Patents

Literature

951results about How to "Improve grinding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

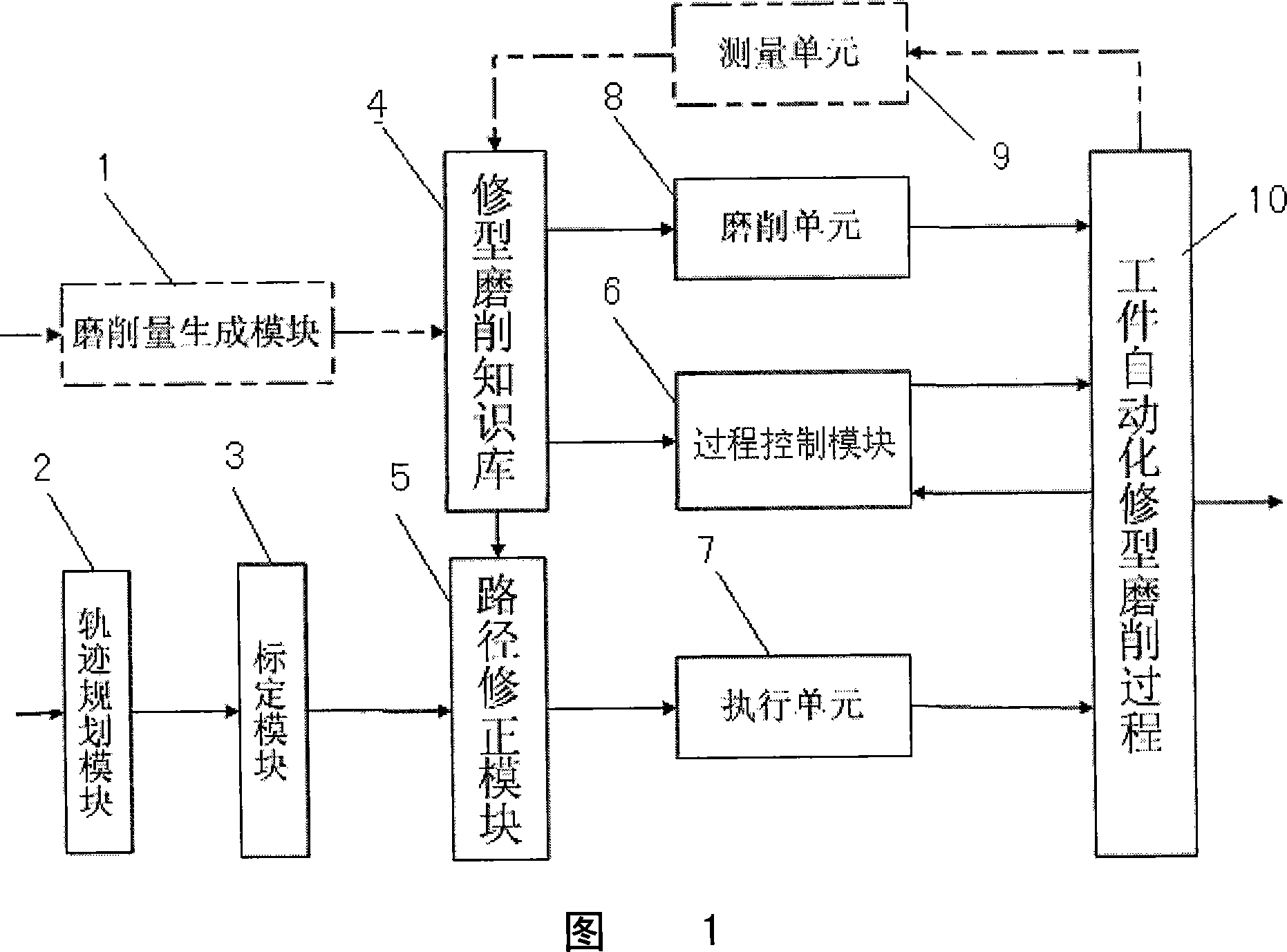

Abrasive belt grinding processing method and device capable of automatic repair and maintain for workpiece

InactiveCN101234479ARealize automatic profile grindingRealize profile grindingBelt grinding machinesAutomatic grinding controlExecution unitHigh dimensional

The invention relates to a belt grinding processing method which can dress workpiece automation and a device thereof. And the invention is a dressing and grinding system formed by a set of automation equipments, adopts intelligent process to control, and realizes the automation dressing and grinding processing of the complex profile workpiece in the manner of grinding belts. The device of the invention comprises a control unit, an execution unit, a grinding unit, etc., sections; wherein, the control unit comprises a plurality of software modules; the grinding and dressing knowledge base is the key software module, which can generate automatically all the grinding parameters according to the grinding amounts of all the input points; and other software modules, for example, path correction module, generate actual processing path finally according to the parameters; the execution unit is a robot or a digital machine tool, which can receive the actual processing path of the control unit, and can generate machining track; the grinding unit is a belt grinder which can receive commands from the execution unit, and can finish the dressing grinding of the workpieces. The belt grinding processing method can be widely applied in the dressing grinding processing of the workpieces with variety of high-dimensional accuracy and complex profile.

Owner:天津智通信息系统集成有限公司

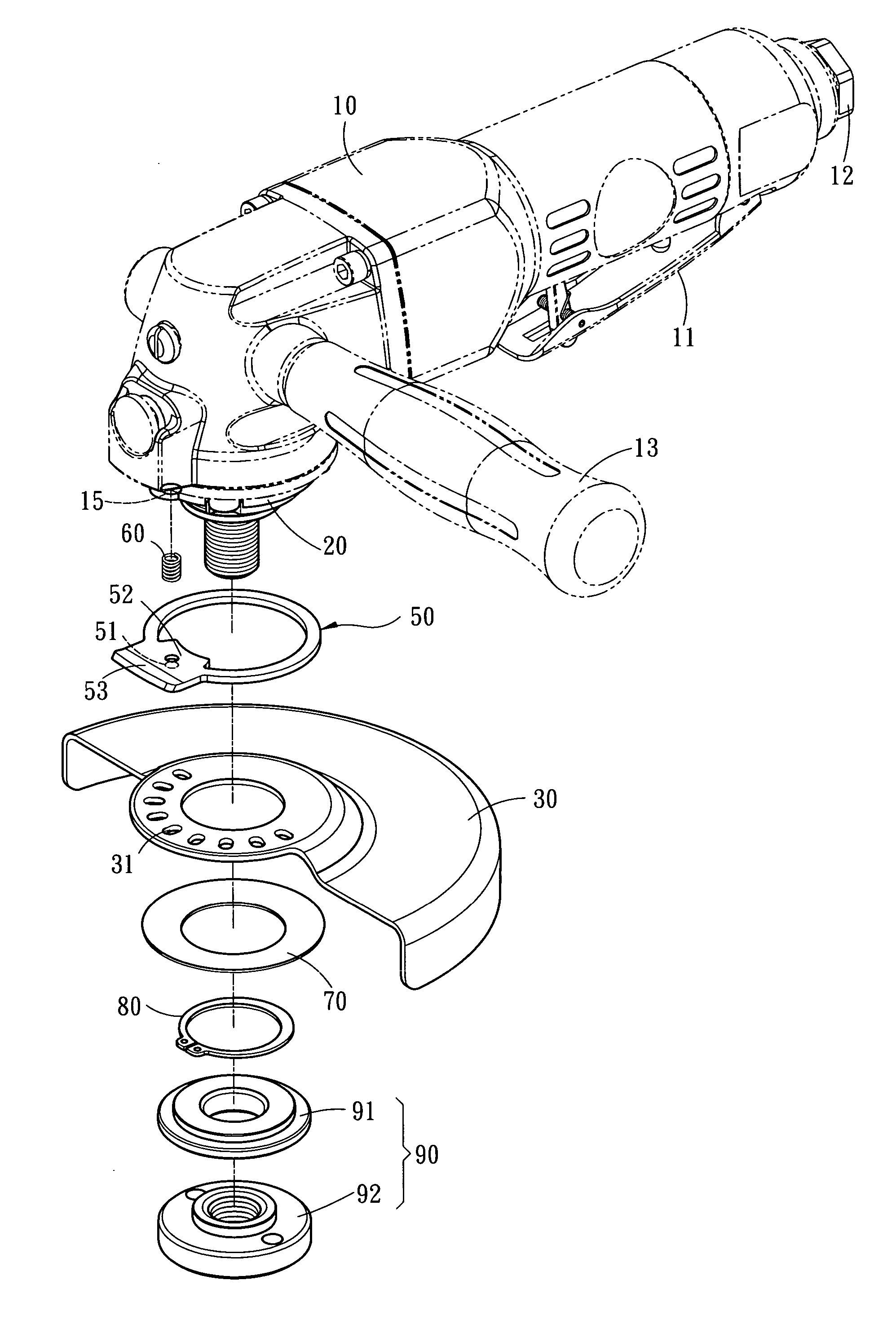

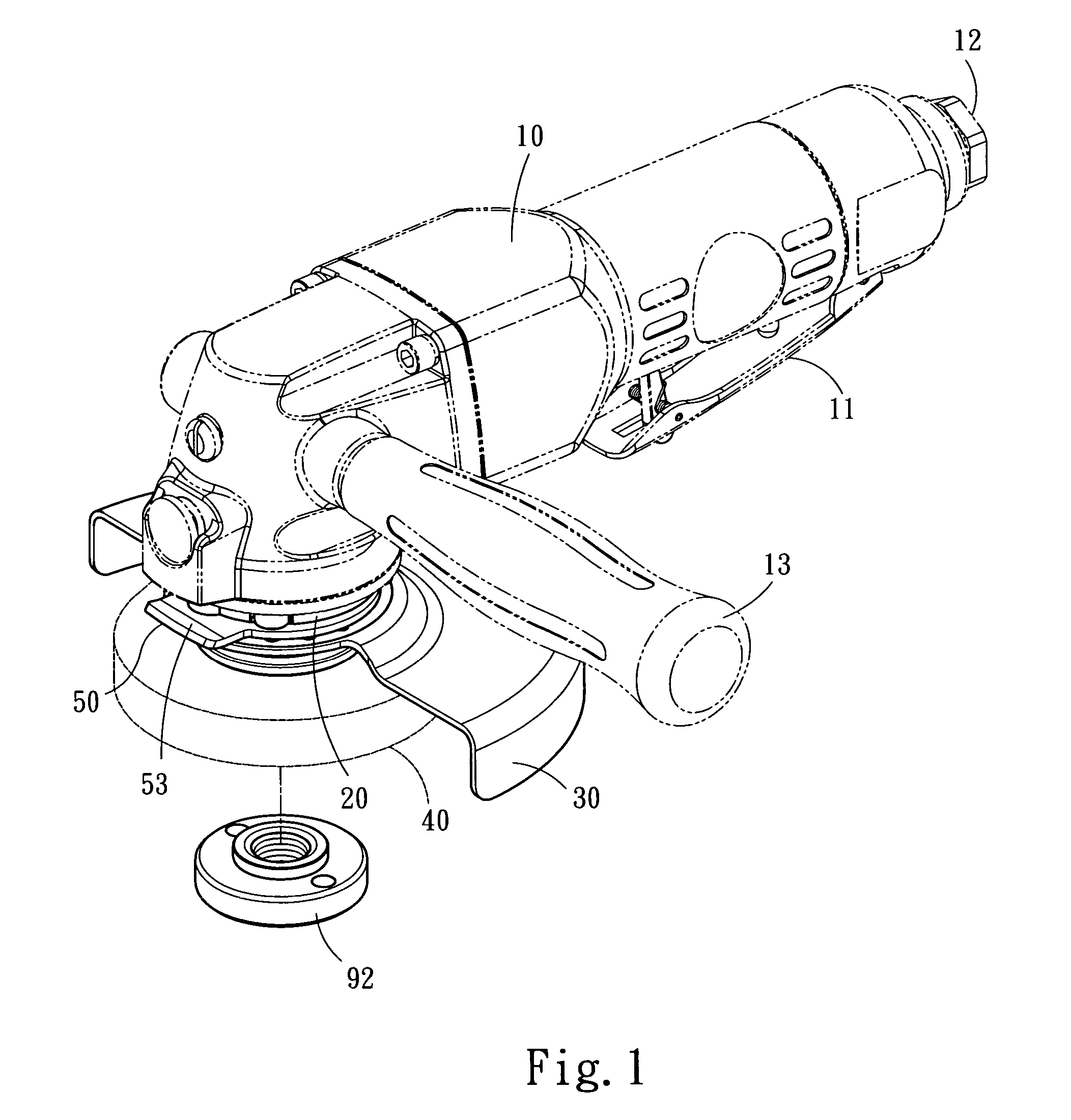

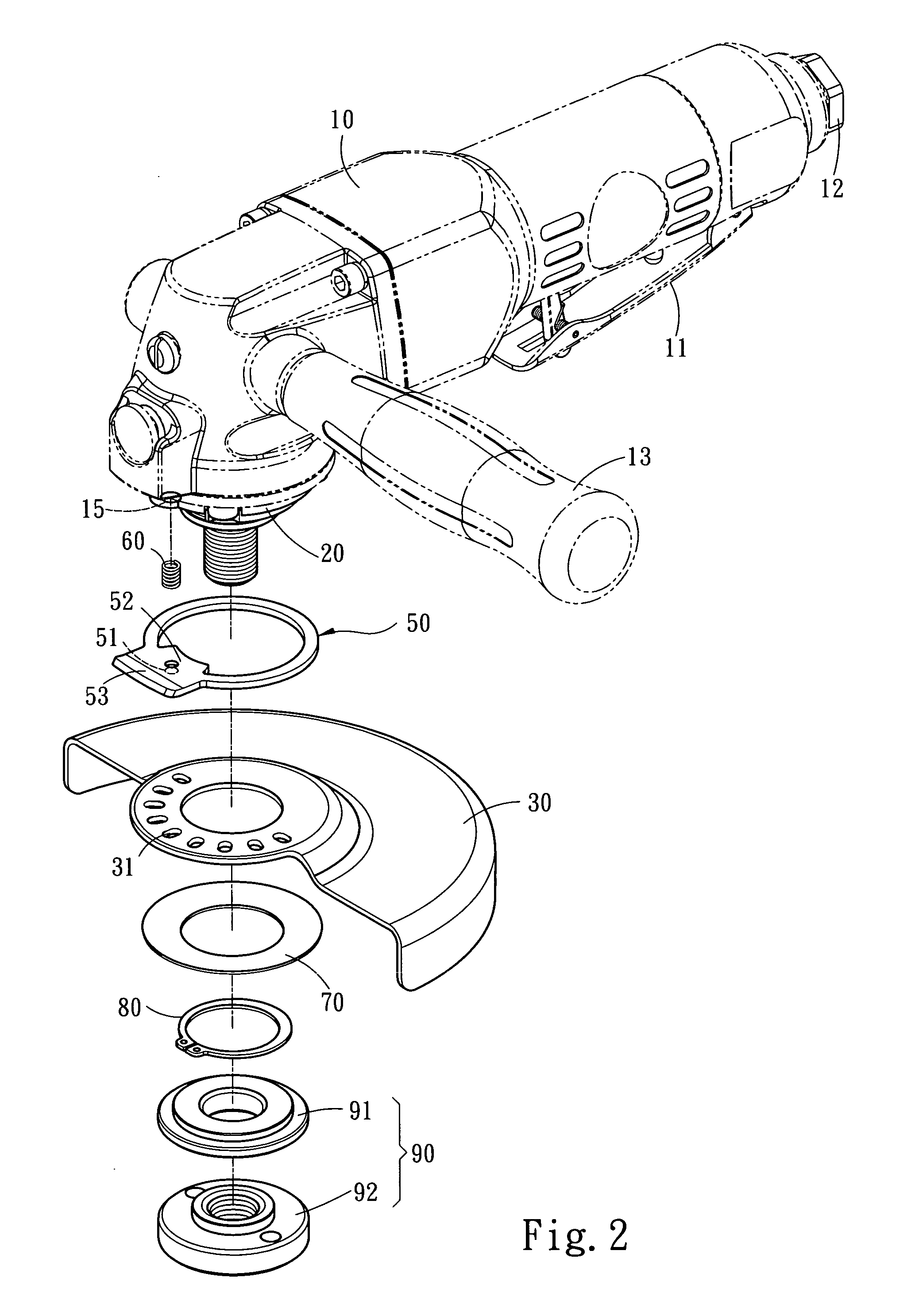

Rotary protecting hood of a pneumatic grinder

InactiveUS20070117499A1Avoid the existing deficienciesImprove conveniencePortable grinding machinesGrinding/polishing safety devicesEngineeringFixed position

The invention discloses a rotary protecting hood of a pneumatic grinder that comprises a connecting end disposed on a pneumatic grinder body, a grinder wheel disposed on the connecting end, and a protecting hood for sheltering the grinder wheel, wherein the connecting end includes a limit member, and the limit member and the protecting hood include a fixing section and a plurality of fixing holes for defining a fixing relation, and the limit member has a first position for defining a fixing relation with the protecting hood and a second position for releasing the fixing relation, such that the angle of the protecting hood can be adjusted and the protecting hood displaces with respect to the body. With the foregoing measure, a user can adjust the fixing position of the protecting hood according to the grinding position and the angle of a work piece to improve the convenience of operation.

Owner:SUNMATCH INDAL

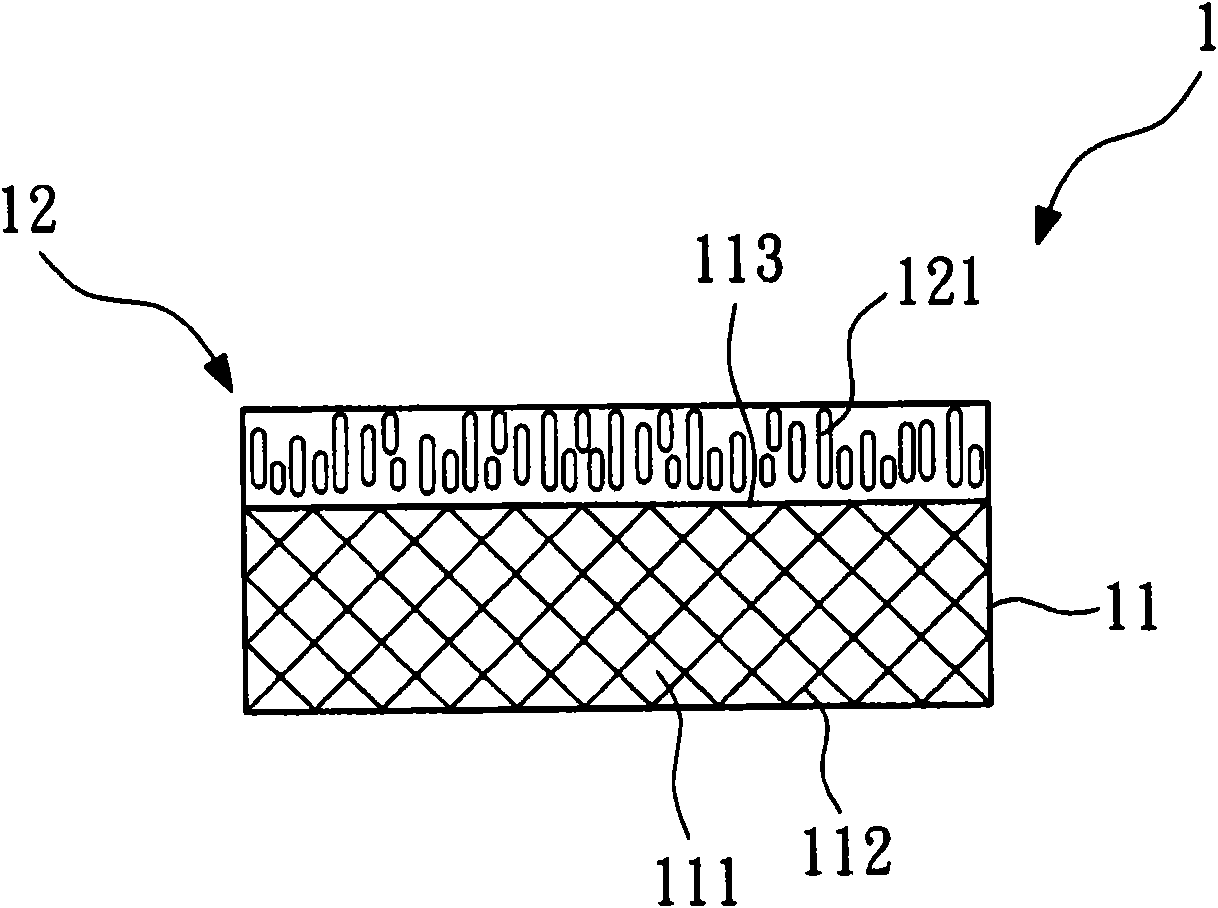

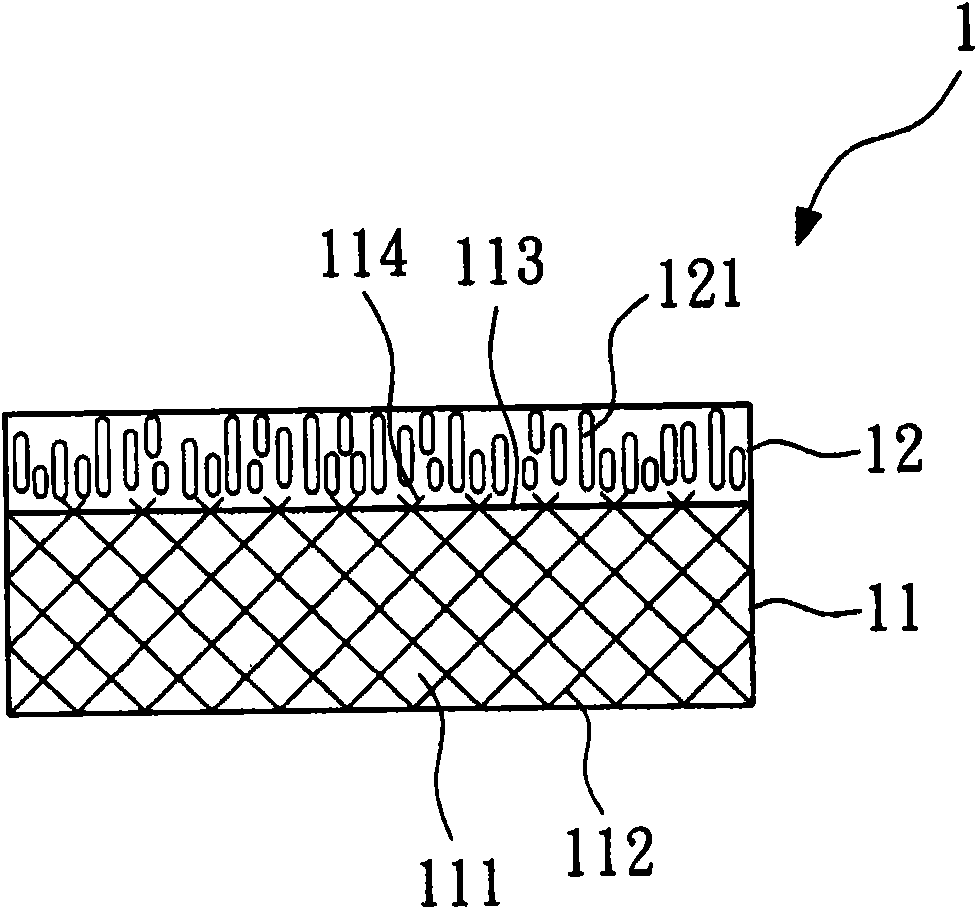

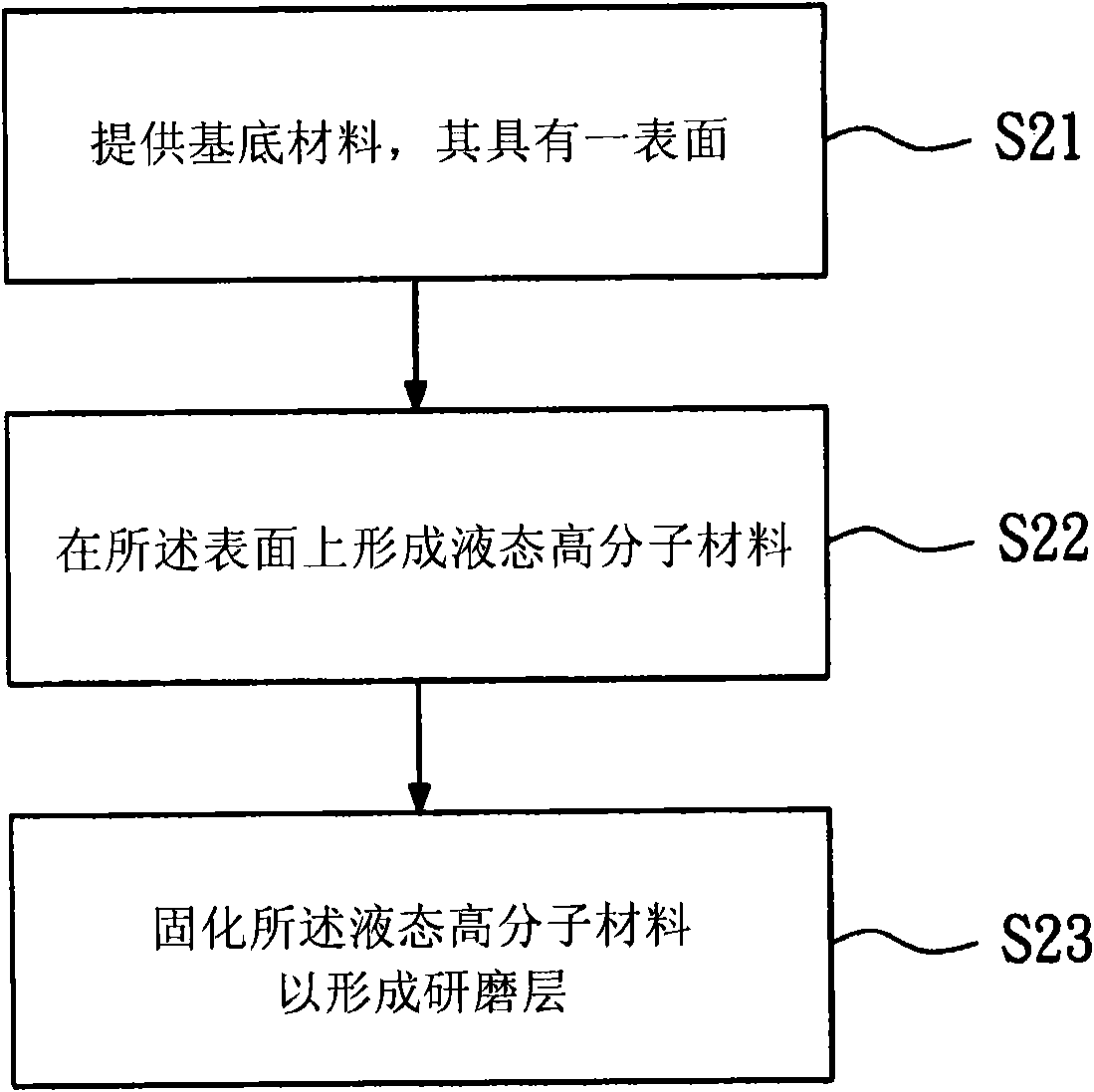

Polishing pad and manufacturing method thereof

InactiveCN101612722AIncrease the compression ratioContaining ability is goodAbrasion apparatusMetallurgyMolecular materials

The invention relates to a polishing pad and a manufacturing method thereof. A liquid polymer material is directly formed on the surface of a substrate material and is solidified to form an even grinding layer, thereby the polishing pad has better integrative performance and better flatness, otherwise, the grinding layer has a long structure and is provided with a plurality of holes which have better inclusion ability for grinding particles in grinding liquid, moreover, the polishing pad has a higher compression ratio, and the polishing pad is in tight contact with an object to be polished and can not scuff the surface of the object to be polished, therefore, the grinding efficiency and the quality can be improved.

Owner:SAN FANG CHEM IND

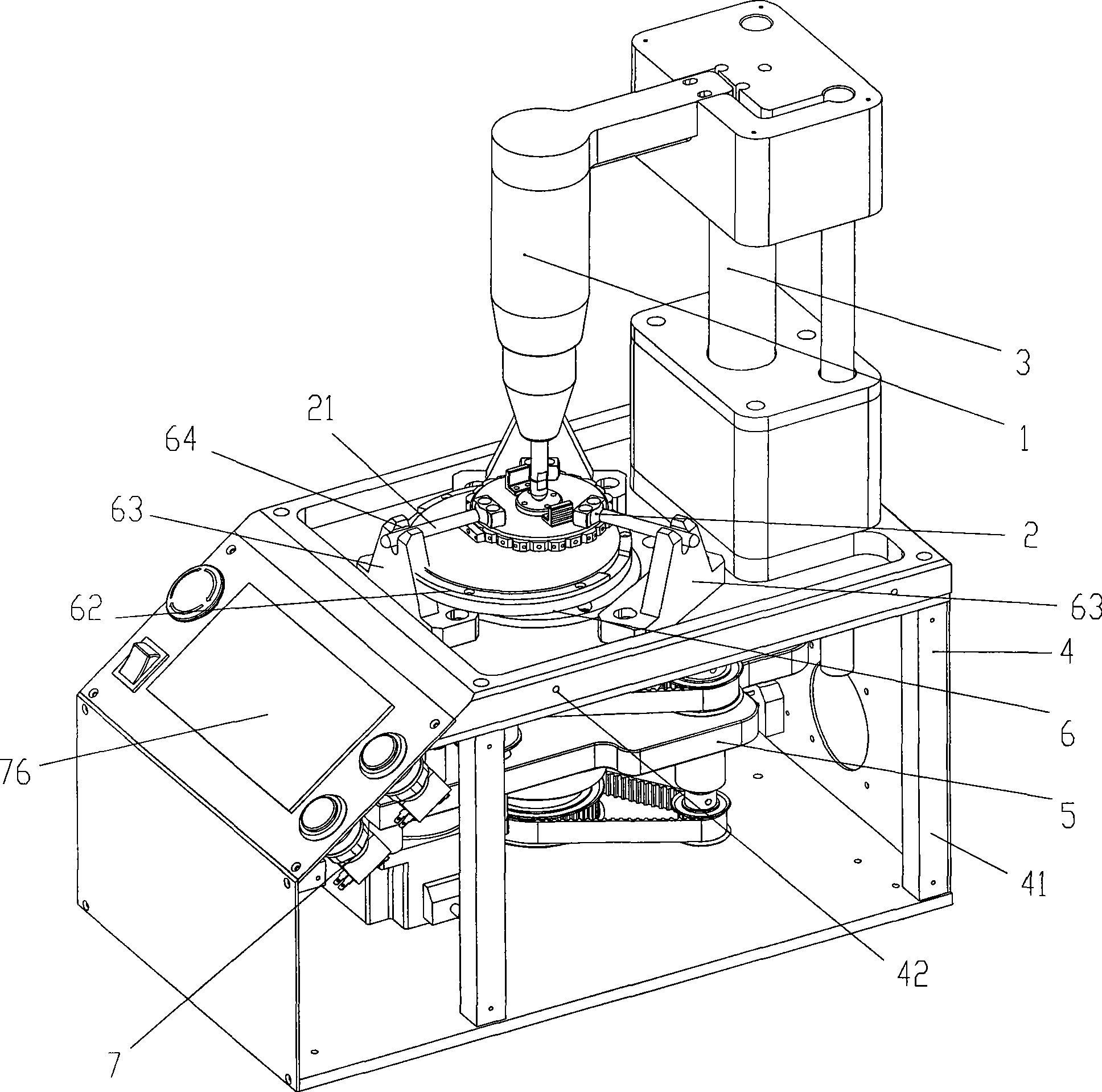

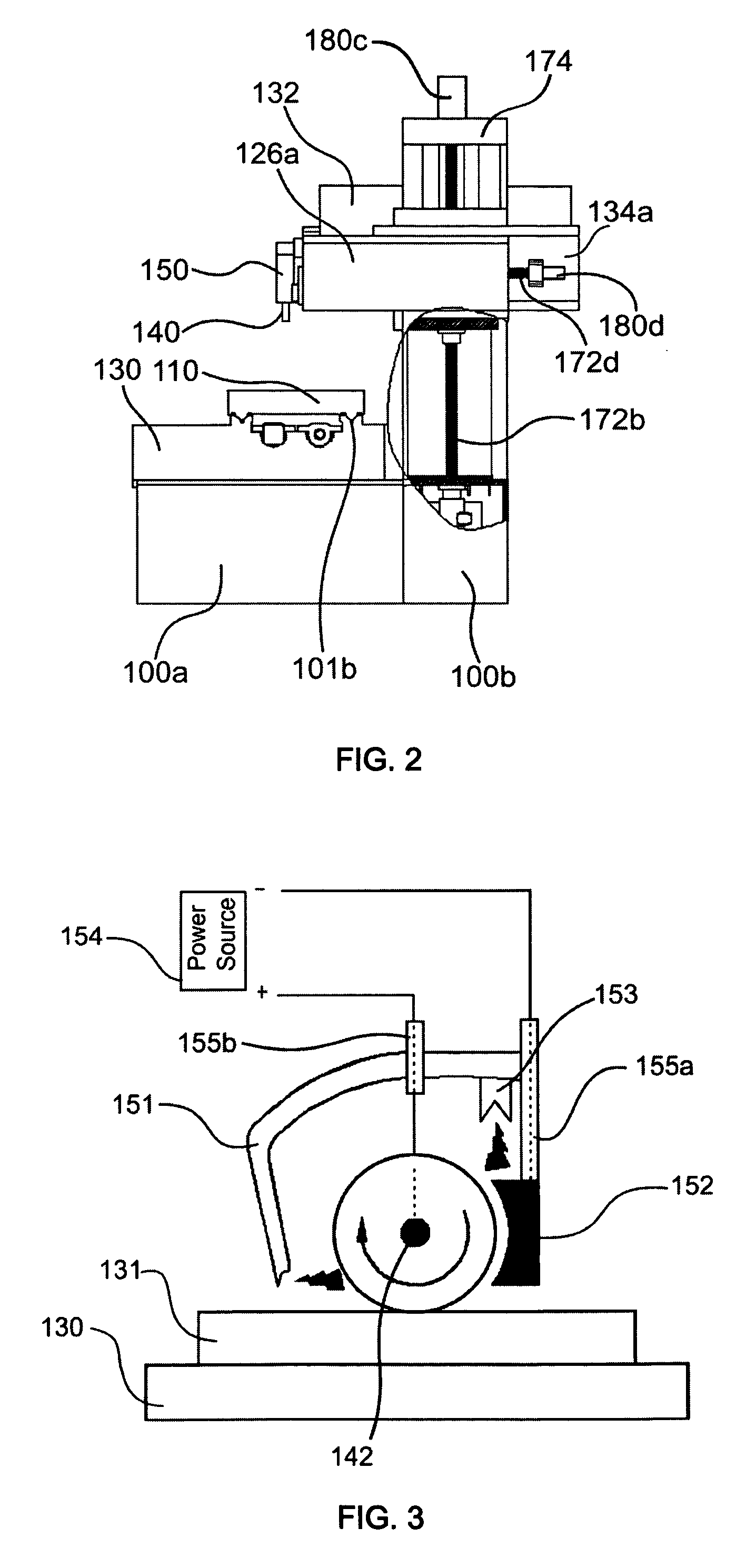

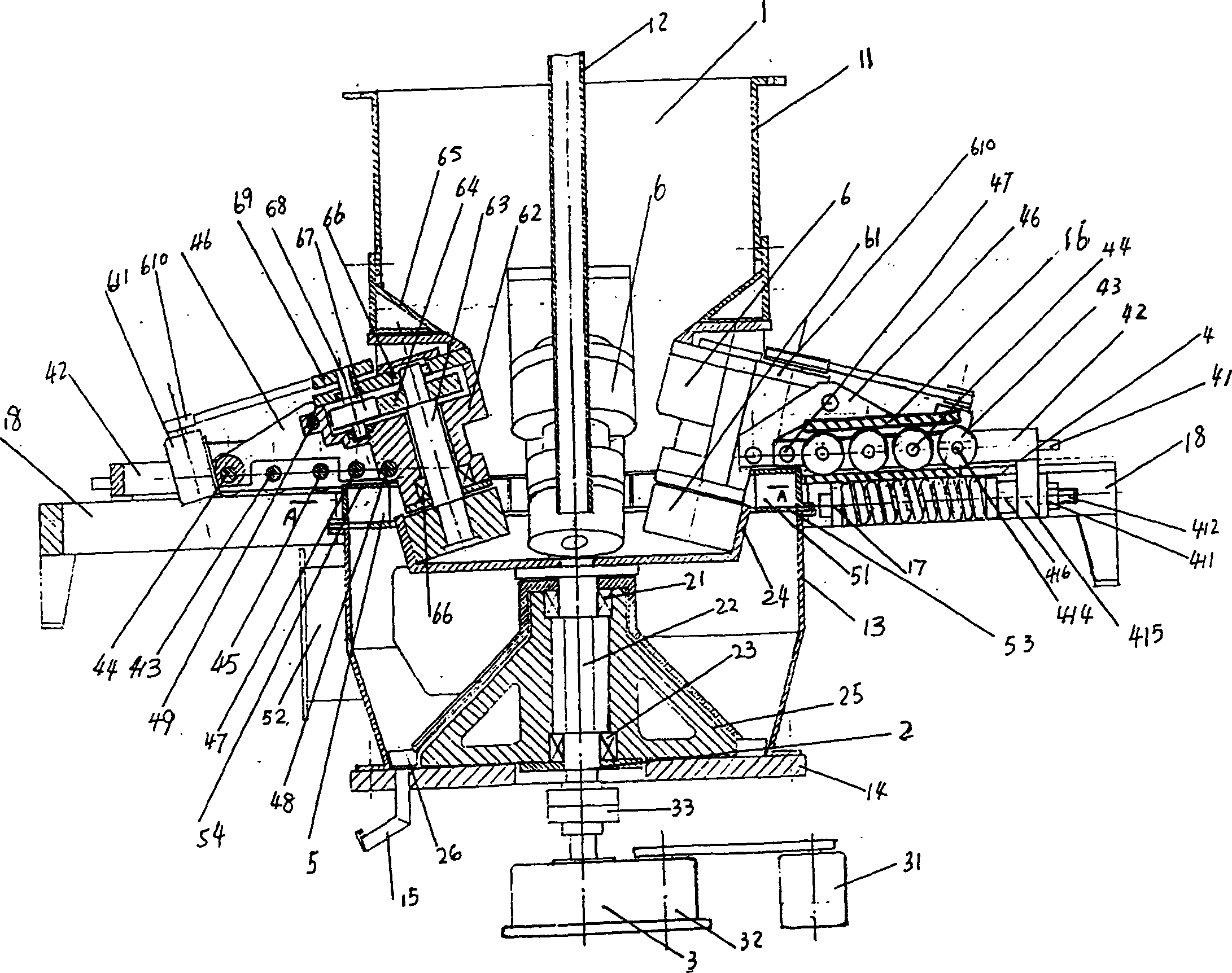

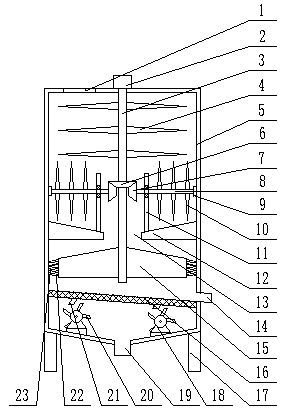

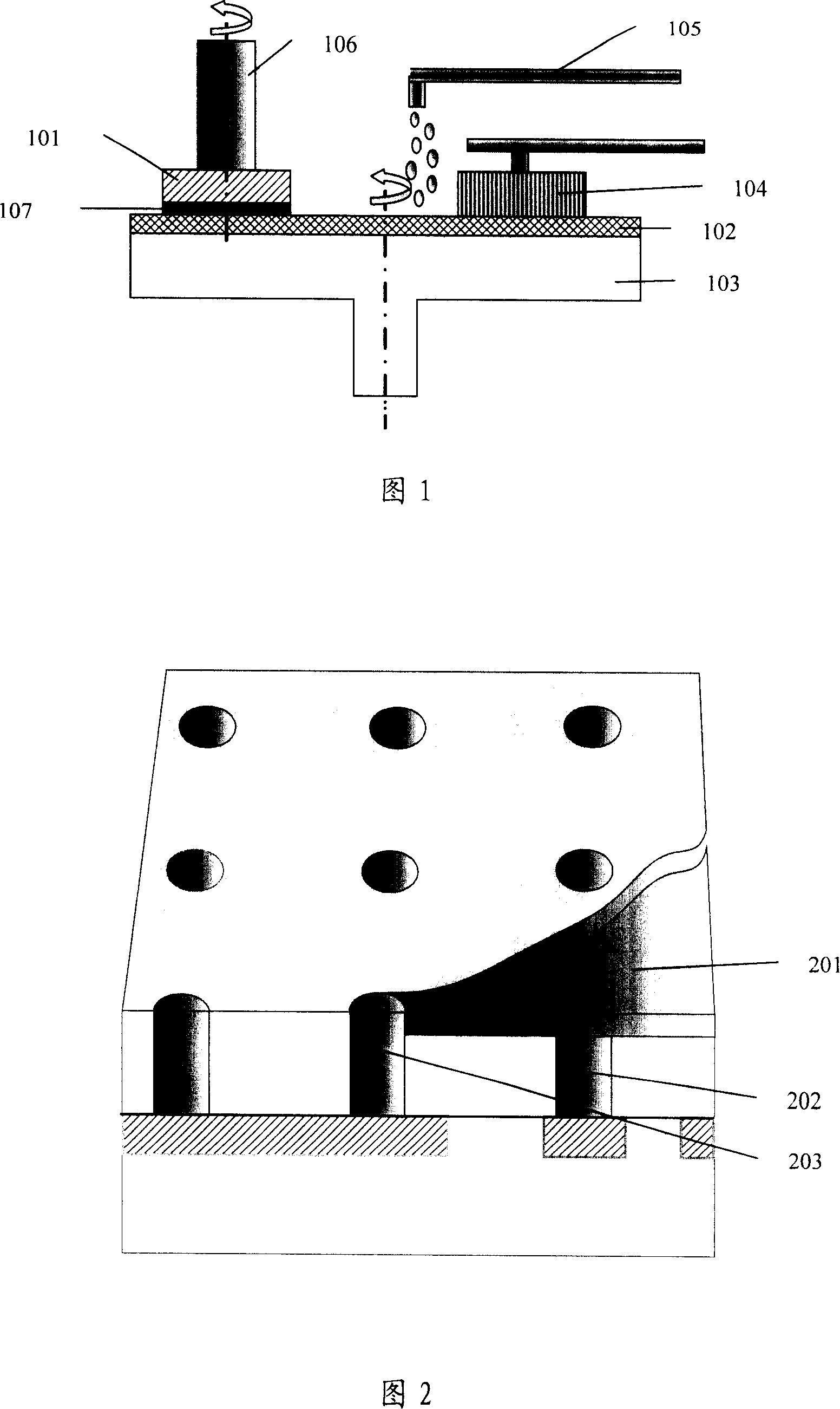

Optical fiber ceramic core automatic grinder and automatic grinding method

InactiveCN101412197AAvoid stabilityAvoid uniformityPlane surface grinding machinesFiberPressure system

The invention relates to an automatic grinder for an optical fiber ceramic insert core and an automatic grinding method. The grinder comprises a stander, a power system arranged on the stander, a grinding system extended out of the stander and driven by the power system, a lifting system arranged on the stand, a pressure system driven by the lifting system to move up and down and a control system, wherein the pressure system and the grinding system are arranged oppositely. The automatic grinding method is as follows: an optical fiber ceramic insert core to be processed is arranged on the grinding system, and the lifting system is controlled to drive the pressure system to compress the fiber ceramic insert core to be processed; the grinding system begins working to grind the lower end face of the fiber ceramic insert core to be processed; and through monitoring pressure change of the pressure system, the control system controls ascending or descending of the lifting system according to the pressure change and / or change of grinding time, to further compress or loosen the optical fiber ceramic insert core, so as to avoid defects of instability and unevenness brought by manual operation. The automatic grinding method has the advantages of accurate control, high precision, safety and reliability.

Owner:SHENZHEN XIANGTONG PHOTOELECTRIC TECH

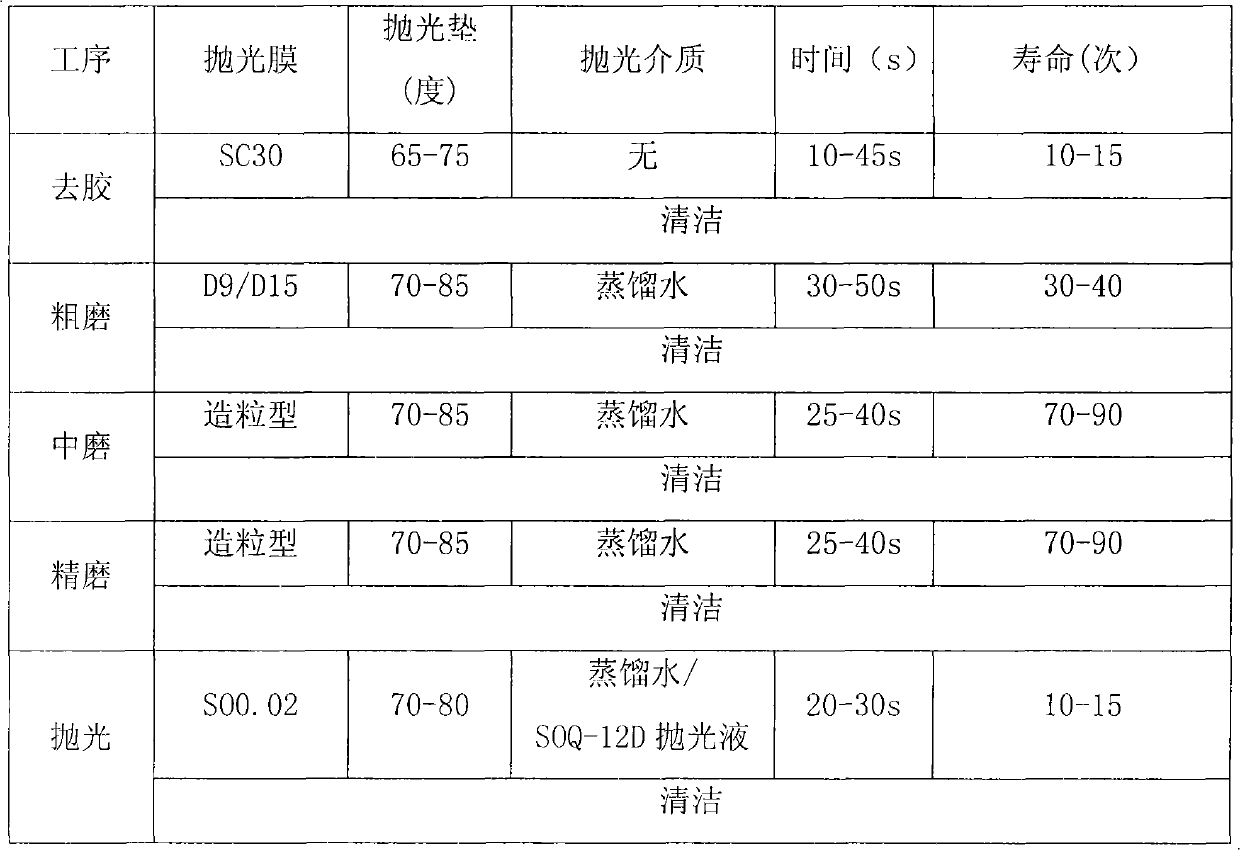

Granulation polishing film, preparing method thereof and application thereof

ActiveCN101767318AImprove surface roughnessImprove grinding efficiencyAbrasion apparatusGrinding machinesPolyesterEpoxy

The present invention provides a for the precise finish of an optical fiber connector with lasting abrasive power and high life time, a preparing method thereof and an application thereof, and can strengthen self-shaping. The granulation polishing film comprises base material and an abrasive layer coated at the surface of the base material, wherein the abrasive layer comprises resinoid bond and composite abrasive grains in global coacervate; the composite abrasive grains are global coacervates prepared by granulating abrasive powder distributed in the mixing liquid of metal oxide sol and organic or inorganic binder; the resinoid bond comprises epoxide resin and epoxide resin toughener, and also comprises one or several kinds of polyester, polyurethane, daiamid, acrylate and polyurea. The granulation polishing film is used for the grinding finish of the optical fiber connector and optical fiber arrays. The life time is one to two times longer than that of the traditional polishing film for the finish of the optical fiber connector, and the processing cost of the optical fiber connector is reduced.

Owner:BEIJING GRISH HITECH

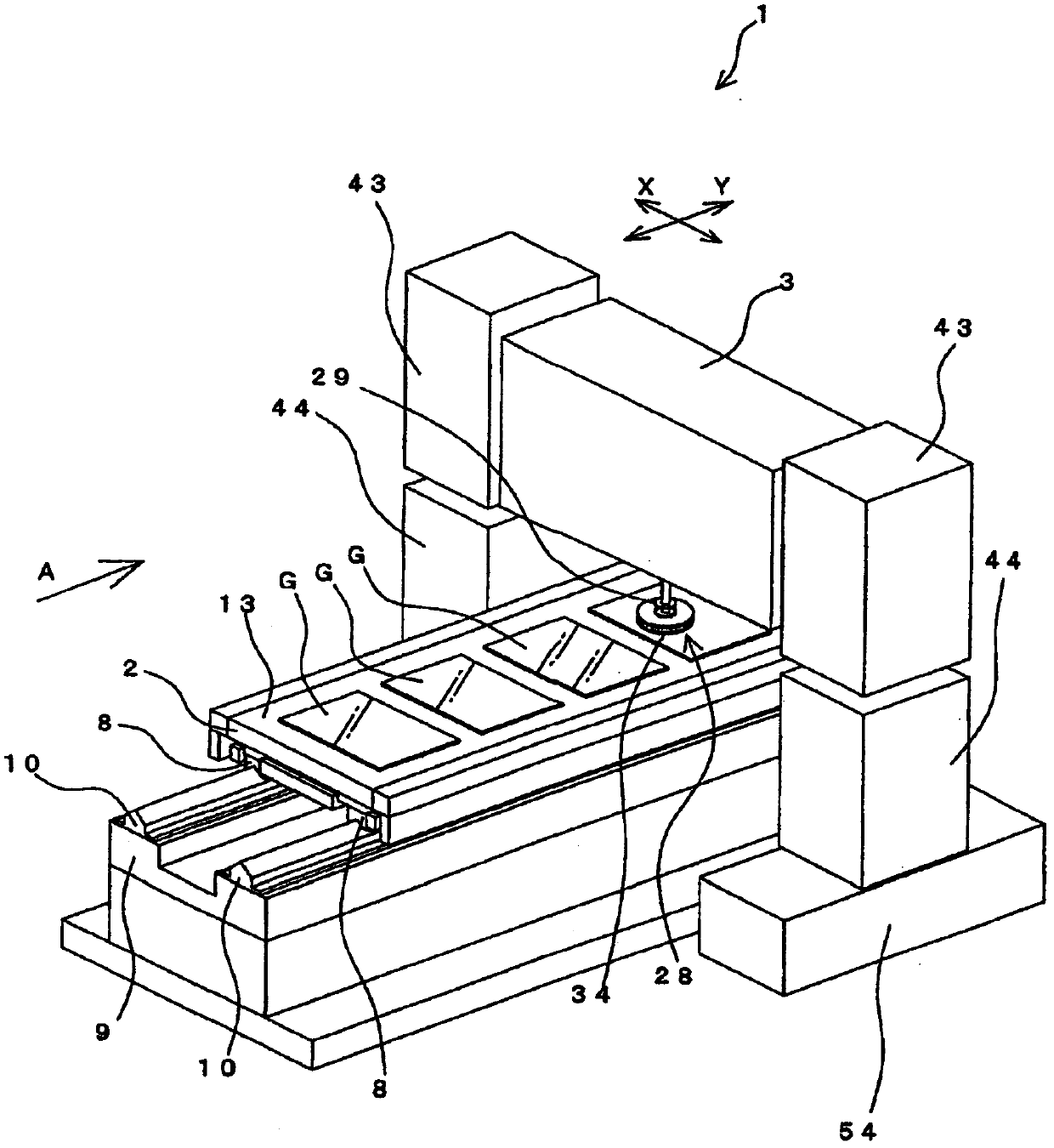

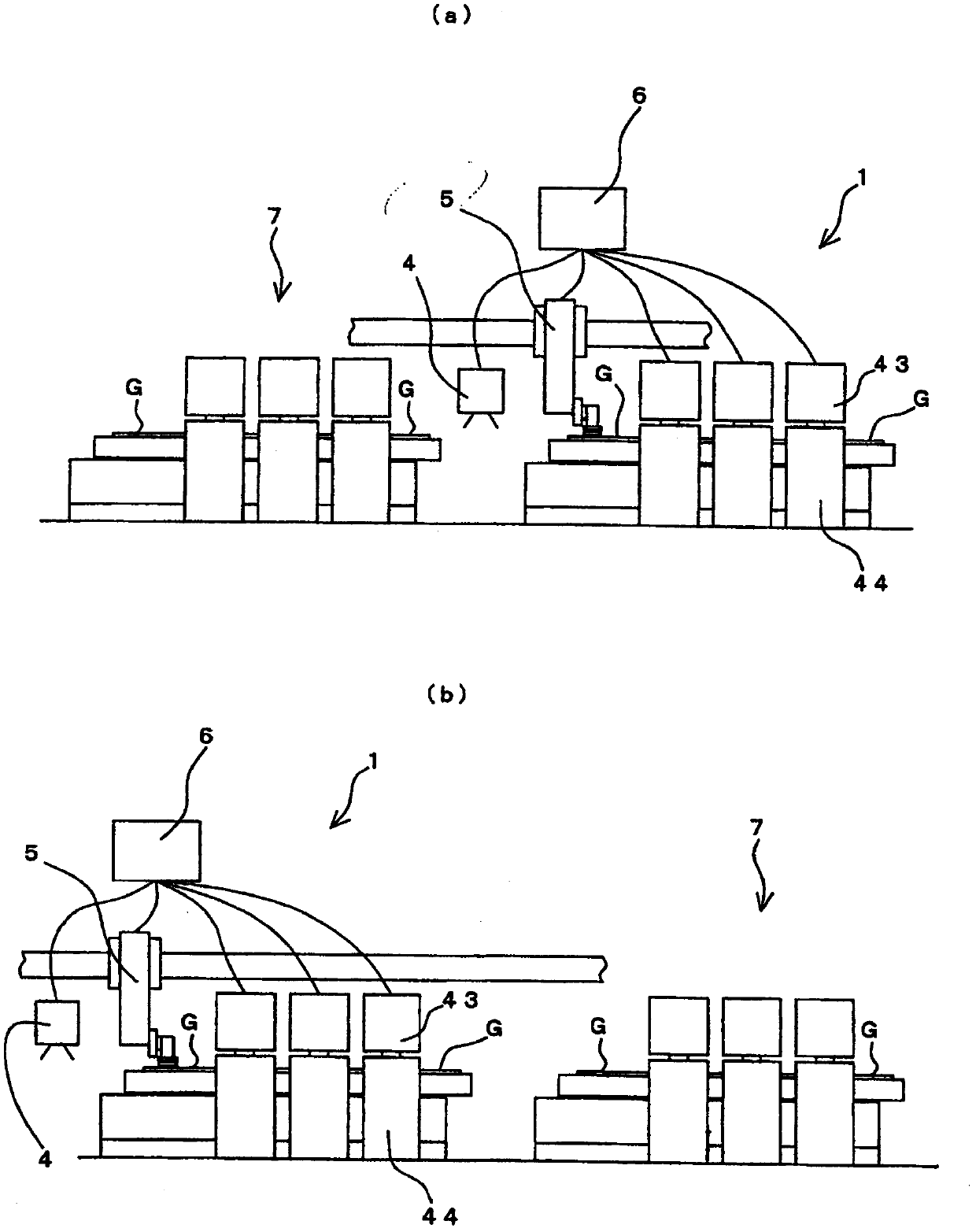

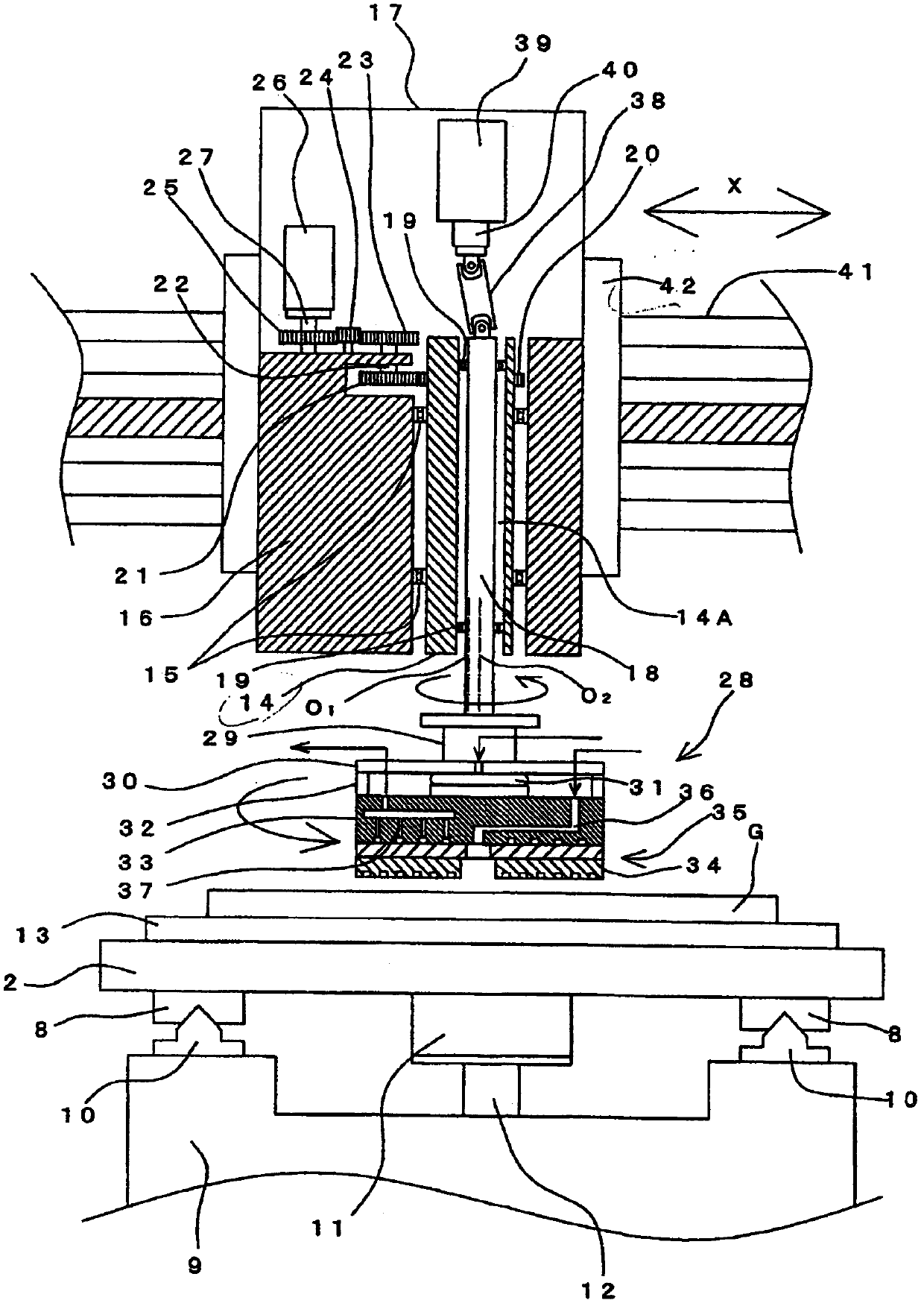

Apparatus and method for locally polishing glass plate, and apparatus and method for producing glass product

ActiveCN102019580AImprove grinding qualitySet up space saving spaceStatic indicating devicesLapping machinesEngineering

The invention provides an apparatus and a method for locally polishing glass plates, and an apparatus and a method for producing glass products, wherein grinding quality is stable and the production efficiency is increased.After the defects on the surface of a glass plate (G) are detected by a detection unit (4), the glass plate (G) is adsorbed and fixed to a work table (2).The positions of the defects (D) detected by the detection unit (4) and the surrounding place are polished by a polishing pad (34) with a smaller dimension compared with the glass plate (G), thereby removing the defects (D) without polishing the whole surface of the glass plate.

Owner:ASAHI GLASS CO LTD

Constant-force grinding and polishing tool system

ActiveCN103786082AReduce the impactSimple structureBelt grinding machinesGrinding feed controlConstant forceMotor vibration

The invention relates to a constant-force grinding and polishing tool system and belongs to grinding and polishing tools. The constant-force grinding and polishing tool system comprises a power device, a gear change grinding tool, a damping device, a guide device, a force compensation and detection device and a counter weight device to realize constant-force grinding. A grinding tool head guarantees the gear change grinding tool to move vertically by the aid of the guide device to form a blade normal grinding and polishing force through total weight resultant force of the tool system and a low-friction countercylinder. A tool head normal force is measured and compared with a set value by an S-type sensor, a final value is fed back to a computer, and the low-friction countercylinder is regulated and controlled for force compensation by an electrical appliance proportional valve. The power device insulates vibration influences of a motor vibration source on the tool system by the aid of the damping device, and high-precision force control is realized through feedback of the S-type sensor. The constant-force grinding and polishing tool system has the advantages that the system is novel in structure, constant-force polishing of blade surfaces with different curvatures is realized, surface uniformity is realized, residual stress is diminished, and polishing efficiency is improved.

Owner:吉林大学重庆研究院

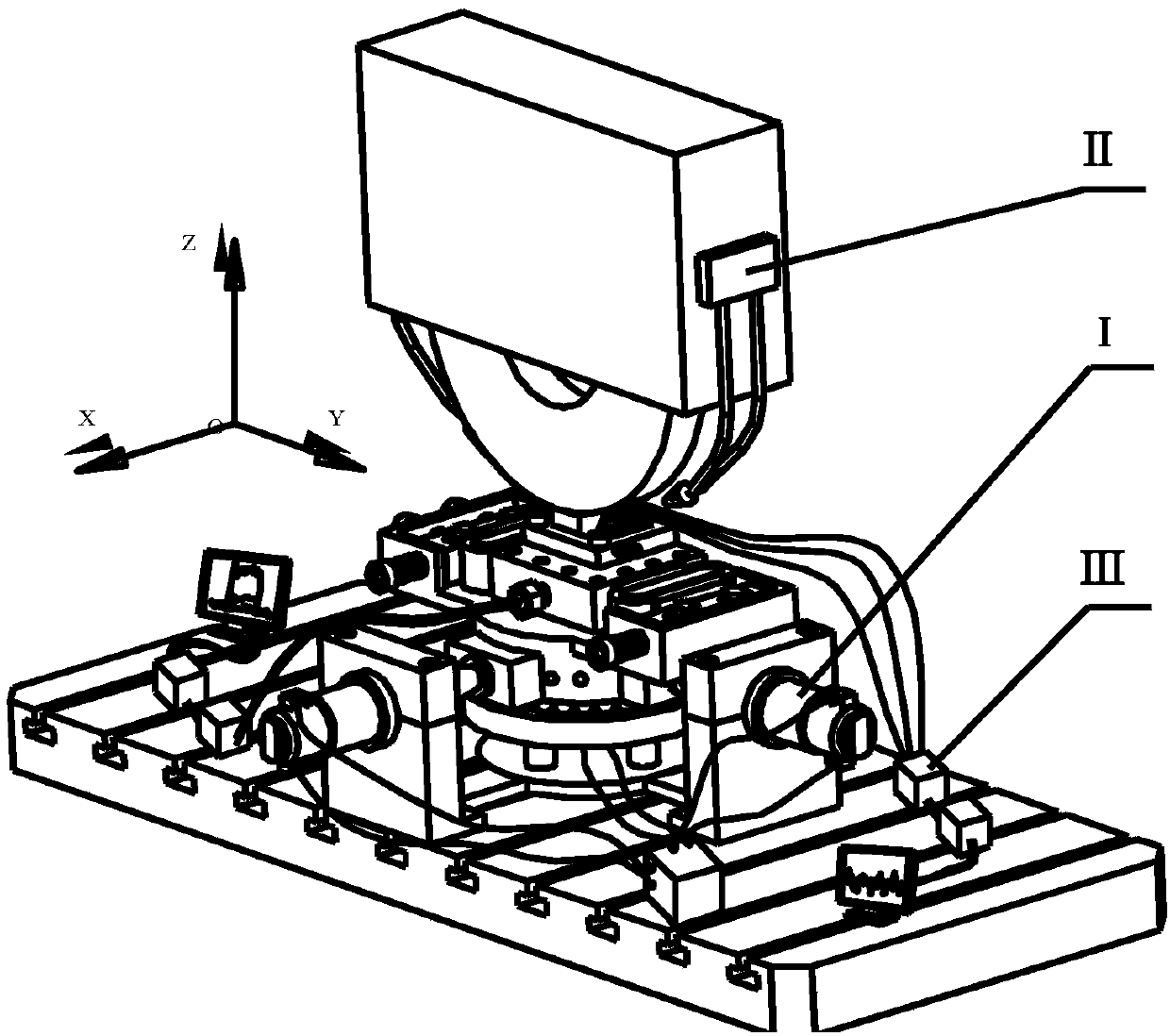

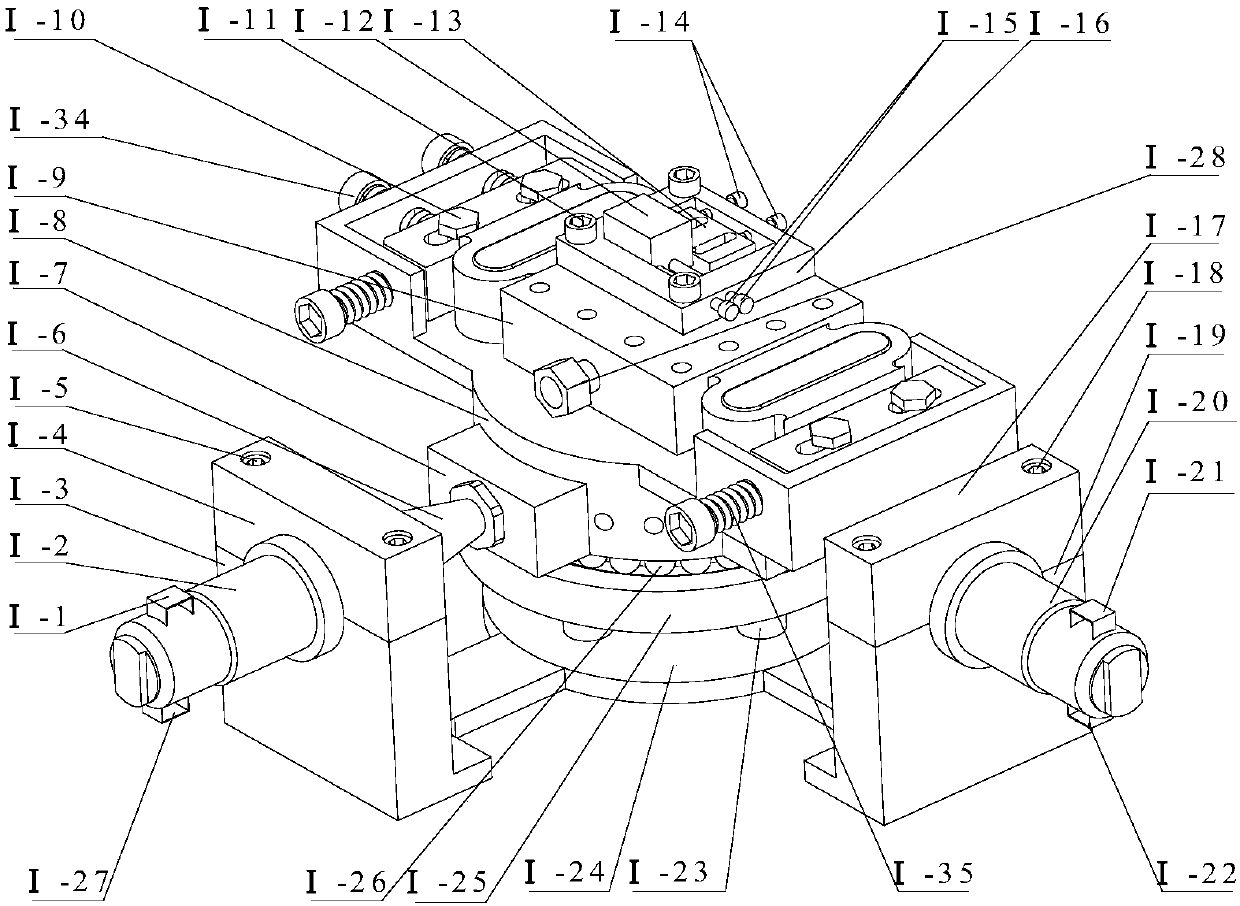

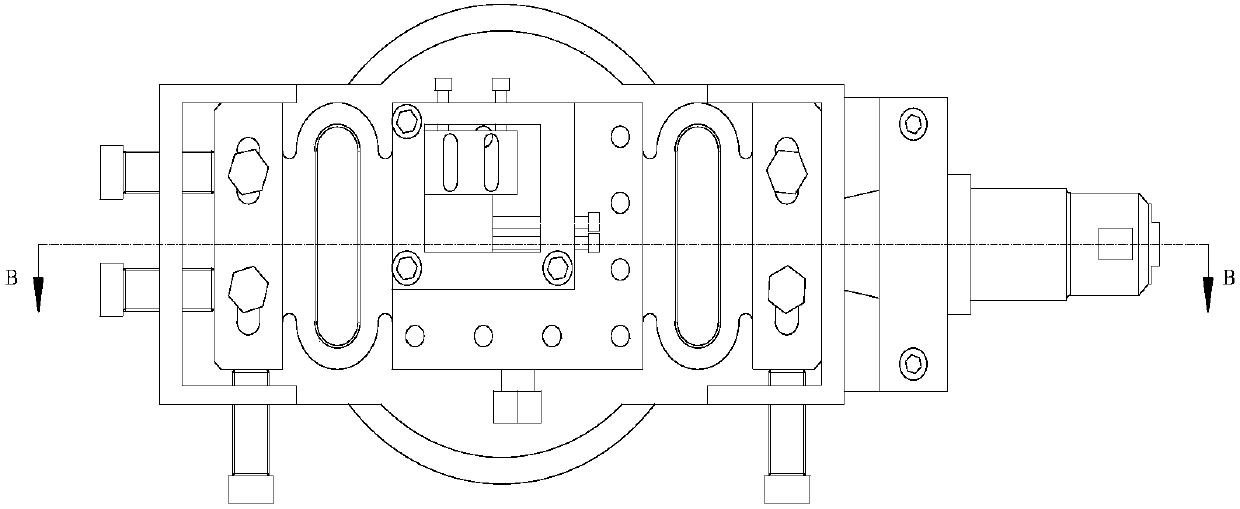

Nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding

InactiveCN107336086AImprove surface qualityDifferent grinding effectsUltrasonic vibrationLubrication

The invention discloses a nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding. The system comprises a magnetism worktable, a workpiece clamp, a measuring cell and an ultrasonic vibration device; the ultrasonic vibration device comprises a tangential ultrasonic vibration device, an axial ultrasonic vibration device, a vibrating base and radial piezoelectric ceramic pieces fixed on the vibrating base; the tangential ultrasonic vibration device and the axial ultrasonic vibration device are respectively fixed on the vibrating base and meanwhile, are respectively fixed on the magnetism worktable by supports, the measuring cell is fixed on the vibrating base and the workpiece clamp is fixed on the measuring cell. The nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding have the advantages that simultaneous online detection of a grinding force and a grinding temperature are realized, time is saved, and the machining errors caused by assembling for multiple times are also avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

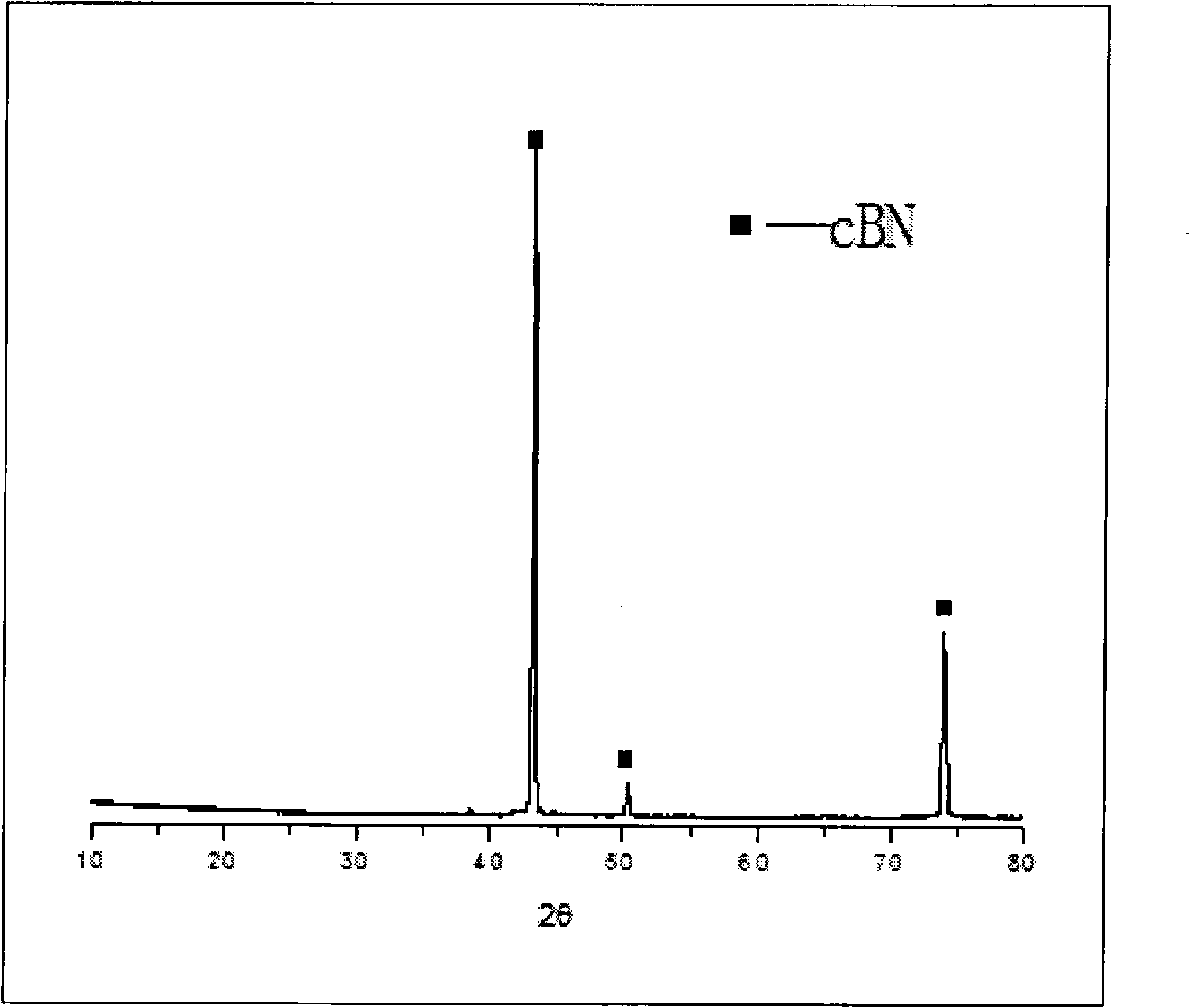

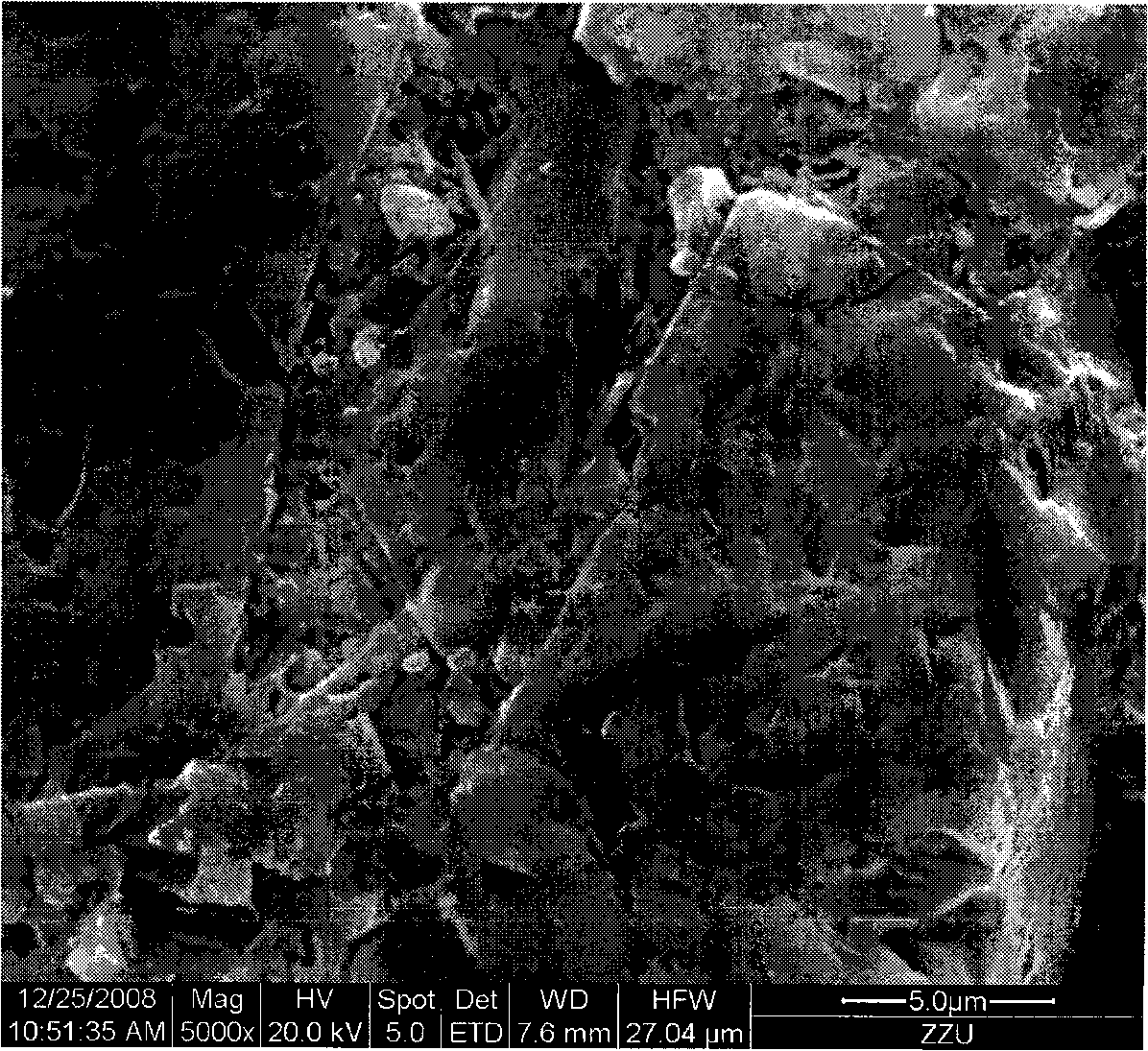

Method for preparing polycrystalline cubic boron nitride

The invention discloses a method for preparing polycrystalline cubic boron nitride, which comprises the following steps: using cubic boron nitride and a bonding agent as raw materials, mixing the cubic boron nitride and the bonding agent and then ball-milling the mixture, wherein the ball material ratio during the ball milling is (1-4):1, the rotating speed is between 400 and 800 revolutions per minute, and the ball milling time is between 4 and 20 hours; drying the mixed mixture after the ball milling, adding an organic binder into the mixture after drying, mixing the mixture evenly, and screening the mixture through a 100-mesh screen; performing cold compression and forming with the pressure of between 0.8 and 2 GPa; and sintering the formed green body at a sintering temperature of between 1,000 and 1,300 DEG C, and keeping the temperature for 4 to 20 hours so that the finished product is obtained after the sintering. The polycrystalline cubic boron nitride PcBN prepared by the method is gray and is a compact block which has the superior performances of high hardness, high grinding efficiency, good impact resistance toughness, easy conditioning, good grinding quality and the like. The method has the advantages of simple equipment, easily-controlled operation, low cost and easy large-scale production, has favorable social value and economic value, and is easy to popularize and apply.

Owner:FUNIK ULTRAHARD MATERIAL +1

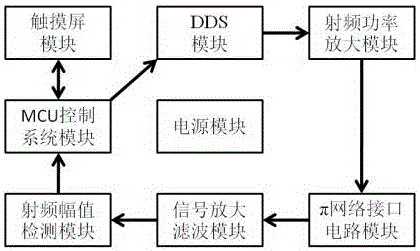

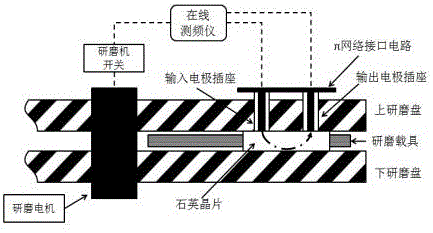

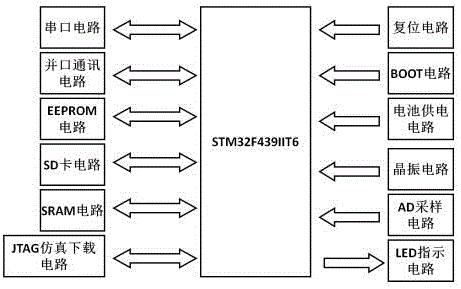

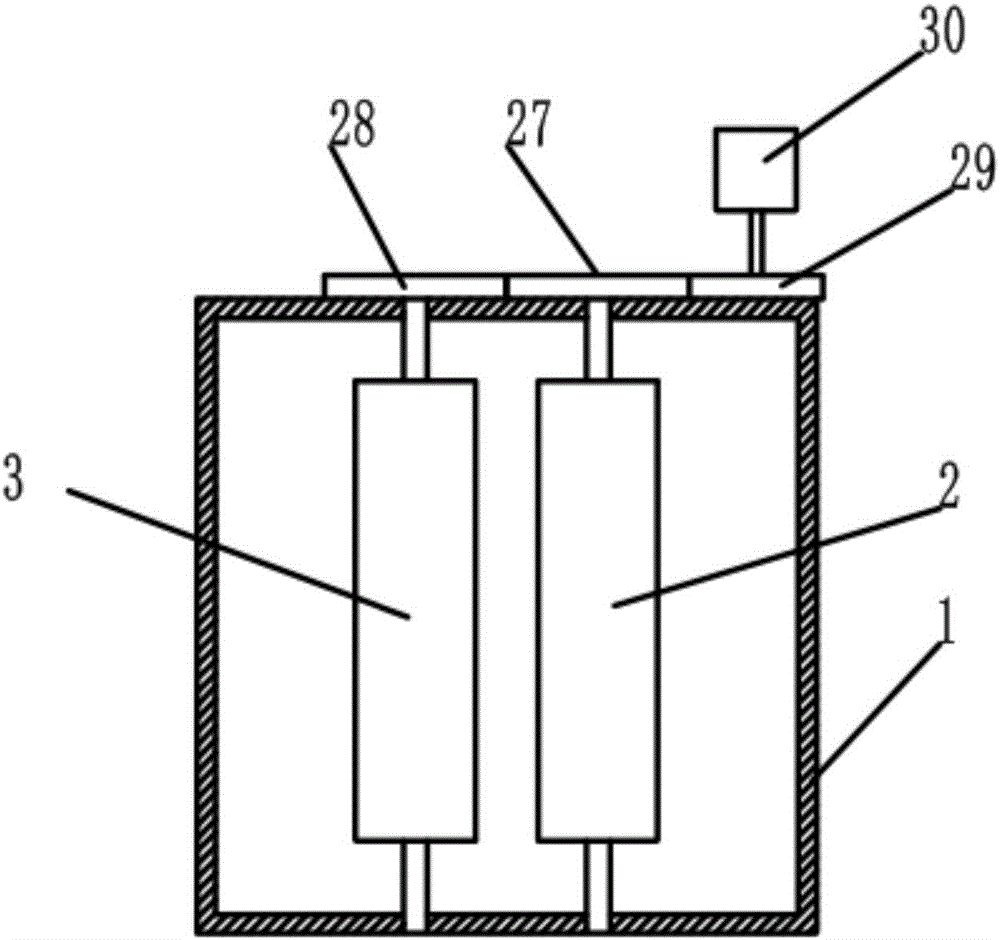

Online frequency measurement system for quartz wafer grinding

InactiveCN105866540AImprove grinding qualityImprove stabilityFrequency measurement arrangementRadio frequencyFrequency band

The invention discloses an online frequency measurement system for quartz wafer grinding. The system comprises a power module, an MCU control system module, a DDS module, a radio-frequency power amplifying module, a pi network interface circuit module, a signal amplifying and filtering module, a radio-frequency amplitude detection module and a touch screen module. According to the system, the anti-interference performance of the system is enhanced through the pi network maximum transmission method detection principle based on a DDS technology, and the problem that in an existing ALC system, frequency measurement value jumping change is generated at some frequency bands is solved; all the frequency bands adopt a unified pi network interface circuit, therefore, the defect that a detection head needs to be replaced at the different frequency bands of the existing ALC system is overcome, the electrical failure risk caused by frequent plugging of a radio-frequency connector is reduced, the working stability of the system is enhanced, and the wafer grinding quality and the product quality stability can be significantly improved; through a hardware system scheme, not only can all the frequency bands related to existing wafer grinding production be covered, but also all the cutting types of quartz wafers can be compatible with the system only through modification of algorithm parameters.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

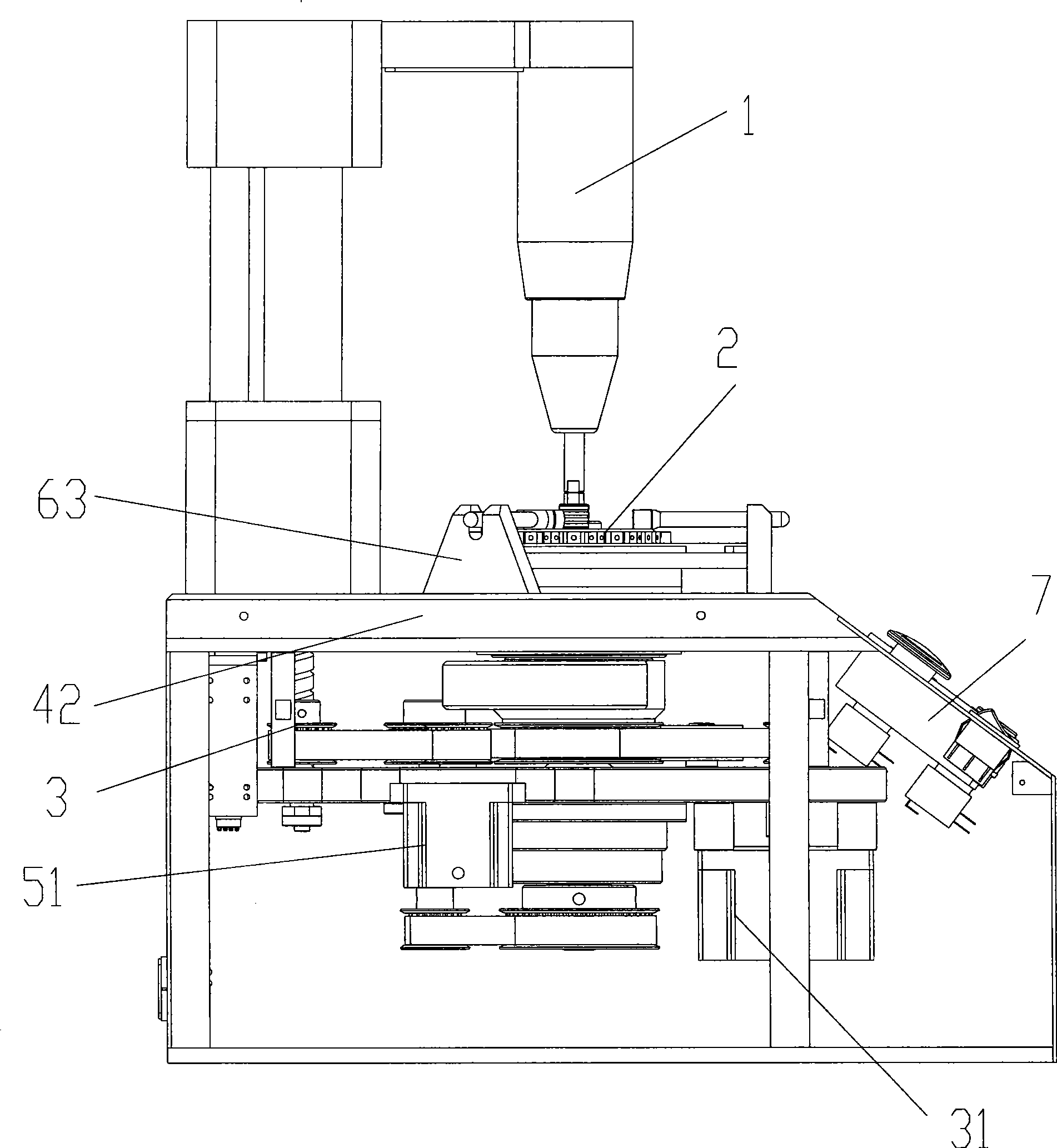

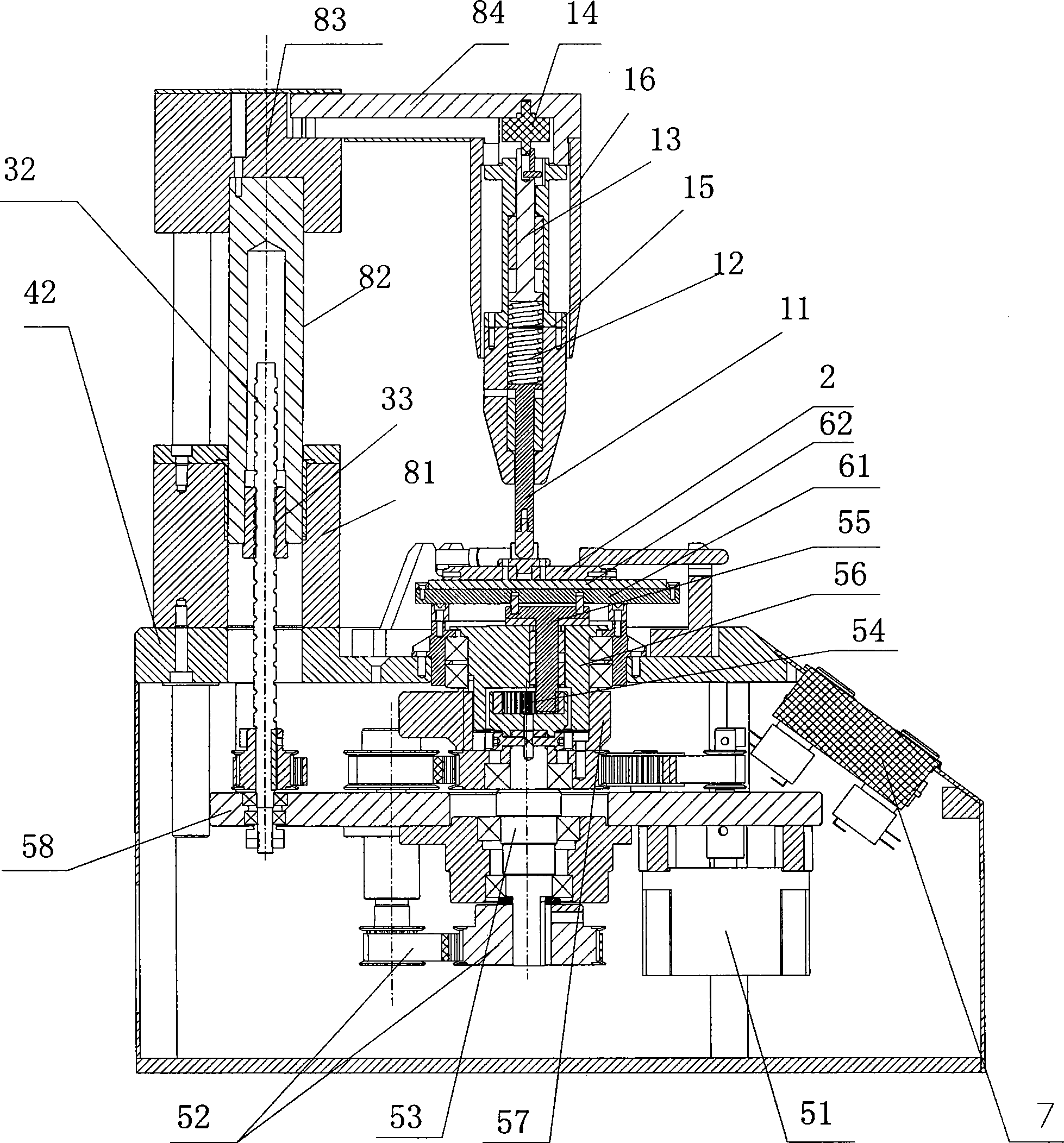

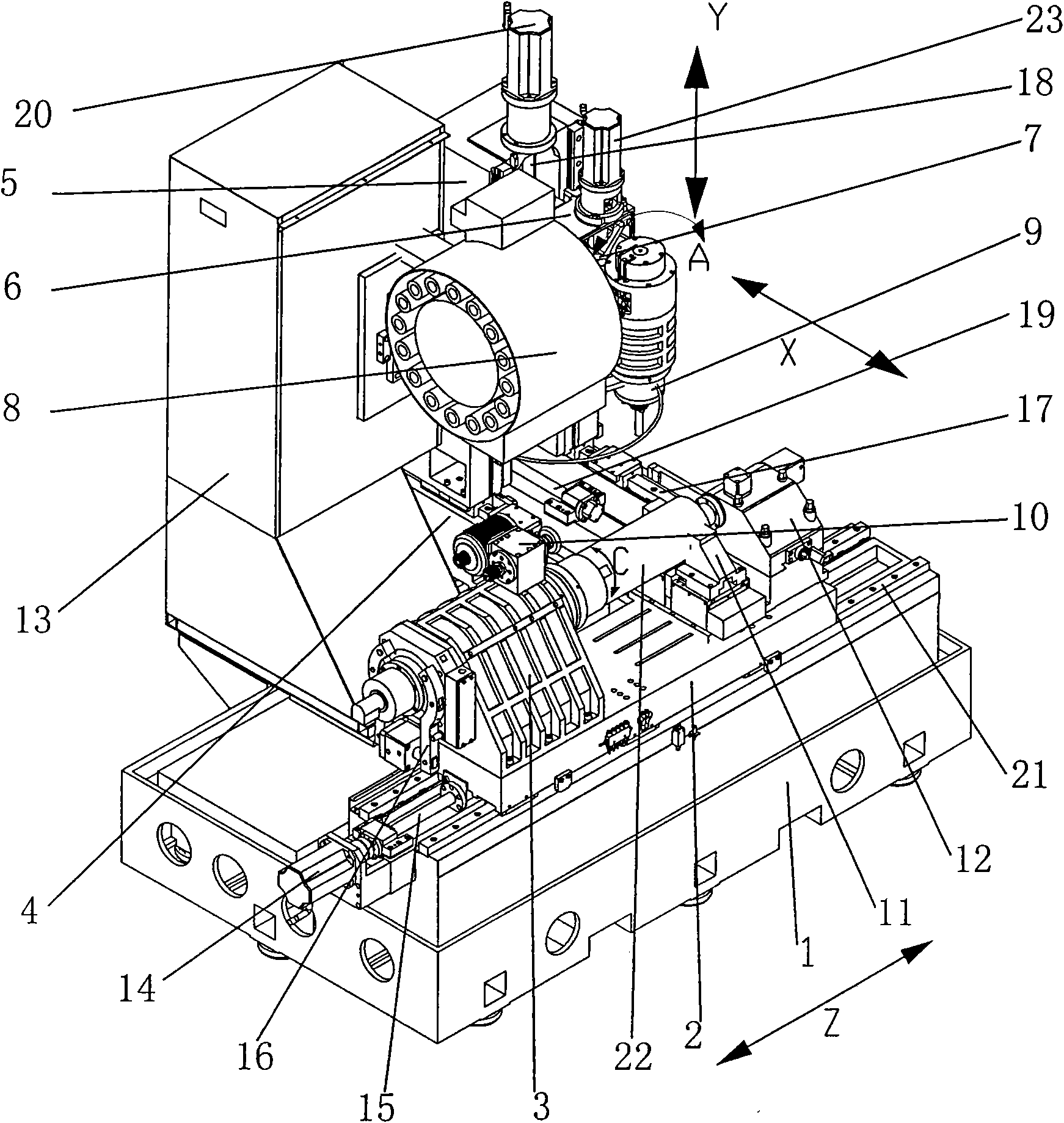

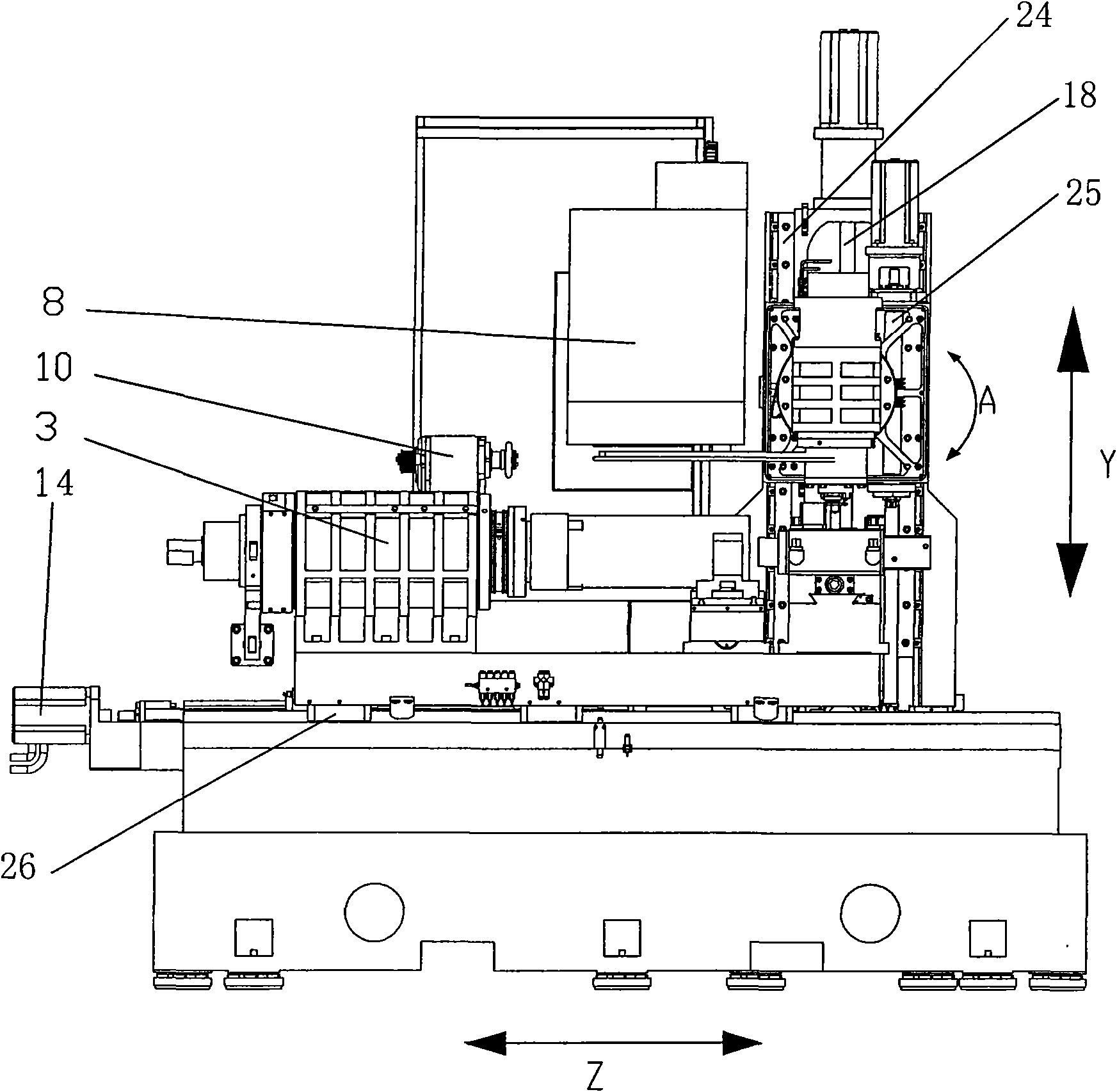

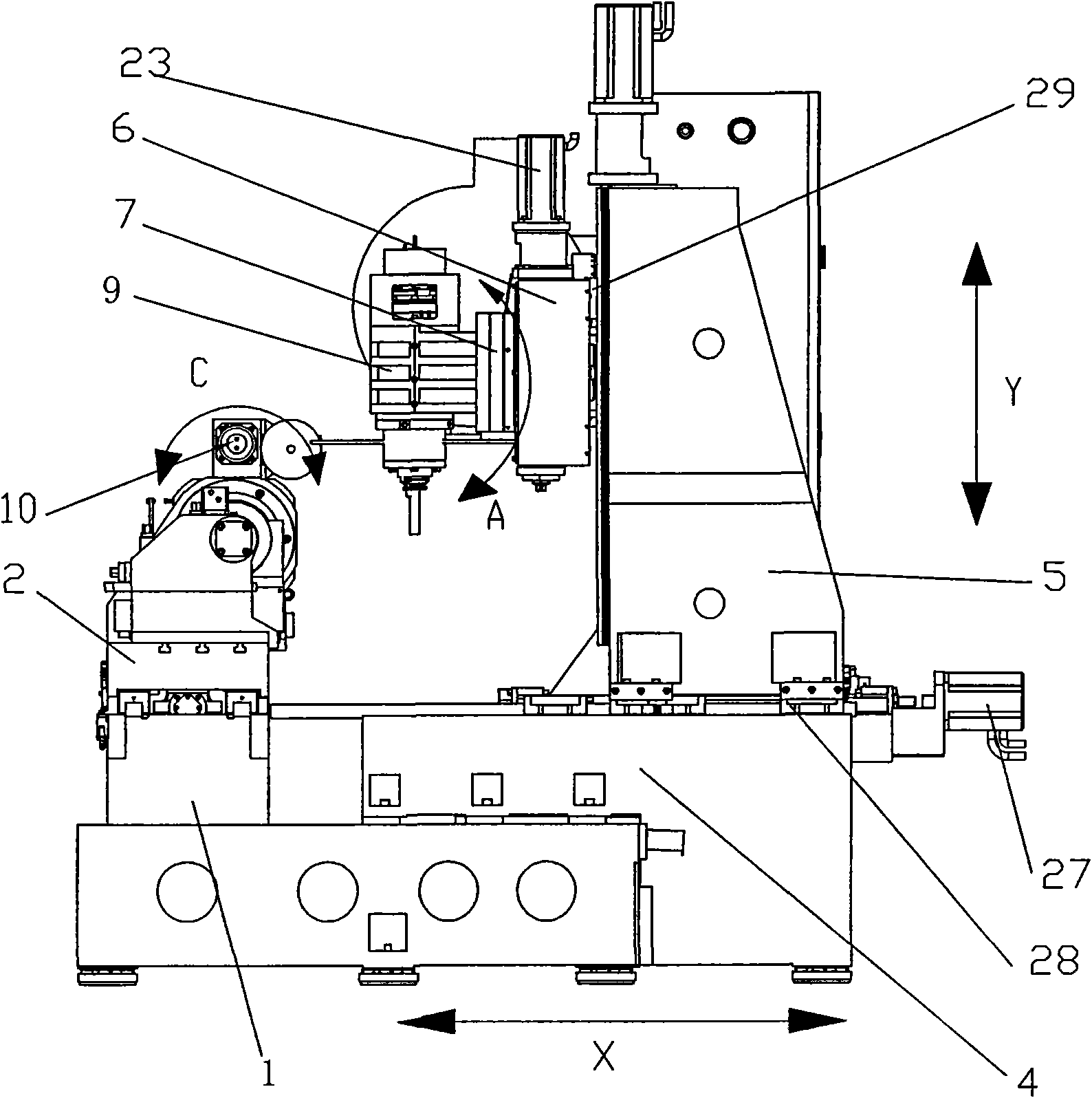

Five-axis multi-functional thread grinding machining center

ActiveCN101513686AImplement fixesSimple structureThread cutting machinesManufacturing cost reductionNumerical control

A five-axis multi-functional thread grinding machining center belongs to the numerically controlled machine tool field. The five-axis multi-functional thread grinding machining center consists of a machine tool body, a Z-direction slide plate, a workpiece electric spindle, a X-direction base plate, a post, a Y-direction slide plate, an A-axis turntable and a grinding electric spindle. A Z-direction servomotor drives a Z-direction lead screw to drive the Z- direction slide plate to perform Z-direction movement, the post is arranged on a X- direction guide rail slider, a X-direction servomotor drives an X-direction lead screw to drive the post to perform X-direction movement, a Y-direction guide rail is fixedly arranged on the post, the Y-direction slide plate is positioned on a Y-direction guide rail slider, a Y-direction servomotor drives a Y-direction lead screw to drive the Y-direction slide plate to perform Y-direction movement, the Z-direction slide plate is provided with the workpiece electric spindle, the A-axis turntable is arranged on the Y-direction slide plate and is connected with an A-axis servomotor, and the grinding electric spindle is fixed on the A-axis turntable by bolt fastening. The five-axis structure is adopted in the grinding machining center, thus simplifying machine tool structure, realizing grinding of super-long nuts, enlarging applicability of the machine tool and lowering manufacturing cost.

Owner:GUANGZHOU CITY AGILE MFG

Mixed ultra-hard abrasive honing stone

InactiveCN104400614AReduce processing costsEasy to manufactureOther chemical processesAbrasion apparatusNickelHot press

The invention discloses a mixed ultra-hard abrasive honing stone. The mixed ultra-hard abrasive honing stone is characterized by comprising the following components in percentage by weight: 20-40 percent of copper, 2-6 percent of silver, 1-10 percent of aluminum, 2-6 percent of zinc, 2-20 percent of tin, 10-20 percent of iron, 5-10 percent of nickel, 5-30 percent of cobalt, 1-9 percent of lead, 5-10 percent of a bonding agent and the balance of an ultra-hard material, wherein the volume ratio is 60-100 percent; the metal purity of the copper, the silver, the aluminum, the zinc, the tin, the iron, the nickel, the cobalt and the lead is over 99 percent; the granularity of the ultra-hard material is 200-1,000 meshes; the honing stone is prepared by performing mixing, cold press molding and vacuum hot press process on the raw materials according to the mixture ratio. The mixed ultra-hard abrasive honing stone disclosed by the invention has the advantages of sharp grinding, high grinding efficiency, large grinding weight, short grinding time, long service life, superior self-sharpening property, low process cost, easiness and convenience in preparation, and the like.

Owner:YINCHUAN HENGYIDA MACHINERY

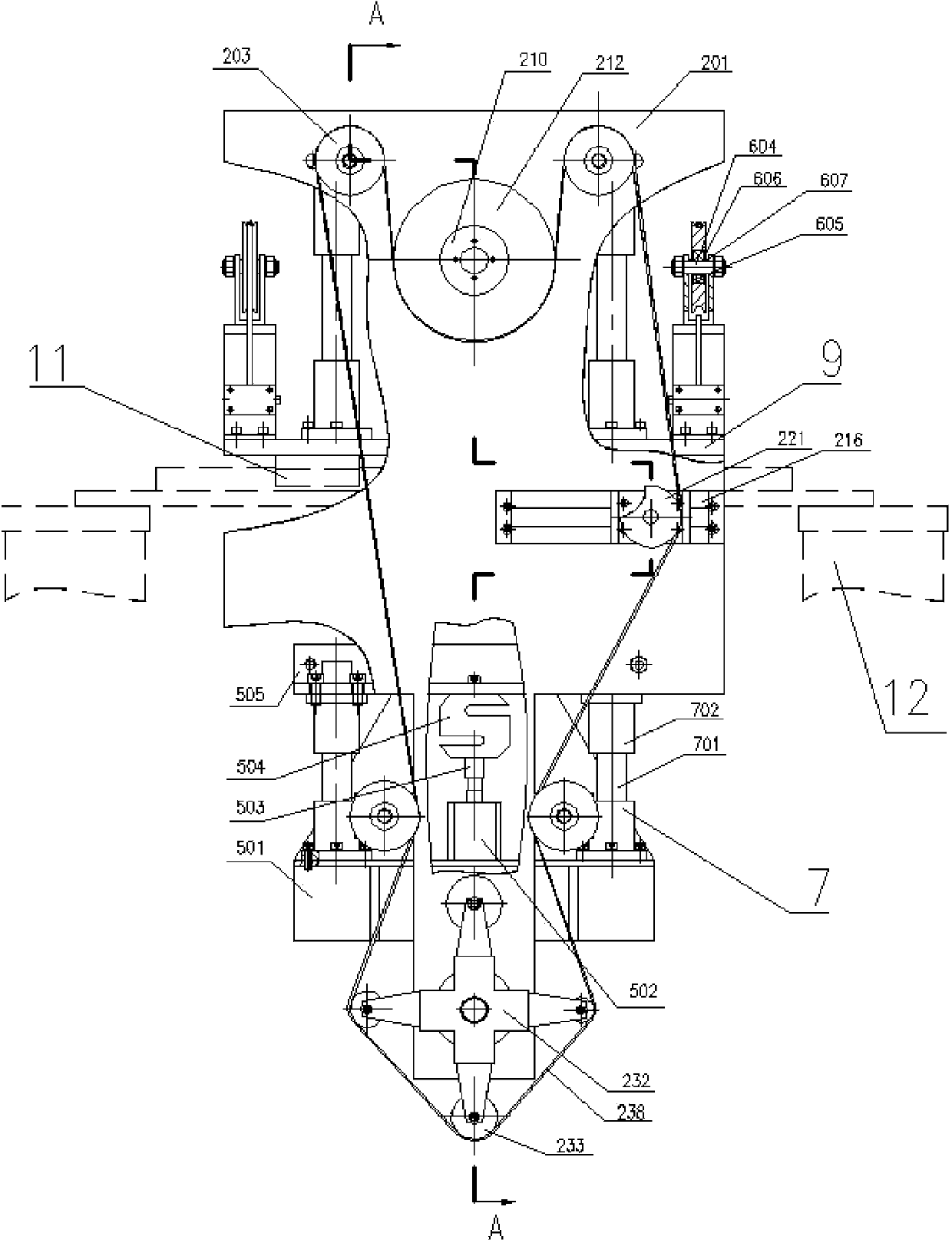

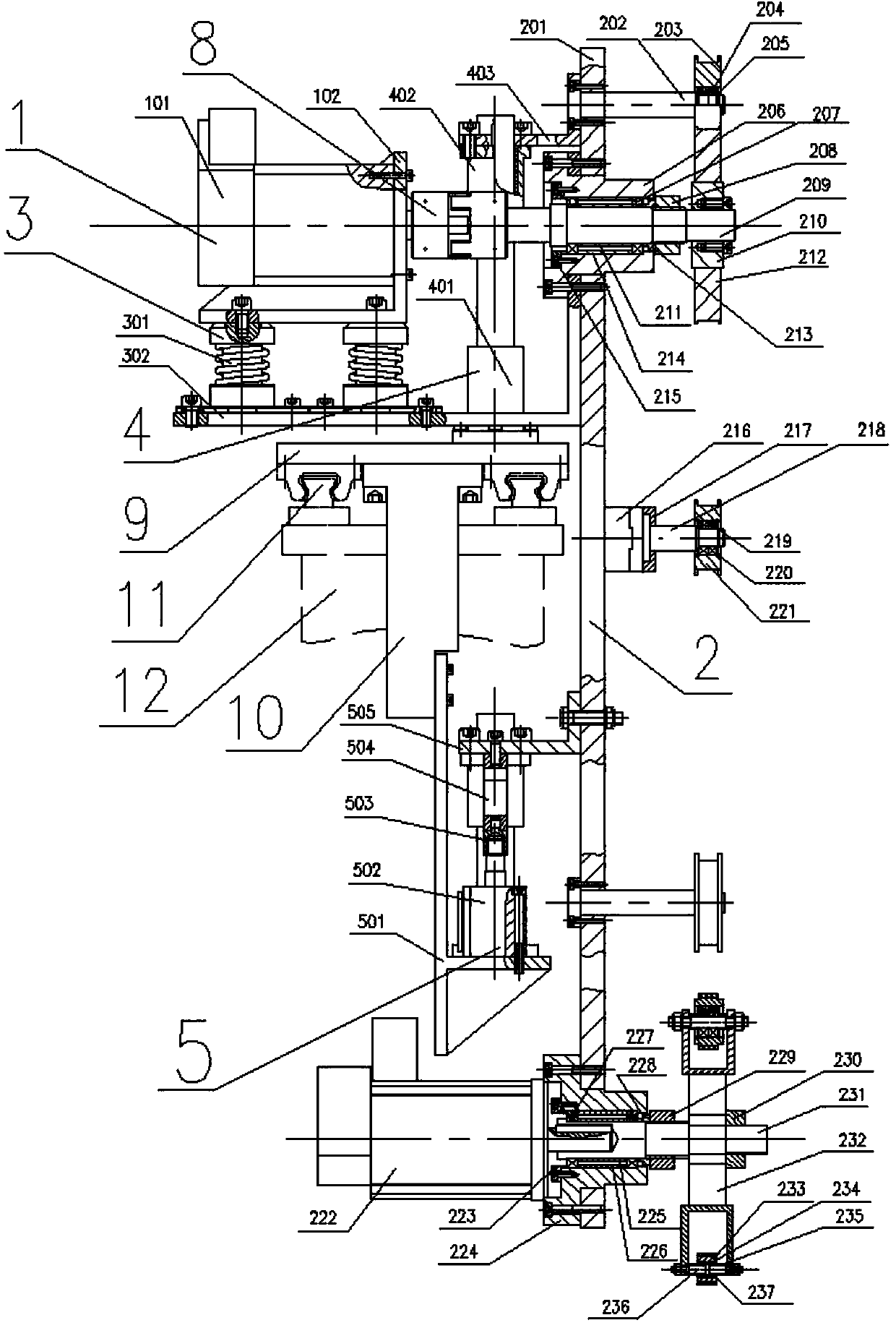

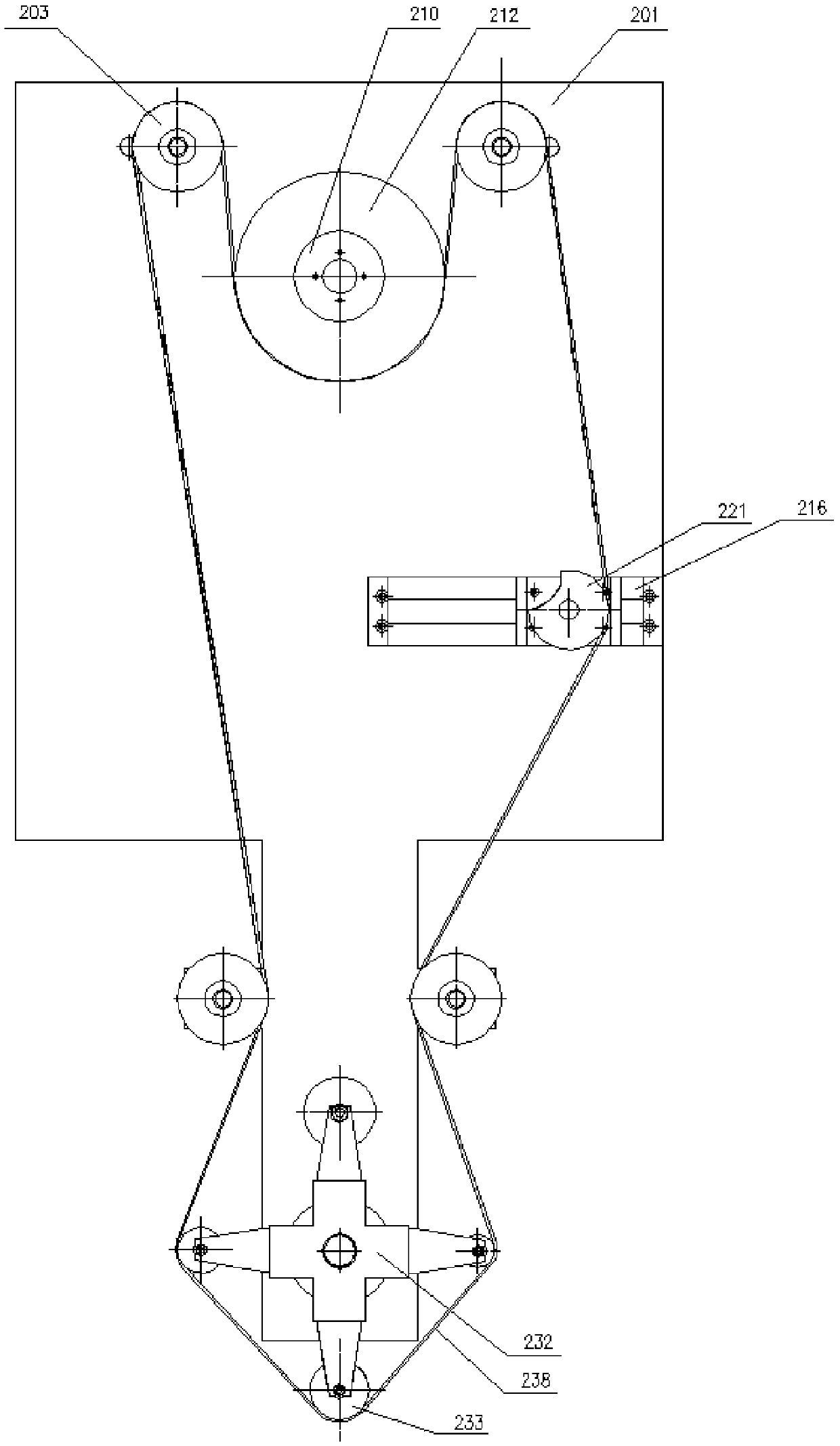

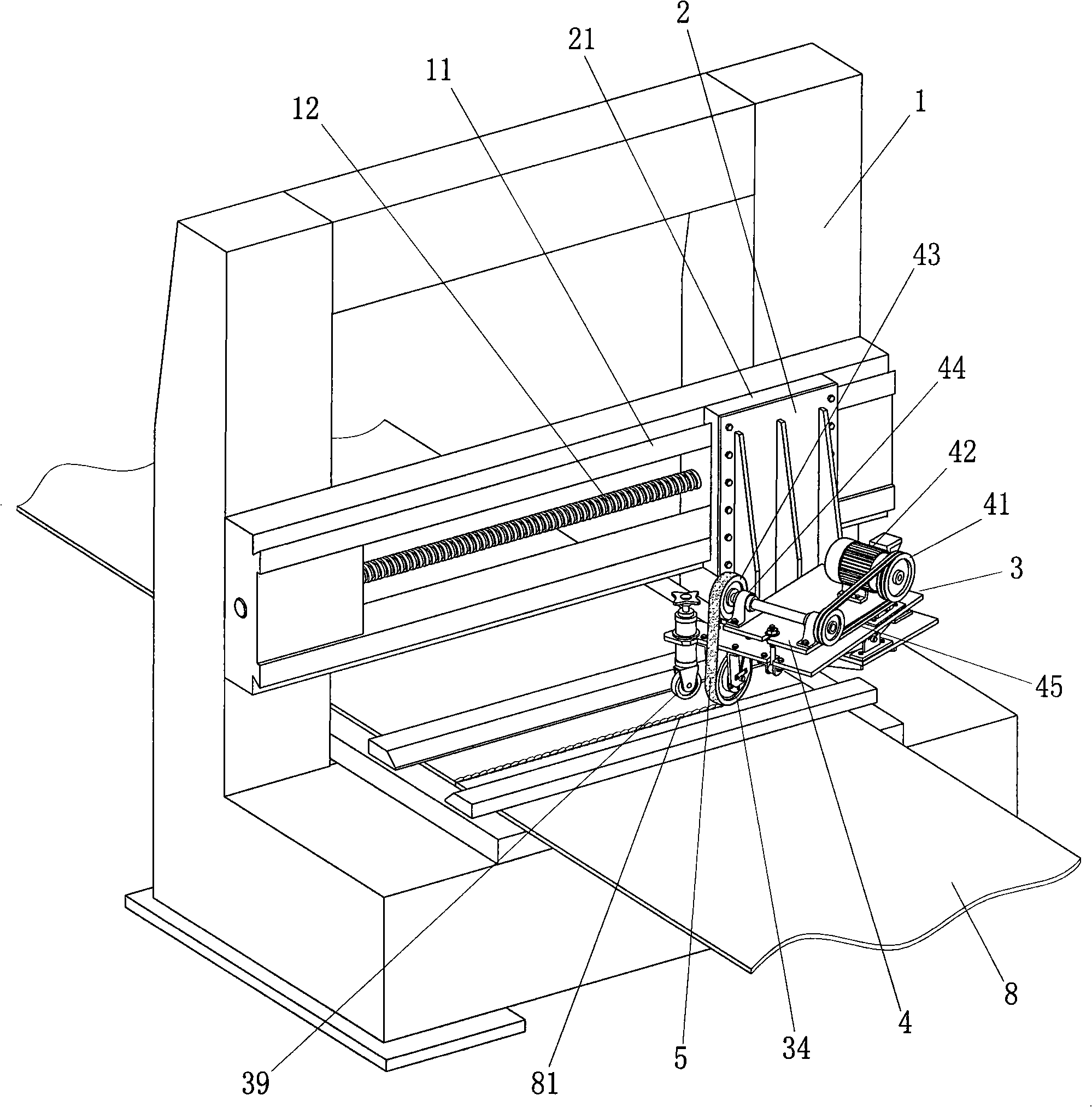

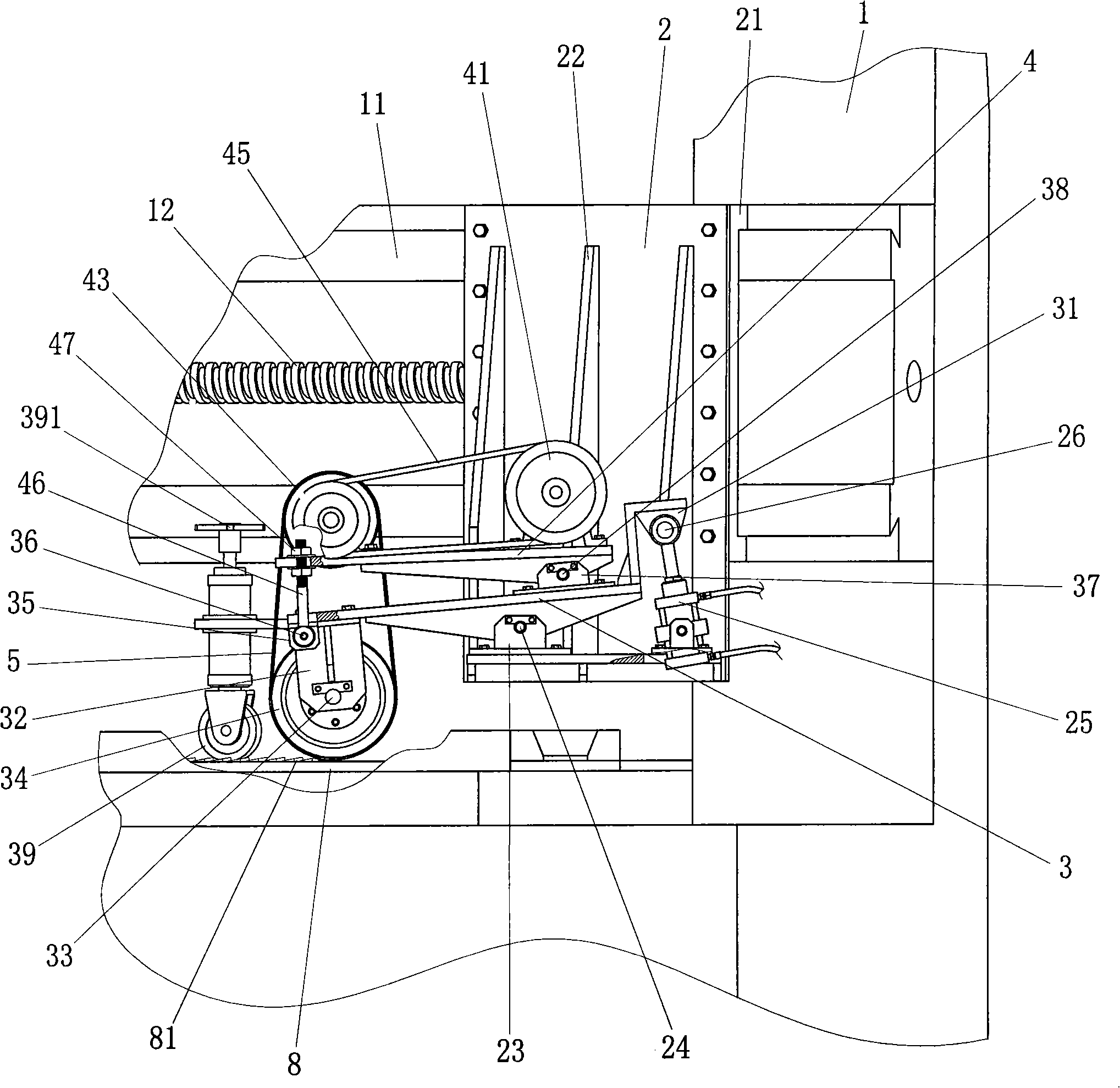

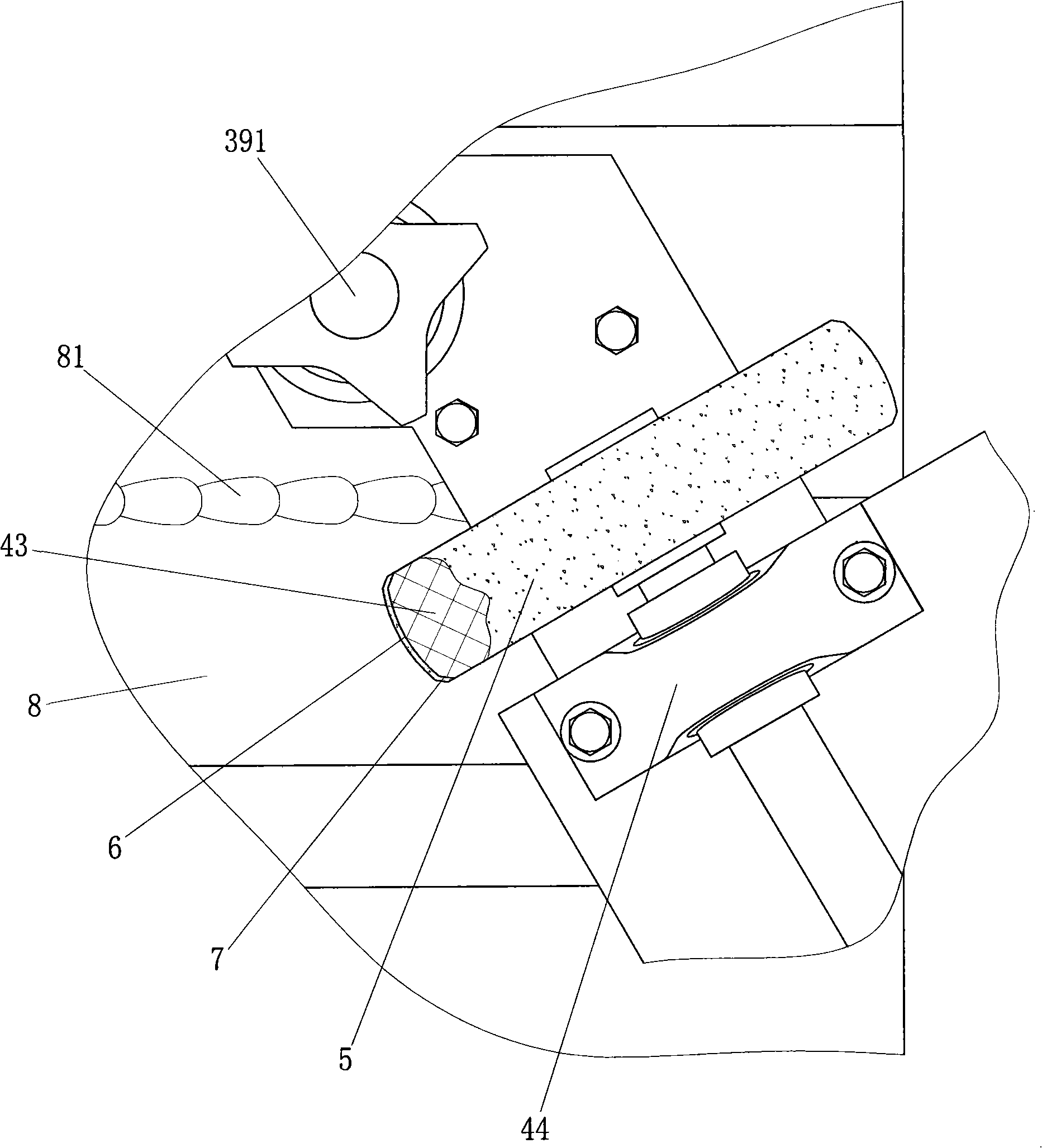

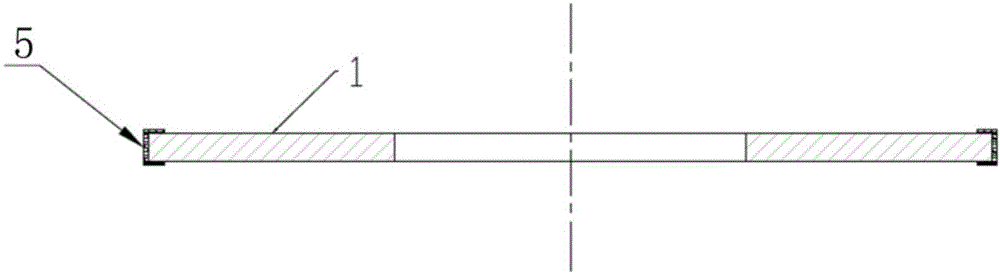

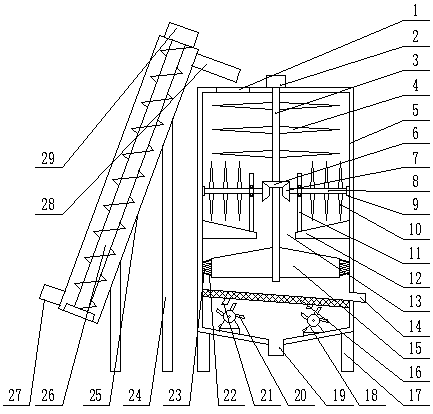

Butt-welding weld joint automatic coping device

ActiveCN101323100AExtended service lifeImprove grinding qualityGrinding drivesBelt grinding machinesWeld seamSteel plates

The invention relates to an automatic coping device for butt welding seams. The device is characterized in that the automatic coping device for the butt welding seams is arranged on a steel plate butt welding machine by a bracket and is movably connected with a horizontal guide rail and a horizontal transmission screw mandrel of the steel plate butt welding machine; on the bracket, a main driving abrasive belt wheel and a lower abrasive belt wheel strain the abrasive belt together which is moderately pressed on the butt welding seam, and the main driving abrasive belt wheel drives the abrasive belt to cope the butt welding seam. Through the improvement, components of the original steel plate butt welding machine can be effectively used for arranging the seam coping device on the original steel plate butt welding machine, thus realizing automatic coping of the butt welding seam on an automatic welding worktable of the original steel plate butt welding machine.

Owner:ZHEJIANG KINGLAND & PIPELINE TECH

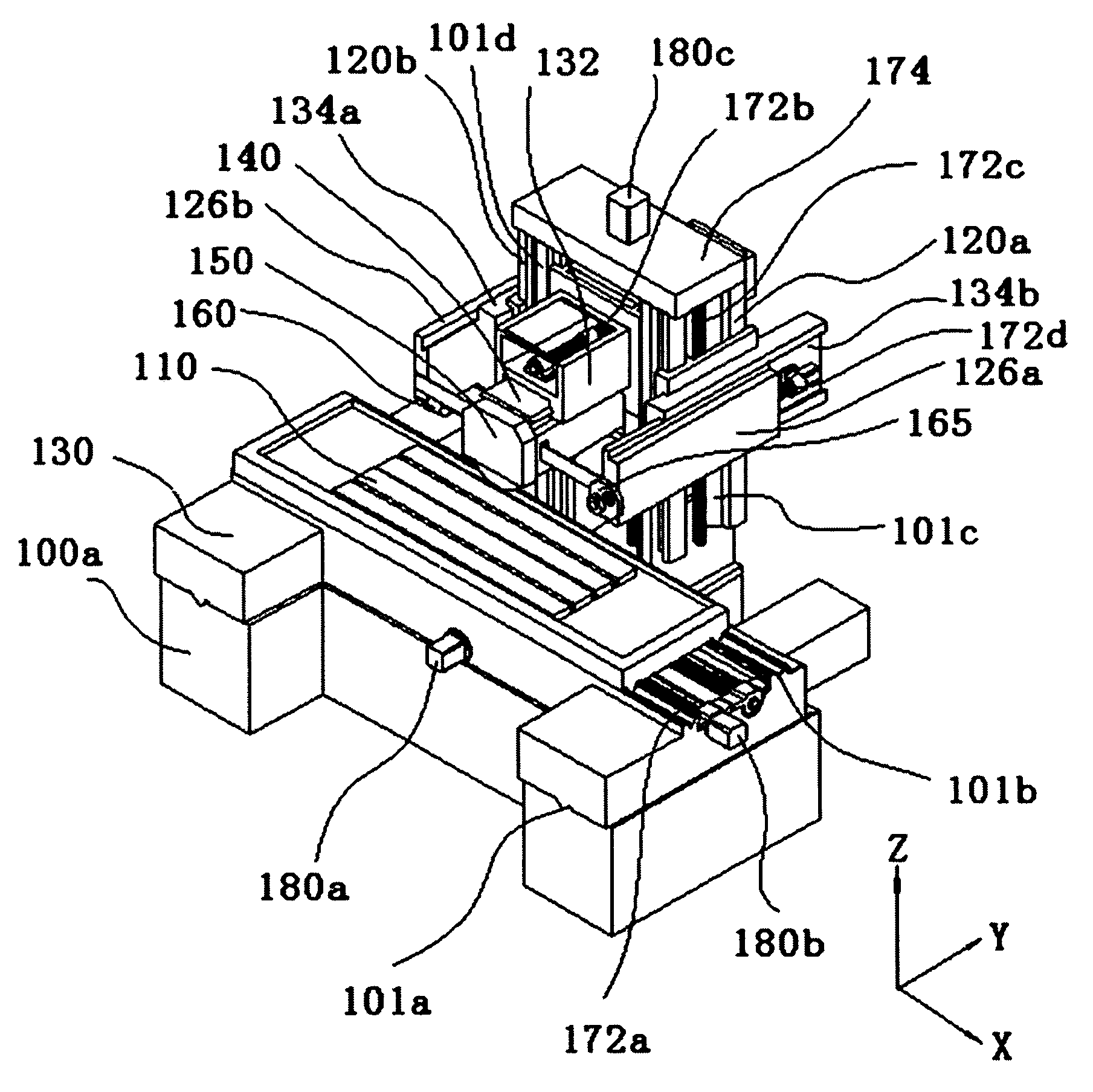

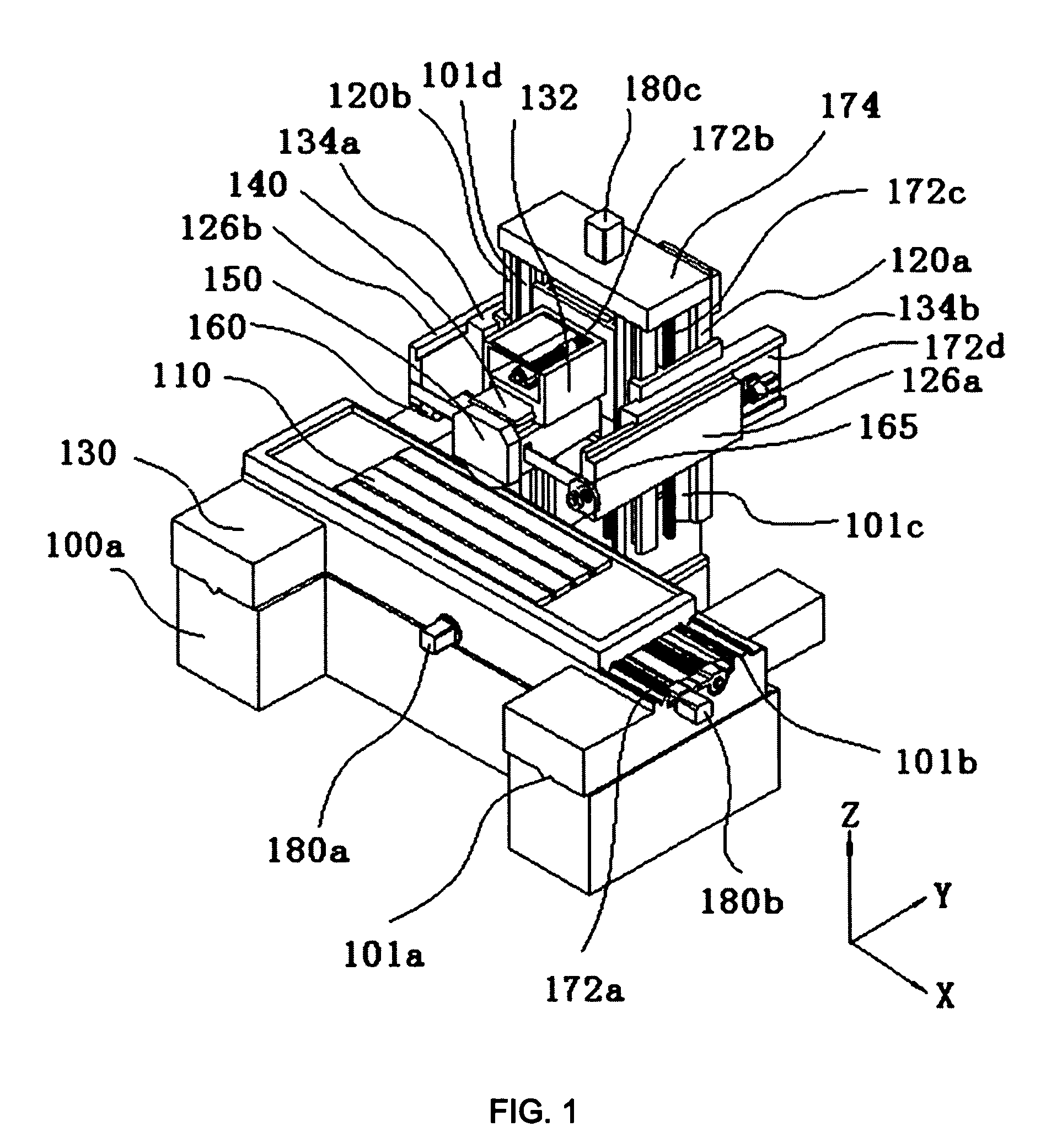

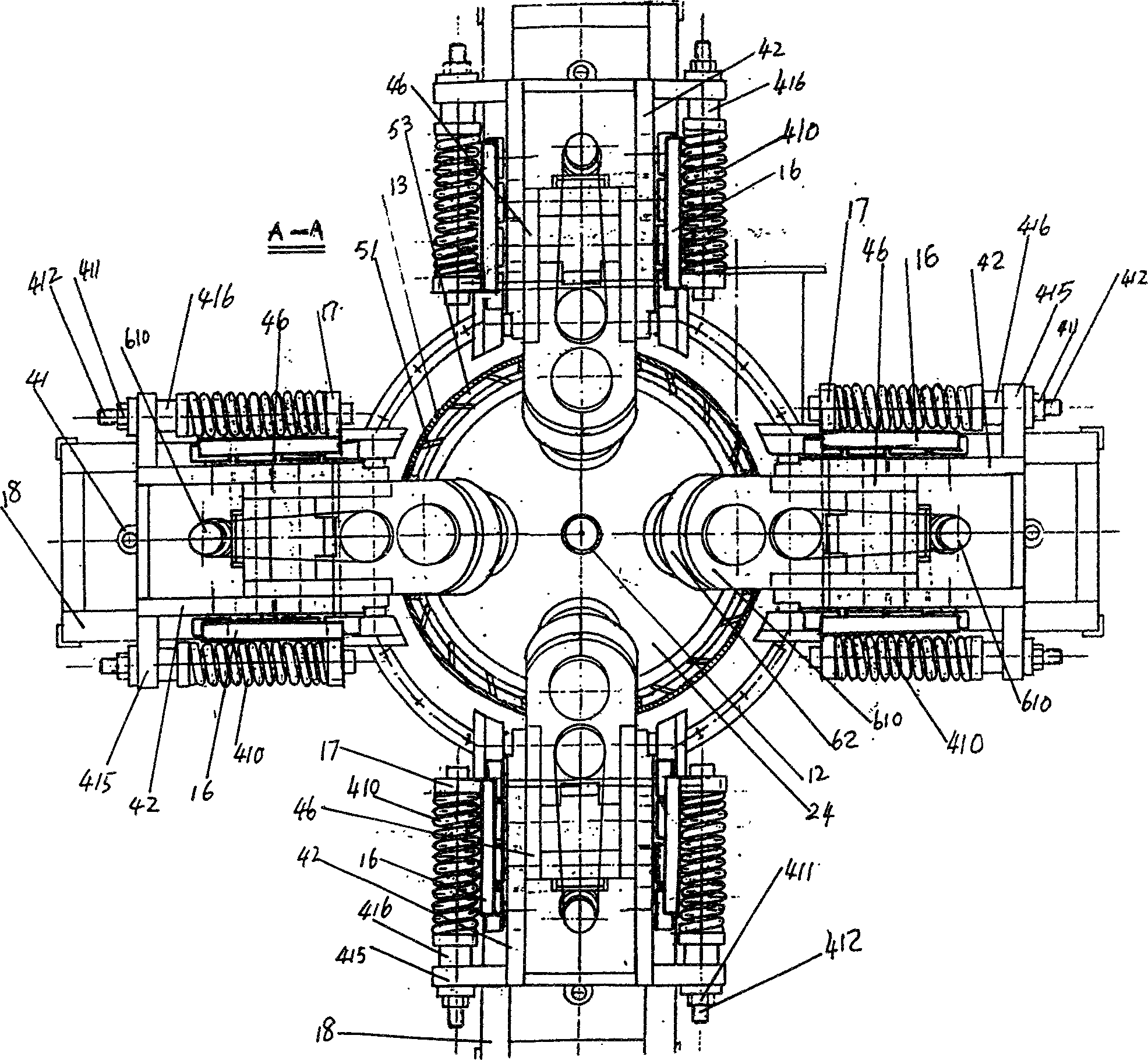

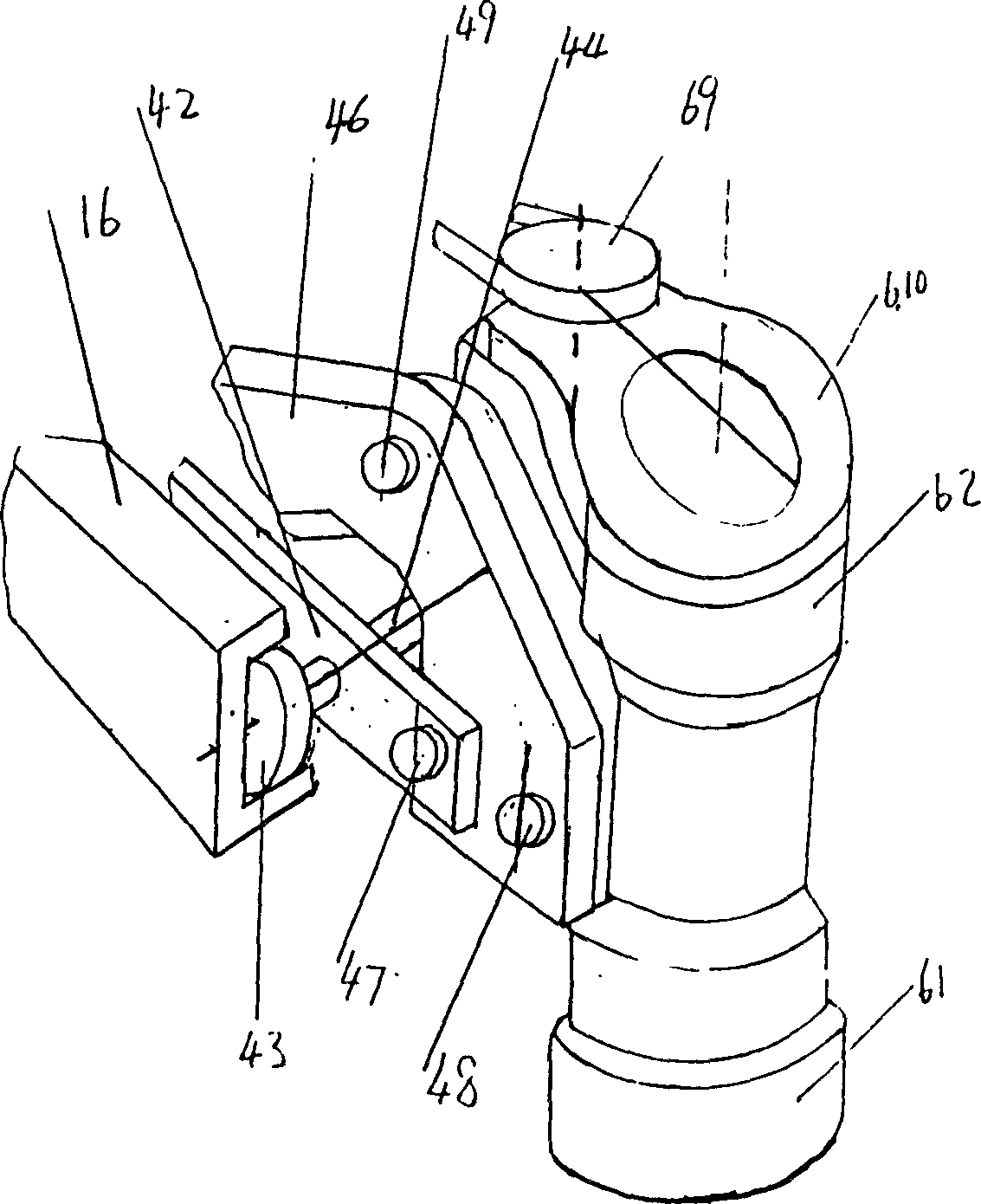

Multi-carriage symmetrical numerically controlled coordinate grinding machine

InactiveUS20120295516A1Simplified structural featuresEasy to manufactureGrinding carriagesGrinding drivesArchitectural engineeringCoordinate-measuring machine

The present invention includes a base, a work table, upright posts, several carriages and a grinding head. Wherein, the upright posts include for example a first upright post and a second upright post which are installed in parallel to each other on the base, and the carriages include a first carriage, a second carriage and several of third carriages; the base is connected to the first carriage and the work table is connected to the first carriage; the second carriage is positioned between the first upright post and the second upright post, the grinding head is installed on the second carriage and the third carriages are symmetrically installed on the outer sides of the first upright post and the second upright post, and each of the third carriages has a slider. The grinding machines of this invention can be used to significantly improve the operating stability and machining precision.

Owner:GUO HUAIZHONG +1

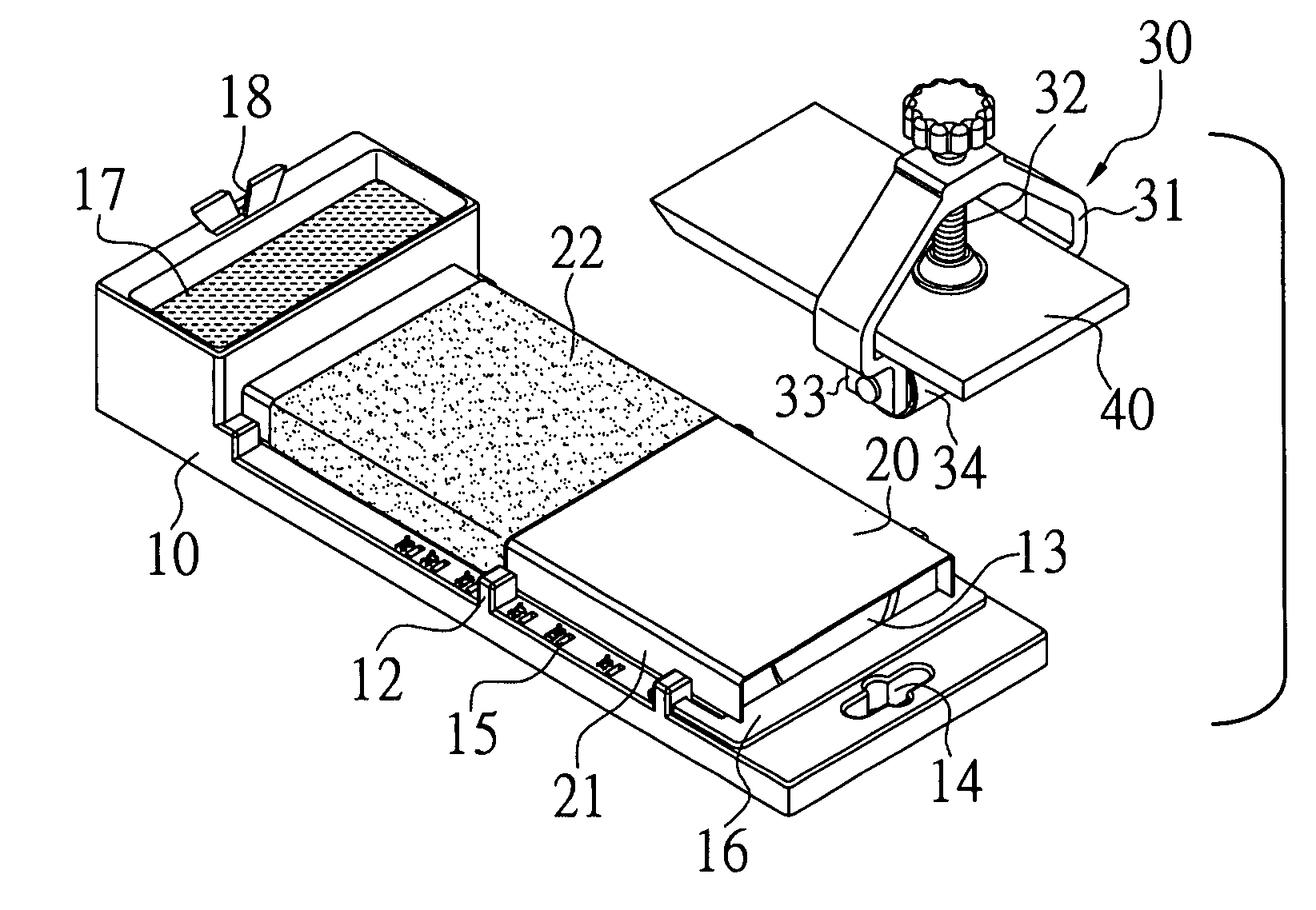

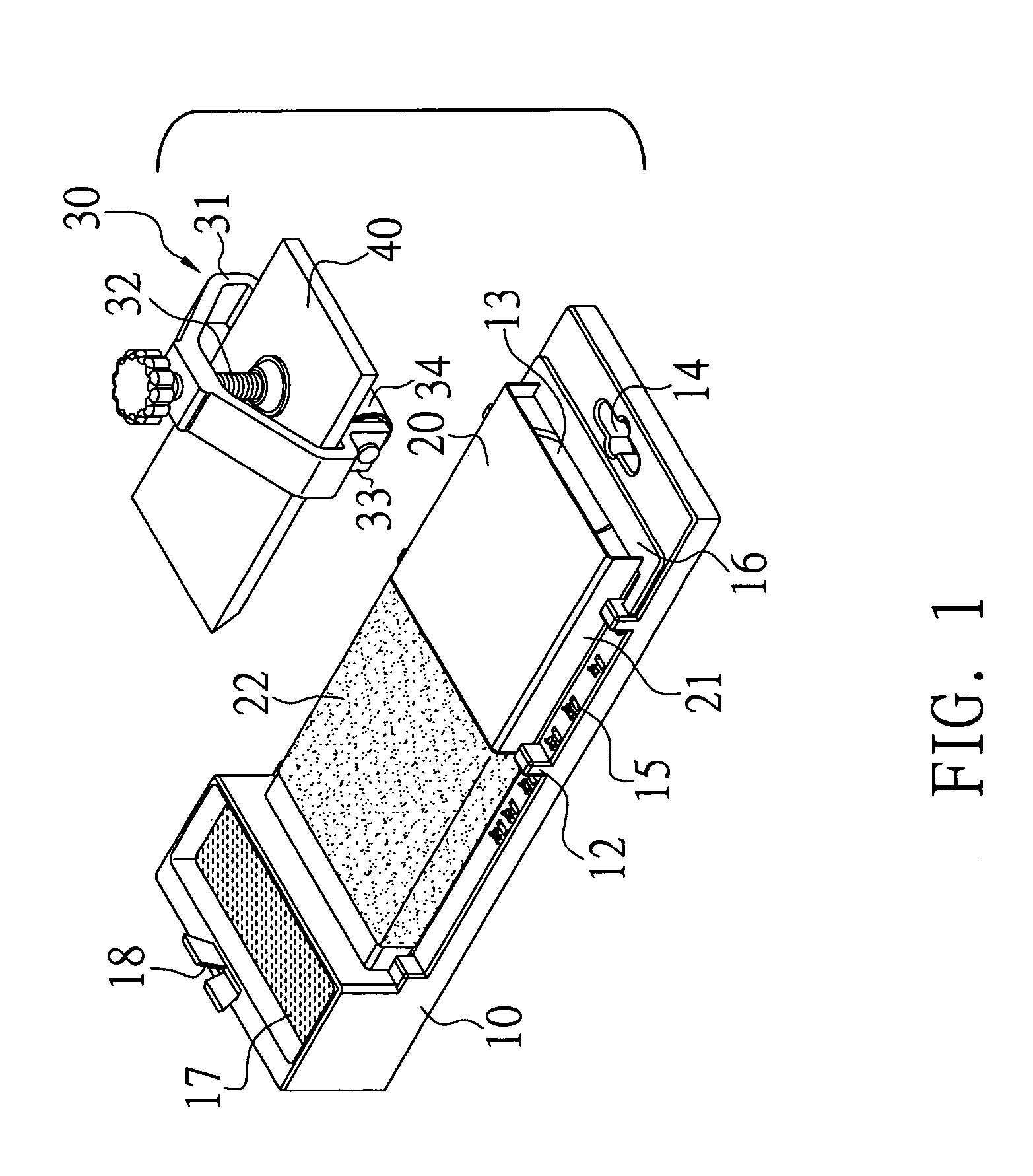

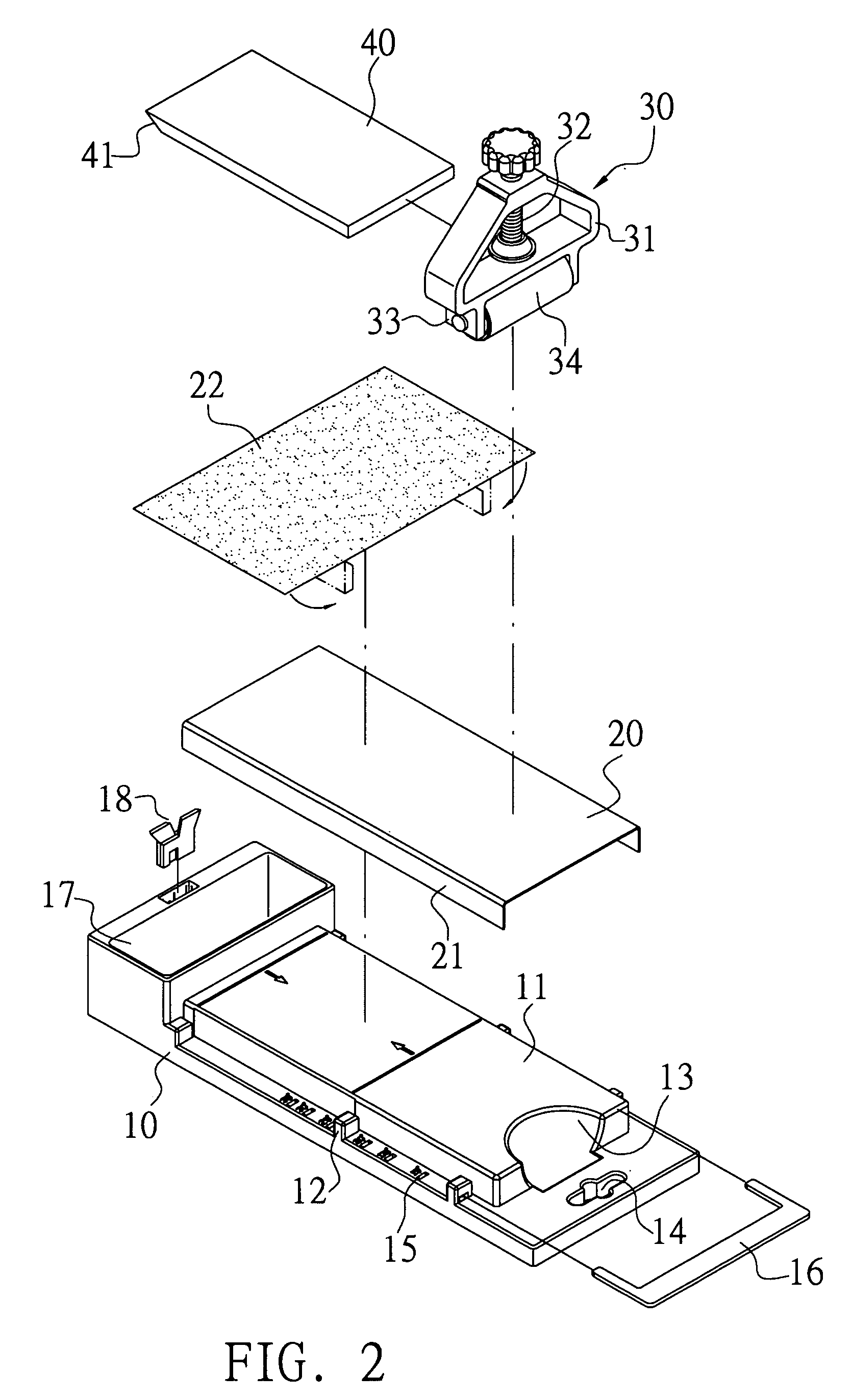

Cutter-grinder

InactiveUS7104876B1Heat dissipationWash awayBelt grinding machinesPortable grinding machinesEngineeringKnife blades

An innovative cutter-grinder comprised of a base, a cutter holder, and a mobile base plate; the base plate being mounted with emery cloth before being placed on a deck of the frame to secure the emery cloth and allow easy replacement of the emery cloth; the cutter holder adapted with a roller at bottom retaining a blade for the user to hold the cutter holder to roll back and forth on the base plate to grind the cutter against the emery cloth; and an angle set plate being inserted onto slots respectively provided on both sides of the deck allowing the adjustment of the grinding angle.

Owner:LIN KUN MENG

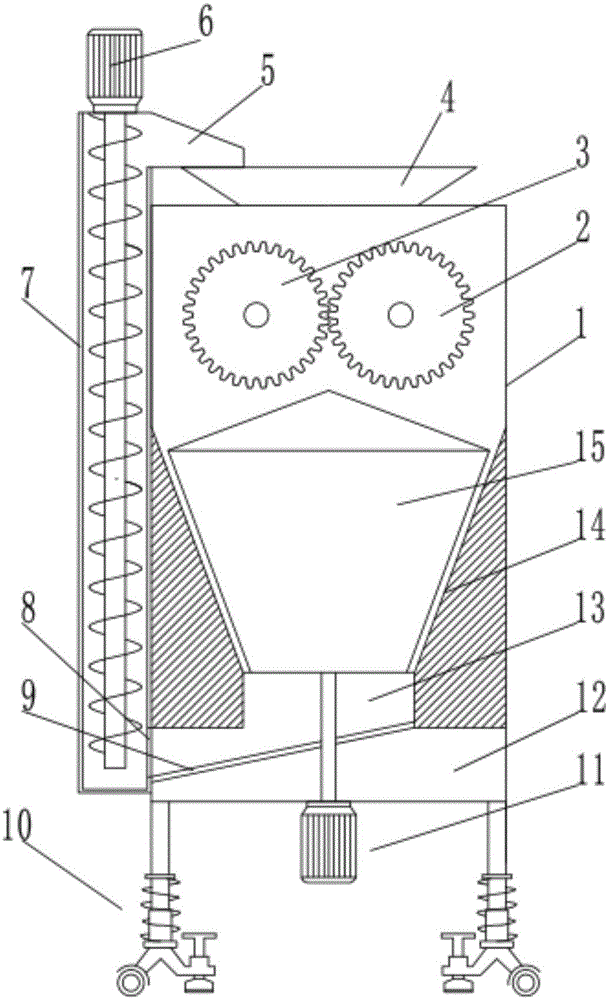

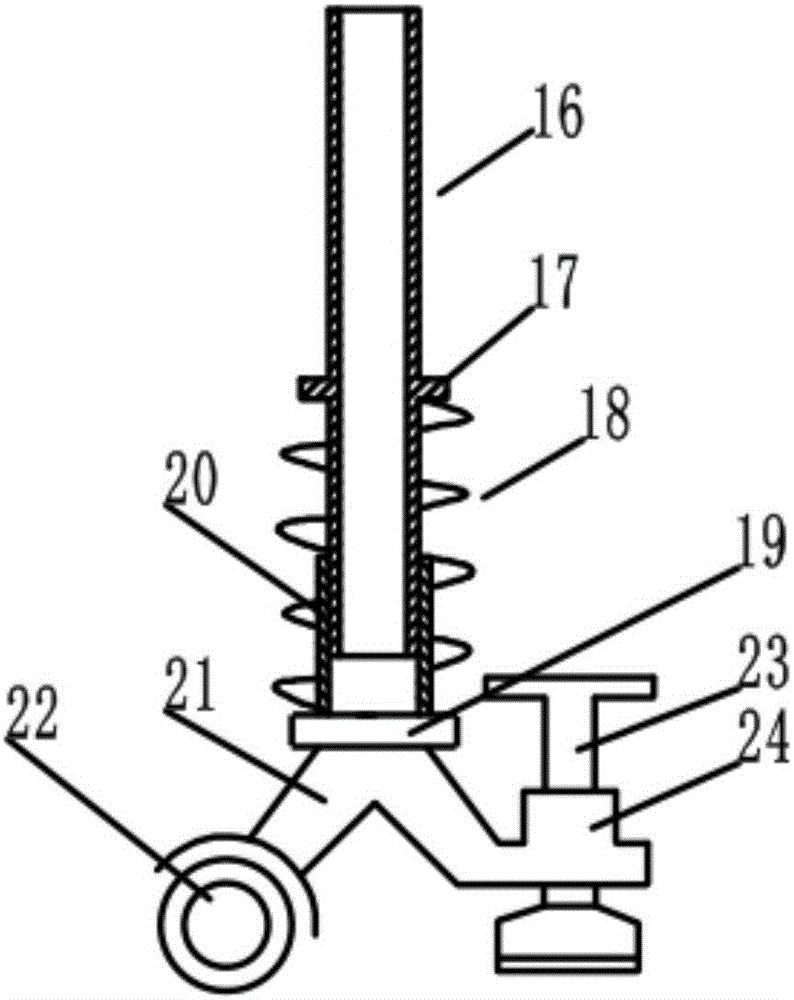

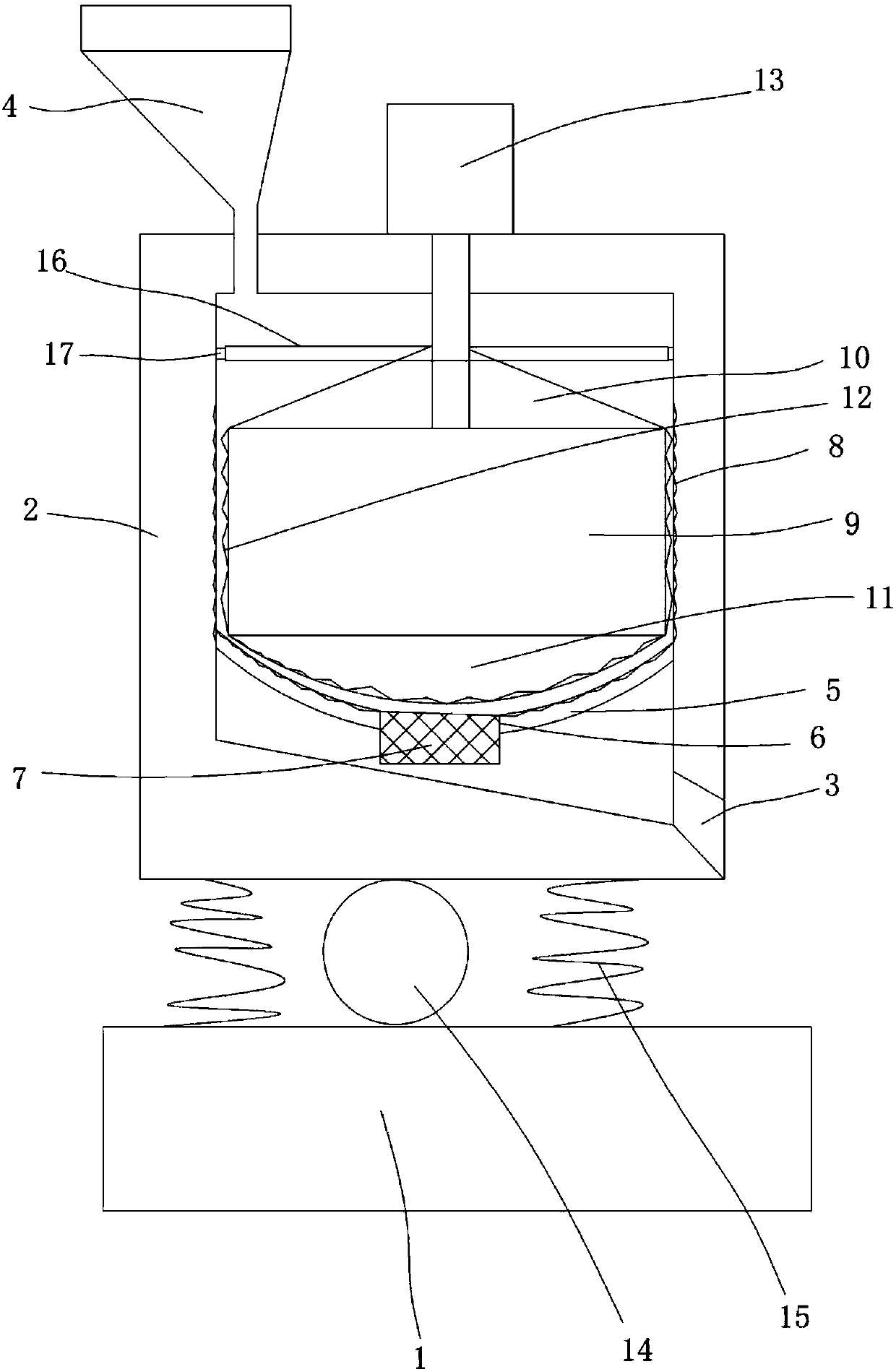

Mobile vibration reduction type high-precision flour milling device

PendingCN107520033AGuaranteed Particle SizeImprove grinding qualityNon-rotating vibration suppressionGrain treatmentsGrindingElectric machinery

The invention discloses a mobile vibration reduction type high-precision flour milling device. The device comprises a flour milling box; a funnel-shaped milling cavity is formed in the flour milling box; a milling cone is arranged in the milling cavity; a working gap is reserved between the milling cone and the milling cavity; the milling cone is driven to operate by a flour milling motor mounted at the bottom of the flour milling box; a driving crushing roller and a driven crushing roller with opposite positions are mounted above the milling cone in the flour milling box; a feeding hopper for feeding is arranged at the top of the flour milling box; an unloading channel communicating with the milling cavity is formed below the milling cavity; and the unloading channel is kept communicating with a discharge channel for discharging. The device has the following beneficial effects: cut materials can be renewedly fed from the feeding hopper by a return auger for crushing and flour milling again, so that the particle size of final finished products can be effectively guaranteed, and the flour milling quality is improved; and the device is convenient to move, meanwhile, is excellent in vibration reducing effect, and can be widely applied to fine grinding of materials.

Owner:ZHENGZHOU UNIV

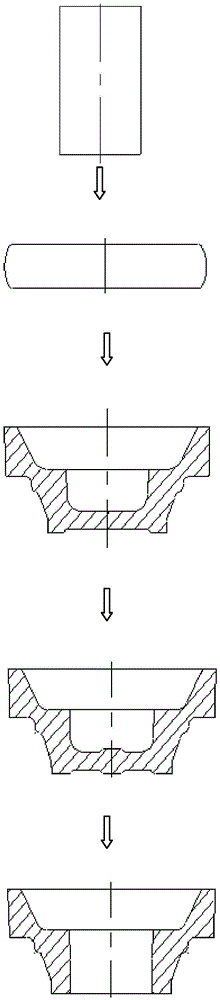

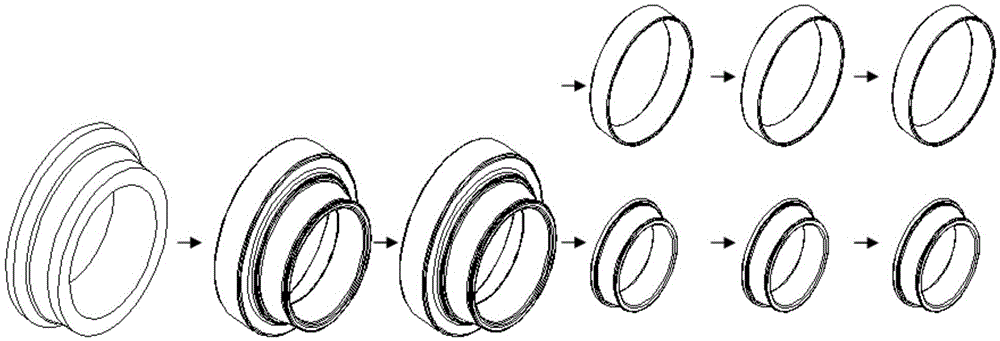

Machining method for inner ring and outer ring of conical roller bearing

The invention discloses a machining method for an inner ring and an outer ring of a conical roller bearing, and relates to a bearing machining method. The method is used for solving the problems that in existing bearing machining, detection omission is prone to occurrence in steel material detection, deformation is large after thermal treatment, grinding amount increase exists, grinding efficiency is reduced, product quality can be not ensured easily, and manufacturing cost is increased. The method includes the steps of firstly, conducting nondestructive examination of steel materials; secondly, cutting off examined steel materials; thirdly, forging an inner and outer one-piece sleeve ring; fourthly, conducting annealing; fifthly, lathing the inner and outer one-piece sleeve ring; sixthly, quenching the lathed inner and outer one-piece sleeve ring; seventhly, separating the sleeve ring into an inner ring and an outer ring; eighthly, conducting chamfering; ninthly, grinding the inner ring and the outer ring. The thermal treatment deformation is greatly reduced, the grinding residual amount is decreased, and grinding efficiency is improved; the method is suitable for machining the inner ring and the outer ring of the bearing.

Owner:哈尔滨汽车轴承有限公司

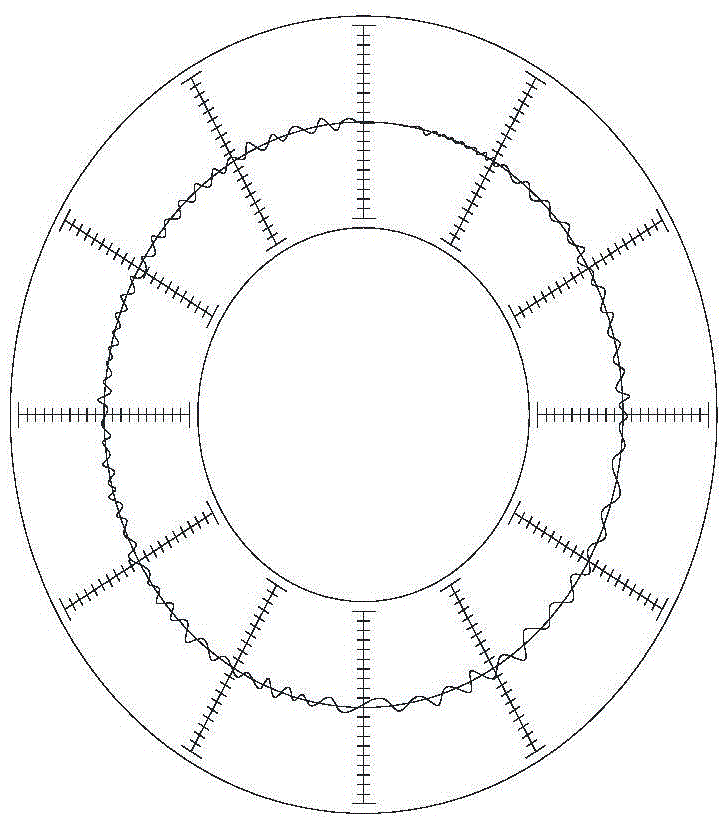

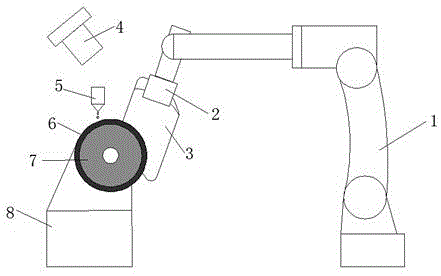

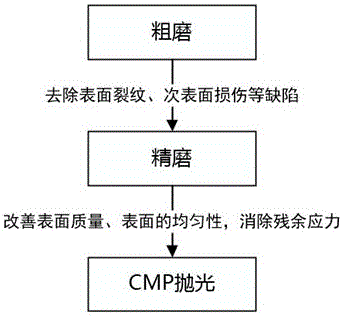

Robot grinding and polishing system based on CMP

ActiveCN105666287AImprove grinding efficiencyImprove efficiencyPolishing machinesGrinding machinesEngineeringMaster controller

The invention discloses a robot grinding and polishing system based on CMP. The robot grinding and polishing system comprises a six-axis robot, a workpiece clamp used for placing workpieces, a contour detection unit used for detecting the workpieces needing to be polished and conducting three-dimensional reconstruction, a grinding wheel with a polishing pad, a base provided with the grinding wheel and a master controller. The free end of the six-axis robot is provided with an electric spindle provided with servo motors. A polishing liquid jetting device capable of jetting CMP polishing liquid to the workpieces is arranged above the workpiece clamp. The workpiece clamp is installed on the electric spindle. The master controller controls the contour detection unit, the six-axis robot, the electric spindle and all the servo motors. The workpiece clamp and the grinding wheel with the polishing pad can also be exchanged in position so as to adapt to polishing of different sizes of workpieces. The robot grinding and polishing system is high in efficiency and good in machining consistency, harmful effects such as mechanical damage and burns which may be caused by common grinding cannot be caused on the workpieces, damage to surfaces or sub surfaces cannot occur, and perfect surfaces can be machined.

Owner:WUHAN UNIV

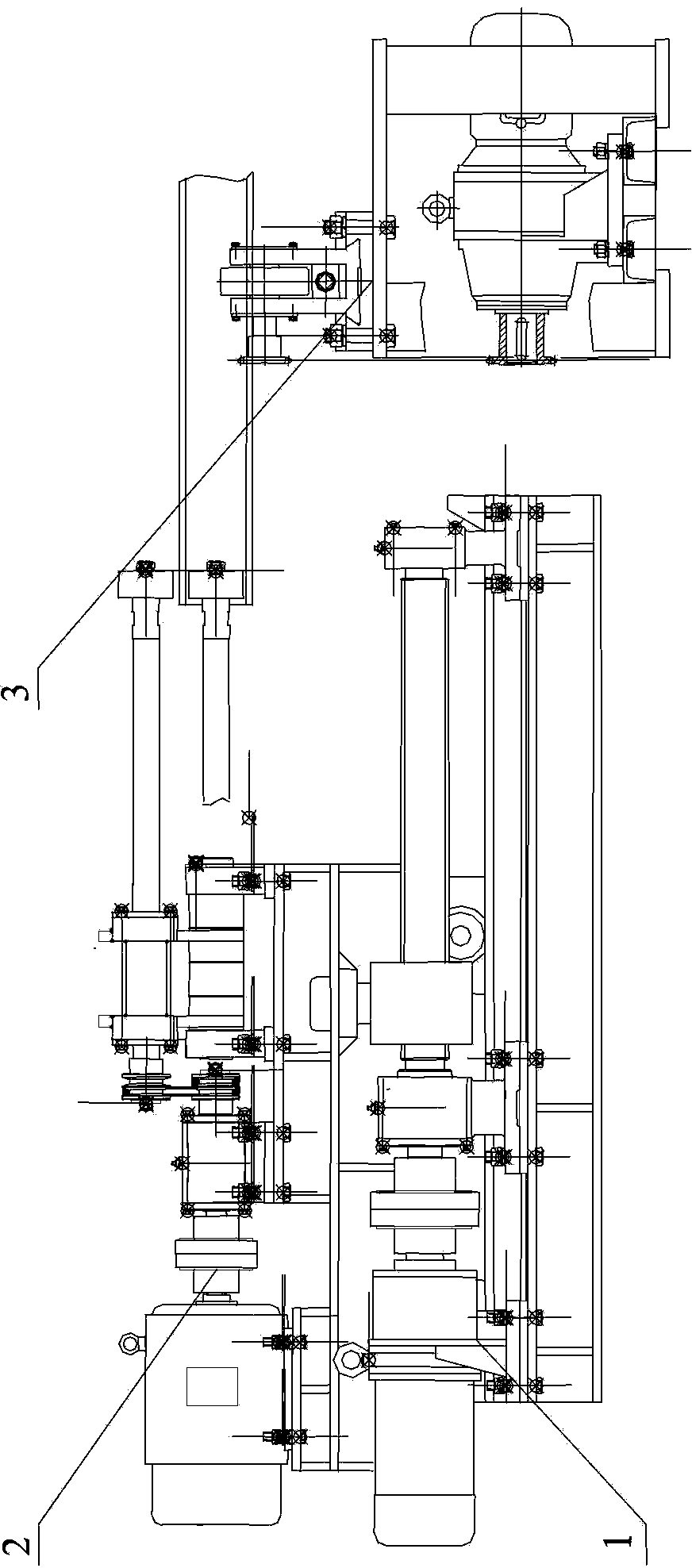

Synchronous grinding device for inner surface and outer surface of steel pipe end

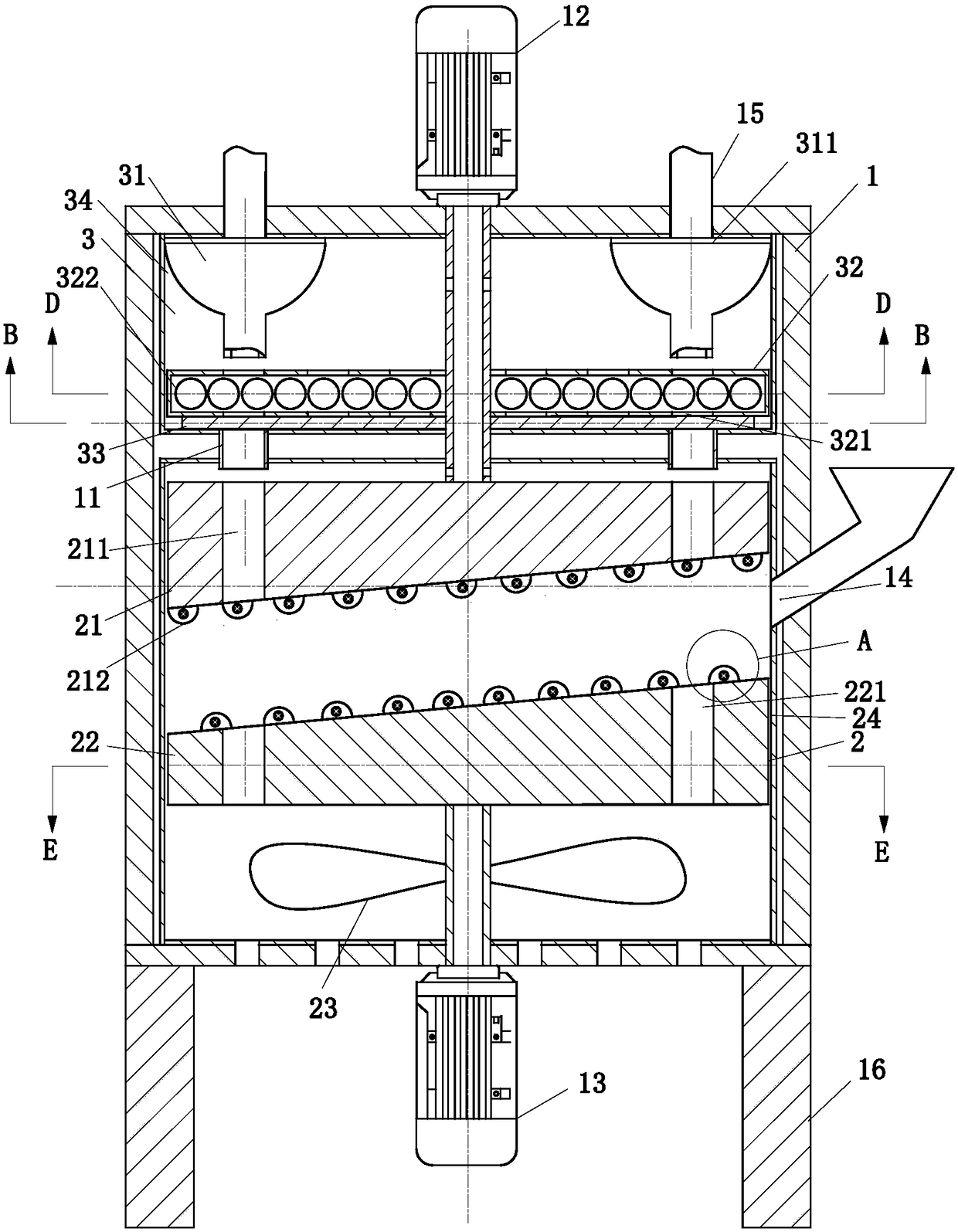

ActiveCN103991013AImprove grinding qualityImprove labor efficiencyRevolution surface grinding machinesGrinding drivesElectric machineryEngineering

The invention relates to a synchronous grinding device for the inner surface and the outer surface of a steel pipe end. The synchronous grinding device comprises an axial feed mechanism and a grinding mechanism driven by the axial feed mechanism to move in the axial direction. The synchronous grinding device is characterized in that the grinding mechanism is a synchronous grinding mechanism and comprises a grinding motor, an inner grinding component, an outer grinding component and a steel pipe rotating roller mechanism; the inner grinding component and the outer grinding component are driven by the grinding motor to rotate synchronously, and the grinding motor drives a grinding head of the inner grinding component and a grinding head of the outer grinding component to rotate; the steel pipe rotating roller mechanism drives chain transmission through a geared motor and drives a roller mechanism to make a steel pipe to rotate in the circumferential direction. According to the synchronous grinding device for the inner surface and the outer surface of the steel pipe end, as the scheme that grinding shafts arranged in two independent swing shaft seats are driven in a single-motor dual-drive mode to achieve synchronous grinding actions, the feed motion of the grinding heads is achieved by driving a nut and a lead screw through the geared motor, and circumferential rotation of the steel pipe is achieved by driving rollers is adopted, the inner surfaces and the outer surfaces of the steel pipe ends with different outer diameters and wall thicknesses can be ground synchronously, grinding quality is improved, labor efficiency is enhanced, auxiliary time is shortened, and production cost is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

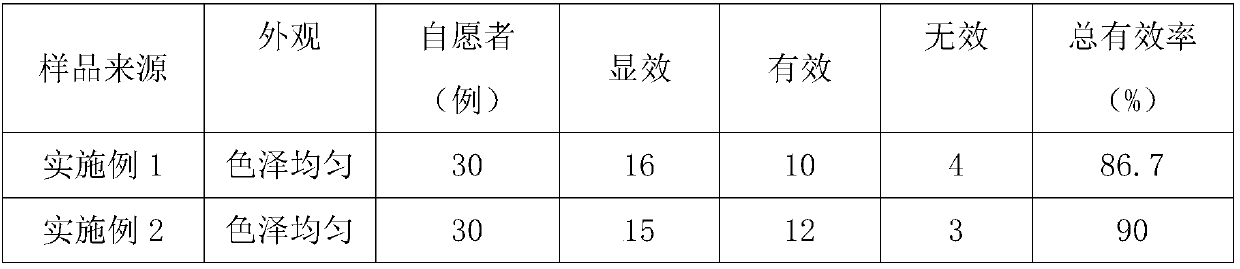

Facial cleanser and grinding machining device thereof

InactiveCN107753352AReasonable structureEasy to operateCosmetic preparationsToilet preparationsCocamidopropyl betaineDIHYDROXYPROPYLTRIMONIUM CHLORIDE

The invention discloses a facial cleanser, which is prepared from the following raw materials in parts by weight: 6-8 parts of fragrant waxplant herb, 10-15 parts of drymoglossum piloselloides presl,5-8 parts of Ling artemisia apiacea hance, 60-80 parts of deionized water, 4-7 parts of Lauryl sulfate ammonium sulfate, 0.5-3 parts of cocamidopropyl betaine, 0.4-0.6 part of essence, 0.01-0.20 partof EDTA disodium, 0.05-0.2 part of spermol, 0.1-0.6 part of sodium chloride, 0.1-0.3 part of guar hydroxypropyl trimethylammonium chloride, and 0.01-0.3 part of panthenol. The grinding machining device has a reasonable structure, is not only convenient and fast to operate, but also can effectively reduce grinding blind area and improve the grinding efficiency and grinding quality, and is good in use stability and strong in practicability.

Owner:苏州兰灵医药科技有限公司

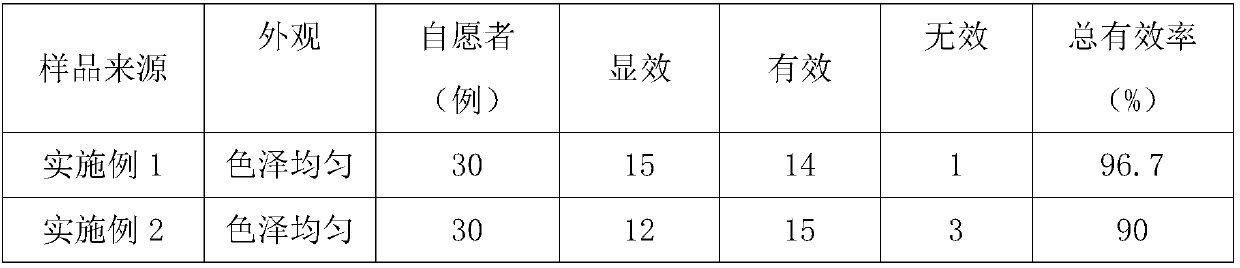

Glass production method

ActiveCN108328907APromote fragmentationImprove grinding efficiencyCocoaGrain treatmentsEngineeringFan blade

The invention belongs to the technical field of glass, and particularly relates to a glass production method. The method comprises the step 1 to the step 6, wherein in the step 2, a used grinding device comprises a tube body, a grinding module and a filtering module; the grinding module is arranged at the bottom of the tube body; the filtering module is arranged on the top of the tube body; the grinding module comprises a No.1 grinding post, a No.2 grinding post, a fan blade and a No.2 installing cabin; semicircular grinding blocks are respectively arranged on the surfaces of the No.1 grindingpost and the No.2 grinding post; a cutting unit arranged in the semicircular grinding block is used for cutting quartz raw materials; the grinding efficiency is improved; the filtering module comprises a funnel, a ball milling disc, a cleaning unit and a No.1 installing cabin; the funnel and the ball milling disc are mutually matched; the ground quartz is selected; the quartz quality is improved.The used device mainly performs collision and cutting grinding on the quartz raw materials; the mixing time of the quartz with sodium carbonate, boracic acid and the like is shortened, so that the glass production efficiency is improved.

Owner:信和光能(安徽)有限公司

Electric tobacco grinder

InactiveUS20170297033A1Reduce repetitionsReduces unnecessary overgrindingCoffee millsSpice millsEngineeringElectric control

This invention discloses an electric tobacco grinder, comprising an electric controlling member and a grinding member, wherein: the electric controlling member comprises a body case for electric controlling member, two batteries, a reducing motor, and a PCBA controlling board; the reducing motor is disposed within the inner center of the body case; the batteries are disposed in the corresponding battery container of the body case, wherein the two battery containers are located adjacent to both sides of the reducing motor; the PCBA controlling board is disposed within a flat port of the body case; the grinding member comprises: a grinding upper case, a grinding lower case, a bottom cover, an upper reamer and a lower reamer; the grinding upper case is embedded to fix itself under the body case; the lower reamer is disposed within the grinding lower case that is screwed up beneath the grinding upper case.

Owner:LRIDER TECH CO LTD

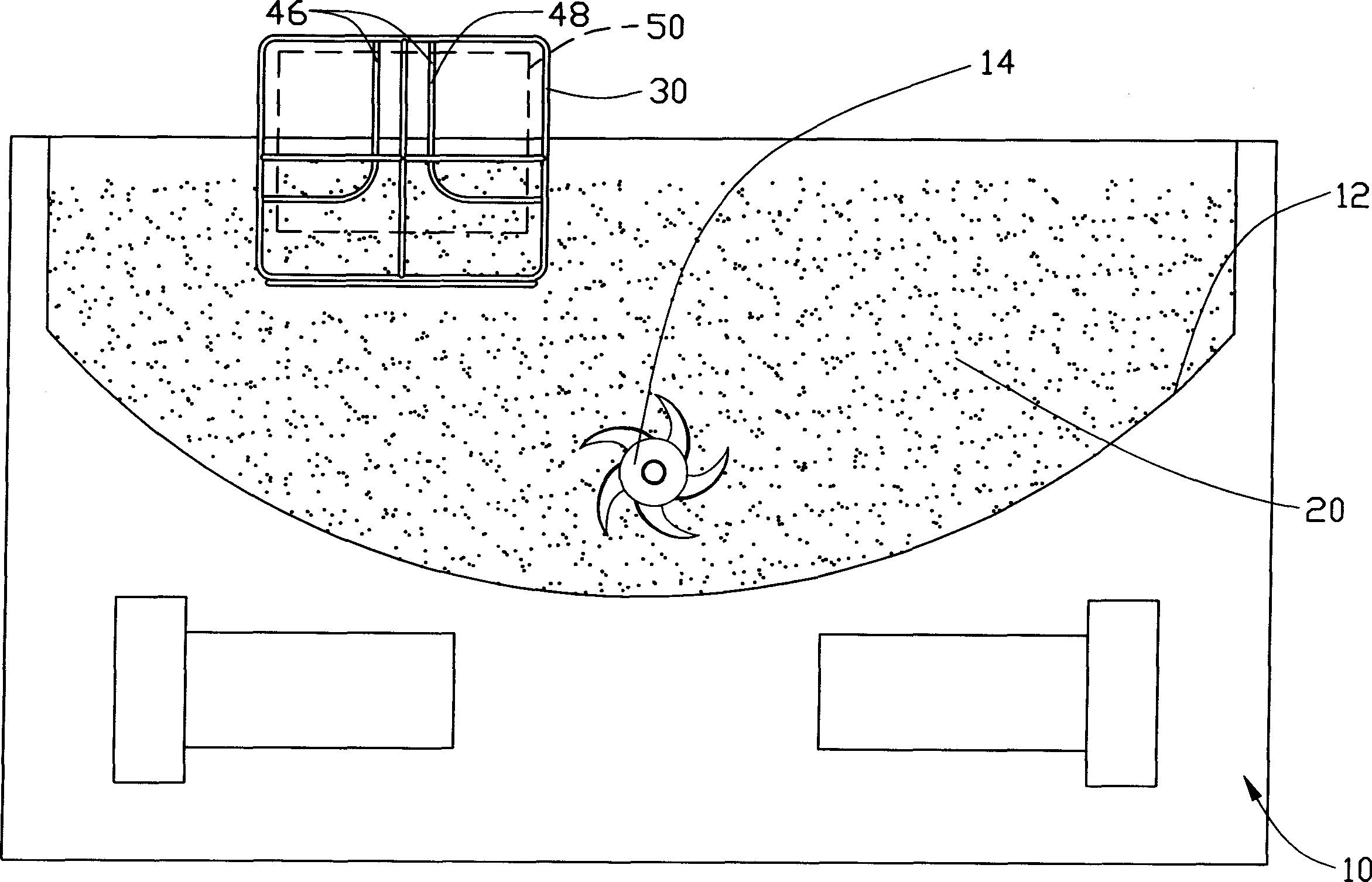

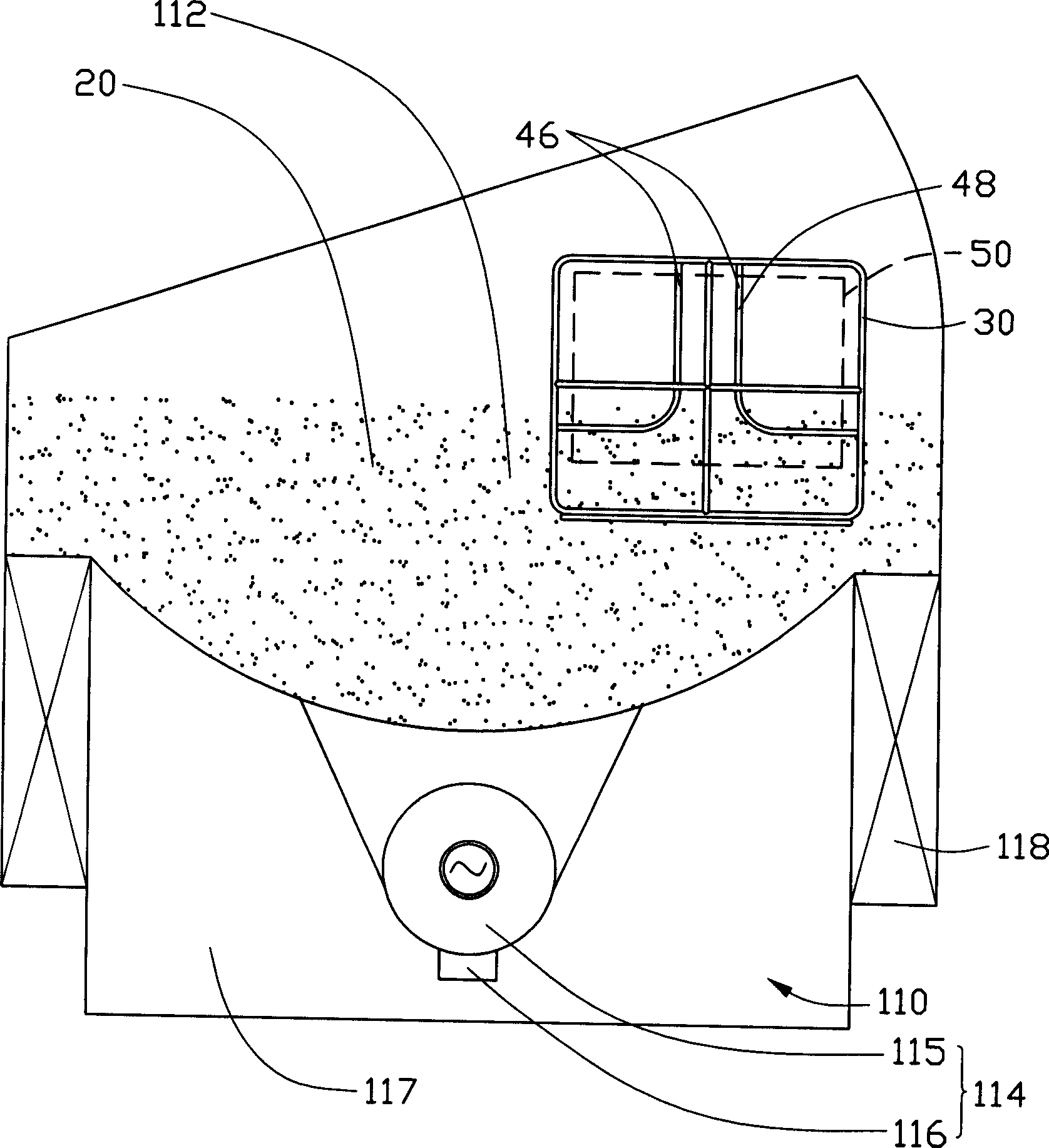

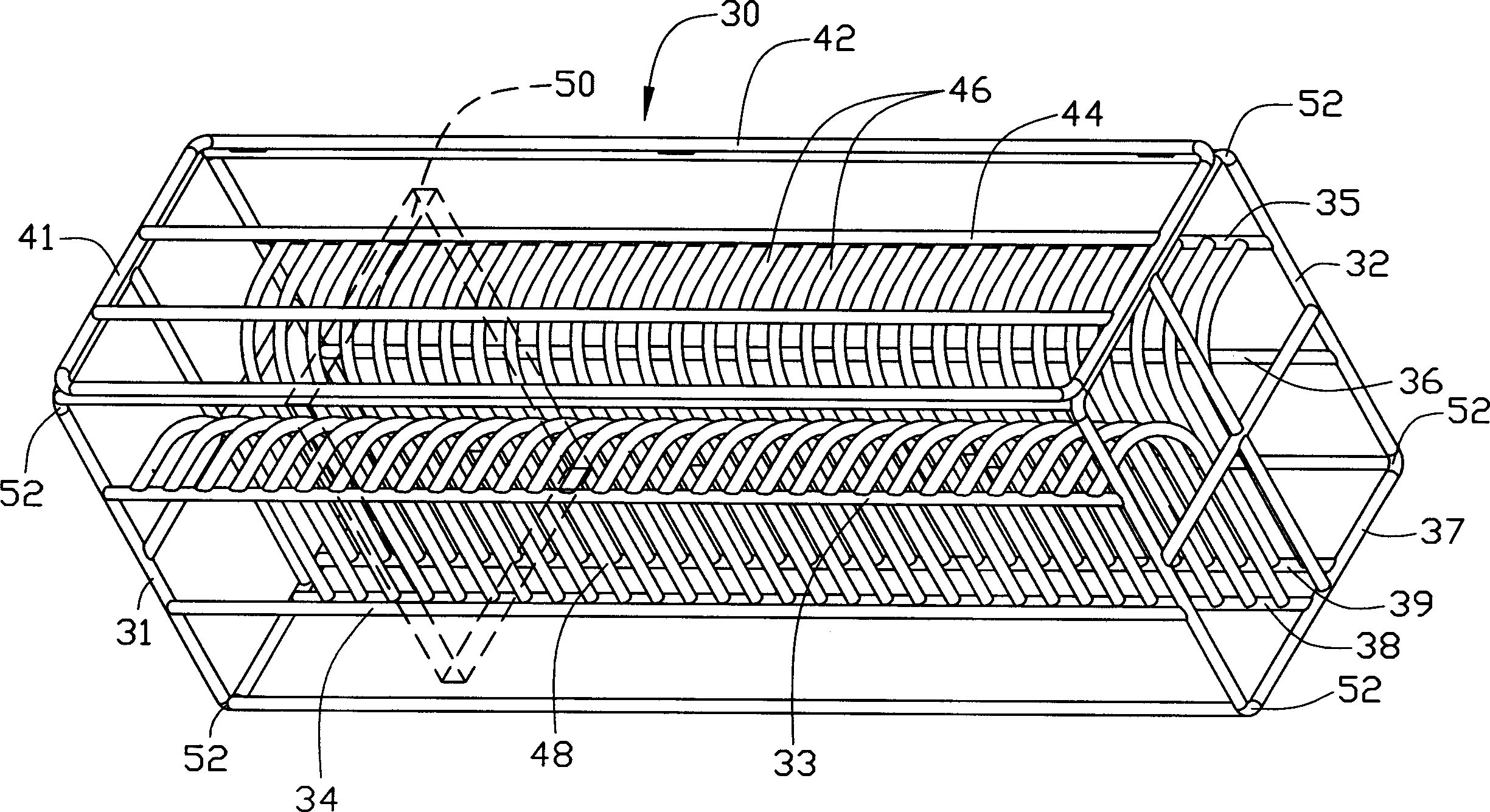

Method and equipment for metal piece vibration grinding polishing and burring

InactiveCN1465468AIncrease the number ofEasy to separateEdge grinding machinesPolishing machinesEngineeringSolid particle

The present invention relates to a method for vibration grinding and polishing metal workpiece and deburing and its equipment. Said invention used as electric vibrator, a certain quantity of polishing material and several receivers for holding metal workpieces. Said vibrator includes a vibration groove, and its vibration frequency can be regulated, and said polishing material is formed from solidgranules with various forms and is placed in the vibration groove, said several receivers are placed on said polishing material. Said receiver is formed into frame structure by using metal wire for holding several metal workpiece, and the metal wire surface is covered with buffer covering layer for preventing the metal workpiece and receiver from producing collision to result into damage.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Superfine ground calcium carbonate powder production method

ActiveCN104845411AImprove grinding efficiencyReduce energy consumptionPigment treatment with macromolecular organic compoundsPigment physical treatmentPowder mixtureGranularity

The invention belongs to the field of nonmetallic mineral processing and specifically relates to a superfine ground calcium carbonate powder production method. The method comprises the following steps: crushing the marble raw material into coarse calcium carbonate having the diameter of less than or equal to 1cm; grinding the coarse calcium carbonate by use of a dry grinding mill to obtain a calcium carbonate powder mixture; performing grading treatment on the calcium carbonate powder mixture to obtain a first-stage powder having the granularity greater than j, a second-stage powder having the granularity within the range of j-k, and the third-stage powder having the granularity less than k, next, returning the first-stage powder to the dry grinding mill for grinding, performing wet grinding on the second-stage powder, directly feeding the third-stage powder to a product homogenization silo for homogenization or wet grinding, wherein k is smaller than j; and after the all wet-ground calcium carbonate slurry is dried and crushed, homogenizing and packaging. The superfine ground calcium carbonate powder production method is capable of effectively saving the energy under the premise of guaranteeing the product quality and the production efficiency.

Owner:SICHUAN SHIMIAN JUFENG POWDER

Vertical roller grinding machine for super-fine powder

InactiveCN1698965AImprove and stabilize the quality of grinding and grindingImprove efficiencyGrain treatmentsReduction driveElectric machinery

This invention relates to a multi-power ultrafine grinding vertical lapping machine, which comprises housing, a grinding board, a power transmitting means, an air intake duct system connecting the grinding board and charging pipe, wherein a motor and a decelerator in the lower of the grinding board constitute an actuating system, and in the grinding board is arranged a corresponding bistrique supported in the locomotive; the grinding roll of the bistrique presses to ginding board edge, and in the bistrique is arranged the grinding head motor used for driving the roll rotating; in the housing is arranged the crosswind gas flow duct channel for driving air flow upwards in housing.

Owner:陆福才 +2

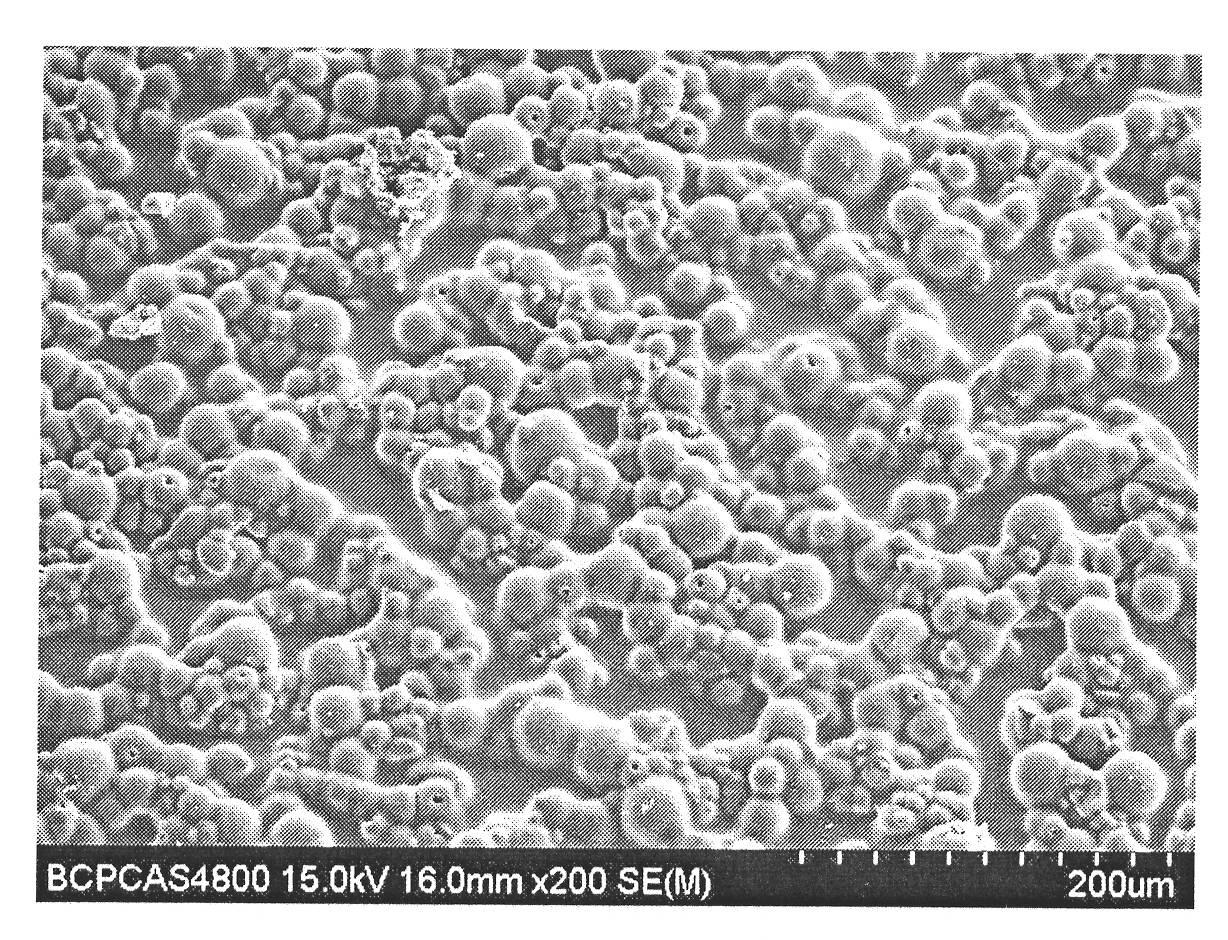

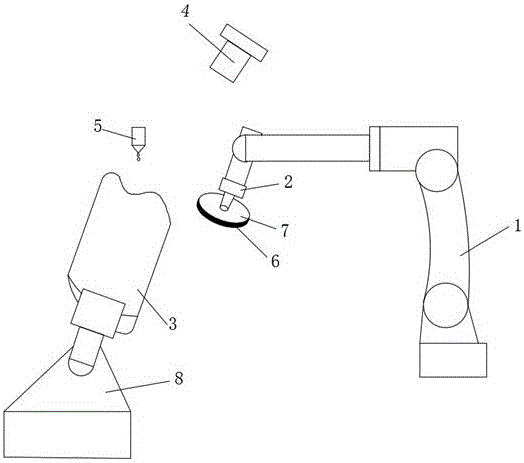

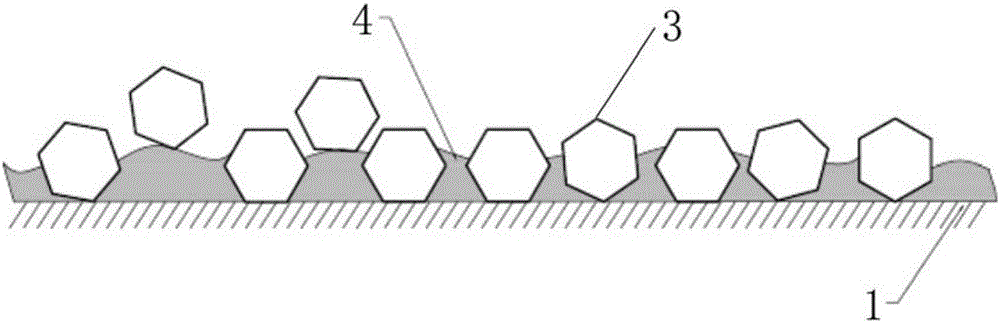

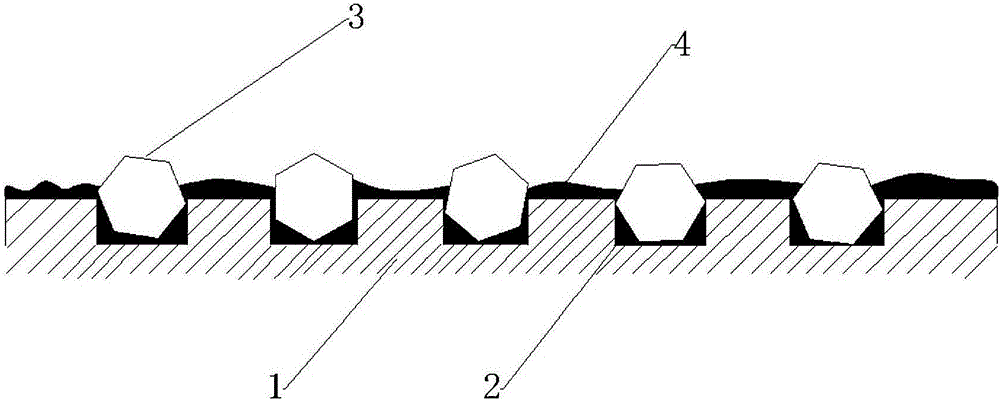

Method for preparing electroplated diamond grinding wheel with orderly arranged abrasive materials

InactiveCN105154958AImprove gripExtended service lifeElectrolytic coatingsLiquid/solution decomposition chemical coatingChemical platingElectroplating

The invention discloses a method for preparing an electroplated diamond grinding wheel with orderly arranged abrasive materials. The method comprises the following steps of forming orderly arranged blind holes in the surface of a grinding wheel substrate to obtain a processed substrate; subjecting the processed substrate to chemical plating to deposit a metal pre-plating layer on the bottoms and the side walls of the blind holes to obtain a pre-plated substrate; placing the diamond abrasive materials on the surface of the pre-plated substrate and carrying out rolling to embed the lower parts of the abrasive materials into the blind holes, so as to obtain a sanded substrate; activating the sanded substrate and electroplating the sanded substrate to deposit metal plating layers on the surface of the grinding wheel substrate and in the blind holes, thereby finally obtaining the electroplated diamond grinding wheel. According to the invention, the diamond abrasive materials can be regularly and orderly arranged on the surface of the grinding wheel substrate; the holding force of the plating layer to the diamond abrasive materials in the electroplating consolidation step is reinforced; the holding force of the diamond grinding wheel to the abrasive materials is strong; the service life is long; the abrasive materials are regularly and orderly arranged on the surface of the grinding wheel substrate; and the grinding quality and the grinding efficiency are increased. Compared with diamond abrasive materials of a same particle size, the abrasive materials in the invention are advantaged in that the electroplating time is shortened by 20-50% than that in the traditional technique, and the uniformity of the electroplating layer is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Chinese medicinal material crushing and grinding device convenient to discharging

PendingCN109012937AImprove crushing efficiencyImprove grinding qualityGrain treatmentsEngineeringGRINDING TOOTH

The invention discloses a Chinese medicinal material crushing and grinding device convenient to discharging. The Chinese medicinal material crushing and grinding device convenient to discharging comprises a shell and supporting legs. A first rotating shaft is connected with the middle of the upper end of the shell through a rotating motor, a first crushing blade is fixedly connected with the outerside of the upper end of the first rotating shaft, and a second crushing blade is arranged below the first crushing blade. A second inclined body is arranged below the second crushing blade, the outer edge of the second inclined body is fixedly connected with first grinding teeth, and the inner side wall of the shell is fixedly connected with second grinding teeth. A screen arranged obliquely isarranged below the second inclined body, elastic blocking plates are fixedly connected with the two sides of the lower end of the screen, vibrating motors are arranged below the elastic blocking plates, and a feeding barrel arranged inclined is arranged on the left side of the shell. According to the Chinese medicinal material crushing and grinding device convenient to discharging, the structure is simple, design is reasonable, automatic feeding can be completed, meanwhile, screening can be carried out after crushing and grinding, the screening speed is high, and a batch of Chinese medicinal materials which meet the requirements can be quickly produced.

Owner:TONGLING FENGDAN PLANTING TECH DEV

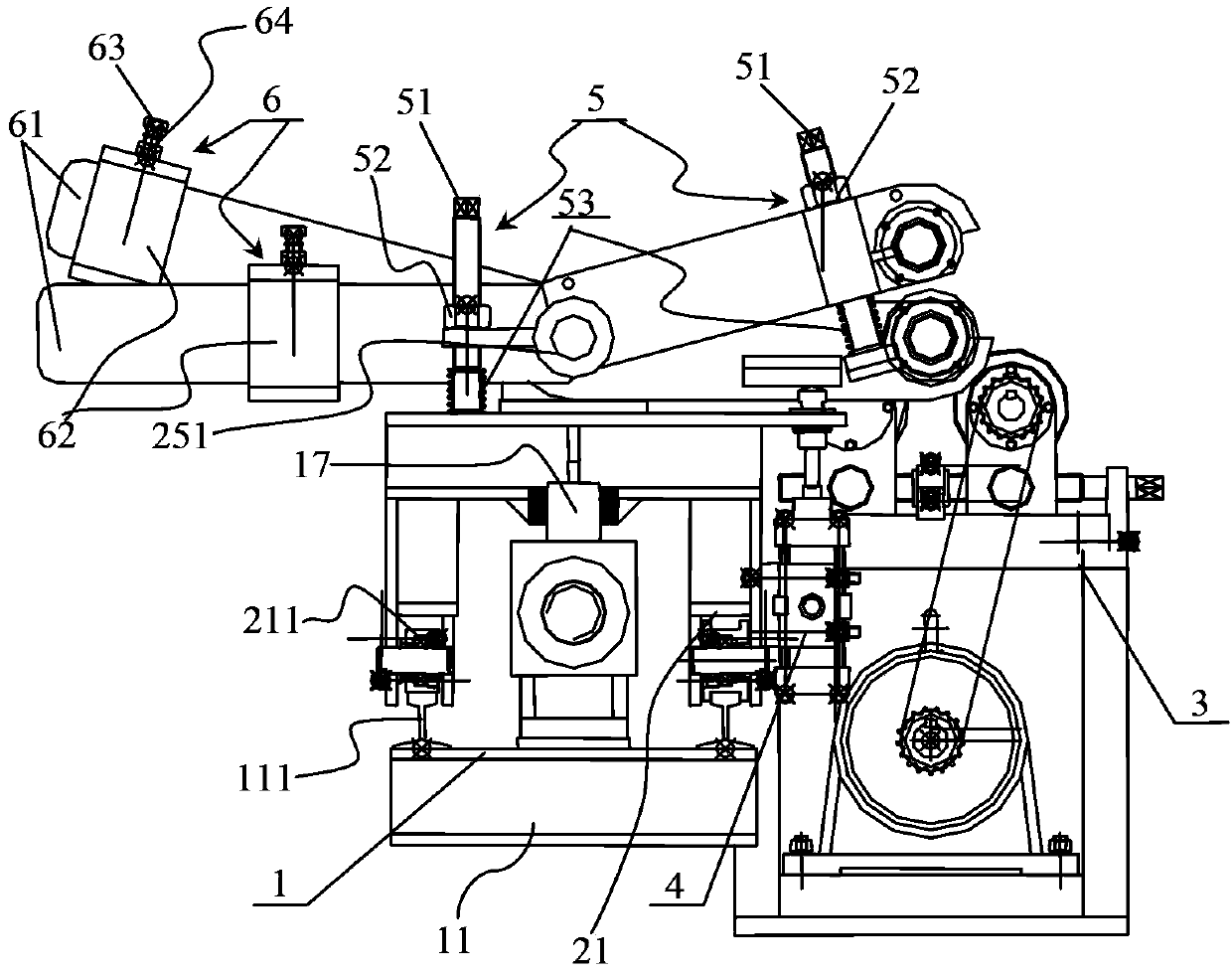

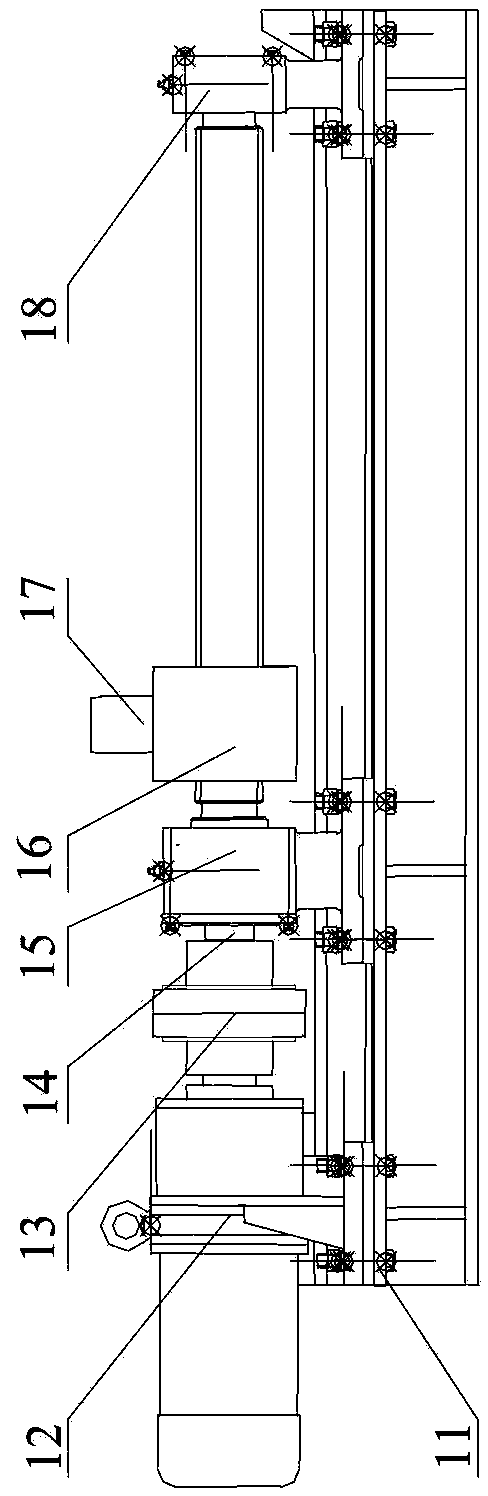

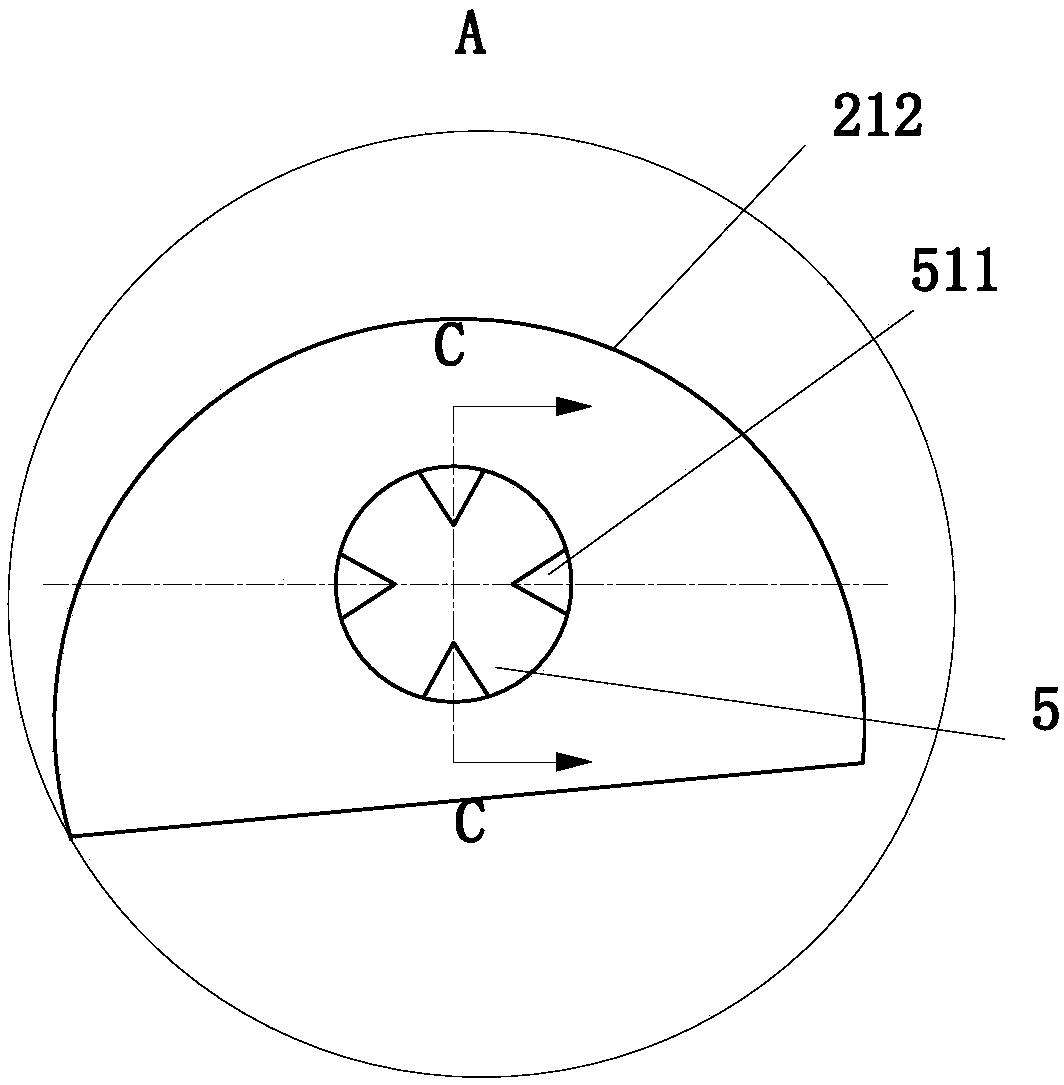

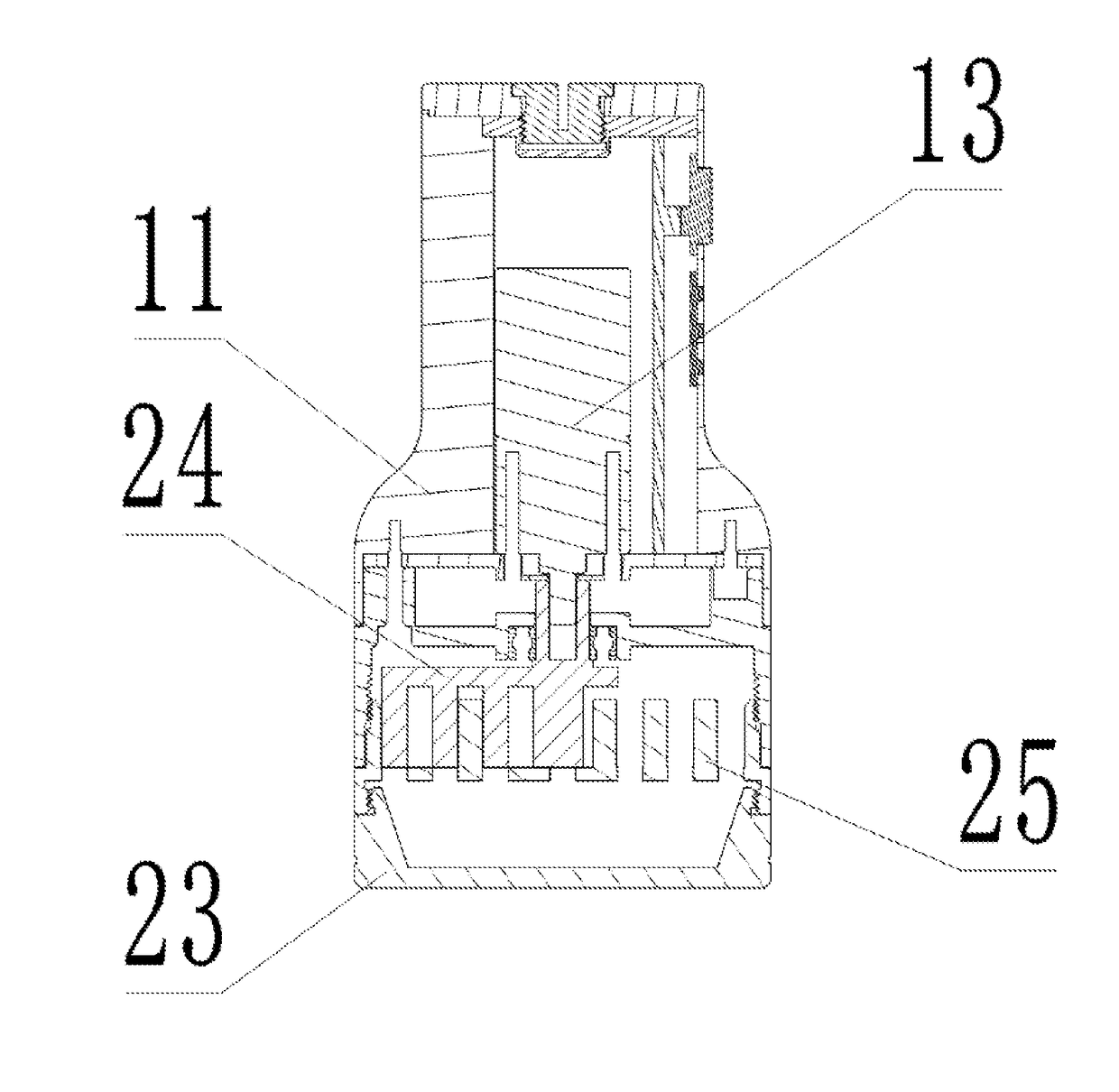

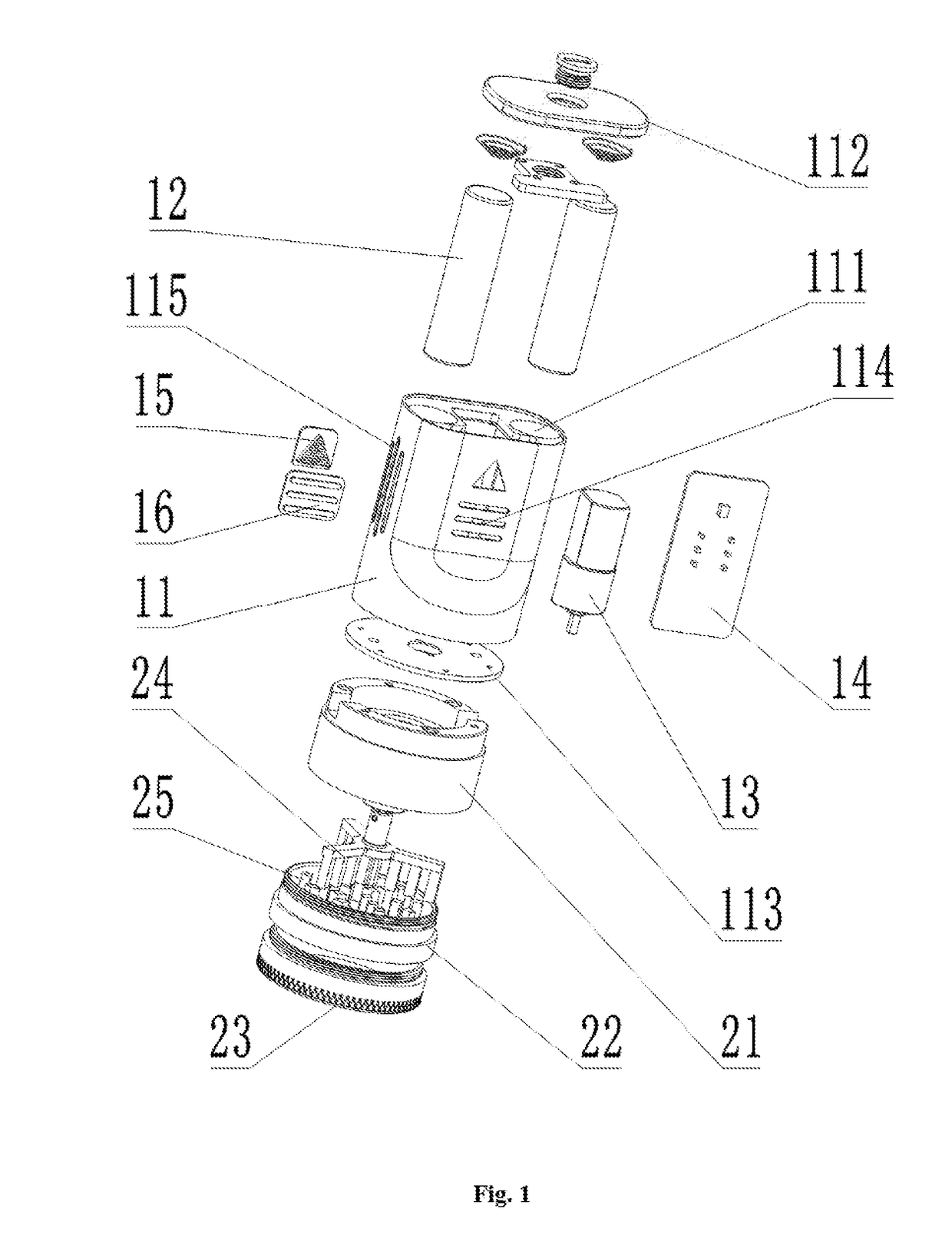

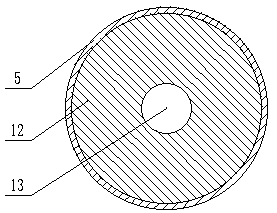

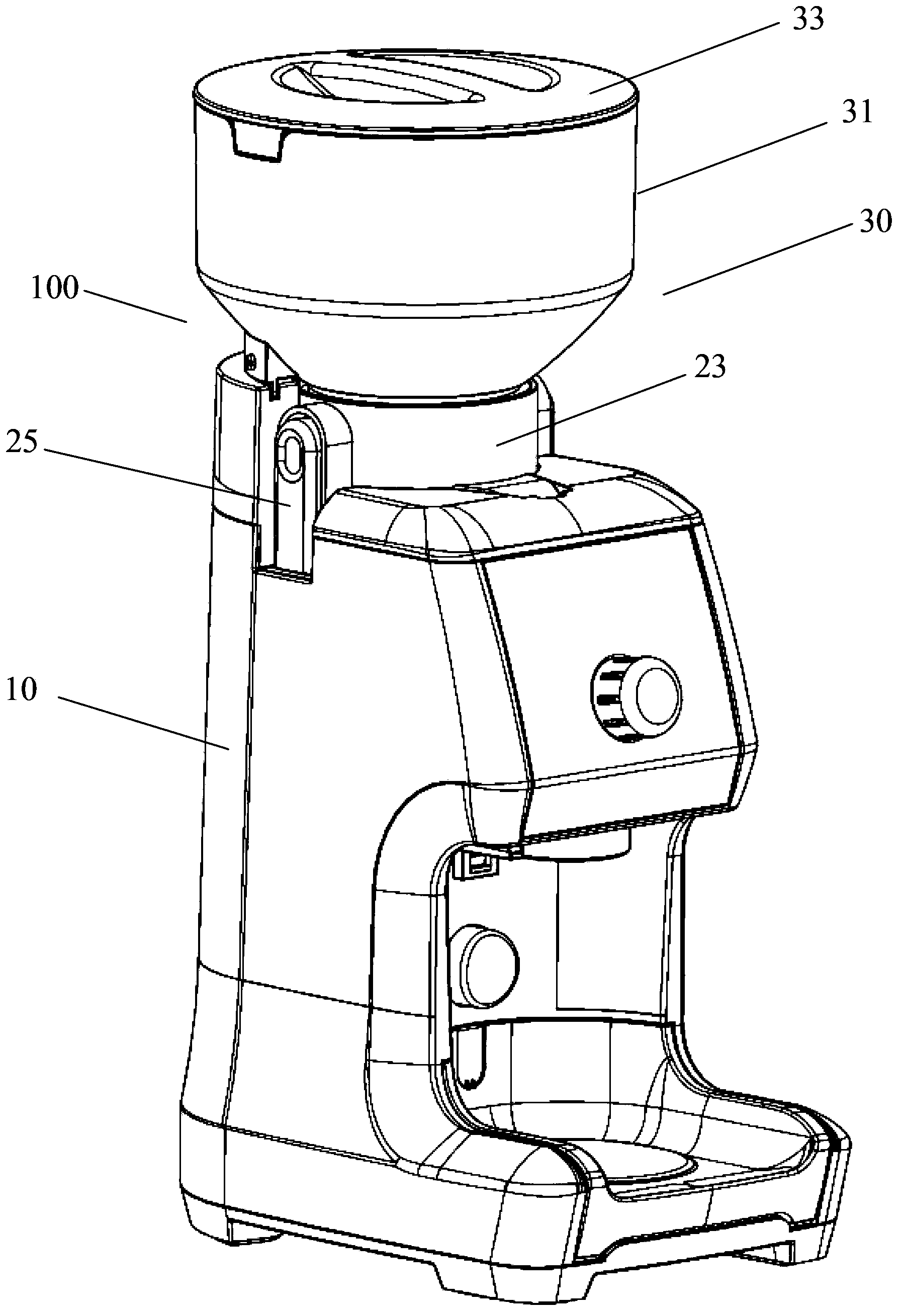

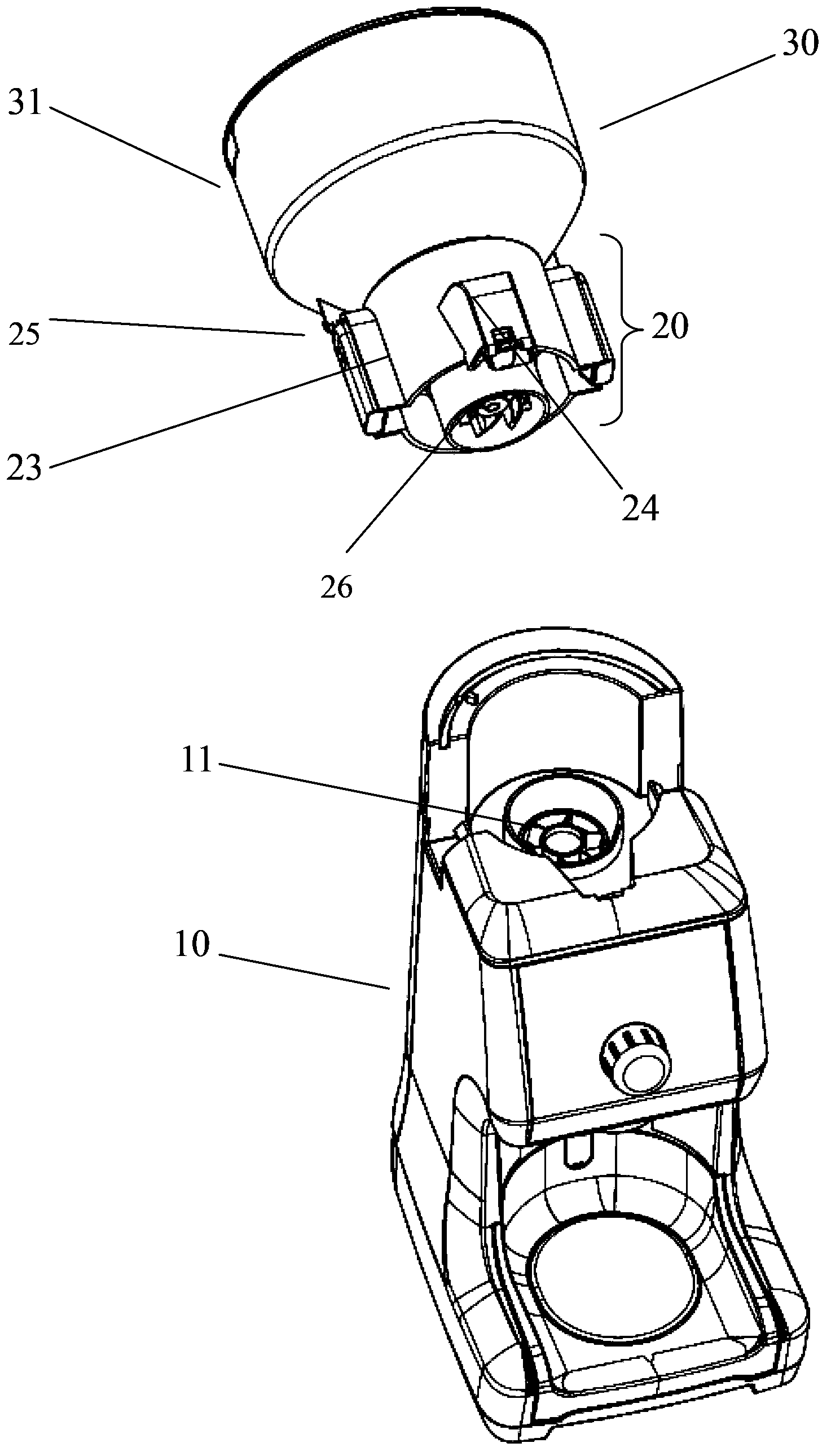

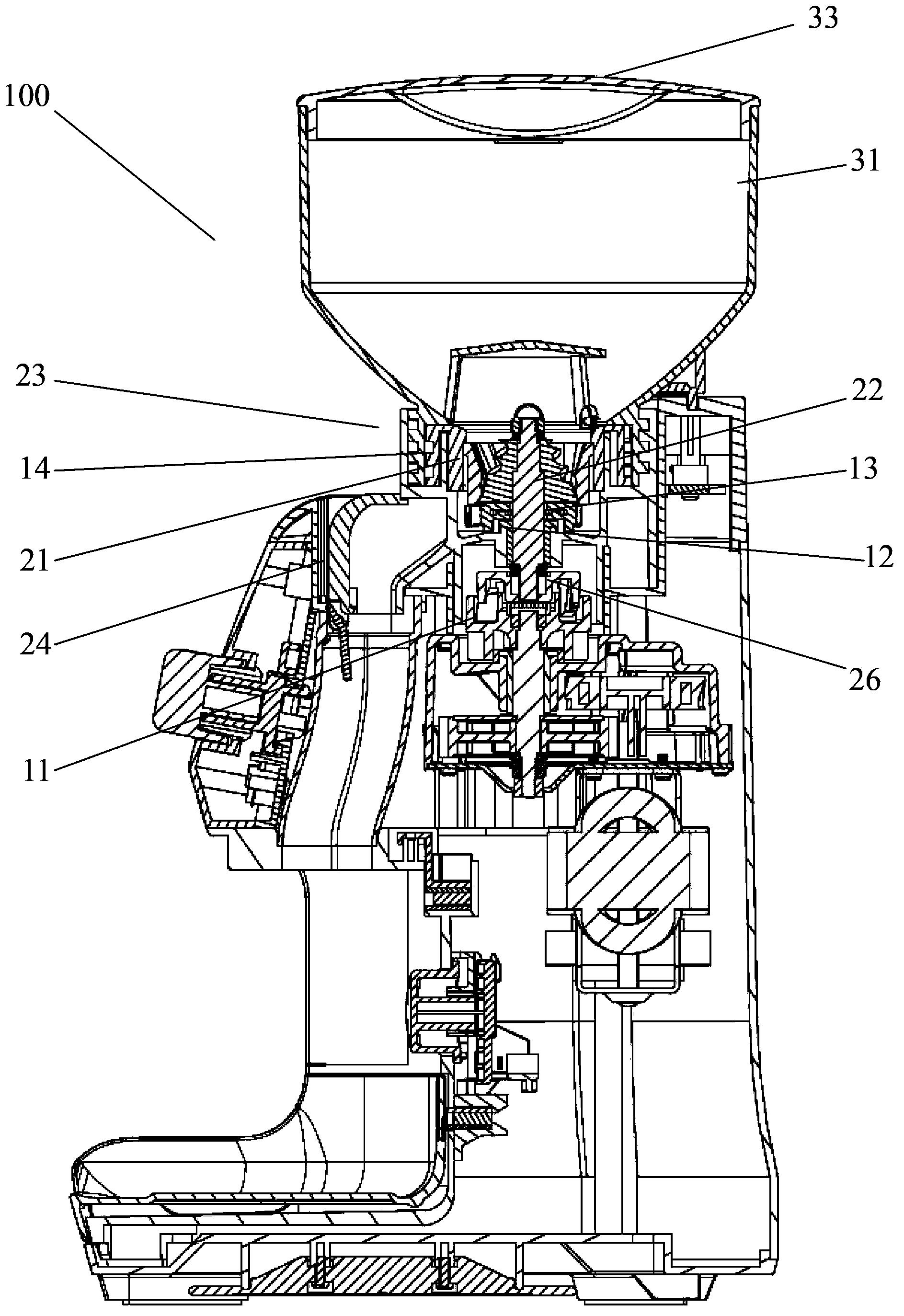

Coffee bean grinding machine

The invention relates to a coffee bean grinding machine. The coffee bean grinding machine comprises a main body (10) driven by a motor, a detachable grinding head assembly (20) arranged at the top of the main body (10), and a hopper device (30) arranged at the top of the detachable grinding head assembly (20), wherein the detachable grinding head assembly (20) comprises grinding heads (21, 22), a locking unit (25) and a coupling (26), the top of the main body (10) is provided with a motor connector (11), and the hopper device (30) comprises a hopper (31) and a hopper cover (33). According to the coffee bean grinding machine, the pair of grinding heads of the detachable grinding head assembly can well grind coffee beans and effectively solves the defects such as blocking and cleaning difficulty; an open-close assembly is used for avoiding spilling of coffee powder; the locking unit is used for locking the position of the grinding head assembly to improving the grinding quality during the grinding process and reduce any form of vibration.

Owner:SUNPOWER ELECTRICAL SHENZHEN +1

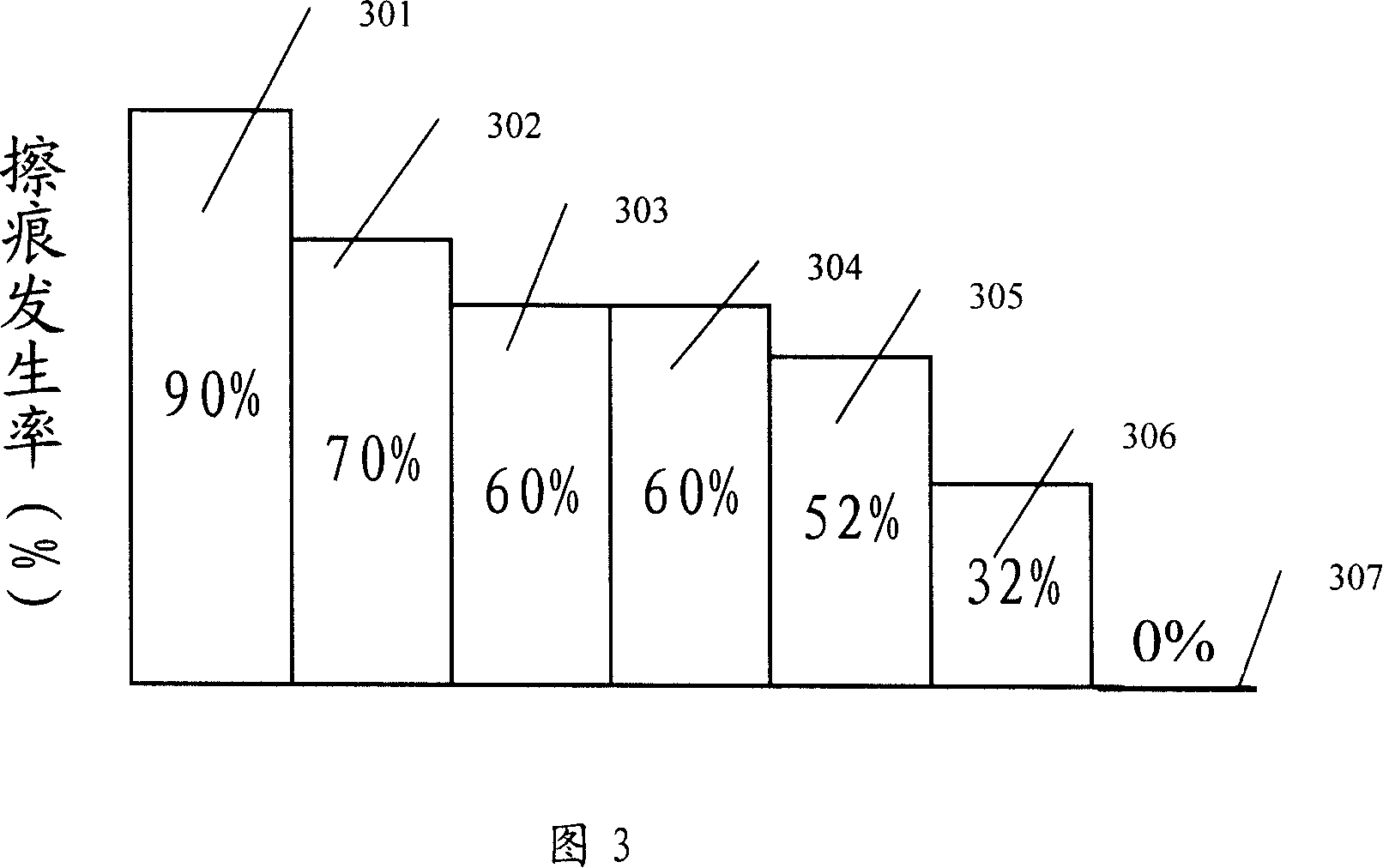

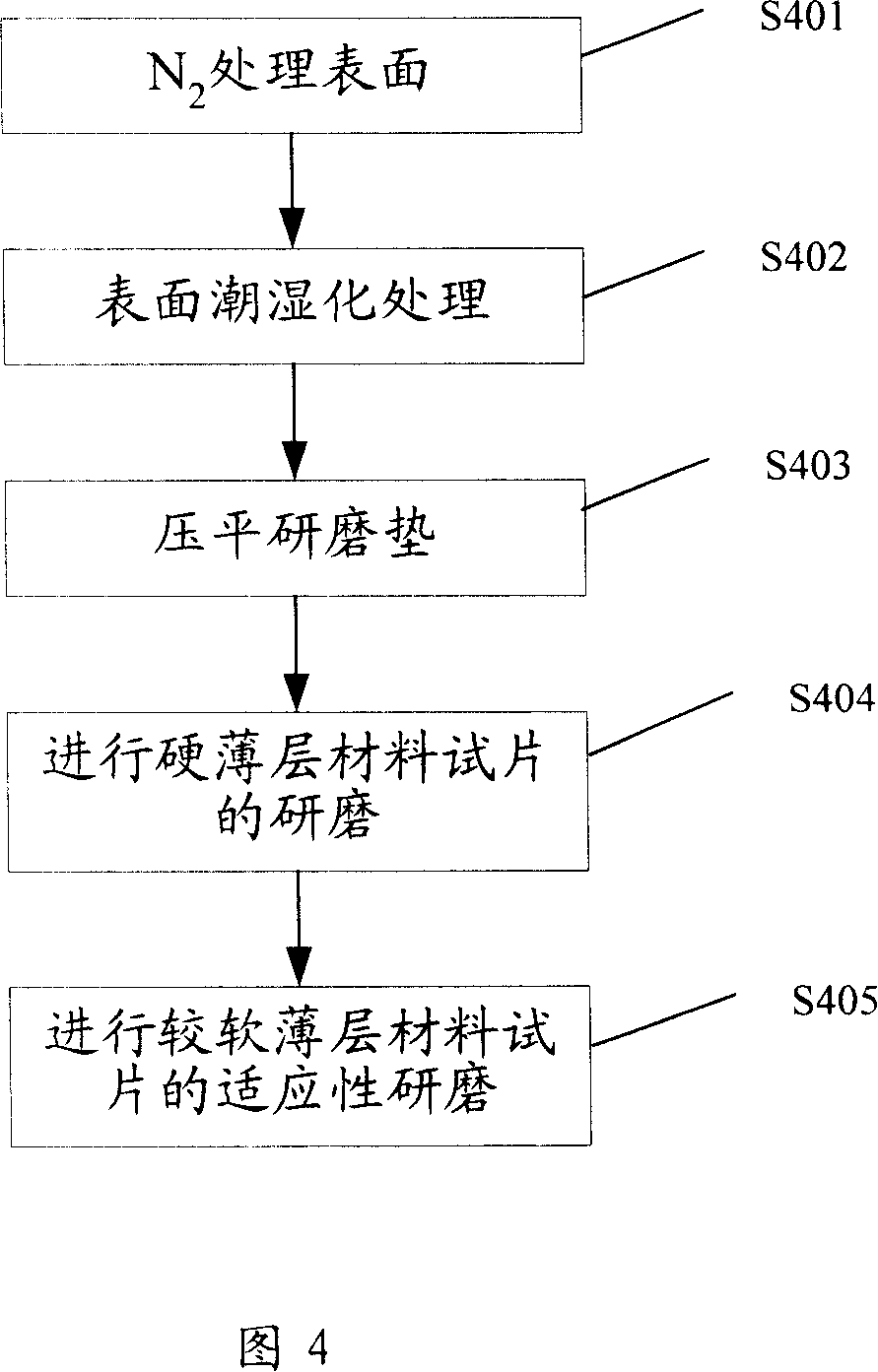

Chemical and mechanical grinding method

ActiveCN101104247AStable working conditionEvenly distributedPolishing machinesSemiconductor/solid-state device manufacturingMetallurgyCompound (substance)

The invention discloses a chemical mechanical grinding method, which reduces or even eliminates scratches produced easily in the chemical mechanical grinding process by processing a grinding pad and improving grinding process. The invention is applicable in various CMP thin materials with characteristics of universality and low cost. On the premise that process difficulty is not increased, the invention improves the rate of the finished products.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for manufacturing abrasive wheels for high-speed railway track slabs by brazing diamonds with laser

ActiveCN101914768AIncrease energy densityFast coolingMetallic material coating processesHeat-affected zoneMaterials science

A method for manufacturing abrasive wheels for high-speed railway track slabs by brazing diamonds with laser comprises the following steps: 1) mixing; 2) coating; 3) spraying; and 4) brazing. The abrasive wheels have the advantages of high grinding efficiency, long life, good grinding quality and the like. Compared with other brazing methods, the method has the following advantages: the energy density of the laser heat source is high, temperature raising and reducing are fast, local heating can be carried out and the heat affected zone is small; the laser beams can be transported by optical fibers, thus machining can be carried out on the parts which are not easy to braze by the conventional methods, the flexibility is good, the workpieces with complex geometrical shapes can be brazed and super-long, super-large, super-thin and super-fine special tools can be manufactured.

Owner:江苏华昌工具制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com