Polishing pad and manufacturing method thereof

A manufacturing method and polishing pad technology, which can be used in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of reducing the service life of polishing pads, storing debris in holes, and reducing bonding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention provides a polishing pad, which is used for grinding or polishing an element to be polished in a chemical mechanical polishing (CMP) process. The components to be polished include (but are not limited to) objects such as semiconductors, storage media base materials, integrated circuits, LCD flat glass, optical glass, and photoelectric panels.

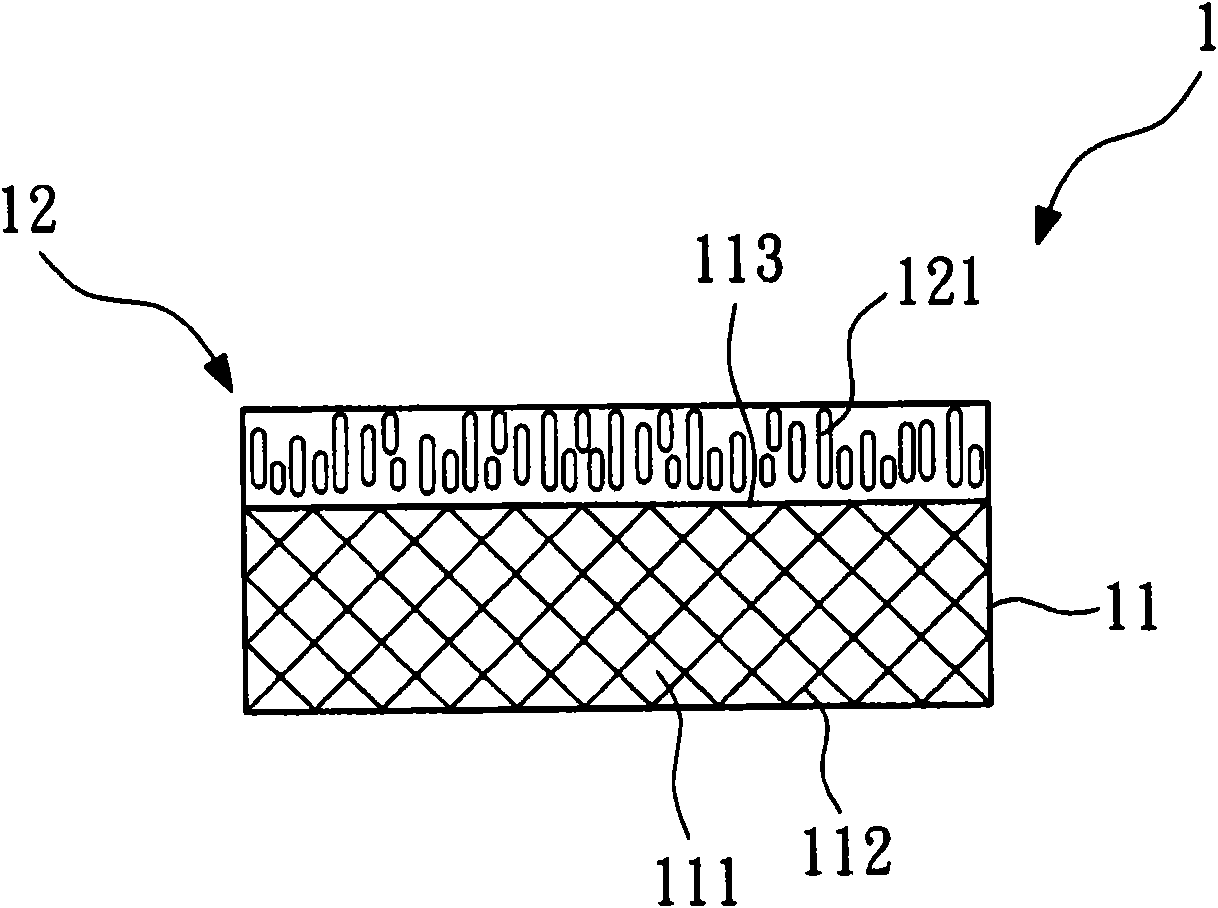

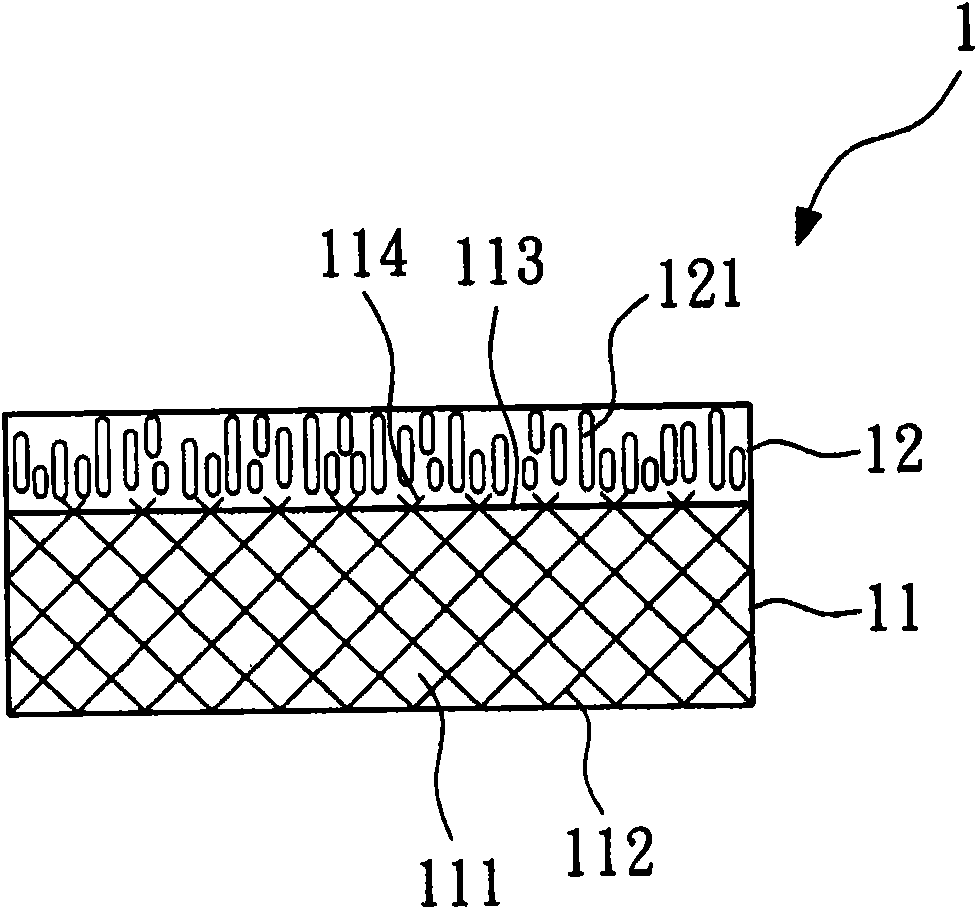

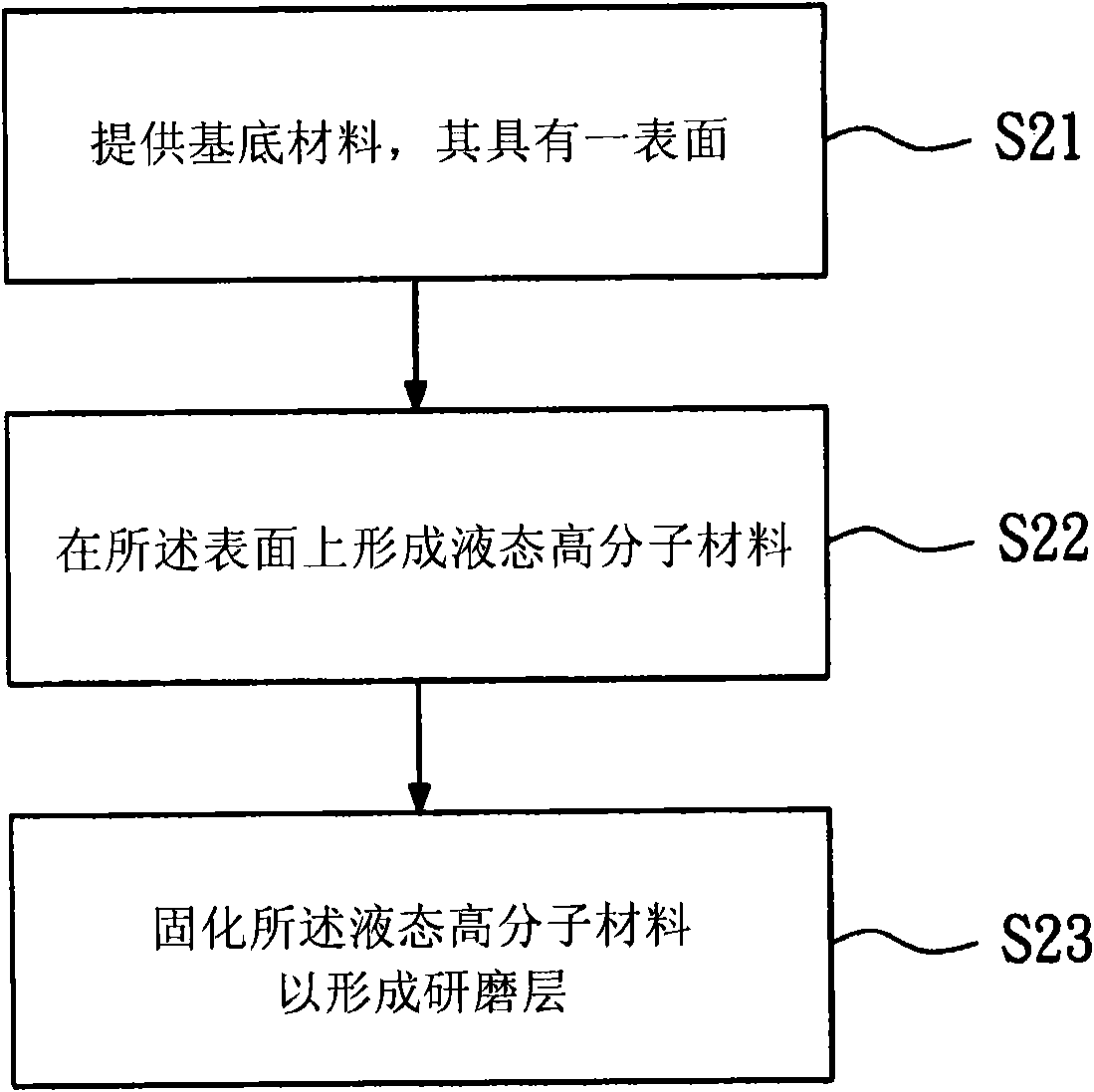

[0014] refer to figure 1 , which shows a schematic diagram of the polishing pad of the present invention. The polishing pad 1 includes a base material 11 and a polishing layer 12 . In this embodiment, the base material 11 is formed by covering the fiber layer 112 with a polymer body 111 , and the base material 11 has a surface 113 . Preferably, said surface 113 is a planarized surface. The fiber layer 112 can be cloth material (for example: non-woven fabric). In this embodiment, the polymer body 111 is a continuous foam. Wherein, the polymer body 111 is selected from polyurea ester (PU), polypropylene (PP), pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com