Method for recycling sulfur dioxide (SO2) and heavy metal in metallurgical gas

A technology for smelting flue gas and heavy metals, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of not considering the removal of low-concentration heavy metals, not considering the separation of sulfur and heavy metals, and secondary pollution of heavy metals, etc. Achieve the effect of resource utilization, avoid heavy metal discharge, and high desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

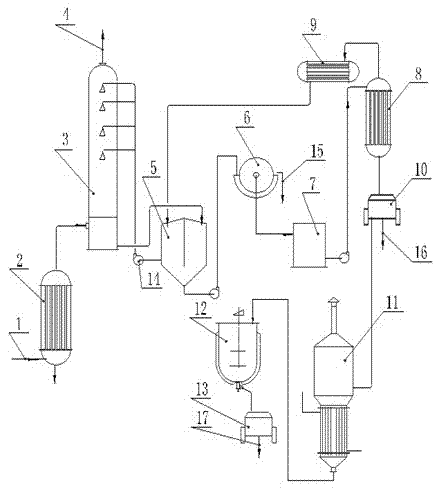

[0052] Example 1: SO in zinc smelting flue gas 2 and heavy metal recycling methods, the details are as follows:

[0053] (1) The flue gas to be treated in this example is zinc smelting flue gas, and the flue gas volume is 10000m 3 / h, the flue gas at the furnace mouth contains SO 2 : 4-6%, Hg: 0.2mg / m 3 , As: 1-5mg / m 3 , Pb: 10-15 mg / m 3 , Cd: 2-7 mg / m 3 ; Zinc smelting flue gas 1 enters cooler 2 after dedusting, and cools the flue gas temperature to below 40°C;

[0054] (2) Atomize the ammonium sulfide solution with a mass percentage concentration of 3% through the vortex nozzle in the absorption tower 3. After cooling, the flue gas enters the absorption tower 3 countercurrently and fully contacts the atomized ammonium sulfide solution. 2 The smelting flue gas is efficiently absorbed, and at the same time, the metal oxides such as mercury, lead, arsenic, and cadmium in the flue gas are effectively absorbed, and the purified flue gas 4 is discharged from the top of the t...

Embodiment 2

[0058] Example 2: SO in lead smelting flue gas 2 and heavy metal recycling methods, the details are as follows:

[0059] (1) The flue gas to be treated in this example is lead smelting flue gas, and the flue gas volume is 50000m 3 / h, the flue gas at the furnace mouth contains SO 2 : 8-15%, Hg: 0.4mg / m 3 , As: 1-5mg / m 3 , Pb: 35-45mg / m 3 , Cd: 1-3 mg / m 3 ;After preliminary dedusting of the smelting flue gas, the temperature of the cooling flue gas is lower than 40°C;

[0060] (2) The ammonium sulfide solution with a mass percentage concentration of 5% is atomized through the vortex nozzle in the absorption tower, and the smelting flue gas is purified and absorbed through the atomized ammonium sulfide solution, and the purified flue gas is discharged to absorb SO 2 The rich solution with heavy metals enters the self-redox reactor, and the rich solution is treated in the reactor for 30 minutes. During this process, metal sulfides such as mercury, lead, arsenic and cadmium...

Embodiment 3

[0063] Example 3: SO in nickel smelting flue gas 2 and heavy metal recycling methods, the details are as follows:

[0064] (1) The flue gas to be treated in this example is nickel smelting flue gas, and the flue gas volume is 36000m 3 / h, the flue gas collected by the converter contains SO 2 : 0.8-1.1%, Hg: 0.2mg / m 3 , As: 3-5mg / m 3 , Pb: 10-25mg / m 3 , Cd: 1-3 mg / m 3 ;After preliminary dedusting of the smelting flue gas, the temperature of the cooling flue gas is lower than 40°C;

[0065] (2) The ammonium sulfide solution with a mass percentage concentration of 4% is atomized through the vortex nozzle in the absorption tower, and the smelting flue gas is purified and absorbed through the atomized ammonium sulfide solution, and the purified flue gas is discharged to absorb SO 2 The rich solution with heavy metals enters the self-redox reactor, and the rich solution is treated in the reactor for 25 minutes. During this process, metal sulfides such as mercury, lead, arseni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com