Treatment method for urea-containing high concentration copper ammonium wastewater

A copper ammonia wastewater and treatment method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of inability to effectively precipitate copper ions, ammonia nitrogen cannot be recycled and reused, etc. Solve problems such as complex operation process, achieve good social and economic benefits, convenient operation, and overcome the effect of complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

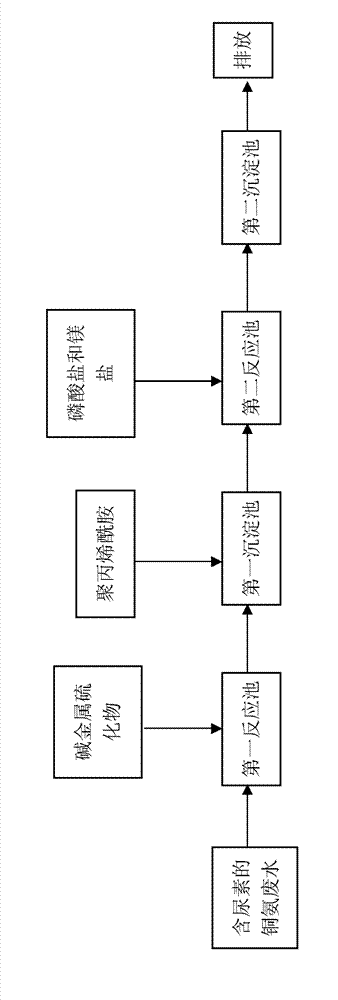

Method used

Image

Examples

Embodiment 1

[0029] Get 15.3kg of urea-containing copper ion concentration and add 55.7gNa 2 S·9H 2 O, blast aeration for 1 h; add organic polymer flocculant polyacrylamide (PAM: waste water = 0.1 wt%), let stand, settle for 10 min. In the supernatant, magnesium chloride solution (1mol / L) and disodium hydrogen phosphate solution (0.5mol / L) were added to make Mg 2+ : NH 4 + :PO 4 3- =1.25:1:1.25 (molar ratio), stirred for 20 minutes, and stood still for 30 minutes. The concentration of total copper (calculated as Cu) in the effluent is below 1 mg / L, the concentration of ammonia nitrogen is 40 mg / L, the removal rate of total copper is more than 99.88%, and the removal rate of ammonia nitrogen is 98.67%.

Embodiment 2

[0031] Get 1000kg urea-containing copper ion concentration is 234mg / L, ammonia nitrogen concentration is 1021mg / L in waste water, add sodium sulfide solution, make S 2- : Cu 2+ =1.2:1 (molar ratio); add organic polymer flocculant polyacrylamide (PAM: waste water = 0.1wt%), let stand, and settle for 10 minutes. In the supernatant, magnesium chloride solution (1mol / L) and disodium hydrogen phosphate solution (0.5mol / L) were added to make Mg 2+ : NH 4 + :PO 4 3- =1.25:1:1.25 (molar ratio), stirred for 20 minutes, and stood still for 30 minutes. The concentration of total copper (calculated as Cu) in the effluent was 1.5 mg / L, the concentration of ammonia nitrogen was 12 mg / L, the removal rate of total copper was 99.36%, and the removal rate of ammonia nitrogen was 98.82%.

Embodiment 3

[0033] Get 1kg of urea-containing copper ion concentration is 2056mg / L, ammonia nitrogen concentration is 800mg / L in waste water, add sodium sulfide solution, make S 2- : Cu 2+ =1.2:1 (molar ratio); add organic polymer flocculant polyacrylamide (PAM: waste water = 0.1wt%), let stand, and settle for 10 minutes. In the supernatant, magnesium chloride solution (1mol / L) and disodium hydrogen phosphate solution (0.5mol / L) were added to make Mg 2+ : NH 4 + :PO 4 3- =1.25:1:1.25 (molar ratio), stirred for 20 minutes, and stood still for 30 minutes. The concentration of total copper (calculated as Cu) in the effluent was 2.7mg / L, the concentration of ammonia nitrogen was 23.8mg / L, the removal rate of total copper was 99.87%, and the removal rate of ammonia nitrogen was 97.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com