Patents

Literature

142 results about "Ammonium sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium sulfide, also known as diammonium sulfide, is an unstable salt with the formula (NH₄)₂S. Aqueous solutions purporting to contain this salt are commercially available. With a pKₐ exceeding 15, the hydrosulfide ion cannot be deprotonated to an appreciable amount by ammonia. Thus, such solutions mainly consist of a mixture of ammonia and SH. Ammonium sulfide solutions are used occasionally in photographic developing, to apply patina to bronze, and in textile manufacturing. Also, due to its offensive smell, it is the active ingredient in a variety of foul pranks including the common stink bomb.

In situ outer prevulcanization method for hydrogenation catalyst

InactiveCN1557556ANo need for high temperature heatingCatalyst activation/preparationAmmonium sulfideActive component

The in-situ hydrogenation catalyst pre-sulfurizing method is to use ammonium sulfide solution containing sulfur to treat petroleum fraction hydrogenating catalyst with oxide of IVB metal Mo or W and VIII metal Co or Ni or their precursor loaded and to convert the oxide of the active component or their precursor into metal sulfide with hydrogenation activity. The outside pre-sulfuizing of the hydrogenation catalyst is utilized to replace available inside pre-sulfuizing, which has complicated operation and expensive cost. The method is suitable for all kinds of petroleum fraction hydrogenating catalyst and the processed catalyst has hydrogenation activity reaching or even exceeding that of internal pre-sulfurized one.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Catalyst for preparing mixing alcohol with low carbon from synthesis gas and its preparing method

InactiveCN1431049AGuaranteed stabilityGuaranteed lifeOrganic compound preparationHydroxy compound preparationHigh resistanceMANGANESE ACETATE

A catalyst for preparing low-carbon alcohol mixture from synthetic gas contains Mo (2-40 %), Ni (4-10%), Mn (0.1-5.0%), K (5-15%), S (20-40%) and bentone, and is prepared through reaction of ammoniumsulfide solution or hydrogen sulfide gas on ammonium molybdate, adding concentrated acetic acid, thermal stirring, cooling for deposition, adding deionized water for dissolving doposit to obtain solution of ammonium thiomolybdate, dropping the solution along with the mixed solution of nickel acetate and manganese acetate in acetic acid to form black deposit, filtering, washing, baking, mixing with bentone, and tabletting. Its advantages are high resistance to S and no carbon deposit.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

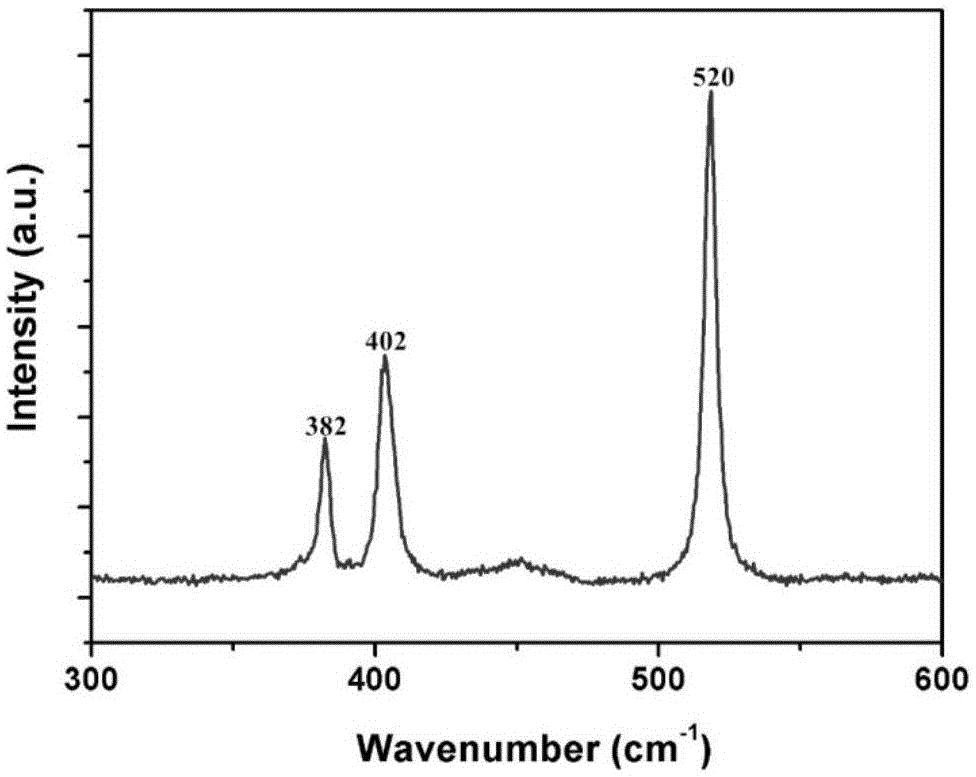

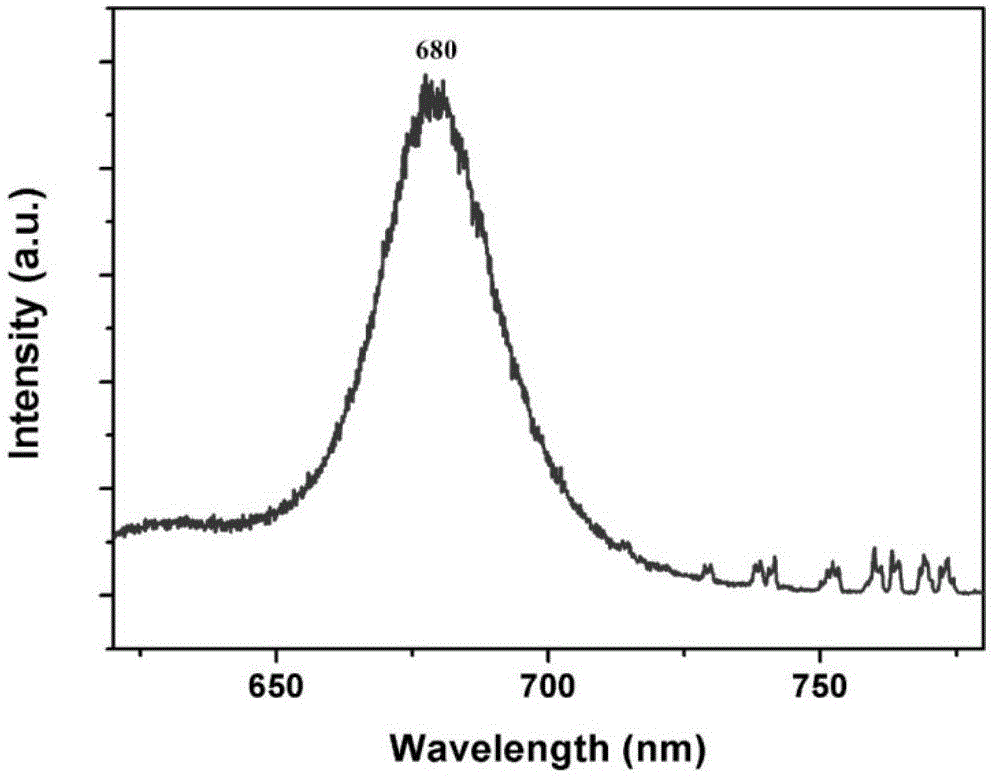

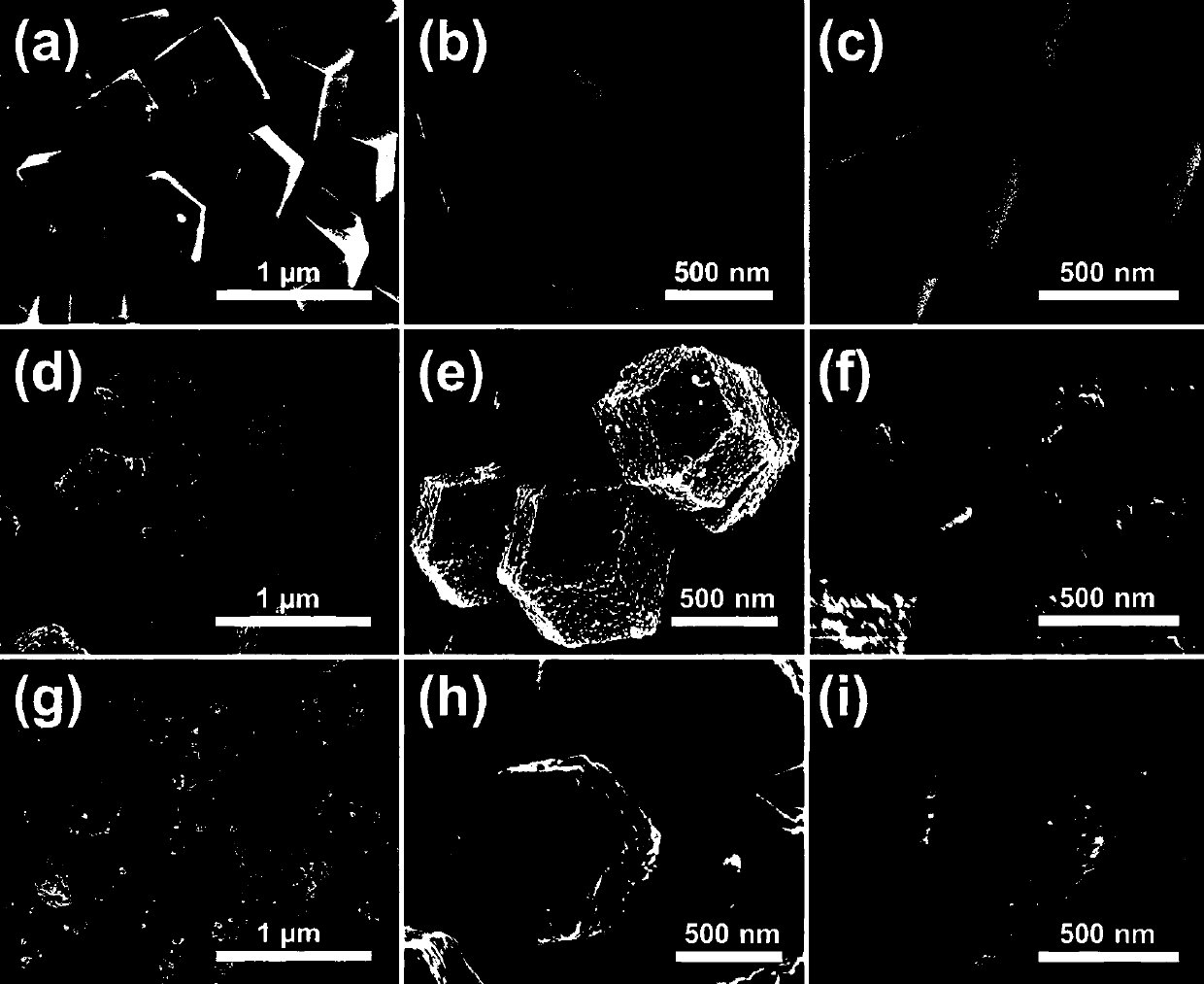

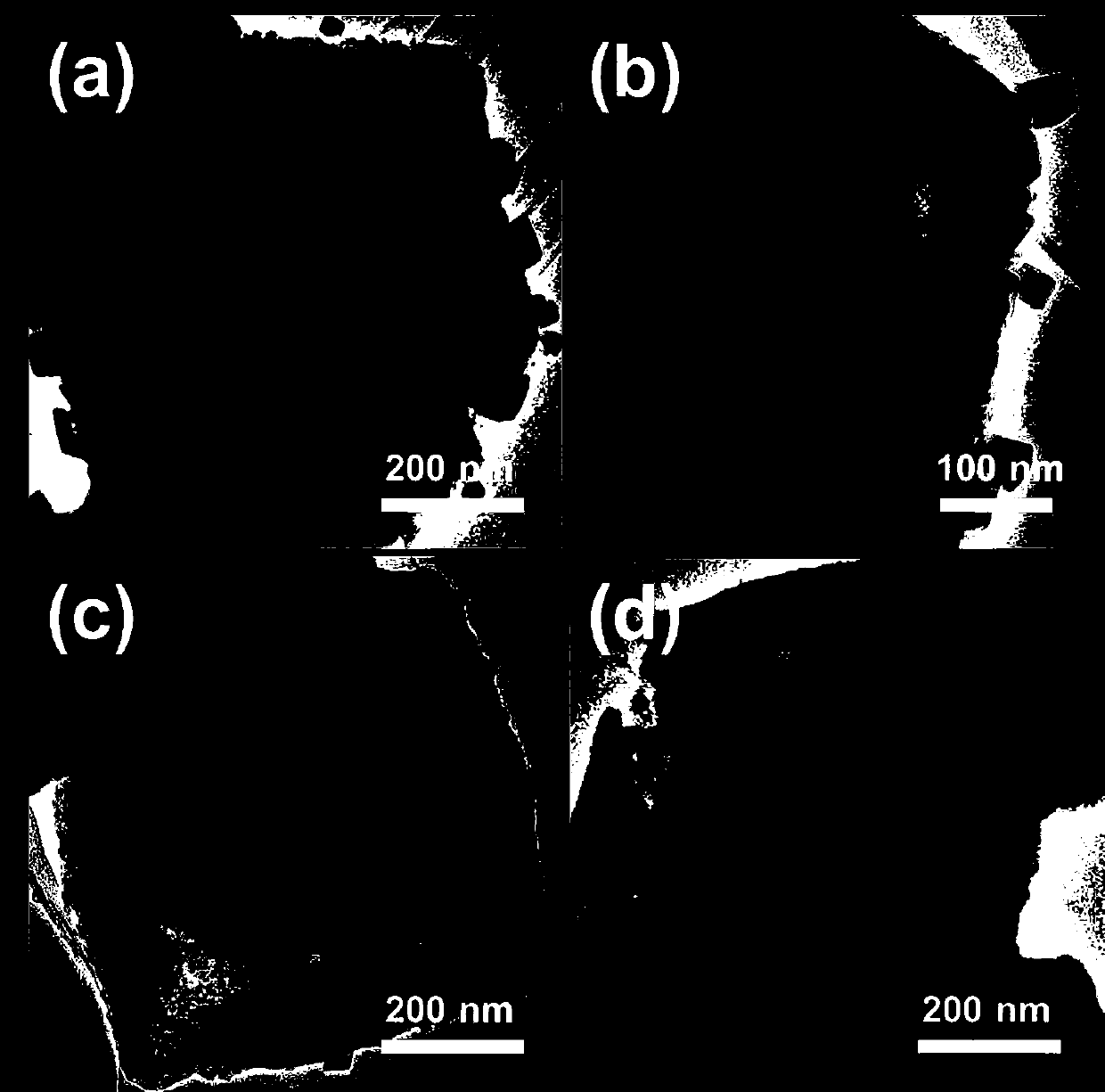

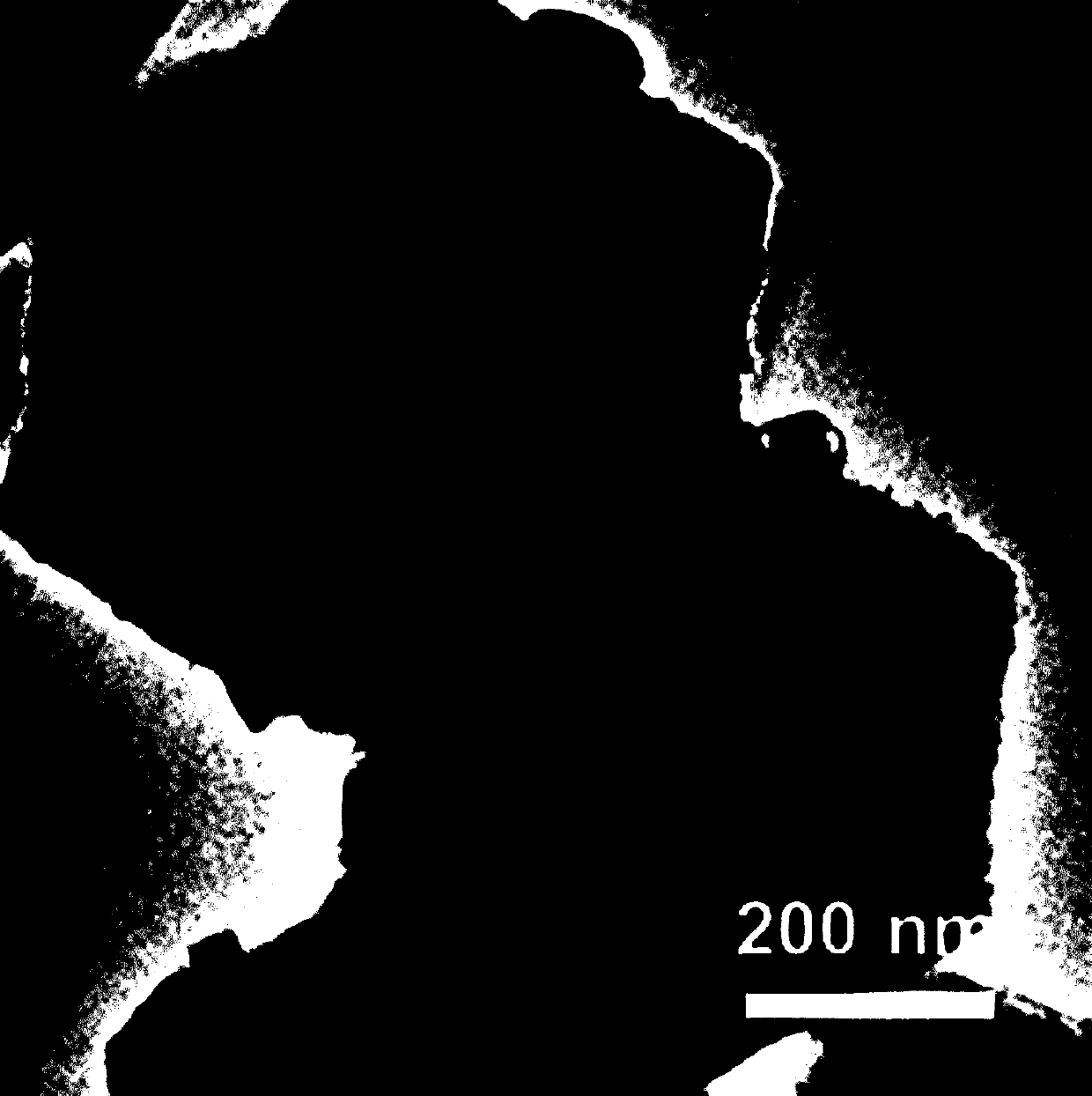

Method for growing substrate-modified large-size monolayer molybdenum disulfide film through chemical vapor deposition

ActiveCN105002476AEfficient preparationChemical vapor deposition coatingSemiconductor materialsGas phase

The invention proposes a method for growing a substrate-modified large-size monolayer molybdenum disulfide film through chemical vapor deposition. Ammonium sulfide serves as a substrate surface modifying agent; a nucleation rate is controlled through such methods as control of a concentration of the modifying agent, a dipping time and a cleaning method; and a film thickness is controlled through such methods as control of a growing temperature, a growing time and an air flow of the chemical vapor deposition. The method can efficiently grow the large-size monolayer molybdenum disulfide film under the condition of a relatively lower growing temperature on the basis of traditional growth chemical vapor deposition equipment. The method for growing large-size monolayer molybdenum disulfide, provided by the invention, is suitable for the growth of large-size monolayer tungsten disulfide, molybdenum diselenide, tungsten diselenide and the like similar to two-dimensional semiconductor materials in structure.

Owner:NANJING UNIV

Production method of electrolytic manganese metal

The invention discloses a production method of electrolytic manganese metal, which sequentially comprises the following steps: (1) simultaneously adding mixed ore powder of manganese dioxide ores, sulfurous iron ores and manganese carbonate ores and sulfuric acid into a leaching combination tank, heating to 90-95 DEG C, performing leaching combination reaction for 4-6 hours, and performing solid-liquid separation to obtain a rough manganese sulfate solution; (2) performing two-stage purification on the rough manganese sulfate solution to remove impurities, wherein in the primary purification process, SDD or BaS is added for impurity removal, and then aluminum sulfate is added for purification; and in the secondary purification process, 10-30% of deep impurity removal agent is added, and then ammonium sulfide is added for zinc removal; reacting for 1-2 hours, checking and regulating the pH value to 6.0-8.0, performing pressure filtration, then transferring into a standing tank, and standing; and (3) injecting the purified manganese sulfate solution into an electrolytic tank, controlling the pH value of an electrolytic tank solution to be 7.0-8.0, and electrolyzing for at least 24 hours to obtain the electrolytic manganese metal product. According to the method disclosed by the invention, manganese ore resources are reasonably utilized, and the production cost is lowered.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

Preparation method of metal sulfide semiconductor nanocrystalline

InactiveCN1522953ASufficient supplyEfficient synthesisNanostructure manufactureSulfur compoundsAmmonium sulfideMetallic sulfide

The method for preparing metal sulfide semiconductor nano crystal by using template includes the following steps: firstly, using collodion cotton liquor and making it into the semi-transparent film which has uniform thickness and can meet designed thickness, size and form as artificial active film template, then using metal ion solution of zinc, cadmium copper, mercury, silver, lead, iron, cobalt and nickel whose concentration is 0.05-0.20 mol / L and ionic mole number ratio is correspondent to product chemical formula and providing the solution of sodium sulfide, ammonium sulfide, potassium sulfide and hydrogen sulfide of sulfur ion, respectively placing them at two sides of artificial active film, reacting for 24-48 hr, under the condition of room temp. and stirring, then centrifugal separating reaction solution, removing clear liquor, successively using acetone and deionized water to wash remained product, naturally-drying so as to obtain the metal sulfide semiconductor nano crystal whose grain size (or diameter) is 20-200 nm.

Owner:TONGJI UNIV

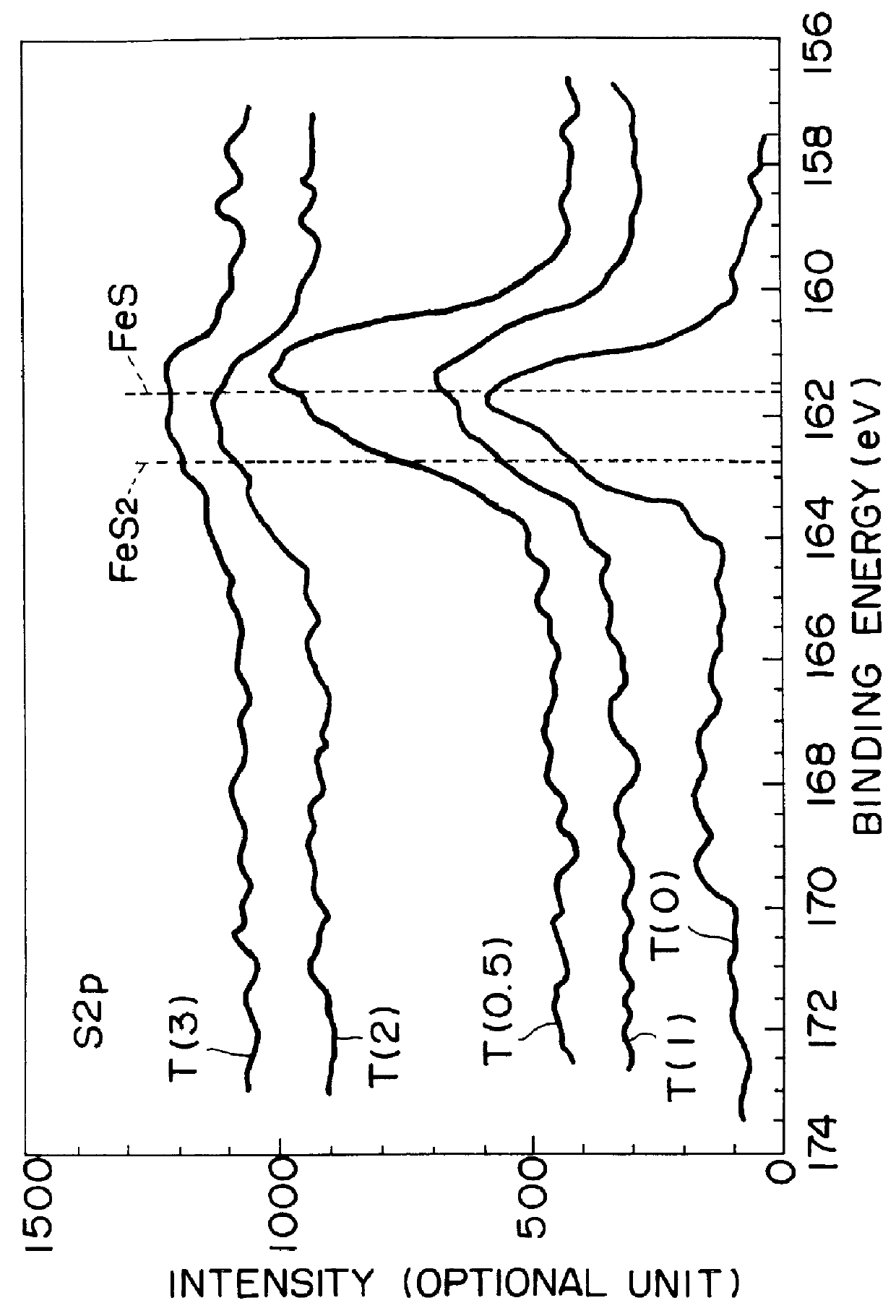

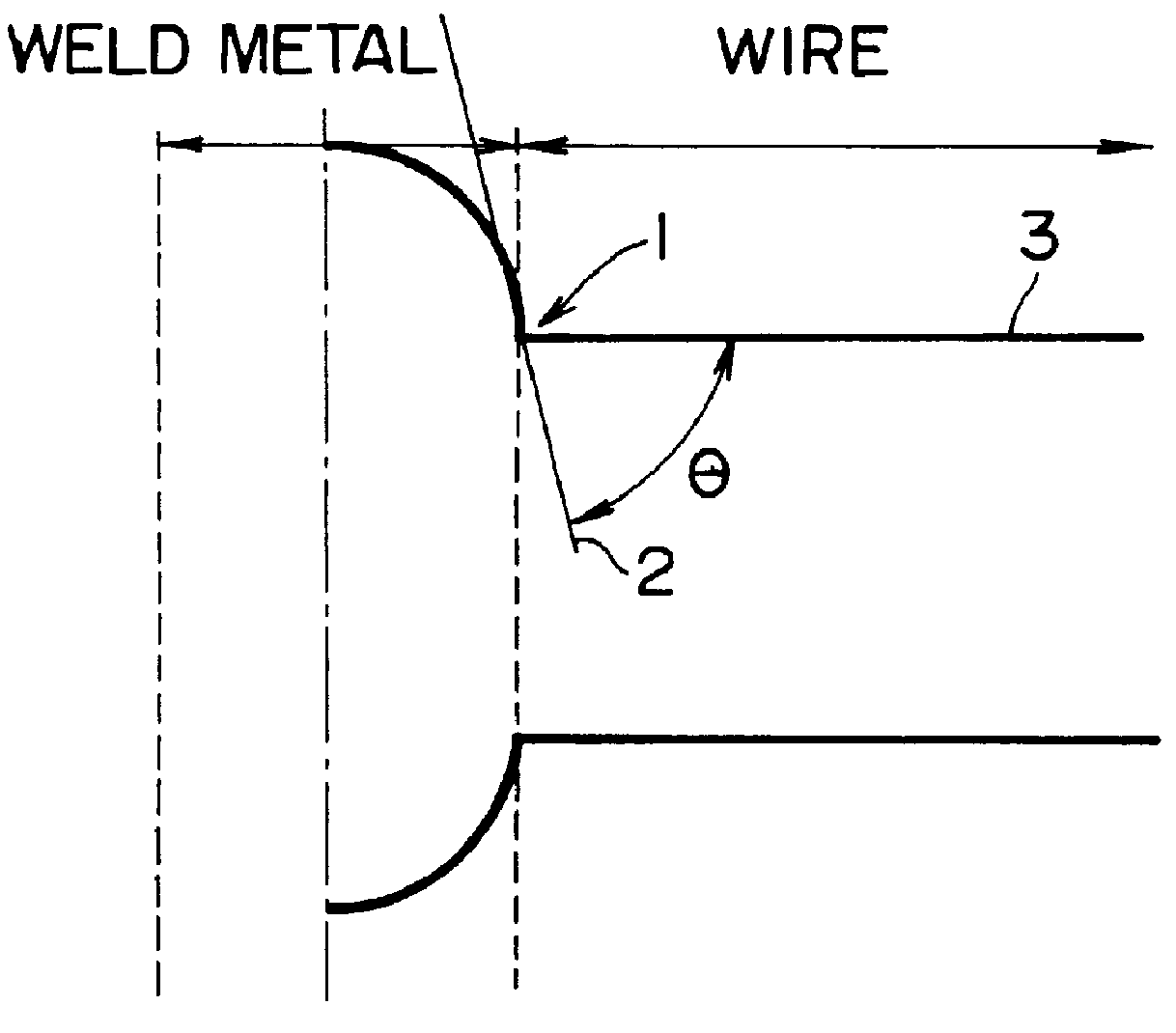

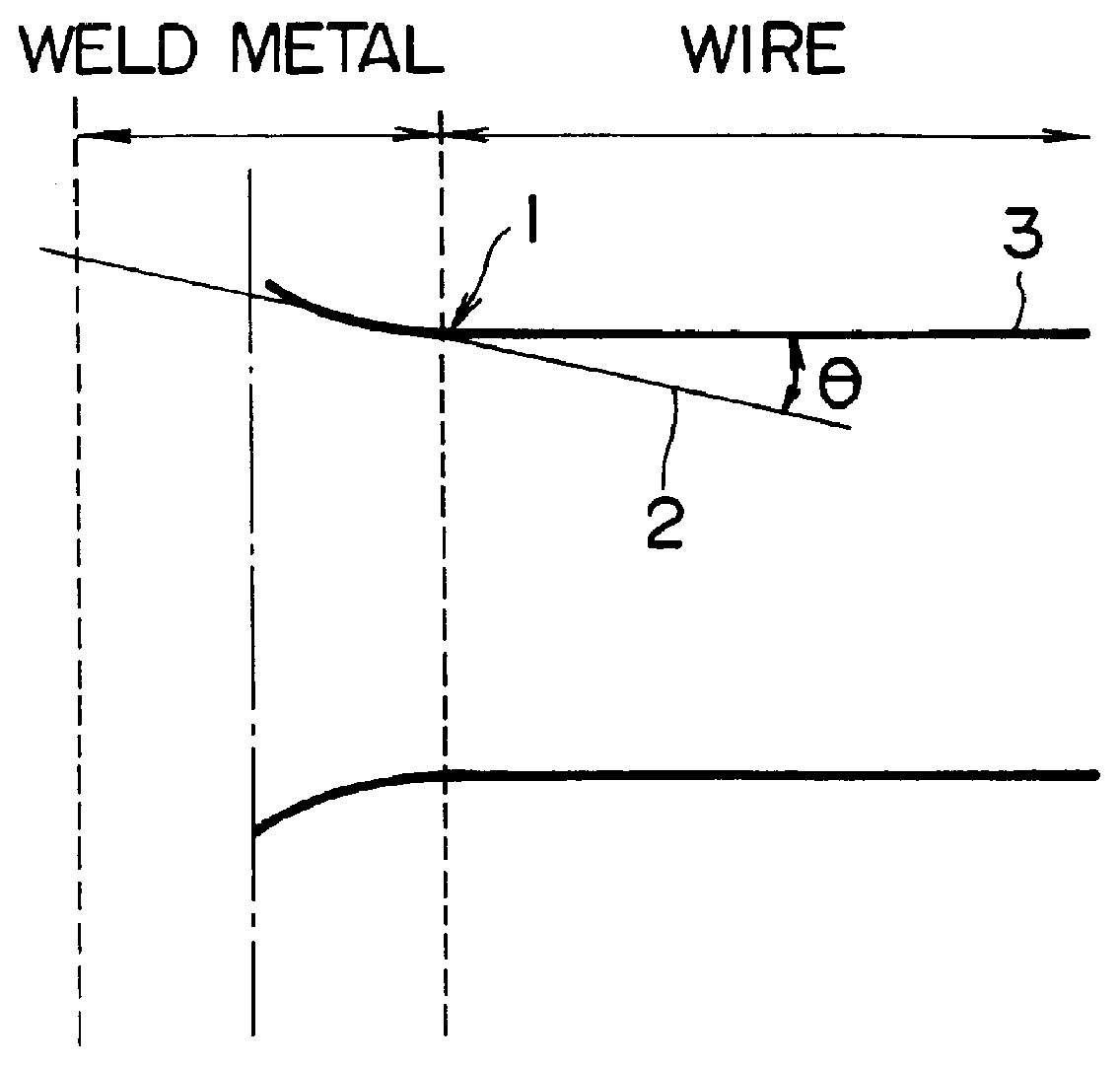

Welding wire

InactiveUS6146768AImprove wettabilityImproves drawabilityWelding/cutting media/materialsNatural mineral layered productsAmmonium sulfideIron sulfide

A welding wire capable of improving wettability between weld metal and wire surface, thereby providing excellent drawability and weldability in resistance welding of wires is provided. A wire is dipped in an aqueous solution of a sulfide of alkali metal or ammonium sulfide to generate iron sulfide (FeS2 or FeS) on the surface, whereby the wettability of weld metal to wire surface is improved in the resistance welding of the resulting wires. The S in the iron sulfide is preferably present in an amount of 0.1-20 atomic % as measured by X-ray photoelectron spectroscopy. At least one sulfide of S with an element of Mn, Ti, Cu, Cr, Ni, Al or Zn can be used instead of or in addition to the iron sulfide.

Owner:KOBE STEEL LTD

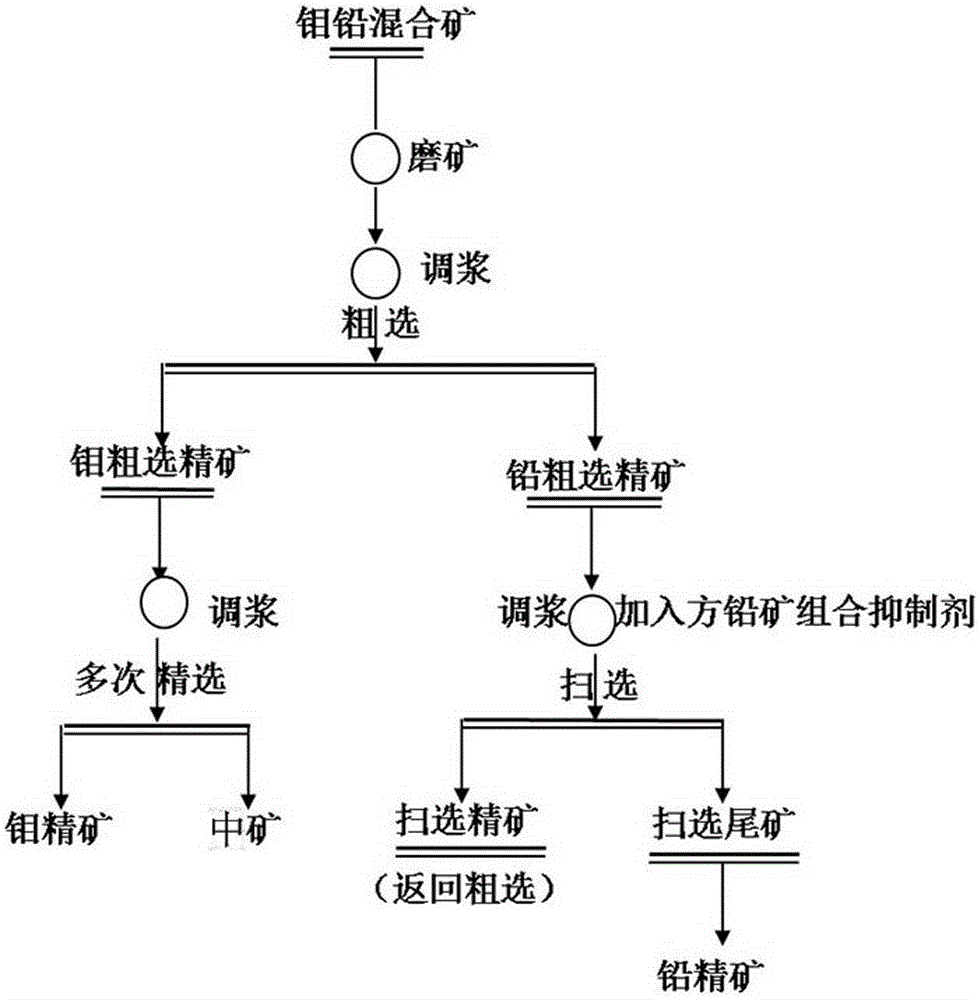

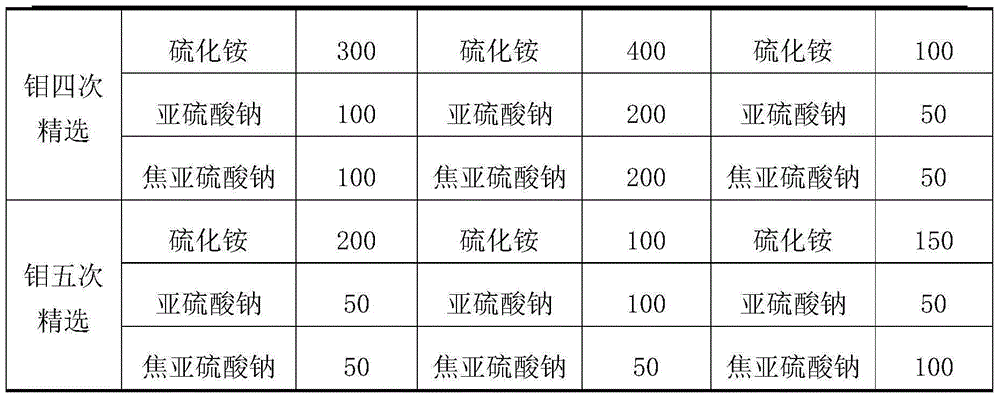

Separation mineral processing method for molybdenite and galena

The invention provides a separation mineral processing method for molybdenite and galena. The method is characterized in that molybdenum lead mixed ore, that is, raw ore is ground to be in the certain fineness, and the concentration and the PH of the slurry are adjusted; a galena combined inhibitor is added to restrain the galena, and a molybdenite collecting agent is added to achieve separation of the molybdenite and the galena; and the galena combined inhibitor is composed of ammonium sulfide, sodium sulfite and sodium pyrosulfite. A medicine agent used in the method is environment-friendly, and finally-obtained molybdenum concentrates and lead concentrates are high in grade. The mineral processing method is simple in technology, management and operation on site are easy, and the higher economic and technical indexes can be obtained through the technology.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

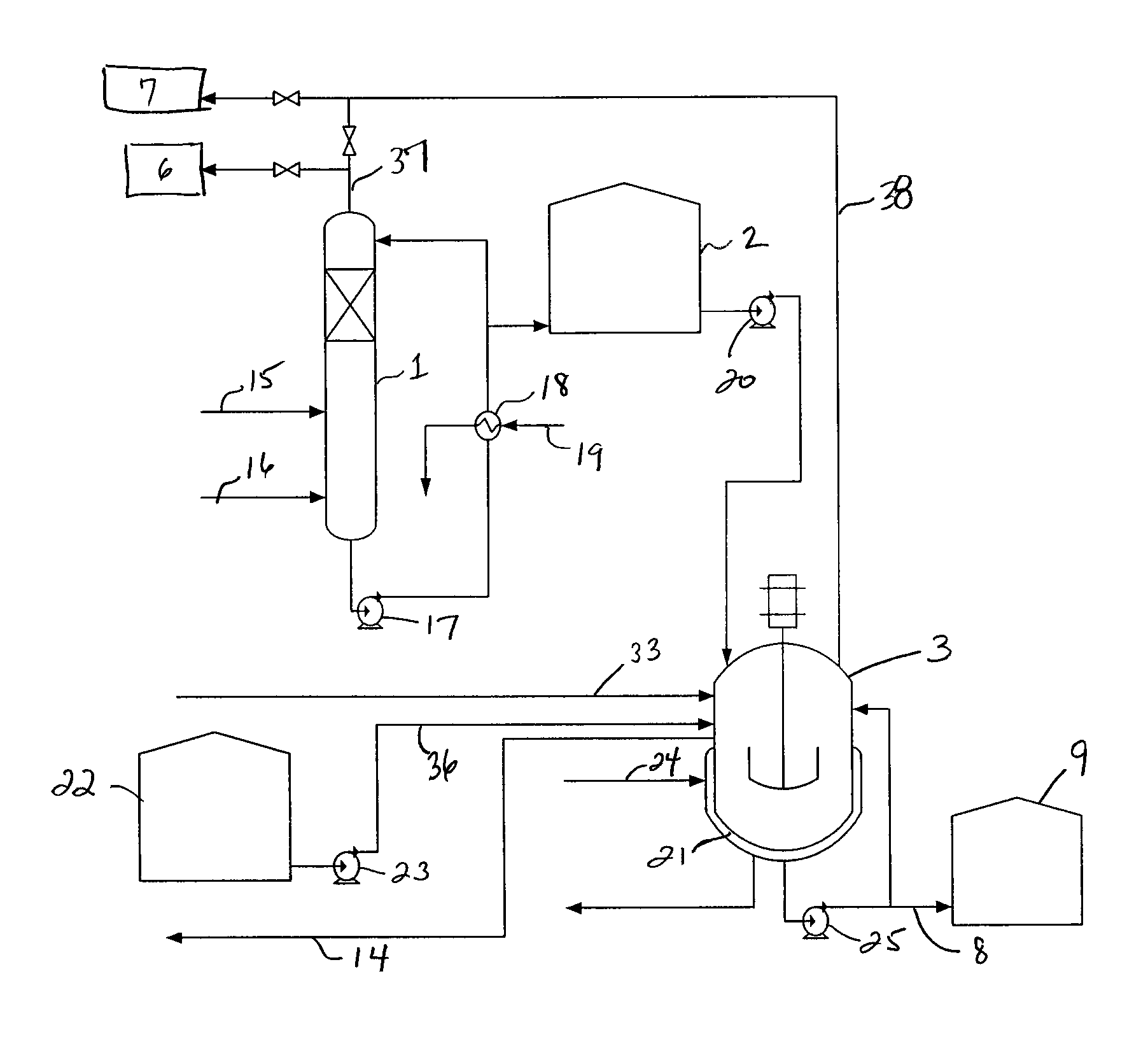

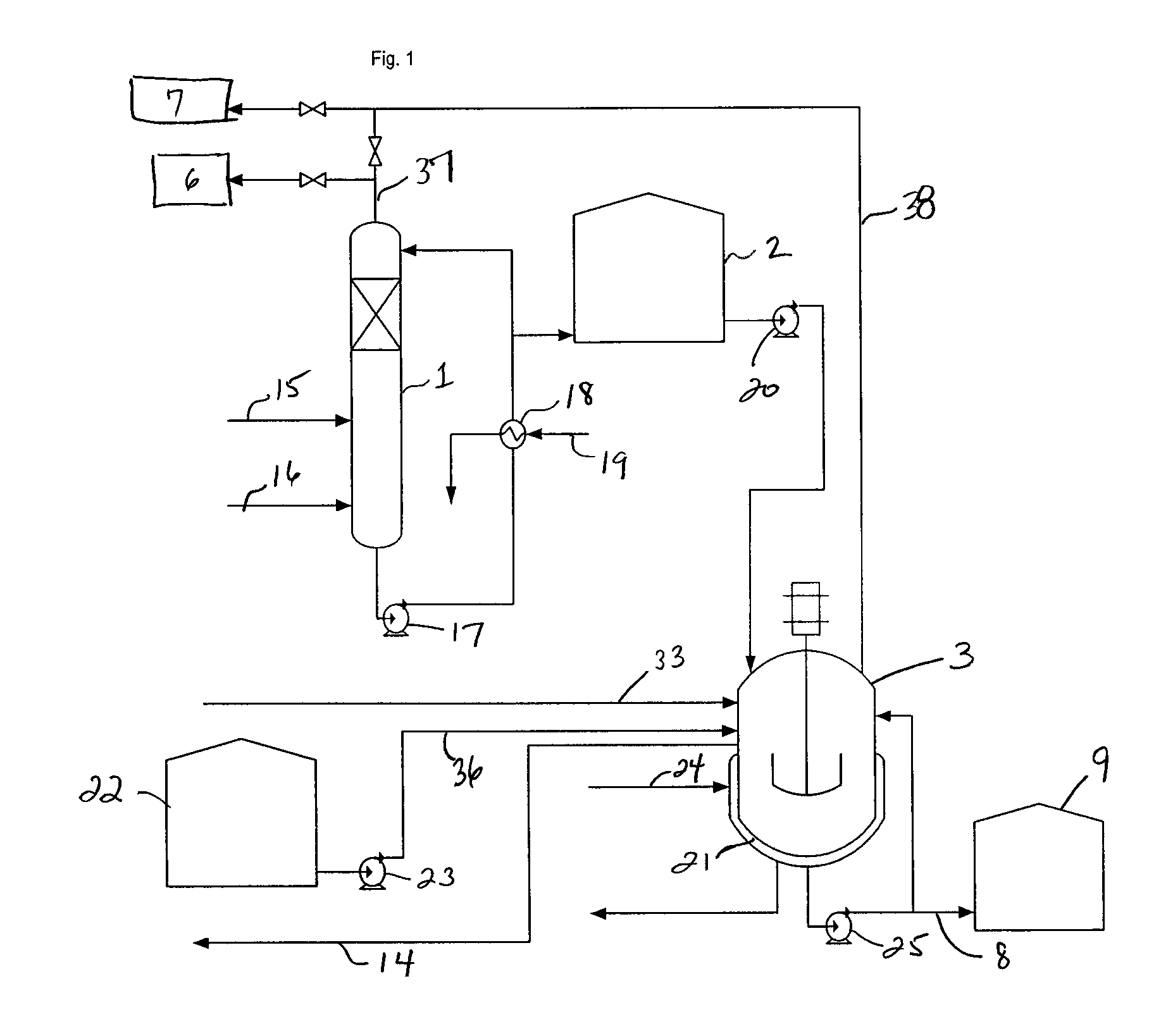

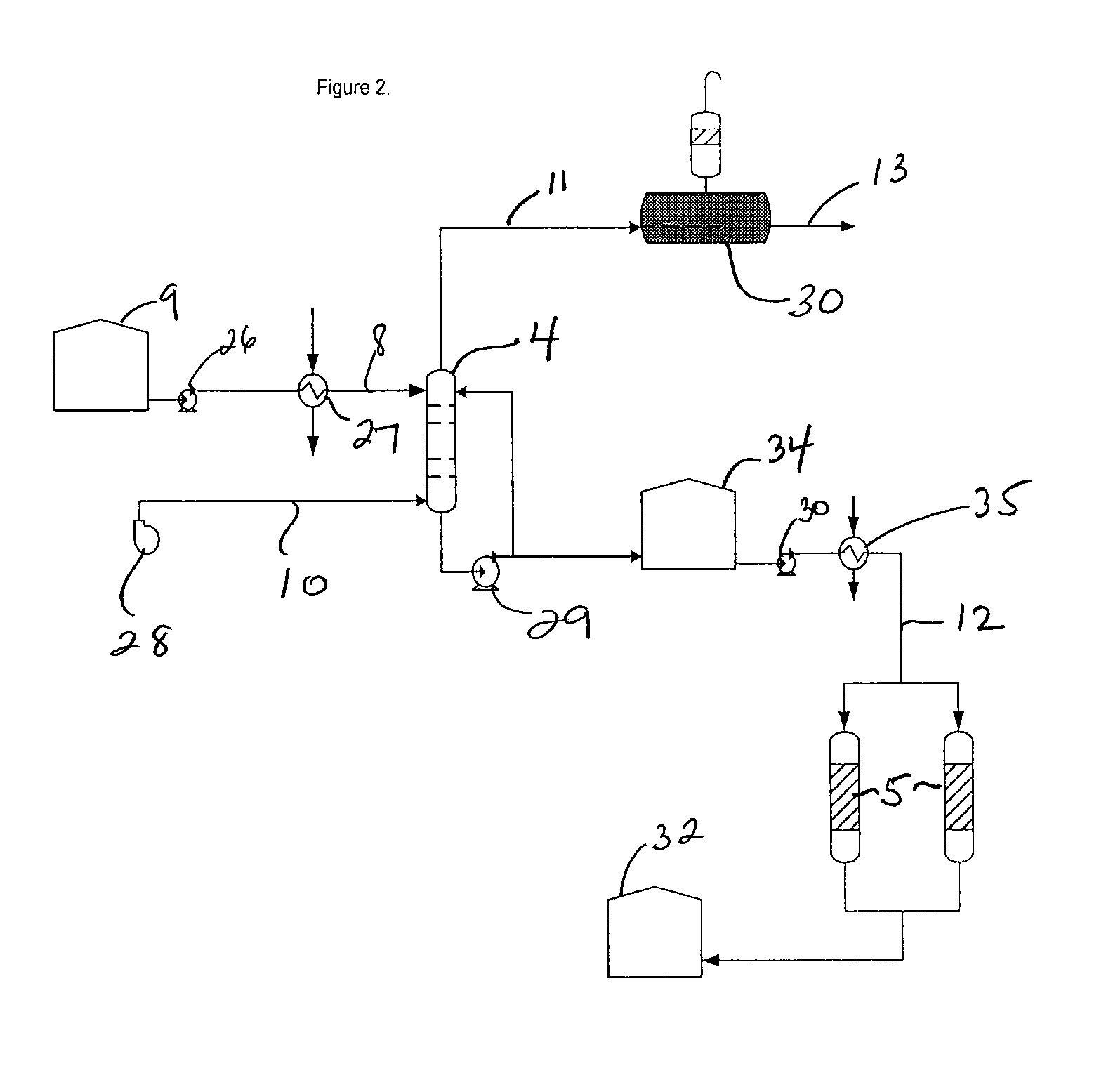

Process for conversion of waste fluid streams from chemical processing plants to beneficiary agriculture products

The present invention is directed to the conversion of gas streams comprising ammonia, hydrogen sulfide, and water in the form of liquids or gases that are generated by petroleum refineries and coke ovens to beneficiary agriculture products, by forming ammonium sulfide and then converting the ammonium sulfide, using sulfuric acid, to pure ammonium sulfate.

Owner:TESSENDERLO KERLEY INC

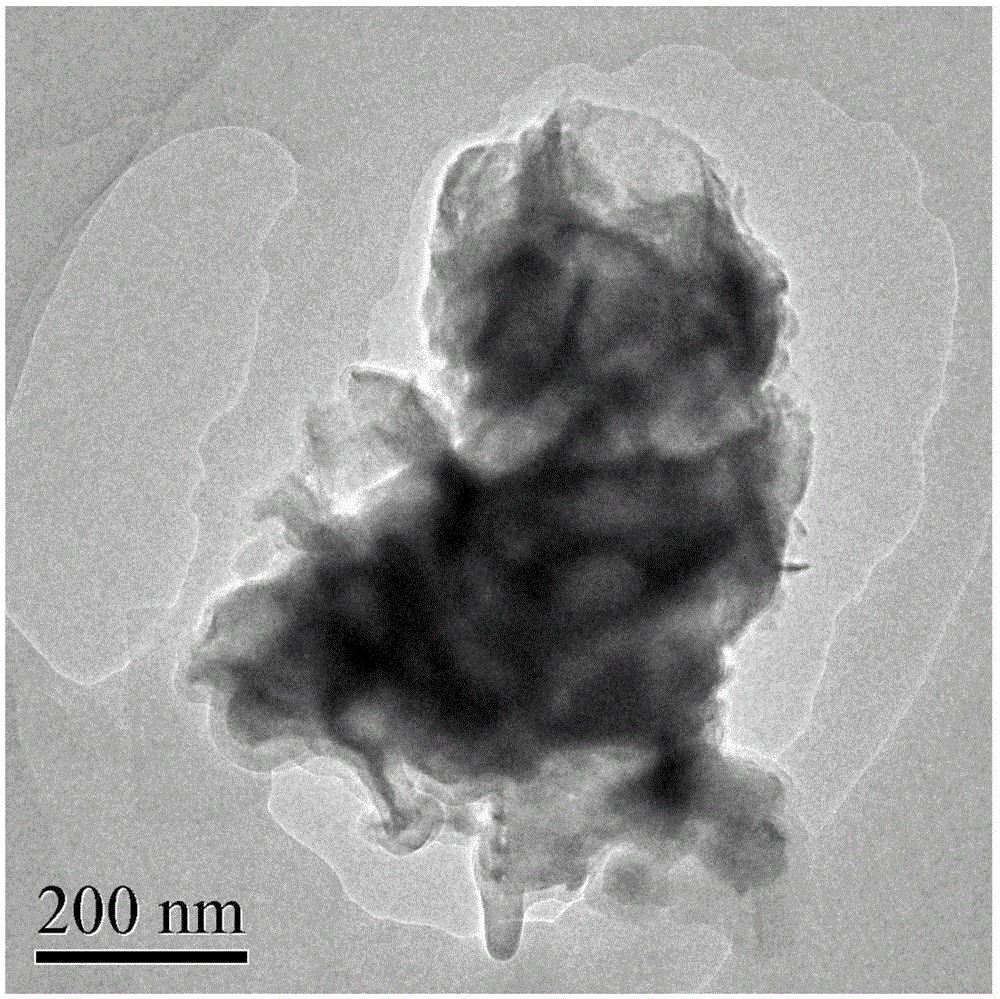

Preparation method of nitrogen and carbon doped cobalt molybdenum sulfide counter electrode catalyst with adjustable yolk-shell structure

ActiveCN110575842AGood chemical stabilitySmall sizeLight-sensitive devicesPhysical/chemical process catalystsPorosityYolk

The invention discloses a preparation method of a nitrogen and carbon-doped cobalt molybdenum sulfide NC-CoS2@Co-MoS2 catalyst with an adjustable yolk-shell structure. The preparation method comprisesthe following steps: dissolving ammonium sulfide and ammonium molybdate in water, adding ammonia water, carrying out an oil bath reaction, adding the obtained solution to a ZIF-67 polyhedral dispersion, performing mixing, and then performing stirring to obtain an intermediate ZIF-67@Co-MoS2; and further carrying out high-temperature vulcanization on the intermediate to obtain the NC-CoS2@Co-MoS2catalyst with the yolk-shell structure. The shell thickness, the core size and the yolk-shell spacing are controlled by regulating the specific reaction time and the reaction mass ratio to form the catalyst with different morphological structures in order to achieve different catalytic effects. The prepared catalyst has the advantages of high specific surface area, high porosity and good electro-catalytic performance, and is used for a dye-sensitized solar cell to achieve a photoelectric conversion efficiency of 9.38%.

Owner:FUZHOU UNIV

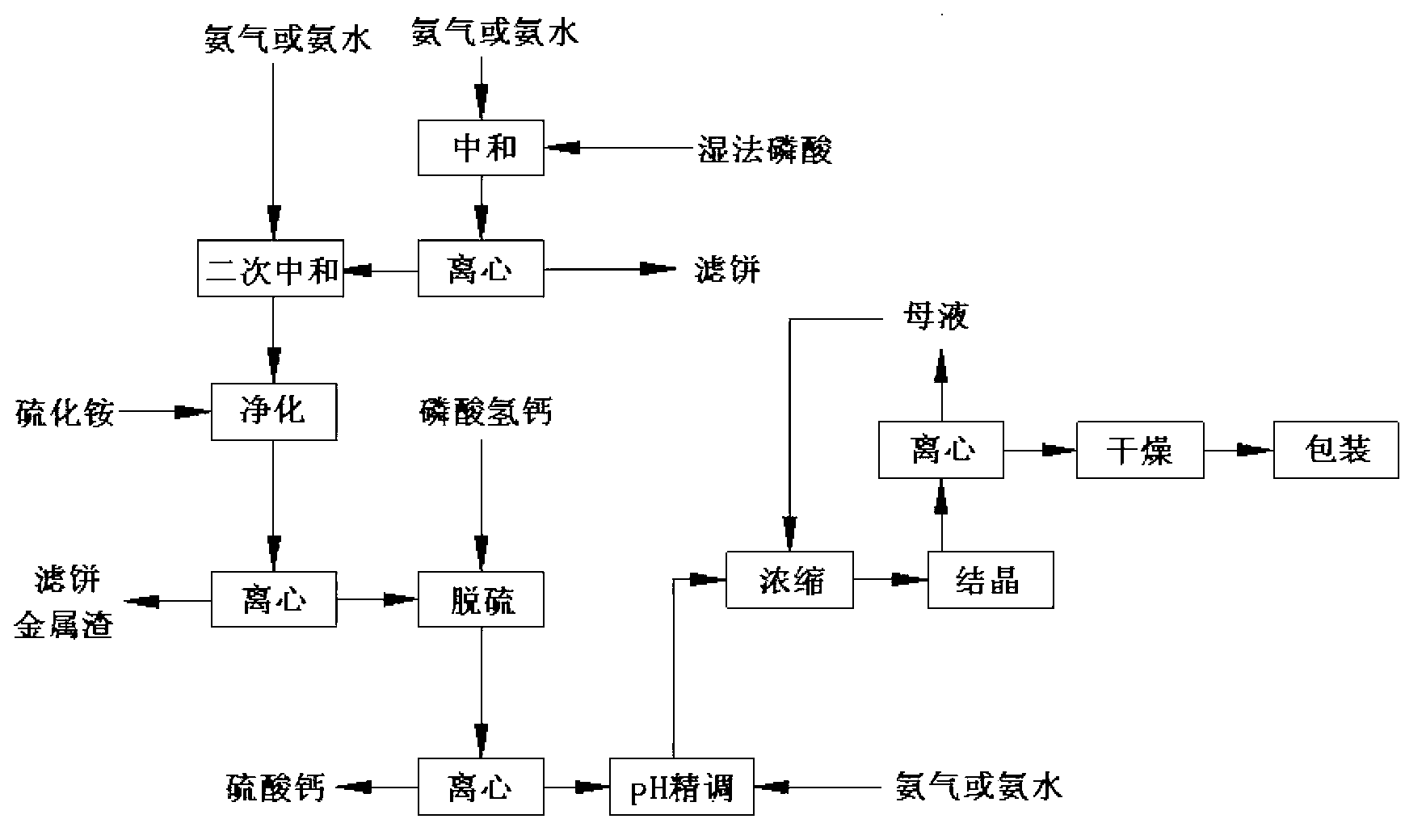

Production method of industrial grade diammonium phosphate with wet-process phosphoric acid

The invention discloses a production method of industrial grade diammonium phosphate with wet-process phosphoric acid, and the wet-process phosphoric acid is used as raw material to prepare the industrial grade diammonium phosphate through two times of neutralization reaction with ammonia. The production method of the industrial grade diammonium phosphate with the wet-process phosphoric acid is characterized by putifying the industrial grade diammonium phosphate with ammonium sulfide in the preparation process of the industrial grade diammonium phosphate, then desulfurizing the purified industrial grade diammonium phosphate with calcium hydrogen phosphate, and further adjusting potential of hydrogen (pH) value, concentrating, crystallizing, drying and packaging the industrial grade diammonium phosphate. The production method of the industrial grade diammonium phosphate with the wet-process phosphoric acid is low in energy consumption and cost, small in pollution in the production process and capable of effectively removing metal impurities in the wet-process phosphoric acid and improving the product quality of the industrial grade diammonium phosphate.

Owner:GUIZHOU KAILIN GRP CO LTD

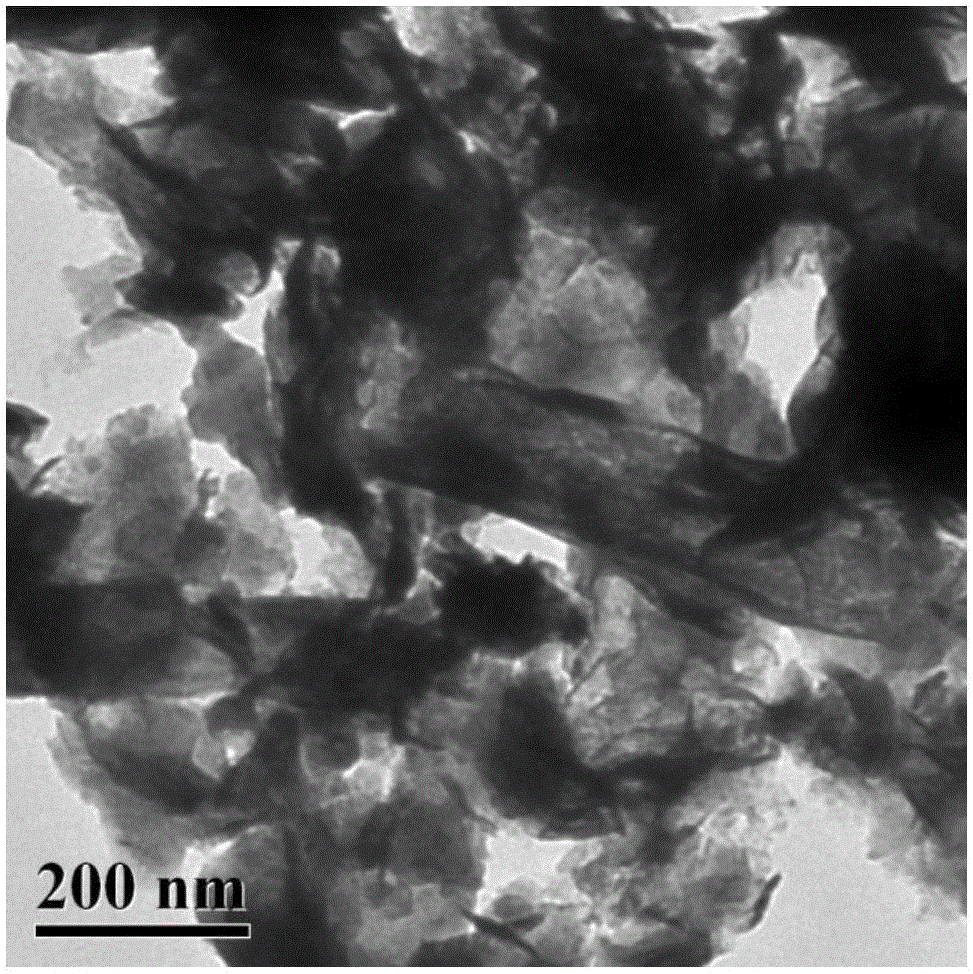

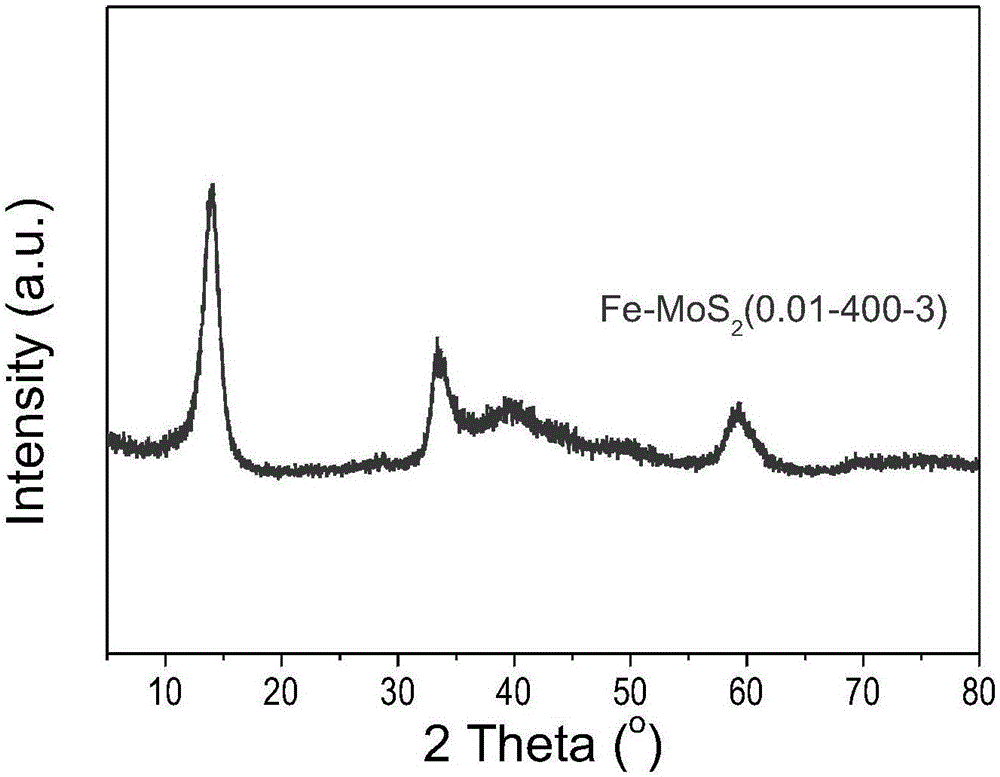

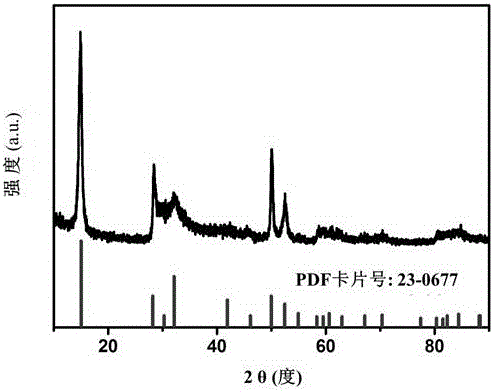

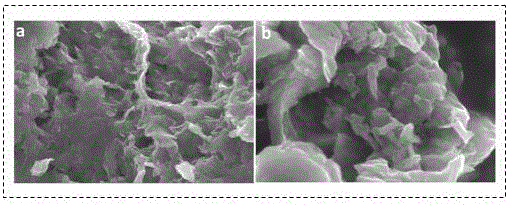

Metal cation doped molybdenum disulfide material, preparation method and applications thereof

ActiveCN106608652AImprove thermal stabilityAcid resistantPhysical/chemical process catalystsMolybdenum sulfidesAmmonium sulfideStrong acids

The present invention relates to a metal cation doped molybdenum disulfide material, a preparation method and applications thereof. The preparation method comprises: dispersing and dissolving a molybdenum precursor in an ammonium sulfide solution, adjusting the pH value of the solution to more than or equal to 10 and less than or equal to 14 with ammonia water, carrying out a reaction at a temperature of 50-100 DEG C, adding a coordination reagent protected metal coordination compound solution to the solution after the reaction, stirring until achieving a dried state, carrying out vacuum drying, grinding the obtained solid powder, placing in an inert atmosphere (nitrogen or argon) gas flow, treating for 0.5-8 h at a temperature of 380-500 DEG C, and cooling to a room temperature to prepare the metal cation doped molybdenum disulfide material. According to the present invention, the metal cations are uniformly dispersed between each layer of molybdenum disulfide through the doping; the crystal structure of the metal cation doped molybdenum disulfide material maintains the two-dimensional layered structure of molybdenum disulfide; the material interlayer spacing fluctuates between 6.15-10.0 angstrom according to different types and different contents of the doped metals; and the metal cation doped molybdenum disulfide material has advantages of good thermal stability, strong-acid resistance and large specific surface area, and has potential applications in the fields of catalysis, electrode materials, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for improving aluminium oxide ceramic abrasive resistance by precipitation reaction

The invention relates to a method for preparing aluminium oxide ceramics with good wear-resisting property, that is, low-cost soluble salt is added in slurry which takes water and aluminum oxide as main raw material, and then dehydration pelleting, molding and sintering are carried out; the specific method is that: one working procedure is added after ball-milling procedure and before pelleting procedure in the original preparation process; proper salt which can be dissolved in water and generates metal ions is added in the slurry with qualified fineness and viscosity by ball-milling; the added metal salt can be one, part or all of magnesium salt, calcium salt, yttrium salt, aluminum salt, strontium salt, barium salt, zircon salt, cerium alt and lanthanum salt, the total adding amount accounts for 0.1-30 percent of the alumina powder material, and the optimized adding amount is from 2 percent to 20 percent; the added precipitators can be one, partial or all of sodium hydroxide, sodium carbonate, sodium bicarbonate, sodium fluoride, sodium sulfide, sodium silicate, sodium aluminate, potassium hydroxide, potassium carbonate, potassium silicate, lithium hydroxide, lithium carbonate, calcium hydroxide, calcium oxide, barium hydroxide, ammonia, ammonium carbonate, ammonium hydrogencarbonate, ammonium fluoride, ammonium sulfide and carbamide, the total adding amount accounts for 0.05-20 percent of the alumina powder material quantity, and the optimized adding amount is 1-10 percent.

Owner:山东鲲鹏新材料科技股份有限公司

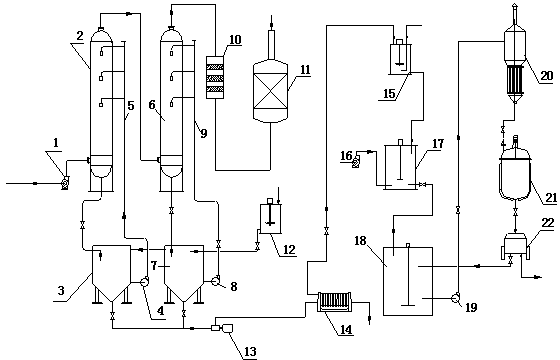

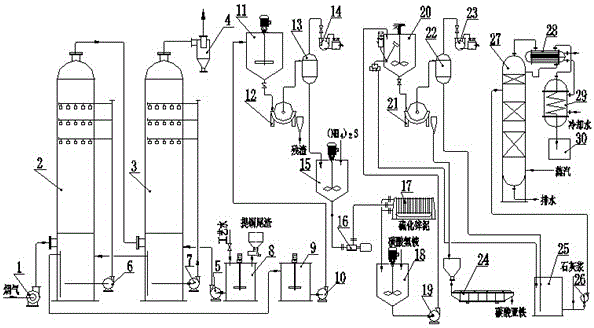

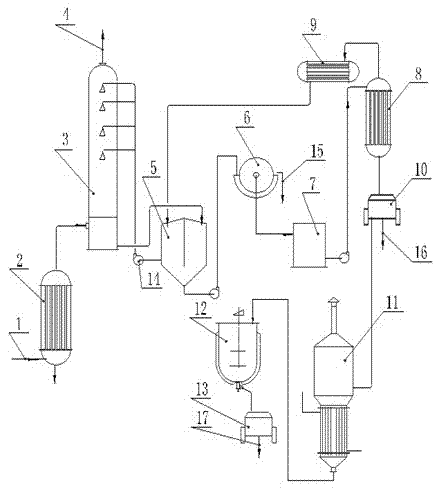

Synergetic purification method and device for SO2 and heavy metals in smelting flue gas

InactiveCN103768910AEasy to removeCatalyticThiosulfates/dithionites/polythionitesDispersed particle separationPurification methodsAmmonium sulfide

The invention discloses a synergetic purification method and a synergetic purification device for SO2 and heavy metals in smelting flue gas and belongs to the technical field of atmospheric pollution. The synergetic purification method comprises the steps of absorbing and purifying the SO2 and the heavy metals (such as Hg, As, Pb, Cd and Zn) through (NH4)2S solution serving as an absorbent; feeding the smelting flue gas subjected to dust removal into a second-level ammonium sulfide solution absorption tower so as to enable the absorbent to absorb and purify the SO2 and the heavy metals in the gas, wherein the heavy metals are settled down in the form of solid sulfide and are recycled after being filtered, and the SO2 is converted into NH4HSO3 and (NH4)2S2O3 which are retained in absorption liquid; after the absorption reaction is terminated, neutralizing, oxidizing and evaporatively crystallizing the absorption liquid to obtain (NH4)2SO4 and (NH4)2S2O3 solid mixtures which can be directly sold as fertilizers. The technology is simple and is easy to operate; the desulfuration efficiency is high, the cost is low, and the synergetic purification method is suitable for industrial application.

Owner:KUNMING UNIV OF SCI & TECH

Method and device for removing SO2 in flue gas with copper extracting tailings and recycling copper extracting tailings

ActiveCN106422716AWith spray densityIncrease contact areaGas treatmentDispersed particle separationMetasilicateAmmonium sulfide

The invention relates to a method and device for removing SO2 in flue gas with copper extracting tailings and recycling the copper extracting tailings, and belongs to the technical field of environmental protection. Ferrous metasilicate (Fe2SiO4), magnesium ferrite (MgFe2O4), hedenbergite (CaFeSi2O6) and other sulfur removal active substances in the copper extracting tailings are used for reacting with SO2 in the flue gas in an aqueous solution to generate sulfite, then sulfate is generated under the action of oxygen in the flue gas, the SO2-containing flue gas makes contact with copper extracting tailing slurry, SO2 is absorbed, and thus the flue gas is purified; by adding ammonium sulfide, ammonium bicarbonate and lime milk step by step, iron ions, zinc ions, copper ions, ammonium ions and other ions in the sulfur removal slurry can be resourcelized to be reused.

Owner:KUNMING UNIV OF SCI & TECH

Process of producing ammonium chloride with waste circuit board etching solution

ActiveCN1931720AReduce processingAchieve recyclingWater/sewage treatment by neutralisationAmmonium halidesAmmonium sulfideCopper

The process of producing ammonium chloride with waste circuit board etching solution includes the following steps: adding agglomerating reductant into both acid and alkaline waste solution and filtering to obtain clear acid and alkaline solutions; neutralizing the acid and alkaline solutions to obtain copper oxychloride crystal; filtering to obtain separated copper oxychloride crystal and solution A; adding ammonium sulfate solution into solution A to sulfurize to obtain copper sulfide and solution B; regulating the pH value of solution B, negative pressure concentrating, and heating to obtain solution C of Baume degree 40-41; and crystallizing solution C, filtering, dewatering and stoving to obtain ammonium chloride. The process of the present invention has the ammonia resource, acid resource and copper resource utilized in producing ammonium and copper oxychloride.

Owner:阮玉根

Purification method in electrolytic metal manganese production process by multi-mine method

ActiveCN103074490AReasonable useReduce manufacturing costPhotography auxillary processesElectrolysisPurification methods

The invention discloses a purification method in an electrolytic metal manganese production process by a multi-mine method. The method successively comprises steps that: mixed mineral powder of manganese oxide ore, pyrite and manganese carbonate ore and a crude manganese sulfate solution prepared through sulfuric acid enter a section of a purification tank for primary purification after filter pressing, SDD or BaS is added for removing impurities in a stirring state, and then aluminum sulfate is added for purification; and the purified solution enters a second section of the purification tank for secondary purification after filter pressing, a deep impurity removing drug is added, ammonium sulfide is input for removing zinc, the PH value is checked and adjusted to be in a range from 6.0 to 8.0 after the reaction lasts for one to two hours, and the mixture is transferred to stand in a standing tank after filter pressing. According to the purification method, various heavy metal impurities in the solution are removed after conventional impurity removal and deep purification are performed to the crude manganese sulfate solution, so that quality standards of electrolytic metal manganese solution production are achieved, and good economic and social benefits are provided for reasonably using manganese ore resources and reducing production costs.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

Preparation method of lithium-sulfur battery cathode composite material

ActiveCN110534742AImprove stabilityImprove electrochemical performanceSecondary cellsPositive electrodesClay mineralsAmmonium sulfide

The invention discloses a preparation method of a lithium-sulfur battery cathode composite material. The preparation method comprises the following steps of: mixing clay minerals with an acid solution, and performing an etching reaction to obtain an etching product; loading transition metal ions on the etching product to obtain a loaded transition metal ion product; reacting a sodium sulfide solution or an ammonium sulfide solution with the loaded transition metal ion product to obtain a sulfide surface modified solid; mixing the sulfide surface modified solid with an organic carbon source solution, and performing drying to obtain a dried product; carrying out heat treatment on the dried product in nitrogen to obtain a carbon-coated solid; mixing the carbon-coated solid with a carbon disulfide solution of sulfur, and carrying out hydrothermal reaction to obtain a sulfur-loaded solid; mixing the sulfur-loaded solid with a water-soluble aluminum salt solution to obtain a mixture; and adding an ammonium fluoride solution into the mixture. According to the method, the surface-modified clay mineral is used as a host material of sulfur particles after being coated with carbon, the clay mineral is cheap and easy to obtain, and the raw material cost of the lithium-sulfur battery cathode composite material can be remarkably reduced.

Owner:JIANGHAN UNIVERSITY

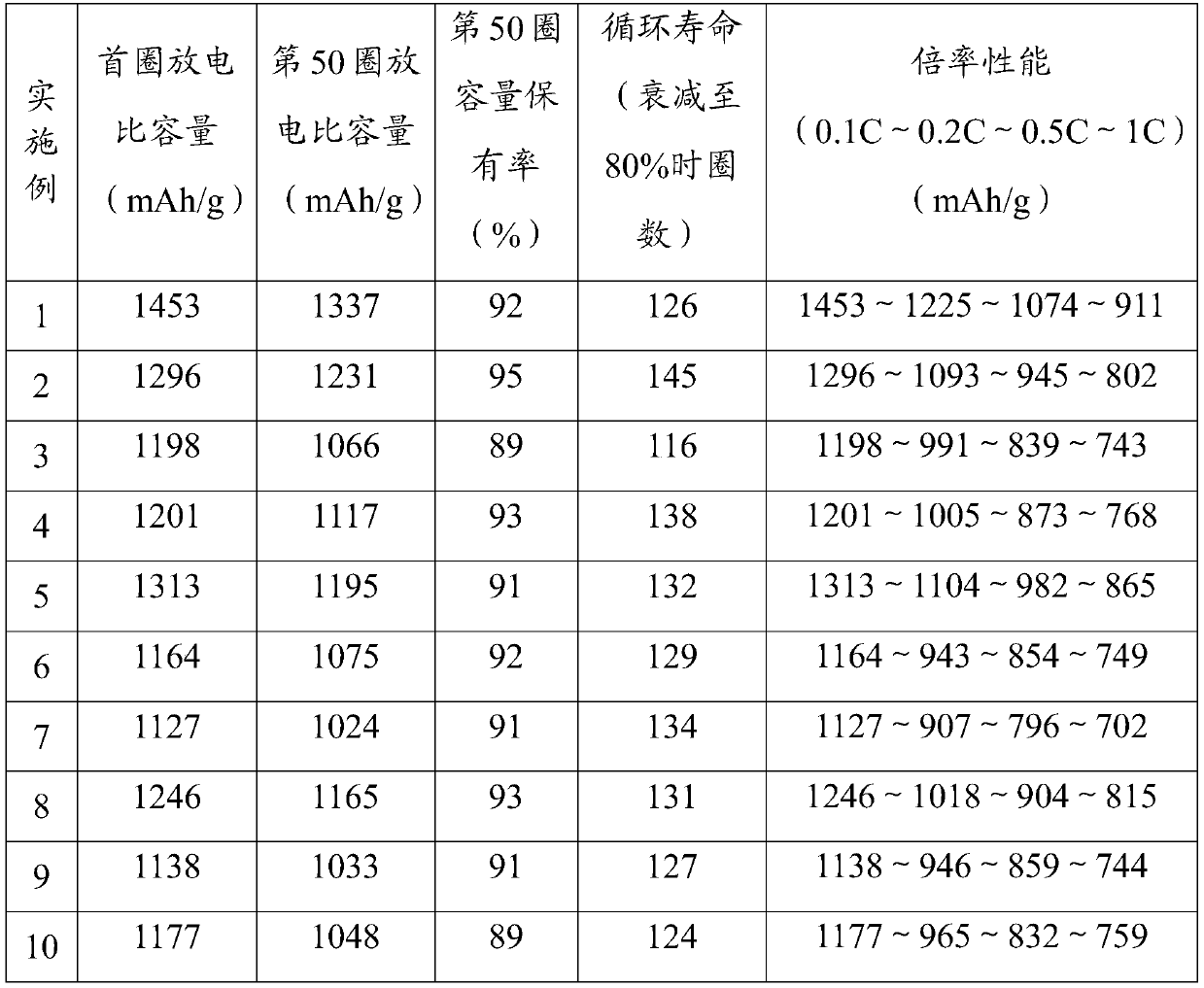

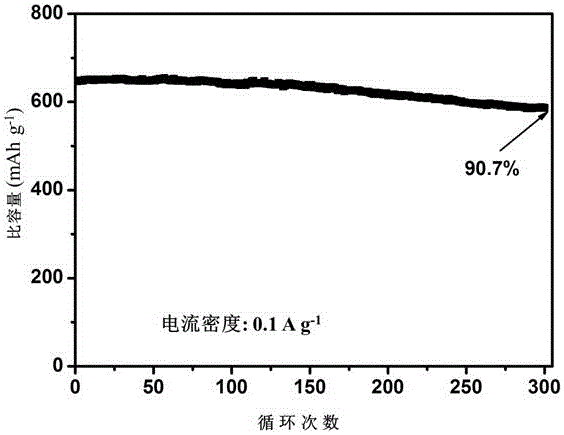

Tin sulfide/graphene sodium ion battery composite cathode material and preparation method thereof

ActiveCN106654192AReduce energy consumptionEasy to operateCell electrodesSecondary cellsFreeze-dryingAmmonium sulfide

The invention discloses a tin sulfide / graphene sodium ion battery composite cathode material and a preparation method thereof. The preparation method includes: dissolving tin sulfide in ammonium sulfide solution, adding graphene oxide solution, performing ultrasonic treatment to enable the graphene oxide solution to be dispersed uniformly, constructing a three-dimensional porous structure through quenching, and freeze-drying for 6-72h to obtain a tin sulfide and graphene composite material precursor; calcining the precursor in inert or reductive atmosphere at 250-500 DEG C for 1-24h to obtain the tin sulfide / graphene sodium ion battery composite cathode material. The composite material can be used as a sodium ion battery cathode material, specific capacity of the composite material can reach 649.5mAh g-1 when current density is 1Ag-1, and specific capacity retention rate after being circulated for 300 times is higher than 90%. Compared with conventional hydrothermal methods, the tin sulfide / graphene sodium ion battery composite cathode material and the preparation method have the advantages of short process, simple course, low energy consumption, high material preparation controllability, easiness in realizing large-scale production and more excellent electrochemical performance.

Owner:SOUTH CHINA UNIV OF TECH

Method for recycling sulfur dioxide (SO2) and heavy metal in metallurgical gas

InactiveCN102949926AEmission complianceImprove removal efficiencyGas treatmentDispersed particle separationAmmonium sulfideSulfur

The invention discloses a method for recycling sulfur dioxide (SO2) and heavy metal in metallurgical gas, and the method is characterized in that after the metallurgical gas is pretreated, the SO2 and the heavy metal in the smoke can be simultaneously removed by utilizing ammonium sulfide solution, and the heavy metal and a sulfuric product are recycled; and the method is simple and easy to operate, high in desulphurization rate, low in cost and applicable to the industrialized use.

Owner:KUNMING UNIV OF SCI & TECH

Process for metal recovery in flotation operations

InactiveUS20190256950A1Significant positive effectReduce activationFlotationPotassium sulfideAmmonium sulfide

The present invention is related to a process for increasing copper or metal recovery in flotation processes, specially of minerals that are dissolved during the grinding stage, by the use of any sulfidizing agent or ionizing sulfide such as, but not limited to, sodium hydrogen sulfide, sodium sulfide, potassium hydrogen sulfide, potassium sulfide, ammonium hydrogen sulfide or ammonium sulfide, hydrogen sulfide (H2S), polysulfides of potassium, calcium, magnesium or ammonium to precipitate during the grinding stage or immediately after the grinding stage, metals that have been dissolved prior or during the milling or grinding stage prior to normal flotation.

Owner:PASSAU SA

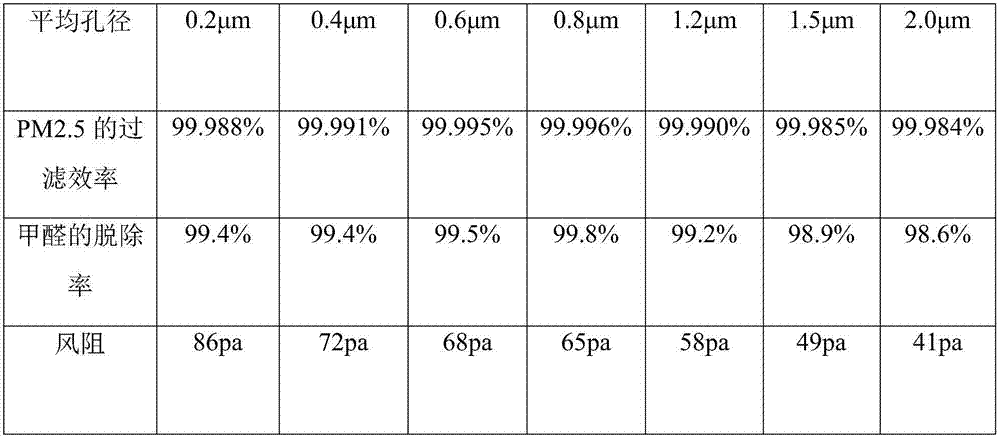

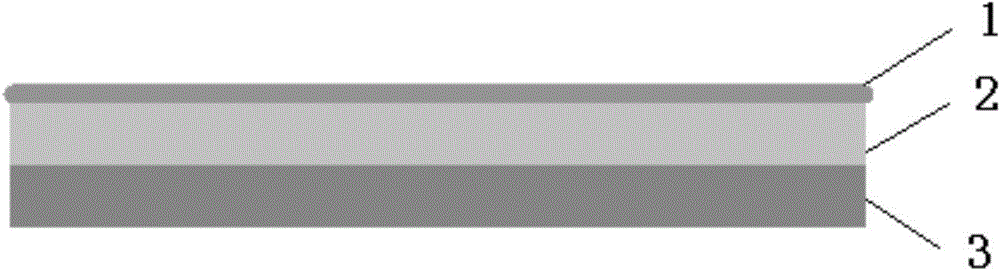

Novel composite filter net for air purifier and preparation method thereof

ActiveCN107308733AIncrease loadExtended service lifeGas treatmentDispersed particle filtrationAmmonium sulfideTungstate

The invention provides a novel composite filter net for an air purifier and a preparation method thereof. The novel composite filter net comprises a matrix layer, a transition layer and an active layer, the matrix layer is a stainless steel wire net after going through etching treatment, the transition layer is loaded on the surface of the matrix layer and is chosen from an aluminum oxide coating and a silicon dioxide coating or a composite coating of the two, and the active layer is arranged on the outermost layer of the composite filter net, loaded on the surface of the transition layer and composed of titanium dioxide, ammonium sulfide and bismuth tungstate. By the novel composite filter net, the problem that existing composite filter nets for the air purifier are high in filtering resistance and short in service life is solved, catalytic activity can be improved, and production cost is further lowered.

Owner:丁海军

Method for producing ammonium metavanadate by using waste catalytic cracking catalyst in oil refinery

InactiveCN104495924AImprove recycling efficiencyVanadium compoundsAmmonium sulfideAluminum ammonium sulfate

The invention relates to a method for producing ammonium metavanadate by using a waste catalytic cracking catalyst in an oil refinery. The method comprises the following steps: mixing the waste catalyst with sulfuric acid, calcium fluoride and water in a mixer, feeding into a curing cabin, and curing in the curing cabin; pulpifying the mixed materials with water; pumping the pulpified liquid into a leaching tank, and heating and stirring for leaching; pumping into a plate filter press for liquid-solid separation, feeding the leachate into a crystallization tank, and adding ammonium sulfate to crystallize; and performing liquid-solid separation, thereby obtaining an aluminum ammonium sulfate product and crystallization master batch; and adding ammonium carbonate into the crystallization master batch to adjust the pH value, adding ammonium persulfate, adding ammonium carbonate to adjust the pH value, heating to react, pumping into the filter press, and performing liquid-solid separation, thereby obtaining ammonium metavanadate. The separated liquid can be also fed into a lanthanum-cerium deposition tank, and ammonium oxalate is added to react to obtain lanthanum oxalate and cerous oxalate, or the separated liquid is fed into a nickel deposition tank, and ammonium sulfide is added to react to obtain nickel sulfide. By adopting the method, the waste catalytic cracking catalyst in the oil refinery can be reused for producing ammonium metavanadate, the problems that the environment can be polluted by the waste catalyst and the land can be occupied are effectively solved, the purity of the produced ammonium metavanadate is even greater than 99%, and the recycling efficiency is high.

Owner:武汉源宸再生资源科技有限公司

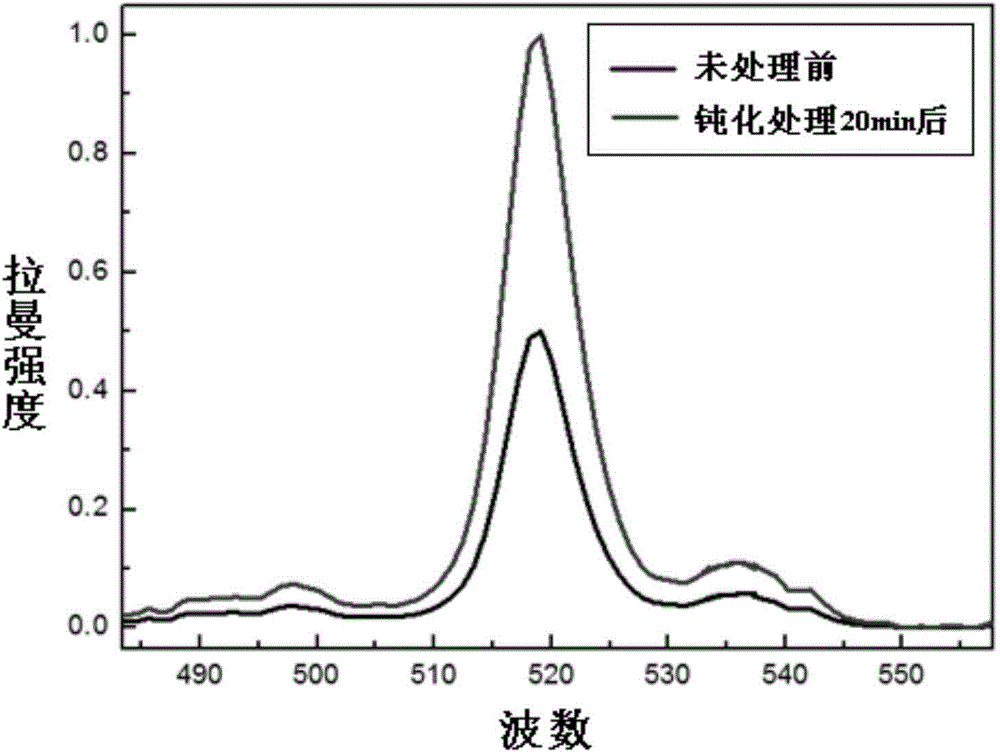

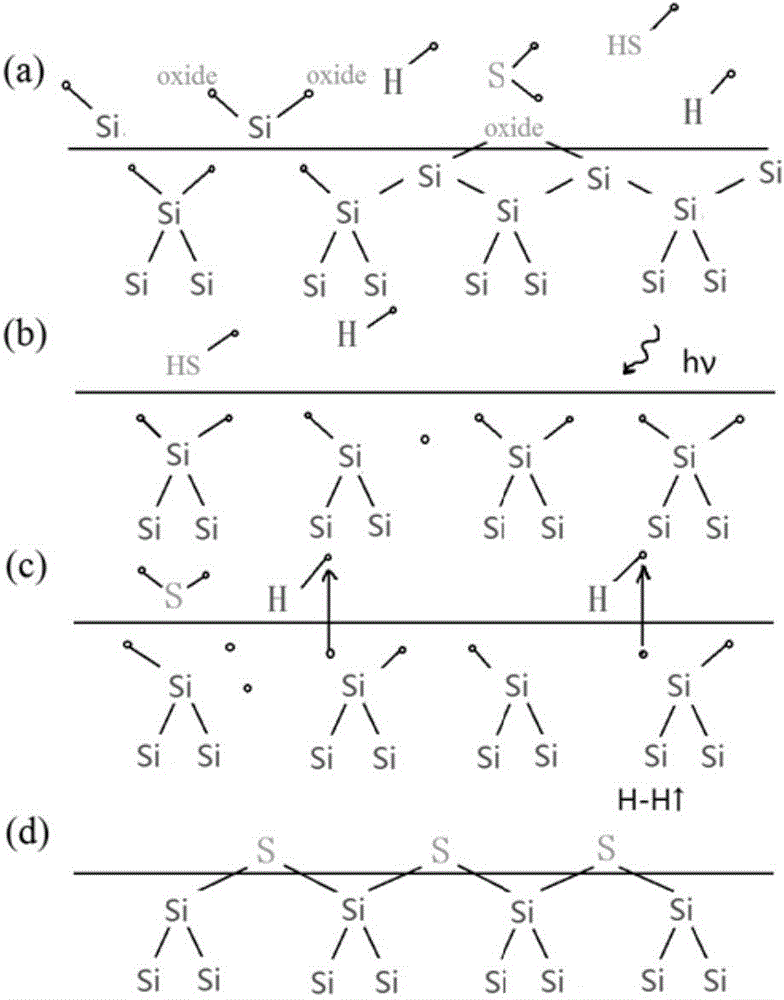

Method for overcoming surface defect of polycrystalline silicon

InactiveCN104795321AImprove surface mobilityExtended service lifeSemiconductor/solid-state device manufacturingHydrogenAmmonium sulfide

The invention relates to the field of semiconductors, and particularly discloses a method for overcoming a surface defect of polycrystalline silicon. The method specifically comprises the steps that surface passivating treatment is conducted on the polycrystalline silicon through sulfur-containing passivating liquid or SCl2 gas, wherein the sulfur-containing passivating liquid is an ammonium sulfide solution or a sodium sulfide solution. According to the method for overcoming the surface defect of the polycrystalline silicon, due to the fact that surface passivating treatment is conducted on the polycrystalline silicon through the sulfur-containing passivating liquid or the SCl2 gas, the surface defect formed on the surface of the polycrystalline silicon in the polycrystalline silicon formation technological process can be effectively overcome, suspended chemical bonds can be effectively removed, the surface mobility of the polycrystalline silicon can be improved to a small extent, and the service life of the high mobility of the polycrystalline silicon can be prolonged. Compared with conventional hydrogen implantation and dehydrogenation technologies, the method has the advantages that operation is easier and more convenient, and the method can be accomplished only through the one-step technological process.

Owner:BOE TECH GRP CO LTD +1

Preparation method of nitrogen- and sulfur-doped fluorescence carbon dots

InactiveCN105542760AGood water solubilityGood optical performanceLuminescent compositionsNatural resourceAmmonium sulfide

The invention discloses a preparation method of nitrogen- and sulfur-doped fluorescence carbon dots. The fluorescence carbon dots are prepared by a hydrothermal method adopting grapefruit juice as a precursor and an N- and S-containing compound as a passivator. The method comprises the following steps: adding the grapefruit juice together with ammonium sulfate, ammonium persulfate, thioacetamide and ammonium sulfide respectively into a reaction kettle and heating for several hours; and centrifuging the reaction liquid, filtering with a filtering membrane and dialyzing to obtain an aqueous solution of carbon dots. According to the preparation method disclosed by the invention, the adopted grapefruit juice comes from natural resources and is easily available; and the doped nitrogen and sulfur are good for enhancing the fluorescence property. The method has the advantages of simple preparation process and controllable conditions and is green and environmentally friendly.

Owner:JIANGNAN UNIV

Method for extracting and separating glutathione from GSCu precipitate

ActiveCN106220708AImprove product qualityReduce usagePeptide preparation methodsPotassium sulfideAmmonium sulfide

The invention provides a method for extracting and separating glutathione from GSCu precipitate. The method comprises the following steps: adding GSCu precipitate and water into a reactor, forming suspension liquid, completely stirring, adding acid to perform acidification, adding sulfide, reacting under the stirring condition, centrifuging or filtering, and removing the generated Cu2S precipitate to prepare a glutathione mother liquid; concentrating and crystallizing to prepare a glutathione crystal pure product, wherein the sulfide is selected from one or more of the following compounds: ammonium sulfide, sodium sulfide and potassium sulfide. By the method, the raw materials are effectively selected, and the proportion and the reaction condition are reasonably controlled and the use of hydrogen sulfide is avoided, so that environmental pollution is reduced, the convenience of production and operation is improved, the prepared glutathione has stable product quality, and the method is quite suitable for large-scale industrialized production. In conclusion, the method for extracting and separating glutathione from the GSCu precipitate, provided by the invention, has good application prospect and market potential.

Owner:SHANGHAI QINGPING PHARMA CO LTD

Process for preparing hydrogen sulfide

The invention discloses a process for preparing hydrogen sulfide through the reaction between sulfuric-acid-containing exhausted liquid (by product of the production process for preparing chemical product and intermediate product by means of chemical reactions) and barium sulphide water soluble liquid phase (prepared from barium sulphide calcined member through water leaching), the produced hydrogen sulfide can be further used in preparing other chemical products, such as sodium hydroxide, sodium hydrogen sulfide, ammonium sulfide, ammonium hydrosulfide, sulfourea, methyl hydrosulfide, ethyl mercaptan and dimethyl sulfur ether.

Owner:唐培堃

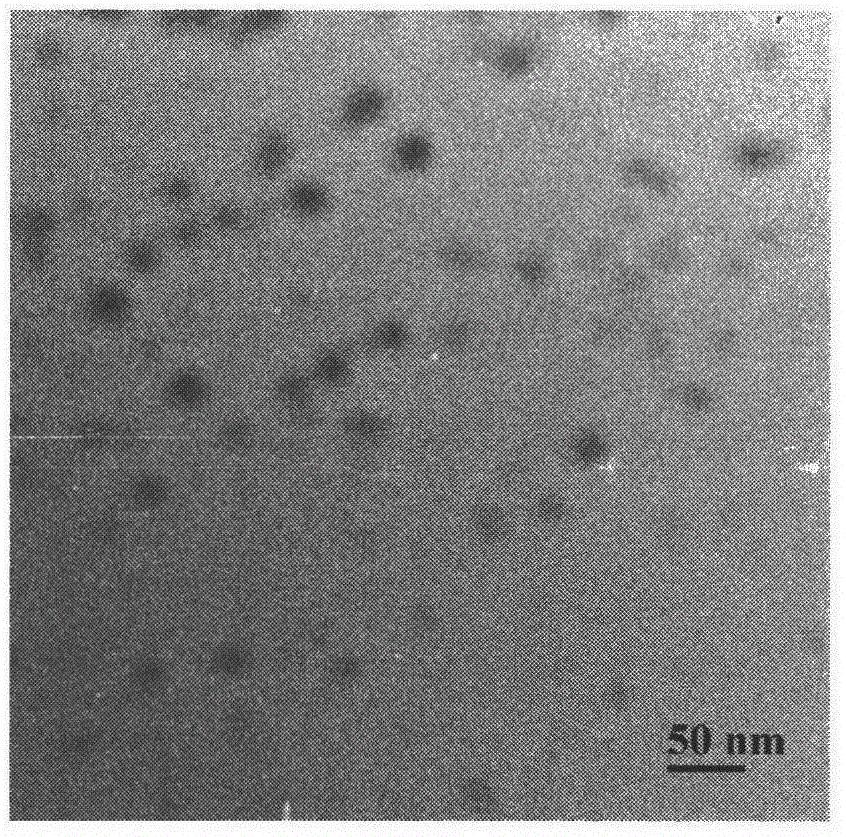

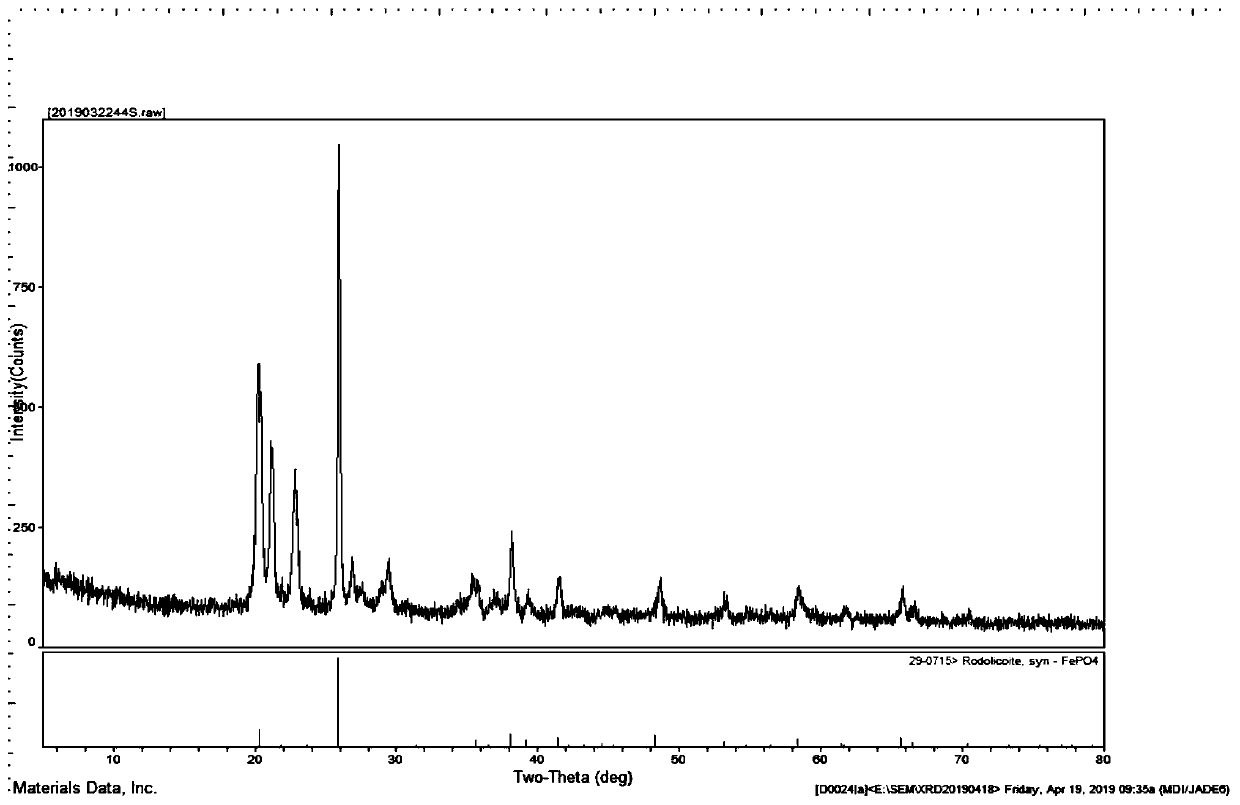

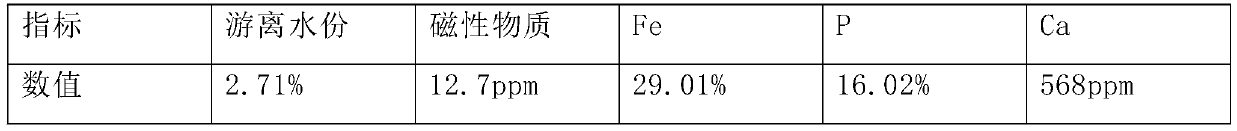

Processing method of waste iron phosphate

InactiveCN110526226ARealize resource utilizationLarge specific surface areaAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersWaste processingResource utilization

The invention discloses a processing method of waste iron phosphate, and belongs to the technical field of waste processing. The method comprises the following steps: adding the waste iron phosphate into a phosphoric acid solution, heating the phosphoric acid solution to react after slurrying is finished, and filtering the phosphoric acid solution to obtain a first filtrate and a first filter residue; adding ammonium sulfide into the obtained first filtrate, and carrying out stirring and reacting; then carrying out filtering to obtain a second filtrate and a second filter residue; mixing the second filtrate with urea, and carrying out reacting until the end point pH is 1.9-2.1, wherein the stirring speed is 100-200 r / min, and the temperature is 95-100 DEG C; carrying out filtering to obtain a third filter residue and a third filtrate; and drying and calcining the third filter residue to obtain battery-grade anhydrous iron phosphate. According to the processing method of the waste ironphosphate, resource utilization of the waste iron phosphate can be realized, high-end circulation is realized, the battery-grade anhydrous iron phosphate is obtained, the additional value of the battery-grade anhydrous iron phosphate is increased, resource utilization of byproducts is realized, and the obtained battery-grade anhydrous iron phosphate is large in specific surface area and good in processing performance.

Owner:王敏

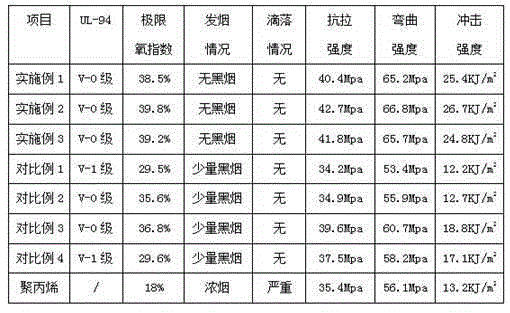

Flame retardant based on organic silicon resin

The invention discloses a flame retardant based on organic silicon resin. The flame retardant is prepared from the following raw materials in parts by weight: 30-50 parts of organic silicon resin, 20-40 parts of organic silicon elastomer, 10-20 parts of ammonium sulfide, 5-7 parts of tellurium dioxide, 1-5 parts of a silane coupling agent, 5-10 parts of sodium hydroxide, 80-120 parts of alcohol, 10-15 parts of magnesium hydroxide, 5-10 parts of diatomite, 5-15 parts of poly(phosphorus oxide), 40-60 parts of deionized water and 2-17 parts of a flame-retardant synergistic composition. The flame retardant based on organic silicon resin is very good in hydrophobic property, and capable of remarkably improving flame resistance, which reaches level UL-94 V-0, of polypropylene, and obviously improving mechanical performances (tensile strength, bending strength and impact strength) of the material; a limit oxygen index of the polypropylene can be higher than 38.5%.

Owner:安徽红阳化工有限公司

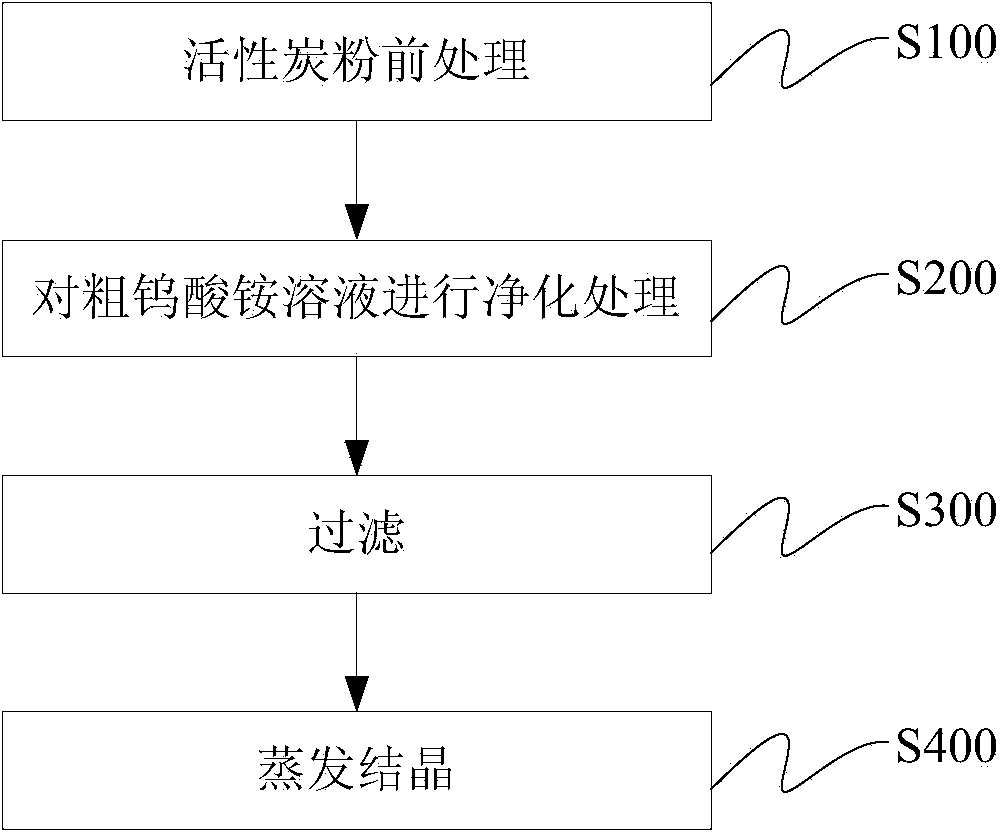

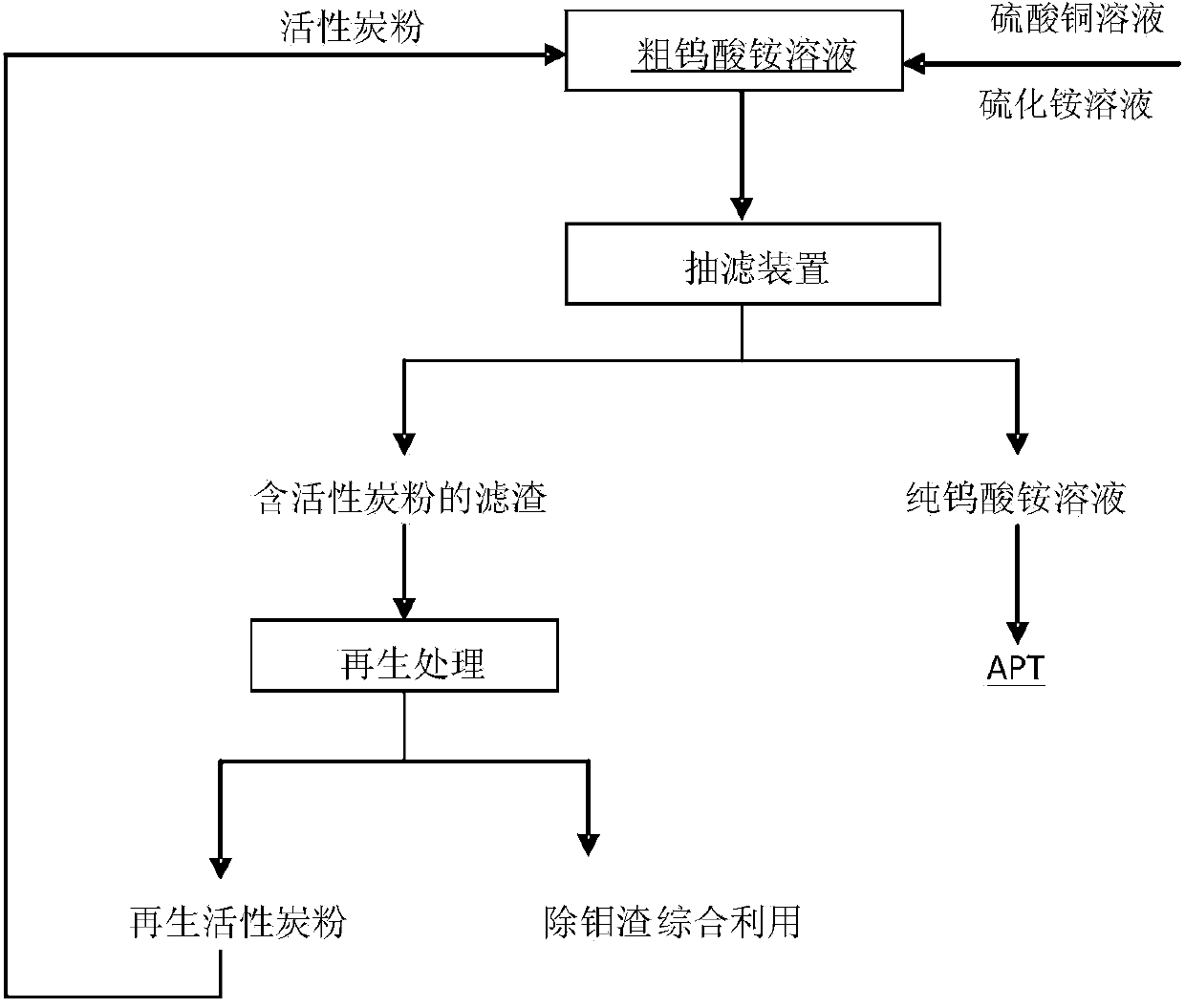

Method for treating crude ammonium tungstate solution

ActiveCN103739016AShorten the production cycleReduce dosageTungsten compoundsActivated carbonAmmonium sulfide

The invention discloses a method for treating a crude ammonium tungstate solution. The method comprises the steps of (1) washing activated carbon powder by utilizing dilute hydrochloric acid; (2) adding an ammonium sulfide solution, a copper sulfate solution and the washed activated carbon powder into the crude ammonium tungstate solution to carry out purification treatment on the crude ammonium tungstate solution; (3) filtering the purified crude ammonium tungstate solution to obtain filter residue containing the activated carbon powder and a pure ammonium tungstate solution; and (4) carrying out evaporation crystallization on the pure ammonium tungstate solution to obtain ammonium paratungstate. By utilizing the method, a lot of sedimentation time and filtering equipment can be saved, the treatment efficiency can be significantly improved, and the treatment cost can be reduced.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

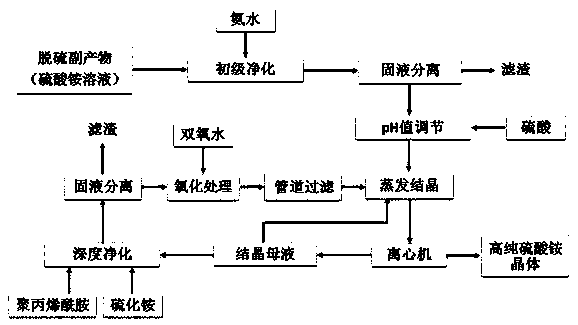

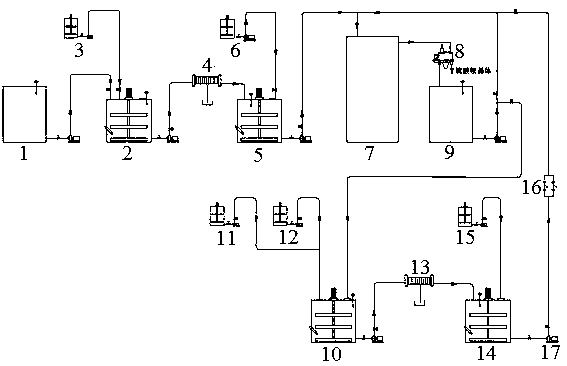

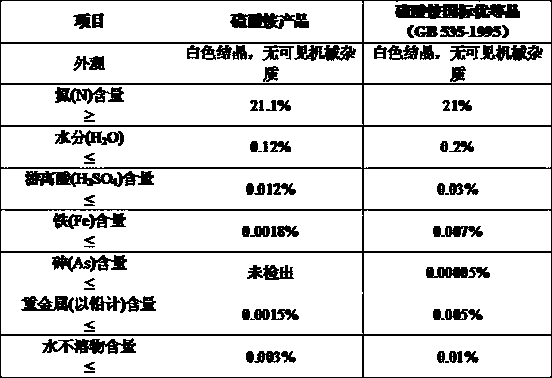

Method and device for deeply purifying by-product ammonium sulfate solution from diachylon ammonium desulphurization

InactiveCN109399667AEnsure complete removalGuaranteed qualityAmmonium sulfatesAmmonium sulfideEvaporation

The invention discloses a method and device for deeply purifying a by-product ammonium sulfate solution from diachylon ammonium desulphurization. The method comprises the steps of primary purificationof the ammonium sulfate solution, adjustment of the pH value, evaporative crystallization, deep purification and oxidization. The device comprises a desulphurization by-product storage tank, a quantitative ammonia water adding device, a primary purification reactor, a primary purification filter, a quantitative sulfuric acid adding device, a pH value adjusting reactor, an evaporation crystallizer, a centrifugal machine, a crystallization mother liquor storage tank, a quantitative ammonium sulfide adding device, a quantitative polyacrylamide adding device, a deep purification reactor, a deep purification filter, a quantitative hydrogen peroxide adding device, an oxidization reactor, a pipeline filter and a delivery pump. By means of the method, high-purity ammonium sulfate which meets therequirements for the superior product in GB / T 535-1995 is prepared, and efficient recycling of resources is achieved. According to the method, the ammonium sulfate is recycled from a filtrate obtainedafter purification of diachylon desulfurization mother liquor, and the method has the advantages of being low in energy consumption, high in product purity, economical and environmentally friendly. The situation that waste liquid containing heavy metals is discharged into the environment to cause environmental pollution is avoided.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com