Sustained release vulcanizing agent, preparation method thereof, and method of using sustained release vulcanizing agent to remove heavy metals and arsenic from acidic solution

An acid solution, vulcanizing agent technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, special compound water treatment, etc., can solve the problems of high harm, high cost, low efficiency, etc. Harm, improve utilization, reduce the effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

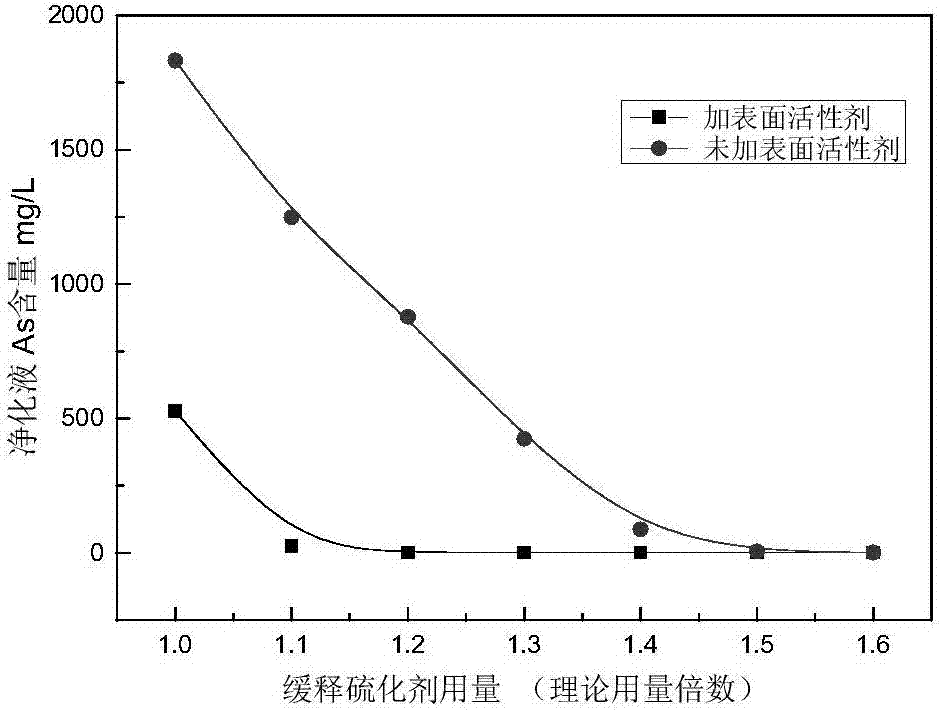

[0049] Using this process to treat the sewage acid of a smelter in Chenzhou, the As content of the sewage acid is as high as 17-20g / L, and the Zn content is as high as about 10g / L. Separately configure Fe with a certain ion concentration 2+ , Mn 2+ , Zn 2+ 1mol / L solution respectively, mix evenly according to the molar ratio of 5:1:1, add vulcanizing agent (sodium sulfide) to the mixed solution at a certain temperature (50°C), and add surfactant butyl xanthate Sodium (C 4 h 6 OCSSNa) and sodium dodecylsulfonate at a molar ratio of 1:1, while stirring at a high speed for 20-30 minutes, and filtering to obtain the desired slow-release vulcanizing agent. Add the slow-release vulcanizing agent into the acidic solution, the amount of the added slow-release vulcanizing agent is 1.2 times of the theoretical amount, stir and react for 0.5h, the reaction temperature is 55°C, after the reaction is completed, add flocculant to settle quickly, and filter and separate, It is high-arse...

Embodiment 2

[0055] Using this process to treat the high-arsenic zinc leach solution of a Chenzhou smelter, the As content of the polluted acid is as high as 22.1g / L, and the Zn content is as high as about 128g / L. Separately configure Fe with a certain ion concentration 2+ , Mn 2+ , Zn 2+ 1mol / L solution respectively, mix evenly according to the molar ratio of 5:1:1, add vulcanizing agent (sodium hydrosulfide) to the mixed solution at a certain temperature (50°C), and add surfactant butyl xanthogen A mixture of sodium dodecyl sulfate sodium (C4H6OCSSNa) and sodium dodecylsulfonate with a molar ratio of 1:1, while stirring at high speed for 20-30 minutes, and filtering to obtain the required slow-release vulcanizing agent. Add the slow-release vulcanizing agent into the acidic solution, the amount of the added slow-release vulcanizing agent is 1.2 times of the theoretical amount, stir and react for 0.5h, the reaction temperature is 60°C, after the reaction is completed, add flocculant to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com