Patents

Literature

875results about How to "Good moldability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic dicyclopentadiene-base open-ring polymers, hydrogenated derivatives thereof, and processes for the preparation of both

InactiveUS6511756B1Improve efficiencyGood moldabilityPlastic/resin/waxes insulatorsSynthetic resin layered productsThermoplasticDouble bond

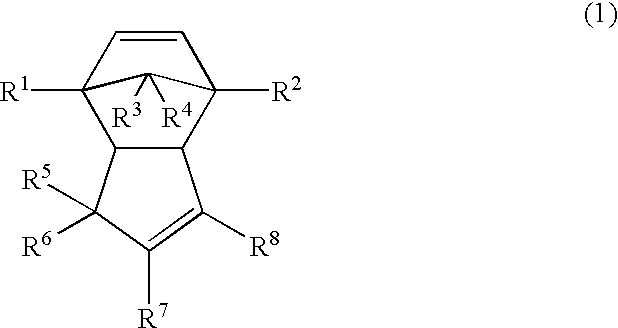

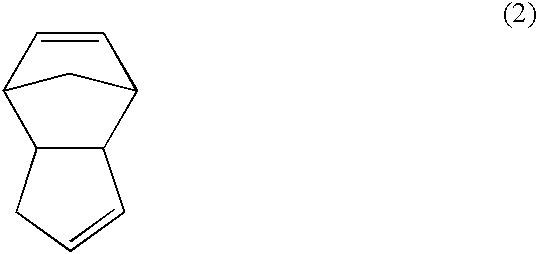

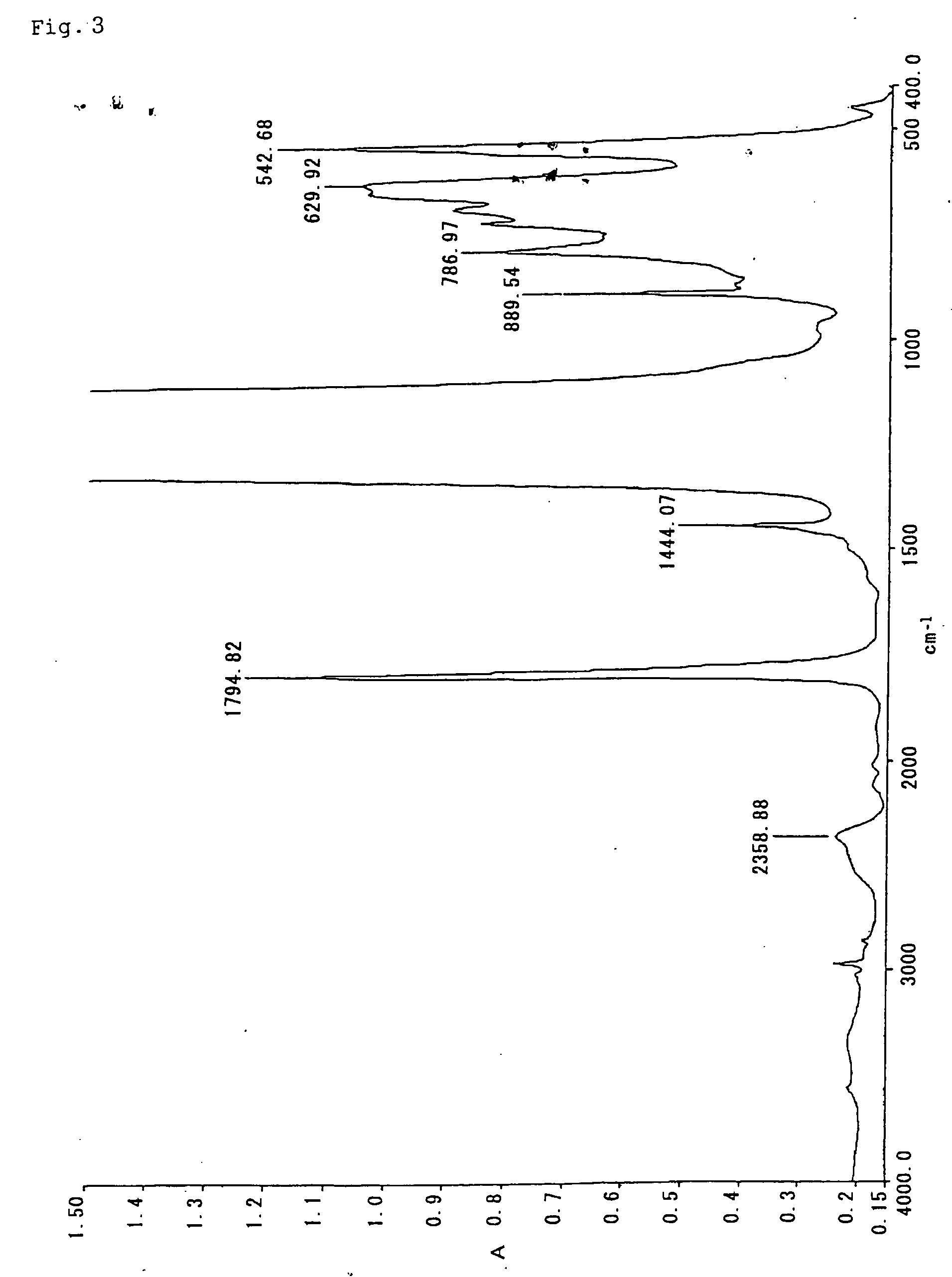

A thermoplastic dicyclopentadiene ring-opening polymer obtained by ring-opening polymerization of a monomer component containing a dicyclopentadiene monomer, characterized in that polycyclic rings which are repeating units of the polymer are bonded in cis-position relative to the carbon-carbon double bond of the main chain of the polymer in 50 mol % or more of the repeating units based on the total repeating units and the content of a low-molecular weight component of 2,000 or less in molecular weight is 10% by weight or less based on the total polymer components, and a hydrogenation product obtained by hydrogenating the carbon-carbon unsaturated bond of the thermoplastic dicyclopentadiene ring-opening polymer.

Owner:ZEON CORP

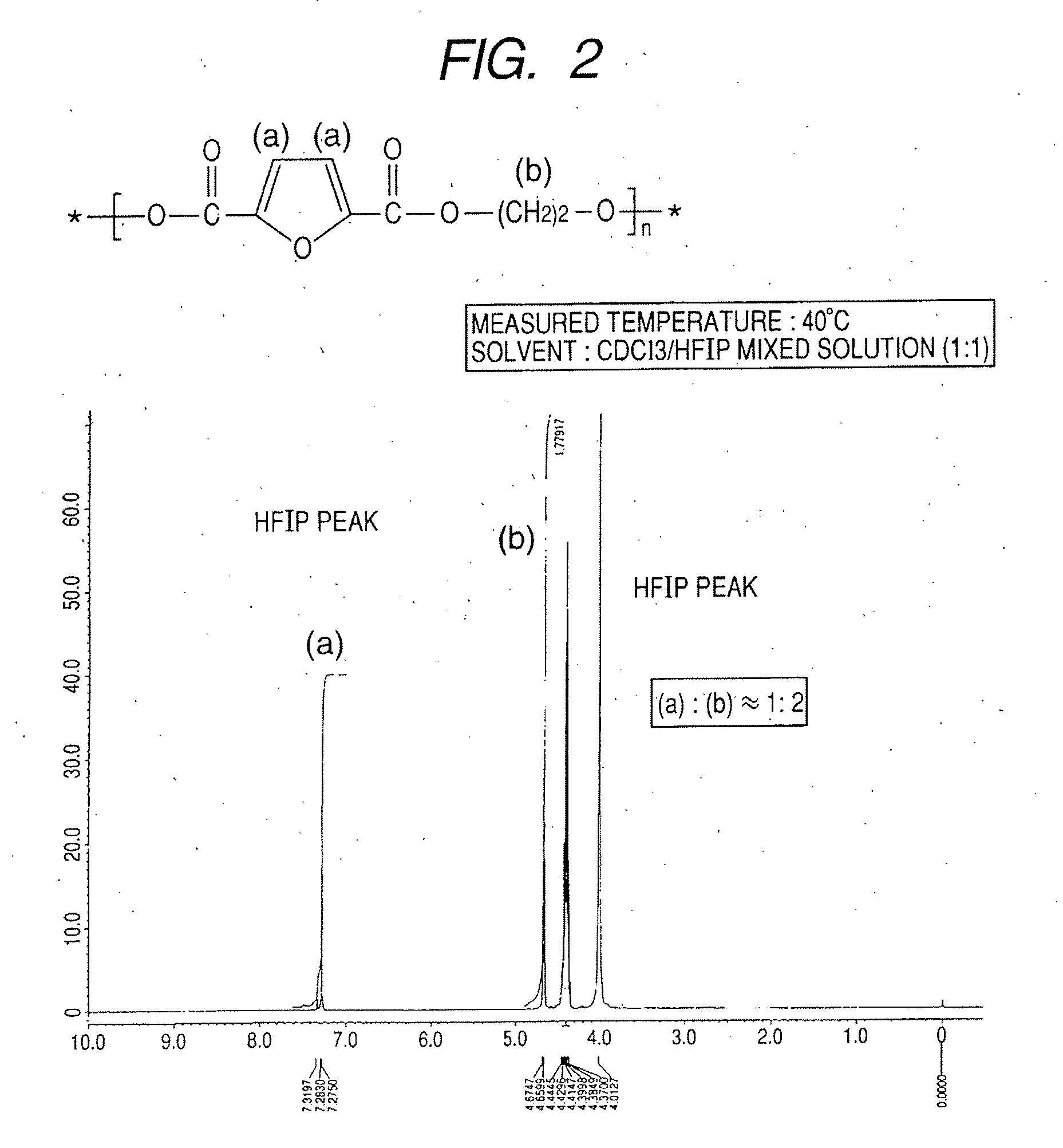

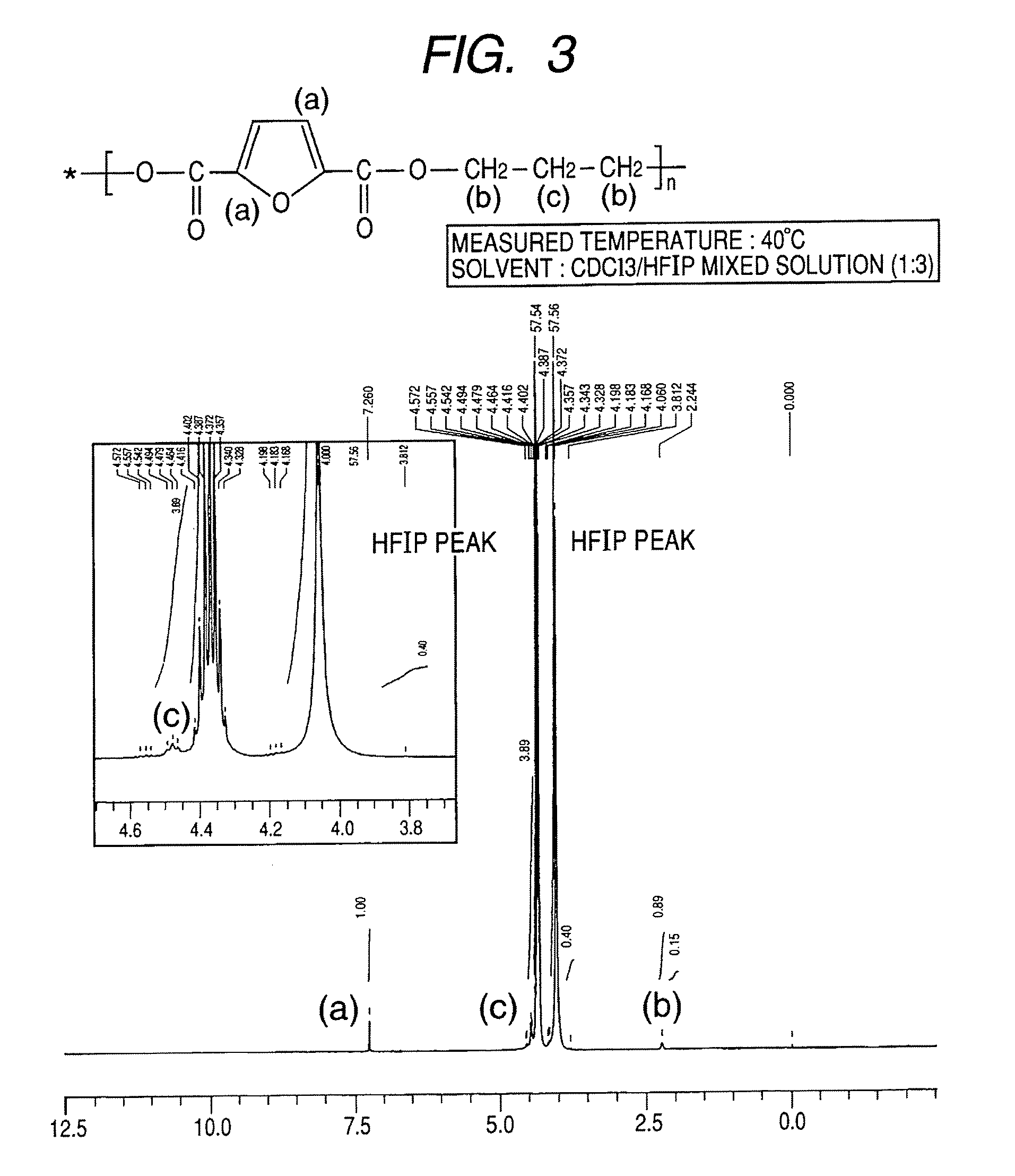

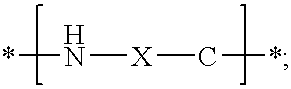

Polymer compound and method of synthesizing the same

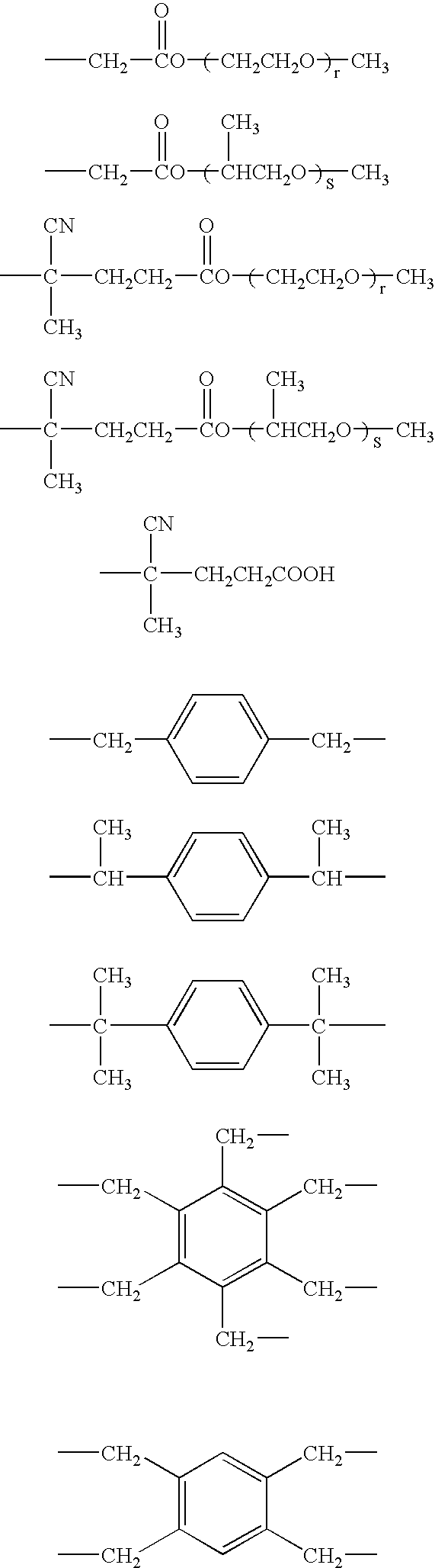

ActiveUS20090124763A1High mechanical strengthGood moldabilityThin material handlingPolymer chemistryFlexural strength

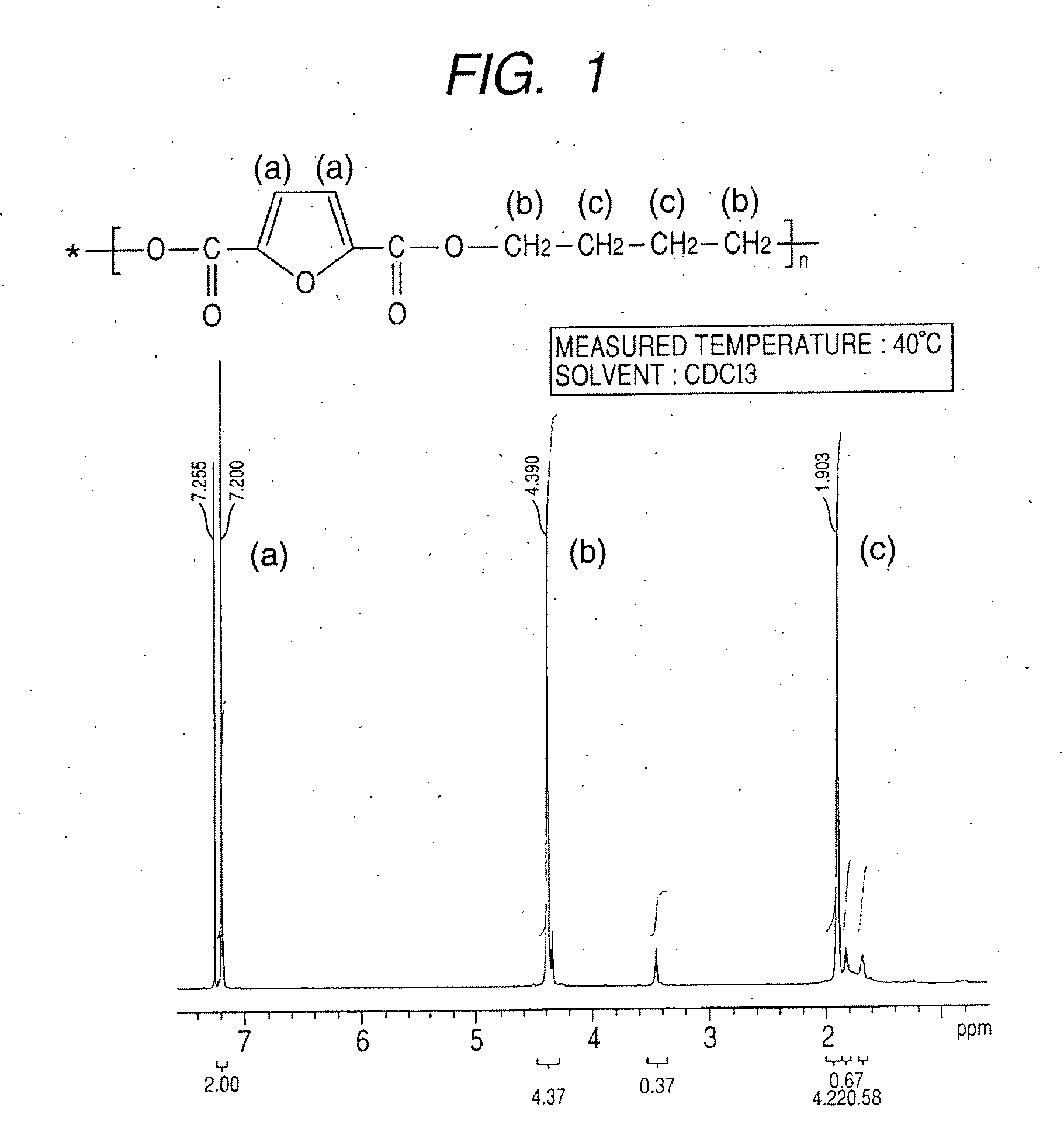

Provided is a polymer compound having a furan ring having a degree of polymerization of 185 or more and 600 or less. This polymer compound has excellent mechanical strength (flexural strength).

Owner:CANON KK

High flow engineering thermoplastic compositions and products made therefrom

InactiveUS20040108623A1Improve moldability and flowabilityGood balance of impact and heat resistanceOrganic dyesThermoplasticAcrylate

High flow engineering thermoplastic compositions made from a thermoplastic host polymer and a low molecular weight flow modifier polymer, and products made therefrom. The flow modifier polymer is made by polymerizing at least one vinyl aromatic monomer and at least one (meth)acrylate monomer. The high flow engineering thermoplastics provide improved flowability and processability without sacrificing impact strength or heat resistance

Owner:JOHNSON POLYMER INC

Thermoplastic resin composition and elastomer composition

Provided are a thermoplastic resin composition which is excellent in oil resistance, heat resistance, weatherability, impact resistance, transparency, and moldability, and which can be produced economically, an elastomer composition with low hardness and high tensile strength which is excellent in oil resistance and compression set, and a molded object produced by molding the thermoplastic resin composition or elastomer composition. The composition is produced by compounding a thermoplastic resin or an elastomer with a block copolymer having at least one methacrylic ester polymer block and at least one acrylic ester polymer block. Also provided are a process for producing a methacrylic ester-acrylic ester-methacrylic ester block copolymer which requires hardly any purification, which is excellent in heat resistance and weatherability, and in which the molecular weight and the molecular-weight distribution are controlled, and a methacrylic ester-acrylic ester-methacrylic ester block copolymer produced by the process.

Owner:KANEKA CORP

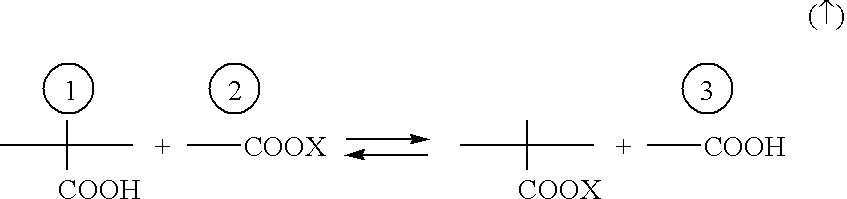

Golf ball material and golf ball

InactiveUS6838501B2Easy to reboundSpeed up the flowFibre treatmentConductive materialIonomerElastomer

A mixture having good thermal stability, flow and moldability and suitable as a golf ball-forming material is obtained when a resinous component including a base resin of an ionomer resin or resins and optionally a non-ionomer thermoplastic elastomer is blended with specific proportions of a fatty acid and / or fatty acid derivative and a basic inorganic metal compound capable of neutralizing acidic groups left unneutralized in the base resin and fatty acid. Using the same material, high-rebound golf balls can be effectively manufactured.

Owner:BRIDGESTONE SPORTS

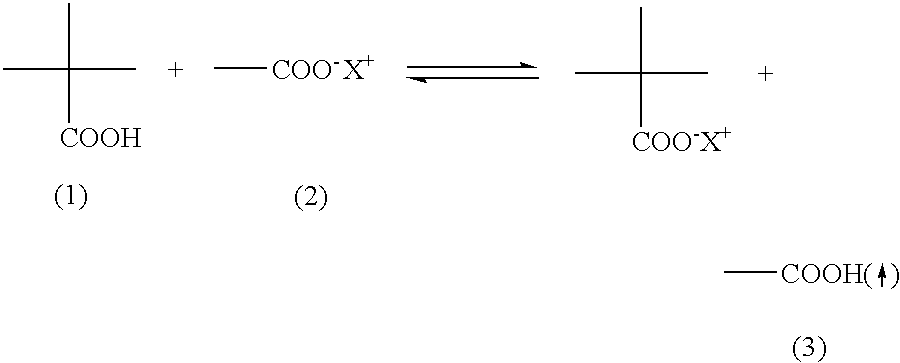

Polymer Solid Electrolyte

InactiveUS6162563AEasy to processGood moldabilityHybrid capacitor electrolytesCell electrodesLithium metalBackbone chain

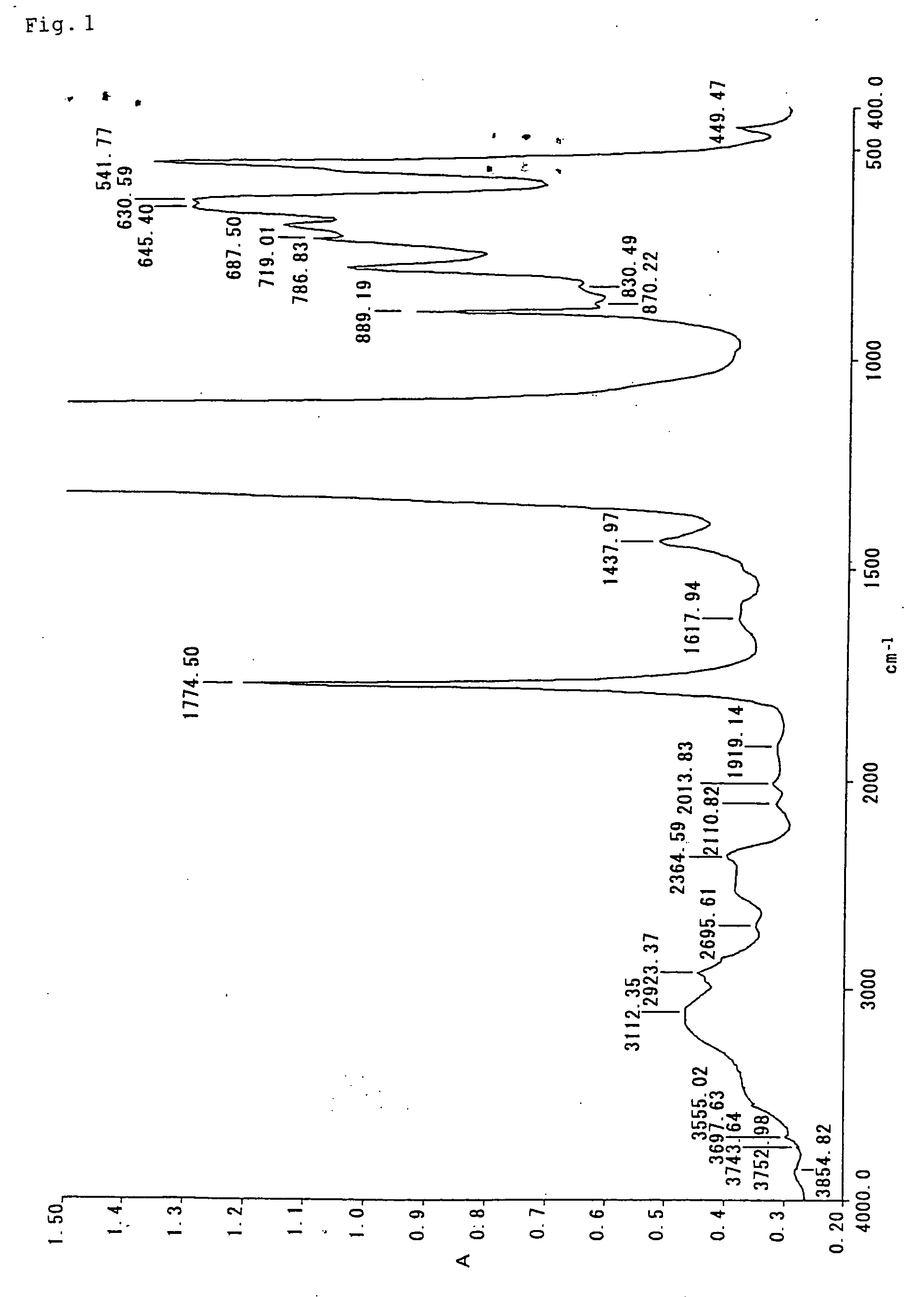

PCT No. PCT / JP97 / 02854 Sec. 371 Date Mar. 11, 1999 Sec. 102(e) Date Mar. 11, 1999 PCT Filed Aug. 19, 1997 PCT Pub. No. WO98 / 07772 PCT Pub. Date Feb. 26, 1998A polymer solid electrolyte obtained by blending (1) a polyether copolymer having a main chain derived form ethylene oxide and an oligooxyethylene side chain, (2) an electrolyte salt compound, and (3) a plasticizer of an aprotic organic solvent or a derivative or metal salt of a polyalkylene glycol having a number-average molecular weight of 200 to 5,000 or a metal salt of the derivative is superior in ionic conductivity and also superior in processability, moldability and mechanical strength to a conventional solid electrolyte. A secondary battery is constructed by using the polymer solid electrolyte in combination with a lithium metal negative electrode and a lithium cobaltate positive electrode.

Owner:OSAKA SODA CO LTD

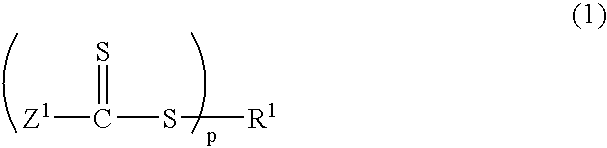

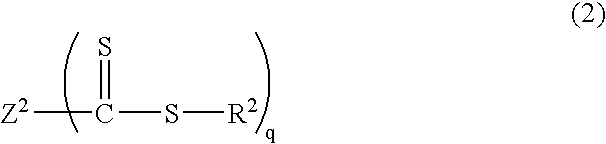

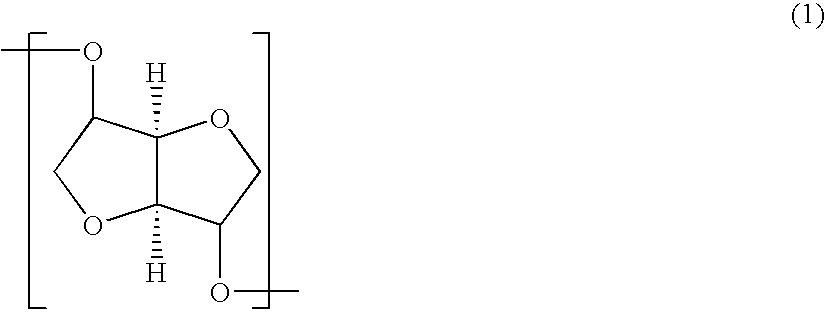

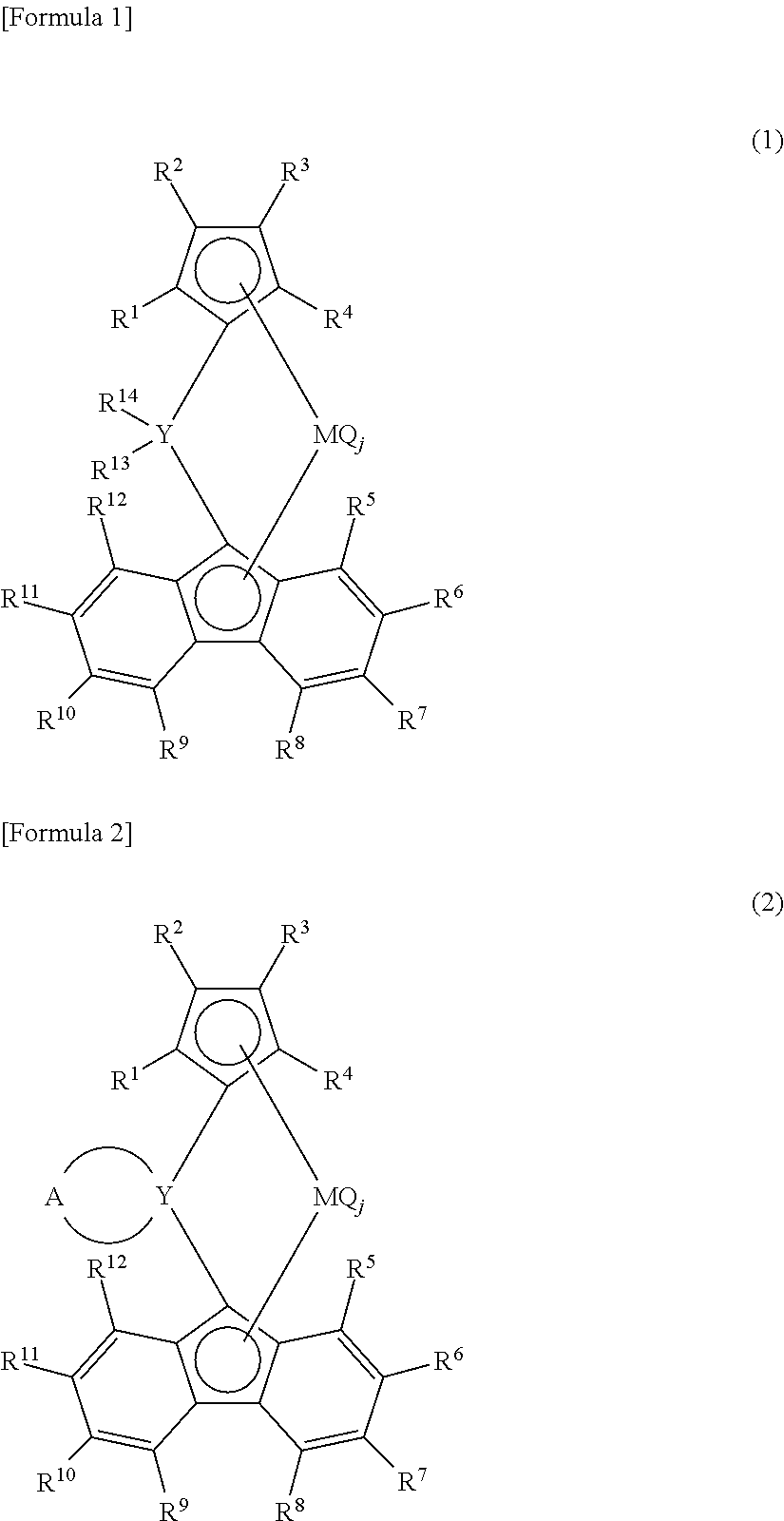

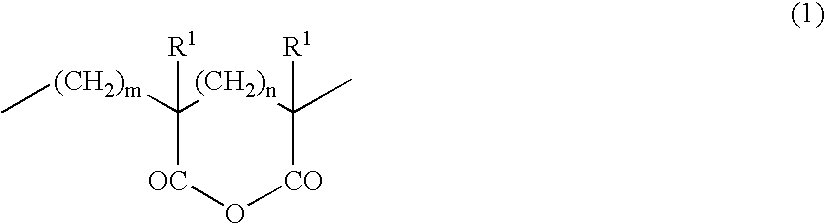

Polycarbonate and process for producing the same

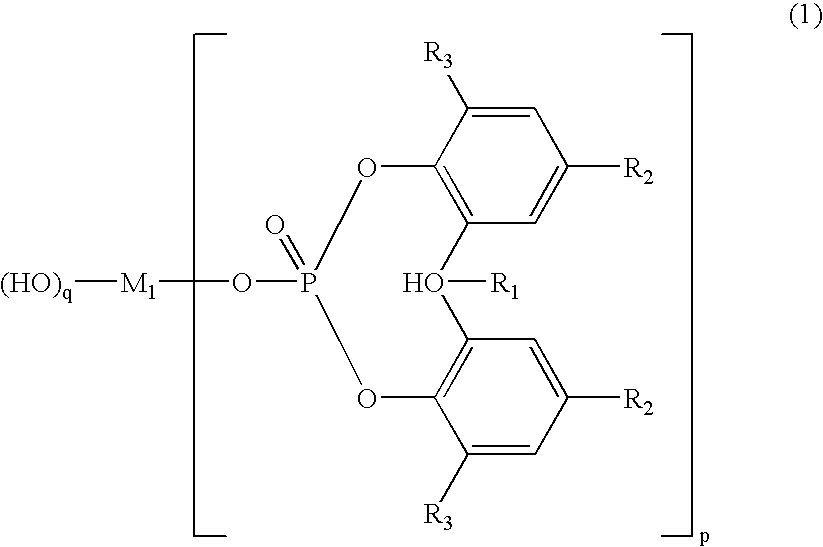

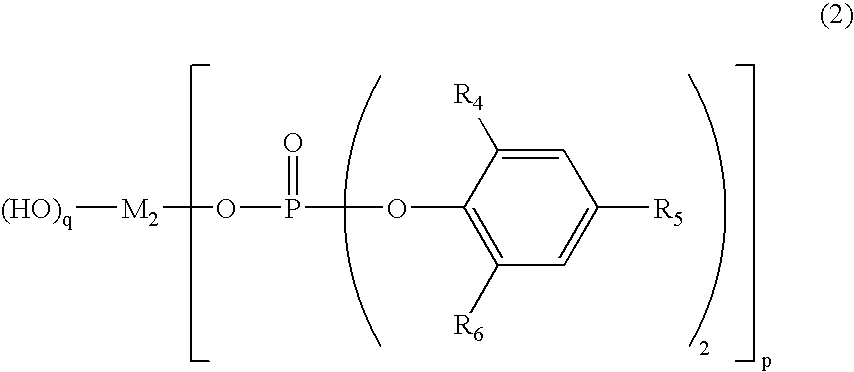

ActiveUS20060149024A1Improve heat resistanceGood moldabilityOrganic-compounds/hydrides/coordination-complexes catalystsEtherDiol

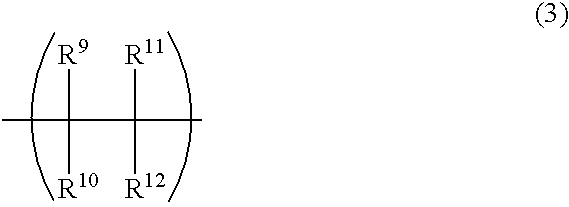

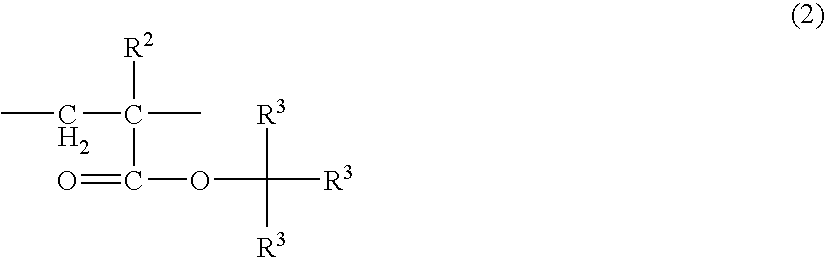

A polycarbonate containing an ether diol residue producible from a polysaccharide and expressed by the following formula (1), and a diol residue expressed by the following formula (2) —O—(CmH2m)—O— (2) (here, m is an integer of 2 to 12), wherein said ether diol residue amounts to 65-98 wt. % of all the diol residues, and having a glass transition temperature of 90° C. or higher.

Owner:TEIJIN LTD

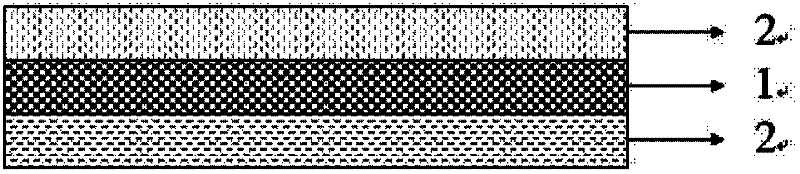

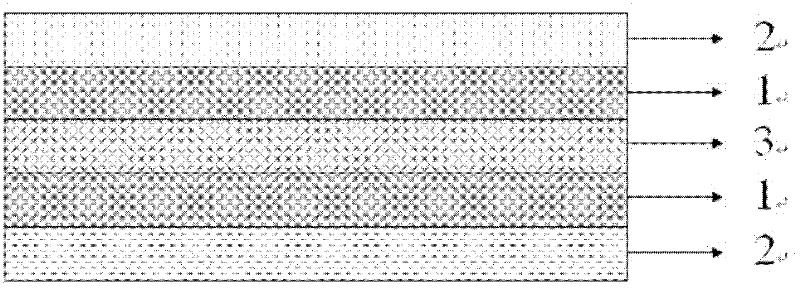

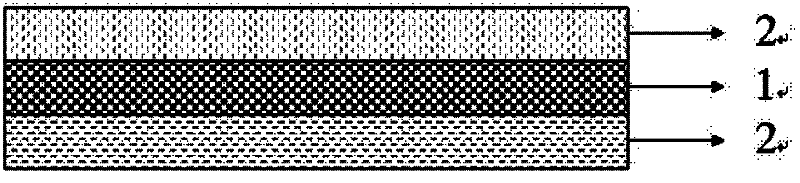

A kind of insulating and heat-conducting double-sided adhesive tape and preparation method thereof

InactiveCN102260466AImprove thermal conductivityGood thermal conductivity and electrical insulationFilm/foil adhesivesPolyureas/polyurethane adhesivesThermal insulationRoom temperature

The invention provides an insulating and heat-conducting double-sided adhesive tape and a preparation method thereof. In the insulating and heat-conducting double-sided adhesive tape, the outer layers on both sides are release paper, and a single layer of insulating and heat-conducting adhesive is arranged between the two layers of release paper. Or the outer layers on both sides are release paper, a single-layer substrate is arranged between the two layers of release paper, and an insulating and heat-conducting adhesive is arranged between the substrate and the release paper. The preparation method is as follows: mixing heat-conducting medium and solvent, adding insulating heat-conducting glue, stirring, coating and drying, and the preparation is completed. The adhesive tape of the invention has the advantages of good thermal conductivity, electrical insulation, stability at room temperature, easy die-cutting, reworkable characteristics, and easy operation.

Owner:ZHONGSHAN KINGLABEL ADHESIVE PRODS

Radiation-curable composition and cured product thereof

To provide a radiation-curable composition which can provide a cured product capable of sufficiently satisfying all of light resistance, transparency and curability and therefore can be useful in much more applications in addition to optical members, lighting members, and automobile members. A radiation-curable composition used after cured by radiation energy, wherein a cured product produced by curing the curable composition by radiation energy of 2 J / cm2 satisfies: an initial light transmittance of 80% or more at a wavelength of 380 nm, and a light transmittance retention of 90% or more after 200 hours of accelerated light resistance test.

Owner:NIPPON SHOKUBAI CO LTD

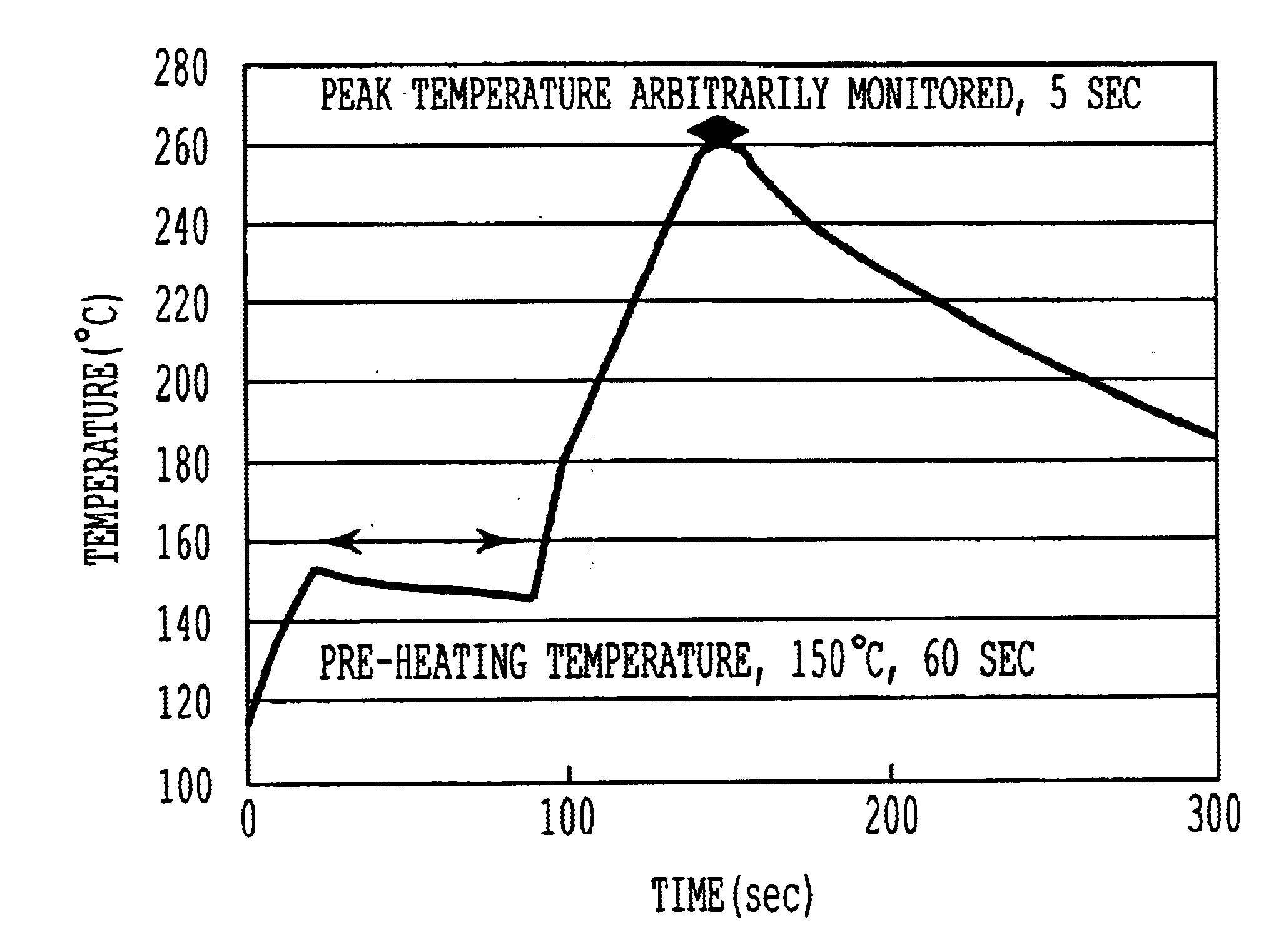

Golf ball materials and golf ball

InactiveUS6962951B1Outstanding reboundEasy to reboundFibre treatmentSynthetic resin layered productsIonomerMetal

A golf ball material comprises a heated mixture having a melt index of at least 1.0 dg / min, which mixture is composed of (A) a thermoplastic resin, (B) a fatty acid or fatty acid derivative having a molecular weight of at least 280, and (C) a basic inorganic metal compound capable of neutralizing acidic groups in components A and B. The material including a highly neutralized ionomer resin has good thermal stability, flow characteristics and moldability. The invention is also directed at high-rebound golf balls which can be easily and efficiently manufactured using the same material.

Owner:BRIDGESTONE SPORTS

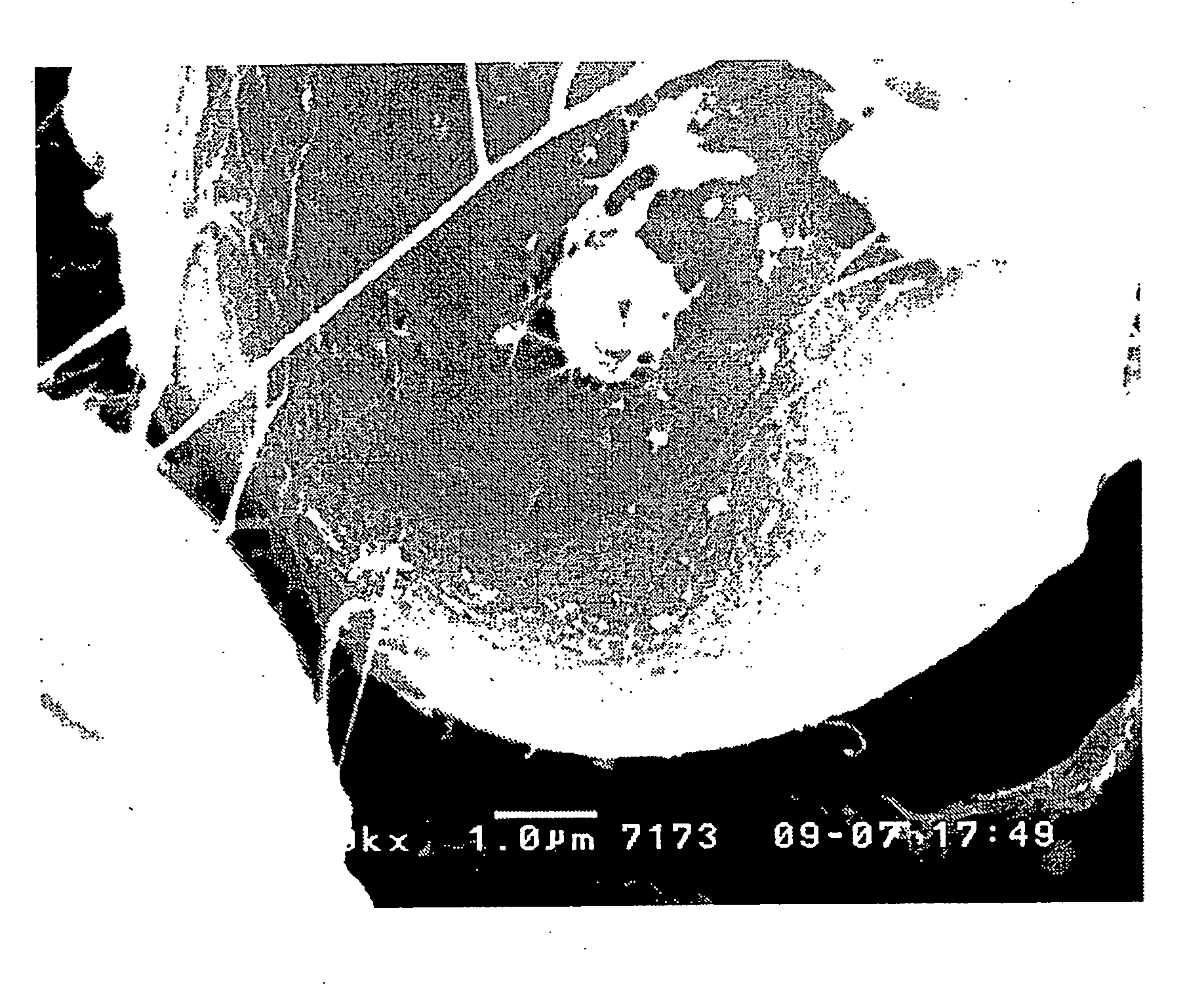

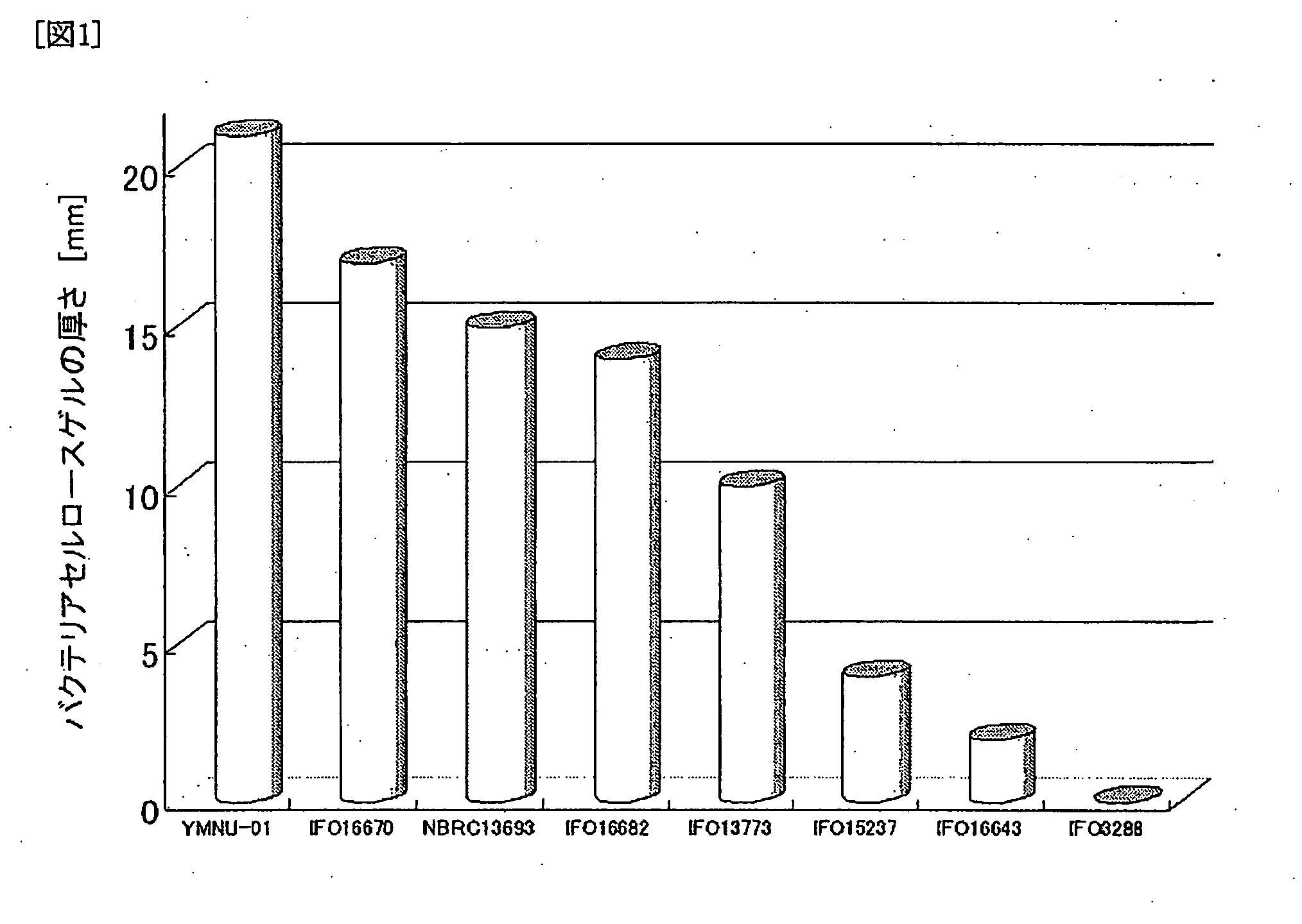

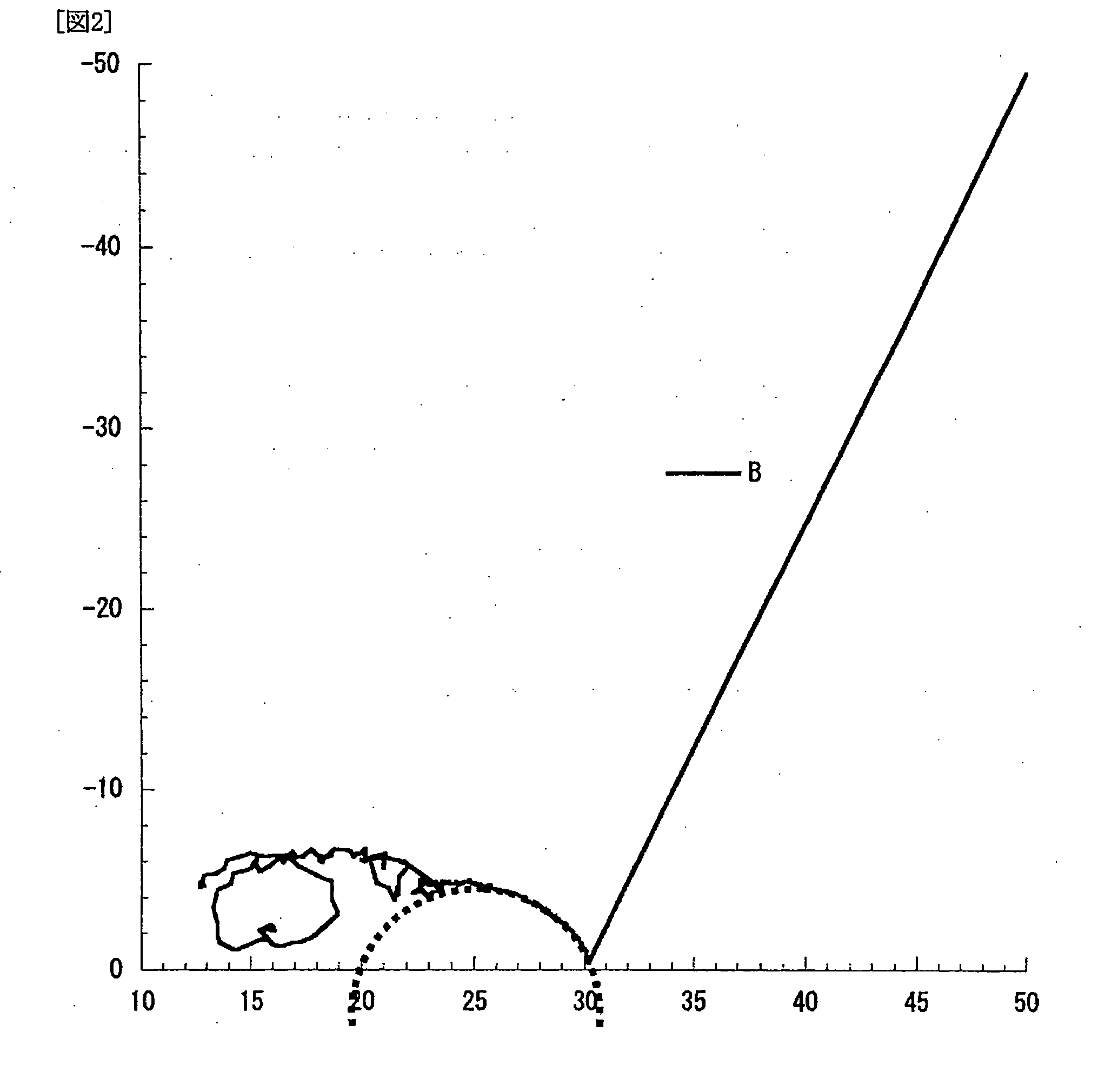

Lithium Ion Conductive Material Utilizing Bacterial Cellulose Organogel, Lithium Ion Battery Utilizing the Same and Bacterial Cellulose Aerogel

InactiveUS20080220333A1High mechanical strengthImprove performanceMaterial nanotechnologyConductive materialConductive materialsSolvent

A lithium ion conductive material that excels in mechanical strength, exhibiting high ion conductivity; a bacterial cellulose composite material having an inorganic material and / or organic material incorporated therein; and a bacterial cellulose aerogel. The water of bacterial cellulose hydrogel is replaced by a nonaqueous solvent containing a lithium compound. Bacterial cellulose producing bacteria are grown in a culture medium having an inorganic material and / or organic material added thereto. The bacterial cellulose hydrogel is dehydrated and dried.

Owner:YANO SHOICHIRO +5

Compositions for manufacturing fiber-reinforced, starch-bound articles having a foamed cellular matrix

InactiveUSRE39339E1Avoid lack of toughnessHigh strengthClosure lidsSolid waste managementPolymer sciencePaperboard

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a fiber-reinforced, starch-bound cellular matrix. Suitable mixtures used to form the articles are prepared by first preparing a viscous preblended mixture comprising water, a gelatinized starch-based binder, and fibers having an average length greater than about 2 mm. The highly viscous preblended mixture effectively transfers the shearing forces of the mixer to the fibers. The final moldable mixture is then prepared by mixing into the preblended mixture the remaining starch-based binder, water, and other desired admixtures, e.g., mold-releasing agents, inorganic filler rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The moldable mixtures are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled foamed structural matrix. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic-based materials and have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

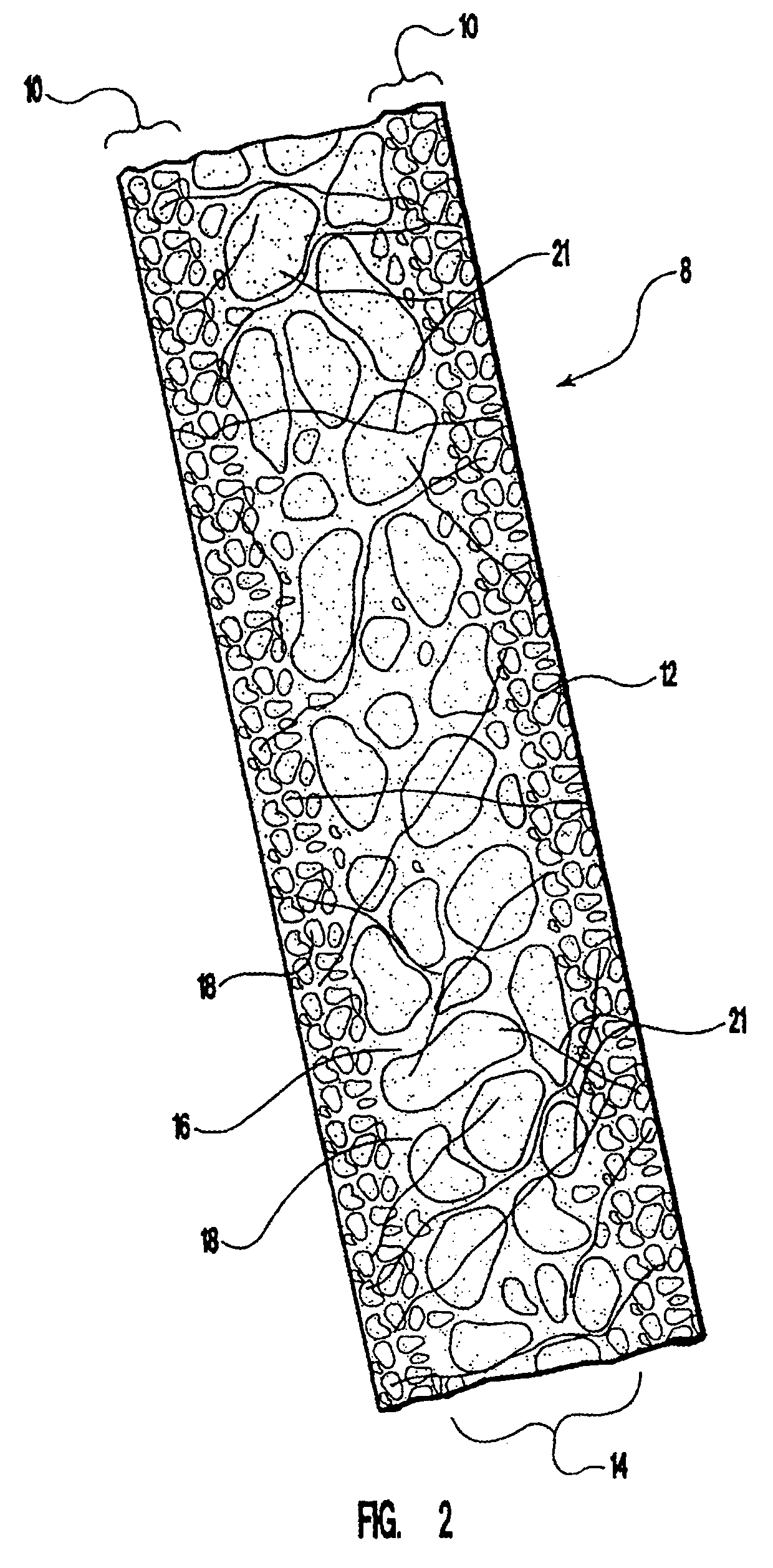

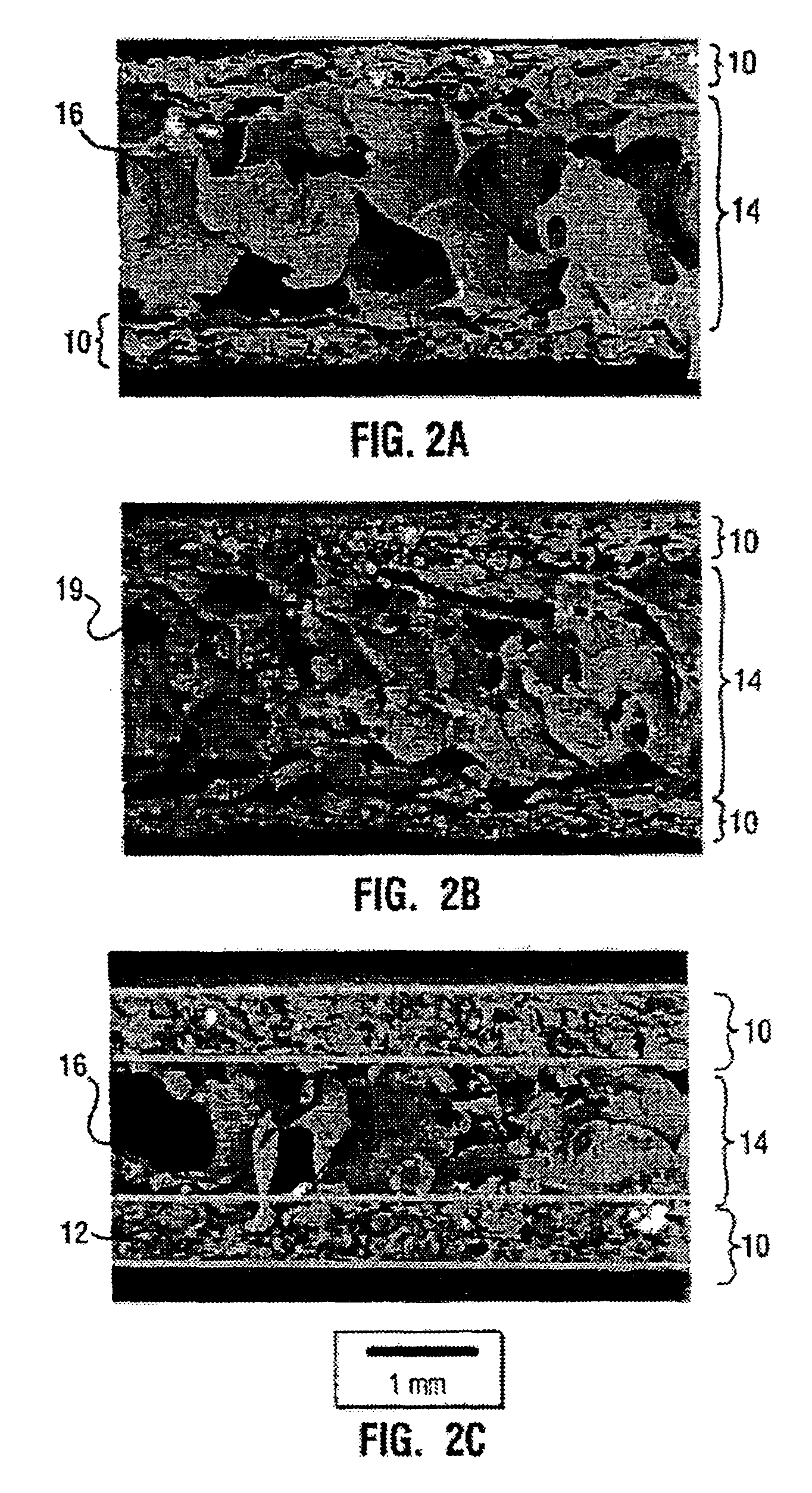

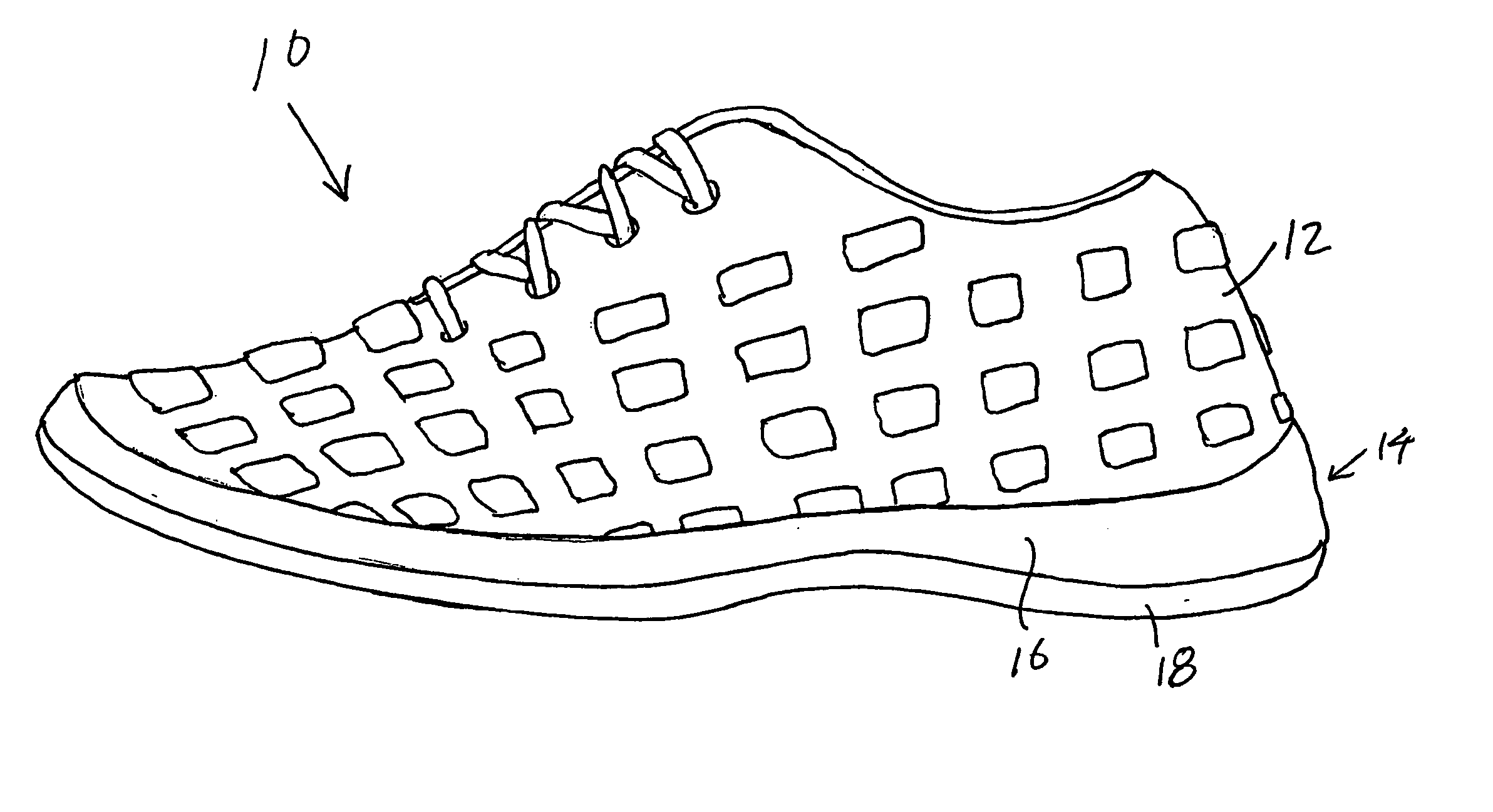

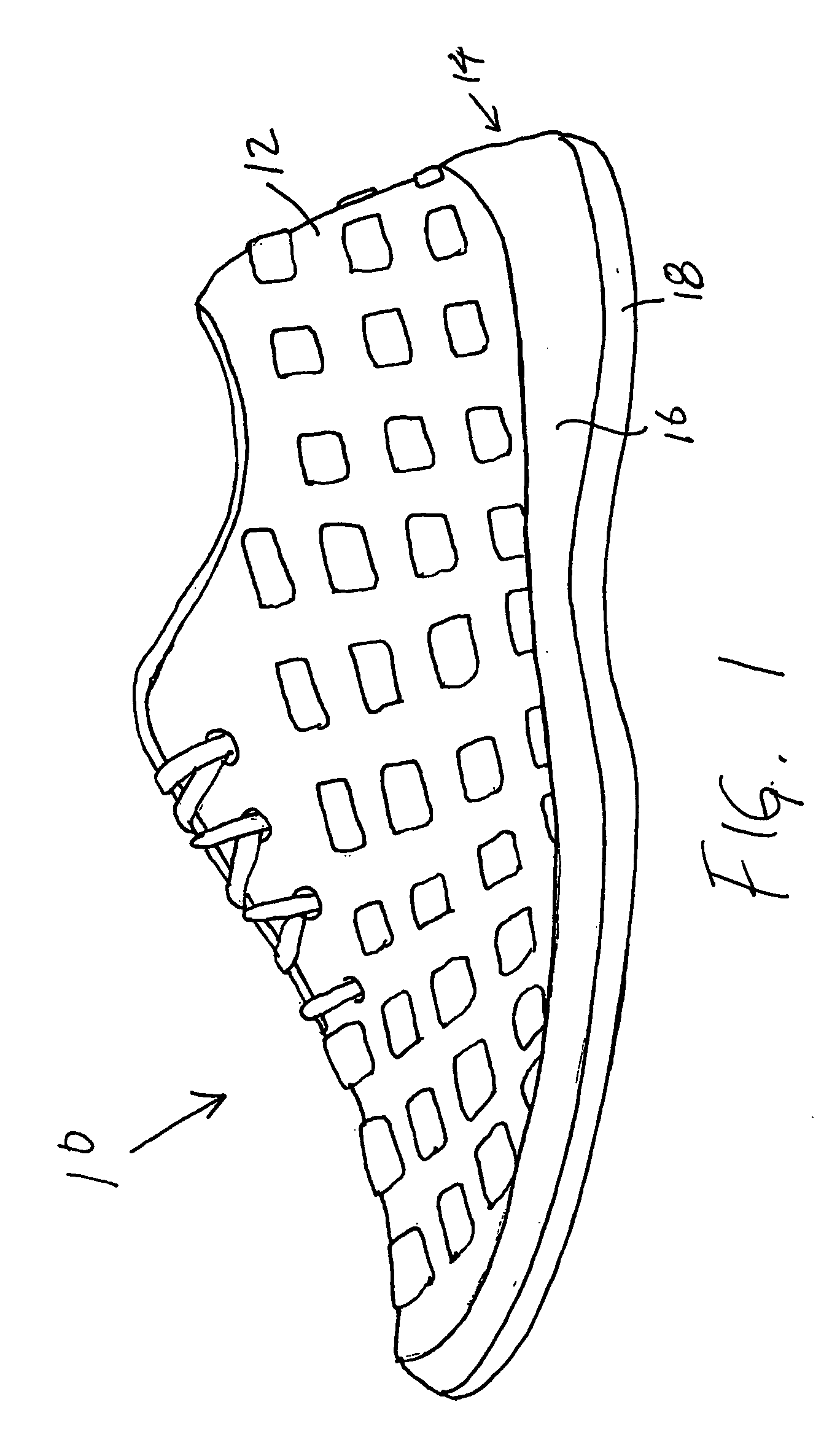

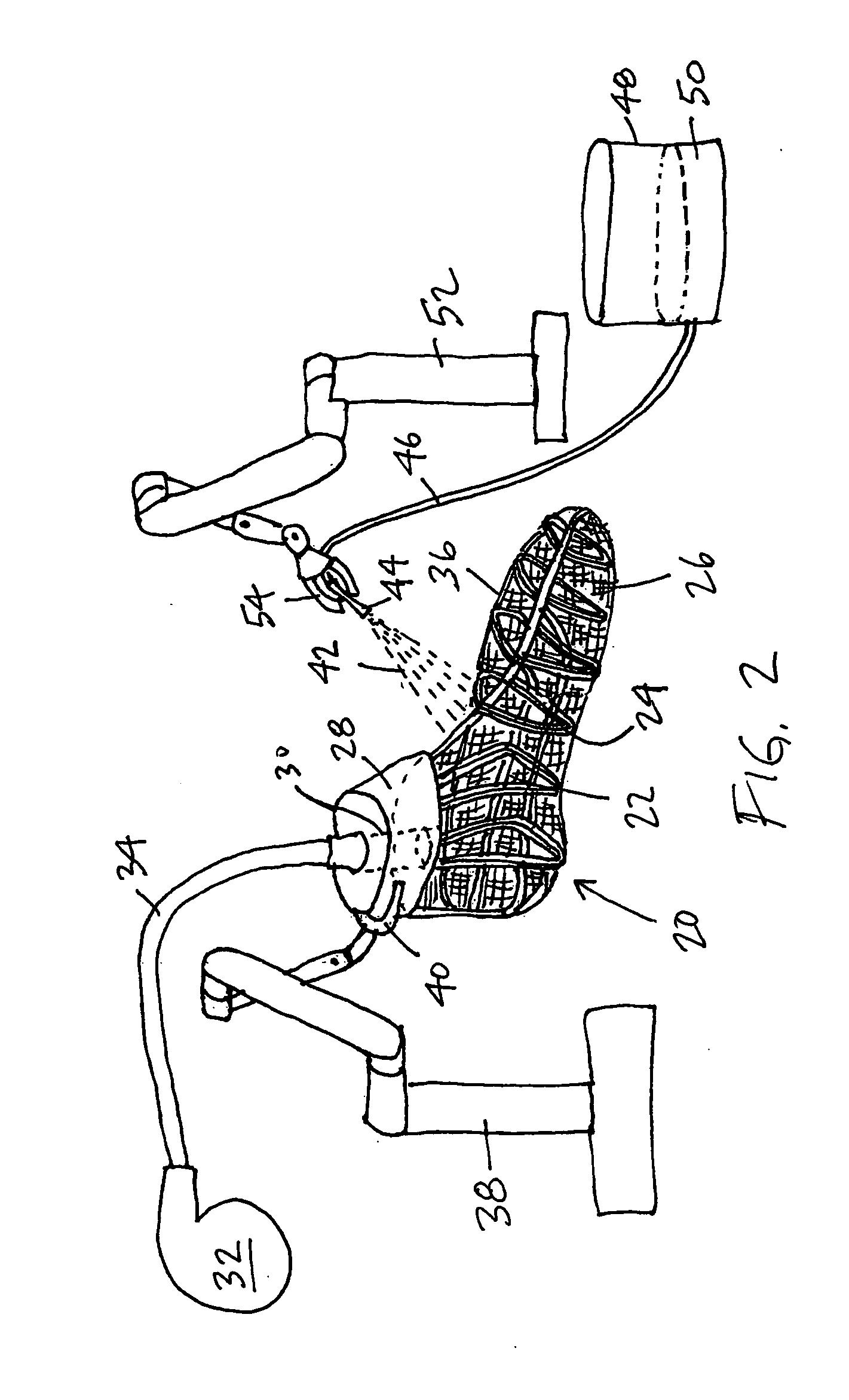

Article of footwear of nonwoven material and method of manufacturing same

InactiveUS20060276095A1Improved breathability and moldability and abrasion resistance and and recovery and water resistance and recyclabilityImprove breathabilityWood working apparatusCeramic shaping apparatusEngineeringFiber

A method of forming a portion of an article of footwear includes the steps of providing a last having an exterior surface, extruding a plurality of polymeric fibers, projecting a stream of the extruded polymeric fibers onto the last to form a mat having the shape of the exterior of the last, and subjecting the mat to heat and pressure in a mold.

Owner:NIKE INC

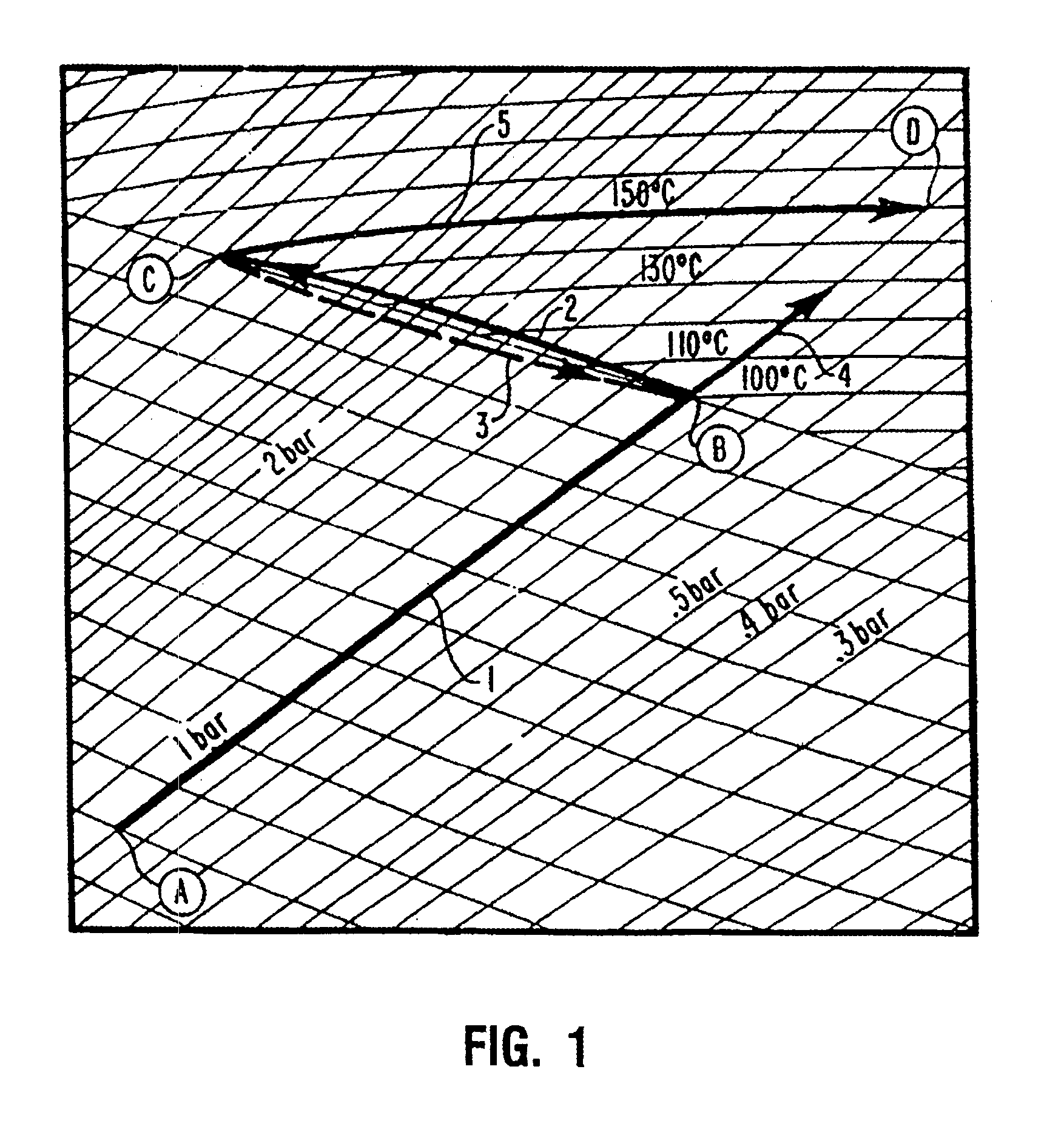

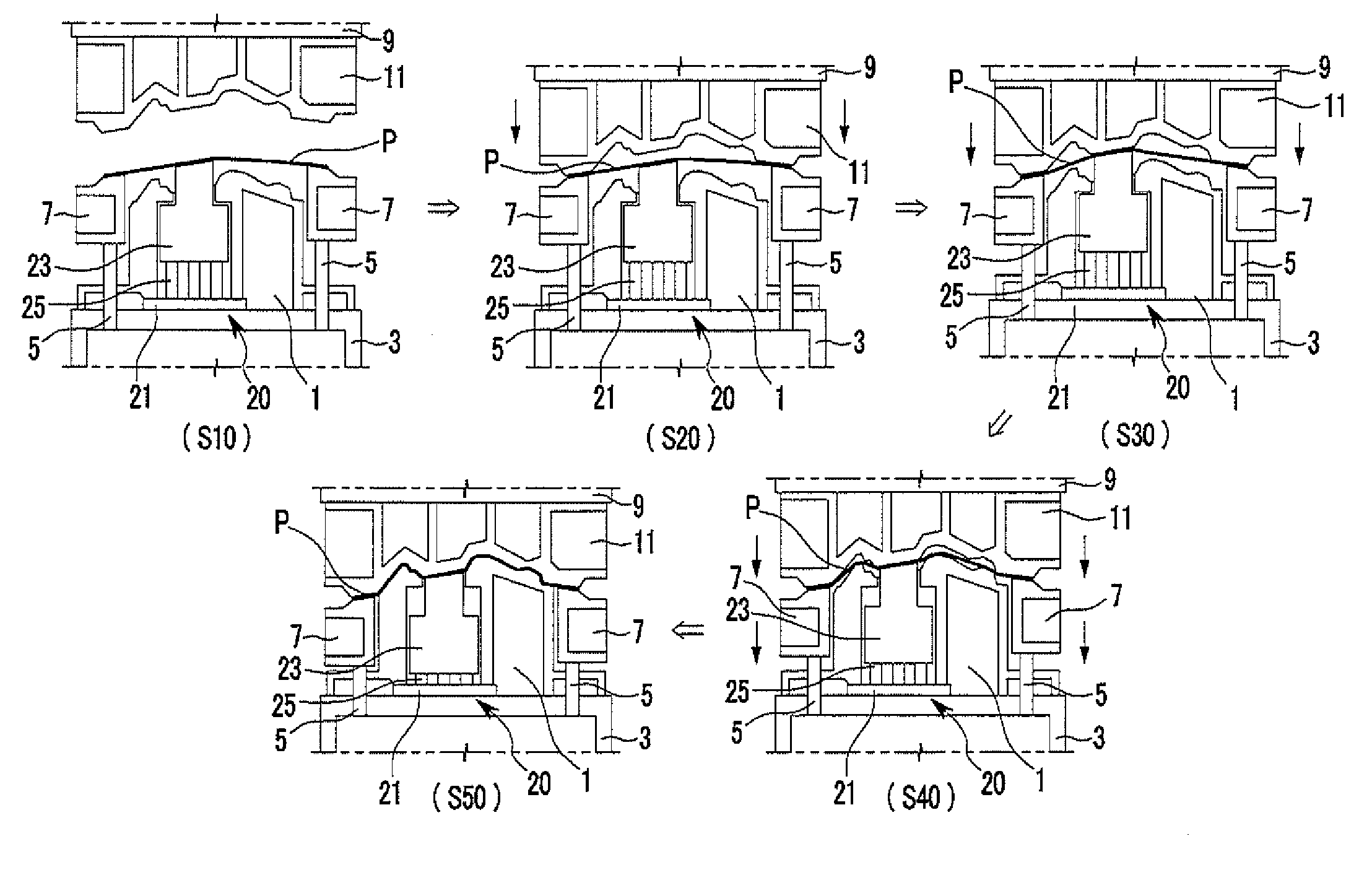

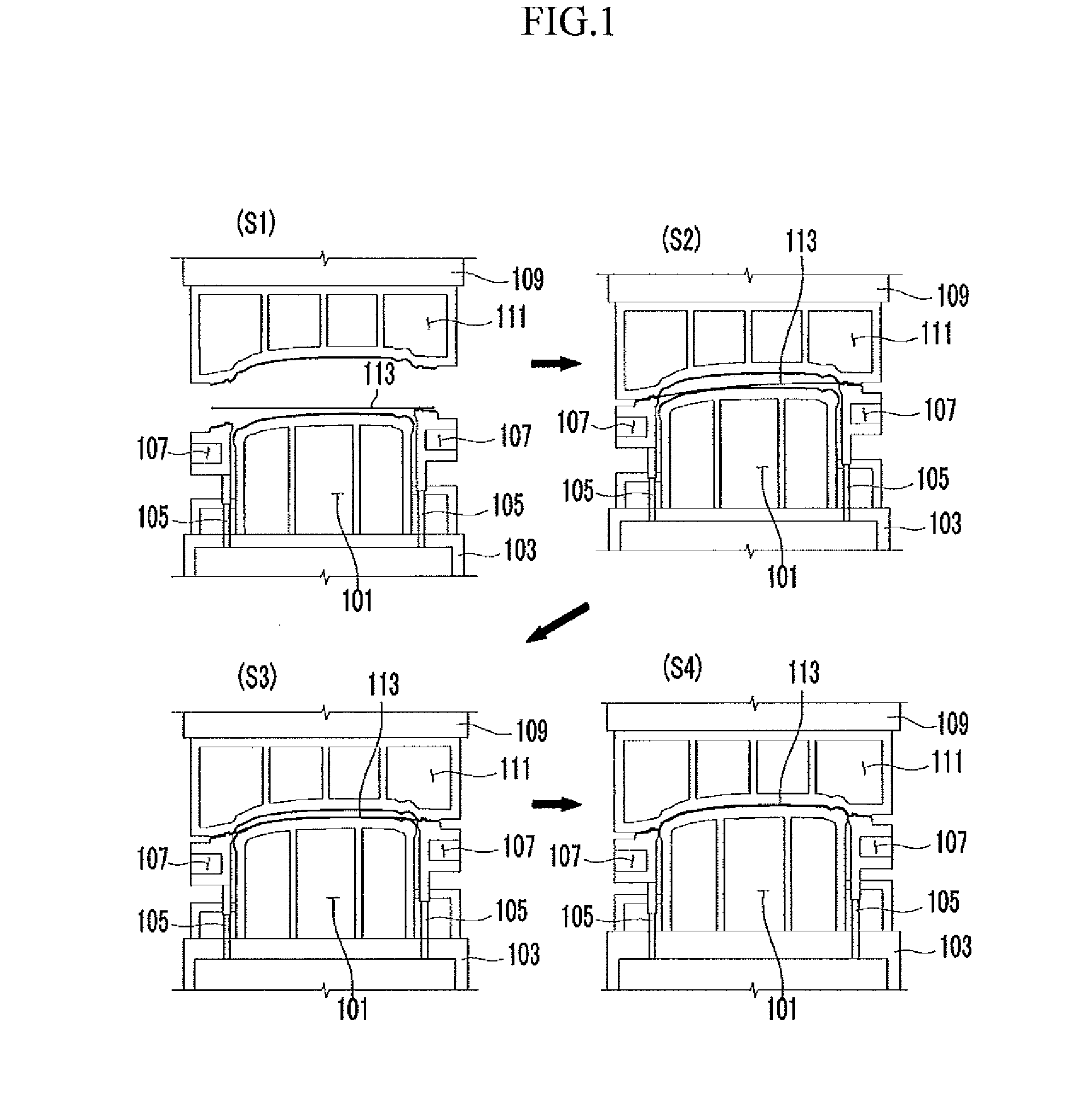

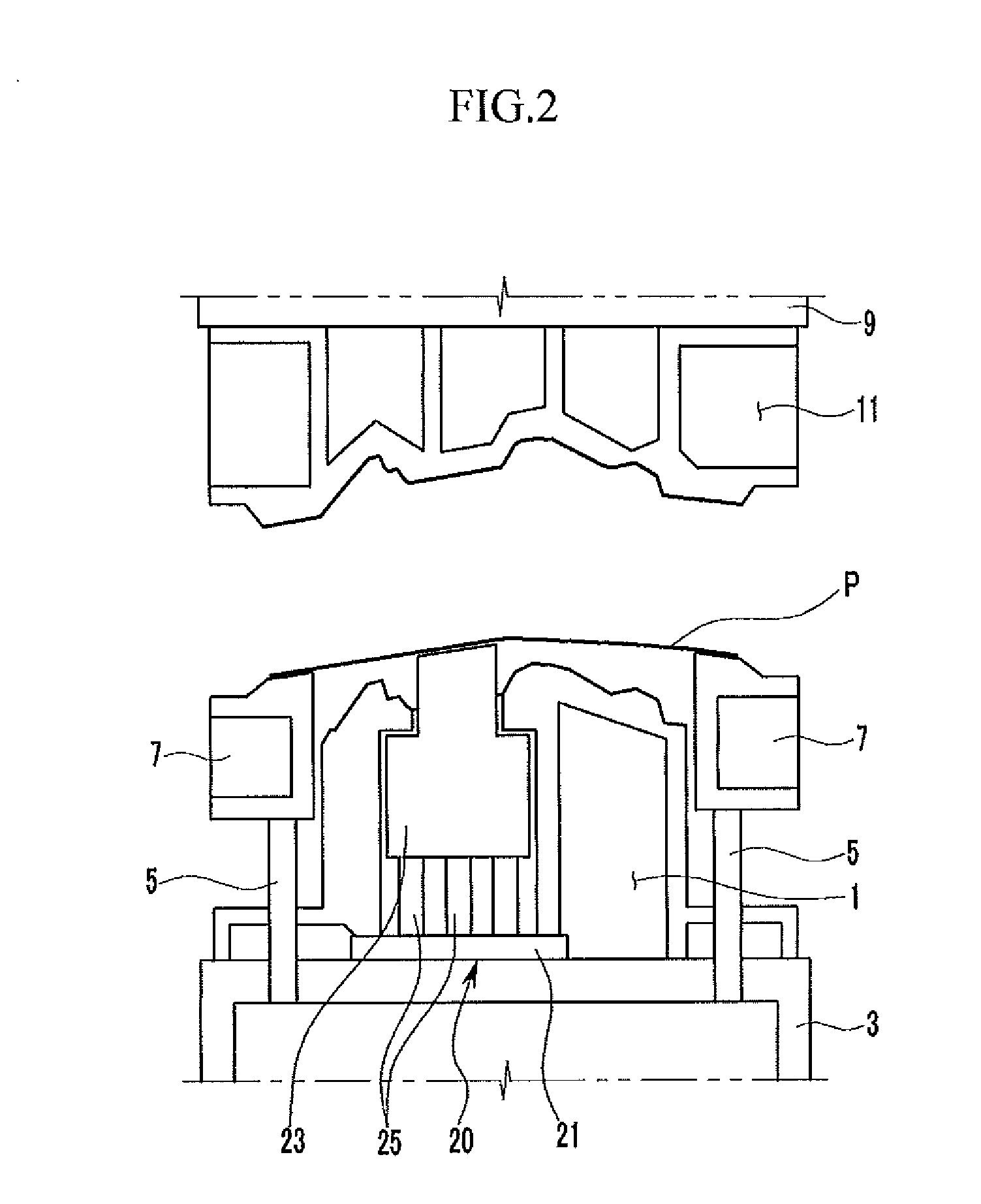

Press system

InactiveUS20120137749A1Good moldabilityImprove marketabilityShaping toolsForging/hammering/pressing machinesEngineeringCushion

Disclosed is a press system having advantages of preventing a molded product panel from bursting or being torn due to a difference in molding depth caused by a protrusion shape to improve the moldability and marketability of the product panel when press molding is performed on a material panel. An illustrative press system comprises: a lower die punch provided on a bolster and having a lower surface shape of a product panel; a blank holder provided on the outside of the lower die punch and mounted on the bolster through cushion pins; an upper die having an upper surface shape of the product panel, mounted on the slider, and pressing a material panel together with the lower die punch to mold the product panel; and a sub blank holder unit provided inside the lower die punch by performing the molding while holding a portion of the material panel to be molded into a protrusion shape together with the upper die such that a difference in molding depth is compensated when molding is performed.

Owner:HYUNDAI MOTOR CO LTD

Polyether copolymer and crosslinked solid polymer electrolyte

InactiveUS6159389AEasy to processGood moldabilityHybrid capacitor electrolytesHybrid capacitor electrodesPolymer electrolytesPolymer science

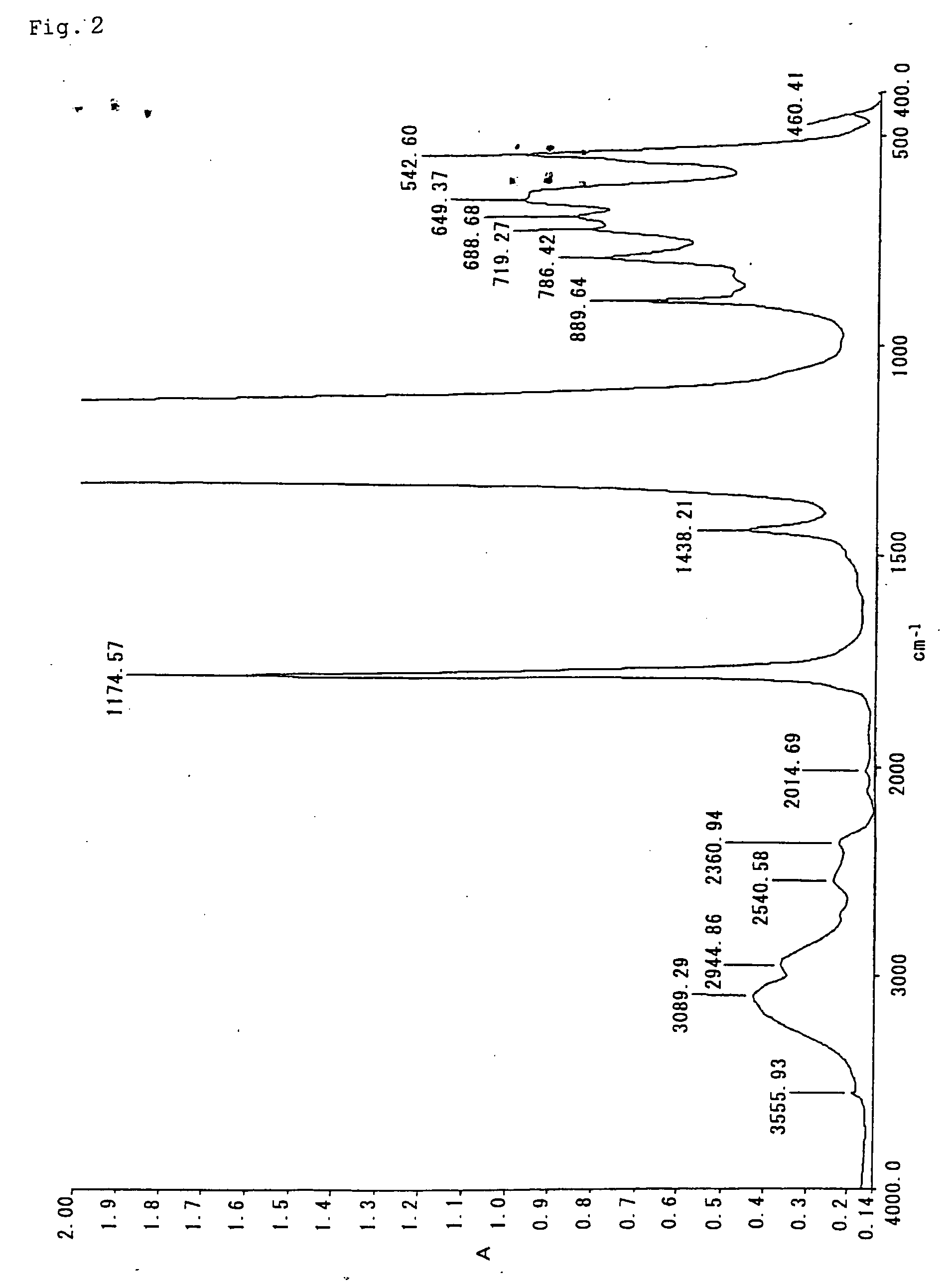

A polyether copolymer having a weight-average molecular weight of 104 to 107, comprising 5 to 40% by mol of a repeating unit derived from epichlorohydrin, 95 to 60% by mol of a repeating unit derived from ethylene oxide, and 0.001 to 15% by mol of a crosslinkable repeating unit derived from a reactive oxirane compound, gives a provide a crosslinked solid polymer electrolyte which is superior in processability, moldability, mechanical strength, flexibility and heat resistance, and has markedly improved ionic conductivity.

Owner:DAISO CO LTD

Polylactic acid composition

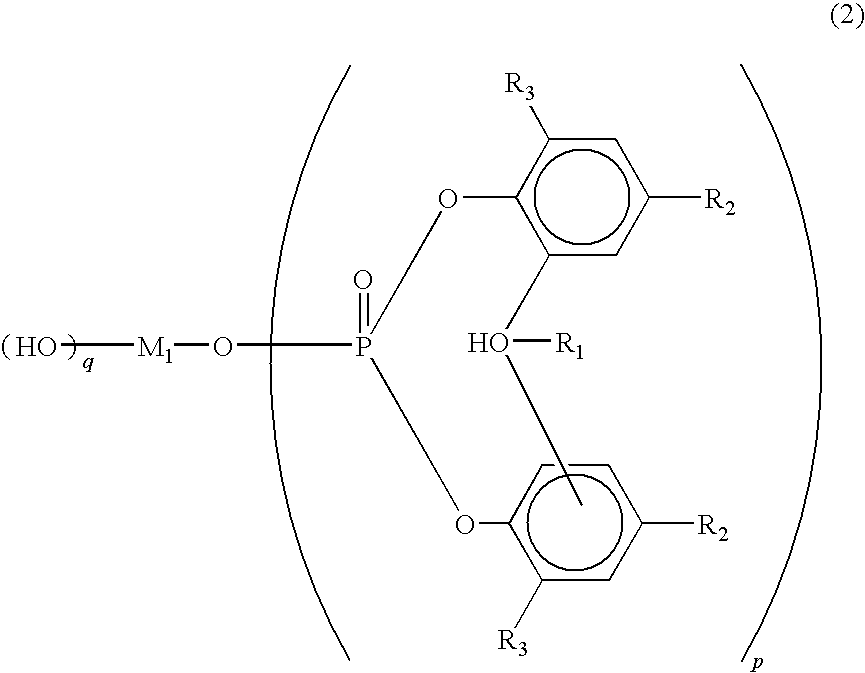

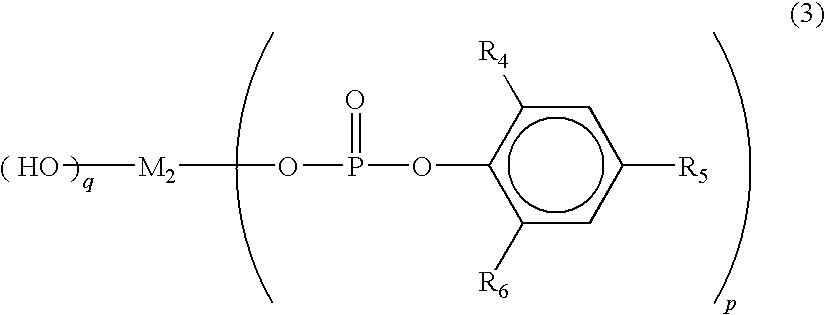

InactiveUS20100093888A1High crystallinityImprove heat stabilityPlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsPhosphoric Acid EstersPolymer science

It is an object of the present invention to provide a polylactic acid composition having excellent crystallinity, wet heat stability and melt stability. It is another object of the present invention to provide a molded article which is obtained from the polylactic acid composition and excellent in appearance and color. The present invention is a composition and molded article thereof which comprises a polylactic acid (component A), a carbodiimide compound (component B) and a phosphoric acid ester metal salt (component C).

Owner:TEIJIN LTD +1

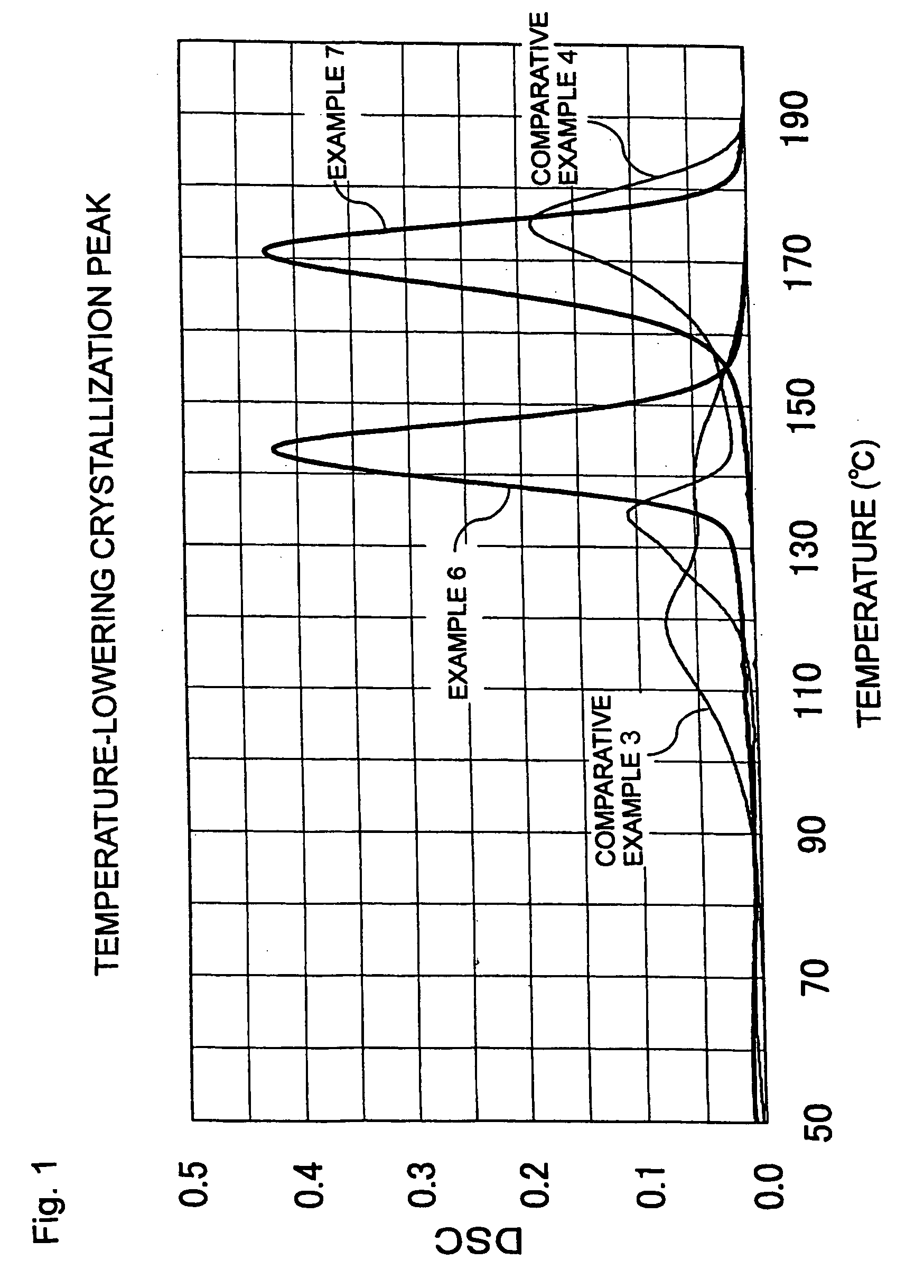

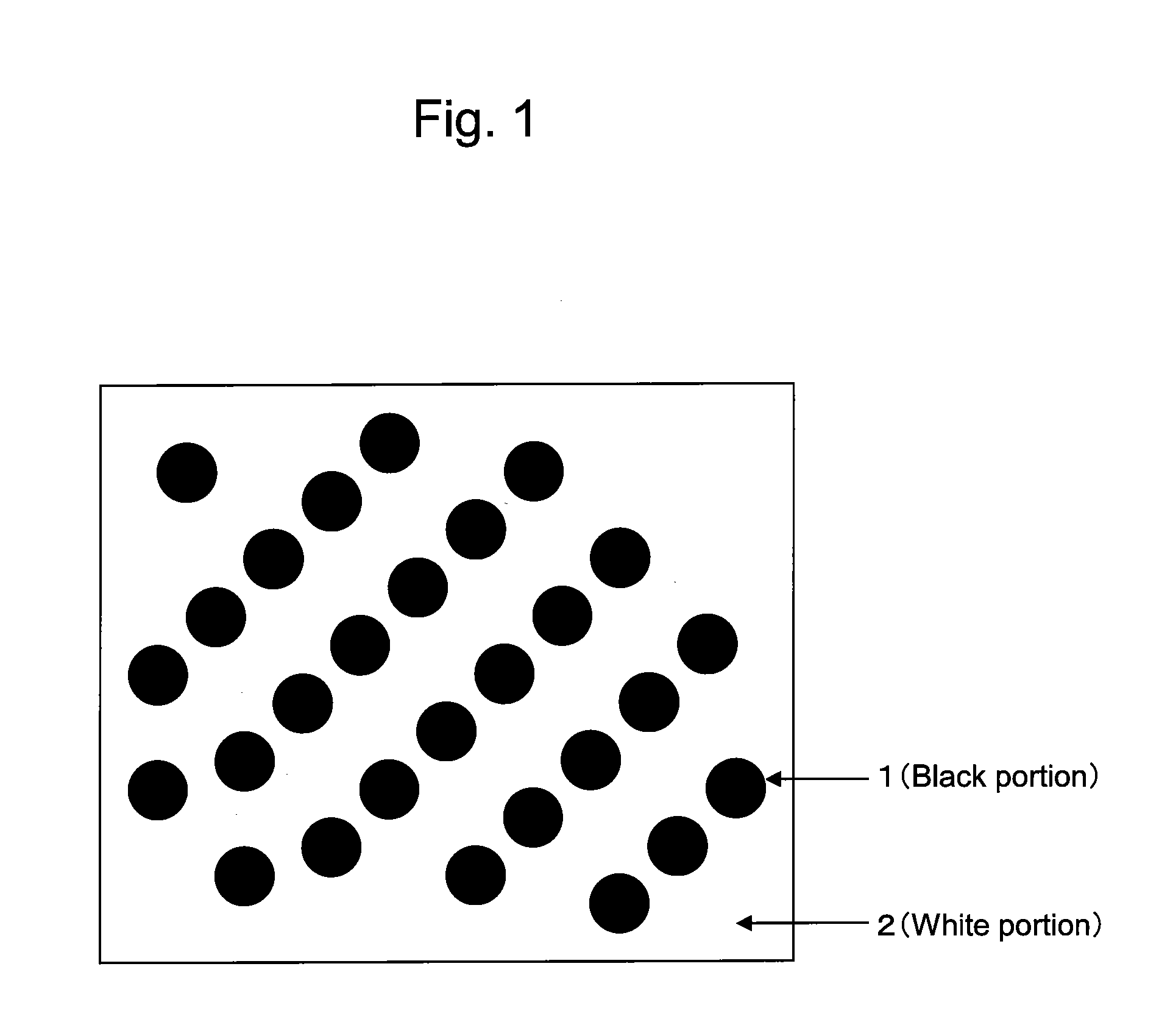

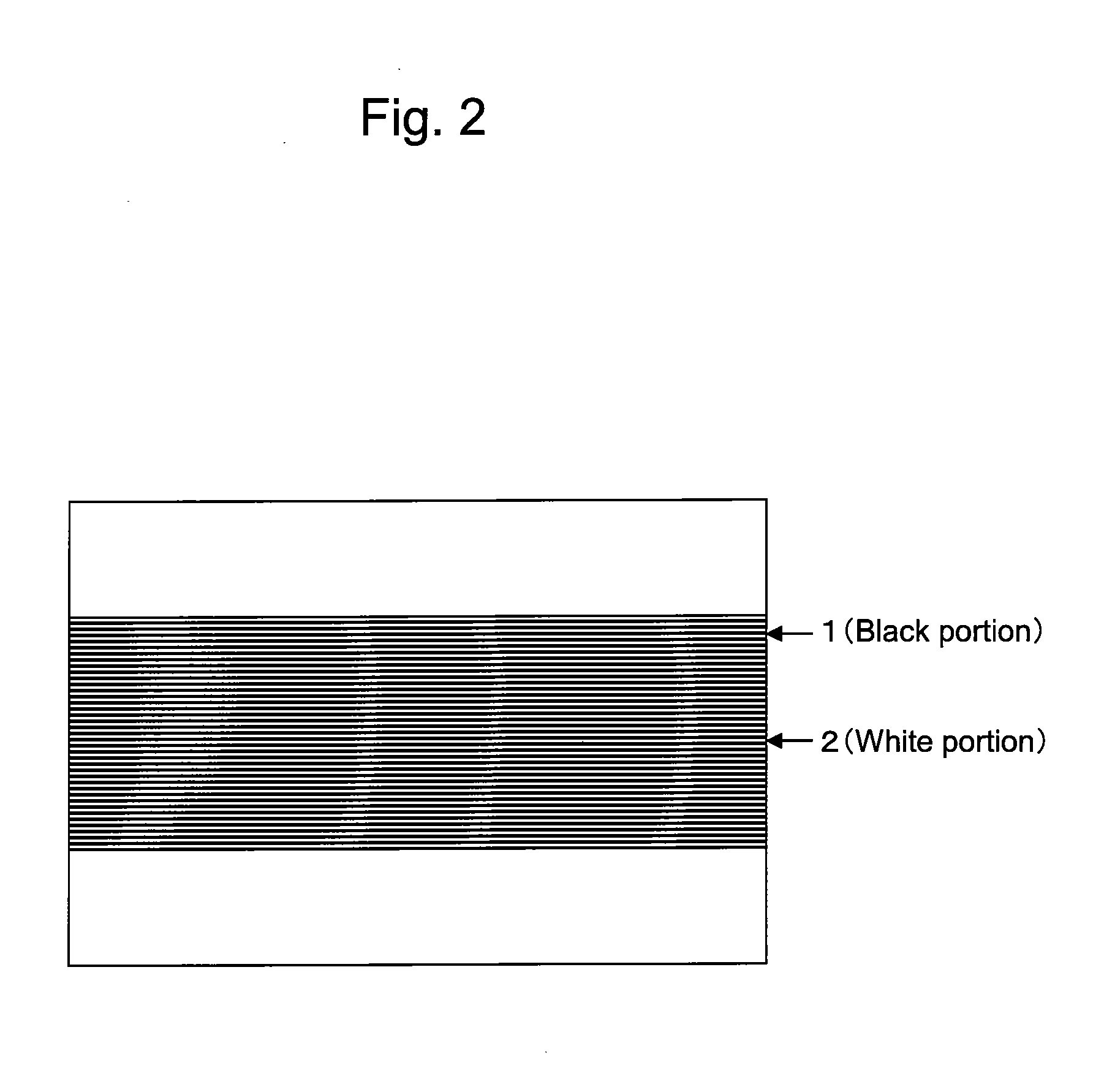

Polylactic acid-based resin compositions, molded articles and process for producing the same

A polylactic acid-based resin composition is provided from which molded articles with a high heat resistance and high impact strength can be molded with improved moldability. Also provided is a heat-resistant polylactic acid-based resin molded article manufactured from the polylactic acid-based resin composition, as well as a process for manufacturing such a heat-resistant molded article. A polylactic acid-based resin composition comprising 0.01 to 5.0 parts by weight of a metal phosphate and 0.01 to 5.0 parts by weight of a basic inorganic aluminum compound, each serving as a nucleating agent, with respect to 100 parts by weight of a polylactic acid-based polymer. The polylactic acid-based resin composition is melted and filled a mold of a molding machine set in a temperature range of not more than the crystallization-initiating point nor less than the glass transition point, as measured by a differential scanning calorimeter (DSC), to be molded the composition under crystallizing.

Owner:ADEKA CORP +1

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS20100068518A1Increase productivitySatisfactory dispersionCoatingsYarnPolymer scienceFiber bundle

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

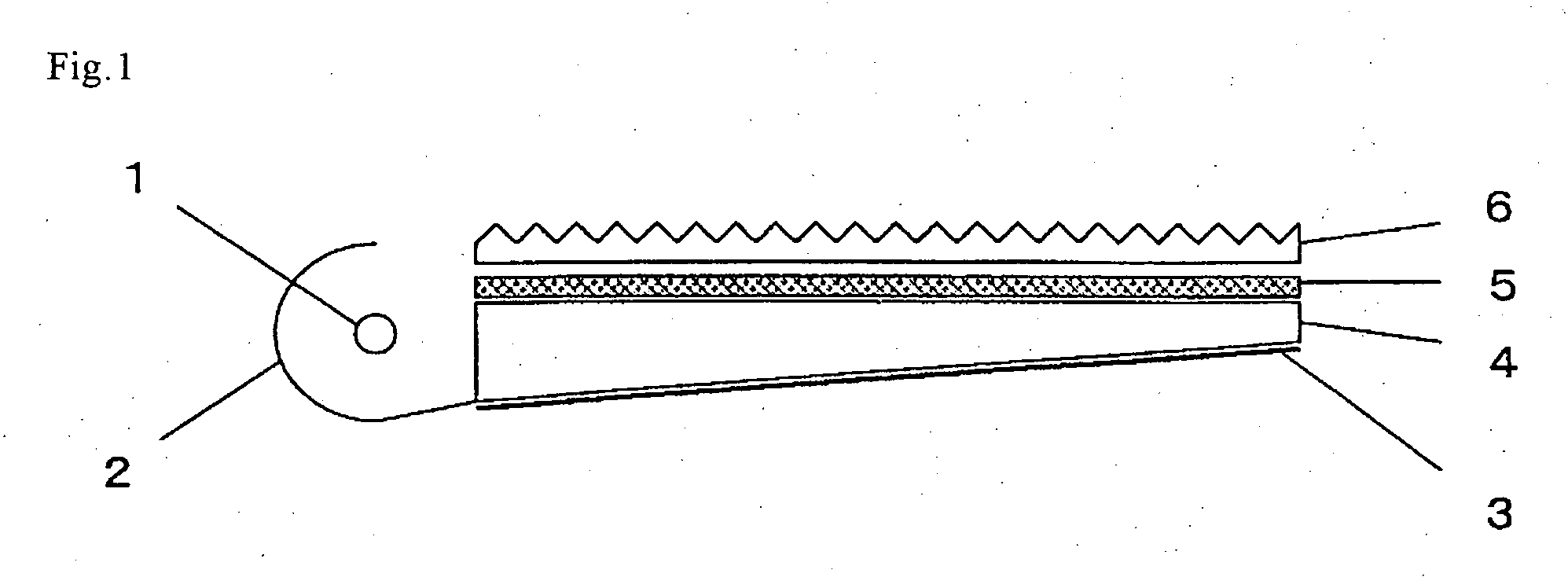

Lighting equipment

InactiveUS6883938B1Light weightExcellent characteristicsMirrorsOptical signallingPolymer scienceLight equipment

A lighting equipment comprising a reflector having a substrate comprised of a thermoplastic resin containing an alicyclic structure on which is formed a reflecting layer having a reflectance of at least 70%. The reflecting layer of the reflector is preferably comprised of a metal. The reflecting layer preferably has a thickness of 5 to 10,000 nm. The amount of the repeating units containing polar groups in the thermoplastic resin containing an alicyclic structure is preferably not more than 50 wt %. The thermoplastic resin containing an alicyclic structure preferably has a melt flow rate of 4 to 100 g / 10 min.

Owner:ZEON CORP

Polyamide Resin Composition

InactiveUS20120165448A1Excellent surface reflectance and heat resistanceGood moldabilityPigmenting treatmentSpecial tyresHeat resistancePolyamide

A polyamide resin composition according to the present invention comprises (A) about 10 to about 70% by weight of crystalline polyamide resin, (B) about 10 to about 70% by weight of amorphous polyamide resin with a glass transition temperature of about 110 to about 200° C., (C) about 10 to about 60% by weight of inorganic filler, (D) about 10 to about 50% by weight of white pigment, and (E) about 0.05 to about 2 parts by weight of light stabilizer, based on about 100 parts by weight of the crystalline polyamide resin (A), the amorphous polyamide resin (B), the inorganic filler (C) and the white pigment (D), and can have excellent surface reflectance, heat resistance, mechanical strength, moldability, light stability and discoloration resistance.

Owner:CHEIL IND INC

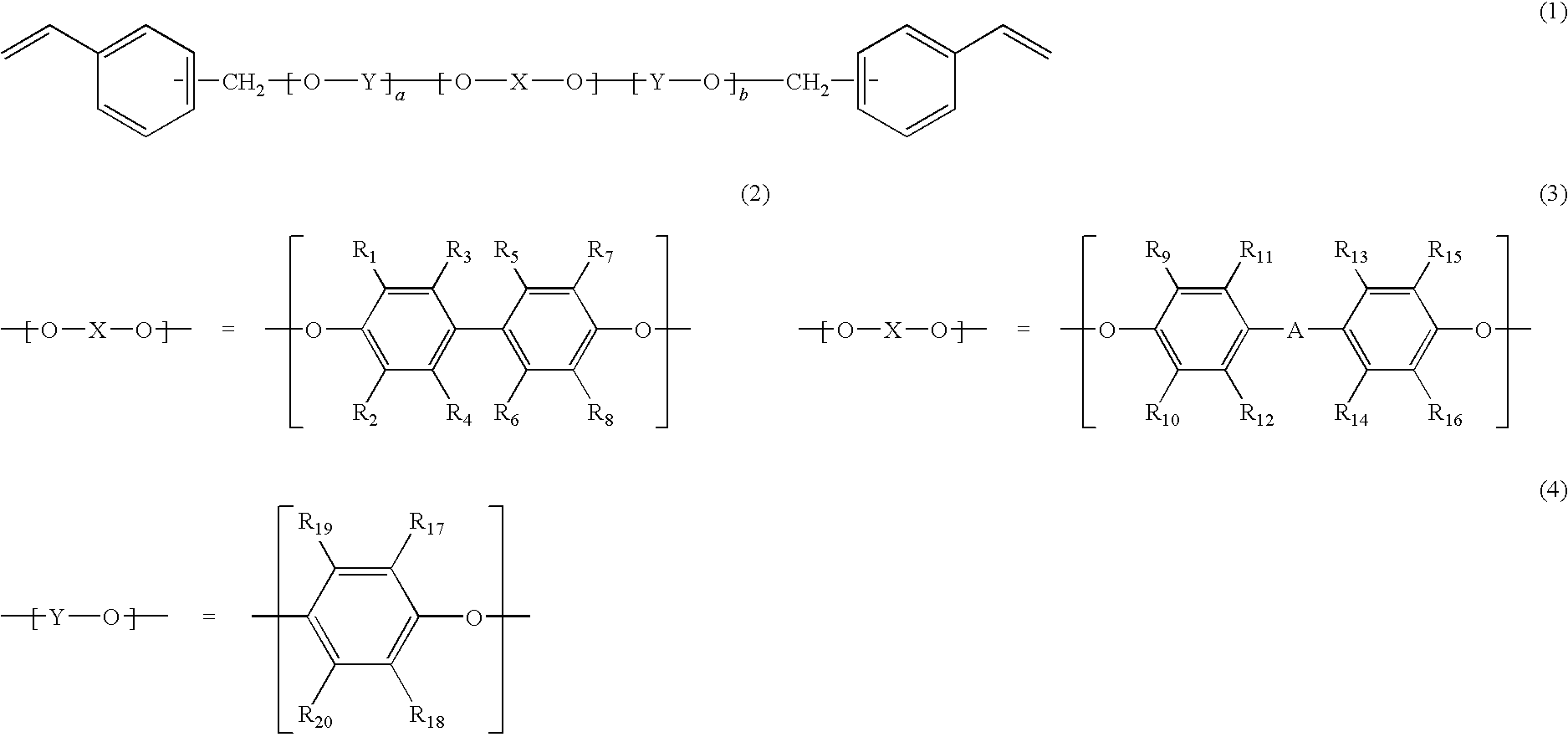

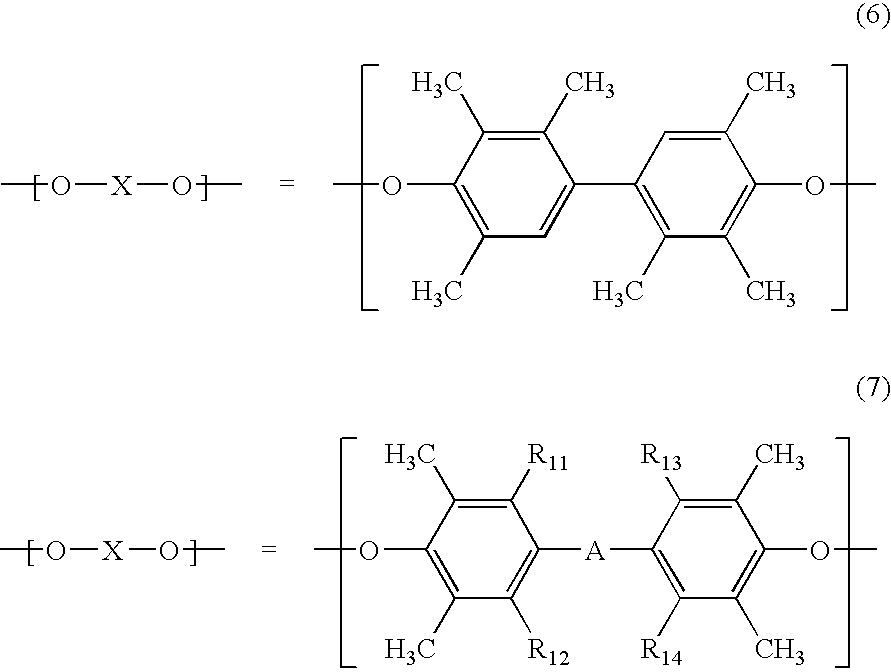

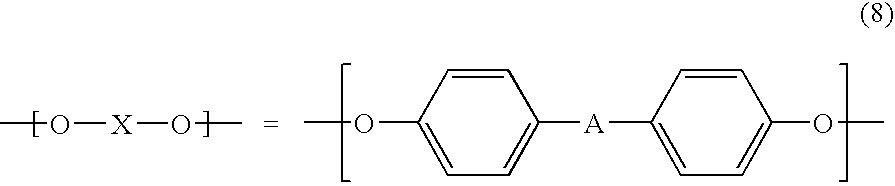

Resin composition, prepreg and metal-foil-clad laminate

ActiveUS20090247032A1Improve suppression propertiesHigh multilayerPrinted circuit aspectsSynthetic resin layered productsMetal foilCopper foil

A vinyl-compound-based resin composition containing a terminal vinyl compound (a) of a bifunctional phenylene ether oligomer having a polyphenylene ether structure, a naphthol aralkyl type cyanate ester resin (b), a bisphenol A cyanate ester resin (c), a brominated flame retardant (d) and an inorganic filler (e), which resin composition is for use in a printed wiring board for high multilayer and high frequency and is improved in moldability and copper foil peel strength, which are conventional problems, without any decrease in electric characteristics and heat resistance after moisture absorption while keeping flame retardancy, a prepreg comprising the above resin composition and a glass woven fabric, a metal-foil-clad laminate obtained by disposing a metal foil on one side or both sides of a stack of at least one prepreg and laminate-molding the resultant set, and a resin sheet obtained by applying a solution of the above resin composition to a surface of a metal foil or a film.

Owner:MITSUBISHI GAS CHEM CO INC

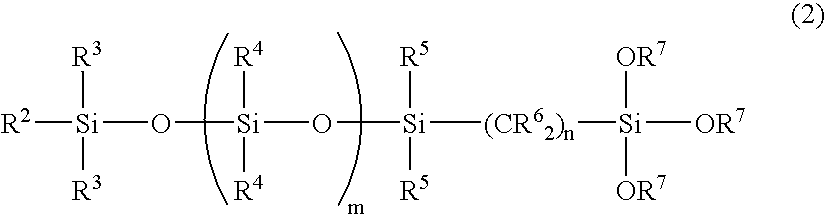

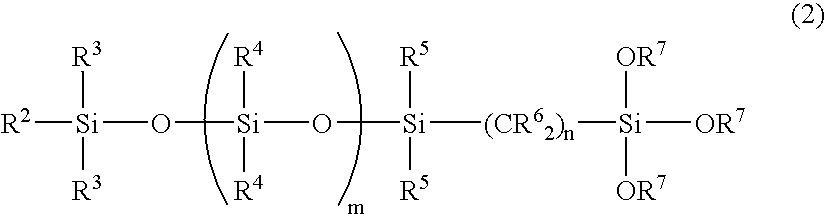

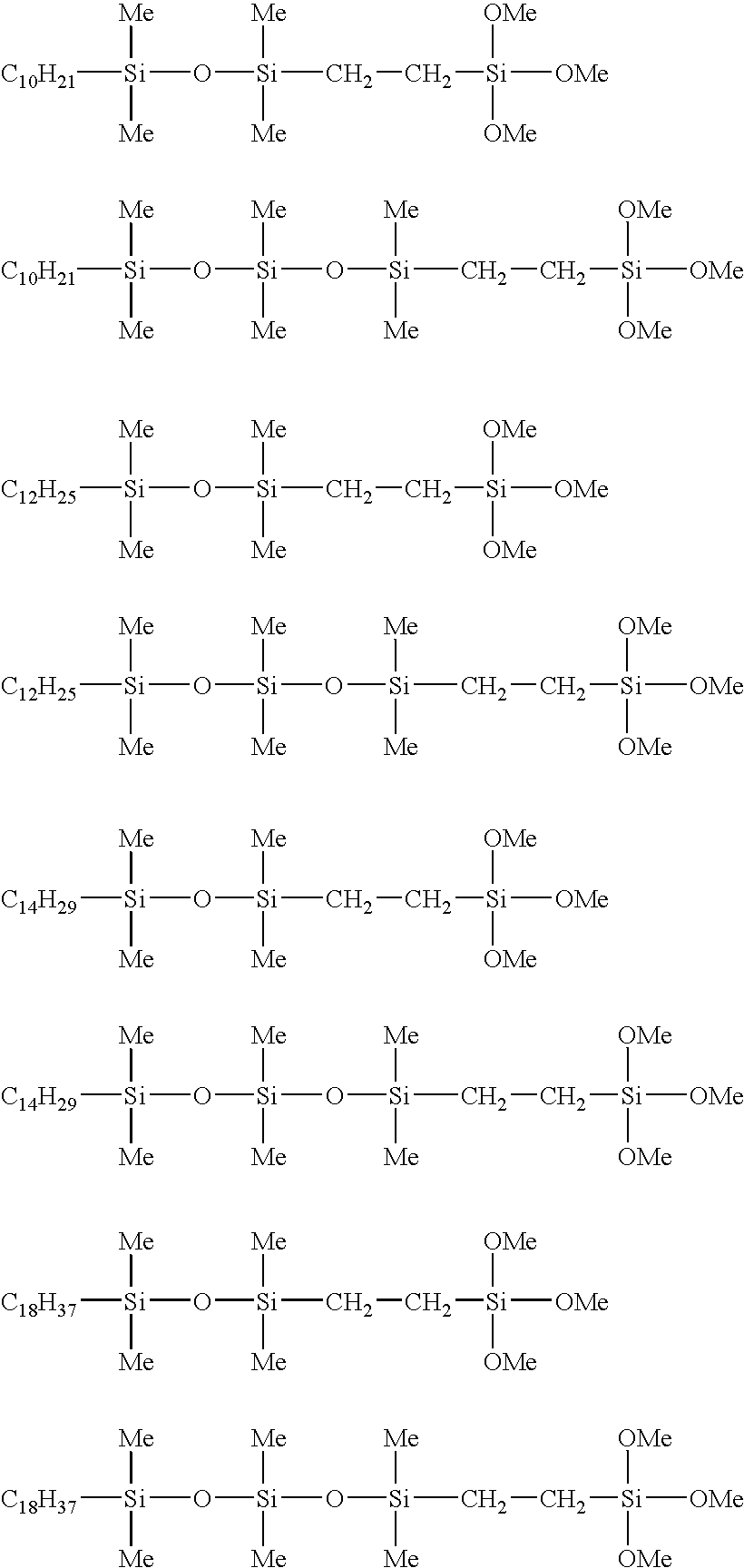

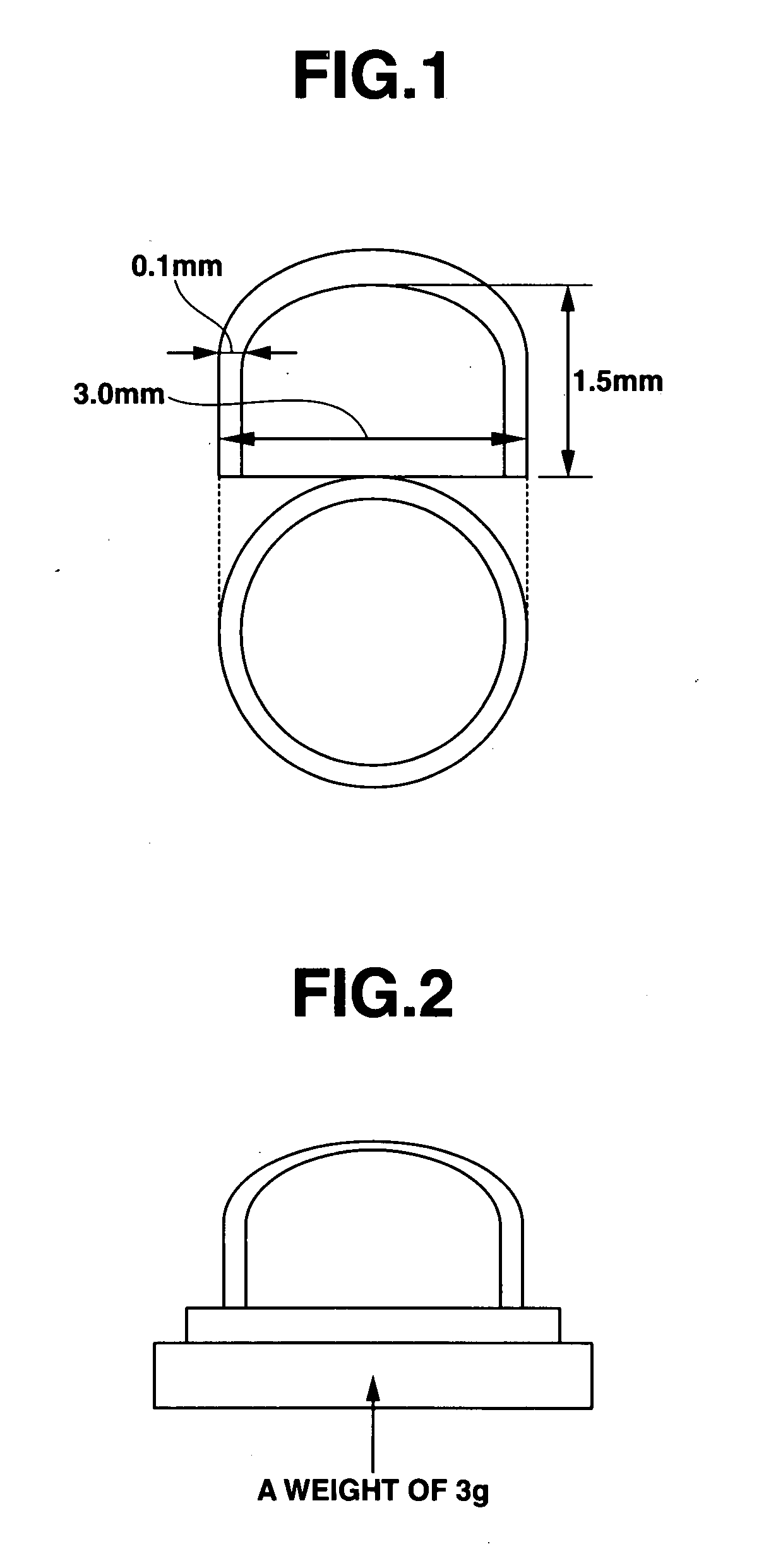

Heat-conductive silicone composition and cured product thereof

ActiveUS20080057325A1Minimal increaseGood flexibilityLayered productsAdhesivesPliabilityElectronic component

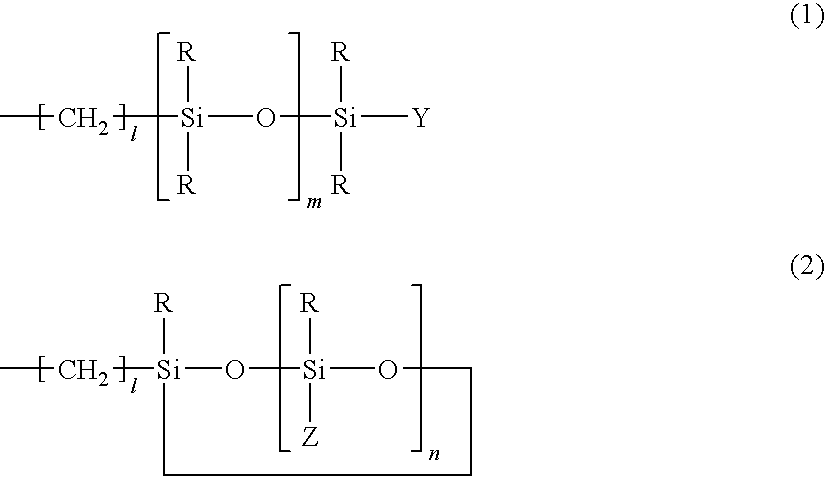

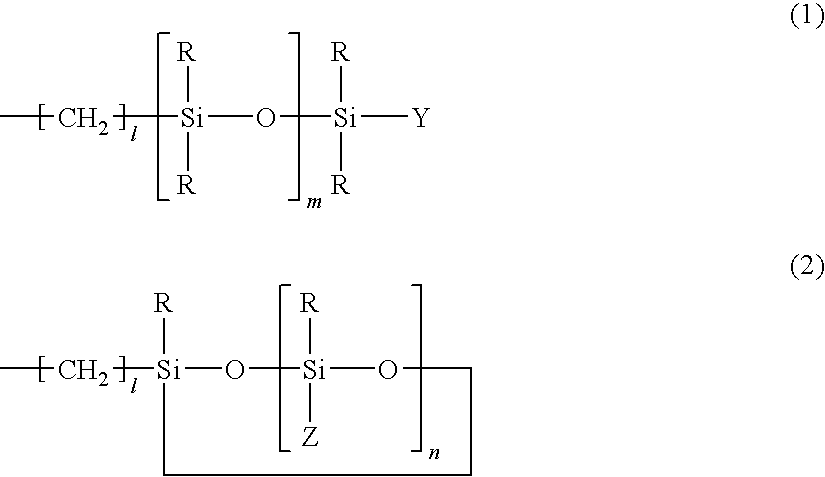

Provided is a heat-conductive silicone composition, including: (A) 100 parts by volume of an organopolysiloxane having a specific structure, (B) 0.1 to 50 parts by volume of an organosilicon compound that functions as a wetter and contains a triorganooxysilyl group bonded to one terminal via an alkylene group that may be branched, (C) 100 to 2,500 parts by volume of a heat-conductive filler, and (D) an effective quantity of a curing agent. Also provided is a heat-conductive silicone cured product obtained by curing this composition. The heat-conductive silicone composition, even when filled with a large quantity of a heat-conductive filler in order to provide superior thermal conductivity, exhibits a minimal increase in viscosity or plasticity, and retains favorable handling properties and moldability. The heat-conductive silicone cured product exhibits excellent flexibility even when filled with a large quantity of a heat-conductive filler. Heat generated by a heat-generating electronic component can be dissipated into a heat-radiating component by sandwiching the cured product between the heat-generating electronic component and the heat-radiating component.

Owner:SHIN ETSU CHEM IND CO LTD

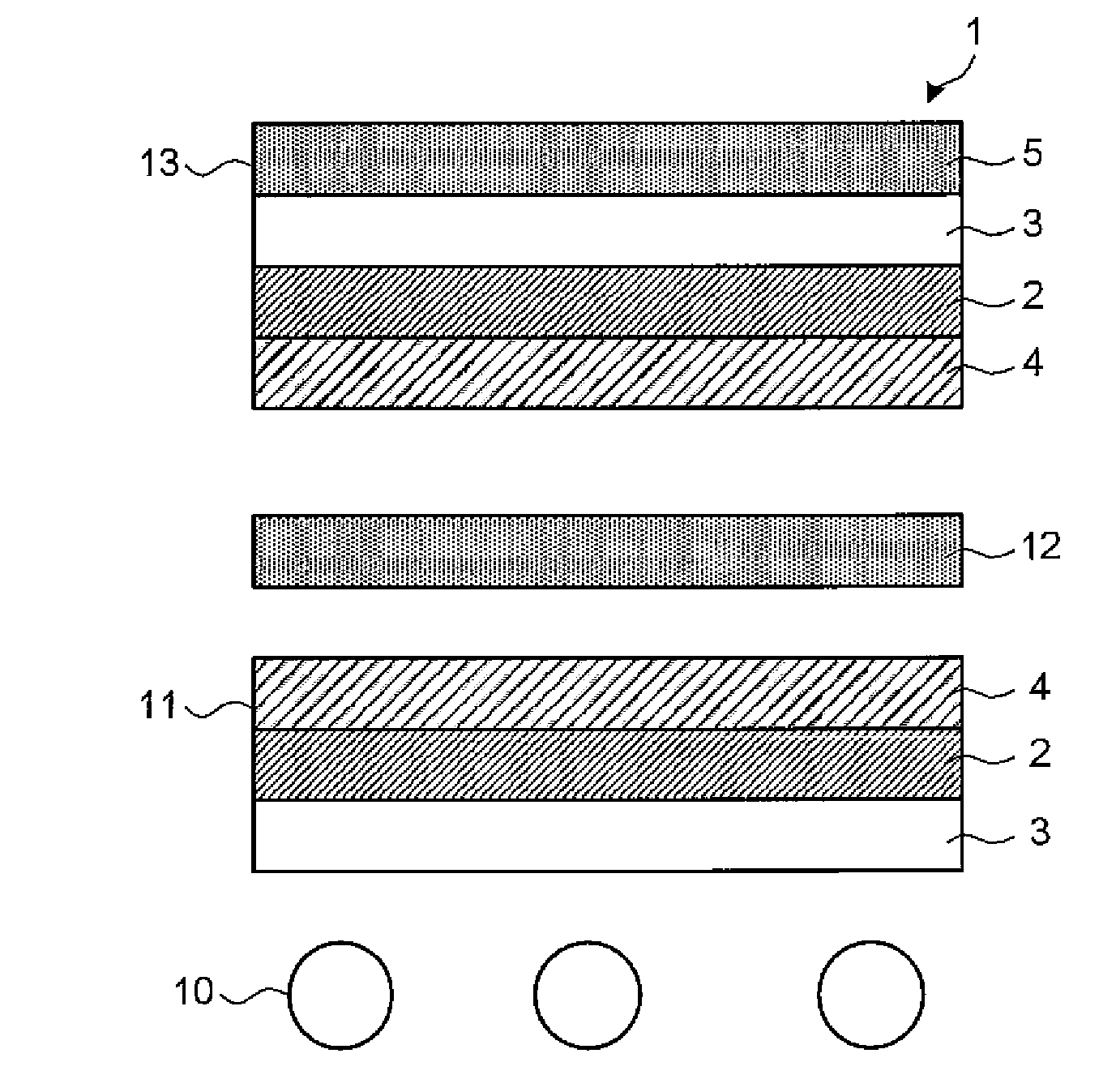

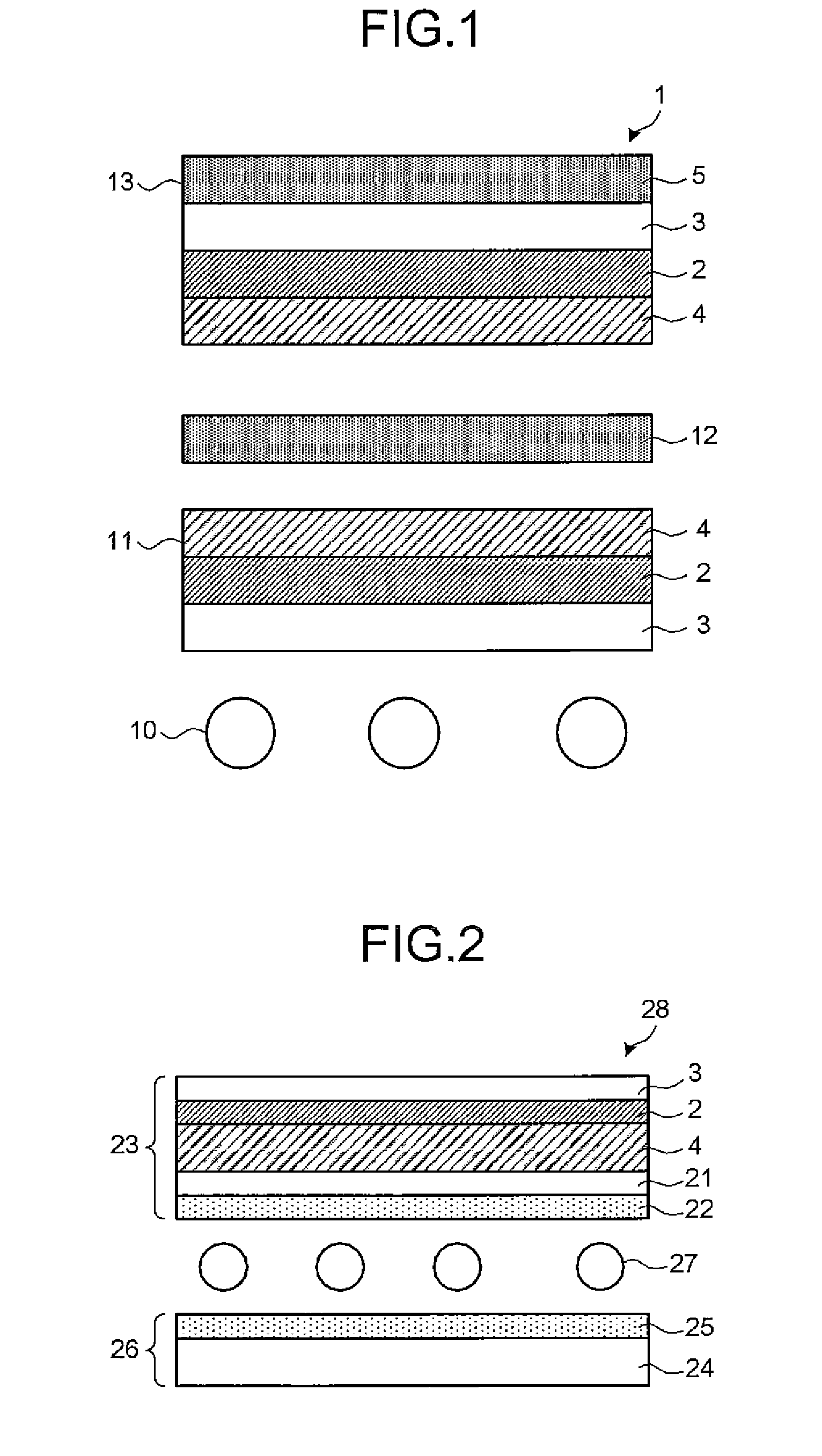

Polarization plate, liquid crystal display device and protective film

ActiveUS20090257003A1Sufficient visibilityExcellent abrasion resistanceAdhesive processesMirrorsTectorial membraneVisibility

Provided are a polarization plate which has a high mechanical strength, which does not impair a visibility even under a high temperature and high humidity, which is excellent in flexibility and abrasion resistance, and which reduces a visible disturbance such as color unevenness due to a size change, as well as a liquid crystal display device using the polarization plate. A film composed of a plurality of layers composed mainly of thermoplastic resins is used as a first protection film used for a visible side of the polarization plate, and at least one surface layer of this first protection film is composed mainly of an acrylic resin. Furthermore, a second protection film having a specific property is disposed at a side of a liquid crystal cell.

Owner:ZEON CORP

Fluorocopolymer, process for producing fluorocopolymer, fluorocopolymer curable composition, and cured object

The present invention has for its object to provide a fluorocopolymer which is available at low cost, has fluidity at room temperature, and is curable, a method of producing the same copolymer and a curable composition having good processability and in situ moldability. The present invention is directed to a fluorocopolymer which is fluid at room temperature and curable, and which is obtainable from a trifluorovinyl group-containing monomer with an ethylenically unsaturated double bond moiety being a trifluorovinyl group.

Owner:DAIKIN IND LTD

Silicone lens and silicone resin composition for molding lens

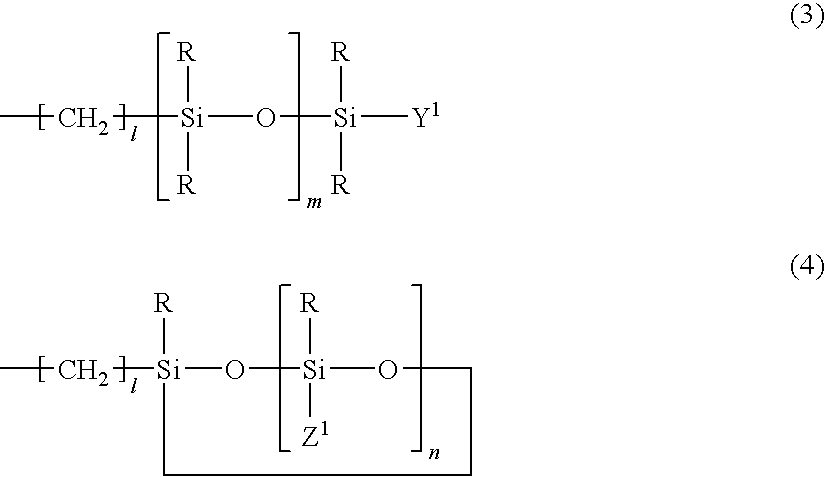

ActiveUS20070249790A1Good flexibilityHigh transparencySurgical adhesivesProsthesisPolymer scienceEthyl group

A colorless transparent silicone lens produced by thermally curing a silicone resin composition comprising(A) an organopolysiloxane having a resin structure comprising R1SiO1.5 unit, R22SiO unit, and R3aR4bSiO(4-a-b) / 2 unit wherein R1, R2, and R3 are independently methyl group, ethyl group, propyl group, cyclohexyl group, or phenyl group, R4 is vinyl group or allyl group, a is 0, 1, or 2, b is 1 or 2, and a+b is 2 or 3, and wherein number of repetition of the R22SiO unit is 5 to 300,(B) an organohydrogen polysiloxane having a resin structure comprising R1SiO1.5 unit, R22SiO unit, and R3cHdSiO(4-c-d) / 2 unit wherein c is 0, 1, or 2, d is 1 or 2, and c+d is 2 or 3, and wherein number of repetition of the R22SiO unit is 5 to 300, the component, and(C) a platinum group catalyst.A silicone lens having excellent flexibility, transparency, and moldability as well as reduced surface tackiness is provided.

Owner:SHIN ETSU CHEM IND CO LTD

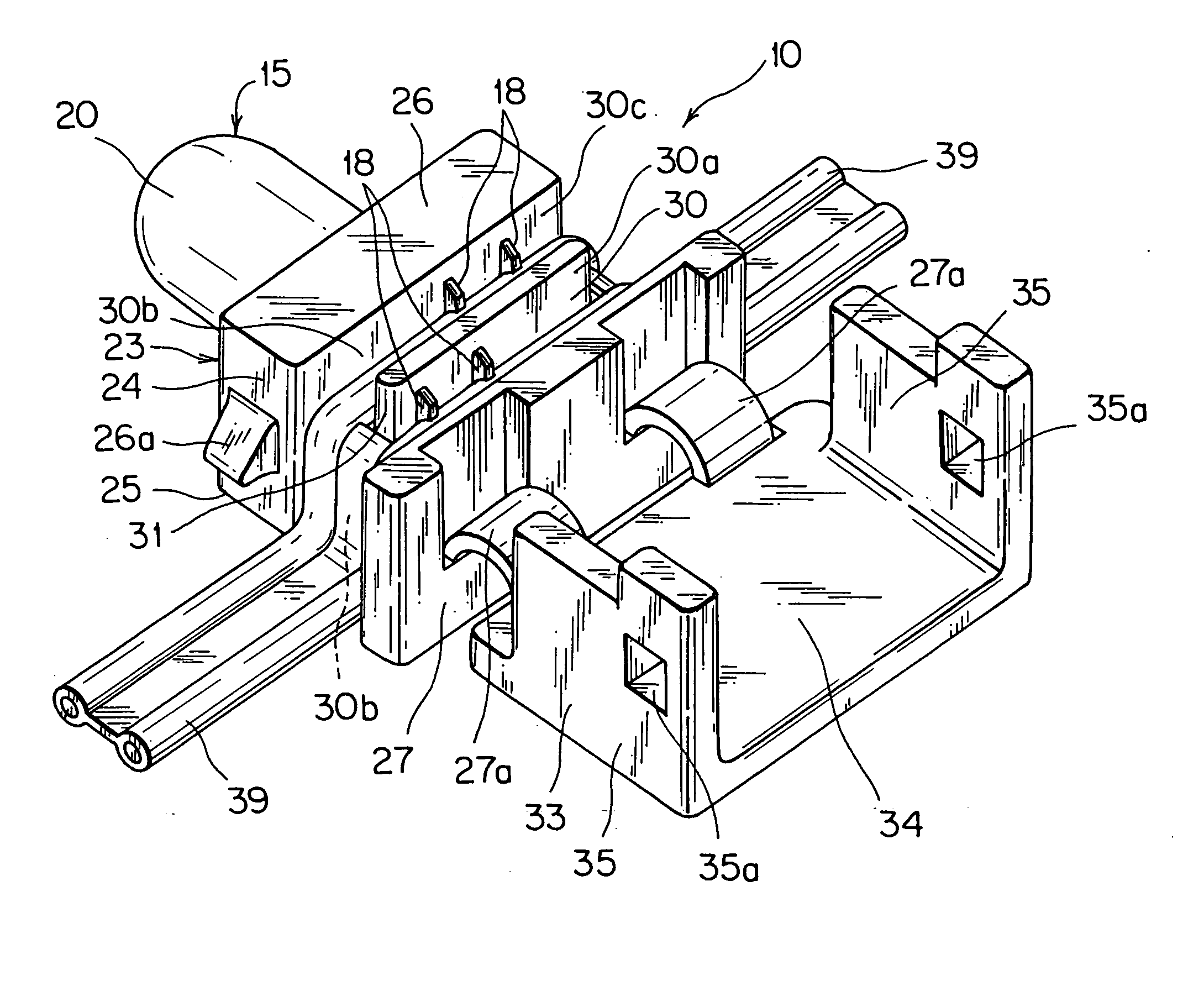

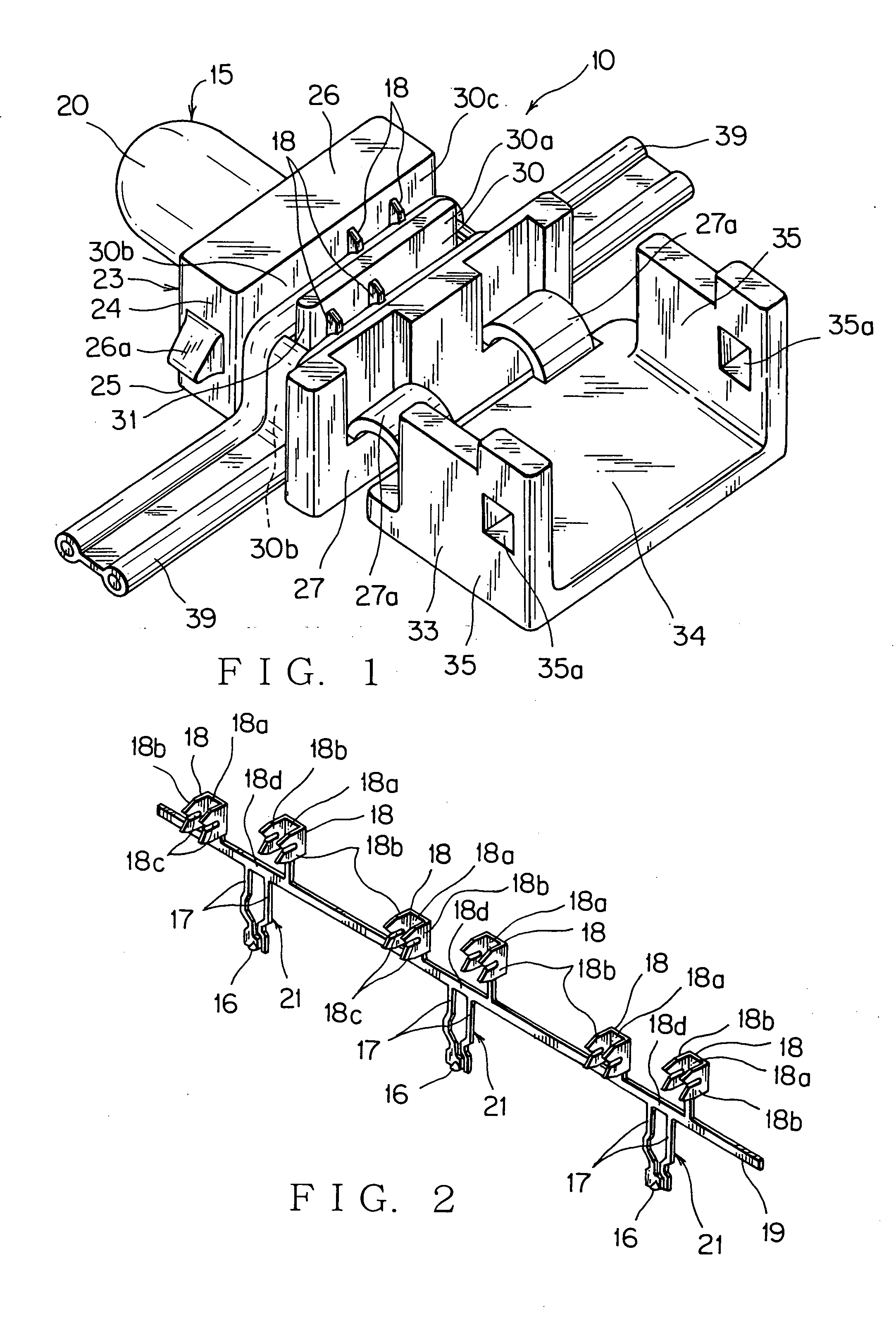

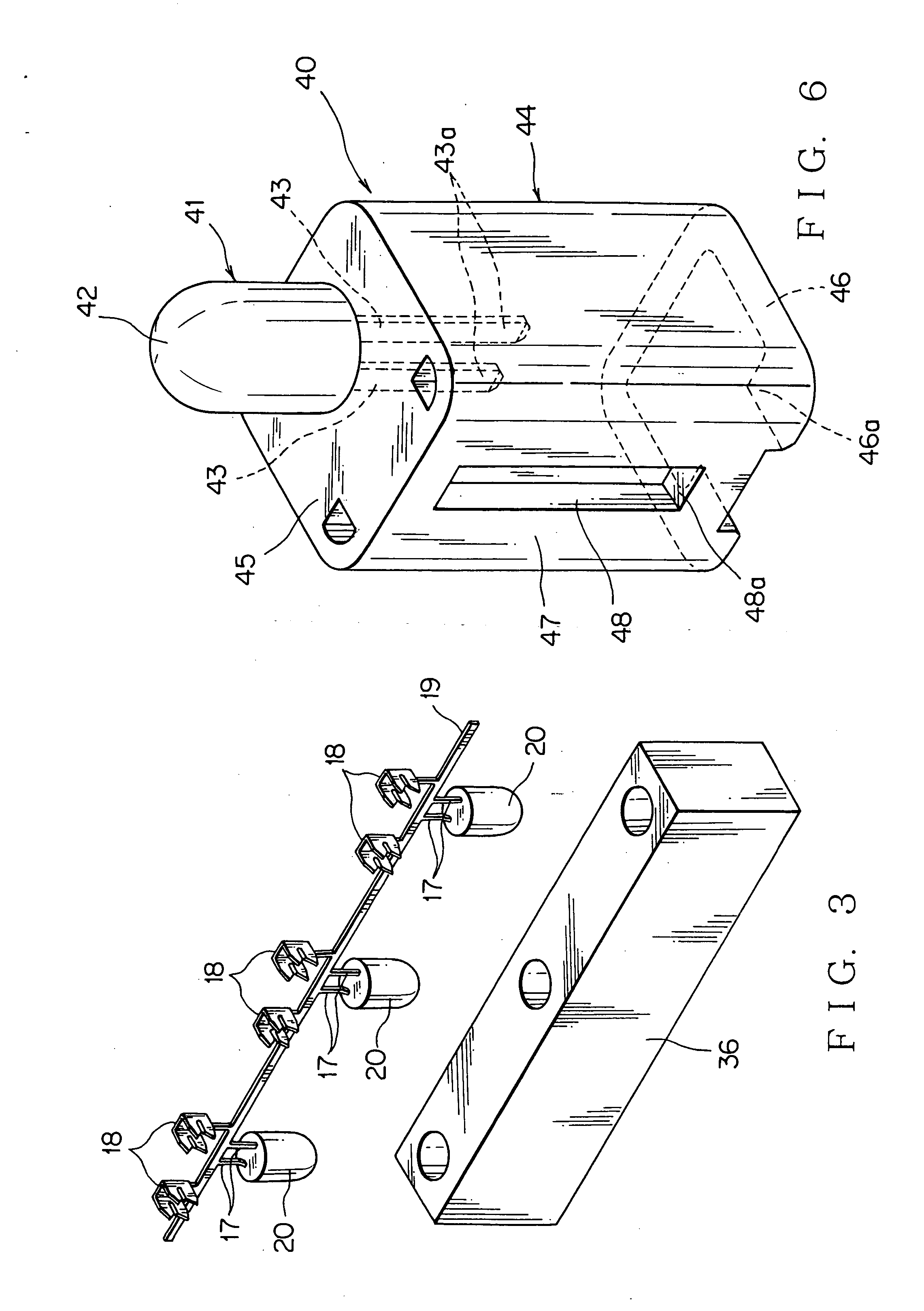

LED lamp module and method for manufacturing the same

InactiveUS20050063181A1Improve manufacturabilityGood workmanshipPoint-like light sourceLighting support devicesEngineeringLight source

Providing an LED lamp module and a method of manufacturing the module preventing deformation and having more freedom for disposing the module, an LED chip for light source, lead terminals having electric-wire pressure contact to be connected with electric wires 39 and supplying source current to the LED chip, an LED lamp 15 including a resin lens 20 sealing the LED chip, and a lamp holder 23 holding the LED chip 15 are molded integrally. Preferably, the resin lens 20 and the lamp holder 23 are molded with different synthetic resin materials by double molding. A connector to be connected with a mating connector is formed at the lamp holder and tab-like terminals continued to the lead terminals project into the connector.

Owner:YAZAKI CORP

4-METHYL-1-PENTENE/a-OLEFIN COPOLYMER, COMPOSITION COMPRISING THE COPOLYMER AND 4-METHYL-1-PENTENE COPOLYMER COMPOSITION

ActiveUS20120220728A1Preferable in of flexibilityPreferable in of mechanical propertyPolymer scienceStress relaxation

The present invention provides a 4-methyl-1-pentene / α-olefin copolymer being excellent in lightness, stress absorption, stress relaxation, vibration damping properties, scratch resistance, abrasion resistance, toughness, mechanical properties and flexibility, having no stickiness during molding operation and being excellent in the balance among these properties; a composition comprising the polymer; and uses thereof. The 4-methyl-1-pentene / α-olefin copolymer (A) of the present invention satisfies specific requirements, and comprises 5 to 95 mol % of a structural unit (i) derived from 4-methyl-1-pentene, 5 to 95 mol % of a structural unit (ii) derived from at least one kind of α-olefin selected from α-olefins having 2 to 20 carbon atoms excluding 4-methyl-1-pentene and 0 to 10 mol % of a structural unit (iii) derived from a non-conjugated polyene, provided that the total of the structural units (i), (ii), and (iii) is 100 mol %.

Owner:MITSUI CHEM INC

Polyamide composition

InactiveUS6887930B2Low water absorptionOvercome lack of heat resistanceCarboxylic acidTerephthalic acid

A polyamide composition comprising 50 to 90 parts by weight of (A) semiaromatic polyamides having dicarboxylic acid units containing 60 to 100 mole % of terephthalic acid units and diamine units containing 60 to 100 mole %, in total, of 1,9-nonanediamine units and / or 2-methyl-1,8-octanediamine units, and 50 to 10 parts by weight of (B) aliphatic polyamides in which the average of total carbon atoms of dicarboxylic acid units and diamine units per one amide group is 7 to 12; having excellent moldability, toughness, light-weightness, hot water and steam resistance, heat resistance, mechanical characteristics, low water absorption, chemical resistance and melt stability; and are applicable for molding at low temperature with a conventional steam-heating or a conventional hot-water-heating type mold to give molded articles having sufficient heat resistance, rigidity at high temperature and dimensional stability.

Owner:KURARAY CO LTD

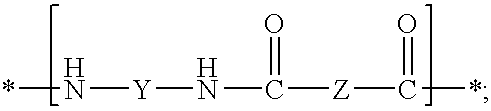

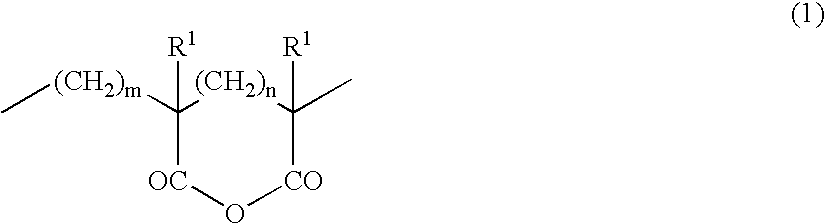

Acrylic block copolymer and thermoplastic resin composition

The present invention provides a novel acrylic block copolymer rich in flexibility and excellent in mechanical strength, moldability, oil resistance, heat resistance, thermal decomposition resistance, weather resistance, and compression set, and further rich in reactivity. The present invention also provides compositions, seal products, and automobile, electric, and electronic parts, all of which include the acrylic block copolymer. The acrylic block copolymer includes a methacrylic polymer block (a) and an acrylic polymer block (b), at least one of the polymer blocks containing, in its main chain, at least one acid anhydride group (c) represented by formula (1): (wherein R1s each represent hydrogen or a methyl group and may be the same or different, n represents an integer of 0 to 3, and m represents an integer of 0 or 1).

Owner:KANEKA CORP

Polyhedral polysiloxane modified product and composition using the modified product

ActiveUS20100099790A1Excellent in moldability and transparency and heat resistance and light resistance and adhesivenessExcellent heat and lightSilicon organic compoundsCoatingsHydrosilylationOrganic chemistry

The present invention has its object to provide a liquid-form modified product of polyhedral polysiloxane which is excellent in moldability and transparency, and a composition produced using the modified product. In addition, the present invention can provide an easy-to-handle modified product and composition. The present invention provides a modified product of polyhedral polysiloxane which is obtainable by modifying a polyhedral polysiloxane compound (a) with a compound (b), and a composition containing the modified product. The polyhedral polysiloxane compound (a) has an alkenyl group and / or a hydrosilyl group, and the compound (b) has a hydrosilyl group and / or an alkenyl group each capable of hydrosilylation with the component (a).

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com