Abrasive belt grinding processing method and device capable of automatic repair and maintain for workpiece

An abrasive belt grinding and grinding technology, applied in the direction of automatic grinding control device, abrasive belt grinder, metal processing equipment, etc., can solve the problem of process control without grinding amount, etc. Simple and reliable, optimized grinding parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

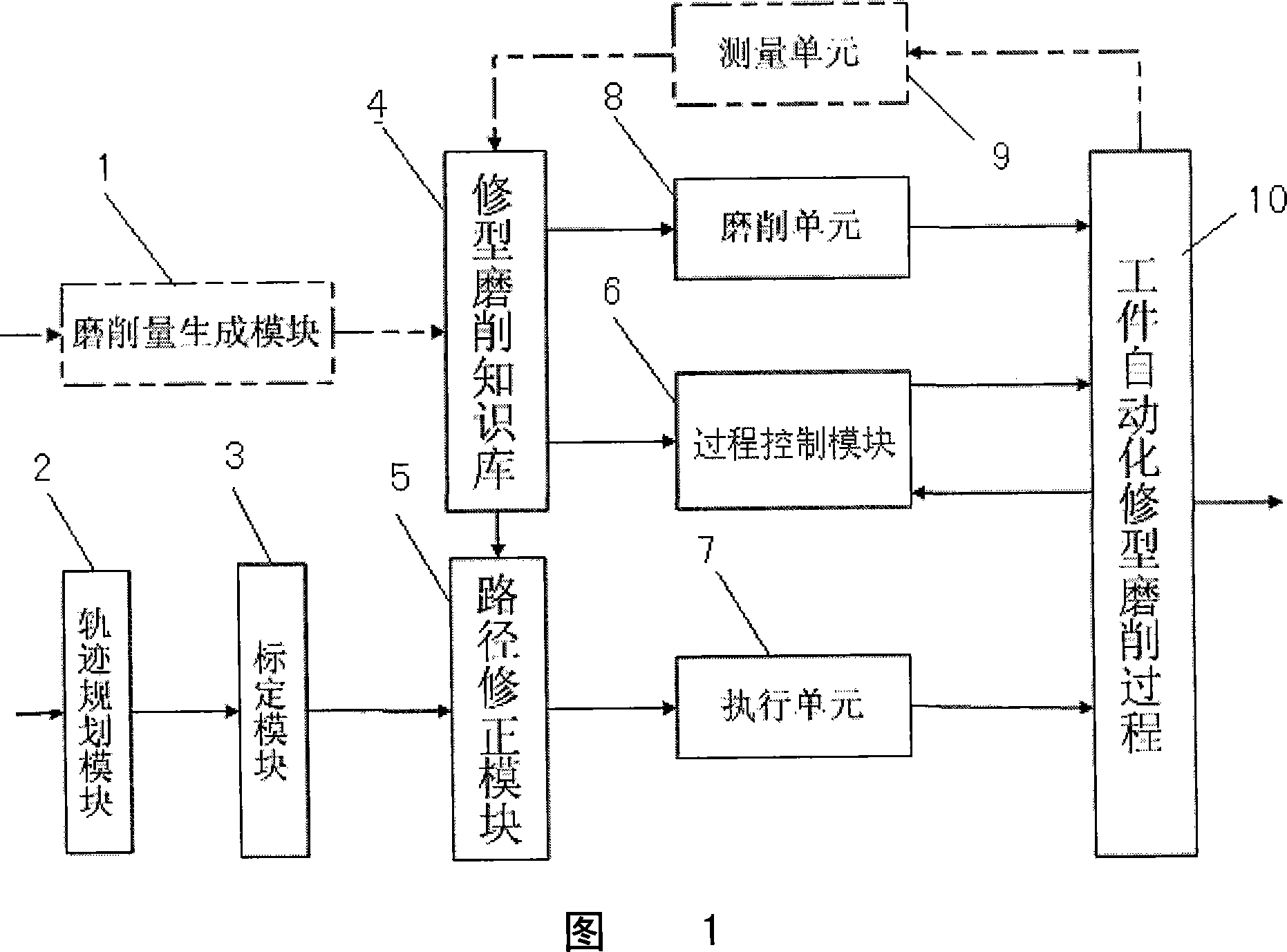

[0020] As shown in Figure 1, the present invention includes a grinding amount generation module 1, a trajectory planning module 2, a calibration module 3, a repair grinding knowledge base 4, a path correction module 5, a process control module 6, an execution unit 7, and a grinding unit 8 and measuring unit 9.

[0021] Grinding amount generation module 1 of the present invention is a software module, and the modification grinding process is the process of realizing the transformation from actual workpiece to ideal workpiece. Therefore, it is hoped that each point on the workpiece will be consistent with the ideal workpiece after grinding, but the actual grinding amount All are measured, and the measurement can only obtain the expected grinding amount of a limited number of points. In the grinding amount generating module 1, if the customer can give t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com