Patents

Literature

115results about How to "Achieve deep removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

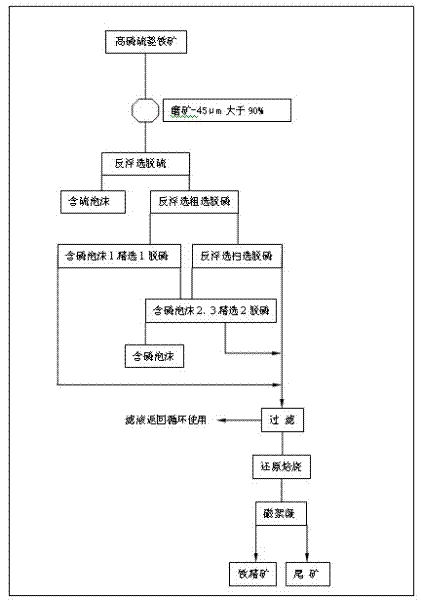

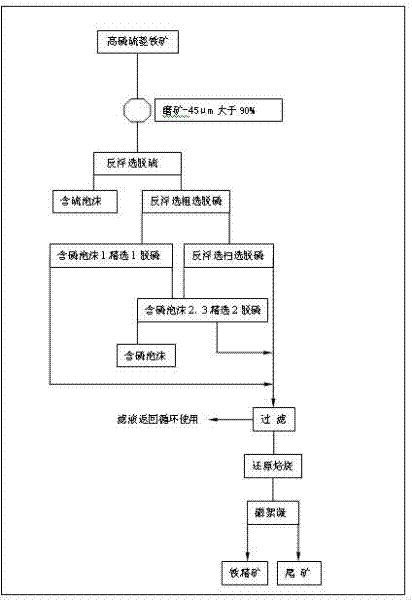

Method for recycling high-phosphorus/sulfur siderite resource

The invention discloses a method for recycling high-phosphorus / sulfur siderite resources. The method comprises the following steps: finely grinding the raw ore, and removing phosphorus and sulfur by asynchronous reverse flotation, to obtain low-phosphorus / sulfur crude concentrate; subjecting the crude concentrate to reduction roasting in a roasting furnace while adding sodium carbonate, to obtain reduced roasted ore; and performing magnetic flocculation-enhanced separation. The process can not only increase the concentrate grade but also effectively improve recovery of magnetic minerals at fine-particle level and micro-fine-particle level and achieve advanced removal of phosphorus and sulfur from the roasted ore, greatly increases the recycling rate of a great amount of refractory high-phosphorus / sulfur siderite resources, and produces iron concentrate having iron grade of more than 65%, iron recovery rate of more than 65%, phosphorus content of less than 0.20% and sulfur content of less than 0.3%.

Owner:KUNMING UNIV OF SCI & TECH

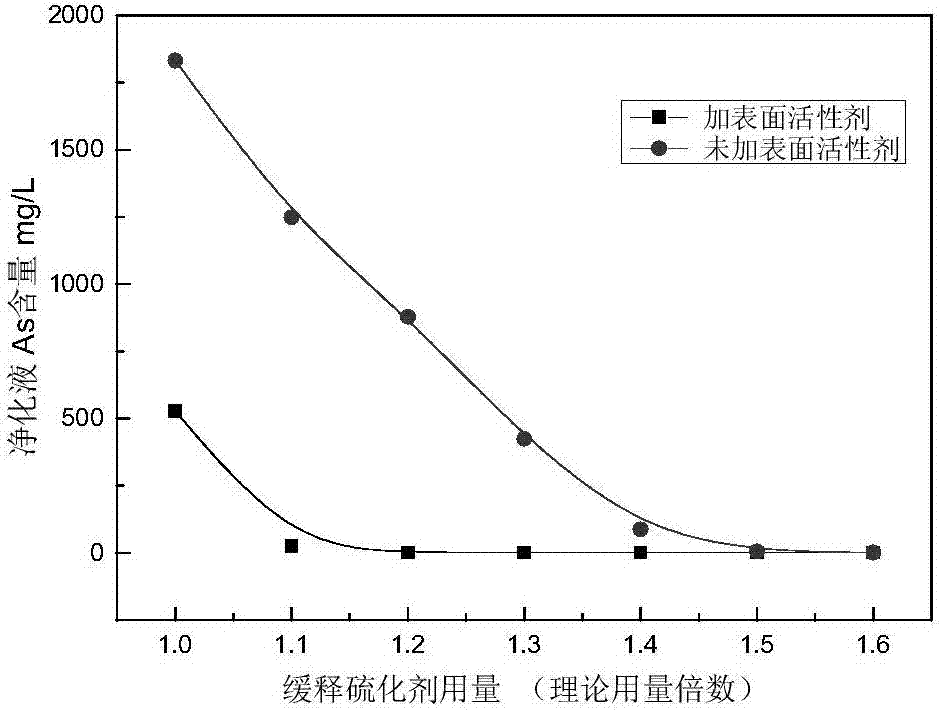

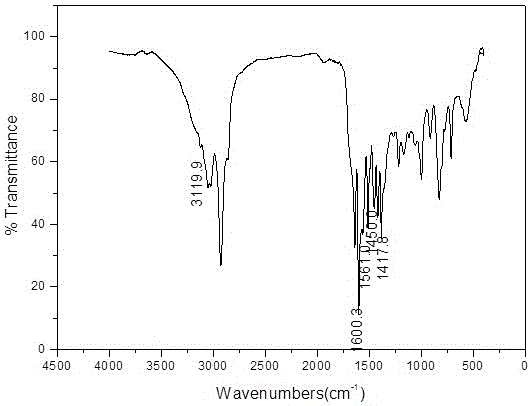

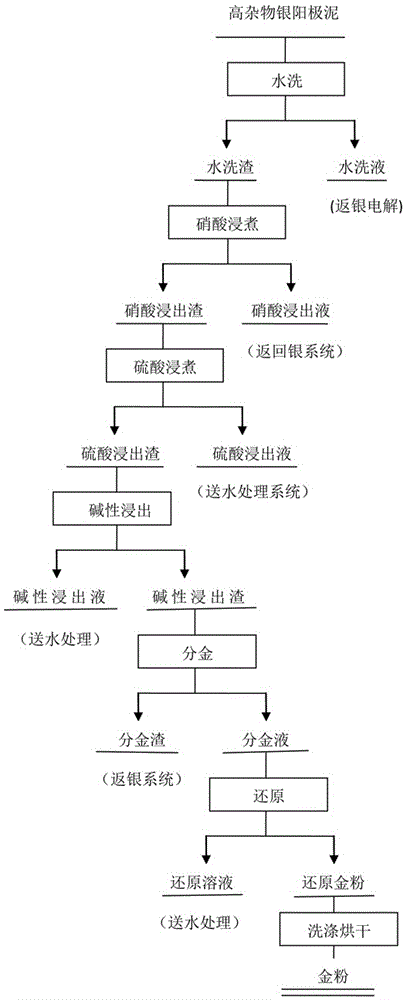

Sustained release vulcanizing agent, preparation method thereof, and method of using sustained release vulcanizing agent to remove heavy metals and arsenic from acidic solution

ActiveCN107188361ASolve the problem of easy release of hydrogen sulfideImprove acid resistanceWater treatment compoundsWater contaminantsSulfideSURFACTANT BLEND

The invention discloses a sustained release vulcanizing agent, a preparation method thereof, and a method of using the sustained release vulcanizing agent to remove heavy metals and arsenic from an acidic solution. A sulfur source and a surfactant are added into a solution containing Fe<2+>, Mn<2+>, and Zn<2+> to carry out reactions to obtain the nano-millimeter metal sulfide sol sustained release vulcanizing agent, which can slowly release S<2-> under a strongly acidic condition; the surface activity is guaranteed, at the same time, the utilization rate of S<2-> is improved; the vulcanizing agent is used to remove heavy metals and arsenic from an acidic solution and has the advantages of high removal efficiency, low using amount, and low hydrogen sulfide release amount; the problems that the using amount of a conventional vulcanizing agent is large, the utilization rate is low, and the H2S pollution is severe can be solved, and the method for removing heavy metals and arsenic from an acidic solution has the advantages of simple process and convenient operation and is suitable for industrial production.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Synthesis and application method of composite function resin for selectively removing nitrate and phosphate at same time

InactiveCN105126790AAchieve deep removalOther chemical processesWater/sewage treatment by sorptionSolubilitySulfate radicals

The invention discloses a synthesis and application method of composite function resin for selectively removing nitrate and phosphate at the same time, and belongs to the technical field of high molecular adsorption resin. The composite function resin having pyridine groups and triethylamine groups at the same time is synthesized. The composite function resin has the selective adsorption effect of pyridine transition metal complex on phosphate and the selective adsorption effect of triethylamine on nitrate at the same time. Nitrate and phosphate can be selectively adsorbed when other solubility coexistence anions such as sulfate radical, bicarbonate radical and / or chloride ions exist in a solution, and therefore the aim of selectively removing nitrate and phosphate at the same time is achieved, and deep removal of low-concentration nitrate and phosphate in secondary discharged water in biochemical treatment in sewage treatment plants is achieved.

Owner:HENAN NORMAL UNIV

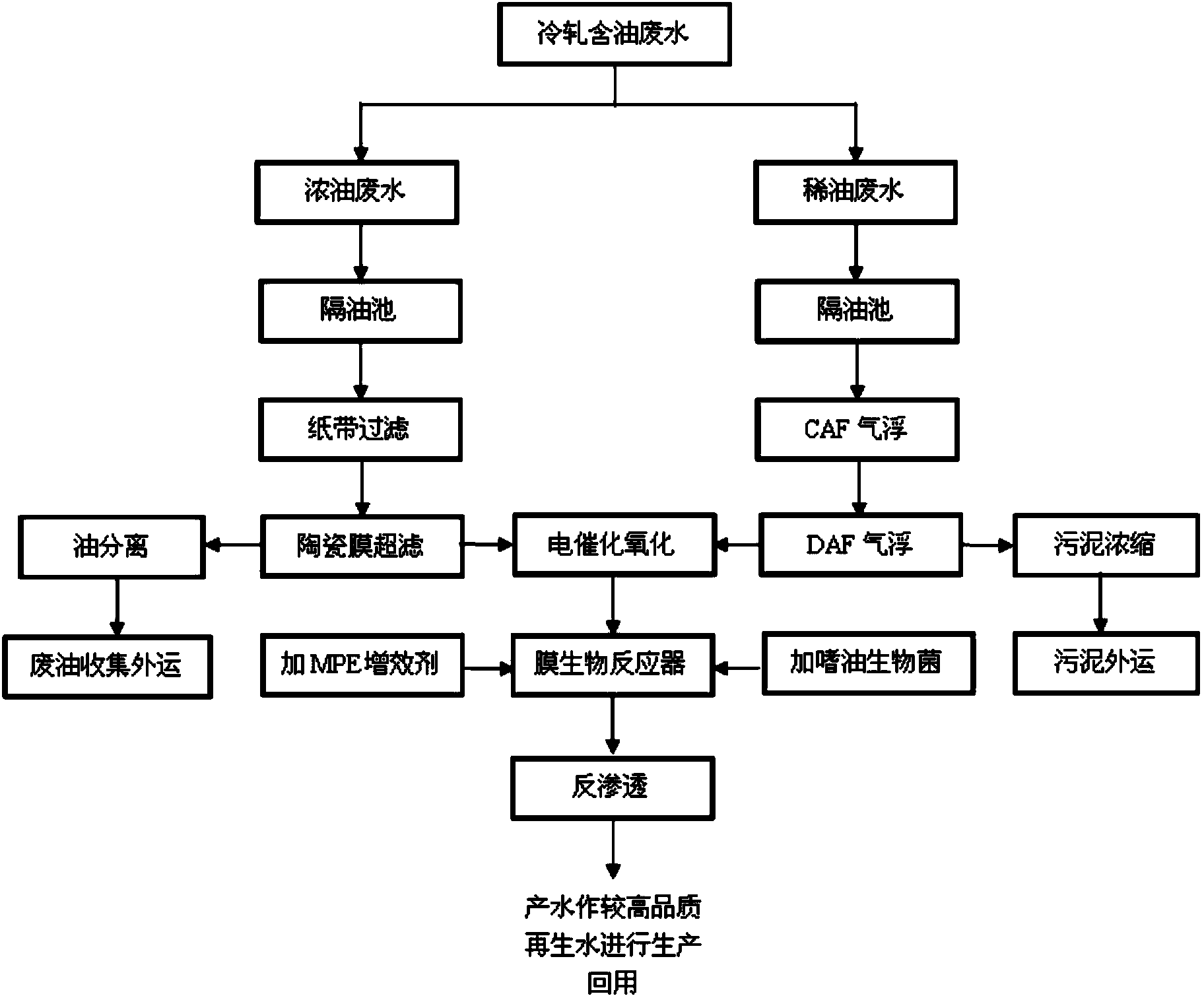

Cold rolling oily wastewater treatment process

InactiveCN103408200AThe treatment effect is stableWide range of adaptationGeneral water supply conservationWaste water treatment from metallurgical processInlet temperatureSystematic process

The invention discloses a cold rolling oily wastewater treatment process, which comprises the following steps of: (1), pretreating thick-oil wastewater sequentially by filtering of an oil separation tank and a paper tape and ultra-filtration process of a ceramic membrane, and pre-treating thin-oil wastewater sequentially by adopting the oil separation tank, a CAF (Cavitation Air Flotation) process and a DAF (Dissolved Air Flotation) process; (2), mixing pre-treated thick-oil wastewater with the pre-treated thin-oil wastewater, carrying out biochemical treatment by adopting an electrochemical catalytic oxidation process and an MBR (Membrane Biological Reactor) process in sequence, controlling the water inlet temperature of the MBR process to be 20-35 DEG C, controlling the water inlet pH value to be 7-9, and adding oil-munching high-efficiency micro-organism complex microbial inoculants and MPE (Metallocene Polyethylene) into an MBR membrane tank; and (3), filtering outlet water (treated through the MBR process) by using a reverse osmosis membrane, and carrying out deep desalination treatment so that outlet water reaches emission or industrial production reuse water standard. The invention provides a set of systematic process specially aiming at treatment and reuse of cold rolling oily wastewater in steel mills; the COD (Chemical Oxygen Demand) of treated outlet water is less than 10mg / L; the electrical conductivity of treated outlet water is less than 50mu s / cm; and oil and suspended solids are nearly eliminated completely.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

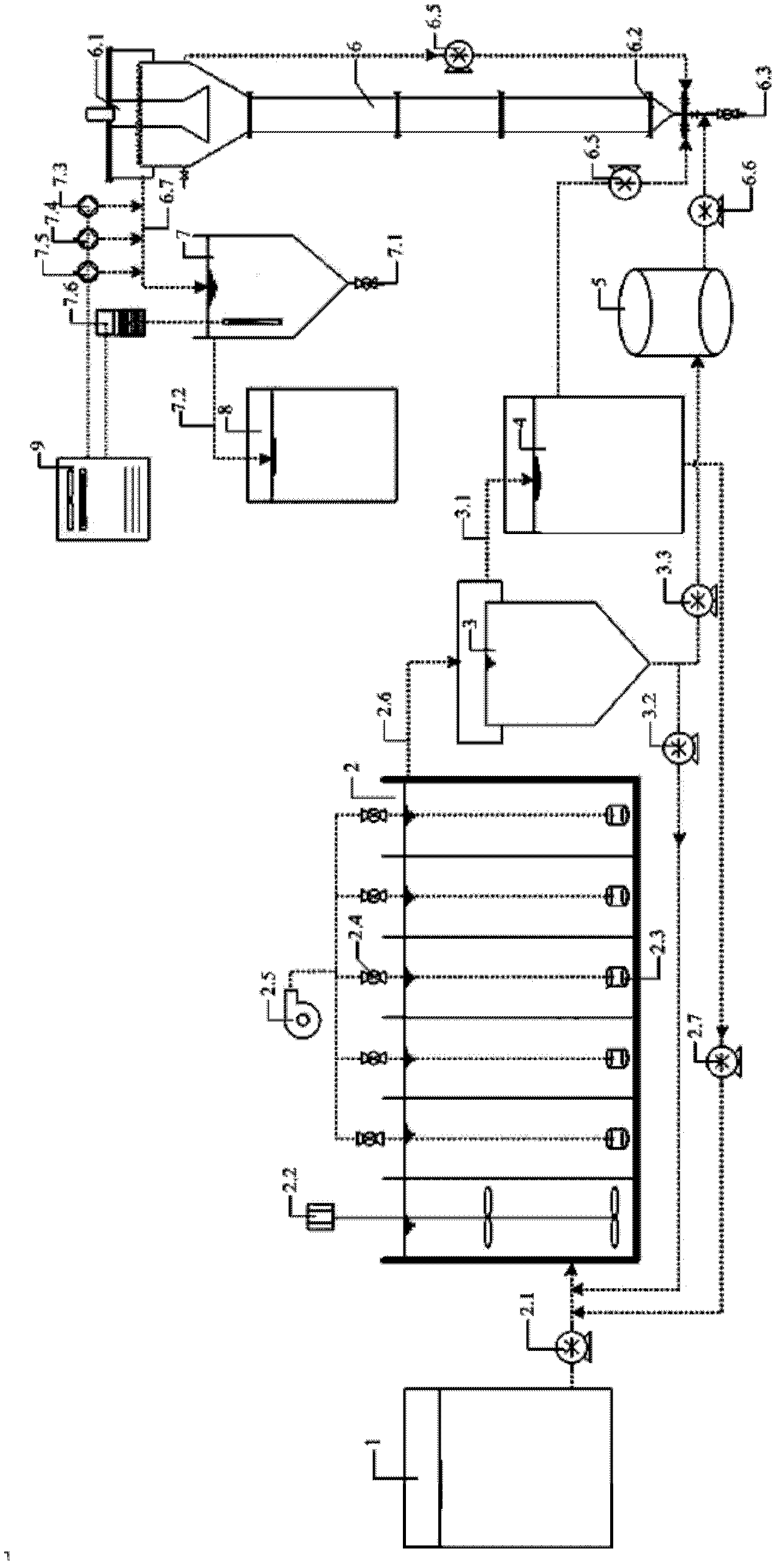

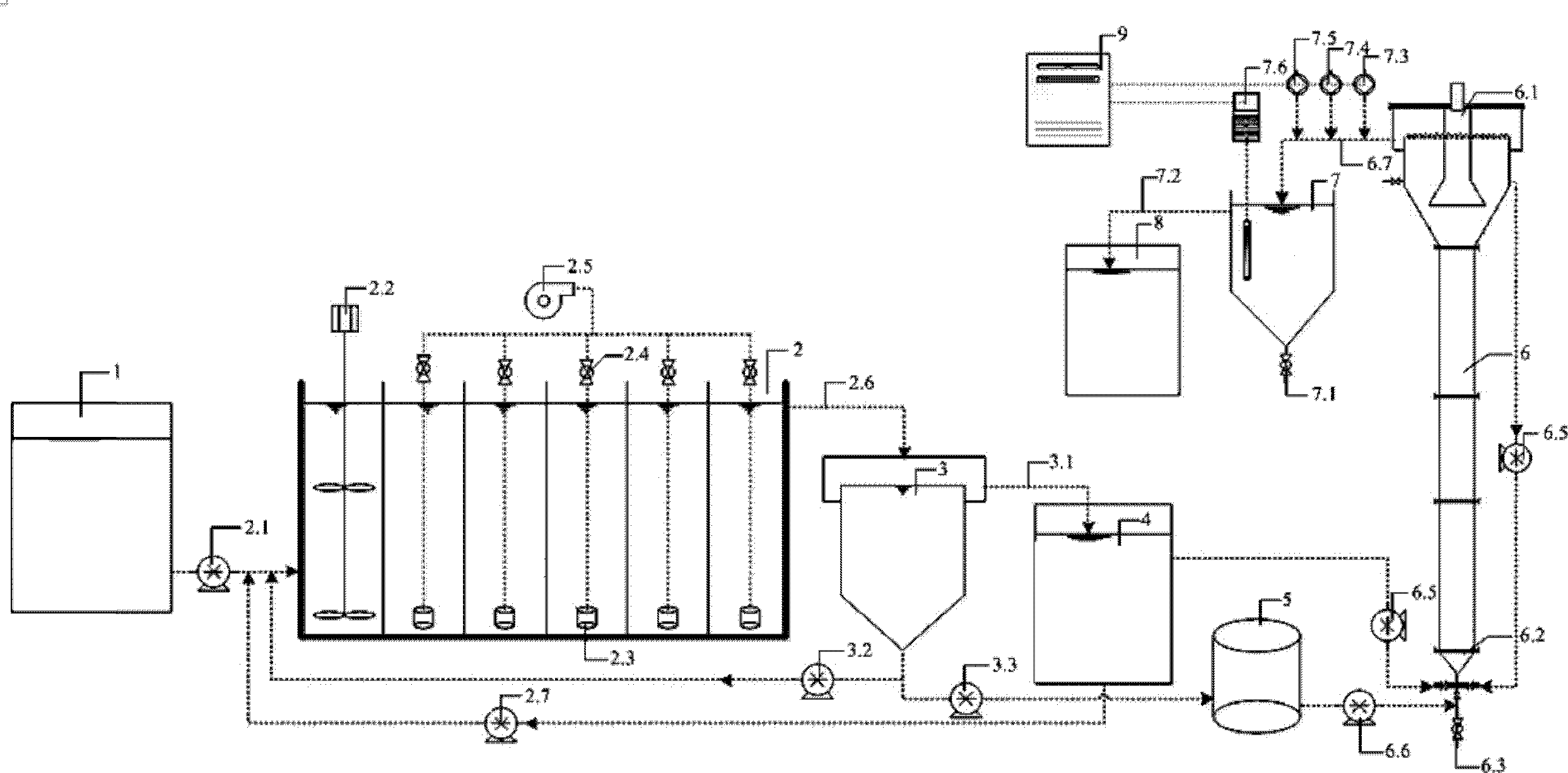

Enhanced sewage denitrification and dephosphorization system exploiting and utilizing carbon source in sludge in situ and enhanced sewage denitrification and dephosphorization method exploiting and utilizing carbon source in sludge in situ

InactiveCN102557360AReduce processing costsAchieve deep removalMultistage water/sewage treatmentBiological sludge treatmentChemical treatmentOxygen

The invention provides an enhanced sewage denitrification and dephosphorization system exploiting and utilizing the carbon source in sludge in situ and an enhanced sewage denitrification and dephosphorization method exploiting and utilizing the carbon source in sludge in situ. The treatment system comprises a raw water tank, an A / O nitrification reactor, a secondary sedimentation tank, an intermediate water tank, a sludge storage tank, an anaerobic fermentation-synchronized denitrification reactor, a chemical precipitation tank, a controller and a drain tank. The method applying the treatment system is as follows: high-ammonia nitrogen concentration sewage and residual sludge are respectively filled up in the raw water tank and the sludge storage tank, the sewage is first nitrified in the A / O nitrification reactor, the sewage and the residual sludge then enter the anaerobic fermentation-synchronized denitrification reactor together, residual sludge fermentation product is utilized as carbon source to carry out denitrification, and finally, the sewage and the sludge enter the chemical precipitation tank assorted with the on-line controller in order to precipitate and remove ammonia nitrogen and phosphorus, and are then discharged. The invention organically integrates the anaerobic biological treatment technology, the aerobic treatment technology and the chemical treatment technology in order to realize the low-carbon consumption treatment of high-pollution sewage and the reduction of residual sludge and recycle resource matters in sewage.

Owner:BEIJING UNIV OF TECH

Diesel oil hydrofining catalyst containing phosphorous or molecular sieve and preparation method thereof

InactiveCN101058748AImprove catalytic performanceHigh catalytic efficiencyHydrocarbon oils refiningCobaltSilicon dioxide

The invention relates to a diesel hydrofining accelerant, wherein a carrier is a modifying product that the titania and the silicon dioxde composite oxides is modified by P, HY molecular sieve or the molecular sieve modifying material; a active component is two metals of cobalt, molybdenum, nickel, tungsten; the hole volume of the accelerant is 0. 4-0. 7ml / g, and the specific surface area of the accelerant is 150-350m2 / g. The invention also relates to a method preparing for the accelerant, which specially relates to the method modifying the property with phosphorus or the molecular sieve, in order to achieve the deep desulfuration, the denitrification and denying aromatic hydrocarbons of the diesel.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

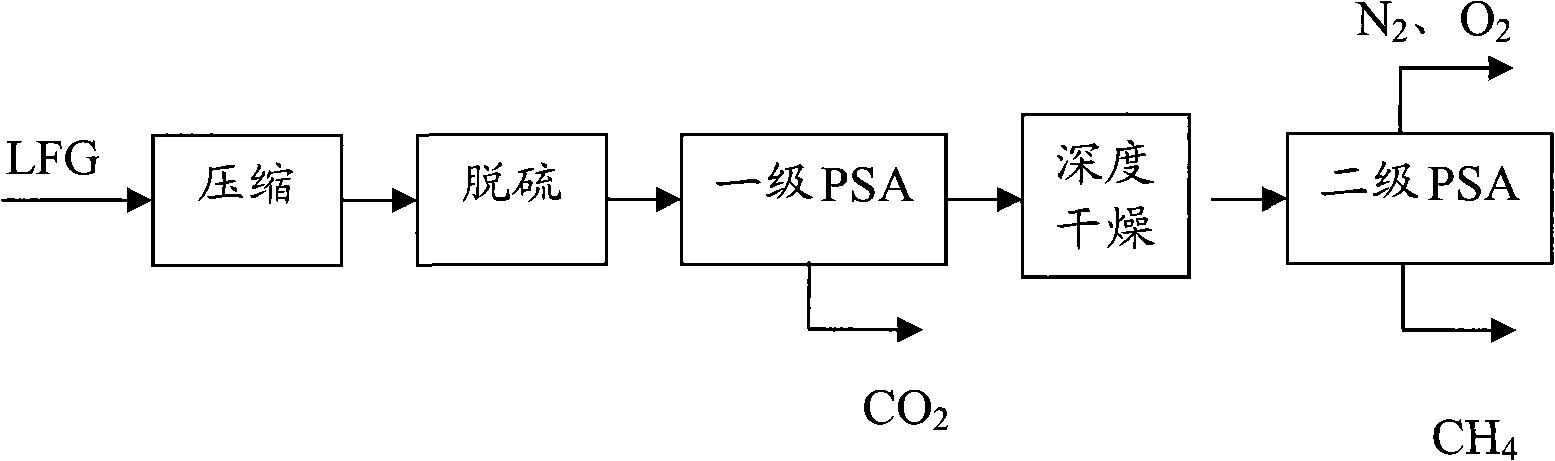

Method for preparing methane by deeply purifying landfill gas

ActiveCN101555186AAvoid mixingSimple processWaste based fuelAdsorption purification/separationNitrogenProduct gas

The invention discloses a method for preparing methane by deeply purifying landfill gas, which adopts pressure varying adsorption method to remove nitrogen and oxygen contained in the landfill gas. The method utilizes the pressure varying adsorption method to separate a small quantity of N2 and O2 from the landfill gas; and the process is simple, the equipment is compact, the operation cost is low and the applicability is high. Simultaneously, the method does not use catalyst hydrogenation for removing oxygen so as to prevent hydrogen from entering purified methane. The methane obtained by the method has high purity which is greater than or equal to 99 percent; and organic impurities can be fundamentally removed and then the purity of methane can meet the application requirement of higher purity methane.

Owner:山东泰正和科技发展有限公司 +1

Method for simultaneously and selectively removing nitrate and phosphate from secondary biochemical effluent

InactiveCN102390879AAchieve deep removalWater/sewage treatment by ion-exchangeWater/sewage treatment by sorptionSolubilityDesorption

The invention discloses a method for simultaneously and selectively removing nitrate and phosphate from secondary biochemical effluent, and belongs to the technical field of water pollution deep treatment. The method comprises the steps of: processing a mixed solution simultaneously containing nitrate, phosphate and other soluble coexisting anions by a double-layer fixed bed adsorption column containing polyvinyl pyridine transition metal complex and strong-basicity anion exchange resin, wherein polyvinyl pyridine transition metal complex is located at the upper part of the adsorption column and the strong-basicity anion exchange resin is located at the lower part of the adsorption column; and desorbing the adsorption column with nitrate and phosphate by using sodium chloride solution, wherein the adsorption column subjected to desorption can be recycled. Through treatment according to the method, NO3<->-N content at the outlet of the adsorption column is reduced to less than 5 mg / L and PO4<3->-P content is reduced to less than 0.5 mg / L; and by the method, synchronous deep removal of low-concentration nitrate and phosphate from secondary effluent of a wastewater treatment plant can be achieved.

Owner:NANJING UNIV

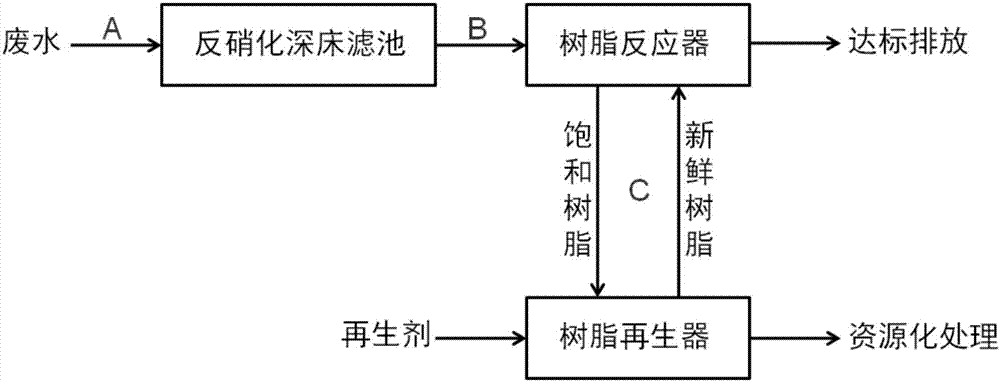

Method for deeply removing high-concentration nitrate nitrogen in wastewater

InactiveCN106892543AEfficient removalAchieve deep removalWater contaminantsWater/sewage treatment by magnetic/electric fieldsHigh concentrationNitrate nitrogen

The invention relates to a method for deeply removing high-concentration nitrate nitrogen in wastewater and belongs to the field of wastewater treatment. The method includes: treating with a denitrification deep-bed filtering tank; using magnetic ion exchange resin for absorption; regenerating the magnetic ion exchange resin. The method has the advantages that the method is economic, efficient and resistant to cold; the technical features of the denitrification deep-bed filtering tank technology and the magnetic ion exchange resin absorption technology are combined to deeply remove the high-concentration nitrate nitrogen in the wastewater.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

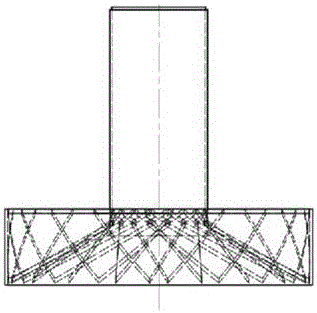

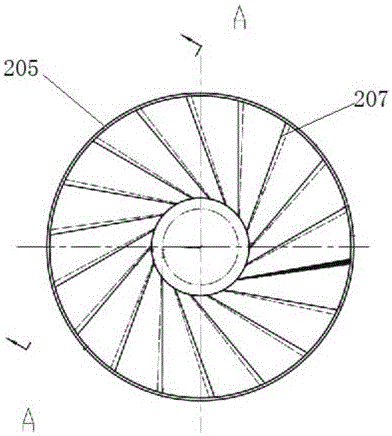

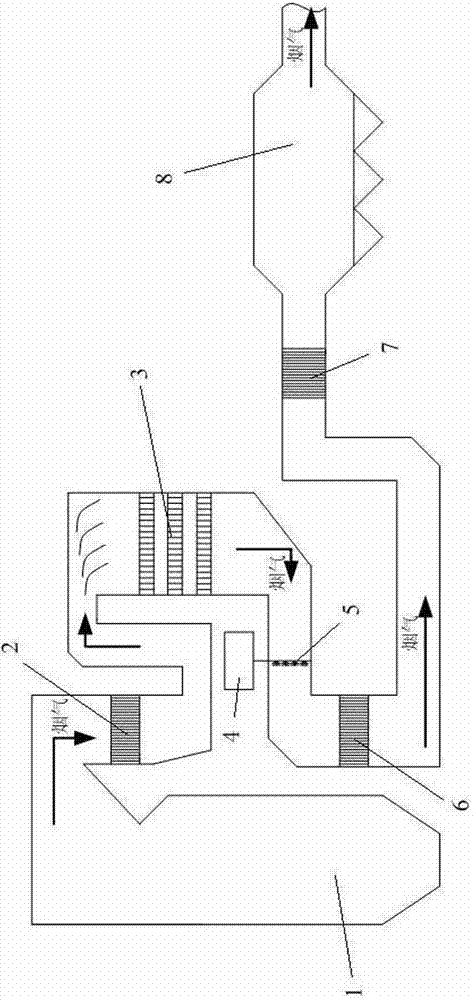

Integrated ultra-clean desulfurization and dust collection device

ActiveCN105727700AIncrease contact timeHigh contact densityCombination devicesGas treatmentSolid phasesContact time

The invention discloses an integrated ultra-clean desulfurization and dust collection device. The integrated ultra-clean desulfurization and dust collection device comprises a tank body, a gas inlet and a chimney, wherein a sealed space is formed by a tank body shell; the chimney is connected with the top part of the tank body shell; and the tank body is provided with a mechanical centrifugal fitting unit, a high-efficiency spraying unit, a high-efficiency energy concentrating ring unit, a multi-tube venturi unit, a mechanical eccentric demisting unit and a washing and spraying layer in sequence from bottom to top. The integrated ultra-clean desulfurization and dust collection device disclosed by the invention has the beneficial effects that flue gas enters an absorbing tower, upward torrential and rotary gas flow formed by the mechanical centrifugal fitting unit, and slurry sprayed by the spraying system from top to bottom generate a controllable torrential space, so that the contact time of a gas phase, a liquid phase and a solid phase is prolonged, the contact density is increased, the fusion is sufficient, the mass transferring efficiency is improved and deep removal of sulfur dioxide is realized; then the flue gas enters a mechanical centrifugal demisting device, and mist droplets and dust are thrown onto the inner wall of a pipe bundle under the action of eccentric force and are captured by a liquid film on the pipe wall simultaneously, so that the deep removal of the mist droplets and the dust is realized.

Owner:TONGZHENG ENVIRONMENT PROTECTION GRP CO LTD

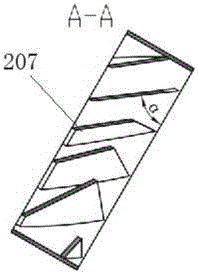

Integrated collaborative sulfur trioxide removal device suitable for high-sulphur coal and working method of integrated collaborative sulfur trioxide removal device

PendingCN106964243AAchieve deep removalReduce dosageGas treatmentDispersed particle separationFlue gasSulfur trioxide

The invention relates to an integrated collaborative sulfur trioxide removal device suitable for high-sulphur coal. The integrated collaborative sulfur trioxide removal device comprises a boiler and a plurality of flues. The integrated collaborative sulfur trioxide removal device is characterized in that a coal economizer, an SCR (selective catalytic reduction) denitration reactor, an air pre-heater, a low-temperature coal economizer and a static dust remover are sequentially arranged in rear of the boiler; the boiler is connected with the coal economizer through the flue, the coal economizer is connected with the SCR denitration reactor through the flue, the SCR denitration reactor is connected with the air pre-heater through the flue, the air pre-heater is connected with the low-temperature coal economizer through the flue, and the low-temperature coal economizer is connected with the static dust remover through the flue; an alkaline absorbent spraying device is arranged in the flue between the SCR denitration reactor and the air pre-heater, and is connected with an alkaline absorbent storage device; a tail flue gas treatment device is arranged in rear of the static dust remover. The invention further relates to a working method of the device.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

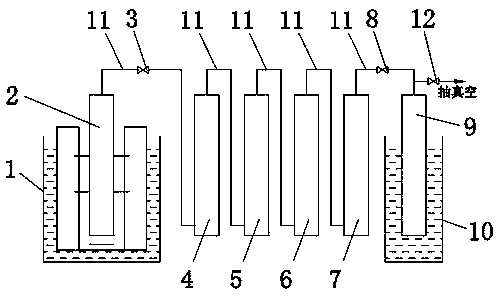

Device and method for deep removing water and carbon dioxide in nitrous oxide

ActiveCN104140085AAdd depthImprove adsorption speedNitrous oxide captureProductsChemical industryChemical reaction

The invention discloses a device and method for deep removing water and carbon dioxide in nitrous oxide, and belongs to the technical field of chemical industry production. The device comprises a raw material bottle, a collecting bottle and adsorbing devices. The adsorbing devices include the 13X molecular sieve adsorbing device, the 5A molecular sieve adsorbing device, the modified molecular sieve adsorbing device and the 3A molecular sieve adsorbing device, wherein the 13X molecular sieve adsorbing device, the 5A molecular sieve adsorbing device, the modified molecular sieve adsorbing device and the 3A molecular sieve adsorbing device are sequentially connected. The raw material bottle is heated by a heating device on the outer side of the raw material bottle, a first pressure reducing device is opened when the pressure of raw gas in the raw material bottle reaches 2.0 MPa to 4.0 MPa, and the raw gas sequentially enters the molecular sieve adsorbing devices. When the pressure of the gas in the adsorbing devices reaches 2.0 MPa to 4.0 MPa, a second pressure reducing device is opened, and the gas with impurities removed through the adsorbing devices is collected into the collecting bottle, wherein a refrigerating device is arranged on the outer side of the collecting bottle. By means of the method, the adsorbing depth and the adsorbing speed of adsorbents are increased through high-pressure adsorption, the physical adsorbing function and the chemical reaction function are achieved by conducting chemical modification on molecular sieves, the adsorbing performance of the adsorbents is improved, the water impurity and the carbon dioxide impurity in the nitrous oxide are deep removed, and a high-purity nitrous oxide product is obtained.

Owner:中昊光明化工研究设计院有限公司

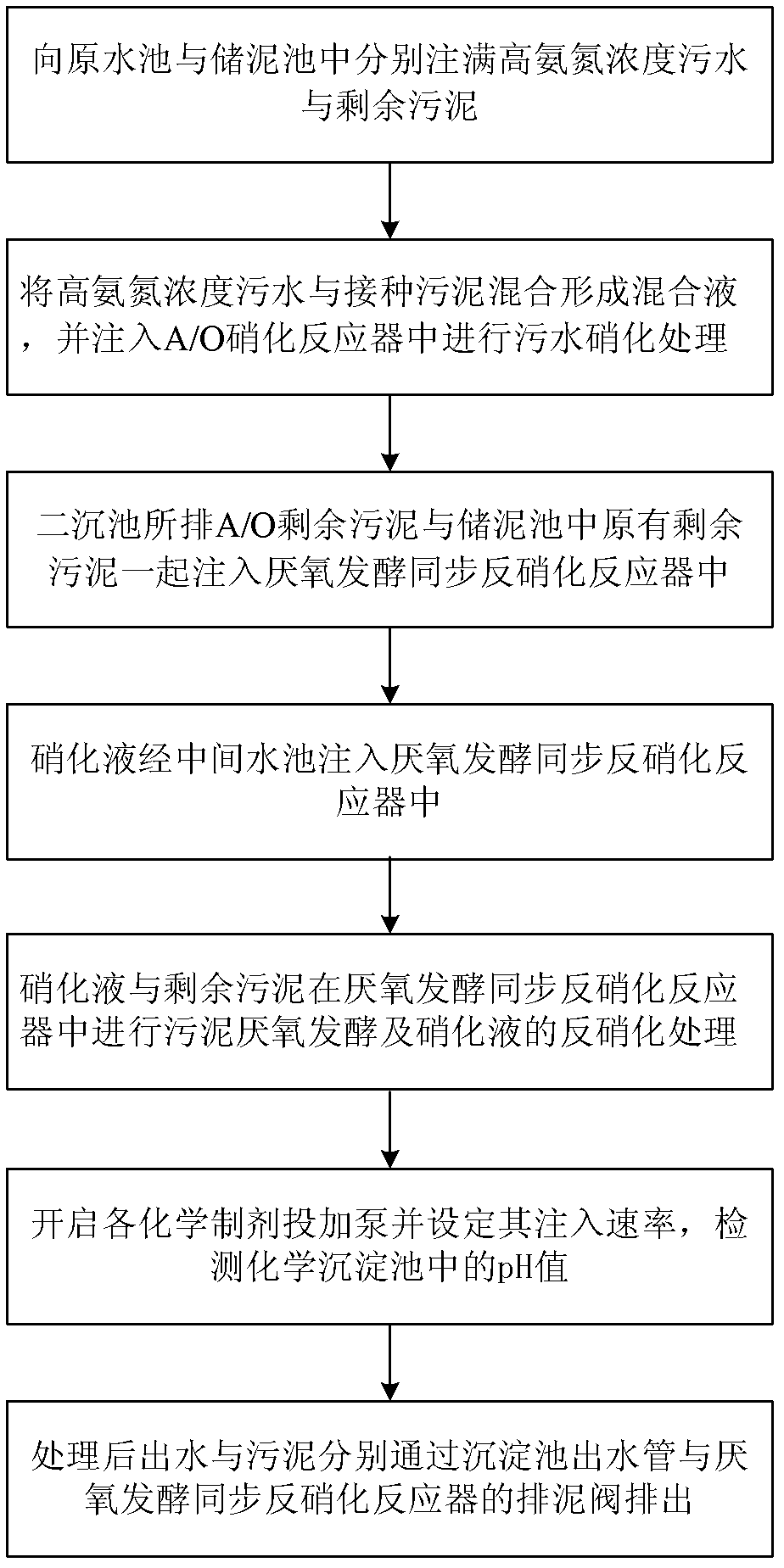

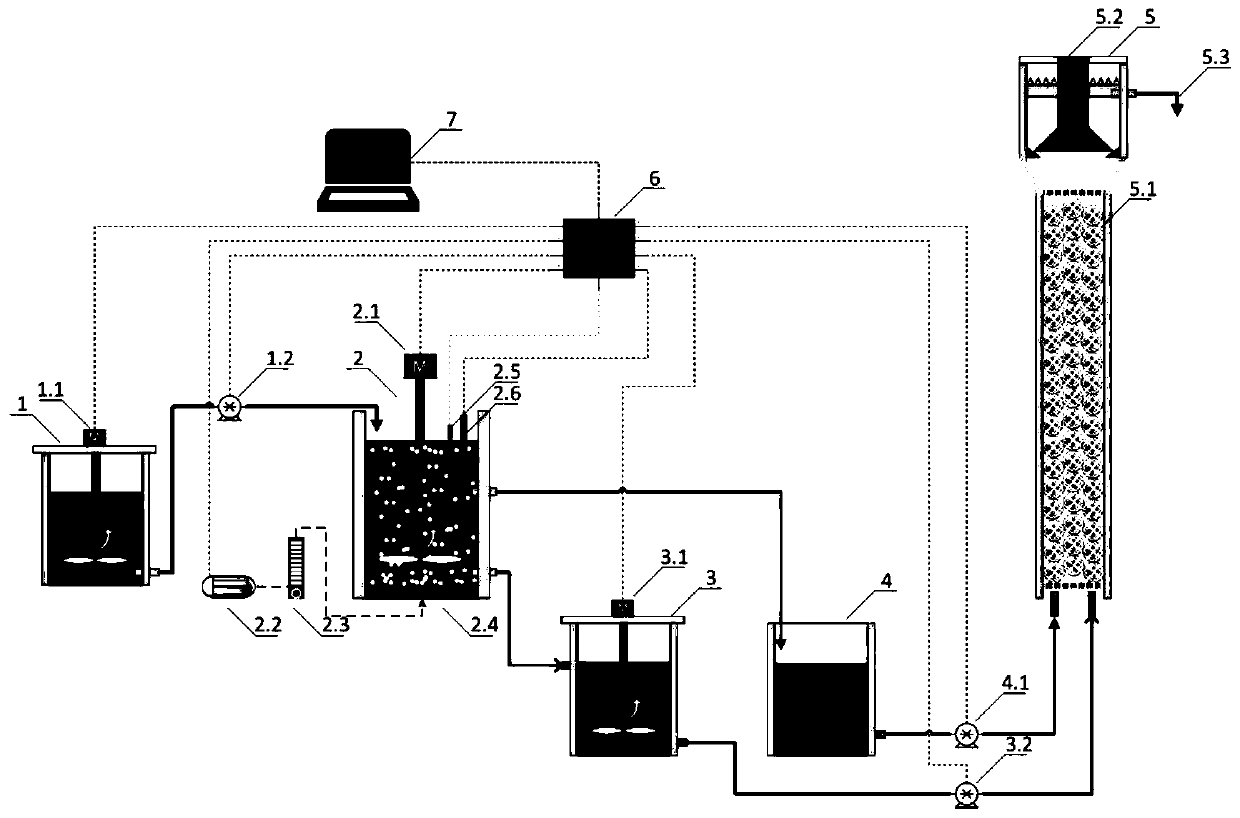

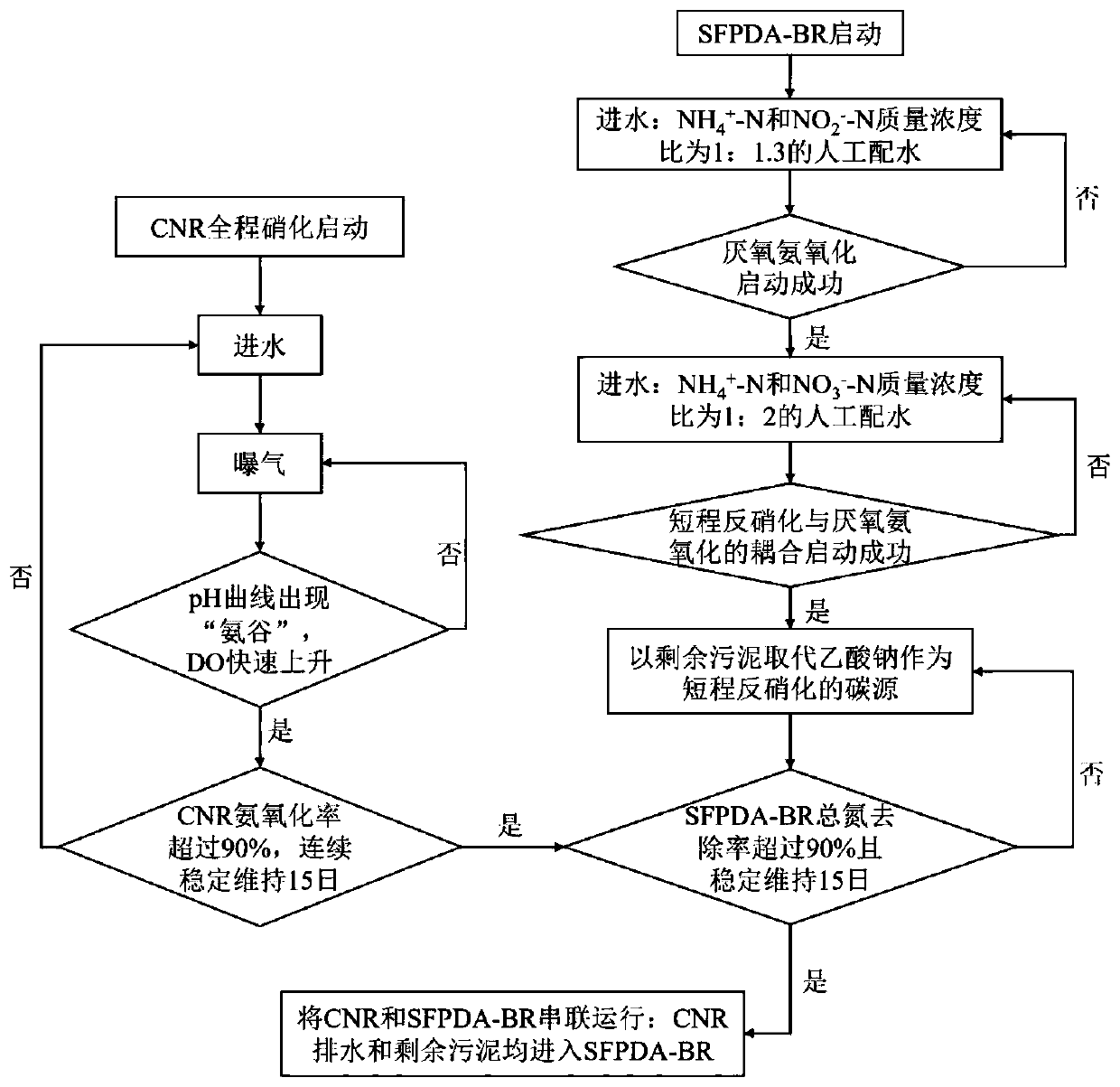

Method for treating high ammonia-nitrogen wastewater by complete nitrification-sludge fermentation coupling short-cut denitrification/anaerobic ammoxidation biofilm technology

ActiveCN110372095APromote growthAvoid churnWater treatment parameter controlSpecific water treatment objectivesAutomatic controlAutomated control system

The invention discloses a method for treating high ammonia-nitrogen wastewater by complete nitrification-sludge fermentation coupling short-cut denitrification / anaerobic ammoxidation biofilm technology, and belongs to the field of sewage sludge treatment. A device includes an original water tank, a complete nitrification reactor (CNR), an intermediate pool, a mud storage pool, a sludge fermentation coupling short-cut denitrification / anaerobic ammoxidation biofilm reactor (SFPDA-BR) and an automatic control system. The sludge fermentation coupling short-cut denitrification / anaerobic ammoxidation biofilm reactor is provided with a padding ball, a three-phase separator and other devices. The method includes the steps that the high ammonia-nitrogen wastewater with 200-400 mg / L concentration ofNH4<+>-N firstly enters the CNR from the original water tank for complete nitrification, the CNR drains the water to the intermediate pool, the CNR discharges mud to mud storage pool, the water of the intermediate pool and the mud of the mud storage pool are together fed into the SFPDA-BR, and sludge fermentation, short-cut denitrification and anaerobic ammoxidation denitrification are simultaneously conducted. The method is suitable for advanced treatment of the high ammonia-nitrogen wastewater, the denitrification process does not require an external carbon source, and finally, the aims ofcarbon source development, short-cut denitrification and anaerobic ammoxidation coupling in sludge are realized.

Owner:BEIJING UNIV OF TECH

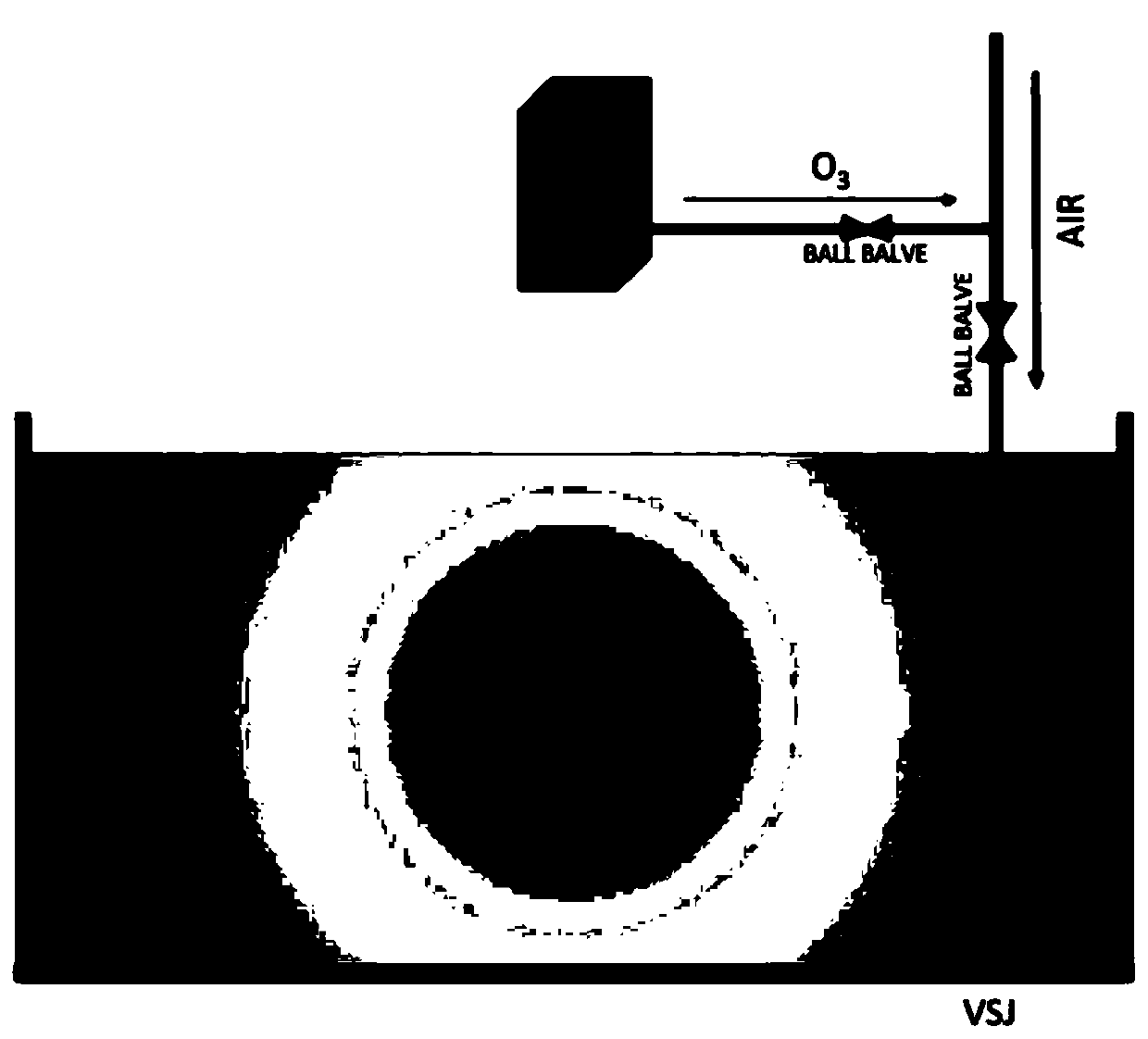

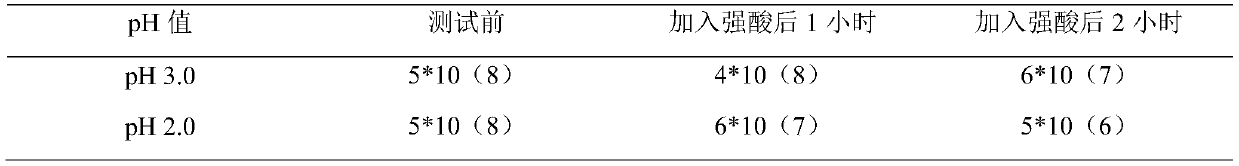

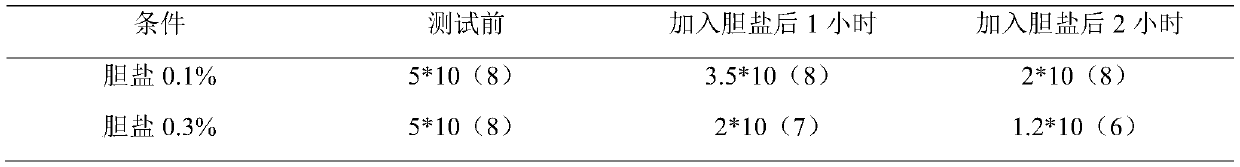

Mixed treatment process of feces and urine

InactiveCN110156276AIncrease dissolved oxygen concentrationImprove the ability to decompose organic matterTreatment using aerobic processesTreatment with aerobic and anaerobic processesMicro nanoFeces

The invention discloses a mixed treatment process of feces and urine, and belongs to the field of feces and urine treatment. The treatment process comprises the following steps: 1) introducing feces and urine into a biochemical treatment tank for aerobic biological treatment, periodically adding a microbial bacterial liquid to the biochemical treatment tank, and simultaneously performing micro-nano aeration treatment; 2) introducing the treated water body in the step 1) into a sedimentation tank for solid-liquid separation; and 3) introducing the obtained supernatant liquid after treatment inthe step 2) into a deep treatment tank, introducing a small amount of ozone to generate a large amount of hydroxyl radicals by using a micro-nano aeration apparatus in the deep treatment tank, performing high-efficiency oxidation, and simultaneously performing micro-nano aeration treatment on the water body. The microbial bacterial liquid added in the step 1) comprises lactobacillus QV1, lactobacillus QV1 is deposited in the General Microbiology Center of the China Microbial Culture Collection Management Committee, and the preservation number is CGMCC No.16350. The treatment process has high treatment efficiency, and the discharge can meet the standard after two weeks of treatment.

Owner:浙江亲水园生物科技有限公司

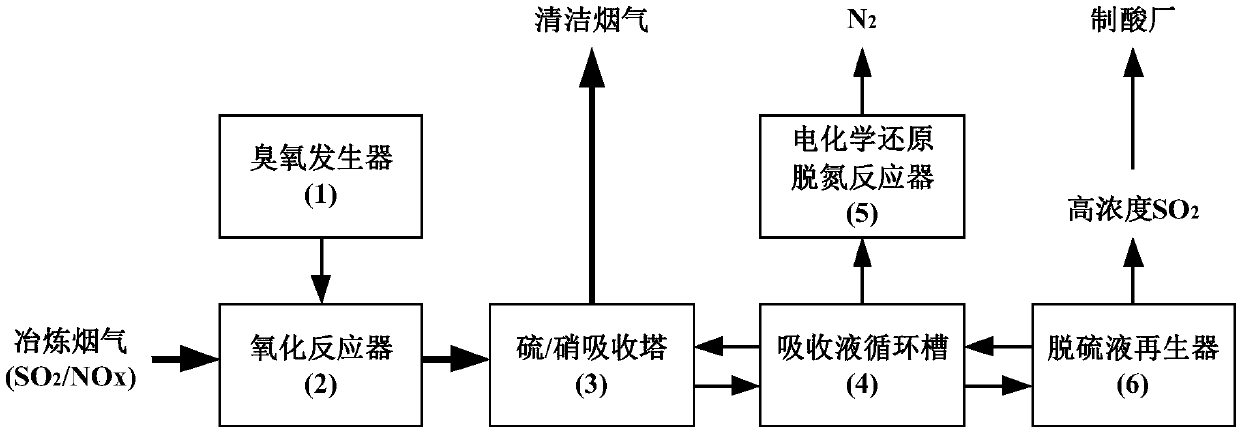

Method for carrying out cooperated desulfuration and denitration on non-ferrous smelting fume by using cycling sodium-alkali method

InactiveCN107737520ARealize coordinated emission reductionAchieve deep removalNitrous oxide captureProductsHigh concentrationSulfite salt

The invention relates to a method for carrying out cooperated desulfuration and denitration on non-ferrous smelting fume by using a cycling sodium-alkali method. The method comprises the steps of adding ozone into the fume to convert NO into NO2, then, carrying out synchronous absorption on NO2 and SO2 coexisting in the fume by using sodium sulfite, then, strengthening a reduced denitrification action on nitrite and nitrate in an absorption solution by dint of an electrochemical method, regenerating produced sodium bisulfite by using steam heating and nitrogen gas protection, and meanwhile, carrying out nitrogen gas extracting concentration so as to obtain recoverable high-concentration SO2, so as to finally achieve the deep denitration, SO2 removal and recovery resource-converting of thesmelting fume. Compared with the prior art, the method has the advantages that by the method, NOx and SO2 can be synchronously and deeply removed from the fume, low-concentration SO2 can be concentrated and enriched, thus, recycling is facilitated, and the cost of desulfuration and denitration of chemical absorption is remarkably reduced, so that the method has extensive application value. The method is applicable to the desulfuration and denitration treatment of non-ferrous metal smelting fume and the like.

Owner:SHANGHAI JIAO TONG UNIV

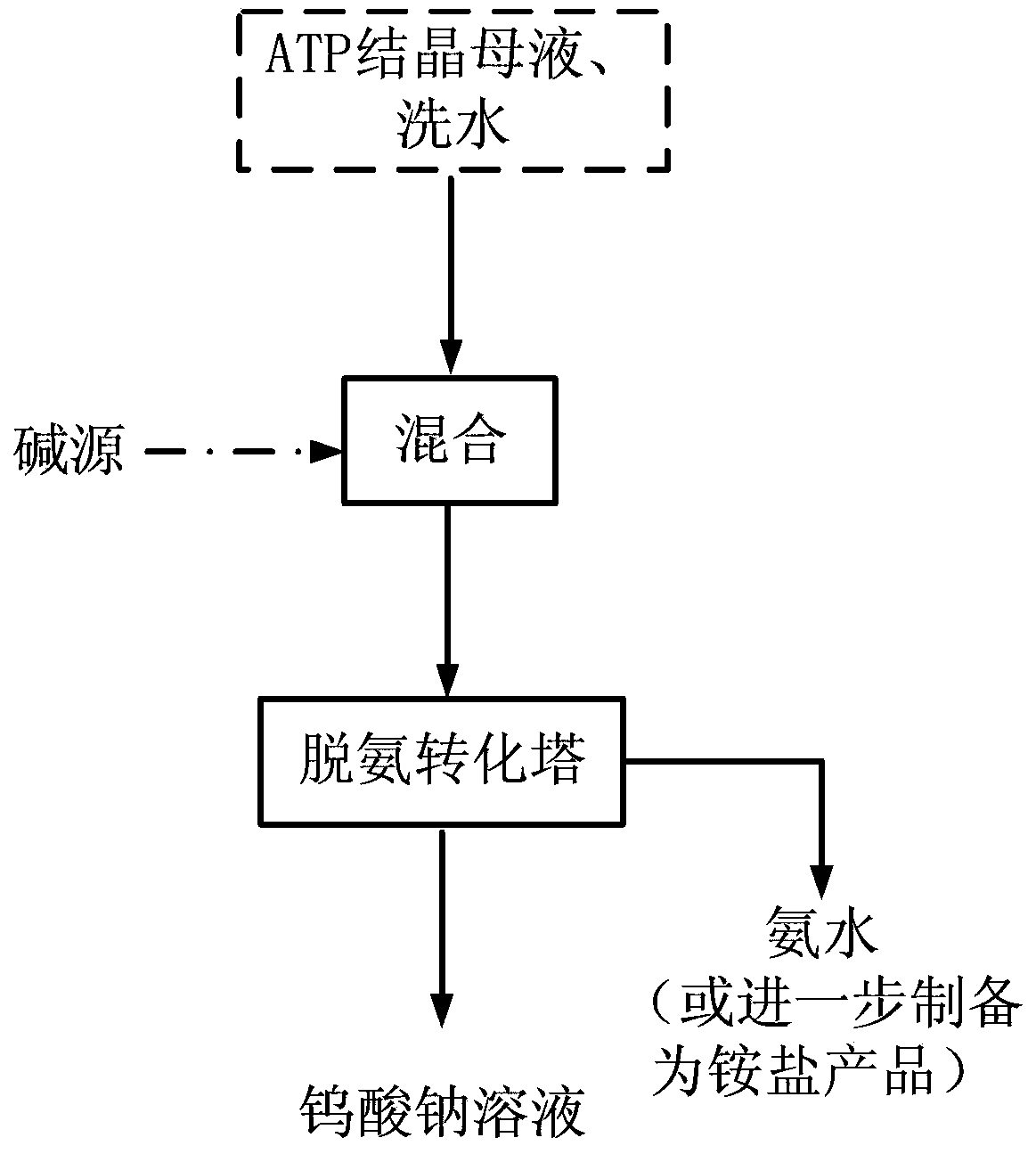

Process of resource comprehensive utilization of tungsten crystal-containing mother solution and washing water

ActiveCN103395841AReduce consumptionAchieve deep removalMultistage water/sewage treatmentTungsten compoundsAmmonium paratungstateTungstate

The invention relates to a process for preparing sodium tungstate and ammonia water and / or an ammonium salt product through resource comprehensive utilization of a tungsten-containing solution, and is applied to a tungsten crystal-containing mother solution and washing water which are produced in a course of preparation of ammonium paratungstate (APT), ammonium metatungstate (AMT) and other products by carrying out evaporation crystallization of an ammonium tungstate solution. The process comprises the following steps: mixing and adding an alkali; preheating; deaminizing and converting; after condensing at a tower top, recycling ammonia water and / or the ammonium salt product; and yielding water from a tower kettle to recycle a sodium tungstate solution as a raw material to be reused in a tungsten smelting system, or to be directly used in production of sodium tungstate or other products. The process can optimize a conventional process course, and has the advantages of simple method, energy saving, emission reduction, low recovery cost, good quality of the recovery product, and high utilization rate of resources.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

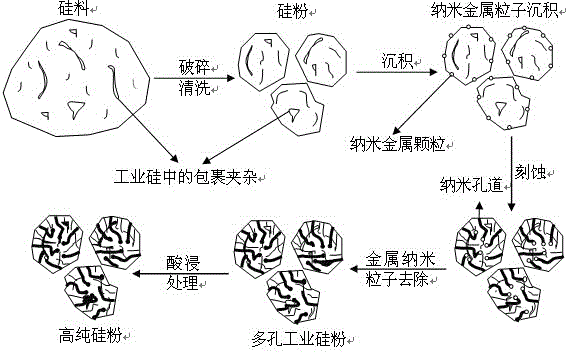

Method for wet impurity removal of industrial silicon

The invention discloses a method for wet impurity removal of industrial silicon, and belongs to the technical field of the preparation of highly pure silicon through wet purification. The method is provided to solve the practical problem of difficult advanced impurity removal due to wrapping of impurities in silicon in the wet purification process of the industrial silicon. The method is characterized in that a large amount of nanopores are drilled on the surface of a silicon material and in the silicon material through a metal nanoparticle assisted etching (MACE) technology in order to make the wrapped impurities fully exposed, and acid dipping treatment is combined to achieve the advanced removal of the impurities in the industrial silicon material. The method has the advantages of simple equipment requirements, easy operation, and suitableness for scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

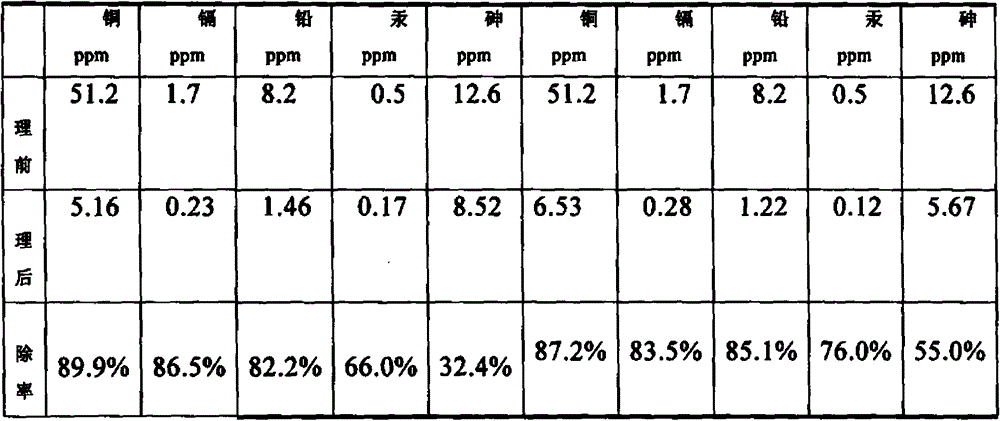

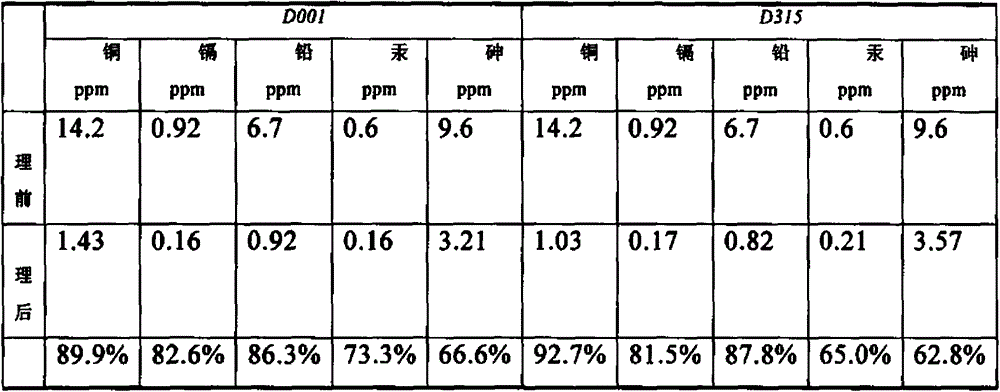

Application of molecular sieve adsorption material in removing of traditional Chinese medicine heavy metal

ActiveCN104474739AThere is no risk of secondary pollutionImprove adsorption capacityIon-exchange process apparatusIon-exchanger regenerationMolecular sieveTraditional medicine

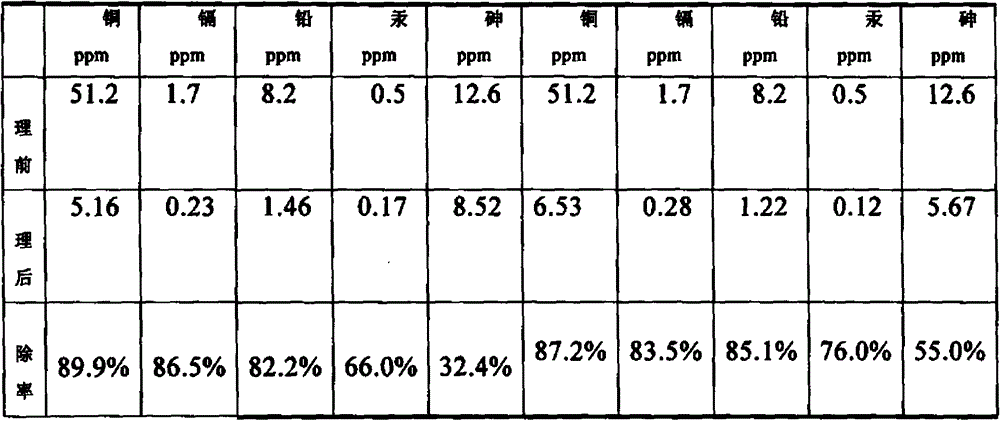

The invention relates to application of a molecular sieve adsorption material in removing of traditional Chinese medicine heavy metal. The application disclosed by the invention comprises the following steps of: (1) extracting Chinese herbal medicines, traditional Chinese medicine extracts or traditional Chinese medicine extractives through a solvent so as to obtain traditional Chinese medicine extracting solution by taking water as the solvent; (2) preparing a Ca-X molecular sieve adsorption material; and (3) suspending the Ca-X molecular sieve adsorption material in the traditional Chinese medicine extracting solution, or filling the Ca-X molecular sieve adsorption material to form an adsorption column, and enabling the traditional Chinese medicine extracting solution to flow through the adsorption column so as to remove heavy metal in the traditional Chinese medicine extracting solution. Compared with the prior art, the molecular sieve adsorption material disclosed by the invention can be used for removing harmful heavy metals always exceeding standards in traditional Chinese medicines, such as copper, cadmium, lead, mercury and arsenic; furthermore, the molecular sieve adsorption material is low in loss of effective components of traditional Chinese medicines; and the molecular sieve adsorption material has the advantages of being high selectivity of heavy metals, strong in removing capability, recyclable and the like.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

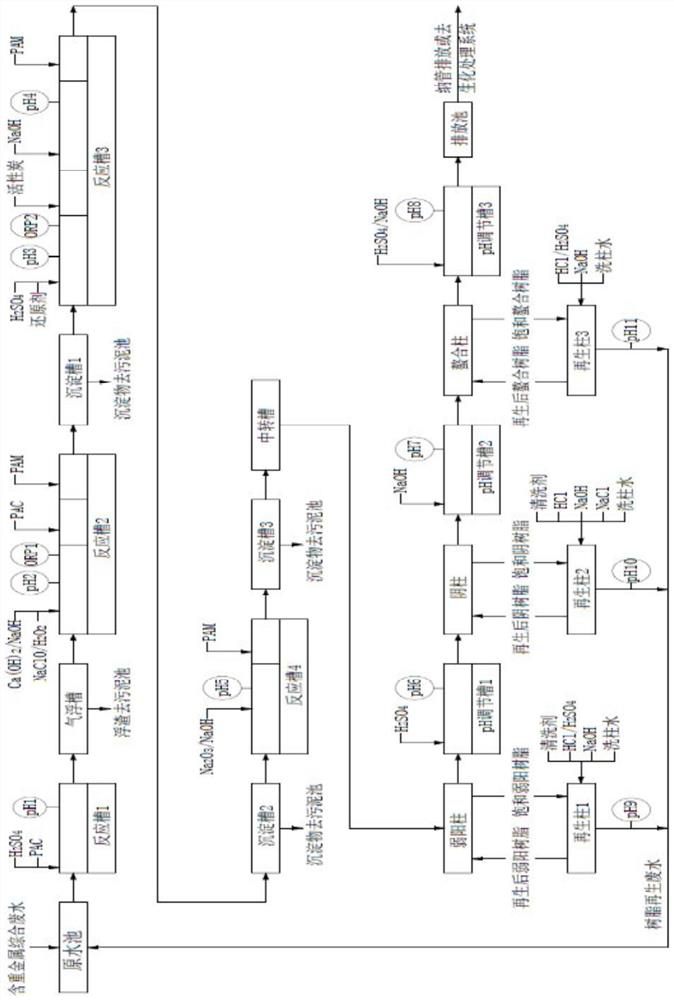

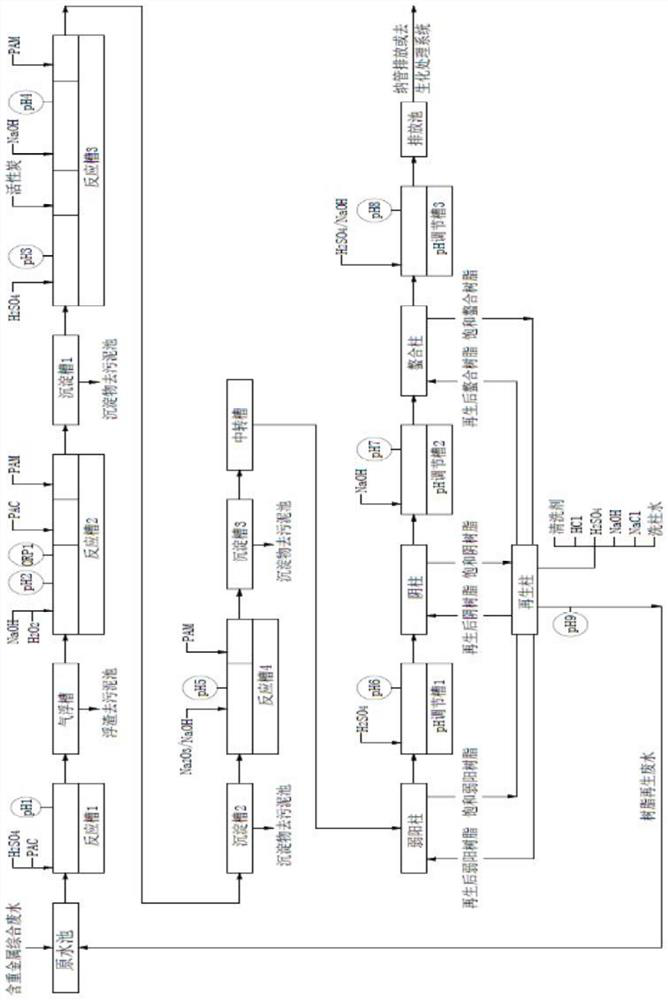

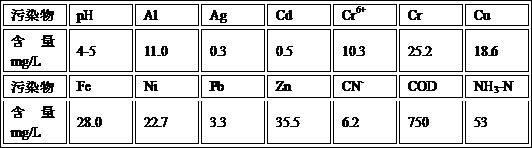

Deep treatment process for comprehensive wastewater containing heavy metals

PendingCN113754198AAchieve deep removalSolve the problem of pollution and poisoningWater treatment parameter controlFatty/oily/floating substances removal devicesIon exchangeEmission standard

The invention relates to an advanced treatment process for comprehensive wastewater containing heavy metals. A system is formed by combining ion exchange resins with different functional groups and is used for advanced treatment of wastewater containing various heavy metals and various organic pollutants, especially wastewater containing various heavy metal complexes, such as comprehensive wastewater in the production process of electroplating or surface treatment parks, PCB and integrated circuits, large-scale nonferrous metallurgy production enterprises and the like. The heavy metal content of the wastewater treated by the method disclosed by the invention can meet the requirements of the highest industrial emission standards, such as the standard of a table 3 of an electroplating pollutant emission standard (GB21900-2008), special emission limits of a copper, nickel and cobalt industrial pollutant emission standard (GB25467-2010) and the like.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

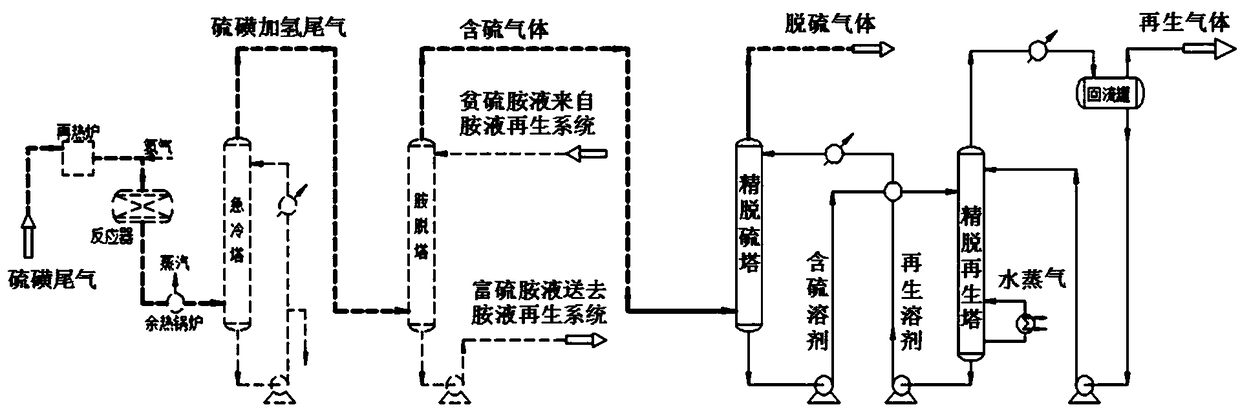

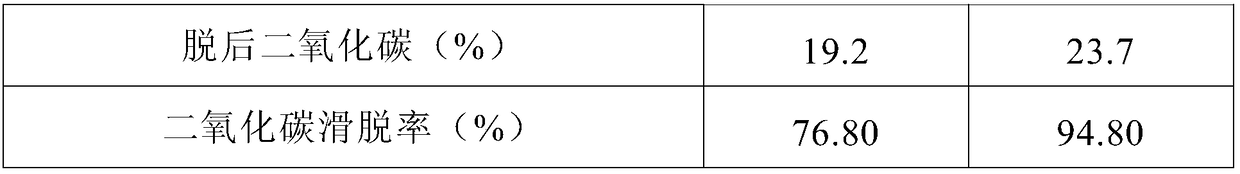

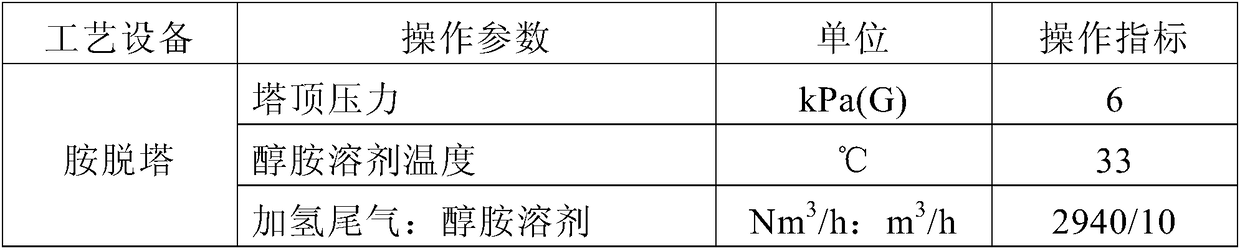

Compound desulfurizing agent and method for deeply desulfurizing sulfur-containing gas

ActiveCN108310915ALow costAchieving direct dischargeGas treatmentDispersed particle separationMorpholinePolyethylene glycol

The invention provides a compound desulfurizing agent and a method for deeply desulfurizing sulfur-containing gas. The compound desulfurizing agent comprises 2-40 parts by weight of sulfone or sulfoxide, 2-30 parts by weight of organic amine desulfurizing agent, 0-20 parts of C6-C12 aromatic hydrocarbons and 5-90 parts by weight of reinforcing agent. The reinforcing agent selects from at least oneof n-formyl morpholine, N-methyl pyrrolidone, polyethylene glycol, triethylene glycol, tetraethylene glycol and propylene carbonate. The compound desulfurizing agent provided by the invention can realize the simultaneous deep removal of hydrogen sulfide in the sulfur-containing gas and organic sulfur components; the method for deeply desulfurizing the sulfur-containing gas by adopting the compound desulfurizing agent also has the advantages of being low in equipment renovation cost and low in running energy consumption.

Owner:HEBEI REFINING TECH CO LTD +2

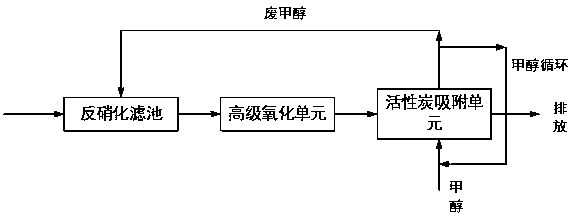

Treatment system and treatment process for deeply removing total nitrogen and organic matters in coking-wastewater biochemical yielding water

InactiveCN107601766AAchieve deep removalReduce CODWater contaminantsMultistage water/sewage treatmentWater qualityTotal nitrogen

The invention discloses a treatment system and a treatment process for deeply removing total nitrogen and organic matters in coking-wastewater biochemical yielding water. The system comprises a denitrification filter tank and an advanced oxidation unit, wherein the denitrification filter tank is connected with the advanced oxidation unit; the rear end of the advanced oxidation unit is provided with an activated carbon adsorption unit; the activated carbon adsorption unit is connected with the denitrification filter tank. The coking-wastewater biochemical yielding water firstly enters to the denitrification filter tank to convert nitric nitrogen into nitrogen gas, and enters to the advanced oxidation unit to degrade the organic matters after the total nitrogen is decreased; afterwards, theyielding water enters to the activated carbon adsorption unit to deeply remove the organic matters; thus, the up-to-standard discharge of wastewater is achieved; the treatment system and the treatmentprocess can be used for realizing the deep removal of the total nitrogen and the organic matters in the coking-wastewater biochemical yielding water, and can be used for effectively guaranteeing theup-to-standard discharge of the yielding water when the water quality and a water amount fluctuate; the impact resistance of the system is improved; moreover, while activated carbon adsorption and methanol solvent regeneration, part of the organic matters, which are biodegradable after advanced oxidation, and waste methanol can be used as denitrification carbon sources; a carbon source does not need to be additionally added; the repeated utilization of the waste methanol and the activated carbon adsorbed organic matters is realized, and the running cost is decreased.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

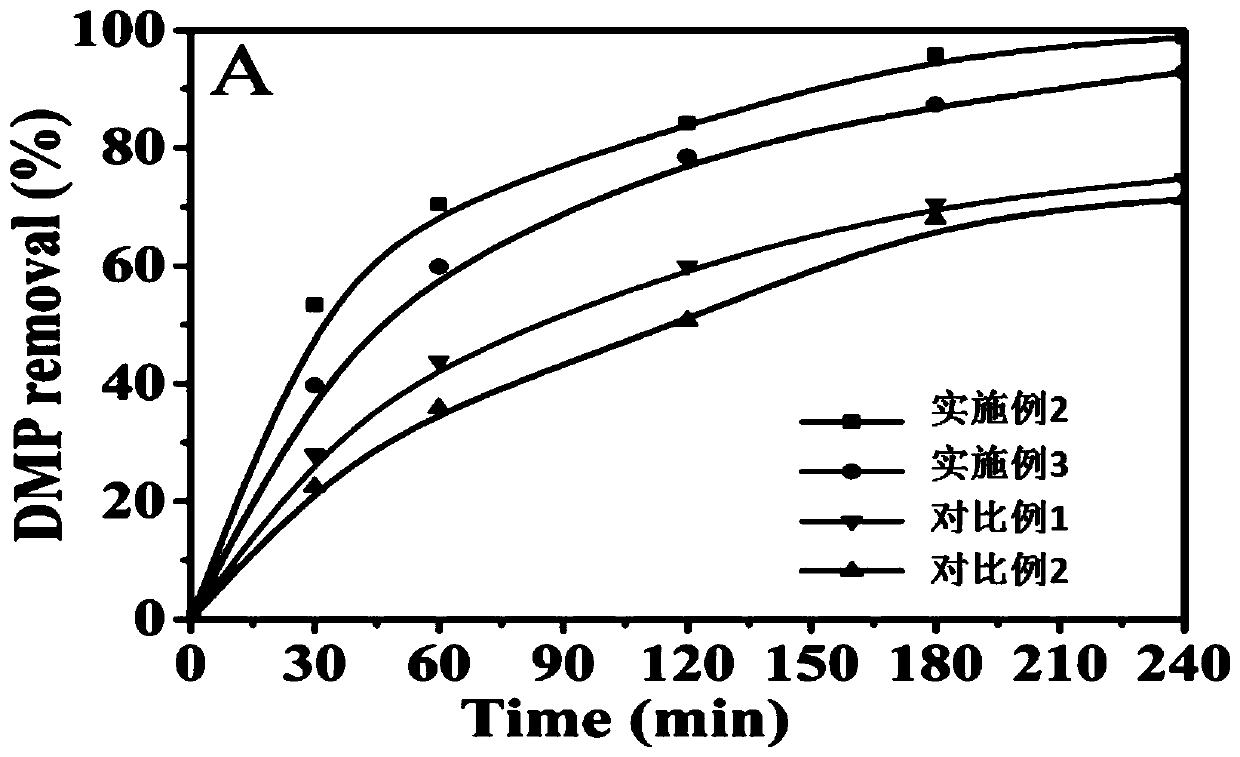

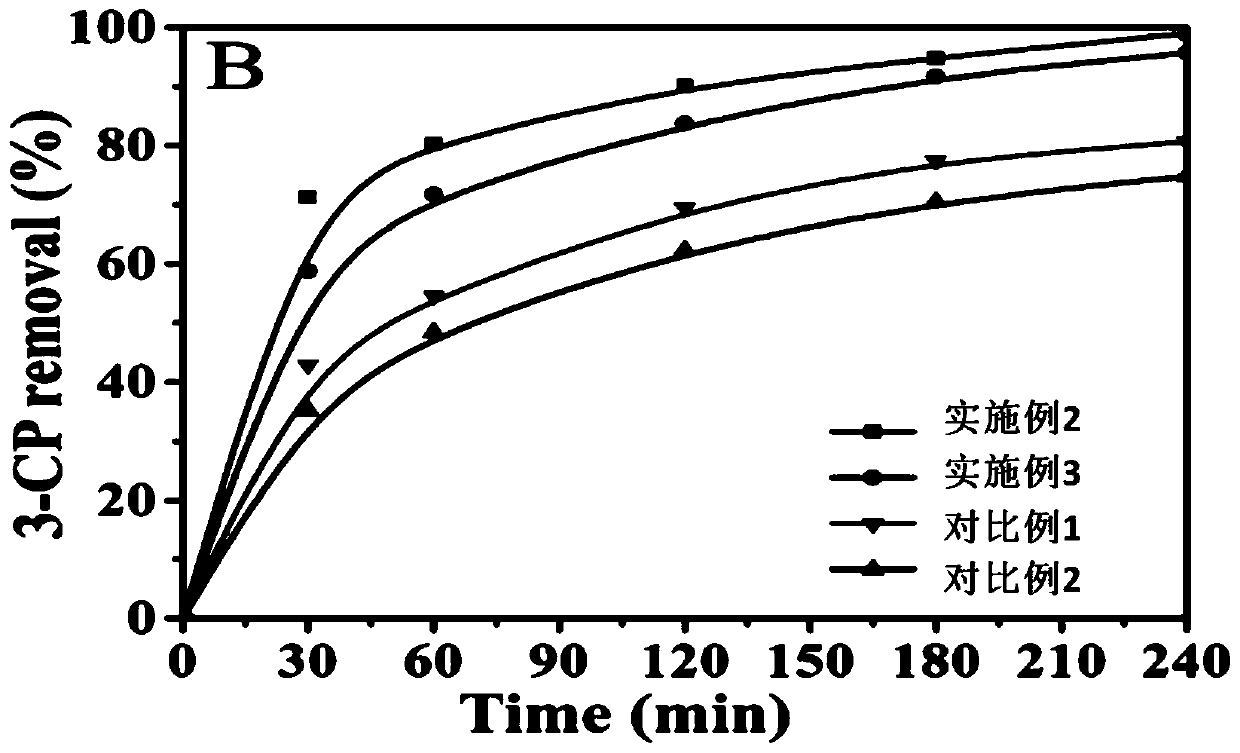

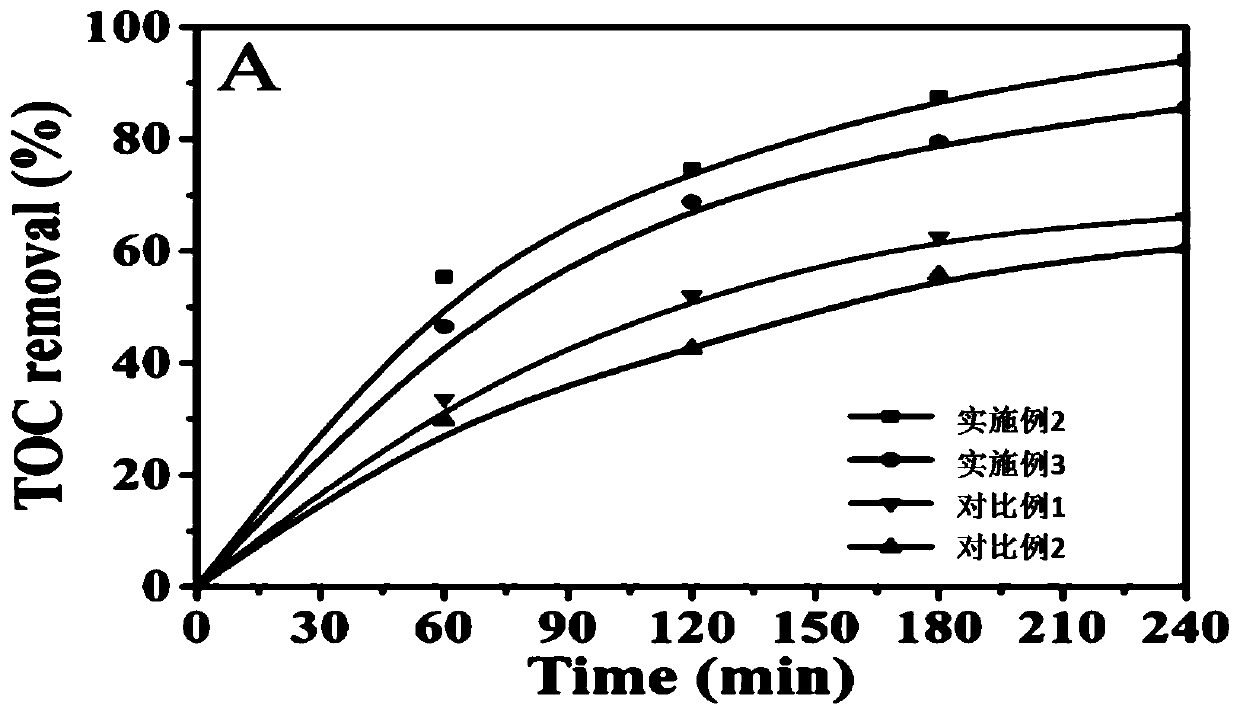

Carbon aerogel for improving divalent Fe reducibility and hydrogen peroxide yield in electrode as well as preparation method and application thereof

ActiveCN111320241AHigh specific surface areaGood electrocatalytic activityWater treatment compoundsAerogel preparationPollutantDoped carbon

The invention relates to a carbon aerogel for improving divalent Fe reducibility and hydrogen peroxide yield in an electrode as well as a preparation method and an application thereof. A metal oxide and a metal sulfide grow in a carbon material skeleton in situ; according to the invention, a novel Fe3O4 / FeSx co-doped carbon aerogel material is provided as an efficient cathode electrode of a heterogeneous electro-Fenton system; the cathode has a high specific surface area, good electrocatalytic activity and 2-electron selectivity, the aerogel can be used for deep degradation of pollutants afterbeing activated, feasibility is provided for efficient mineralization and degradation of DMP and 3-CP under acidic conditions, and the aerogel has a very wide application prospect in actual sewage treatment. Compared with the prior art, the method has the advantages that the pollutant removal rate is high, the iron-sulfur leaching rate is low, and the effective degradation efficiency is still kept after multiple times of repetition.

Owner:TONGJI UNIV

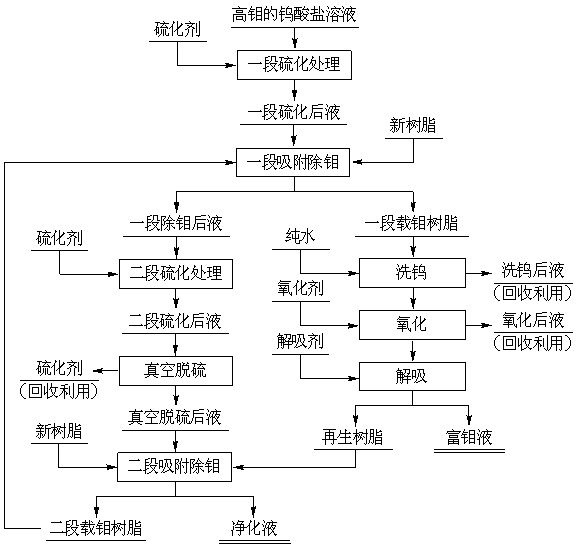

Process for removing molybdenum from tungstate solution through ion exchange method

ActiveCN108642309ARealize deep purificationAchieve deep removalProcess efficiency improvementMolybdateTungstate

The invention discloses a process for removing molybdenum from a tungstate solution through an ion exchange method. According to the process, deep purification of high content of molybdenum is achieved with adoption of a two-section sulfuration-resin adsorption molybdenum removal method. Through first-section sulfidizing, most molybdenum in the solution is converted into dithio-molybdate and trithio-molybdate under the condition of low quantity of sulfurizing agent, and most molybdenum is adsorbed to resin in a first-section adsorption molybdenum removal mode; through second-section deep sulfidizing, the small amount of molybdenum left in the solution is converted into tetrathiomolybdate having higher affinity with strong base anion exchange resin under the condition of excessively-high quantity of the sulfurizing agent, and then the redundant sulfurizing agent is removed from the sulfurized solution and recovered in a vacuum volatilization mode; and the solution is subjected to second-section adsorption molybdenum removal after vacuum sulfurizing, so that a purified solution is obtained, and deep removal of molybdenum is achieved.

Owner:JIANGXI UNIV OF SCI & TECH

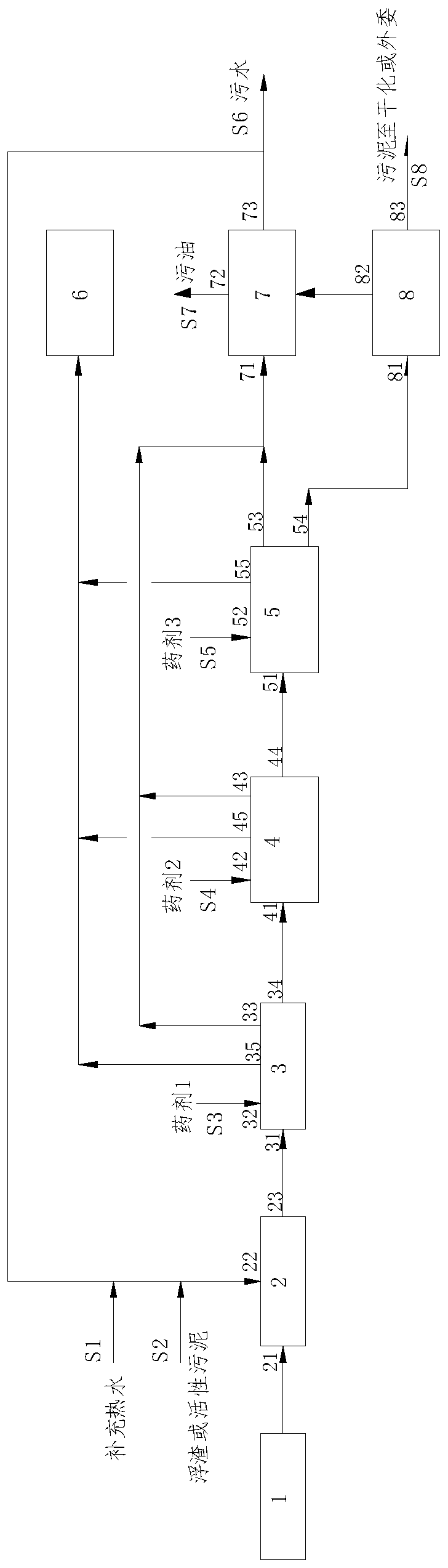

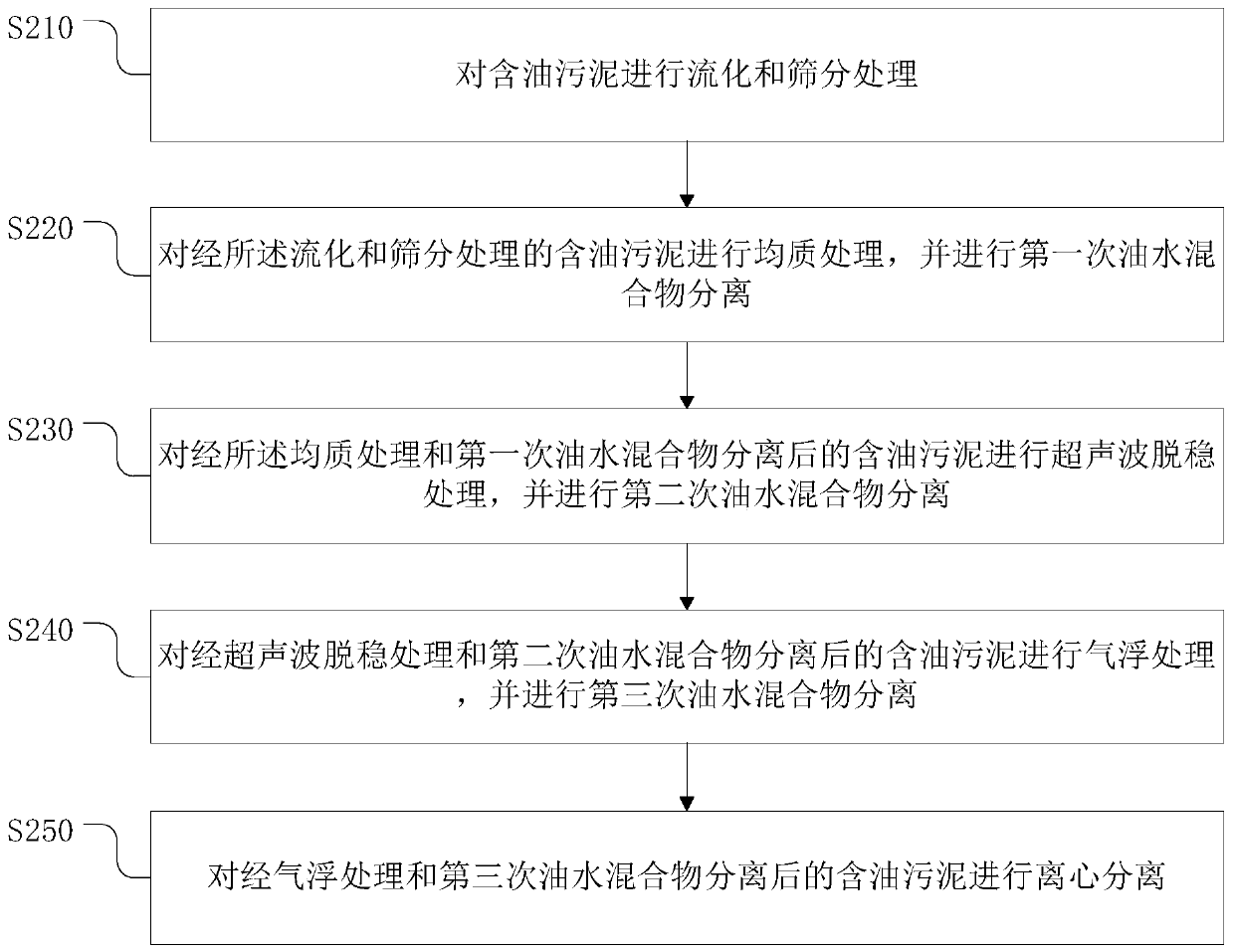

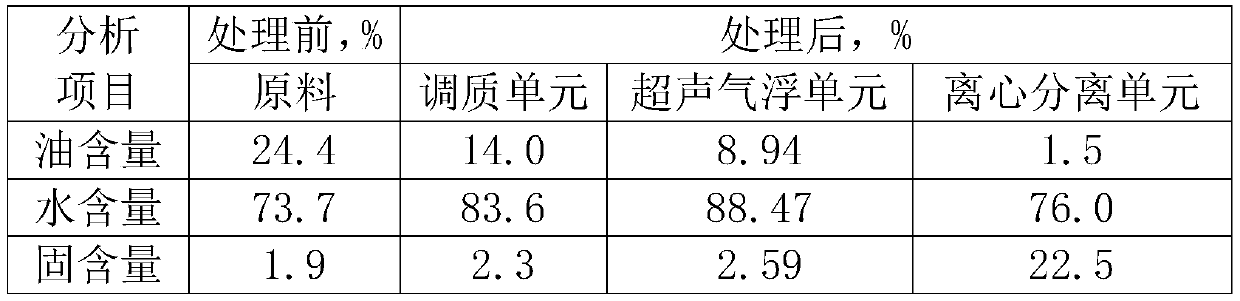

Oil-containing sludge deoiling and dewatering apparatus and oil-containing sludge deoiling and dewatering method

InactiveCN110436732AAchieve deep removalReduce oil contentSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisJet flowSludge

The present invention provides an oil-containing sludge deoiling and dewatering apparatus and an oil-containing sludge deoiling and dewatering method. The apparatus comprises: an ultrasonic wave destabilization tank, wherein the ultrasonic wave destabilization tank comprises a first material inlet, at least a jetting input end, a first separation material outlet and a second separation material outlet, and the first separation material outlet has a first forking branch and a second forking branch; an ultrasonic wave transmitting device arranged on the ultrasonic wave destabilization tank; a jetting stirring device, wherein the jetting stirring device comprises a first input end and at least a jet flow spraying nozzle, the first input end is connected to the first forking branch, and the jet flow spraying nozzle is connected to the jetting input end of the ultrasonic wave destabilization tank; an air flotation deoiling tank, wherein the air flotation deoiling tank comprises a second material inlet, a third separation material outlet and a fourth separation material outlet; and an air flotation generating device arranged in the air flotation deoiling tank. According to the present invention, the oil-containing sludge deoiling and dewatering apparatus has characteristics of treatment effect improving, high efficiency and cost reducing, and is convenient for popularization and use.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD +1

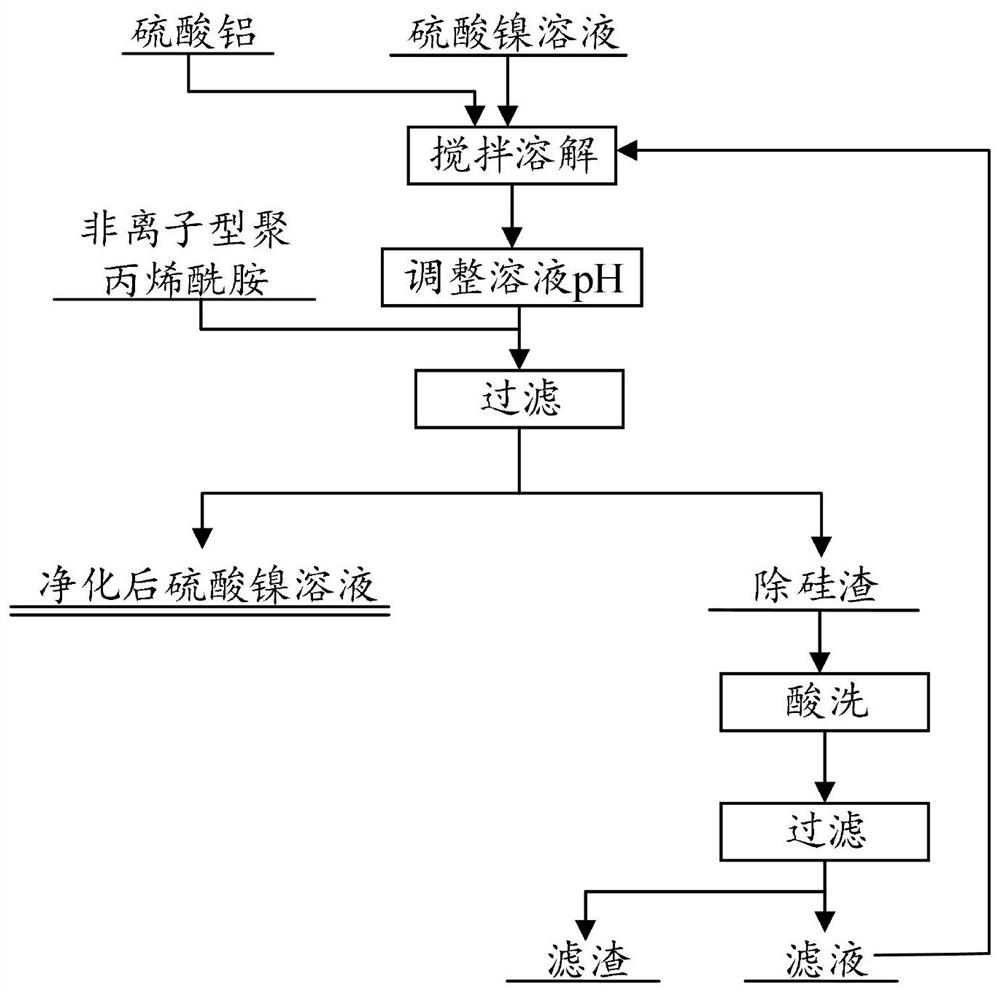

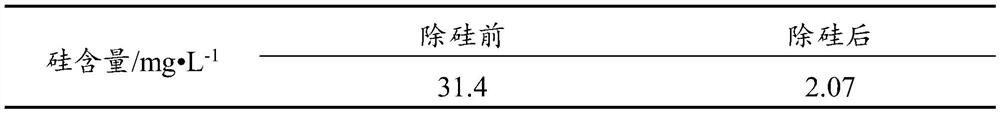

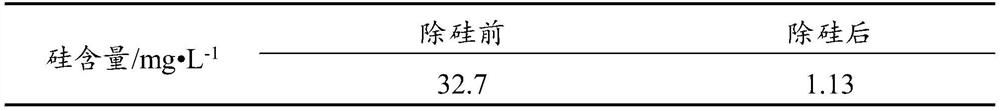

Method for removing trace silicon in high-concentration nickel sulfate solution

The invention discloses a method for deeply removing trace silicon in a high-concentration nickel sulfate solution, which adopts aluminum sulfate as a precipitator and non-ionic polyacrylamide (NAPM) as a flocculant to construct an Al2 (SO4) 3-NAPM composite system to realize deep removal of trace silicon, and the silicon content in the obtained nickel sulfate purified solution can be reduced to below 1mg / L, leached filtrate obtained after acid pickling of the silicon removal slag can be returned for silicon removal, and recycling of the silicon removal agent aluminum salt is achieved. The method is excellent in silicon removal effect and low in nickel loss, the adopted silicon removal agent is low in price and easy to obtain, operation is easy, and industrialization is easy to achieve.

Owner:CENT SOUTH UNIV

Application of a molecular sieve adsorption material in the removal of heavy metals in traditional Chinese medicine

ActiveCN104474739BThere is no risk of secondary pollutionImprove adsorption capacityIon-exchange process apparatusIon-exchanger regenerationMolecular sievePhysical chemistry

The invention relates to application of a molecular sieve adsorption material in removing of traditional Chinese medicine heavy metal. The application disclosed by the invention comprises the following steps of: (1) extracting Chinese herbal medicines, traditional Chinese medicine extracts or traditional Chinese medicine extractives through a solvent so as to obtain traditional Chinese medicine extracting solution by taking water as the solvent; (2) preparing a Ca-X molecular sieve adsorption material; and (3) suspending the Ca-X molecular sieve adsorption material in the traditional Chinese medicine extracting solution, or filling the Ca-X molecular sieve adsorption material to form an adsorption column, and enabling the traditional Chinese medicine extracting solution to flow through the adsorption column so as to remove heavy metal in the traditional Chinese medicine extracting solution. Compared with the prior art, the molecular sieve adsorption material disclosed by the invention can be used for removing harmful heavy metals always exceeding standards in traditional Chinese medicines, such as copper, cadmium, lead, mercury and arsenic; furthermore, the molecular sieve adsorption material is low in loss of effective components of traditional Chinese medicines; and the molecular sieve adsorption material has the advantages of being high selectivity of heavy metals, strong in removing capability, recyclable and the like.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

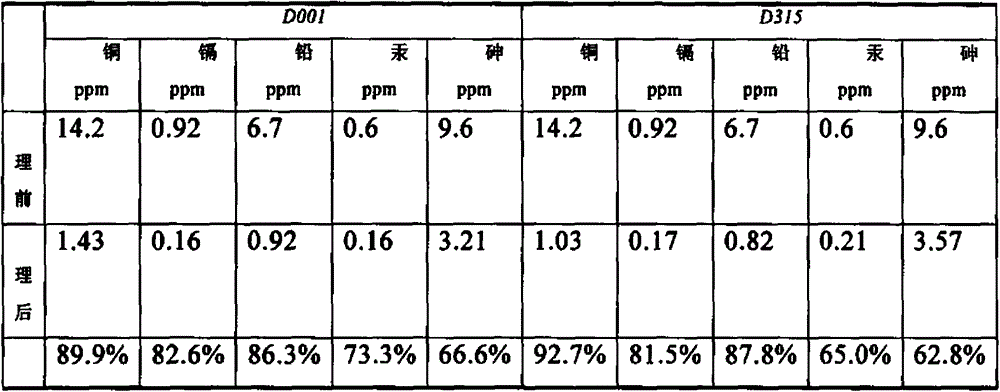

Treatment method for extracting gold from high-impurity silver anode slime

ActiveCN106756047AEasy to purify and refineHigh removal rate of impuritiesProcess efficiency improvementBase metalAnode

The invention discloses a treatment method for extracting gold from high-impurity silver anode slime. The treatment method mainly comprises the following steps: high-impurity silver anode slime is washed to remove soluble compounds; then base metals are removed through acid digestion; and after that, alkaline oxidation leaching, gold dissolution, reduction and washing are performed to obtain 99.99% gold dust. The treatment method is high in impurity removal rate, can comprehensively recover valuable metals and is reliable in process.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for simultaneously and selectively removing nitrate and phosphate from secondary biochemical effluent

InactiveCN102390879BAchieve deep removalWater/sewage treatment by ion-exchangeWater/sewage treatment by sorptionSolubilityPhosphate

The invention discloses a method for simultaneously and selectively removing nitrate and phosphate from secondary biochemical effluent, and belongs to the technical field of water pollution deep treatment. The method comprises the steps of: processing a mixed solution simultaneously containing nitrate, phosphate and other soluble coexisting anions by a double-layer fixed bed adsorption column containing polyvinyl pyridine transition metal complex and strong-basicity anion exchange resin, wherein polyvinyl pyridine transition metal complex is located at the upper part of the adsorption column and the strong-basicity anion exchange resin is located at the lower part of the adsorption column; and desorbing the adsorption column with nitrate and phosphate by using sodium chloride solution, wherein the adsorption column subjected to desorption can be recycled. Through treatment according to the method, NO3<->-N content at the outlet of the adsorption column is reduced to less than 5 mg / L and PO4<3->-P content is reduced to less than 0.5 mg / L; and by the method, synchronous deep removal of low-concentration nitrate and phosphate from secondary effluent of a wastewater treatment plant can be achieved.

Owner:NANJING UNIV

Compound adsorbing material for heavy metal wastewater treatment and preparation method thereof

InactiveCN106732345AImprove adsorption capacityStrong reductionOther chemical processesAluminium silicatesReaction rateSodium salt

The invention discloses a compound adsorbing material for heavy metal wastewater treatment and a preparation method thereof. The compound adsorbing material for the heavy metal wastewater treatment is formed by the following raw materials by weight: 20-30 parts of kaolin, 15-25 parts of shell powder, 10-20 parts of zeolite powder, 20-40 parts of mesoporous molecular sieve, 40-60 parts of edetic acid metallic sodium salt, 70-80 parts of copper chloride, and 30-50 parts of magnesium chloride. The compound adsorbing material for the heavy metal wastewater treatment is prepared through the combined action of the kaolin, the shell powder, the zeolite powder and the porous structure prepared by the mesoporous molecular sieve. The prepared adsorbing material has strong adsorption capacity and reducing capacity, and has the advantages of high removal rate and rapid reaction rate. Multiple heavy metal ions, such as lead ion, cadmium ion and chromium ion, are efficiently removed from the water body, and the zinc ions and the magnesium ions are loaded on the adsorbing material for synergistic effect. The capacity for reducing the heavy metal is stronger, and the deep removal can be realized.

Owner:HENAN SHUIJINGTOU CULTURAL MEDIA CO LTD

Advanced treatment method of sewage

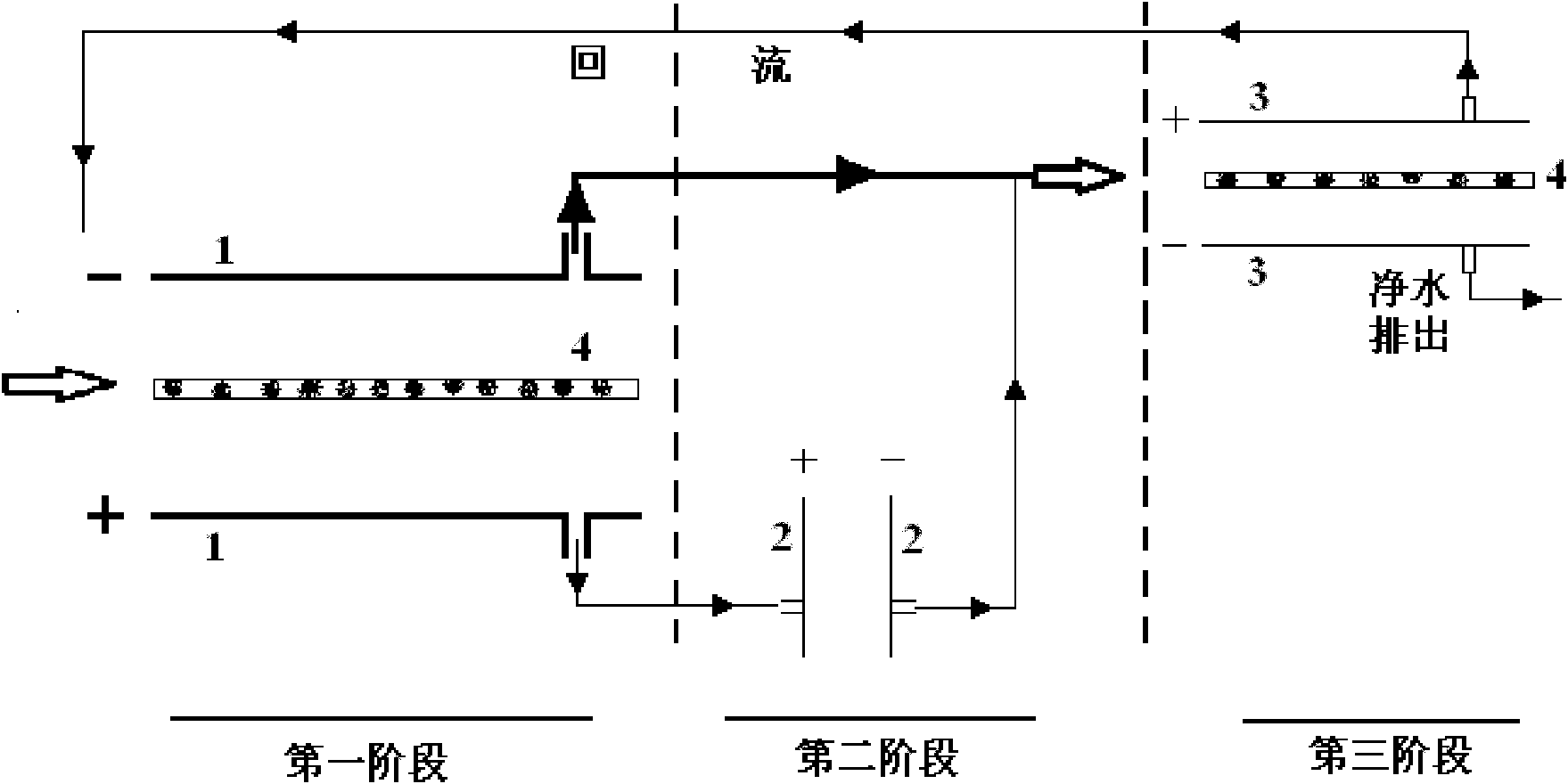

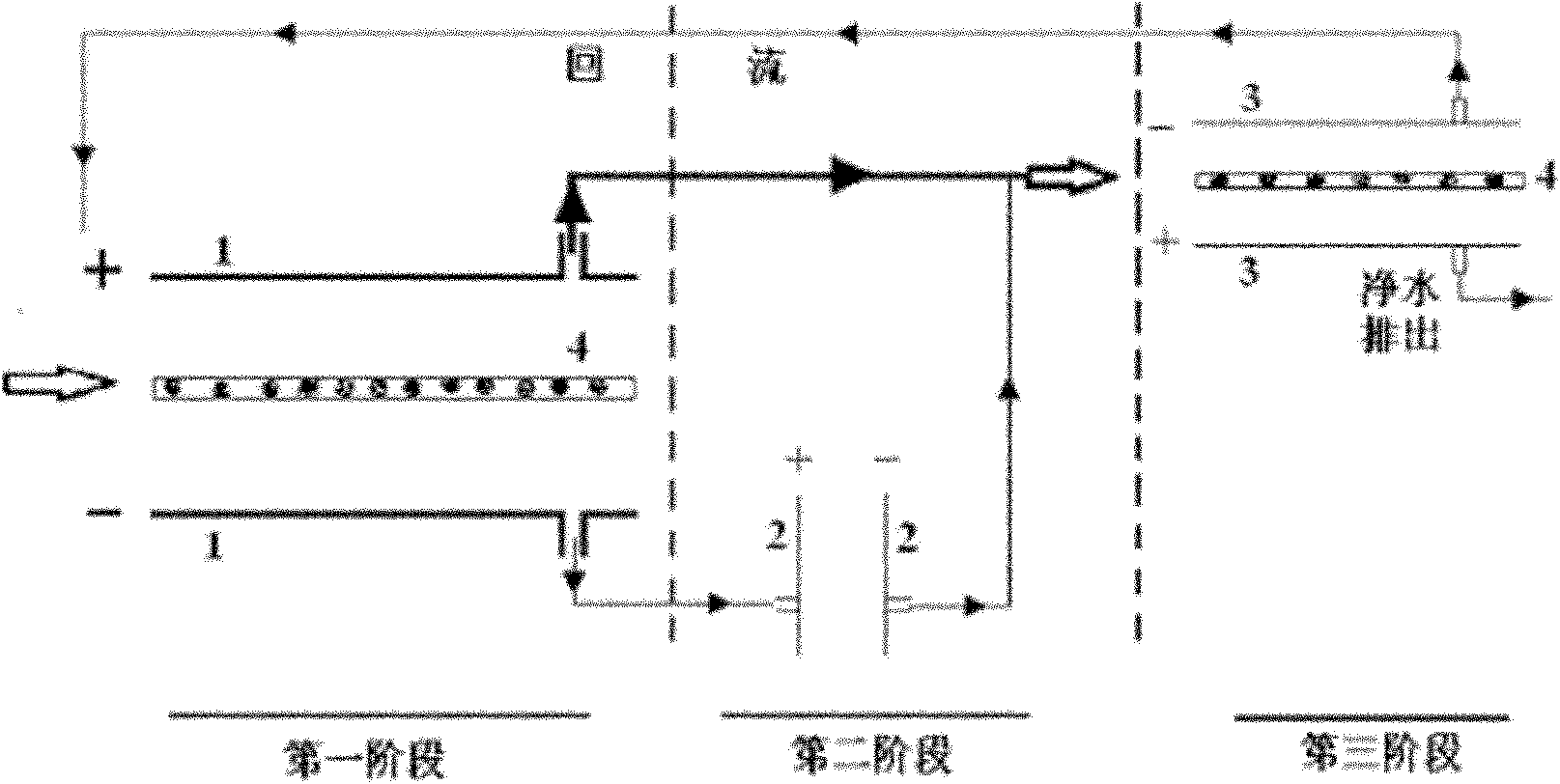

ActiveCN102010091ARich varietyAchieve deep removalWater/sewage treatmentMultistage water/sewage treatmentChemical industryLow voltage

The invention relates to an advanced treatment method of sewage. In the method, various pollutants in the water to be treated are removed in an advanced manner through low-voltage electrochemical separation process and higher-voltage electrochemical degradation process, and meanwhile, the method can farthest save the economic cost generally by over 20%. The method has the characteristics of strong industrial applicability, high treatment capability, obvious purification effect, high electrochemical efficiency, capability of ensuring the treated common urban domestic sewage to achieve class 2 water quality specified by the nation, capability of ensuring the treated chemical industrial sewage to achieve class 3 water quality specified by the nation, low materials consumption, recyclability, long service period, no secondary pollution and the like, and is convenient in process operation.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com