Patents

Literature

356 results about "Magnesium ammonium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

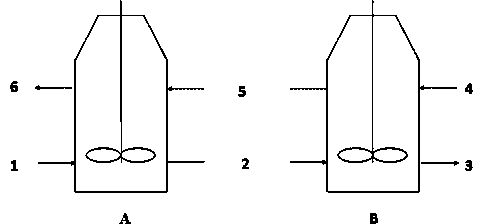

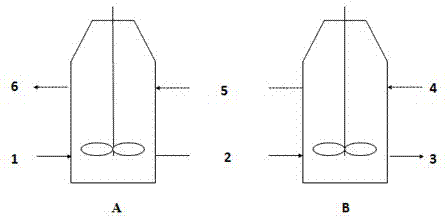

Integrated nitrogen and phosphorus recovery device in struvite method

InactiveCN101817581AImprove recycling efficiencyAvoid churnWater/sewage treatment by flocculation/precipitationPhosphorus compoundsTrappingStruvite Crystals

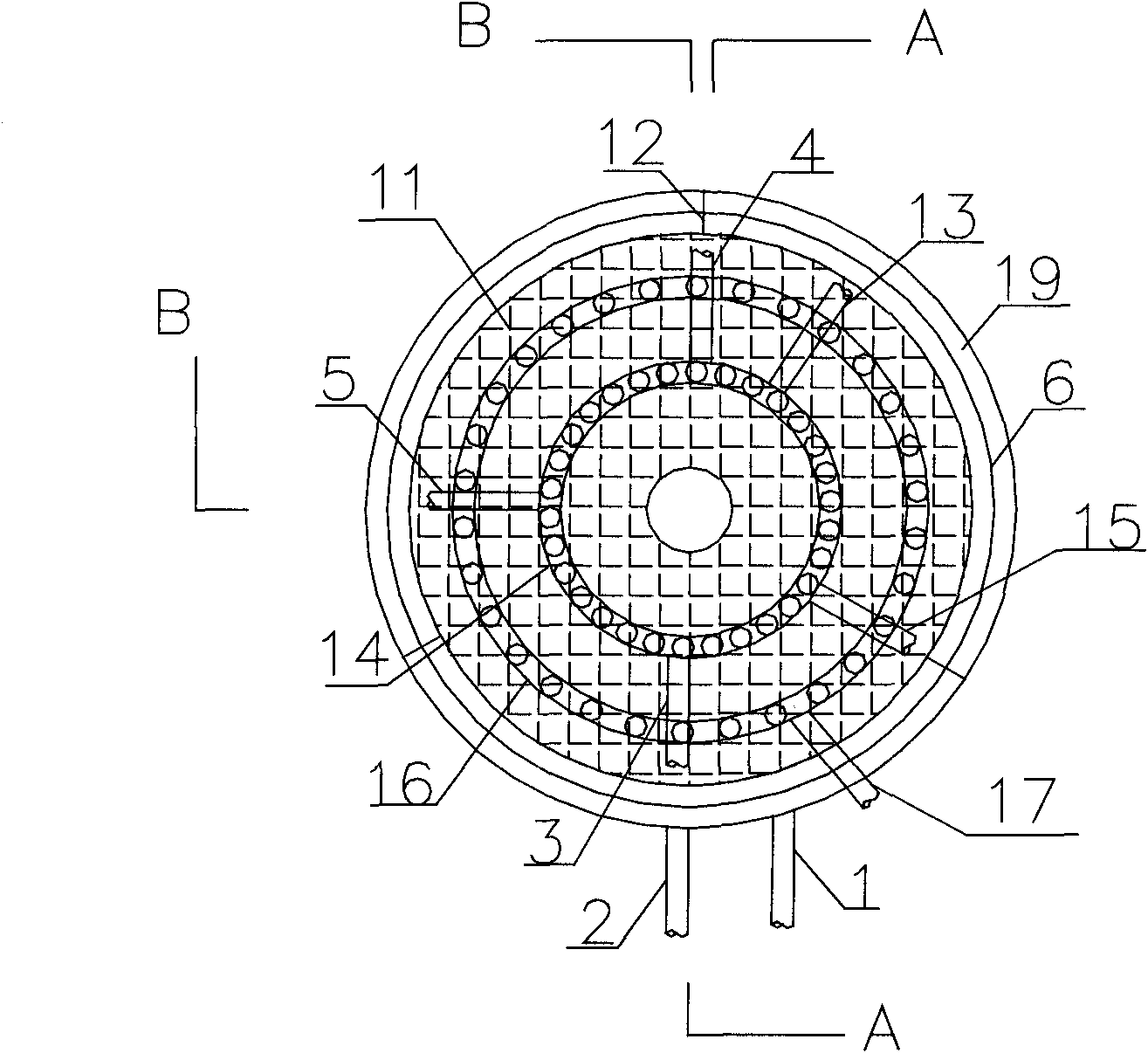

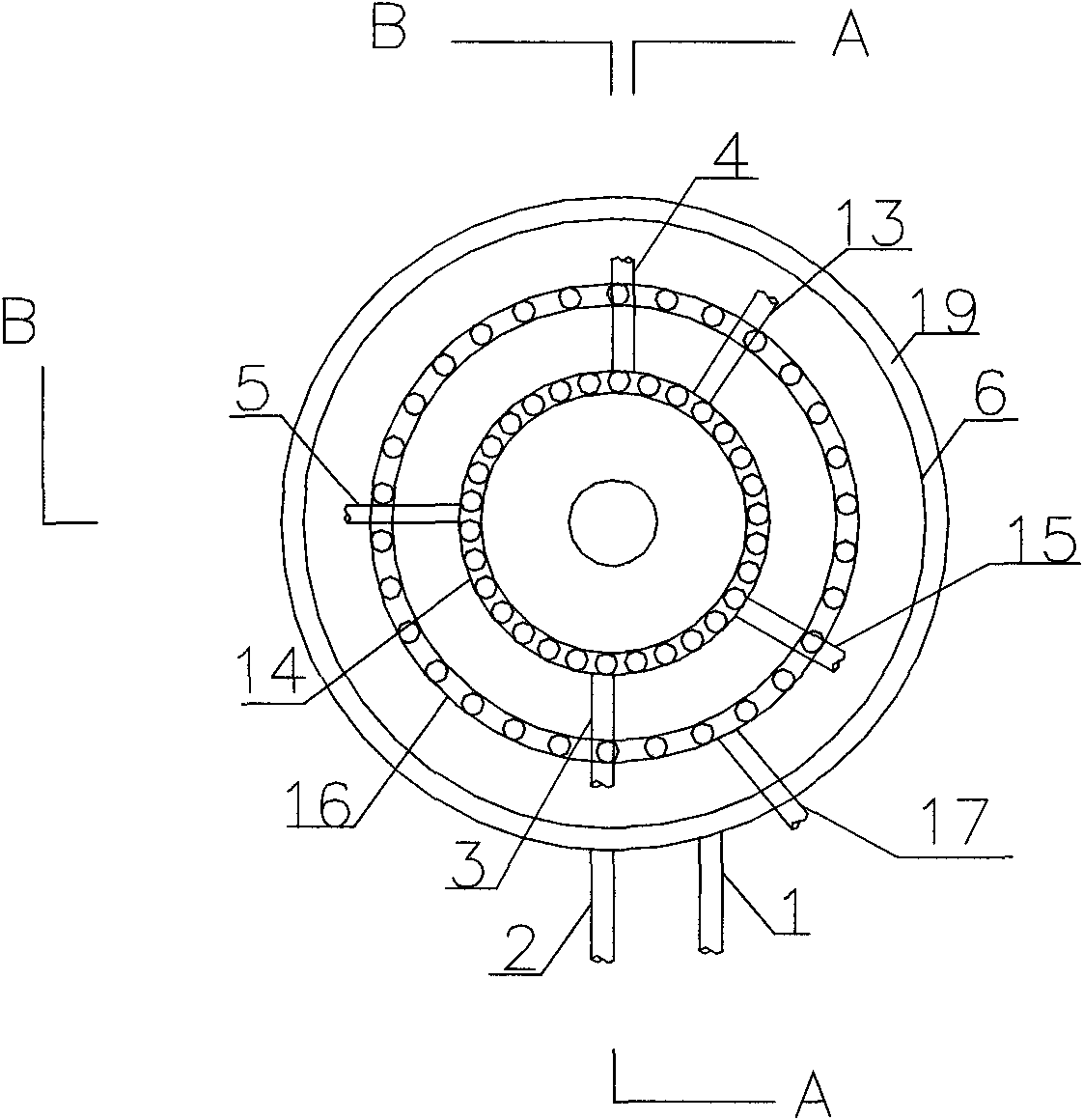

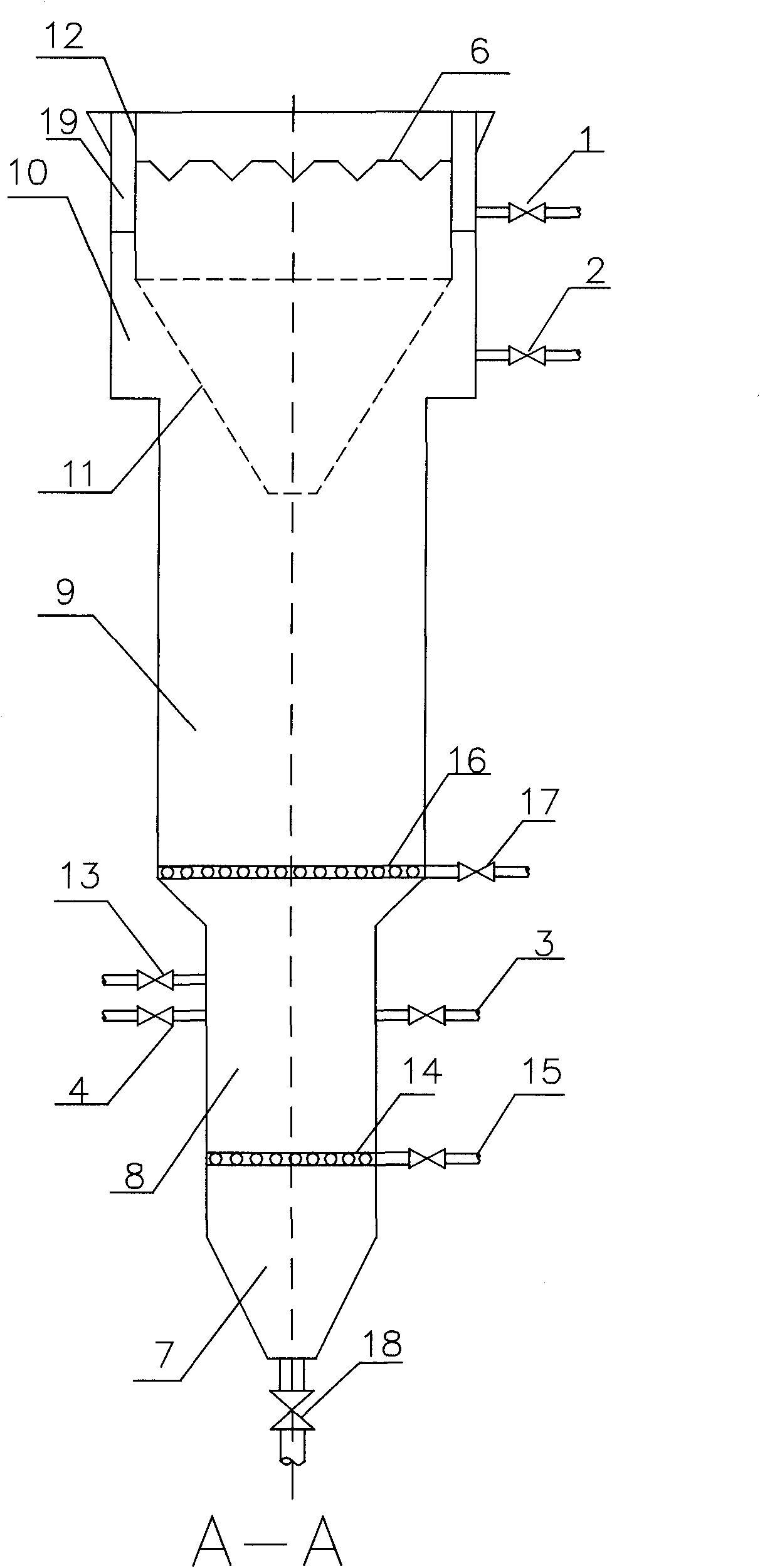

The invention discloses an integrated nitrogen and phosphorus recovery device in a struvite method, which relates to the field of environmental engineering water treatment and is a reactor for treating nitrogen and phosphorus-containing wastewater in a physicochemical method. Substances nitrogen and phosphorus in the wastewater are removed in a magnesium ammonium phosphate (struvite) form, and the substances are recovered and reused. The reaction device is in an integrated form, which comprises a precipitation zone, a mixing reaction zone, a crystal growth zone and a crystal trapping and water discharging zone from bottom to top sequentially, the mixing reaction zone is provided with a first-grade aerator, which is mainly a wastewater and reagent fully mixing and reacting zone; the crystal growth zone is provided with a second-grade aerator, which is mainly a struvite growth zone; in the precipitation zone, large-grain struvite crystals are mainly precipitated; and the crystal trapping and water discharging zone recovers the struvite crystals by a filter screen. In addition, the device uses external reflux to reinforce and to control the supersaturated rate of the struvite reaction, thus promoting the crystal growth. The device has simple technological process and has the advantages of short hydraulic retention time, high nitrogen and phosphorus recovery efficiency, high recovery pureness, little occupied area, low operation and maintenance cost and the like.

Owner:TONGJI UNIV

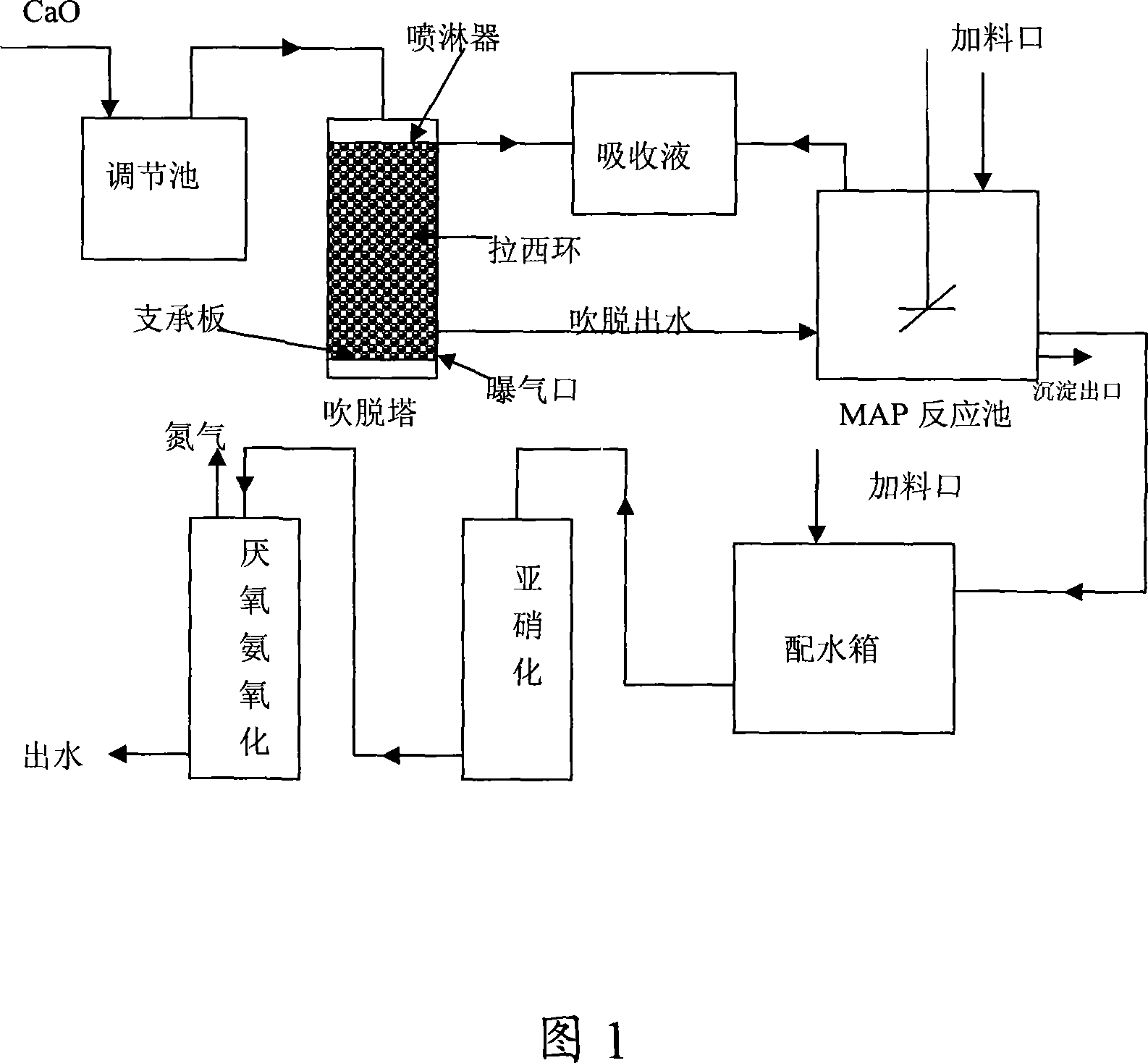

Combined treatment process for high-concentration ammonia nitrogen waste water

InactiveCN101066822AHigh total removal rateReduce energy consumptionTreatment with anaerobic digestion processesMultistage water/sewage treatmentHigh concentrationMagnesium ammonium phosphate

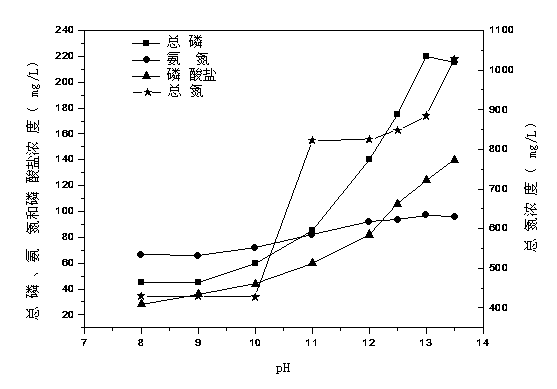

The combined treatment process of high concentration ammonia nitrogen waste water belongs to the field of waste water treating technology. The combined treatment process of high concentration ammonia nitrogen waste water features the combination of blow-off method, MAP method and nitrosation-anaerobic ammoxidation biological method. The treating process of the present invention includes the steps of: adding lime into the waste water in a regulating tank to reach pH of 11-12; blow-off and aerating in a blow-off tank, with the blow-off tail gas entering to an absorbing tank and the blow-off water entering to a MAP reaction tank; treating the blow-off effluent in the MAP reaction tank with thrown disodium hydrogen phosphate and magnesia to produce magnesium ammonium phosphate precipitate exhausted; and the final nitrosation-anaerobic ammoxidation biological treatment. The process has low power consumption and other advantages.

Owner:SHANGHAI UNIV

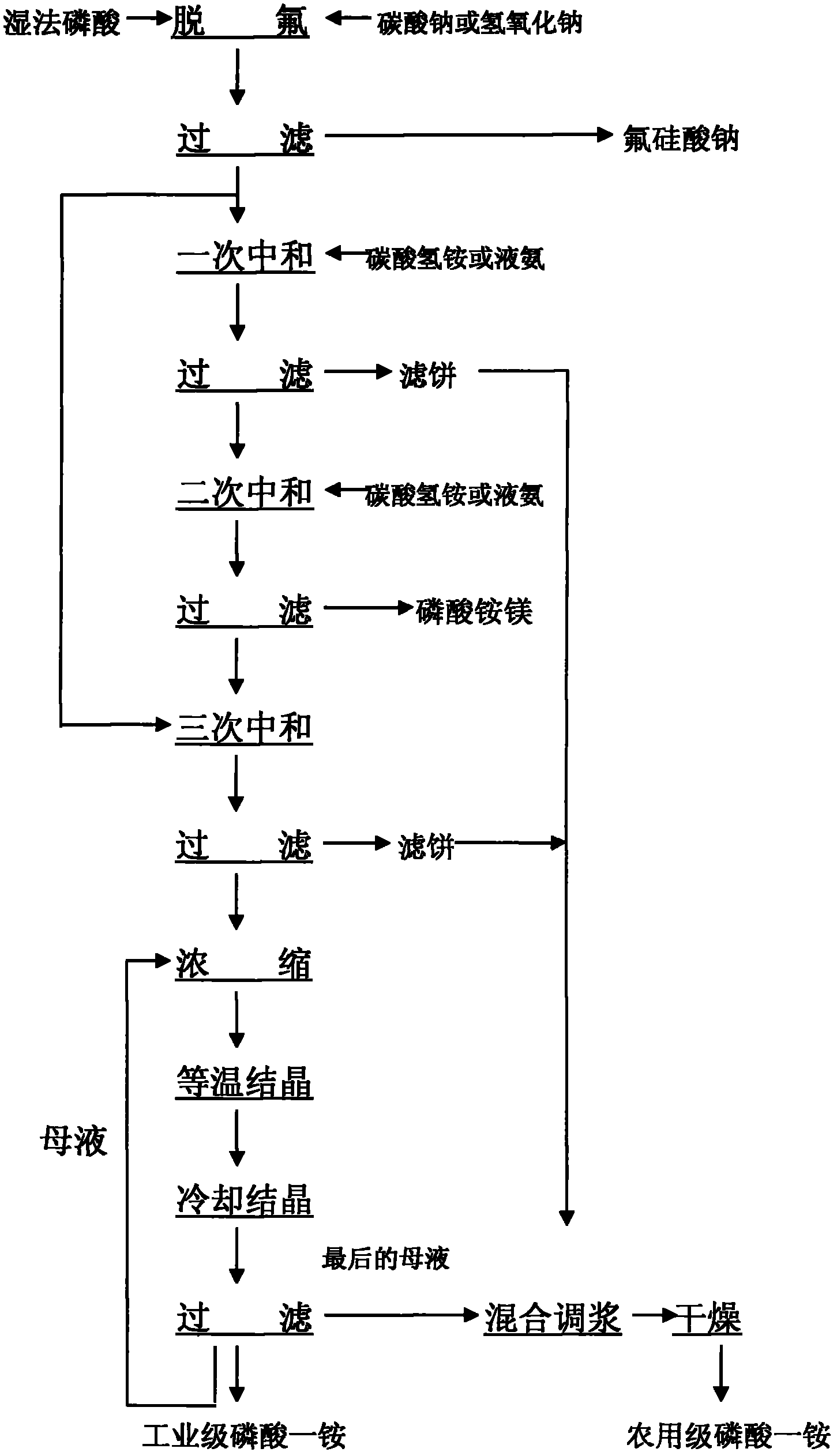

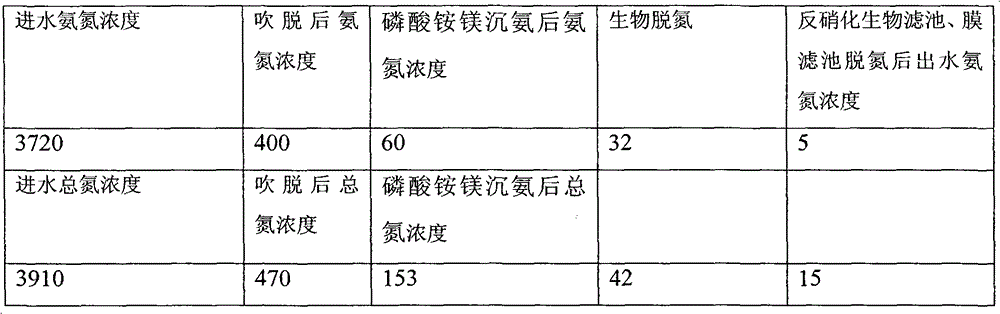

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

ActiveCN102020256AImprove purification effectTroubleshoot follow-up issuesPhosphatesO-Phosphoric AcidAgricultural engineering

The invention provides a method for producing industrial and agricultural grade monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid. The wet-process phosphoric acid is taken as a raw material. Sodium fluosilicate, monoammonium phosphate solution, monoammonium phosphate filter cakes and magnesium ammonium phosphate are respectively obtained through defluorination and a three-section substep neutralization process, wherein the monoammonium phosphate solution is concentrated and crystallized to obtain high-quality water soluble industrial monoammonium phosphate, and the monoammonium phosphate filter cakes and the monoammonium phosphate mother solution subjected to repeated crystallization are subjected to size mixed and dried to obtain qualified agricultural monoammonium phosphate. The magnesium ammonium phosphate is a good slow release nitrogenous fertilizer per se. The process has the advantages of little investment of equipment, good adaptability of raw material, low production cost and good product quality. The water soluble industrial monoammonium phosphate with low cost can provide a cheap and good water soluble phosphatic fertilizer for modern facility agriculture.

Owner:昆明隆祥化工有限公司

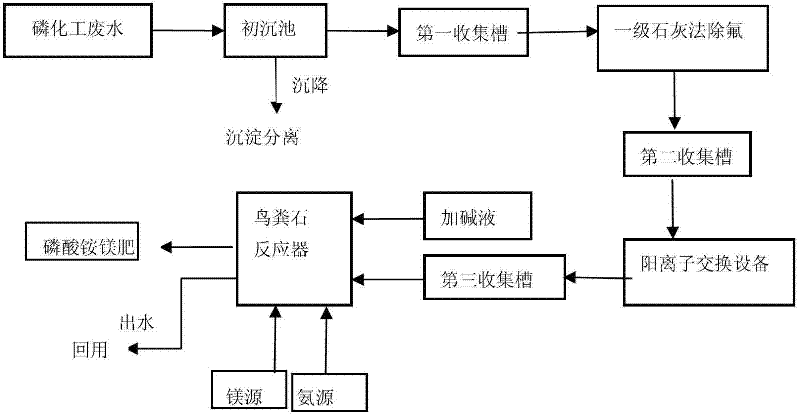

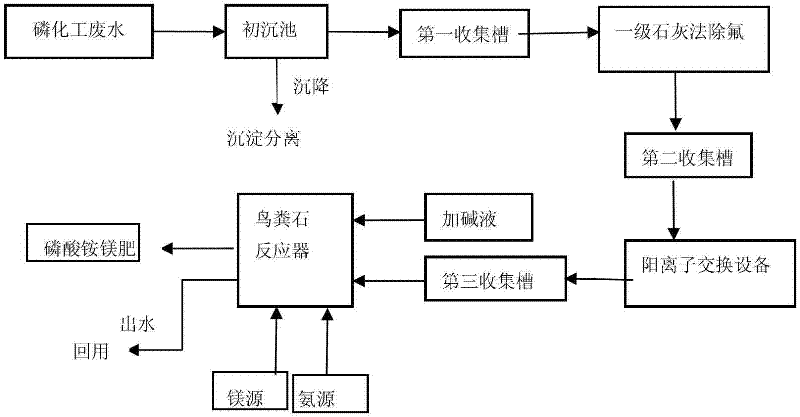

Method for recovering phosphorus in phosphorus chemical wastewater by using struvite production technology

InactiveCN102690000ALess sludgeReduce distractionsMultistage water/sewage treatmentIon exchangeMagnesium ammonium phosphate

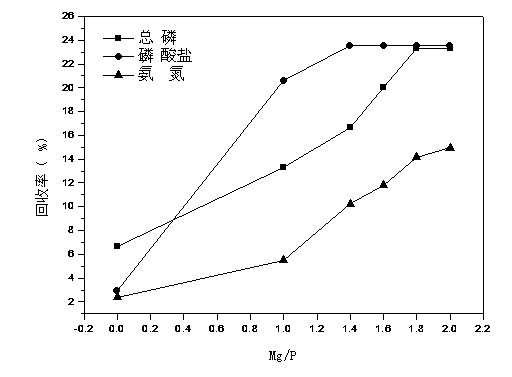

The invention relates to a method for recovering phosphorus in phosphorus chemical wastewater by using a struvite production technology. The method is carried out according to the following steps of: firstly carrying out preliminary sedimentation on the phosphorus chemical wastewater, removing impurity precipitation in the wastewater, and collecting the processed wastewater in a first collecting tank; removing inorganic fluoride ion in wastewater in the first collecting tank by adopting a first-level quick lime method, and collecting the processed wastewater into a second collecting tank; removing inorganic cations in the wastewater in the second collecting tank via a cation exchange device, and collecting the processed ion exchange wastewater into a third collecting tank; finally adjusting pH value of the ion exchange wastewater to 7-9 in a struvite reactor by alkali liquor and adding magnesium source and nitrogen source, wherein the molar ratio of magnesium / phosphorus is 1.0-1.5; and the molar ratio of nitrogen / phosphorus is 1.0-1.5; and generating a magnesium ammonium phosphate granulated fertilizer in a crystalline state in the reactor. The water from the struvite reactor achieves the secondary standard of the national wastewater discharge standard and can be directly reused in a phosphorus chemical production system or discharged up to the standard.

Owner:HUBEI FORBON TECH

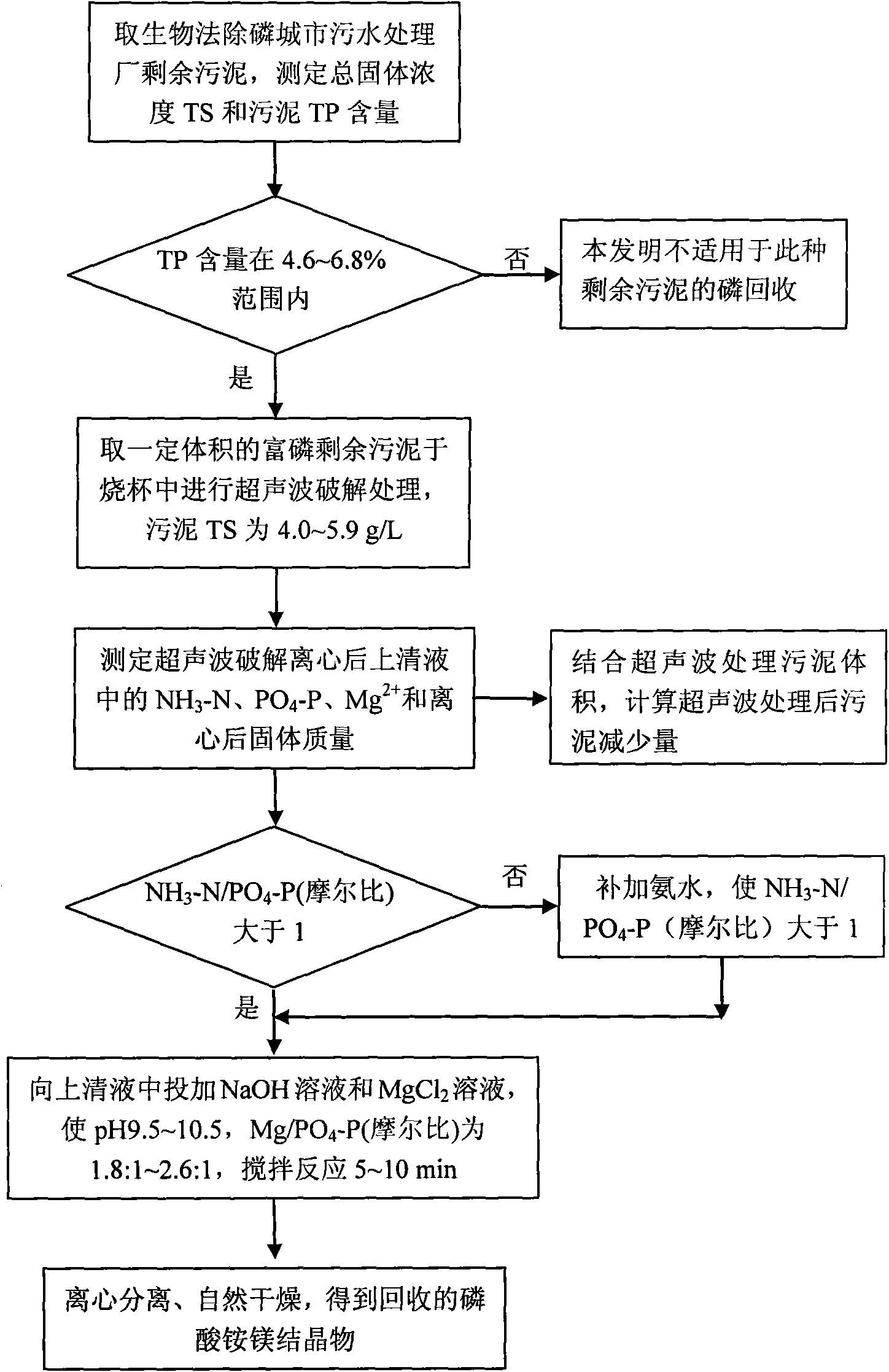

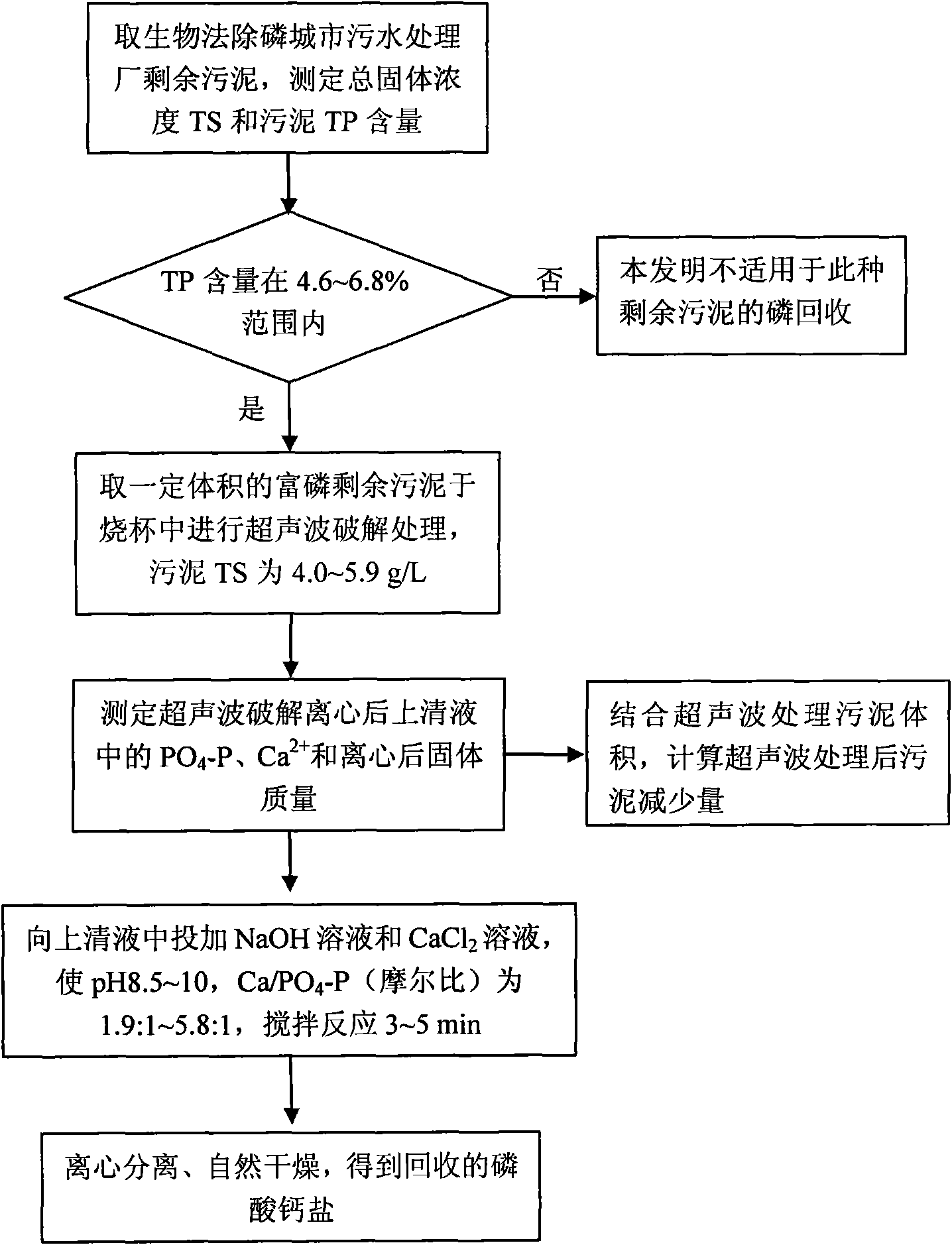

Method for recovering phosphonium compound from phosphorous excess sludge of urban sewage treatment plant

InactiveCN101654238AEasy to recycleImprove biodegradabilitySludge treatmentPhosphorus compoundsPhosphate crystalsSludge

The invention relates to a method for recovering a phosphonium compound from phosphorous excess sludge of an urban sewage treatment plant, comprising the following steps: a. obtaining phosphorous excess sludge from a biological dephosphorization urban sewage treatment system; b. carrying out ultrasonic cracking treatment on the excess sludge obtained from the step a to release pnicogen in the sludge, centrifuging the sludge and carrying out solid-liquid separation on the sludge after cracking, collecting supernatant and carrying out the step c or d; c. obtaining a recovered ammoniomagnesium phosphate crystal by adopting a magnesium ammonium phosphate precipitation process; and d. obtaining recovered phosphoric acid calcium salt by adopting a phosphoric acid calcium salt precipitation process. The invention can recovery the phosphonium compound from the excess sludge, reduce the sludge volume and lower the sludge treatment expense and is beneficial to the management operation of the urban sewage treatment plant.

Owner:EAST CHINA UNIV OF SCI & TECH

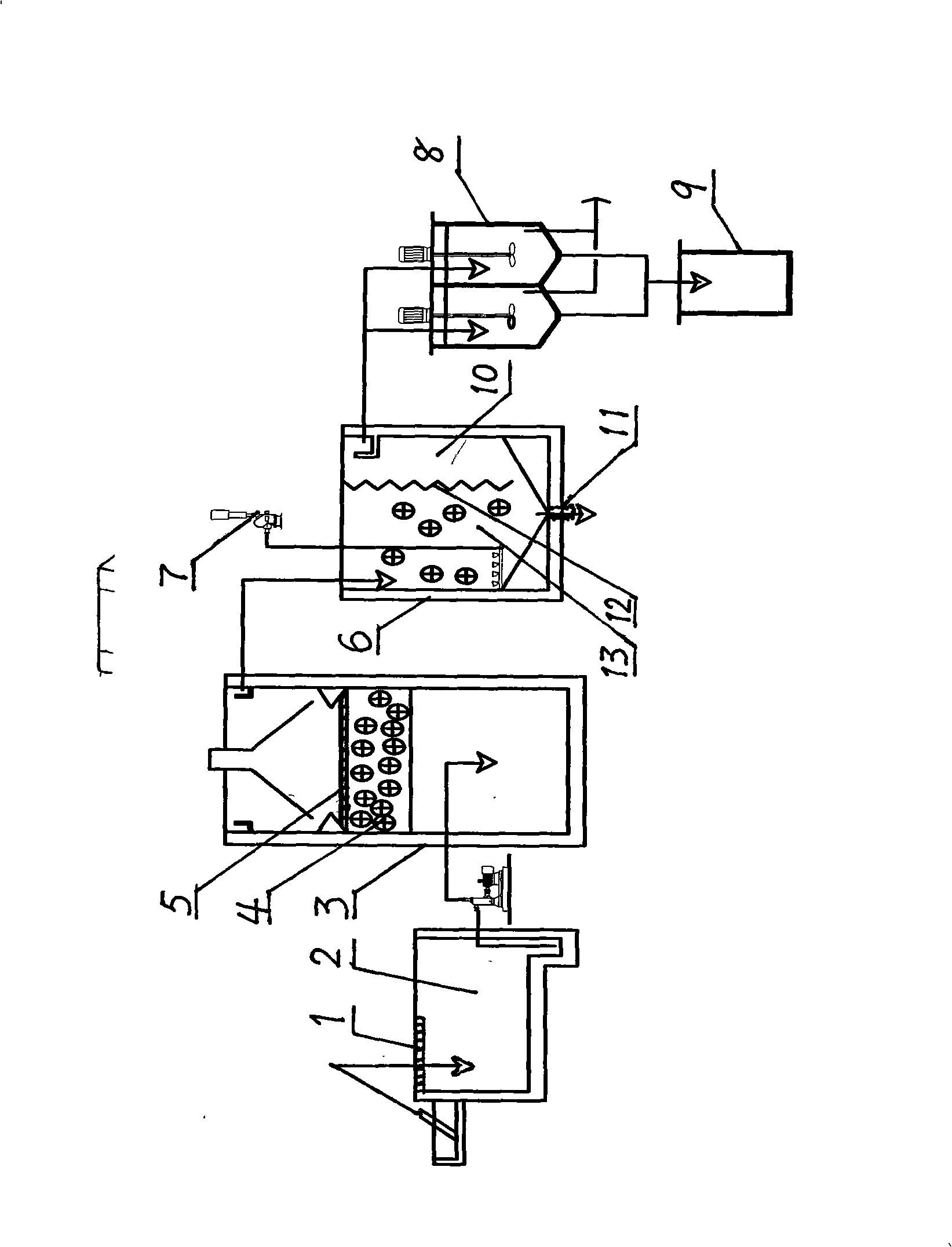

Comprehensive treatment method for wastewater of livestock and poultry cultivation

InactiveCN101343133AEasy to handleDeal with land savingTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical reactionMagnesium ammonium phosphate

Disclosed is a comprehensive treatment method of livestock and poultry breeding wastewater, which adopts the following three steps that: firstly, an upflow anaerobic sludge blanket treater (3) is used for anaerobic biological treatment and killing bacteria and viruses. Secondly, an improved moving bed biomembrane treater (6) is used for aerobic biological treatment, a longitudinal clapboard (12) is added into the treater (6) to partition the treater into an aerobic zone (13) and a solid-liquid separation zone (10), an air pump (7) is used for increasing oxygen while guiding the sewage, and a simultaneous nitrification and denitrification method is used to remove total nitrogen (TN) and decompose organics under the action of microorganisms. Thirdly, a chemical reaction method is adopted to remove P and N in the sewage, after the former two steps of treatment, mass P and N with a certain amount still exist in the sewage, liquid magnesium oxide is again added for generating magnesium ammonium phosphate precipitates, and the supernatant is discharged when reaching the standards. The method has advantages of speediness, land saving, energy saving, complete material transfer, small influence under external conditions and good purification effects when treating wastewater.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

Method of economically recycling phosphor from excess sludge

ActiveCN103641283AEasy to recycleSatisfy the requirements of sedimentationSludge treatmentO-Phosphoric AcidMagnesium salt

The invention relates to a method of economically recycling phosphor from excess sludge. The method comprises the following steps: (1), pre-treating the excess sludge; (2), carrying out alkaline hydrolysis on the excess sludge, wherein the alkaline hydrolysis is carried out by a single-stage alkaline hydrolysis method or a two-stage alkaline hydrolysis method; measuring concentration of orthophosphate and ammonia nitrogen in liquid supernatant; and (3), adding magnesium salt aqueous liquor with a Mg / P molar ratio of 0.8-2, stirring and reacting for 10 minutes-120 minutes, gravitationally or centrifugally separating precipitates, naturally drying the precipitates to obtain a magnesium ammonium phosphate crude product. Organic substances remained in the liquid supernatant can be used for producing methane by anaerobic fermentation or supplementing a carbon source by a reflux wastewater treatment system, also can be used for supplementing alkalinity needed for an anaerobic unit, so that comprehensive utilization of excess sludge is facilitated. The method disclosed by the invention has the advantages that nutrient elements in the sludge are comprehensively utilized, process is simple, and phosphor can be recycled by only adding the magnesium salt; and meanwhile, ammonia nitrogen can be partly recycled without regulating pH, and the obtained magnesium ammonium phosphate crude product can be used for producing fertilizers.

Owner:SOUTH CHINA UNIV OF TECH

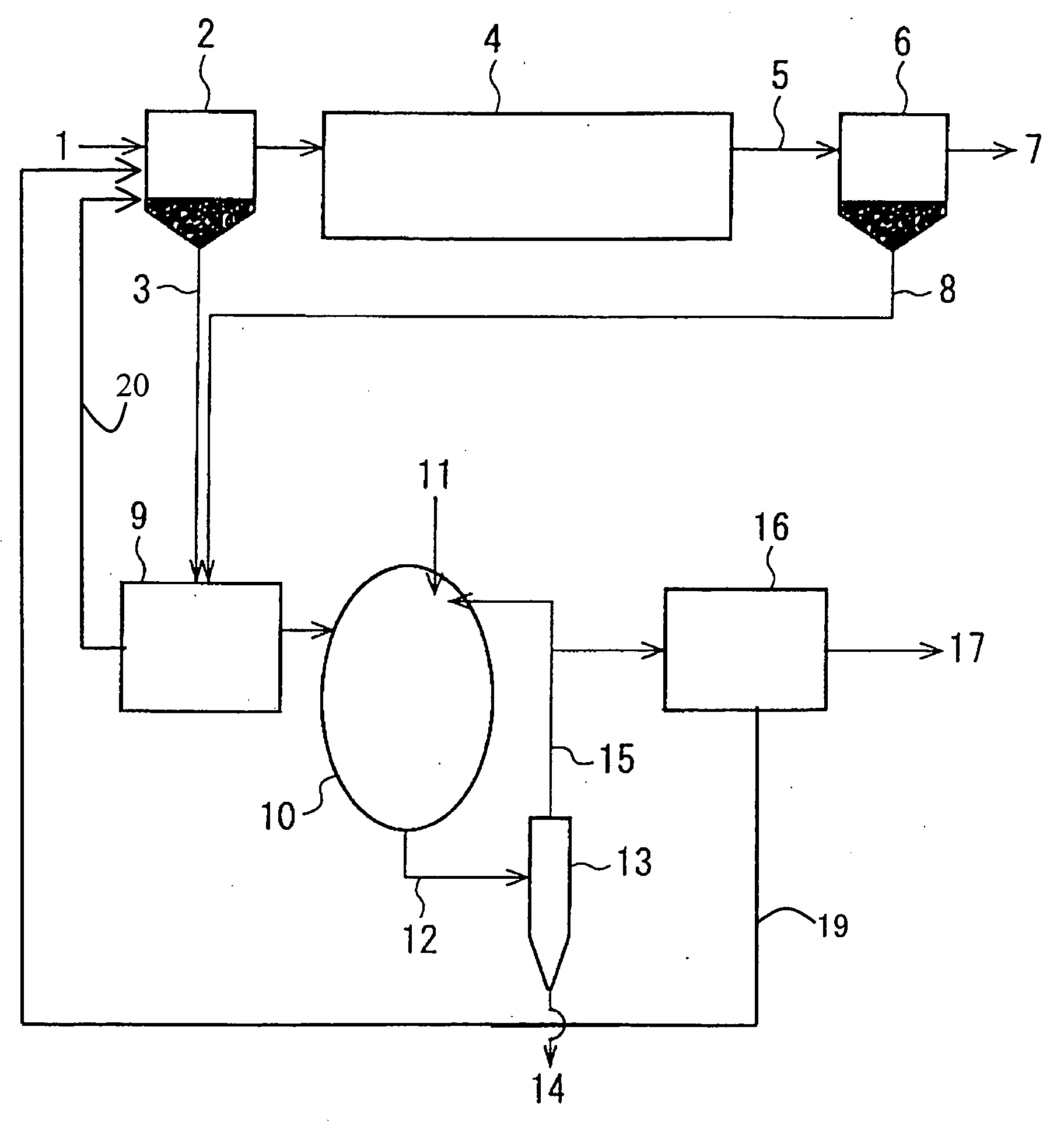

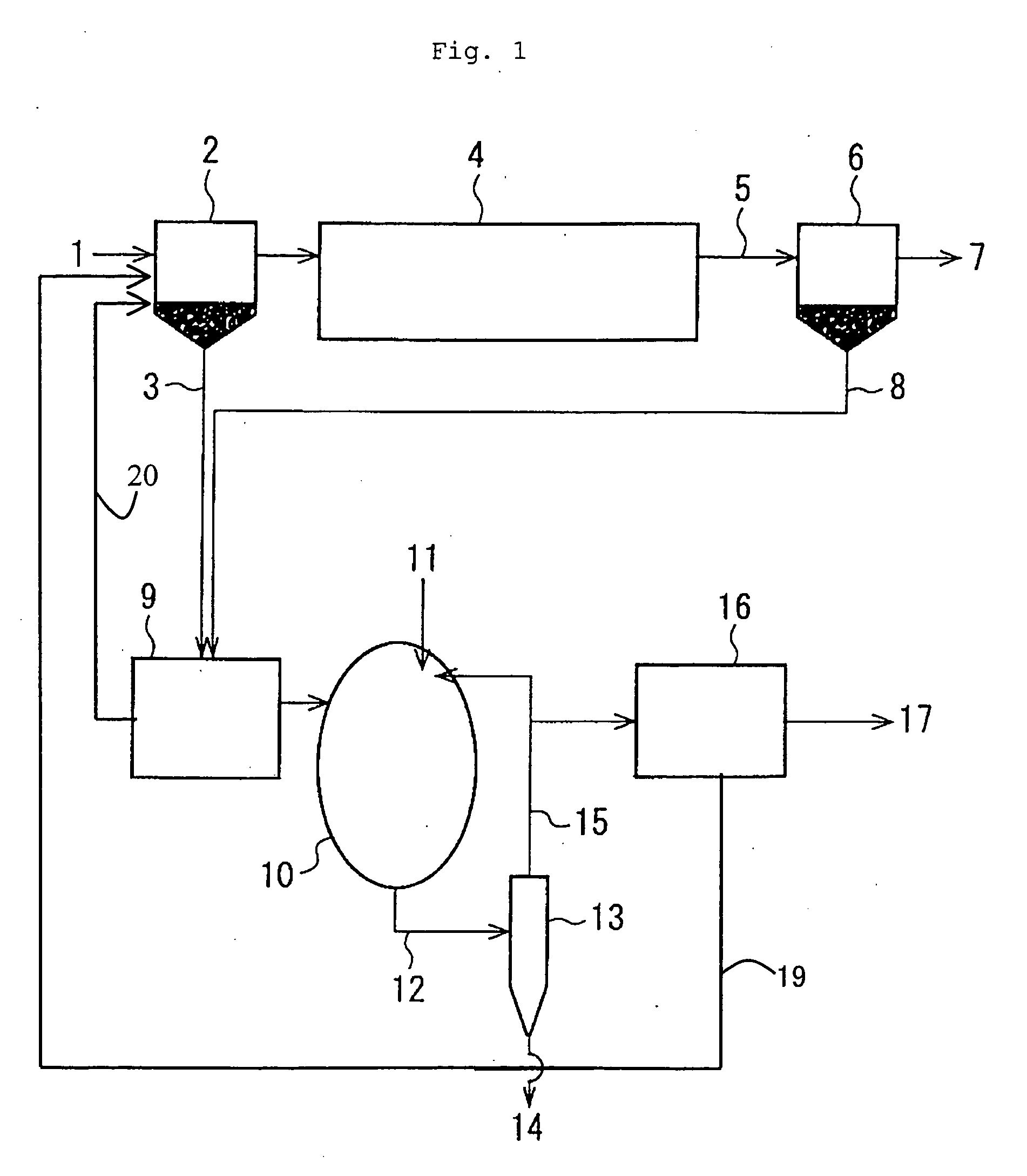

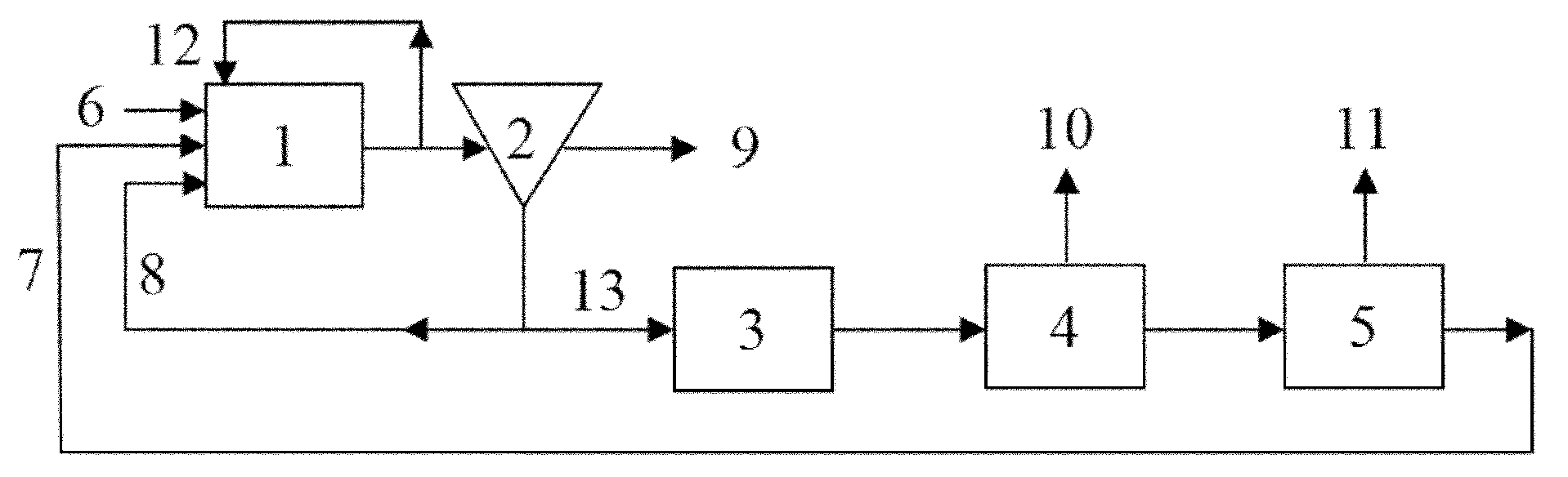

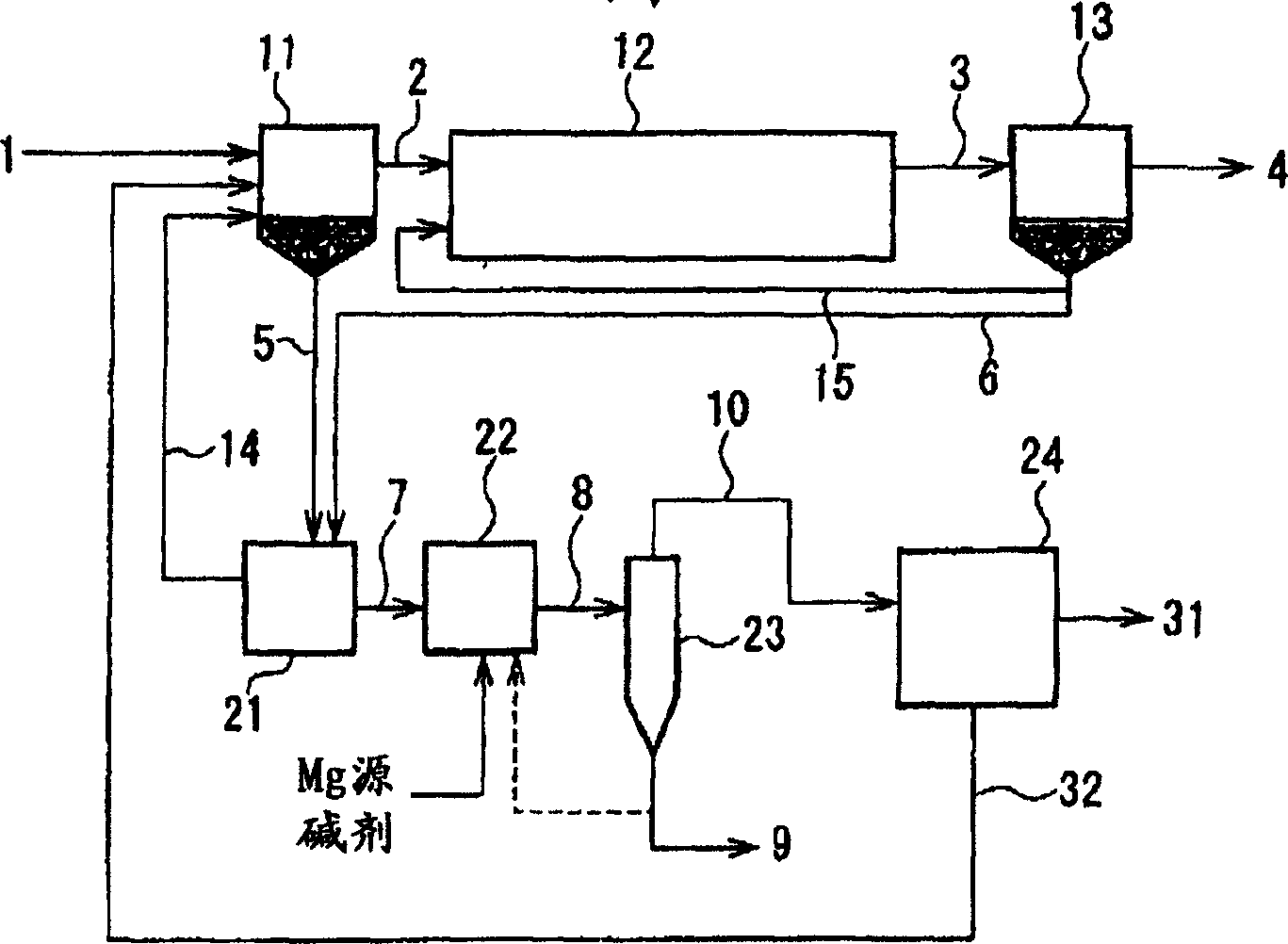

Method of treating organic wastewater and sludge and treatment apparatus therefor

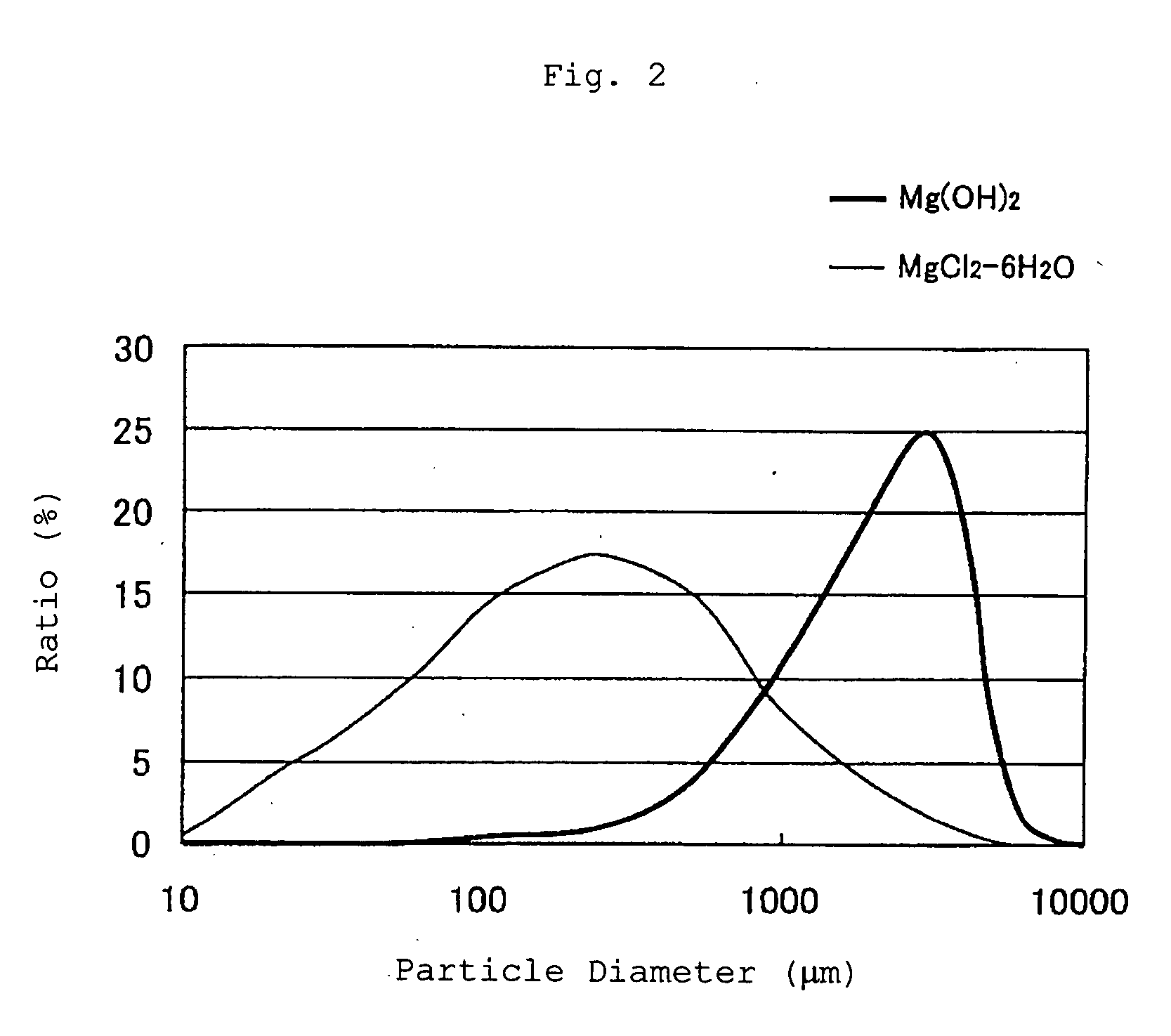

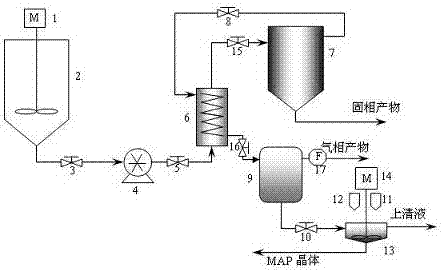

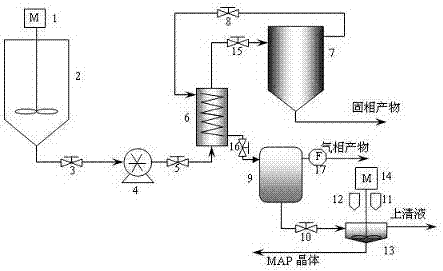

InactiveUS20050016919A1Reduce the amount requiredImprove and stabilize removal ratioWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningHigh concentrationHuman waste

The present invention has an object to provide a process and an apparatus for efficiently recovering magnesium ammonium phosphate (hereinafter referred to as “MAP”) crystals of high purity and good quality in the technique of removing phosphorus and the like as MAP crystals from wastewater containing high concentration organic substance, phosphorus and nitrogen such as a digested supernatant liquor of human waste sewage and septic tank sludge, a digested liquor of sludge, chemical plant wastewater, and simultaneously recovering the MAP crystals. As the means to achieve such an object, the present invention provides a sludge treatment process comprising treating a sludge mixed liquor formed in the biological treatment system for organic wastewater in an anaerobic digestion tank to effect the digestion of sludge, simultaneously adding a magnesium source to the anaerobic digestion tank to allow crystals particles of MAP to form and grow in the anaerobic digestion tank, withdrawing a sludge mixed liquor containing the crystals of MAP from the anaerobic digestion tank, separating and recovering solids containing MAP crystal particles from the withdrawn sludge mixed liquor, and returning part of the sludge mixed liquor after separation and recovery of MAP crystal particles to the anaerobic digestion tank.

Owner:EBARA ENG SERVICE

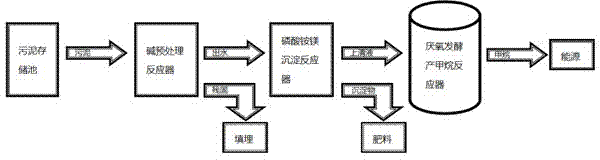

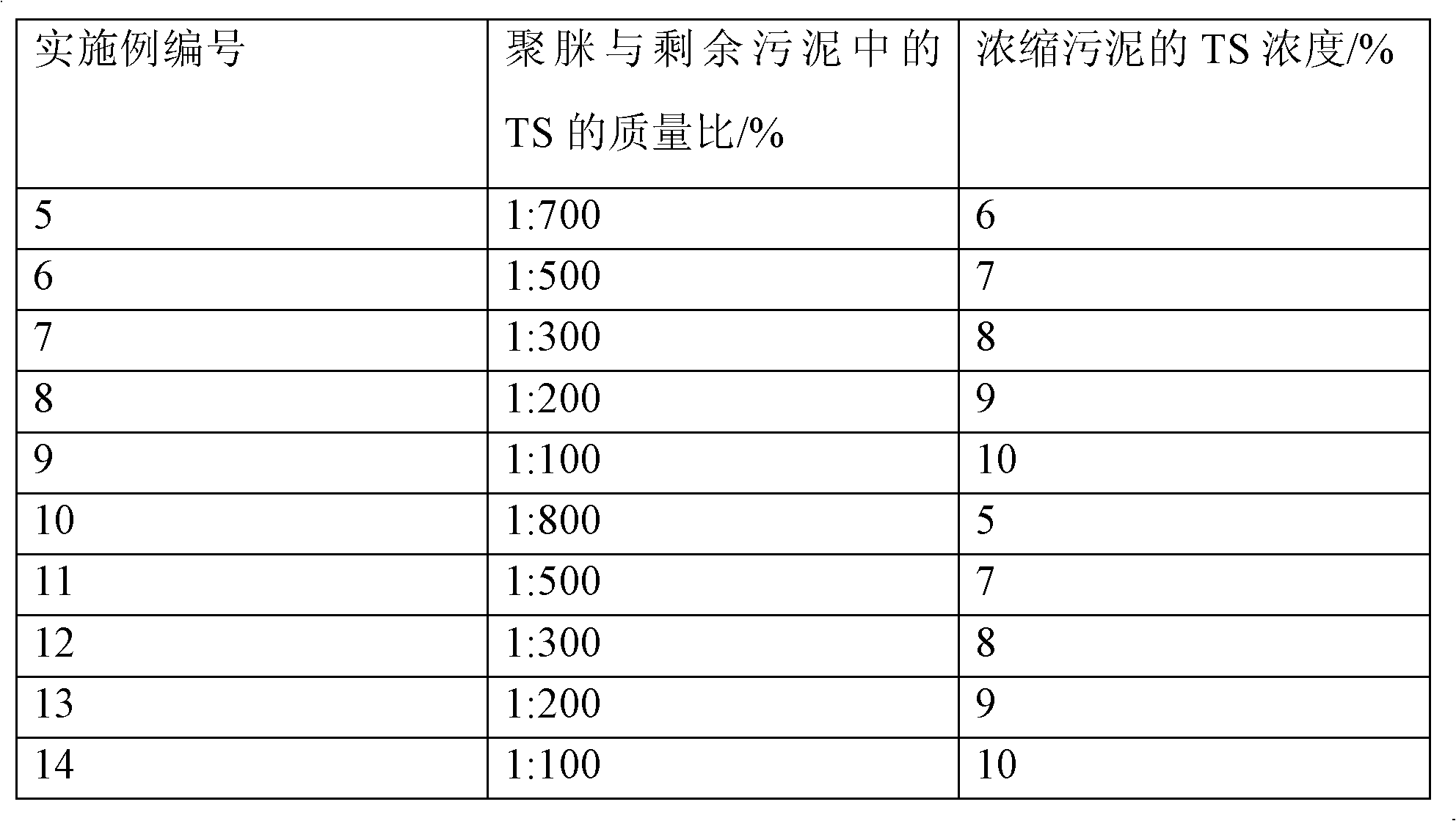

Method for processing residual sludge with integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on magnesium ammonium phosphate method and methane production based on anaerobic digestion

ActiveCN103693828AReduce consumptionGive full play to the role of alkaline hydrolysis pretreatmentWaste based fuelSludge processingChemical oxygen demandMagnesium salt

The invention discloses a method for processing residual sludge with an integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on a magnesium ammonium phosphate method and methane production based on anaerobic digestion. The method comprises the steps of: preprocessing residual sludge with a secondary alkaline hydrolysis method to obtain supernate, adding a magnesium salt solution to separate precipitates, subjecting the supernate to anaerobic processing, and drying the precipitates naturally to obtain crude magnesium ammonium phosphate; injecting the supernate into an anaerobic reactor, and inoculating with 10-60% anaerobic granular sludge, wherein the volumetric loading is controlled to be 0.30-0.75kg COD (Chemical Oxygen Demand) / (m<3>.d), and the productivity of methane reaches 200-400mL CH4 / gCOD within 72h. The method disclosed by the invention has the advantages that nutrition elements in the residual sludge are utilized comprehensively, the process is simple and is consistent in flow with low chemical consumption and electricity consumption, methane is recovered while crude magnesium ammonium phosphate is obtained, moreover, residual alkaline solids are beneficial to subsequent processing, and the reduction, stabilization and recycling of the residual sludge are realized comprehensively.

Owner:SOUTH CHINA UNIV OF TECH

Fertilizer specially used for rice and preparation method thereof

ActiveCN103964971AIncrease profitEasy to breatheFertilizer mixturesPotassiumMagnesium ammonium phosphate

The invention discloses a fertilizer specially used for rice and a preparation method thereof. The fertilizer comprises an organic fertilizer and an inorganic fertilizer, wherein the inorganic fertilizer is prepared from the following raw materials: urea, monoammonium phosphate, potassium chloride, lime nitrogen, magnesium ammonium phosphate, zinc sulfate, boric acid, a sterilizing agent, urea formaldehyde, diatomite, ATS and dicyandiamide; the urea formaldehyde containing ammonium thiosulfate and dicyandiamide serves as a coating, and the diatomite is attached to the outer side of the coating; the other raw materials are contained in the coating. The organic fertilizer is prepared from the following raw materials: sterilizing agent decoction dregs, chicken manure, bagasse, xylitol residue, cottonseed cake and plant ash. The fertilizer can meet the requirement of the whole rice growth period after being applied once, manual labor is saved, the soil aeration, fertilizer absorption and water retention characteristics can be improved, steady growth of rice plants is promoted, and the yield is increased by 10-20 percent per mu.

Owner:JINAN BADUN FERTILIZER

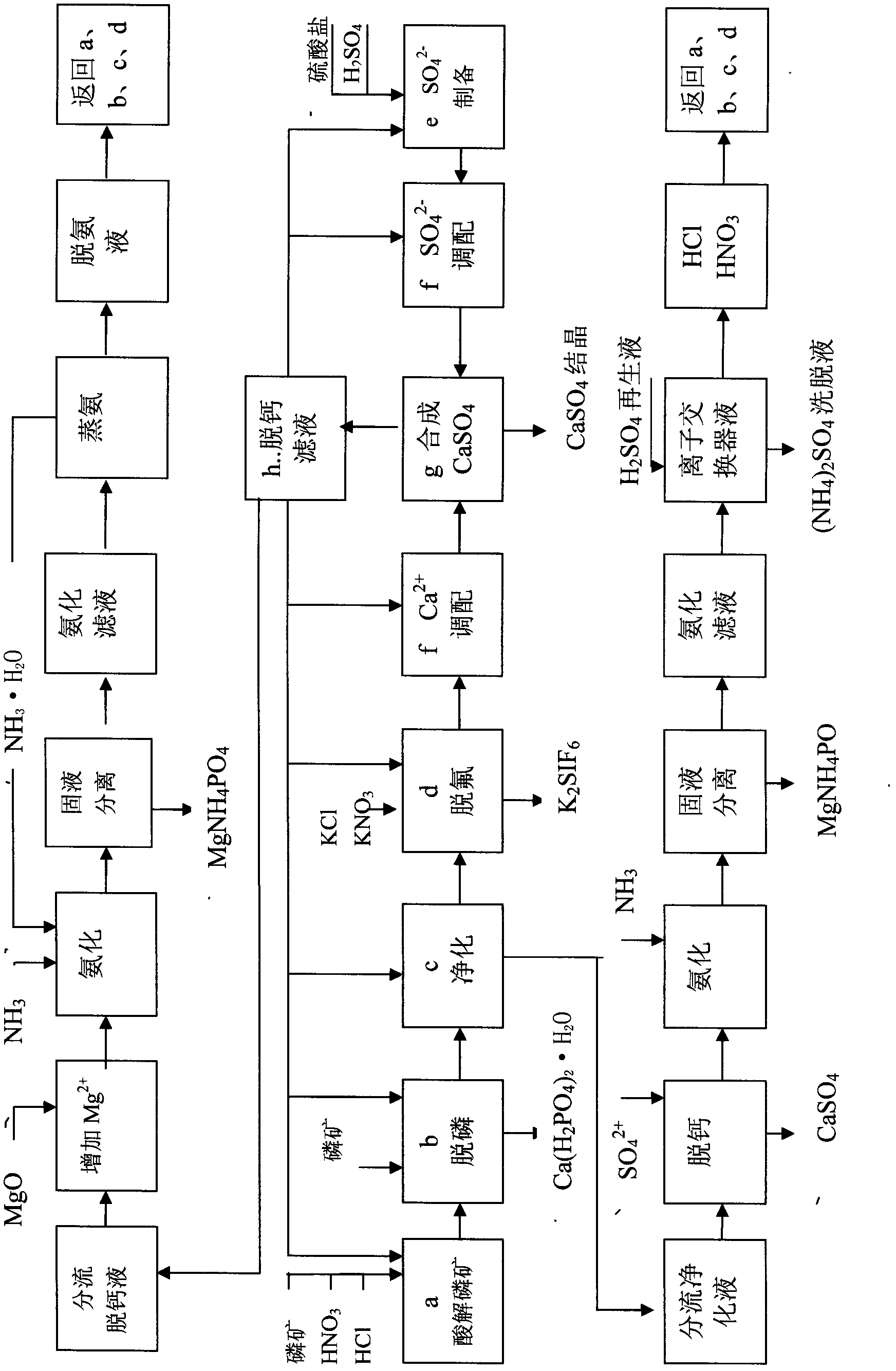

Acidolysis method of magnesium-containing phosphate rock

ActiveCN102417169AAchieving Theoretical UtilizationEasy to processCalcium/strontium/barium sulfatesAmmonium sulfatesHigh magnesiumPhosphor

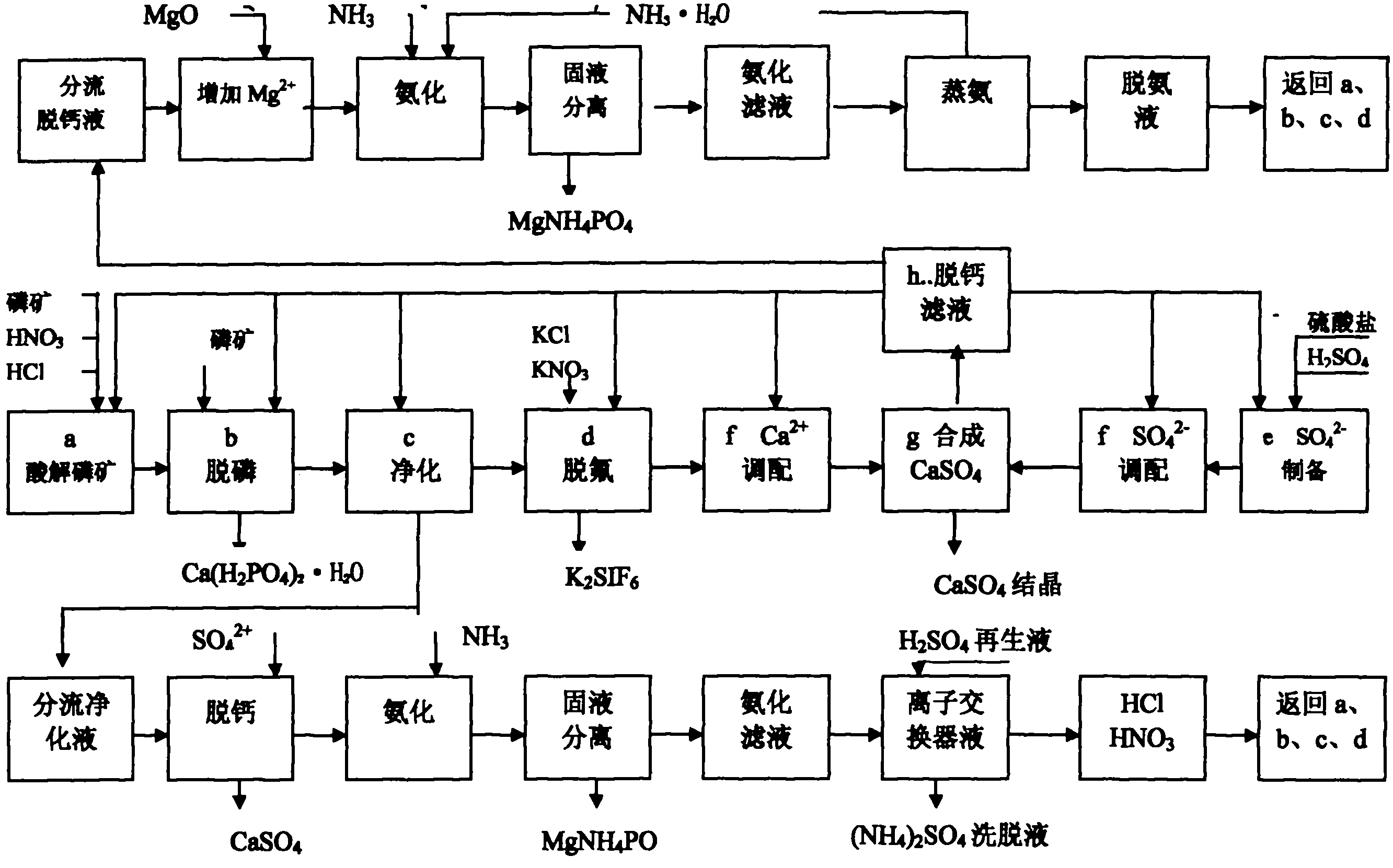

The invention discloses an acidolysis method of magnesium-containing phosphate rock. The method provided by the invention is characterized by comprising the following steps of: carrying out acidolysis on the magnesium-containing phosphate rock to obtain a water-soluble calcium, magnesium and phosphoric acid containing acidolysis solution, carrying out acidolysis on the phosphate rock by using the generated phosphoric acid to generate Ca(H2PO4)2.H2O solid, performing a reaction between H2SO4 and water-soluble calcium to generate high-pureness calcium sulfate whisker, and performing a reaction between water-soluble magnesium and phosphor in the acidolysis solution and NH3 to generate character separation magnesium ions of a MgNH4PO4 solid so as to realize complete high-efficiency comprehensive utilization of the acidolyzed magnesium-containing phosphate rock. The focus of the invention is to change magnesium ions into controllable parameters which are beneficial to circulation of the acidolysis solution. The magnesium-containing phosphate rock can be efficiently utilized, and also the compound magnesium ammonium phosphate can be used to realize the separation of phosphor magnesium from a circulation medium HCl or HNO3 or CaCL, Ca(NO3)2, thus realizing the combination and combined production with a present ammonium phosphate and phosphor product processing technology. The method provided by the invention has advantages of concise technology, less investment, low energy consumption, low cost, high benefit and no discharge of ''three wastes (waste gas, wastewater and industrial residue)'', and fully presents great business value and great resource value of the high magnesium-containing phosphate rock.

Owner:武善东 +1

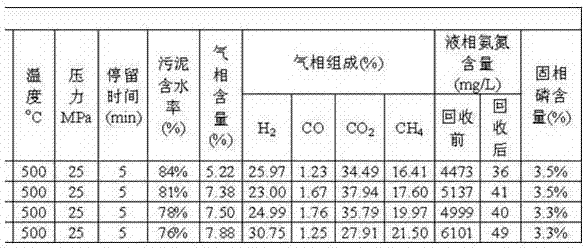

Method and equipment for resource utilization of dewatered sludge in sewage plant by supercritical treatment

InactiveCN102267789AImprove liquidityImprove processing efficiencyOther chemical processesSolid waste disposalSorbentResource utilization

The invention discloses a method and equipment for supercritical treatment and resource utilization of dewatered sludge of a sewage plant. The method is characterized in that: the dewatered sludge (the water content is 77 to 85 percent) is directly treated in a supercritical water vaporization mode, the flowability of the sludge is improved through a high-speed stirring device, blockage of a tubular reactor is prevented by adopting a high-pressure fluidized bed device, high heat of a gas-liquid separation process is fully utilized, and the low-temperature sludge is heated by using a heat exchanger; and the liquid phase product with high ammonia nitrogen content is directly recycled by a magnesium ammonium phosphate (MAP) method. The method has the advantages that: any moisture is not added in the vaporization process, and the sludge treatment efficiency is high; the heat can be utilized in the process; ammonia nitrogen in the liquid phase product is timely reclaimed so as to reduce secondary pollution; the reclaimed supernate can be recycled, the periodically discharged solid phase product with low heavy metal content can be directly used as a phosphate fertilizer, and the solid phase product with high heavy metal content can be used as an adsorbent; and the treatment expense of the whole system is reduced by resource utilization of the liquid phase product and the solid phaseproduct.

Owner:HOHAI UNIV

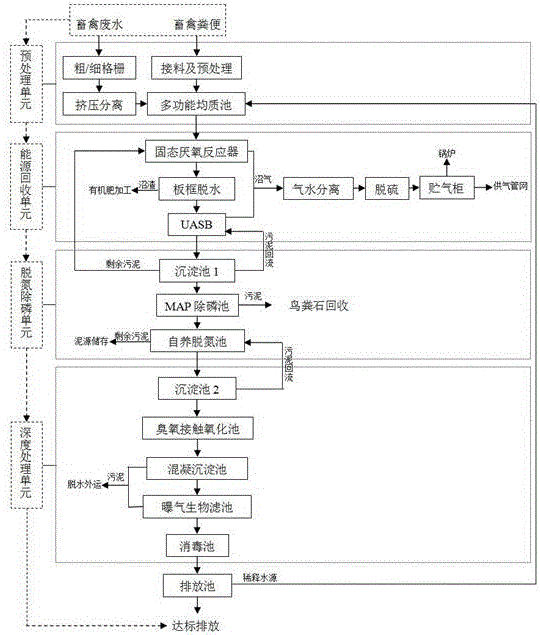

Recycling treatment method for feces and wastewater in large-scale livestock and poultry breeding farm

InactiveCN106242162ANo need to addReduce aerationSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesAnimal fecesEnergy recovery

A recycling treatment method for feces and wastewater in a large-scale livestock and poultry breeding farm includes the following steps: (1) pre-treating the feces and wastewater in the large-scale livestock and poultry breeding farm in a pretreatment unit to form slurry; (2) feeding the slurry into an energy recovery unit, and performing solid anaerobic digestion in a solid anaerobic reactor to obtain an energy gas, methane; (3) performing solid-liquid separation to the digested slurry to generate wastewater, which is then fed into a UASB reactor to perform further anaerobic fermentation to remove organic pollutants from the wastewater; (4) feeding the treated wastewater into a nitrogen and phosphorus removal unit to perform nitrogen and phosphorus removal treatment; (5) separating and purifying a precipitate, which is generated in the nitrogen and phosphorus removal unit and mainly includes magnesium ammonium phosphate, to obtain an organic fertilizer additive, wherein the nitrogen removal process is autotrophic nitrogen removal and can reduce aeration quantity by 62.5% without addition of any carbon sources, thus saving large quantity of operation cost; and (6) feeding the treated wastewater into a deep-treatment unit to remove bio-refractory substances and disinfect the wastewater so as to finally reach emission and recovery standards of wastewater.

Owner:SOUTH VENTURE TIANJIN TECH DEV CO LTD

Device and method for improving biological dephosphorizing and denitriding efficiency of low carbon source sewage

InactiveCN102060412ASmall volumeReduce initial investmentSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSolubilityHigh concentration

The invention provides a device and a method for improving the biological dephosphorizing and denitriding efficiency of low carbon source sewage, belonging to the technical fields of sewage treatment and residual sludge treatment. The method comprises the following steps of: under the microwave alkaline hydrolysis condition, hydrolyzing solid organic matters in the residual sludge into soluble organic matters; recovering and hydrolyzing nitrogen and phosphor in supernate by adopting a magnesium ammonium phosphate setting method; and adding the hydrolyzed supernate subjected to dephosphorizing and denitriding treatment in the low carbon source sewage and carrying out biological dephosphorizing and denitriding treatment on the hydrolyzed supernate so as to improve the biological dephosphorizing and denitriding efficiency of the low carbon source sewage. According to the invention, by carrying out the microwave alkaline hydrolysis treatment on the residual sludge to produce high-concentration soluble organic matters easy to biodegrade, the product can be used as a low-price carbon source subjected to biological dephosphorizing and denitriding treatment in the lower carbon source sewage, and the biological dephosphorizing and denitriding efficiency in the lower carbon source sewage can be improved; meanwhile, sludge minimization, reclamation and harmlessness can be realized. The VSS (Volatile Suspended Solids) solubility in the sludge can be improved to 82 percent, so that the effluent quality of the low carbon source sewage treated by the device and the method achieves the first-class B standard 'Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant' (GB18918-2002).

Owner:TIANJIN URBAN CONSTR COLLEGE

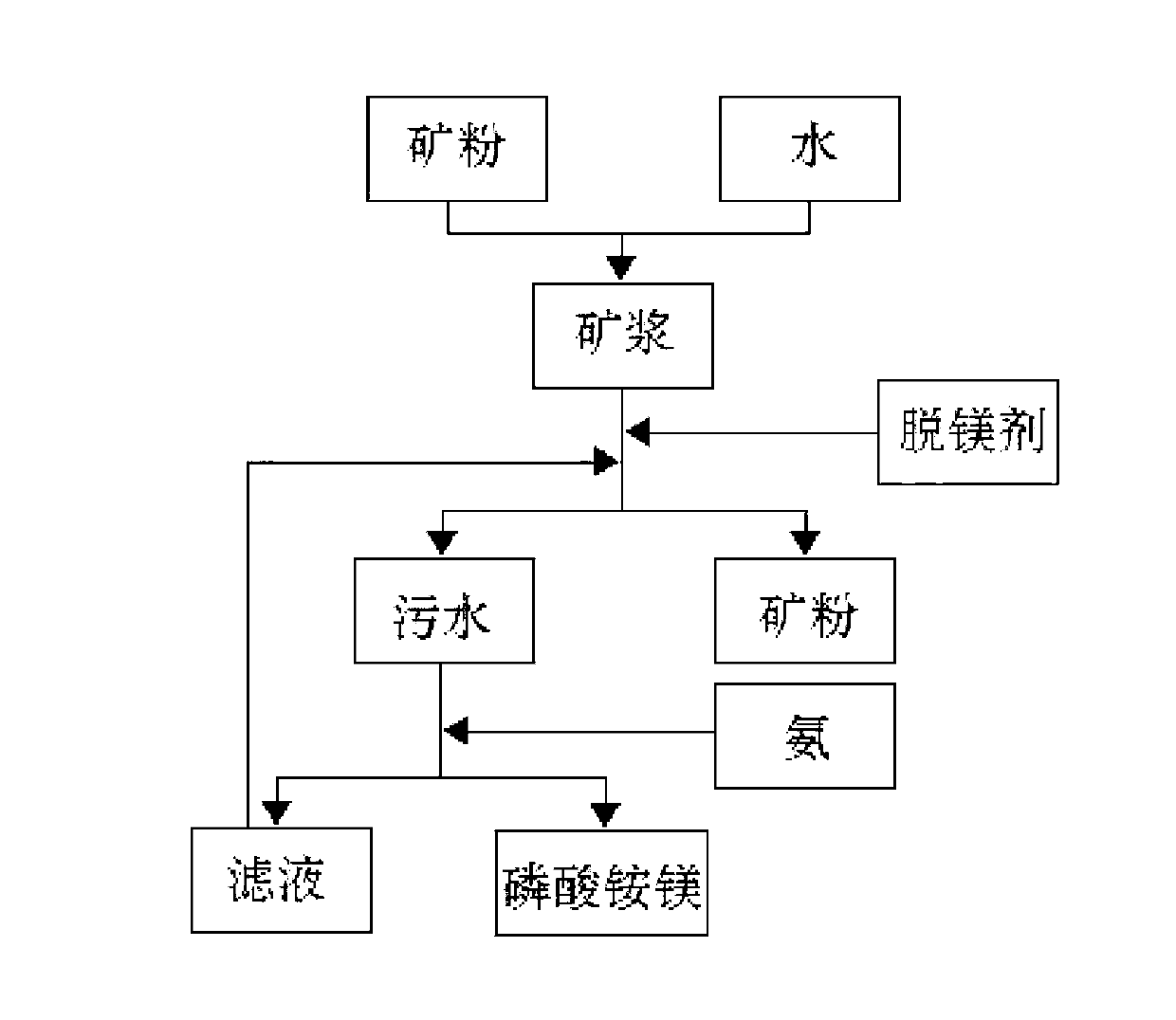

High-magnesium phosphorite de-magging method with by-product magnesium ammonium phosphate

InactiveCN102992284AHigh removal rateReduce contentRaw phosphate material treatmentPhosphoric acidMagnesium ammonium phosphate

The invention discloses a high-magnesium phosphorite de-magging method with a by-product magnesium ammonium phosphate. The method is as below: mixing a mineral powder and water to obtain a pulp; then adding a magnesium removal agent into the pulp for reaction; then separating wastewater and mineral powder after magnesium removal; adding ammonia into the wastewater to generate magnesium ammonium phosphate; filtering to obtain a magnesium ammonium phosphate product; and adding a recycled filtrate from filter into the pulp. The invention has advantages of economical equipment investment and good operating environment; sulfuric acid and / or phosphoric acid is used as a magnesium removal agent, has high removal rate of magnesium, significantly reduces magnesium content in the phosphate, and especially has obvious effect on phosphate with high magnesium content, so as to reduce loss of phosphorus pentoxide in the phosphate; the wastewater can be recycled to save water resource, and causes no impact on the environment; the treated concentrate in a wet production significantly improves bubble phenomenon and filtering performance, so as to improve production capacity and labor productivity of the whole device, and reduce the production cost; and magnesium in the phosphate can be used for production of a magnesium ammonium phosphate slow release fertilizer, and generates good economic benefit.

Owner:GUIZHOU KAILIN GRP CO LTD

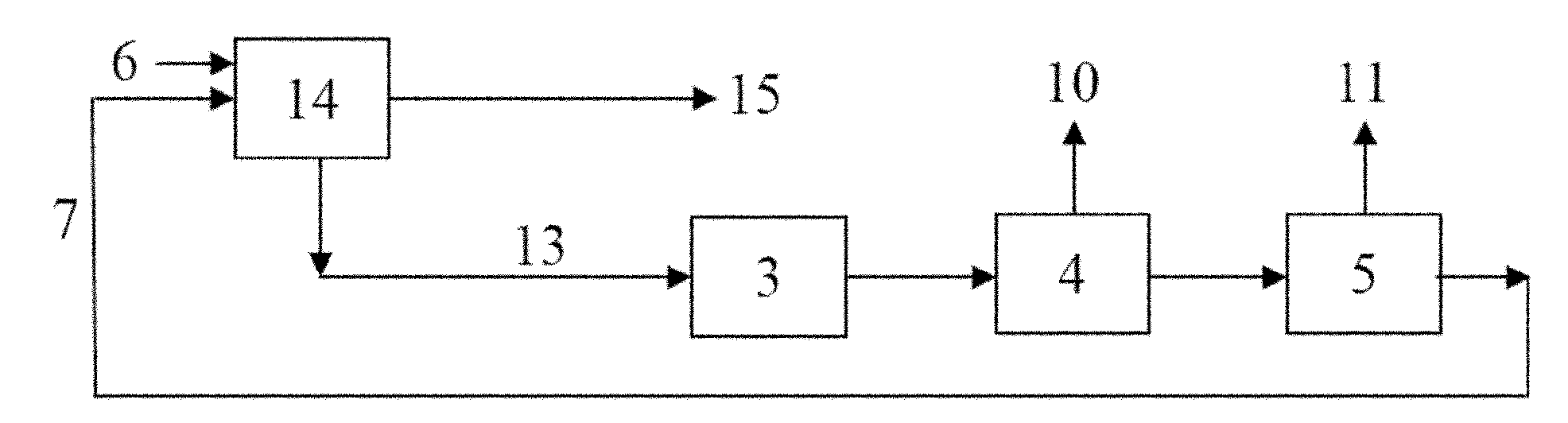

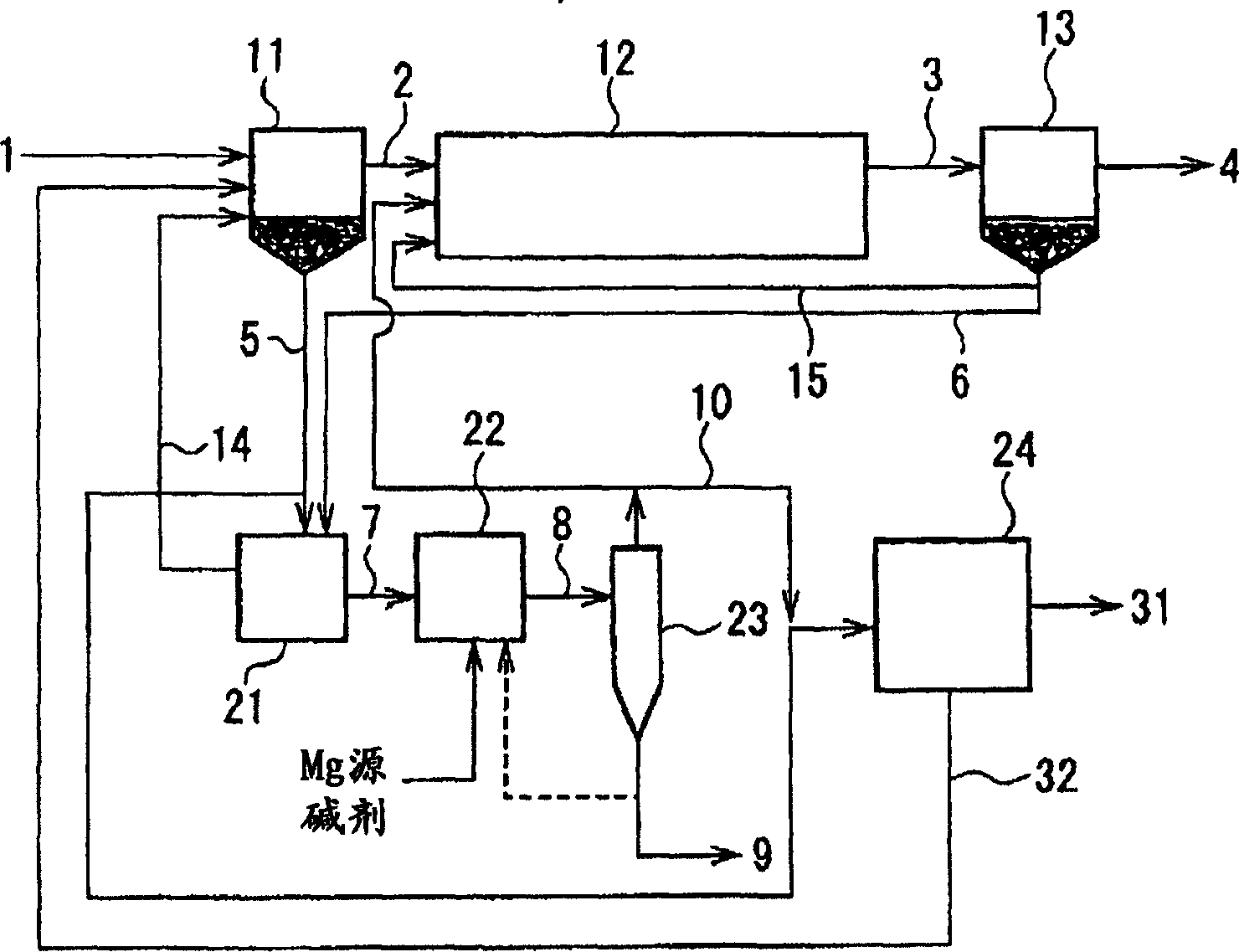

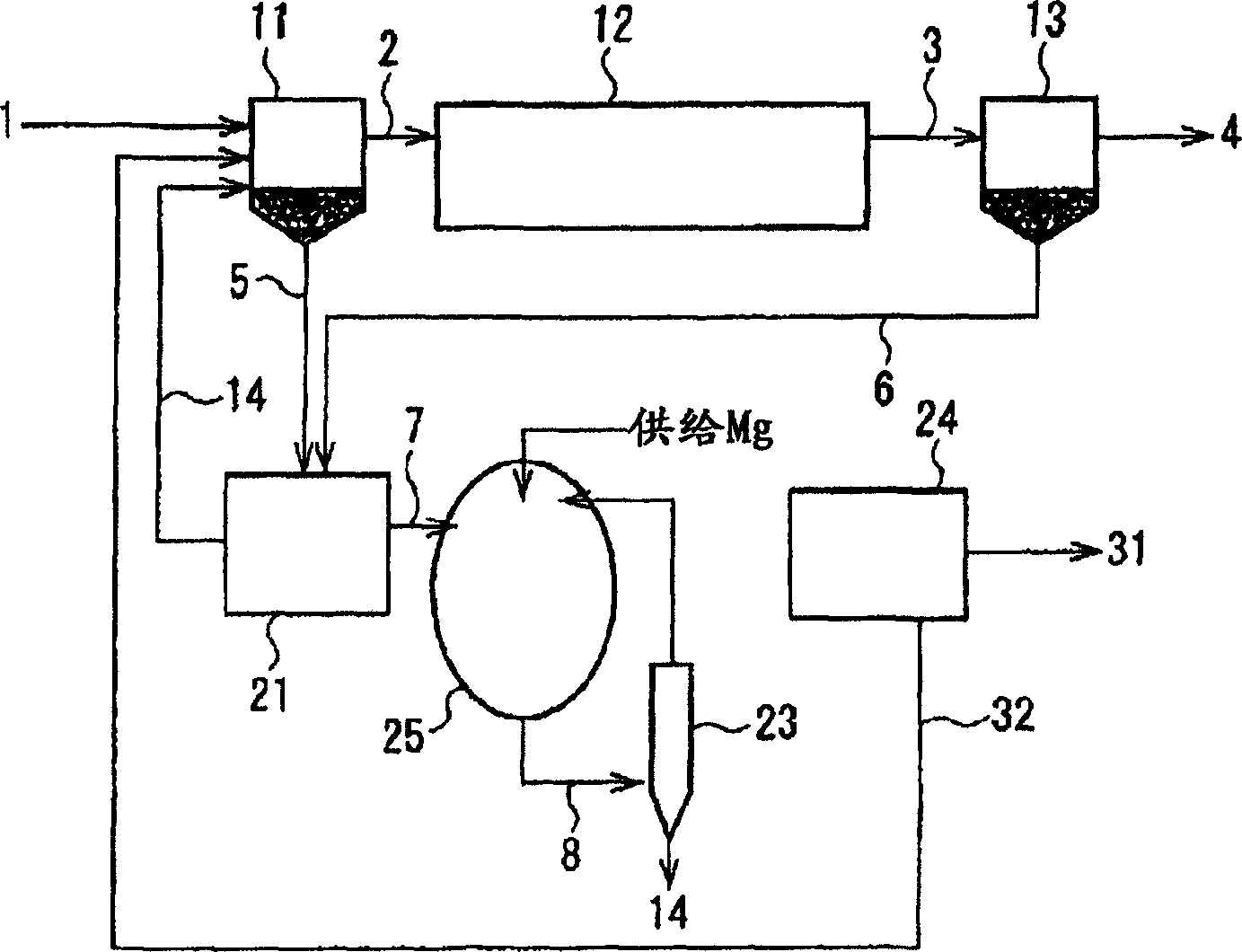

Method of formation/recovery of magnesium ammonium phosphate and apparatus therefor

ActiveCN1894167AKeep it easy to manageSuppress generationSludge treatment by de-watering/drying/thickeningAlkali orthophosphate fertiliserRecovery methodPhosphate ion

A method and apparatus in which in a biological treating system for organic wastewater, not only is phosphorus, etc. efficiently recovered as MAP crystal from a wastewater containing organic matter, phosphorus and nitrogen but also the biological denitrification / dephosphorization treatment capability is strikingly improved. There is provided a method of treating sludge generated in the process for biological treatment of organic wastewater utilizing microbial metabolism, characterized in that a biological treatment composed mainly of acid fermentation by facultative anaerobes is carried out with the sludge to thereby leach phosphate ion and ammonium ion from the sludge; a magnesium source is added to the sludge to thereby form grains of magnesium ammonium phosphate from the leached phosphate ion and ammonium ion; and grains of magnesium ammonium phosphate are separated from the sludge containing formed grains of magnesium ammonium phosphate. Further, there is provided an apparatus for carrying out the method.

Owner:EBARA ENG SERVICE

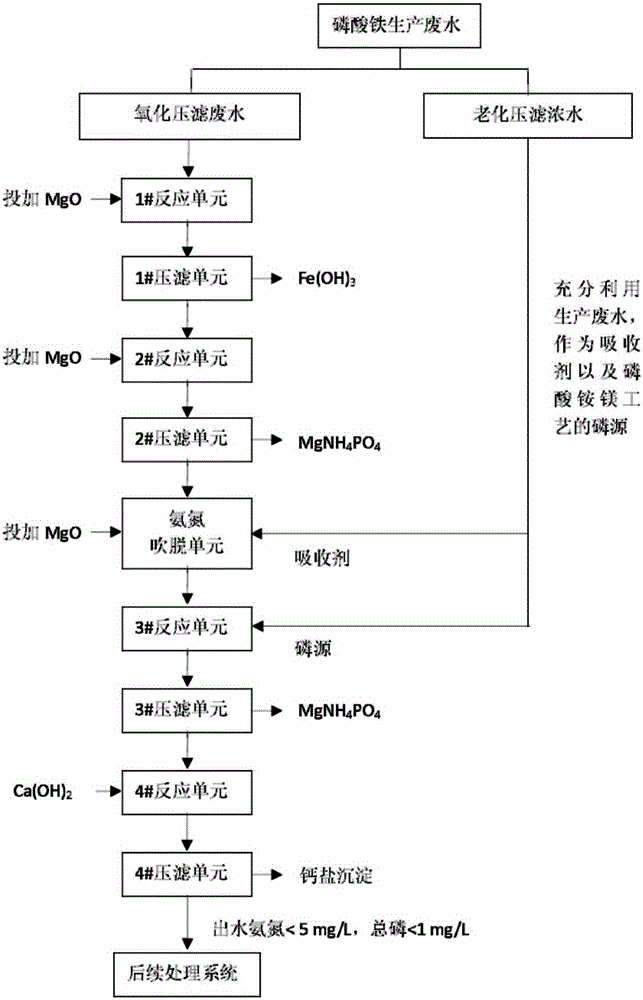

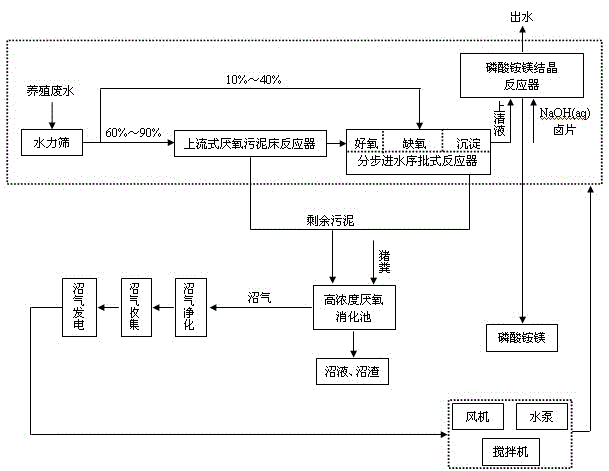

Efficient-nitrogen-and-phosphorus-removing and resource recycling technology and device for iron phosphate production wastewater

ActiveCN105417771AEfficient use ofReasonable workmanshipTreatment involving filtrationMultistage water/sewage treatmentHigh concentrationWater quality

The invention discloses an efficient-nitrogen-and-phosphorus-removing and resource recycling technology and device for iron phosphate production wastewater. According to the characteristics of the extremely-low pH value, the high concentration of pollutants such as nitrogen, phosphorus, sulfur and iron and the like of the iron phosphate production wastewater, based on analysis of the quality and the quantity of the production wastewater, the wastewater treatment and nitrogen and phosphorus resource recycling treating technology in which waste is controlled by waste is provided. The technology includes the steps that magnesium oxide serves as a pH-value regulating agent and a precipitating agent, different pollutants are removed in a stepping-and-grading mode, the characteristic that aging filtering-pressing concentrated water is rich in phosphorus is fully used, one part of the concentrated water serves as an absorbing agent of an ammonia nitrogen blowing-off unit, the other part of the concentrated water serves as a precipitating agent of the magnesium ammonium phosphate technology, waste is controlled by waste, and wastewater treating cost is greatly reduced. By means of the technology, nitrogen and phosphorus removing can be effectively achieved, and nitrogen and phosphorus resources are recycled in ammonium-phosphate and magnesium-ammonium-phosphate modes while wastewater pollution is solved. The technology is suitable for industry and agriculture wastewater containing high-concentration nitrogen and high-concentration phosphorus at the same time and particularly suitable for the iron phosphate production wastewater.

Owner:SHANGHAI SHIYUAN ENVIRONMENT PROTECTION TECH

Deep denitrification process for wastewater

InactiveCN102910788AUndisturbedLow costMultistage water/sewage treatmentHigh concentrationMagnesium ammonium phosphate

The invention provides a deep denitrification process for wastewater. The deep denitrification process comprises the following specific steps of: firstly, performing microwave irradiation and coagulating sedimentation on the wastewater, wherein a certain quantity of NaOH is added into the high-concentration ammonia-nitrogen wastewater to adjust the pH value of the wastewater to 11-13, and a flocculant and a coagulant are added into the wastewater at an alkaline condition to perform the coagulating sedimentation, thus obtaining supernatant liquor; secondly, introducing the supernatant liquor obtained in the first step into an air stripping tower, wherein a sprayer is arranged at the top of the air stripping tower, multiple packing layers are arranged in the middle in a tower body, after passing through the sprayer, the wastewater becomes fine flow and flows through the packing layers, an air blower introduces air into the tower through an aeration port at the bottom of the tower, the air is in contact with the fine flow on the surface of packing, and exhaust for air stripping enters an absorption cell containing waste hydrochloric acid or waste sulphuric acid absorption liquid to absorb a part of ammonia nitrogen; thirdly, performing continuous circulating ammonia sedimentation on pyrolysis products of magnesium ammonium phosphate (MAP), and after the sedimentation of the MAP, processing effluent by a biological nitrogen removal process; fourthly, performing anaerobic (A)-anoxia (4)-oxic (O) biological nitrogen removal process on the effluent in the third step; and fifthly, performing denitrification on the left less nitrogen by a denitrification biofilter and a membrane filter. Therefore, ammonia nitrogen and total nitrogen of the effluent of the processed wastewater can reach a first-level A standard in the discharge standard of pollutants for municipal wastewater treatment plants (GB18918-2002).

Owner:NANJING UNIV

Method for producing monoammonium phosphate and magnesium ammonium phosphate by using wet concentrated phosphoric acid residues

ActiveCN104058378AReduce solid particlesEffective liquid-solid separationPhosphatesMagnesium phosphatePhosphoric acid

The invention provides a method for producing monoammonium phosphate and magnesium ammonium phosphate by using wet concentrated phosphoric acid residues. According to the method, concentrated phosphoric acid residues are adopted as raw materials and sodium fluorosilicate, industrial monoammonium phosphate and magnesium ammonium phosphate are respectively obtained through the processes of dilution and sedimentation, defluorination, fractional multistep neutralization, concentration and crystallization, primary mother liquor pH value adjustment, size mixing of filter cake and secondary mother liquor, magnesia powder neutralization and the like. The method is little in equipment investment, low in production cost and good in product quality and has the advantages that the problem that acid residues of ammonium phosphate plants can be only used for producing low value-added products is solved and the low-cost industrial monoammonium phosphate slow release fertilizer magnesium ammonium phosphate with high quality and inexpensive can be obtained.

Owner:昆明隆祥化工有限公司

Method for removing ammonia and nitrogen in garbage percolate

InactiveCN101186408AEasy to handleImprove the conditions of subsequent biochemical treatmentDispersed particle separationMultistage water/sewage treatmentMagnesium saltSlag

The invention discloses a method of removing ammonia nitrogen in landfill leachate, pertaining to the wastewater treatment field. The method mainly comprises the steps that magnesium salts and phosphates are first added into the landfill leachate, regulating the pH value and the mole ratio of the magnesium salts and the phosphates and the ammonia nitrogen, which are mixed and stirred so as to produce deposit of magnesium ammonium phosphate; supernatant and the deposit are next separated and precipitation and dehydration are then carried out; blast furnace slag is then added into the dehydrated magnesium ammonium phosphate, the weight ratio of the magnesium ammonium phosphate and the blast furnace slag is controlled, mixed by adding water, and then the magnesium ammonium phosphate is treated with pyrolysis with pyrolysis time and temperature being controlled; ammonia gas generated by the pyrolysis is treated by bio-trickling filter bed and a solid product by the pyrolysis is recovered and recycled in the treatment of the ammonia nitrogen. The invention can not only remove the ammonia nitrogen by recycling chemical precipitation agent with charges saved, but also realize reclamation utilization of the blast furnace slag. The concentration of effluent of the ammonia nitrogen can decrease below 100mg / l after being treated by the invention, which greatly improves conditions for consequent biochemical treatment.

Owner:NANJING UNIV

Slow release fertilizer spike

InactiveUS6120574AHigh physical integritySignificant attritionBiocideAlkali orthophosphate fertiliserParticulatesMagnesium phosphate

An attrition resistant fertilizer spike composition, exhibiting a mechanical strength which allows the spike to be hammered unsupported into the soil without suffering damage, to provide an effective source of slow releasing plant nutrients to the soil. The composition comprises between 93 and 98 percent of particulate plant nutrient compounds containing one phosphate ion chemically combined with one divalent cation and one monovalent cation, including the compounds magnesium ammonium phosphate and magnesium potassium phosphate. The composition includes a coating of between 2 and 7 percent of thermoplastic adhesive with a softening temperature between 65 and 160 DEG C. on the particles. The coated particles are formed into an attrition and shatter resistant spike shape, suitable for hammering into the soil, by pressing into a die at a temperature higher than the softening temperature of the thermoplastic adhesive and then cooling to a temperature lower than the softening temperature. A method of preparing these improved spikes is provided. In the method the thermoplastic adhesive is applied as an aqueous dispersion or emulsion along with a die lubricant prior to pressing the coated particles into a spike exhibiting a high degree of physical integrity.

Owner:AGRINUTRIENTS TECH GRP INC

Treatment method of nitrogen and phosphorus-containing waste water

InactiveCN108002661AStable waterLow concentration requirementWater treatment parameter controlAlkali orthophosphate fertiliserHigh concentrationMagnesium ammonium phosphate

The invention discloses a treatment method of nitrogen and phosphorus-containing waste water. The three-step treatment including magnesium ammonium phosphate reaction, biochemical treatment and deep treatment is sequentially performed on nitrogen and phosphorus waste water phosphorus containing high-concentration ammonium salt and phosphate; a great number of ammonium salts and phosphate can sequentially react with Mg<2+>; MgNH4PO4.6H2O is recovered to be reused as a slow-release fertilizer; through the biochemical treatment on primary treatment liquid supernatant containing low-content ammonium salt and phosphate, ammonia, nitrogen and partial PO4<3-> ions can be removed; finally, through Ca<2+> ions, a small number of PO4<3-> ions remained after the biochemical treatment can be treated;the outlet water stability can be ensured; the standard reaching discharging is reached.

Owner:SHIFANG CHANGFENG CHEM CO LTD

Method for recovering nitrogen and phosphorous from urine

InactiveCN102167434AHigh recovery rateImprove recycling efficiencyWater/sewage treatment by flocculation/precipitationPhosphorus compoundsMagnesium saltNitrogen

The invention belongs to the technical field of separation of domestic sewage sources and relates to a chemical method for urine treatment and recovery of nutrient elements, in particular to a method for recovering nitrogen and phosphorous from urine. The method comprises the following steps of: collecting fresh urine and then naturally covering and storing, and recovering nitrogen and phosphorus after the pH reaches above 9, wherein the pH can raise to 9 after the urine is stored for about 10 days according to the difference of seasons and environment temperatures, and the pH monitoring is subjected to the storage process; sampling and detecting the NH4+-N concentration and the PO43--P concentration, feeding Na2HPO4 and MgCl2 according to mol ratio of n(Mg): n(P): n(N) of 1.3: 1: 1, controlling the stirring speed of 100r / min and the reaction time of 10min, precipitating for 1h and then separating supernate to obtain the MAP (Magnesium Ammonium Phosphate) precipitate. In the invention, the phosphate and magnesium salts are fed according to certain mol ratio in accordance with the NH4<+>-N concentration and the PO4<3->-P concentration after the urine is hydrolyzed, the nitrogen and the phosphorus are furthest recovered in an MAP precipitate way by reasonably controlling reaction conditions so that the nitrogen and phosphorus contents are greatly reduced, and the recovery rate of the nitrogen and the phosphorus can reach up to about 95 percent.

Owner:CHANGZHOU UNIV

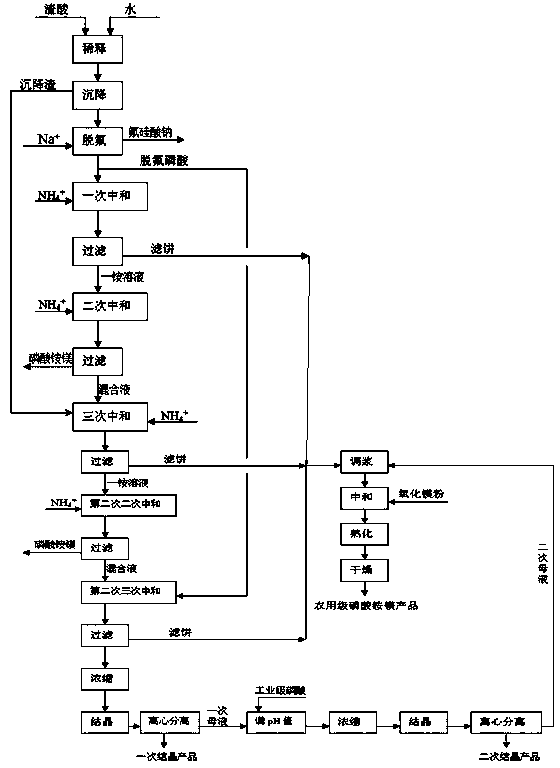

High-efficiency and low-consumption standard-reaching treatment method for wastewater from scale piggery raising

InactiveCN102616982AHigh removal rateLow running costWaste based fuelMultistage water/sewage treatmentSequencing batch reactorChemical oxygen demand

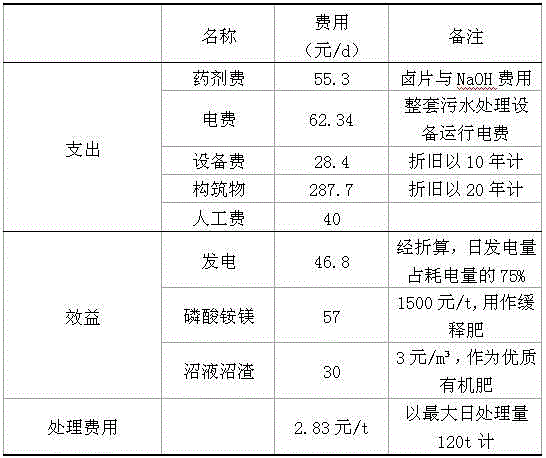

The invention discloses a high-efficiency and low-consumption standard-reaching treatment method for wastewater from scale piggery raising. According to the high-efficiency and low-consumption standard-reaching treatment method, after the wastewater from raising is subjected to solid-liquid separation through a hydraulic screen, 60-90 percent of wastewater enters an up-flow type anaerobic sludge blanket reactor; mostly COD (Chemical Oxygen Demand) is converted and methane is recovered; effluent enters an aerobic zone of a step-fed sequencing batch reactor for treatment; after the aerobic treatment is finished, the effluent and 10-40 percent wastewater enter an anoxic zone for denitrification; meanwhile, the basicity is replenished and the mixer enters a precipitation zone; supernate enters a magnesium ammonium phosphate crystallization reactor for recovering nitrogen and phosphorus; pig manure is added into residual sludge generated by the up-flow type anaerobic sludge blanket reactor and the step-fed sequencing batch reactor for treatment and then the mixture is fermented in a high-concentration anaerobic digester to generate methane; biogas slurry and biogas residue which are used as high-quality organic fertilizer are fertilized to the farmland; the generated methane is used for generating power; and electric energy is supplied to wastewater treatment equipment for operating. The high-efficiency and low-consumption standard-reaching treatment method disclosed by the invention has the advantages of simple process, convenience in resource recycling, long-term stable and reliable treatment effect and proper construction, operation and maintenance expenses.

Owner:ZHEJIANG UNIV

Soil conditioner as well as preparation method thereof

InactiveCN103275726AImprove qualityImprove fertilityAgriculture tools and machinesOrganic fertilisersSpray GranulationArray data structure

The invention relates to a soil conditioner which comprises the following components in parts by mass: 35-48 parts of mineral materials, 25-40 parts of decaying livestock and poultry manure, 5-10 parts of magnesium ammonium phosphate and 2-5 parts of microbial agents. The invention also provides a method for preparing the soil conditioner, wherein the method comprises the following steps of: 1) crushing the mineral materials and forging at 900-1200 DEG C for 1-2 hours, sieving by an 80-mesh sieve, thereby obtaining a forged mineral product; 2) carrying out spray granulation on the decaying livestock and poultry manure, putting into a drying machine, drying, and sieving by an 80-meshes sieve; 3) mixing the 35-48 parts of forged mineral product and 25-40 parts of decaying livestock and poultry manure uniformly for the sieved material in proportion in the steps above, thereby obtaining a mixed material; and 4) adding 5-10 parts of magnesium ammonium phosphate and 2-5 parts of microbial agents in the mixed material obtained from the step 3), mixing uniformly, crushing, and sieving in an 100-mesh sieve, thereby obtaining the soil conditioner. The soil conditioner provided by the invention can be used for modifying soil, intensifying the disease-prevention capability, and improving the crop yield, the quality of agricultural products and the fertility of soil.

Owner:YANTAI SANHE BIOLOGICAL SCI & TECH CO LTD

High-phosphorus high-potassium controlled-release fertilizer for peanuts and preparation method thereof

ActiveCN103342605AGood nutritional needsLong release periodFertilizer mixturesMagnesium ammonium phosphateRoot rot

The invention discloses a high-phosphorus high-potassium controlled-release fertilizer for peanuts and a preparation method of the high-phosphorus high-potassium controlled-release fertilizer, belonging to the technical field of fertilizers. The high-phosphorus high-potassium controlled-release fertilizer comprises the following raw materials in parts by weight: 20-30 parts of urea, 60-80 parts of diammonium phosphate, 30-40 parts of potassium chloride, 8-10 parts of magnesium ammonium phosphate, 8-10 parts of potassium feldspar, 1-2 parts of boric acid, 1-2 parts of ferrous sulfate, 1-2 parts of manganese sulfate, 1-2 parts of zinc sulfate, 1-2 parts of sodium molybdate, 5-10 parts of traditional Chinese medicine additive, 8-10 parts of gypsum powder and 20-30 parts of urea formaldehyde. When being used, the traditional Chinese medicine additive is decocted to form a traditional Chinese medicine extracting solution by adding water; the urea formaldehyde containing Chinese herb extracts serves as an envelope, and the gypsum powder is adhered outside the envelope; and the other raw materials are wrapped in the envelope. After being fertilized for one time, the high-phosphorus high-potassium controlled-release fertilizer meets the requirements of crops on nutrients such as nitrogen, phosphorus, potassium, calcium and sulfur in the entire growth period. Meanwhile, the high-phosphorus high-potassium controlled-release fertilizer can be used for increasing the setting ratio and the yield by above 15% and meanwhile greatly reducing the occurrence rate of stem rots, root rots and the like of peanuts.

Owner:JINAN BADUN FERTILIZER

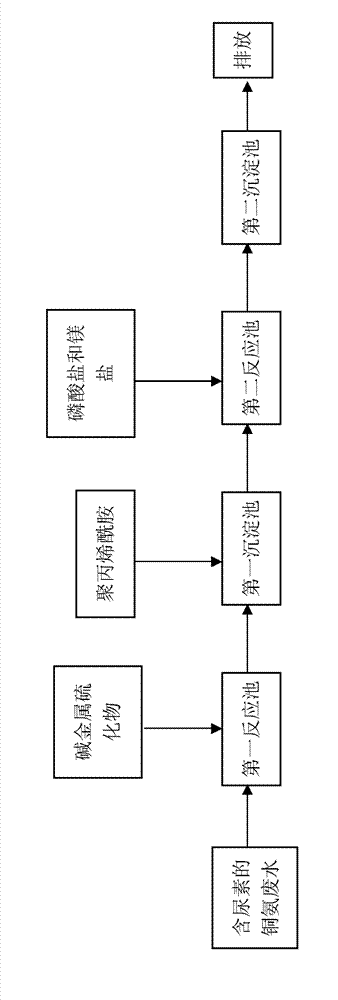

Treatment method for urea-containing high concentration copper ammonium wastewater

ActiveCN102765829AReduced release rateImprove fertilizer efficiencyMultistage water/sewage treatmentHigh concentrationMagnesium ammonium phosphate

The present invention provides a treatment method for urea-containing copper ammonia wastewater. The method is directed at that the existence of a stable copper ammonia complex and a specific reason of containing urea seriously affect the treating process and effect of wastewater treatment for high concentration copper ammonium wastewater, employs the process of a combination method combined the copper sulfide precipitation method for removing copper with the magnesium ammonium phosphate precipitation method to process the copper ammonia complex, helps to solve the treatment of high concentration copper ammonia complex-containing wastewater, helps to overcome the problems that the urea removal for high concentration ammonia nitrogen wastewater is complex in operation process, high in processing costs, and high in energy consumption, has no need of an independent high temperature and high pressure treatment for the urea, is easy in operation and low in cost, and does not need to control the pH value and the temperature in the process. The treatment method can achieve the purpose of recycling resources, and has good social and economic benefits.

Owner:SHANGHAI HUAYI ENERGY CHEM

Method for processing refuse-burning fly-ash by using magnesium ammonium phosphate sedimentation sludge

ActiveCN1884116AAdjustable pHImprove nutritional structureClimate change adaptationSewage/sludge fertilisersSludgeMagnesium ammonium phosphate

The invention discloses a together-disposing method of burnt rubbish ash and high-density ammonia nitrogen waste water, which comprises the following steps: testing density of ammonia nitrogen in the waste water; putting Mg2+ and PO43- in the waste water according to 1:0.9-1.0:1.0-1.2 molar rate for NH4+:Mg2+:PO43-; stirring or aerating for 20-120 min; sedimenting 20-60 min; removing supernatant; adjusting liquid-solid rate at 1:3 for remained mud and burnt rubbish ash; stirring evenly; curing 1-2 day at normal temperature; testing heavy metal immersed density of sample; burying directly or making soil modifier or fertilizer after reaching national standard limit.

Owner:TONGJI UNIV

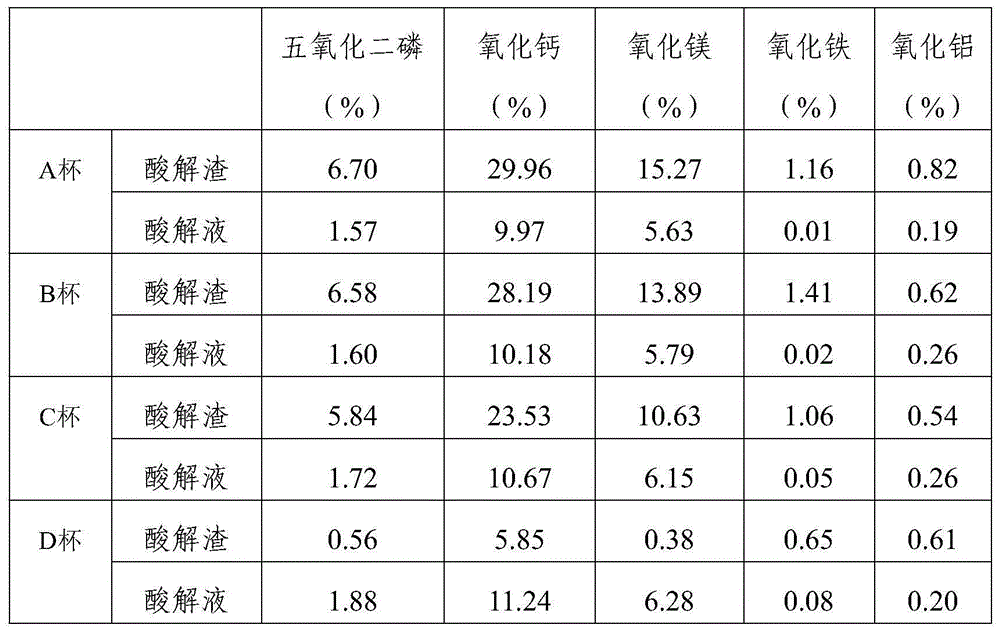

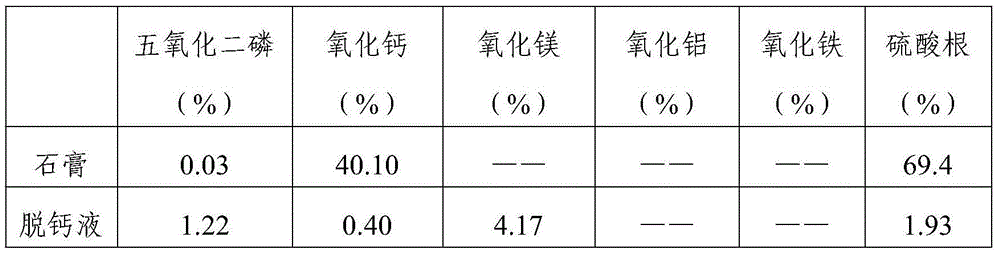

Method for preparing magnesium ammonium phosphate and magnesium ammonium nitrate with phosphate tailings

InactiveCN104860287AEfficient recyclingSolve being occupiedSolid waste disposalMagnesium compoundsMagnesium phosphateMagnesium ammonium phosphate

The invention discloses a method for preparing magnesium ammonium phosphate and magnesium ammonium nitrate with phosphate tailings. The method comprises the steps of using nitric acid for carrying out acidolysis on phosphate tailings, filtering and washing reaction feed liquid to obtain acidolysis liquid and acidolysis residues, preheating the acidolysis liquid, adding an ammonium sulfate solution into the acidolysis liquid, stirring the mixture for some time for reaction under a certain temperature and then filtering the mixture to obtain gypsum and a decalcifying solution, adding ammonia water into the decalcifying solution for neutralization and filtering the mixture to obtain a neutralization solution and residues, pelletizing the residues to obtain magnesium ammonium phosphate, and pelletizing the neutralization solution after concentrating the neutralization solution to obtain magnesium ammonium nitrate. With the method, phosphate tailings can be treated in a large-scale mode, the problem that phosphate tailings piles up in bulk is effectively solved, and the obtained products, namely magnesium ammonium phosphate and magnesium ammonium nitrate, contain active magnesium, and have good fertilizer efficiency.

Owner:GUIZHOU RES INST OF CHEM IND +1

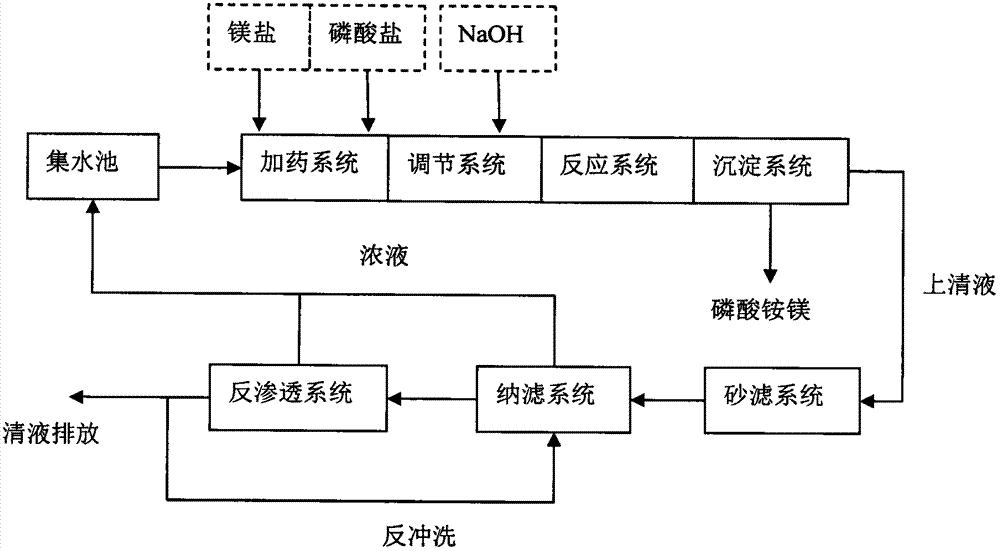

Method for treating ammonia nitrogen in wastewater by using integrated process

InactiveCN102964003AGuaranteed emission standardsZero emissionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentRetention timeMagnesium salt

The invention relates to a method for treating ammonia nitrogen in wastewater by using an integrated process, and the method comprises a magnesium ammonium phosphate chemical precipitation process and a membrane treatment process and comprises the processing steps of collecting water, dosing, adjusting the pH (potential of Hydrogen) value, reacting, precipitating and filtering. The method has the technical characteristics that magnesium salt and phosphate are added during the dosing; a NaOH solution is added to regulate the pH to 8.5-10 during the adjustment; during the reaction, the wastewater retention time is greater than or equal to 30 minutes, the ammonia ion in the wastewater is fully reacted to generate magnesium ammonium phosphate precipitates and heavy metal ion is converted into hydroxide precipitates; the precipitation time is greater than or equal to 6 hours to realize solid-liquid separation during the precipitation; and the supernatant liquid enters a membrane treatment system, the reverse osmosis clear water can be directly discharged and the concentrated water returns to a water collecting tank or is subjected to nanofiltration. The method has the advantages that ammonia nitrogen-containing wastewater with various concentrations can be treated; heating is not needed in the treatment process; the ammonia nitrogen content in the effluent can meet the national first grade effluent standard; and the content of other pollutants such as heavy metals and the like in the effluent can be used for achieving the effluent standard. The method is suitable for treating low-biodegradability ammonia nitrogen-containing wastewater and the ammonia nitrogen-containing wastewater of factories without heat resources.

Owner:CECEP L&T ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com