Patents

Literature

540 results about "Liquid polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surgical adhesive and uses therefore

InactiveUS20050129733A1Controlled strengthLess erosiveSurgical adhesivesPharmaceutical delivery mechanismIn situ polymerizationEnteroceles

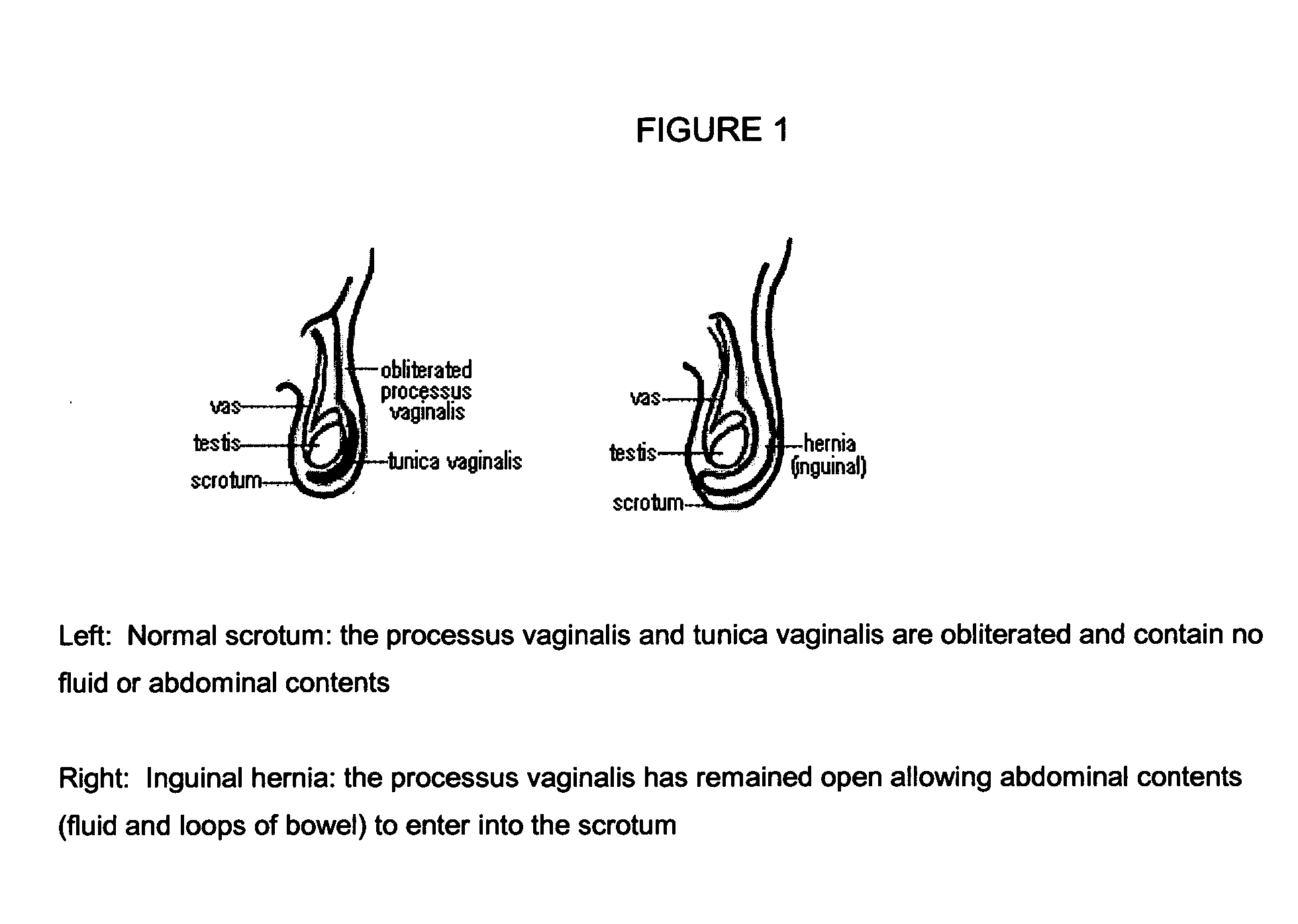

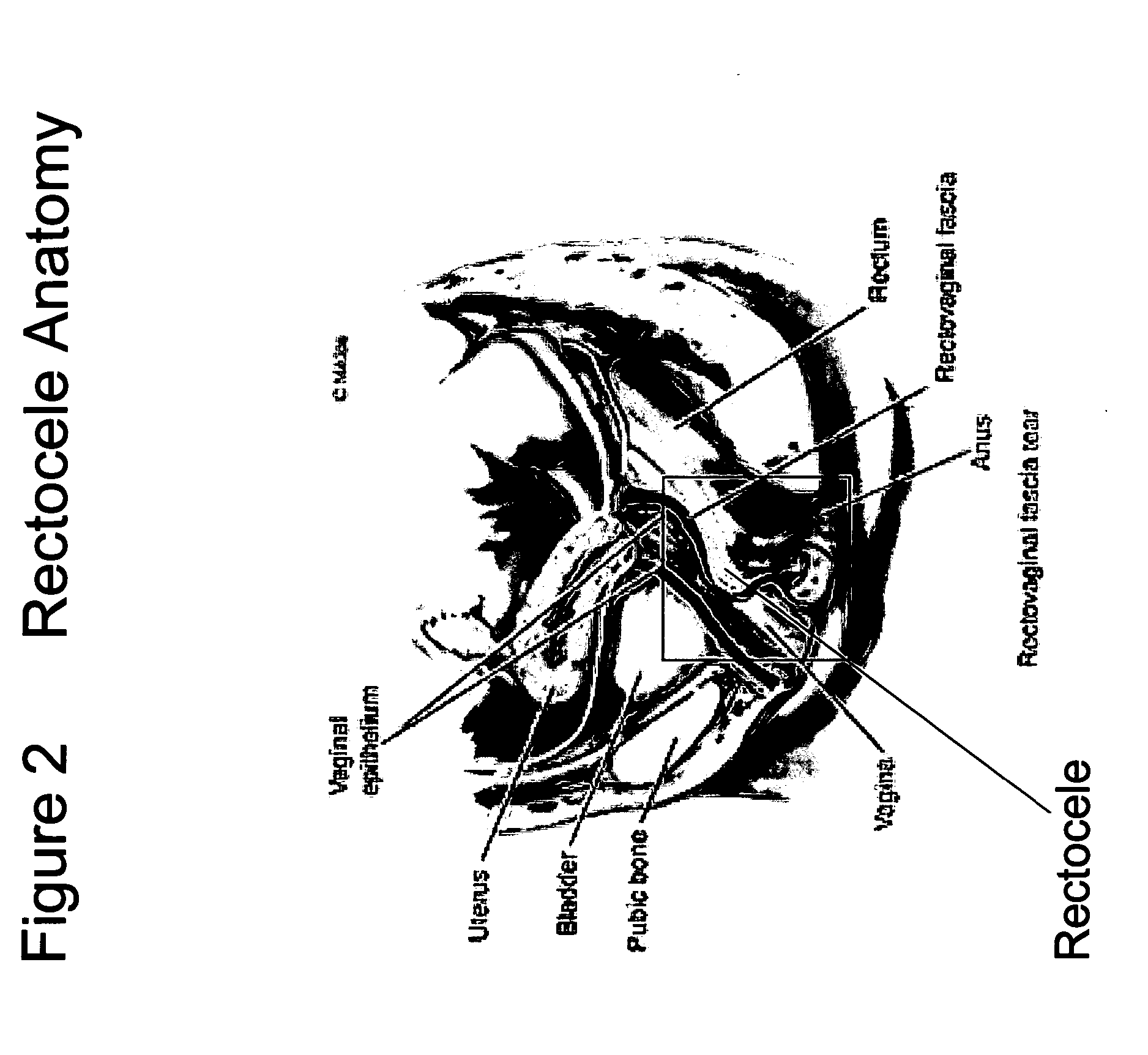

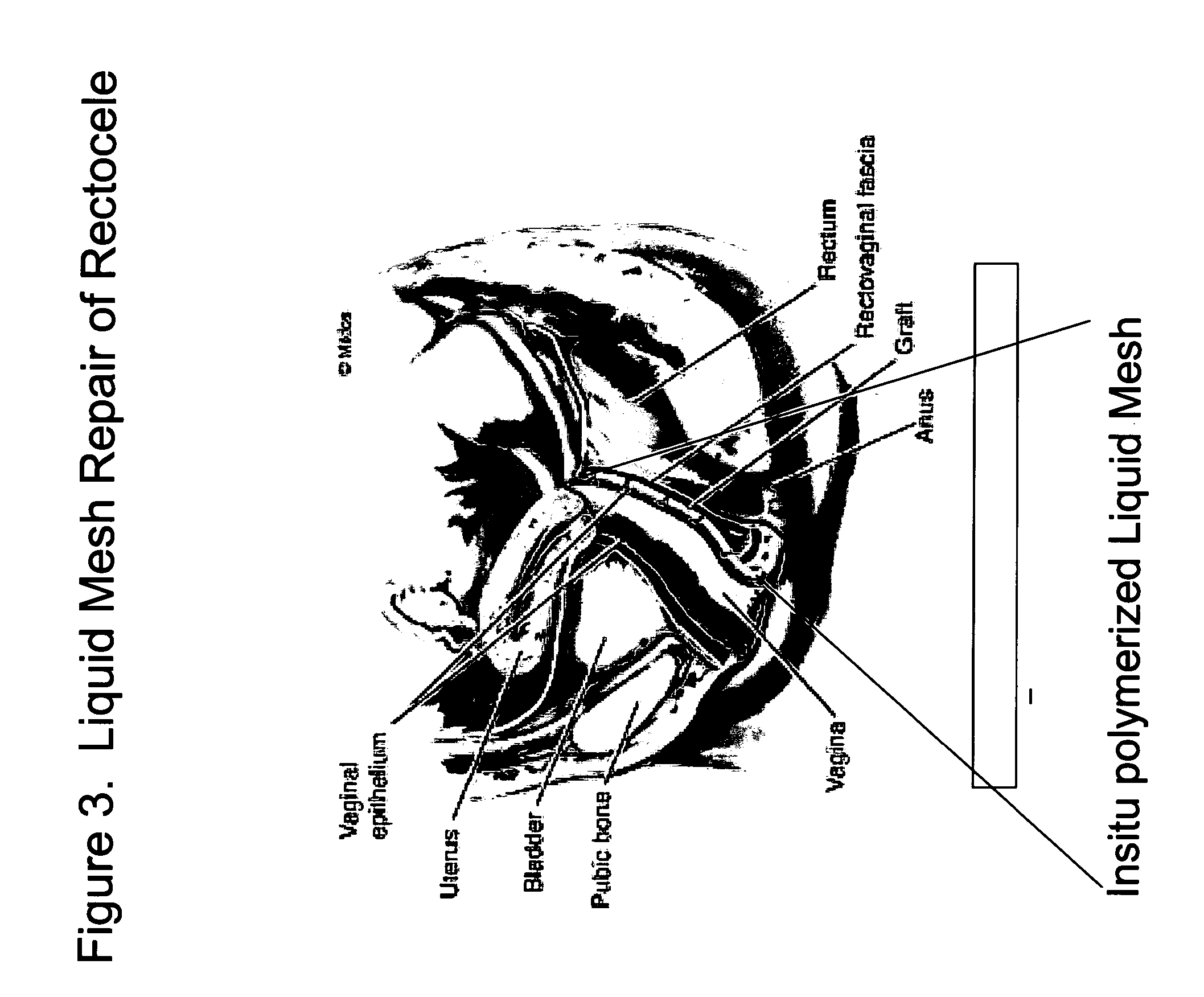

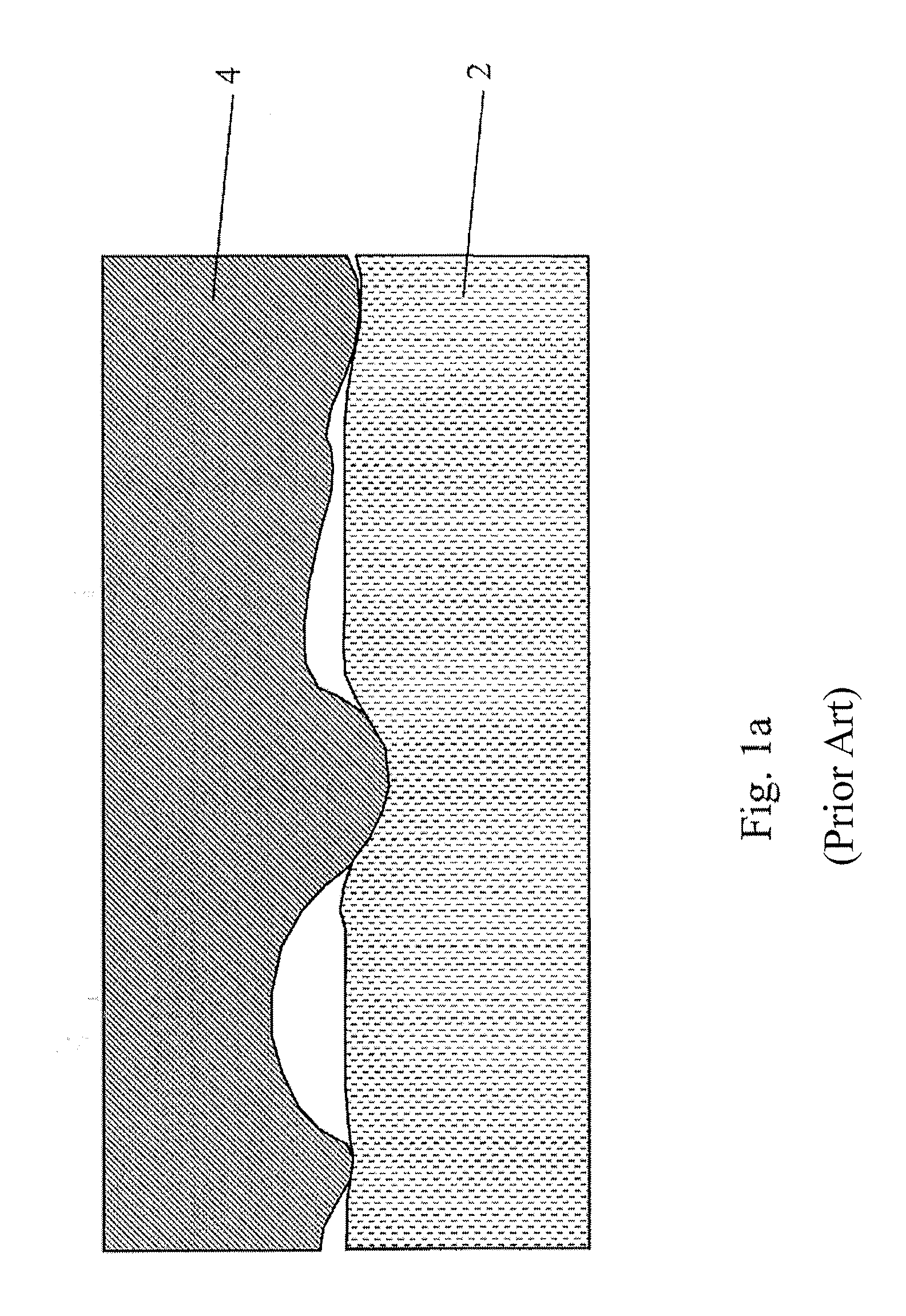

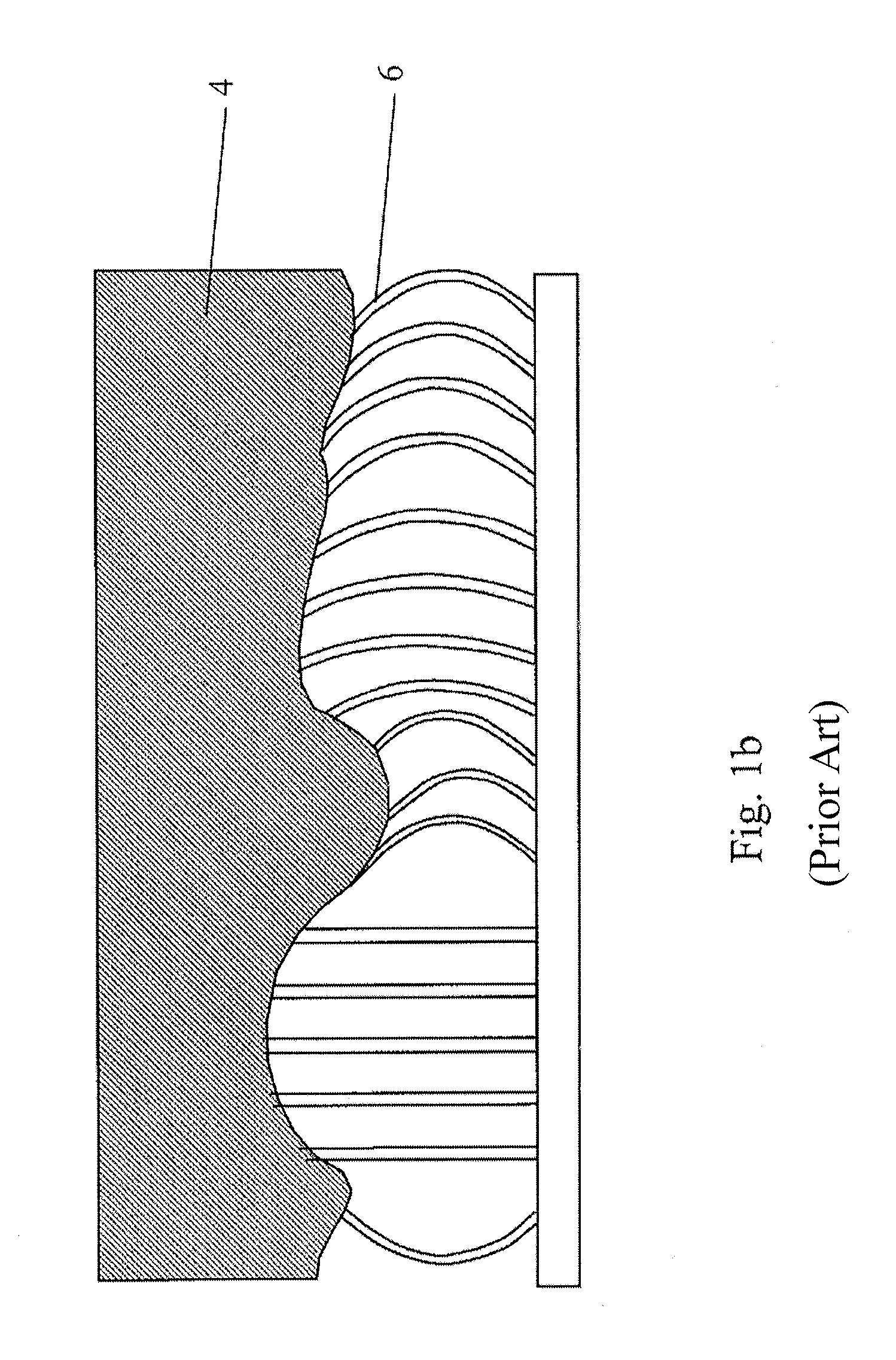

The present invention provides a liquid polymer composition which can be implanted into a living mammal and which forms a solid hydrogel by in situ polymerization upon contact with body fluid and tissue. The composition also can be used as a coating on a medical device, or for the formation of a medical device. Formation of a solid implant or coating involves crosslinking of the adhesive with itself and with surrounding tissue. The liquid implant, by itself or in conjunction with various prostheses, can be used for many purposed, including fixation of the urethra for providing treatment for incontinence, and repair of herniations in the abdominal cavity, including rectocele, cystocele, enterocele, and inguinal hernia. The adhesive may be used to establish adhesion prevention during such repairs, in part by coating or being the material of a repair mesh.

Owner:PROMETHEAN SURGICAL DEVICES

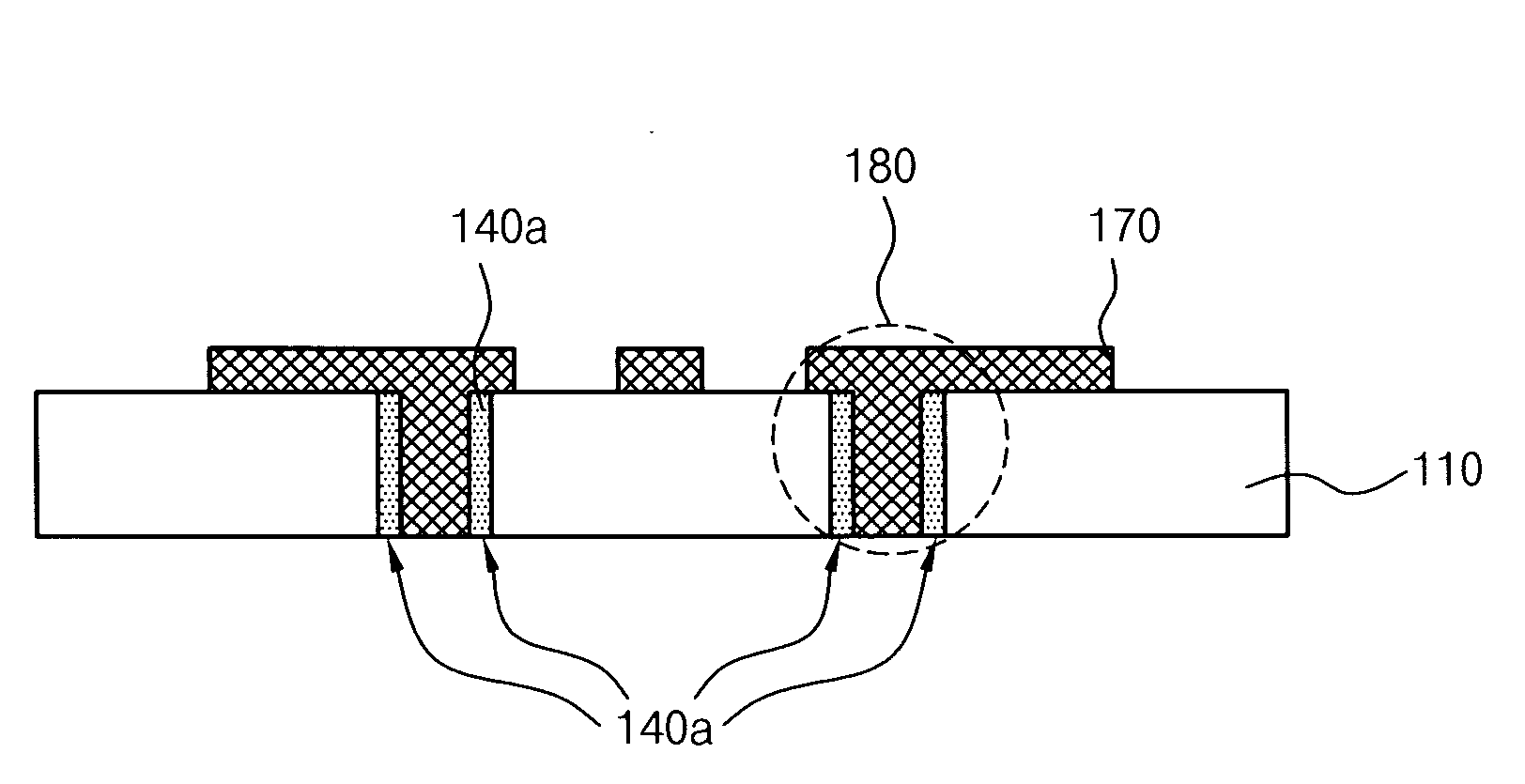

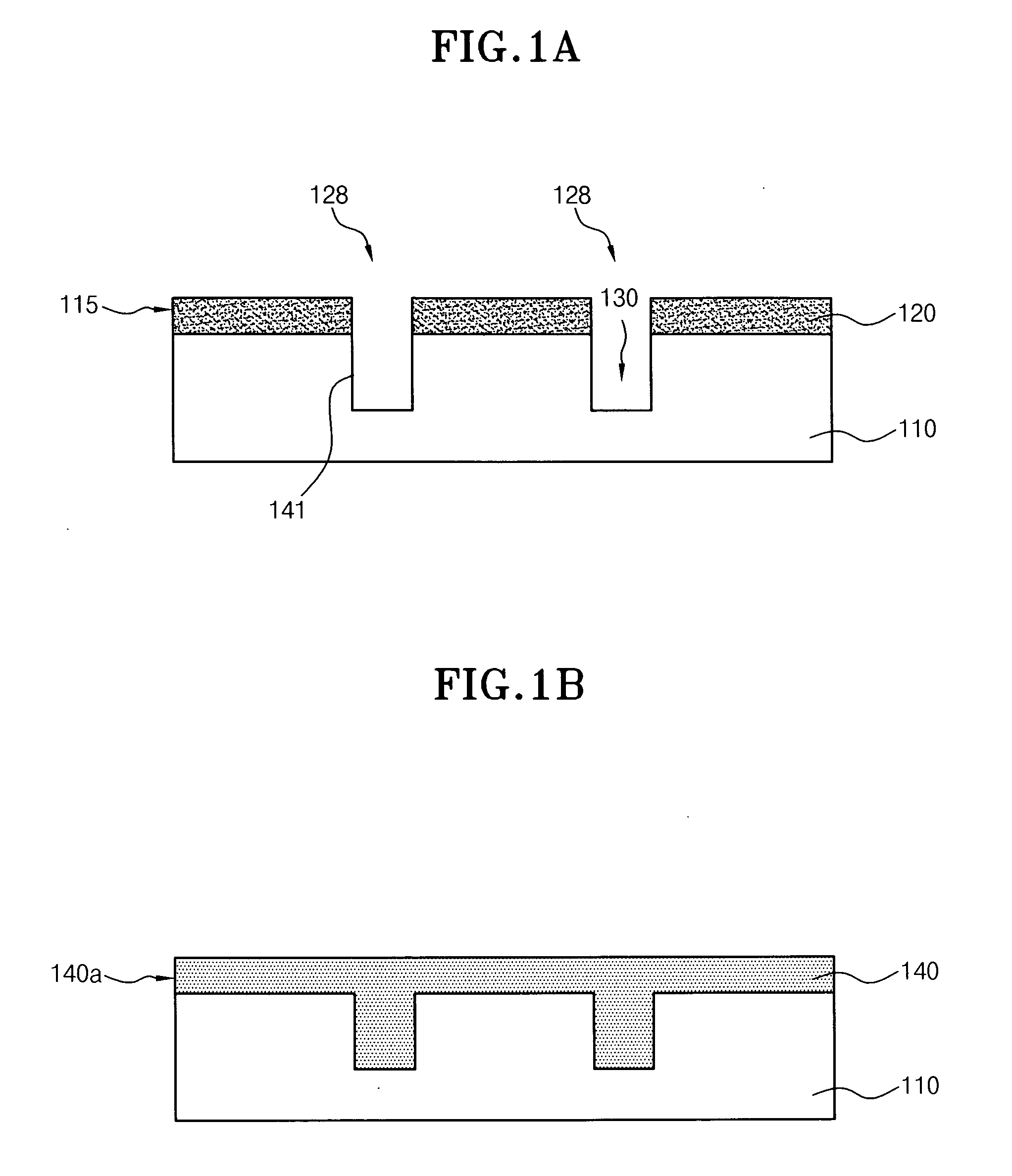

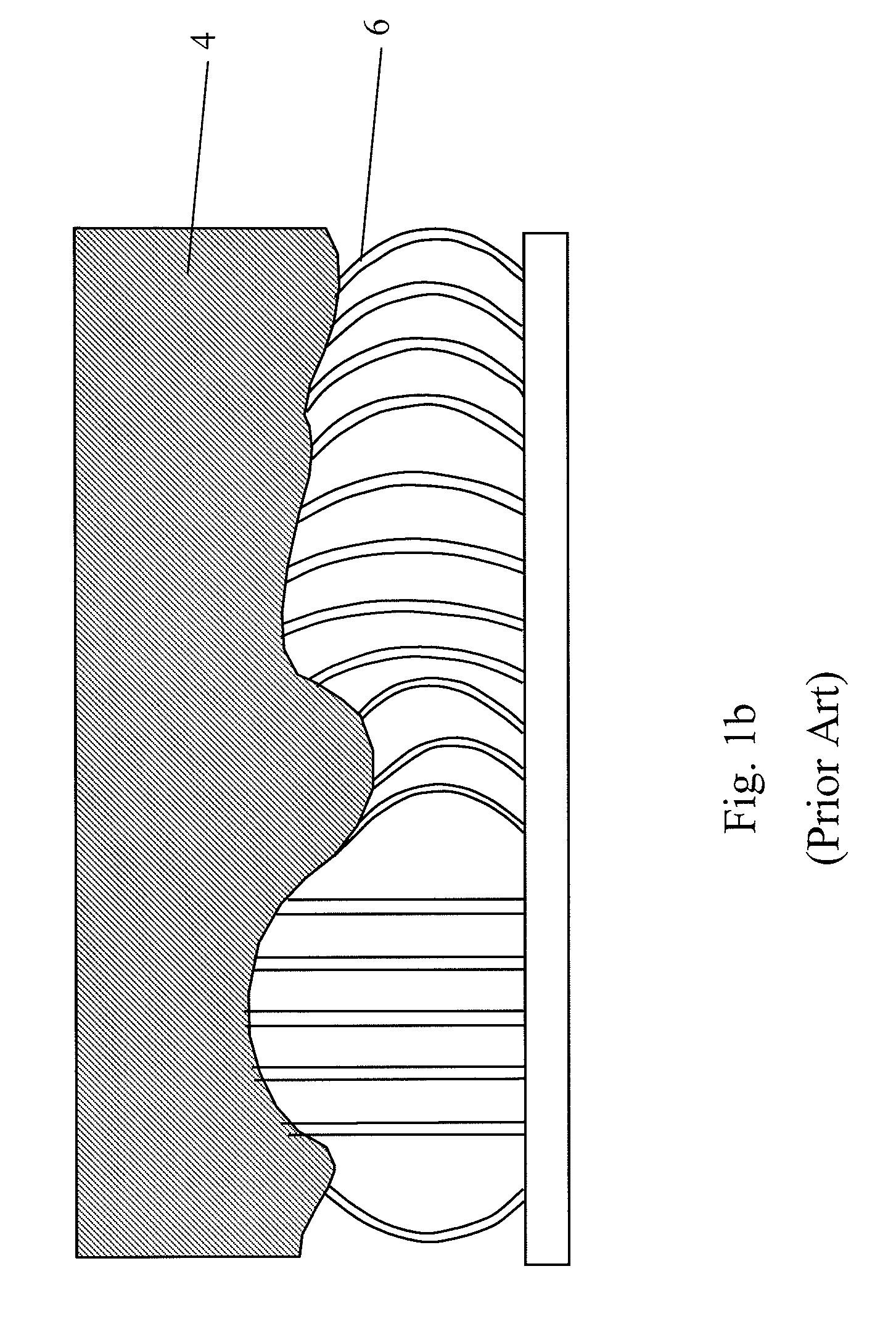

Through-silicon via and method for forming the same

InactiveUS20080079121A1Low costSecure characteristicSemiconductor/solid-state device detailsSolid-state devicesInsulation layerSemiconductor chip

A method for forming a through-silicon via includes the steps of defining a groove in each chip of a wafer which has a plurality of semiconductor chips; applying liquid polymer on the wafer to fill the groove; forming an insulation layer on a sidewall of the groove through patterning the polymer; forming a metal layer to fill the groove which is formed with the insulation layer on the sidewall thereof; and back-grinding a backside of the wafer to expose the metal layer filled in the groove.

Owner:SK HYNIX INC

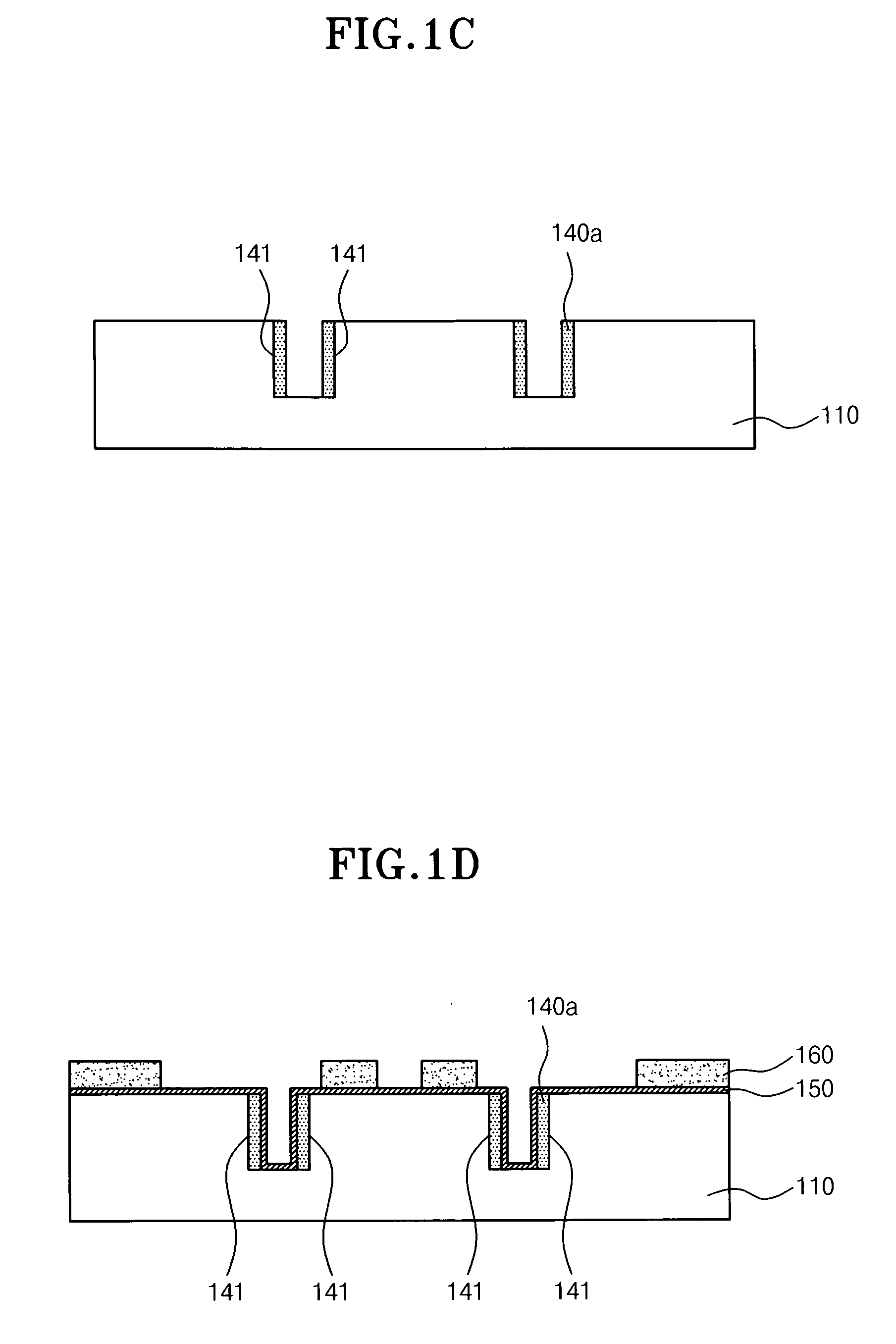

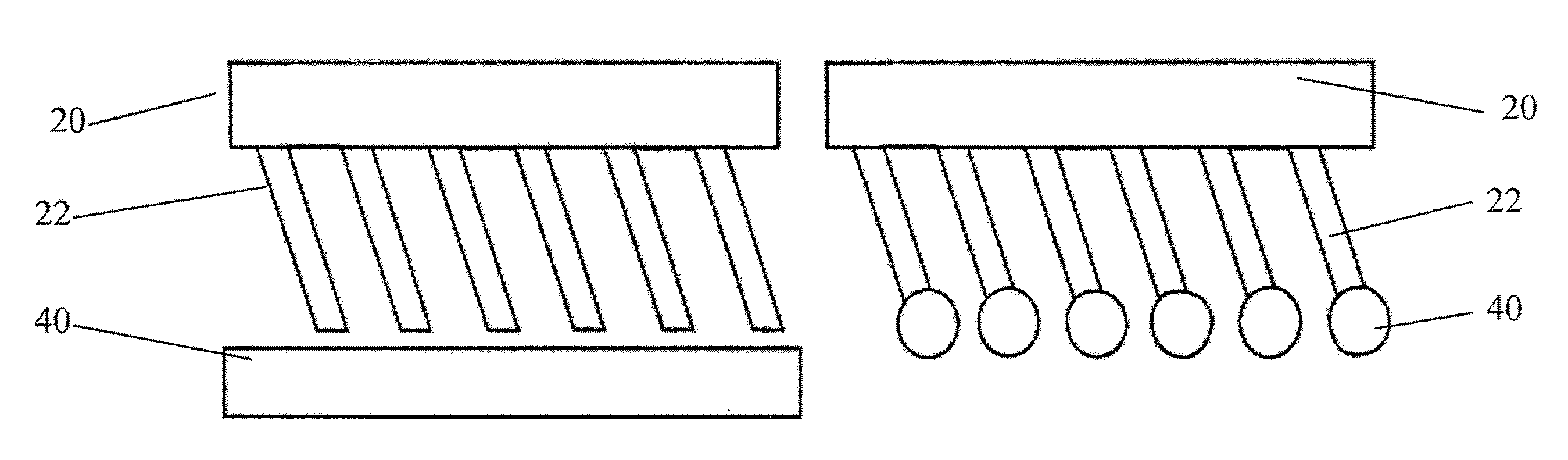

High conducting thin-film nanoprobe card and its fabrication method

InactiveUS7012441B2Compensating for such errorLine/current collector detailsElectrically conductive connectionsPolymer resinNanotube

A conducting thin-film nanoprobe card fabrication method includes the steps of: (a) arranging nanotubes on a substrate in vertical; (b) covering the nanotubes with a liquid polymeric resin and then hardening the polymeric resin to form a conducting nanomembrane; (c) removing a part of the polymeric resin from the conducting nanomembrane to expose one end of each nanotube to outside; (d) removing the substrate and preparing a ceramic substrate having contacts at one side and metal bumps at the other side and plated through holes electrically respectively connected with the contacts and the metal bumps; (e) mounting the nanomembrane on the ceramic substrate to hold the nanotubes in contact with the contacts of the ceramic substrate, and (f) forming recessed holes in the nanomembrane by etching and inserting a metal rod in each recessed hole to form a respective probe.

Owner:IND TECH RES INST

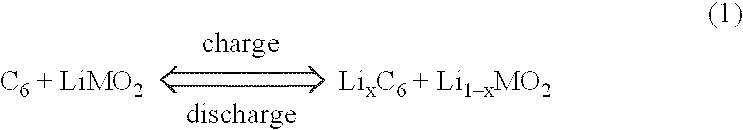

Lithium ion polymer electrolytes

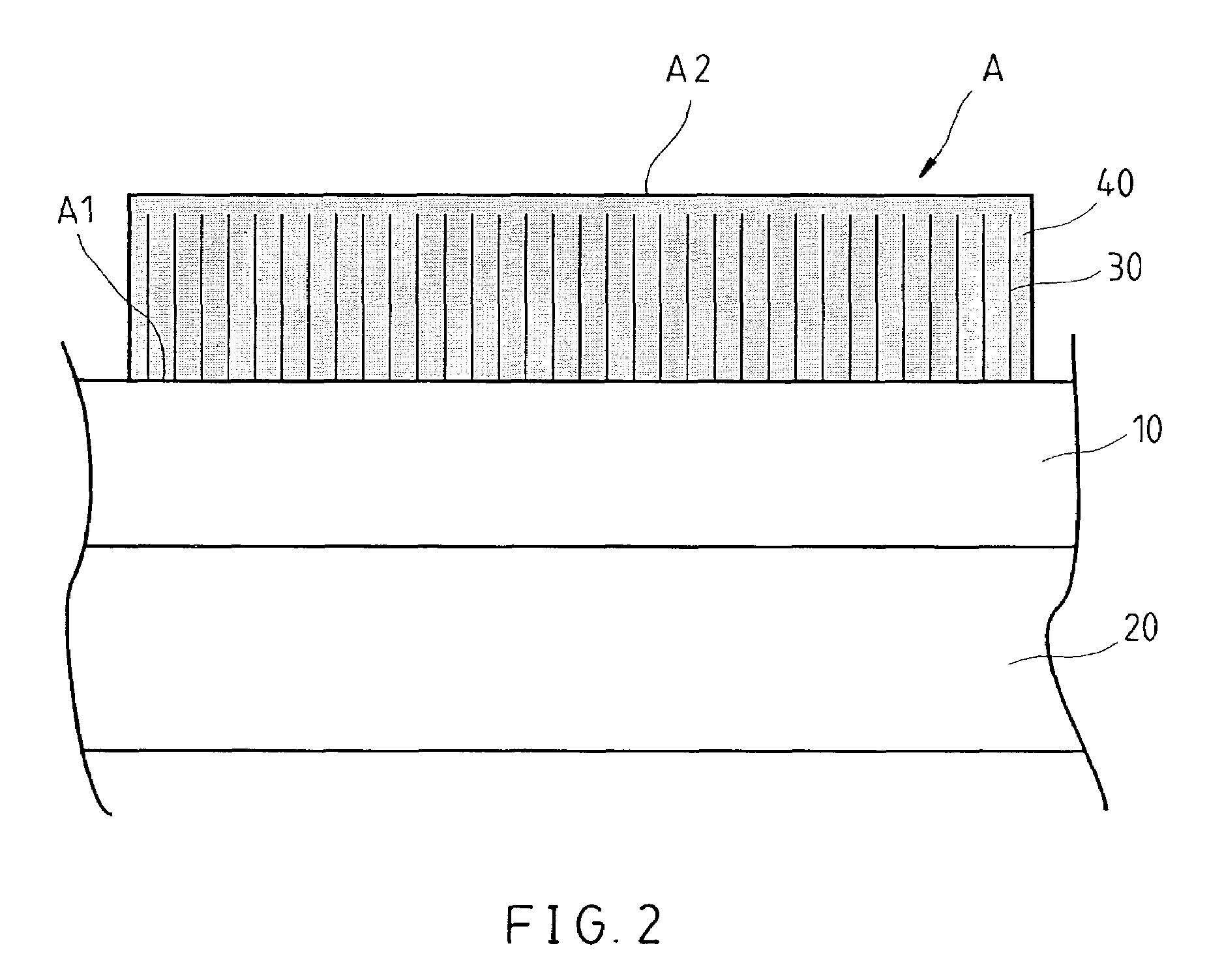

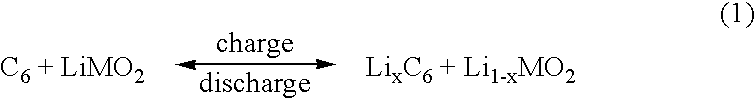

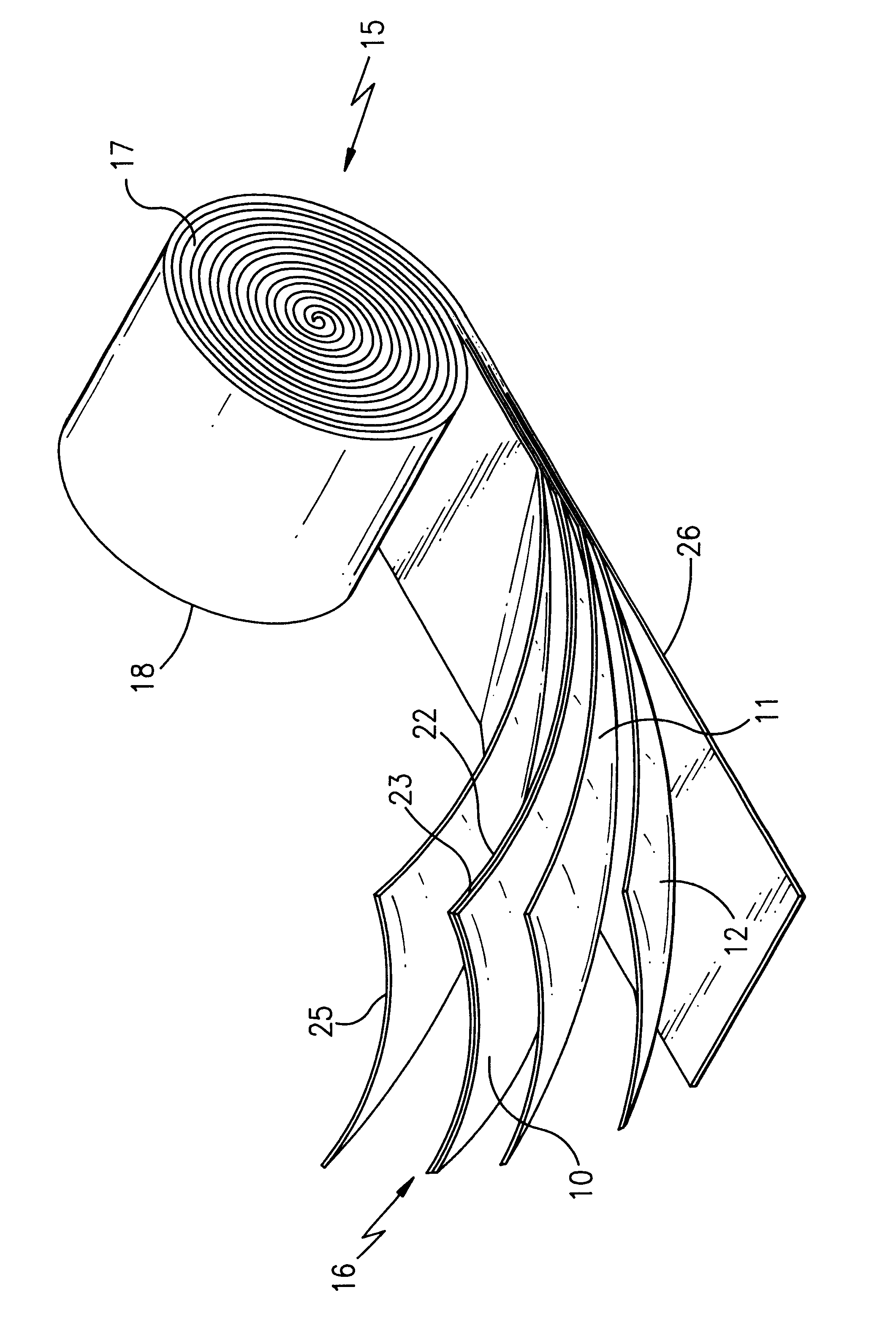

InactiveUS6413676B1Prevent kinkingAvoid deformationElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

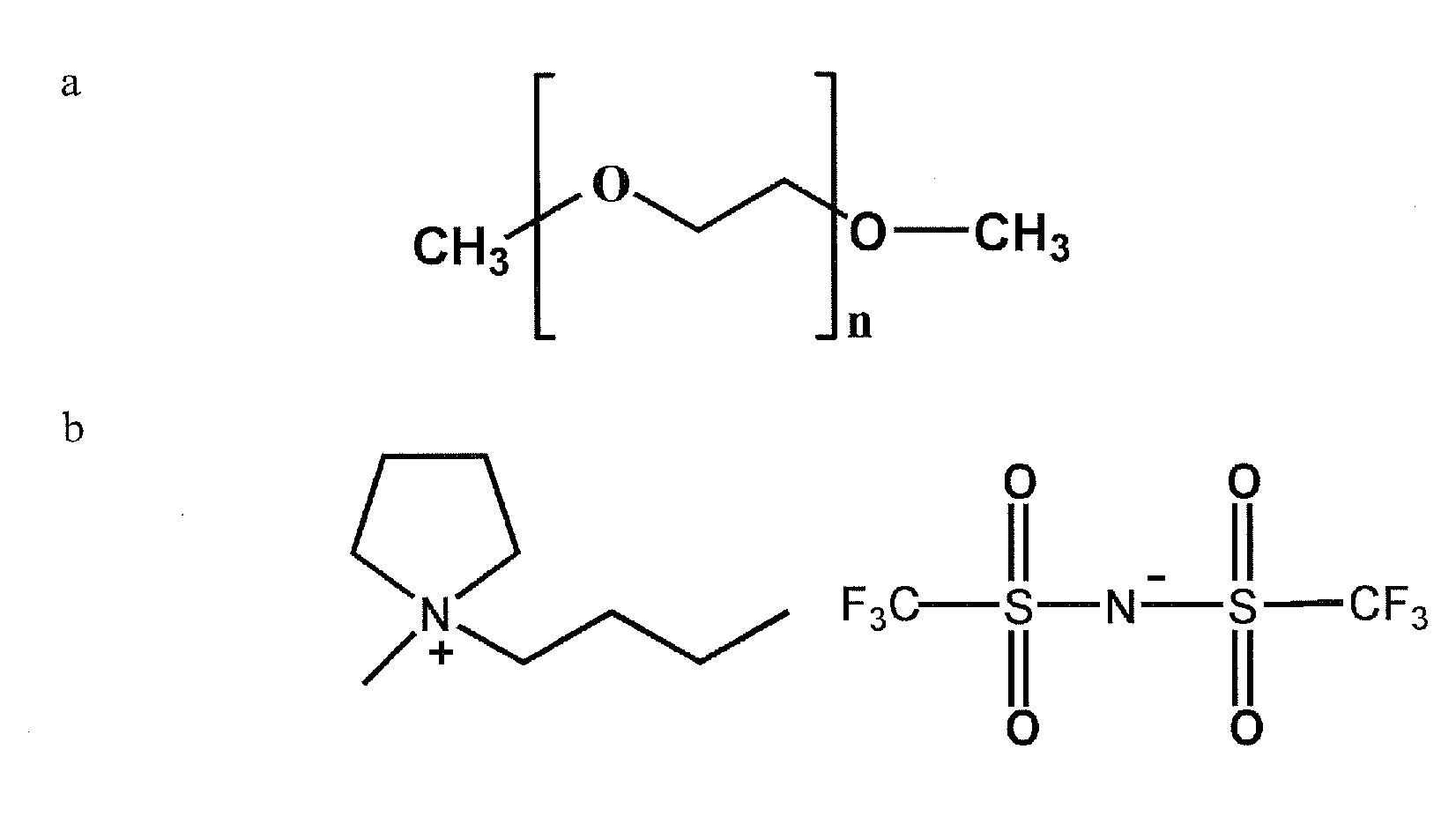

Electrolyte mixtures useful for li-ion batteries

InactiveUS20090286163A1Safer and thermally stable systemImprove compatibilityElectrode carriers/collectorsSolid electrolyte cellsDisplay devicePotassium

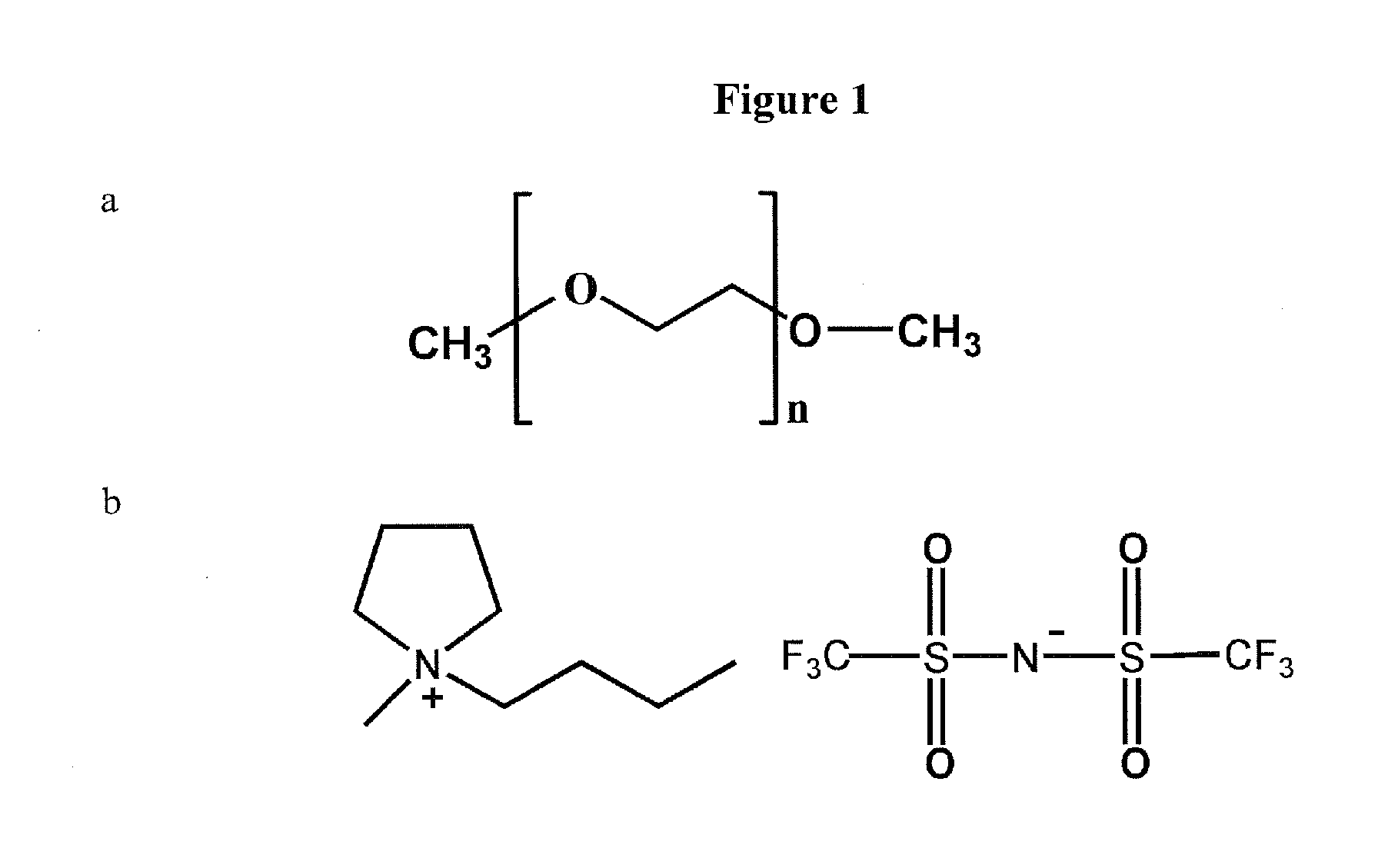

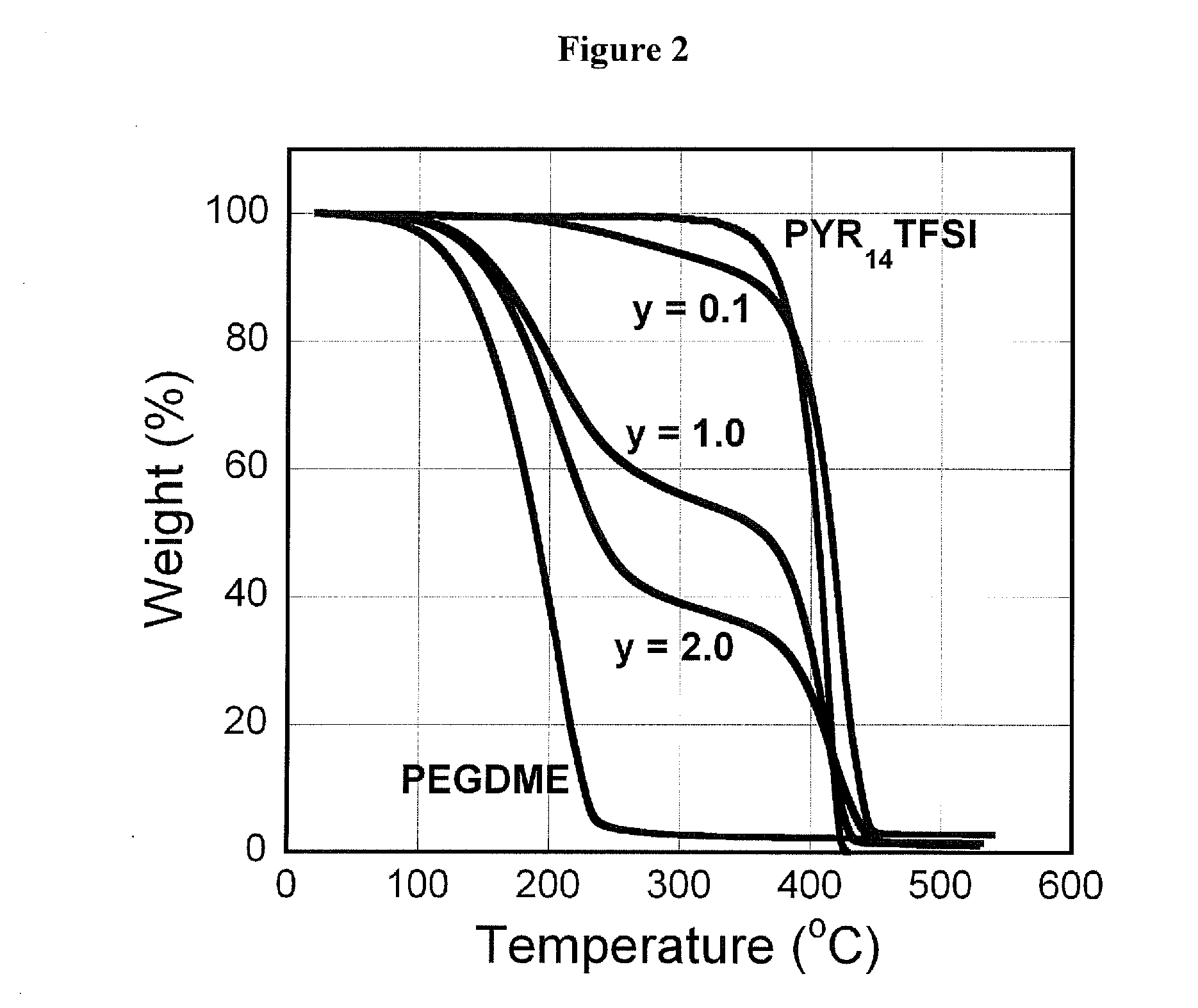

The present invention provides for the preparation of ionic liquid-lithium salt-low molecular weight liquid polymer mixtures. The mixture is useful as an electrolytic solution. Thus, the mixture is suitable as an electrolyte in batteries and supercapacitors as well as an active material for solid state light-emitting devices or polymer light-emitting displays or an electro deposition of alkali metals such as lithium, sodium, or potassium in the field of research or industry. The present invention further provides for a method making the mixture. Additionally, the present invention provides for a lithium battery comprising the mixture and a method of making the lithium battery.

Owner:RGT UNIV OF CALIFORNIA

Low Viscosity Liquid Polymeric Delivery System

InactiveUS20090181068A1Heavy metal active ingredientsNervous disorderPolymer sciencePolymer solution

Owner:DUNN RES & CONSULTING

Rubber composition for tire and tire made therefrom

A rubber composition for tires which comprises 100 parts by mass of (A) copolymer (a) which is a styrene-butadiene copolymer having a weight-average molecular weight of 4.0×105 to 3.0×106; as obtained in accordance with gel permeation chromatography and expressed as the value of corresponding polystyrene, a content of the bound styrene St(a) of 10 to 50% by mass and a content of the vinyl unit in the butadiene portion of 20 to 70%; 10 to 200 parts by mass of (B) copolymer (b) which is a hydrogenated styrene-butadiene copolymer having a weight-average molecular weight of 5.0×103 to 2.0×105, as obtained in accordance with gel permeation chromatography and expressed as the value of corresponding polystyrene, a content of the bound styrene St(b) which is in the range of 25 to 70% by mass and satisfies a relation expressed by equation (I) and a fraction of hydrogenated double bond in the butadiene portion of 60% or greater and (C) at least one substance selected from resins providing tackiness to the rubber composition and liquid polymers having a weight-average molecular weight of 1,000 to 50,000. St(b)≧St(a)+10 (I)

Owner:BRIDGESTONE CORP

Rubber composition for tire tread having high performance on ice and pneumatic tire using the same

InactiveUS6550508B1Good physical propertiesReduce hardnessNon-inflatable tyresSpecial tyresFiberVulcanization

Owner:YOKOHAMA RUBBER CO LTD

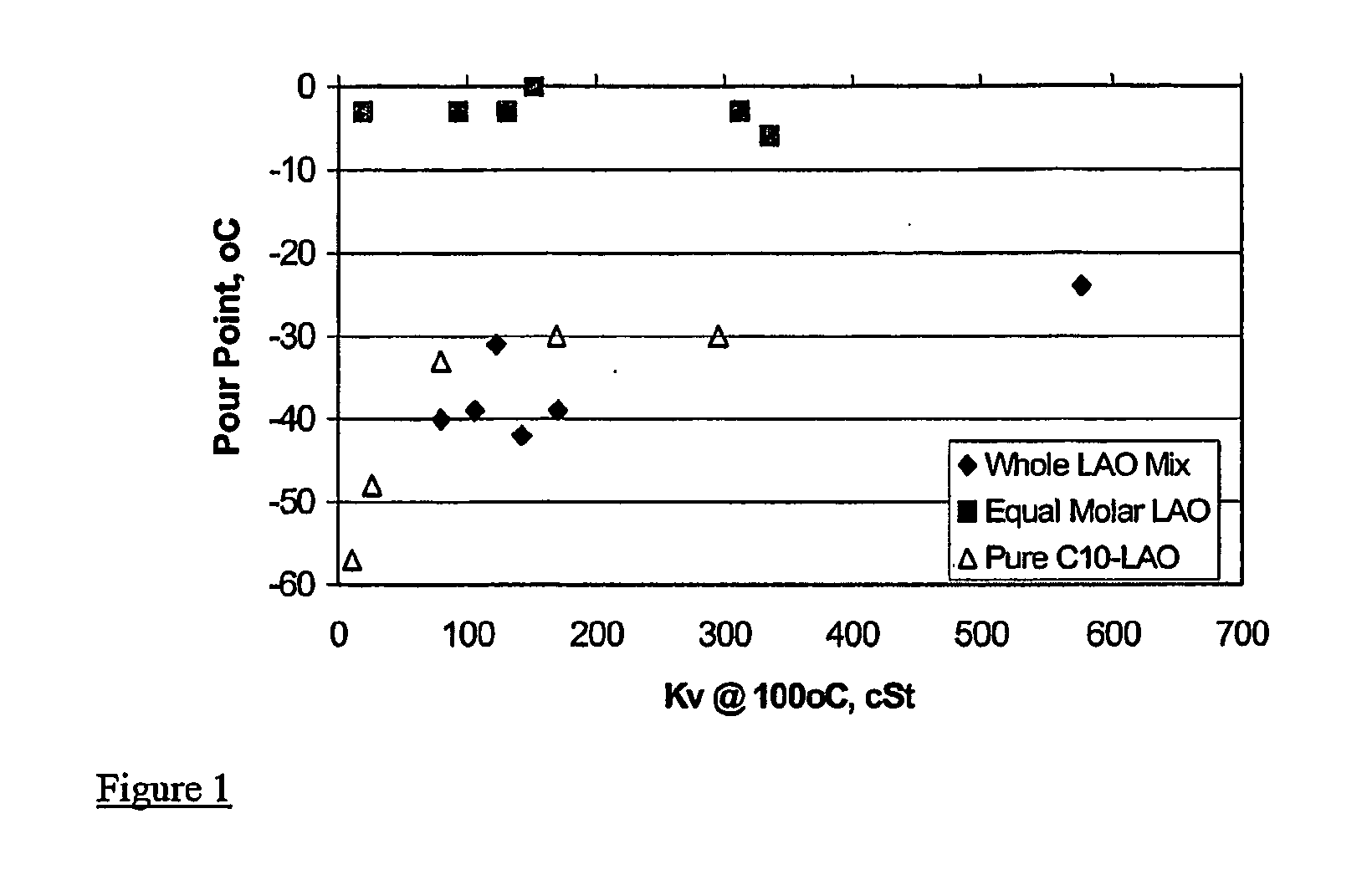

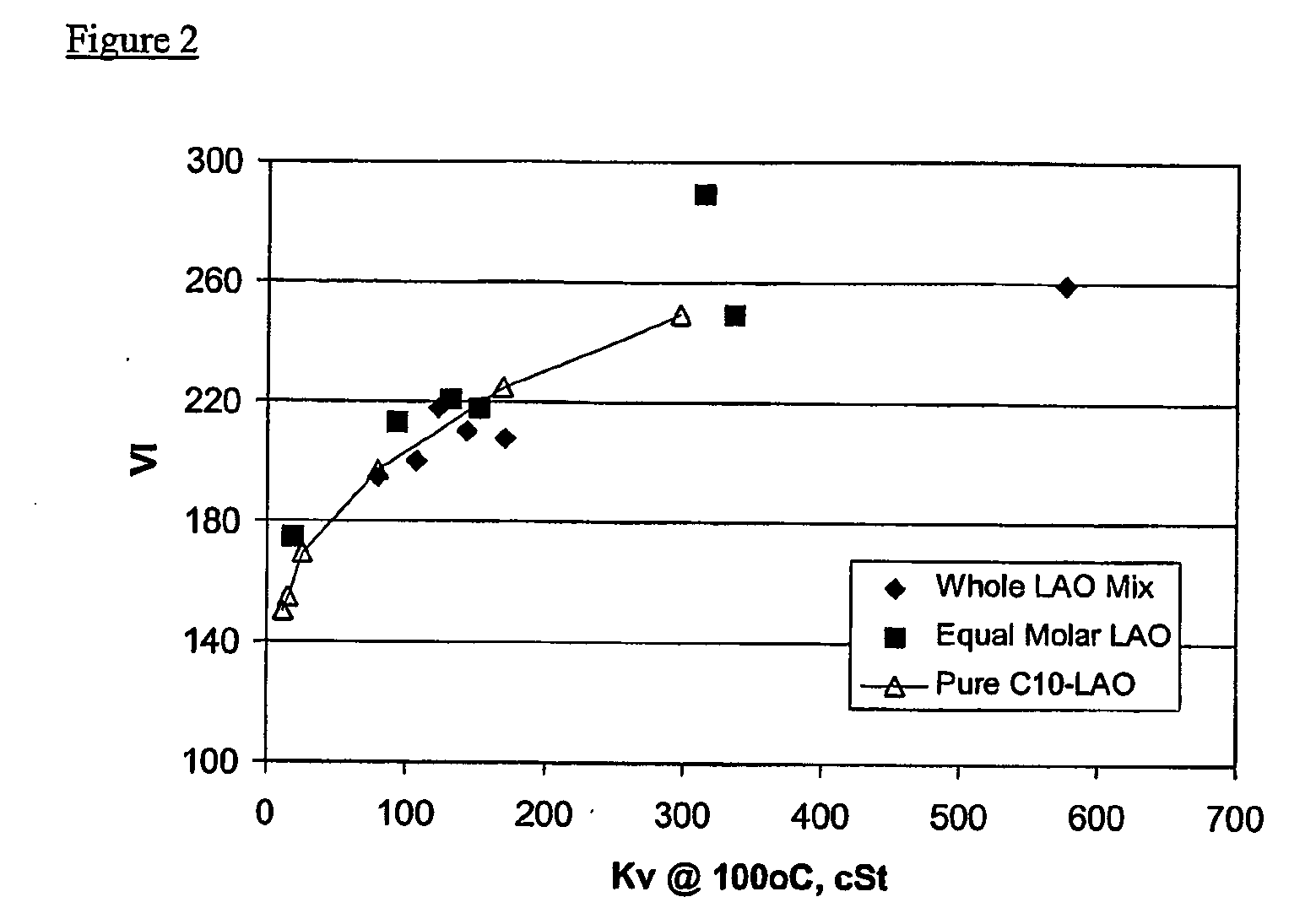

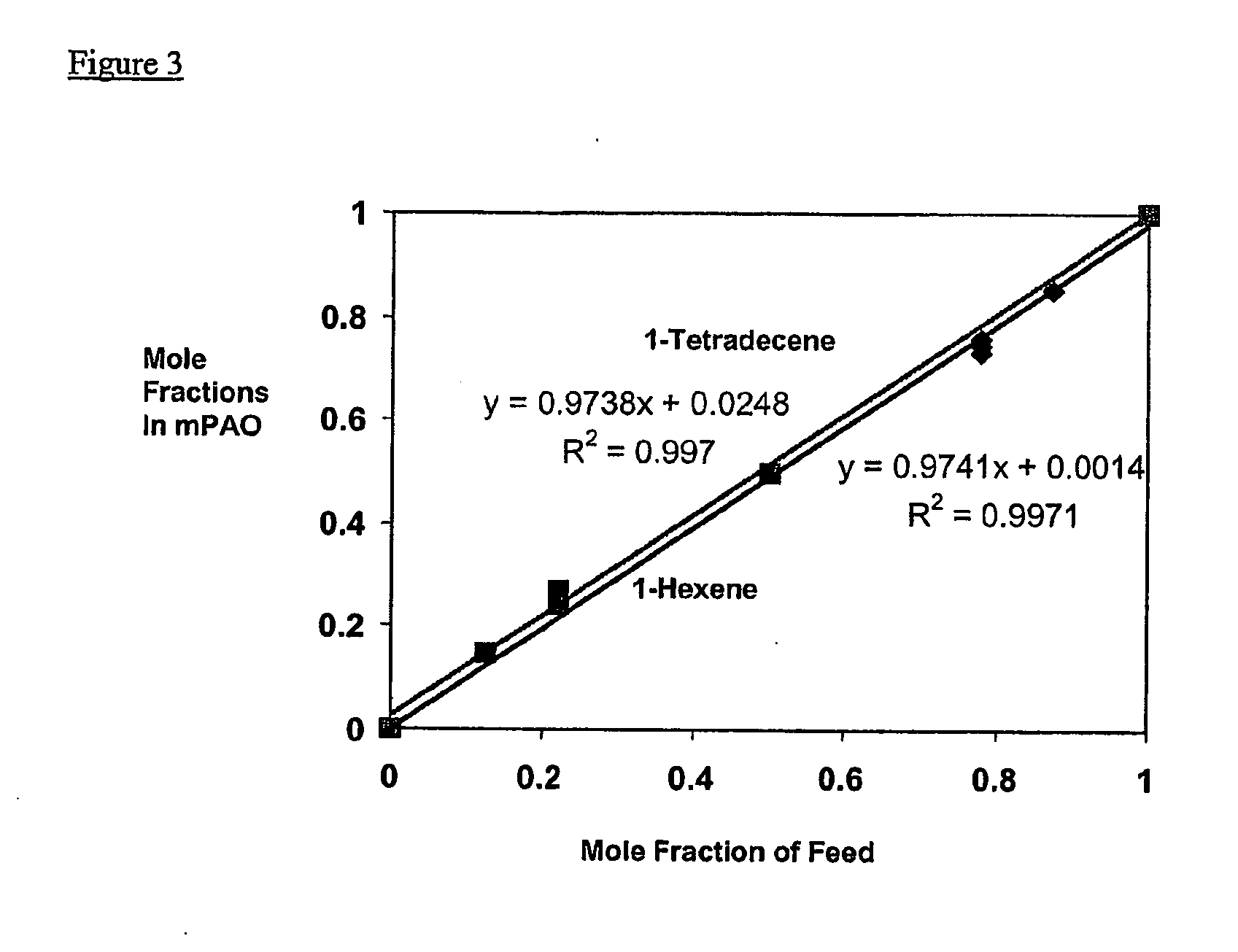

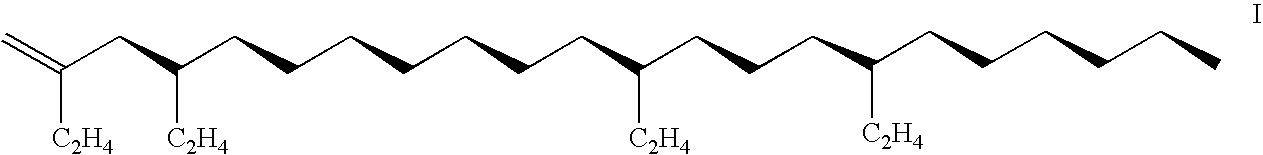

Lubricants from Mixed Alpha-Olefin Feeds

ActiveUS20100292424A1Useful lubricant propertyNarrow molecular weight distributionLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlpha-olefinAlkene

This invention discloses an improved process which employs mixed alpha-olefins as feed over activated metallocene catalyst systems to provide essentially random liquid polymers particularly useful in lubricant components or as functional fluids.

Owner:EXXONMOBIL CHEM PAT INC

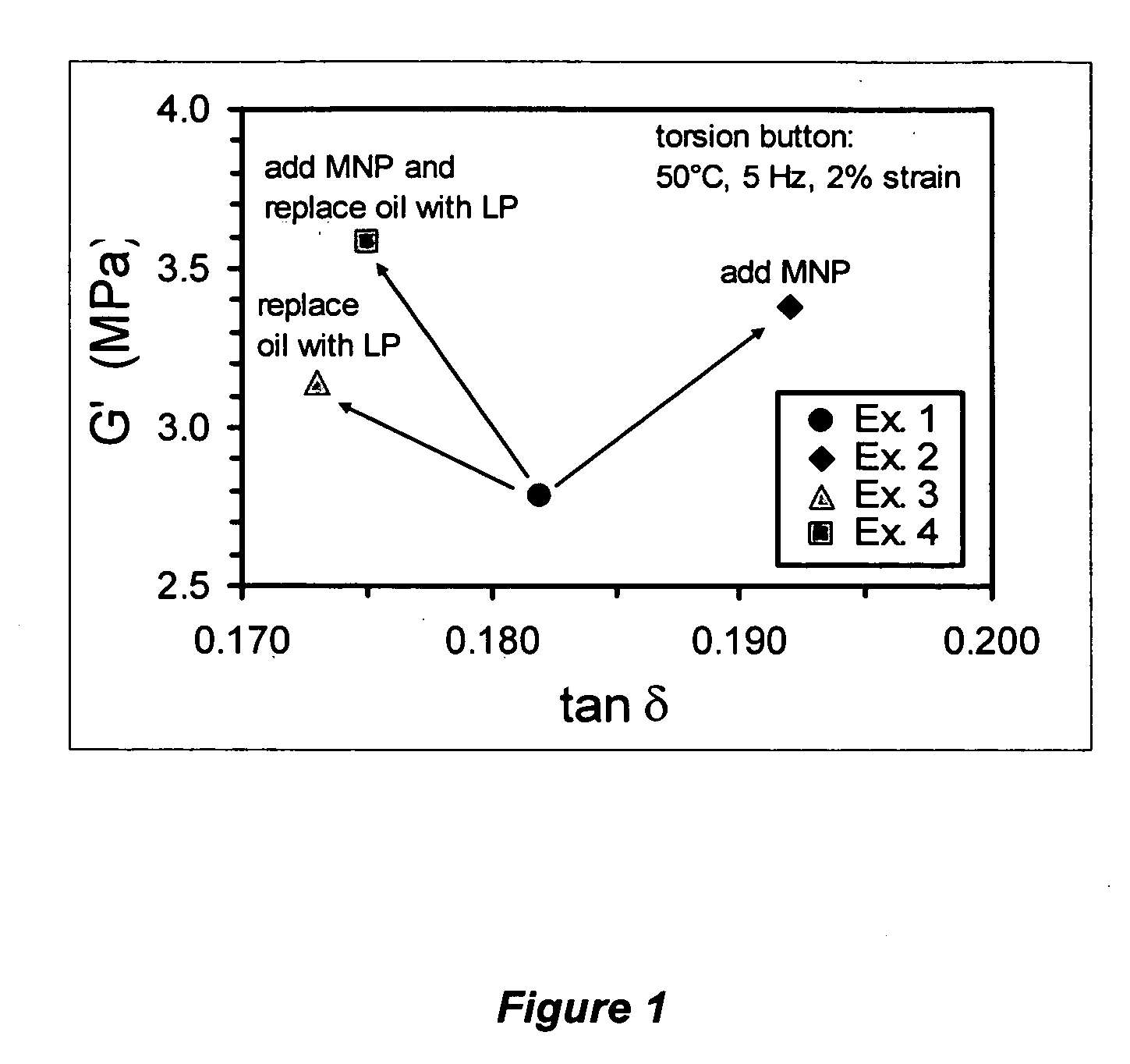

Combined use of liquid polymer and polymeric nanoparticles for rubber applications

The present invention provides a rubber composition comprising (a) a liquid polymer, (b) polymer nanoparticles, and (c) a rubbery matrix. The composition may comprise less or even no aromatic oil. Rubber articles manufactured from such composition, such as tires and power belts, have gained improved reinforcement and controllable hysteresis properties.

Owner:BRIDGESTONE CORP

Ionically conductive polymer electrolytes

InactiveUS20030091904A1Good flexibilityLower resistanceElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

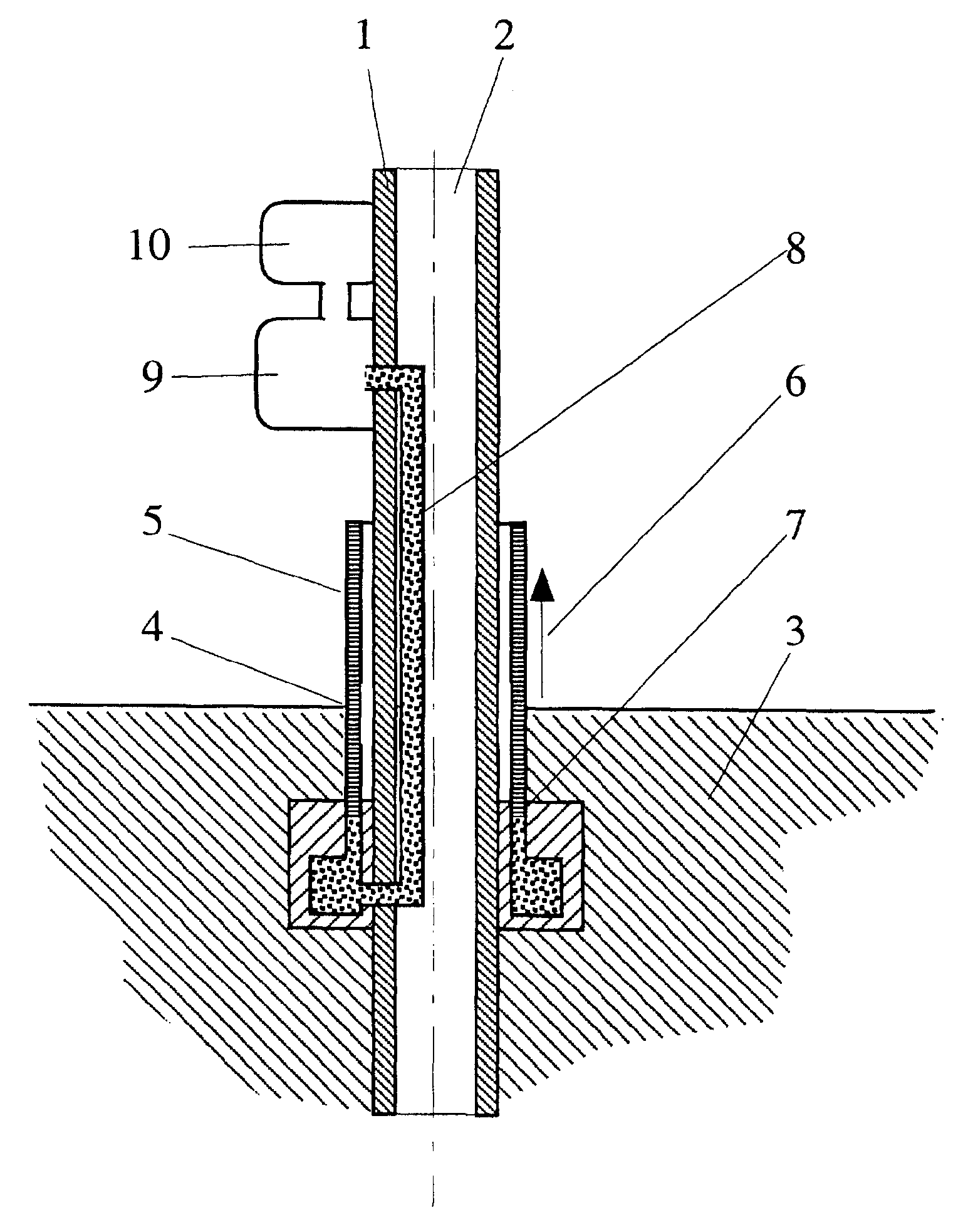

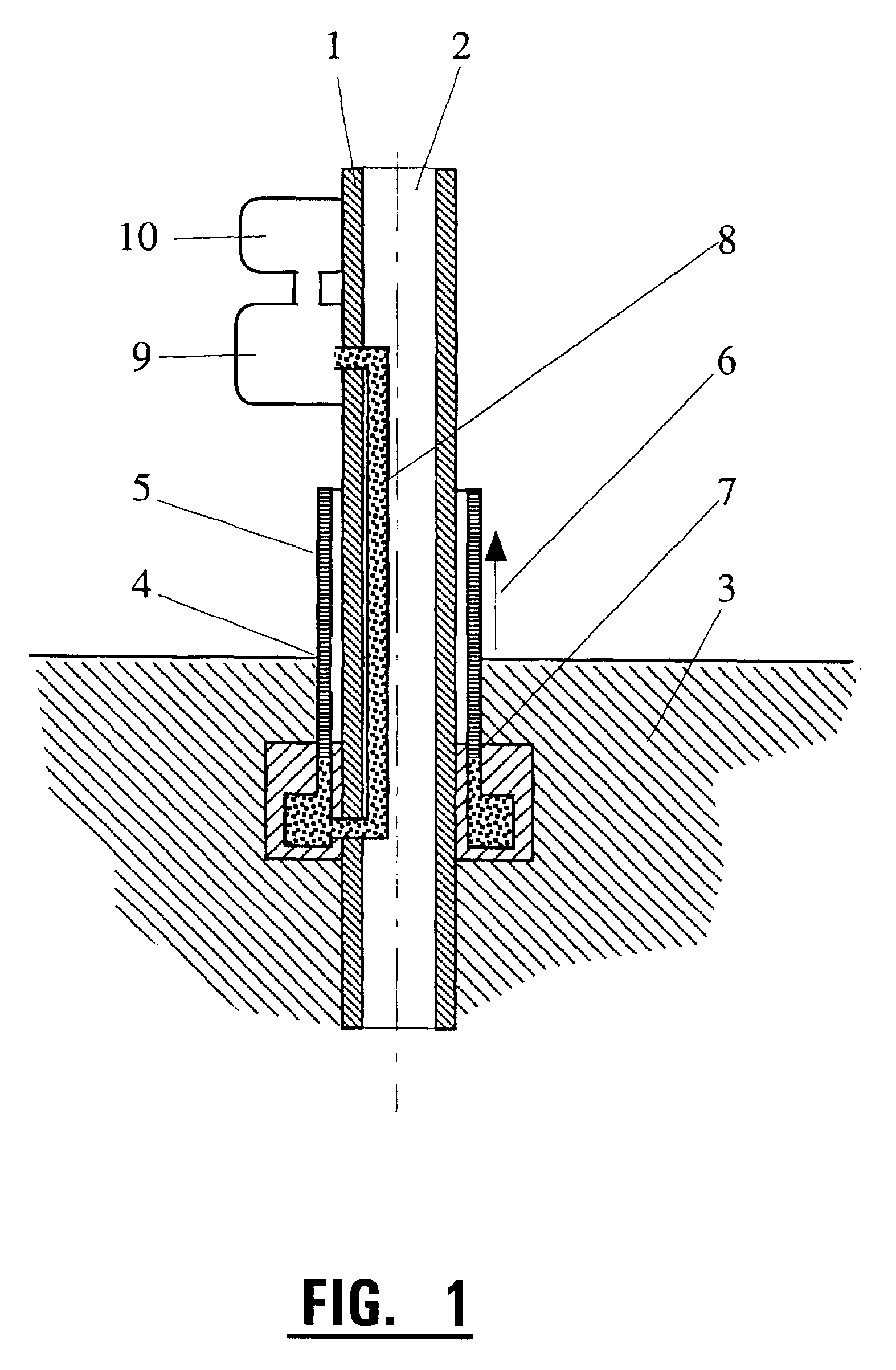

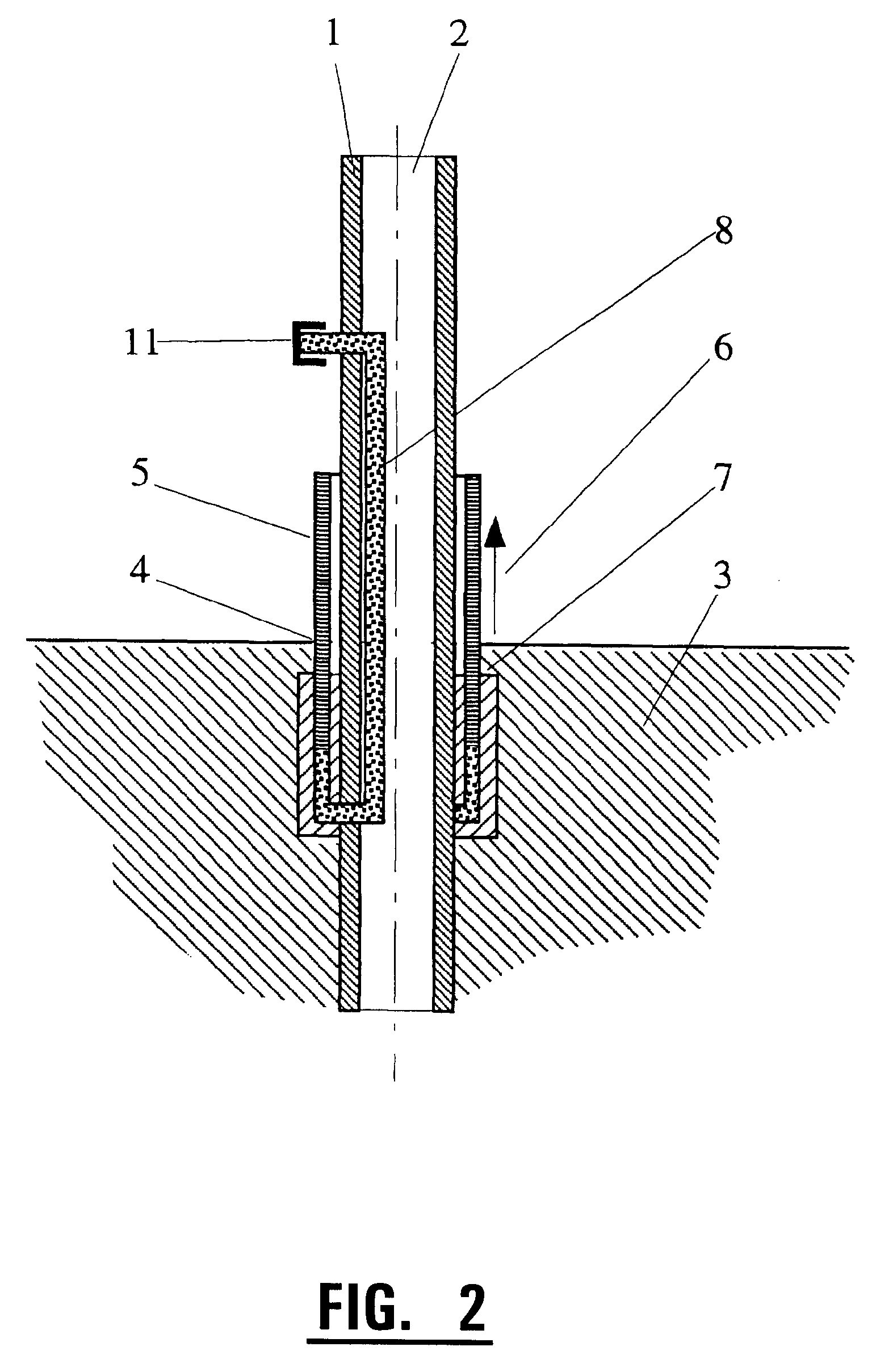

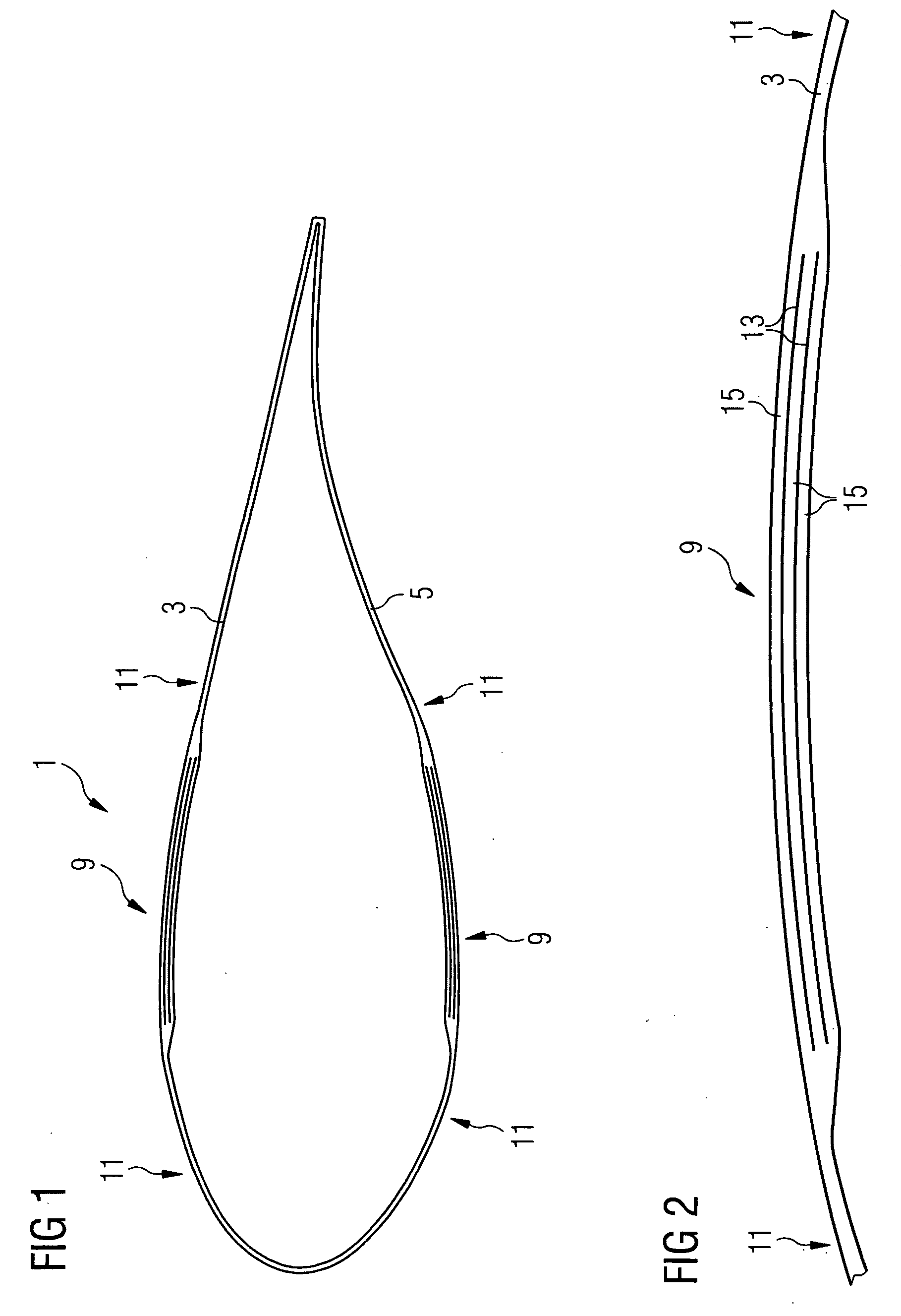

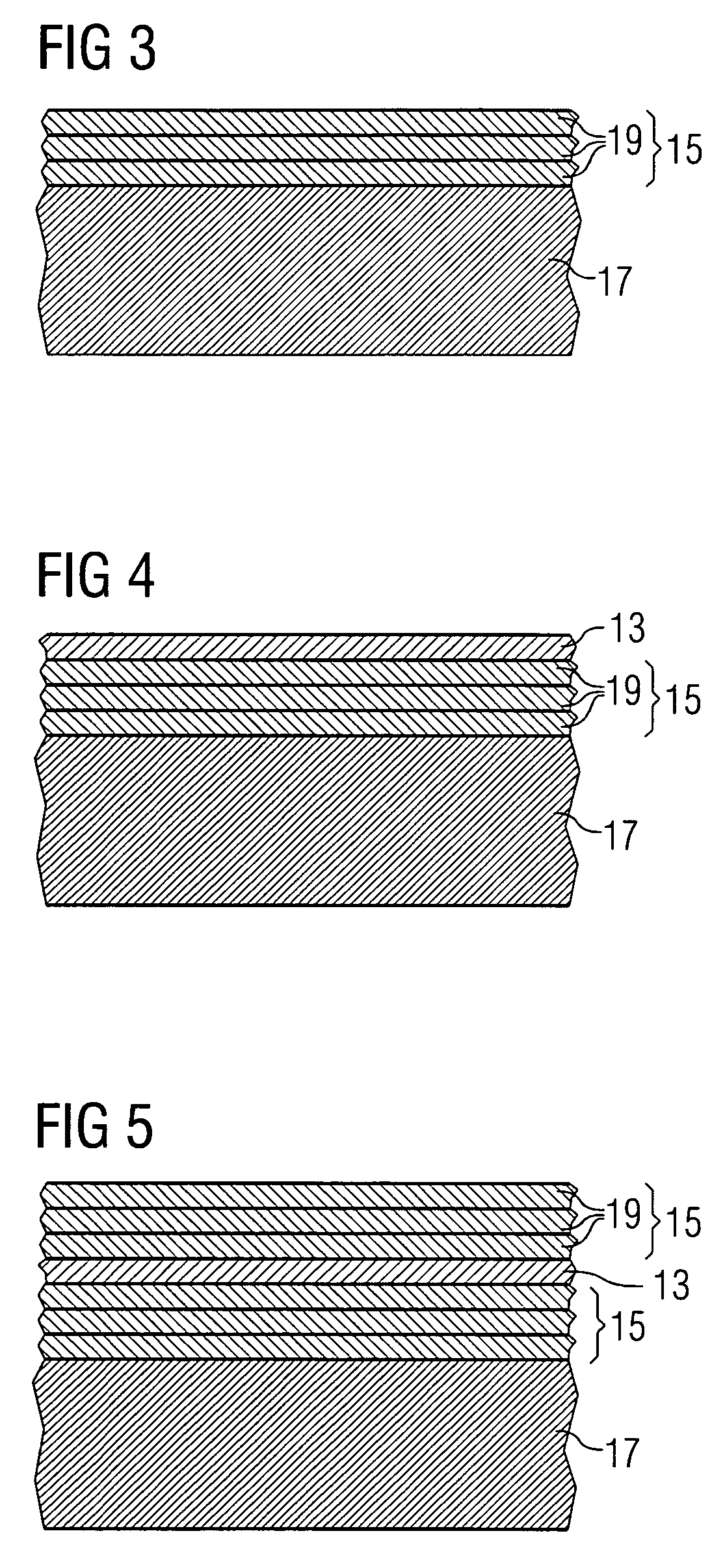

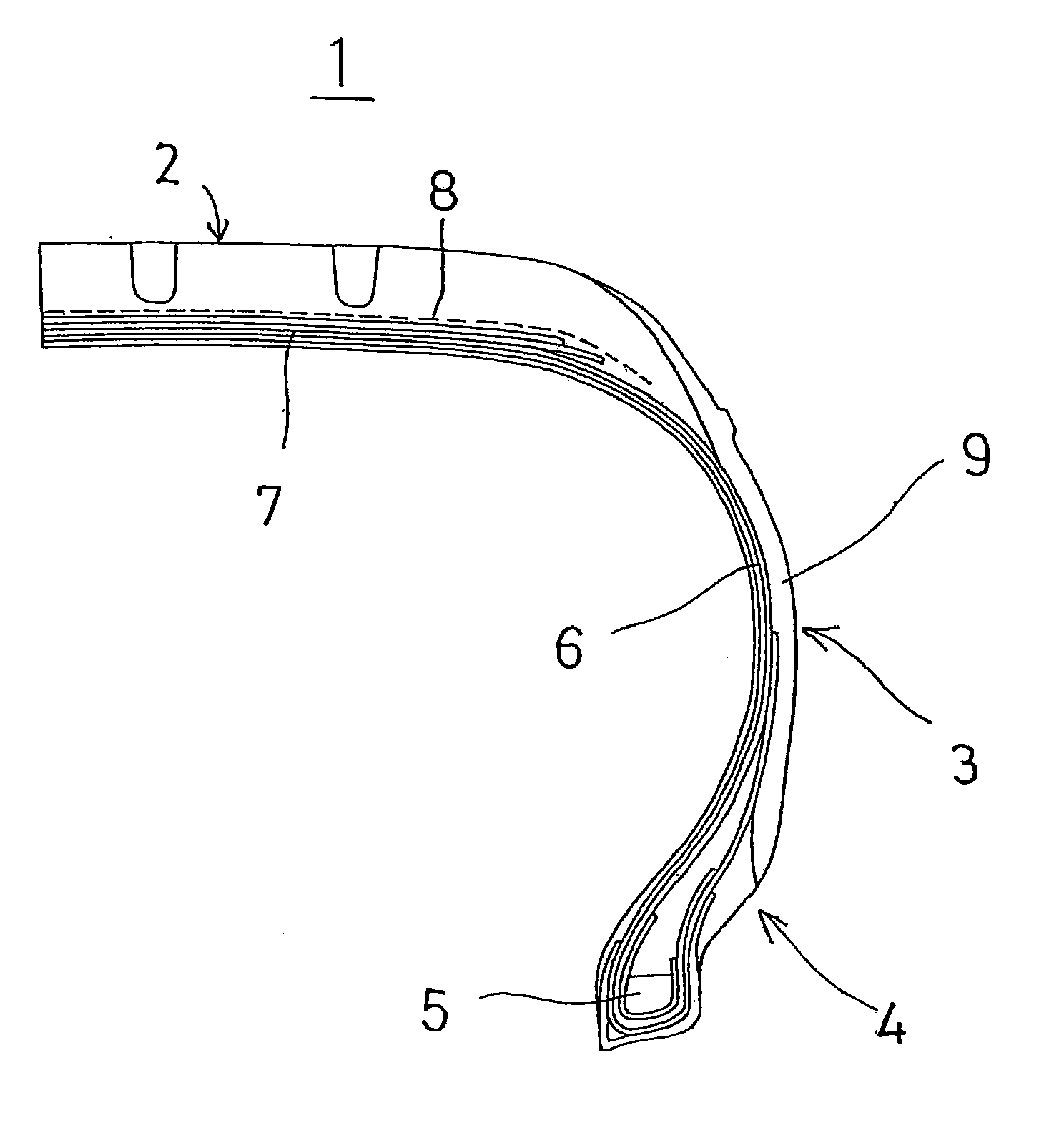

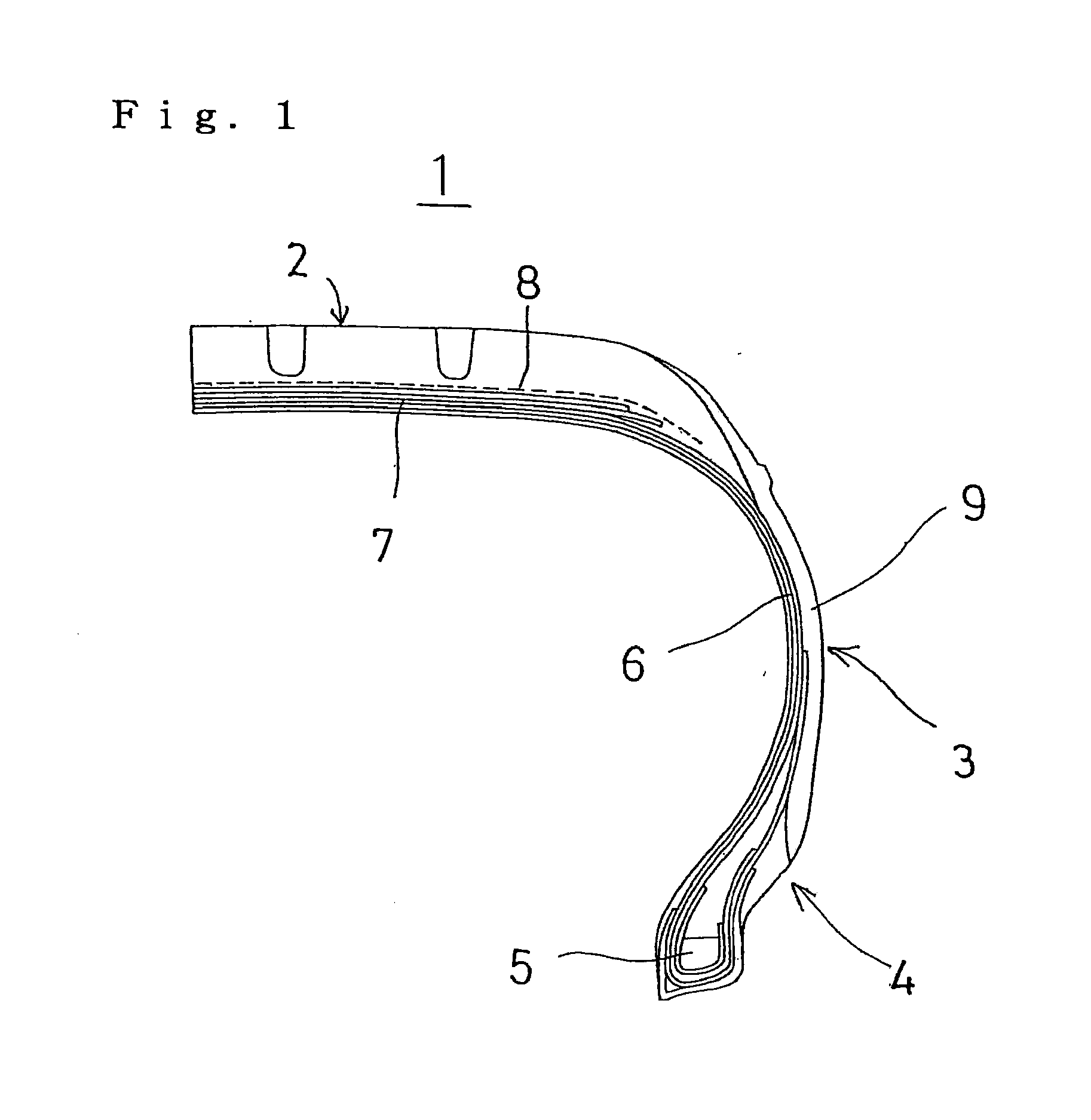

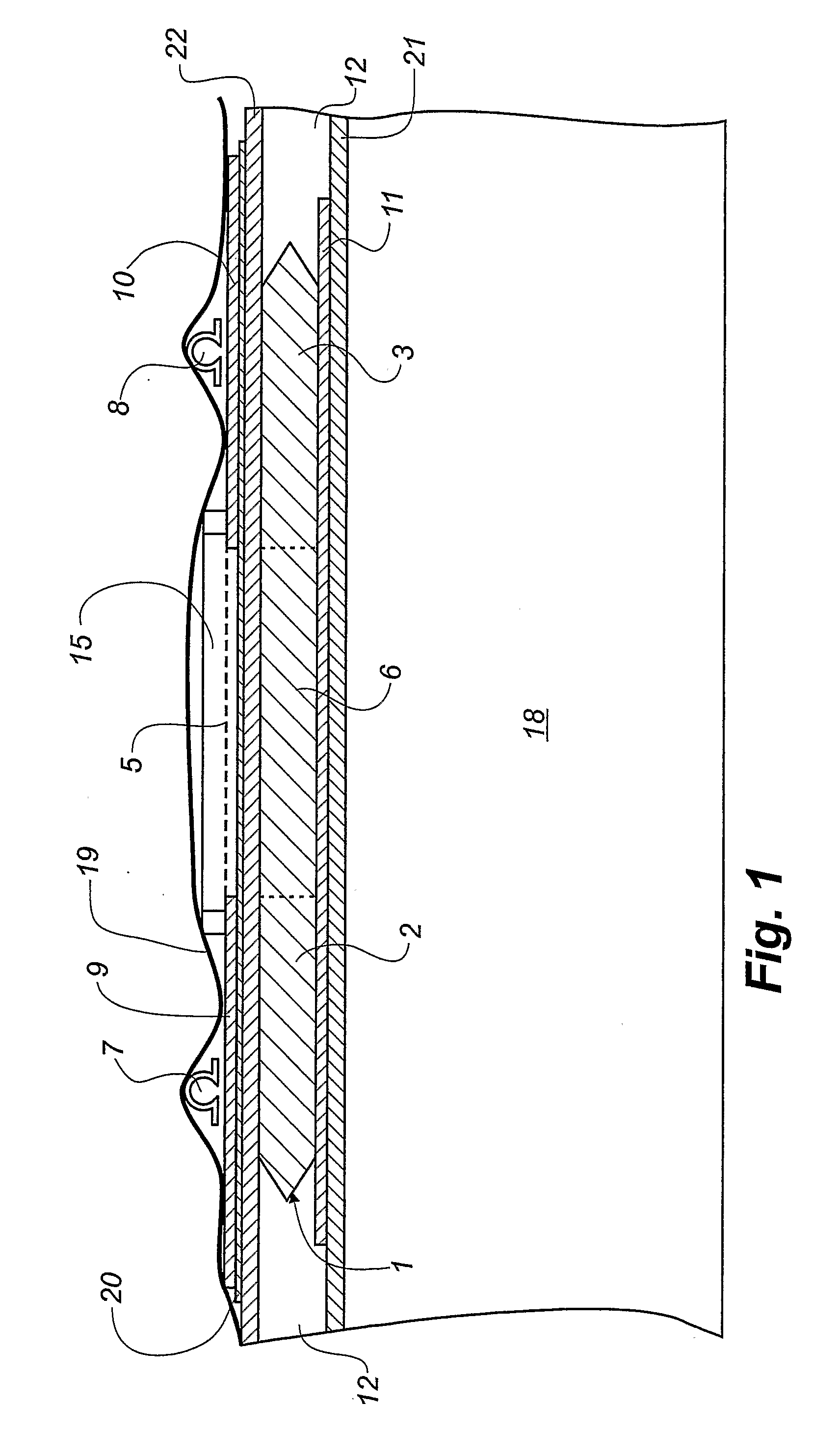

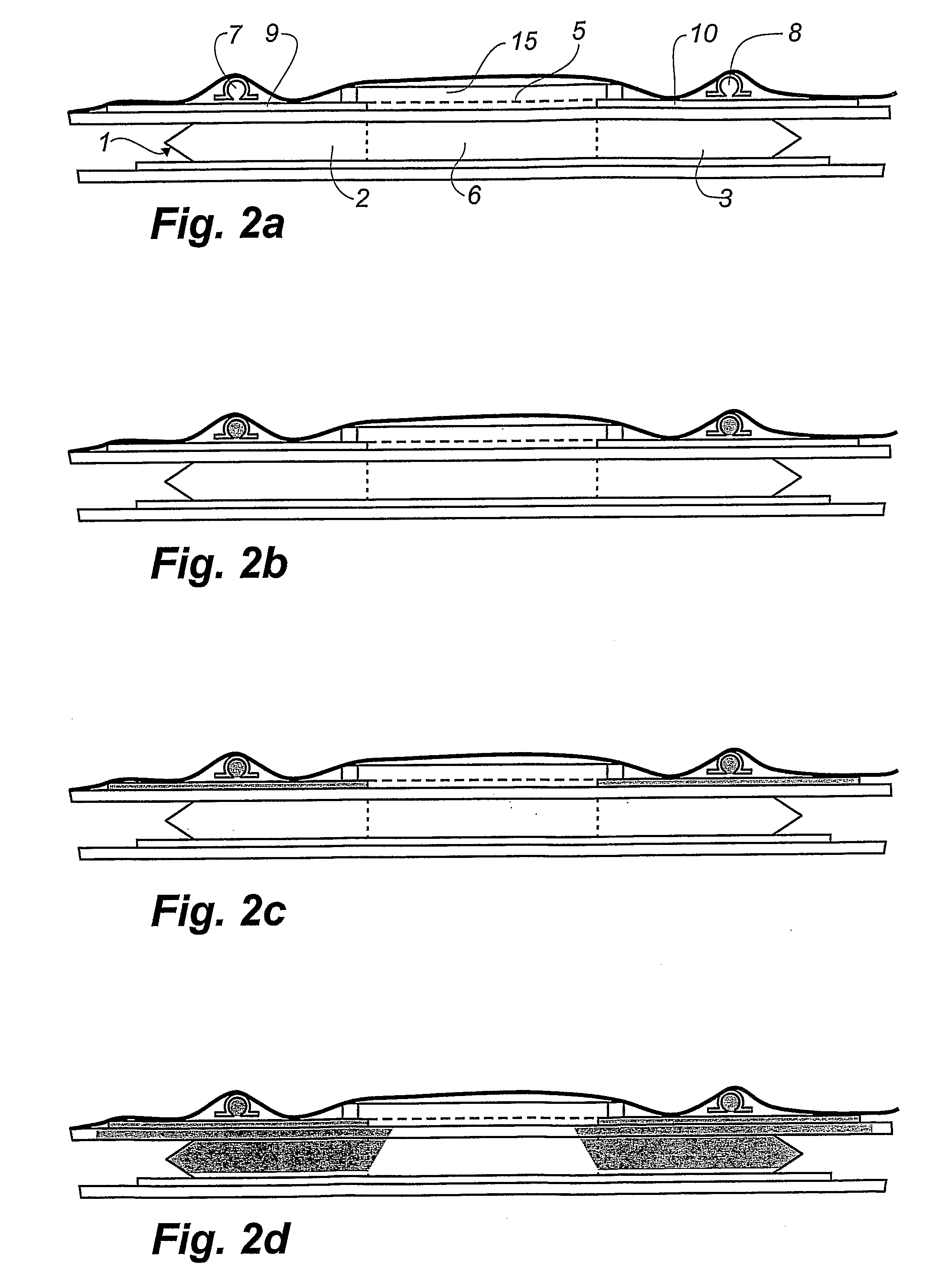

Apparatus and method for generation of a protective sleeve against infections for an artificial lead

An apparatus and method for generation of a protective sleeve against infections for a percutaneous lead through human or animal skin. The percutaneous lead (1) includes an extrusion port (7). When the lead extends through a body (3) of a patient, a pump (9) in operative connection with the lead is operative to move biocompatible liquid polymer material from a reservoir (10) through the extrusion port. As the polymer material comes in contact with body tissues of the patient it forms a protective sleeve against infections (5). The protective sleeve must be periodically clipped as it continuously or intermittently grows in an upward direction (6) outside of the body. The continual formation of the protective sleeve prevents the formation of a biofilm on the percutaneous lead that can cause the body tissue to separate from the percutaneous lead.

Owner:BIOCONCEPT

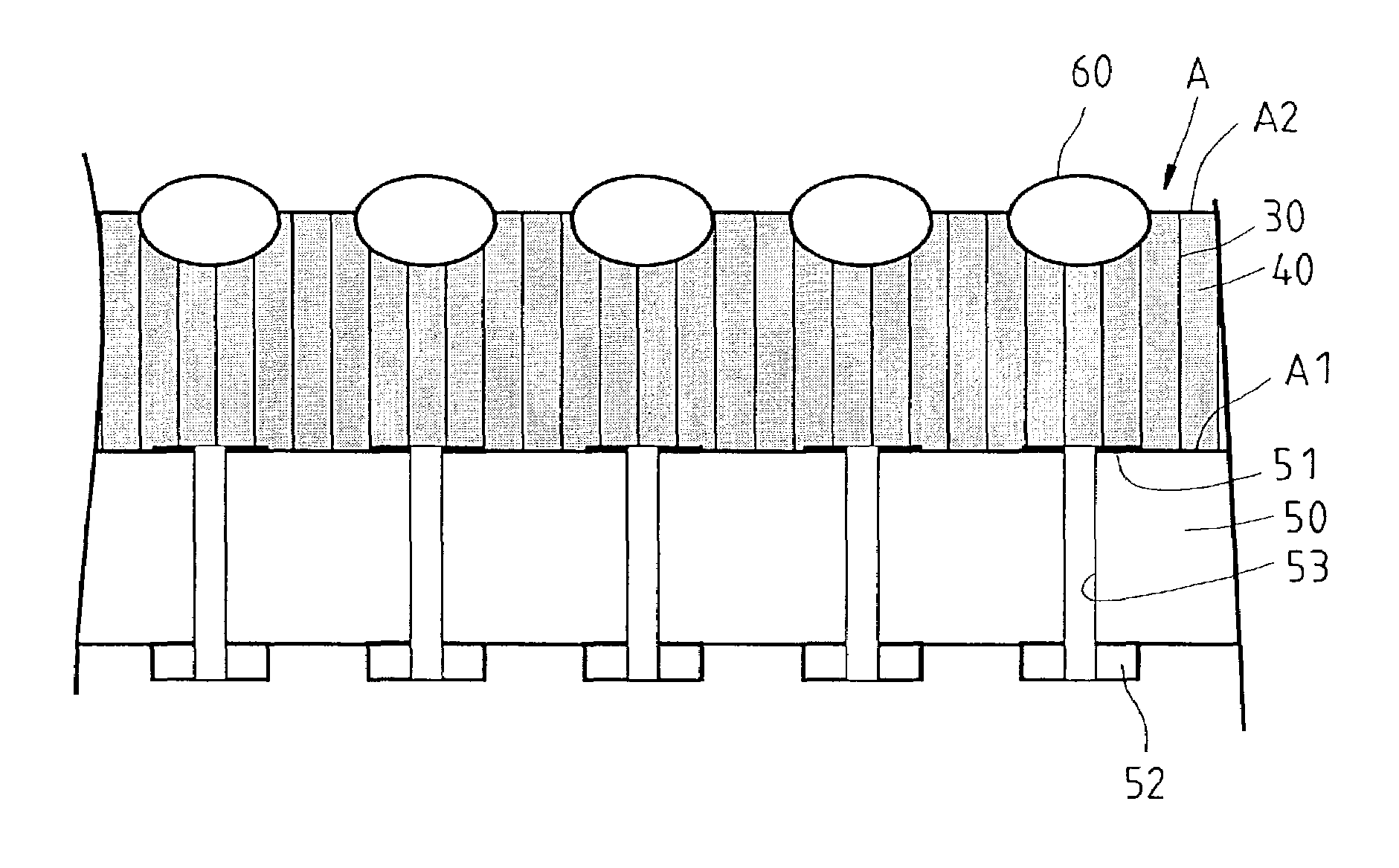

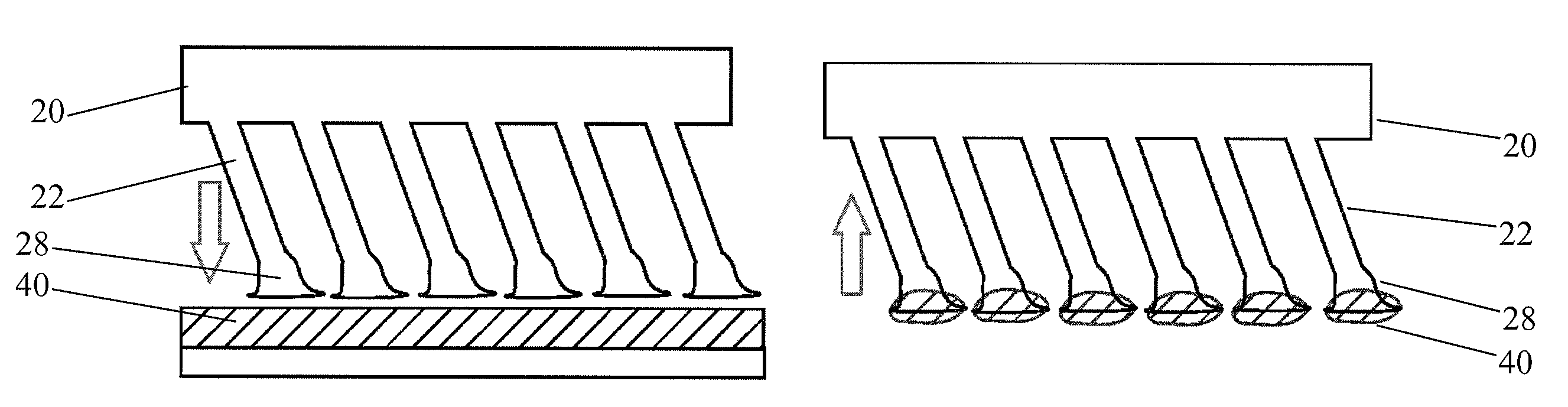

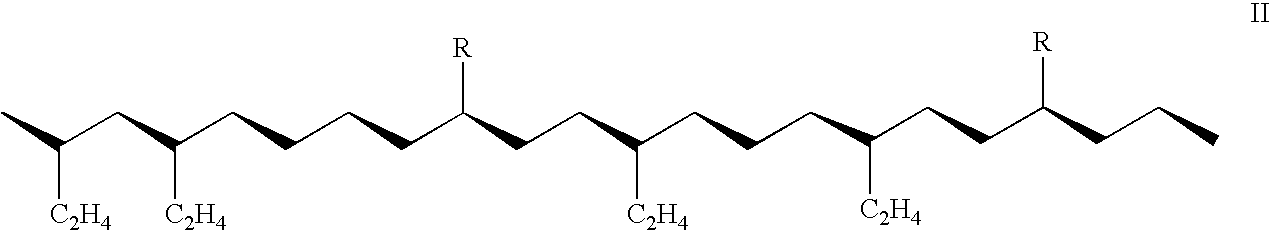

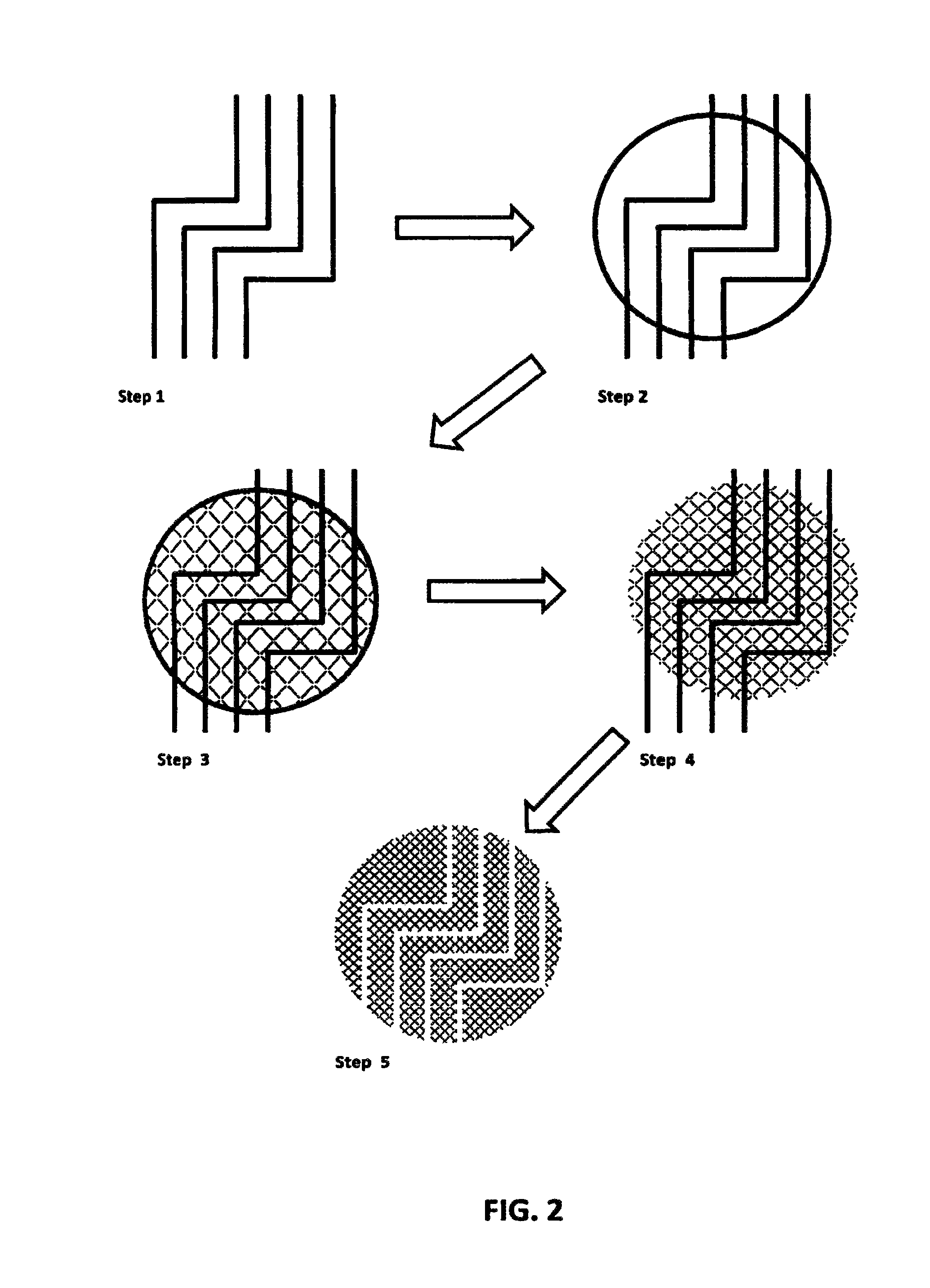

Methods of making dry adhesives

ActiveUS8206631B1Increase contact areaIncrease in interfacial resistanceMaterial nanotechnologyLiquid surface applicatorsAdhesivePolymer chemistry

Dry adhesives and methods of making dry adhesives including a method of making a dry adhesive including applying a liquid polymer to the second end of the stem, molding the liquid polymer on the stem in a mold, wherein the mold includes a recess having a cross-sectional area that is less than a cross-sectional area of the second end of the stem, curing the liquid polymer in the mold to form a tip at the second end of the stem, wherein the tip includes a second layer stem; corresponding to the recess in the mold, and removing the tip from the mold after the liquid polymer cures.

Owner:CARNEGIE MELLON UNIV

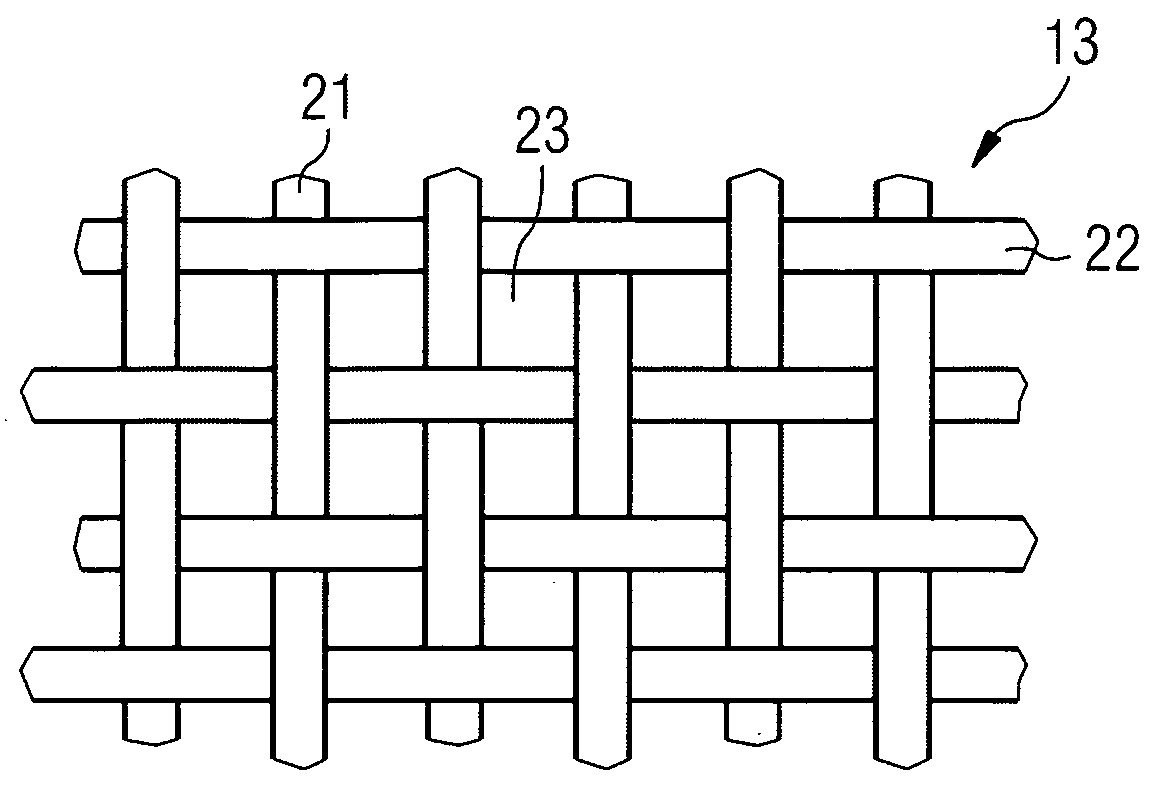

Method for producing fibre reinforced laminated structures

InactiveUS20080277053A1Fully moistenedReduce riskFinal product manufactureDomestic articlesLiquid statePolymer chemistry

There is described a method of producing fibre reinforced laminated structures by layering a number of dry fibre reinforcement layers by placing them on top of each other in a mould, infusing a curable viscous or liquid polymer into the mould after the fibre reinforcement layers have been layered in the mould and curing the polymer, wherein a flow enhancing layer for enhancing the polymer flow during infusion of the polymer is placed between two fibre reinforcement layers when layering the number of dry fibre reinforcement layers and wherein a pre-cured solid layer is used as the flow enhancing layer.

Owner:SIEMENS AG

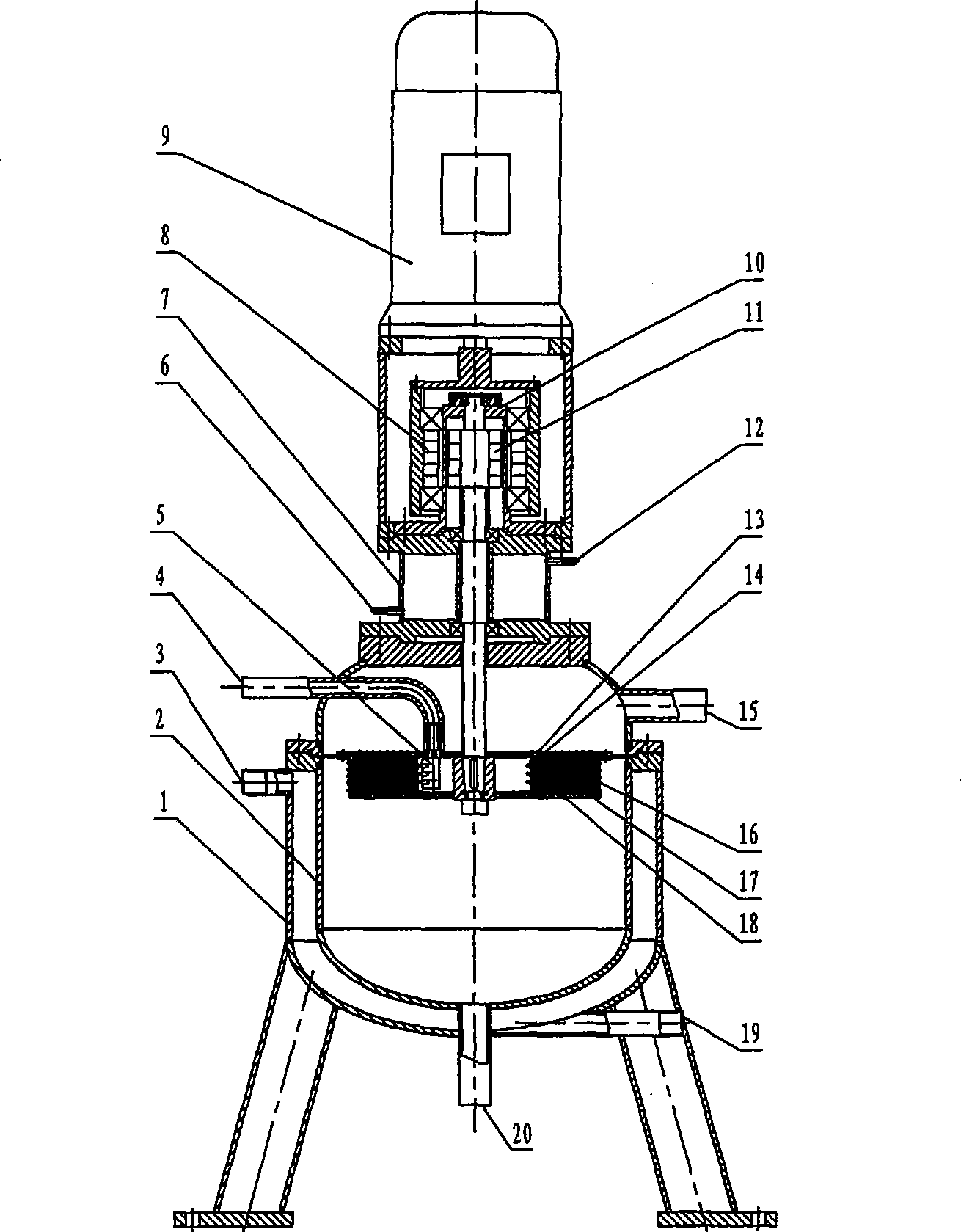

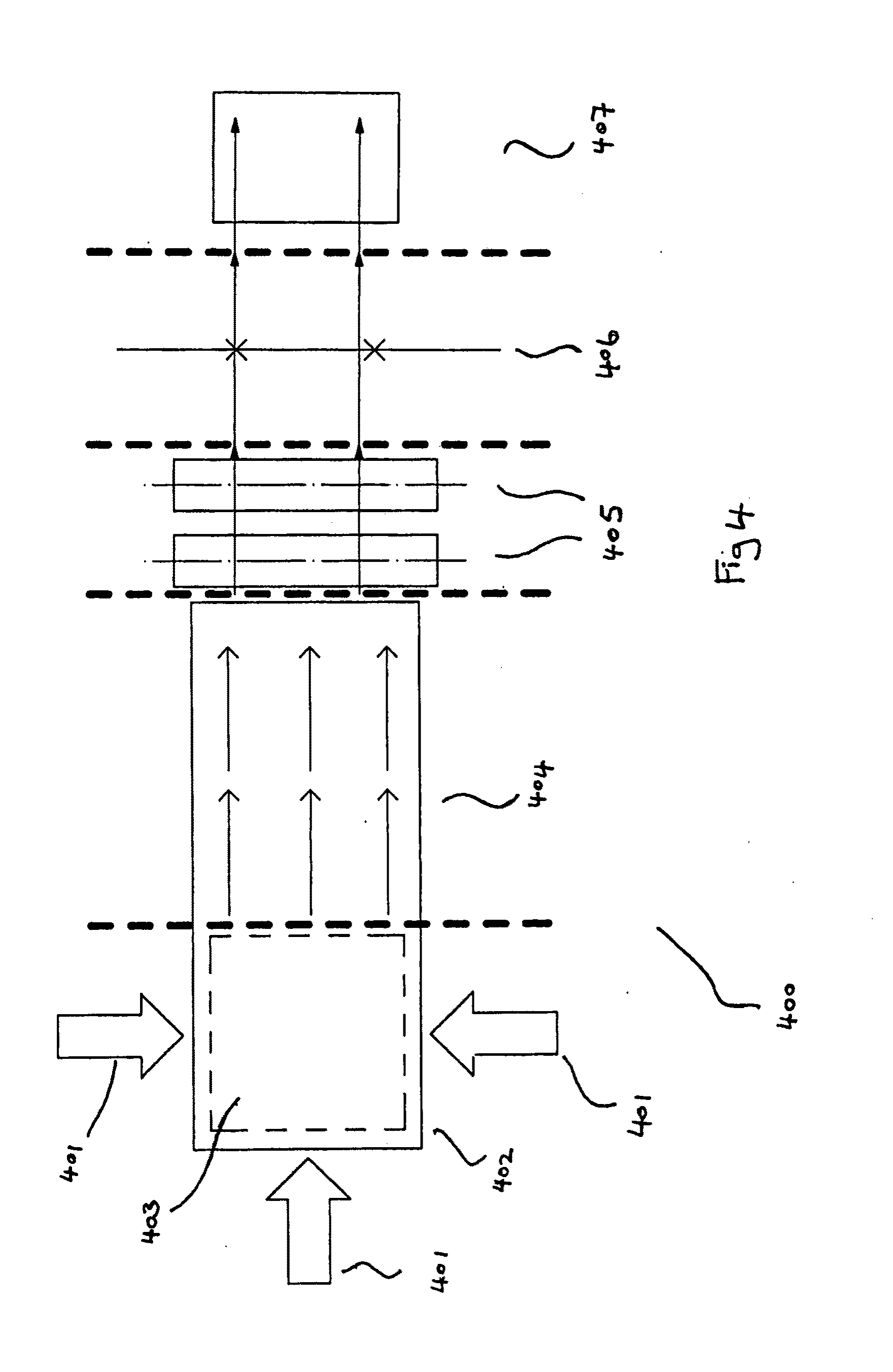

Method and apparatus for removing polymer volatile component

ActiveCN101372522AAchieve the purpose of devolatilizationSimple processLiquid degasificationDesorptionProduct gas

The invention provides a method for the desorption of volatile component in polymer and a device thereof; the device comprises a shell and a rotor which is filled with ring-shaped filler; a polymer feeding duct enters the filler from a material inlet of the shell, one end of a pipeline is provided with a material distributor which extends into a hollow cavity of the filler, and the distributor is provided with a plurality of outlets that are corresponding to a liquid receiving ring arranged at the inner side of the cavity of the filler along the direction of vertical height; the filler is concentric ring-shaped multilayer assembly sizing filler. Liquid polymer is transported into the hollow cavity of the filler to be evenly distributed in the hollow cavity of the filler in a layering way along the axial direction, the rotating speed of the rotor is adjusted to lead the supergravity level of the rotor to reach 30-1000g, and the liquid polymer flows through the filler from the cavity towards outside according to the customizing path of the sizing filler. In the supergravity environment, the invention doses not need to desorb gas by enforcing polymer fluid to flow through the filler according to the changing path of the sizing filler, strengthening the interface to update and producing local perturbation, thus simplifying the process and having high devolatilization rate.

Owner:BEIJING UNIV OF CHEM TECH

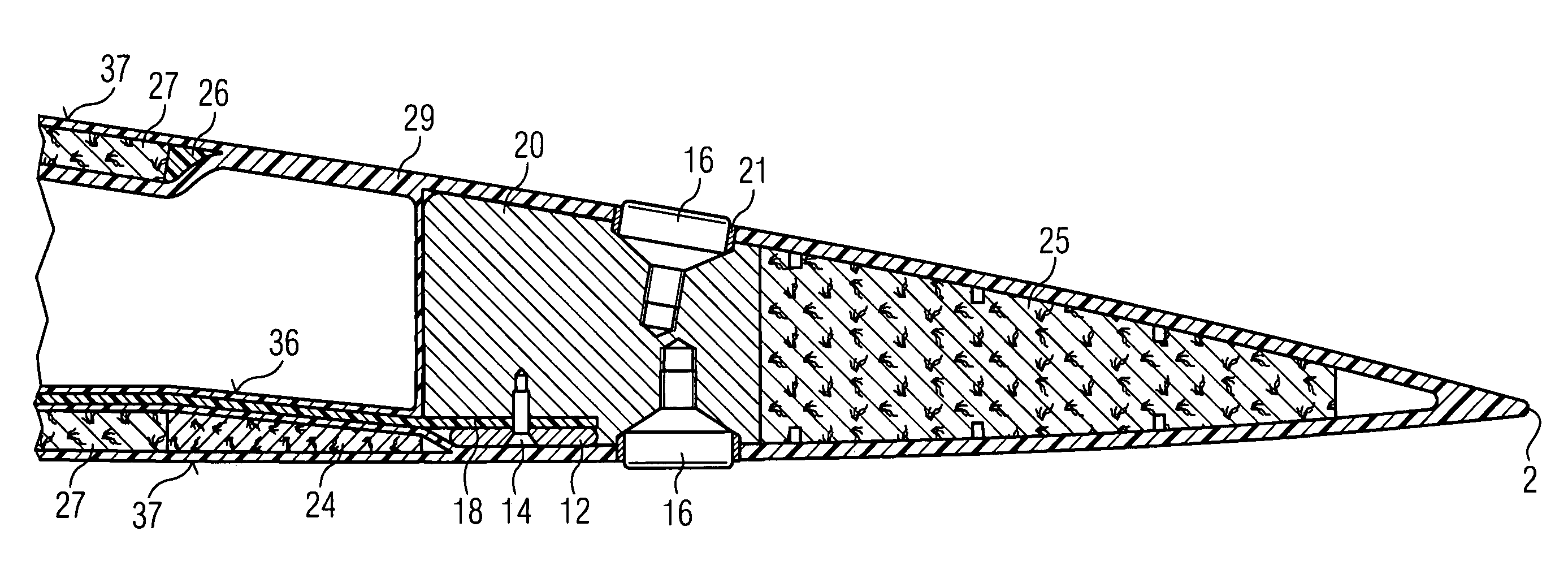

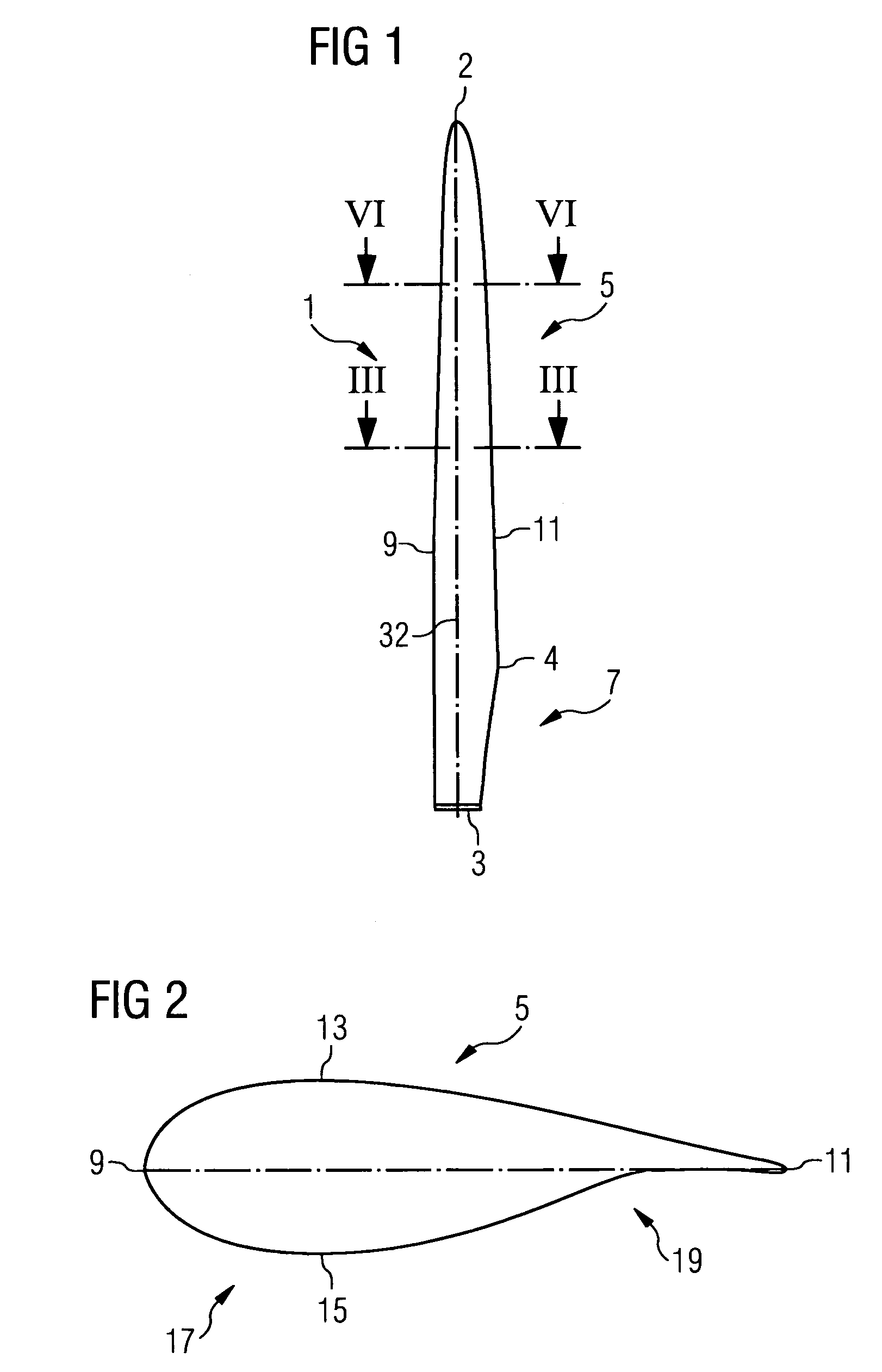

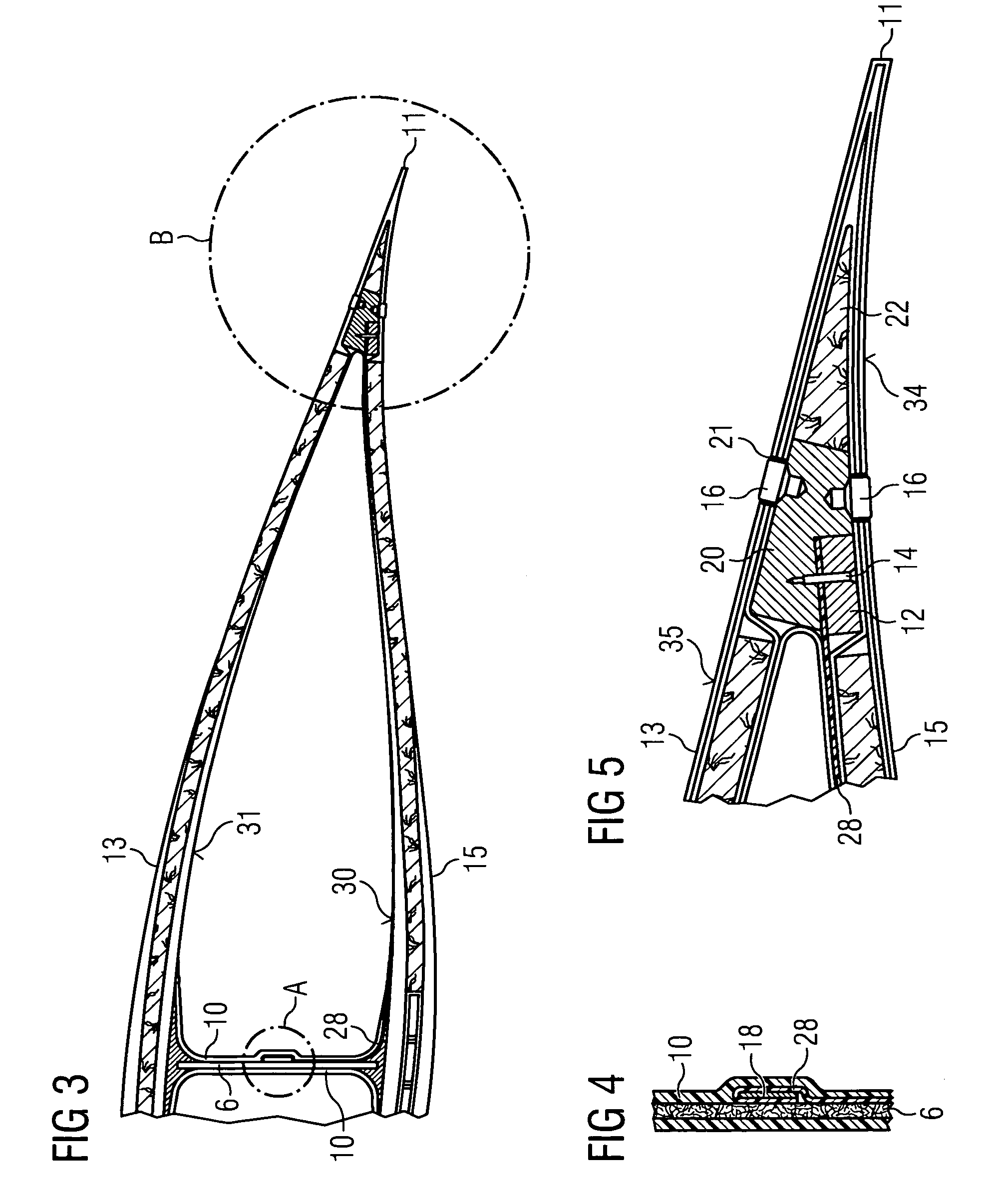

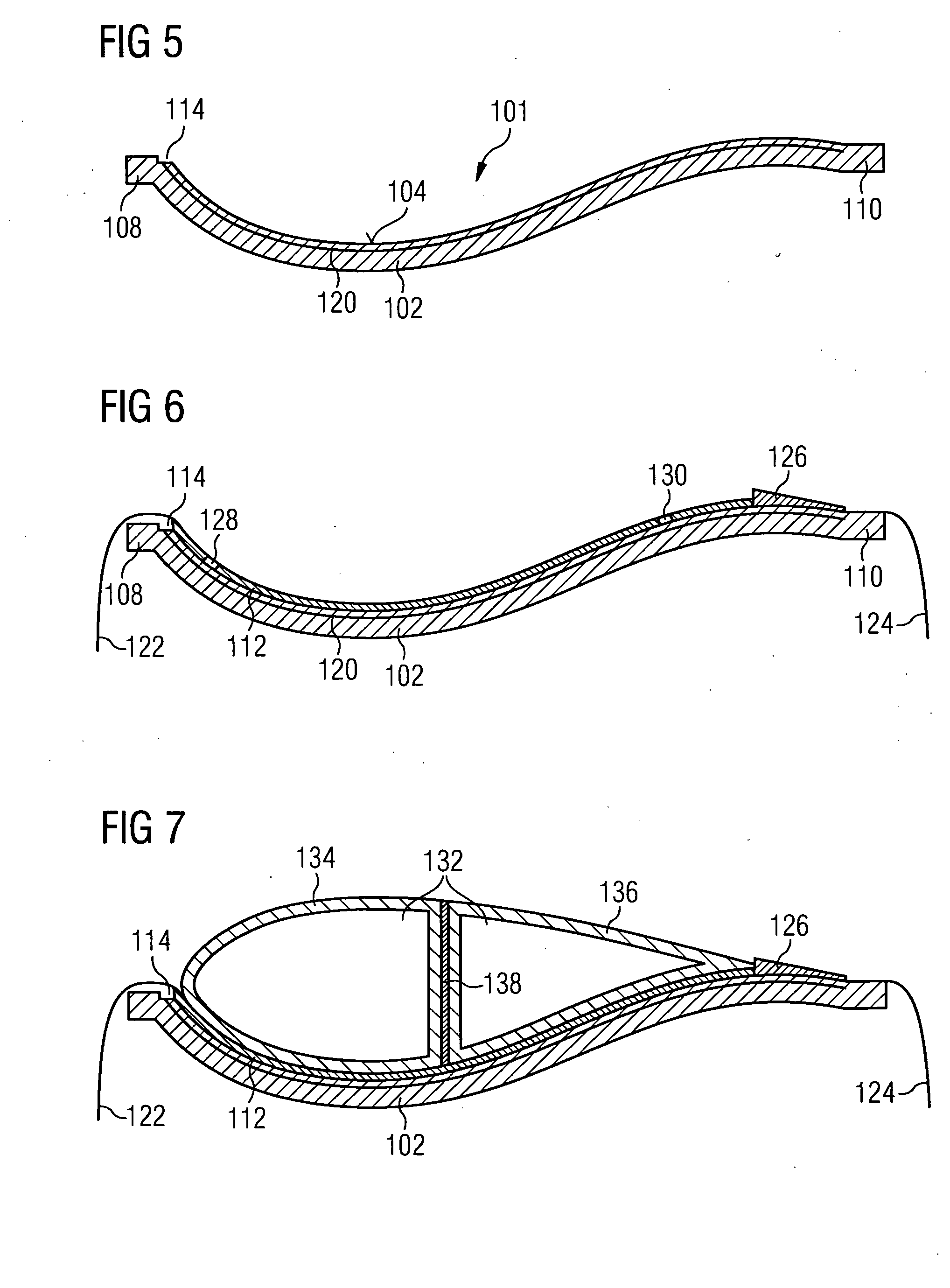

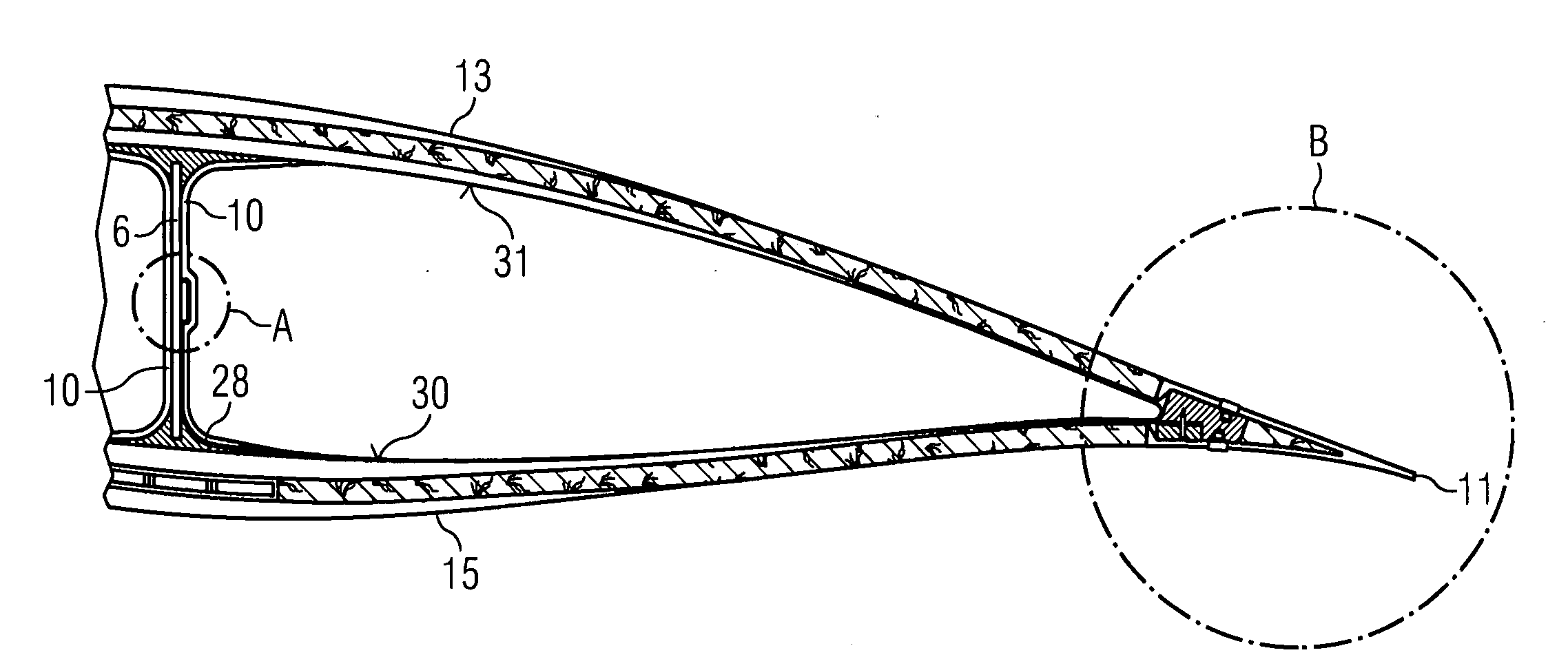

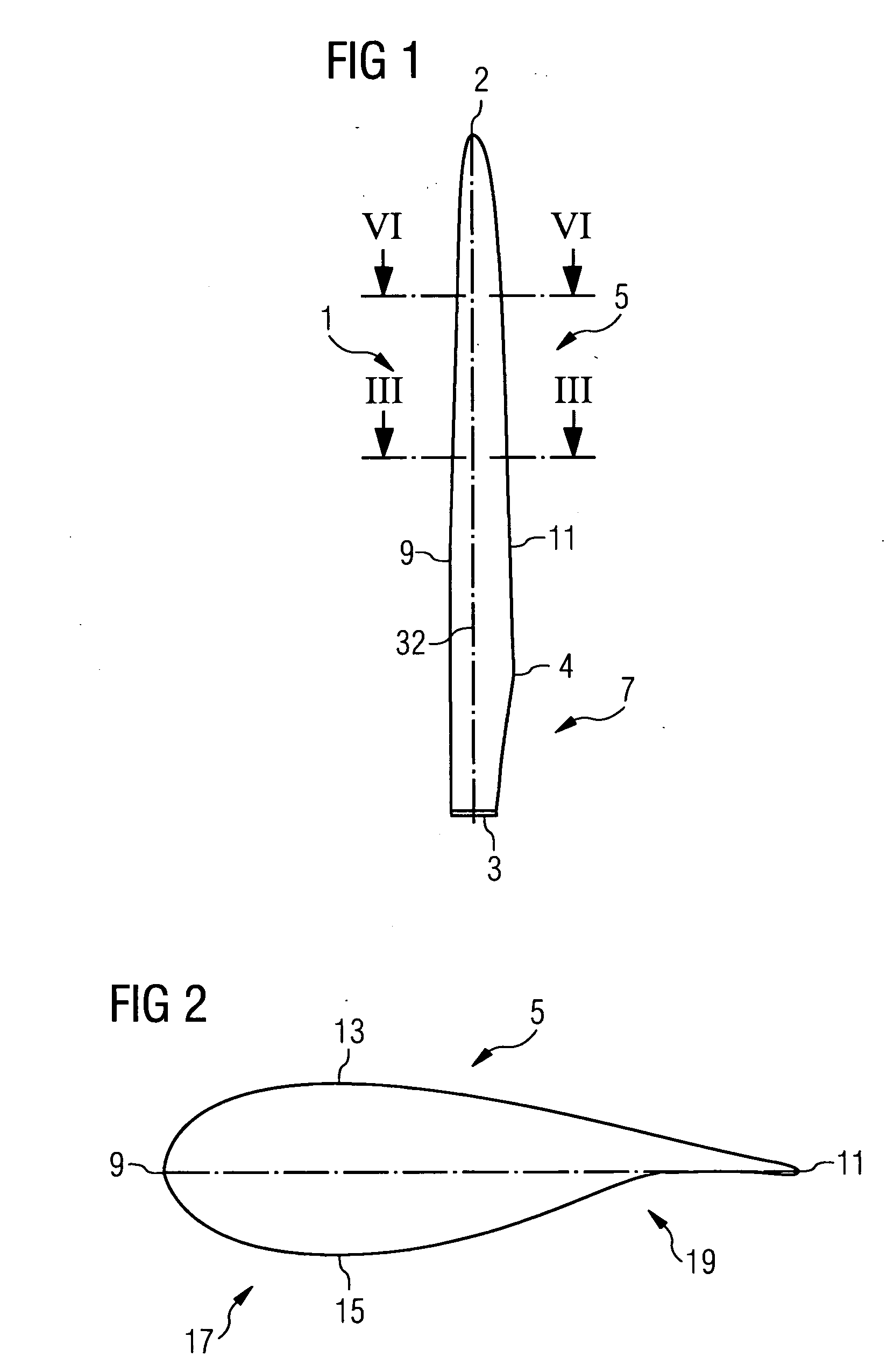

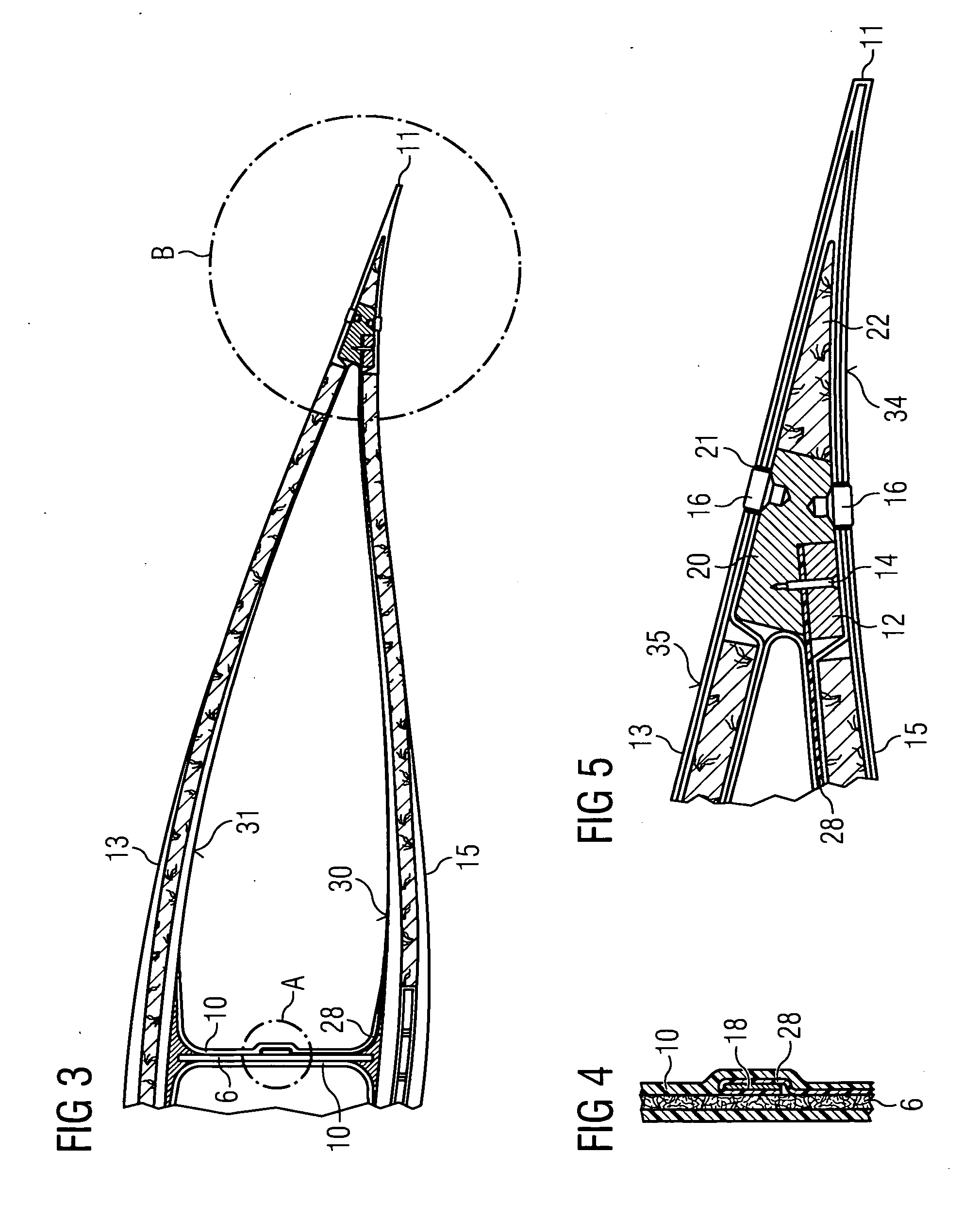

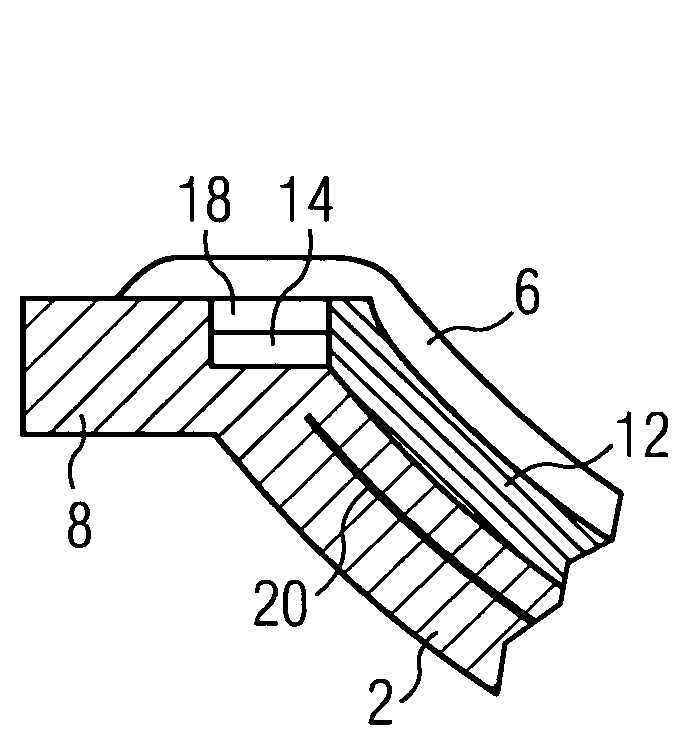

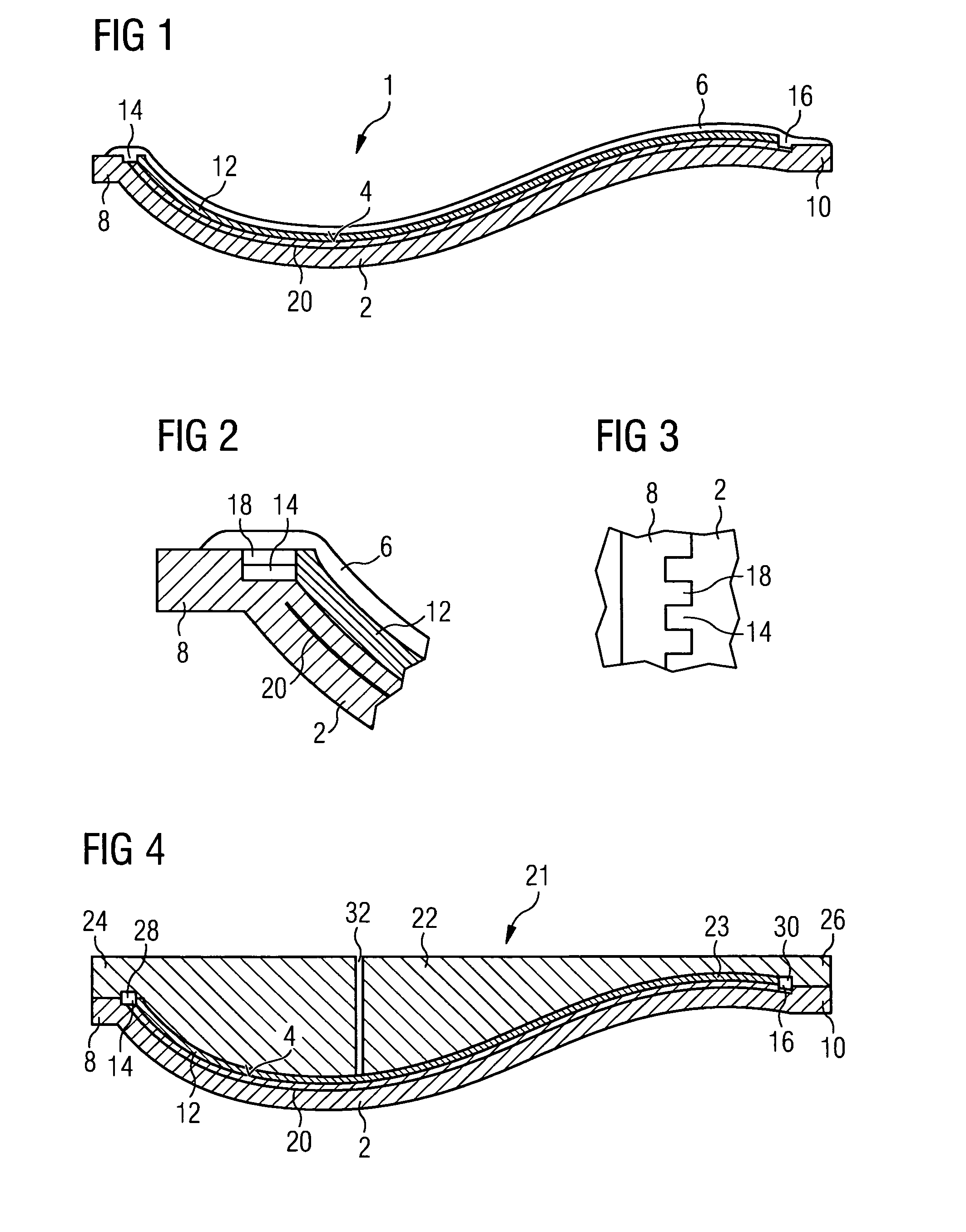

Method for manufacturing wind turbine blade with an integrated lightning conductor

ActiveUS8191255B2Optimally protected against corrosionLower self-esteemFinal product manufactureMachines/enginesElectrical conductorTurbine blade

A method is provided for manufacturing a wind turbine rotor blade in which the blade is formed as a laminated structure by laying a composite material of fiber reinforcement material and / or core material in a mold defining the shape of the blade; evacuating the mold after laying the composite material; introducing a liquid polymer into the evacuated mold and wetting the composite material; curing the liquid polymer after the composite material has been wetted; and removing the mold after curing the liquid. At least one lightning conductor is integrated into the composite material before wetting it with the liquid polymer. Moreover, a wind turbine rotor blade made from a single laminated structure is provided with at least one lightning conductor is integrated into the laminated structure.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Apparatus and method for lining large diameter pipe with an environmentally compatible impervious membrane

Owner:QUEST INSPAR

Synthetic lubricant composition and process

ActiveUS7022784B2Hydrocarbon by isomerisationHydrocarbon by hydrogenationPolymer scienceAlpha-olefin

A liquid polymer suitable for use as a lubricant base oil is produced by polymerizing ethylene and at least one alpha-olefin using a metallocene catalyst to provide a polymer which is then isomerized and hydrogenated to produce the liquid polymer.

Owner:EXXON RES & ENG CO

Anti-blowby cement slurry

InactiveCN102492404ABlocking channelingSmall brittleness coefficientDrilling compositionPolymer adhesiveWell cementing

The invention relates to anti-blowby cement slurry, and relates to the technical field of cement slurry. The anti-blowby cement slurry consists of the following components in percentage by mass: 90 to 95 percent of cement matrix, 1 to 8 percent of polymer rubber latex powder, 0.1 to 0.7 percent of drag reducer, 0.3 to 3.5 percent of filtration-reducing agent, 0.1 to 1.5 percent of cement defoaming agent and 0.05 to 3.5 percent of thickening time control agent. The anti-blowby cement slurry is a single-component system; and due to the adoption of the rubber latex powder, the brittleness coefficients and elastic modulus of cement are reduced, the well cementation quality can be improved effectively, the fluid channeling can be prevented, and the problem generated when liquid polymer rubber latex is used is solved; and the anti-blowby cement slurry is stirred only by adding water at a construction site, and is convenient to prepare, store, transport and use, so the construction process is simplified, the cost is reduced, and the anti-blowby cement slurry has a bright application prospect.

Owner:JIAHUA SPECIAL CEMENT

Methods of forming dry adhesive structures

ActiveUS20120319320A1Inexpensive to fabricateHigh yieldMaterial nanotechnologyLiquid surface applicatorsAdhesivePolymer chemistry

Methods of forming dry adhesives including a method of making a dry adhesive including applying a liquid polymer to the second end of the stem, molding the liquid polymer on the stem in a mold, wherein the mold includes a recess having a cross-sectional area that is less than a cross-sectional area of the second end of the stem, curing the liquid polymer in the mold to form a tip at the second end of the stem, wherein the tip includes a second layer stem; corresponding to the recess in the mold, and removing the tip from the mold after the liquid polymer cures.

Owner:CARNEGIE MELLON UNIV

Mould and method for vacuum assisted resin transfer moulding

ActiveUS20090250847A1Reduce complexityLow costFinal product manufactureConfectioneryVacuum assistedShell molding

A mould and method for vacuum assisted resin transfer moulding of a fibre reinforced laminated structure are provided. The mould includes a first mould part and a second mould part. The first mould part defines a negative impression of the laminated structure, being structurally stable and forming a support for fibre reinforcement layers of the laminated structure. The second mould part connectable to the first mould part for closing the mould and defines together with the first mould part an enclosed space which can be evacuated. The mould further includes a flow duct for guiding a liquid polymer which is formed as a recess in the first mould part and / or a recess in the second mould part that is open towards the enclosed space and extends along a section of the periphery of the first mould part and / or the second mould part.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Bone replacement materials utilizing bioabsorbable liquid polymers

The present invention is directed to bone replacement devices and compositions containing a synthetic, bioabsorbable, biocompatible liquid polymer that is the reaction product of a polybasic acid or derivative thereof, a polyol and a fatty acid, the liquid polymer having a melting point less than about 40° C., as determined by differential scanning calorimetry.

Owner:ETHICON INC

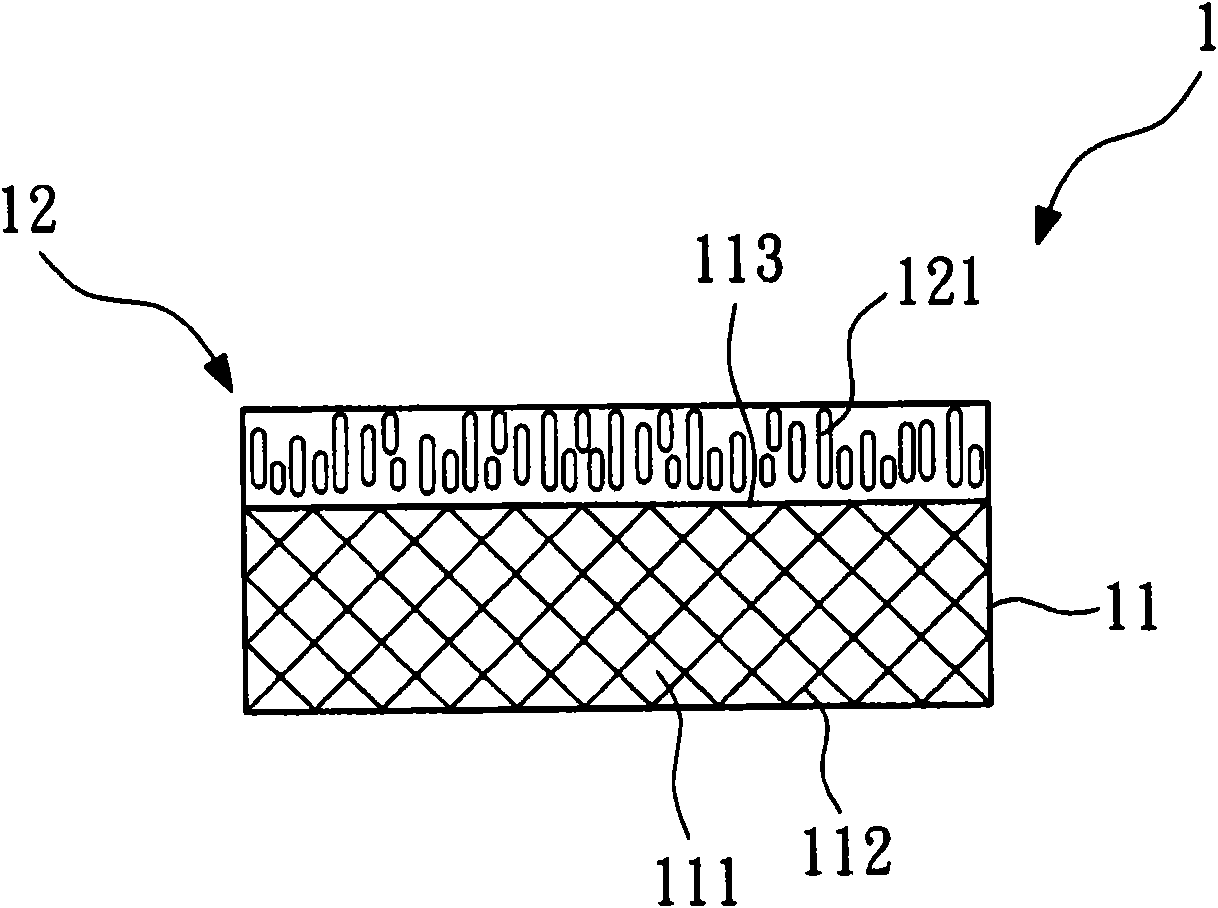

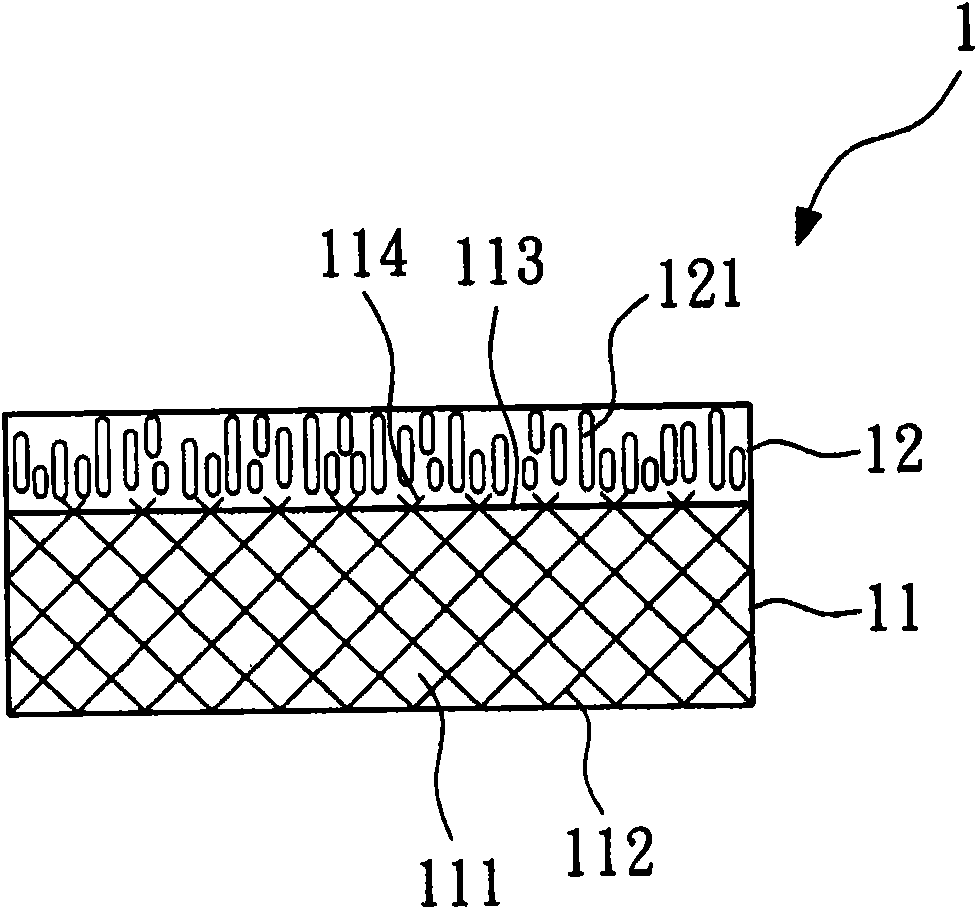

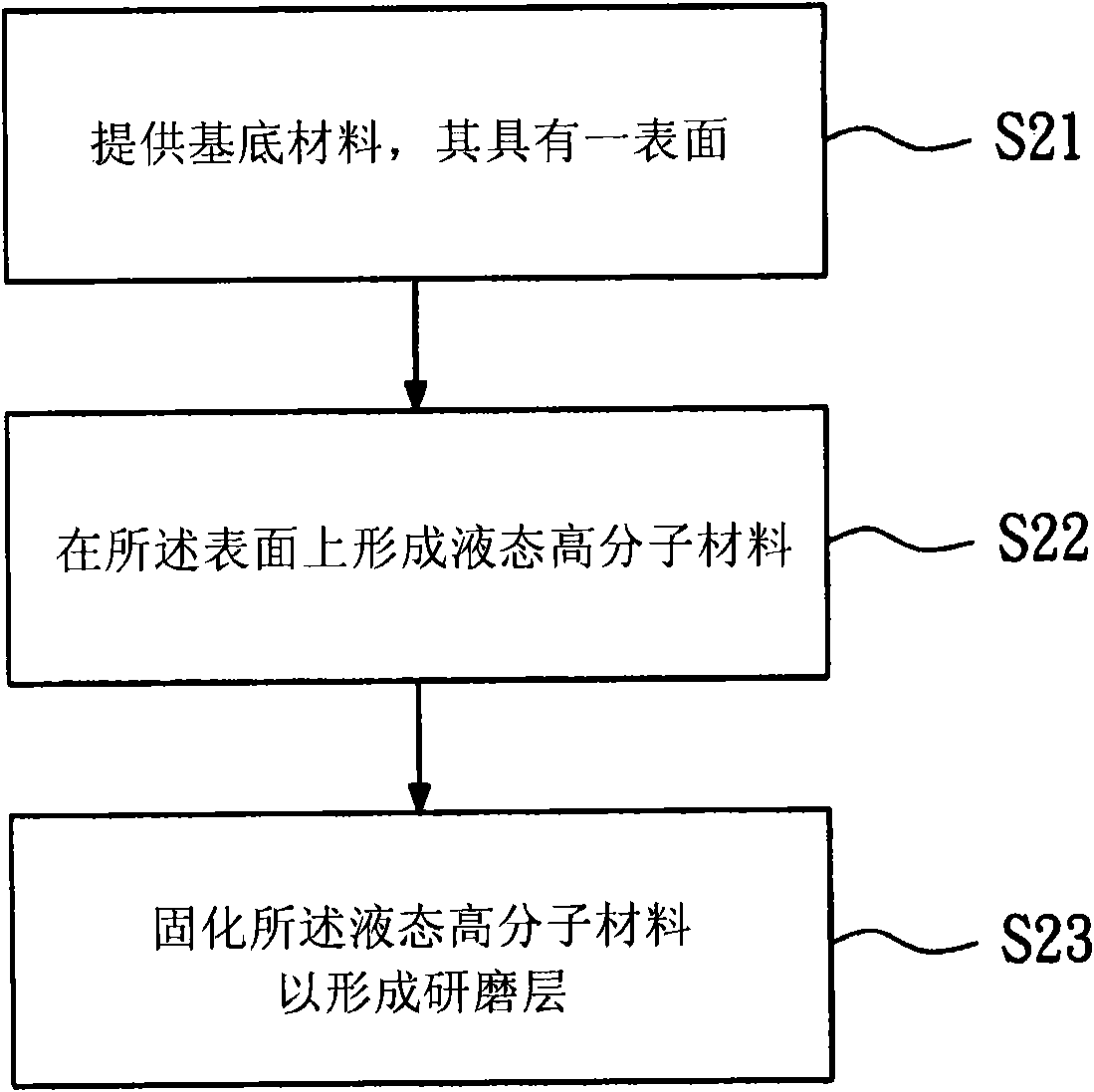

Polishing pad and manufacturing method thereof

InactiveCN101612722AIncrease the compression ratioContaining ability is goodAbrasion apparatusMetallurgyMolecular materials

The invention relates to a polishing pad and a manufacturing method thereof. A liquid polymer material is directly formed on the surface of a substrate material and is solidified to form an even grinding layer, thereby the polishing pad has better integrative performance and better flatness, otherwise, the grinding layer has a long structure and is provided with a plurality of holes which have better inclusion ability for grinding particles in grinding liquid, moreover, the polishing pad has a higher compression ratio, and the polishing pad is in tight contact with an object to be polished and can not scuff the surface of the object to be polished, therefore, the grinding efficiency and the quality can be improved.

Owner:SAN FANG CHEM IND

Wind Turbine Blade with an Integrated Lightning Conductor and Method for Manufacturing the Same

ActiveUS20090257881A1Reduce mechanical stressEasy to mergeFinal product manufactureLaminationElectrical conductorTurbine blade

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Mould and method for vacuum assisted resin transfer moulding

ActiveUS7980840B2Reduce complexityLow costFinal product manufactureConfectioneryVacuum assistedShell molding

A mold and method for vacuum assisted resin transfer molding of a fiber reinforced laminated structure are provided. The mold includes a first mold part and a second mold part. The first mold part defines a negative impression of the laminated structure, being structurally stable and forming a support for fiber reinforcement layers of the laminated structure. The second mold part connectable to the first mold part for closing the mold and defines together with the first mold part an enclosed space which can be evacuated. The mold further includes a flow duct for guiding a liquid polymer which is formed as a recess in the first mold part and / or a recess in the second mold part that is open towards the enclosed space and extends along a section of the periphery of the first mold part and / or the second mold part.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

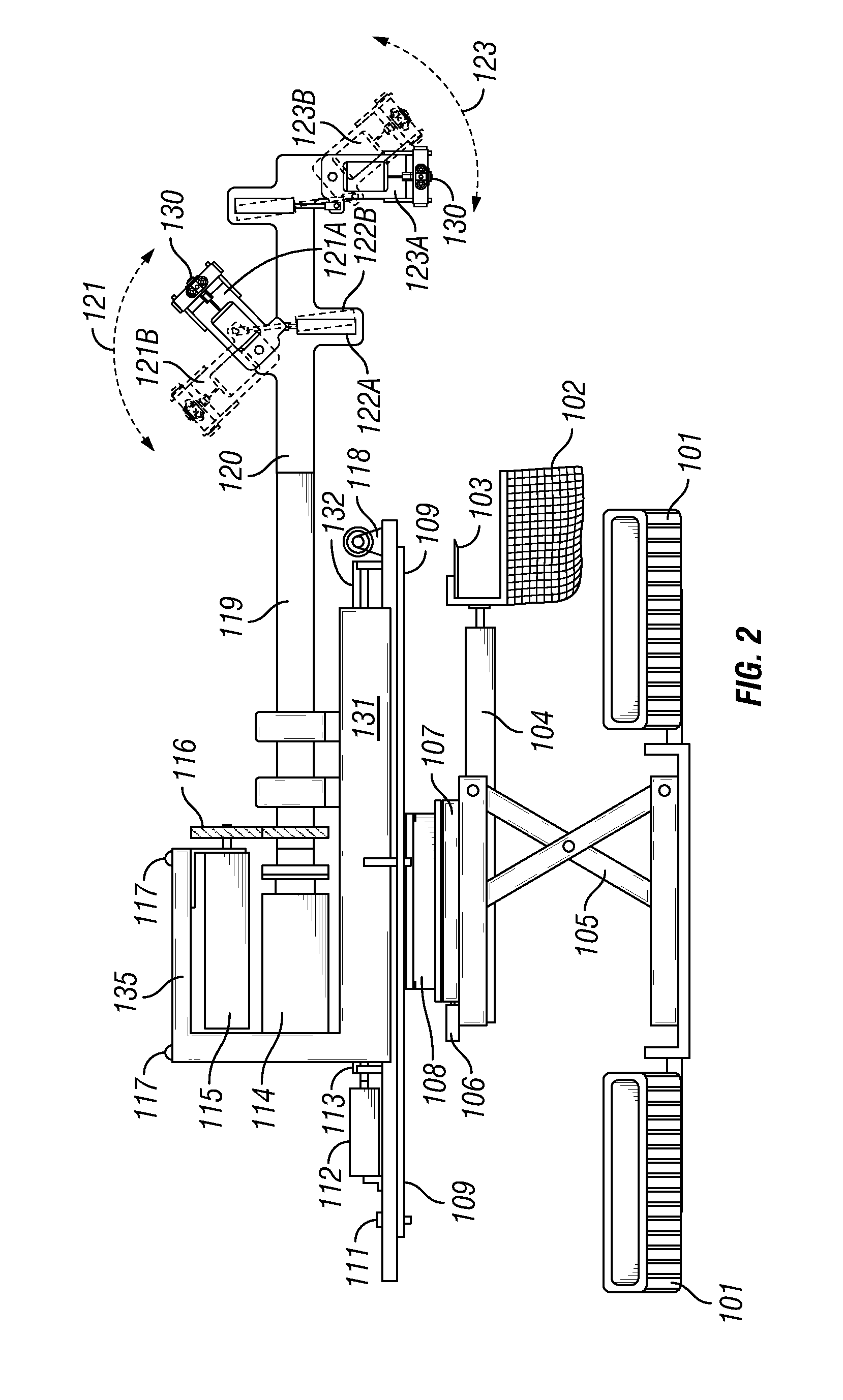

Material handling platform, components and methods of production thereof

InactiveUS20100064946A1Mass productionInaccurate and slowDomestic articlesCoatingsProduction lineGlass fiber

A method of manufacturing a sheet material using fibreglass, such as glass fibres 802,803, fibre glass matting 801 and / or fibreglass webbing / tape 601, and polymer, such as polypropylene. The fibreglass is coated in liquid polymer and formed into sheet material 800, preferably by compression rollers 808,810. The material product is formed, by bending / folding, into desired shapes, such as box sections to form pallet / support platform sections. The formed sections can be fastened together, such as by elongate members passing through a series of aligned apertures between adjacent sections. The elongate members can be heat staked to the sections. Inserts can be used in the ends of the sections to provide additional rigidity and strength. Thus, a composite pallet / support platform can be manufactured in production line form.

Owner:CAS HLDG AUSTRALIA

Rubber composition for side wall and pneumatic tire

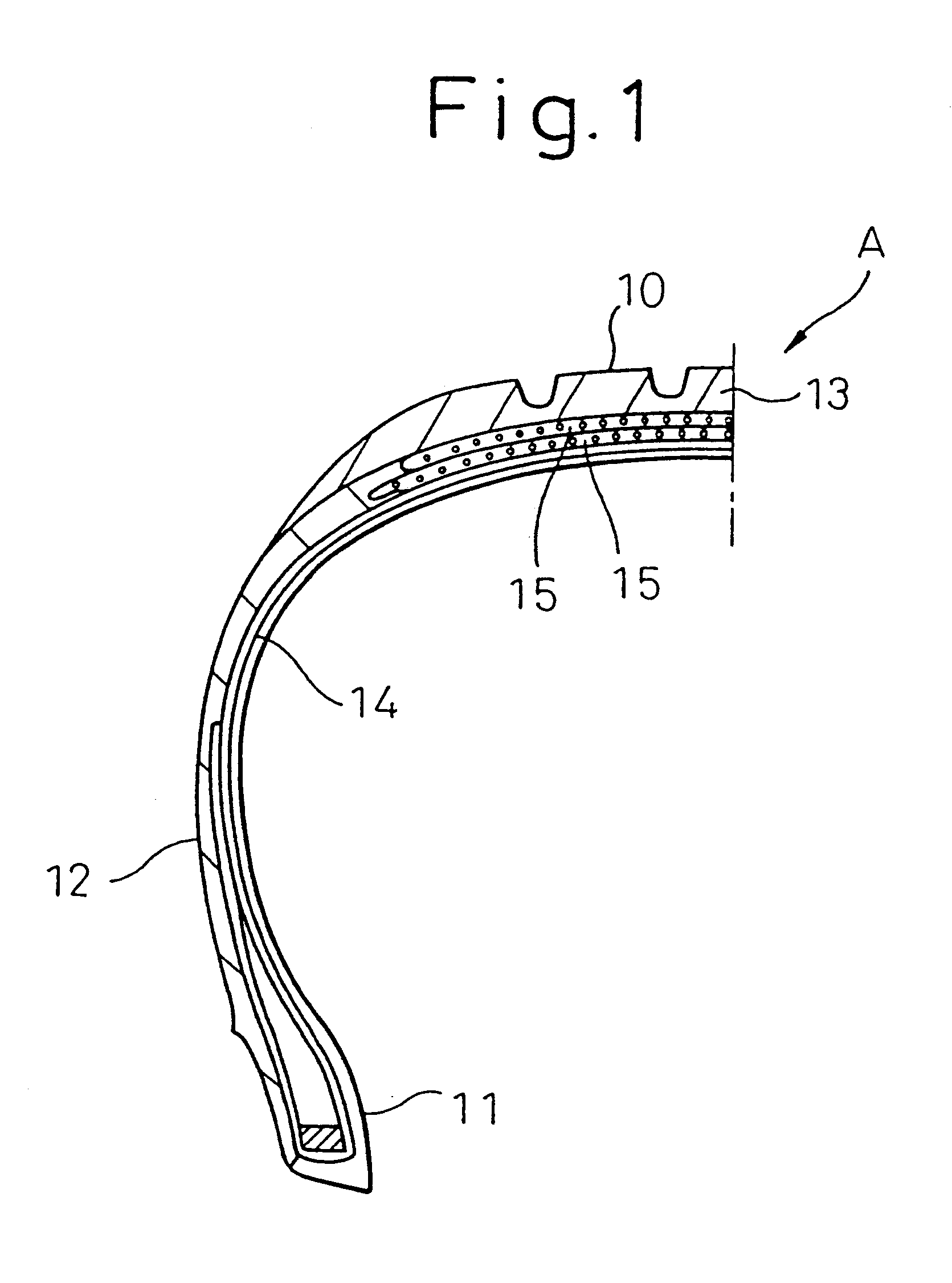

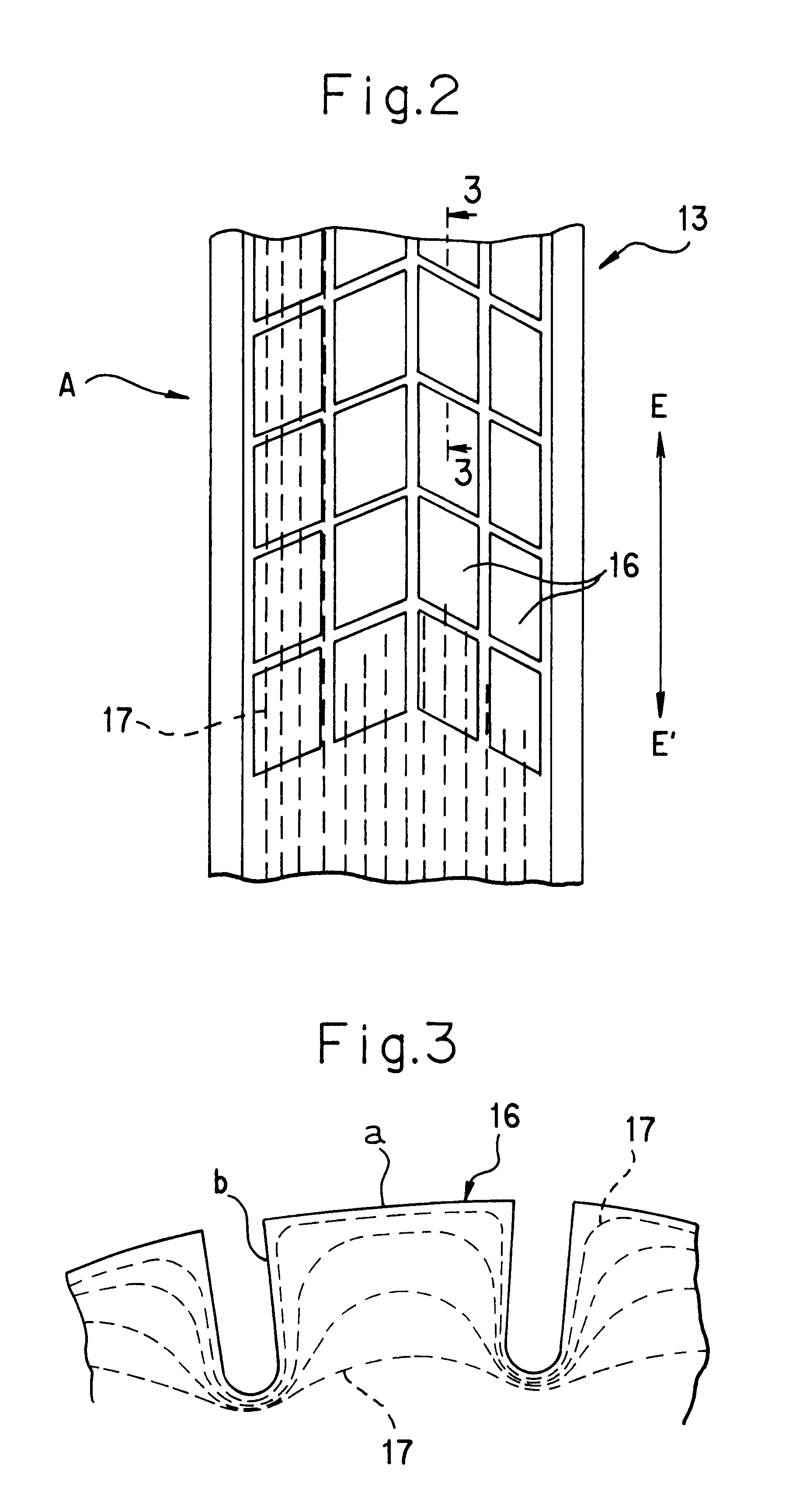

A rubber composition for a side wall contains 100 parts by weight of a diene rubber component, from 30 to 70 parts by weight of a reinforcing filler, and from 2 to 20 parts by weight of a liquid polymer having a number average molecular weight of from 3,000 to 90,000. A pneumatic tire contains the rubber composition as a side wall of the tire.

Owner:TOYO TIRE & RUBBER CO LTD

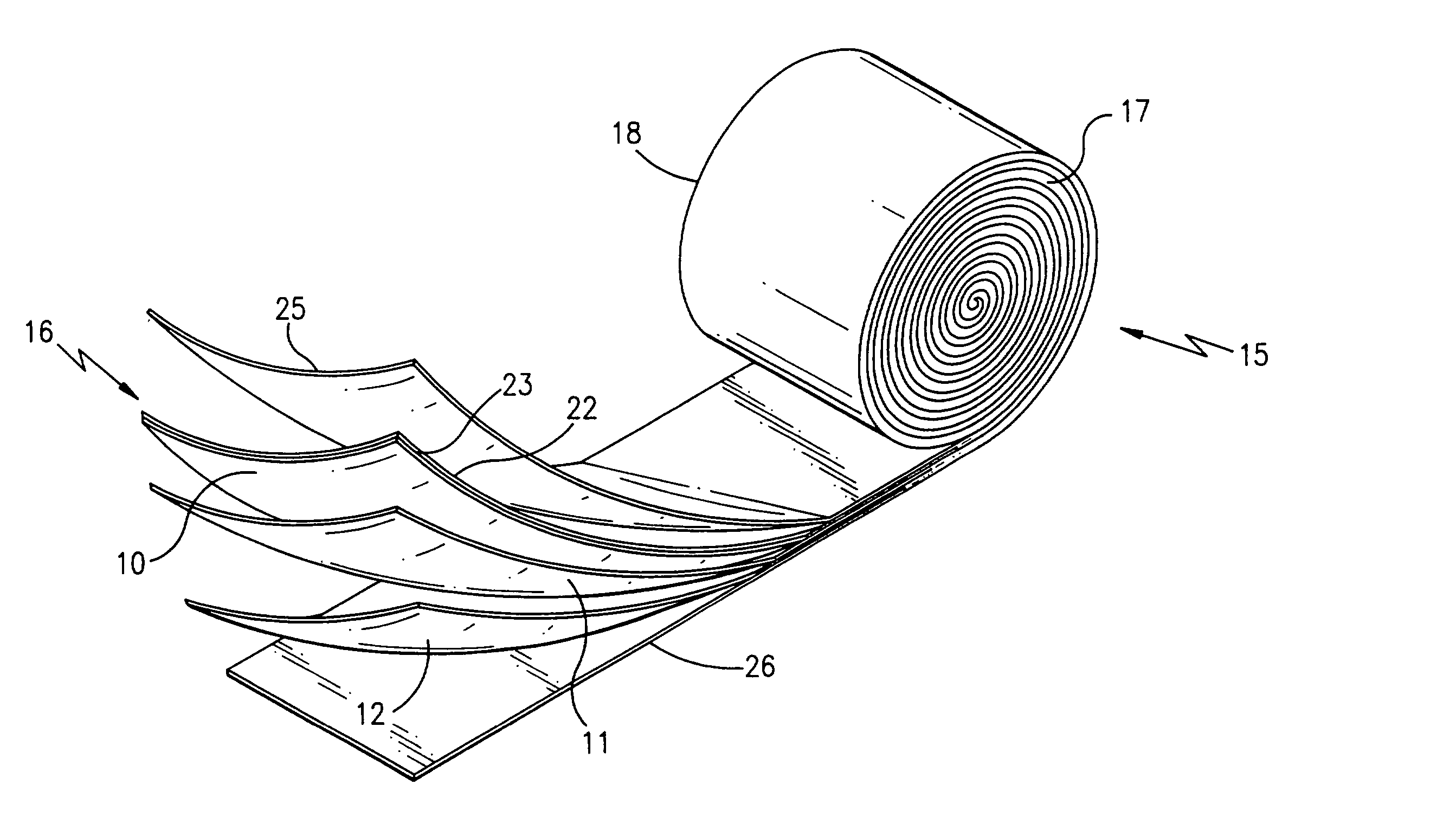

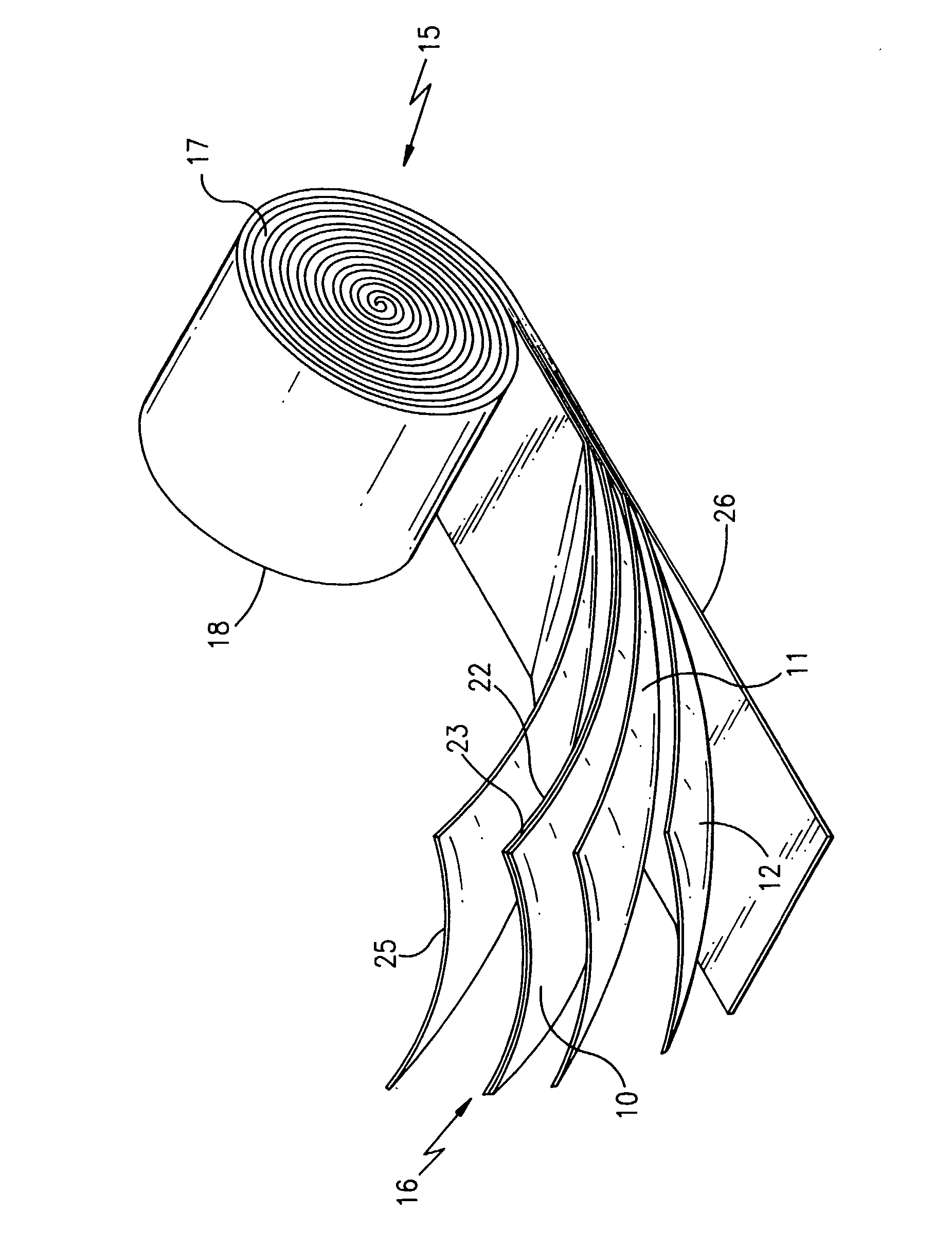

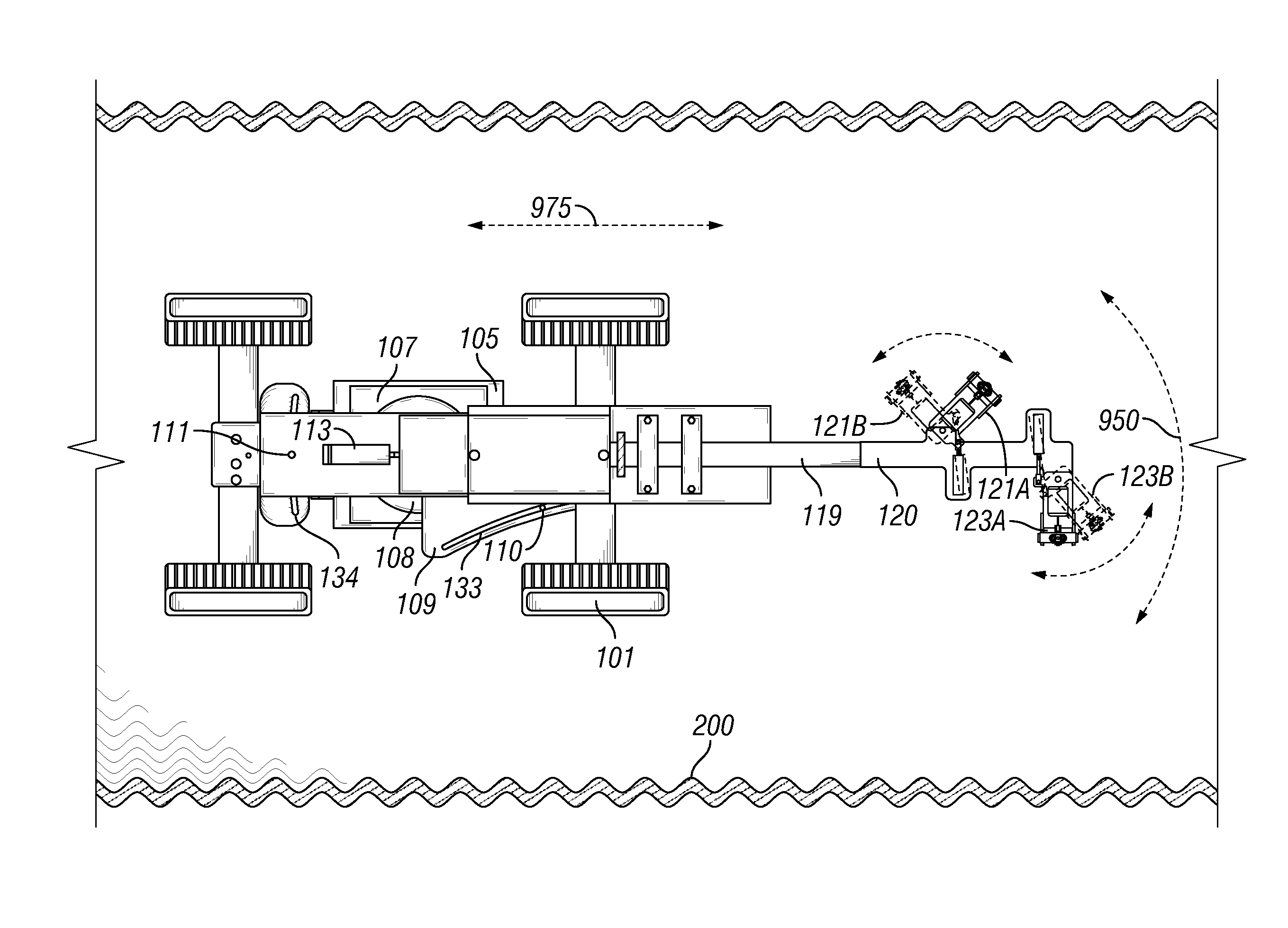

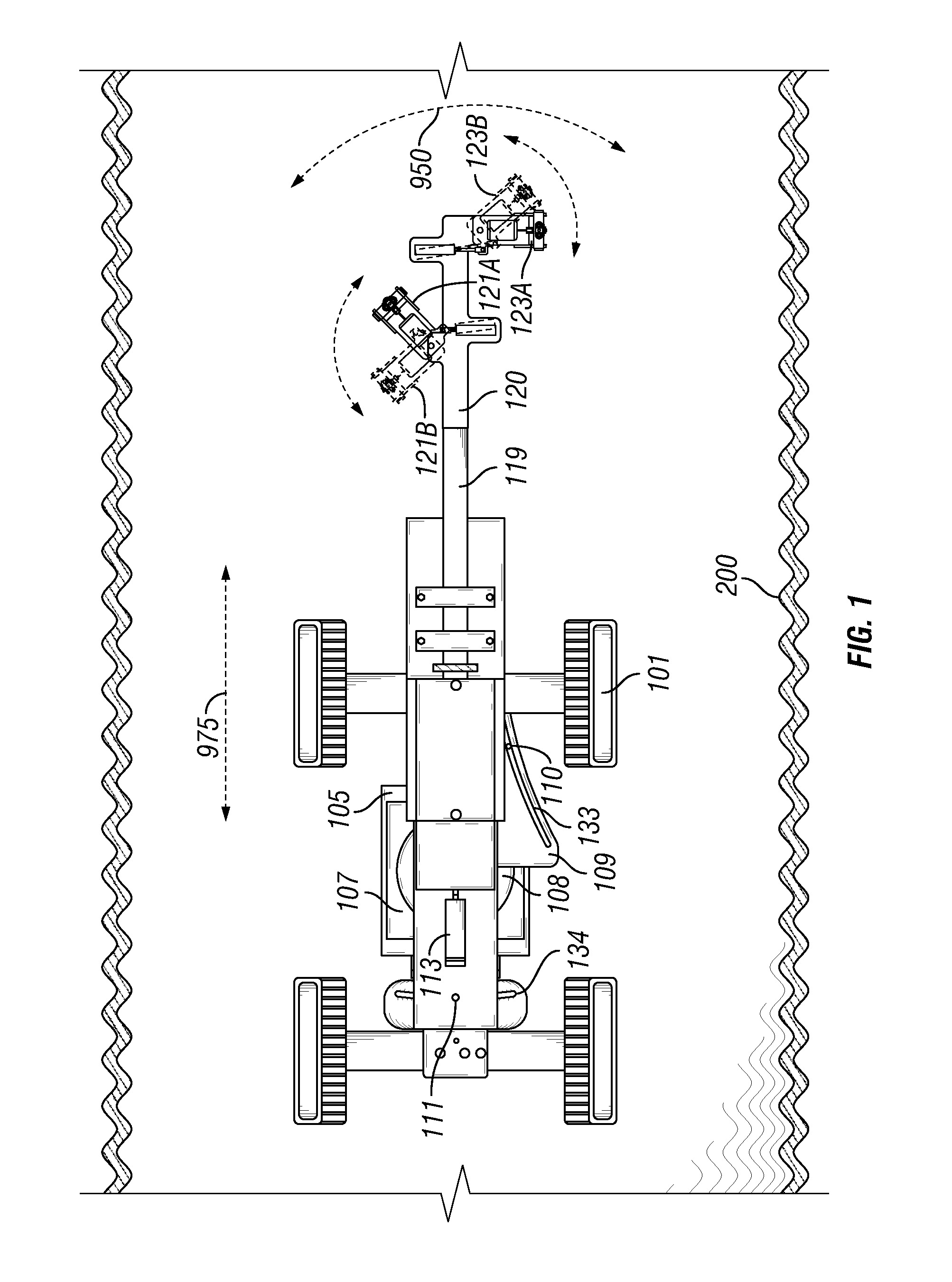

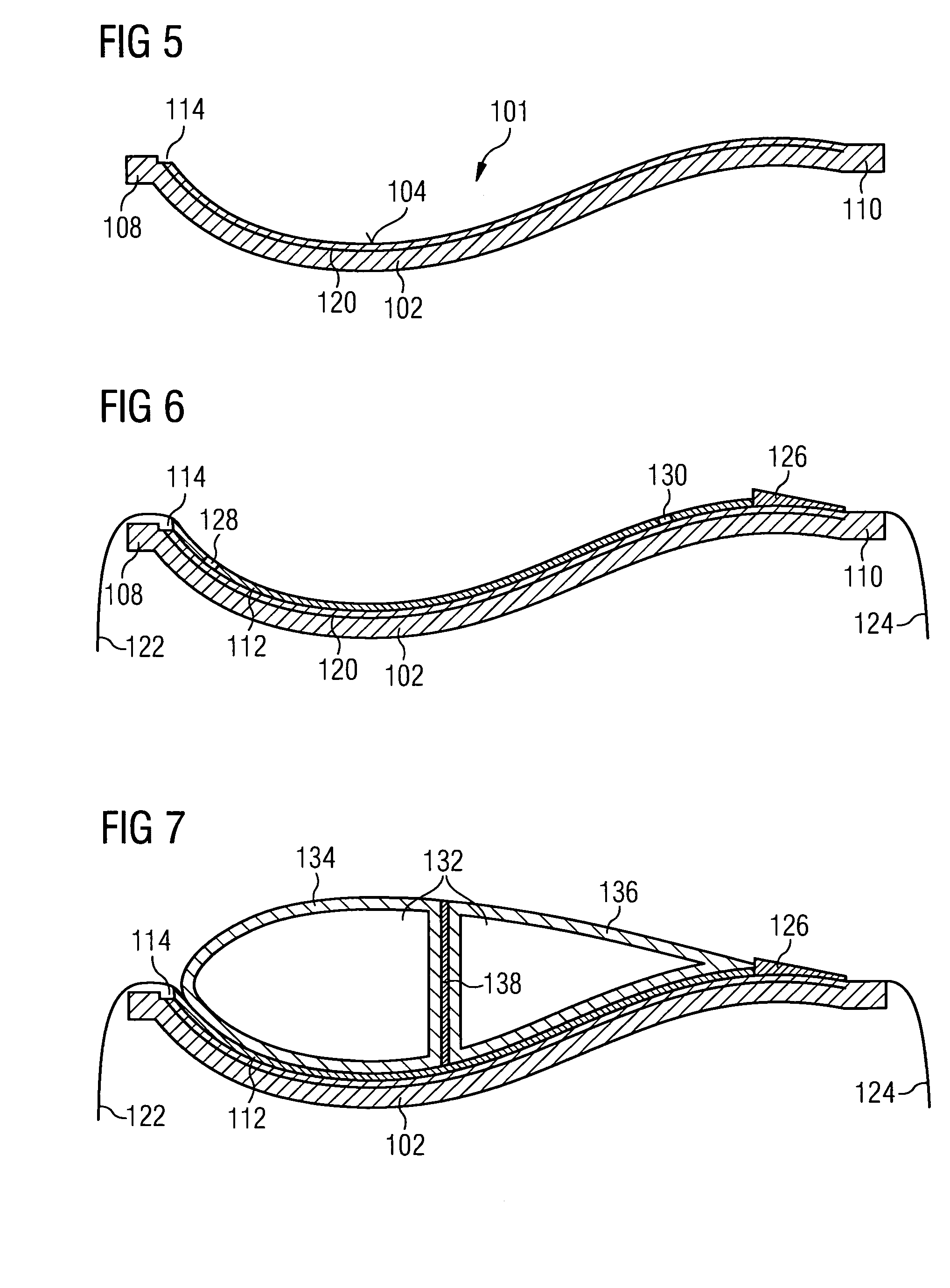

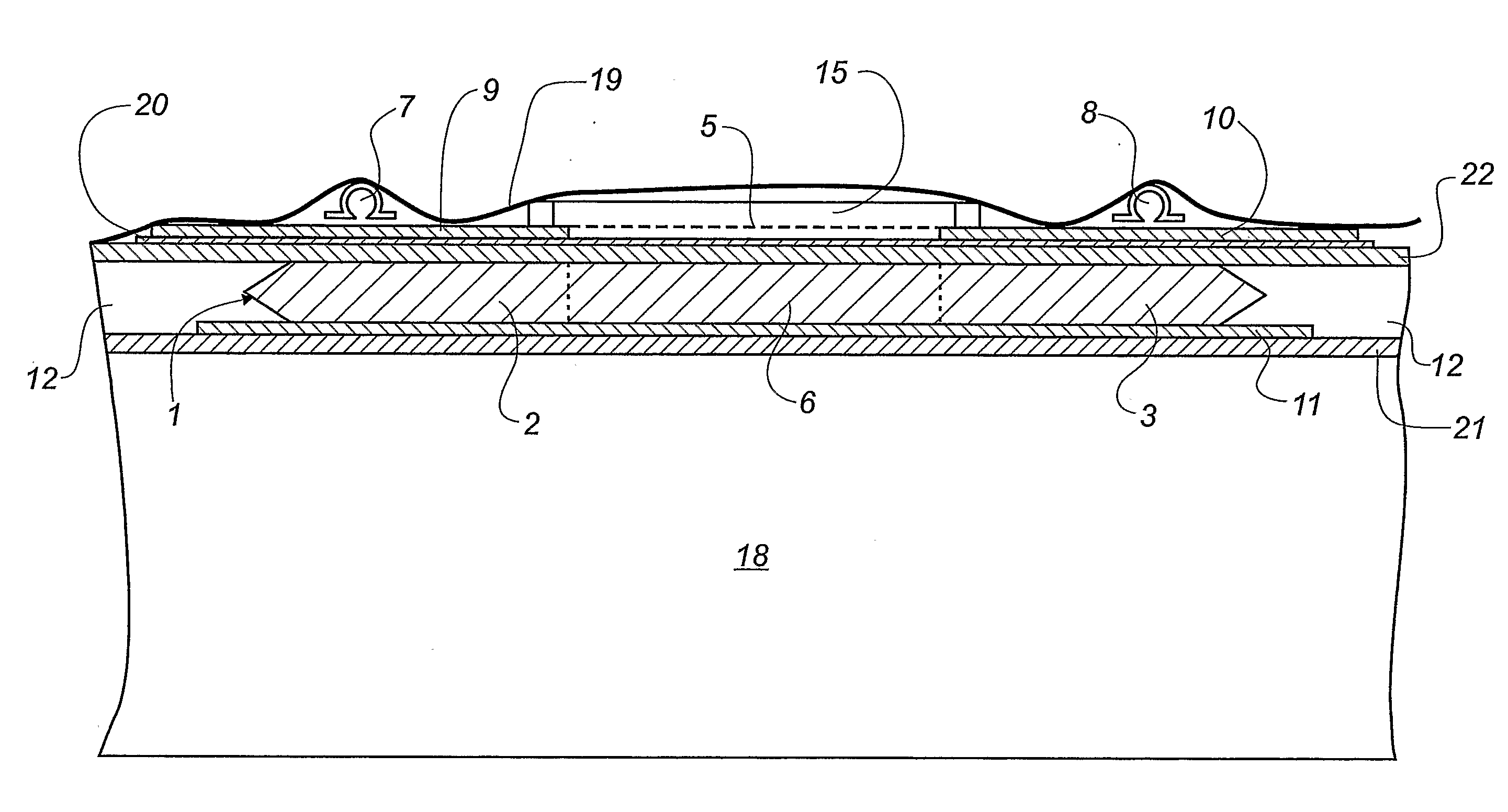

Method and Apparatus for Providing polymer to be Used at Vacuum Infusion

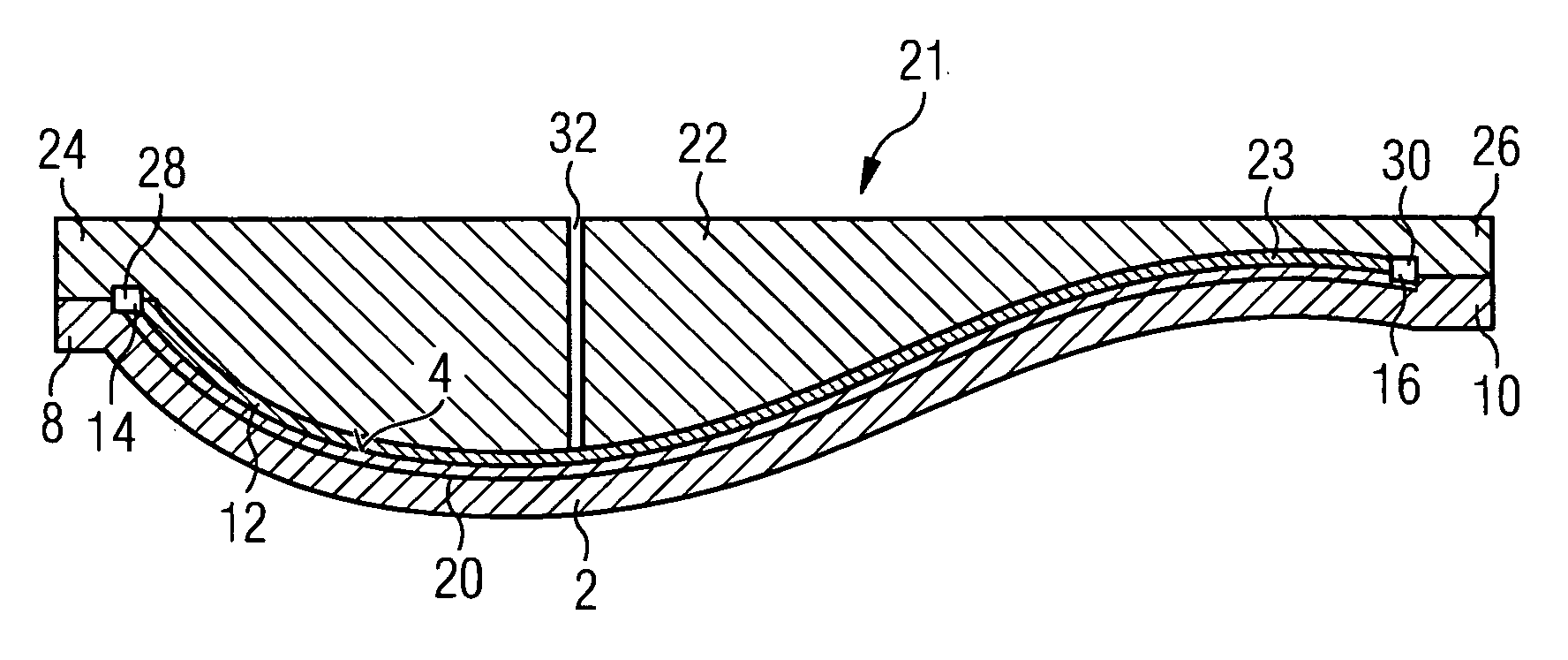

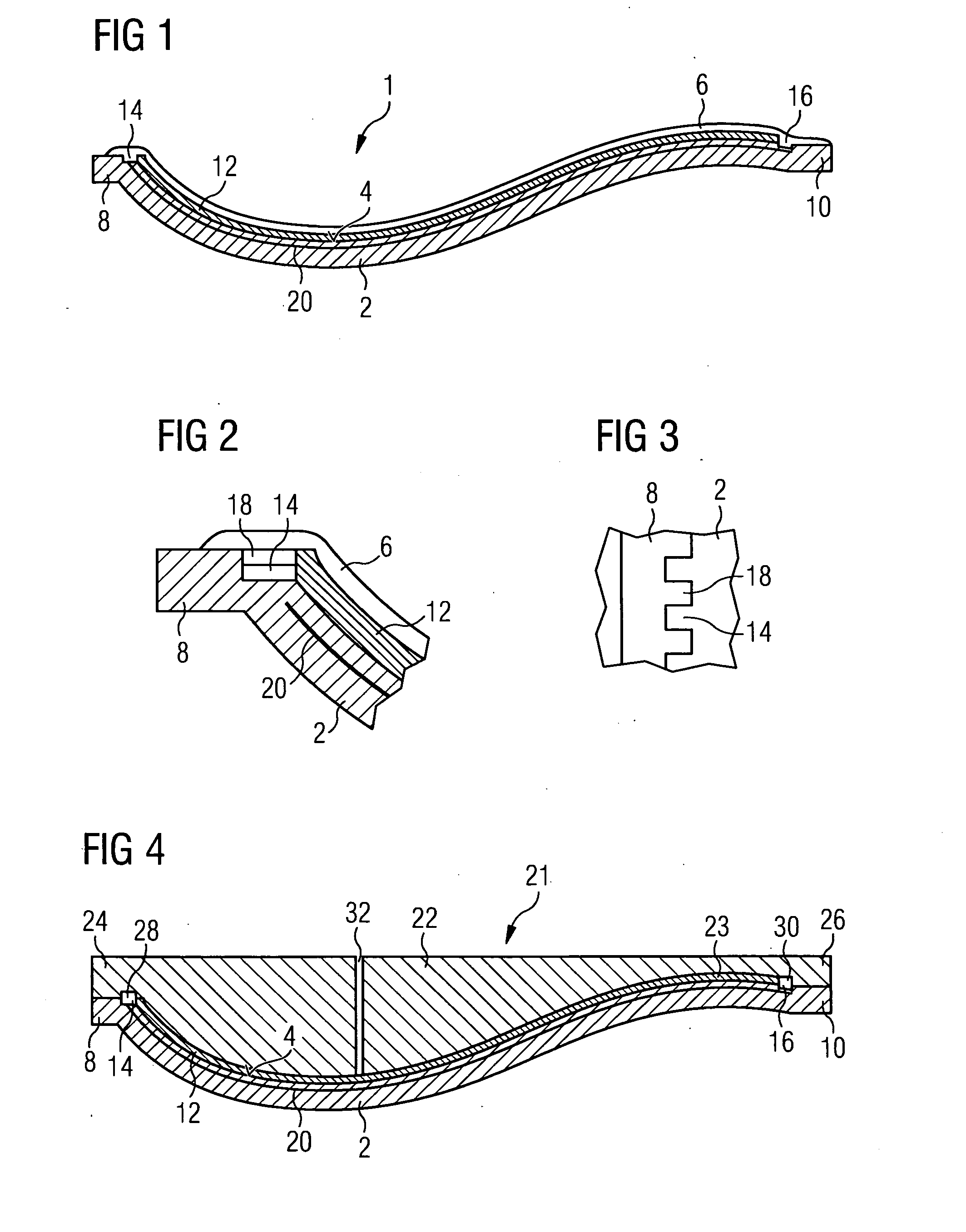

ActiveUS20090051076A1Time for filling the mould,Risk of dryFinal product manufactureLaminationInlet channelLiquid state

The invention relates to a method of producing a shell member of fibre composite material by means of vacuum infusion, where the fibre material is impregnated with liquid polymer, and applying a mould (18) with a mould cavity. In the mould cavity a lower distribution layer (11) is placed. A fibre insertion (1) including a plurality of fibre layers is placed above the lower distribution layer (11). A first upper distribution layer (9) and a second upper distribution layer (10) are placed at a transverse distance of each other above the fibre insertion, so that at least a part of the first distribution layer overlaps a first zone (2) of the fibre insertion (1), and at least a part of the second distribution layer overlaps a second zone (3) of the fibre insertion (1), the first zone (2) and the second zone (3) being separated by an intermediate zone (6) neither overlapping the first nor the second distribution layer (9, 10). A first inlet channel (7) is placed above the first distribution layer (9), and a second inlet channel (8) is placed on top of the second distribution layer (10). Above the intermediate zone (6) of the fibre insertion (1) a semi-permeable membrane (5) is placed, which may expand overlappingly over the first distribution layer (9) and / or the second distribution layer (10), and which is permeable to gasses and substantially impermeable to liquid polymer, said semi-permeable membrane (5) communicating with a vacuum source. Finally, in a manner known per se, a vacuum bag (19) is placed on top of the mould (18), which is evacuated of air by means of the vacuum source, and polymer is directed into the mould via the first and the second inlet channels (7, 8). The invention also relates to an apparatus for providing polymer for use with the method.

Owner:LM GLASSFIBER

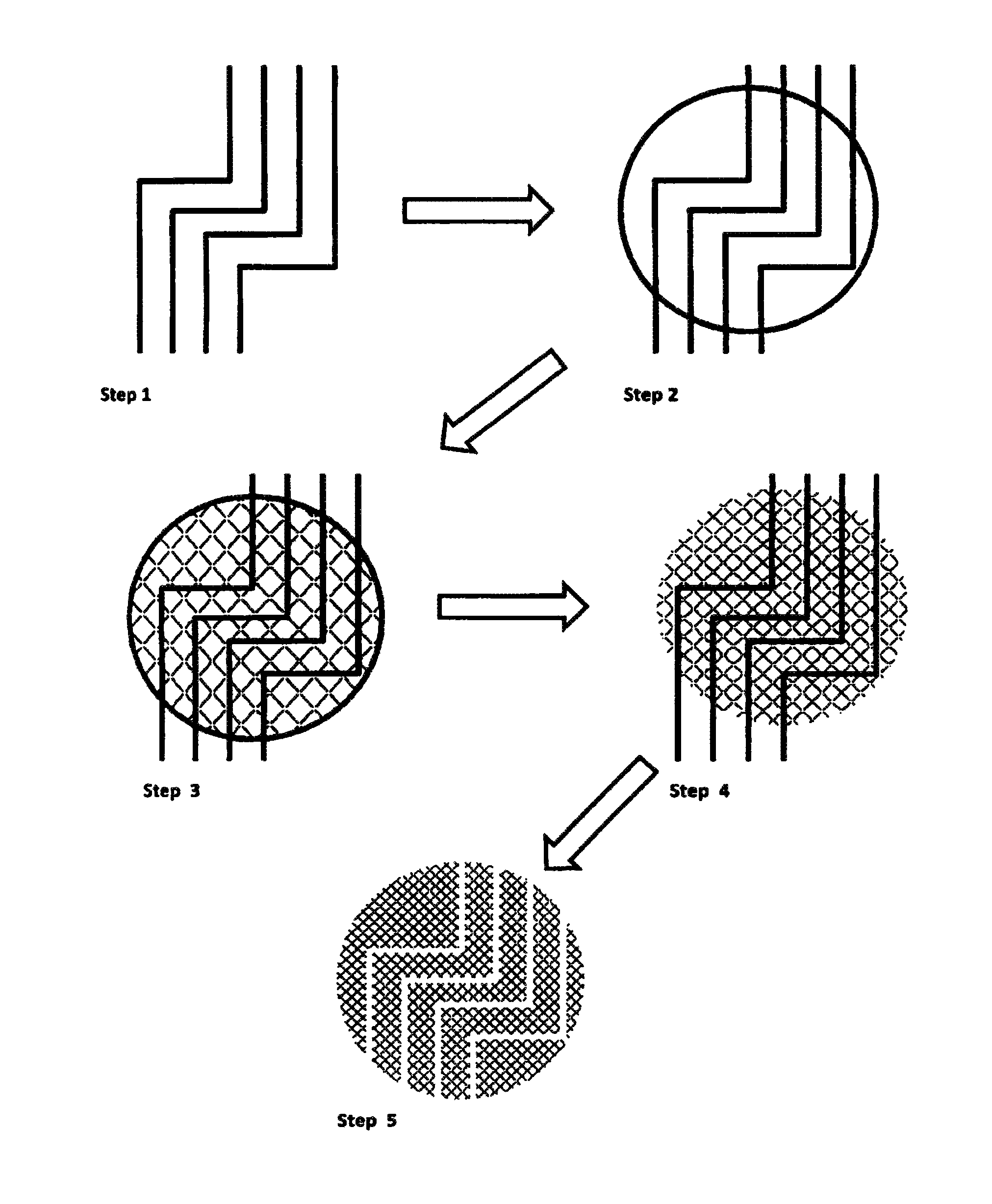

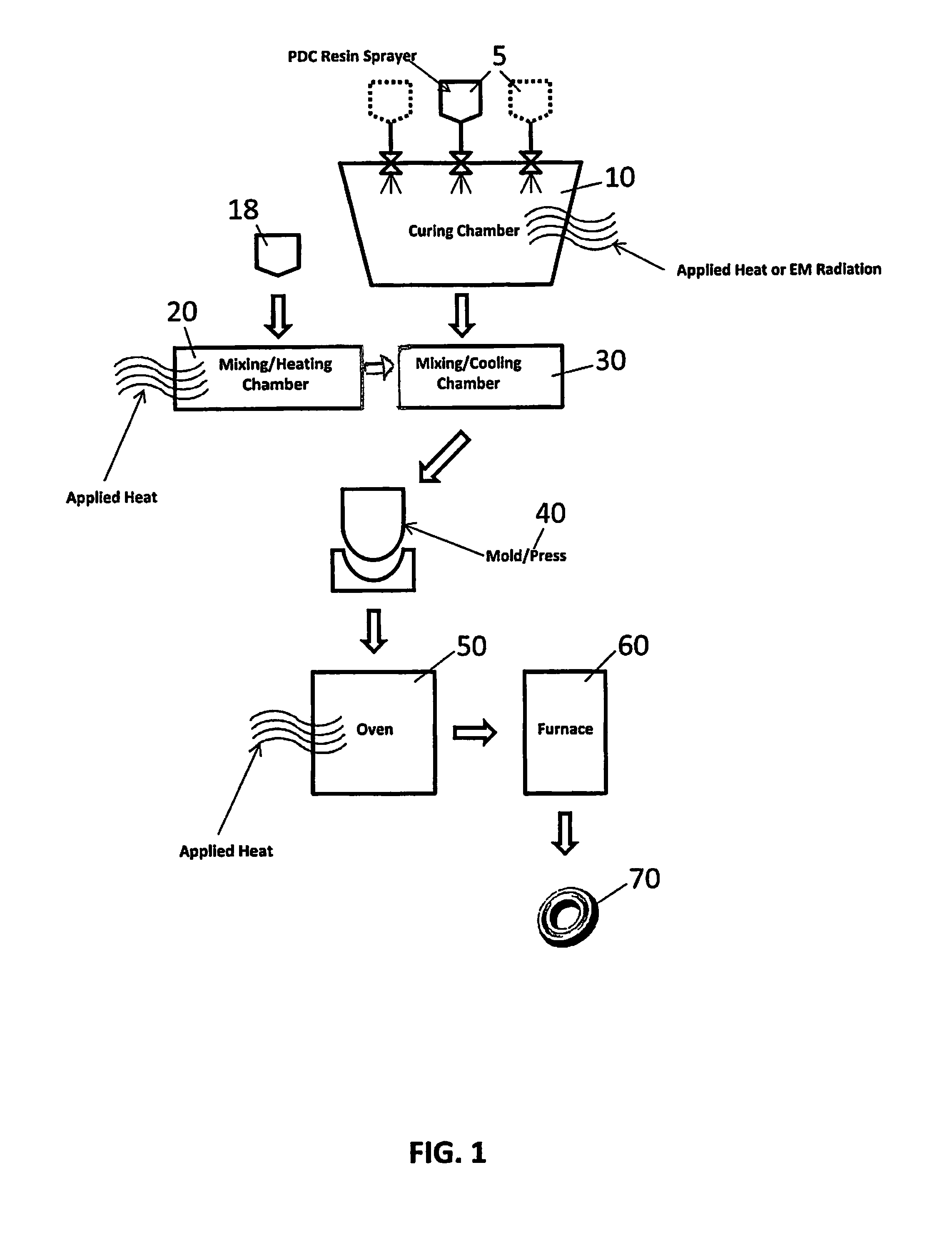

Method for producing bulk ceramic components from agglomerations of partially cured gelatinous polymer ceramic precursor resin droplets

Methods, processes, and systems for producing bulk ceramics from agglomerations of partially cured gelatinous polymer ceramic precursor resin droplets, without using sponge materials to form gas pathways in the polymer bodies. Ceramics can be formed in hours. Resin droplets can be produced with a sprayer where liquid polymer precursors, mixed with a curing agent, are sprayed forming droplets which are partially cured, collected, and compressed into shapes. Ceramic porosity can be varied, droplet particle sizes can be controlled by adjusting liquid and gas pressure, orifice size, during spraying. Partially cured droplets can be formed via an emulsion process and size controlled by emulsion liquid and surfactant selection parameters.

Owner:DYNAMIC MATERIAL SYST

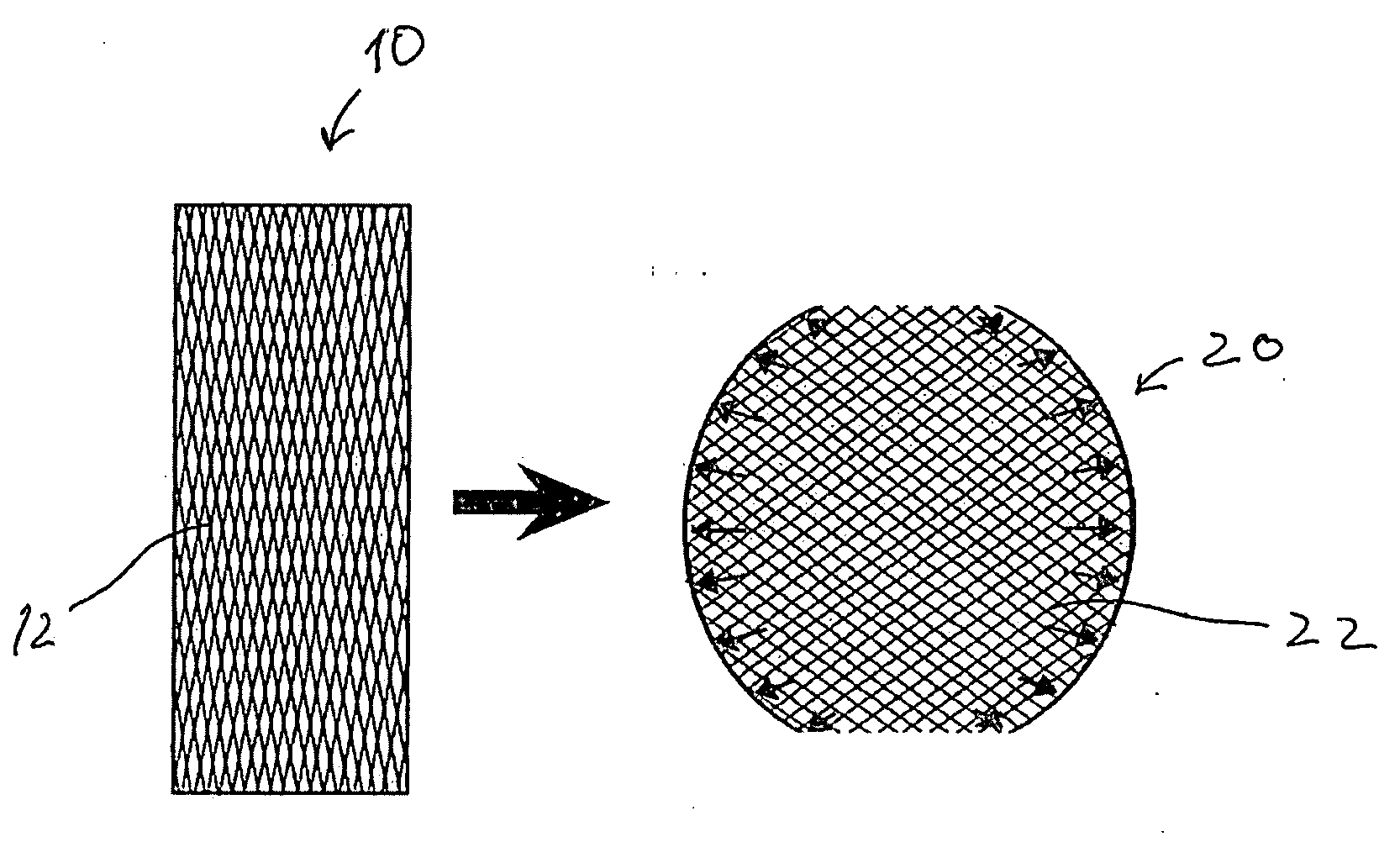

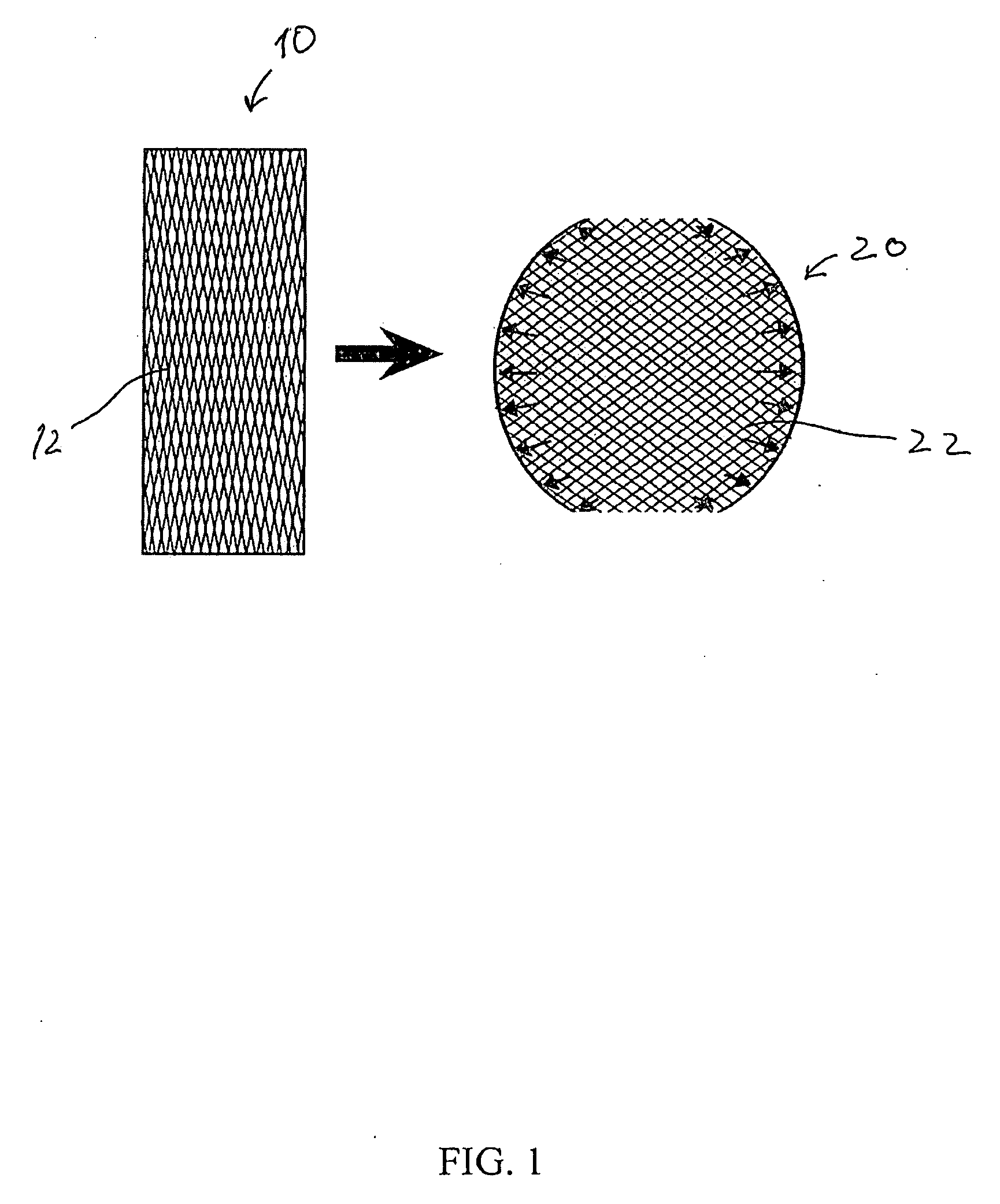

Structurally reinforced spinal nucleus implants

InactiveUS20090149958A1Reduced dimensionLamination ancillary operationsHollow inflatable ballsSpinal cordIntervertebral space

A spinal nucleus implant is provided which includes a braided three-dimensional reinforcement member having a polymeric matrix imbued therein, the implant configured to have a shape consistent with a cavity within an intervertebral disc space. The polymeric matrix may be a fluid absorbing polymer, e.g., a hydrogel or a substantially non-fluid absorbing in-situ curable elastic polymer. A method of making a spinal nucleus implant is provided which includes providing a braided three-dimensional reinforcement member configured and dimensioned to have a shape consistent with a cavity in an intervertebral space and infusing the braided three-dimensional reinforcement member with a liquid polymer capable of forming a polymeric matrix. Also provided is a spinal nucleus implant including a three-dimensional reinforcement member adapted and configured to undergo anisotropic expansion, the implant configured to have a shape consistent with a cavity within an intervertebral disc space. A method of treating a degenerating intervertebral disc includes creating an incision in an annulus; removing at least a portion of a nucleus pulposus; and inserting, through the incision, a spinal nucleus implant according to the present disclosure.

Owner:REPLICATION MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com