Method for preparing polycrystalline cubic boron nitride

A cubic boron nitride and polycrystalline cubic technology, applied in the field of advanced cutting tools, can solve the problems of high pressure required for forming, high sintering temperature, and complicated equipment, and achieve the effect of low cost, low sintering temperature, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

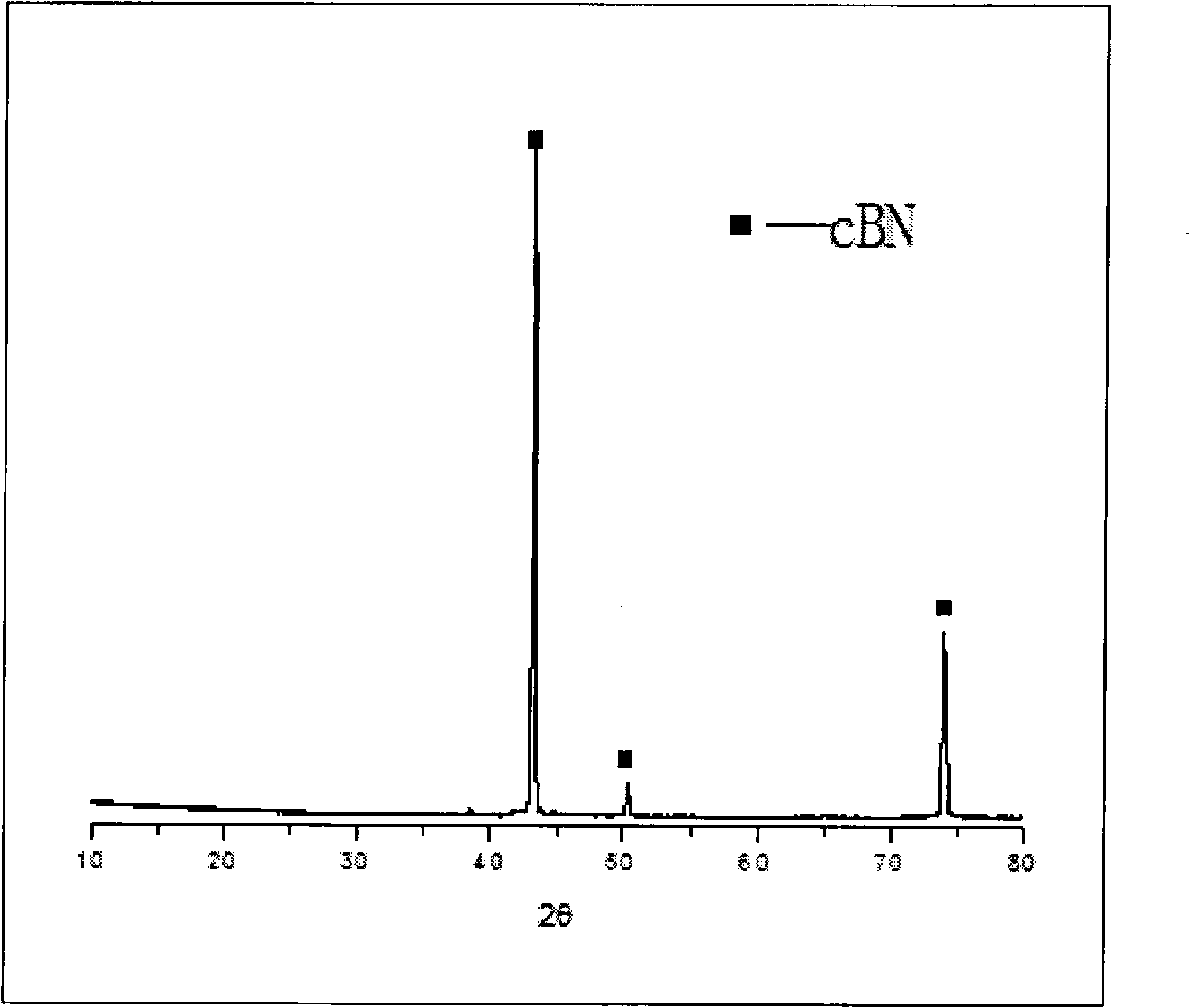

[0026] The preparation method of polycrystalline cubic boron nitride PcBN of the present invention is as follows: weigh 0.6g Al, 0.3g SiO 2 , 0.15g Al 2 o 3 , 0.06 g H 3 BO 3 , 0.6g Si 3 N 4 , mix it evenly to be the binding agent; then weigh 4.2g cubic boron nitride cBN (see X-ray diffraction diagram figure 1 ), the particle size range is 30-40 μm; the binder and cBN are mixed in a planetary ball mill, the ball-to-material ratio is 2:1, the ball-milling medium is water, the rotating speed is 600 rpm, and the ball-milling time is 4 hours; Put the final mixture into a drying oven at 60°C for drying; take it out and put it in a mortar, add polyvinyl alcohol PVA as an organic binder, mix evenly, and pass through a 100-mesh screen; weigh 0.5g of the mixture, and use a Φ8 mold Forming on a press, the initial pressure is 4MPa, and the pressure holding time is 100 seconds; after the pressure is released, a pressure of 8MPa is applied, and the pressure is held for 100s; after th...

Embodiment 2

[0028] The preparation method of polycrystalline cubic boron nitride PcBN of the present embodiment is as follows: Weigh 1.2g potassium feldspar, 0.42gSi, 0.18g Si 3 N 4 , mix it evenly to get the binding agent; then weigh 4.2g cubic boron nitride cBN (see X-ray diffraction diagram figure 1 ), the particle size range is 22-36 μm; the prepared binder and cBN are mixed in a planetary ball mill, the ball-to-material ratio is 3:1, the ball-milling medium is water, the speed is 600 rpm, and the ball-milling time is 8 hours Put the ball-milled mixture into a drying oven at 60°C for drying; take it out and put it in a mortar, add PVA as a binder, mix evenly, and pass through a 100-mesh screen; weigh 0.5g of the mixture, and use a Φ8 mold in the The press is formed, the initial pressure is 4MPa, and the pressure holding time is 100 seconds; after the pressure is released, a pressure of 8MPa is applied, and the pressure is held for 100s; after the pressure is released, a pressure of 1...

Embodiment 3

[0030] The preparation method of the polycrystalline cubic boron nitride PcBN of the present embodiment is as follows: Weigh 1.2g potassium feldspar, 0.42gSi, 0.18g Si 3 N 4 , and mix it evenly to get the binder; then weigh 4.2g of Ti-plated cBN, the particle size range is 30-40μm; put the binder and cBN in a planetary ball mill and mix them with a ball-to-material ratio of 4:1, and ball mill The medium is water, the rotating speed is 600 rpm, and the ball milling time is 16 hours; put the ball-milled mixture into a drying oven at 60°C for drying; take it out and put it in a mortar, add PVA as a binder, mix evenly, and pass 100-mesh screen; weigh 0.5g of the mixture, use a Φ8 mold to form it in a press, the initial pressure is 4MPa, and the pressure holding time is 100 seconds; after the pressure is released, the pressure is added to 8MPa, and the pressure is held for 100s; then the pressure is released and loaded to 12MPa The pressure of 100s is maintained for 100s; then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com