A kind of insulating and heat-conducting double-sided adhesive tape and preparation method thereof

A technology of insulating heat-conducting adhesive and double-sided tape, which is applied in the direction of adhesives, other rubber adhesives, adhesive types, etc., and can solve problems such as reducing the loose fit between interfaces, low thermal resistance, and easy breakage. Achieve good room temperature stability and moldability, good thermal conductivity and electrical insulation, easy to die-cut and rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

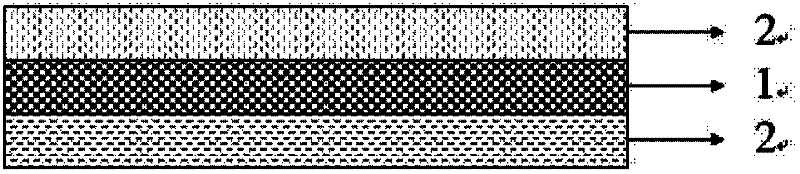

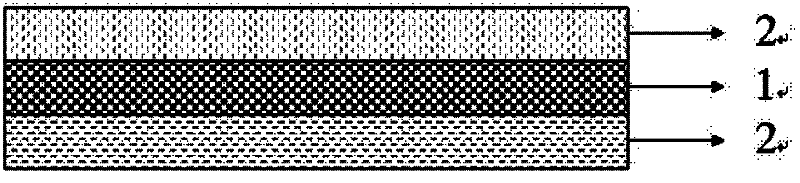

[0036] see figure 1 , an insulating and heat-conducting double-sided adhesive tape, the outer layers on both sides are release paper 2, and a single-layer insulating and heat-conducting adhesive layer 1 is arranged between the two release papers 2.

Embodiment 2

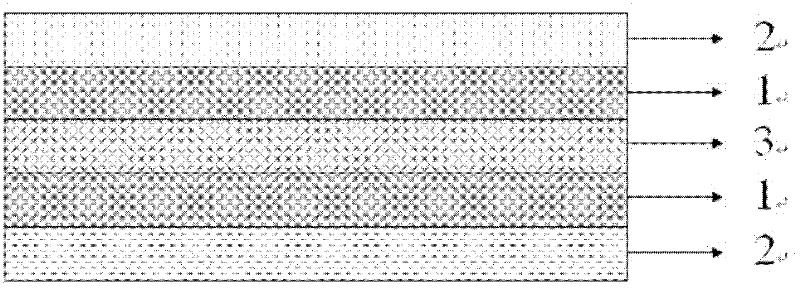

[0038] see figure 2 , an insulating and heat-conducting double-sided adhesive tape, the outer layers on both sides are release paper 2, a single-layer substrate 3 is arranged between the two layers of release paper 2, and an insulating layer is provided between the substrate 3 and the release paper 2. Thermally conductive adhesive layer 1.

[0039] The beneficial effects of the present invention are reflected in the following aspects:

[0040] 1. The insulating and heat-conducting double-sided tape of the present invention has good heat-conducting effect and electrical insulation after being filled with a certain superior proportion of heat-conducting medium.

[0041] 2. The insulating and heat-conducting double-sided adhesive tape of the present invention does not contain halogens and heavy metals, and will not corrode the attached object when used.

[0042] 3. The insulating and heat-conducting double-sided adhesive tape of the present invention is solid at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com