Method of formation/recovery of magnesium ammonium phosphate and apparatus therefor

A magnesium ammonium phosphate and phosphoric acid technology, applied in the direction of magnesium phosphate fertilizer, ammonium orthophosphate fertilizer, fertilization equipment, etc., to achieve the effect of improving treatment performance, avoiding fly ash problems, and maintaining easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

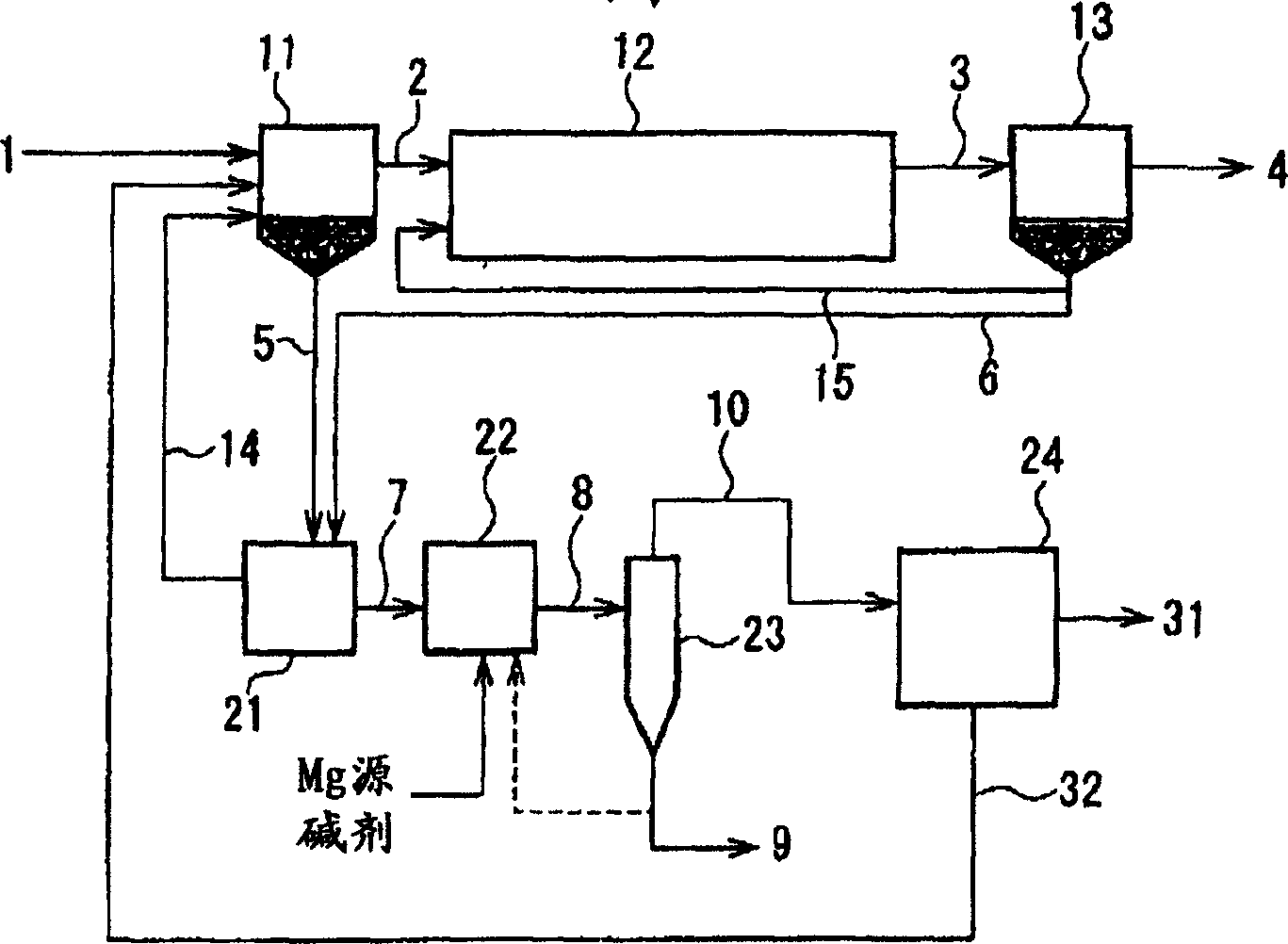

[0064] This embodiment is an experimental example obtained by using the sludge from the A sewage treatment plant and using the pilot test device, and the flow process is the same as that shown previously. figure 1 The process is the same. A sewage treatment plant adopts activated sludge treatment using anaerobic anaerobic aerobic method. In this example, the primary sedimentation sludge and excess sludge taken from A sewage treatment plant were mixed at a ratio of about 1:1, and concentrated by a centrifugal thickener. The thickened sludge is introduced into the phosphoric acid and ammonium ion elution and MAP production tank 22 . The bottom of the tank 22 is hopper-shaped, and the inside of the tank is stirred by a stirrer, and the MAP particles at the bottom of the tank flow through the entire tank by continuously circulating the sludge stirred from the bottom of the tank to the upper part of the tank. Other conditions of the tank 22 were set as follows: hydraulic residenc...

Embodiment 2

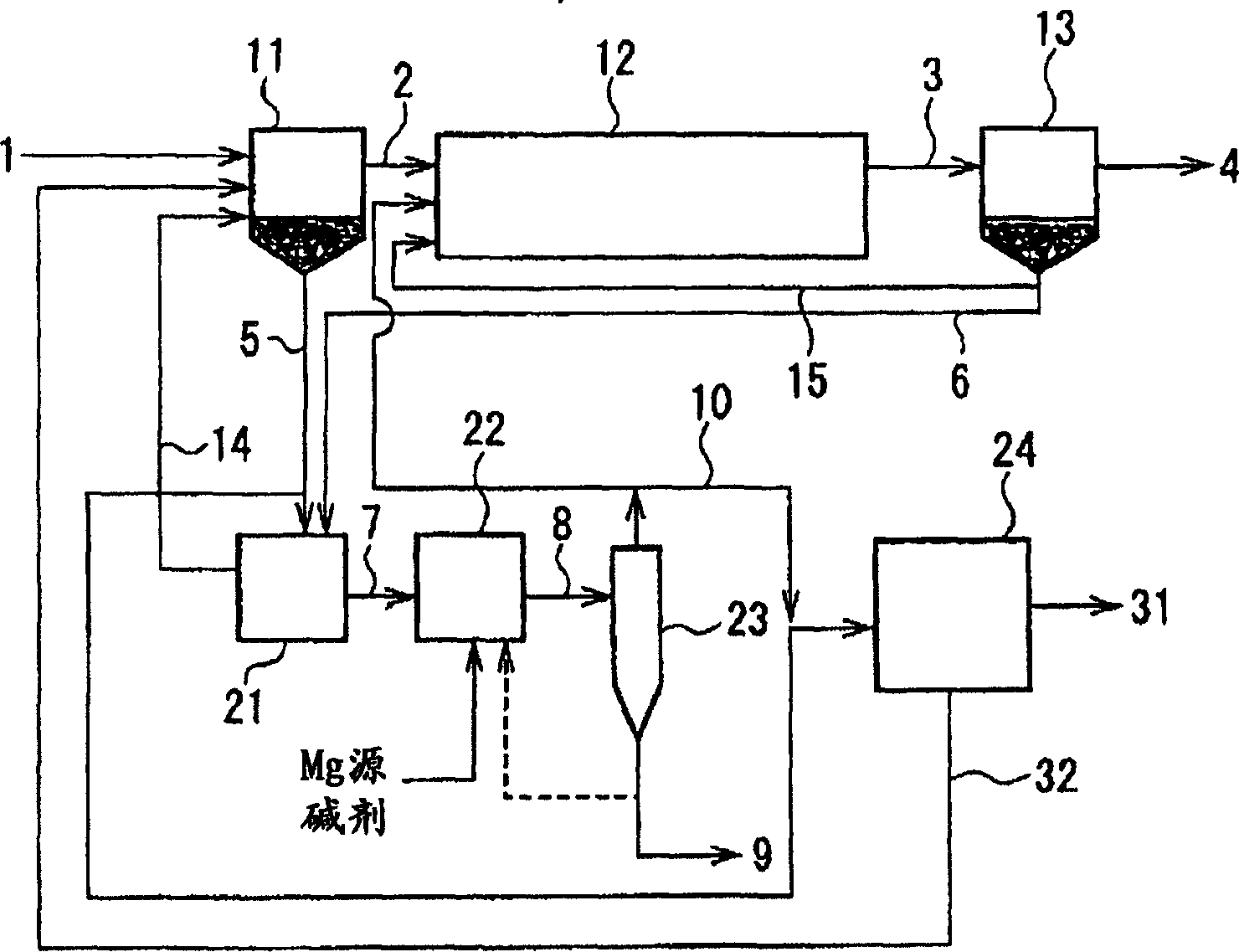

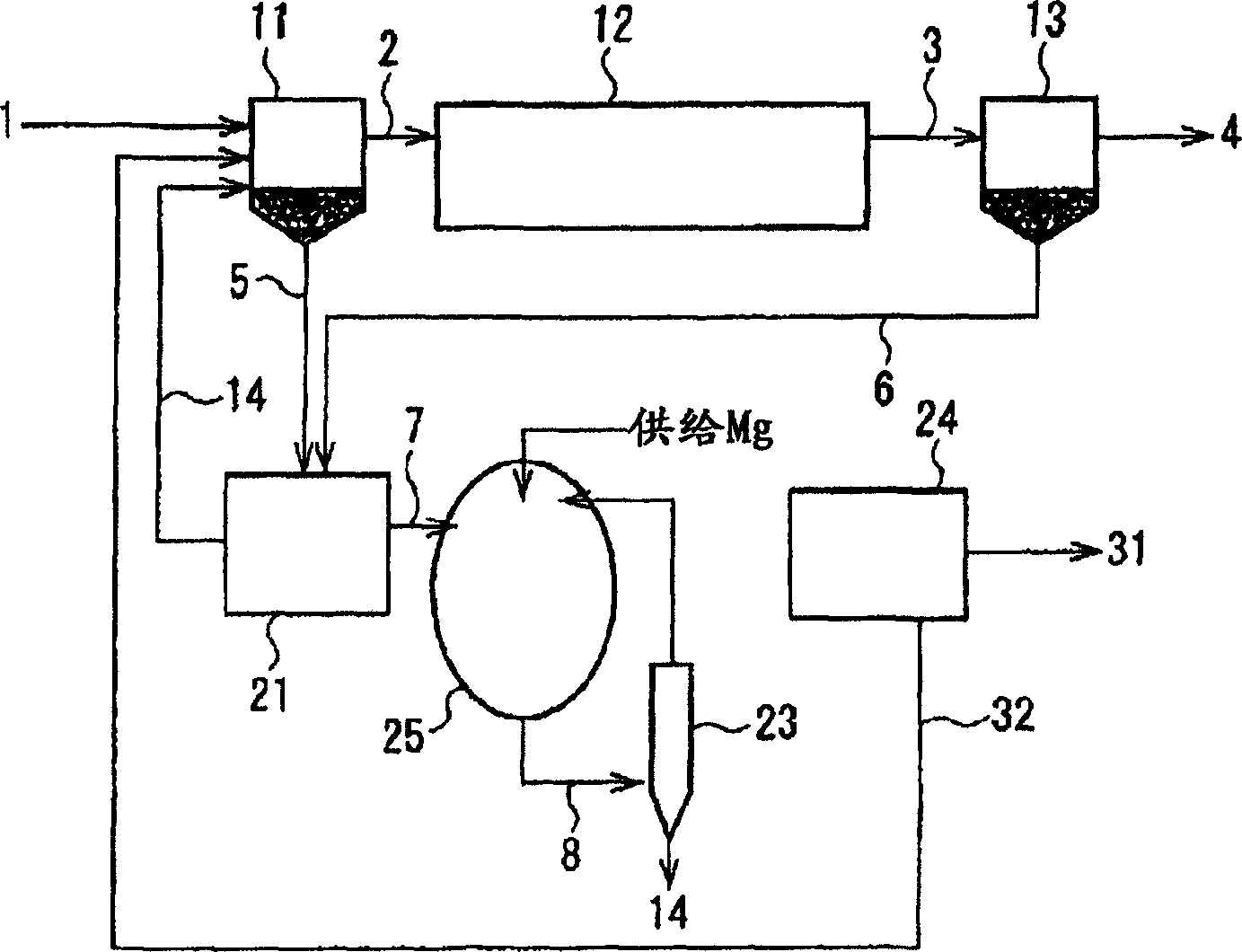

[0071] Next, an example of the operation result of the experimental equipment of another form in which the wastewater treatment technology of the present invention is actually applied will be described. However, the present invention is not limited to this example. This embodiment is an experimental example obtained by using the sludge of A food wastewater treatment plant and utilizing a pilot test device, and the flow process is the same as that previously shown figure 2 The process is the same. A treatment plant adopts activated sludge treatment by anaerobic anaerobic aerobic method as biological water treatment process 12 . In this example, the primary sedimentation sludge and excess sludge taken from A treatment plant were mixed at a ratio of about 2:1, and concentrated using a gravity thickener. The thickened sludge is introduced into the phosphoric acid and ammonium ion elution and MAP production tank 22 . The tank 22 is provided with an ultrasonic treatment device a...

Embodiment 3

[0079] Moreover, an example of the operation result of the experimental plant of another form which actually applied the wastewater treatment technique of this invention is demonstrated. However, the present invention is not limited to this example.

[0080] This example is an experimental example obtained from an in-use test device using sludge from a wastewater treatment plant of a food factory, and the flow is the same as that shown previously. figure 2 The process is the same. The wastewater treatment plant of Factory A adopts activated sludge treatment using anaerobic anaerobic aerobic method. In this example, the primary sedimentation sludge and excess sludge collected from the treatment plant of A factory were mixed at about 2:1, and concentrated by a gravity thickener. Thickened sludge is first introduced into the ozone treatment tank (in figure 2(not shown in the figure), after the solubilization treatment by ozone was carried out, phosphoric acid and ammonium io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com