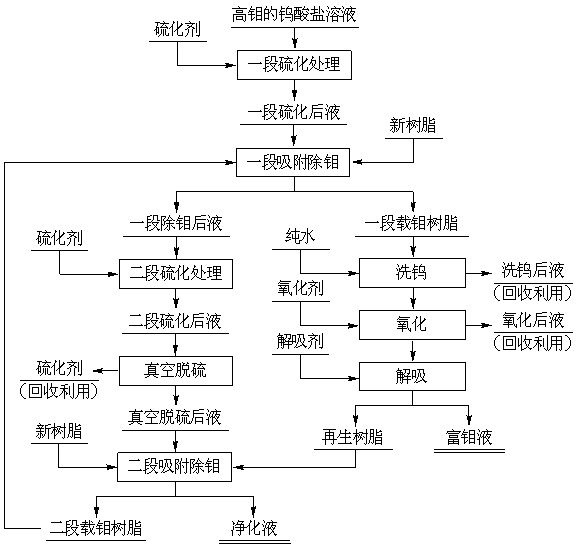

Process for removing molybdenum from tungstate solution through ion exchange method

A technology of ion exchange and tungstate, which is applied in the field of solution purification and impurity removal, can solve the problems of resin exchange capacity attenuation, severe heat release of oxidation reaction, etc., and achieve the effect of shortening the vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] For the crude sodium tungstate solution containing 249g / L tungsten trioxide and 3g / L molybdenum, add sodium sulfide solution according to the molar ratio of sulfur and molybdenum to 3, then add ammonium chloride to adjust the pH value to 9.5, and vulcanize at 70°C React for 0.5 hours, then mix with new resin, stir and react at 40°C for 1 hour to obtain a section of molybdenum-loaded resin and a section of molybdenum-removed liquid. The molybdenum content in the first-stage molybdenum-removed liquid is 0.91g / L. A section of molybdenum-removed solution was added to sodium hydrosulfide solution according to the ratio of sulfur and molybdenum substances to 6, and the vulcanization reaction was carried out at 70°C for 2 hours, and then the solution was volatilized and desulfurized at 90°C and vacuum degree -20kPa for 2 hours, and used The crude sodium tungstate solution containing 249g / L tungsten trioxide and 3g / L molybdenum that has not been added with a vulcanizing agent ab...

Embodiment 2

[0025] For the crude ammonium tungstate solution containing 193g / L tungsten trioxide and 15.6g / L molybdenum, add ammonium sulfide solution according to the molar ratio of sulfur and molybdenum to 2.5, vulcanize at 10°C for 2 hours, and then mix with new resin, Stir and react at 10°C for 5 hours to obtain a section of molybdenum-loaded resin and a section of molybdenum-removed liquid, the molybdenum content of the first-stage molybdenum-removed liquid is 1.39g / L. Add ammonium sulfide solution to a section of molybdenum-removed solution according to the ratio of sulfur and molybdenum to 9, and react for 8 hours at 10°C for sulfidation, then place the solution at 40°C and vacuum degree of -95kPa for 2 hours for volatilization and desulfurization, and use untreated The crude ammonium tungstate solution containing 193g / L tungsten trioxide and 15.6g / L molybdenum added with vulcanizing agent absorbs the volatilized vulcanizing agent, and it can be observed that the color of the soluti...

Embodiment 3

[0028] For the crude sodium tungstate solution containing 181g / L tungsten trioxide and 28.9g / L molybdenum, add sodium sulfide solution according to the molar ratio of sulfur and molybdenum to 3, and then add ammonium chloride to adjust the pH to 9.5. Vulcanize for 1 hour, then mix with new resin, stir and react at 40°C for 4 hours to obtain a section of molybdenum-loaded resin and a section of molybdenum-removed liquid. The molybdenum content in the first-stage molybdenum-removed liquid is 2.52g / L. Add ammonium sulfide solution to a section of molybdenum-removed liquid according to the molar ratio of sulfur and molybdenum to 12, vulcanize and react at 70°C for 2 hours, then place the solution at 90°C and vacuum degree of -75kPa for 2 hours for volatilization and desulfurization, and use untreated The crude sodium tungstate solution containing 181g / L tungsten trioxide and 28.9g / L molybdenum added with vulcanizing agent absorbs the volatilized vulcanizing agent, and it can be obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com