Humic-acid-containing modified-starch-coated slow-release fertilizer and preparation method thereof

A technology of coated slow-release and humic acid, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of non-environmental degradation, soil pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

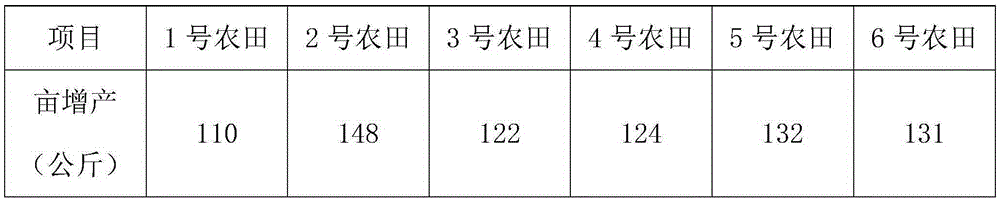

Image

Examples

Embodiment 1

[0024]A modified starch-coated slow-release fertilizer containing humic acid proposed by the present invention, its raw materials include the following components in parts by weight, 80 parts of urea, 3.5 parts of potassium superphosphate, 2.0 parts of sodium hydroxide, N,N'- 6 parts of methylene bisacrylamide, 3 parts of ammonium sulfate, 4 parts of ammonium chloride, 2.5 parts of potassium dihydrogen phosphate, 4 parts of deionized water, 5 parts of microcrystalline paraffin, 3 parts of colloidal phosphate rock powder, and 5 parts of sodium alginate 9 parts of modified starch, 6 parts of cellulose derivatives, 2.0 parts of humic acid, 4 parts of acrylic acid, 5.5 parts of copper potassium pyrophosphate, 4 parts of ammonium polyacrylate, and 5 parts of water retaining agent.

[0025] A kind of preparation method that the present invention proposes containing the modified starch coated slow-release fertilizer of humic acid, comprises the steps:

[0026] S1. Preparation of slow...

Embodiment 2

[0030] A modified starch-coated slow-release fertilizer containing humic acid proposed by the present invention, its raw materials include the following components in parts by weight: 75 parts of urea, 5 parts of potassium superphosphate, 1 part of sodium hydroxide, N,N'- 9 parts of methylene bisacrylamide, 1 part of ammonium sulfate, 6 parts of ammonium chloride, 1 part of potassium dihydrogen phosphate, 6 parts of deionized water, 2 parts of microcrystalline paraffin, 5 parts of colloidal rock powder, 2 parts of sodium alginate 12 parts of modified starch, 3 parts of cellulose derivatives, 3 parts of humic acid, 2 parts of acrylic acid, 8 parts of copper potassium pyrophosphate, 2 parts of ammonium polyacrylate, and 8 parts of water retaining agent.

[0031] A kind of modified starch-coated slow-release fertilizer containing humic acid proposed by the present invention comprises the following steps:

[0032] S1. Preparation of slow-release fertilizer coating material: Weigh ...

Embodiment 3

[0036] A modified starch-coated slow-release fertilizer containing humic acid proposed by the present invention, its raw materials include the following components by weight: 85 parts of urea, 2 parts of potassium superphosphate, 3 parts of sodium hydroxide, N,N'- 3 parts of methylene bisacrylamide, 5 parts of ammonium sulfate, 2 parts of ammonium chloride, 4 parts of potassium dihydrogen phosphate, 2 parts of deionized water, 8 parts of microcrystalline paraffin, 1 part of colloidal rock powder, 8 parts of sodium alginate 6 parts, 6 parts of modified starch, 9 parts of cellulose derivatives, 1 part of humic acid, 6 parts of acrylic acid, 3 parts of copper potassium pyrophosphate, 6 parts of ammonium polyacrylate, 2 parts of water retaining agent.

[0037] A kind of preparation method that the present invention proposes containing the modified starch coated slow-release fertilizer of humic acid, comprises the steps:

[0038] S1. Preparation of slow-release fertilizer coating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com