Whole-space error compensation method of mining inclinometer

An error compensation, full-space technology, used in surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of great influence of data volume, not fully applicable to the coal mine field, and heavy quality of installed outer pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

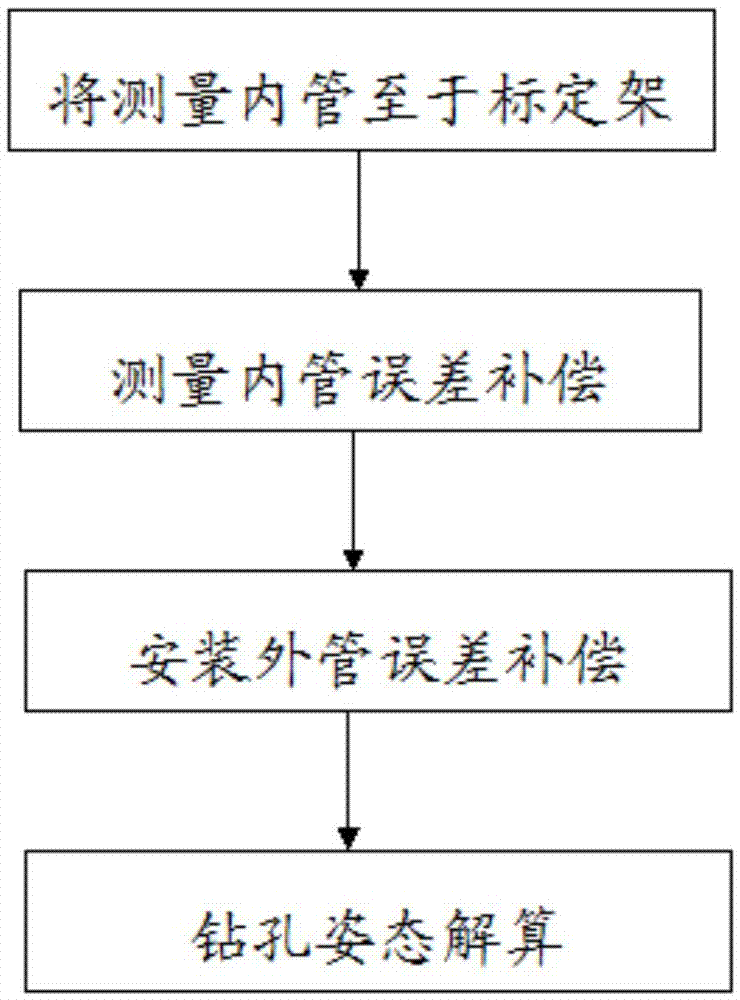

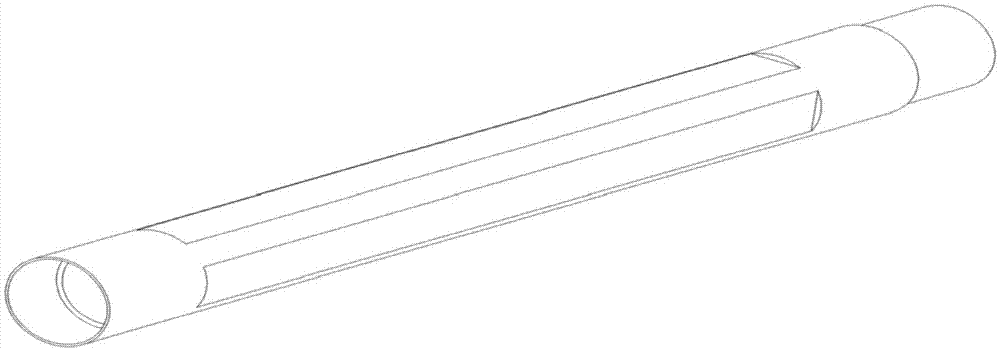

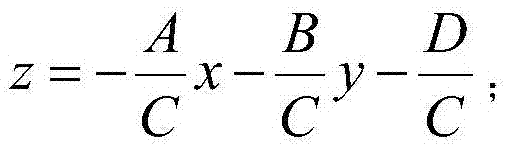

[0050] An embodiment of the present invention provides a full-space error compensation method for a mining inclinometer, such as figure 1 As shown, the method is: select at least six different measurement points in the whole space, determine the correction coefficient of the inner tube error according to the collected triaxial acceleration of the measurement points and the value of the triaxial magnetic sensor, and finally according to the internal The correction coefficient of the tube error recalculates the measurement parameters of the borehole; the measurement inner tube is assembled into the installation outer tube, and it is rotated one circle in two mutually perpendicular planes on which the outer tube is installed, as shown in figure 2 As shown, the values of the three-axis magnetic sensors at different angles are collected at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com