Method for shaping, grinding and processing abrasive band based on standard workpiece

A technology for grinding and standard workpieces, which is used in abrasive belt grinders, workpiece feed motion control, and metal processing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

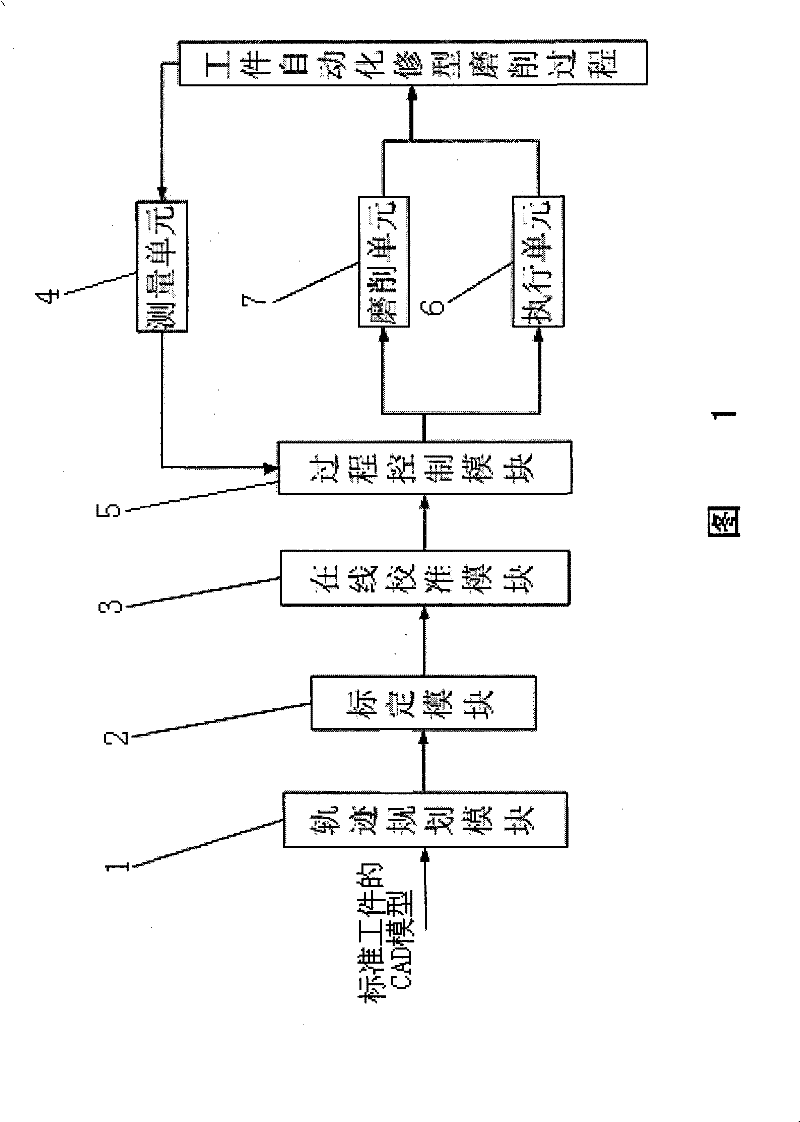

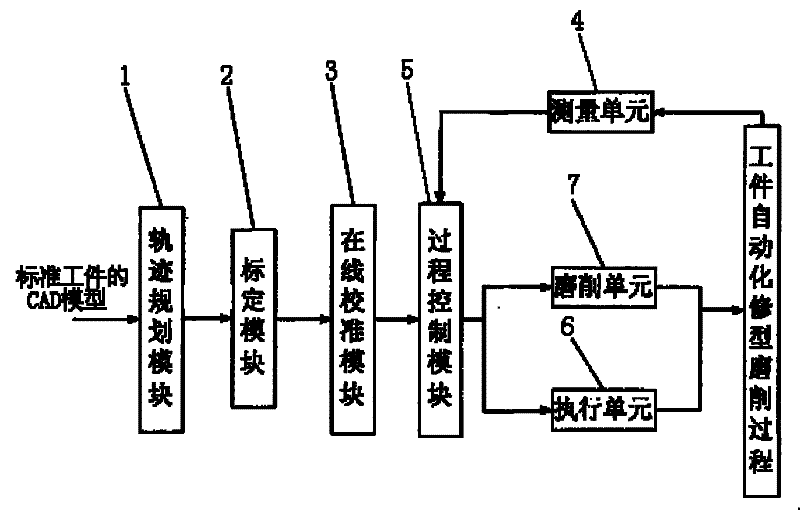

[0012] like figure 1 As shown, the present invention includes a trajectory planning module 1 , a calibration module 2 , an online calibration module 3 , a measurement unit 4 , a process control module 5 , an execution unit 6 and a grinding unit 7 .

[0013] Trajectory planning module 1 is an off-line programming module for grinding and polishing developed on the basis of ABB simulation software RobotStudio. It generates an initial grinding program on the computer according to the input CAD model of a standard workpiece and inputs it into calibration module 2 . The main steps of generating the grinding program are as follows: 1) Input the CAD model of the standard workpiece; 2) Select the surface on the CAD model; 3) Generate curves on the selected surface according to the requirements (the number and method of generating curves); 4) Create a process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com