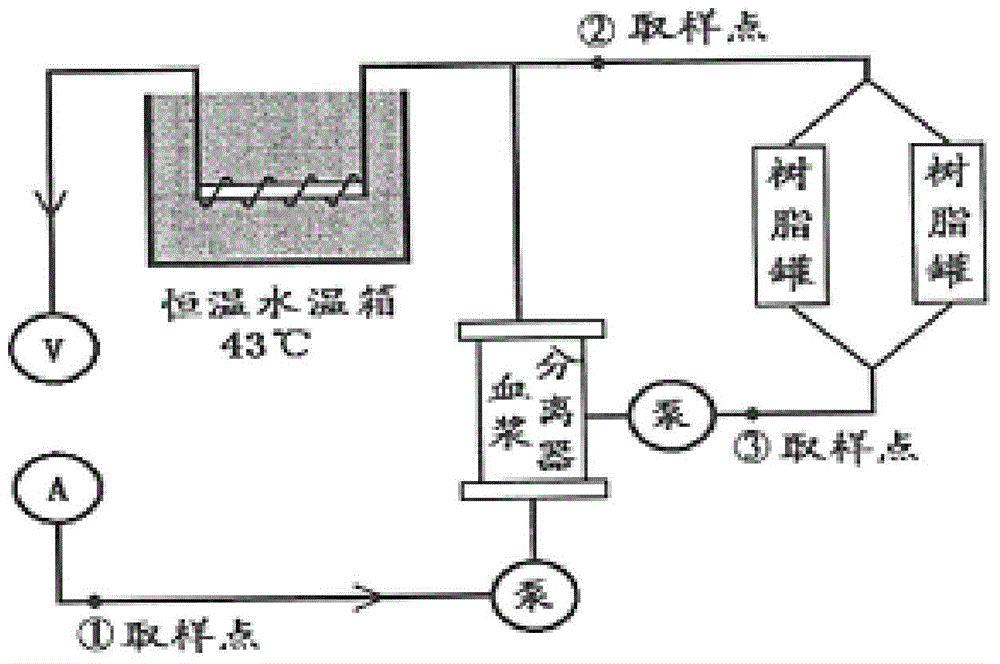

InactiveCN103980403AFactor content decreasedSuitable for long-term applicationOther chemical processesOther blood circulation devicesInflammatory factorsPolymer science

The invention provides a styrene system ion exchange resin as well as a preparation method and application thereof. The styrene system ion exchange resin is prepared by taking styrene and toluylene as monomers and is a milk-white nontransparent spherical particle; the diameter is 0.05-1.20 mm; the density is as follows: the true wet density is 1.06-1.10 g / ml, and the apparent wet density is 0.65-0.75 g / ml; the strength (attrited sphericity) is more than or equal to 95%; the surface active group is -N+(CH3)2; the aperture is 80-100 nanometers; the porosity is 45%-22%; the pore volume is 0.75-0.84 ml / g; the specific area is 850-1000 m<2> / g; the full exchange capacity of dry resin is 3.7 mmol / g, and the full exchange capacity of wet resin is 1.1 mmol / g. The styrene system ion exchange resin provided by the invention is an effective cell factor adsorbing material, achieves outstanding adsorption effect on endotoxins and inflammatory factors which are contained in blood and can be applied to the aspect of resin hemoperfusion apparatus.

Owner:李涛

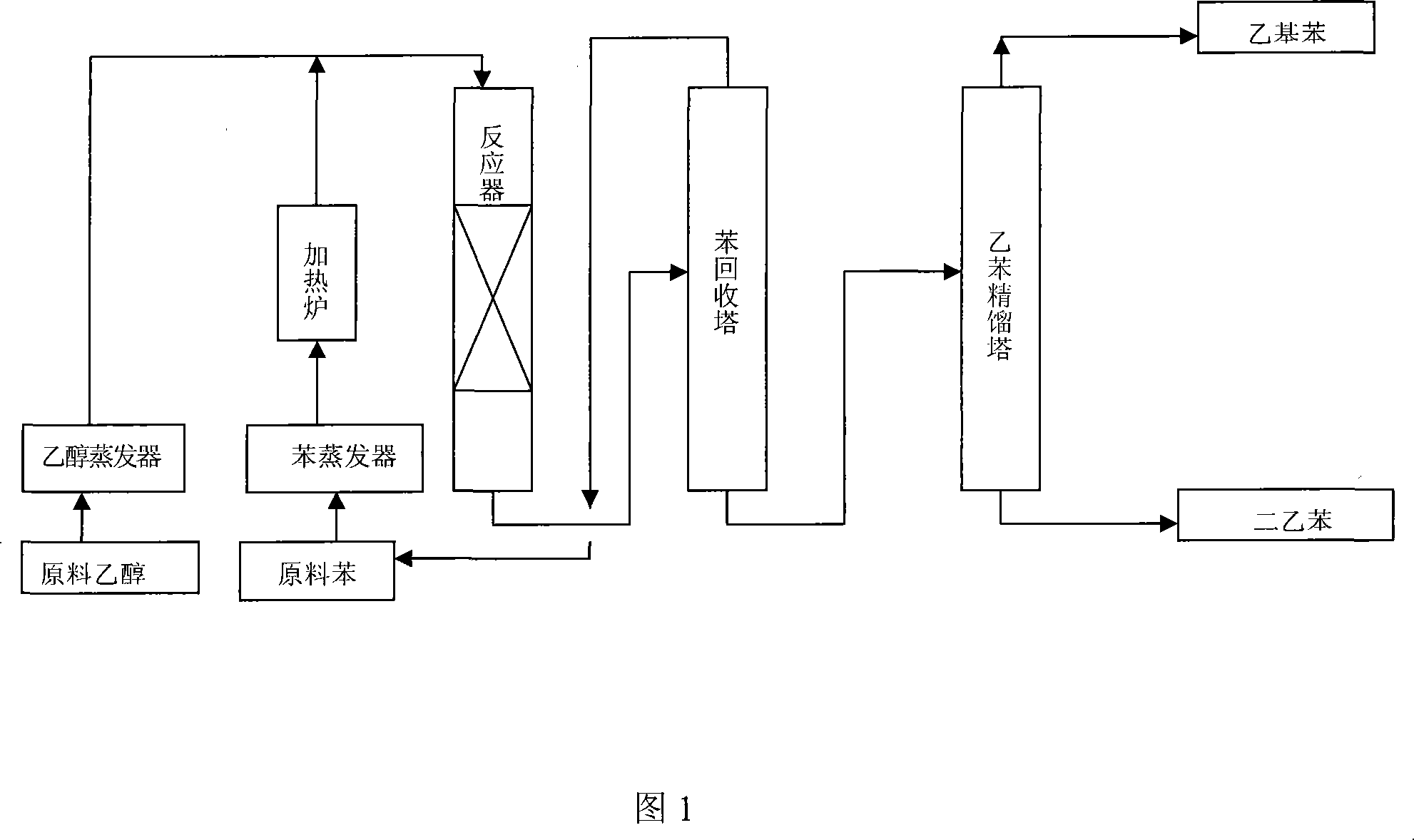

Method for synthesizing ethyl benzene and diethyl benzene

InactiveCN101085711AEliminate the dehydration stepIncrease profitDistillation purification/separationHydrocarbon by hydrocarbon and non-hydrocarbon condensationOperational costsDiethyl benzene

The invention discloses a method for synthesizing ethyl benzene and diethyl. It takes benzene and ethanol as raw material and comprises following steps: (A) benzene ethylization: heating benzene and ethanol for gasification, feeding them into reactor filled with molecular screen catalyst, the molar ratio between benzene and ethanol is 4- 8: 1, and the condition is at 350- 420 Deg. C and 0.7- 2 MPa; (B) recovering benzene: distilling reactant of ethylization, separating and getting mixture of benzene and ethyl benzene and diethyl; dewatering recovered benzene and using it as material for ethylization in step (A); (C) separating and refining: distilling said mixture, separating and getting ethyl benzene and diethyl. The invention replaces ethane with ethanol and finishes ethylization with one step. It is characterized by simnple process, high utilization rate of ethanol and saved investment and operational cost.

Owner:常州世鑫化工有限公司

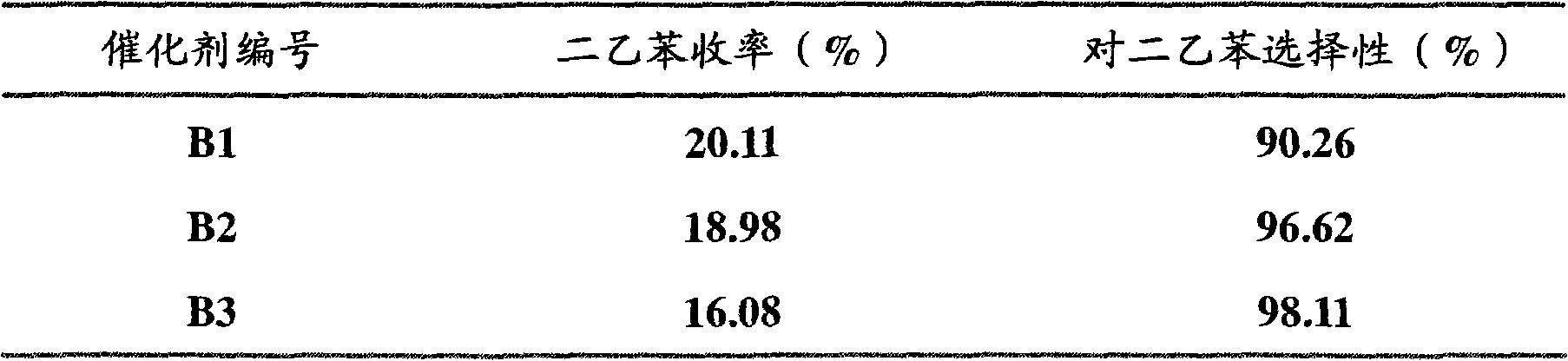

Shape-selective catalyst preparation method

InactiveCN101455978APromote regenerationHigh selectivityMolecular sieve catalystsHydrocarbonsAlkyl transferRare earth

The invention relates to a method for preparing a shape-selective alkylation catalyst, in particular to a method for preparing high-selectivity synthetic p-diethylbenzene catalyst by use of rare earth modification. The method has a main technical characteristic that rare earth modification is completed in two mutually linked steps, namely hot impregnation and cold impregnation. The high-selectivity catalyst prepared by the method has the advantages of high activity, long single-pass reaction period and good regeneration repeatability.

Owner:DALIAN UNIV OF TECH

Selective absorption method for reducing propylene in catalytic cracking dry gas

The propylene absorbing process is to eliminate propylene from catalytically cracked dry gas from oil refinery without any purifying and refining in a propylene selectively absorber. The dry gas and the absorbent are contacted through convection. The absorbent may be benzene, ethyl benzene, diethyl benzene, triethyl benzene, polyethyl benzene, diesel oil, gasoline, etc. or their mixture. The absorption conditions include operation temperature of -10 deg.c to +40 deg.c, pressure of 0.1-3.5 MPa, and the absorbent / dry gas volume ratio of 3-25 ml / L. The desorption conditions for the absorbed absorbent include temperature of 20-300 deg.c, pressure of 0.1-3.5 MPa, the sweeping gas / absorbent volume ratio of 1-15, and the sweeping time of 1-10 hr. The sweeping gas may be N2, H2, methane, ethane, etc. or their mixture. The desorbed absorbent may be reused.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for reacting poisoned sorbent

InactiveCN1565719ARestore the function of adsorption and separationEfficient removalOther chemical processesCombustible gas purificationMolecular sieveAromatic solvent

Owner:CHINA PETROLEUM & CHEM CORP +1

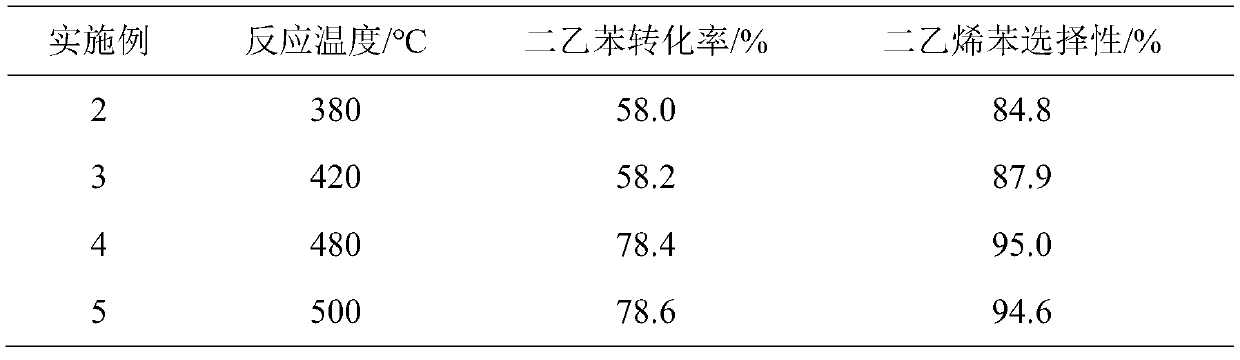

Method for producing diethylbenzene through dehydrogenation of diethyl benzene

ActiveCN1915941AHigh selectivityImprove anti-coking performanceHydrocarbonsBulk chemical productionDivinylbenzeneDiethyl benzene

This invention relates to a method for preparing divinylbenzene by diethylbenzene dehydrogenation. The method uses Fe-K-Ce-Mo catalyst system, and keeps high catalytic selectivity and anti-carbon deposition ability by adjusting the ratio of the above elements as well as adding multiple rare earth compounds. The method has a high divinylbenzene yield, and can be used for divinylbenzene industrial manufacture.

Owner:CHINA PETROLEUM & CHEM CORP +1

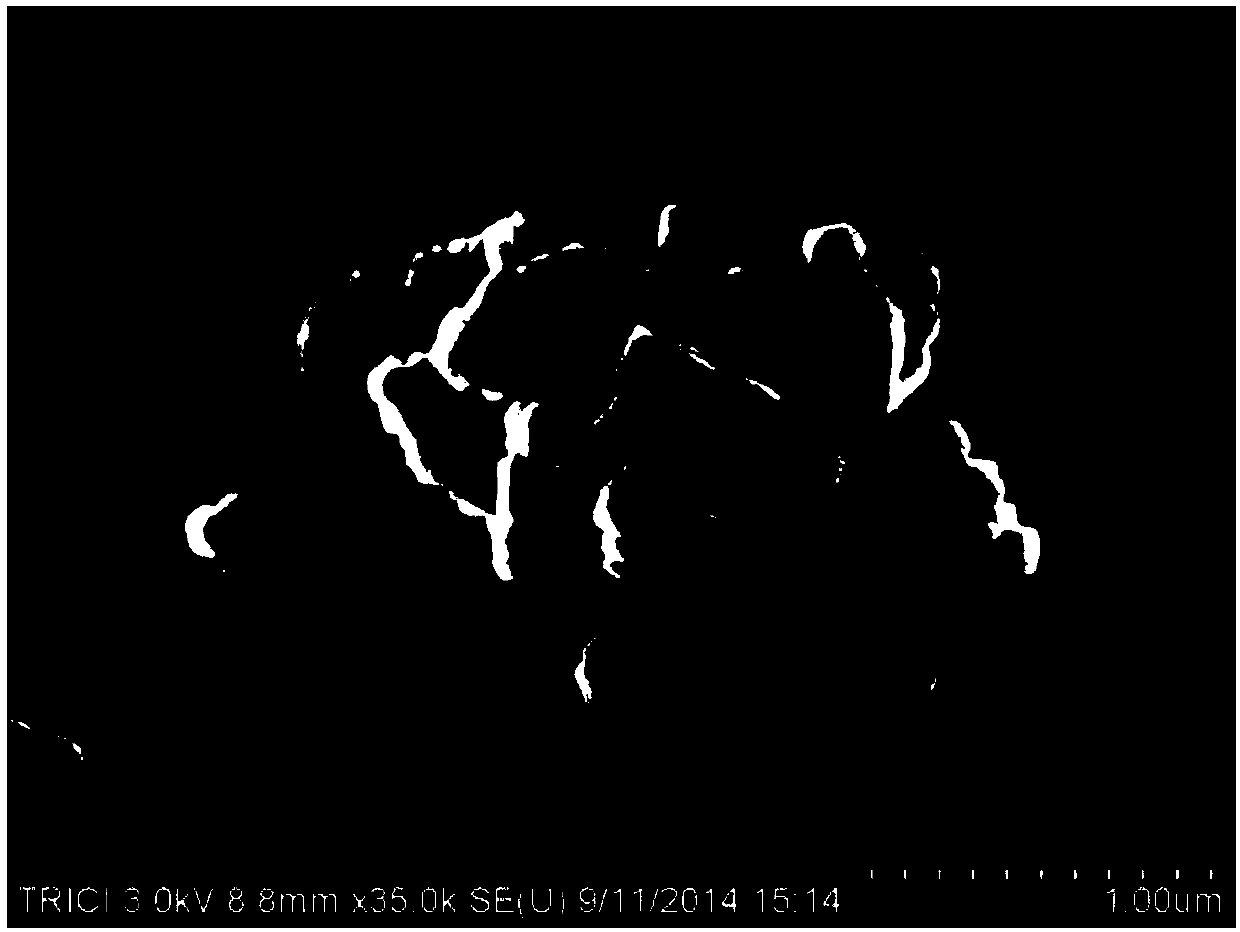

Preparation method of p-diethylbenzene catalyst by using high-efficiency alkylation of ethylbenzene

ActiveCN107913727AImprove stabilityGuaranteed selectivityMolecular sieve catalystsMolecular sieve catalystAlkyl transferHydrogen

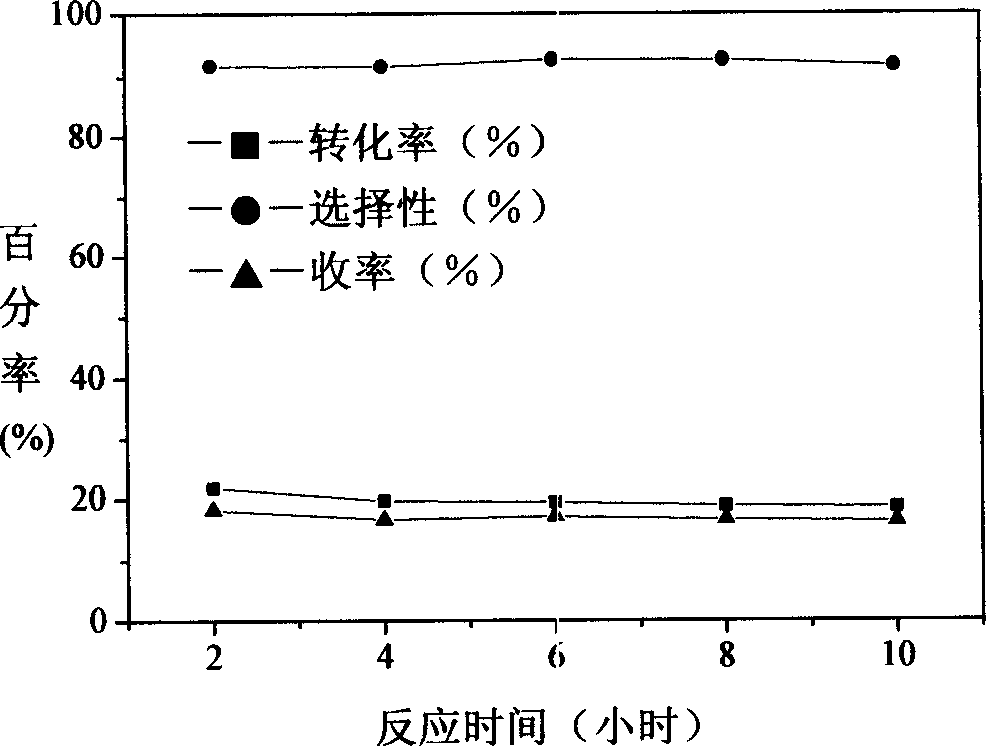

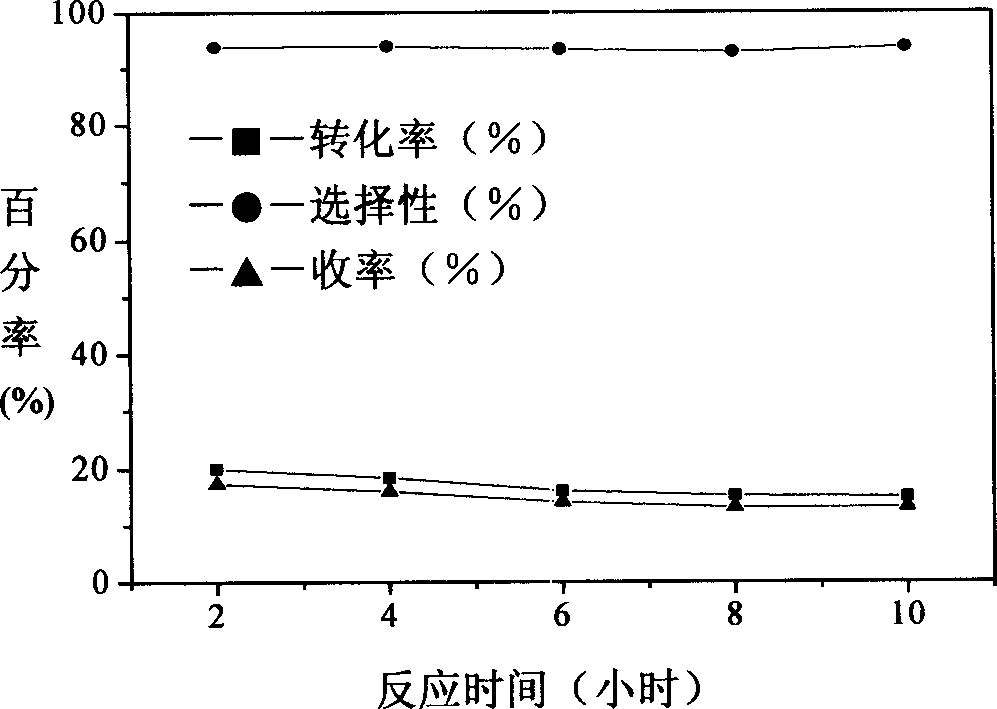

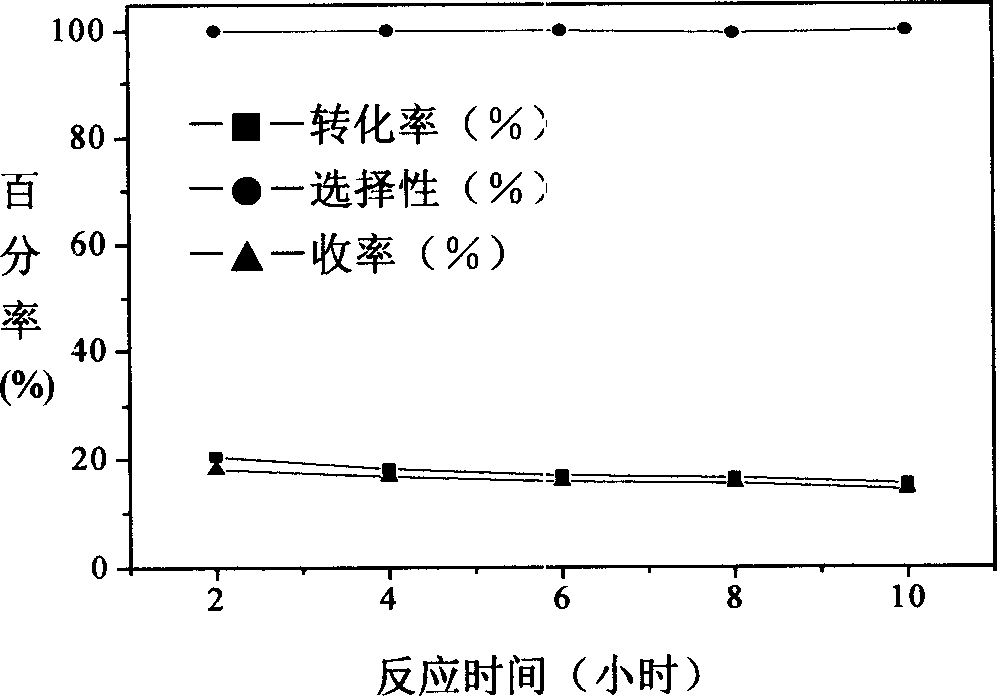

The invention discloses a preparation method of a p-diethylbenzene catalyst by using high-efficiency alkylation of ethylbenzene, and belongs to the technical field of preparation of catalysts. The preparation method comprises the following steps of mixing a nanometer hydrogen type ZSM-5 molecular sieve, an adhesive and an extrusion additive; adding an inorganic acid solution and modified components of magnesium and phosphor in the kneading process, mixing, peptizing, extruding, forming, and treating by hydrothermal aging, so as to improve the stability of the catalyst; impregnating the modified component of silicon in the carrier by one step, so as to obtain the catalyst, wherein the pore size of the molecular sieve of the catalyst and the acidity at the outer surface are modified, and thereaction property and stability are obviously improved under the synergistic modifying function of magnesium, silicon and phosphor. The preparation method has the advantages that compared with the prior art, the modified components of magnesium and phosphor can be directly lead in the strip extruding process, so that the preparation process is simplified, and the industrial production cost is reduced; after the prepared catalyst is evaluated by a fixed bed miniature reaction device in a laboratory, the selectivity on p-diethylbenzene reaches 98.5%, the conversion rate of ethylbenzene reaches20%, and the stable running period is 350h.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

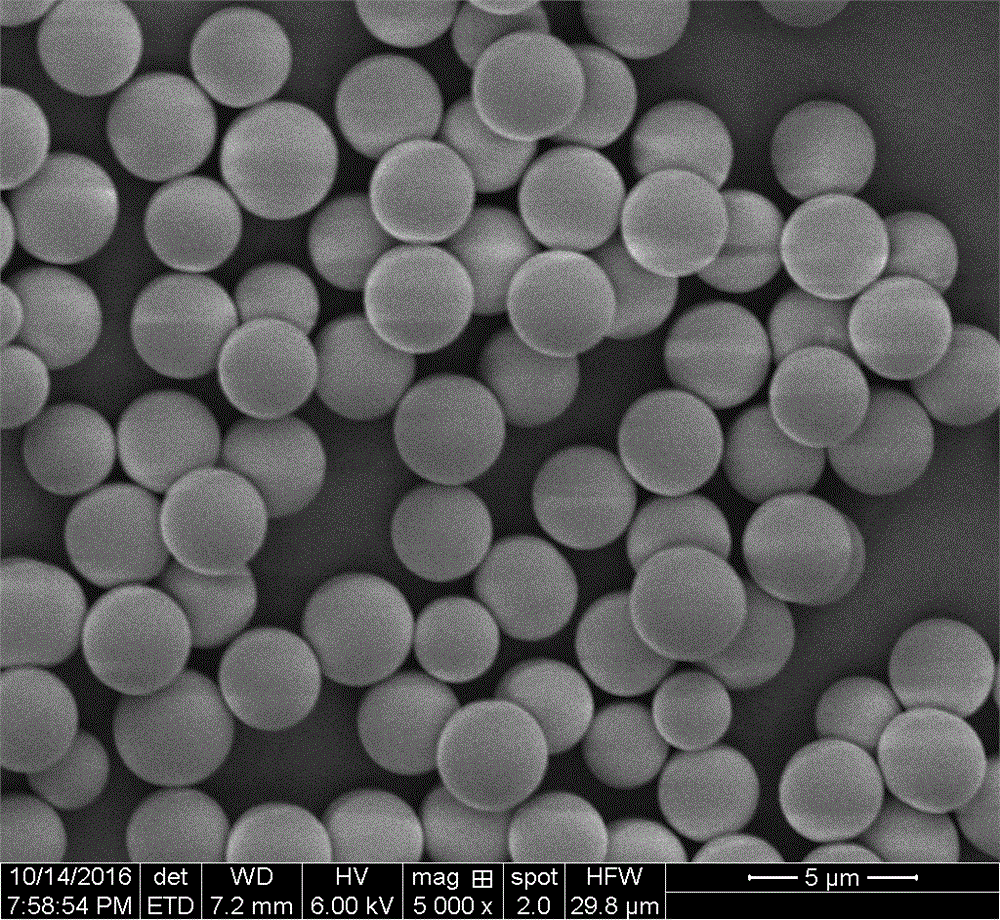

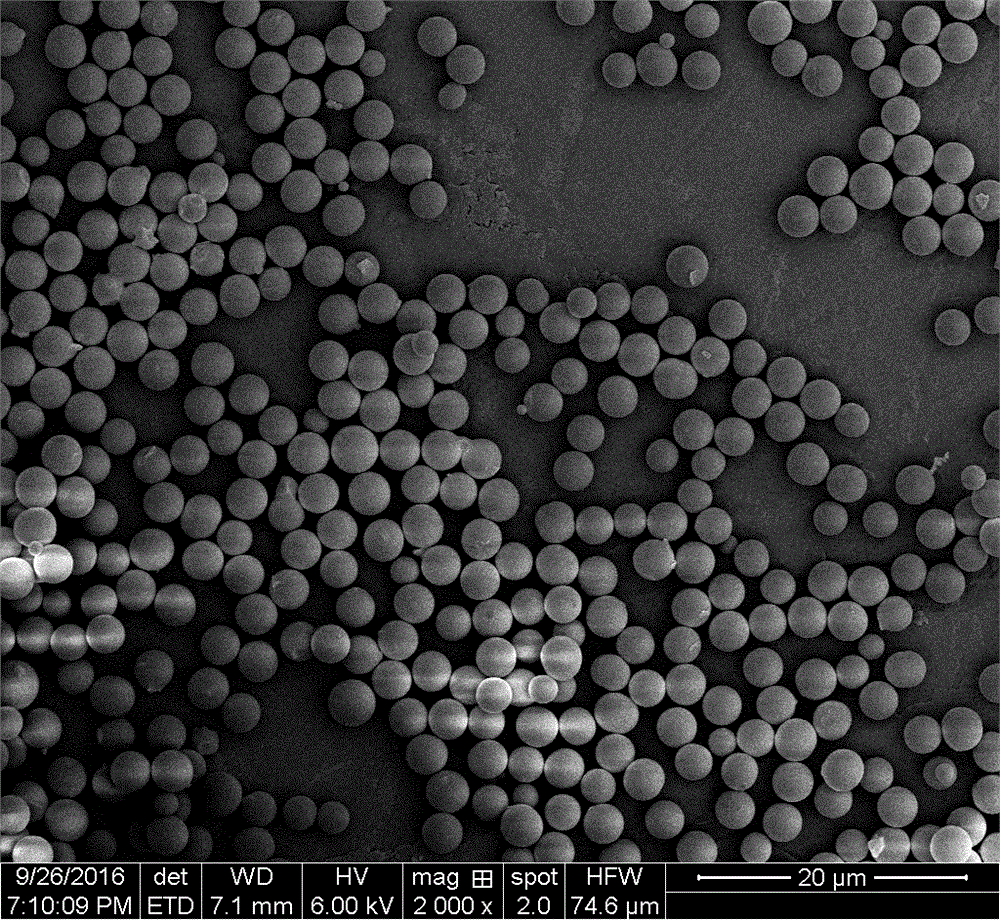

Carboxyl functional high-cross-linking monodisperse polymer microsphere and preparation method thereof

InactiveCN106832084AHigh yieldEasy to makeMicroballoon preparationMicrocapsule preparationCross-linkDiethyl benzene

The invention relates to a carboxyl functional high-cross-linking monodisperse polymer microsphere and a preparation method thereof. The method comprises the following steps: adopting solvent thermal precipitation polymerization for adding methacrylic acid, diethyl benzene and initiator into solvent and uniformly mixing; placing into a stainless steel reaction kettle; increasing temperature and polymerizing; controlling the reaction temperature within 82 DEG C-200 DEG C and the reaction time within 1-12 hours; washing the acquired product with the solvent; centrifugally precipitating and drying, thereby acquiring the carboxyl functional high-cross-linking monodisperse polymer microsphere. The preparation method provided by the invention is simple; the monomer dosage reaches 20%; the microsphere yield is above 90%; the acquired microsphere is high in carboxyl content and is excellent in hydrophilicity.

Owner:UNIV OF JINAN

Catalyst containing MCM-22 zeolite

ActiveCN1647855AIncrease acidityExtended operating cycleMolecular sieve catalystsCrystalline aluminosilicate zeolitesHalogenDiethyl benzene

The present invention is a kind of catalyst containing MCM-22 zeolite 30-90 wt%, halogen counting in simple substance 0.1-2 wt% and alumina matrix in the balanced amount. The catalyst is used in liquid phase benzene alkylating reaction, and compared with available technology, the catalyst has raised ethyl benzene selectivity, lowered diethyl benzene and triethyl benzene selectivity, and 7.3-10.0 % raised ethyl benzene STY.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the separation of diethylbenzene in carbon deka-aromatic hydrocarbons

ActiveCN101343207AEasy to separateImprove thermal stabilityDistillation purification/separationExtraction purification/separationBoiling pointExtractive distillation

The invention relates to a method for utilizing an extractive distillation process to separate diethyl benzene from C10 arene, comprising: firstly, mixed components of meta-diethyl benzene in C10 arene and other high boiling point components are separated off, with a rectification temperature of between 176 and 182DEG C; then an extractant is added in a meta-diethyl benzene mixture for separating out m-diethyl benzene, wherein, the extractant is dimethyl phthalate, dibutyl phthalate or a mixture thereof; and the extractant and the mixed components of meta-diethyl benzene have a feeding weight ratio of 5 to 20:1, the charging temperature of the extractant is between 120 and 190 DEG C, and the separation temperature is 160 to 190 DEG C; and finally the extractant and the p-diethyl benzene are separated for recovering the extractant through distillation separation; and the method has advantages of simple process, stable operation, low energy consumption, high purity of separated products, good separation effect and thermal stability of extractant, economy and acquirability, and the p-diethyl benzene content can reach over 98 percent, and the m-diethyl benzene content can reach above 70 percent.

Owner:PETROCHINA CO LTD

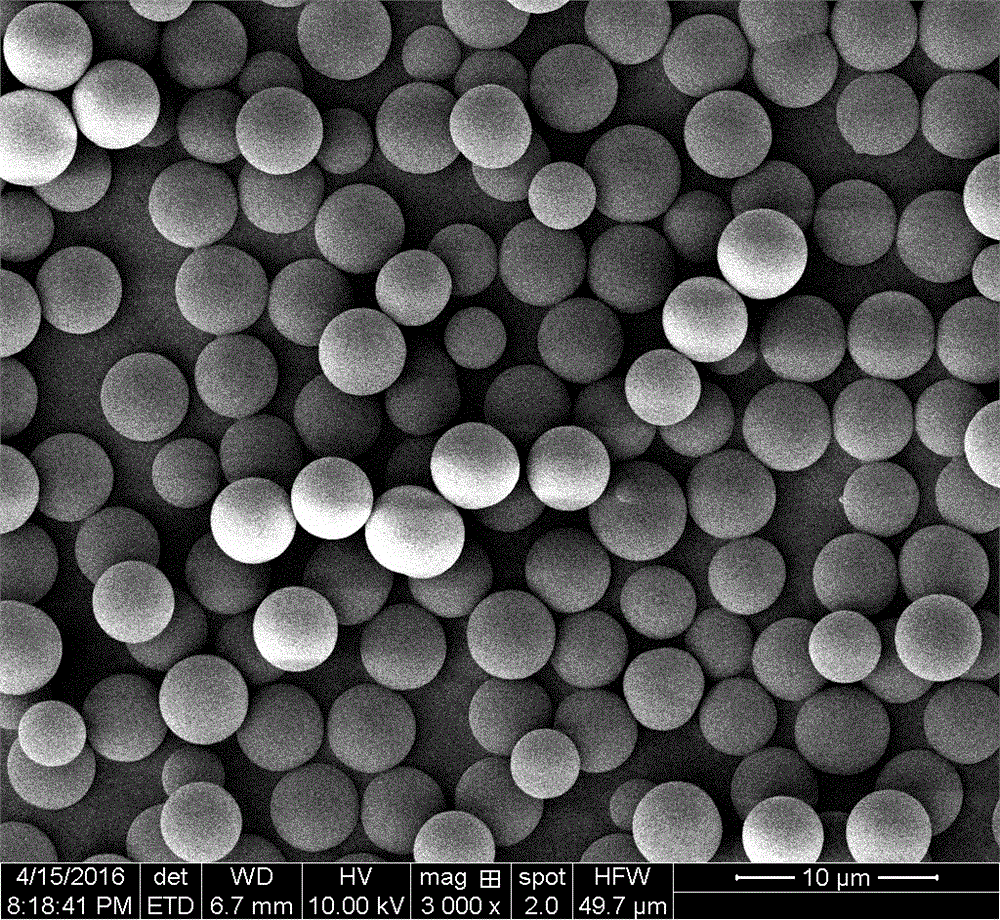

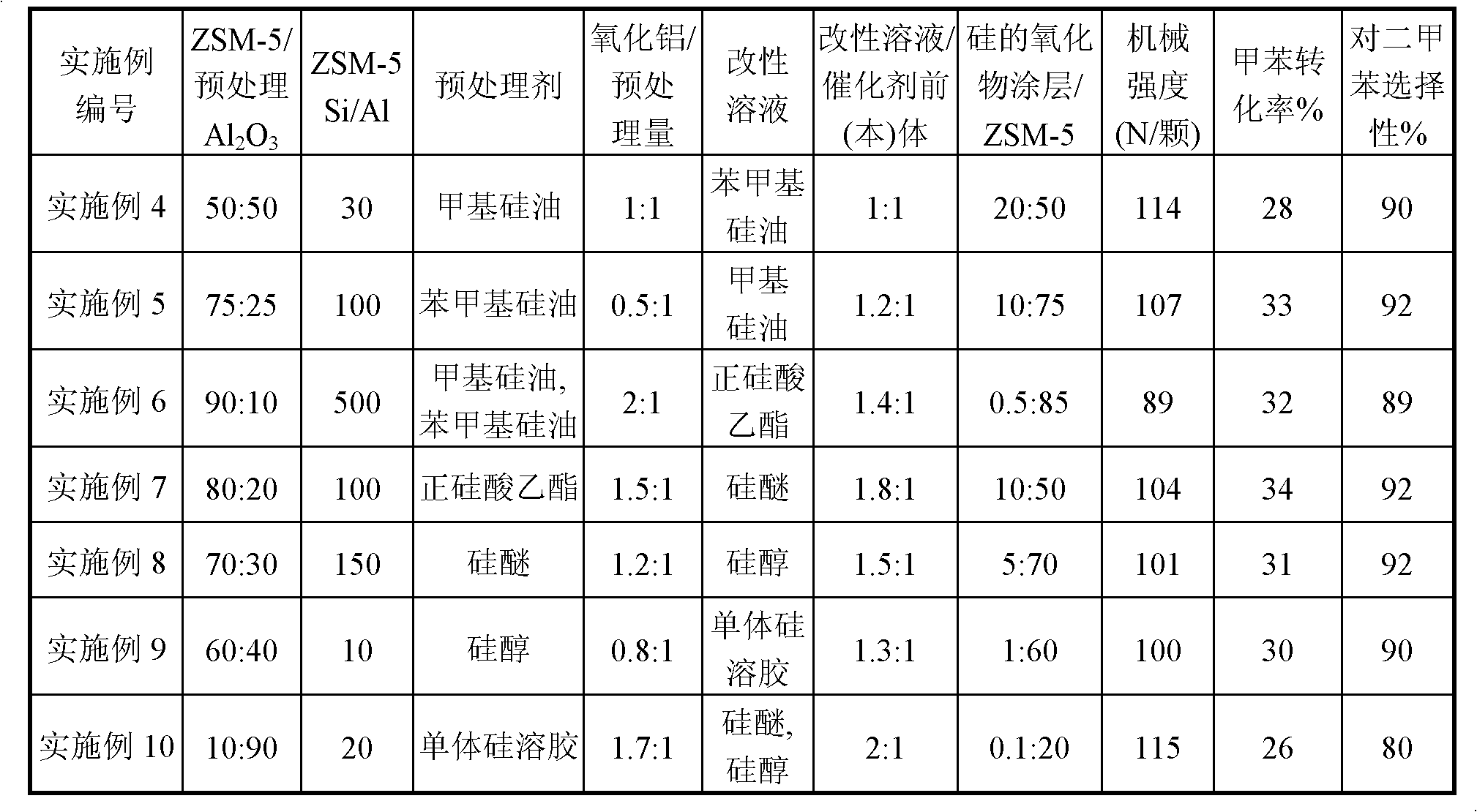

Catalyst for arene shape selective reaction and preparation method thereof

ActiveCN103120951ALow resolutionHigh strengthMolecular sieve catalystsHydrocarbonsSilicon oxideUltimate tensile strength

The invention relates to a catalyst for arene shape selective reaction and a preparation method thereof, and is mainly used for solving the technical problems that in the prior art, the catalyst strength is low when silica sol is used as a bonder and the shape selectivity of the catalyst is low when an aluminum oxide bonder is used. The catalyst for arene shape selective reaction provided by the invention comprises 10-90 parts of ZSM-5 zeolite with SiO2 / Al2O3 molar ratio of 10-500, 10-90 parts of processed aluminum oxide carrier and 0.1-20 parts of silicon oxide coating by weight. The technical scheme better solves the problems, and the catalyst can be used to industrial production of arene shape selective reaction such as preparation of paraxylene by selective disproportionation of methylbenzene, preparation of p-diethylbenzene by selective disproportionation of ethylbenzene, preparation of paraxylene by shape selective methylation of methylbenzene and preparation of p-diethylbenzene by shape selective methylation of ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the production of para-diethylbenzene

The present invention relates to a process for the selective production of para-diethyl benzene from a mixed aromatic feedstock containing ethyl benzene and at least one other aromatic compound selected from benzene, alkylated benzene having alkyl group with carbon number 1 to 6, mono-alkyl aromatics, dialkyl aromatics, trialkyl aromatics, tetraalkyl aromatics, pentaalkyl aromatics, hexaalkyl aromatics, containing side chains having 1 to 6 carbon atoms, and any mixtures thereof, the process comprising of (a) alkylating the feedstock under alkylating conditions, over a selectivated metallosilicate composite catalyst; and (b) recovering a product stream containing at least 95 wt % para-diethyl benzene, the product stream being substantially free from other isomers of diethylbenzene, C8 aromatics, C9 aromatics, C10+ heavy aromatics other than diethyl benzene isomers, sulphur, halogen, olefinic compound and carbonyl compounds.

Owner:INDIAN PETROCHEMICALS CORPORATION LIMITED

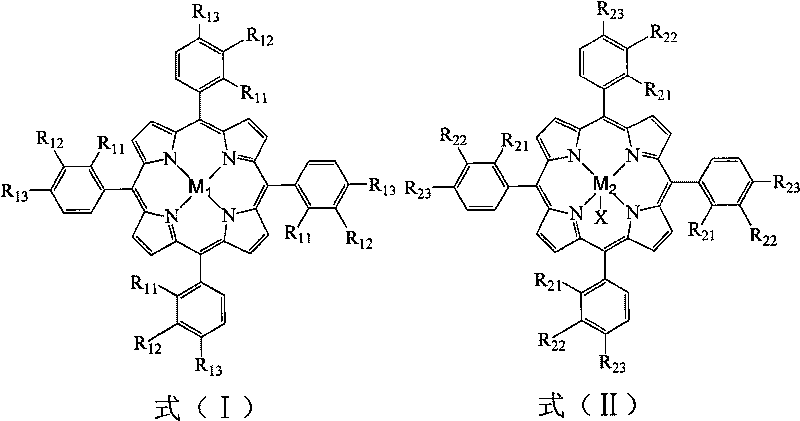

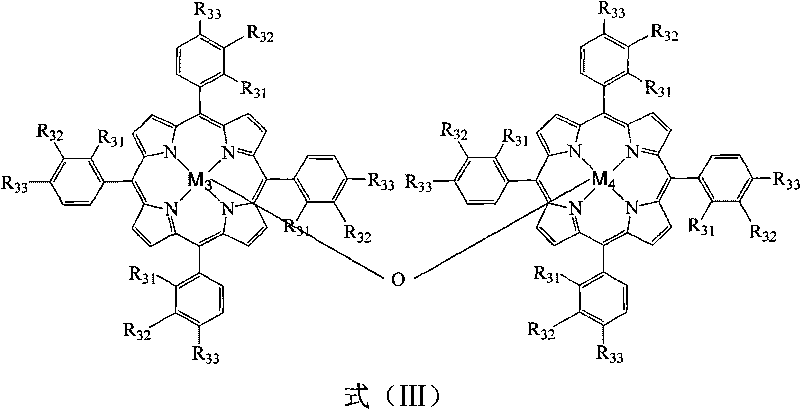

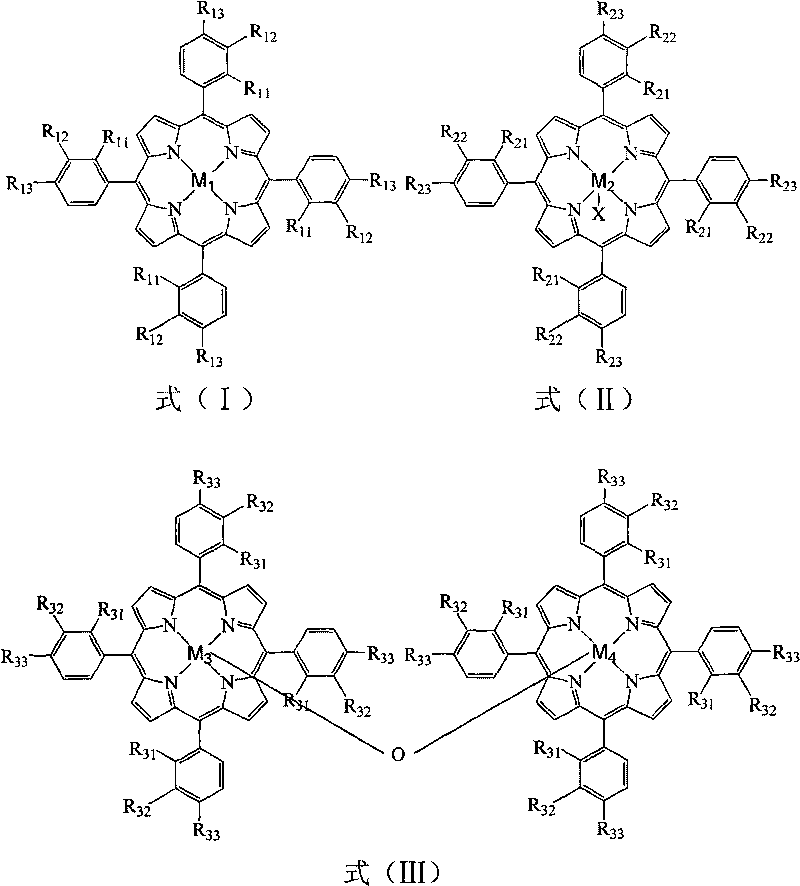

Method for preparing p-diacetylbenzene by biomimetic catalytic oxidation of p-diethylbenzene with oxygen

InactiveCN101759541AReduce pollutionReduce manufacturing costOrganic compound preparationCarbonyl compound preparationPtru catalystDiethyl benzene

The invention relates to a method for preparing p-diacetylbenzene by biomimetic catalytic oxidation of p-diethylbenzene with oxygen, comprising the following steps: taking p-diethylbenzene as the raw material, selecting any one of 1-30ppm of mononuclear metalloporphyrin and mu-oxo-dinuclear metalloporphyrin or the composition of the two substances as the catalyst under normal pressure and in the absence of solvents, introducing oxygen at the flow rate of 10-60mL / min, initiating reaction at 140-170 DEG C and then carrying out reaction at 80-130 DEG C for 10-20h, thus obtaining the p-diacetylbenzene. In the method, the way of high temperature quick initiation and low temperature reaction is adopted, thus minimizing the reaction initiation time, greatly shortening the reaction time, improving the reaction efficiency, reducing the energy consumption, lowering the operation cost and improving the reaction safety.

Owner:BEIJING UNIV OF TECH

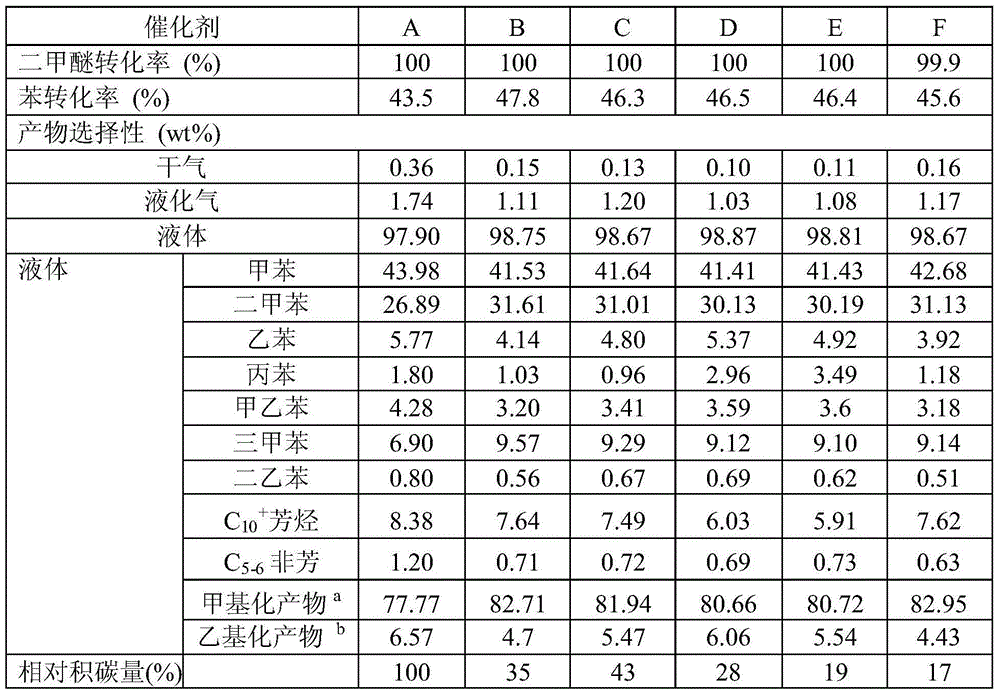

Preparation method and application of molecular sieve catalyst containing aluminum phosphate binder

ActiveCN104415776AImprove conversion ratePromote generationMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationCarbon numberDiethyl benzene

A preparation method and an application of a molecular sieve catalyst containing an aluminum phosphate binder particularly comprises following steps: (1) exchanging a prepared ultrafine rare earth ZSM-11 molecular sieve with an ammonium nitrate solution, drying the molecular sieve and roasting the molecular sieve to prepare an H-rare earth ZSM-11 molecular sieve; (2) supporting zinc on the H-rare earth ZSM-11 molecular sieve by a zinc salt through a conventional impregnation method, drying the molecular sieve and roasting the molecular sieve; and (3) mixing a phosphoric acid solution and boehmite to generate colloidal aluminium phosphate and uniformly mixing the colloidal aluminium phosphate with the zinc-type molecular sieve prepared in the last step according to a certain weight ratio, drying the molecular sieve and roasting the molecular sieve to obtain the molecular sieve catalyst. When the molecular sieve catalyst is used in an alkylation reaction between dimethyl ether and benzene, aromatic hydrocarbon with carbon number being 7-9 can be prepared at a high yield. The molecular sieve catalyst, compared with a molecular sieve catalyst which only contains an aluminum oxide binder, is increased in conversion rate of benzene and can promote generation of alkylation products of benzene (methyl benzene, dimethyl benzene and trimethyl benzene) and meanwhile inhibit generation of ethylation products of benzene (ethyl benzene and diethyl benzene). In addition, the molecular sieve catalyst is significantly improved in anti-carbon deposition performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

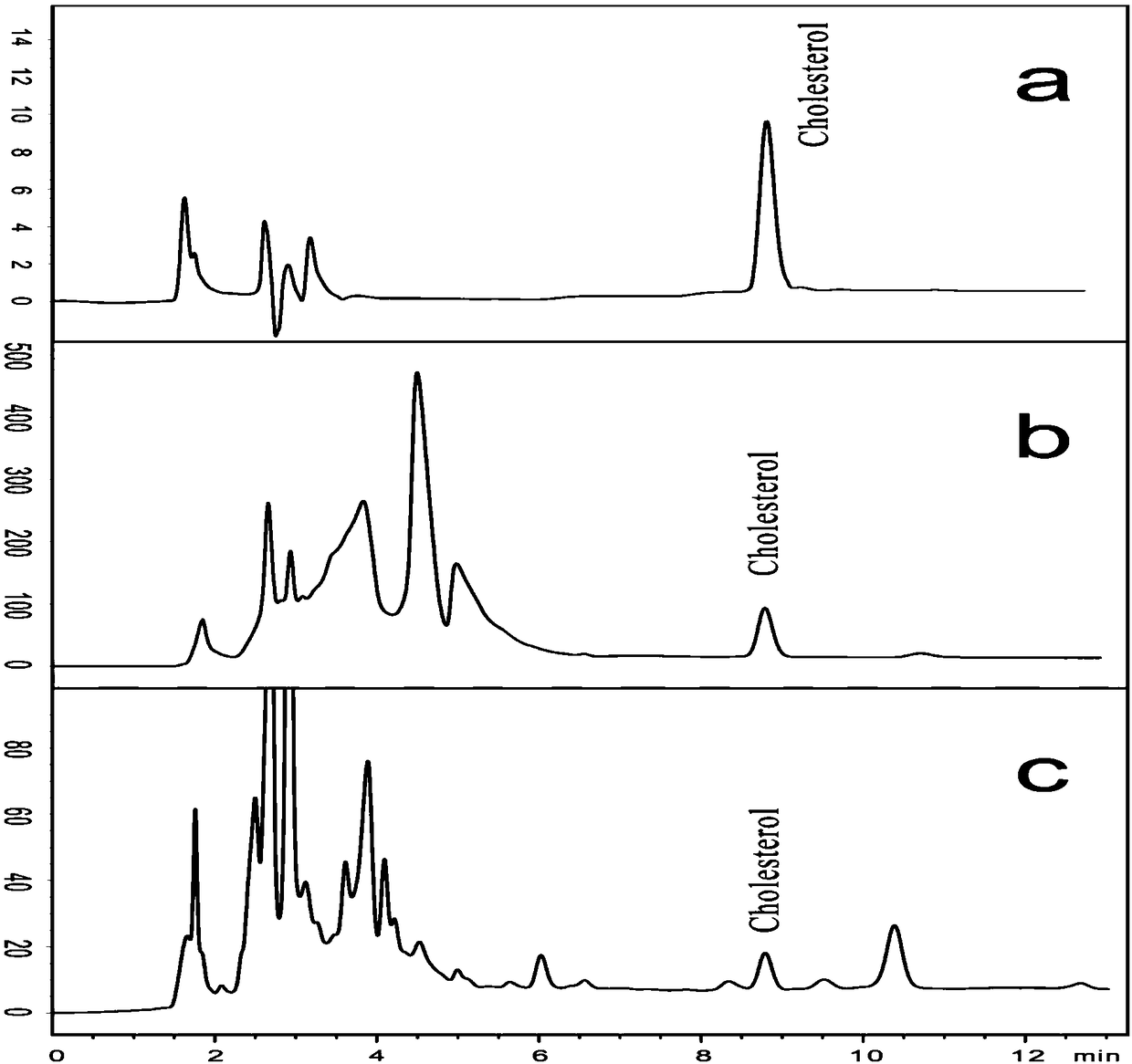

Polystyrene-diethyl benzene heating-free solid phase saponification extraction column and preparation method and applications thereof

InactiveCN108939614AEasy to useEasy to prepareComponent separationSolid sorbent liquid separationDiethyl benzenePolystyrene

The invention discloses a polystyrene-diethyl benzene heating-free solid phase saponification extraction column and a preparation method and applications thereof. The extraction column comprises a hollow column. An outlet screen plate, a polystyrene-diethyl benzene particle filled layer, an isolation screen plate, and a KOH powder filled layer are arranged in the hollow column from bottom to top in sequence. The prepared extraction column can be used to preprocess lipid containing liquid. Compared with the prior art, the preparation method is simple, the saponification is obviously reduced, the steps of heating and solid phase extraction are eliminated, a large amount of time is saved, and the detection sensitivity and the work efficiency are improved.

Owner:NORTHWEST UNIV

Method for producing divinyl benzene by dehydrogenating diethylbenzene

ActiveCN111056909AImprove conversion rateImprove technical effectHeterogenous catalyst chemical elementsCatalystsPtru catalystDiethyl benzene

The invention relates to a method for producing divinyl benzene by dehydrogenation of diethylbenzene, and mainly solves the technical problems of low conversion rate of diethylbenzene and high ratio of monoene to diene during long-term operation in the prior art. The method is characterized in that a raw material system composed of diethylbenzene and water reacts with a dual-catalyst system in a fixed bed reactor, and the reaction steps comprise that: a) the raw material system contacts a first catalyst M to generate a material flow I; and b) the material flow I contacts with a second catalystN to generate divinyl benzene, so that the technical problem is well solved, and the method can be used for industrial production of divinyl benzene through dehydrogenation of diethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

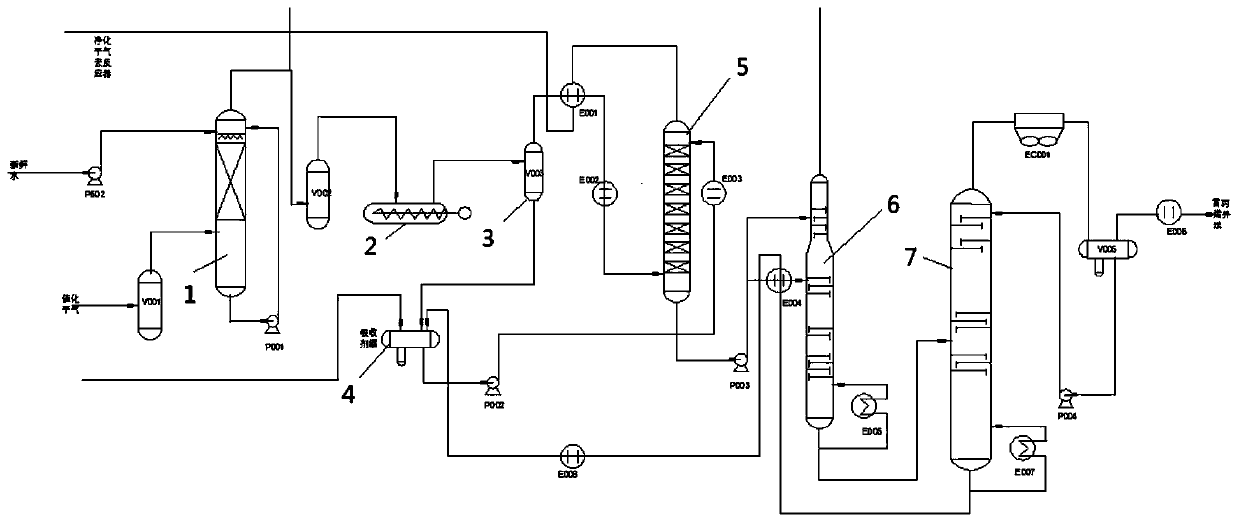

A device for removing propylene in dry gas and a method for removing propylene in dry gas

ActiveCN107099340BAchieve deep removalLow propylene contentCombustible gas purificationDiethyl benzeneBuffer tank

The invention provides a method for removing propylene in dry gas. The method includes steps of washing the catalytic dry gas by a water wash tower; pressurizing the catalytic dry gas by the aid of a dry gas compressor; buffering the catalytic dry gas by a buffer tank and absorbing the catalytic dry gas by absorbents in a propylene absorption tower to obtain tower top purified dry gas and absorption tower bottom liquid; treating the absorption tower bottom liquid by the aid of an ethylene removal tower to obtain ethylene-rich dry gas and ethylene removal tower bottom liquid; treating the ethylene removal tower bottom liquid by the aid of a propylene removal tower to obtain propylene-rich dry gas. The absorbents comprise benzene and diethylbenzene. The method has the advantages that steps of washing, pressurizing, buffering, absorbing and the like are carried out on the catalytic dry gas, accordingly, the dry gas at an ultimate outlet is low in propylene content, and the propylene can be deeply removed; the ethylene-rich dry gas and the propylene-rich dry gas can be obtained by the aid of the method and further can be applied to downstream production.

Owner:SHANDONG CHAMBROAD PETROCHEMICALS CO LTD

Dehydrogenation catalyst and application thereof in preparation of divinylbenzene by dehydrogenation of diethylbenzene

ActiveCN111375449AHigh activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsPtru catalystDiethyl benzene

The invention belongs to the field of catalytic chemistry, and particularly relates to a dehydrogenation catalyst and application thereof in preparation of divinylbenzene through dehydrogenation of diethylbenzene. The catalyst is prepared from the following components in parts by weight: 20 to 40 parts of lanthanide modified heteropolyacid salt, 10 to 20 parts of macroporous cross-linked polymer loaded nano alpha-Fe2O3, and 40-70 parts of one or more of oxides of CeO2, MnO2, ZrO2 and WO3. The supported catalyst is applied to a diethylbenzene dehydrogenation reaction, and product distribution can be effectively optimized by adjusting components in heteropolyacid salt. Water vapor is not needed in the reaction process, the reaction rate is high, selectivity is high, product system separationis simple, the technological process is safe and environmentally friendly, and industrial production is facilitated.

Owner:JIANGSU UNIV

Beta-zeolite catalyst activation method and its uses in ethyl benzene synthesis

The invention discloses an active method of beta zeolite catalyst, which is characterized by the following: adapting inert gas with less than 0.1%(V / V) water content to pass the catalytic bed layer at 100-5000 mg / (g)h , 350-600 Deg C for 0.5-10h; fitting for benzene and ethane alkyl to synthesize ethylbenzene, benzene and diethyl benzene and or multiple ethylbenzene alkyls to produce ethylbenzene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

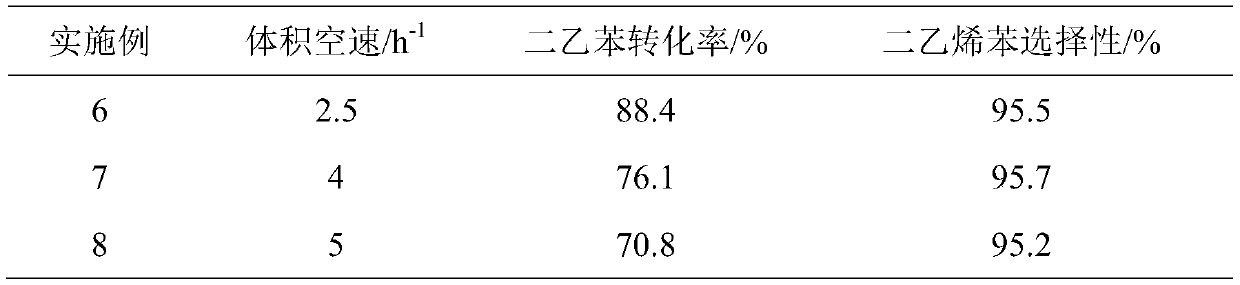

Method for extracting rubidium, cesium and lithium from sodium chloride slag

PendingCN112725630ASolving Recycling ProblemsResolve enrichmentProcess efficiency improvementLithiumDiethyl benzene

The invention discloses a method for extracting rubidium, cesium and lithium from sodium chloride slag. The method for extracting rubidium, cesium and lithium from sodium chloride slag comprises the following steps that (1) the sodium chloride slag is dissolved in water to form a solution, hydrochloric acid is added to adjust the pH of the solution to range from 2 to 3, the solution is heated and concentrated, when the concentration liquid level is 1 / 4-1 / 3, filter pressing is carried out on concentration liquid, and filtrate is extracted; (2) sodium hydroxide is added into the filtrate in the step (1), a rubidium-cesium solution with the alkalinity of 0.5-1 mol / L is prepared, and continuous stirring is carried out for 20-40 min by using a stirrer; and (3) the solution treated in the step (2) is added into an extracting agent consisting of t-BAMBP, diethylbenzene and sulfonated kerosene, and stirring is carried out until rubidium and cesium in the solution are not detected. According to the method for extracting rubidium, cesium and lithium from the sodium chloride slag, the problem of enrichment of low-concentration rubidium, cesium and lithium is solved, the problem of recovery of rubidium, cesium and lithium from solid slag is solved, the recovery cost is low, and the production period is short.

Owner:江西赣锋循环科技有限公司

Preparation method of a phosphoric acid modified microporous molecular sieve shape-selective catalyst

InactiveCN104492478AHigh activityHigh shape selectivityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferAlcohol

The invention relates to a preparation method of a phosphoric acid modified microporous molecular sieve shape-selective catalyst. The method uses a microporous molecular sieve ZSM-5 or MCM-22 as a matrix, phosphoric acid as a precursor and ethanol as a solvent, and employs an impregnating method to load phosphorus oxide on the microporous molecular sieve, wherein the content of phosphorus oxide in the catalyst accounts for 5%-10% of the total weight of the catalyst. The shape-selective catalyst obtained by the invention has good shape-selective catalysis performance on the synthesis of p-diethyl benzene by styralyl alcohol alkylation.

Owner:CHANGZHOU UNIV

Process for recovering para-xylene using a metal organic framework adsorbent in a simulated moving-bed process

ActiveUS10358401B2Lower requirementEasy to separateHydrocarbon by isomerisationDistillation purification/separationDistillationSorbent

Para-xylene is separated from a mixture of C8 aromatics using a simulated moving bed (SMB) adsorption process, wherein a MOF is used as an adsorbent and an alkane or alkene having 7 or less carbon atoms, such as hexane or heptane is used as desorbent. Because of the difference in boiling points of a hexane or heptane desorbent as compared to conventional desorbents such as toluene or para-diethylbenzene, less energy is required to separate hexane or heptane from C8 aromatics by distillation than the energy required to separate toluene or diethylbenzene from C8 aromatics by distillation.

Owner:GEORGIA TECH RES CORP +1

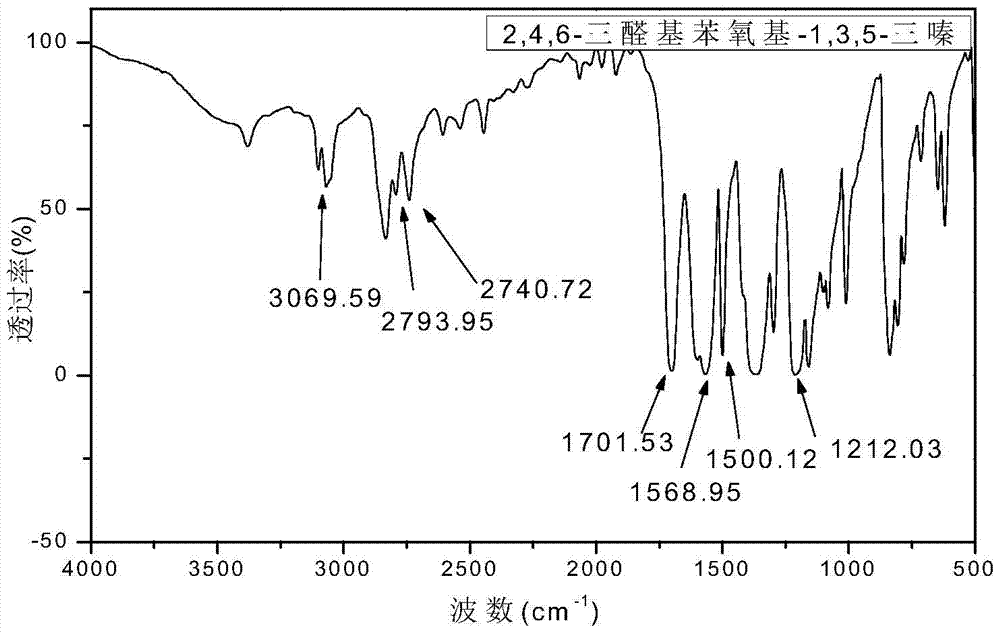

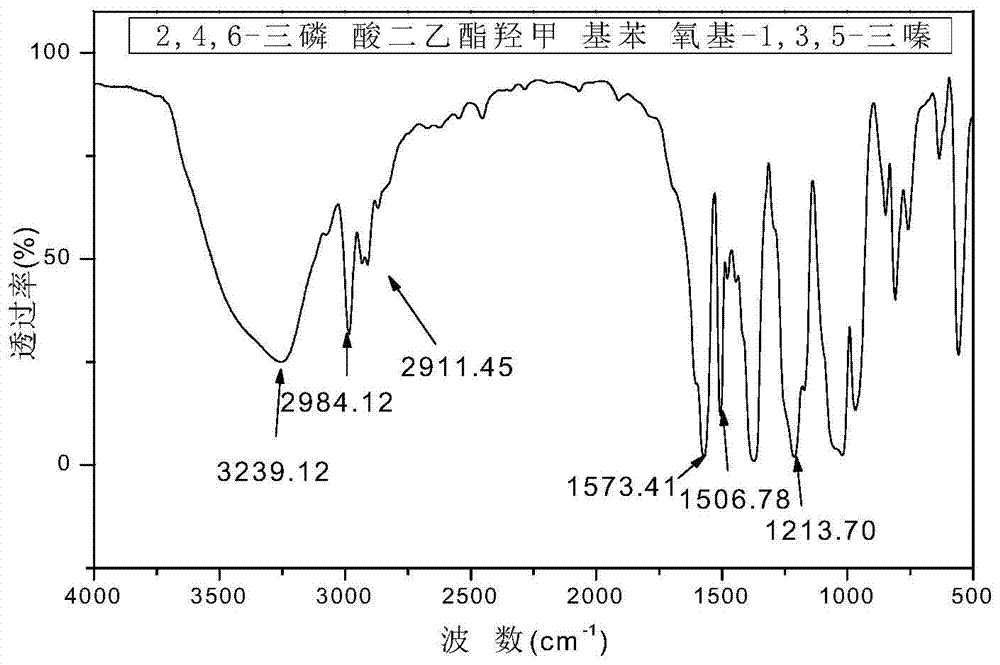

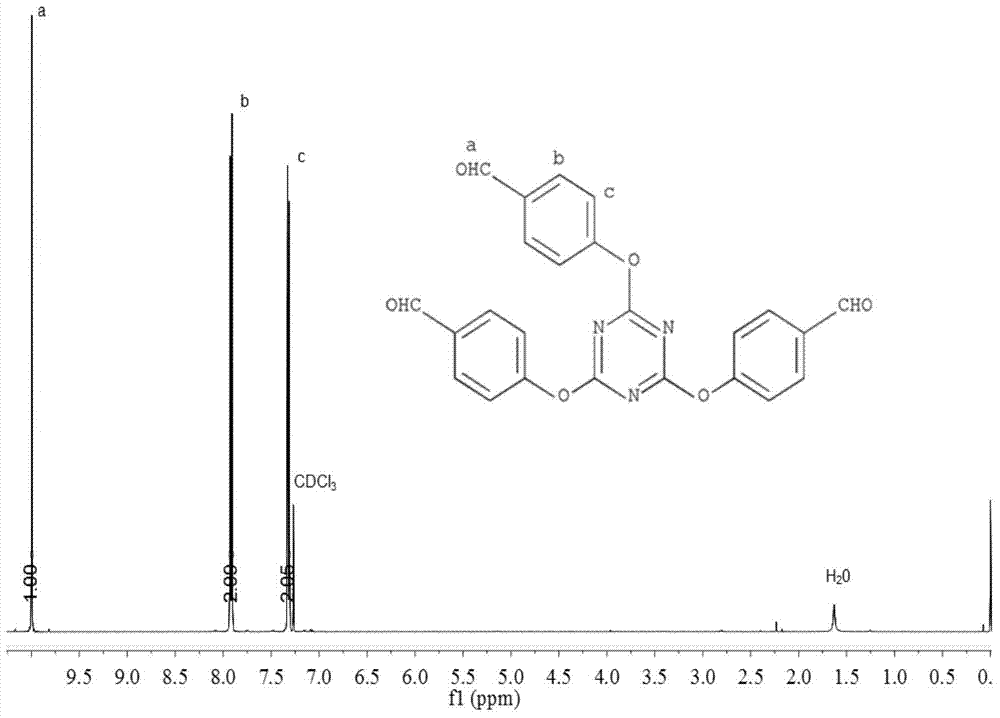

2,4,6-diethyl triphosphate hydroxymethylphenoxy-1,3,5-triazine flame retardant and preparation method

ActiveCN105131330BImprove thermal stabilityImprove flame retardant performanceGroup 5/15 element organic compoundsDiethyl benzeneEvaporation

The invention discloses a 2,4,6-triphosphate diethyl hydroxymethylphenoxy-1,3,5-triazine flame retardant and a preparation method thereof, belonging to the technical field of flame retardancy. Add cyanuric chloride, p-hydroxybenzaldehyde, and a catalyst to an organic solvent, heat to reflux for reaction, and then undergo a post-processing step to obtain a white solid powder 2,4,6-trialdehyde-phenoxy-1,3,5 ‑triazine; then 2,4,6‑3 formylphenoxy‑1,3,5‑triazine, diethyl phosphite, and triethylamine are heated and refluxed in an organic solvent, and the reaction product is decompressed After distilling off the organic solvent and triethylamine, a 2,4,6-diethyl triphosphate hydroxymethylphenoxy-1,3,5-triazine flame retardant is obtained. The preparation process of the 2,4,6-triphosphate diethyl hydroxymethylphenoxy-1,3,5-triazine involved in the present invention is simple and easy to operate, has high yield, strong practicability, environmental protection and pollution-free, and can large-scale industrial production.

Owner:CHANGZHOU UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com